_________________________Quick Start

The MAX1002/MAX1003 EV kits are fully assembled

and tested. Follow these steps to verify proper board

operation. Do not turn on the power supplies until all

connections to the EV kit are completed.

1) Connect a +5V power supply to the pad marked

VCC. Connect this supply’s ground to the pad

marked GND.

2) Connect a +3.3V (MAX1003) or +5V (MAX1002)

power supply to the pad labeled VCCO. Connect

the supply ground to the pad marked OGND.

3) Connect a +4V power supply to the pad marked

VTUNE. Connect the supply ground to the GND

pad.

4) Remove the shunt from jumper JU5. This sets a

250mVp-p full-scale range.

_______________General Description

The MAX1002/MAX1003 evaluation kits (EV kits) simplify

evaluation of the 60Msps MAX1002 and 90Msps

MAX1003 dual, 6-bit analog-to-digital converters (ADCs).

The kits include the basic components necessary to

operate the on-chip oscillator as a voltage-controlled

oscillator (VCO). Each board can also be easily modified

to accommodate an external clocking source.

Connectors for power supplies, analog inputs, and digital

outputs simplify connections to the device. The PC board

features an optimized layout to ensure the best possible

dynamic performance. The EV kits include a MAX1002 or

MAX1003.

____________________________Features

♦ 5.85 Effective Number of Bits at 20MHz Analog

Input Frequency

♦ Separate Analog and Digital Power and Ground

Connections with Optimized PC Board Layout

♦ Matched Single-Ended or Differential Analog

Inputs for Both I and Q Channels

♦ Square-Pin Header for Easy Connection of Logic

Analyzer to Digital Outputs

♦ User-Selectable ADC Full-Scale Gain Ranges

♦ Fully Assembled and Tested

Evaluate: MAX1002/MAX1003

MAX1002/MAX1003 Evaluation Kits

________________________________________________________________

Maxim Integrated Products

1

19-1250; Rev 0; 6/97

QTY DESCRIPTION

C1, C10,

C11, C12

4

C2, C3,

C6, C7

4

C4, C15 2

0.22µF, 25V min, 10% ceramic

capacitors

C5 1

C8, C9,

C13, C14

4

0.1µF, 10V min, 10% ceramic

capacitors

R1 1

R2, R3 2

R4–R7 4

L1 1

220nH inductor

Coilcraft 1008CS-221TKBC

MAX1003CAX, 90Msps

D1 1

Varactor diode

M/A-COM MA4ST079CK-287, SOT23

IIN+, IIN-,

QIN+, QIN-

4 BNC connectors

None 1 MAX1002/MAX1003 circuit board

5pF, 10V min, 10% ceramic capacitor

(MAX1003)

47pF, 25V min, 5% ceramic capacitors

0.01µF, 25V min, 10% ceramic

capacitors

SUPPLIER* PHONE FAX

AVX (803) 946-0690 (803) 626-3123

______________Component Suppliers

DESIGNATION

10kΩ, 5% resistor

47kΩ, 5% resistors

49.9Ω, 1% resistors

____________________Component List

______________Ordering Information

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

Coilcraft (847) 639-6400 (847) 639-1469

M/A-COM (617) 564-3100 (617) 564-3050

Sprague (603) 224-1961 (603) 224-1430

JU1, JU2,

JU6, JU7

4 0Ω resistors

JU3, JU4,

JU8, JU9

4 2-pin headers

JU5 1 3-pin header

JU11 1 2-pin header (MAX1002 only)

J1 1 26-pin connector

None 1 Shunt for JU5

22pF, 10V min, 10% ceramic capacitor

(MAX1002)

U1 1

MAX1002CAX, 60Msps

*

Please indicate that you are using the MAX1002/MAX1003

when contacting these component suppliers.

PART

MAX1002EVKIT-SO

MAX1003EVKIT-SO 0°C to +70°C

0°C to +70°C

TEMP. RANGE BOARD TYPE

Surface Mount

Surface Mount

C16, C17 2

10µF, 10V min, 20% tantalum caps

AVX TAJC106K016

查询MAX1002EVKIT供应商

Evaluate: MAX1002/MAX1003

5) Using an RF power splitter-combiner, connect a

250mVp-p, 20MHz sine-wave source to both analog

inputs at BNC J3 and J6. The analog input impedance is 50Ω for each channel.

6) Connect a logic analyzer to connector J1 to monitor

the digital outputs.

7) Turn on all power supplies and signal sources.

8) Observe the digitized analog input signals with the

logic analyzer.

_______________Detailed Description

EV Kit Jumpers

The MAX1002/MAX1003 EV kits contain several

jumpers that control board and part options. The following sections describe the different jumpers and their

purposes. Table 1 lists the jumpers on the EV kits and

their default positions.

Table 1. EV Kit Jumpers and Default

Positions

Power Requirements

Both the MAX1002 and the MAX1003 require +5V at

about 65mA for their analog VCCsupply. Power-supply

requirements for the digital outputs, however, are different for the two devices. 0Ω resistors are installed at

jumper sites JU1, JU2, JU6, and JU7, and can be

removed to sense device power-supply currents with

an ammeter.

MAX1003 Digital Outputs Supply

The MAX1003 requires +3.3V for the V

CCO

supply. The

current requirement from the power supply is a function

of the sampling clock and analog input frequencies, as

well as the capacitive loading on the digital outputs.

With 15pF loads and a 20MHz analog input frequency

sampled at 90Msps, the current draw is about 10mA.

MAX1002 Digital Outputs Supply

The MAX1002 uses +5V for its V

CCO

supply. As with

the MAX1003, the current requirement is a function of

the analog input frequency and capacitive loading on

the outputs. With 15pF loads and a 20MHz analog input

sampling at 60Msps, the current requirement is about

13mA. You can also use a single power supply for both

the VCCand V

CCO

supplies by installing jumper JU11,

located near the EV kit power-supply connectors.

However, for best dynamic performance, use separate

analog and digital power supplies.

Analog Inputs

The analog inputs to the dual ADCs are provided

through BNC connectors IIN+, IIN-, QIN+, and QIN-.

The connectors are terminated with 49.9Ω to ground

and are AC coupled to the converter’s analog inputs,

which are internally self-biased at 2.35V DC. A typical

application circuit drives the IIN+ and QIN+ noninverting analog inputs using AC-coupled in-phase and quadrature signals. The nominal 20kΩ input resistance of the

analog inputs, plus the 0.1µF AC-coupling capacitor

value, sets the low-frequency corner at about 80Hz.

You can drive the analog inputs either single-ended or

differentially using AC- or DC-coupled inputs. Either the

inverting or the noninverting input can be driven singleended. If the inverting input is driven, then the digital

output codes are inverted (complemented). Refer to the

MAX1002 or MAX1003 data sheet for typical circuits.

ADC Gain Selection

The single GAIN-select pin on the MAX1002 or

MAX1003 controls the full-scale input range for both the

I and the Q channels. Jumper JU5 is used to manually

select the desired gain range as shown in Table 2. The

EV kits are shipped with the mid-gain range selected

(jumper pins open).

Table 2. Gain-Selection Jumper JU5

Settings

MAX1002/MAX1003 Evaluation Kits

2 _______________________________________________________________________________________

Open

Offset-correction

amplifier enabled

JU3, JU4,

JU8, JU9

Shorted with 0Ω

resistors

Power-supply currentsense ports

JU1, JU2,

JU6, JU7

DEFAULT

POSITION

FUNCTIONJUMPER(S)

Open

VCCO tied to VCC for

single-supply operation

(MAX1002)

JU11

Open

ADC full-scale range

selection

JU5

Mid-gain, 250mVp-p

No pins shorted

Low-gain, 500mVp-pPins 1 and 2 shorted

ADC GAIN RANGECONNECTIONJU5 SETTING

High-gain, 125mVp-pPins 2 and 3 shorted

JU5

1

2

3

JU5

1

2

3

JU5

1

2

3

Table 3 lists the possible input-drive combinations for

the mid-gain (250mVp-p) full-scale range selection.

Drive levels are referenced to the open-circuit, common-mode voltage of the analog inputs (typically

2.35V) if DC coupled, or to ground if AC coupling is

used. If the low-gain (500mVp-p) range is selected, the

input-drive requirements are twice those listed in Table

3. If the high-gain (125mVp-p) range is selected, the

input-drive requirements are half those listed in Table 3.

Table 3. Typical Input-Drive Requirements

for Mid-Gain

Offset-Correction Amplifiers

The offset-correction amplifiers included on the

MAX1002 and MAX1003 are usually enabled in a typical AC-coupled application circuit. For DC-coupled

applications, the amplifiers must be disabled by

installing shorting blocks on jumpers JU3, JU4 (I channel); and JU8, JU9 (Q channel). These jumpers short

device pins IOCC+ (pin 2), IOCC- (pin 3), QOCC- (pin

16), and QOCC+ (pin 17) to ground and disable the

amplifiers. The MAX1002/MAX1003 EV kits are configured with the offset-correction amplifiers enabled

(jumpers open) and AC-coupled analog inputs.

Voltage-Controlled-Oscillator Operation

The EV kits include a voltage-controlled-oscillator

(VCO) circuit to set the analog-to-digital converter

(ADC) sampling rate using an external resonant tank

and a varactor diode. A voltage applied to the VTUNE

pad changes the varactor diode’s capacitance to

adjust the tank’s resonant frequency, which sets the

oscillator’s sampling frequency. VTUNE voltage can be

varied from 0V to a maximum of 8V.

The EV kits are designed so that a nominal VTUNE control voltage of about 4V sets the ADC sampling rate to

either 60Msps for the MAX1002 or 90Msps for the

MAX1003. The VTUNE control voltage should be well

filtered, as any noise on the supply contributes to jitter

in the internal oscillator and degrades the converters’

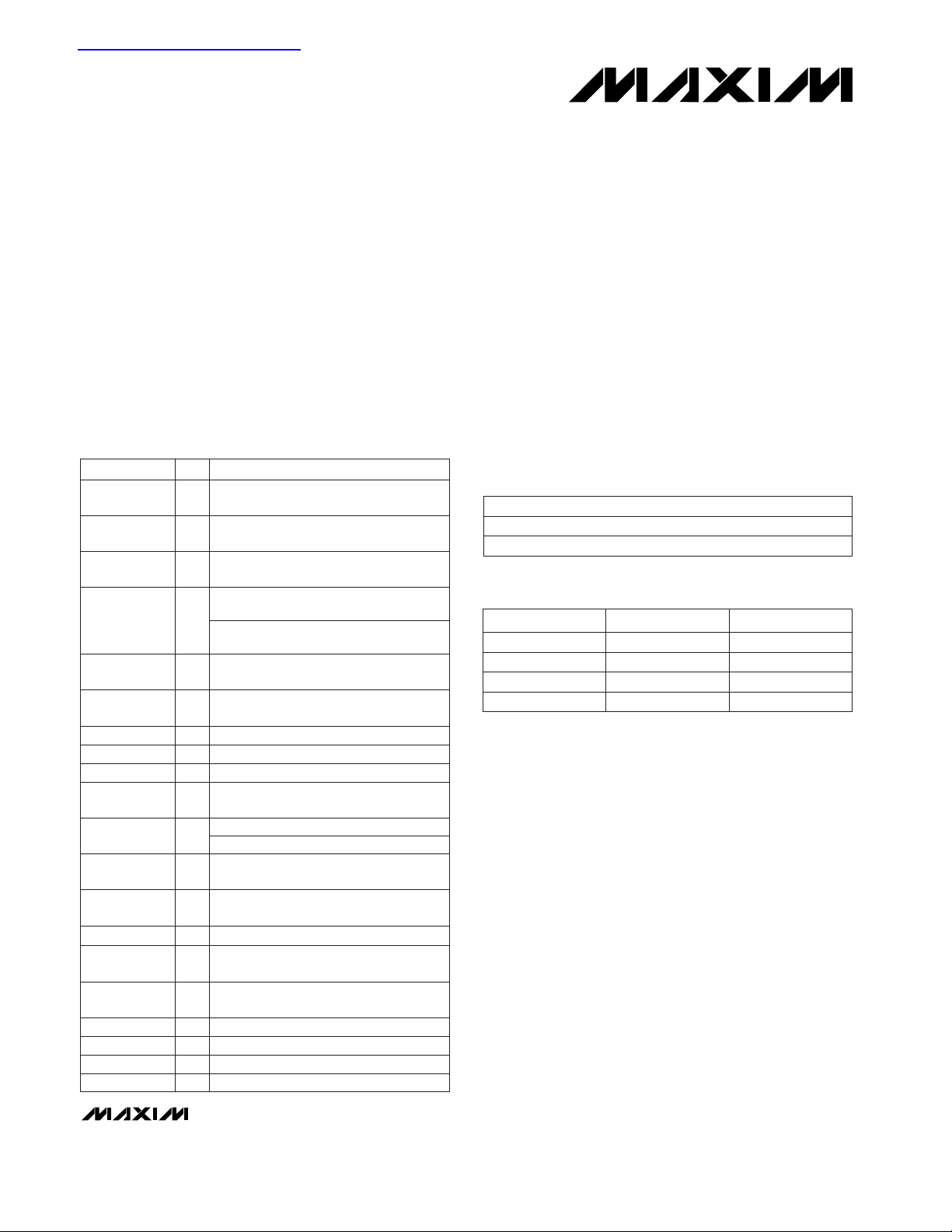

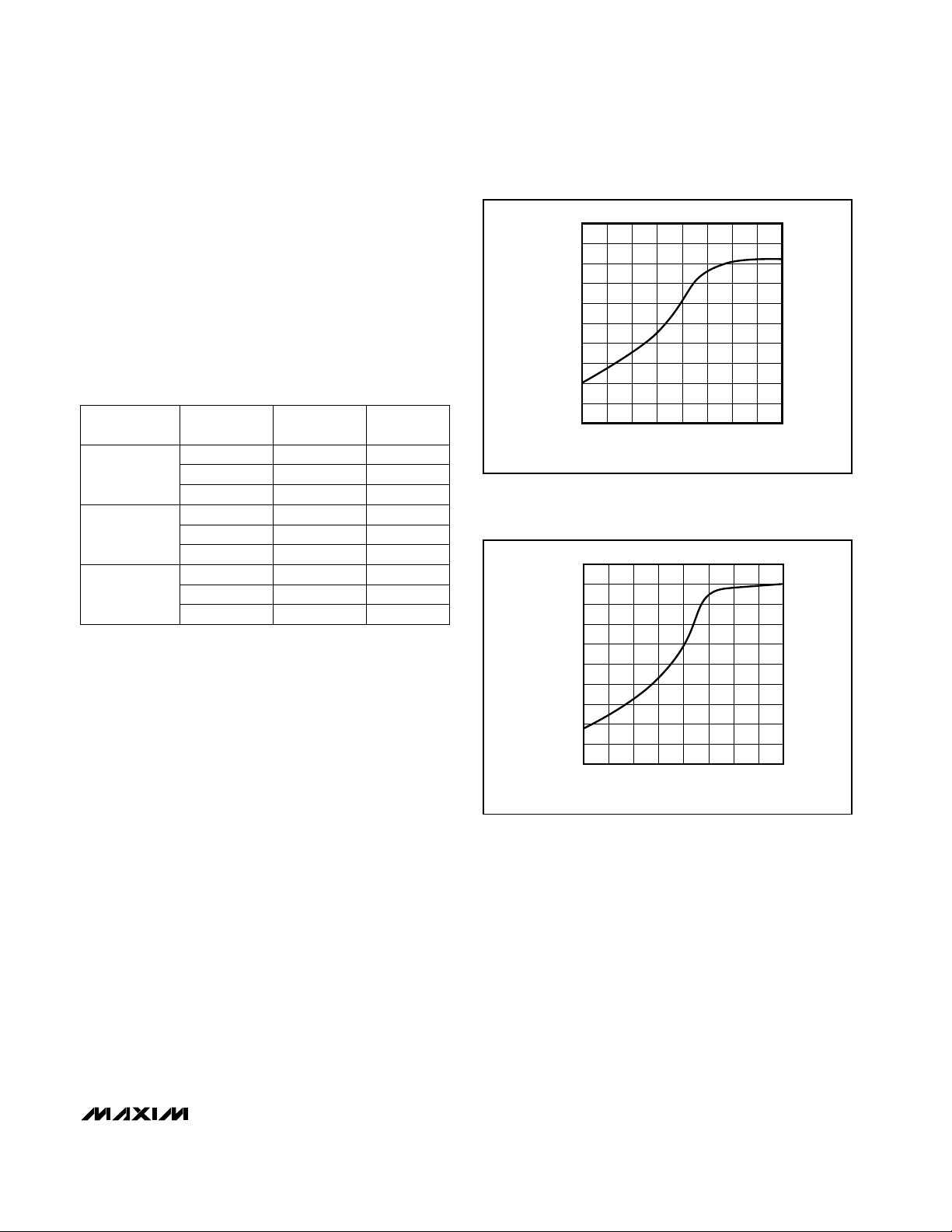

dynamic performance. Figures 1 and 2 show the

VTUNE control-voltage typical frequency-adjustment

ranges for the MAX1002 and MAX1003 EV kits, respectively.

Evaluate: MAX1002/MAX1003

MAX1002/MAX1003 Evaluation Kits

_______________________________________________________________________________________ 3

INPUT DRIVE

Single-Ended

Noninverting

0

+125mV

QIN+ or IIN+

-125mV

Open Circuit

Open Circuit

QIN- or IIN-

Open Circuit

100000

111111

OUTPUT

CODE

000000

Open Circuit

Open Circuit

Open Circuit

0

+125mV

-125mV

Single-Ended

Inverting

011111

000000

111111

0

+62.5mV

-62.5mV

0

-62.5mV

+62.5mV

Differential

100000

111111

000000

Figure 1. MAX1002 Oscillator Frequency vs. VTUNE Control

Voltage

60

70

65

80

75

90

85

95

105

100

110

0 2 31 4 5 6 7 8

MAX100/1003-fig2

VTUNE CONTROL VOLTAGE (V)

FREQUENCY (MHz)

Figure 2. MAX1003 Oscillator Frequency vs. VTUNE Control

Voltage

70

68

66

64

62

60

58

FREQUENCY (MHz)

56

54

52

50

0 2 31 4 5 6 7 8

VTUNE CONTROL VOLTAGE (V)

MAX100/1003-fig1

Evaluate: MAX1002/MAX1003

External Clock Operation

The MAX1002/MAX1003 EV kits can be converted to

drive the ADCs from an external clock source. This

involves removing the external resonator components

from the VCO circuit and adding a few new components. Table 4 lists the EV kit changes required to convert the board to accept an external clock source. The

resulting schematic is shown in Figure 4.

The new 49.9Ω value of R3 shown in Figure 4 provides

proper termination for a 50Ω external signal generator.

AC-coupling capacitor C6 couples the external clock

signal to the MAX1002/MAX1003 oscillator circuitry at

TNK+ (pin 9). R2 and C7 ensure that the impedance at

both ports of the oscillator is balanced. After all modifications are complete, connect an external clock source

to the BNC connector on the EV kit marked CLOCK

OVERDRIVE. The recommended clock amplitude is

1Vp-p; however, the ADC operates correctly with as little as 100mVp-p or up to 2.5Vp-p on CLOCK OVERDRIVE.

The external clock source should have low phase noise

for best dynamic performance. A low-phase-noise

sine-wave oscillator serves this purpose well. A squarewave clock source is not necessary to drive the

MAX1002/MAX1003. The devices contain sufficient

gain to amplify even a low-level-input sine wave to drive

the ADC comparators, while ensuring excellent dynamic performance.

Digital Outputs

The TTL/CMOS-compatible digital outputs are presented in parallel from both I and Q channels at connector

J1. The data format is offset binary with the MSB as D5

and the LSB as D0. The row of pins closest to the

board edge is digital output ground (OGND), while the

data bits occupy the inside row. Located in the middle

of the connector is the pin for the output clock labeled

DCLK. This signal can be used to latch the parallel output data for capture into a logic analyzer or external

DSP circuitry. Both digital outputs are updated on

DCLK’s rising edge (see the timing diagram in the

MAX1002 or MAX1003 data sheet).

_____________Layout Considerations

The MAX1002/MAX1003 EV kit layouts have been optimized for high-speed signals. Careful attention has

been given to grounding, power-supply bypassing, and

signal-path layout to minimize coupling between the

analog and digital sections of the circuit. For example,

the ground plane has been removed under the tank circuitry to reduce stray capacitive loading on the relatively small capacitors required in the external resonant

tank formed by C5, L1, and D1. Other layout considerations are detailed in the following sections.

Power Supplies and Grounding

The EV kits feature separate analog and digital power

supplies and grounds for best dynamic performance. A

thin trace located on the backside of the circuit board

near the VCC power-supply connector ties the analog

and output ground planes together. This trace can be

cut if the power-supply grounds are referenced elsewhere.

Referencing analog and digital grounds together at a

single point usually avoids ground loops and corruption

of sensitive analog circuitry by noise from the digital

outputs. If the ground trace on the backside of the

board is cut, observe the absolute maximum ratings

between the two grounds.

MAX1002/MAX1003 Evaluation Kits

4 _______________________________________________________________________________________

5pF capacitor (MAX1003),

22pF capacitor (MAX1002)

Clock input BNC

connector

DESCRIPTION

47pF capacitors

COMPONENT

Clock Overdrive

C6, C7

C5

Remove

Add

MODIFICATION

Replace with

0.01µF capacitors

10kΩ resistor

220nH inductor

Remove

Remove

47kΩ resistors

Replace with

49.9Ω resistors

L1

R2, R3

R1

Varactor diode RemoveD1

Table 4. External Clock Source EV Kit

Modifications

Bypassing

Proper bypassing is essential to achieve the best

dynamic performance from the converters. The

MAX1002/MAX1003 EV kits use 10µF bypass capacitors located close to the power-supply connectors on

the board to filter low-frequency supply ripple. High-frequency bypassing is accomplished with ceramic chip

capacitors located very close to the device’s supply

pins.

As the digital outputs toggle, transient currents in the

V

CCO

supply can couple into sensitive analog circuitry

and severely degrade the converters’ effective number

of bits performance. Of particular concern is effectively

bypassing V

CCO

to OGND. For best results, locate the

bypass capacitors on the same side of the board and

place them close to the device. This avoids the use of

through-holes and results in lower series inductance.

The capacitor size chosen for the EV kits (size 0603)

keeps the layout compact. Finally, the modest value

(47pF) and small size result in a high self-resonant frequency for effective high-frequency bypassing.

__________Applications Information

To achieve the full dynamic potential from the converters, minimize the capacitive loading on the digital outputs to reduce the transient currents at V

CCO

and

OGND. The maximum capacitance per output bit

should be less than 15pF. For example, the capacitance of the digital output traces and the J1 connector

on the EV kits is about 3pF per trace. In an applications

circuit, this could be further reduced by locating the

digital receiving chip very close to the MAX1002/

MAX1003 and removing the ground plane from under

the output bit traces.

A logic analyzer can be connected to the J1 connector

on the EV kits for evaluation purposes. The analyzer

should be directly connected to the EV kit without any

additional ribbon cables. Even a short length of ribbon

cable can exceed the maximum recommended capacitive loading of the digital outputs. A typical high-speed

logic analyzer probe adds about another 8pF loading

per digital bit, which is acceptable for good dynamic

performance.

Evaluate: MAX1002/MAX1003

MAX1002/MAX1003 Evaluation Kits

_______________________________________________________________________________________ 5

Evaluate: MAX1002/MAX1003

MAX1002/MAX1003 Evaluation Kits

6 _______________________________________________________________________________________

36

35

34

33

32

31

30

29

28

27

26

25

24

23

1

1 3

JU5

2

2

3

4

5

6

7

8

9

10

11

12

13

14

MAX1003

(MAX1002)

22

21

20

19

15

QIN-

V

CC

GND

GND

TNK-

TNK+

VCCGND

VCCIIN-

IIN+

IOCC-

IOCC+

GAIN

IIN+

QIN-

QIN+

BNC

BNC

R4

49.9Ω

R5

49.9Ω

R3

47k

C10

0.01µF

C4

0.22µF

R1

10k

D1

R2

47k

R7

49.9Ω

R6

49.9Ω

VTUNE

VCC

BNC

(22pF)

BNC

= ANALOG GROUND (GND)

= DIGITAL GROUND (OGND)

1

2

3

C8

0.1µF

C9

0.1µF

JU4

VCC

JU3

JU6

0Ω

C13

0.1µF

C1

0.01µF

C3

47pF

C2

47pF

C11

0.01µF

C12

0.01µF

C14

0.1µF

C6

47pF

C7

47pF

C5

5pF

L1

220nH

VCC

JU7

0Ω

IIN-

GND

QOCC+

QOCC-

QIN+

V

CC

DI5

DI4

DI3

DI2

DI1

DQ2

DI0

DCLK

V

CC

OGND

V

CC

DQ0

DQ1

GND

DQ3

DQ4

DQ5

J1–1

J1–3

J1–5

J1–7

J1–9

J1–11

J1–13

JU2

0Ω

JU1

0Ω

VCC

VCCO

J1–15

J1–17

J1–19

J1–21

J1–23

J1–25

J1–4

J1–6

J1–8

J1–10

J1–12

J1–2

J1–16

J1–18

J1–20

J1–22

J1–24

J1–26

J1–14

U1

16

17

18

VTUNE VTUNE

= MAX1002

C16

10µF

VCC

VCCO

JU11

CUT HERE

TO SEPARATE

GROUNDS

JU9

JU8

VCC

GND

VCCO

C15

0.22µF

C17

10µF

OGND

( )

Figure 3. MAX1002/MAX1003 EV Kit Schematic (Voltage-Controlled-Oscillator Mode)

Evaluate: MAX1002/MAX1003

MAX1002/MAX1003 Evaluation Kits

_______________________________________________________________________________________ 7

36

35

34

33

32

31

30

29

28

27

26

25

24

23

1

1 3

JU5

2

2

3

4

5

6

7

8

9

10

11

12

13

14

MAX1003

(MAX1002)

22

21

20

19

15

QIN-

V

CC

GND

GND

TNK-

TNK+

VCCGND

VCCIIN-

IIN+

IOCC-

IOCC+

GAIN

VCC

IIN+

QIN-

QIN+

BNC

BNC

R4

49.9Ω

R5

49.9Ω

C10

0.01µF

C4

0.22µF

R6

49.9Ω

VCC

BNC

BNC

C8

0.1µF

C9

0.1µF

C6

0.01µF

C7

0.01µF

JU4

JU3

0Ω

JU6

C13

0.1µF

C1

0.01µF

C3

47pF

C2

47pF

C11

0.01µF

C12

0.01µF

C14

0.1µF

VCC

JU7

0Ω

IIN-

GND

QOCC+

QOCC-

QIN+

V

CC

DI5

DI4

DI3

DI2

DI1

DQ2

DI0

DCLK

V

CC

OGND

V

CC

DQ0

DQ1

GND

DQ3

DQ4

DQ5

R7

49.9Ω

J1–1

J1–3

J1–5

J1–7

J1–9

J1–11

J1–13

JU2

0Ω

JU1

0Ω

VCC

VCCO

J1–15

J1–17

J1–19

J1–21

J1–23

J1–25

J1–4

J1–6

J1–8

J1–10

J1–12

J1–2

J1–16

J1–18

J1–20

J1–22

J1–24

J1–26

J1–14

BNC

CLK_IN

R3

49.9Ω

R2

49.9Ω

= ANALOG GROUND

= DIGITAL GROUND

U1

16

17

18

VTUNE VTUNE

= MAX1002

C16

10µF

VCC

VCCO

JU11

CUT HERE

TO SEPARATE

GROUNDS

JU9

JU8

VCC

GND

VCCO

C15

0.22µF

OGND

C17

10µF

( )

Figure 4. MAX1002/MAX1003 EV Kit Schematic (External Clock Operation)

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

8

___________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

© 1997 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Evaluate: MAX1002/MAX1003

MAX1002/MAX1003 Evaluation Kits

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

8

___________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

© 1997 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Figure 5. MAX1002/MAX1003 EV Kit Component Placement

Guide—Component Side

Figure 6. MAX1002/MAX1003 EV Kit Component Placement

Guide—Solder Side

Figure 7. MAX1002/MAX1003 EV Kit PC Board Layout—

Component Side

Figure 8. MAX1002/MAX1003 EV Kit PC Board Layout—

Solder Side

1.0"

1.0"

1.0"

1.0"

Loading...

Loading...