Page 1

s

www.maxim-ic.com

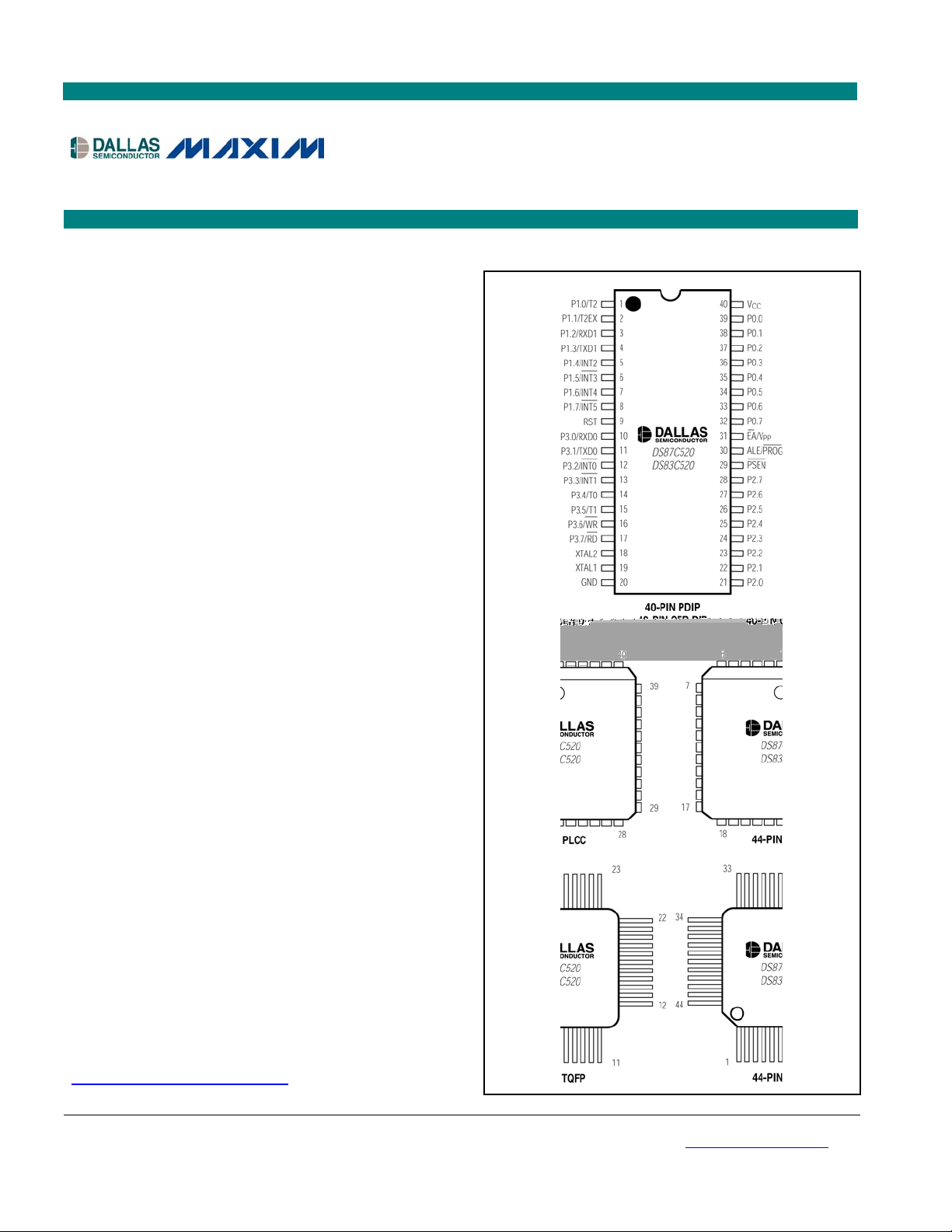

DS87C520/DS83C520

EPROM/ROM High-Speed Microcontroller

FEATURES

80C52 Compatible

8051 Pin- and Instruction-Set Compatible

Four 8-Bit I/O Ports

Three 16-Bit Timer/Counters

256 Bytes Scratchpad RAM

Large On-Chip Memory

16kB Program Memory

1kB Extra On-Chip SRAM for MOVX

ROMSIZE Feature

Selects Internal ROM Size from 0 to 16kB

Allows Access to Entire External Memory Map

Dynamically Adjustable by Software

Useful as Boot Block for External Flash

High-Speed Architecture

4 Clocks/Machine Cycle (8051 = 12)

Runs DC to 33MHz Clock Rates

Single-Cycle Instruction in 121ns

Dual Data Pointer

Optional Variable Length MOVX to Access

Fast/Slow RAM/Peripherals

Power Management Mode

Programmable Clock Source to Save Power

CPU Runs from (crystal/64) or (crystal/1024)

Provides Automatic Hardware and Software Exit

EMI Reduction Mode Disables ALE

Two Full-Duplex Hardware Serial Ports

High Integration Controller Includes:

Power-Fail Reset

Early-Warning Power-Fail Interrupt

Programmable Watchdog Timer

13 Interrupt Sources with Six External

Available in 40-pin PDIP, 44-Pin PLCC, 44-Pin

TQFP, and 40-Pin Windowed CERDIP

Factory Mask DS83C520 or EPROM (OTP)

DS87C520

PIN CONFIGURATIONS

TOP VIEW

The High-Speed Microcontroller User’s Guide must be used in

conjunction with this data sheet. Download it at:

www.maxim-ic.com/microcontrollers.

Note: Some revisions of this device may incorporate deviations from published specifications known as errata. Multiple revisions of any device

may be simultaneously available through various sales channels. For information about device errata, click here: www.maxim-ic.com/errata

1 of 45

REV: 022207

.

Page 2

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

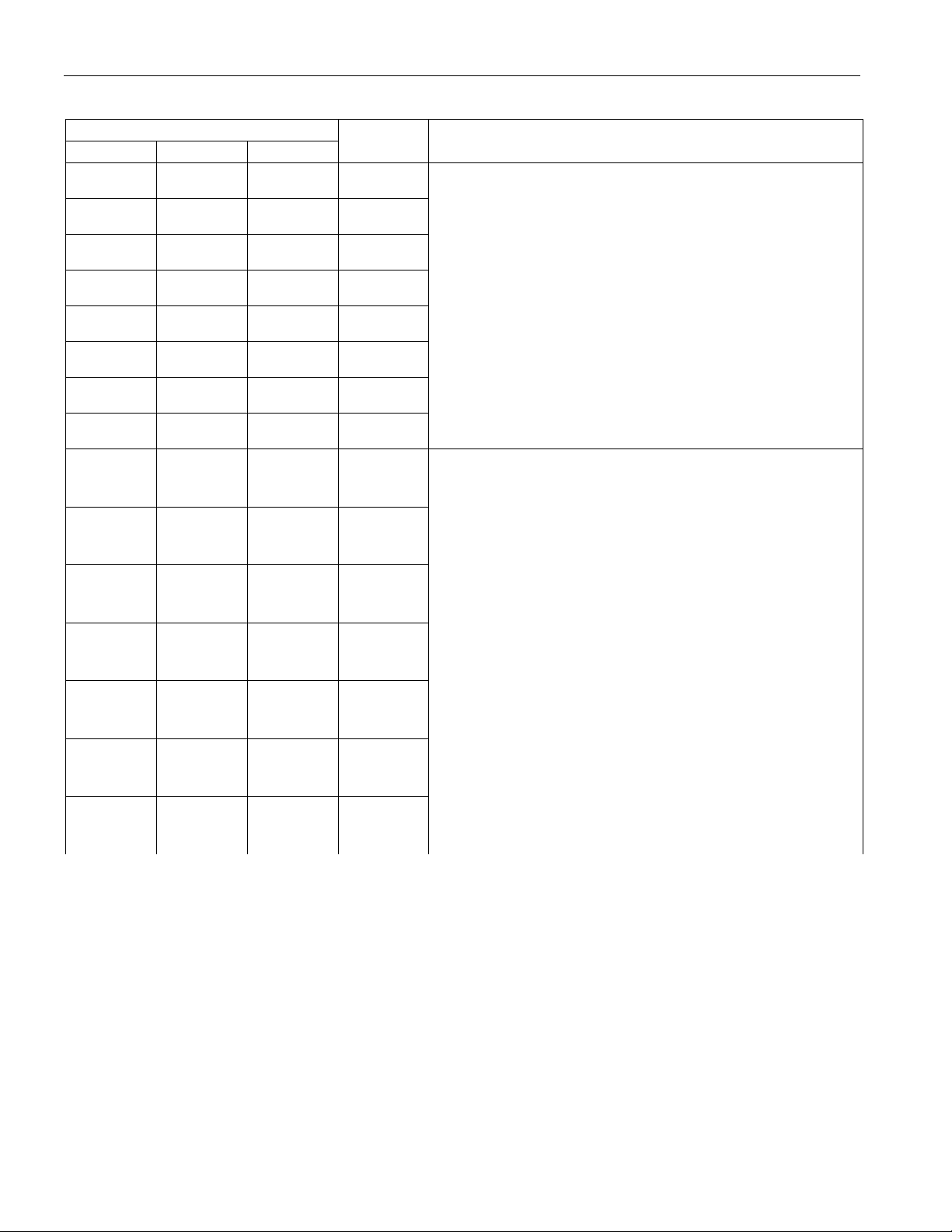

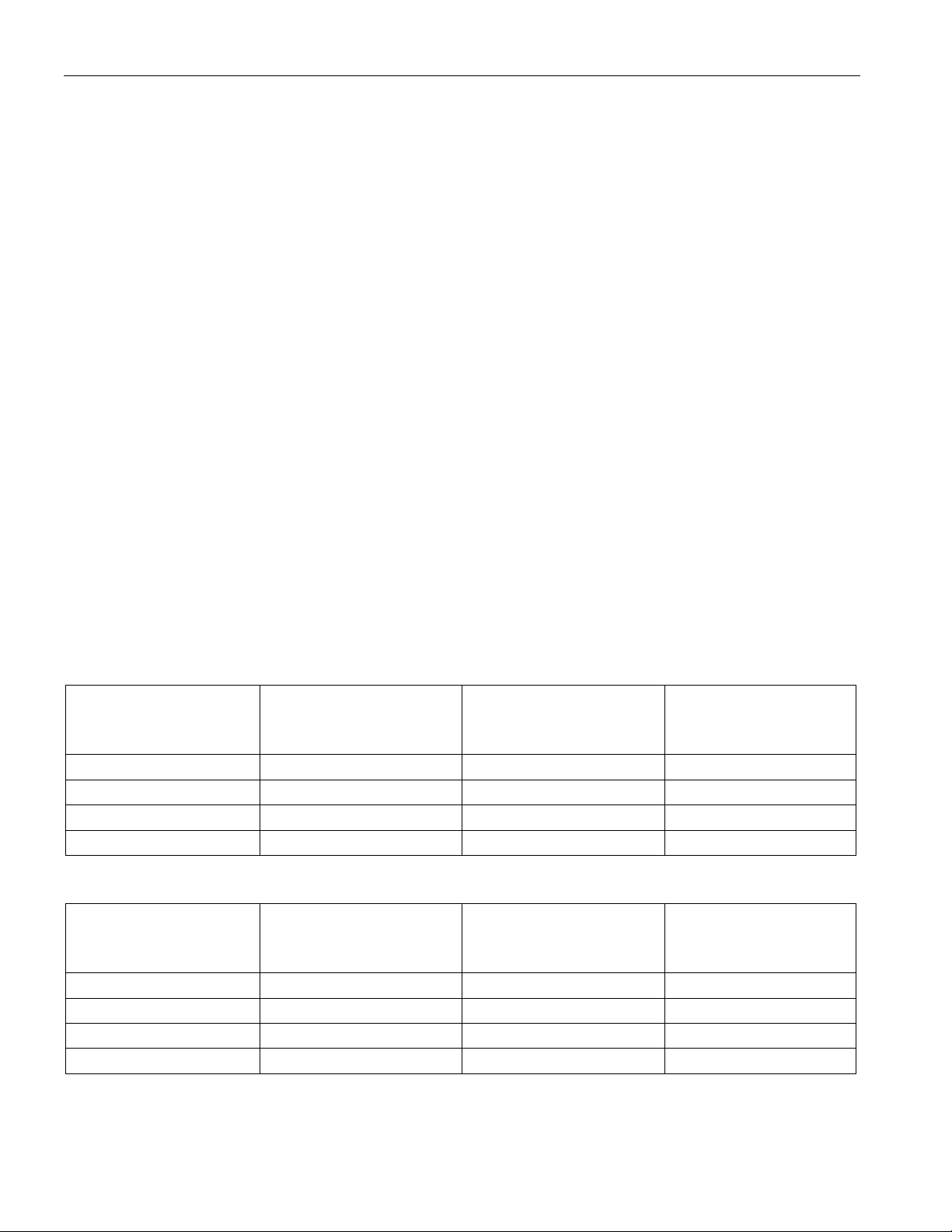

ORDERING INFORMATION

PART TEMP RANGE

MAX CLOCK

SPEED (MHz)

DS87C520-MCL 0˚C to +70˚C 33 40 Plastic DIP

DS87C520-MCL+ 0˚C to +70˚C 33 40 Plastic DIP

DS87C520-QCL 0˚C to +70˚C 33 44 PLCC

DS87C520-QCL+ 0˚C to +70˚C 33 44 PLCC

DS87C520-ECL 0˚C to +70˚C 33 44 TQFP

DS87C520-ECL+ 0˚C to +70˚C 33 44 TQFP

DS87C520-MNL -40˚C to +85˚C 33 40 Plastic DIP

DS87C520-MNL+ -40˚C to +85˚C 33 40 Plastic DIP

DS87C520-QNL -40˚C to +85˚C 33 44 PLCC

DS87C520-QNL+ -40˚C to +85˚C 33 44 PLCC

DS87C520-ENL -40˚C to +85˚C 33 44 TQFP

DS87C520-ENL+ -40˚C to +85˚C 33 44 TQFP

DS87C520-WCL* 0˚C to +70˚C 33 40 Windowed CERDIP

DS83C520-MCL 0˚C to +70˚C 33 40 Plastic DIP

DS83C520-MCL+ 0˚C to +70˚C 33 40 Plastic DIP

DS83C520-QCL 0˚C to +70˚C 33 44 PLCC

DS83C520-QCL+ 0˚C to +70˚C 33 44 PLCC

DS83C520-ECL 0˚C to +70˚C 33 44 TQFP

DS83C520-ECL+ 0˚C to +70˚C 33 44 TQFP

DS83C520-MNL -40˚C to +85˚C 33 40 Plastic DIP

DS83C520-MNL+ -40˚C to +85˚C 33 40 Plastic DIP

DS83C520-QNL -40˚C to +85˚C 33 44 PLCC

DS83C520-QNL+ -40˚C to +85˚C 33 44 PLCC

DS83C520-ENL -40˚C to +85˚C 33 44 TQFP

DS83C520-ENL+ -40˚C to +85˚C 33 44 TQFP

PIN-PACKAGE

+ Denotes a Pb-free/RoHS-compliant device.

* The windowed ceramic DIP package is intrinsically Pb free.

2 of 45

Page 3

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

DESCRIPTION

The DS87C520/DS83C520 EPROM/ROM high-speed microcontrollers are fast 8051-compatible

microcontrollers. They feature a redesigned processor core without wasted clock and memory cycles. As

a result, the devices execute every 8051 instruction between 1.5 and 3 times faster than the original for

the same crystal speed. Typical applications will see a speed improvement of 2.5 times using the same

code and the same crystal. The DS87C520/DS83C520 offer a maximum crystal speed of 33MHz,

resulting in apparent execution speeds of 82.5MHz (approximately 2.5X).

The DS87C520/DS83C520 are pin compatible with all three packages of the standard 8051, and include

standard resources such as three timer/counters, serial port, and four 8-bit I/O ports. They feature 16kB of

EPROM or mask ROM with an extra 1kB of data RAM. Both OTP and windowed packages are

available.

Besides greater speed, the microcontroller includes a second full hardware serial port, seven additional

interrupts, programmable Watchdog Timer, Brownout Monitor, and Power-Fail Reset. The device also

provides dual data pointers (DPTRs) to speed block data memory moves. It also can adjust the speed of

MOVX data memory access from two to nine machine cycles for flexibility in selecting external memory

and peripherals.

A new Power Management Mode (PMM) is useful for portable applications. This feature allows software

to select a lower speed clock as the main time base. While normal operation has a machine cycle rate of 4

clocks per cycle, the PMM runs the processor at 64 or 1024 clocks per cycle. For example, at 12MHz,

standard operation has a machine cycle rate of 3MHz. In Power Management Mode, software can select

either 187.5kHz or 11.7kHz machine cycle rate. There is a corresponding reduction in power

consumption when the processor runs slower.

The EMI reduction feature allows software to select a reduced emission mode. This disables the ALE

signal when it is unneeded.

The DS83C520 is a factory mask ROM version of the DS87C520 designed for high-volume, costsensitive applications. It is identical in all respects to the DS87C520, except that the 16kB of EPROM is

replaced by a user-supplied application program. All references to features of the DS87C520 will apply to

the DS83C520, with the exception of EPROM-specific features where noted. Please contact your local

Dallas Semiconductor sales representative for ordering information.

3 of 45

Page 4

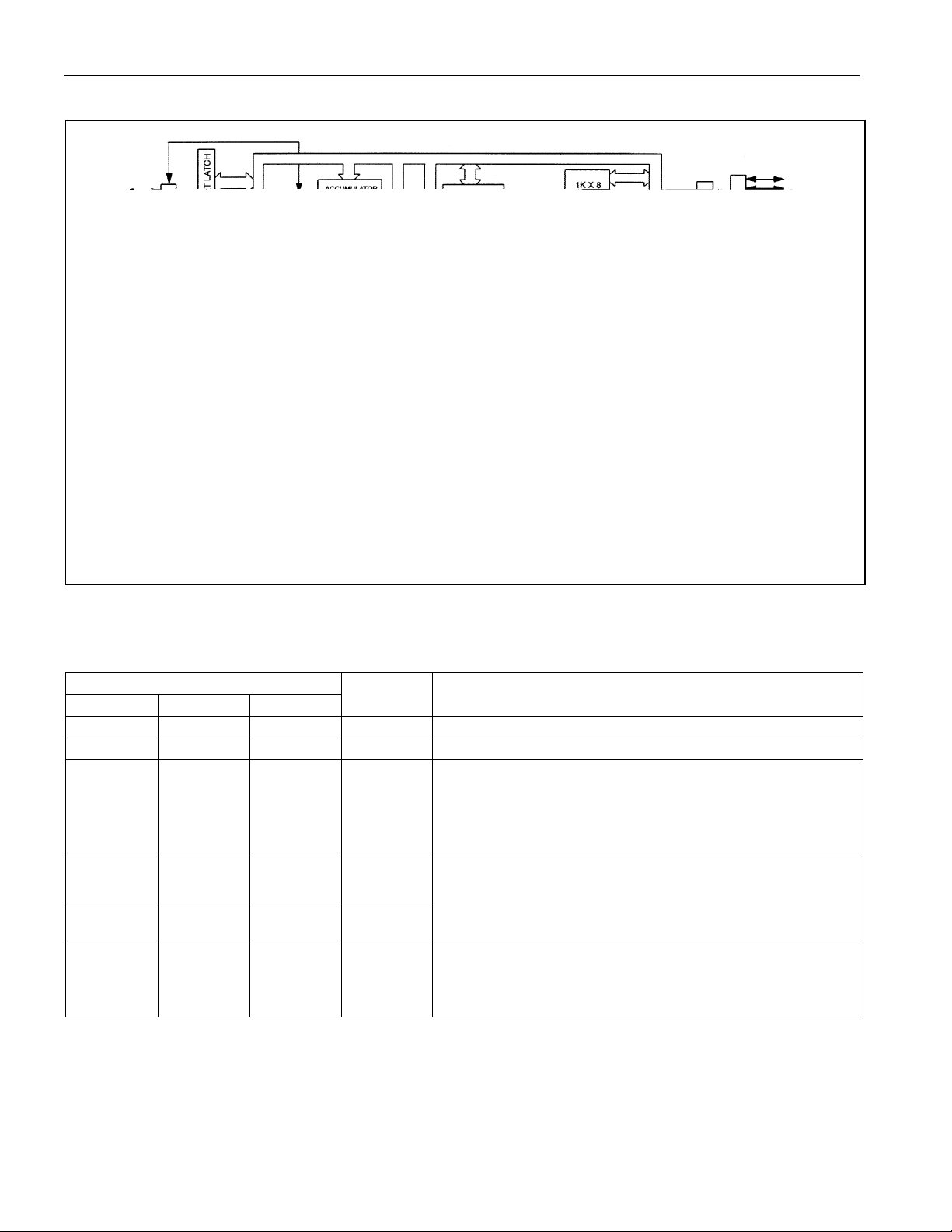

Figure 1. Block Diagram

DS87C520/

DS83C520

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

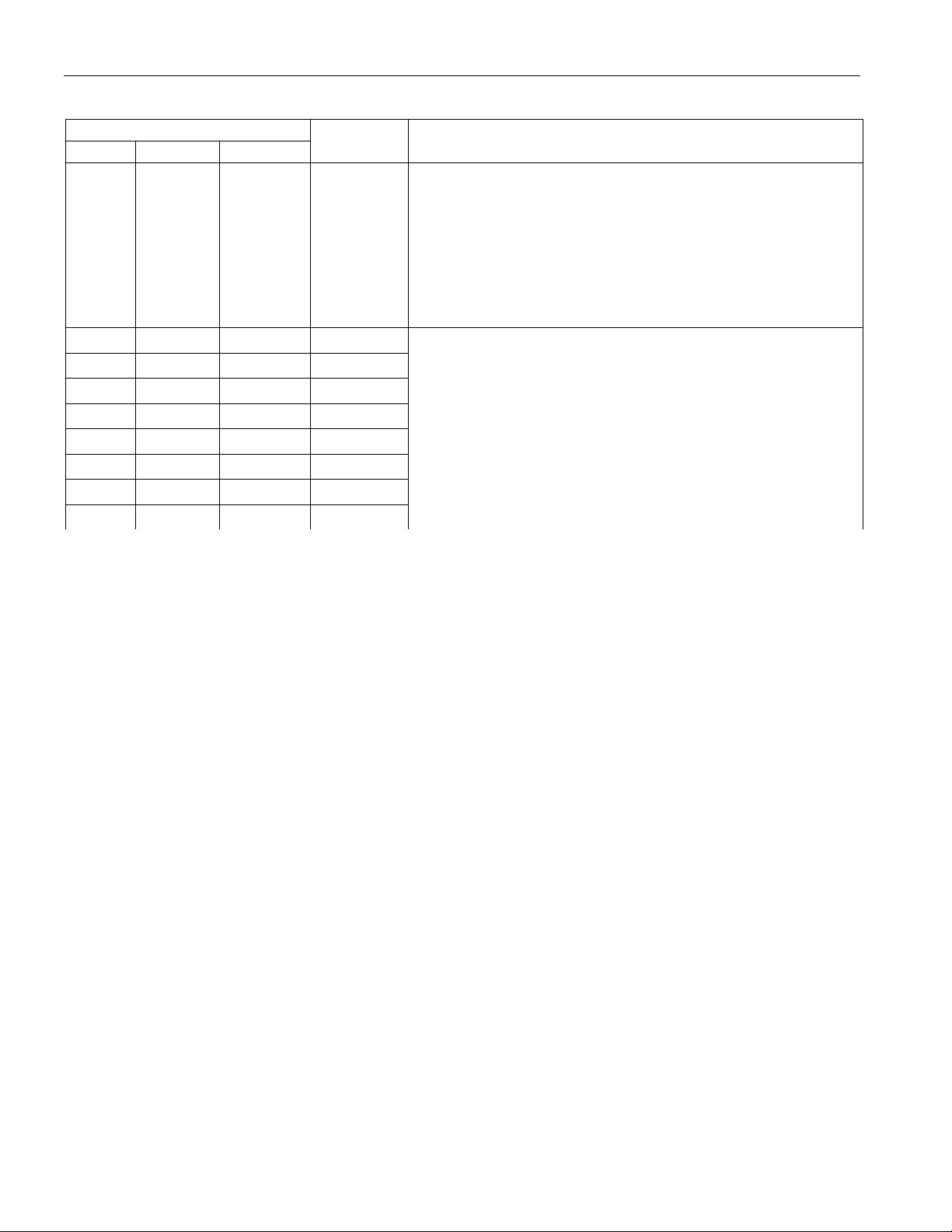

PIN DESCRIPTION

PIN

DIP PLCC TQFP

40 44 38 V

20 1, 22, 23 16, 17, 39 GND

9 10 4 RST

18 20 14 XTAL2

19 21 15 XTAL1

29 32 26 PSEN

NAME FUNCTION

CC

Positive Supply Voltage. +5V

Digital Circuit Ground

Reset Input. The RST input pin contains a Schmitt voltage input

to recognize external active high Reset inputs. The pin also

employs an internal pulldown resistor to allow for a combination

of wired OR external reset sources. An RC is not required for

power-up, as the device provides this function internally.

Crystal Oscillator Pins. XTAL1 and XTAL2 provide support for

parallel-resonant, AT-cut crystals. XTAL1 acts also as an input if

there is an external clock source in place of a crystal. XTAL2

serves as the output of the crystal amplifier.

Program Store-Enable Output. This active-low signal is

commonly connected to optional external ROM memory as a chip

enable. PSEN provides an active-low pulse and is driven high

when external ROM is not being accessed.

4 of 45

Page 5

PIN DESCRIPTION (continued)

PIN

DIP PLCC TQFP

30 33 27 ALE

39 43 37 P0.0 (AD0)

38 42 36 P0.1 (AD1)

37 41 35 P0.2 (AD2)

36 40 34 P0.3 (AD3)

35 39 33 P0.4 (AD4)

34 38 32 P0.5 (AD5)

33 37 31 P0.6 (AD6)

32 36 30 P0.7 (AD7)

NAME FUNCTION

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

Address Latch Enable Output. The ALE functions as a clock to

latch the external address LSB from the multiplexed address/data bus

on Port 0. This signal is commonly connected to the latch enable of an

external 373 family transparent latch. ALE has a pulse width of 1.5

XTAL1 cycles and a period of four XTAL1 cycles. ALE is forced

high when the DS87C520/DS83C520 are in a reset condition. ALE

can also be disabled and forced high by writing ALEOFF = 1

(PMR.2). ALE operates independently of ALEOFF during external

memory accesses.

Port 0 (AD0–7), I/O. Port 0 is an open-drain, 8-bit, bidirectional I/O

port. As an alternate function Port 0 can function as the multiplexed

address/data bus to access off-chip memory. During the time when

ALE is high, the LSB of a memory address is presented. When ALE

falls to a logic 0, the port transitions to a bidirectional data bus. This

bus is used to read external ROM and read/write external RAM

memory or peripherals. When used as a memory bus, the port

provides active high drivers. The reset condition of Port 0 is tri-state.

Pullup resistors are required when using Port 0 as an I/O port.

5 of 45

Page 6

PIN DESCRIPTION (continued)

PIN

DIP PLCC TQFP

NAME FUNCTION

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

21 24 18 P2.0 (A8)

22 25 19 P2.1 (A9)

23 26 20 P2.2 (A10)

24 27 21 P2.3 (A11)

25 28 22 P2.4 (A12)

26 29 23 P2.5 (A13)

27 30 24 P2.6 (A14)

28 31 25 P2.7 (A15)

10 11 5 P3.0

11 13 7 P3.1

12 14 8 P3.2

13 15 9 P3.3

Port 2 (A8–15), I/O. Port 2 is a bidirectional I/O port. The reset

condition of Port 2 is logic high. In this state, a weak pullup holds

the port high. This condition also serves as an input mode, since

any external circuit that writes to the port will overcome the weak

pullup. When software writes a 0 to any port pin, the

DS87C520/DS83C520 will activate a strong pulldown that

remains on until either a 1 is written or a reset occurs. Writing a 1

after the port has been at 0 will cause a strong transition driver to

turn on, followed by a weaker sustaining pullup. Once the

momentary strong driver turns off, the port again becomes both the

output high and input state. As an alternate function Port 2 can

function as MSB of the external address bus. This bus can be used

to read external ROM and read/write external RAM memory or

peripherals.

Port 3, I/O. Port 3 functions as both an 8-bit, bidirectional I/O

port and an alternate functional interface for External Interrupts,

Serial Port 0, Timer 0 and 1 Inputs, and RD and WR strobes. The

reset condition of Port 3 is with all bits at a logic 1. In this state, a

weak pullup holds the port high. This condition also serves as an

input mode, since any external circuit that writes to the port will

overcome the weak pullup. When software writes a 0 to any port

pin, the DS87C520/DS83C520 will activate a strong pulldown that

remains on until either a 1 is written or a reset occurs. Writing a 1

after the port has been at 0 will cause a strong transition driver to

14 16 10 P3.4

15 17 11 P3.5

16 18 12 P3.6

17 19 13 P3.7

6 of 45

Page 7

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

COMPATIBILITY

The DS87C520/DS83C520 are fully static CMOS 8051-compatible microcontrollers designed for high

performance. In most cases, the DS87C520/DS83C520 can drop into an existing socket for the 8xc51

family to improve the operation significantly. While remaining familiar to 8051 family users, the devices

have many new features. In general, software written for existing 8051-based systems works without

modification on the DS87C520/DS83C520. The exception is critical timing since the high-speed

microcontrollers performs instructions much faster than the original for any given crystal selection. The

DS87C520/DS83C520 run the standard 8051 family instruction set and are pin compatible with DIP,

PLCC, or TQFP packages.

The DS87C520/DS83C520 provide three 16-bit timer/counters, full-duplex serial port (2), 256 bytes of

direct RAM plus 1kB of extra MOVX RAM. I/O ports have the same operation as a standard 8051

product. Timers will default to a 12-clock per cycle operation to keep their timing compatible with

original 8051 family systems. However, timers are individually programmable to run at the new four

clocks per cycle if desired. The PCA is not supported.

The DS87C520/DS83C520 provide several new hardware features implemented by new special function

registers. A summary of these SFRs is provided below.

PERFORMANCE OVERVIEW

The DS87C520/DS83C520 feature a high-speed 8051-compatible core. Higher speed comes not just from

increasing the clock frequency but also from a newer, more efficient design.

This updated core does not have the dummy memory cycles that are present in a standard 8051. A

conventional 8051 generates machine cycles using the clock frequency divided by 12. In the

DS87C520/DS83C520, the same machine cycle takes 4 clocks. Thus the fastest instruction, 1 machine

cycle, executes three times faster for the same crystal frequency. Note that these are identical instructions.

The majority of instructions on the DS87C520/DS83C520 will see the full 3-to-1 speed improvement.

Some instructions will get between 1.5 and 2.4 to 1 improvement. All instructions are faster than the

original 8051.

The numerical average of all opcodes gives approximately a 2.5 to 1 speed improvement. Improvement of

individual programs will depend on the actual instructions used. Speed-sensitive applications would make

the most use of instructions that are three times faster. However, the sheer number of 3 to 1 improved

opcodes makes dramatic speed improvements likely for any code. These architecture improvements

produce a peak instruction cycle in 121ns (8.25 MIPs). The Dual Data Pointer feature also allows the user

to eliminate wasted instructions when moving blocks of memory.

INSTRUCTION SET SUMMARY

All instructions perform the same functions as their 8051 counterparts. Their effect on bits, flags, and

other status functions is identical. However, the timing of each instruction is different. This applies both

in absolute and relative number of clocks.

For absolute timing of real-time events, the timing of software loops can be calculated using a table in the

High-Speed Microcontroller User’s Guide. However, counter/timers default to run at the older 12 clocks

per increment. In this way, timer-based events occur at the standard intervals with software executing at

higher speed. Timers optionally can run at 4 clocks per increment to take advantage of faster processor

operation.

7 of 45

Page 8

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

The relative time of two instructions might be different in the new architecture than it was previously. For

example, in the original architecture, the “MOVX A, @DPTR” instruction and the “MOV direct, direct”

instruction used two machine cycles or 24 oscillator cycles. Therefore, they required the same amount of

time. In the DS87C520/DS83C520, the MOVX instruction takes as little as two machine cycles or eight

oscillator cycles but the “MOV direct, direct” uses three machine cycles or 12 oscillator cycles. While

both are faster than their original counterparts, they now have different execution times. This is because

the DS87C520/DS83C520 usually use one instruction cycle for each instruction byte. The user concerned

with precise program timing should examine the timing of each instruction for familiarity with the

changes. Note that a machine cycle now requires just 4 clocks, and provides one ALE pulse per cycle.

Many instructions require only one cycle, but some require five. In the original architecture, all were one

or two cycles except for MUL and DIV. Refer to the High-Speed Microcontroller User’s Guide for

details and individual instruction timing.

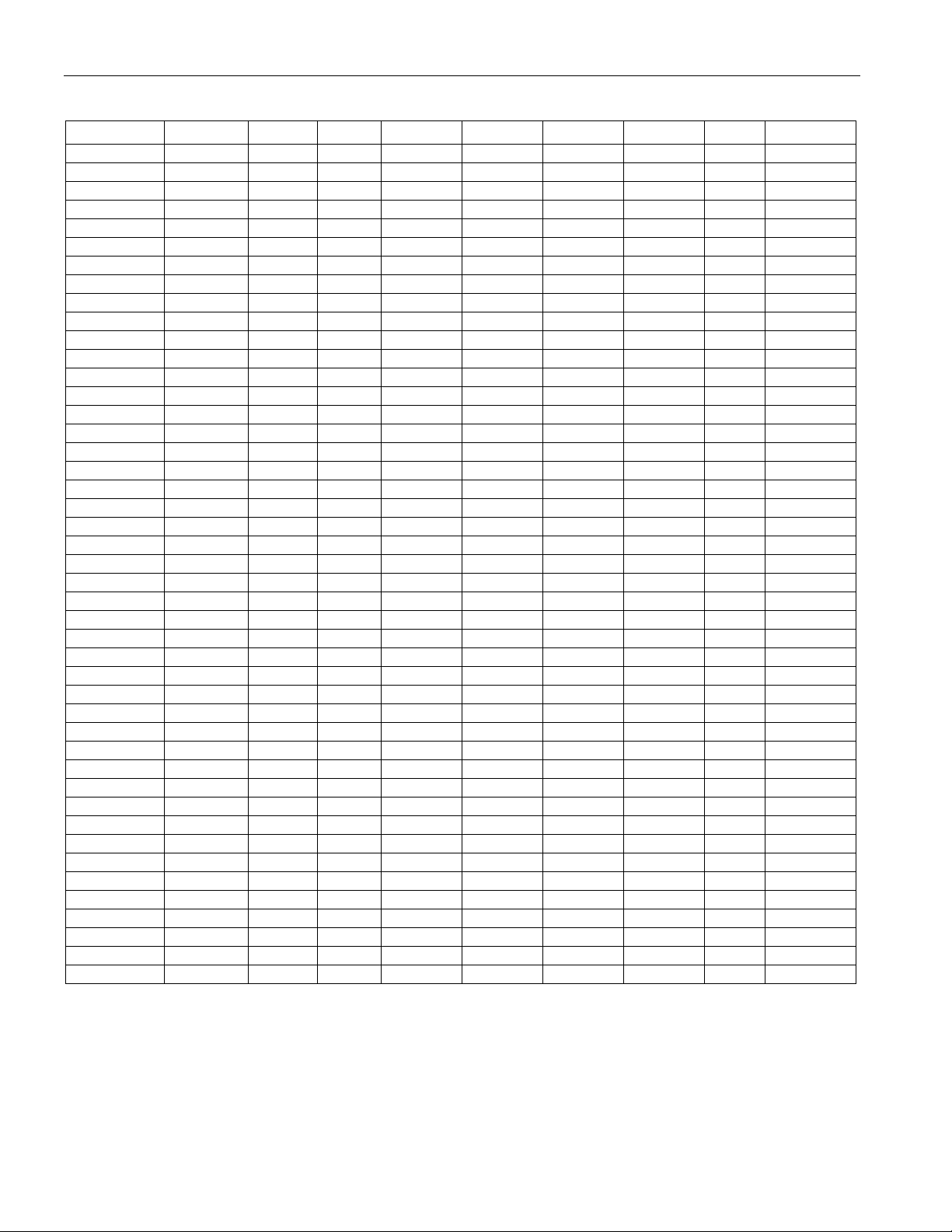

SPECIAL FUNCTION REGISTERS

Special Function Registers (SFRs) control most special features of the DS87C520/DS83C520. This

allows the DS87C520/DS83C520 to have many new features but use the same instruction set as the 8051.

When writing software to use a new feature, an equate statement defines the SFR to an assembler or

compiler. This is the only change needed to access the new function. The DS87C520/DS83C520

duplicate the SFRs contained in the standard 80C52. Table 1 shows the register addresses and bit

locations. The High-Speed Microcontroller User’s Guide describes all SFRs.

8 of 45

Page 9

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

Table 1. Special Function Register Locations

REGISTER BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0 ADDRESS

P0

SP

DPL

DPH

DPL1

DPH1

DPS

PCON

TCON

TMOD

TL0

TL1

TH0

TH1

CKCON

PORT1

EXIF

SCON0

SBUF0

P2

IE

SADDR0

SADDR1

P3

IP

SADEN0

SADEN1

SCON1

SBUF1

ROMSIZE

PMR

STATUS

TA

T2CON

T2MOD

RCAP2L

RCAP2H

TL2

TH2

PSW

WDCON

ACC

EIE

B

EIP

Note: New functions are in bold.

P0.7 P0.6 P0.5 P0.4 P0.3 P0.2 P0.1 P0.0 80h

81h

82h

83h

84h

85h

0 0 0 0 0 0 0 SEL

SMOD_0

TF1 TR1 TF0 TR0 IE1 IT1 IE0 IT0 88h

GATE

8Ah

8Bh

8Ch

8Dh

WD1 WD0 T2M T1M T0M MD2 MD1 MD0

P1.7 P1.6 P1.5 P1.4 P1.3 P1.2 P1.1 P1.0 90h

IE5 IE4 IE3 IE

SM0/FE_0 SM1_0 SM2_0 REN_0 TB8_0 RB8_0 TI_0 RI_0 98h

99h

P2.7 P2.6 P2.5 P2.4 P2.3 P2.2 P2.1 P2.0 A0h

EA ES1 ET2 ES0 ET1 EX1 ET0 EX0 A8h

A9h

AAh

P3.7 P3.6 P3.5 P3.4 P3.3 P3.2 P3.1 P3.0 B0h

— PS1 PT2 PS0 PT1 PX1 PT0 PX0 B8h

B9h

BAh

SM0/FE_1 SM1_1 SM2_1 REN_1 TB8_1 RB8_1 TI_1 R1_1

SB7 SB6 SB5 SB4 SB3 SB2 SB1 SB0

— — — — —

CD1 CD0 SWB — XTOFF ALEOFF DME1 DME0

PIP HIP LIP XTUP SPTA1 SPTA1 SPTA0 SPRA0

TF2 EXF2 RCLK TCLK EXEN2 TR2

— — — — — — T2OE DCEN C9h

CAh

CBh

CCh

CDh

CY AC F0 RS1 RS0 OV FL P D0h

SMOD_1 POR EPFI PFI WDIF WTRF EWT RWT

E0h

— — —

F0h

— — —

SMOD0

C/T

— — GF1 GF0 STOP IDLE 87h

M1 M0 GATE

XT/RG

EWDI EX5 EX4 EX3 EX2

PWDI PX5 PX4 PX3 PX2

C/T

RGMD RGSL BGS

RMS2 RMS1 RMS0

M1 M0 89h

C/T2 C/RL2

86h

8Eh

91h

C0h

C1h

C2h

C4h

C5h

C7h

C8h

D8h

E8h

F8h

9 of 45

Page 10

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

MEMORY RESOURCES

Like the 8051, the DS87C520/DS83C520 use three memory areas. The total memory configuration of the

DS87C520/DS83C520 is 16kB of ROM, 1kB of data SRAM and 256 bytes of scratchpad or direct RAM.

The 1kB of data space SRAM is read/write accessible and is memory mapped. This on-chip SRAM is

reached by the MOVX instruction. It is not used for executable memory. The scratchpad area is 256 bytes

of register mapped RAM and is identical to the RAM found on the 80C52. There is no conflict or overlap

among the 256 bytes and the 1kB as they use different addressing modes and separate instructions.

OPERATIONAL CONSIDERATION

The erasure window of the windowed CERDIP should be covered without regard to the

programmed/unprogrammed state of the EPROM. Otherwise, the device may not meet the AC and DC

parameters listed in the data sheet.

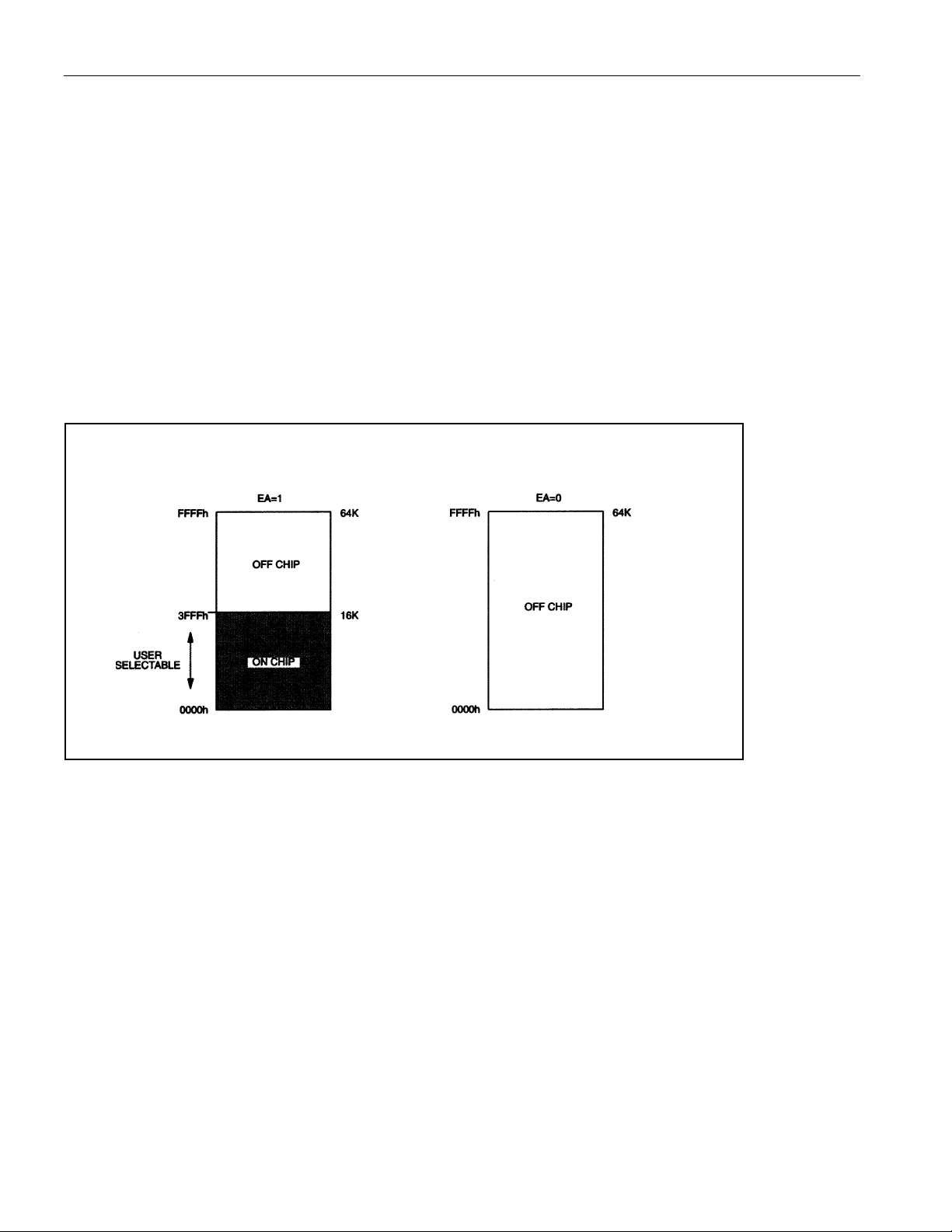

PROGRAM MEMORY ACCESS

On-chip ROM begins at address 0000h and is contiguous through 3FFFh (16kB). Exceeding the

maximum address of on-chip ROM will cause the device to access off-chip memory. However, the

maximum on-chip decoded address is selectable by software using the ROMSIZE feature. Software can

cause the DS87C520/DS83C520 to behave like a device with less on-chip memory. This is beneficial

when overlapping external memory, such as Flash, is used. The maximum memory size is dynamically

variable. Thus a portion of memory can be removed from the memory map to access off-chip memory,

and then restored to access on-chip memory. In fact, all of the on-chip memory can be removed from the

memory map allowing the full 64kB memory space to be addressed from off-chip memory. ROM

addresses that are larger than the selected maximum are automatically fetched from outside the part via

Ports 0 and 2. A depiction of the ROM memory map is shown in Figure 2.

The ROMSIZE register is used to select the maximum on-chip decoded address for ROM. Bits RMS2,

RMS1, RMS0 have the following effect.

RMS2 RMS1 RMS0 MAXIMUM ON-CHIP ROM ADDRESS

0 0 0 0kB

0 0 1 1kB/03FFh

0 1 0 2kB/07FFh

0 1 1 4kB/0FFFh

1 0 0 8kB/1FFFh

1 0 1 16kB (default)/3FFFh

1 1 0 Invalid—reserved

1 1 1 Invalid—reserved

The reset default condition is a maximum on-chip ROM address of 16kB. Thus no action is required if

this feature is not used. When accessing external program memory, the first 16kB would be inaccessible.

To select a smaller effective ROM size, software must alter bits RMS2–RMS0. Altering these bits

requires a Timed-Access procedure as explained later.

Care should be taken so that changing the ROMSIZE register does not corrupt program execution. For

example, assume that the DS87C520/DS83C520 are executing instructions from internal program

memory near the 12kB boundary (~3000h) and that the ROMSIZE register is currently configured for a

16kB internal program space. If software reconfigures the ROMSIZE register to 4kB (0000h–0FFFh) in

the current state, the device will immediately jump to external program execution because program code

10 of 45

Page 11

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

from 4kB to 16kB (1000h–3FFFh) is no longer located on-chip. This could result in code misalignment

and execution of an invalid instruction. The recommended method is to modify the ROMSIZE register

from a location in memory that will be internal (or external) both before and after the operation. In the

above example, the instruction which modifies the ROMSIZE register should be located below the 4kB

(1000h) boundary, so that it will be unaffected by the memory modification. The same precaution should

be applied if the internal program memory size is modified while executing from external program

memory.

Off-chip memory is accessed using the multiplexed address/data bus on P0 and the MSB address on P2.

While serving as a memory bus, these pins are not I/O ports. This convention follows the standard 8051

method of expanding on-chip memory. Off-chip ROM access also occurs if the EA pin is a logic 0. EA

overrides all bit settings. The PSEN signal goes active (low) to serve as a chip enable or output enable

when Ports 0 and 2 fetch from external ROM.

Figure 2. ROM Memory Map

ROM SIZE ADJUSTABLE

DEFAULT = 16kB

ROM SIZE IGNORED

DATA MEMORY ACCESS

Unlike many 8051 derivatives, the DS87C520/DS83C520 contain on-chip data memory. They also

contain the standard 256 bytes of RAM accessed by direct instructions. These areas are separate. The

MOVX instruction accesses the on-chip data memory. Although physically on-chip, software treats this

area as though it was located off-chip. The 1kB of SRAM is between address 0000h and 03FFh.

Access to the on-chip data RAM is optional under software control. When enabled by software, the data

SRAM is between 0000h and 03FFh. Any MOVX instruction that uses this area will go to the on-chip

RAM while enabled. MOVX addresses greater than 03FFh automatically go to external memory through

Ports 0 and 2.

11 of 45

Page 12

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

When disabled, the 1kB memory area is transparent to the system memory map. Any MOVX directed to

the space between 0000h and FFFFh goes to the expanded bus on Ports 0 and 2. This also is the default

condition. This default allows the DS87C520/DS83C520 to drop into an existing system that uses these

addresses for other hardware and still have full compatibility.

The on-chip data area is software selectable using 2 bits in the Power Management Register at location

C4h. This selection is dynamically programmable. Thus access to the on-chip area becomes transparent to

reach off-chip devices at the same addresses. Th

12 of 45

Page 13

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

setting. When desiring maximum speed, software should select a Stretch value of 0. When using very

slow RAM or peripherals, select a larger Stretch value. Note that this affects data memory only and the

only way to slow program memory (ROM) access is to use a slower crystal.

Using a Stretch value between 1 and 7 causes the microcontroller to stretch the read/write strobe and all

related timing. Also, setup and hold times are increased by 1 clock when using any Stretch greater than 0.

This results in a wider read/write strobe and relaxed interface timing, allowing more time for

memory/peripherals to respond. The timing of the variable speed MOVX is in the Electrical

Specifications section. Table 3 shows the resulting strobe widths for each Stretch value. The memory

Stretch uses the Clock Control Special Function Register at SFR location 8Eh. The Stretch value is

selected using bits CKCON.2–0. In the table, these bits are referred to as M2 through M0. The first

Stretch (default) allows the use of common 120ns RAMs without dramatically lengthening the memory

access.

Table 3. Data Memory Cycle Stretch Values

CKCON.2-0

MEMORY CYCLES

M2 M1 M0

0 0 0 2 (forced internal) 2 60

0 0 1 3 (default external) 4 121

0 1 0 4 8 242

0 1 1 5 12 364

1 0 0 6 16 485

1 0 1 7 20 606

1 1 0 8 24 727

1 1 1 9 28 848

RD OR WR STROBE

WIDTH IN CLOCKS

STROBE WIDTH

TIME at 33MHz (ns)

DUAL DATA POINTER

The timing of block moves of data memory is faster using the Dual Data Pointer (DPTR). The standard

8051 DPTR is a 16-bit value that is used to address off-chip data RAM or peripherals. In the

DS87C520/DS83C520, this data pointer is called DPTR0, located at SFR addresses 82h and 83h. These

are the original locations. Using DPTR requires no modification of standard code. The new DPTR at SFR

84h and 85h is called DPTR1. The DPTR Select bit (DPS) chooses the active pointer. Its location is the

lsb of the SFR location 86h. No other bits in register 86h have any effect and are 0. The user switches

between data pointers by toggling the lsb of register 86h. The increment (INC) instruction is the fastest

way to accomplish this. All DPTR-related instructions use the currently selected DPTR for any activity.

Therefore it takes only one instruction to switch from a source to a destination address. Using the Dual

Data Pointer saves code from needing to save source and destination addresses when doing a block move.

The software simply switches between DPTR0 and 1 once software loads them. The relevant register

locations are as follows:

DPL 82h Low byte original DPTR

DPH 83h High byte original DPTR

DPL1 84h Low byte new DPTR

DPH1 85h High byte new DPTR

DPS 86h DPTR Select (lsb)

13 of 45

Page 14

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

POWER MANAGEMENT

Along with the standard Idle and power down (Stop) modes of the standard 80C52, the

DS87C520/DS83C520 provide a new Power Management Mode. This mode allows the processor to

continue functioning, yet to save power compared with full operation. The DS87C520/DS83C520 also

feature several enhancements to Stop mode that make it more useful.

POWER MANAGEMENT MODE (PMM)

Power Management Mode offers a complete scheme of reduced internal clock speeds that allow the CPU

to run software but to use substantially less power. During default operation, the DS87C520/DS83C520

use four clocks per machine cycle. Thus the instruction cycle rate is Clock/4. At 33MHz crystal speed,

the instruction cycle speed is 8.25MHz (33/4). In PMM, the microcontroller continues to operate but uses

an internally divided version of the clock source. This creates a lower power state without external

components. It offers a choice of two reduced instruction cycle speeds (and two clock sources - discussed

below). The speeds are (Clock/64) and (Clock/1024).

Software is the only mechanism to invoke the PMM. Table 4 illustrates the instruction cycle rate in PMM

for several common crystal frequencies. Since power consumption is a direct function of operating speed,

PMM 1 eliminates most of the power consumption while still allowing a reasonable speed of processing.

PMM 2 runs very slow and provides the lowest power consumption without stopping the CPU. This is

illustrated in Table 5.

Note that PMM provides a lower power condition than Idle mode. This is because in Idle mode, all

clocked functions such as timers run at a rate of crystal divided by 4. Since wake-up from PMM is as fast

as or faster than from Idle, and PMM allows the CPU to operate (even if doing NOPs), there is little

reason to use Idle mode in new designs.

Table 4. Machine Cycle Rate

CRYSTAL SPEED

(MHz)

11.0592 2.765 172.8 10.8

16 4.00 250.0 15.6

25 6.25 390.6 24.4

33 8.25 515.6 32.2

FULL OPERATION

(4 CLOCKS)

(MHz)

Table 5. Typical Operating Current in PMM

CRYSTAL SPEED

(MHz)

11.0592 13.1 5.3 4.8

16 17.2 6.4 5.6

25 25.7 8.1 7.0

33 32.8 9.8 8.2

FULL OPERATION

(4 CLOCKS)

(mA)

14 of 45

PMM1

(64 CLOCKS)

(kHz)

PMM1

(64 CLOCKS)

(mA)

PMM2

(1024 CLOCKS)

(kHz)

PMM2

(1024 CLOCKS)

(mA)

Page 15

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

CRYSTAL-LESS PMM

A major component of power consumption in PMM is the crystal amplifier circuit. The

DS87C520/DS83C520 allow the user to switch CPU operation to an internal ring oscillator and turn off

the crystal amplifier. The CPU would then have a clock source of approximately 2MHz to 4MHz, divided

by either 4, 64, or 1024. The ring is not accurate, so software cannot perform precision timing. However,

this mode allows an additional saving of between 0.5mA and 6.0mA, depending on the actual crystal

frequency. While this saving is of little use when running at 4 clocks per instruction cycle, it makes a

major contribution when running in PMM1 or PMM2.

PMM OPERATION

Software invokes the PMM by setting the appropriate bits in the SFR area. The basic choices are divider

speed and clock source. There are three speeds (4, 64, and 1024) and two clock sources (crystal and ring).

Both the decisions and the controls are separate. Software will typically select the clock speed first. Then,

it will perform the switch to ring operation if desired. Lastly, software can disable the crystal amplifier if

desired.

There are two ways of exiting PMM. Software can remove the condition by reversing the procedure that

invoked PMM or hardware can (optionally) remove it. To resume operation at a divide-by-4 rate under

software control, simply select 4 clocks per cycle, then crystal-based operation if relevant. When

disabling the crystal as the time base in favor of the ring oscillator, there are timing restrictions associated

with restarting the crystal operation. Details are described below.

There are three registers containing bits that are concerned with PMM functions. They are Power

Management Register (PMR; C4h), Status (STATUS; C5h), and External Interrupt Flag (EXIF; 91h).

Clock Divider

Software can select the instruction cycle rate by selecting bits CD1 (PMR.7) and CD0 (PMR.6) as

follows:

CD1 CD0 CYCLE RATE

0 0 Reserved

0 1 4 clocks (default)

1 0 64 clocks

1 1 1024 clocks

The selection of instruction cycle rate will take effect after a delay of one instruction cycle. Note that the

clock divider choice applies to all functions including timers. Since baud rates are altered, it will be

difficult to conduct serial communication while in PMM. There are minor restrictions on accessing the

clock selection bits. The processor must be running in a 4-clock state to select either 64 (PMM1) or 1024

(PMM2) clocks. This means software cannot go directly from PMM1 to PMM2 or visa versa. It must

return to a 4-clock rate first.

15 of 45

Page 16

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

Switchback

To return to a 4-clock rate from PMM, software can simply select the CD1 and CD0 clock control bits to

the 4 clocks per cycle state. However, the DS87C520/DS83C520 provide several hardware alternatives

for automatic Switchback. If Switchback is enabled, then the device will automatically return to a 4-clock

per cycle speed when an interrupt occurs from an enabled, valid external interrupt source. A Switchback

will also occur when a UART detects the beginning of a serial start bit if the serial receiver is enabled

(REN = 1). Note the beginning of a start bit does not generate an interrupt; this occurs on reception of a

complete serial word. The automatic Switchback on detection of a start bit allows hardware to correct

baud rates in time for a proper serial reception. A switchback will also occur when a byte is written to

SBUF0 or SBUF1 for transmission.

Switchback is enabled by setting the SWB bit (PMR.5) to a 1 in software. For an external interrupt,

Switchback will occur only if the interrupt source could really generate the interrupt. For example, if

INT0 is enabled but has a low priority setting, then Switchback will not occur on INT0 if the CPU is

servicing a high priority interrupt.

Status

Information in the Status register assists decisions about switching into PMM. This register contains

information about the level of active interrupts and the activity on the serial ports.

The DS87C520/DS83C520 support three levels of interrupt priority. These levels are Power-fail, High,

and Low. Bits STATUS.7-5 indicate the service status of each level. If PIP (Power-fail Interrupt Priority;

STATUS. 7) is a 1, then the processor is servicing this level. If either HIP (High Interrupt Priority;

STATUS.6) or LIP (Low Interrupt Priority; STATUS.5) is high, then the corresponding level is in

service.

Software should not rely on a lower priority level interrupt source to remove PMM (Switchback) when a

higher level is in service. Check the current priority service level before entering PMM. If the current

service level locks out a desired Switchback source, then it would be advisable to wait until this condition

clears before entering PMM.

Alternately, software can prevent an undesired exit from PMM by entering a low priority interrupt service

level before entering PMM. This will prevent other low priority interrupts from causing a Switchback.

Status also contains information about the state of the serial ports. Serial Port 0 Receive Activity

(SPRA0;STATUS.0) indicates a serial word is being received on Serial Port 0 when this bit is set to a 1.

Serial Port 0 Transmit Activity (SPTA0; STATUS.1) indicates that the serial port is still shifting out a

serial transmission. STATUS.2 and STATUS.3 provide the same information for Serial Port 1,

respectively. These bits should be interrogated before entering PMM1 or PMM2 to ensure that no serial

port operations are in progress. Changing the clock divisor rate during a serial transmission or reception

will corrupt the operation.

16 of 45

Page 17

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

Crystal/Ring Operation

The DS87C520/DS83C520 allow software to choose the clock source as an independent selection from

the instruction cycle rate. The user can select crystal-based or ring oscillator-based operation under

software control. Power-on reset default is the crystal (or external clock) source. The ring may save

power depending on the actual crystal speed. To save still more power, software can then disable the

crystal amplifier. This process requires two steps. Reversing the process also requires two steps.

The XT/ RG bit (EXIF.3) selects the crystal or ring as the clock source. Setting XT/ RG = 1 selects the

crystal. Setting XT/ RG = 0 selects the ring. The RGMD (EXIF.2) bit serves as a status bit by indicating

the active clock source. RGMD = 0 indicates the CPU is running from the crystal. RGMD = 1 indicates it

is running from the ring. When operating from the ring, disable the crystal amplifier by setting the

XTOFF bit (PMR.3) to 1. This can only be done when XT/ RG = 0.

When changing the clock source, the selection will take effect after a one-instruction cycle delay. This

applies to changes from crystal to ring and vise versa. However, this assumes that the crystal amplifier is

running. In most cases, when the ring is active, software previously disabled the crystal to save power. If

ring operation is being used and the system must switch to crystal operation, the crystal must first be

enabled. Set the XTOFF bit to 0. At this time, the crystal oscillation will begin. The

DS87C520/DS83C520 then provide a warm-up delay to make certain that the frequency is stable.

Hardware will set the XTUP bit (STATUS.4) to a 1 when the crystal is ready for use. Then software

should write XT/ RG to 1 to begin operating from the crystal. Hardware prevents writing XT/ RG to 1

before XTUP=1. The delay between XTOFF = 0 and XTUP = 1 will be 65,536 crystal clocks in addition

to the crystal cycle startup time.

Switchback has no effect on the clock source. If software selects a reduced clock divider and enables the

ring, a Switchback will only restore the divider speed. The ring will remain as the time base until altered

by software. If there is serial activity, Switchback usually occurs with enough time to create proper baud

rates. This is not true if the crystal is off and the CPU is running from the ring. If sending a serial

character that wakes the system from crystal-less PMM, then it should be a dummy character of no

importance with a subsequent delay for crystal startup.

Figure 3 illustrates a typical decision set associated with PMM. Table 6 is a summary of the bits relating

to PMM and its operation.

17 of 45

Page 18

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

Table 6. PMM Control and Status Bit Summary

BIT LOCATION FUNCTION RESET WRITE ACCESS

XT/RG

RGMD EXIF.2

CD1, CD0

SWB PMR.5

XTOFF PMR.3

PIP STATUS.7 Status. 1 indicates a power-fail interrupt in service. 0 None

HIP STATUS.6 Status. 1 indicates high priority interrupt in service. 0 None

LIP STATUS.5 Status. 1 indicates low priority interrupt in service. 0 None

XTUP STATUS.4 Status. 1 indicates that the crystal has stabilized. 1 None

SPTA1 STATUS.3 Status. Serial transmission on serial port 1. 0 None

SPRA1 STATUS.2 Status. Serial word reception on serial port 1. 0 None

SPTA0 STATUS.1 Status. Serial transmission on serial port 0. 0 None

SPRA0 STATUS.0 Status. Serial word reception on serial port 0. 0 None

EXIF.3

PMR.7,

PMR.6

Control. XT/RG = 1, runs from crystal or external

clock; XT/RG = 0, runs from internal ring oscillator.

Status. RGMD = 1, CPU clock = ring; RGMD = 0,

CPU clock = crystal.

Control. CD1, 0 = 01, 4 clocks; CS1, 0 = 10, PMM1;

CD1, 0 = 11, PMM2.

Control. SWB = 1, hardware invokes switchback to 4

clocks, SWB = 0, no hardware switchback.

Control. Disables crystal operation after ring is

selected.

X

0 None

0, 1

0 Unrestricted

0

0 to 1 only when

XTUP = 1 and

XTOFF = 0

Write CD1, 0 = 10

or 11 only from

CD1, 0 = 01

1 only when

XT/RG = 0

18 of 45

Page 19

Figure 3. Invoking and Clearing PMM

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

19 of 45

Page 20

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

IDLE MODE

Setting the lsb of the Power Control register (PCON;87h) invokes the Idle mode. Idle will leave internal

clocks, serial ports and timers running. Power consumption drops because the CPU is not active. Since

clocks are running, the Idle power consumption is a function of crystal frequency. It should be

approximately one-half the operational power at a given frequency. The CPU can exit the Idle state with

any interrupt or a reset. Idle is available for backward software compatibility. The system can now reduce

power consumption to below Idle levels by using PMM1 or PMM2 and running NOPs.

STOP MODE ENHANCEMENTS

Setting Bit 1 of the Power Control register (PCON; 87h) invokes the Stop mode. Stop mode is the lowest

power state since it turns off all internal clocking. The ICC f a standard Stop mode is approximately 1μA

(but is specified in the Electrical Specifications). The CPU will exit Stop mode from an eternal interrupt

or a reset condition. Internally generated interrupts (timer, serial port, Watchdog) are not useful since they

require clocking activity.

The DS87C520/DS83C520 provide two enhancements to the Stop mode. As documented below, the

device provides a bandgap reference to determine Power-Fail Interrupt and Reset thresholds. The default

state is that the bandgap reference is off while in Stop mode. This allows the extremely low-power state

mentioned above. A user can optionally choose to have the bandgap enabled during Stop mode. With the

bandgap reference enabled, PFI and Power-fail Reset are functional and are a valid means for leaving

Stop mode. This allows software to detect and compensate for a brownout or power supply sag, even

when in Stop mode. In Stop mode with the bandgap enabled, I

with 1μA with the bandgap off. If a user does not require a Power-fail Reset or Interrupt while in Stop

mode, the bandgap can remain disabled. Only the most power-sensitive applications should turn off the

bandgap, as this results in an uncontrolled power-down condition.

The control of the bandgap reference is located in the Extended Interrupt Flag register (EXIF; 91h).

Setting BGS (EXIF.0) to a 1 will keep the bandgap reference enabled during Stop mode. The default or

reset condition is with the bit at a logic 0. This results in the bandgap being off during Stop mode. Note

that this bit has no control of the reference during full power, PMM, or Idle modes.

The second feature allows an additional power saving option while also making Stop easier to use. This is

the ability to start instantly when exiting Stop mode. It is the internal ring oscillator that provides this

feature. This ring can be a clock source when exiting Stop mode in response to an interrupt. The benefit

of the ring oscillator is as follows.

Using Stop mode turns off the crystal oscillator and all internal clocks to save power. This requires that

the oscillator be restarted when exiting Stop mode. Actual startup time is crystal-dependent, but is

normally at least 4ms. A common recommendation is 10 ms. In an application that will wake up, perform

a short operation, then return to sleep, the crystal startup can be longer than the real transaction. However,

the ring oscillator will start instantly. Running from the ring, the user can perform a simple operation and

return to sleep before the crystal has even started. If a user selects the ring to provide the startup clock and

the processor remains running, hardware will automatically switch to the crystal once a power-on reset

interval (65,536 clocks) has expired. Hardware uses this value to assure proper crystal start even though

power is not being cycled.

The ring oscillator runs at approximately 2MHz to 4MHz but will not be a precise value. Do not conduct

real-time precision operations (including serial communication) during this ring period.

will be approximately 50μA compared

CC

Figure 3 shows

20 of 45

Page 21

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

how the operation would compare when using the ring, and when starting up normally. The default state

is to exit Stop mode without using the ring oscillator.

The RGSL - Ring Select bit at EXIF.1 (EXIF; 91h) controls this function. When RGSL = 1, the CPU will

use the ring oscillator to exit Stop mode quickly. As mentioned above, the processor will automatically

switch from the ring to the crystal after a delay of 65,536 crystal clocks. For a 3.57MHz crystal, this is

approximately 18ms. The processor sets a flag called RGMD-Ring Mode, located at EXIF.2, that tells

software that the ring is being used. The bit will be a logic 1 when the ring is in use. Attempt no serial

communication or precision timing while this bit is set, since the operating frequency is not precise.

Figure 4. Ring Oscillator Exit from Stop Mode

STOP MODE WITHOUT RING STARTUP

STOP MODE WITH RING STARTUP

NOTE: DIAGRAM ASSUMES THAT THE OPERATION FOLLOWING STOP REQUIRES

LESS THAN 18ms TO COMPLETE.

EMI REDUCTION

One of the major contributors to radiated noise in an 8051-based system is the toggling of ALE. The

microcontroller allows software to disable ALE when not used by setting the ALEOFF (PMR.2) bit to 1.

When ALEOFF = 1, ALE will still toggle during an off-chip MOVX. However, ALE will remain in a

static mode when performing on-chip memory access. The default state of ALEOFF = 0 so ALE toggles

at a frequency of XTAL/4.

21 of 45

Page 22

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

PERIPHERAL OVERVIEW

The DS87C520/DS83C520 provide several of the most commonly needed peripheral functions in microcomputer-based systems. These new functions include a second serial port, power-fail reset, power-fail

interrupt, and a programmable watchdog timer. These are described in the following paragraphs. More

details are available in the High-Speed Microcontroller User’s Guide.

SERIAL PORTS

The DS87C520/DS83C520 provide a serial port (UART) that is identical to the 80C52. In addition it

includes a second hardware serial port that is a full duplicate of the standard one. This port optionally

uses pins P1.2 (RXD1) and P1.3 (TXD1). It has duplicate control functions included in new SFR

locations.

Both ports can operate simultaneously but can be at different baud rates or even in different modes. The

second serial port has similar control registers (SCON1 at C0h, SBUF1 at C1h) to the original. The new

serial port can only use Timer 1 for timer generated baud rates.

TIMER RATE CONTROL

There is one important difference between the DS87C520/DS83C520 and 8051 regarding timers. The

original 8051 used 12 clocks per cycle for timers as well as for machine cycles. The

DS87C520/DS83C520 architecture normally uses four clocks per machine cycle. However, in the area of

timers and serial ports, the DS87C520/DS83C520 will default to 12 clocks per cycle on reset. This allows

existing code with real-time dependencies such as baud rates to operate properly.

If an application needs higher speed timers or serial baud rates, the user can select individual timers to run

at the 4-clock rate. The Clock Control register (CKCON;8Eh) determines these timer speeds. When the

relevant CKCON bit is a logic 1, the DS87C520/DS83C520 use 4 clocks per cycle to generate timer

speeds. When the bit is a 0, the DS87C520/DS83C520 use 12 clocks for timer speeds. The reset condition

is a 0. CKCON.5 selects the speed of Timer 2. CKCON.4 selects Timer 1 and CKCON.3 selects Timer 0.

Unless a user desires very fast timing, it is unnecessary to alter these bits. Note that the timer controls are

independent.

POWER-FAIL RESET

The DS87C520/DS83C520 use a precision bandgap voltage reference to decide if V

While powering up, the internal monitor circuit maintains a reset state until VCC rises above the V

level. Once above this level, the monitor enables the crystal oscillat

is out of tolerance.

CC

RST

22 of 45

Page 23

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

POWER-FAIL INTERRUPT

The voltage reference that sets a precise reset threshold also generates an optional early warning PowerFail Interrupt (PFI). When enabled by software, the processor will vector to program memory address

0033h if V

drops below V

CC

. PFI has the highest priority. The PFI enable is in the Watchdog Control

PFW

SFR (WDCON–D8h). Setting WDCON.5 to a logic 1 will enable the PFI. Application software can also

read the PFI flag at WDCON.4. A PFI condition sets this bit to a 1. The flag is independent of the

interrupt enable and software must manually clear it.

WATCHDOG TIMER

To prevent software from losing control, the DS87C520/DS83C520 include a programmable Watchdog

Timer. The Watchdog is a free-running timer that sets a flag if allowed to reach a preselected timeout. It

can be (re)started by software.

A typical application is to select the flag as a reset source. When the Watchdog times out, it sets its flag,

which generates reset. Software must restart the timer before it reaches its timeout or the processor is

reset.

Software can select one of four timeout values. Then, it restarts the timer and enables the reset function.

After enabling the reset function, software must then restart the timer before its expiration or hardware

will reset the CPU. Both the Watchdog Reset Enable and the Watchdog Restart control bits are protected

by a “Timed Access” circuit. This prevents errant software from accidentally clearing the Watchdog.

Timeout values are precise since they are a function of the crystal frequency as shown in

reference, the time periods at 33MHz also are shown.

The Watchdog also provides a useful option for systems that do not require a reset circuit. It will set an

interrupt flag 512 clocks before setting the reset flag. Software can optionally enable this interrupt source.

The interrupt is independent of the reset. A common use of the interrupt is during debug, to show

developers where the Watchdog times out. This indicates where the Watchdog must be restarted by

software. The interrupt also can serve as a convenient time-base generator or can wake-up the processor

from power saving modes.

The Watchdog function is controlled by the Clock Control (CKCON-8Eh), Watchdog Control (WDCOND8h), and Extended Interrupt Enable (EIE-E8h) SFRs. CKCON.7 and CKCON.6 are WD1 and WD0

respectively and they select the Watchdog timeout period as shown in Table 7.

Table 7. Watchdog Timeout Values

Table 7. For

WD1 WD2

0 0 217 clocks 3.9718 ms 2

0 1 220 clocks 31.77 ms 2

1 0 223 clocks 254.20 ms 2

1 1 226 clocks 2033.60 ms 2

INTERRUPT

TIMEOUT

TIME (33 MHz) RESET TIMEOUT TIME (33 MHz)

17

+ 512 clocks 3.9874 ms

20

+ 512 clocks 31.79 ms

23

+ 512 clocks 254.21 ms

26

+ 512 clocks 2033.62 ms

As shown in Table 7, the Watchdog Timer uses the crystal frequency as a time base. A user selects one of

four counter values to determine the timeout. These clock counter lengths are 2

17

= 131,072 clocks;

220 = 1,048,576; 223 = 8,388,608 clocks; and 226 = 67,108,864 clocks. The times shown in Table 7 are

with a 33MHz crystal frequency. Once the counter chain has completed a full interrupt count, hardware

23 of 45

Page 24

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

will set an interrupt flag. Regardless of whether the user enables this interrupt, there are then 512 clocks

left until the reset flag is set. Software can enable the interrupt and reset individually. Note that the

Watchdog is a free running timer and does not require an enable.

There are 5 control bits in special function registers that affect the Watchdog Timer and two status flags

that report to the user. WDIF (WDCON.3) is the interrupt flag that is set at timer termination when there

are 512 clocks remaining until the reset flag is set. WTRF (WDCON.2) is the flag that is set when the

timer has completely timed out. This flag is normally associated with a CPU reset and allows software to

determine the reset source.

EWT (WDCON.1) is the enable for the Watchdog timer reset function. RWT (WDCON.0) is the bit that

software uses to restart the Watchdog Timer. Setting this bit restarts the timer for another full interval.

Application software must set this bit before the timeout. Both of these bits are protected by Timed

Access. As mentioned previously, WD1 and 0 (CKCON .7 and 6) select the timeout. The Reset

Watchdog Timer bit (WDCON.0) should be asserted prior to modifying the Watchdog Timer Mode

Select bits (WD1, WD0) to avoid corruption of the watchdog count. Finally, the user can enable the

Watchdog Interrupt using EWDI (EIE.4). The Special Function Register map is shown above.

INTERRUPTS

The DS87C520/DS83C520 provide 13 interrupt sources with three priority levels. The Power-Fail

Interrupt (PFI) has the highest priority. Software can assign high or low priority to other sources. All

interrupts that are new to the 8051 family, except for the PFI, have a lower natural priority than the

originals.

Table 8. Interrupt Sources and Priorities

NAME FUNCTION VECTOR

PFI Power-Fail Interrupt 33h 1 DALLAS

INT0

TF0 Timer 0 0Bh 3 8051

INT1

TF1 Timer 1 1Bh 5 8051

SCON0 TI0 or RI0 from serial port 0 23h 6 8051

TF2 Timer 2 2Bh 7 8051

SCON1 TI1 or RI1 from serial port 1 3Bh 8 DALLAS

INT2 External Interrupt 2 43h 9 DALLAS

INT3

INT4 External Interrupt 4 53h 11 DALLAS

INT5

WDTI Watchdog Timeout Interrupt 63h 13 DALLAS

External Interrupt 0 03h 2 8051

External Interrupt 1 13h 4 8051

External Interrupt 3 4Bh 10 DALLAS

External Interrupt 5 5Bh 12 DALLAS

NATURAL

PRIORITY

8051/DALLAS

24 of 45

Page 25

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

TIMED-ACCESS PROTECTION

It is useful to protect certain SFR bits from an accidental write operation. The Timed Access procedure

stops an errant CPU from accidentally changing these bits. It requires that the following instructions

precede a write of a protected bit.

MOV 0C7h, #0Aah

MOV 0C7h, #55h

Writing an AAh then a 55h to the Timed Access register (location C7h) opens a 3-cycle window for write

access. The window allows software to modify a protected bit(s). If these instructions do not immediately

precede the write operation, then the write will not take effect. The protected bits are:

EXIF.0 BGS Bandgap Select

WDCON.6 POR Power-On Reset flag

WDCON.1 EWT Enable Watchdog Reset

WDCON.0 RWT Restart Watchdog

WDCON.3 WDIF Watchdog Interrupt Flag

ROMSIZE.2 RMS2 ROM Size Select 2

ROMSIZE.1 RMS1 ROM Size Select 1

ROMSIZE.0 RMS0 ROM Size Select 0

EPROM PROGRAMMING

The DS87C520 follows standards for a 16kB EPROM version in the 8051 family. It is available in a UVerasable, ceramic-windowed package and in plastic packages for one-time user-programmable versions.

The part has unique signature information so programmers can support its specific EPROM options.

ROM-specific features are described later in this data sheet.

Most commercially available device programmers will directly support Dallas Semiconductor

microcontrollers. If your programmer does not, please contact the manufacturer for updated software.

PROGRAMMING PROCEDURE

The DS87C520 should run from a clock speed between 4MHz and 6MHz when being programmed. The

programming fixture should apply address information for each byte to the address lines and the data

value to the data lines. The control signals must be manipulated as shown in Table 9. The diagram in

Table 5 shows the expected electrical connection for programming. Note that the programmer must apply

addresses in demultiplexed fashion to Ports 1 and 2 with data on Port 0. Waveforms and timing are

provided in the Electrical Specifications section.

Program the DS87C520 as follows:

1) Apply the address value,

2) Apply the data value,

3) Select the programming option from Table 9 using the control signals,

4) Increase the voltage on V

5) Pulse the

PROG signal five times for EPROM array and 25 times for encryption table, lock bits, and

from 5V to 12.75V if writing to the EPROM,

PP

other EPROM bits,

6) Repeat as many times as necessary.

25 of 45

Page 26

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

Table 9. EPROM Programming Modes

MODE RST

Program Code Data H L PL 12.75V L H H H H

Verify Code Data H L H H L L L H H

PSEN

ALE/PROG EA/VPP P2.6 P2.7 P3.3 P3.6 P3.7

Program Encryption Array

Address 0-3Fh

LB1 H L PL 12.75V H H H H H

Program Lock Bits

Program Option Register

Address FCh

Read Signature or Option

Registers 30, 31, 60 FCh

LB2 H L PL 12.75V H H H L L

LB3 H L PL 12.75V H L H H L

H L PL 12.75V L H H L H

H L PL 12.75V L H H L L

H L H H L L L L L

Table 10. DS87C520 EPROM Lock Bits

LEVEL

1 U U U

2 P U U

3 P P U

LOCK BITS

LB1 LB2 LB3

No program lock. Encrypted verify if encryption table was

programmed.

Prevent MOVC instructions in external memory from reading

program bytes in internal memory. EA is sampled and latched on

reset. Allow no further programming of EPROM.

Level 2 plus no verify operation. Also, prevent MOVX

instructions in external memory from reading SRAM (MOVX) in

internal memory.

PROTECTION

4 P P P Level 3 plus no external execution.

SECURITY OPTIONS

The DS87C520 employs a standard three-level lock that restricts viewing of the EPROM contents. A 64byte Encryption Array allows the authorized user to verify memory by presenting the data in encrypted

form.

Lock Bits

The security lock consists of three lock bits. These bits select a total of four levels of security. Higher

levels provide increasing security but also limit application flexibility. Table 10 shows the security

settings. Note that the programmer cannot directly read the state of the security lock. User software has

access to this information as described in the Memory section.

26 of 45

Page 27

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

Encryption Array

The Encryption Array allows an authorized user to verify EPROM without allowing the true memory to

be dumped. During a verify, each byte is Exclusive NORed (XNOR) with a byte in the Encryption Array.

This results in a true representation of the EPROM while the Encryption is unprogrammed (FFh). Once

the Encryption Array is programmed in a non-FFh state, the verify value will be encrypted.

For encryption to be effective, the Encryption Array must be unknown to the party that is trying to verify

memory. The entire EPROM also should be a non-FFh state or the Encryption Array can be discovered.

The Encryption Array is programmed as shown in Table 9. Note that the programmer cannot read the

array. Also note that the verify operation always uses the Encryption Array. The array has no impact

while FFh. Simply programming the array to a non-FFh state will cause the encryption to function.

OTHER EPROM OPTIONS

The DS87C520 has user selectable options that must be set before beginning software execution. These

options use EPROM bits rather than SFRs.

Program the EPROM selectable options as shown in

Table 9. The Option Register sets or reads these

selections. The bits in the Option Control Register have the following function:

Bits 7 to 4 Reserved, program to a 1.

Bit 3 Watchdog POR default. Set = 1; watchdog reset function is disabled on power-up.

Set = 0; watchdog reset function is enabled automatically.

Bits 2 to 0 Reserved. Program to a 1.

SIGNATURE

The Signature bytes identify the product and programming revision to EPROM programmers. This

information is at programming addresses 30h, 31h, and 60h.

ADDRESS VALUE MEANING

30h DAh Manufacturer

31h 20h Model

60h 01h Extension

27 of 45

Page 28

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

Figure 5. EPROM Programming Configuration

ROM-SPECIFIC FEATURES

The DS83C520 supports a subset of the EPROM features found on the DS87C520.

SECURITY OPTIONS

Lock Bits

The DS83C520 employs a lock that restricts viewing of the ROM contents. When set, the lock will

prevent MOVC instructions in external memory from reading program bytes in internal memory. When

locked, the

EA pin is sampled and latched on reset. The lock setting is enabled or disabled when the

devices are manufactured according to customer specifications. The lock bit cannot be read in software,

and its status can only be determined by observing the operation of the device.

Encryption Array

The DS83C520 Encryption Array allows an authorized user to verify ROM without allowing the true

memory contents to be dumped. During a verify, each byte is Exclusive NORed (XNOR) with a byte in

the Encryption Array. This results in a true representation of the ROM while the Encryption is

unprogrammed (FFh)

Array is programmed (or optionally left unprogrammed) when the devices are manufactured according to

customer specifications.

. Once the Encryption Array is programmed in a non-FFh state, the Encryption

28 of 45

Page 29

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

DS83C520 ROM VERIFICATION

The DS83C520 memory contents can be verified using a standard EPROM programmer. The memory

address to be verified is placed on the pins shown in Figure 5, and the programming control pins are set to

the levels shown in Table 9. The data at that location is then asserted on port 0.

DS83C520 SIGNATURE

The Signature bytes identify the DS83C520 to EPROM programmers. This information is at

programming addresses 30h, 31h, and 60h. Because mask ROM devices are not programmed in device

programmers, most designers will find little use for the feature, and it is included only for compatibility.

ADDRESS VALUE MEANING

30h DAh Manufacturer

31h 21h Model

60h 01h Extension

29 of 45

Page 30

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

ABSOLUTE MAXIMUM RATINGS

Voltage Range on Any Pin Relative to Ground……………………………………………………….-0.3V to (VCC + 0.5V)

Voltage Range on V

Operating Temperature Range……………………………………………………………………………….-40°C to +85°C

Storage Temperature……………………………………………………………… …………………………-55°C to +125°C

Soldering Temperature..………………………………………………………..See IPC/JEDEC J-STD-020 Specification

This is a stress rating only and functional operation of the device at these or any other conditions above those indicated in the operation

sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods of time may affect reliability.

DC ELECTRICAL CHARACTERISTICS

(VCC = 4.5V, TA = -40°C to +85°C.) (Note 1)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Supply Voltage VCC 4.5 5.0 5.5 V 2

Power-Fail Warning

Voltage

Supply Current Active Mode

at 33MHz

Supply Current Idle Mode at 33MHz I

Supply Current Stop Mode, Bandgap

Disabled

(0°C to +70°C)

Supply Current Stop Mode, Bandgap

Disabled

(-40°C to +85°C)

Supply Current Stop Mode, Bandgap

Enabled

(0°C to +70°C)

Supply Current Stop Mode, Bandgap

Enabled

(-40°C to +85°C)

Input Low Level VIL -0.3 +0.8 V 2

Input High Level

(except XTAL1 and RST)

Input High Level XTAL1 and RST V

Output Low Voltage, Ports 1 and 3

at I

= 1.6mA

OL

Output Low Voltage Ports 0 and 2,

ALE, PSEN at I

Output High Voltage Ports 1, 2, 3,

ALE, PSEN at I

Output High Voltage Ports 1, 2, 3

at I

= -1.5mA

OH

Output High Voltage Port 0, 2,

ALE, PSEN in Bus Mode at I

Input Low Current Ports 1, 2, 3 at 0.45V IIL -70 μA 12

Relative to Ground..………………………………………………………………….-0.3V to +6.0V

CC

DS87C520 4.25 4.38 4.5

DS83C520

DS87C520 4.0 4.13 4.25 Minimum Operating

DS83C520

V

PFW

V

RST

30 45 mA 3

I

CC

15 25 mA 4

IDLE

4.25 4.38 4.55

4.0 4.13 4.275

1 100

I

STOP

1 150

V 2

V 2

μA

μA

50 170 μA 5

I

SPBG

= 3.2mA

OL

= -50μA

OH

= -8mA

OH

50 195

V

2.0 VCC + 0.3 V 2

IH

3.5 VCC + 0.3 V 2

IH2

V

0.15 0.45 V 2

OL1

0.15 0.45 V 2

V

OL2

V

2.4 V 2, 7

OH1

V

2.4 V 2, 8

OH2

V

2.4 V 2, 6

OH3

μA

5

5

5

30 of 45

Page 31

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

DC ELECTRICAL CHARACTERISTICS (continued)

(VCC = 4.5V, TA = -40°C to +85°C.)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Transition Current from 1 to 0 Ports 1, 2, 3

at 2V

Input Leakage Port 0, and EA pins, I/O

Mode

-800 μA 9

I

TL

I

-10 +10 μA 11

L

Input Leakage Port 0, Bus Mode IL -300 +300 μA 10

RST Pulldown Resistance R

Note 1:

Note 2:

Note 3:

Note 4:

Note 5:

Note 6:

Note 7:

Note 8:

Note 9:

Note 10:

Note 11:

Note 12:

All parameters apply to both commercial and industrial temperature operation, unless othe rwise noted.

All voltages are referenced to ground.

Active current measured with 33MHz clock source on XTAL1, V

Idle mode current measured with 33MHz clock source on XTAL1, V

disconnected.

Stop mode current measured with XTAL1 and RST grounded, V

When addressing external memory. This specification only applies to the first clock cycle following the transition.

RST = V

state during I/O mode.

During a 0-to-1 transition, a one-shot drives the ports hard for two clock cycles. This measurement reflects port in

transition mode.

Ports 1, 2, and 3 source transition current when being pulled down externally. It reaches its maxim um at a pproximately

2V.

0.45 < V

occurs near the input transition point of the latch, approximately 2V.

0.45 < V

This is the current required from an external circuit to hold a logic low level on an I/O pin while the corresponding port

latch bit is set to 1. This is only the current required to hold the low level; transitions from 1 to 0 on an I/O pin will also

have to overcome the transition current.

. This condition mimics operation of pins in I/O mode. Port 0 is tri-stated in reset and when at a logic high

CC

< VCC. Not a high-impedance input. This port is a weak address holding latch in Bus Mode. Peak current

IN

< VCC. RST = VCC. This condition mimics operation of pins in I/O mode.

IN

50 200

RST

= RST = 5.5V, other pins disconnected.

CC

= 5.5V, RST at ground, other pins

CC

= 5.5V, all other pins disconnected.

CC

kΩ

TYPICAL I

vs. FREQUENCY

CC

31 of 45

Page 32

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

AC ELECTRICAL CHARACTERISTICS (Note 1)

PARAMETER SYMBOL

Oscillator

Frequency

External Oscillator 0 33 0 33

External Crystal

ALE Pulse Width t

Port 0 Address Valid to ALE Low t

Address Hold after ALE Low t

ALE Low to Valid Instruction In t

ALE Low to PSEN Low

PSEN Pulse Width

PSEN Low to Valid Instruction In

Input Instruction Hold after PSEN

Input Instruction Float after PSEN

Port 0 Address to Valid Instruction In t

Port 2 Address to Valid Instruction In t

PSEN Low to Address Float

Note 1:

Note 2:

All parameters apply to both commercial and industrial temperature range operation unless otherwise noted.

Specifications to -40°C are guaranteed by design and are not producti on tested. AC electrical characteristics are not

100% tested, but are characterized and guaranteed by design. All signals charac ter ized wit h load c apa citance of 80p F

except Port 0, ALE, PSEN, RD, and WR with 100pF. Interfacin g to memory devices with float times (turn off times)

over 25ns may cause contention. This will not damage the parts, but will cause an increase in operating current.

Specifications assume a 50% duty cycle for the oscillator. Port 2 an d ALE timing will change in relation to duty c ycle

variation.

Address is driven strongly until ALE falls, and is then held in a weak latch until overdriven externa lly.

33 MHz VARIABLE CLOCK

MIN MAX MIN MAX

1/t

CLCL

40 1.5t

LHLL

10 0.5t

AVLL

(Note 2) (Note 2) ns

LLAX1

43 2.5t

LLIV

t

4 0.5t

LLPL

t

55 2t

PLPH

t

37 2t

PLIV

t

0 0 ns

PXIX

t

26 t

PXIZ

59 3t

AVIV1

68 3.5t

AVIV2

t

(Note 2) (Note 2) ns

PLAZ

1 33 1 33

-5 ns

CLCL

-5 ns

CLCL

CLCL

-11 ns

CLCL

-5 ns

CLCL

-24 ns

CLCL

-5 ns

CLCL

-32 ns

CLCL

CLCL

UNITS

MHz

-33 ns

-38 ns

32 of 45

Page 33

MOVX CHARACTERISTICS

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

PARAMETER SYMBOL

Data Access ALE Pulse Width t

Port 0 Address Valid to ALE Low t

Address Hold after ALE Low for

MOVX Write

RD Pulse Width t

WR Pulse Width t

RD Low to Valid Data In t

Data Hold After Read t

Data Float after Read t

ALE Low to Valid Data In t

VARIABLE CLOCK

MIN MAX

LHLL2

AVLL2

t

LLAX2

1.5t

2t

0.5t

0.5t

2t

RLRH

WLWH

RLDV

0 ns —

RHDX

RHDZ

LLDV

2t

-5 t

CLCL

-5

CLCL

-5 t

CLCL

-5

t

CLCL

-10 t

CLCL

t

-7

CLCL

-5 t

CLCL

t

-10

MCS

-5 t

CLCL

t

-10

MCS

2t

t

t

2t

2.5t

t

MCS+tCLCL

-22 t

CLCL

-24

MCS

-5 t

CLCL

-5

CLCL

-31 t

CLCL

-26

UNITS STRETCH

=0

ns

ns

ns

ns

ns

ns

ns

ns

MCS

t

MCS

MCS

t

MCS

MCS

t

MCS

MCS

t

MCS

MCS

t

MCS

MCS

t

MCS

MCS

t

MCS

MCS

t

MCS

>0

=0

>0

=0

>0

=0

>0

=0

>0

=0

>0

=0

>0

=0

>0

Port 0 Address to Valid Data In t

Port 2 Address to Valid Data In t

ALE Low to RD or WR Low t

AVDV1

AVDV2

3t

t

3.5t

0.5t

-10 0.5t

CLCL

t

MCS

-29 t

CLCL

MCS

+2t

CLCL

-

29

-37 t

CLCL

+2.5t

CLCL

-

37

+5 t

CLCL

ns

ns

MCS

t

MCS

MCS

t

MCS

MCS

=0

>0

=0

>0

=0

33 of 45

Page 34

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

MOVX CHARACTERISTICS (continued)

M2 M1 M0 MOVX CYCLES t

MCS

0 0 0 2 machine cycles 0

0 0 1 3 machine cycles (default) 4 t

0 1 0 4 machine cycles 8 t

0 1 1 5 machine cycles 12 t

1 0 0 6 machine cycles 16 t

1 0 1 7 machine cycles 20 t

1 1 0 8 machine cycles 24 t

1 1 1 9 machine cycles 28 t

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

EXTERNAL CLOCK CHARACTERISTICS

PARAMETER SYMBOL MIN TYP MAX UNITS

Clock High Time t

Clock Low Time t

Clock Rise Time t

Clock Fall Time t

10 ns

CHCX

10 ns

CLCX

5 ns

CLCL

5 ns

CHCL

SERIAL PORT MODE 0 TIMING CHARACTERISTICS

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Serial Port Clock Cycle

Time

Output Data Setup to

Clock Rising

Output Data Hold from

Clock Rising

Input Data Hold after

Clock Rising

Clock Rising Edge to

Input Data Valid

t

XLXL

t

QVXH

t

XHQX

t

XHDX

t

XHDV

SM2 = 0, 12 clocks per cycle 12t

SM2 = 1, 4 clocks per cycle 4t

SM2 = 0, 12 clocks per cycle 10t

SM2 = 1, 4 clocks per cycle 3t

SM2 = 0, 12 clocks per cycle 2t

SM2 = 1, 4 clocks per cycle t

SM2 = 0, 12 clocks per cycle t

SM2 = 1, 4 clocks per cycle t

SM2 = 0, 12 clocks per cycle 11t

SM2 = 1, 4 clocks per cycle 3t

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

ns

ns

ns

ns

ns

34 of 45

Page 35

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

EXPLANATION OF AC SYMBOLS

In an effort to remain compatible with the original 8051 family, the DS87C520 and DS83C520 specify

the same parameters as such devices, using the same symbols. For completeness, the following is an

explanation of the symbols.

t Time

A Address

C Clock

D Input data

H Logic level high

I Instruction

P PSEN

Q Output data

R RD signal

V Valid

W WR signal

X No longer a valid logic

level

Z Tri-State

L Logic level low

POWER-CYCLE TIMING CHARACTERISTICS

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Cycle Startup Time t

Power-On Reset Delay t

1.8 ms 1

CSU

65,536 t

POR

2

CLCL

Note 1: Startup time for crystals varies with load capacitance and manufacturer. Time shown is for an 11.0592MHz crystal

manufactured by Fox.

Note 2: Reset delay is a synchronous counter of crystal oscillations after crystal startup. Counting begins when the level

on the XTAL1 pin meets the V

criteria. At 33MHz, this time is 1.99ms.

IH2

EPROM PROGRAMMING AND VERIFICATION

(VCC = 4.5V to 5.5V, TA = +21°C to +27°C.)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Programming Voltage VPP 12.5 13.0 V 1

Programming Supply Current IPP 50 mA

Oscillator Frequency 1/t

Address Setup to PROG Low

Address Hold after PROG

Data Setup to PROG Low

Data Hold after PROG

Enable High to VPP t

VPP Setup to PROG Low

VPP Hold after PROG

PROG Width

Address to Data Valid t

Enable Low to Data Valid t

Data Float after Enable t

PROG High to PROG Low

Note 1:

All voltages are referenced to ground.

4 6 MHz

CLCL

t

48t

AVGL

t

48 t

GHAX

t

48 t

DVGL

t

48 t

GHDX

48 t

EHSH

t

10 μs

SHGL

t

10 μs

SHGL

t

90 110 μs

GLGH

48 t

AVQV

48 t

ELQV

0 48 t

EHQZ

t

10 μs

GHGL

35 of 45

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

Page 36

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

EXTERNAL PROGRAM MEMORY READ CYCLE

EXTERNAL DATA MEMORY READ CYCLE

t

AVLL2

36 of 45

Page 37

DS87C520/DS83C520 EPROM/ROM High-Speed Microcontrollers

EXTERNAL DATA MEMORY WRITE CYCLE

2

DATA MEMORY WRITE WITH STRETCH = 1