Page 1

A

A

A

A

A

A

A

www.maxim-ic.com

GENERAL DESCRIPTION

The DS620 digital thermometer and thermostat

provides low-voltage (1.7V ≤ V

measurements with ±0.5°C accuracy from 0°C to

+70°C and an operating temperature range of -55°C

to +125°C. The DS620 communicates over a 2-wire

digital interface. For distributed-sensing applications,

it is multidroppable with three address pins that allow

up to eight DS620s to operate on a single bus.

The DS620 has thermostat functionality with userdefined thresholds stored in EEPROM registers, and

it can be configured for standalone thermostat

operation. The programmable output (PO) pin serves

as the thermostat output, and this pin can also be

configured to function as an active-low control for

peripheral devices.

≤ 3.5V) temperature

DD

APPLICATIONS

Portable Applications

Low-Voltage Temperature-Sensitive Applications

Computers/Servers

Test Equipment

Medical Instruments

Industrial Applications

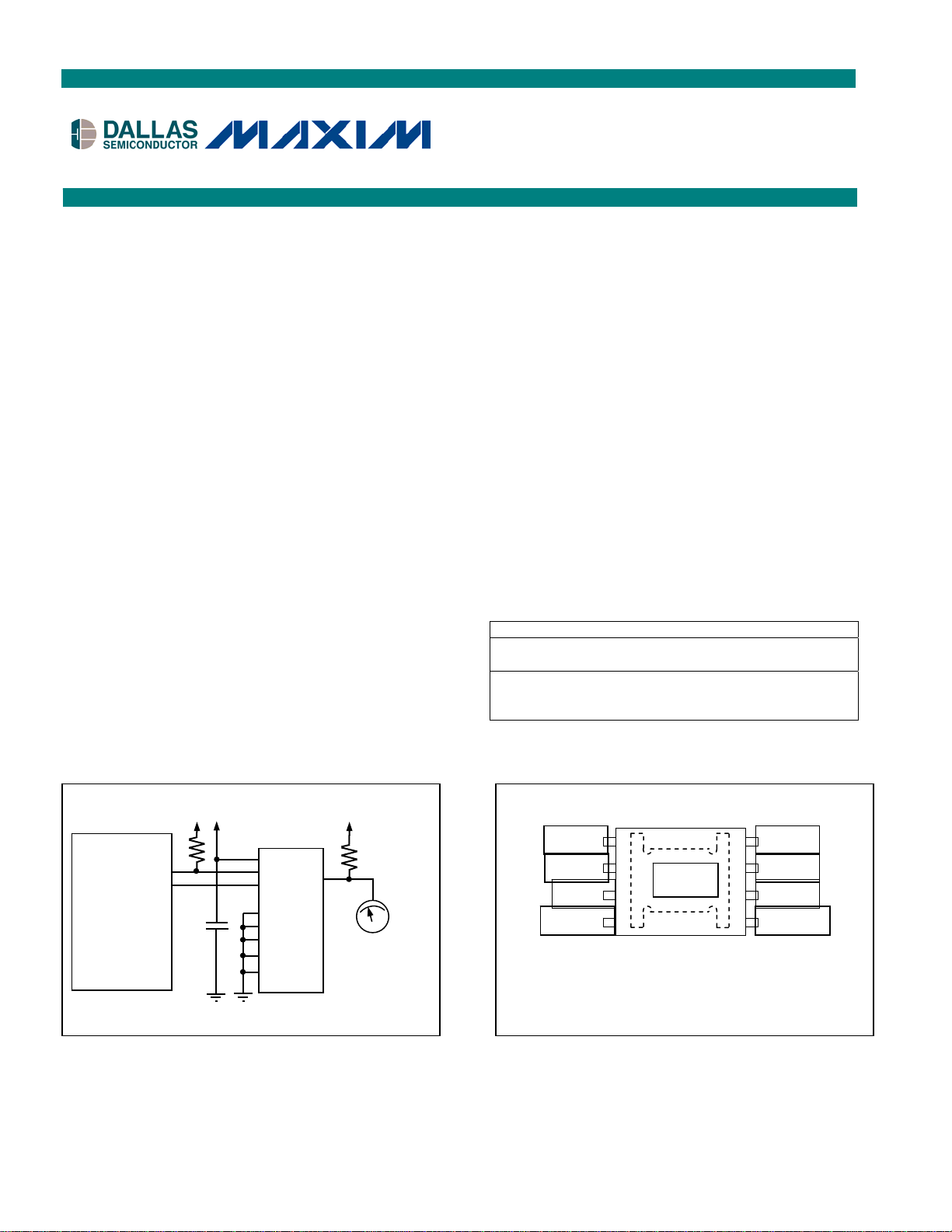

TYPICAL OPERATING CIRCUIT

DS620

0

1

2

1.7V to 3.5V

PO

Thermostat

1.7V to 3.5V

.

HOST

SDA

SCL

VDD

SDA

SCL

GND

PAD

DS620

Low-Voltage, ±0.5°C Accuracy

Digital Thermometer and Thermostat

FEATURES

Low-Voltage Operation: 1.7V to 3.5V

±0.5°C Accuracy from 0°C to +70°C

Operating Temperature Range: -55°C to +125°C

(-67°F to +257°F)

Temperature Measurements Require No

External Components

Resolution is User-Selectable to 10-, 11-, 12-, or

13-Bits (0.5°C, 0.25°C, 0.125°C, and 0.0625°C

LSb Weight, Respectively)

Multidroppable

Fast (200ms max) Temperature-to-Digital

Conversion Time

Thermostatic Settings are User-Definable and

Nonvolatile

Standalone Thermostat Capability

Data is Read/Written Through a 2-Wire Serial

Interface

Package: 8-Pin μSOP

ORDERING INFORMATION

PART TEMP RANGE PIN-PACKAGE

DS620U -55°C to +125°C

DS620U/T&R -55°C to +125°C

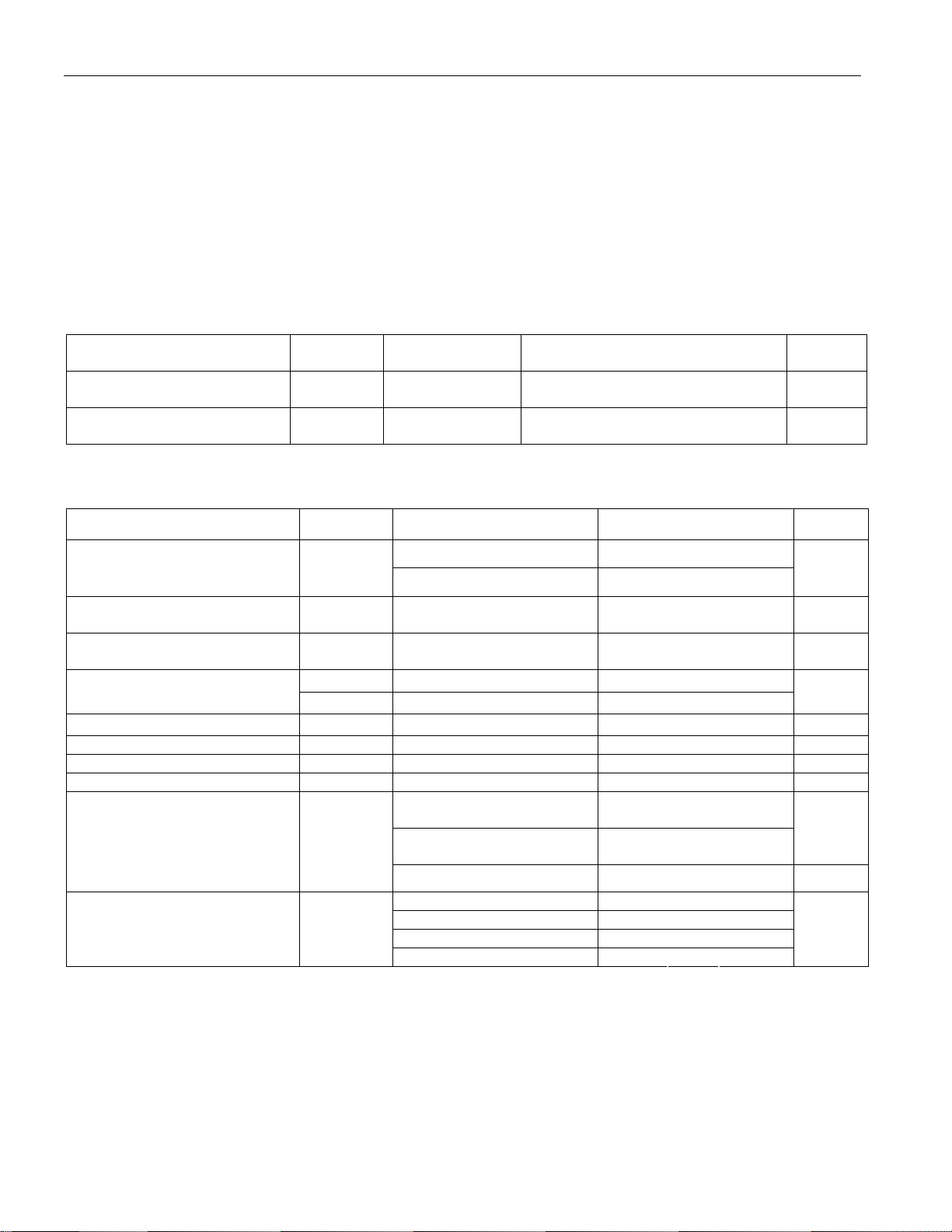

PIN CONFIGURATION

SD

SCL

PO

GND

8-Pin

μSOP Package

Exposed Pad

PAD

8 µSOP,

Exposed Pad

8 µSOP

Exposed Pad

Tape-and-Reel

VDD

0

1

2

1 of 15

041607

Page 2

DS620 Digital Thermometer and Thermostat

PIN DESCRIPTION

PIN NAME FUNCTION

1 SDA

2 SCL

3 PO

4 GND

5 A2

6 A1

7 A0

8 VDD

PAD

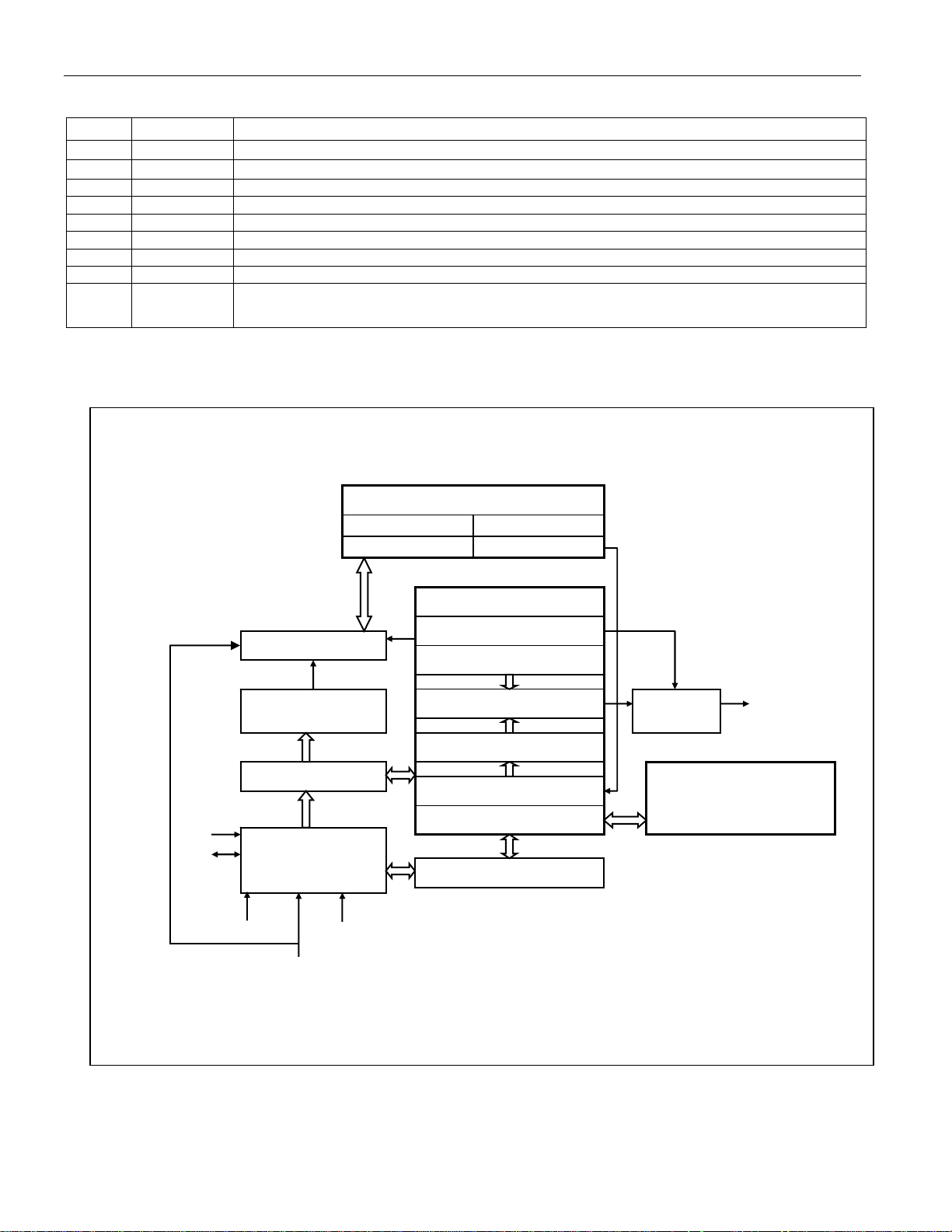

Figure 1. Block Diagram

DS620

SCL

SDA

Data Input/Output Pin for serial communication. Open drain. (No diode connection to VDD).

Clock Input Pin for 2-wire serial communication.

Programmable Output Pin. Open drain. (No diode connection to VDD).

Ground Pin.

Address Input Pin.

Address Input Pin. Also serves as an input to trigger one-shot conversions during standalone use.

Address Input Pin.

Supply Voltage Pin. +1.7V to +3.5V power supply pin.

PAD. Connect to GND or float. DO NOT CONNECT TO SUPPLY. The exposed pad is the best way to conduct

temperature into the package. Connecting PAD to a ground plane can assist in properly measuring the

temperature of the circuit board.

Temp. Core

Digital Control

Conversion Control

Address/Command

Decode

Address Counter

Memory Array

Configuration Register

TH, TL Registers

Digital Comparator

Temperature Register

Temperature Counter

User EEPROM Registers

Bandgap

ADC POR

2-Wire Interface

A2

A0

Memory Interface Logic

PO Pin

Control

Charge Pump

PO

A1

2 of 15

Page 3

DS620 Digital Thermometer and Thermostat

ABSOLUTE MAXIMUM RATINGS

Voltage Range on Any Pin, Relative to Ground -0.5V to +4.5V

Operating Temperature Range -55°C to +125°C

Storage Temperature Range

Soldering Temperature

-55°C to +125°C

See IPC/JEDEC J-STD-020A Specification

ESD rating on all pins 4KV HBM

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is

not implied. Exposure to the absolute maximum rating conditions for extended periods may affect device.

RECOMMENDED DC OPERATING CONDITIONS

(3.5V ≥ VDD ≥ 1.7V, TA = -55°C to +125°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Voltage Range on Any Pin,

Relative to Ground

Supply Voltage for EEPROM

Writes

(Note 1) 1.7 3.5 V

V

DD

(Note 1) 2.0 3.5 V

V

DD

DC ELECTRICAL CHARACTERISTICS

(3.5V ≥ VDD ≥ 1.7V, TA = -55°C to +125°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

0°C to +70°C ±0.5

Thermometer Error T

Input Logic High VIH (Note 1)

Input Logic Low VIL (Note 1) - 0.5

SDA Output Logic Low Voltage

ERR

V

OL1

V

OL2

-55°C to +125°C ±2

0.7 x

V

DD

3mA sink current (Note 1) 0 0.4

6mA sink current (Note 1) 0 0.6

V

DD

0.5

0.3 x

V

DD

+

PO Saturation Voltage VOL 4mA sink current (Note 1) 0 0.4 V

Input Current for each I/O pin 0.4 < V

I/O Capacitance C

Standby Current I

10 pF

I/O

0°C to +70°C (Note 2) 2 µA

STBY

Temperature conversion, 55°C to +85°C (Note 3)

Active Supply Current IDD

Temperature conversion,

+85°C to +125°C (Note 3)

2

write (Note 3) 500 µA

E

< 0.9 x VDD -10 +10 µA

I/O

800

900

10 bit 25

Temperature Conversion Time TTC

11 bit 50

12 bit 100

13 bit 200

Note 1: All voltages are referenced to GND.

Note 2: Specified with SDA = V

Note 3: Specified with A

, A1, A2 = 0V or VDD.

0

; A0, A1, A2 = 0V or VDD.

DD

°C

V

V

V

µA

ms

3 of 15

Page 4

DS620 Digital Thermometer and Thermostat

AC ELECTRICAL CHARACTERISTICS

EEPROM AC Electrical Characteristics

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

EEPROM Write Cycle Time TWR -40°C to +85°C 10 ms

-40°C ≤ TA ≤ +85°C

EEPROM Writes N

EEPROM Data Retention t

EEWR

EEDR

(Note 1)

T

= +25°C (Note 1) 40k 80k

A

-40°C to +125°C (Note 2) 10 years

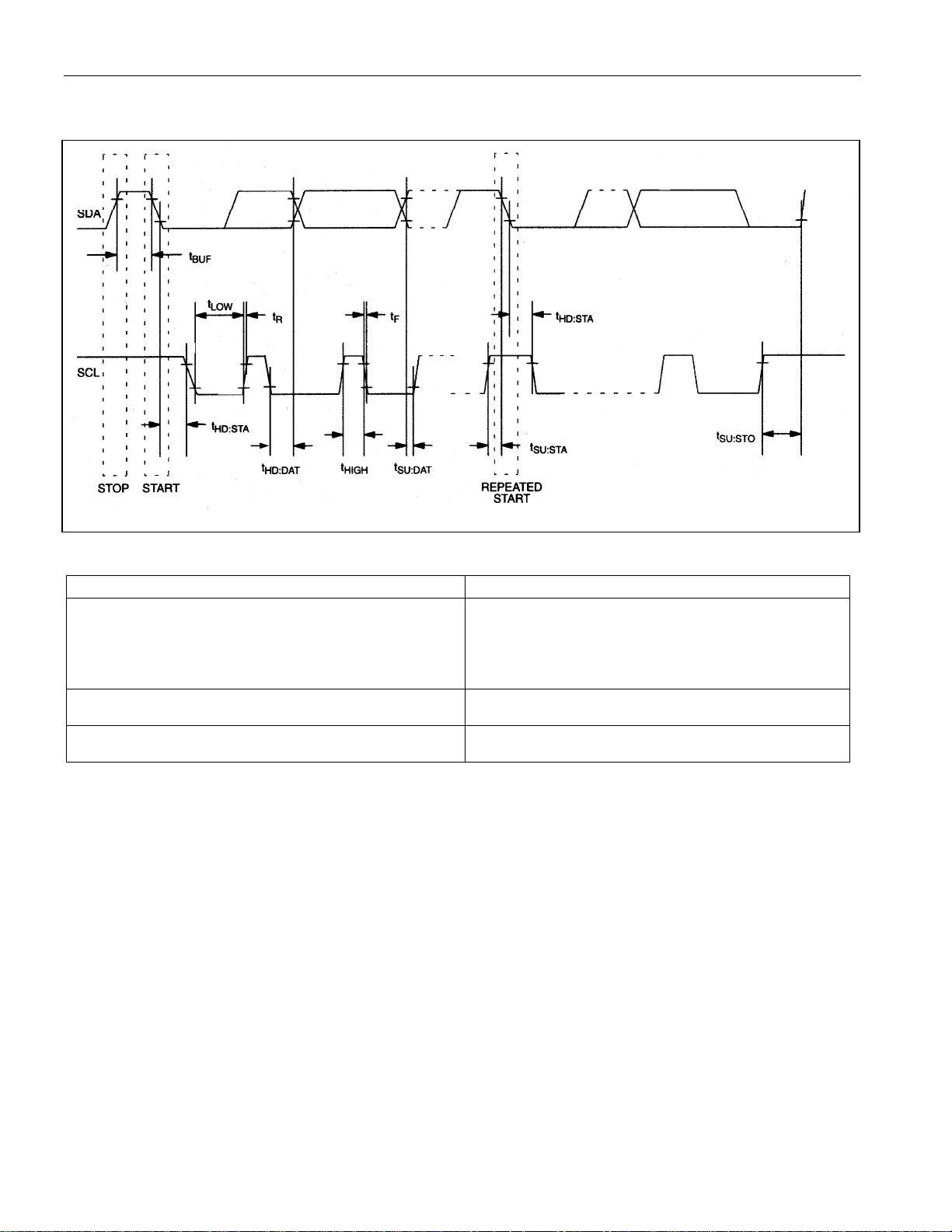

2-Wire AC Electrical Characteristics

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCL Frequency f

Bus Free Time Between a

STOP and START Condition

START and Repeat START

Hold Time from Falling SCL

Low Period of SCL t

High Period of SCL t

Repeated START Condition

Setup Time to Rising SCL

Data-Out Hold Time from

Falling SCL

Data-In Setup Time to Rising

SCL

0 400 KHz

SCL

t

1.3 µs

BUF

t

(Note 3, 4) 0.6 µs

HD:STA

(Note 3) 1.3 µs

LOW

(Note 3) 0.6 µs

HIGH

t

(Note 3) 0.6 µs

SU:STA

t

(Note 3) 0 0.9 µs

HD:DAT

(Note 3) 100 ns

t

SU:DAT

Rise Time of SDA and SCL tR (Note 3, 5)

Fall Time of SDA and SCL tF (Note 3, 5)

STOP Setup Time to Rising

SCL

Capacitive Load for Each BUS

Line

T

0.6 µs

SU:STO

C

400 pF

B

Input Capacitance CI 10 pF

Spike Pulse Width that can be

Suppressed by Input Filter

Note 1: V

Note 2: Write done at 25°C.

Note 3: All values referenced to 0.9 V

Note 4: After this period the first clock pulse is generated.

Note 5: For example, if C

must be 2.0V to 3.5V.

DD

= 300pF, then tR(MIN) = tF(MIN) = 50ns.

B

and 0.1 V

DD

0 50 ns

.

DD

10k 20k

20 +

0.1xC

20 +

0.1xC

B

B

1000 ns

300 ns

writes

4 of 15

Page 5

Figure 2. Timing Diagram

DS620 Digital Thermometer and Thermostat

Table 1. Register Summary

Parameter Information

TH and TL Registers

Size: 2-Bytes

Note that the 3 LSbs are always “don’t cares” for writes

(i.e., they are not saved) and always read out as 0s.

Configuration Register

Size: 2-Bytes

Temperature Register

Size: 2-Bytes

EEPROM

Factory State:

TH = 15ºC (0000 0111 1000 0000) [0780h]

TL = 10ºC (0000 0101 0000 0000) [0500h]

SRAM and EEPROM. See Figure 4 and Table 5 for

detailed information and power-up/factory state.

SRAM Power-Up State: -60ºC

(1110 0010 0000 0000) [E200h]

TEMPERATURE MEASUREMENT

The DS620 measures temperature using a bandgap-based temperature sensor. A delta-sigma, analog-to-digital

converter (ADC) converts measured temperature to a 10-, 11-, 12-, or 13-bit (user-selectable) digital value that is

calibrated in °C; for °F applications, a lookup table or conversion routine must be used. Throughout this data sheet,

the term “conversion” is used to refer to the entire temperature measurement and ADC sequence.

The DS620 can be configured to power up either automatically converting temperature or in a low-power standby

state. The preferred power-up mode can be set using the AUTOC bit in the configuration register as explained in

the Configuration Register section of this data sheet.

The DS620 can be programmed to perform continuous consecutive conversions (continuous conversion mode) or

to perform single conversions on command (one-shot mode). The conversion mode is programmed through the

1SHOT bit in the configuration register as explained in the Configuration Register section of this data sheet. In

continuous conversion mode, conversions are performed after a Start Convert command is issued (or upon powerup if the AUTOC bit in the configuration register is set to 1) until a Stop Convert command is issued, at which time

the device goes into a low-power standby state. Continuous conversions can be restarted at any time using the

Start Convert command. In one-shot mode, the DS620 performs a single temperature conversion either at powerup (if AUTOC = 1) or when a Start Convert command is issued (if AUTOC = 0). When the conversion is complete,

5 of 15

Page 6

DS620 Digital Thermometer and Thermostat

the device enters a low-power standby state and remains in that state until a temperature conversion is again

initiated by a Start Convert command.

The R0 and R1 bits in the configuration register allow the user to set the conversion resolution to be 10, 11, 12, or

13 bits (0.5°C, 0.25°C, 0.125°C, and 0.0625°C LSb weight, respectively) as shown in Table 6. The default

resolution at power-up is 13-bits. Note that the conversion time doubles for each additional bit of resolution.

After each conversion, the digital temperature is stored as a 16-bit two’s complement number in the 2-byte

temperature register as shown in Figure 3. The temperature register is located in address spaces AAh (MSB) and

ABh (LSB) of the DS620 memory. The sign bit (S) indicates if the temperature is positive (S = 0) or negative (S =

1). Bits 2, 1, and 0 of the temperature register are hardwired to 0. When the device is configured for 13-bit

resolution, the 13 MSbs (bits 15 through 3) of the temperature register will contain temperature data. For 12-bit

resolution, the 12 MSbs (bits 15 through 4) of the temperature register will contain data, and bit 3 will be 0.

Likewise, for 11-bit resolution, the 11 MSbs (bits 15 through 5) will contain data, and for 10-bit the 10 MSbs (bits 15

through 6) will contain data, and all unused LSbs will contain 0s. Table 2 gives examples of 13-bit resolution output

data and the corresponding temperatures.

Figure 3. Temperature, TH, And TL Register Format

MS Byte

LS Byte

bit 15 bit 14 bit 13 Bit 12 bit 11 bit 10 bit 9 bit 8

S 2

bit 7 bit 6 bit 5 Bit 4 bit 3 bit 2 bit 1 bit 0

0

2

2

7

2

-1

2

6

2

-2

2

5

2

-3

2

4

2

-4

0 0 0

3

2

2

2

1

Table 2. 13-Bit Resolution Temperature/Data Relationship

Temperature (°C)

+125 0011 1110 1000 0000 3E80h

+25.0625 0000 1100 1000 1000 0C88h

+10.125 0000 0101 0001 0000 0510h

+0.5 0000 0000 0100 0000 0040h

0 0000 0000 0000 0000 0000h

-0.5 1111 1111 1100 0000 FFC0h

-10.125 1111 1010 1111 0000 FAF0h

-25.0625 1111 0011 0111 1000 F378h

-55 1110 0100 1000 0000 E480h

Digital Output (binary) Digital Output (hex)

WRITING TO THE TEMPERATURE REGISTER

The user is given access to write to the DS620 temperature register. This feature can be used for system test and

debugging by allowing the user to force the temperature reading above or below fault thresholds without having to

heat or cool the device.

If data is written to the temperature register while conversions are in progress, the result of the next completed

conversion will overwrite any data that was written to the temperature register. Additionally, no update of the flag

bits in the configuration register, nor an update of the PO pin occur as a result of the temperature being written if a

conversion is taking place. To avoid this from happening, conversions should first be stopped before writing to the

temperature register. When writing to the temperature register, both the MSB and the LSB should be written. An

update of the flag bits and PO pin will only occur after the LSB has been written. See Writing to the DS620 for more

information.

6 of 15

Page 7

DS620 Digital Thermometer and Thermostat

g

g

THERMOSTAT OPERATION

The PO pin on the DS620 operates as the thermostat output when it is configured as PO

P01 and P02 bits of the configuration register. In both of these configurations, PO is updated after every

temperature conversion or write to the temperature register, and remains at the updated value until the next

conversion or write completes. PO

user-defined upper and lower trip-points. PO

-HIGH

and PO

-HIGH

the value stored in the upper trip-point register (T

value stored in the lower trip-point register (T

hysteresis into the output response. Similarly, PO

below the value stored in the low trip-point register (T

the value stored in the upper trip-point register (T

A0h (MSB) and A1h (LSB) and the T

register is located in address spaces A2h (MSB) and A3h (LSB) of the

L

are active-low and are activated and deactivated based on

-LOW

is activated when the measured temperature meets or exceeds

), and stays active until the temperature meets or falls below the

H

) (see Figure 4a). This allows the user to program any amount of

L

is activated when the measured temperature meets or goes

-LOW

), and stays active until the temperature meets or exceeds

L

) (see Figure 4b). The TH register is located in address spaces

H

DS620 memory.

-HIGH

or PO

through the

-LOW

The T

and TL registers (see Table 1) contain centigrade temperature values in two’s complement format and are

H

stored in EEPROM; therefore, they are nonvolatile (NV) and can be programmed prior to installation of the DS620

for use in standalone applications. All bits in the T

and TL registers are used in the comparison to the temperature

H

value in the temperature register for the thermostat operation, regardless of the number of bits used for the

temperature conversions as decided by the R0 and R1 bits in the configuration register. Therefore, to ensure

proper thermostat operation, any bits not used for the temperature measurement should be set to 0 in the T

T

registers. For example, for 11-bit temperature conversions, bits 3 and 4 in the TH and TL register should be set to

L

0 prior to comparison to the measured temperature. (Bits 0 to 2 are automatically set to 0).

Another thermostat feature is the temperature high and low flags (THF and TLF) in the configuration register.

These bits provide a record of whether the temperature has ever been equal to or greater than T

less than T

exceeds the T

meets or falls below the T

at anytime since power up or since the bits were last cleared. If the temperature ever meets or

L

register value, the THF bit in the configuration register is set to 1, and if the temperature ever

H

value, the TLF bit in the configuration register is set to 1. Once THF or TLF has been

L

or equal to or

H

set, it remains set until the power is cycled or it is overwritten with a 0 by the user.

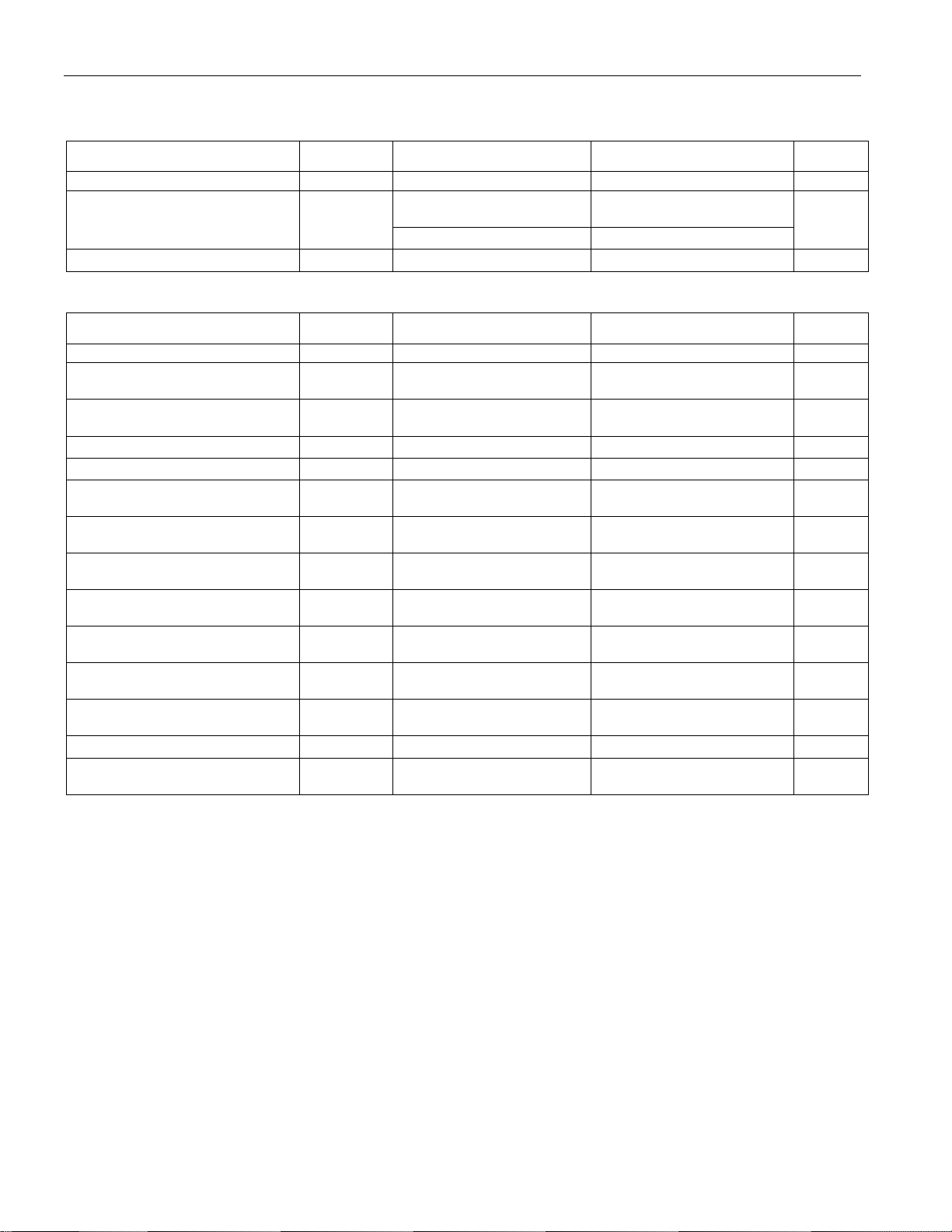

Figure 4. Thermostat Operation

a) PO-high

ic 1

Lo

Logic 0

TL

Tem

Temp

T

H

b) PO-low

Lo

ic 1

Logic 0

Tem

T

L

TH

Temp

STANDALONE THERMOSTAT OPERATION

The DS620 can function as a standalone thermostat, i.e., it can provide thermostat functionality without requiring

communication with a microcontroller. For standalone thermostat operation, the T

must be programmed to the desired values prior to installation. For standalone operation, the AUTOC bit in the

configuration register must be set to 1 so that measurements begins automatically at power up. This also

configures the A1 pin as an input pin that can trigger a conversion. In addition, PO must be configured as PO

or PO

. The 1SHOT bit in the configuration register is used to enable the DS620 to perform continuous

-LOW

conversions at power up (1SHOT = 0) or a single conversion (one-shot) at power up or upon request (1SHOT = 1).

In one-shot mode, one conversion is performed at power-up and then the device enters a low-power standby state

until A1 is toggled high. The A1 pin must be toggled low and back high again to start another conversion.

, TL, and configuration registers

H

and

H

-HIGH

7 of 15

Page 8

DS620 Digital Thermometer and Thermostat

PO PIN

The PO pin is a user-programmable open-drain output, which is configured through the PO1 and PO2 bits in the

configuration register. PO can operate as a thermostat output (PO

of peripheral devices. When PO is configured as PO

Thermostat Operation section. This pin can be reconfigured at anytime to switch between functions. Table 3

defines the various configuration options for this pin.

-HIGH

or PO

-HIGH

or PO

, this pin operates as described in the

-LOW

), or it can be forced low for control

-LOW

Table 3. PO Configuration

Function PO2 PO1

Thermostat Output (PO-high) 1 1

Thermostat Output (PO-low) 1 0

Force PO Low 0 X

EEPROM REGISTERS AND MEMORY MAP

The DS620 has a 14-byte linear address space with registers for temperature, thermostat thresholds, and control

as well as four bytes of user EEPROM for general use. All address space is shadowed by RAM. The DS620

Memory Map is shown in Table 4.

See the Writing to the DS620 and the Reading from the DS620 sections for details in writing to and reading from

the DS620 EEPROM registers and memory map.

Table 4. Memory Map

Address (hex) Description

A0 TH MSB

A1 TH LSB

A2 TL MSB

A3 TL LSB

A4 User

A5 User

A6 User

A7 User

A8 Undefined

A9 Undefined

AA Temperature MSB

AB Temperature LSB

AC Configuration MSB

AD Configuration LSB

CONFIGURATION REGISTER

The configuration register allows the user to program various DS620 options such as conversion resolution,

operating mode, and thermostat capability. It also provides information to the user about conversion status,

EEPROM activity, device address, and thermostat activity. The configuration register is arranged as shown in

Figure 5 and detailed descriptions of each bit are provided in Table 5. It is located in address spaces ACh (MSB)

and ADh (LSB) in the DS620 memory. Note that the R0, R1, AUTOC, 1SHOT, and PO1 bits are stored in

EEPROM so they can be programmed prior to installation if desired. All other configuration bits are SRAM and

power up in the state shown in Table 5.

8 of 15

Page 9

DS620 Digital Thermometer and Thermostat

Figure 5. Configuration Register

MS Byte

LS Byte

*

Stored in EEPROM

Table 5. Configuration Register Bit Descriptions

Bit Name User Access Functional Description

DONE

NVB

THF

TLF

*

R1

*

R0

AUTOC

1SHOT

*

*

bit 15 bit 14 bit 13 bit 12 bit 11 bit 10 bit 9 bit 8

Address ACh

DONE NVB THF TLF R1* R0* AUTOC

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

PO2 PO1

*

Address ADh

A2 A1 A0 M* M* M*

At power-up, DONE = 1. (Unless AUTOC = 1)

Read Only

DONE = 0—Temperature conversion is in progress.

DONE = 1—Temperature conversion is complete.

Read Only

At power-up, NVB = 0

NVB = 1—Write to an E

2

memory cell is in progress

NVB = 0—Nonvolatile memory is not busy.

At power-up, THF = 0

THF = 1—The measured temperature has reached or exceeded the value

Read/Write

stored in the T

register at anytime since power-up or since the bit was last

H

cleared. THF remains a 1 until the power is cycled or it is overwritten with a

0 by the user.

At power-up, TLF = 0

TLF = 1—The measured temperature has met or fallen below the value

Read/Write

stored in the T

register at anytime since power-up or since the bit was last

L

cleared. TLF remains a 1 until the power is cycled or it is overwritten with a

0 by the user.

Read/Write

Read/Write

Used to set conversion resolution (see Table 6).

Factory state = 1

Used to set conversion resolution (see Table 6).

Factory state = 1

Determines whether the DS620 powers up idle or converting.

Read/Write

Factory state = 0

AUTOC = 1—DS620 powers-up converting temperature.

AUTOC = 0—DS620 powers-up idle.

Configures temperature conversion mode. Factory state = 0

1SHOT = 1: One-shot mode

For AUTOC = 0, the device powers up idle The Start Convert

command causes a single temperature conversion and then the

device returns to a low-power standby state.

If AUTOC = 1, the A1 pin is reconfigured as a conversion trigger for

standalone operation and the device powers up and performs 1

Read/Write

conversion. Single conversions can be initiated using the Start

Convert command or by toggling A1 high.

1SHOT = 0: Continuous conversion mode

For AUTOC = 0, the Start Convert command initiates continuous

conversions.

For AUTOC = 1, the device powers up performing continuous

conversions. Note: Changing the 1SHOT bit to 1 while continuous

conversions are in progress does not stop the conversions. A Stop

Convert command must first be issued after which one-shot

*

1SHOT*

9 of 15

Page 10

DS620 Digital Thermometer and Thermostat

conversions can be performed.

See Writing the 1SHOT Bit Command Sequence section for writing more

information on writing the 1SHOT bit.

At power-up, PO2 = 1.

PO2

Read/Write

PO2 = 0 forces the PO pin low (see Table 3)

PO2 = 1 configures PO as the thermostat output (PO

-HIGH

or PO

-LOW

, as

determined by PO1).

PO1*

Read/Write

When PO2 = 1, PO1 configures the PO pin as either PO

Table 3)

When PO2 = 0, PO1 is a “don’t care”.

-HIGH

or PO

-LOW

(see

Factory state = 0

A2 Read Only Shows address bit A2, as determined by pin A2.

A1 Read Only Shows address bit A1, as determined by pin A1.

A0 Read Only Shows address bit A0, as determined by pin A0.

M* Read/Write User memory for general-purpose data storage.

*

Stored in EEPROM

Table 6. Resolution Configuration

R1 R0 Resolution LSb Weight (°C)

0 0 10-bit 0.5 25

0 1 11-bit 0.25 50

1 0 12-bit 0.125 100

1 1 13-bit 0.0625 200

Max Conversion

Time (ms)

2-WIRE SERIAL DATA BUS

The DS620 communicates over a standard bidirectional 2-wire serial data bus that consists of a serial clock (SCL)

signal and serial data (SDA) signal. The DS620 interfaces to the bus through the SCL input pin and open-drain

SDA I/O pin. All communication is MSb first.

The following terminology is used to describe 2-wire communication:

Master Device: Microprocessor/microcontroller that controls the slave devices on the bus. The master device

generates the SCL signal and START and STOP conditions.

Slave: All devices on the bus other than the master. The DS620 always functions as a slave.

Bus Idle or Not Busy: Both SDA and SCL remain high. SDA is held high by a pullup resistor when the bus is idle,

and SCL must either be forced high by the master (if the SCL output is push-pull) or pulled high by a pullup resistor

(if the SCL output is open-drain).

Transmitter: A device (master or slave) that is sending data on the bus.

Receiver: A device (master or slave) that is receiving data from the bus.

START Condition: Signal generated by the master to indicate the beginning of a data transfer on the bus. The

master generates a START condition by pulling SDA from high to low while SCL is high (see Figure 6). A

“repeated” START is sometimes used at the end of a data transfer (instead of a STOP) to indicate that the master

will perform another operation.

STOP Condition: Signal generated by the master to indicate the end of a data transfer on the bus. The master

generates a STOP condition by transitioning SDA from low to high while SCL is high (see Figure 6). After the

STOP is issued, the master releases the bus to its idle state.

Acknowledge (ACK): When a device (either master or slave) is acting as a receiver, it must generate an

acknowledge (ACK) on the SDA line after receiving every byte of data. The receiving device performs an ACK by

pulling the SDA line low for an entire SCL period (see Figure 6). During the ACK clock cycle, the transmitting

device must release SDA. A variation on the ACK signal is the “not acknowledge” (NACK). When the master device

10 of 15

Page 11

DS620 Digital Thermometer and Thermostat

is acting as a receiver, it uses a NACK instead of an ACK after the last data byte to indicate that it is finished

receiving data. The master indicates a NACK by leaving the SDA line high during the ACK clock cycle.

Slave Address: Every slave device on the bus has a unique 7-bit address that allows the master to access that

device. The DS620’s 7-bit bus address is 1 0 0 1 A

corresponding input pins. The three address pins allow up to eight DS620s to be multidropped on the same bus.

Control Byte: The control byte is transmitted by the master and consists of the 7-bit slave address plus a

read/write (R/W¯¯) bit (see Figure 7). If the master is going to read data from the slave device then R/W¯¯ = 1, and if

the master is going to write data to the slave device then R/W¯¯ = 0.

Address Byte: The address byte is used by the master to tell the DS620 which address location in the memory

map in Table 4 is going to be accessed during communication or which command should be performed. See

Command Set section.

2 A1 A0

, where A2, A1, and A0 are user-selectable via the

Figure 6. START, STOP, AND ACK SIGNALS

SDA

SCL

START

Condition

ACK (or NACK)

From Receiver

STOP

Condition

Figure 7. Control Byte

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

1 0 0 1 A2 A

A

1

0

R/W¯¯

GENERAL 2-WIRE INFORMATION

All data is transmitted MSb first over the 2-wire bus.

One bit of data is transmitted on the 2-wire bus each SCL period.

A pullup resistor is required on the SDA line and, when the bus is idle, both SDA and SCL must remain in a logic-

high state.

All bus communication must be initiated with a START condition and terminated with a STOP condition. During a

START or STOP is the only time SDA is allowed to change states while SCL is high. At all other times, changes

on the SDA line can only occur when SCL is low: SDA must remain stable when SCL is high.

After every 8-bit (1-byte) transfer, the receiving device must answer with an ACK (or NACK), which takes one

SCL period. Therefore, nine clocks are required for every one-byte data transfer.

INITIATING 2-WIRE COMMUNICATION

To initiate 2-wire communication, the master generates a START followed by a control byte containing the DS620

slave address. The R/W bit of the control byte must be a 0 (write) since the master next writes a command byte or

an address byte. The DS620 responds with an ACK after receiving the control byte. This must be followed by a

command byte from the master which indicates what type of command operation is to be performed, or an address

byte when the master intends to write to or read from the DS620. The DS620 again responds with an ACK after

receiving the command or address byte. The master can then issue a STOP to signal the end of the

communication sequence, or continue writing to the address memory. See the Command Set section for details on

11 of 15

Page 12

DS620 Digital Thermometer and Thermostat

the DS620 commands. See Writing to the DS620 or Reading from the DS620 for more information on reading from

and writing to the DS620.

WRITING TO THE DS620

The master can write data to the DS620 by issuing an address byte following the control byte. The R/W bit in the

control byte must be a 0 (write). After receiving an ACK from the DS620 in response to the control byte, the master

sends the address of the first register byte to be written, loading the address counter with the desired location. The

DS620 responds with another ACK, after which the master sends the data to be written. After receiving each byte

of data, the DS620 responds with an ACK. The master continues to write data to successive address locations until

it indicates there is no more data to be written by sending a STOP or repeated START condition. The DS620

ignores any data written once the address increments past ADh, the last defined register in the DS620 memory,

and indicates this by sending a NACK after each byte. It also ignores data written to undefined addresses A8h and

A9h. All writes to the DS620 are made to the shadow RAM. Once data is written to the shadow RAM, it is only

stored to EEPROM by issuance of a Copy Data command from the master. At that time all registers are copied to

EEPROM, except the Temperature registers, which are SRAM only, and the undefined registers. The DS620 must

be set to the continuous conversion mode and be actively converting temperature to enable the Copy Data

command to function properly. See Copying to EEPROM Command Sequence for more information.

READING FROM THE DS620

The master can read data from the DS620 by issuing an address byte following the control byte. The R/W bit in the

control byte must be a 0 (write). After receiving an ACK from the DS620 in response to the control byte, the master

writes the address of the first register byte to be read, loading the address counter with the desired location. The

DS620 will respond with another ACK. The master then must issue a repeated START (or a STOP and a START)

followed by a control byte with the same slave address as the first control byte. However, this time the R/W bit must

be a 1 which tells the DS620 that a “read” is being performed. After the DS620 sends an ACK in response to this

control byte, it begins transmitting the requested data on the next clock cycle. The master responds with an ACK

between each byte of data read from the DS620 until no further bytes of data are to be read, at which time the

master responds with a NACK followed by a STOP. The DS620 sends all 1’s (FFh) once the address increments

past ADh, the last defined register in the DS620 memory. There is no guaranteed state of data read from the

undefined registers, A8h and A9h. The Recall Data command should be issued before a read to assure that the

contents of the EEPROM will be in the Shadow RAM when read.

COMMAND SET

The DS620 command set is detailed below:

Start Convert [ 51h ] 0101 0001

Initiates temperature conversions. If the part is in one-shot mode (1SHOT = 1), only one conversion is performed.

In continuous mode (1SHOT = 0), continuous temperature conversions are performed until a Stop Convert

command is issued (even if 1SHOT is changed to a 1).

Stop Convert [ 22h ] 0010 0010

Stops temperature conversions when the device is in continuous conversion mode (1SHOT = 0). This command

has no function if the device is in one-shot mode (1SHOT = 1)

Recall Data [ B8h ] 1011 1000

Refreshes SRAM shadow register with EEPROM data.

Copy Data [ 48h ] 0100 1 000

Copies data from all SRAM shadow registers to EEPROM.

NOTE: The DS620 must be set to the continuous conversion mode and be actively converting temperature to

enable the Copy Data command to function properly. See example command sequence in the Copying to

EEPROM Command Sequence section for more information.

Software POR [ 54h ] 0101 0100

Initiates a software power-on-reset (POR), which stops temperature conversions and resets all registers and logic

to their power-up states. The software POR allows the user to simulate cycling the power without actually powering

down the device. This command should not be issued while a Copy Data command is in progress.

12 of 15

Page 13

DS620 Digital Thermometer and Thermostat

COPYING TO EEPROM COMMAND SEQUENCE

Data is written to DS620 and then copied from SRAM to EEPROM

BUS

MASTER

MODE

TX RX START Bus master initiates a START condition. 1

TX RX <address, 0>

RX TX ACK

TX RX A4h

RX TX ACK DS620 generates acknowledge. 5

TX RX <data>

RX TX ACK DS620 generates acknowledge. 7

TX RX <data>

RX TX ACK DS620 generates acknowledge. 9

TX RX <data>

RX TX ACK DS620 generates acknowledge. 11

TX RX <data>

RX TX ACK DS620 generates acknowledge. 13

TX RX START Bus master generates a repeated start condition. 14

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge. 16

TX RX ACh

RX TX ACK DS620 generates acknowledge. 18

TX RX xxxxxxx0b

RX TX ACK DS620 generates acknowledge. 20

TX RX START Bus master generates a repeated start condition. 21

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge 23

TX RX 51h

RX TX ACK

TX RX START Bus master generates a repeated start condition. 26

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge. 28

TX RX ACh

DS620

MODE

DATA

(MSB

FIRST)

COMMENTS

Bus master sends DS620 address, R/W = 0.

DS620 generates acknowledge bit. 3

Bus master sends the address location of the first byte

of data to be written. (In this case the first byte of user

EEPROM).

Bus master sends one byte of data to the SRAM

location for EEPROM address A4h.

Bus master sends one byte of data to the SRAM

location for EEPROM for address A5h.

Bus master sends one byte of data to the SRAM

location for EEPROM for address A6h.

Bus master sends one byte of data to the SRAM

location for EEPROM for address A7h.

Bus master sends DS620 address, R/W = 0.

Bus master sends the address location of the MSb of

the configuration register (contains the 1SHOT bit).

This writes to the SRAM location corresponding the

EEPROM location. NOTE: Sequence numbers 17

through 23 need to be done only if DS620 is in 1SHOT

mode: 1SHOT = 1.

Bus master writes to the configuration register putting

the DS620 in continuous conversion mode: 1SHOT =

0.

Bus master sends DS620 address, R/W = 0.

Master sends START CONVERT command to DS620

to start temperature conversions.

DS620 generates acknowledge bit and begins

conversions.

Bus master sends DS620 address, R/W = 0.

Bus master sends the address location of the MSb of

the configuration register (contains the 1SHOT bit).

This writes to the SRAM location corresponding the

EEPROM location. NOTE: command sequence

numbers 29 through 34 need only be done if a return to

1SHOT mode operation is needed.

SEQUENCE

NUMBER

2

4

6

8

10

12

15

17

19

22

24

25

27

29

13 of 15

Page 14

DS620 Digital Thermometer and Thermostat

RX TX ACK DS620 generates acknowledge. 30

TX RX xxxxxxx1b

TX RX START Bus master generates a repeated start condition. 32

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge. 34

TX RX 48h

RX TX ACK DS620 generates acknowledge. 36

TX RX START Bus master generates a repeated start condition. 37

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge. 39

TX RX 22h

RX TX ACK DS620 generates acknowledge. 41

TX RX STOP

Bus master writes to the configuration register putting

the DS620 back in 1SHOT mode: 1SHOT = 1.

Bus master sends DS620 address, R/W = 0.

Master sends COPY DATA command to DS620 to

copy data in from SRAM memory to EEPROM memory.

Bus master sends DS620 address, R/W = 0.

Bus master sends a STOP CONVERT command to

stop the DS620 from continuously converting

temperature. NOTE: Bus master should ensure that

EEPROM copy operation is complete before executing

the STOP CONVERT command by either waiting 10ms

from the time of the COPY DATA command or

checking the NVB bit in configuration register

Bus master sends STOP condition to end

communication with DS620. (The bus master could

send a repeated start condition if additional

communication with the DS620 is desired.)

WRITING THE 1SHOT BIT COMMAND SEQUENCE

Configuring from continuous mode to 1SHOT mode.

BUS

MASTER

MODE

TX RX START Bus master initiates a START condition. 1

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge bit. 3

TX RX 51h

RX TX ACK

TX RX START Bus master generates a repeated start condition. 6

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge. 8

TX RX ACh

RX TX ACK DS620 generates acknowledge. 10

TX RX xxxxxxx1b

RX TX ACK DS620 generates acknowledge. 12

TX RX START Bus master generates a repeated start condition. 13

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge. 15

TX RX 48h

DS620

MODE

DATA

(MSB FIRST)

COMMENTS

Bus master sends DS620 address, R/W = 0.

Master sends START CONVERT command to DS620

to start temperature conversions.

DS620 generates acknowledge bit and begins

conversions.

Bus master sends DS620 address, R/W = 0.

Bus master sends the address location of the MSb of

the configuration register (contains the 1SHOT bit).

This writes to the SRAM location corresponding the

EEPROM location.

Bus master writes to the configuration register putting

the DS620 in 1SHOT mode: 1SHOT = 1.

Bus master sends DS620 address, R/W = 0.

Master sends COPY DATA command to DS620 to

copy data in from SRAM memory to EEPROM

memory.

31

33

35

38

40

42

SEQUENCE

NUMBER

2

4

5

7

9

11

14

16

14 of 15

Page 15

DS620 Digital Thermometer and Thermostat

RX TX ACK DS620 generates acknowledge. 17

TX RX START Bus master generates a repeated start condition. 18

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge. 20

TX RX 22h

RX TX ACK DS620 generates acknowledge. 22

TX RX STOP

Configuring from 1SHOT to mode to continuous conversion mode.

BUS

MASTER

MODE

TX RX START Bus master initiates a START condition. 1

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge bit. 3

TX RX ACh

RX TX ACK DS620 generates acknowledge. 5

TX RX xxxxxxx0b

RX TX ACK DS620 generates acknowledge. 7

TX RX START Bus master generates a repeated start condition. 8

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge. 10

TX RX 51h

RX TX ACK

TX RX START Bus master generates a repeated start condition. 13

TX RX <address, 0>

RX TX ACK DS620 generates acknowledge. 15

TX RX 48h

RX TX ACK DS620 generates acknowledge. 17

TX RX STOP

DS620

MODE

DATA

(MSB

FIRST)

Bus master sends DS620 address, R/W = 0.

Bus master sends STOP CONVERT command to

stop the DS620 from continuously converting

temperature. NOTE: Bus master should ensure that

EEPROM copy operation is complete before

executing the STOP CONVERT command by either

waiting 10ms from the time of the COPY DATA

command or checking the NVB bit in configuration

register

Bus master sends STOP condition to end

communication with DS620. (The bus master could

send a repeated start condition if additional

communication with the DS620 is desired.)

COMMENTS

Bus master sends DS620 address, R/W = 0.

Bus master sends the address location of the MSb of

the configuration register (contains the 1SHOT bit).

This writes to the SRAM location corresponding the

EEPROM location.

Bus master writes to the configuration register putting

the DS620 in continuous conversion mode: 1SHOT =

0.

Bus master sends DS620 address, R/W = 0.

Master sends START CONVERT command to DS620

to start temperature conversions.

DS620 generates acknowledge bit and begins

conversions.

Bus master sends DS620 address, R/W = 0.

Master sends COPY DATA command to DS620 to

copy data in from SRAM memory to EEPROM

memory.

Bus master sends STOP condition to end

communication with DS620. (The bus master could

send a repeated start condition if additional

communication with the DS620 is desired.)

19

21

23

SEQUENCE

NUMBER

2

4

6

9

11

12

14

16

18

15 of 15

Loading...

Loading...