Page 1

查询DS4000供应商

www.maxim-ic.com

GENERAL DESCRIPTION

The DS4000 digitally controlled temperature-compensated crystal oscillator (DC-TCXO) features a digital

temperature sensor, one fixed-frequency temperaturecompensated square-wave output (F

), one

1

programmable temperature-compensated squarewave output (F

), and digital communication for

2

frequency tuning (SDA, SCL).

APPLICATIONS

Reference Oscillators in PLL Circuits

Global Positioning Systems

SATCOM

Telecom

Wireless Base Stations

ORDERING INFORMATION

PART TEMP RANGE PIN-PACKAGE

DS4000

DS4000N

Selector Guide appears end of data sheet.

0°C to +70°C 24 BGA

-40°C to +85°C 24 BGA

DS4000

Digitally Controlled TCXO

FEATURES

§ Aging ≤1.0ppm (First Year)

§ Frequency Stability ±1.0ppm from -40°C to +85°C

§ Frequency Versus Supply Stability of ±1.0ppm per

Volt

Base Frequency is Digitally Tunable by ±10ppm

One Fixed-Frequency Output and One

(n + 1) or 2(n + 1) Division of the Base

Frequency Output

§ Temperature Measurements from -40C° to +85°C

with 10-Bit/+0.25°C Resolution and ±3°C

Accuracy

§ 2-Wire Serial Interface

PIN CONFIGURATION

TOP VIEW

GND

A B C D

SCL

SDA

A0

OSC

N.C.

GND

6

5

4

3

2

1

BGA

F2

V

CC

F1

V

OSC

GND

GND

Note: Some revisions of this device may incorporate deviations from published specifications known as errata. Multiple revisions of any device

may be simultaneously available through various sales channels. For information about device errata, click here: www.maxim-ic.com/errata

.

1 of 16

REV: 072403

Page 2

DS4000 Digitally Controlled TCXO

ABSOLUTE MAXIMUM RATINGS

Voltage Range on Any Pin Relative to Ground -0.3V to +6.0V

Storage Temperature Range -55°C to +85°C

Operating Voltage Range V

= 5V ±5%

CC

Operating Temperature Range

Commercial 0°C to +70°C

Industrial -40°C to +85°C

Soldering Temperature See IPC/JEDEC J-STD-020A (2x max)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is

not implied. Exposure to absolute maximum rating conditions for extended periods can affect device reliability.

RECOMMENDED DC OPERATING CONDITIONS

(VCC = 5V ±5%, over the operating temperature range.)

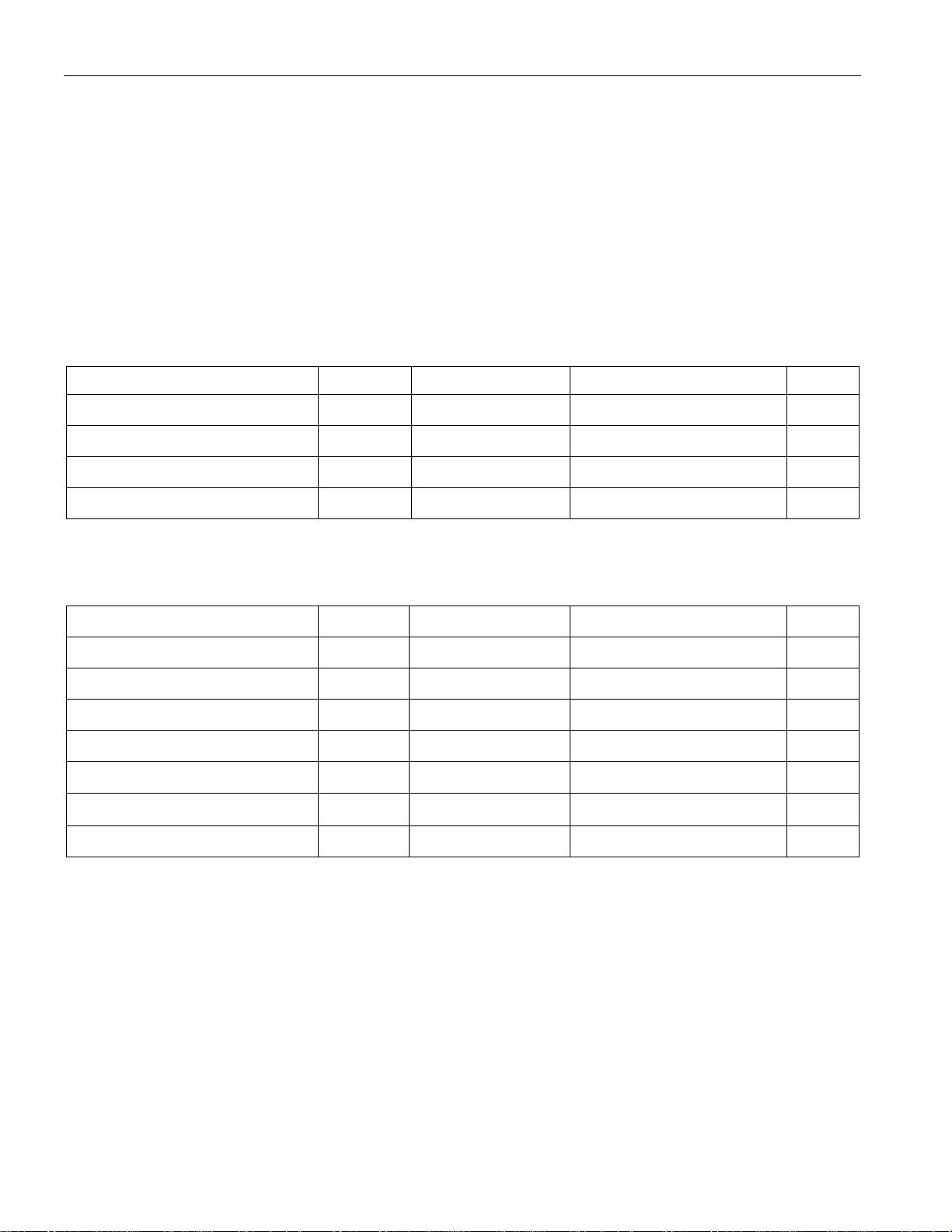

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage VCC (Notes 1, 2) 4.75 5.0 5.25 V

Oscillator Supply Voltage V

(Notes 1, 2) 4.75 5.0 5.25 V

OSC

Input Logic High VIH (Note 1) 2.2 VCC + 0.3 V

Input Logic Low VIL (Note 1) -0.3 +0.8 V

DC ELECTRICAL CHARACTERISTICS

(VCC = 5V ±5%, over the operating temperature range.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Active Supply Current ICC (Notes 3, 4) 1.5 2 mA

Active Oscillator Supply Current I

Output Logic High 2.4V IOH (Note 1) -1 mA

Output Logic Low 0.4V IOL (Note 1) 4 mA

Input Leakage ILI

I/O Leakage ILO

Temperature Conversion Time t

Note 1: All voltages are referenced to ground.

Note 2: For ±10% operating range, contact factory.

Note 3: Typical values are at +25°C and nominal supplies.

Note 4: These parameters are measured with the outputs disabled.

(Notes 3, 4) 3.5 5.5 mA

OSC

(Note 3) 250 300 ms

CONVT

1

1

mA

mA

2 of 16

Page 3

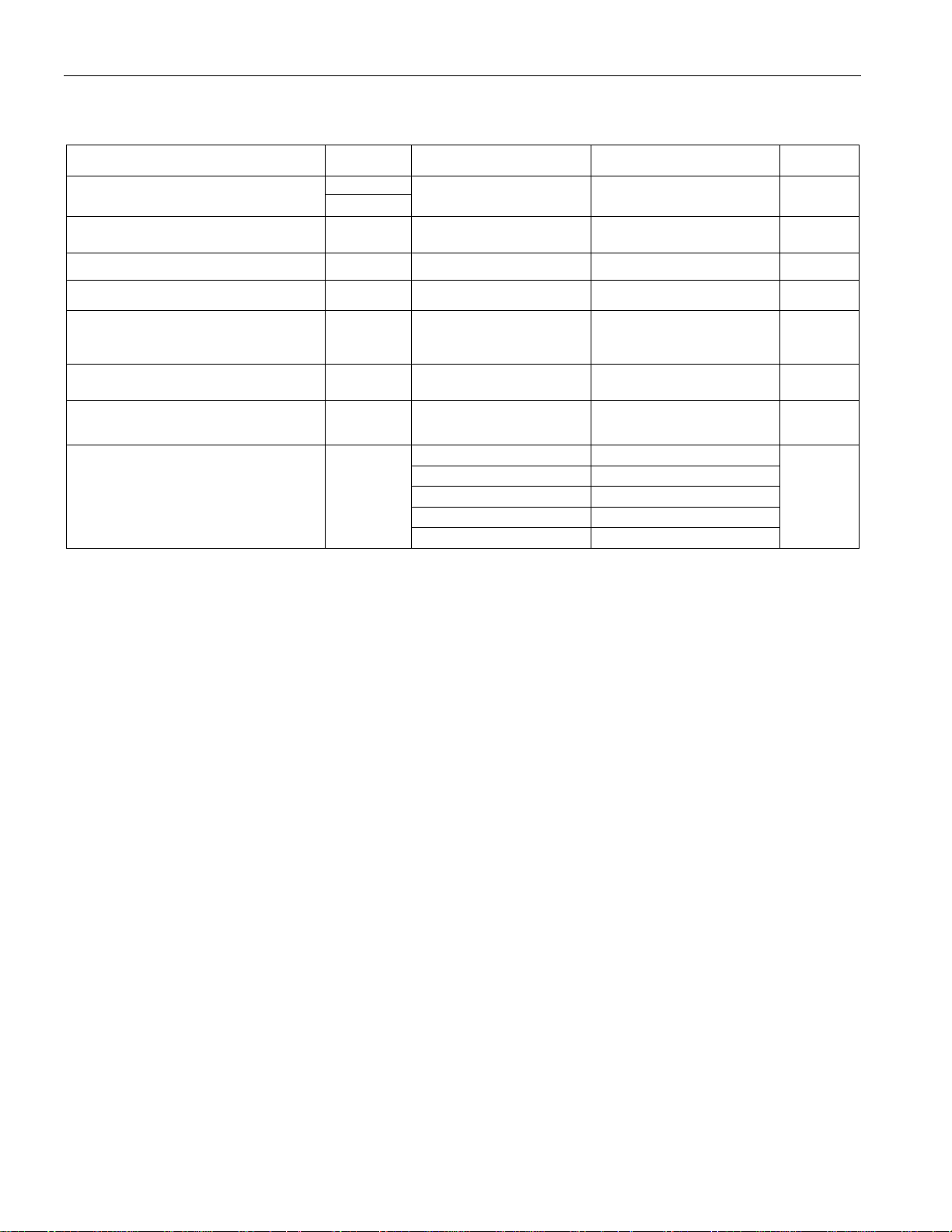

AC ELECTRICAL CHARACTERISTICS: TCXO

(VCC = 5V ±5%, over the operating temperature range.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Output Frequency

Frequency Stability vs.

Temperature

Frequency Stability vs. Voltage

F1

F

2

DF/T

DF/V

CMOS (Note 5) 10 20 MHz

-1.0 +1.0 ppm

A

(Note 6) ±1.0 ppm/V

DS4000 Digitally Controlled TCXO

Frequency Stability vs. Aging

F1, F2 Rise and Fall Time, 10% to

90%

DF/Yr

t

, tF 4 ns

R

±1.0 ppm/Yr

Max Output Capacitive Load CL 10 pF

Duty Cycle tW / t 40 50 60 %

10Hz -85

100Hz -115

Phase Noise f1 Output (Note 7)

1kHz -129

f

N

dBc/Hz

10kHz -134

100kHz -139

Note 5: F1 is the base frequency as defined by the package markings. F2 is a programmable frequency output. The output frequency of F2 is

derived from the base frequency, F

register. The minimum output frequency is F

Note 6: First year typical.

Note 7: 16.384MHz, 5V, +25°C with one of the two outputs enabled.

, by programming the F2 frequency select register and duty cycle (DC) bit in the TCXO control

1

/ (28 + 1) with DC = 0 and f1 / [2 x (28 + 1)] with DC = 1.

1

3 of 16

Page 4

DS4000 Digitally Controlled TCXO

AC ELECTRICAL CHARACTERISTICS—2-WIRE SERIAL INTERFACE

(VCC = 4.75 to 5.25V, TA = -40°C to +85°C)

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS

Fast mode 0 400

SCL Clock Frequency f

SCL

Standard mode 0 100

kHz

Bus Free Time Between

a STOP and START

Condition

Hold Time (Repeated)

START Condition

Low Period of SCL

Clock

High Period of SCL

Clock

Setup Time for a

Repeated START

Condition

Data Hold Time t

Data Setup Time t

t

BUF

t

HD:STA

t

LOW

t

HIGH

t

SU:STA

HD:DAT

SU:DAT

Fast mode 1.3

ms

Standard mode 4.7

Fast mode (Note 7) 0.6

Standard mode (Note 7) 4.0

ms

Fast mode 1.3

Standard mode 4.7

ms

Fast mode 0.6

ms

Standard mode 4.0

Fast mode 0.6

ms

Standard mode 4.7

Fast mode (Note 8) 0 0.9

ms

Standard mode (Note 8) 0 0.9

Fast mode (Note 9) 100

ns

Standard mode (Note 9) 250

Rise Time of Both SDA

and SCL

Fall Time of Both SDA

and SCL

Setup Time for STOP

Condition

Capacitive Load for

Each Bus Line

Input Capacitance

Note 7: After this period, the first clock pulse is generated.

Note 8: The maximum t

Note 9: A fast-mode device can be used in a standard mode system, but the requirement t

Note 10: C

the case if the device does not stretch the LOW period of the SCL signal. If such a device does stretch the LOW period of the SCL

signal, it must output the next data bit to the SDA line t

: Total capacitance of one bus line in pF.

B

has only to be met if the device does not stretch the LOW period (t

HD:DAT

tR

tF

t

SU:STO

CB

CI

Fast mode (Note 9) 20 + 0.1CB 300

Standard mode (Note 9) 20 + 0.1CB 1000

Fast mode (Note 10) 20 + 0.1CB 300

Standard mode (Note 10) 20 + 0.1CB 1000

Fast mode 0.6

Standard mode 4.0

(Note 10) 400 pF

5 pF

+ t

RMAX

4 of 16

(1000 + 250 = 1250ns) before the SCL line is released.

SU:DAT

) of the SCL signal.

LOW

>250ns must then be met. This is automatically

SU:DAT

ns

ns

ms

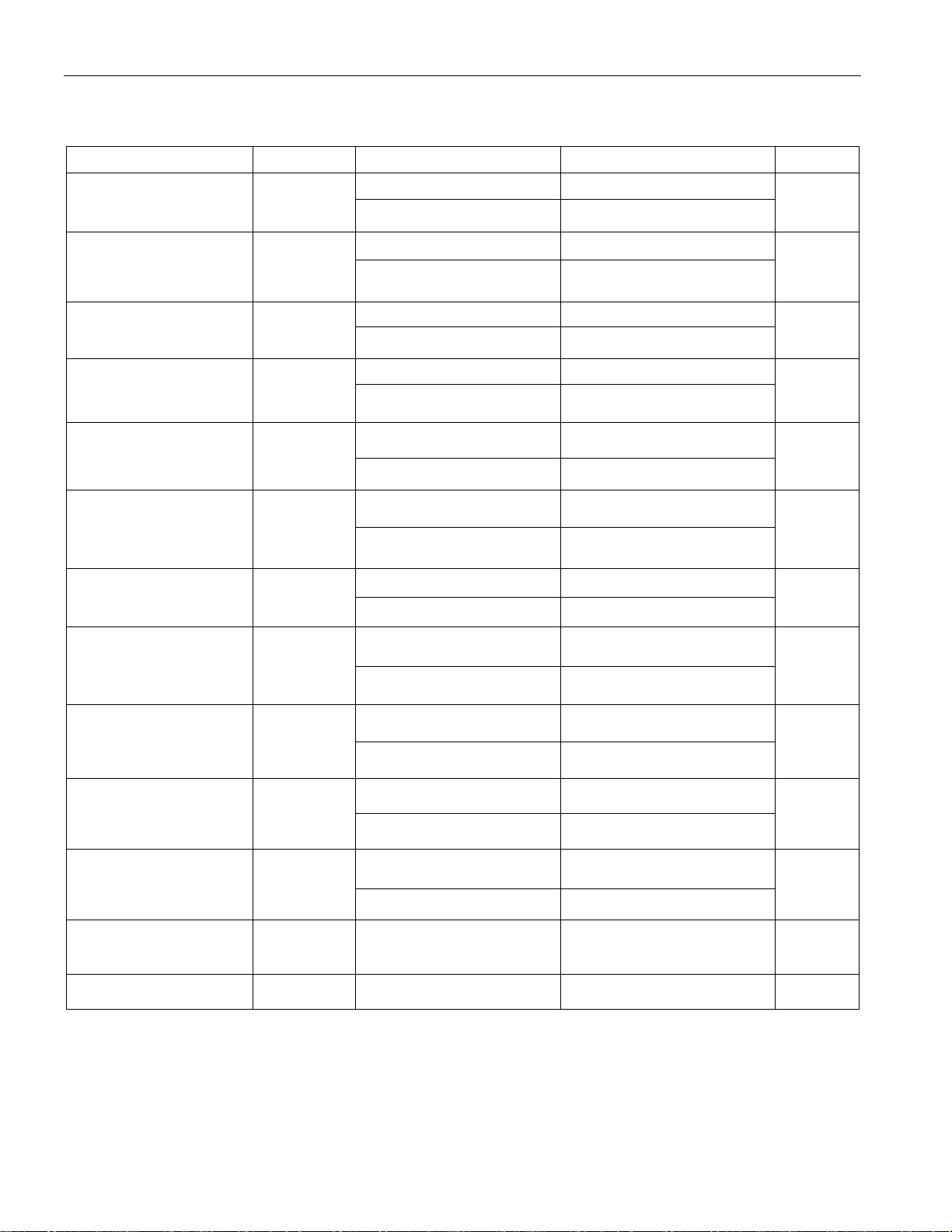

Page 5

Figure 1. Timing Diagram

DS4000 Digitally Controlled TCXO

PIN DESCRIPTION

PIN NAME FUNCTION

1A, 1B, 1C,

1D, 2C, 2D

2A, 2B N.C. No Connection. (Do not connect to ground.)

3A, 3B GND

3C, 3D V

4A, 4B A0 2-Wire Slave Address Input. This pin is used to configure the slave address.

4C, 4D F1 DC-TCXO Frequency Output

5A, 5B SDA

5C, 5D VCC Power Supply. DC power is provided to the device on these pins.

6A, 6B SCL

6C, 6D F2 DC-TCXO Frequency Output

GND Ground. DC power is provided to the device on these pins.

Oscillator Ground. DC power is provided to the oscillator on these pins.

OSC

Oscillator Power Supply. DC power is provided to the oscillator on these pins.

OSC

2-Wire Serial-Data Input/Output. SDA is the input/output pin for the 2-wire serial

interface. The SDA pin is open drain and requires an external pullup resistor.

2-Wire Serial-Clock Input. SCL is used to synchronize data movement on the serial

interface. The SCL pin is open drain and requires an external pullup resistor.

5 of 16

Page 6

DS4000 Digitally Controlled TCXO

DETAILED DESCRIPTION

The DS4000 digitally controlled temperature-compensated crystal oscillator (DC-TCXO) features a digital

temperature sensor, one fixed-frequency temperature-compensated square-wave output (F

temperature-compensated square-wave output (F

), and digital communication for frequency tuning (SDA, SCL).

2

Figure 2. Block Diagram

VCC

SDA

SCL

A0

2-WIRE

SERIAL

INTERFACE

DS4000

GND

V

OSC

TEMPERATURE-

COMPENSATED

OSCILLATOR

TEMPERATURE

OSC

GND

CRYSTAL

DIGITAL

SENSOR

), one programmable

1

F

2

F

1

6 of 16

Page 7

DS4000 Digitally Controlled TCXO

TEMPERATURE-COMPENSATED CRYSTAL OSCILLATOR

The DS4000 can either function as a standalone TCXO or as a digitally controlled TCXO. When used as a

standalone TCXO, the only requirements needed to function properly are power, ground, and an output. However,

the 2-wire interface must be used to tune (push and pull) the crystal.

The DS4000 is capable of supplying two different outputs, F

is the base frequency of the crystal unit inside of the device. The output type is a CMOS square wave.

1) F

1

is a programmable frequency output. The frequency select register can program this output to an integer

2) F

2

division of the base (F

division of F

.

1

) frequency. The duty cycle (DC) bit determines if the output is an n + 1 or a 2(n + 1)

1

and F2.

1

FREQUENCY SELECT REGISTER (FSR) (5Dh)

F

2

Bit

7 6 5 4 3 2 1 0

Name D7 D6 D5 D4 D3 D2 D1 D0

Default 0 0 0 0 0 0 0 0

F

= F1 / (FSR value + 1); with DC = 0

2

F

= F1 / [2 x (FSR value + 1)]; with DC = 1

2

TCXO CONTROL REGISTER (60h)

Bit

7 6 5 4 3 2 1 0

Name X X X X F2OE F1OE FT DC

Default 0 0 0 0 0 0 0 0

DC, Duty Cycle Bit: If 50% duty cycle is desired, then this bit must be set to logic 1. The default condition at

power-up is logic 0.

: This bit must be programmed by the user to 0.

F

T

F

OE, F1 Output Enable Bit: This bit allows the user to disable/enable the F1 output.

1

OE, F2 Output Enable Bit: This bit allows the user to disable/enable the F2 output.

F

2

7 of 16

Page 8

DS4000 Digitally Controlled TCXO

DIGITAL TUNING THE BASE CRYSTAL FREQUENCY

When using the 2-wire interface for tuning the base frequency, the frequency tuning register is used. The frequency

tuning register contains two’s complement data. The data is used to add or subtract an offset from the crystal

loading register. When the tuning register is programmed with a value, the next temperature-update cycle sums the

programmed value with the factory-compensated value. This allows the user/system to digitally control the base

frequency by a microcontroller using the 2-wire protocol.

FREQUENCY TUNING REGISTER (66h)

Bit

Name SIGN FO6 FO5 FO4 FO3 FO2 FO1 FO0

Default 0 0 0 0 0 0 0 0

FOS[6:0], Frequency Offset: These bits are used to tune the base crystal frequency. Each bit represents

approximately 0.08ppm and, therefore, for a value of 07FH, pushes or pulls the base frequency by approximately

10.16ppm.

SIGN, Sign Bit: This bit is used to determine whether to add or subtract the frequency offset from the crystal

loading.

Table 1. Frequency Tuning Relationship

7 6 5 4 3 2 1 0

CALCULATED

FREQUENCY OFFSET

(ppm)

-10.16 0111 1111 7Fh

-8.00 0110 0100 64h

-5.28 0100 0010 42h

-1.84 0001 0111 17h

-0.08 0000 0001 01h

0.0 0000 0000 00h

+0.08 1111 1111 FFh

+1.84 1110 1000 E8h

+5.28 1011 0011 B3h

+8.00 1001 1100 9Ch

+10.16 1000 0000 80h

DIGITAL DATA

(Binary)

DIGITAL DATA

(hex)

8 of 16

Page 9

DS4000 Digitally Controlled TCXO

DIGITAL TEMPERATURE SENSOR

The digital temperature sensor provides 10-bit temperature readings that indicate the temperature of the device.

Temperature readings are communicated from the DS4000 over a 2-wire serial interface. No additional

components are required. The DS4000 has an external address bit that allows a user to choose the slave address

from two possible values.

The factory-calibrated temperature sensor requires no external components. Upon power-up, the DS4000 starts

performing temperature conversions with a resolution of 10 bits (+0.25°C resolution). Following an 8-bit command

protocol, temperature data can be read over the 2-wire interface. The host can periodically read the value in the

temperature register, which contains the last completed conversion. As conversions are performed in the

background, reading the temperature register does not affect the conversion in progress.

READING TEMPERATURE

The DS4000 measures temperature through the use of an on-chip temperature-measurement technique with an

operation range from 0°C to +70°C (commercial) or -40°C to +85°C (industrial). The device performs continuous

conversions with the most recent result being stored in the temperature register. The digital temperature is

retrieved from the temperature register using the READ TEMPERATURE command, as described in detail in the

following paragraphs.

Table 2 shows the exact relationship of output data to measured temperature. The data is transmitted serially over

the 2-wire serial interface, MSB first. The MSB of the temperature register contains the “sign” (S) bit, denoting

whether the temperature is positive or negative. For Fahrenheit usage, a lookup table or conversion routine must

be used.

TEMPERATURE/DATA RELATIONSHIP (UNIT = °C)

MSB (64h)

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

S 26 2

LSB (65h)

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

2-1 2

-2

0 0 0 0 0 0

Table 2. Temperature/Data Relationship

5

2

4

2

3

2

2

2

1

2

0

TEMPERATURE

(°C)

DIGITAL OUTPUT

(Binary)

DIGITALOUTPUT

(hex)

+85 0101 0101 0000 0000 5500h

+75 0100 1011 0000 0000 4B00h

+0.5 0000 0000 1000 0000 0080h

0 0000 0000 0000 0000 0000h

-0.5 1111 1111 1000 0000 FF80h

-20 1110 1100 0000 0000 EC00h

Note: Internal power dissipation raises the temperature above the ambient. The delta between ambient and the die temperature depends on

power consumption, PC board layout, and airflow.

-40 1101 1000 0000 0000 D800h

9 of 16

Page 10

DS4000 Digitally Controlled TCXO

READ TEMPERATURE COMMAND

This command reads the last temperature conversion result from the temperature register in the format described

in the Reading Temperature section. If an application can accept temperature resolutions of +1.0°C, then the

master can read the first data byte and follow with a NACK and STOP. For higher resolution, both bytes must be

read.

Table 3. Command Set

2-WIRE BUS DATA

INSTRUCTION FUNCTION PROTOCOL

Frequency Select

Register (Note 1)

TCXO Control

Register (Note 1)

Read Temperature

(Note 2)

Frequency Tuning

Register (Note 2)

Defines F

Enables/disables F1 and F2;

sets duty cycle of F

output frequency 5Dh

2

2

60h

Reads 10-bit temperature register 64h Read 1 or 2 data bytes

Digitally adds/subtracts an offset

from oscillator

66h

AFTER ISSUING

PROTOCOL

Read or write 1 data

byte

Read or write 1 data

byte

Read or write 1 data

byte

Note 1: The slave does not increment the internal address pointer between instructions. The address pointer must be reinitialized after each

Note 2. If the user only desires 8-bit thermometer readings, the master can read one data byte, and follow with a NACK and STOP. If higher

access.

resolution is required, both bytes must be read.

10 of 16

Page 11

DS4000 Digitally Controlled TCXO

2-WIRE SERIAL INTERFACE

The DS4000 supports a bidirectional 2-wire serial bus and data transmission protocol. The bus must be controlled

by a master device, which generates the serial clock (SCL), controls the bus access, and generates the START

and STOP conditions. The DS4000 operates as a slave on the 2-wire bus. The DS4000 works in a regular mode

(100kHz clock rate) and a fast mode (400kHz clock rate), which are defined within the bus specifications.

Connections to the bus are made by the open-drain I/O signals SDA and SCL.

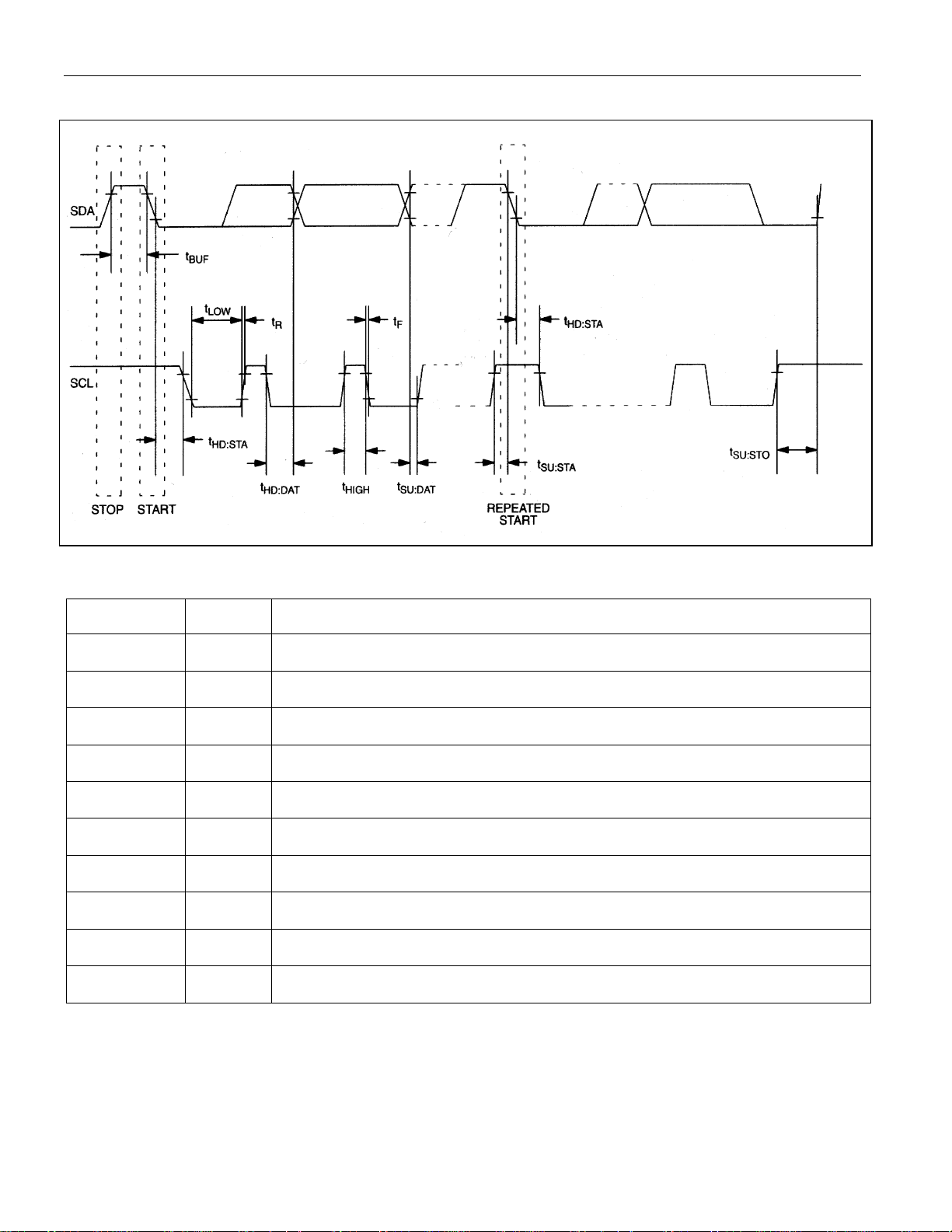

The following bus protocol has been defined (Figure 3):

§ Data transfer can be initiated only when the bus is not busy.

§ During data transfer, the data signal must remain stable whenever the clock signal is HIGH. Changes in the

data signal while the clock signal is HIGH are interpreted as control signals.

Accordingly, the following bus conditions have been defined:

Bus Not Busy: Both data and clock signals remain HIGH.

Start Data Transfer: A change in the state of the data signal, from HIGH to LOW, while the clock line is HIGH,

defines the START condition.

Stop Data Transfer: A change in the state of the data signal, from LOW to HIGH, while the clock line is HIGH,

defines the STOP condition.

Data Valid: The state of the data signal represents valid data when, after a START condition, the data signal is

stable for the duration of the HIGH period of the clock signal. The data on the line must be changed during the

LOW period of the clock signal. There is one clock pulse per bit of data.

Each data transfer is initiated with a START condition and terminated with a STOP condition. The number of data

bytes transferred between START and STOP conditions is not limited and is determined by the master device. The

information is transferred byte-wise and each receiver acknowledges with a ninth bit.

Acknowledge: Each receiving device, when addressed, is required to generate an acknowledge after reception of

each byte. The master device must generate an extra clock pulse that is associated with this acknowledge bit.

A device that acknowledges must pull down the serial data (SDA) signal during the acknowledge clock pulse in

such a way that the SDA signal is stable LOW during the HIGH period of the acknowledge-related clock pulse. Of

course, setup and hold times must be taken into account. A master must signal an end-of-data to the slave by not

generating an acknowledge bit on the last byte that has been clocked out of the slave. In this case, the slave must

leave the data signal HIGH to enable the master to generate the STOP condition.

11 of 16

Page 12

Figure 3. Data Transfer On 2-Wire Serial Bus

SDA

MSB

SLAVE

ADDRESS

R/W BIT

ACKNOWLEDGEMENT

SIGNAL FROM

RECEIVER

DS4000 Digitally Controlled TCXO

ACKNOWLEDGEMENT

SIGNAL FROM

RECEIVER

SCL

START

CONDITION

123-56789

ACK ACK

REPEATED IF

MORE BYTES ARE

TRANSFERRED

893-712

STOP CONDITION

OR REPEATED

START CONDITION

DATA TRANSFER

Figures 4 and 5 detail how data transfer is accomplished on the 2-wire bus.

Depending on the R/W bit in the transmission protocols as shown, two types of data transfer are possible:

1) Data transfer from a master transmitter to a slave receiver. The first byte transmitted by the master is the

slave address. Next follows a number of data bytes. The slave returns an acknowledge bit after each received

byte. Data is transferred with the most significant bit (MSB) first.

2) Data transfer from a slave transmitter to a master receiver. The master transmits the first byte (the slave

address). The slave then returns an acknowledge bit. Next follows a number of data bytes transmitted by the

slave to the master. The master returns an acknowledge bit after all received bytes other than the last byte. At

the end of the last received byte, a “not acknowledge” is returned. The master device generates all of the serial

clock pulses and the START and STOP conditions. A transfer is ended with a STOP condition or with a

repeated START condition. Since a repeated START condition is also the beginning of the next serial transfer,

the bus is not released.

12 of 16

Page 13

DS4000 Digitally Controlled TCXO

SLAVE ADDRESS

The slave address is the first byte received following the START condition generated by the master device. The

address byte consists of a 7-bit slave address and the R/

100010A

, where A0 is externally hardwired to a HIGH or LOW state. This allows design flexibility to set the slave’s

0

address to one of two possible address locations. The last bit following the slave address is the direction bit (R/

and defines the operation to be performed by the master, transmit data (R/

Following the START condition, the DS4000 monitors the SDA bus by checking the slave address being

transmitted. Upon receiving the proper slave address and R/

on the SDA line regardless of the operation mode.

The DS4000 can operate in the following two modes:

1) Slave Receiver Mode: Serial data and clock are received through SDA and SCL. After each byte is received,

an acknowledge bit is transmitted. START and STOP conditions are recognized as the beginning and end of a

serial transfer. Address recognition is performed by the hardware after reception of the slave address and

direction bit (Figure 4).

2) Slave Transmitter Mode: The first byte is received and handled as in the slave receiver mode. However, in

this mode, the direction bit indicates that the transfer direction is reversed. Serial data is transmitted on SDA by

the DS4000 while the serial clock is input on SCL. START and STOP conditions are recognized as the

beginning and end of a serial transfer (Figure 5).

Figure 4. Data Write—Slave Receiver Mode

<SLAVE ADDRESS>

<DATA ADDRESS> <DATA (n)>

R/W

S 100010A0 0 A XXXXXXXX A XXXXXXXX A P

S = START

A = ACKNOWLEDGE

P = STOP

Figure 5. Data Read—Slave Transmitter Mode

<SLAVE ADDRESS>

S 100010A0 1 A XXXXXXXX A XXXXXXXX A XXXXXXXX A XXXXXXXX AP

R/W

<DATA (n)>

<DATA (n + 1)> <DAT A (n + 2)>

W direction bit. The DS4000 slave address is set to

W)

W = 0), or receive data (R/W = 1).

W bit, the slave device outputs an acknowledge signal

<DATA (n + X)>

S = START

A = ACKNOWLEDGE

P = STOP

A = NOT ACKNOWLEDGE

13 of 16

Page 14

SELECTOR GUIDE

DS4000 Digitally Controlled TCXO

PART TEMP RANGE PIN-PACKAGE TOP MARK

DS4000A0/WBGA 0°C to +70°C

DS4000A0N/WBGA -40°C to +85°C

DS4000CW/WBGA 0°C to +70°C

DS4000CWN/WBGA -40°C to +85°C

24 BGA DS4000A0 10.00000

24 BGA

DS4000A0

###XX N

24 BGA DS4000CW 12.80000

24 BGA

DS4000CW

###XX N

FREQUENCY

DESIGNATOR (MHz)

10.00000

12.80000

DS4000D0/WBGA 0°C to +70°C 24 BGA DS4000D0 13.00000

DS4000D0N/WBGA -40°C to +85°C 24 BGA

DS4000D0

###XX N

13.00000

DS4000EC/WBGA 0°C to +70°C 24 BGA DS4000EC 14.31818

DS4000ECN/WBGA -40°C to +85°C 24 BGA

DS4000EC

###XX N

14.31818

DS4000G0/WBGA 0°C to +70°C 24 BGA DS4000G0 16.00000

DS4000G0N/WBGA -40°C to +85°C 24 BGA

DS4000G0

###XX N

16.00000

DS4000GF/WBGA 0°C to +70°C 24 BGA DS4000GF 16.38400

DS4000GFN/WBGA -40°C to +85°C 24 BGA

DS4000GF

###XX N

16.38400

DS4000GW/WBGA 0°C to +70°C 24 BGA DS4000GW 16.80000

DS4000GWN/WBGA -40°C to +85°C 24 BGA

DS4000GW

###XX N

16.80000

DS4000KI/WBGA 0°C to +70°C 24 BGA DS4000KI 19.44000

DS4000KIN/WBGA -40°C to +85°C 24 BGA

DS4000KI

###XX N

19.44000

14 of 16

Page 15

DS4000 Digitally Controlled TCXO

PACKAGE INFORMATION

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information, go to

www.maxim-ic.com/DallasPackInfo

NOTE: THE BGA IS SOLDER-MASKED DEFINED.

.)

15 of 16

Page 16

DS4000 Digitally Controlled TCXO

PACKAGE INFORMATION (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information, go to

www.maxim-ic.com/DallasPackInfo

PAD: 0.85mm

.)

1.27

SOLDERMASK: 0.60mm

1.27

8.89

DIMENSIONS IN MILLIMETERS

Maxim/Dallas Semiconductor cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim/Dallas Semiconductor product.

No circuit patent licenses are implied. Maxim/Dallas Semiconductor reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2003 Maxim Integrated Products · Printed USA

16 of 16

Loading...

Loading...