www.maxim-ic.com

GENERAL DESCRIPTION

The DS2792 provides a user-programmable fuel

gauge solution for Li-Ion and NiMH chemistry battery

packs. A low-power, 16-bit MAXQ20 microcontroller

with generous program and data memory, combined

with an accurate measurement system for battery

current, voltage, and temperature provide the ideal

platform for customized fuel-gauge algorithms.

EEPROM data memory supports nonvolatile (NV)

in-pack storage of charge parameters, cell

characteristics, usage history, and manufacturing/lot

tracking data.

APPLICATIONS

Digital Video Cameras

SLR Digital Still Cameras

Subnotebook PCs and Ultra-Portable PCs

Industrial PDAs, Handheld Computers, and GPS

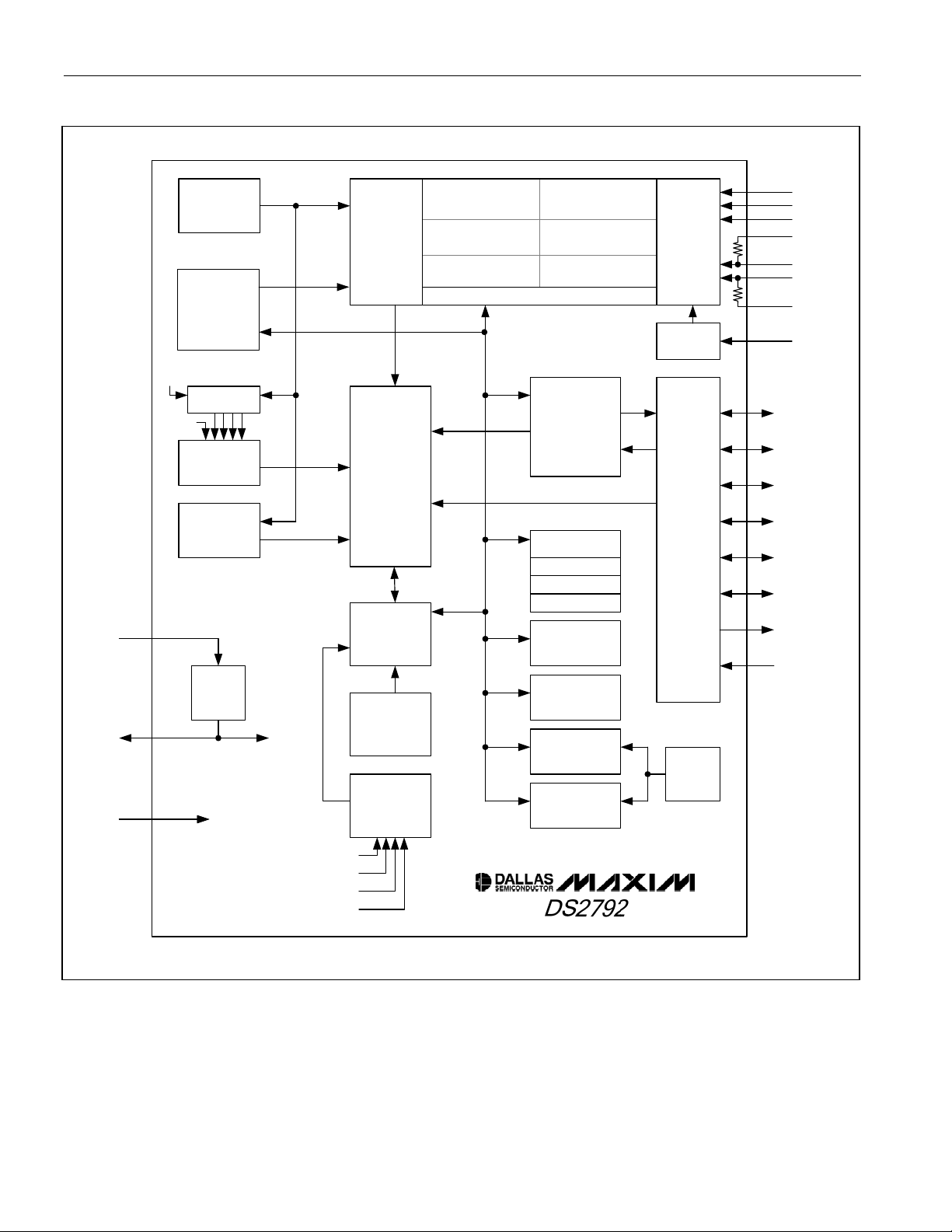

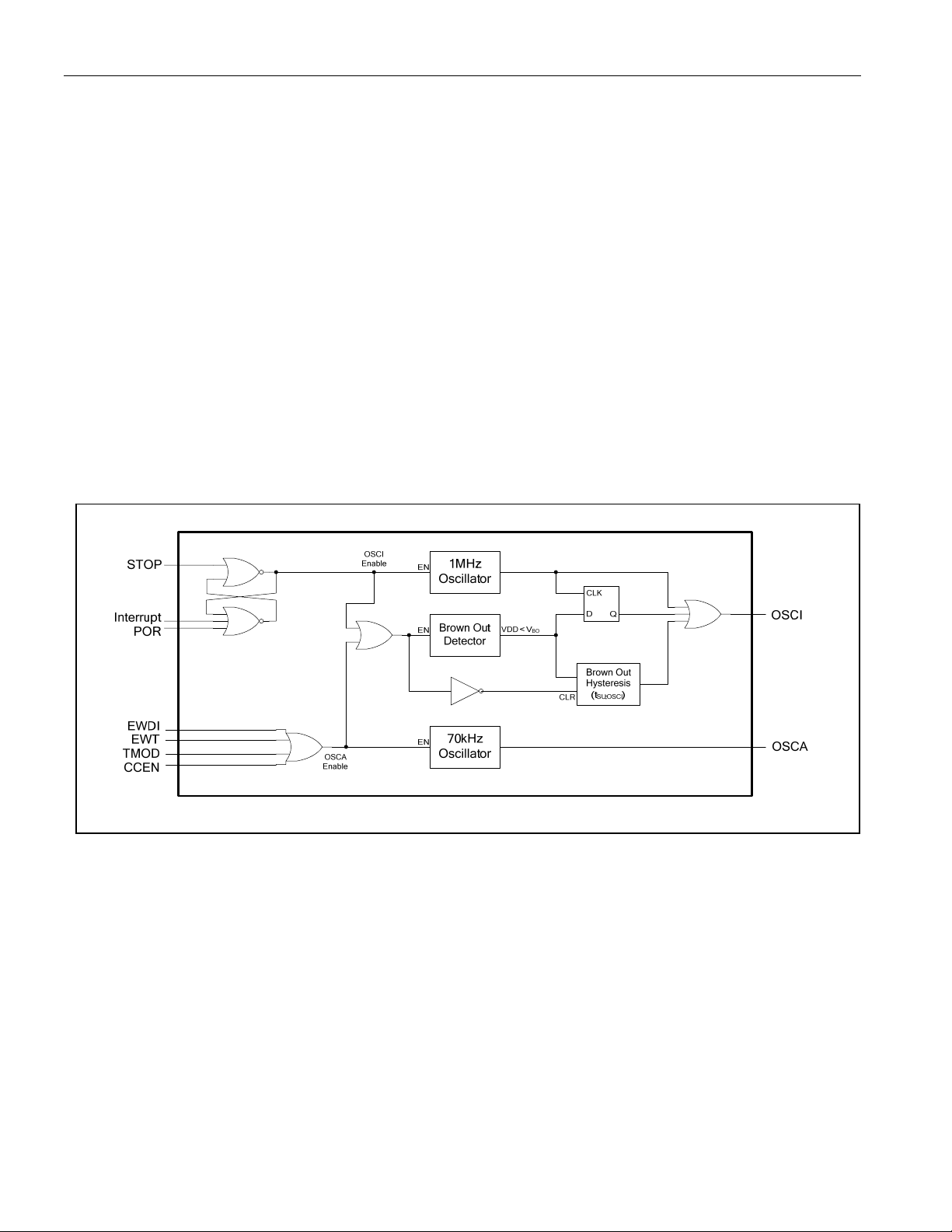

FUNCTIONAL DIAGRAM

MAXQ is a registered trademark of Maxim Integrated Products,

Inc.

DS2792

Programmable Fuel Gauge

with UART Interface

FEATURES

Accurate Current Measurement for Coulomb

Counting (Current Accumulation)

1.5% ±4µV Over ±64mV Input Range

1.5% ±267µA Over ±4.2A Range Using an

External 15mΩ Series Resistor

High-Resolution Current Reporting

12-Bit + Sign Average Every 0.88ms

15-Bit + Sign Average Every 2.8s

Three Voltage Measurement Sources

10-Bit Average from VIN1, VIN2–VIN1, and Vx

Inputs

Temperature Measurement

10-Bit Using On-Chip Sensor

Ratiometric Input for External Thermistor (Vx)

16-Bit MAXQ20 Low-Power Microcontroller

Efficient C-Language Programming

8k Words Total Program Memory:

4k Words EEPROM Program Memory

4k Words ROM Program Memory

64 Words Data EEPROM

256 Words Data RAM

Password-Protected Programming

On-Chip, Low Drop-Out Regulator

2.5V to 10V Operating Range

SHA-1 Hash Algorithm in ROM

19.2kbps UART Interface

Internal Oscillator: No Crystal Required

Low-Power Consumption

1.5mA CPU Mode (1MHz), 145µA ANALOG

Mode, 50µA SLEEP Mode

ORDERING INFORMATION

PART TEMP RANGE PIN-PACKAGE

DS2792G+ -20ºC to +70ºC TDFN-28

+ Denotes lead-free package.

Contact factory concerning Mask ROM devices.

Pin Configuration appears at end of data sheet.

Note: Some revisions of this device may incorporate deviations from published specifications known as errata. Multiple revisions of any device

may be simultaneously available through various sales channels. For information about device errata, click here: www.maxim-ic.com/errata

1 of 40 REV: 021607

.

DS2792 Programmable Fuel Gauge with UART Interface

ABSOLUTE MAXIMUM RATINGS

VDD, VIN2 to VSS.......................................................................................................................................-0.3V to +12V

P0.4, P0.5 to V

AV

to VSS..............................................................................................................................................-0.3V to +0.3V

SS

All Other Pins to V

................................................................................................................................-0.3V to VB +0.3V

SS

..................................................................................................................................-0.3V to +6V

SS

TXD, P0.0–P0.5 Continous Sink Current ...............................................................................20mA Each, 50mA Total

Operating Temperature Range.............................................................................................................. -40ºC to +85ºC

Storage Temperature Range ...............................................................................................................-55ºC to +125ºC

Soldering Temperature ................................................................................See IPC/JEDEC J-STD-020 Specification

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions beyone those indicated in the operational sections of the specifications is

not implied. Exposure to the absolute maximum rating conditions for extended periods may affect device.

RECOMMENDED DC OPERATING CHARACTERISTICS

(VDD = 2.5V to 10V, TA = -20°C to +70°C, unless otherwise noted. Typical values are at TA = +25°C, VDD = 5.0V.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage VDD (Note 1) +2.5 +10 V

Voltage Range: VIN1, TXD, RXD,

P0.0–P0.3, SNS1, SNS2

Voltage Range: P0.4–P0.5 (Note 1) -0.3 VB + 0.3 V

(Note 1) -0.3 5.5 V

Voltage Range: VIN2 (Note 1) -0.3 +10 V

Voltage Range: Vx (Note 1) -0.3 VB + 0.3 V

> 3.5V, IO = 2mA,

V

Output Voltage: VB V

VB

DD

(Note 1)

3.0 3.3 3.6 V

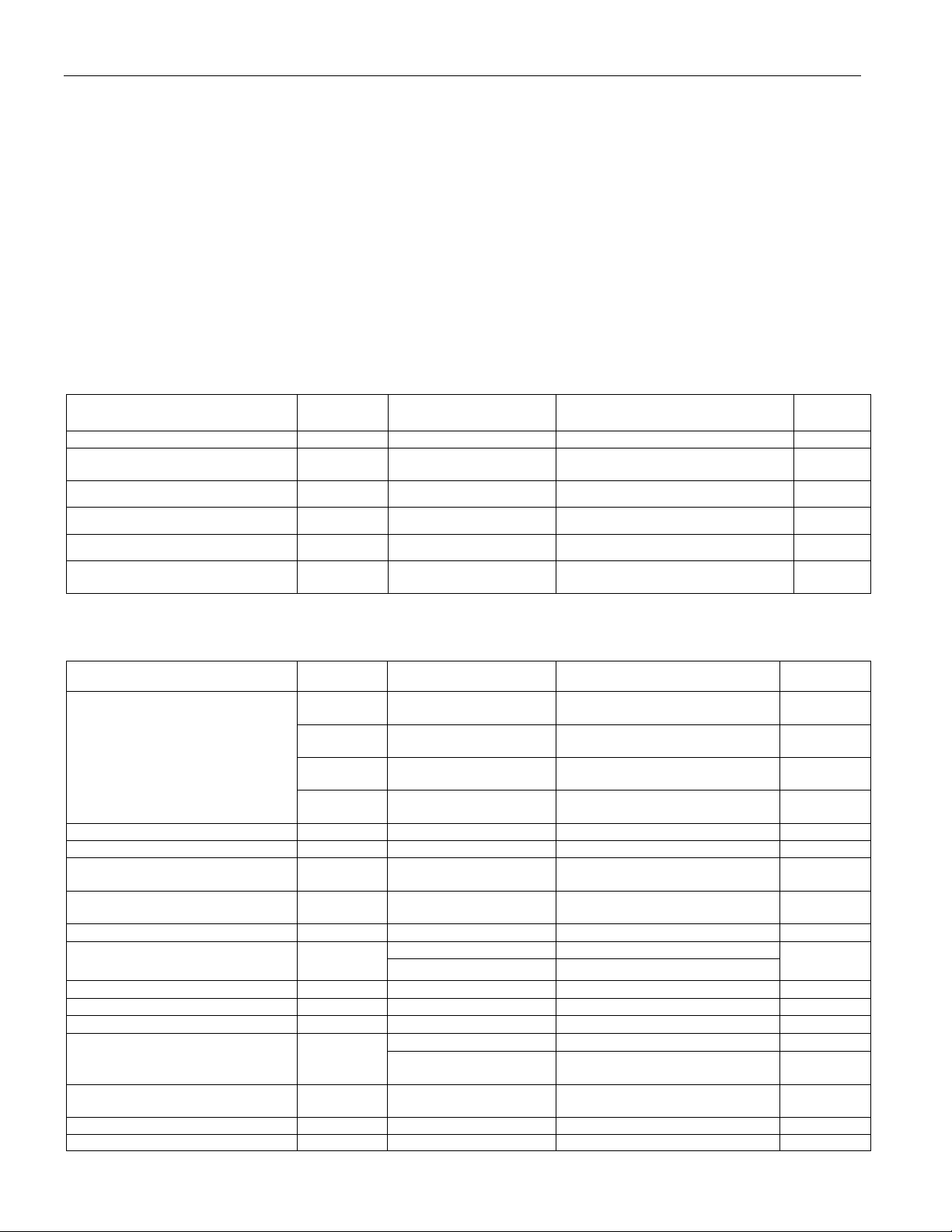

ELECTRICAL CHARACTERISTICS

(VDD = 2.5V to 10V, TA = -20°C to +70°C, unless otherwise noted. Typical values are at TA = +25°C, VDD = 5.0V.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I

SLEEP

I

SUSP

Supply Current

I

ANALOG

I

CPU

Power-On Reset Threshold V

RESET

Brownout Threshold VBO (Note 10) 2.0 2.2 2.4 V

Regulator Drop-Out V

Current Measurement Input

Range

Current Measurement Resolution I

Current Measurement Gain Error I

Current Measurement Offset Error I

DO:VB

I

FS

LSB

GERR

OERR

Accumulated Current Range qFS -204.8 +204.8 mVh/R

Accumulated Current Resolution q

LSB

Accumulated Current Offset qCA

Temperature Measurement

Range

Temperature Measurement LSb T

Temperature Measrement Error T

T

FS

LSB

ERR

2 of 40

SLEEP mode

(Note 2)

SUSPEND mode

(Note 3)

ANALOG mode

(Note 4)

CPU mode

(Note 5)

25 50

25 50

110 145

μA

μA

μA

0.8 1.5 mA

1.0 1.6 2.2 V

= 2.5V,

V

DD

V

= 2.0mA, (Note 6)

I

VB

-64 +64 mV

IS1–VIS2

15.625

0oC TA +50oC -0.5 +0.5

-1 +1

-7.8 +7.8

6.25

OBEN = 1 -94 0

OBEN = 1,

= 0.015

R

SNS

-40 +85 oC

0.125

-3 +3

0.15 V

μV/R

SNS

% Full

Scale

μV/R

SNS

SNS

μVh/R

SNS

μVh/Day

-6.3 0 mAh/Day

oC

o

C

DS2792 Programmable Fuel Gauge with UART Interface

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

VIN1 Input Range (VIN1–VSS) V

VIN1 LSb V

VIN2 Input Range (VIN2–VIN1) V

VIN2 LSb V

VIN1, VIN2 Gain Error V

VIN1, VIN2 Offset V

Vx Input Range (Vx–VSS) V

Vx LSb V

Vx Error V

VIN1, VIN2, Vx

Input Resistance

Current Measurement Sample

Frequency

Analog System Clock Frequency f

(Notes 1, 7) 0 4.99 V

FS1

4.88 mV

LSB1

(Notes 1, 7) 0 4.99 V

FS2

4.88 mV

LSB2

-1 +1 %

GERR

-1 +1 LSb

OERR

(Note 1) 0 VB V

FSX

VB/1024 —

LSBX

-1 +1

ERRX

15 M

R

IN

f

(Note 8) 1456 Hz

SAMPLE

69.9 kHz

OSCA

VDD > 2.7V, TA = +25oC -0.7 +0.7

Analog System Clock Error f

ERR:OSCA

VDD > 2.7V,

o

0

C TA +50oC

-2 +2

-5 +5

OSCA active 1

CPU System Clock Startup Time t

CPU System Clock Frequency f

CPU System Clock Error f

Suspend Period Error t

Filter Resistors

IS1 to SNS1, IS2 to SNS2

Input Logic High: RXD V

Input Logic Low: RXD V

Input Logic High: P0.0–P0.5 V

Input Logic Low: P0.0–P0.5 V

SU:OSCI

OSCI

ERR:OSCI

ERR:SUS

R

KS

IH:RXD

IL:RXD

IH:P0

IL:P0

From SLEEP,

OSCA inactive

OSCA inactive 1000 kHz

OSCA active 14 x f

OSCA inactive -20 +20

OSCA active f

700

kHz

OSCA

ERR:OSCA

-30 +30 %

7 10 13 k

(Note 1) 1.5 V

(Note 1) 0.6 V

(Note 1) 0.7 x VB V

(Note 1) 0.3 x VB V

Output Logic Low: TXD, P0.X VOL IOL = 4mA (Note 1) 0.4 V

= VIH,

V

P0.0–P0.3

Weak Pullup Current

I

PU:P0

Output Logic High: P0.4–P0.5 VOH

RXD, TXD Pulldown Current I

RXD, TXD Pullup Current V

RXD, TXD Capacitance C

RXD Pulse Rejection t

P0.0–P0.5 Pulse Rejection t

PD:UART

PU:UART

UART

SP:UART

SP:P0

Rising and falling edges 10 ns

PIN

V

> 2.7V

DD

0.15 22.0

Bits PPU:0,1,2,3 set

= 1mA

I

PIN

Bits PPU:4,5 set

PIN = V

V

Bits PPU:6,7 clear

PIN = V

V

Bits PPU:6,7 set

,

IL

,

IL

- 0.4 V

V

B

0.3 1.2 3

0.3 1.2 3

50 pF

Rising and falling edges

(Note 9)

50 ns

EEPROM RELIABILITY SPECIFICATION

(VDD = 2.5V to 10V, TA = -20°C to +70°C, unless otherwise noted. Typical values are at TA = +25°C, VDD = 5.0V.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

% Full

Scale

%

μS

%

μA

μA

μA

EEPROM Copy Time t

EEPROM Copy Endurance N

10 15 ms

EEC

TA = +50°C 50,000 Cycles

EEC

3 of 40

DS2792 Programmable Fuel Gauge with UART Interface

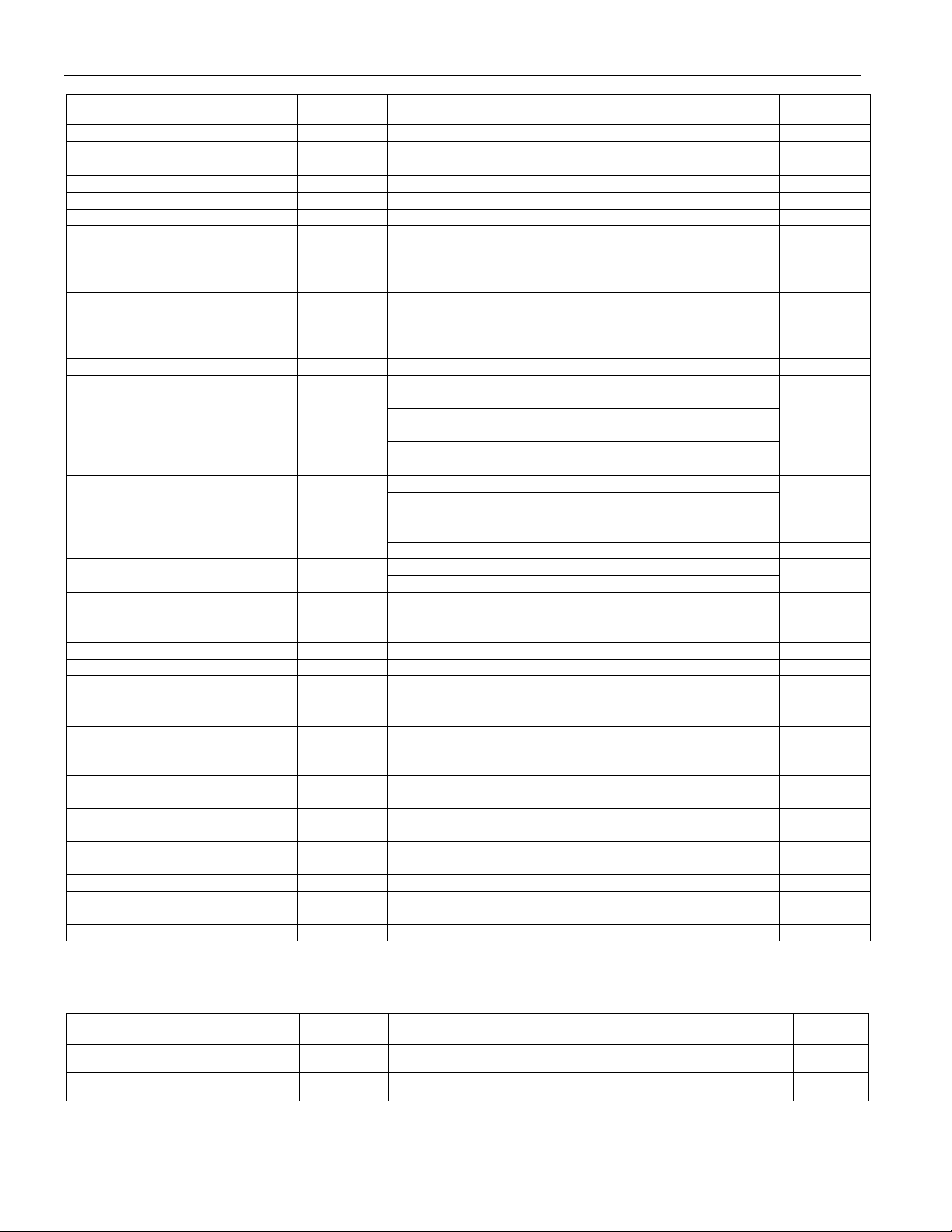

ELECTRICAL CHARACTERISTICS: JTAG INTERFACE

(VDD = 2.5V to 10V, TA = -20°C to +70°C, unless otherwise noted. Typical values are at TA = +25°C, VDD = 5.0V.)

(See Figure 1.)

JTAG Logic Reference V

TCK High Time tTH 4.0 µs

TCK Low Time tTL 4.0 µs

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

(Note 1) VB ÷ 2 V

REF

TCK Low to TDO Output t

TMS, TDI Input Setup to TCK

High

TMS, TDI Input Hold after TCK

High

1.0 µs

TLQ

1.0 µs

t

DVTH

t

4.0 µs

THDX

Note 1: All voltages referenced to V

Note 2: Internal voltage regulator remains active in SLEEP mode. RAM and registers are powered to maintain contents. RXD and

Note 3: Internal voltage regulator and suspend timer are active in SUSPEND mode. RAM and registers are powered to maintain

Note 4: Internal voltage regulator and ADC are active in ANALOG mode. RAM and registers are powered to maintain contents. ADC data

Note 5: MAXQ core fetches and executes instructions in CPU mode.

Note 6: Parameters guaranteed by design.

Note 7: Voltage A/D readings saturate at 4.85V.

Note 8: f

Note 9: The filter on RXD suppresses noise spikes at the input buffers and delays the sampling instant.

Note 10: V

internal interrupts can be armed by firmware.

contents.

is collected and updated to registers including current accumulation to ACR register.

= 48 × f

OSCA

and VBO will never overlap.

RESET

SAMPLE

.

.

SS

Figure 1. JTAG Timing Diagram

4 of 40

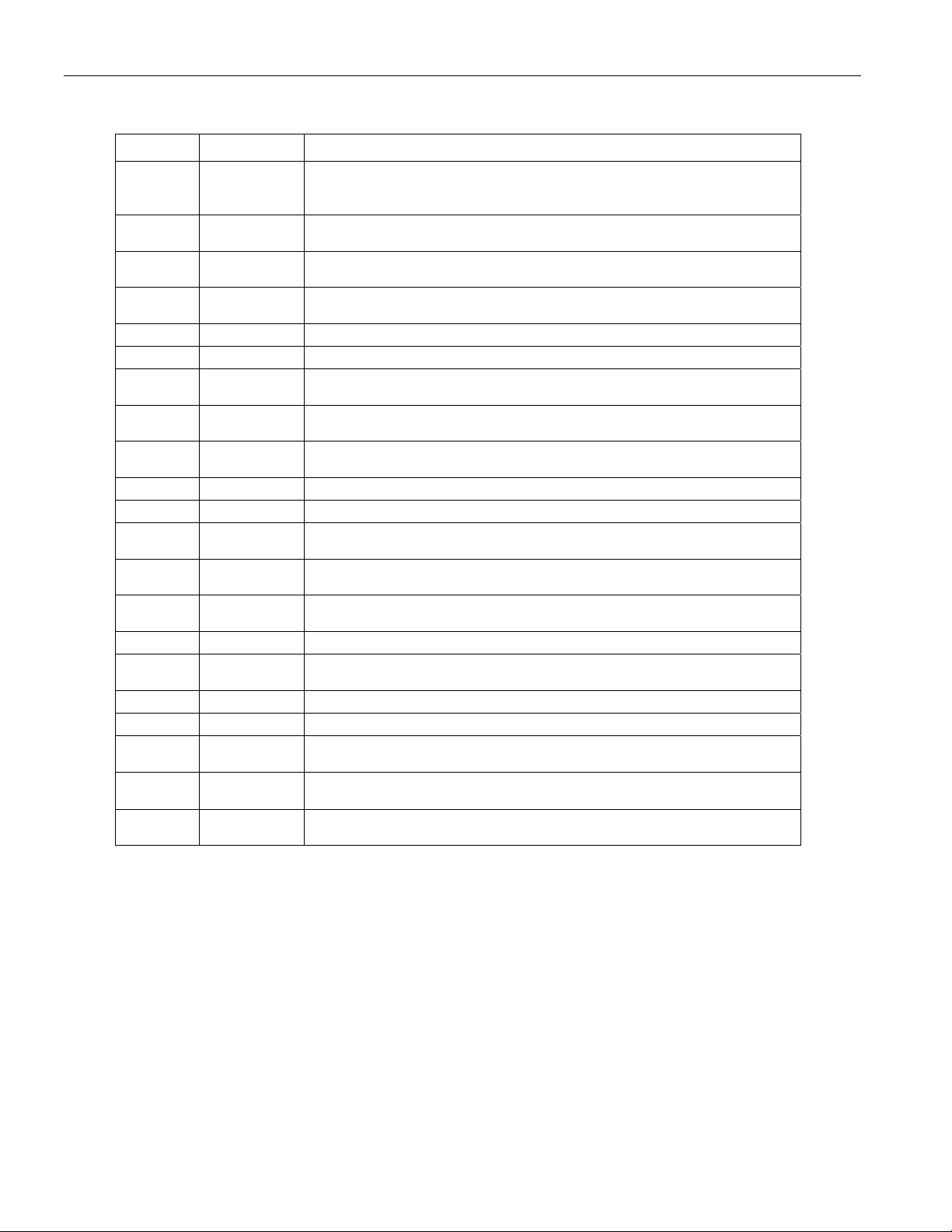

PIN DESCRIPTION

PIN NAME FUNCTION

1, 7–10,

21, 25,

26, 28

2 VIN2

3 VIN1

4 Vx

5 TXD Serial Interface Data Transmit. Maximum of 19200bps.

6 RXD Serial Interface Data Recieve. Maximum of 19200bps.

11 P0.0

12 P0.1

13 SNS2

14 IS2

15 IS1

16 SNS1

17 AVSS

18 VSS

19 P0.2

20 P0.3

22 P0.4 Programmable I/O Pin. Alternate function: [JTAG TDO]

23 P0.5

24 VB

27 VDD

— PAD

N.C.

DS2792 Programmable Fuel Gauge with UART Interface

No Connection

Battery Voltage Sense Input 2. Voltage measurement on VIN2 is

relative to VIN1.

Battery Voltage Sense Input 1. Voltage measurement on VIN1 is

relative to AV

SS

.

Auxiliary ADC Input. Voltage measured ratiometrically with respect

to V

pin voltage or absolutely with respect to internal reference.

B

Programmable I/O Pin. Alternate functions: external interrupt input

INT0, [JTAG TDI].

Programmable I/O Pin. Alternate functions: external interrupt input

INT1, [JTAG TMS].

Current-Sense Input. SNS2 attaches to the pack end of current-

sense resistor.

Current Filter Input 2

Current Filter Input 1

Current-Sense Input. SNS1 attaches to the battery end of current-

sense resistor and V

Analog Supply Return Node. AV

SS

.

attaches to negative battery

SS

terminal.

Digital Supply Return Node. V

attaches to negative battery

SS

terminal.

Programmable I/O Pin. Alternate functions: reset input pin RST.

Programmable I/O Pin. Alternate functions: timer/counter input pin

TCK, [JTAG TCK].

Programmable I/O Pin

Bias Supply Output. Internally regulated to 3.3V. Bypass V

to V

B

SS

with 0.1µF.

Input Supply. +2.5V to +10.0V input range. Bypass V

to VSS with

DD

0.1μF.

Exposed PAD. Not electrically connected to IC. Connect to V

SS

or

leave floating.

5 of 40

FUNCTIONAL DIAGRAM

DS2792 Programmable Fuel Gauge with UART Interface

PRECISION

ANALOG

OSCILLATOR

SUSPEND

TIMER

TTCK0:1

CLK DIV

P0.3

TIMER/

COUNTER

WATCHDOG

TIMER

VDD

LDO

Regulator

VB VDD_INT

VSS

VSS_INT

TCI

WDI

A/D

CONTROL

BOI, VI,

CI, TI

INTERRUPT

CONTROLLER

MAXQ20

16-BIT RISC

CORE

INSTRUCTION

OSCILLATOR

(1MHz)

JTAG

BOOTLOAD

AND DEBUG

INTERFACE

VOLTAGE1

(VIN1 - AVSS)

VOLTAGE2

(VIN2 - VIN1)

AUX VOLTAGE

(VX - AVSS)

SCI,

SDI

INT0,

INT1

CURRENT

(IS1 - IS2)

AVG CURRENT

TEMPERATURE

ANALOG REGISTERS

UART

INTERFACE

AND

BOOTLOADER

REGISTER FILE

DP[0]

DP[1]

BP[Offs]

256 X 16 SRAM

(DATA)

4K X 16 ROM

(UTILITY)

4K X 16

EEPROM

(PROGRAM)

64 X 16

EEPROM

(DATA)

Tx

Rx

ANALOG

FRONT

END

ADC / MUX

VREF

PORT

PIN

DRIVERS

EEPROM

CHARGE

PUMP

VIN1

VIN2

VX

SNS1

IS1

IS2

SNS2

AVSS

P0.0/INT0/TDI

P0.1/INT1/TMS

P0.2/RST

P0.3/TCK

P0.4/TDO

P0.5

TXD

RXD

P0.3/TCK

P0.1/TMS

P0.0/TDI

P0.4/TDO

6 of 40

DS2792 Programmable Fuel Gauge with UART Interface

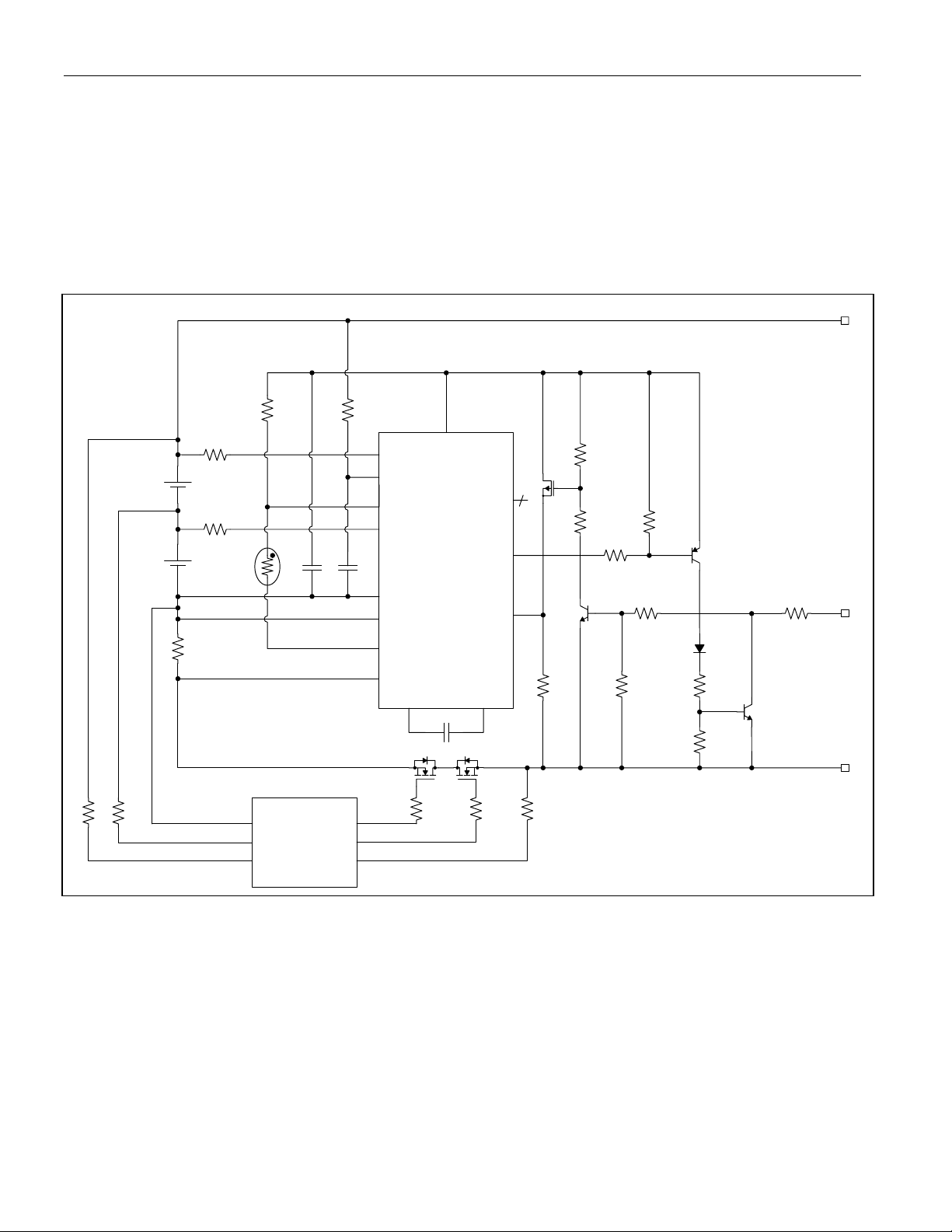

TYPICAL OPERATING CIRCUIT

In Figure 2, the DS2792 is connected to the battery side of the pack protector. VDD is isolated with a 150 resistor.

Both V

and the internally regulated voltage VB have 0.1µF bypass capacitors. The VIN1 and VIN2 pins sample

DD

the voltage of each cell. Current flow through the cell pack is monitored by measuring the voltage drop across the

sense resistor R

. Cell temperature is measured ratiometrically through the general-purpose voltage input Vx.

SNS

The GPIO pin P0.5 gates the thermistor circuit to limit current flow between measurements. The UART signals

RXD and TXD are combined into a single 3.3V bidirectional I/O line. The I/O circuit causes no extra current drain

when idle.

Figure 2. Example Pack Circuit with Regulated I/O

PACK+

15010K

1K

1K

AT103-2

VIN2

VDD

Vx

VIN1

0.1µF0.1µF

VB

[P0.0-P0.4]

TxD

BSS84

100

1K

1K

100

2N3906

DS2792

VSS, AVSS

SNS1

R

SNS

P0.5

SNS2

IS1

RxD

IS2

0.1µF

2N2222

1K 1K

100 100

DATA

100

2N2222

1K

PACK-

2-Cell Protection

IC

DETAILED DESCRIPTION

The following is an introduction to the primary features of the DS2792 programmable 2-cell Li-Ion fuel gauge. More

detailed descriptions of the device features can be found in the errata sheets and user's guides described later in

the Additional Documentation section.

DS2792 Overview

The DS2792 incorporates the 16-bit MAXQ20 microcontroller core with 16 accumulators and 16-level hardware

stack. Four memory blocks provide application code space, utility code space, RAM memory, and EEPROM

memory. Specialized peripherals are integrated to perform battery monitoring, coulomb counting, and UART

communication functions. The MAXQ20 core along with the specialized peripherals provide a flexible solution for

fuel gauging of Li-Ion or NiMH battery packs. Flexibility is further enhanced as the solution allows for upgrading of

7 of 40

DS2792 Programmable Fuel Gauge with UART Interface

the program and data EEPROM contents over the UART interface. Updates to the program and data EEPROM are

protected against unauthorized writes by a 256-bit user password. A read protection bit is provided to prevent

reading either EEPROM.

MAXQ20 Core Architecture

The DS2792 employs a MAXQ20 low-cost, high-performance, CMOS, fully static, 16-bit RISC microcontroller with

EEPROM memory. Fetch and execution operations are completed in one cycle without pipelining, since the

instruction contains both the op code and data. The highly efficient core is supported by 16 accumulators and a 16level hardware stack, enabling fast subroutine calling and task switching. Data can be quickly and efficiently

manipulated with three internal data pointers. Multiple data pointers allow more than one function to access data

memory without having to save and restore data pointers each time. The data pointers can automatically increment

or decrement following an operation, eliminating the need for software intervention.

Instruction Set

The instruction set is composed of fixed-length, 16-bit instructions that operate on registers and memory locations.

The instruction set is highly orthogonal, allowing arithmetic and logical operations to use any register along with the

accumulator. Special-function registers control the peripherals and are subdivided into register modules. The family

architecture is modular, so that new devices and modules can reuse code developed for existing products.

The architecture is transport-triggered. This means that writes or reads from certain register locations can also

cause side effects to occur. These side effects form the basis for higher level op codes, such as ADDC, OR, JUMP,

etc. The op codes are implemented as MOVE instructions between register locations, while the assembler handles

the encoding, which need not be a concern to the programmer. The 16-bit instruction word is designed for efficient

execution.

Bit 15 indicates the format for the source field of the instruction. Bits 0 to 7 of the instruction represent the source

for the transfer. Depending on the value of the format field, this can either be an immediate value or a source

register. If this field represents a register, the lower four bits contain the module specifier and the upper four bits

contain the register index in that module.

Bits 8 to 14 represent the destination for the transfer. This value always represents a destination register, with the

lower four bits containing the module specifier and the upper three bits containing the register subindex within that

module. Any time that it is necessary to directly select one of the upper 24 registers as a destination, the prefix

register PFX is needed to supply the extra destination bits. This prefix register write is inserted automatically by the

assembler and requires only one additional execution cycle. Refer to the MAXQ Family User's Guide for complete

instruction set information.

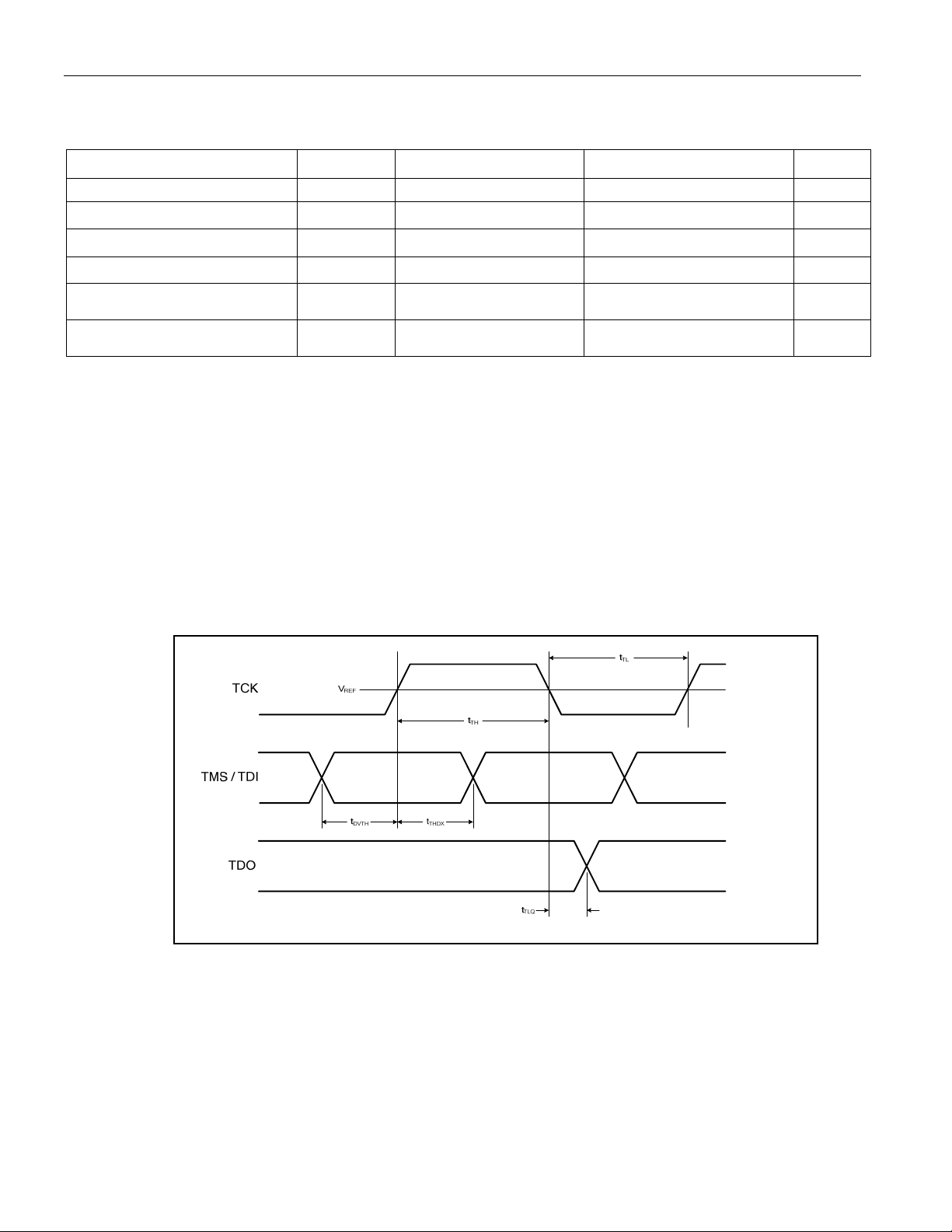

Memory Organization

The DS2792 incorporates several memory areas:

4k Words of utility ROM contain a debugger, program loader, and SHA-1 routines

4k Words of EEPROM memory for application program storage

256 Words of SRAM for storage of temporary variables

64 Words of EEPROM memory for data storage

10 Words of ADC conversion data information

16-level stack memory for storage of program return addresses and general-purpose use

The memory is implemented using the Harvard architecture, with separate address spaces for program and data

memory. A pseudo-Von Neumann memory map is also utilized placing ROM, application code, and data memory

into a single contiguous memory map. The pseudo-Von Neuman memory map allows data memory to be mapped

into program space, permitting code execution from data memory. In addition, program memory can be mapped

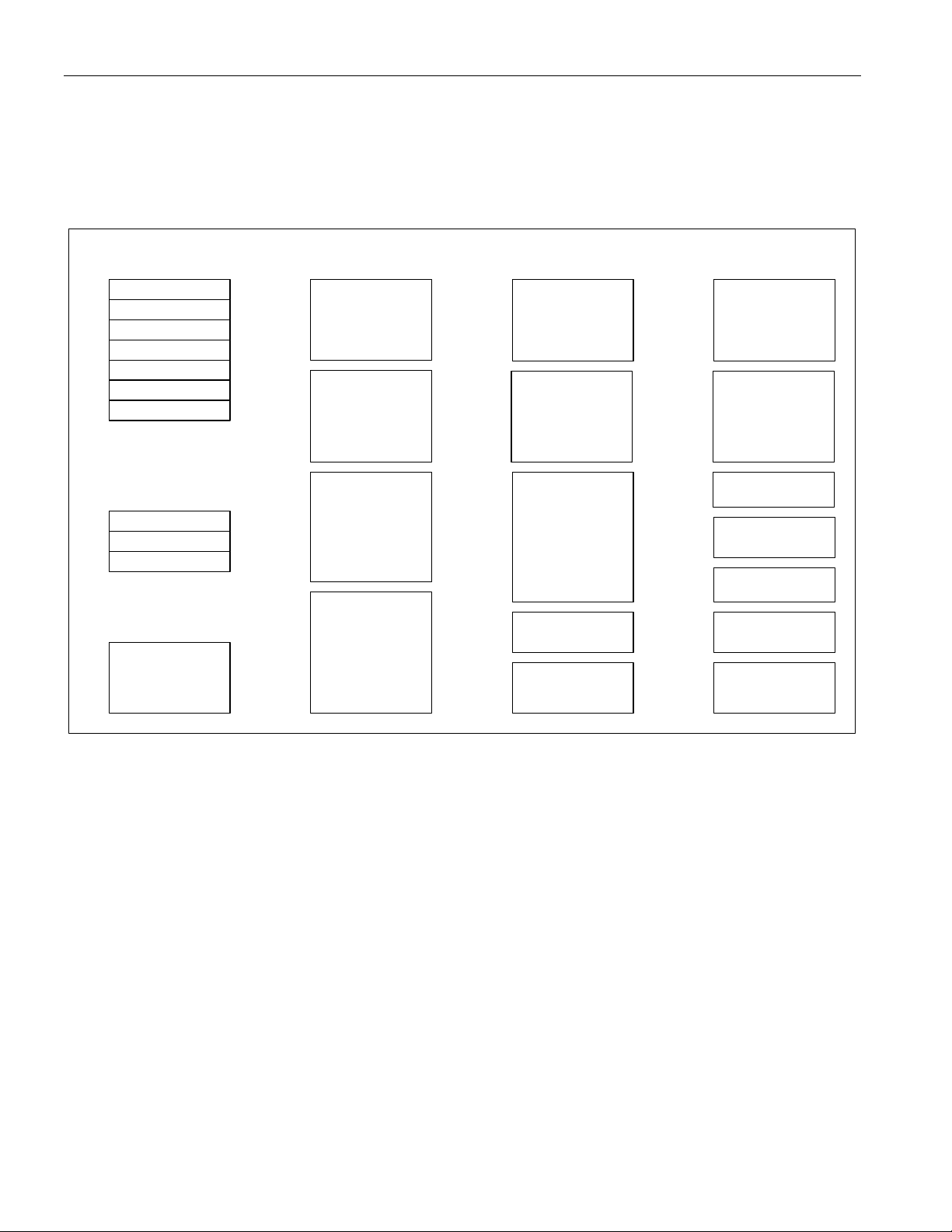

into data space, permitting code constants to be accessed as data memory. Figure 3 shows the DS2792’s memory

map when executing from program memory space. Refer to the MAXQ Family User's Guide: DS2792 Supplement

for memory map information when executing from data or ROM space.

8 of 40

DS2792 Programmable Fuel Gauge with UART Interface

The incorporation of EEPROM memory allows field upgrade of the firmware. EEPROM memory can be password

protected with a 16-word key, denying access to program memory by unauthorized individuals. ROM memory is

also available for high-volume, low-cost applications. Contact Dallas Semiconductor for more information on the

availability of ROM-based devices.

Figure 3. DS2792 Memory Map

SYSTEM

REGISTERS

8h

9h

Bh

Ch

Dh

Eh

Fh

00h 0Fh

0h

1h

2h

00h 1Fh

AP

A

PFX

IP

SP

DPC

DP

PERIPHERAL

REGISTERS

M0

M1

M2

16 × 16

STACK

FFFFh

8FFFh

8000h

0FFFh

0000h

PROGRAM

MEMORY SPACE

4K × 16

UTILITY ROM

4K × 16

USER PROGRAM

MEMORY

FFFFh

9FFFh

8000h

027Fh

0200h

01FFh

0000h

DATA MEMORY

(BYTE MODE)

8K × 8

UTILITY ROM

128 × 8

EEPROM DATA

512 × 8

SRAM DATA

FFFFh

8FFFh

8000h

600Ah

6000h

013Fh

0100h

00FFh

0000h

DATA MEMORY

(WORD MODE)

4K × 16

UTILITY ROM

11 × 16

ADC DATA

64 × 16

EEPROM DATA

256 × 16

SRAM DATA

Stack Memory

A 16-bit, 16-level internal stack provides storage for program return addresses and general-purpose use. The stack

is used automatically when the CALL, RET, and RETI instructions are executed and interrupts serviced. The stack

can also be used explicitly to store and retrieve data by using the PUSH, POP, and POPI instructions.

On reset, the stack pointer (SP) initializes to the top of the stack (0Fh). The CALL, PUSH, and interrupt-vectoring

operations increment SP, then store a value at the location pointed to by SP. The RET, RETI, POP, and POPI

operations retrieve the value pointed to by SP, and then decrement SP.

Utility ROM

The utility ROM is a 4k Word block of internal ROM memory that defaults to a starting address of 8000h. The utility

ROM consists of subroutines that can be called from application software. These include:

In-system programming (bootstrap loader) over JTAG or serial interfaces

In-circuit debug routines

Internal self-test routines

Callable routines for in-application EEPROM programming and SHA-1 calculations

Following any reset, execution begins in the utility ROM. The ROM software determines whether the program

execution should immediately jump to location 0000h, the start of application code, or to one of the special routines

9 of 40

DS2792 Programmable Fuel Gauge with UART Interface

mentioned. Routines within the utility ROM are firmware-accessible and can be called as subroutines by the

application software. More information on the utility ROM contents is contained in the MAXQ Family User's Guide:

DS2792 Supplement.

Some applications require protection against unauthorized viewing of program code memory. For these

applications, access to in-system programming, in-application programming, or in-circuit debugging functions is

prohibited until a password has been supplied. The password is defined as the 16 words of physical program

memory at addresses x0010h to x001Fh. Upon startup, code in the ROM examines the password, if a password is

defined (password is other than all zeros or all ones), and the PWL bit remains set, which prohibits access to

commands to read memory contents over the JTAG and serial interfaces.

A single password lock (PWL) bit is implemented in the SC register. When the PWL is set to one (power-on reset

default), the password is required to access the utility ROM, including in-circuit debug and in-system programming

routines that allow reading or writing of internal memory. When PWL is cleared to zero, these utilities are fully

accessible without password. The password is automatically set to all ones following a mass erase.

PROGRAMMING

The EEPROM memory of the microcontroller can be programmed by two different methods: in-system

programming and in-application programming. Both methods afford great flexibility in system design as well as

reduce the life-cycle cost of the embedded system. These features can be password protected to prevent

unauthorized access to code memory.

In-System Programming

An internal bootstrap loader allows the device to be programmed over the JTAG or serial interfaces. As a result,

system software can be upgraded in-system, eliminating the need for a costly hardware retrofit when software

updates are required. Remote software uploads are possible that enable physically inaccessible applications to be

frequently updated. The JTAG interface hardware can be a JTAG connection to another microcontroller, or a

connection to a PC serial port using a serial to JTAG converter such as the MAXQJTAG-001 (3.3V reference

voltage required), available from Maxim Integrated Products. The UART interface hardware can be a connection to

another microcontroller, or a connection to a PC USB port using a USB to UART converter such as the DS9123O,

available from Dallas Semiconductor. A commercial gang programmer can also be used for programming.

Activating the JTAG interface and loading the test access port (TAP) with the system programming instruction

invokes the bootstrap loader for use over the JTAG interface. Setting the SPE bit to 1 during reset through the

JTAG interface executes the bootstrap-loader-mode program that resides in the utility ROM. When programming is

complete and the bootstrap loader exited, the SPE bit will clear and the IC will reset, allowing execution of the

application software.

Performing a program request over the serial interface also invokes the bootstrap loader. The user must

successfully complete a password match (if PWL = 1). The bootstrap loader functions are then fully supported over

the serial interface. When programming is complete, the exit loader function is used to reset the DS2792 and begin

execution of the application software.

The following bootstrap loader functions are supported:

Information commands

Load EEPROM code and data

Dump EEPROM code and data

CRC EEPROM code and data

Verify EEPROM code and data

Erase EEPROM code and data

10 of 40

DS2792 Programmable Fuel Gauge with UART Interface

In-Application Programming

The in-application programming feature allows the microcontroller to modify its own EEPROM program memory.

This allows on-the-fly software updates in mission-critical applications that cannot afford downtime. Alternatively, it

allows the application to develop custom loader software that can operate under the control of the application

software. The utility ROM contains firmware-accessible EEPROM programming functions that erase and program

EEPROM memory. These functions are described in detail in the MAXQ Family User's Guide: DS2792

Supplement.

SYSTEM TIMING

The DS2792 generates its 1MHz instruction clock (OSCI) internally. This quick starting oscillator is used for

instruction fetch and execution by the MAXQ20 core. The analog oscillator (OSCA) is a bandgap-based RC

oscillator that is trimmed to better than 2% accuracy (f

serves as the clock source for the ADC, watchdog timer, and interval timer. OSCA is enabled by the watchdog

timer signals EWDI or EWT, by the timer/counter (TMOD), or by the coulomb counter (CCEN).

OSCI is enabled through either a system interrupt or system POR and disabled through a system stop. A voltage

brownout-detection circuit disables OSCI if V

waits t

OSCI is slaved to OSCA when OSCA is active.

before re-enabling OSCI. To improve overall system timing and meet UART timing requirements,

SU:OSCI

falls below VBO. Once VDD raises above VBO, a hysteresis circuit

DD

ERR:OSCA

Figure 4. System Clocks

). The analog clock runs independent of OSCI and

11 of 40

DS2792 Programmable Fuel Gauge with UART Interface

SYSTEM RESET

Several reset sources are provided for microcontroller control. Although code execution is halted in the reset state,

OSCI continues to run.

Power-On Reset: An internal power-on reset circuit enhances system reliability. This circuit forces the device to

perform a power-on reset whenever a rising voltage on V

climbs above V

DD

. At this point the following events

POR

occur:

All registers and circuits enter their reset state.

The POR flag (WDCN.7) is set to indicate the source of the reset.

Code execution begins at location 8000h.

Watchdog Timer Reset: Software can determine if a reset is caused by a watchdog timeout by checking the

watchdog timer reset flag (WTRF) in the WDCN register. Execution resumes at location 8000h following a

watchdog timer reset.

External System Reset: Asserting the external RST (port P0.2) pin low causes the device to enter the reset state.

The external reset function is described in the MAXQ Family User's Guide. Execution resumes at location 8000h

after the RST pin is released.

MAXQ20 CORE POWER MANAGEMENT

The DS2792 is designed for low-power battery-monitoring applications. The peripherals have been designed with

the ability to wake the processor from SLEEP or ANALOG mode any time software intervention is needed. Power

management is optimized in the applications by performing any necessary processing as quickly as possible, and

re-entering the low power SLEEP or ANALOG mode. Processing resumes from SLEEP or ANALOG mode via any

of the following sources (when enabled):

An external interrupt is triggered.

An external reset signal is applied to the RST pin.

A watchdog timer interrupt occurs.

An internal interrupt event occurs.

Note: No division of the internal system clock is supported, subsequently the PMME and CD[1:0] bits described in

the MAXQ Family User’s Guide are not implemented in the DS2792.

WATCHDOG TIMER

The watchdog timer provides a mechanism to reset the processor in the case of undesirable code execution. The

watchdog timer is a hardware timer designed to be periodically reset by the application software. If the software

operates correctly, the timer is reset before it reaches its maximum count. However, if undesireable code execution

prevents a reset of the watchdog timer, the timer reaches its maximum count and resets the processor.

The watchdog timer in the DS2792 differs in two respects from the one described in the MAXQ Family User's

Guide: 1) the clock used by the timer is the 70kHz OSCA clock that runs independently of the 1MHz OSCI (or

system) clock, and 2) the watchdog interrupt is an asynchronous interrupt that can bring the processor out of stop

mode.

The watchdog timer is controlled through bits in the WDCN register. Its timeout period can be set to one of the four

programmable intervals ranging from 2

occurs at the end of this timeout period, which is 512 OSCA clock periods, or 7.3ms, before the reset.

12

to 221 OSCA clock periods (59ms up to 30s). The watchdog interrupt

12 of 40

DS2792 Programmable Fuel Gauge with UART Interface

DS2792 POWER MODES

When power is first applied to the DS2792, a power-on-reset (POR) circuit transitions the IC to brownout state

where cell voltage is monitored. If V

and begins code execution. Firmware determines if the IC switches to ANALOG mode or low-power SLEEP mode

when a STOP halts CPU operation.

The DS2792 enters SLEEP mode after a CPU STOP if the ADC and all internal timers are disabled and the

suspend timer is off. In SLEEP mode, all IC operation becomes inactive except for external activity interrupts.

Brownout detection does not occur in SLEEP mode. Any interrupt generated by UART communication or external

input on ports P0.0 or P0.1 will transition the DS2792 from SLEEP to brownout to verify cell voltage before

returning to CPU mode. If the suspend timer is enabled, the IC will transition from SLEEP to ANALOG mode if a

suspend timeout occurs.

The DS2792 enters ANALOG mode after a CPU STOP if any one of the following is active: the ADC, the interval

timer, or the watchdog timer. An external interrupt or an interrupt from any active internal circuit causes the DS2792

to transition back to CPU mode to service the condition.

If the DS2792 is in ANALOG or CPU mode, and V

enters the brownout state. In brownout state, the processor is halted without changing the instruction pointer. If V

voltage rises above V

within a time of t

BO

interrupt (if enabled). Otherwise, if V

waits to receive an interrupt.

Note that the supply rise time at initial power up of the IC must be faster than t

entering SLEEP mode prior to software enabling external interrupts. If this situation occurs, the DS2792 remains in

SLEEP until power cycled.

Figure 5. DS2792 State Diagram

voltage is above the brownout threshold VBO, the DS2792 enters CPU mode

DD

falls below VBO, a brownout condition occurs and the DS2792

DD

, the DS2792 returns to CPU mode and generates a brown-out

SU:OSCI

remains below V

DD

BO

for t

, the DS2792 again enters SLEEP mode and

SU:OSCI

to prevent the DS2792 from

SU:OSCI

Power On Reset

DD

Brown-Out

VDD < V

BO

Brown-Out Recovery

VDD > VBO for t

SU:OSCI

CPU Disabled.

B

r

o

T

i

t

>

w

m

n

e

t

S

U

:

External

Interrupt

u

t

-

O

t

o

u

I

S

C

O

Brown-Out

External Interrupts

Monitored

ADC Active

Interrupt

CPU STOP

Analog Circuits Active

VDD < V

Code Execution

BO

CPU STOP

Analog Circuits Inactive

Suspend Timeout

Suspend Timer Enabled

13 of 40

DS2792 Programmable Fuel Gauge with UART Interface

SUSPEND TIMER

The suspend timer allows the DS2792 to periodically monitor the cell while spending the majority of its time in a

low-power state. Suspend operation is managed through the coulomb counter control register (CCCON). A timout

value between 0.5s and 2.0s can be selected through the suspend timeout bits (CCSUS). When the suspend timer

is enabled and a timeout occurs, the DS2792 will transition from SLEEP mode to ANALOG mode, and eventually to

CPU mode. Upon transition to ANALOG mode, the coulomb counter enable bit (CCEN) is automatically set and the

ADC block becomes active. The DS2792 may then perform all needed cell-monitoring operations before clearing

the CCEN bit and returned to SLEEP mode. The process repeats after each timeout.

Figure 6. CCCON Register Format

FIELD BIT FORMAT ALLOWABLE VALUES

Reserved

CCSUS 2:1 R/W Suspend Timeout

CCEN 0 R/W Coulomb Counter Enable

7:3 Read Only Undefined

0 0 = Suspend Timeout Disabled

0 1 = 0.5s timeout

1 0 = 1.0s timeout

1 1 = 2.0s timeout

0 = ADC block disabled

1 = ADC block enabled

REGISTER SET

Most functions of the device are controlled by sets of registers. These registers provide a working space for

memory operations as well as configuring and addressing peripheral registers on the device. Registers are divided

into two major types: system registers and peripheral registers. The common register set, also known as the

system registers, includes the ALU, accumulator registers, data pointers, interrupt vectors and control, and stack

pointer. The peripheral registers define additional functionality that may be included by different products based on

the MAXQ20 architecture. This functionality is broken up into discrete modules so that only the features required

for a given product need to be included. Tables 1 through 6 detail the DS2792 register set.

Table 1. System Register Map

MODULE NAME (BASE SPECIFIER) REGISTER

INDEX

00h AP

01h APC

02h —

03h —

04h PSF

05h IC

06h IMR

07h —

08h SC

09h —

0Ah —

0Bh

0Ch —

0Dh —

0Eh CKCN

0Fh WDCN

Note: Names that appear in italics indicate that all bits of a register are read-only. Names that appear in bold indicate that a register is 16 bits

wide. Registers in module AP are bit addressable.

AP (8h) A (9h) PFX (Bh) IP (Ch) SP (Dh) DPC (Eh) DP (Fh)

IIR

A[0] PFX IP

A[1]

A[2]

A[3]

A[4]

A[5]

A[6]

A[7]

A[8]

A[9]

A[10]

A[11]

A[12]

A[13]

A[14]

A[15]

— —

— —

— — — Offs

— — —

— — —

— —

— —

— — — GRS —

— — — GRH —

— — — GRXL —

— — FP —

—

— — — — —

— — — — —

— — — — —

— — — — —

— — —

SP

IV

LC0

LC1 BP DP1

—

—

—

—

DP0

DPC

GR

GRL —

—

—

14 of 40

Table 2. System Register Bit Functions

REGISTER

AP

APC

PSF

IC

IMR

SC

IIR

CKCN

WDCN

A[n] (0..15)

PFX

IP

SP

IV

LC[0]

LC[1]

Offs

DPC

GR

GRL

BP

GRS

GRH

GRXL

FP

DP[0]

DP[1]

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

— — — — AP (4 bits)

CLR IDS — — — MOD2 MOD1 MOD0

Z S — GPF1 GPF0 OV C E

— — CGDS — — — INS IGE

IMS — —

TAP — —

IIS — —

—

POR EWDI

— — — — — — — — — — — — SP (4 bits)

Offs (8 bits)

— — — — — — — — — — — WBS2 WBS1 WBS0 SDPS1 SDPS0

GR.15 GR.14 GR.13 GR.12 GR.11 GR.10 GR.9 GR.8 GR.7 GR.6 GR.5 GR.4 GR.3 GR.2 GR.1 GR.0

GRL.7 GRL.6 GRL.5 GRL.4 GRL.3 GRL.2 GRL.1 GRL.0

GRS.15 GRS.14 GRS.13 GRS.12 GRS.11 GRS.10 GRS.9 GRS.8 GRS.7 GRS.6 GRS.5 GRS.4 GRS.3 GRS.2 GRS.1 GRS.0

GRH.7 GRH.6 GRH.5 GRH.4 GRH.3 GRH.2 GRH.1 GRH.0

GRXL.15 GRXL.14 GRXL.13 GRXL.12 GRXL.11 GRXL.10 GRXL.9 GRXL.8 GRXL.7 GRXL.6 GRXL.5 GRXL.4 GRXL.3 GRXL.2 GRXL.1 GRXL.0

DS2792 Programmable Fuel Gauge with UART Interface

REGISTER BIT NUMBER

A[n] (16 bits)

PFX (16 bits)

IP (16 bits)

IV (16 bits)

LC[0] (16 bits)

LC[1] (16 bits)

BP (16 bits)

FP (16 bits)

DP[0] (16 bits)

DP[1] (16 bits)

— — —

— —

— — —

— — — — — — —

— —

WDIF WTRF EWT RWT

IM1 IM0

ROD PWL —

II1 II0

15 of 40

DS2792 Programmable Fuel Gauge with UART Interface

Table 3. System Register Bit Reset Values

REGISTER

AP 0 0 0 0 0 0 0 0

APC 0 0 0 0 0 0 0 0

PSF 1 0 0 0 0 0 0 0

IC 0 0 0 0 0 0 0 0

IMR 0 0 0 0 0 0 0 0

SC 0 0 0 0 0 0 s 0

IIR 0 0 0 0 0 0 0 0

CKCN 0 s s 0 0 0 0 0

WDCN s s 0 0 0 0 0 0

A[n] (0..15) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

PFX 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

IP 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

SP 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1

IV 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

LC[0] 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

LC[1] 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Offs 0 0 0 0 0 0 0 0

DPC 0 0 0 0 0 0 0 0 0 0 0 1 1 1 0 0

GR 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GRL 0 0 0 0 0 0 0 0

BP 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GRS 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GRH 0 0 0 0 0 0 0 0

GRXL 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

FP 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

DP0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

DP1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Note: s indicates bit reflects pin state.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

REGISTER BIT

16 of 40

DS2792 Programmable Fuel Gauge with UART Interface

Table 4. Peripheral Register Map

REGISTER

INDEX

00h PO

01h PPU

02h PAF — — 12h — — —

03h

04h

05h

06h

07h TCC — — 17h — — —

08h

09h — — — 19h

0Ah — SADEN — 1Ah

0Bh — SADDR — 1Bh ICDF — —

0Ch —

0Dh — — ECNTL 1Dh ICDA — —

0Eh — —

0Fh — —

Note: Names that appear in italics indicate that all bits of a register are read-only. Names that appear in bold indicate that a register is 16 bits.

All locations are bit addressable.

M0 (0h) M1 (1h) M2 (2h)

EIC SMD

EINT

CCCON

TC PR

PI

MODULE MODULE

SINT

SMASK

SBUF — 14h — — —

SCON — 15h — — —

— — 18h

BRE

— 10h — — —

— 11h — — —

— 13h — — —

— 16h — — —

— 1Ch ICDB — —

EADDR

EDATA

REGISTER

INDEX

1Eh ICDD — —

1Fh — — —

M0 (0h) M1 (1h) M2 (2h)

ICDT0

ICDT1

ICDC

— —

— —

— —

17 of 40

Table 5. Peripheral Register Bit Functions

REGISTER

PO

PPU

PAF

EIC

EINT

CCCON

TC

TTC

PI

ICDT0

ICDT1

ICDC

ICDF

ICDB

ICDA

ICDD

SINT

SMASK

SMD

SBUF

SCON

PR

SADEN

SADDR

BRE

Note: Names that appear in italics indicate a read-only register bit.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

— — PO.5 PO.4 PO .3 PO.2 PO.1 PO .0

TxD_PU RxD_PU PPU.5 PPU.4 PPU.3 PPU.2 PPU.1 PPU.0

— RSTD PAF.5 PAF.4 PAF.3 PAF. 2 PAF.1 PAF.0

MBOI MSCI MSDI

BOI SCI SDI

THI.7 THI.6 THI.5 THI.4 THI.3 THI.2 THI.1 THI.0 TLOW.7 TLOW.6 TLOW.5 TLOW.4 TLOW.3 TLOW.2 TLOW.1 TLOW.0

— — — — — TTCK.1 TTCK.0 TMOD

—

ICDT0.15 ICDT0.14 ICDT0.13 ICDT0.12 ICDT0.11 ICDT0.10 ICDT0.9 ICDT0.8 ICDT0.7 ICDT0.6 ICDT0.5 ICDT0.4 ICDT0.3 ICDT0.2 ICDT0.1 ICDT0.0

ICDT1.15 ICDT1.14 ICDT1.13 ICDT1.12 ICDT1.11 ICDT1.10 ICDT1.9 ICDT1.8 ICDT1.7 ICDT1.6 ICDT1.5 ICDT1.4 ICDT1.3 ICDT1.2 ICDT1.1 ICDT1.0

— — — — PSS.1 PSS.0 SPE TXC

ICDB.7 ICDB.6 ICDB.5 ICDB. 4 ICDB.3 ICDB.2 ICDB.1 ICDB.0

ICDA.15 ICDA.14 ICDA.13 ICDA.12 ICDA.11 ICDA.10 ICDA.9 ICDA.8 ICDA.7 ICDA.6 ICDA.5 ICDA.4 ICDA.3 ICDA.2 ICDA.1 ICDA.0

ICDD.15 ICDD.14 ICDD.13 ICDD.12 ICDD.11 ICDD.10 ICDD.9 ICDD.8 ICDD.7 ICDD.6 ICDD.5 ICDD.4 ICDD.3 ICDD.2 ICDD.1 ICDD.0

— — — — — — TINT RINT

— — — — — — MTI MRI

— — TXDi RXDi — — SMOD FEDE

SBUF.7 SBUF.6 SBUF.5 SBUF.4 SBUF.3 SBUF.2 SBUF.1 SBUF.0

FE/SM0 SM1 SM2 REN T B8 RB8 TI RI

PR.15 PR.14 PR.13 PR.12 PR.11 PR.10 PR.9 PR.8 PR.7 PR.6 PR.5 PR.4 PR.3 PR.2 PR.1 PR.0

SAME.7 SAME.6 SAME.5 SAME.4 SAME.3 SAME. 2 SAME.1 SAME.0

SAD.7 SAD.6 SAD.5 SAD.4 SAD.3 SAD.2 SAD.1 SAD.0

BRE.15 BRE.14 BRE.13 BRE.12 BRE.11 BRE.10 BRE.9 BRE.8 BRE.7 BRE.6 BRE.5 BRE.4 BRE.3 BRE.2 BRE.1 BRE.0

—

— — MVI MCI MTI MTCI PIP.1 PIP.0 PIT.1 PIT.0 PIE.1 PIE.0

—

— — VI CI TI TCI — — —

DS2792 Programmable Fuel Gauge with UART Interface

REGISTER BIT NUMBER

INT.1 INT.0

RST

— — — — — CCSUS.1 CCSUS.0 CCEN

RxDI PI.5 PI.4 PI.3 PI.2 PI.1 PI.0

DME — REGE — CMD.3 CMD.2 CMD.1 CMD.0

18 of 40

DS2792 Programmable Fuel Gauge with UART Interface

Table 6. Peripheral Register Reset Values

REGISTER

PO

PPU

PAF

EIC

EINT

CCCON

TC

TTC

PI

ICDT0

ICDT1

ICDC

ICDF

ICDB

ICDA

ICDD

SINT

SMASK

SMD

SBUF

SCON

PR

SADEN

SADDR

BRE

Note: s indicates bit reflects pin state.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 1 1 1 1 1 1

0 0 0 0 0 1 0 0

0 0 0 0 0 1 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

s s s s s s s s

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

REGISTER BIT NUMBER

ON-CHIP REGULATOR

The DS2792 provides a regulated 3.3V output on the VB pin capable of supplying up to 2mA of current to external

circuitry. The regulated supply can be used to level shift the I/O lines and/or provide a reference voltage for the Vx

pin to measure a pack ID resistor or thermistor. The regulator output is always active regardless of the DS2792’s

mode of operation.

SYSTEM INTERRUPTS

Multiple interrupt sources are available for quick response to internal and external events. The MAXQ20

architecture uses a single interrupt vector (IV), single interrupt-service routine (ISR) design. For maximum flexibility,

interrupts can be enabled globally, individually, or by module. When an interrupt condition occurs, its individual flag

is set, even if the interrupt source is disabled at the local, module, or global level. Interrupt flags must be cleared

within the firmware-interrupt routine to avoid repeated interrupts from the same source. Application software must

ensure a delay between the write to the flag and the RETI instruction to allow time for the interrupt hardware to

remove the internal interrupt condition. Asynchronous interrupt flags require a one-instruction delay and

synchronous interrupt flags require a two-instruction delay.

When an enabled interrupt is detected, execution jumps to a user-programmable interrupt vector location. The IV

register defaults to 0000h on reset or power-up, so if it is not changed to a different address, application firmware

must determine whether a jump to 0000h came from a reset or interrupt source.

Once control has been transferred to the ISR, the interrupt identification register (IIR) can be used to determine if a

system register or peripheral register was the source of the interrupt. The specified module can then be

interrogated for the specific interrupt source and software can take appropriate action. Interrupts are evaluated by

application code allowing the definition of a unique interrupt priority scheme for each application. Interrupt sources

are available from the watchdog timer described in the MAXQ Users Guide, the SINT register described in the

UART Interrupts section, and the EINT register as shown in Figure 7.

19 of 40

DS2792 Programmable Fuel Gauge with UART Interface

EINT Register

The EINT register contains interrupts generated by the ADC, the timer counter, the general-purpose port pins, and

the UART RXD pin. Their masks and their configuration bits, along with the RST pin status and control, are present

in the EIC and PAF registers of module 0.

Figure 7. EINT Register Interrupt Sources

GENERATOR INTERRUPT MASK DESCRIPTION FREQUENCY

Ports and Pins

INT0 PAF.0/PIE.0

INT1 PAF.1/PIE.1

SCI MSCI

SDI MSDI

The interrupt from pin P0.0 is configurable

via the PAF.0, PIT.0, and PIP.0 bits.

The interrupt from pin P0.1 is configurable

via the PAF.1, PIT.1, and PIP.1 bits.

The serial connect interrupt is generated

when RXD becomes high.

The serial disconnect interrupt is generated

when RXD is low for at least 220ms.

Dependent on external

conditions.

Dependent on external

conditions.

Rising edge on RXD.

Once every 220ms if RXD

is held low. The first

interrupt may take up to

440ms from the time RXD

goes low. Interrupt will not

trigger if the ADC is off.

Brownout

Detector

A/D Converter

Timer/

Counter

BOI MBOI

VI MVI

CI MCI

TI MTI

TCI MTCI

The brownout interrupt indicates that V

was below V

the microcontroller's stop mode. It will interrupt

the microcontroller, if MBOI is 1, after a

charger brings V

microcontroller to run.

The voltage interrupt indicates the voltage

registers in the data peripheral memory block

have fresh voltage averages.

The current interrupt indicates that the

current register (6004h) in the data peripheral

memory block has a fresh reading and that the

ACR has also been updated.

The temperature interrupt indicates that the

temperature register in the data peripheral

memory block has a fresh average.

The timer/counter interrupt indicates that the

timer/counter has been reloaded after reaching

its end-count.

in the past. It will not terminate

BO

above VBO and causes the

DD

DD

Every time after exiting

brownout.

Once every 13.8ms.

Never if the ADC is off.

Once every 88ms. Never if

the ADC is off.

Once every 220ms. Never

if the ADC is off.

Dependent on TMOD and

TTCK[1:0].

20 of 40

DS2792 Programmable Fuel Gauge with UART Interface

I/O PORTS

The DS2792 includes a simple input/output (I/O) data port. From a software perspective, the port appears as a

group of special-function registers within module M0. The simple I/O port defined for this product is described

below:

CMOS input buffers

Four open-drain output drivers with selectable tri-state or weak pullups

Two selectable open-drain or push-pull output drivers with selectable tri-state

Support alternate functions and TAP controller interface signals

Two pins have interrupt capability

The port is accessed through five peripheral registers (PO, PI, PAF, PPU, and EIC) addressed either by byte or by

individual bit locations. The I/O port is designed to provide programming flexibility for the application. All individual

I/O pins are independently configured; and can be defined as an input, output, or alternate function. Table 7

summarizes the functionality of the I/O pins.

Table 7. I/O Port Pins

FUNCTIONS CHARACTERISTICS

Primary Alternate TAP* Bidirectional

P0.0 INT0 TDI* Configurable, [In] — Configurable, [Off] —

P0.1 INT1 TMS* Configurable, [In] — Configurable, [Off] —

P0.2

RST* —

Configurable, [In] — Configurable, [Off] —

P0.3 — TCK* Configurable, [In] — Configurable, [Off] —

P0.4 — TDO* Configurable, [In] — — Configurable, [Off]

P0.5 — — Configurable, [In] — — Configurable, [Off]

TXD — — Output Configurable, [On] Configurable, [Off] —

RXD — — Input Configurable, [On] Configurable, [Off] —

Note: Reset values are denoted with an * and by [ ].

PI Register: The PI register is a read-only input of the I/O pins. When the register is read, the logic level of each

pin is reported in the corresponding bit locations. Reading a logic-low or high on a pin does not change the output

drive on that pin.

PO Register: The PO register controls the output state of the I/O pins. Data written to this register determines the

pin output drive. When a bit is written to a “0” (cleared), the n-channel output drive transistor is enabled, and the

pullup is disabled. When bit is written to a “1” (set), the n-channel output drive transistor is disabled, and the pullup

enabled (if so configured). The PO bits are set asynchronously during power-on reset to disable the N-channel

output drive. PO bits are not altered in SLEEP mode, however drive to the n-channel is disabled.

PPU Register: The PPU register contains independent bits that define each pin as high impedance or pulled up

when its n-channel output drive transistor is disabled. P0.0 through P0.3 have weak pullups, P0.4 and P0.5 have

strong pullups. When the output is disabled and the PPU bit is cleared, the pin is high impedance. When the output

is disabled and the PPU bit is set, the pin’s weak or strong pullup is enabled. When the PPU bit is set and the

device enters STOP mode, the weak pullup remains enabled.

PAF Register: The PAF register enables or disables the alternate functions of P0.0–P0.2. When a pin’s PAF bit is

cleared, the pin is controlled by the PI, PO, PPU, and EIC registers. When the PAF bit is set, the pin operates in it’s

alternate function mode. The RST function of P0.2 can be disabled by writing the RSTD bit to 1.

EIC Register: The lower six bits of the EIC register are the port interrupt control bits. The port interrupt control bits

are used to enable and configure detection of external interrupts. Interrupt enable bits, PIE.0 and PIE.1, enable

detection of an interrupt on pins P0.0 and P0.1, respectively. Interrupt type bits, PIT.0 and PIT.1, define the type

(level or edge) of interrupt on pins P0.0 and P0.1, respectively. Interrupt polarity bits, PIP.0 and PIP.1, determine

the interrupt polarity on pins P0.0 and P0.1, respectively.

Weak Passive

Pulldown

Weak Active Pullup Strong Active Pullup

21 of 40

DS2792 Programmable Fuel Gauge with UART Interface

Table 8. P0 Interrupt Configuration

PIE.x PIT.x PIP.x RESULT

0 X X Interrupt Disabled

1 0 0 Interrupt Enabled, Triggered on Logic-Low

1 0 1 Interrupt Enabled, Triggered on Logic-High

1 1 0 Interrupt Enabled, Triggered on Falling Edge

1 1 1 Interrupt Enabled, Triggered on Rising Edge

Figure 8. Port Pin Schematics

22 of 40

DS2792 Programmable Fuel Gauge with UART Interface

PROGRAMMABLE TIMER/COUNTER

The timer/counter block operates as a simple 8-bit interval timer or counter. The start value is programmable and is

automatically reloaded when a rollover occurs. The TMOD bit in the TCC register selects between the counter and

timer modes. In the counter mode, external events on the P0.3 pin are counted. In the timer mode, OSCA clock

source cycles are counted. The OSCA clock and brownout detectors continue to run if the CPU is stopped.

Figure 9. Timer/Counter Block Diagram

The timer low byte (TLOW) is used to count input events, while the timer high byte (THI) is used to store the reload

value. Firmware must initialize TLOW and THI with the same value for the first count to be the same as succeeding

counts. TLOW counts up until FFh is reached, it is then automatically reloaded with the value in THI. THI remains

unchanged unless modified by firmware. The clock source is selected with TTCK[1:0] bits. Table 9 describes the

possible resolution and range of the timer.

Table 9. Programmable Timer Configuration

TMOD TTCK[1:0] CLOCK PERIOD TIMER RANGE (t x 28)

1 0 0 14.3µs 3.66ms

1 0 1 343µs 87.9ms

1 1 0 6.86ms 1.76s

1 1 1 220ms 56.3s

0 N/A Counter Mode

23 of 40

DS2792 Programmable Fuel Gauge with UART Interface

SERIAL INTERFACE MODULE

The DS2792 supports a universal asynchronous receiver/transmitter (UART) module for serial communication with

framing error detection and automatic address recognition. The UART is initialized through a configuration register

(SMD). Communication is managed through a control register (SCON) and a transmit/receive register (SBUF). The

SBUF register location provides access to both transmit and receive registers, where a read is directed to the

receive buffer and a write is directed to the transmit buffer. SBUF allows the serial interface to receive an incoming

word before software has read the previous one provided SBUF is read before the stop bit of the next word is

recieved.

If the DS2792 detects a start bit of an incoming transmission while in SLEEP mode, the instruction clock will be

enabled to allow reception of data. Note that the instruction clock will not achieve accuracy tolerance required for

UART communication unless the analog oscillator is also active. All outgoing transmission must be completed, and

the RXD pin must be in the inactive logic state (see RXDi bit), before the DS2792 will transition back to SLEEP

mode.

Figure 10. Serial Interface Control Register (SCON)

FIELD BIT FORMAT ALLOWABLE VALUES

Serial Interface Mode Bit 0/Framing Error Flag

The operation of this bit depends on the state of the FEDE bit

of the SMD register. When FEDE is cleared to 0, this bit

functions as SM0 and controls the operating mode. See Serial

FE/SM0 7 R/W

SM1 6 R/W

SM2 5 R/W

REN 4 R/W

TB8 3 R/W

RB8 2 R/W

TI 1 R/W

RI 0 R/W

Interface Modes, Table 10.

When FEDE is set to 1, this bit functions as a framing error flag

and will automatically be set to 1 when the incoming stop bit

has been received as a logic 0. When used as FE, this flag

must be cleared to 0 by software.

Serial Interface Mode Bit 1

See Serial Interface Modes, Table 10

Serial Interface Mode Bit 2

Mode 1 operation:

0 = Normal operation

1 = RXI flag not set if incoming stop is logic 0

Modes 2 and 3 operation:

0 = Multiprocessor mode disabled

1 = Multiprocessor mode enabled

Reciever Enable

0 = Reciever enabled

1 = Reciever disabled

Transmit Data Bit 8

When in mode 2 or 3, this bit determines the state of the ninth

transmitted data bit. This bit is not used in mode 1.

Received Data Bit 8

When in mode 2 or 3, this bit indicates the state of the incoming

ninth data bit. In mode 1, this bit indicates the state of the stop

bit.

Transmit Interrupt Flag

Set to 1 at the end of the last data bit transmitted.

TI must be cleared by software.

Recieve Interrupt Flag

Set to 1 at the end of the stop bit sampling window when in

mode 1. Set to 1 at the end of the sampling window of the ninth

data bit when in mode 2 or 3.

RI must be cleared by software.

24 of 40

DS2792 Programmable Fuel Gauge with UART Interface

Figure 11. Serial Interface Configuration Register (SMD)

FIELD BIT FORMAT ALLOWABLE VALUES

Reserved

7:6 Read Only

Undefined

TXD Invert Bit

TXDi 6 R/W

0 = Normal operation

1 = TXD output signal inverted

RXD Invert Bit

RXDi 5 R/W

0 = Normal operation

1 = RXD input data inverted

Reserved

3:2 Read Only

Undefined

Baud Rate Doubler

SMOD 1 R/W

0 = Baud rate divided by 2 (mode 2)

0 = Baud rate divided by 4 (modes 1 and 3)

1 = Baud rate unchanged

Framing Error Enable Flag

FEDE 0 R/W

0 = SICON bit 7 controls communication mode (SM0)

1 = SICON bit 7 flags framing errors (FE)

Figure 12. Serial Interface Block Diagram

SBUF Output Shift Register

RI

TI

Modes 2&3 only

D7

Stop

D8

D0

Start

Bit

Latch

TXD

BAUD Clock

÷16

TB8

SBUF Input Register

RB8

D8 (Modes 2&3)

Stop bit (Mode 1)

D8

Stop

Modes 2&3 only

Input Shift Register

D7

D7

D0

D0

Start

REN

Start Detect

Bit

Detect

RXD

25 of 40

DS2792 Programmable Fuel Gauge with UART Interface

Serial Interface Modes of Operation

The UART operates in one of three asynchronous full-duplex communication modes with different protocols and

baud rates. Two mode bits (SM1, SM0 in the SCON register) are used to select the modes of operation. The

operating modes are summarized in Table 10.

Table 10. Serial Interface Modes

SM1 SM0 MODE FUNCTION CLOCK LENGTH START/STOP

0 1 1

1 0 2

1 1 3

Mode 1

Mode 1 is asynchronous, full duplex with a 10-bit data stream consisting of a logic 0 start bit, eight data bits, and

logic 1 stop bit. The data is transferred least significant bit first. The UART begins transmission several cycles after

the first baud clock of the baud rate generator following a write to SBUF. Transmission on the TXD pin begins with

the start bit, data then is shifted out on the pin, least significant bit first, followed by the stop bit. The TI bit is set two

clock cycles after the stop bit is transmitted. All bits are shifted out at the rate determined by the baud rate

generator. Baud rate generation is discussed in the Baud Rate Generation section.

Once the baud rate generator is active, reception can begin at any time. The REN bit in SCON must be set to logic

1 to enable the reception. The falling edge of a start bit on the RXD pin will begin the reception process. Data will

be shifted in at the selected baud rate. At the middle of the stop bit time slot, certain conditions must be met to load

SBUF with the received data from the receive shift register:

RI must be 0, and

if SM2 is 0, the state of the stop bit does not matter, or

if SM2 is 1, the state of the stop bit must be 1

If these conditions are true, the SBUF register will be loaded with the received byte, the RB8 bit will be loaded with

the stop bits and the RI bit will be set. If these conditions are false, then SBUF and RB8 will not be loaded, the

received data will be lost and the RI bit will not be set. Regardless of the receive word status, the receive logic will

go back to looking for a 1 to 0 transition on the RXD pin after the middle of the stop bit time.

Each data bit received is sampled on the 7th, 8th, and 9th clock from the baud rate generator (running 16 times

faster than communication speed). Using majority voting, two equal samples out of the three determine the logic

value for each received bit. If the start bit was determined to be invalid, then the receive logic returns to looking for

a 1 to 0 transition on the RXD pin in order to start the reception again.

Asynchronous

Full Duplex

Asynchronous

Full Duplex

Asynchronous

Full Duplex

Phase Delta

Register

Instruction Clock 9 1 Start, 1 Stop TB8, RB8

Phase Delta

Register

8 1 Start, 1 Stop N/A

9 1 Start, 1 Stop TB8, RB8

9th BIT

FUNCTION

26 of 40

DS2792 Programmable Fuel Gauge with UART Interface

Figure 13. Timing Diagram for Serial Interface Mode 1

Mode 2

Mode 2 is asynchronous, full-duplex communication with an 11-bit data stream consisting of a logic 0 start bit, eight

data bits, a programmable 9th bit, and a logic 1 stop bit. The data is transferred least significant bit first. Similar to

mode 1, transmissions occur on the TXD pin and reception on the RXD pin. For transmission purposes, the 9th bit

can be configured as logic 0 or 1. A common use is to load this location with a parity bit. The 9th bit is transferred

from the TB8 bit position in the SCON register during the write to SBUF. The UART will begin transmission a few

cycles after the first rollover of the clock source divided by 16 following a write to SBUF. Transmission begins with

the start bit being placed on the TXD pin, data is then shifted onto the pin, least significant bit first, followed by the

9th bit, and finally the stop bit. The TI bit is set at the same time the stop bit is transmitted on the TXD pin. All bits

are shifted out at the rate determined by the baud rate generator. Baud rate generation is discussed in the Baud

Rate Generation section.

Once the baud rate generator is active, reception can begin at any time. The REN bit must be set to a logic 1 to

enable the reception. The falling edge of a start bit on the RXD pin will begin the reception process. Data will be

shifted in at the selected baud rate. At the middle point of the 9th bit time slot, certain condition must be met to load

SBUF with the received data from the receive shift register:

RI must be 0, and

if SM2 is 0, the state of the stop bit does not matter, or

if SM2 is 1, the state of the 9th bit must be 1

27 of 40

DS2792 Programmable Fuel Gauge with UART Interface

If these conditions are true, then SBUF will be loaded with the received byte, the RB8 bit will be loaded with the 9th

bit, and the RI bit will be set. If these conditions are false, then SBUF and RB8 will not be loaded, the received data

will be lost, and RI bit will not be set. Regardless of the receive word status, the receive logic will go back to looking

for a 1 to 0 transition on the RXD pin after the middle point of the stop bit time slot.

Each data bit received is sampled on the 7th, 8th, and 9th clock from the baud rate generator (running 16 times

faster than communication speed). Using majority voting, two equal samples out of the three determine the logic

value for each received bit. If the start bit was determined to be invalid, then the receive logic goes back to looking

for a 1 to 0 transition on the RXD pin in order to start the reception again.

Mode 3

Operation of mode 3 is identical to mode 2 except for the baud rate source. Baud rate generation is discussed in

the Baud Rate Generation section.

Figure 14. Timing Diagram for Serial Interface Modes 2 and 3

Transmit Frequency

Serial Interface Clock So urce divided by 16

Start

7th, 8th, and 9th Samples

Start

D1D0 D8 Stop

of each bit

D1D0 D8 Stop

D2 D3 D4 D5 D6 D7

D2 D3 D4 D5 D6 D7

Transmit Frequency

Serial Interface Clock So urce divided by 16

Detection of Framing Errors

A framing error occurs during communication when a valid stop bit is not detected. The result is a possible

improper reception of the serial word. The serial inteface will notify the system by setting the framing error (FE) bit

in the SCON register to 1. When set, the FE bit must be cleared by software or a system reset. Receiving a

properly framed serial word will not clear the FE bit.

28 of 40

DS2792 Programmable Fuel Gauge with UART Interface

Note that both the FE and the serial mode bit 0 (SM0) share the same bit location in the SCON register, but this

information is actually stored in different registers. The setting of FEDE in the SMD register determines which

register is accessed: logic 0 allows access to the SM0 bit and a logic 1 allows access to the FE bit. The FEDE must

be set to 1 while reading or writing the FE bit.

Multiprocessor Communication Mode

Multiprocessor communication mode makes special use of the 9th data bit in modes 2 and 3 if the SM2 bit of the

SCON register is set. If enabled, the 9th data bit is used to signify that the incoming byte is an address. This allows

the processor to be interrupted only if the correct address is received as defined by the serial address (SADDR)

and serial address enable (SADEN) registers. The receive interrupt, if enabled, will only occur when a recognized

address is received.

When multiprocessor mode is enabled and a serial word is received with the 9th bit set, the byte will be assumed to

be an address. The address will be compared to an internally stored address. If it matches, a receive interrupt will

occur. The internal address is derived from the SADDR and SADEN registers. The SADDR register specifies an

absolute address. This is the user specified address of the device. The SADEN register indicates which address

bit(s) will be used in the comparison. This allows broadcast transmissions that reach multiple microcontrollers or all

microcontrollers on the serial interface. The user defines this protocol.

Software will write an 8-bit address to the SADDR register. This is the microcontroller’s individual address. Any bit

in SADEN that contains logic 0 will cause the corresponding bit in SADDR to be ignored in comparison. Thus, logic

0 bits in SADEN create don’t care bit states for address comparisons. When an address is received, each address

bit that is not masked by a don’t care will be compared to the SADDR. The microcontroller will interrupt on any

address that matches this comparison. Any address that meets this comparison is called a given address. The

following example shows how one address can be directed to an individual processor or two out of three.

Micro 1 Micro 2 Micro 3

SADDR 11110000 SADDR 11110001 SADDR 11110010

SADEN 11111010 SADEN 11111001 SADEN 11111010

––––––––––––––– ––––––––––––––– –––––––––––––––

Given 11110x0x Given 11110xx1 Given 11110x1x

Note that an address of 11110000 reaches only microcontroller 1. An address of 11110001 reaches microcontroller

1 and microcontroller 2. An address of 11110010 reaches only microcontroller 3. The microcontroller also matches

on any address that corresponds to the broadcast address. This is the logical OR of the SADDR and SADEN

registers, with any 0s defined as don’t cares.

UART Interrupts

Interrupts generated by the serial interface are controlled through the serial interface interrupt register (SINT) and

the serial interface interrupt mask register (SMASK). Writing either the receive interrupt mask (MRI) bit or transmit

interrupt mask (MTI) bit to 1 will enable interrupts to occur whenever the corresponding transaction successfully

completes. Writing either of these bits to 0 disables the corresponding interrupt. The RINT, TINT bits of the SMASK

are a logical AND of the RI flag, TI flag bits of the control register, and the corresponding interrupt mask bits.

Upon successful reception of a data word on RXD, the RI flag of the SCON register will be set. If MRI is set to 1,

the RINT flag will be set and an interrupt will be generated. System software can then read the SINT register to

determine the source of the interrupt. The RINT flag and the interrupt are cleared by writing the RI flag to 0. After

transmission of a data word on TXD, the TI flag of the SCON register will be set. If MTI is set to 1, the TINT flag will

be set and an interrupt will be generated. System software can then read the SINT register to determine the source

of the interrupt. The TINT flag and the interrupt are cleared by writing the TI flag to 0.

29 of 40

DS2792 Programmable Fuel Gauge with UART Interface

Command Codes

The DS2792 has two reserved command codes: a software power-on reset (POR) of the IC and an instruction to

begin program loading over the serial interface. Each command code is enabled by transmitting a <break>, 0xFE,

<break>, followed directly by the command instruction. There are no associated data bytes with either command.

Any other serial communication between the instructions negates the operation. See the MAXQ Family User's

Guide: DS2792 Supplement for the serial interface programming procedure. These command codes are fixed

inside the DS2792 and cannot be altered. System firmware should avoid using FEh as a command code during

device operation. A <break> instruction is defined as holding the RXD line low until a framing error is generated.

Table 11. Serial Interface Command Codes

COMMAND HEX CODE PURPOSE

Command Enable <break>, FEh, <break> Enable soft POR or program command.

Soft POR FEh Causes a reset of the IC.

Request Programming FDh Initiates programming over the serial interface.

Available

00h–FCh, FFh Defined by application firmware.

Baud Rate Generation

The baud rate for serial communication is derived directly from the instruction oscillator OSCI. The method for baud

rate generation depends on the serial interface’s operating mode. In operating modes 1 and 3, the baud rate is

determined by the value stored in the phase delta (PR) register. In operating mode 2, the OSCI oscillator sets the

baud rate directly. The baud rate doubler (SMOD) bit in the SMD register can be used to double the baud rate in

mode 2 or quadruple the baud rate in modes 1 and 3. Note that the baud clock frequency generated by this circuit

will be the sampling frequency used by the serial interface and is therefore 16 times the actual communication rate.

Figure 15. Baud Rate Generation Circuit

In mode 2, baud rates are generated directly from the system clock. The baud rate for mode 2 is given by the

formula: Baud Rate = (2

the system clock frequency. In the above formula, the numerator is expressed as two to the power of SMOD,

where SMOD is either a 0 or 1. The SMOD bit effectively doubles the baud rate when set to logic 1. The SMOD bit

is set to logic 0 on reset, which gives the lower speed baud rate.

SMOD

÷ 32) × f

. The result of this formula generates a baud rate of either 1/16 or 1/32 of

OSCI

30 of 40

DS2792 Programmable Fuel Gauge with UART Interface

In modes 1 and 3, the baud rate generator creates a phase accumulator that generates a baud clock as the result

of phase overflow into the most significant bit of the phase shift circuitry. As shown in Figure 15, a 16-bit phase

delta register (PR) is used to select a suitable phase delta for its baud clock. The phase delta is used to provide a

predetermined phase increment to the phase accumulator. The phase accumulator is formed by a 17-bit register

and a 16-bit adder. When the baud rate generator is enabled, the content of the phase delta register adds to the

value of the 17-bit register triggered by the system clock, essentially performing a phase accumulation. The baud

clock is the result of the adder carry output to the most significant bit of the 17-bit register. The baud rate for modes

1 and 3 are given by the formula: baud rate = (PR × f

) ÷ 223 × 2

OSCI

(SMOD×2)

. The SMOD bit effectively quadruples

the baud rate when set to logic 1. The SMOD bit is set to logic 0 on reset, which gives the lower speed baud rate.

Table 12. Sample Baud Rate Settings

MODE SMOD

PR REGISTER

BAUD RATE

2 0 N/A 30583 baud

2 1 N/A 61166 baud

1 or 3 1 1416h 2400 baud

1 or 3 1 282Dh 4800 baud

1 or 3 1 505Bh 9600 baud

1 or 3 1 A0B7h 19200 baud

1 or 3 0 282Dh 1200 baud

Baud rate calculations are based on a system clock frequency of 978.656KHz. Note that the analog oscillator must

be active for reliable serial communication. If OSCA is inactive, the OSCI timebase error f

ERR:OSCI

may be greater

than the UART communication standard of 3%.

Baud Rate Error Adjustment

The baud rate error (BRE) register provides error information that can be used by software to correct small errors in

the DS2792’s baud rate compared to the transmitting IC’s baud rate by adjusting the value loaded in the phase

delta register. At the end of each data word successfully received, the BRE register is updated with a 0.125%

resolution two’s complement value representing the percent difference between the expected final logic transition

on TXD compared to the final logic transition as measured by the bit sampler. A positive error means the UART is

running too slow and a negative error means the UART is running too fast.

Figure 16. Baud Rate Error Register Format

S 2

14

213 212 211 210 29 28 27 26 25 24 23 22 21 2

0

MSb LSb

“S”: sign bit(s)

For example: Communication is occurring at 9600 baud (PR register contains 505Bh) in mode 1, and a value of