Page 1

General Description

The DS2788 measures voltage, temperature, and current, and estimates available capacity for rechargeable

lithium-ion (Li+) and Li+ polymer batteries. Cell characteristics and application parameters used in the calculations are stored in on-chip EEPROM. The available

capacity registers report a conservative estimate of the

amount of charge that can be removed given the current temperature, discharge rate, stored charge, and

application parameters. Capacity estimation is reported

in mAh remaining and percentage of full.

LED display drivers and a debounced input make display of the capacity information easy. The LED pins can

directly sink current, requiring only a resistor for setting

the current in the LED display, thus reducing space and

cost.

Applications

Power Tools

Electric Bicycles

Electric Vehicles

Uninterruptible Power Supply

Digital Cameras

Features

♦ Five 30mA Open-Drain Drivers for Driving LED

Fuel-Gauge Display

♦ Debounced Fuel-Gauge Display Enable

♦ Internal Voltage Measurement Gain Register for

Trimming External Voltage-Divider

♦ Pin for Driving FETs to Enable Voltage-Divider

Only During Voltage Measurement, Conserving

Power

♦ Precision Voltage, Temperature, and Current

Measurement System

♦ Accurate, Temperature-Stable, Internal Time Base

♦ Absolute and Relative Capacity Estimated from

Coulomb Count, Discharge Rate, Temperature,

and Battery Cell Characteristics

♦ Accurate Warning of Low Battery Conditions

♦ Automatic Backup of Coulomb Count and Age

Estimation to Nonvolatile (NV) EEPROM

♦ Gain and Tempco Calibration Allows the Use of

Low-Cost Sense Resistors

♦ 24-Byte Battery/Application Parameter EEPROM

♦ 16-Byte User EEPROM

♦ Unique ID and Multidrop 1-Wire

®

Interface

♦ 14-Pin TSSOP Package

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

________________________________________________________________

Maxim Integrated Products

1

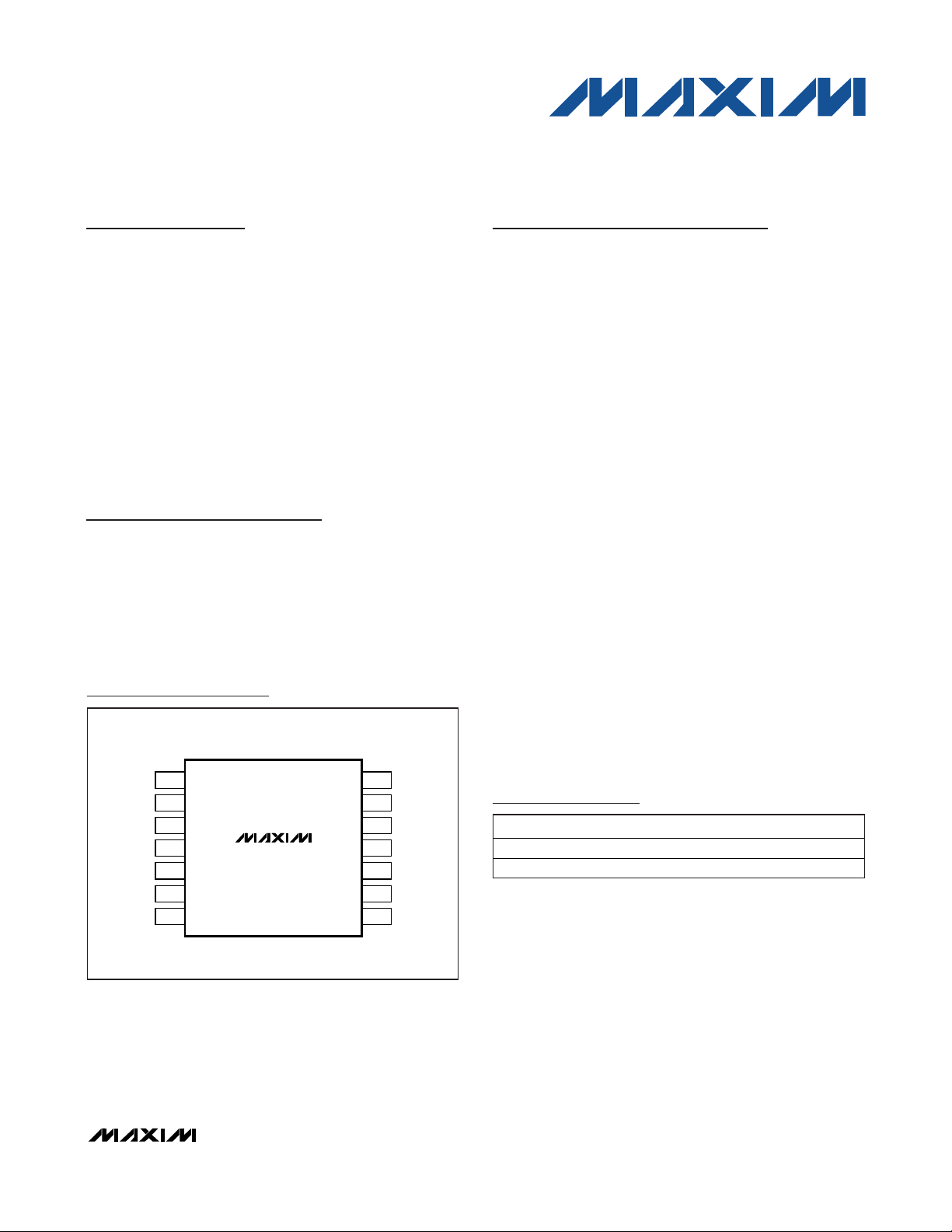

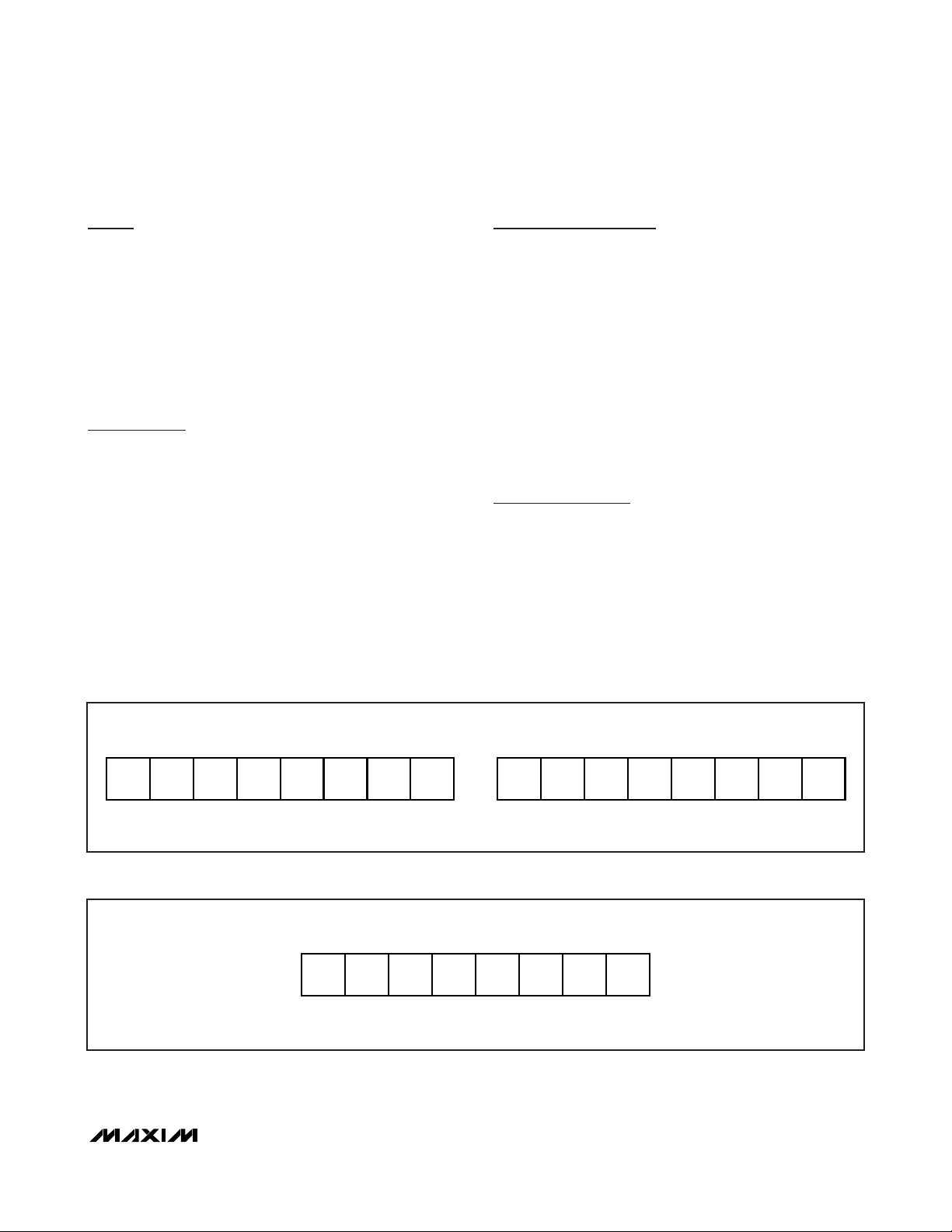

Pin Configuration

Ordering Information

Rev 1; 6/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

+

Denotes a lead-free/RoHS-compliant package.

T&R = Tape and reel.

Typical Operating Circuit appears at end of data sheet.

1-Wire is a registered trademark of Maxim Integrated Products, Inc.

TOP VIEW

LED1

V

+

2

SS

4

DD

5OVD

SS

DS2788

14 LED31LED2

13 LED4

12 LED53DV

PIO

11

10 V

IN

9 SNS6V

8 VMA7DQ

PART TEMP RANGE PIN-PACKAGE

DS2788E+ -25°C to +70°C 14 TSSOP

DS2788E+T&R -25°C to +70°C 14 TSSOP

TSSOP

Page 2

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

RECOMMENDED DC OPERATING CHARACTERISTICS

(VDD= 2.5V to 5.5V, TA= -25°C to +70°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage Range on Any Pin Relative to V

SS..............

-0.3V to +6.0V

Voltage Range on V

IN

, VMA Relative to V

SS ...

-0.3V to VDD+ 0.3V

DV

SS

to V

SS .....................................................................

-0.3V to +0.3V

LED1–5.................................................................60mA each pin

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range .............................-55°C to +125°C

Soldering Temperature (10s) ................Refer to IPC/JEDEC-020

Specification.

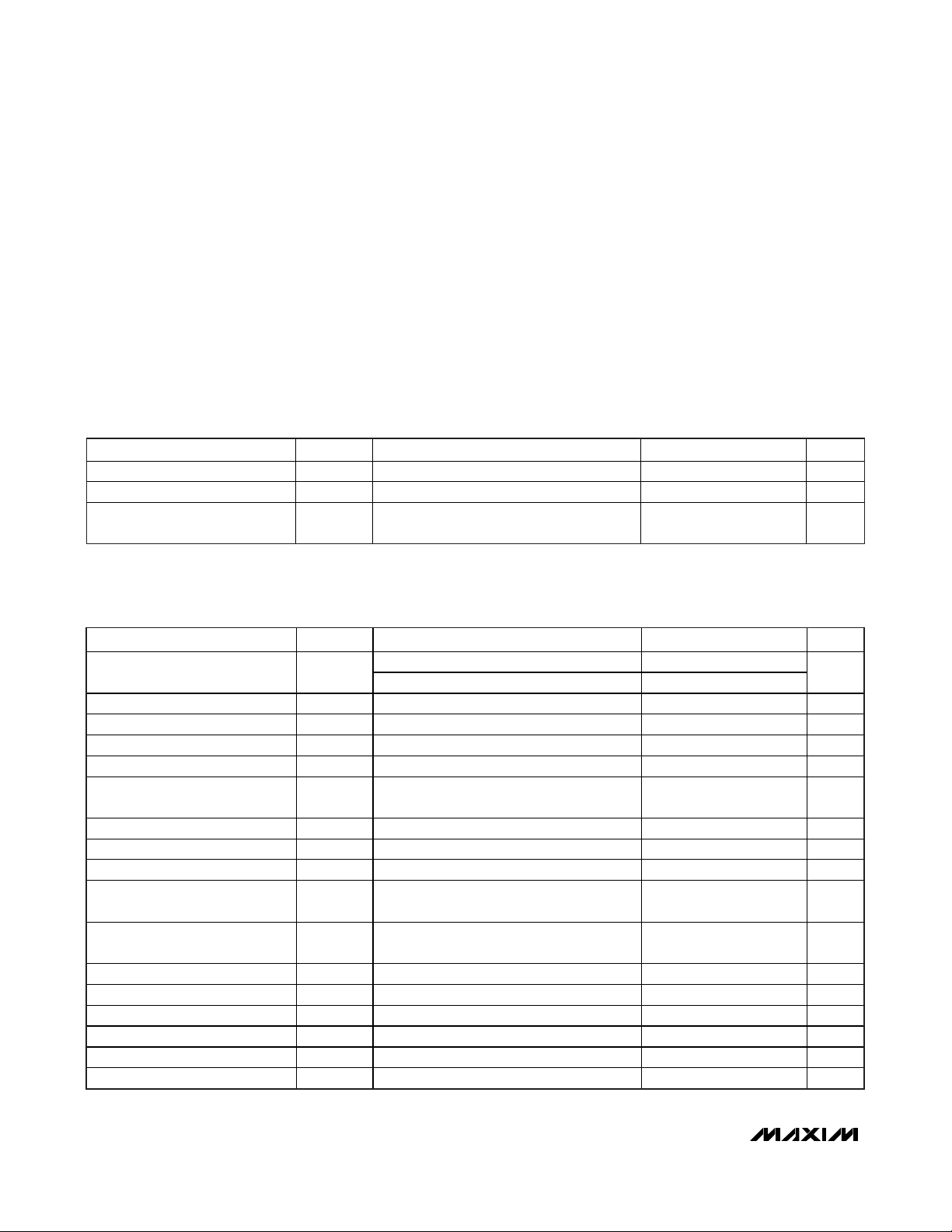

DC ELECTRICAL CHARACTERISTICS

(VDD= 2.5V to 5.5V, TA= -25°C to +70°C, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage VDD (Note 1) +2.5 +5.5 V

VIN, VMA Voltage Range (Note 1) 0 VDD V

DQ, PIO, OVD, LED1–LED5

Voltage Range

(Note 1) 0 +5.5 V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ACTIVE Current I

SLEEP Mode Current I

Input Logic-High: DQ, PIO VIH (Note 1) 1.5 V

Input Logic-Low: DQ, PIO VIL (Note 1) 0.6 V

Output Logic-Low: DQ, PIO, VMA VOL IOL = 4mA (Note 1) 0.4 V

Output Logic-High: VMA VOH IOH = 1mA (Note 1)

VMA Precharge Time t

Pulldown Current: DQ, PIO IPD VDQ, V

Output Logic-Low: LED1–LED5 VOL IOL = -30mA (Note 1) 1 V

Input Logic-High: OVD VIH (Note 1)

Input Logic-Low: OVD VIL (Note 1)

VIN Input Resistance RIN 15 M

DQ SLEEP Timeout t

Undervoltage SLEEP Threshold V

PIO Switch Debounce 100 130 m s

LED1 Displa y Blink Rate 50% duty cycle 0.9 1.0 1.1 Hz

LED Display-On Time 3.6 4.0 4.4 s

ACTIVE

SLEEP

PRE

SLEEP

SLEEP

2.5V VDD 4.2V 70 95

105

1 3 μA

13.3 14.2 ms

= 0.4V 0.2 5 μA

PIO

DQ < VIL 1.8 2.0 2.2 s

(Note 1) 2.40 2.45 2.50 V

V

-

V

DD

0.5

DD

0.2

-

V

V

V

+

SS

0.2

μA

V

Page 3

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS: TEMPERATURE, VOLTAGE, CURRENT

(VCC= 2.5V to 5.5V, TA= -25°C to +70°C, unless otherwise noted. Typical values are at TA= +25°C.)

ELECTRICAL CHARACTERISTICS: 1-Wire INTERFACE, STANDARD

(VCC= 2.5V to 5.5V, TA= -25°C to +70°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Temperature Reso lution T

Temperature Error T

Voltage Reso lution V

Voltage Full-Scale VFS 0 4.992 V

Voltage Error V

Current Resolution I

Current Ful l-Scale IFS ±51.2 mV

Current Ga in Error I

Current Offset Error I

Accumulated Current Offset q

Timebase Error t

0.125 °C

LSB

±3 °C

ERR

4.88 mV

LSB

±50 mV

ERR

1.56 μV

LSB

(Note 2) ±1

GERR

OERR

OERR

ERR

0°C TA +70°C, 2.5V VDD 4.2V

(Notes 3, 4)

0°C TA +70°C, 2.5V VDD 4.2V,

= VSS (Notes 3, 4, 5)

V

SNS

VDD = 3.8V, TA = +25°C ±1

0°C TA +70°C, 2.5V VDD 4.2V ±2

±3

-7.82 +12.5 μV

-188 0

% Full

Scale

μVhr/

day

%

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Time Slot t

Recovery Time t

Write-0 Low Time t

Write-1 Low Time t

Read Data Valid t

Reset-Time High t

Reset-Time Low t

Presence-Detect High t

Presence-Detect Low t

60 120 μs

SLOT

1 μs

REC

60 120 μs

LOW0

1 15 μs

LOW1

15 μs

RDV

480 μs

RSTH

480 960 μs

RSTL

15 60 μs

PDH

60 240 μs

PDL

Page 4

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

4 _______________________________________________________________________________________

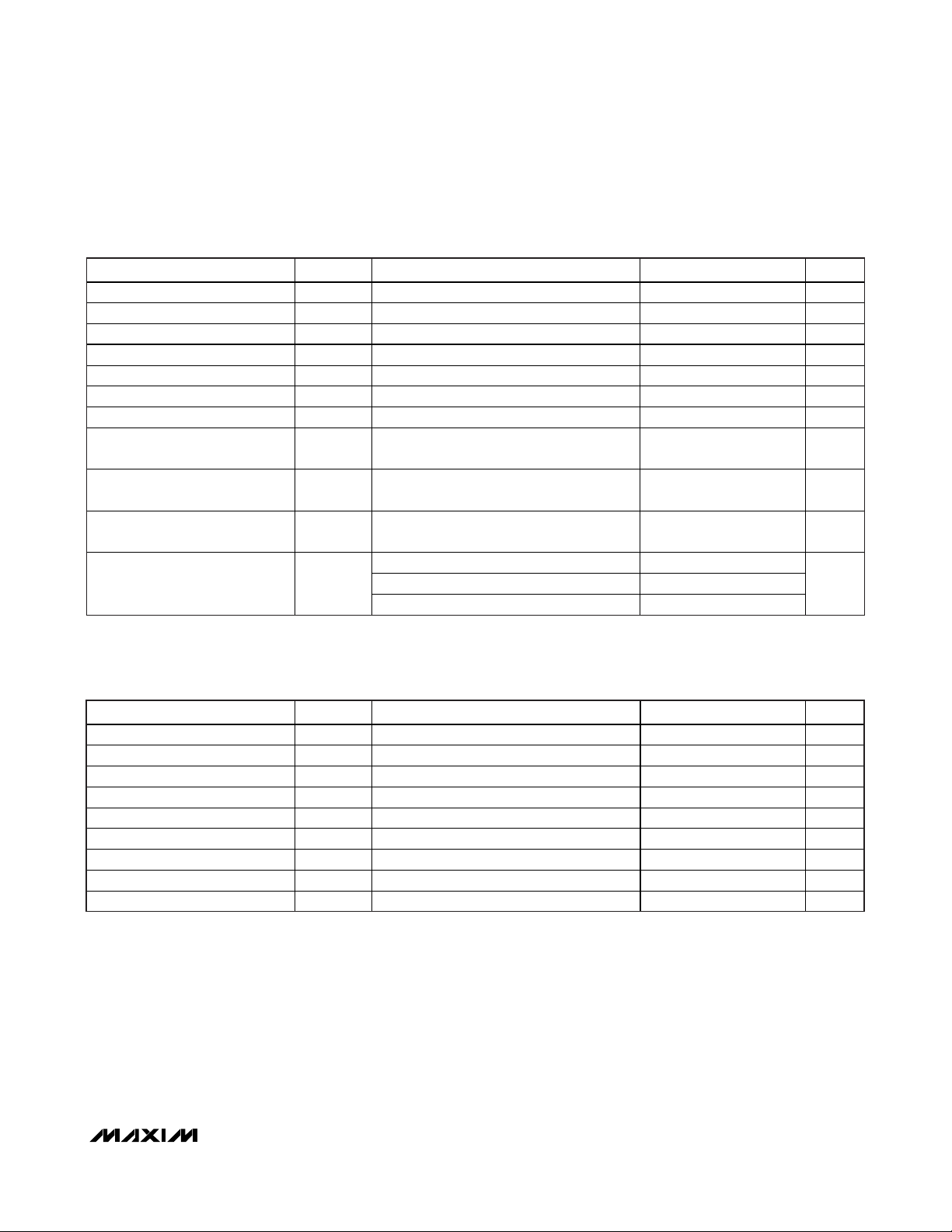

Note 1: All voltages are referenced to VSS.

Note 2: Factory-calibrated accuracy. Higher accuracy can be achieved by in-system calibration by the user.

Note 3: Parameters guaranteed by design.

Note 4: At a constant regulated V

DD

voltage, the Current Offset Bias register can be used to obtain higher accuracy.

Note 5: Accumulation Bias register set to 00h.

Note 6: EEPROM data retention is 10 years at +50°C.

ELECTRICAL CHARACTERISTICS: 1-Wire INTERFACE, OVERDRIVE

(VCC= 2.5V to 5.5V, TA= -25°C to +70°C.)

EEPROM RELIABILITY SPECIFICATION

(VCC= 2.5V to 5.5V, TA= -25°C to +70°C, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Time Slot t

Recovery Time t

Write-0 Low Time t

Write-1 Low Time t

Read Data Valid t

Reset-Time High t

Reset-Time Low t

Presence-Detect High t

Presence-Detect Low t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

EEPROM Copy Time t

EEPROM Copy Endurance N

6 16 μs

SLOT

1 μs

REC

6 16 μs

LOW0

1 2 μs

LOW1

2 μs

RDV

48 μs

RSTH

48 80 μs

RSTL

2 6 μs

PDH

8 24 μs

PDL

10 ms

EEC

TA = +50°C (Note 6) 50,000 Cycles

EEC

Page 5

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

_______________________________________________________________________________________ 5

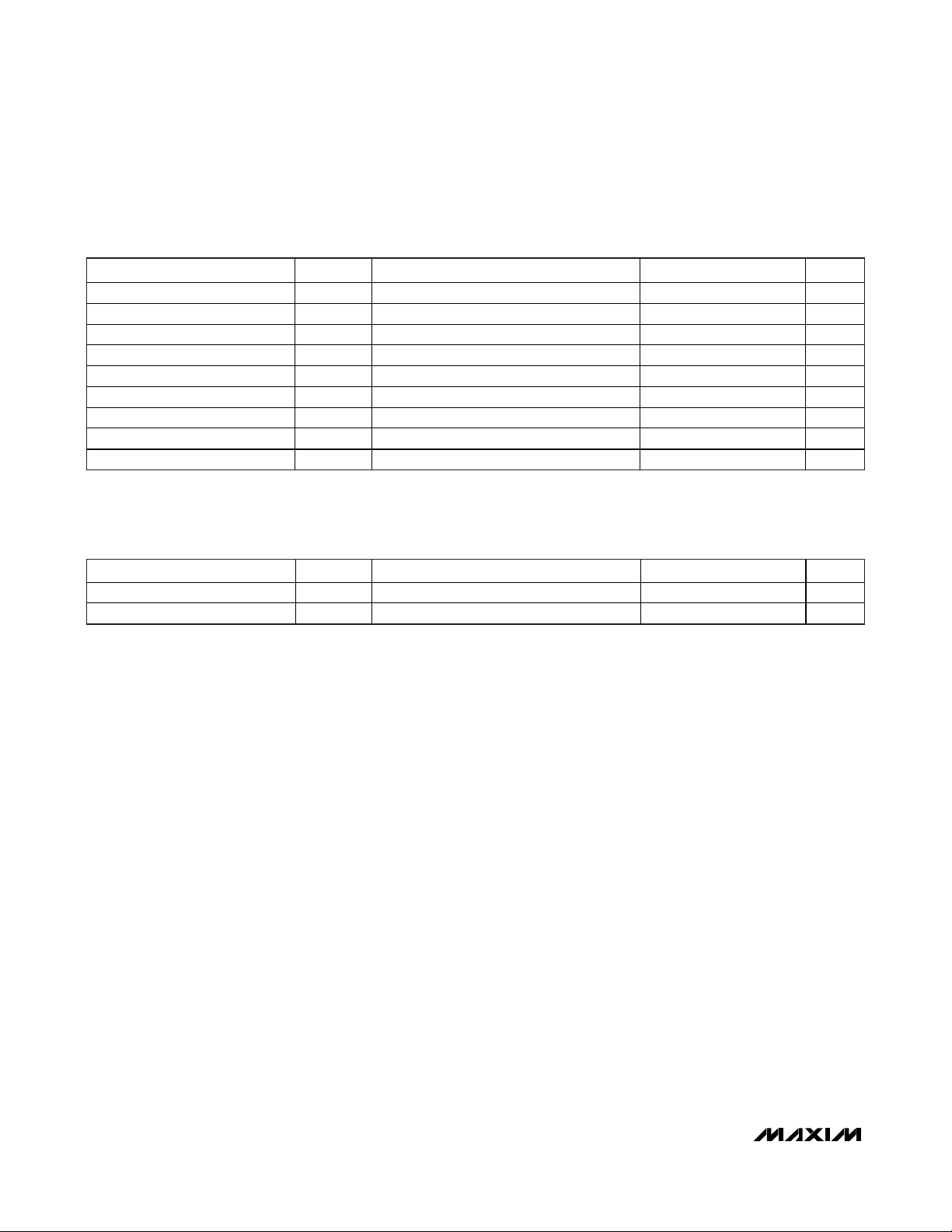

Pin Description

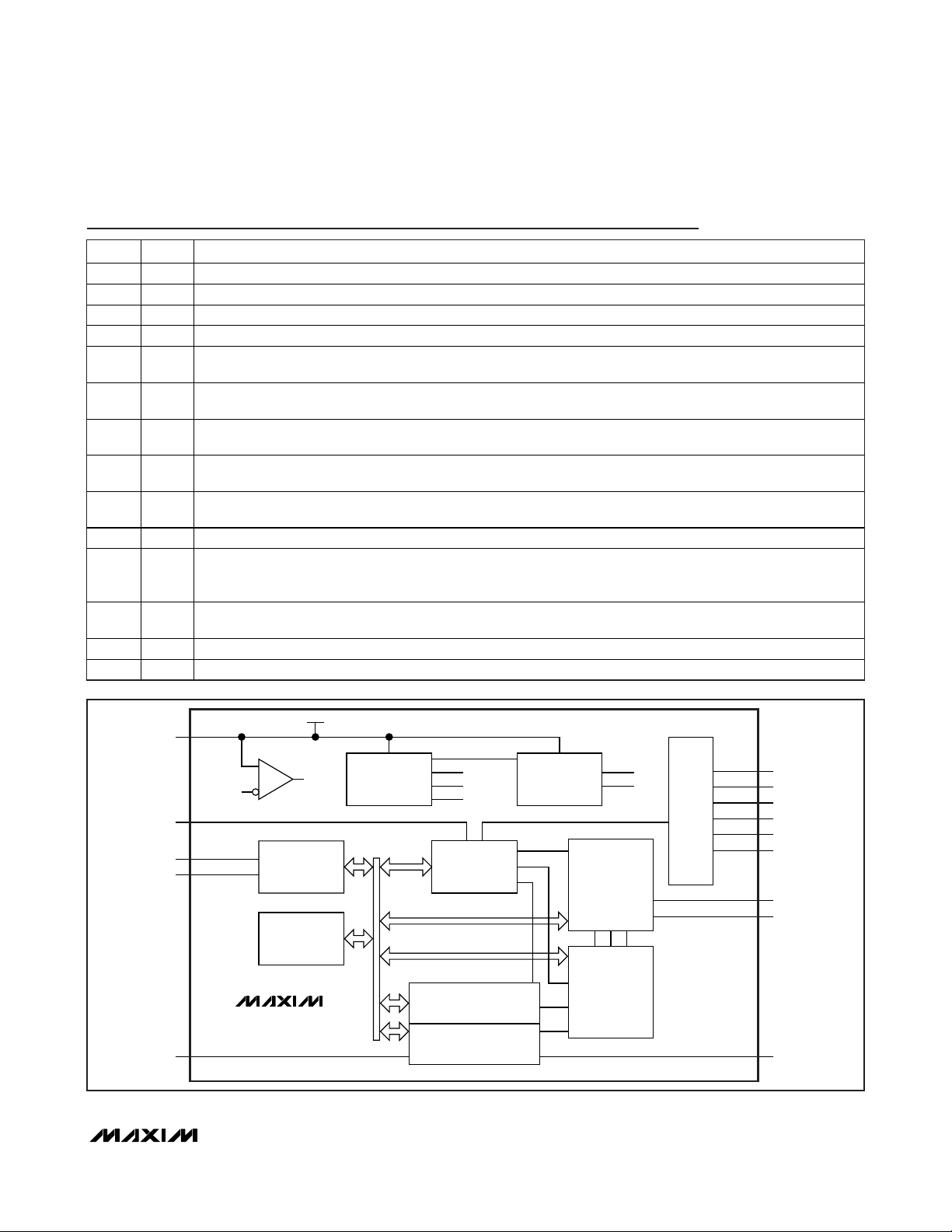

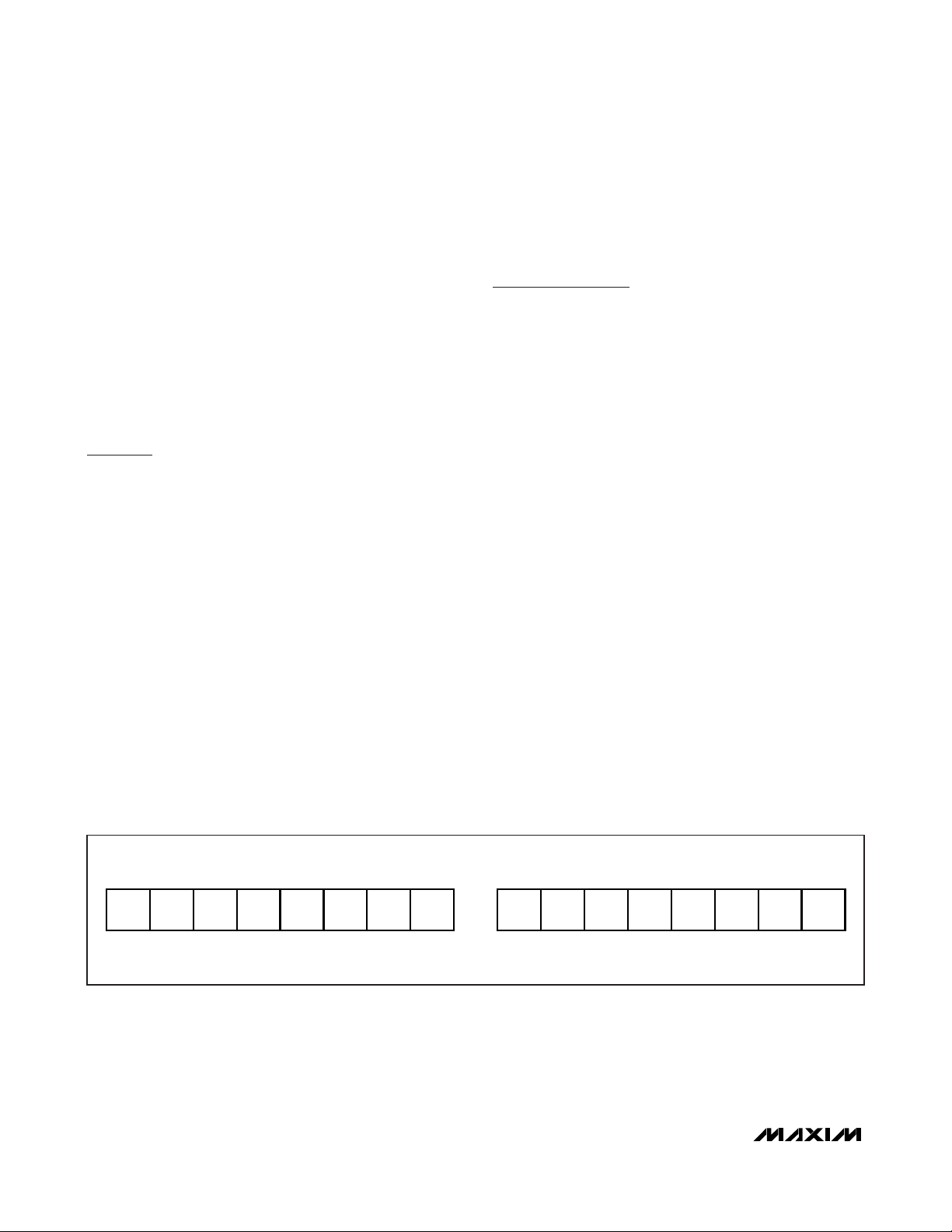

Figure 1. Block Diagram

PIN NAME FUNCTION

1 LED2 Di spla y Driver. Connect to an LED connected to VDD for display of relative pack capacity.

2 LED1 Display Driver. Connect to an LED connected to VDD for display of relative pack capacity.

3 DVSS Display Ground. Ground connection for the LED display drivers. Connect to VSS.

4 VDD Power-Supply Input. Connect to the positive terminal of the battery cel l through a decoupling networ k.

5 OVD

6 V

7 DQ

8 VMA

9 SNS

10 VIN Voltage Sense Input. The voltage of the battery cell is monitored through thi s input p in.

11 PIO

12 LED5

13 LED4 Displa y Driver. Connect to an LED connected to VDD for display of relative pack capacity.

14 LED3 Displa y Driver. Connect to an LED connected to VDD for display of relative pack capacity.

1-Wire Bus Speed Control. Input logic level selects the speed of the 1-Wire bus. Logic 1 selects overdrive (OVD)

and Logic 0 selects standard (STD) timing. On a multidrop bus, all devices must operate at the same speed.

Device Ground. Connect directl y to the negative terminal of the battery cel l. Connect the sen se resi stor

SS

between V

and SNS.

SS

Data Input/Output. 1-Wire data line, open-drain output driver. Connect thi s pin to the DATA terminal of the

battery pac k. This pin has a weak internal pulldown (I

) for sensing pack disconnection from host or charger.

PD

Voltage Measurement Active. Output is driven high before the start of a voltage conversion and driven low at

the end of the conversion cycle.

Sense Resistor Connection. Connect to the negative terminal of the battery pack. Connect the sense resistor

between V

and SNS.

SS

Programmable I/O Pin. Can be configured as input or output to monitor or control u ser-defined external

circuitry. Output driver is open drain. This pin has a weak internal pulldown (IPD). When configured as an input,

upon recognition of a rising edge, the fuel-gauge displa y is enab led.

Display Driver. Connect to an LED connected to V

for display of relative pack capacity. Leave floating in

DD

LED4 conf iguration.

V

DD

PIO

DQ

OVD

SNS

V

POR

EN

1-Wire

INTERFACE

EEPROM

STATUS

AND

CONTROL

ACCUMULATED

CURRENT

TIME BASEBIAS/VREF

LED

DRIVERS

TEMP

AND

VOLTAGE

ADC

RATE AND

TEMPERATURE

COMPENSATION

LED5

LED4

LED3

LED2

LED1

DV

VMA

V

IN

SS

DS2788

CURRENT ADC

15-BIT + SIGN

V

SS

Page 6

DS2788

Detailed Description

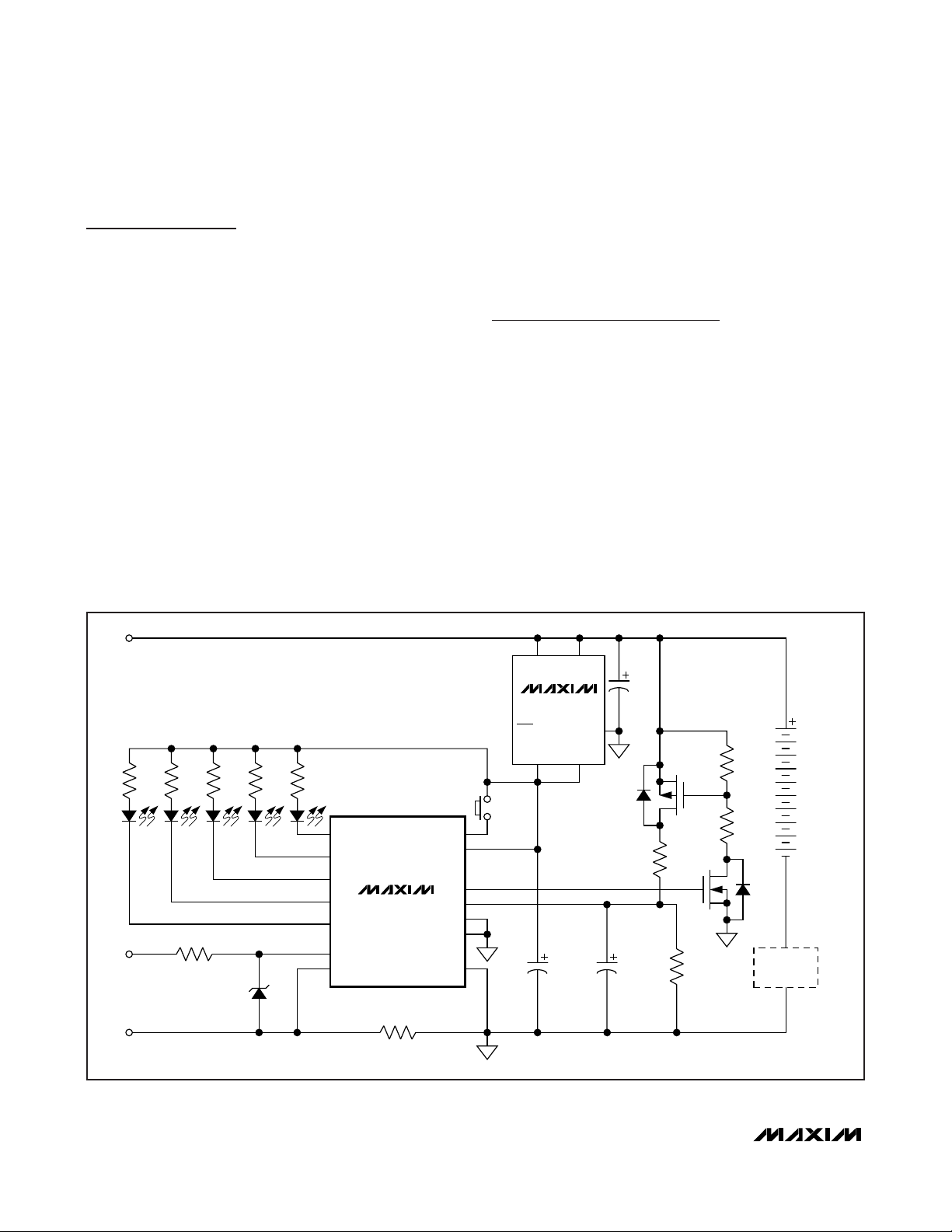

The DS2788 operates directly from 2.5V to 5.5V and

supports single-cell Li+ battery packs. As shown in

Figure 2, the DS2788 accommodates multicell applications by adding a trim resistor for calibration of an

external voltage-divider for VIN. NV storage is provided

for cell compensation and application parameters.

Host-side development of fuel-gauging algorithms is

eliminated. On-chip algorithms and convenient status

reporting of operating conditions reduce the serial

polling required of the host processor.

Additionally, 16 bytes of EEPROM memory are made

available for the exclusive use of the host system

and/or pack manufacturer. The additional EEPROM

memory can be used to facilitate battery lot and date

tracking and NV storage of system or battery usage

statistics.

A 1-Wire interface provides serial communication at the

standard 16kbps or overdrive 140kbps speeds, allowing access to data registers, control registers, and user

memory. A unique, factory-programmed, 64-bit regis-

tration number (8-bit family code + 48-bit serial number

+ 8-bit CRC) assures that no two parts are alike and

enables absolute traceability. The 1-Wire interface on

the DS2788 supports multidrop capability so that multiple slave devices can be addressed with a single pin.

Power Modes

The DS2788 has two power modes: ACTIVE and

SLEEP. On initial power-up, the DS2788 defaults to

ACTIVE mode. While in ACTIVE mode, the DS2788 is

fully functional with measurements and capacity estimation continuously updated. In SLEEP mode, the

DS2788 conserves power by disabling measurement

and capacity estimation functions, but preserves register contents. SLEEP mode is entered under two different conditions and an enable bit for each condition

makes entry into SLEEP optional. SLEEP mode can be

enabled using the power mode (PMOD) bit or the

undervoltage enable (UVEN) bit.

The PMOD type SLEEP is entered if the PMOD bit is set

and DQ is low for t

SLEEP

(2s nominal). The condition of

DQ low for t

SLEEP

can be used to detect a pack discon-

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

6 _______________________________________________________________________________________

Figure 2. Multicell Application Example

PK+

330Ω330Ω330Ω330Ω330Ω

LEDs

LED1

LED2

LED3

LED4

DS2788

LED5

DATA

PK-

150Ω

5.6V

DQ

SNS

R

SNS

20mΩ

VMA

OVD

DV

MAX6765TTLD2+

RST GND

B3F-1000

PIO

V

DD

V

IN

SS

V

SS

IN ENABLE

OUT TIMEOUT

BSS84

10μF 100kΩ

0.1μF

10kΩ

10kΩ

900kΩ

2N7002

0.1μF

PROTECTION

10-CELL

Li+ BATTERY

CIRCUIT

Page 7

nection or system shutdown, in which no charge or discharge current flows. A PMOD SLEEP condition transitions back to ACTIVE mode when DQ is pulled high.

The second option for entering SLEEP is an undervoltage condition. When the UVEN bit is set, the DS2788

transitions to SLEEP if the voltage on V

IN

is less than

V

SLEEP

(2.45V nominal) and DQ is stable at a low or

high logic level for t

SLEEP

. An undervoltage condition

occurs when a pack is fully discharged, where loading

on the battery should be minimized. UVEN SLEEP

relieves the battery of the I

ACTIVE

load until communi-

cation on DQ resumes.

Note: PMOD and UVEN SLEEP features must be disabled when a battery is charged on an external charger

that does not connect to the DQ pin. PMOD SLEEP can

be used if the charger pulls DQ high. UVEN SLEEP can

be used if the charger toggles DQ. The DS2788

remains in SLEEP and therefore does not measure or

accumulate current when a battery is charged on a

charger that fails to properly drive DQ.

Initiating Communication

in Sleep

When beginning communication with a DS2788 in

PMOD SLEEP, DQ must be pulled up first and then a

1-Wire reset pulse must be issued by the master. In

UVEN SLEEP, the procedure depends on the state of

DQ when UVEN SLEEP was entered. If DQ was low,

DQ must be pulled up and then a 1-Wire reset pulse

must be issued by the master as with PMOD SLEEP. If

DQ was high when UVEN SLEEP was entered, then the

DS2788 is prepared to receive a 1-Wire reset from the

master. In the first two cases with DQ low during

SLEEP, the DS2788

does not respond

to the first rising

edge of DQ with a presence pulse.

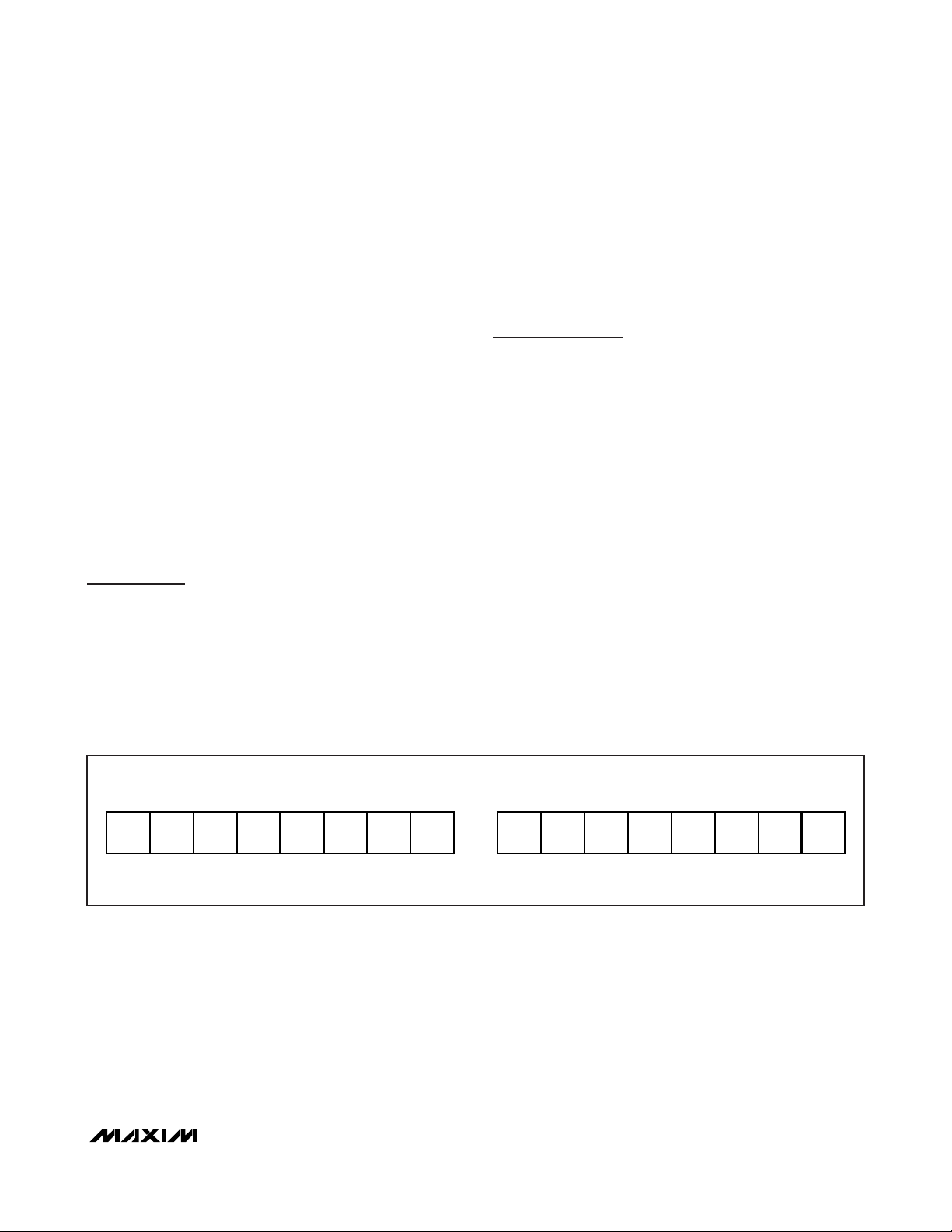

Voltage Measurement

Battery voltage is measured at the VINinput with

respect to VSSover a range of 0 to 4.992V, with a resolution of 4.88mV. The result is updated every 440ms

and placed in the Voltage (VOLT) register in two’s complement form. Voltages above the maximum register

value are reported at the maximum value; voltages

below the minimum register value are reported at the

minimum value. Figure 3 shows the format of the

Voltage register.

VINis usually connected to the positive terminal of a

single-cell Li+ battery by a 1kΩ resistor. The input

impedance is sufficiently large (15MΩ) to be connected

to a high-impedance voltage-divider in order to support

multiple-cell applications. The pack voltage should be

divided by the number of series cells to present a single-cell average voltage to the VINinput. In Figure 2,

the value of R can be up to 1MΩ without incurring significant error due to input loading. The VMA pin is driven high t

PRE

before the voltage conversion begins.

This allows an external switching element to enable the

voltage-divider, and allows settling to occur before the

start of the conversion.

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

_______________________________________________________________________________________ 7

Figure 3. Voltage Register Format

VOLT READ ONLY

MSB—ADDRESS 0Ch LSB—ADD RESS 0Dh

9

S 2

MSb LSb MSb LSb

“S”: SIGN BIT(S), “X”: RESERVED UNITS: 4.88mV

28 27 26 25 24 23 22 21 20 X X X X X

Page 8

DS2788

Temperature Measurement

The DS2788 uses an integrated temperature sensor to

measure battery temperature with a resolution of

0.125°C. Temperature measurements are updated

every 440ms and placed in the Temperature (TEMP)

register in two’s complement form. Figure 4 shows the

format of the Temperature register.

Current Measurement

In the ACTIVE mode of operation, the DS2788 continually measures the current flow into and out of the battery by measuring the voltage drop across a low-value

current-sense resistor, R

SNS

. The voltage-sense range

between SNS and V

SS

is ±51.2mV. The input linearly

converts peak signal amplitudes up to 102.4mV as long

as the continuous signal level (average over the conversion cycle period) does not exceed ±51.2mV. The

ADC samples the input differentially at 18.6kHz and

updates the Current (CURRENT) register at the completion of each conversion cycle.

The Current register is updated every 3.515s with the

current conversion result in two’s complement form.

Charge currents above the maximum register value are

reported at the maximum value (7FFFh = +51.2mV).

Discharge currents below the minimum register value

are reported at the minimum value (8000h = -51.2mV).

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

8 _______________________________________________________________________________________

Figure 4. Temperature Register Format

Figure 5. Current Register Format

TEMP READ ONLY

MSB—ADDRESS 0Ah LSB—ADDRESS 0Bh

9

S 2

MSb LSb MSb LSb

“S”: SIGN BIT(S), “X”: RESERVED UNITS: 0.125°C

28 27 26 25 24 23 22 21 20 X X X X X

CURRENT READ ONLY

MSB—ADDRESS 0Eh LSB—ADDRESS 0Fh

14

S 2

MSb LSb MSb LSb

“S”: SIGN BIT(S) UNITS: 1.5625μV/R

213 212 211 210 29 28 27 26 25 24 23 22 21 2

CURRENT RESOLUTION (1 LSB)

R

VSS- V

SNS

1.5625μV 78.13μA 104.2μA 156.3μA 312.5μA

20m 15m 10m 5m

SNS

0

SNS

Page 9

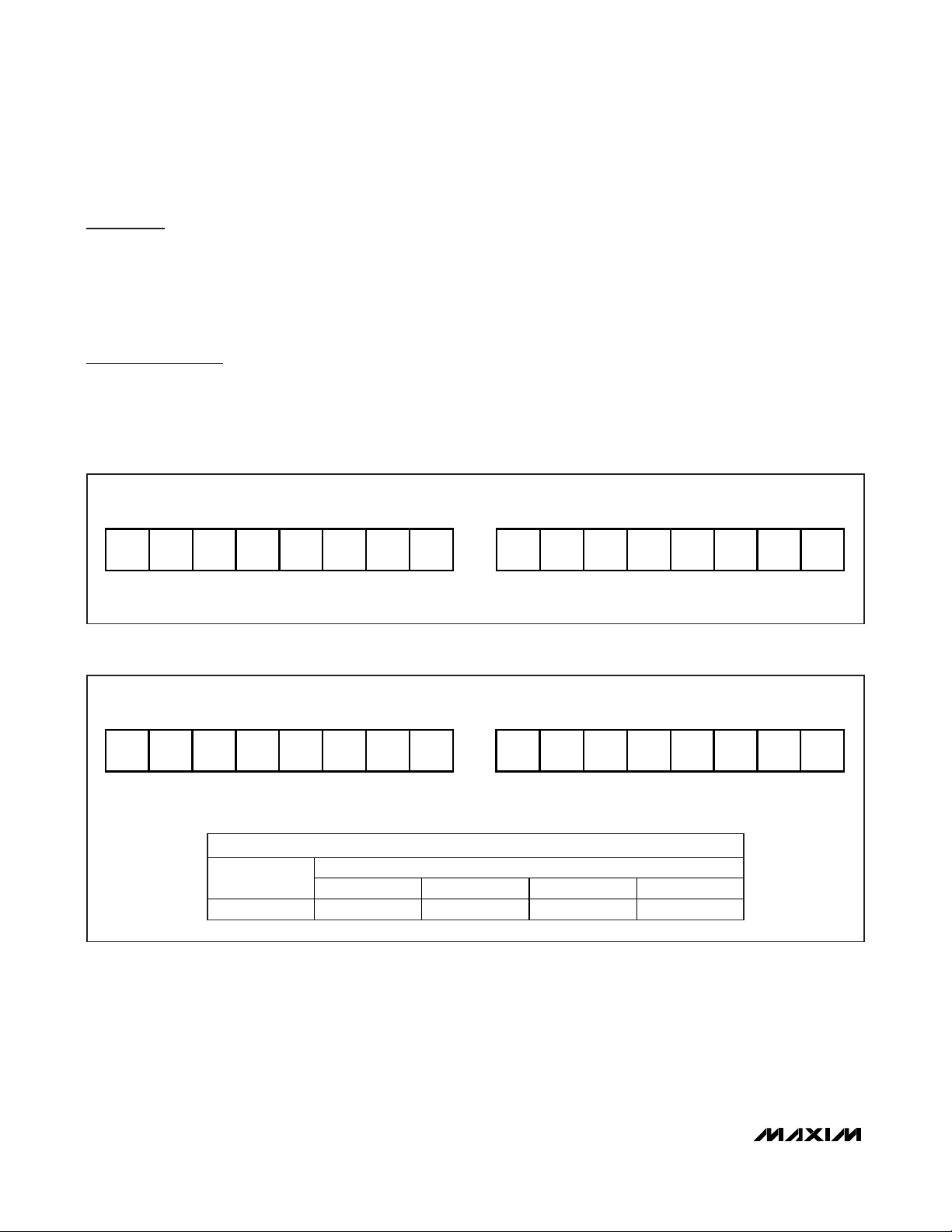

Average Current Measurement

The Average Current (IAVG) register reports an average current level over the preceding 28 seconds. The

register value is updated every 28s in two’s complement form, and is the average of the eight preceding

Current register updates. Figure 6 shows the format of

the Average Current register. Charge currents above

the maximum register value are reported at the maximum value (7FFFh = +51.2mV). Discharge currents

below the minimum register value are reported at the

minimum value (8000h = -51.2mV).

Current Offset Correction

Every 1024th conversion the ADC measures its input

offset to facilitate offset correction. Offset correction

occurs approximately once per hour. The resulting correction factor is applied to the subsequent 1023 measurements. During the offset correction conversion, the

ADC does not measure the sense resistor signal. A

maximum error of 1/1024 in the Accumulated Current

(ACR) register is possible; however, to reduce the

error, the current measurement made just prior to the

offset conversion is displayed in the Current register

and is substituted for the dropped current measurement in the current accumulation process. This results

in an accumulated current error due to offset correction

of less than 1/1024.

Current Offset Bias

The Current Offset Bias (COB) register allows a programmable offset value to be added to raw current measurements. The result of the raw current measurement

plus COB is displayed as the current measurement

result in the Current register, and is used for current

accumulation. COB can be used to correct for a static

offset error, or can be used to intentionally skew the current results and therefore the current accumulation.

COB allows read and write access. Whenever the COB

is written, the new value is applied to all subsequent

current measurements. COB can be programmed in

1.56µV steps to any value between +198.1µV and -

199.7µV. The COB value is stored as a two’s complement value in nonvolatile memory.

Current Measurement

Calibration

The DS2788’s current measurement gain can be

adjusted through the RSGAIN register, which is factorycalibrated to meet the data sheet specified accuracy.

RSGAIN is user accessible and can be reprogrammed

after module or pack manufacture to improve the current measurement accuracy. Adjusting RSGAIN can

correct for variation in an external sense resistor’s nominal value, and allows the use of low-cost, nonprecision

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

_______________________________________________________________________________________ 9

Figure 6. Average Current Register Format

Figure 7. Current Offset Bias Register Format

IAVG READ ONLY

MSB—ADDRESS 08h LSB—ADDRESS 09h

14

S 2

MSb LSb MSb LSb

“S”: SIGN BIT(S) UNITS: 1.5625μV/R

COB RW AND EE

ADDRESS 7Bh

S 2

MSb LSb

“S”: SIGN BIT(S) UNITS: 1.56μV/R

213 212 211 210 29 28 27 26 25 24 23 22 21 2

6

25 24 23 22 21 20

SNS

0

SNS

Page 10

DS2788

current-sense resistors. RSGAIN is an 11-bit value

stored in 2 bytes of the parameter EEPROM memory

block. The RSGAIN value adjusts the gain from 0 to

1.999 in steps of 0.001 (precisely 2

-10

). The user must

program RSGAIN cautiously to ensure accurate current

measurement. When shipped from the factory, the gain

calibration value is stored in two separate locations in

the parameter EEPROM block: RSGAIN, which is reprogrammable, and FRSGAIN, which is read only. RSGAIN

determines the gain used in the current measurement.

The read-only FRSGAIN (address B0h and B1h) is provided to preserve the factory value only and is not used

in the current measurement.

Sense Resistor Temperature

Compensation

The DS2788 is capable of temperature compensating

the current-sense resistor to correct for variation in a

sense resistor’s value over temperature. The DS2788 is

factory programmed with the sense resistor temperature

coefficient, RSTC, set to zero, which turns off the temperature compensation function. RSTC is user accessible and can be reprogrammed after module or pack

manufacture to improve the current accuracy when

using a high temperature coefficient current-sense

resistor. RSTC is an 8-bit value stored in the parameter

EEPROM memory block. The RSTC value sets the temperature coefficient from 0 to +7782ppm/°C in steps of

30.5ppm/°C. The user must program RSTC cautiously to

ensure accurate current measurement.

Temperature compensation adjustments are made

when the Temperature register crosses 0.5°C boundaries. The temperature compensation is most effective

with the resistor placed as close as possible to the V

SS

terminal to optimize thermal coupling of the resistor to

the on-chip temperature sensor. If the current shunt is

constructed with a copper PCB trace, run the trace

under the DS2788 package if possible.

Current Accumulation

Current measurements are internally summed, or accumulated, at the completion of each conversion period

with the results displayed in the ACR. The accuracy of

the ACR is dependent on both the current measurement and the conversion time base. The ACR has a

range of 0 to 409.6mVh with an LSb (least significant

bit) of 6.25µVh. Additional read-only registers (ACRL)

hold fractional results of each accumulation to avoid

truncation errors. Accumulation of charge current

above the maximum register value is reported at the

maximum register value (7FFFh); conversely, accumulation of discharge current below the minimum register

value is reported at the minimum value (8000h).

Read and write access is allowed to the ACR. The ACR

must be written MSB (most significant byte) first, then

LSB (least significant byte). The write must be completed within 3.515s (one ACR register update period). A

write to the ACR forces the ADC to perform an offset

correction conversion and update the internal offset

correction factor. Current measurement and accumulation begins with the second conversion following a write

to the ACR. Writing the ACR clears the fractional values

in ACRL. ACR’s format is shown in Figure 8, and

ACRL’s format is shown in Figure 9.

To preserve the ACR value in case of power loss, the

ACR value is backed up to EEPROM. The ACR value is

recovered from EEPROM on power-up. See the memory map in Table 3 for specific address location and

backup frequency.

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

10 ______________________________________________________________________________________

Figure 8. Accumulated Current Register (ACR) Format

ACR R/W AND EE

MSB—ADDRESS 10h LSB—ADDRESS 11h

15

214 213 212 211 210 29 28 27 26 25 24 23 22 21 2

2

MSb LSb MSb LSb

UNITS: 6.25μVh/R

0

SNS

Page 11

Current Blanking

The current blanking feature modifies the current measurement result prior to being accumulated in the ACR.

Current blanking occurs conditionally when a current

measurement (raw current + COB) falls in one of two

defined ranges. The first range prevents charge currents less than 100µV from being accumulated. The

second range prevents discharge currents less than

25µV in magnitude from being accumulated. Chargecurrent blanking is always performed, however, discharge-current blanking must be enabled by setting

the NBEN bit in the Control register. See the register

description for additional information.

Accumulation Bias

The Accumulation Bias (AB) register allows an arbitrary

bias to be introduced into the current-accumulation

process. The AB can be used to account for currents

that do not flow through the sense resistor, estimate

currents too small to measure, estimate battery self-discharge, or correct for static offset of the individual

DS2788 device. The AB register allows a user-programmed positive or negative constant bias to be

included in the current accumulation process. The

user-programmed two’s complement value, with bit

weighting the same as the Current register, is added to

the ACR once per current conversion cycle. The AB

value is loaded on power-up from EEPROM memory.

Figure 10 shows the format of the AB register.

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

______________________________________________________________________________________ 11

Figure 9. Fractional/Low Accumulated Current Register (ACRL) Format

Figure 10. Accumulation Bias Register Formats

ACRL READ ONLY

MSB—ADDRESS 12h LSB—ADDRESS 13h

11

2

210 29 28 27 26 25 24 23 22 21 20 X X X X

MSb LSb MSb LSb

“X”: reserved UNITS: 1.526nVHr/R

ACR LSb

R

R

SNS

SNS

VSS- V

SNS

6.25μVh 312.5μAh 416.7μAh 625μAh 1.250mAh

VSS- V

SNS

±409.6mVh ±20.48Ah ±27.30Ah ±40.96Ah ±81.92Ah

AB EE

ADDRESS 61h

20m 15m 10m 5m

ACR RANGE

20m 15m 10m 5m

SNS

6

S 2

MSb LSb

“S”: SIGN BIT(S) UNITS: 1.5625μV/R

25 24 23 22 21 20

SNS

Page 12

DS2788

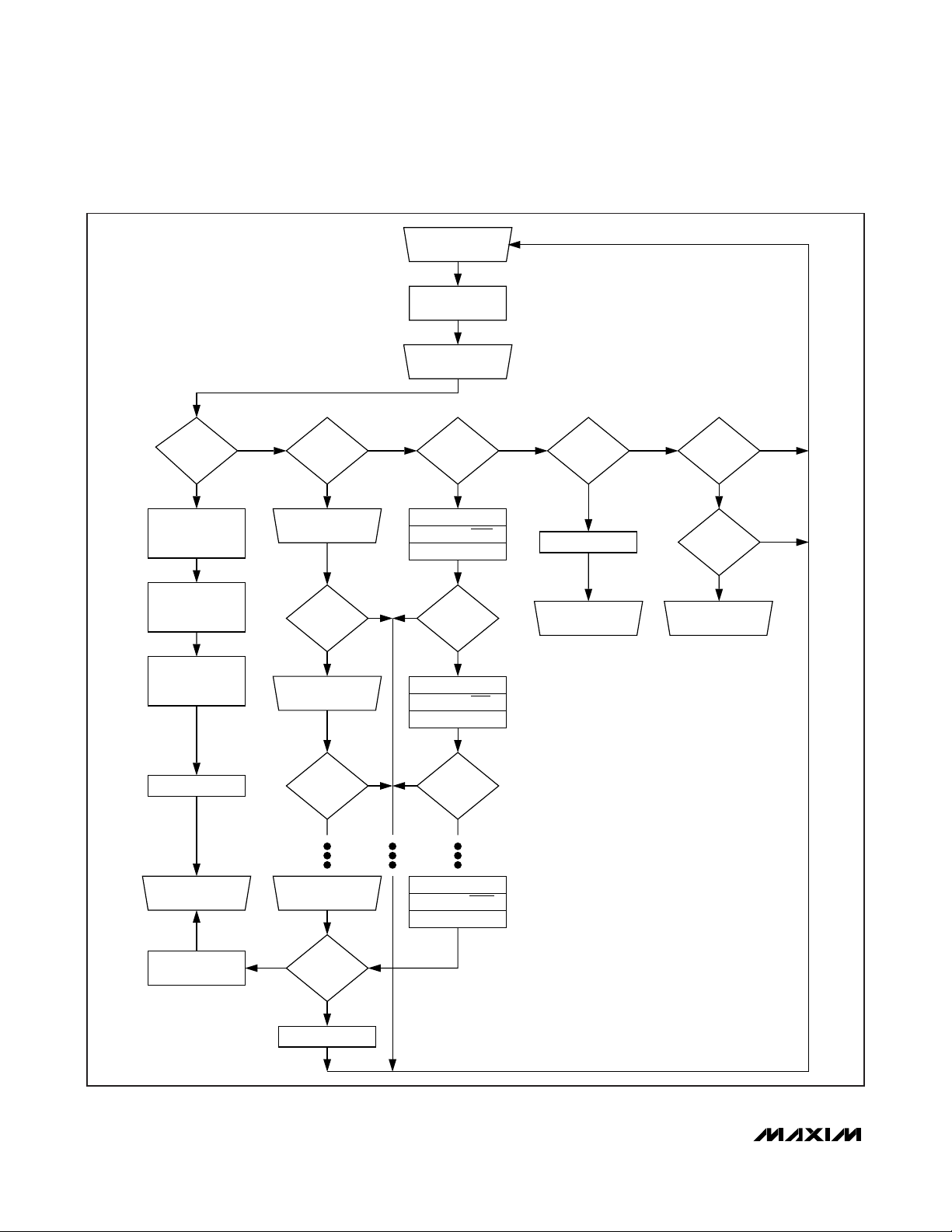

Capacity Estimation Algorithm

Remaining capacity estimation uses real-time measured values and stored parameters describing the cell

characteristics and application operating limits. Figure

11 describes the algorithm inputs and outputs.

Modeling Cell Stack

Characteristics

To achieve reasonable accuracy in estimating remaining capacity, the cell stack performance characteristics

over temperature, load current, and charge termination

point must be considered. Since the behavior of Li+

cells is nonlinear, these characteristics must be included in the capacity estimation to achieve an acceptable

level of accuracy in the capacity estimation. The

FuelPack™ method used in the DS2788 is described in

general in Application Note 131:

Lithium-Ion Cell Fuel

Gauging with Dallas Semiconductor Battery Monitor

ICs

. To facilitate efficient implementation in hardware, a

modified version of the method outlined in AN131 is

used to store cell characteristics in the DS2788. Full

and empty points are retrieved in a lookup process that

retraces piece-wise linear model consisting of three

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

12 ______________________________________________________________________________________

Figure 11. Top Level Algorithm Diagram

FuelPack is a trademark of Maxim Integrated Products, Inc.

VOLTAGE (R) FULL FULL(T) (R)

TEMPERATURE (R)

CURRENT (R)

ACCUMULATED

CURRENT (ACR) (RW)

AVERAGE CURRENT (R)

CELL PARAMETERS

16 BYTES

(EEPROM)

CAPACITY LOOKUP

AVAILABLE CAPACITY CALCULATION

ACR HOUSEKEEPING

AGE ESTIMATOR

LEARN FUNCTION

ACTIVE EMPTY AE(T) (R)

STANDBY EMPTY SE(T) (R)

REMAINING ACTIVE ABSOLUTE

CAPACITY (RAAC) mAh (R)

REMAINING STANDBY ABSOLUTE

CAPACITY (RSAC) mAh (R)

REMAINING ACTIVE RELATIVE

CAPACITY (RARC) % (R)

REMAINING STANDBY RELATIVE

CAPACITY (RSRC) % (R)

AGING CAPACITY (AC)

(2 BYTES EE)

AGE SCALAR (AS)

(1-BYTE EE)

SENSE RESISTOR PRIME (RSNSP)

(1 -BYTE EE)

CHARGE VOLTAGE (VCHG)

(1-BYTE EE)

MINIMUM CHARGE CURRENT (IMIN)

(1-BYTE EE)

ACTIVE EMPTY VOLTAGE (VAE)

(1-BYTE EE)

ACTIVE EMPTY CURRENT (IAE)

(1-BYTE EE)

Page 13

curves named full, active empty, and standby empty.

Each model curve is constructed with five line segments, numbered 1 through 5. Above +50°C, the segment 5 model curves extend infinitely with zero slope,

approximating the nearly flat change in capacity of Li+

cells at temperatures above +50°C. Segment 4 of each

model curves originates at +50°C on its upper end and

extends downward in temperature to +25°C. Segment

3 joins with segment 2, which in turn joins with segment

1. Segment 1 of each model curve extends from the

junction with segment 2 to infinitely colder temperatures. Segment slopes are stored as µVh ppm change

per °C. The two junctions or breakpoints that join the

segments (labeled TBP12 and TBP23 in Figure 12) are

programmable in 1°C increments from -128°C to

+25°C. They are stored in two’s complement format,

TBP23 at 7Ch, and TBP12 at 7Dh. The slope or derivative for segments 1, 2, 3, and 4 are also programmable.

Full: The full curve defines how the full point of a given

cell stack depends on temperature for a given charge

termination. The charge termination method used in the

application is used to determine the table values. The

DS2788 reconstructs the full line from cell characteristic

table values to determine the full capacity of the battery

at each temperature. Reconstruction occurs in onedegree temperature increments. Full values are stored

as ppm change per °C. For example, if a cell had a

nominal capacity of 1214mAh at +50°C, a full value of

1199mAh at +25°C, and 1182mAh at 0°C (TBP23), the

slope for segment 3 would be:

((1199mAh - 1182mAh) / (1214mAh / 1M)) /

(25°C - 0°C) = 560ppm/°C

1 LSB of the slope registers equals 61ppm so the full

segment 3 slope register (location 0x6Dh) would be

programmed with a value of 0x09h. Each Slope register

has a dynamic range 0ppm to 15555ppm.

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

______________________________________________________________________________________ 13

Figure 12. Cell Model Example Diagram

SEGMENT 1

100%

SEGMENT 2

SEGMENT 3 SEGMENT 4

SEGMENT 5

DERIVATIVE

(ppm/°C)

ACTIVE

EMPTY

FULL

STANDBY

EMPTY

CELL

CELL

CHARACTERIZATION

CHARACTERIZATION

+50°C+25°CTBP23TBP12

Page 14

DS2788

Active Empty: The active empty curve defines the temperature variation in the empty point of the discharge

profile based on a high-level load current (one that is

sustained during a high-power operating mode) and

the minimum voltage required for system operation.

This load current is programmed as the active empty

current (IAE), and should be a 3.5s average value to

correspond to values read from the Current register

and the specified minimum voltage, or active empty

voltage (VAE) should be a 250ms average to correspond to values read from the Voltage register. The

DS2788 reconstructs the active empty line from cell

characteristic table values to determine the active

empty capacity of the battery at each temperature.

Reconstruction occurs in one-degree temperature

increments. Active empty segment slopes are stored

the same as described for the full segments.

Standby Empty: The standby empty curve defines the

temperature variation in the empty point in the discharge defined by the application standby current and

the minimum voltage required for standby operation.

Standby empty represents the point that the battery

can no longer support a subset of the full application

operation, such as memory data retention or organizer

functions on a wireless handset. Standby empty segment slopes are stored the same as described for the

full segments.

The standby load current and voltage are used for

determining the cell characteristics but are not programmed into the DS2788. The DS2788 reconstructs

the standby empty line from cell characteristic table

values to determine the standby empty capacity of the

battery at each temperature. Reconstruction occurs in

one-degree temperature increments.

Cell Stack Model Construction

The model is constructed with all points normalized to

the fully charged state at +50°C. The cell parameter

EEPROM block stores the initial values, the +50°C full

value in mVh units, and the +50°C active empty value

as a fraction of the +50°C value. Standby empty at

+50°C is by definition zero and therefore no storage is

required. The slopes (derivatives) of the 4 segments for

each model curve are also stored in the cell parameter

EEPROM block along with the break point temperatures

of each segment. Table 1 shows an example of data

stored in this manner.

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

14 ______________________________________________________________________________________

Table 1. Example Cell Characterization Table (Normalized to +50°C)

Figure 13. Lookup Function Diagram

Manufacturer’s Rated Cell Capacity: 1220mAh

Charge Voltage: 4.2V Charge Current: 500mA Termination Current: 50mA

Active Empty (V, I): 3.0V, 500mA Standby Empty (V, I): 3.0V, 4mA

Sense Resistor: 0.020

SEGMENT BR EAKPOINTS

TBP12 = -12°C

TBP23 = 0°C

CALCULATED VALUE

+50°C NOMINAL

(mAh)

SEGMENT 1

(ppm/°C)

SEGMENT 2

(ppm/°C)

SEGMENT 3

(ppm/°C)

SEGMENT 4

(ppm/°C)

Ful l 1214 488 549 1587 2686

Active Empty 854 1526 2686 3113

Standby Empty 244 183 916 244

CELL MODEL

PARAMETERS

15 BYTES

(EEPROM)

TEMPERATURE

LOOKUP

FUNCTION

FULL(T)

AE(T)

SE(T)

Page 15

Application Parameters

In addition to cell model characteristics, several application parameters are needed to detect the full and

empty points, as well as calculate results in mAh units.

Sense Resistor Prime (RSNSP)

RSNSP stores the value of the sense resistor for use in

computing the absolute capacity results. The value is

stored as a 1-byte conductance value with units of

mhos. RSNSP supports resistor values of 1Ω to

3.922mΩ. RSNSP is located in the parameter EEPROM

block.

Charge Voltage (VCHG)

VCHG stores the charge voltage threshold used to

detect a fully charged state. The value is stored as a

1-byte voltage with units of 19.52mV and can range

from 0 to 4.978V. VCHG should be set marginally less

than the cell voltage at the end of the charge cycle to

ensure reliable charge termination detection. VCHG is

located in the parameter EEPROM block.

Minimum Charge Current (IMIN)

IMIN stores the charge current threshold used to detect

a fully charged state. The value is stored as a 1-byte

value with units of 50µV and can range from 0 to

12.75mV. Assuming R

SNS

= 20mΩ, IMIN can be programmed from 0 to 637.5mA in 2.5mA steps. IMIN

should be set marginally greater than the charge current at the end of the charge cycle to ensure reliable

charge termination detection. IMIN is located in the

parameter EEPROM block.

Active Empty Voltage (VAE)

VAE stores the voltage threshold used to detect the

active empty point. The value is stored in 1 byte with

units of 19.52mV and can range from 0 to 4.978V. VAE

is located in the parameter EEPROM block.

Active Empty Current (IAE)

IAE stores the discharge current threshold used to

detect the active empty point. The unsigned value represents the magnitude of the discharge current and is

stored in 1 byte with units of 200µV and can range from

0 to 51.2mV. Assuming R

SNS

= 20mΩ, IAE can be programmed from 0mA to 2550mA in 10mA steps. IAE is

located in the parameter EEPROM block.

Aging Capacity (AC)

AC stores the rated battery capacity used in estimating

the decrease in battery capacity that occurs in normal

use. The value is stored in 2 bytes in the same units as

the ACR (6.25µVh). Setting AC to the manufacturer’s

rated capacity sets the aging rate to approximately

2.4% per 100 cycles of equivalent full capacity discharges. Partial discharge cycles are added to form

equivalent full capacity discharges. The default estimation results in 88% capacity after 500 equivalent cycles.

The estimated aging rate can be adjusted by setting

AC to a different value than the cell manufacturer’s rating. Setting AC to a lower value, accelerates the estimated aging. Setting AC to a higher value retards the

estimated aging. AC is located in the parameter

EEPROM block.

Age Scalar (AS)

AS adjusts the capacity estimation results downward to

compensate for cell aging. AS is a 1-byte value that

represents values between 49.2% and 100%. The LSB

is weighted at 0.78% (precisely 2-7). A value of 100%

(128 decimal or 80h) represents an unaged battery. A

value of 95% is recommended as the starting AS value

at the time of pack manufacture to allow learning a larger capacity on batteries that have an initial capacity

greater than the nominal capacity programmed in the

cell characteristic table. AS is modified by the cyclecount-based age estimation introduced above and by

the capacity learn function. The host system has read

and write access to AS, however caution should be

exercised when writing AS to ensure that the cumulative aging estimate is not overwritten with an incorrect

value. Typically, it is not necessary for the host to write

AS because the DS2788 automatically saves AS to

EEPROM on a periodic basis. (See the

Memory

section

for details.) The EEPROM-stored value of AS is recalled

on power-up.

Capacity Estimation Utility

Functions

Aging Estimation

As previously discussed, the AS register value is

adjusted occasionally based on cumulative discharge.

As the ACR register decrements during each discharge

cycle, an internal counter is incremented until equal to

32 times AC. AS is then decremented by one, resulting

in a decrease in the scaled full battery capacity of

0.78%. See the AC register description for recommendations on customizing the age estimation rate.

Learn Function

Since Li+ cells exhibit charge efficiencies near unity, the

charge delivered to a Li+ cell from a known empty point

to a known full point is a dependable measure of the

cell capacity. A continuous charge from empty to full

results in a “learn cycle.” First, the active empty point

must be detected. The learn flag (LEARNF) is set at this

point. Second, once charging starts, the charge must

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

______________________________________________________________________________________ 15

Page 16

DS2788

continue uninterrupted until the battery is charged to

full. Upon detecting full, LEARNF is cleared, the chargeto-full (CHGTF) flag is set, and the age scalar (AS) is

adjusted according to the learned capacity of the cell.

ACR Housekeeping

The ACR register value is adjusted occasionally to

maintain the coulomb count within the model curve

boundaries. When the battery is charged to full (CHGTF

set), the ACR is set equal to the age-scaled full lookup

value at the present temperature. If a learn cycle is in

progress, correction of the ACR value occurs after the

age scalar (AS) is updated.

When an empty condition is detected (AEF or LEARNF

set), the ACR adjustment is conditional. If AEF is set

and LEARNF is not, the active empty point was not

detected and the battery is likely below the active

empty capacity of the model. The ACR is set to the

active empty model value only if it is greater than the

active empty model value. If LEARNF is set, the battery

is at the active empty point and the ACR is set to the

active empty model value.

Full Detect

Full detection occurs when the voltage (VOLT) readings

remain continuously above the VCHG threshold for the

period between two average current (IAVG) readings,

where both IAVG readings are below IMIN. The two

consecutive IAVG readings must also be positive and

nonzero. This ensures that removing the battery from

the charger does not result in a false detection of full.

Full detect sets the charge-to-full (CHGTF) bit in the

Status (STATUS) register.

Active Empty Point Detect

Active empty point detection occurs when the Voltage

register drops below the VAE threshold and the two

previous current readings are above IAE. This captures

the event of the battery reaching the active empty

point. Note that the two previous current readings must

be negative and greater in magnitude than IAE, that is,

a larger discharge current than specified by the IAE

threshold. Qualifying the voltage level with the discharge rate ensures that the active empty point is not

detected at loads much lighter than those used to construct the model. Also, active empty must not be

detected when a deep discharge at a very light load is

followed by a load greater than IAE. Either case would

cause a learn cycle on the following charge-to-full to

include part of the standby capacity in the measurement of the active capacity. Active empty detection

sets the learn flag bit (LEARNF) in STATUS.

Result Registers

The DS2788 processes measurement and cell characteristics on a 3.5s interval and yields seven result registers. The result registers are sufficient for direct display

to the user in most applications. The host system can

produce customized values for system use or user display by combining measurement, result, and user

EEPROM values.

FULL(T): The full capacity of the battery at the present

temperature is reported normalized to the +50°C full

value. This 15-bit value reflects the cell model full value

at the given temperature. FULL(T) reports values

between 100% and 50% with a resolution of 61ppm

(precisely 2

-14

). Though the register format permits values greater than 100%, the register value is clamped to

a maximum value of 100%.

Active Empty, AE(T): The active empty capacity of the

battery at the present temperature is reported normalized to the +50°C full value. This 13-bit value reflects

the cell model active empty at the given temperature.

AE(T) reports values between 0% and 49.8% with a

resolution of 61ppm (precisely 2

-14

).

Standby Empty, SE(T): The standby empty capacity of

the battery at the present temperature is reported normalized to the +50°C full value. This 13-bit value

reflects the cell model standby empty value at the current temperature. SE(T) reports values between 0% and

49.8% with a resolution of 61ppm (precisely 2

-14

).

Remaining Active Absolute Capacity, RAAC [mAh]:

RAAC reports the capacity available under the current

temperature conditions at the active empty discharge

rate (IAE) to the active empty point in absolute units of

milliamp/hours (mAh). RAAC is 16 bits. See Figure 14.

Remaining Standby Absolute Capacity, RSAC [mAh]:

RSAC reports the capacity available under the current

temperature conditions at the standby empty discharge

rate (ISE) to the standby empty point capacity in

absolute units of mAh. RSAC is 16 bits. See Figure 15.

Remaining Active Relative Capacity, RARC [%]:

RARC reports the capacity available under the current

temperature conditions at the active empty discharge

rate (IAE) to the active empty point in relative units of

percent. RARC is 8 bits. See Figure 16.

Remaining Standby Relative Capacity, RSRC [%]:

RSRC reports the capacity available under the current

temperature conditions at the standby empty discharge

rate (ISE) to the standby empty point capacity in relative units of percent. RSRC is 8 bits. See Figure 17.

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

16 ______________________________________________________________________________________

Page 17

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

______________________________________________________________________________________ 17

Figure 14. Remaining Active Absolute Capacity Register Format

Figure 15. Remaining Standby Absolute Capacity Register Format

Figure 16. Remaining Active Relative Capacity Register Format

Figure 17. Remaining Standby Relative Capacity Register Format

RAAC READ ONLY

MSB—ADDRESS 02h LSB—ADDRESS 03h

15

214 213 212 211 210 29 28 27 26 25 24 23 22 21 2

2

MSb LSb MSb LSb

UNITS: 1.6mAhr

RSAC READ ONLY

MSB—ADDRESS 04h LSB—ADDRESS 05h

14

213 212 211 210 29 28 27 26 25 24 23 22 21 2

2

LSb MSb LSb

UNITS: 1.6mAhr

RARC RE AD ONLY

ADDRESS 06h

7

2

MSb LSb

UNITS: 1%

26 25 24 23 22 21 20

0

0

RSRC READ ONLY

ADDRESS 07h

7

2

MSb LSb

UNITS: 1%

26 25 24 23 22 21 20

Page 18

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

18 ______________________________________________________________________________________

The Status register contains bits that report the device

status. The bits can be set internally by the DS2788.

The CHGTF, AEF, SEF, LEARNF, and VER bits are

read-only bits that can be cleared by hardware. The

UVF and PORF bits can only be cleared through the

1-Wire interface.

*This bit can be set by the DS2788, and can only be cleared through the 1-Wire interface.

**LEARNF is only cleared if ACR reaches 0 after VOLT < VAE.

Figure 18. Status Register Format

Calculation of Results

RAAC [mAh] = (ACR[mVh] - AE(T) × FULL50[mVh]) × RSNSP [mhos]

RSAC [mAh] = (ACR[mVh] - SE(T) × FULL50[mVh]) × RSNSP [mhos]

RARC [%] = 100% × (ACR[mVh] - AE(T) × FULL50[mVh]) / {(AS × FULL(T) - AE(T)) × FULL50[mVh]}

RSRC [%] = 100% × (ACR[mVh] - SE(T) × FULL50[mVh]) / {(AS × FULL(T) - SE(T)) × FULL50[mVh]}

Status Register

ADDRESS 01h BIT DEFINITION

Field Bit Format Allowable Values

Charge Termination F lag

CHGTF 7 Read Only

AEF 6 Read Only

Set to 1 when: (VOLT > VCHG) and (0 < IAVG < IMIN) continuously for a period

between two IAVG register updates (28s to 56s).

Cleared to 0 when: RA RC < 90%

Active Empty Flag

Set to 1 when: VOLT < VAE

Cleared to 0 when: RA RC > 5%

Standby Empty Flag

SEF 5 Read Only

LEARNF 4 Read Only

Reserved 3 Read Only Undefined

UVF 2 Read/Write*

PORF 1 Read/Write*

Reserved 0 Read Only Undefined

Set to 1 when: RSRC < 10%

Cleared to 0 when: RSRC > 15%

Learn Flag—When set to 1, a charge cycle can be used to learn battery capacity.

Set to 1 when: (VOLT falls from above VAE to below VAE) and (CURRENT > IAE)

Cleared to 0 when: (CHGTF = 1) or (CURRENT < 0) or (ACR = 0**) or (ACR

written or recalled from EEPROM) or (SLEEP Entered).

Undervoltage Flag

Set to 1 when: VOLT < V

Cleared to 0 by: User

Power-On Reset Flag—Useful for reset detection, see text below.

Set to 1 when: upon power-up by hardware.

Cleared to 0 by: User

SLEEP

Page 19

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

______________________________________________________________________________________ 19

All Control register bits are read and write accessible.

The Control register is recalled from parameter

EEPROM memory at power-up. Register bit values can

be modified in shadow RAM after power-up. Shadow

RAM values can be saved as the power-up default values by using the Copy Data command.

Control Register

Figure 19. Control Register Format

ADDRESS 60h BIT DEFINITION

Field Bit Format Allowable Values

Negative Blan king Enable

NBEN 7 Read/Write

UVEN 6 Read/Write

PMOD 5 Read/Write

RNAOP 4 Read/Write

DC 3 Read/Write

Reserved 0:2 Undefined

0: Allows negative current readings to always be accumulated.

1: Enables blanking of negative current readings up to -25μV.

Undervoltage SLEEP Enable

0: Disables transition to SLEEP mode based on V

1: Enabl es transition to SLEEP mode if V

logic level for t

Power Mode Enable

0: Disables trans ition to SLEEP mode based on DQ logic state.

1: Enables tran sit io n to SLEEP mode if DQ is at a logic- low for t

Read Net Address Op Code

0: Read net addres s command = 33h.

1: Read net addres s command = 39h.

Display Control

0: Enables LED5 fuel-gauge display.

1: Enables LED4 fuel-gauge display.

SLEEP.

voltage.

IN

< V

IN

and DQ are stable at either

SLEE P

SLEEP.

Page 20

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

20 ______________________________________________________________________________________

Fuel-Gauge Display

The DS2788 provides five open-drain drivers capable

of sinking 30mA. These can be used to directly drive

either 4 or 5 LEDs to display Remaining Active Relative

Pack Capacity (RARC). The LEDs are enabled when

the PIO is configured as an input and the PIO pin recognizes a rising edge. The display lights for 4s and

then is disabled regardless of the state of the PIO pin.

Further presses or releases of the button connected to

the PIO pin after the 100ms debounce delay causes

the display to be enabled (the display does not light

continuously if the button is held down).

Table 2 summarizes how the LEDs are enabled. B signifies that the LED is blinking at a 50% duty cycle, 0.5s

on, 0.5s off, to be repeated for the display time of 4s. L

signifies the pin is pulled low, and the LED is lit. X signifies the pin is high impedance, and the LED is unlit.

Table 2. Fuel-Gauge Display Summary

Special Feature Register

Figure 20. Special Feature Register Format

All Special Feature register bits are read and write accessible, with default values specified in each bit definition.

ADDRESS 15h BIT DEFINITION

Field Bit Format Allowable Values

Reserved 1:7 Undefined

PIO Sense and Control

Read values:

0: PIO pin V

1: PIO pin V

PIOSC 0 Read/Write

Write va lue s:

0: Activates PIO pin open-drain output driver, forcing the PIO pin low.

1: Disables the output dri ver, allowing the PIO pin to be pulled high or used as

an input.

Power-up and SLEEP mode default: 1 (PIO pin is high-Z).

Note: PIO pin has weak pulldown.

IL

IH

CAPACITY

RARC 10 XXXXB XXXB

10 < RARC 20 XXXXL XXXL

20 < RARC 25 XXXLL XXXL

25 < RARC 40 XXXLL XXLL

40 < RARC 50 XXLLL XXLL

50 < RARC 60 XXLLL XLLL

60 < RARC 75 XLLLL XLLL

75 < RARC 80 XLLLL LLLL

80 < RARC 100 LLLLL LLLL

5 LEDs, DC: 0

LED5–LED1

4 LEDs, DC: 1

LED4–LED1

Page 21

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

______________________________________________________________________________________ 21

The EEPROM register provides access control of the

EEPROM blocks. EEPROM blocks can be locked to prevent alteration of data within the block. Locking a block

disables write access to the block. Once a block is

locked, it cannot be unlocked. Read access to EEPROM

blocks is unaffected by the lock/unlock status.

EEPROM Register

Figure 21. EEPROM Register Format

ADDRESS 1Fh BIT DEFINITION

Field Bit Format Allowable Values

EEPROM Copy Flag

Set to 1 when: Copy Data command executed.

EEC 7 Read Only

LOCK 6

Reserved 2:6 Undefined

BL1 1 Read Only

BL0 0 Read Only

Read/Write

to 1

Cleared to 0 when: Copy Data command completes.

Note: Whi le EEC = 1, writes to EEPROM addresse s are ignored.

Power-up default: 0

EEPROM Lock Enable

Host write to 1: Enables the Lock command. Host must issue Lock command as

next command after writing loc k enable bit to 1.

Cleared to 0 when: Loc k command completes or when Lock command is not the

command issued immediately fo llowing the Write command used to set the lock

enable bit.

Power-up default: 0

EEPROM Block 1 Lock Flag (Parameter EEPROM 60h–7Fh)

0: EEPROM is not locked.

1: EEPROM block is locked.

Factor y default: 0

EEPROM Block 0 Lock Flag (User EEPROM 20h–2Fh)

0: EEPROM is not locked.

1: EEPROM block is locked.

Factor y default: 0

Page 22

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

22 ______________________________________________________________________________________

Memory

The DS2788 has a 256-byte linear memory space with

registers for instrumentation, status, and control, as well

as EEPROM memory blocks to store parameters and

user information. Byte addresses designated as

“Reserved” return undefined data when read. Reserved

bytes should not be written. Several byte registers are

paired into two-byte registers in order to store 16-bit values. The MSB of the 16-bit value is located at a even

address and the LSB is located at the next address

(odd) byte. When the MSB of a two-byte register is read,

the MSB and LSB are latched simultaneously and held

for the duration of the Read-Data command to prevent

updates to the LSB during the read. This ensures synchronization between the two register bytes. For consistent results, always read the MSB and the LSB of a

two-byte register during the same read data command

sequence.

EEPROM memory consists of the NV EEPROM cells overlaid with volatile shadow RAM. The Read Data and Write

Data commands allow the 1-Wire interface to directly

accesses only the shadow RAM. The Copy Data and

Recall Data function commands transfer data between

the shadow RAM and the EEPROM cells. To modify the

data stored in the EEPROM cells, data must be written to

the shadow RAM and then copied to the EEPROM. To

verify the data stored in the EEPROM cells, the EEPROM

data must be recalled to the shadow RAM and then read

from the shadow RAM.

User EEPROM

A 16-byte user EEPROM memory (block 0, addresses

20h–2Fh) provides NV memory that is uncommitted to

other DS2788 functions. Accessing the user EEPROM

block does not affect the operation of the DS2788. User

EEPROM is lockable, and once locked, write access is

not allowed. The battery pack or host system manufacturer can program lot codes, date codes, and other

manufacturing, warranty, or diagnostic information and

then lock it to safeguard the data. User EEPROM can

also store parameters for charging to support different

size batteries in a host device as well as auxiliary model

data such as time to full charge estimation parameters.

Parameter EEPROM

Model data for the cells and application operating

parameters are stored in the parameter EEPROM memory (block 1, addresses 60h–7Fh). The ACR (MSB and

LSB) and AS registers are automatically saved to EEPROM when the RARC result crosses 4% boundaries.

This allows the DS2788 to be located outside the protection FETs. In this manner, if a protection device is

triggered, the DS2788 cannot lose more that 4% of

charge or discharge data.

Table 3. Memory Map

ADDRESS (HEX) DESCRIPTION READ/WRITE

00 Reserved R

01 STATUS: Status Register R/W

02 RAAC: Remaining Active Absolute Capacity MSB R

03 RAAC: Remaining Active Absolute Capacity LSB R

04 RSAC: Remaining Standby Absolute Capacit y MSB R

05 RSAC: Remaining Standby Absolute Capacit y LSB R

06 RARC: Remaining Active Relative Capacity R

07 RSRC: Remaining Standby Relative Capacity R

08 IAVG: Average Current Register MSB R

09 IAVG: Average Current Register LSB R

0A TEMP: Temperature Register MSB R

0B TEMP: Temperature Register LSB R

0C VOLT: Voltage Register MSB R

0D VOLT: Voltage Register LSB R

0E CURRENT: Current Register MSB R

0F CURRENT: Current Register LSB R

10 ACR: Accumulated Current Register MSB R/W*

11 ACR: Accumulated Current Register LSB R/W*

Page 23

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

______________________________________________________________________________________ 23

Table 3. Memory Map (continued)

Table 4. Parameter EEPROM Memory Block 1

*Register value is automatically saved to EEPROM during ACTIVE mode operation and recalled from EEPROM on power-up.

ADDRESS (HEX) DESCRIPTION READ/WRITE

12 ACRL: Low Accumulated Current Register MSB R

13 ACRL: Low Accumulated Current Register LSB R

14 AS: Age Scalar R/W*

15 SFR: Special Feature Register R/W

16 FULL: Full Capacity MSB R

17 FULL: Full Capacit y LSB R

18 AE: Active Empty MSB R

19 AE: Active Empty LSB R

1A SE: Standby Empty MSB R

1B SE: Standby Empty LSB R

1C to 1E Reserved —

1F EEPROM: EEPROM Register R/W

20 to 2F User EEPROM, Lockable, Block 0 R/W

30 to 5F Reserved —

60 to 7F Parameter EEPROM, Loc kable, Block 1 R/W

80 to AD Reserved —

AE FVGAIN: Factory Voltage Gain MSB R

AF FVGAIN: Factory Voltage Gain LSB R

B0 FRSGAIN: Factory Sense Re si stor Gain MS B R

B1 FRSGAIN: Factory Sense Re si stor Gain LSB R

B2 to FF Reserved —

ADDRESS (HEX) DESCRIPTION ADDRESS (HEX) DESCRIPTION

60 CONTROL: Control Register 70 AE Segment 4 Slope

61 AB: Accumulation Bias 71 AE Segment 3 Slope

62 AC: Aging Capacity MSB 72 AE Segment 2 Slope

63 AC: Aging Capacity LSB 73 AE Segment 1 Slope

64 VCHG: Charge Voltage 74 SE Segment 4 S lope

65 IMIN: Minimum Charge Current 75 SE Segment 3 Slope

66 VAE: Active Empty Voltage 76 SE Segment 2 Slope

67 IAE: Acti ve Empty Current 77 SE Segment 1 Slope

68 Active Empty 50 78 RSGAIN: Sense Resistor Gain MSB

69 RSNSP: Sense Resi stor Prime 79 RSGAIN: Sense Resistor Gain LSB

6A Full 50 MSB 7A RSTC: Sense Res istor Temp Coeff icient

6B Full 50 LSB 7B COB: Current Offset Bias

6C Full Segment 4 S lope 7C TBP 23

6D Full Segment 3 S lope 7D TBP 12

6E Full Segment 2 Slope 7E VGAIN: Voltage Gain MSB

6F Full Segment 1 Slope 7F VGAIN: Voltage Gain LSB

Page 24

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

24 ______________________________________________________________________________________

1-Wire Bus System

The 1-Wire bus is a system that has a single bus master and one or more slaves. A multidrop bus is a 1-Wire

bus with multiple slaves. A single-drop bus has only

one slave device. In all instances, the DS2788 is a

slave device. The bus master is typically a microprocessor in the host system. The discussion of this

bus system consists of four topics: 64-bit net address,

hardware configuration, transaction sequence, and

1-Wire signaling.

64-Bit Net Address

Each DS2788 has a unique, factory-programmed

1-Wire net address that is 64 bits in length. The first

eight bits are the 1-Wire family code (32h for DS2788).

The next 48 bits are a unique serial number. The last

eight bits are a cyclic redundancy check (CRC) of the

first 56 bits (see Figure 22). The 64-bit net address and

the 1-Wire I/O circuitry built into the device enable the

DS2788 to communicate through the 1-Wire protocol

detailed in the

1-Wire Bus System

section.

CRC Generation

The DS2788 has an 8-bit CRC stored in the MSB of its

1-Wire net address. To ensure error-free transmission

of the address, the host system can compute a CRC

value from the first 56 bits of the address and compare

it to the CRC from the DS2788. The host system is

responsible for verifying the CRC value and taking

action as a result. The DS2788 does not compare CRC

values and does not prevent a command sequence

from proceeding as a result of a CRC mismatch. Proper

use of the CRC can result in a communication channel

with a very high level of integrity.

The CRC can be generated by the host using a circuit

consisting of a shift register and XOR gates as shown

in Figure 23, or it can be generated in software.

Additional information about the Maxim 1-Wire CRC is

available in Application Note 27:

Understanding and

Using Cyclic Redundancy Checks with Maxim iButton

Products

.

In the circuit in Figure 23, the shift register bits are initialized to 0. Then, starting with the LSb of the family

code, one bit at a time is shifted in. After the 8th bit of

the family code has been entered, then the serial number is entered. After the 48th bit of the serial number

has been entered, the shift register contains the CRC

value.

Hardware Configuration

Because the 1-Wire bus has only a single line, it is

important that each device on the bus be able to drive

it at the appropriate time. To facilitate this, each device

attached to the 1-Wire bus must connect to the bus

with open-drain or three-state output drivers. The

DS2788 uses an open-drain output driver as part of the

bidirectional interface circuitry shown in Figure 24. If a

bidirectional pin is not available on the bus master,

separate output and input pins can be connected

together.

Figure 22. 1-Wire Net Address Format

Figure 23. 1-Wire CRC Generation Block Diagram

i

Button is a registered trademark of Maxim Integrated Products, Inc.

8-BIT CRC 48-BIT SERIAL NUMBER

MSb LSb

MSb XOR XOR

8-BIT FAMILY

CODE (32h)

INPUT

LSb

XOR

Page 25

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

______________________________________________________________________________________ 25

The 1-Wire bus must have a pullup resistor at the busmaster end of the bus. For short line lengths, the value

of this resistor should be approximately 5kΩ. The idle

state for the 1-Wire bus is high. If, for any reason, a bus

transaction must be suspended, the bus must be left in

the idle state to properly resume the transaction later. If

the bus is left low for more than 120µs (16µs for overdrive speed), slave devices on the bus begin to interpret the low period as a reset pulse, effectively

terminating the transaction.

The DS2788 can operate in two communication speed

modes, standard and overdrive. The speed mode is

determined by the input logic level of the OVD pin with

a logic 0 selecting standard speed and a logic 1

selecting overdrive speed. The OVD pin must be at a

stable logic level of 0 or 1 before initializing a transaction with a reset pulse. All 1-Wire devices on a multinode bus must operate at the same communication

speed for proper operation. 1-Wire timing for both standard and overdrive speeds are listed in the

Electrical

Characteristics: 1-Wire Interface

tables.

Transaction Sequence

The protocol for accessing the DS2788 through the

1-Wire port is as follows:

• Initialization

• Net Address Command

• Function Command

• Transaction/Data

The sections that follow describe each of these steps in

detail.

All transactions of the 1-Wire bus begin with an initialization sequence consisting of a reset pulse transmitted

by the bus master, followed by a presence pulse simultaneously transmitted by the DS2788 and any other

slaves on the bus. The presence pulse tells the bus

master that one or more devices are on the bus and

ready to operate. For more details, see the

1-Wire

Signaling

section.

Net Address Commands

Once the bus master has detected the presence of one

or more slaves, it can issue one of the net address

commands described in the following paragraphs. The

name of each ROM command is followed by the 8-bit

op code for that command in square brackets.

Figure 25 presents a transaction flowchart of the net

address commands.

Read Net Address [33h or 39h]. This command allows

the bus master to read the DS2788’s 1-Wire net

address. This command can only be used if there is a

single slave on the bus. If more than one slave is present, a data collision occurs when all slaves try to transmit at the same time (open drain produces a

wired-AND result). The RNAOP bit in the Status register

selects the op code for this command, with RNAOP = 0

indicating 33h and RNAOP = 1 indicating 39h.

Figure 24. 1-Wire Bus Interface Circuitry

BUS MASTER

Rx

Tx

V

PULLUP

(2.0V TO 5.5V)

4.7kΩ

Rx = RECEIVE

Tx = TRANSMIT

0.2μA

(TYP)

DS2788 1-Wire PORT

Rx

Tx

100Ω MOSFET

Page 26

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

26 ______________________________________________________________________________________

Match Net Address [55h]. This command allows the

bus master to specifically address one DS2788 on the

1-Wire bus. Only the addressed DS2788 responds to

any subsequent function command. All other slave

devices ignore the function command and wait for a

reset pulse. This command can be used with one or

more slave devices on the bus.

Skip Net Address [CCh]. This command saves time

when there is only one DS2788 on the bus by allowing

the bus master to issue a function command without

specifying the address of the slave. If more than one

slave device is present on the bus, a subsequent function command can cause a data collision when all

slaves transmit data at the same time.

Search Net Address [F0h]. This command allows the

bus master to use a process of elimination to identify

the 1-Wire net addresses of all slave devices on the

bus. The search process involves the repetition of a

simple three-step routine: read a bit, read the complement of the bit, then write the desired value of that bit.

The bus master performs this simple three-step routine

on each bit location of the net address. After one complete pass through all 64 bits, the bus master knows

the address of one device. The remaining devices can

then be identified on additional iterations of the

process. See Chapter 5 of the

Book of iButton

Standards

for a comprehensive discussion of a net

address search, including an actual example

(www.maxim-ic.com/ibuttonbook

).

Resume [A5h]. This command increases data throughput in multidrop environments where the DS2788 needs

to be accessed several times. Resume is similar to the

Skip Net Address command in that the 64-bit net

address does not have to be transmitted each time the

DS2788 is accessed. After successfully executing a

Match Net Address command or Search Net Address

command, an internal flag is set in the DS2788. When

the flag is set, the DS2788 can be repeatedly accessed

through the Resume command function. Accessing

another device on the bus clears the flag, thus preventing two or more devices from simultaneously responding to the Resume command function.

Function Commands

After successfully completing one of the net address

commands, the bus master can access the features of

the DS2788 with any of the function commands

described in the following paragraphs. The name of

each function is followed by the 8-bit op code for that

command in square brackets. Table 5 summarizes the

function commands.

Read Data [69h, XX]. This command reads data from

the DS2788 starting at memory address XX. The LSb of

the data in address XX is available to be read immediately after the MSb of the address has been entered.

Because the address is automatically incremented after

the MSb of each byte is received, the LSb of the data at

address XX + 1 is available to be read immediately

after the MSb of the data at address XX. If the bus master continues to read beyond address FFh, data is read

starting at memory address 00 and the address is automatically incremented until a reset pulse occurs.

Addresses labeled “Reserved” in the memory map

contain undefined data values. The read data command can be terminated by the bus master with a reset

pulse at any bit boundary. Reads from EEPROM block

addresses return the data in the shadow RAM. A Recall

Data command is required to transfer data from the

EEPROM to the shadow. See the

Memory

section for

more details.

Write Data [6Ch, XX]. This command writes data to the

DS2788 starting at memory address XX. The LSb of the

data to be stored at address XX can be written immediately after the MSb of address has been entered.

Because the address is automatically incremented after

the MSb of each byte is written, the LSb to be stored at

address XX + 1 can be written immediately after the

MSb to be stored at address XX. If the bus master continues to write beyond address FFh, the data starting at

address 00 is overwritten. Writes to read-only addresses, reserved addresses, and locked EEPROM blocks

are ignored. Incomplete bytes are not written. Writes to

unlocked EEPROM block addresses modify the shadow RAM. A Copy Data command is required to transfer

data from the shadow to the EEPROM. See the

Memory

section for more details.

Page 27

DS2788

Stand-Alone Fuel-Gauge IC with

LED Display Drivers

______________________________________________________________________________________ 27

Copy Data [48h, XX]. This command copies the con-

tents of the EEPROM shadow RAM to EEPROM cells for

the EEPROM block containing address XX. Copy data

commands that address locked blocks are ignored.

While the copy data command is executing, the EEC bit

in the EEPROM register is set to 1 and writes to

EEPROM addresses are ignored. Reads and writes to

non-EEPROM addresses can still occur while the copy

is in progress. The copy data command takes t

EEC

time

to execute, starting on the next falling edge after the

address is transmitted.

Recall Data [B8h, XX]. This command recalls the contents of the EEPROM cells to the EEPROM shadow

memory for the EEPROM block containing address XX.

Lock [6Ah, XX]. This command locks (write protects)

the block of EEPROM memory containing memory

address XX. The lock bit in the EEPROM register must

be set to 1 before the lock command is executed. To

help prevent unintentional locks, one must issue the

lock command immediately after setting the lock bit

(EEPROM register, address 1Fh, bit 06) to a 1. If the

lock bit is 0 or if setting the lock bit to 1 does not immediately precede the lock command, the lock command

has no effect. The lock command is permanent; a

locked block can never be written again.

Table 5. Function Commands

COMMAND DESCRIPTION

Read Data Reads data from memory starting at address XX. 69h, XX Master Rx

Write Data Writes data to memory starting at address XX. 6Ch, XX Master Tx

Copy Data

Recall Data Recalls EEPROM block containing address XX to RAM. B8h, XX Master Reset None

Lock

Copies shadow RAM data to EEPROM block containing

address XX.

Permanently loc ks the block of EEPROM

containing address XX.

COMMAND

PROTOCOL

48h, XX Master Reset None

6Ah, XX Master Reset None

BUS STATE AFTER