r

www.maxim-ic.com

GENERAL DESCRIPTION

The DS2714 is ideal for standalone charging of 1 to 4

AA or AAA NiMH “loose” cells. NiCd cells can also be

charged. Temperature, voltage and charge time are

monitored to provide proper fast charging control

algorithms for Nickel Metal Hydride (NiMH) batteries.

Battery tests are included to detect defective or

inappropriate cells such as Alkaline primary batteries.

The DS2714 supports a parallel charging topology,

with independent monitoring and control of each cell.

APPLICATIONS

Desktop/Standalone Chargers (AAA/AA)

Digital Still Cameras

Music Players

Games

Toys

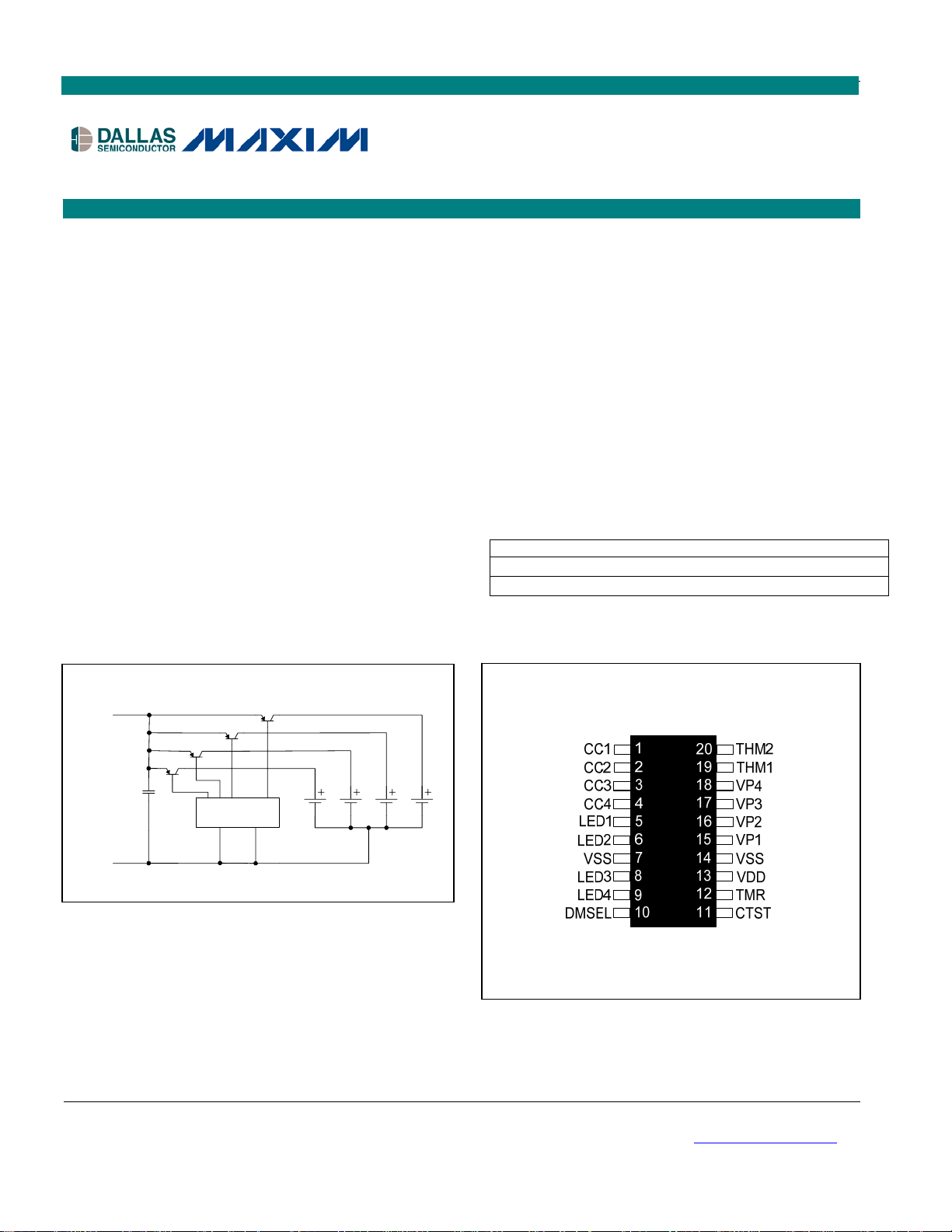

CHARGE TOPOLOGY

DS2714

Quad Loose Cell NiMH Charge

FEATURES

Charges 1 to 4 NiMH Cells

Detects and Avoids Charging Alkaline Cells

Pre-Charges Deeply Depleted Cells

Fast Charges NiMH with -ΔV Termination

Sensitivity of 2mV (typ)

Monitors Voltage, Temperature and Time for

Safety and Secondary Termination

Works with Regulated Charge Current Source

Drives PNP Type Pass Element

Compatible with Integrated Primary-Side PWM

Controllers

20-pin TSSOP Package

ORDERING INFORMATION

PART MARKING PIN-PACKAGE

DS2714E+ DS2714 20 TSSOP

DS2714E+T&R DS2714 20 TSSOP Tape-and-Reel

+Denotes lead-free package.

PIN CONFIGURATION

Controlled

Current

Source

GND

4-Cell NiMH Charger

DS2714

TSSOP

Note: Some revisions of this device may incorporate deviations from published specifications known as errata. Multiple revisions of any device

may be simultaneously available through various sales channels. For information about device errata, click here: www.maxim-ic.com/errata

1 of 12

REV: 080206

.

DS2714: Quad Loose Cell NiMH Charger

ABSOLUTE MAXIMUM RATINGS

Voltage Range on Any Pin Relative to V

Voltage on DMSEL V

Continuous Sink Current CC1-4, LED1-4

Operating Temperature Range -40°C to +85°C

Storage Temperature Range

Soldering Temperature

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is

not implied. Exposure to the absolute maximum rating conditions for extended periods may affect device reliability.

-55°C to +125°C

See IPC/JEDECJ-STD-020A

-0.3V to +6V

SS

+ 0.3V

DD

20mA

RECOMMENDED DC OPERATING CONDITIONS

(4.0V ≤ VDD ≤ 5.5V; T

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage VDD (Note 1) 4.0 5.5 V

Input Voltage Range LEDx, DMSEL -0.3 5.5 V

= -20°C to +70°C)

A

DC ELECTRICAL CHARACTERISTICS

(4.0V ≤ VDD ≤ 5.5V; TA = -20°C to +70°C. Unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Current, VDD I

Output Voltage Low, CC1-4.

LED1-4

Leakage Current,

CC1-4 LED1-4

Threshold Voltage,

-ΔV Termination

Mode Test Current, DMSEL I

Input Logic High, DMSEL, VIH (Note 1)

Operating mode 500 750

DD

VDD = 5.0V,

V

OL1

I

LKG

V

MTST

-ΔV

= 20mA (Note 1)

I

OL

VDD = 5.0V,

Output inactive

After t

THO

Pulse high/low once

<5ms after power-up

1.0 2.0 3.0 mV

1.0 V

-1 +1

- 5 15

V

-

DD

0.2V

V

μA

μA

μA

Input Logic Low, DMSEL, VIL (Note 1) 0.2 V

Input Leakage Current,

DMSEL

Threshold Voltage, Cell Test

Accuracy

Threshold Voltage, Cell Test

Range

Threshold Voltage, Cell

Voltage Low

Threshold Voltage, Cell

Voltage Max1

Threshold Voltage, Cell

Voltage Max2

Threshold Voltage, Thermistor

- Min

Threshold Voltage, Thermistor

- Max

Threshold Voltage, Thermistor

- Stop

Threshold Current, TMR Pin

Suspend

I

IL1

V

CTST-ACC

V

CTST-RANGE

V

BAT-LOW

V

BAT-MAX1

V

BAT-MAX2

V

THM-MIN

V

THM-MAX

V

THM-STOP

I

TMR-SUS

After power-up mode

select,

DMSEL = V

R

= 80KΩ

TMR

or VSS

DD

-1 +1

μA

-15 15 %

32 400 mV

CC1 = CC2 = hi-Z

(Note 1, 2)

CC1 = CC2 = hi-Z

(Note 1, 2)

CC1, CC2 active

(Note 1, 2)

(Note 1, 2, 6)

(Note 1, 2, 6) 0.30

(Note 1, 2, 6)

0.1 0.5

0.9 1.0 1.1 V

1.55 1.65 1.75 V

1.64 1.75 1.86 V

V

x

DD

0.73

V

DD

0.33

V

DD

0.29

x

x

V

0.36 V

V

μA

2 of 12

DS2714: Quad Loose Cell NiMH Charger

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Presence Test Current, VP1-4 I

Reverse Leakage Current,

VP1, VP2, VP3, VP4

10 15

PTST

VDD = 0V, VPx = 1.5V

I

LKGR

2

μA

μA

ELECTRICAL CHARACTERISTICS: TIMING

(4.0V ≤ VDD ≤ 5.5V; TA = -20°C to +70°C. Unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Internal Timebase Period t

Internal Timebase

Accuracy

Duty Factor, Fast Charge DF1 CCx 0.234

(Note 5) 0.48 s

BASE

-10 +10 %

Duty Factor, PreCharge/Top-Off

Duty Factor, Maintenance

Charge

Cell Test Interval t

Pre-Charge Time-out t

Fast Charge Termination

Hold-Off Period

Fast Charge Flat Voltage

Time-out

DF2 CCx 0.0625

DF3 CCx Note 4 0.0078

(Note 3) 31 s

CTST

V

PCHG

t

3.6 4 4.4 minutes

THO

V

t

FLAT

< V

CELL

not increasing 14.4 16 17.6 minutes

CELL

30.6 34 37.4 minutes

BAT-MIN

Charge Timer Accuracy -5 +5 %

Charge Timer Range t

CTMR-RANGE

0.5 10 h

Note 1: Voltages relative to V

Note 2: Specification applicable during charge cycle with TA = 0°C to +70°C.

Note 3: One time slot out of every 16 available slots gets a Cell Test.

Note 4: One time slot out of every 32 available time slots gets a charge pulse.

0.48 seconds is one charge time slot. A complete cycle of 4 time slots (one charge time slot per cell) is 1.92 sec.

Note 5:

Note 6: V

Note 7: I

THM-MIN, VTHM-MAX, and VTHM-STOP are fixed ratios of V

MTST current is applied as a source current and as a sink current within 5ms after power-up.

.

SS

Their ranges never overlap.

.

DD

3 of 12

DS2714: Quad Loose Cell NiMH Charger

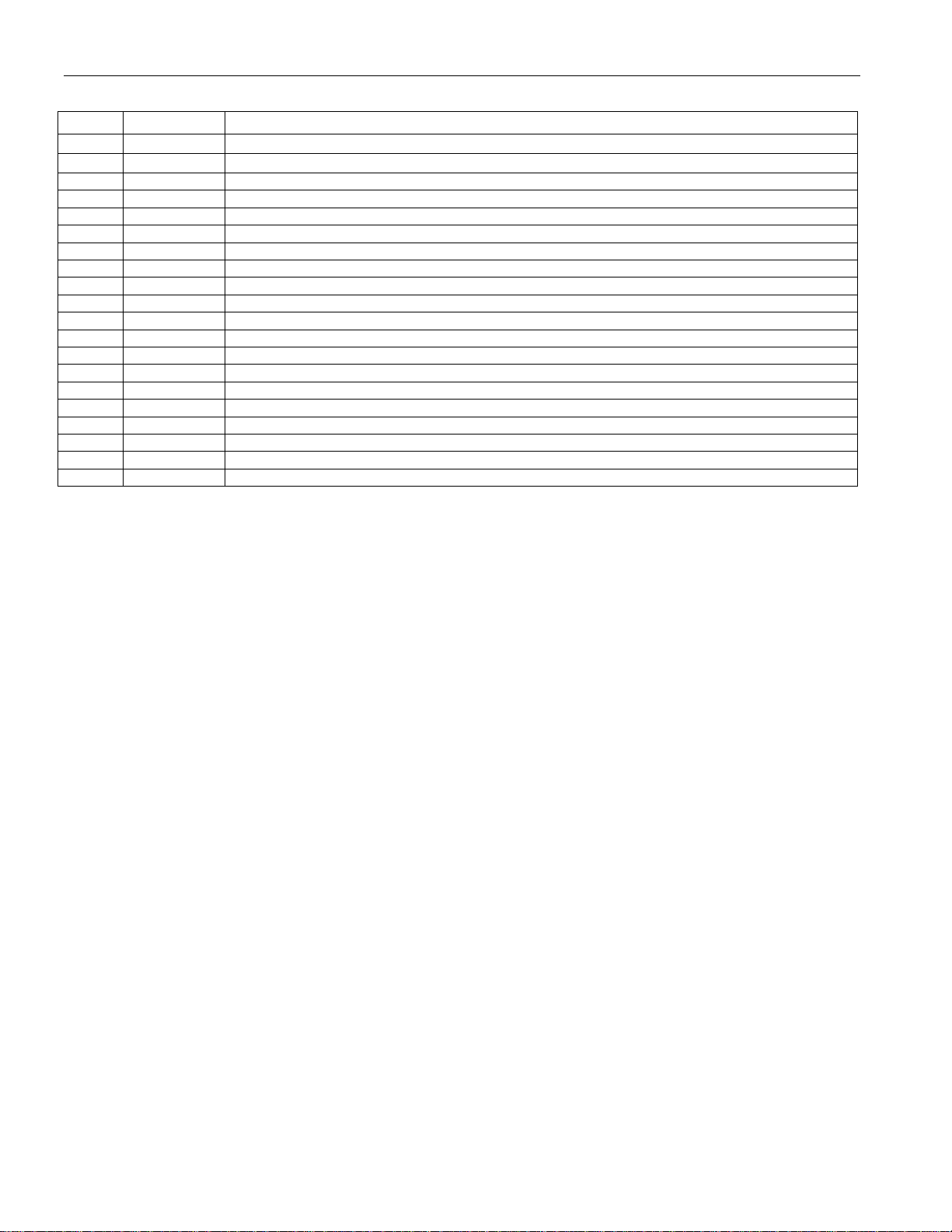

PIN DESCRIPTION

PIN NAME FUNCTION

1 CC1

2 CC2

3 CC3

4 CC4

5 LED1

6 LED2

7 VSS

8 LED3

9 LED4

10 DMSEL

11 CTST

12 TMR

13 VDD

14 VSS

15 VP1

16 VP2

17 VP3

18 VP4

19 THM1

20 THM2

Charge Control 1. Turn on and off the charge PNP for Cell 1.

Charge Control 2. Turn on and off the charge PNP for Cell 2.

Charge Control 3. Turn on and off the charge PNP for Cell 3.

Charge Control 4. Turn on and off the charge PNP for Cell 4.

LED 1. Open drain output for LED. Display Cell 1 status.

LED 2. Open drain output for LED. Display Cell 2 status.

Device Ground. Return current path for LEDx pins. Both VSS pins must be connected to ground.

LED 3. Open drain output for LED. Display Cell 3 status.

LED 4. Open drain output for LED. Display Cell 4 status.

Display Mode Select. Select the LED blink rate.

Cell Test Resistor. Cell test threshold set.

Timer Resistor. Charge timer set.

Power-Supply Input. Chip supply input (4.0V to 5.5V).

Device Ground. Internally connected to Pin 7. Both VSS pins must be connected to ground.

Voltage Sense 1. Positive terminal sense input for Cell 1.

Voltage Sense 2. Positive terminal sense input for Cell 2.

Voltage Sense 3. Positive terminal sense input for Cell 3.

Voltage Sense 4. Positive terminal sense input for Cell 4.

Thermister 1. Thermister input for Cell 1 and 2.

Thermister 2. Thermister input for Cell 3 and 4.

4 of 12

Figure 1. Block Diagram

DS2714: Quad Loose Cell NiMH Charger

5 of 12

Figure 2. State Diagram

DS2714: Quad Loose Cell NiMH Charger

6 of 12

DS2714: Quad Loose Cell NiMH Charger

Figure 3. Application Example: Regulated Current Source Charger

7 of 12

DS2714: Quad Loose Cell NiMH Charger

DETAILED DESCRIPTION

CHARGE ALGORITHM OVERVIEW

A charge cycle begins in one of three ways: With the application of power to the DS2714 with cell(s) already

inserted, with the detection of cell insertion after power-up, or when exiting suspend mode with cell(s) inserted. The

charge cycle begins with Pre-charge qualification to prevent Fast charging of deeply depleted cells or charging

under extreme temperature conditions. Pre-charging is performed at a reduced rate until the cell being charged

reaches V

charging of alkaline cells or NiMH cells which are worn-out or damaged. Fast charging continues as long as the cell

temperature is less than 50°C (based on Thermistor sensors THM 1, 2), the open circuit cell voltage(s) are

between V

Fast charging terminates by the -ΔV (negative delta voltage) or flat voltage method. The Top-Off charge phase

follows to completely charge the cell. After the Top-off charge timer expires, the Maintenance charge phase

continues indefinitely to keep the cells fully charged. Maximum voltage, temperature and charge time monitoring

during all charge phases act as secondary or safety termination methods to provide additional protection from

overcharge. A cell voltage greater than V

than 50°C (see Table 1) will result in either Fault or Maintenance depending on which charge state the device was

last in. Each cell is monitored independently, and the charge phase of each cell is independently controlled. If a cell

is removed while being charged, the algorithm for that cell slot is completely reset to its Presence Test state without

affecting the charge control states of the other cells.

CHARGE CONFIGURATION

The DS2714 supports four slot standalone chargers. It alternates charge to the four slots every two seconds, with

one half second available to each cell. Removal or insertion of a cell into the charger does not disturb the charge

timing or charge rates of the other cells. Charge pulses are fed alternately to each cell under the control of the CCx

pins so that the charge regimes occur in parallel. The duty cycle on the CCx pins are completely independent of

one another. Transitions from Pre-charge to Fast charge, Fast charge to Top-off and Top-off to Maintenance occur

independently for each cell. The configuration shown in Figure 3 is for charging four cells with a current limited

source of 2A. The effective average fast charge current for each cell is 2A x 0.25 x 15/16 = 0.469A. The 15/16 term

is due to the fact that every 16

current is delivered to the cell during that time. Mechanical design of the holders is required to prevent insertion of

more than one cell in each slot. The holder design should also prevent electrical contact with reverse polarity

insertion.

PERFORMANCE REQUIREMENTS OVER TEMPERATURE AND VOLTAGE

INTERNAL OSCILLATORS AND CLOCK GENERATION

An internal oscillator provides the main clock source used to generate timing signals for internal chip operation. The

pre-charge timer, hold-off timers, and duty factors for the charging operations are derived from this timebase. There

are two separate timers for the impedance test and Fast Charge/Topoff functions.

(1V). The algorithm proceeds to a Fast charge phase which includes cell tests to avoid accidental

BAT-LOW

BAT-LOW

(1.0V) and V

BAT-MAX1

(1.65V) and the closed ciruit cell voltage(s) are less than V

BAT-MAX2

th

charge time slot is used for negative delta-voltage and impedance testing. No

(1.75V) will result in a fault condition, and temperature greater

BAT-MAX2

Valid NiMH

Charge Range

Below Operating

Voltage Range

Low

Temperature

Range

High

Temperature

Range

Abs. Max

Operating

Range

(1.75V).

8 of 12

DS2714: Quad Loose Cell NiMH Charger

CHARGE TIMER

The Charge Timer monitors the duration of charge in Fast and Top-Off charge phases, and is reset at the

beginning of each phase. The time-out period is set with an external resistor connected from the TMR pin to V

SS

.

Resistors can be selected to support Fast charge time-out periods of 0.5 to 10 hours and Top-off charge time-out

periods of 0.25 to 5 hours. If the timer expires in Fast charge, the timer count is reset and charging proceeds to the

Top-Off charge phase. The Top-Off time-out period is half of the Fast charge time-out period. When the timer

expires in Top-Off, charging proceeds to the Maintenance phase. The programmed charge time approximately

follows the equation:

t = 1.5

R / 1000 (time in minutes)

*

SUSPEND

Suspension of charge activity is possible by floating the TMR pin. All CCx outputs become high-Z and the Charge

Timer stops. The state machine and all timers are reset to their Presence Test conditions.

TEMPERATURE SENSE

Connecting an external 10kΩ NTC thermistor between THM1 or THM2 (THMx) and VSS, and a 10kΩ bias resistor

between V

and THMx allows the DS2714 to sense temperature. In order to sense the temperature of the battery

DD

cells, locate the thermistor close to the body of the battery cell. The THM1 thermistor should be placed between

cells 1 and 2, and THM2 thermistor between cells 3 and 4. Alternatively, the thermistors can sense ambient

temperature by locating them away from the cells. THM1 and THM2 can be tied together to sense temperature

using a single thermistor and bias resistor. The temperature qualification function can be defeated by tying THMx

pins to a single resistor divider supplying a voltage between the Thermistor-Min and Thermistor-Max threshold

voltages.

MIN, MAX TEMPERATURE COMPARE

The voltage thresholds of the THMx inputs (V

45°C when using the recommended 10kΩ bias and 10kΩ thermistor. If Fast charging is in progress, and the

voltage on THMx reaches V

THM-STOP (TA

> 50°C), Fast charging stops and the maintenance phase begins. In Pre-

charge the device will transition to the Fault state if the voltage on THMx reaches V

THM-MIN

, V

THM-MAX

) are set to allow Fast charging to start if 0°C < TA <

THM-STOP

.

Table 1. THM1, THM2 Thresholds

TEMPERATURE

THM

THRESHOLD

MIN 0.73 27.04k 0°C 4°C

MAX 0.33 4.925k 45°C 42°C

STOP 0.29 4.085k 50°C 47°C

RATIO

OF VDD

THERMISTOR

RESISTANCE

Semitec

103AT-2

Fenwal

197-103LAG-A01

173-103LAF-301

CELL VOLTAGE MONITORING

Individual cell voltages are monitored for minimum and maximum values, using the V

threshold limits. Upon inserting a cell or power-up with cells inserted, cell voltages must be less than the V

MAX2

threshold before charging begins. The V

MAX1

BAT-LOW

threshold determines whether a Pre-charge cycle should

precede the Fast charge cycle, and when to transition from Pre-charge to Fast charge. Once Fast charging

commences, cell voltages are compared to the V

BAT-MAX2

threshold once every 2 seconds. The comparison occurs

while the charge control pin (CC1-4) controlling current to the cell is active (low). When the charge control pin is

active such that charge is applied to the cell, the cell voltage is referred to as the V

control pin is inactive, the cell voltage is referred to as the V

displayed if V

than V

BAT-MAX1

is greater than V

ON

BAT-MAX2

. Charging is also halted and a fault condition is entered if V

. While Fast charge is in progress, cell voltage measurements are stored and compared to future

voltage. Charging is halted and a Fault condition is

OFF

ON

measurements for charge termination and cell test purposes.

BAT-LOW

, V

BAT-MAX1

and V

BAT-

BAT-

voltage. When the charge

is greater

OFF

9 of 12

DS2714: Quad Loose Cell NiMH Charger

CELL TESTS

Two types of tests are performed to detect primary Alkaline and Lithium cells or defective NiMH or NiCd secondary

cells. The first test checks the absolute closed circuit cell voltage (V

in open circuit cell voltage (V

seconds. During fast charge, V

V

, the cell test fails. Cells are tested individually so that a single improper or defective cell can be detected

CTST

quickly. V

is set by the resistance from the CTST pin to ground. The nominal sensitivity of 100mV is set by

CTST

connecting an 80kΩ resistor between CTST and V

) and (VON). VON for each cell is compared to the V

OFF

ON

- V

of each cell is compared to the cell test threshold, V

OFF

. The impedance threshold can be set from 32mV to 400mV.

SS

), and the second test checks the difference

ON

BAT-MAX2

threshold once every 2

. If VON - V

CTST

OFF

>

The following formula approximates the setting for the impedance threshold

V

= 8000/R (value in volts)

CTST

-ΔV AND FLAT VOLTAGE TERMINATION

During Fast charge, -ΔV detection is performed by comparing successive voltage measurements for a drop of 2mV

in the cell voltage. A Hold-off period for -ΔV detection begins at the start of Fast charging and prevents false

termination in the first few minutes of the charge cycle. Once the hold-off period expires, cell voltage

measurements are acquired every 16th charge time slot (approximately 31 seconds, during the CCx off time).

When a newly acquired voltage measurement is greater than any previous one, the new value is retained as the

maximum value. When the cell voltage no longer increases, the maximum value is retained and compared against

subsequent values. If the cell voltage drops below the -ΔV threshold, V

the cell voltage remains flat such that the maximum value persists for a period of 16 minutes (t

, (2mV typ), Fast charging is terminated. If

-ΔV

), Fast charge

FLAT

terminates and Top-Off charging begins.

TOP-OFF, PRE-CHARGE AND MAINTENANCE

In Top-off and Pre-charge modes, the charger scales the cell current to 1/16 of the DC current set by the current

source, i.e, one charge pulse for every 16 main clock pulses, or one in four available time slots for a given cell. The

ratio of average Top-off/Pre-charge current to average fast charge current is 0.286. When the charge timer expires

in Top-Off, the charger enters Maintenance and delivers 1/128 of the DC charge source current to the cells (one

time slot in every 32 available to that cell). This is slightly more than 3% of the average DC Fast Charge current.

Maintenance charge remains continuous until power is removed, the cell(s) are removed or the DS2714 is cycled

into and out of suspend mode by floating the TMR pin.

CCx OUTPUTS

The CC1 through CC4 pins operate as open-drain outputs that drive active low to connect the charge source to the

NiMH cells. During charge, the behavior of these outputs depends on the charge states of the cells and on how

many cells have been installed.

FAST CHARGE

Referring to the application circuit shown in Figure 3, CC1 controls the PNP switch that gates current to the cell in

slot 1. CC2 controls the PNP switch that gates current to the cell in slot 2, and so on. During Fast charge, current is

gated to each slot sequentially, with charge pulses occurring in alternating time frames. The cell in one slot charges

while the others relax. Each cell skips a charge pulse every 16 of its allocated charge time slots (approximately

once every 31 seconds) to facilitate independent testing of the open and closed circuit cell voltages (V

respectively). Since the charge regime of each cell is independent, one cell may complete a charge phase before

the other without affecting the charging of the other cells. In the case of an improper or faulty cell (ex. alkaline)

being inserted along with proper cells (NiMH or NiCd), charging of the improper cell would be stopped, while the

proper cells will be charged to full.

and VON,

OFF

10 of 12

EXAMPLE TIMING DIAGRAM FOR THE DS2714

DS2714: Quad Loose Cell NiMH Charger

Note 1: Cell test time slot for Cell 2.

Note 2: Cell test time slot for Cell 3.

In this timing diagram, the pulses represent charge current into the individual cells. Cell 1 is in Precharge (the timing of Precharge is the same as Top-off). It

gets one charge pulse out of every four available times slots.

Cell 2 is in initially in Fast Charge and it transitions to Topoff charge during the N+7th time interval (Note 1)shown in the diagram.

Cell 3 is in Fast charge. Cell testing is performed during the interval marked Note 2. This cell is not ready to go into Top-off and it resumes Fast charge.

Cell 4 is in maintenance mode, one out of every 32 available time slots gets a charge pulse.

11 of 12

DS2714: Quad Loose Cell NiMH Charger

LEDx OUTPUTS, DISPLAY MODE SELECT

Open-drain outputs LEDx pull low to indicate charge status. When inactive, the outputs are high impedance. LED1

displays the status for the cell monitored by VP1, LED2 displays the status for the cell monitored by VP2 and so on.

The LED pins drive low in three “blink” patterns to annunciate the charge status. Table 2 summarizes the LED

operation in each display mode (DM0, DM1, DM2) for each charge condition.

Table 2. Display Patterns By Display Mode and Charge Activity

Display Mode Charge Activity

DM0

DM1

DM2

DMSEL pin No Battery

Low Hi-Z Low

Float Hi-Z Low Hi-Z

High Hi-Z

Pre/Fast/Top-off

Charging

0.80s Low

0.16s Hi-Z

Maintenance Fault

0.80s Low

0.16s Hi-Z

Low

0.48s Low

0.48s Hi-Z

0.16s Low

0.16s Hi-Z

0.16s Low

0.16s Hi-Z

PACKAGE INFORMATION

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package

outline information, go to www.maxim-ic.com/DallasPackInfo

.)

Maxim/Dallas Semiconductor cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim/Dallas Semiconductor product.

No circuit patent licenses are implied. Maxim/Dallas Semiconductor reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel D rive, Sunnyvale, CA 94086 408-737-7600

The Maxim logo is a registered trademark of Maxim Integrated Products, Inc. The Dallas logo is a registered trademark of Dallas Semiconductor Corporation.

© 2006 Maxim Integrated Products • Printed USA

12 of 12

Loading...

Loading...