Loose Cell NiMH Chargers

DS2711/DS2712

www.maxim-ic.com

DESCRIPTION

The DS2711 and DS2712 are ideal for in-system or

stand-alone charging of 1 or 2 AA or AAA NiMH

“loose” cells. Temperature, voltage, and charge time

are monitored to provide proper fast charging control

algorithms for nickel metal hydride (NiMH) batteries.

Battery tests are included to detect defective or

inappropriate cells such as alkaline primary batteries.

The DS2711/DS2712 support series and parallel

topologies, with independent monitoring and control of

each cell. Charging of NiCd chemistry cells is also

supported.

FEATURES

§ Charge 1 or 2 NiMH Cells

§ Detect and Avoid Charging Alkaline Cells

§ Precharge Deeply Depleted Cells

§ Fast Charge NiMH with -DV Termination

Sensitivity of 2mV (typ)

§ Monitor Voltage, Temperature, and Time for

Safety and Secondary Termination

§ Regulate Charge Current:

Linear Control (DS2711)

Switch-Mode Control (DS2712)

§ Drive PMOS or PNP-Type Pass Element or

Switch, or an Optocoupler

§ Compatible with Popular Optocouplers and

Integrated Primary Side PWM Controllers

§ Small 16-Pin SO or TSSOP Package

APPLICATIONS

Desktop/Stand-Alone Chargers (AAA/AA)

Digital Still Cameras

Music Players

Games

Toys

PIN CONFIGURATION

CC1

CC2

LED1

VSS

LED2

CSOUT

VN1

VN0

16 SO (150 mil) / TSSOP (4.4 mm)

See Table 1 for Ordering Information.

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

VP2

VP1

THM2

THM1

VDD

TMR

CTST

9

DMSEL

PIN DESCRIPTION

PIN NAME FUNCTION

1 CC1 Cell 1 Charge-Control Output

2 CC2 Cell 2 Charge-Control Output

3 LED1 Cell 1 Status

4 VSS

5 LED2 Cell 2 Status, Mode-Select Input

6 CSOUT Current-Sense Output

7 VN1 Current-Sense + Input

8 VN0 Current-Sense - Input

9 DMSEL Display-Mode Select

10 CTST Cell Test Threshold Set

11 TMR Charge Timer Set

12 VDD Chip-Supply Input (4.0V to 5.5V)

13 THM1 Cell 1 Thermistor Input

14 THM2 Cell 2 Thermistor Input

15 VP1 Cell 1 Positive-Terminal Sense Input

16 VP2 Cell 2 Positive-Terminal Sense Input

Ground Reference and Chip-Supply

Return

1 of 14 080905

DS2711/DS2712: Loose Cell NiMH Charger

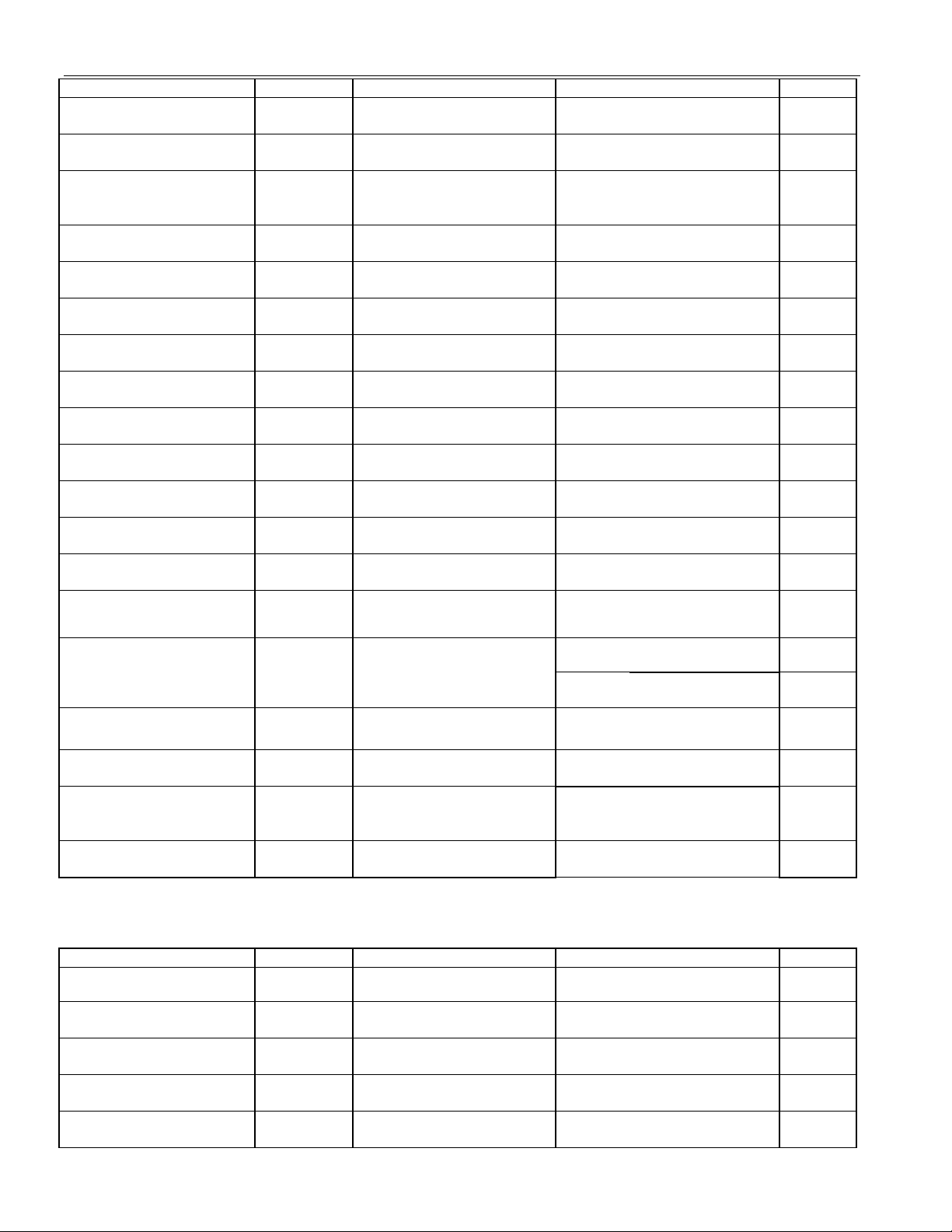

Table 1. ORDERING INFORMATION

PART MARKING PIN-PACKAGE

DS2711Z

DS2711

16 SO

DS2711Z/T&R DS2711 16 SO, Tape-and-Reel

DS2712Z

DS2712

16 SO

DS2712Z/T&R DS2712 16 SO, Tape-and-Reel

DS2711Z+

DS2711

16 SO

DS2711Z+T&R DS2711 16 SO, Tape-and-Reel

DS2712Z+

DS2712

16 SO

DS2712Z+T&R DS2712 16 SO, Tape-and-Reel

DS2711E+

DS2711

16 TSSOP

DS2711E+T&R DS2711 16 TSSOP, Tape-and-Reel

DS2712E+

DS2712

16 TSSOP

DS2712E+T&R DS2712 16 TSSOP, Tape-and-Reel

+ Denotes lead-free package.

ABSOLUTE MAXIMUM RATINGS*

Voltage on All Pins Relative to VSS -0.3V to +6V

Voltage on DMSEL V

+ 0.3V

DD

Continuous Sink Current CC1, CC2, LED1, LED2 and CSOUT 20mA

Operating Temperature Range -40°C to +85°C

Storage Temperature Range -55°C to +125°C

Soldering Temperature See IPC/JEDECJ-STD-020

*This is a stress rating only and functional operation of the device at these or any other conditions above those

indicated in the operation sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods of time may affect reliability.

RECOMMENDED DC OPERATING CONDITIONS

(4.0V £ VDD £ 5.5V; TA = -20°C to +70°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage VDD (Note 1) 4.0 5.5 V

Input Voltage Range LED2, DMSEL -0.3 +5.5 V

DC ELECTRICAL CHARACTERISTICS

(4.0V £ VDD £ 5.5V, TA = -20°C to +70°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Current, VDD I

UVLO Threshold V

UVLO Hysteresis V

Output-Voltage Low,

CC1, CC2, LED1, LED2

Output-Voltage Low,

CSOUT

Leakage Current,

CC1, CC2, LED1, LED2,

CSOUT

Threshold Voltage,

-DV Termination

Mode Test Current,

DMSEL, LED2

Operating mode 250 500

DD

VDD rising (Note 1) 3.5 3.9 V

UVLO

falling from above

V

UHYS

V

OL1

V

OL2

I

LKG

V

-DV

I

(Notes 2, 3) 5 15

MTST

DD

V

UVLO

= 5.0V,

V

DD

= 20mA (Note 1)

I

OL

= 5.0V,

V

DD

I

= 20mA (Note 1)

OL

= 5.0V,

V

DD

Output inactive

After t

1.0 2.0 3.0 mV

THO

2 of 14

mA

40 mV

1.0 V

0.75 1.25 V

-1 +1

mA

mA

DS2711/DS2712: Loose Cell NiMH Charger

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Input Logic-High,

DMSEL, LED2

Input Logic-Low, DMSEL,

LED2

Input Leakage Current,

DMSEL

Threshold Voltage, Cell

Test

Threshold Voltage, Cell

Voltage Low

Threshold Voltage, Cell

Voltage Max1

Threshold Voltage, Cell

Voltage Max2

Threshold Voltage Delta V

Threshold Voltage,

Thermistor - Min

Threshold Voltage,

Thermistor - Max

Threshold Voltage,

Thermistor - Stop

Threshold Current, TMR

Pin Suspend

Presence Test Current,

VP1, VP2

Reverse Leakage

Current, VP1, VP2

V

(Note 1)

IH

V

(Note 1) 0.2 V

IL

After power-up mode

I

IL1

V

CTST

V

BAT-LOW

V

BAT-MAX1

V

BAT-MAX2

BAT-MAX∆

V

THM-MIN

V

THM-MAX

V

THM-STOP

I

TMR-SUS

I

PTST

I

LKGR

select,

- V

or VSS

DD

BAT-MAX1

DMSEL = V

= 80kW

R

CTST

CC1 = CC2 = high-Z

(Note 4)

CC1 = CC2 = high-Z

(Note 4)

CC1, CC2 active

(Note 4)

V

BAT-MAX2

(Note 5)

(Notes 1, 4, 6)

(Notes 1, 4, 6) 0.30

(Notes 1, 4, 6)

0.1 0.5

Parallel: V

Series: V

= 0V, VP1 = 1.5V,

V

DD

VP2 = 3.0V

≥ 4.0V,

DD

≥ 4.5V

DD

-

V

DD

0.2V

-1 +1

V

mA

85 100 115 mV

0.9 1.0 1.1 V

1.55 1.65 1.75 V

1.64 1.75 1.86 V

90 100 110 mV

x

V

DD

0.73

V

DD

0.33

V

DD

0.29

x

x

V

0.36 V

V

mA

10 15

2

mA

mA

Current-Sense Reference

Voltage

Gain, Current-Sense

Error Amp

Gain, Current-Sense

Comparator

Propagation Time,

Current-Sense

Comparator

Hysteresis, CurrentSense Comparator

V

(Note 1, 4, 7)

IREF

G

DS2711 (Note 8) 0.9 1.5

M

G

DS2712 (Note 8) 10

M

t

PDLY

V

HYS-COMP

DS2712, 2mV

over/underdrive

DS2712 22 24 26 mV

125 mV

-6% +6% %

-1

W

-1

W

0.25

ms

ELECTRICAL CHARACTERISTICS: TIMING

(4.0V £ VDD £ 5.5V, TA = -20°C to +70°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Internal Timebase Period t

Internal Timebase

Accuracy

Duty Factor, Series Fast

Charge

Duty Factor, Series

Precharge/Top-Off

Duty Factor, Parallel Fast

Charge

0.96 s

BASE

-10 +10 %

CC1 0.969

CC1 0.250

CC1, CC2 0.484

3 of 14

DS2711/DS2712: Loose Cell NiMH Charger

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Duty Factor, Parallel

Precharge/Top-Off

Duty Factor, Maintenance

Charge

CC1, CC2 0.125

CC1, CC2 0.0156

Cell Test Interval t

Precharge Time-Out t

Fast-Charge Termination

Hold-Off Period

Fast-Charge Flat Voltage

Time-Out

Charge Timer Period t

PCHG

t

t

CTMR

Charge Timer Accuracy

Charge Timer Range t

Note 1:

Note 2:

Note 3:

Note 4:

Note 5:

Note 6:

Note 7:

Note 8:

Voltages relative to V

I

current is applied as a source current and as a sink current within 5ms after power-up.

MTST

When operating in two-cell-series charge configuration, the DMSEL pin must have less than 50pF of external load capacitance

for proper operation. If the load capacitance is greater than 50pF, a resistor voltage divider should be used to maintain DMSEL

/ 2.

at V

DD

Specification applicable during charge cycle with T

V

V

Tested with I

Gain tested with 1mV step with I

and V

BAT-MAX1

THM-MIN, VTHM-MAX,

BAT-MAX1

CSOUT

CTMR-RANGE

.

SS

are generated from the same reference. Their ranges never overlap.

and V

THM-STOP

= -1mA.

31 s

CTST

V

4 minutes

THO

V

FLAT

< V

CELL

not increasing 16 minutes

CELL

= 100kW

R

TMR

= 100kW

R

TMR

34 minutes

BAT-MIN

2.5 h

-5 +5 %

0.5 10 h

= 0°C to +70°C.

A

are fixed ratios of V

= -1mA.

CSOUT

Their ranges never overlap.

DD.

4 of 14

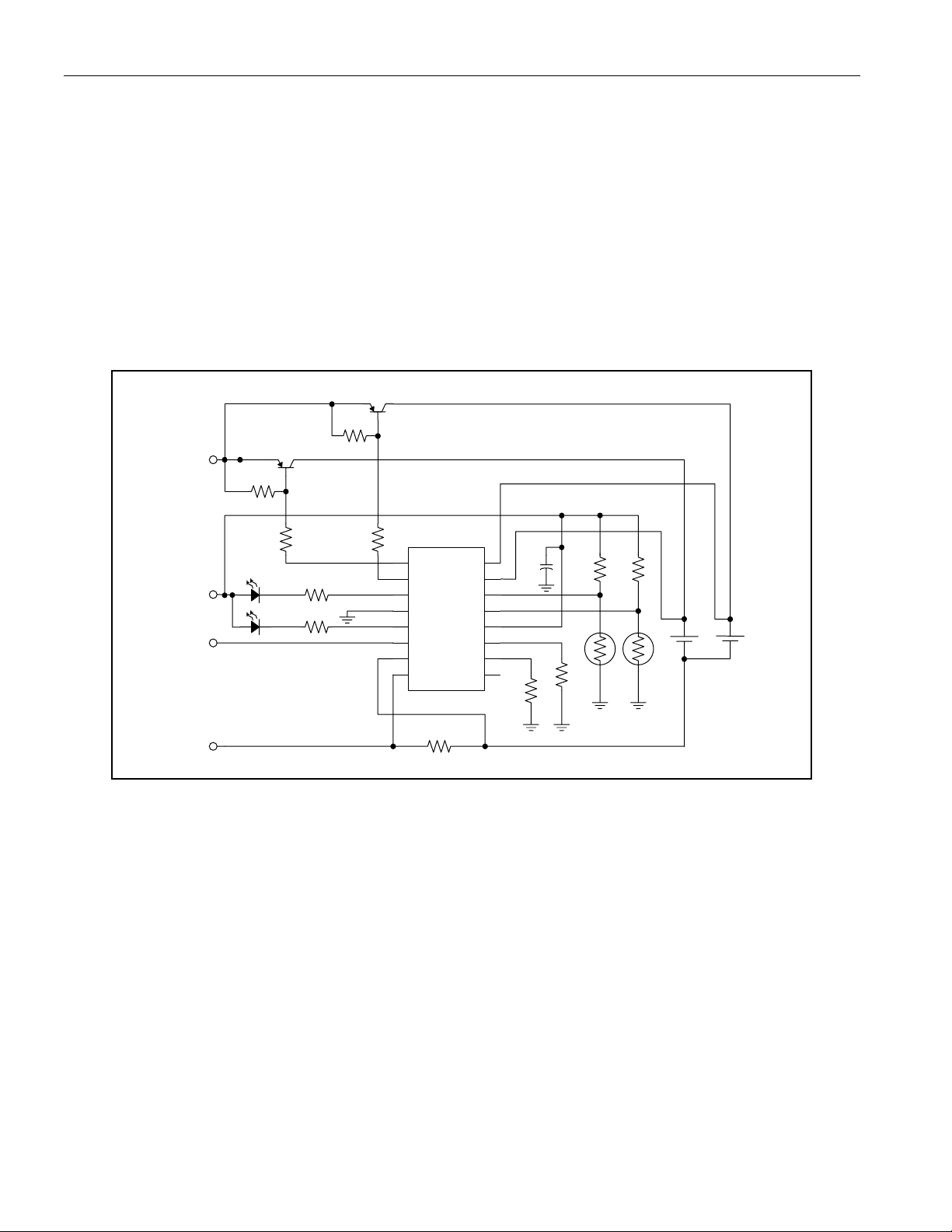

Figure 1. BLOCK DIAGRAM

DS2711/DS2712: Loose Cell NiMH Charger

VDD

CC1

CC2

LED1

LED2

DMSEL

CTST

TMR

3.7V

Cell

Test

Charge

Timer

Charge

Mod e

Sele ct

0.1V

BIAS

UVLO

Oscillator

State Machine

Presence Test

Pre-Charge

Fast Charge

Cell Tests

Top-Off Charge

Maintenance Charge

Watchdog

ABORT

I

PTST

I

PTST

VP1

Voltage

and

Temperature

Measurement

VP2

VN1

THM1

THM2

+

&

-

VN0

VSS

-

CSOUT

+

0.125V

DS2711

SUSPEND

+

DS2712

5 of 14

Figure 2. STATE DIAGRAM

R

V

t

R

V

R

R

t

f

t

R

t

R

t

R

V

V

V

k

t

V

VDD < VPOR -VHYS

(asynchronously from

anywhere)

PO

Standby power

CCx = Hi-Z

LEDx = Hi-Z

VDD > VPOR (3.7V)

Presence

TEST

CCx = Hi-Z

LEDx = No Battery

DS2711/DS2712: Loose Cell NiMH Charger

VBAT > 1.75

O

T < 0C

O

T > 45C

t < PCTimeou

O

VBAT < 1V

t < Fast Timeou

t < Topoff Timeout

VBAT > 1V

AND

t < PCTimeou

AND

T < 50C

CHG

CCx = Act ive

48% Par., 97% Ser.

LEDx = Charging

delta-V detec

t > Fast Timeou

Topof

CHG

CCx = Act ive

12.5% Par., 25% Ser.

LEDx = Charging

PreCHG

CCx = Act ive

12.5% Par., 25% Ser.

LEDx = Charging

PASS

Fast

O

t > PCTimeou

VBAT > 1.75

Cell Test

CCx = Hi-Z

LEDx = Charging

32 cloc

interval

t > Topoff Timeout

VBAT < 1.65

O

T > 50

OR

FAIL:

VON - VOFF > V

T > 50

O

VBAT > 1.75

FAULT

Standby power

CCx = Hi-Z

LEDx = Fault

CTST

VBAT > 1.75

T > 50

MAINT

CCx = Act ive 1/64

LEDx = Ma intenance

VBAT > 1.75

(asynchronously

from anywhere)

t < 1s

6 of 14

DS2711/DS2712: Loose Cell NiMH Charger

DETAILED DESCRIPTION

Charge Algorithm Overview

A charge cycle begins in one of three ways: with the application of power to the DS2711 with cell(s) already

inserted, with the detection of cell insertion after power-up, or when exiting suspend mode with cell(s) inserted. The

charge cycle begins with precharge qualification to prevent fast charging of deeply depleted cells or charging under

extreme temperature conditions. precharging is performed at a reduced rate until each cell reaches 1V. The

algorithm proceeds to a fast-charge phase, which includes cell tests to avoid accidental charging of alkaline cells or

NiMH cells that are worn-out or damaged. Fast charging continues as long as the cell temperature(s) are less than

50°C (based on THM1, THM2 voltages) and the open-circuit cell voltage(s) are between 1.0V and 1.75V. Fast

charging terminates by the -DV (negative delta voltage) method. The top-off charge phase follows to completely

charge the cells. After the top-off charge timer expires, the maintenance charge phase continues indefinitely to

keep the cells at a full state of charge. Maximum voltage, temperature, and charge-time monitoring during all

charge phases act as secondary or safety termination methods to provide additional protection from overcharge.

Each cell is monitored independently, and in parallel mode the charge phase of each cell is independently

controlled.

Series Charge Configuration

The DS2711/DS2712 series configuration supports one or two-slot stand-alone and one or two cell in-system

chargers. The single-cell-series mode charges one cell while the two-cell-series mode charges two series cells.

Since the cells are charged in series, cell sizes should not be mixed in the series configuration. In the application

example in Figure 3, charge current is gated to the battery cells by a PNP transistor under the control of the CC1

pin of the DS2711. Current regulation is performed outside of this example schematic using the current-sense

feedback provided by the DS2711 CSOUT pin. The DS2712 can also be used in this circuit to provide switch-mode

control on the CSOUT pin. RSNS = 0.125W sets the charge source current, ICHG, to 1A. In series mode, the

effective charge current is 0.969 x ICHG = 969mA.

Figure 3. SERIES CONFIGURATION WITH EXTERNAL CURRENT

REGULATION

ICHG

+5V

IFB

GND

10K

FCX718

270

100

DS2711/12

CC1

CC2

LED1

VSS

LED2

VN1

VN0

RSNS

0.125

VP2

VP1

THM2

THM1

VDD

TMRCSOUT

CTST

DMSEL

75K

0.1

100K

10K

x2

103AT-2

x2

7 of 14

DS2711/DS2712: Loose Cell NiMH Charger

Parallel Charge Configuration

The parallel configuration supports two slot stand-alone chargers. Charge pulses are fed alternately to each cell

under the control of the CC1 and CC2 pins so the charge regimes occur in parallel. The duty cycle on CC1 and

CC2 are independent of one another. Transitions from precharge to fast charge, fast charge to top-off, and top-off

to maintenance occur independently for each cell.

The configuration shown in Figure 4 is for charging two cells with the current-sense feedback regulating the charge

source to 2A (RSNS = 0.068W). The effective charge current for each cell is 2A x 0.484 = 0.968A. A charger with

battery holders designed to accept either AA or AAA cell sizes can be constructed with the current-sense

resistance split between two separate resistors so each cell type (AA or AAA) is charged at a different rate.

Mechanical design of the holders is required to prevent insertion of more than one cell in each slot. The holder

design must also prevent electrical contact with reverse polarity insertion.

Figure 4. PARALLEL CONFIGURATION WITH EXTERNAL CURRENT

REGULATION

FCX718

270

270

10K

100

DS2711/12

CC1

CC2

LED1

VSS

LED2

VN1

VN0

RSNS

VP2

VP1

THM2

THM1

VDD

TMRCSOUT

CTST

DMSEL

75K

100K

10K

x2

103AT-2

x2

0.1

ICHG

FCX718

10K

100

+5V

IFB

GND

0.068

The series or parallel charge configuration is programmed by strapping LED2 in the low, high, or high-Z (float) state

during power-up. In this example and the following one, the parallel charge mode is selected by pulling LED2 pin

high during power-up. This is accomplished in this example by the LED and 270W resistor. In applications where

only one LED is used, a 100kW pullup resistor is recommended. See Table 3. CHARGE MODE SELECTION on

page 13 for additional configuration programming information.

8 of 14

DS2711/DS2712: Loose Cell NiMH Charger

DS2712 Parallel Charge Configuration with Switch-Mode Charge Current Regulation

The example in Figure 5 uses the DS2712 to regulate charge current as a switching (buck) regulator. ICHG is set

to 2A using RSNS = 0.056W. The effective charge current for each cell is ICHG x 0.484 = 968mA. The CSOUT

comparator output switches OFF when the voltage across the sense resistor goes above 0.125V and back ON

when the voltage drops below 0.100V. In this mode, the operating frequency is determined primarily by the value of

the inductor, the hysteresis, the input voltage, and the voltage on the cells. In some cases, a damping network may

be required to prevent overshoot with the batteries removed.

Figure 5. PARALLEL CONFIGURATION WITH SWITCH-MODE CURRENT

REGULATION (DS2712 ONLY)

FCX718

10K

+5V

47u

270

270

680

1u

FCX718

10K

100 100

150

FCX718

47uHy

DS2712

CC1

CC2

LED1

VSS

LED2

CSOUT

VN1

VN0

0.1

THM2

THM1

VDD

TMR

CTST

DMSEL

10

10k

10k

VP2

VP1

ICHG

100k

75k

103AT-2C1 47uF

103AT-2

RSNS

0.056

GND

9 of 14

DS2711/DS2712: Loose Cell NiMH Charger

Undervoltage Lockout (UVLO)

The UVLO circuit serves as a power-up and brownout detector by monitoring VDD to prevent charging until VDD

rises above V

, or when VDD drops below V

UVLO

UVLO

- V

. If UVLO is active, charging is prevented, the state

HYS

machine is forced to the RESET state, and all charge timers are reset. A 10ms deglitch circuit provides noise

immunity.

Internal Oscillator and Clock Generation

An internal oscillator provides the main clock source used to generate timing signals for internal chip operation. The

precharge timer, hold-off timers, and timings for CC1/CC2 operation and cell testing are derived from this timebase.

In case the internal clock should ever fail, a watchdog detection circuit halts charging. The watchdog safety circuit

and charge timer set by the TMR pin are derived from separate oscillators than the main clock source.

Current-Sense Amplifier (DS2711)

An error amplifier block provides several options to regulate the charge current. The 20mA open-drain output can

drive a PMOS or PNP pass element for linear regulation, or the output can drive an optocoupler for isolated

feedback to a primary-side PWM controller. The VN0 pin is a remote-sense return and should be connected to the

grounded side of the sense resistor using a separate, insulated conductor.

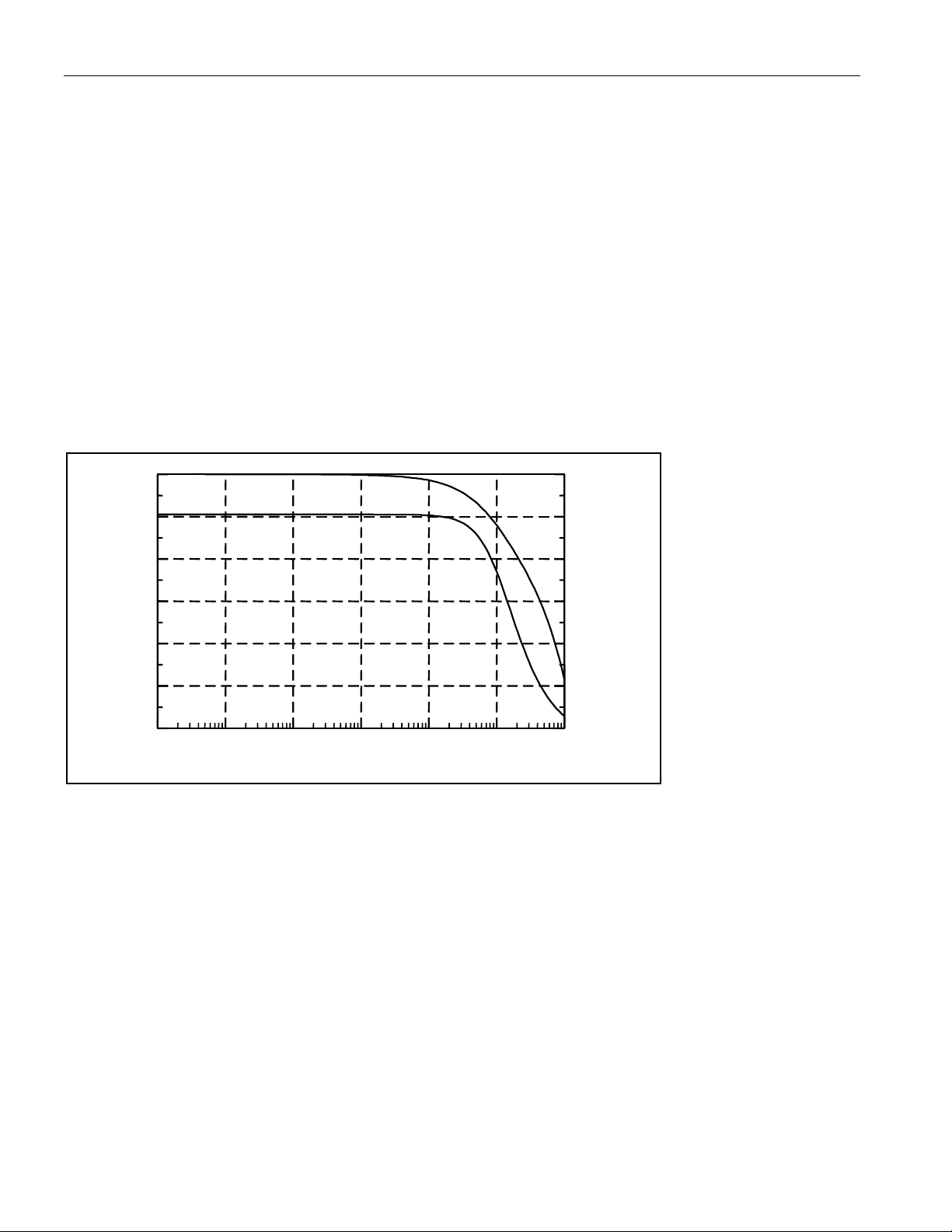

Figure 6. Current-Sense Amplifier Response

1.20

1.00

0.80

0.60

Gain Phase

Gain

0.40

0.20

0.00

10

1

10

2

10

3

10

4

5

10

6

10

Frequency (Hertz)

0

-50

-100

-150

Phase

-200

-250

-300

7

10

The open-loop amplifier response shown in Figure 6 was measured with I

the current-sense signal (across a sense resistor) and the 0.125V internal reference is produced so the voltage

across the sense resistor is maintained at V

in a closed-loop circuit.

IREF

= -1mA. An error signal between

CSOUT

Current-Sense Comparator (DS2712)

The comparator in the DS2712 switches between ON and OFF and is capable of driving a PNP bipolar or a PMOS

transistor, enabling the use of a switched-mode power stage. Hysteresis on the comparator input provides noise

rejection. In the closed-loop regulation circuit of Figure 5, the comparator regulates voltage across the sense

resistor to a DC average of:

V

= V

RSNS

- 0.5 x V

IREF

HYS-COMP

= 0.125V

10 of 14

DS2711/DS2712: Loose Cell NiMH Charger

Charge Timer

The charge timer monitors the duration of charge in fast and top-off charge phases, and is reset at the beginning of

each phase. The time-out period is set with an external resistor connected from the TMR pin to V

. Resistors can

SS

be selected to support fast-charge time-out periods of 0.5 to 10 hours and top-off charge time-out periods of 0.25 to

5 hours. If the timer expires in fast-charge, the timer count is reset and charging proceeds to the top-off charge

phase. The top-off time-out period is half of the fast charge time-out period. If the timer expires in top-off, charging

proceeds to the maintenance phase. The programmed charge time approximately follows the equation:

t = 1.5 x R / 1000 (time in minutes)

Suspend

Suspension of charge activity is possible by floating the TMR pin. The CC1 and CC2 outputs become high-Z and

the charge timer stops. The state machine and all timers are reset to their presence test conditions.

Temperature Sense

Connecting an external 10kW NTC thermistor between THM1 or THM2 (THMx) and VSS, and a 10kW bias resistor

between V

and THMx allows the DS2711 to sense temperature. To sense the temperature of the battery cells,

DD

locate the thermistor close to the body of the battery cell so THM1 monitors the temperature of cell-1 and THM2

monitors the temperature of cell-2. Alternatively, the thermistor can sense ambient temperature by locating it away

from the cells. THM1 and THM2 can be connected together to sense temperature using a single thermistor and

bias resistor. The temperature qualification function can be defeated by connecting THM1 and THM2 to a single

resistor-divider supplying a voltage between the Thermistor-Min and Thermistor-Max threshold voltages. Several

recommended 10kW thermistors are shown in Table 2.

Min, Max Temperature Compare

The voltage thresholds of the THMx inputs (VTHM-MIN, VTHM-MAX) are set to allow fast charging to start if 0°C <

T

< 45°C when using the recommended 10kW bias and 10kW thermistor. If fast charging is in progress, and the

A

voltage on THMx reaches VTHM-STOP, fast charging stops and the maintenance phase begins.

Table 2. THM1, THM2 THRESHOLDS

THM

THRESHOLD

RATIO

OF V

DD

THERMISTOR

RESISTANCE

(W)

Semitec

103AT-2

MIN 0.73 27.04k

MAX 0.33 4.925k

STOP 0.29 4.085k

45°C 42°C

50°C 47°C

Figure 7. CELL VOLTAGE SENSE POINTS

Series Configuration

Charge Source

CC1

VP2

Vcell2

VP1

Vcell1

VN1

VN0

Charge Source

TEMPERATURE (°C)

Fenwal

197-103LAG-A01

173-103LAF-301

0°C 4°C

Parallel Configuration

CC2

CC1

VP1

Vcell1 Vcell2

VN1

VN0

VP2

11 of 14

DS2711/DS2712: Loose Cell NiMH Charger

Cell Voltage Monitoring

In the 2-cell series mode, the voltage difference between VP2 and VP1 is used to determine the Vcell2 voltage in

the two-cell series stack. The voltage difference between VP1 and VN1 is used to determine the Vcell1 voltage. In

the 1-cell series mode, the difference between VP1 and VN1 is used as the cell voltage. VP2 can be left floating in

the 1-cell series mode. In parallel mode, the difference between VP2 and VN1 is used for the Vcell2 voltage, and

the difference between VP1 and VN1 is used for Vcell1 voltage.

Individual cell voltages are monitored for minimum and maximum values, using the V

threshold limits. Upon inserting a cell or power-up with cells inserted, cell voltages must be less than the V

threshold before charging begins. The V

threshold determines whether a precharge cycle should precede the

BAT-MIN

BAT-MIN

, V

BAT-MAX1

and V

BAT-MAX2

BAT-MAX1

fast charge cycle, and when to transition from precharge to fast charge. Once fast charging commences, cell

voltages are compared to the V

BAT-MAX2

threshold once per second. The comparison occurs while the charge

control pin (CC1 or CC2) controlling current to the cell is active (low). When the charge control pin is active so

charge is applied to the cell, the cell voltage is referred to as the V

inactive, the cell voltage is referred to as the V

voltage. If V

OFF

BAT-MAX2

voltage. When the charge-control pin is

ON

is exceeded in fast charge, charging is halted

and a fault condition is displayed. While fast charge is in progress, cell voltage measurements are stored and

compared to future measurements for charge termination and cell test purposes.

Two types of tests are performed to detect primary alkaline and lithium cells or defective NiMH or NiCd secondary

cells. Cells are tested individually in the series and parallel configurations, so that a single improper or defective

cell can be detected quickly. In the series configuration, a single defective cell will terminate charge for both cells,

whereas the parallel mode continues charging the good cell and stops charging the defective cell.

V

is set by the resistance from the CTST pin to ground. The nominal sensitivity of 100mV is set by connecting

CTST

an 80kW resistor between CTST and V

. The detection threshold can be set from 32mV to 400mV. The following

SS

formula approximates the setting for the detection threshold.

V

= 8000/R (value in volts)

CTST

-∆V and Flat Voltage Termination

During fast charge, -DV detection is performed by comparing successive voltage measurements for a drop of 2mV

in the cell voltage. A hold-off period for -DV detection begins at the start of fast charging and prevents false

termination in the first few minutes of the charge cycle. Once the hold-off period expires, cell voltage

measurements are acquired every 32 clock cycles (during the CCx off time). When a newly acquired voltage

measurement is greater than any previous one, the new value is retained as the maximum value. When the cell

voltage no longer increases, the maximum value is retained and compared against subsequent values. If the cell

voltage drops by the -DV threshold, V

that the maximum value persists for a period of 16 minutes (t

, (2mV typ), fast charging is terminated. If the cell voltage remains flat such

-DV

), fast charge terminates and top-off charging

FLAT

begins.

Top-Off and Maintenance

In top-off mode, the charger scales the cell current to 25% of the fast charge current. The charge timer is reset and

restarted with a time-out period of one half the fast-charge duration. When the charge timer expires in top-off, the

charger enters maintenance and delivers 1/64 of the charge source current to the cells. Maintenance charge

continuous until power is removed, the cell(s) are removed or the DS2711/DS2712 is cycled into and out of

suspend mode by floating the TMR pin.

Selecting the Charge Mode

The charge mode configuration is selected by testing the LED2 pin during startup. An internal current source tests

the state of the LED2 pin by pulling up and pulling down on the pin to determine if it is high, low, or floating. The

recommended pullup or pulldown resistor value (if used) is 100kW. In the parallel charging circuit diagrams on page

8, no resistor is shown. The current path through the LED and 270W resistor is sufficient to pull the LED2 pin high

at power-up to select the parallel mode. Refer to the mode test current (I

Characteristics table to select other pullup values.

) specification in the Electrical

MTST

12 of 14

DS2711/DS2712: Loose Cell NiMH Charger

Table 3. CHARGE MODE SELECTION

LED2 PIN STRAPPING MODE

Low 1-Cell Series

Floating 2-Cell Series

High Parallel

CC1 and CC2 Outputs

The CC1 and CC2 operate as open-drain outputs that drive active low to connect the charge source to the battery

cell. During charge, the behavior of the CC1 and CC2 outputs depends on the charge-mode configuration. In

parallel mode, CC1 and CC2 are driven low in alternating time slots. The charge source is loaded by just one cell

during any time slot. In the 1-cell and 2-cell series mode, only CC1 is driven. Except for the periodic performance of

impedance and -DV tests, series mode charging is continuous during the fast charge phase rather than pulsed in

parallel mode.

Parallel Mode Fast Charge

Referring to Figure 4. PARALLEL CONFIGURATION WITH EXTERNAL CURRENT REGULATION, CC1 controls

the PNP switch that gates current to the cell in slot 1. CC2 controls the PNP switch that gates current to the cell in

slot 2. During fast charge, current is gated to each slot sequentially, with charge pulses occurring in alternating time

frames. The cell in one slot charges while the other relaxes and the effective fast-charge current is 48.4% of the

magnitude set by the charge-source current limit. The parallel configuration skips a charge pulse every 32 clock

cycles to facilitate independent testing of the open- and closed-circuit cell voltages (V

Since the charge regime of each cell is independent, one cell may complete a charge phase before the other. The

more fully charged cell of a pair inserted at the same time could terminate fast charge by -DV, then charge in top-off

while the less charged cell continues in fast charge. In the case of an improper or faulty cell (e.g., alkaline) being

inserted along with a proper cell (NiMH or NiCd), charging of the faulty cell would be stopped, while the proper cell

is charged to full.

and VON, respectively).

OFF

Series Mode Fast Charge

Referring to Figure 3. SERIES CONFIGURATION WITH EXTERNAL CURRENT REGULATION, CC1 controls the

PNP switch that gates current to the cell(s). In series mode, 1 or 2 cells can be charged, depending on whether the

1-cell or 2-cell series mode has been selected. During fast charge, current is gated to the cell(s) almost

continuously, with the effective fast-charge current approximately equal to current limit of the charge source. The

series configuration deactivates CC1 briefly every 32 clock cycles to facilitate independent testing of V

of each cell. The one second deactivation makes the duty factor 0.969 and therefore the effective current equals

approximately 97% of the charge-source current limit. In the 2-cell series mode, the characteristics of each cell are

evaluated individually; however charging stops if either cell is determined to be improper or faulty.

In the 1-cell charge series mode, CC1 gates the charge current as in the 2-cell series mode. The cell voltage is

monitored between VP1 and VN1, and temperature is monitored with THM1. The VP2 and THM2 pins can be left

floating in the 1-cell series mode.

and VON

OFF

EXAMPLE CAPACITIES AND CHARGE RATES

Parallel Charging Example:

A 1700mAH cell is charged using a 1A regulated charge source. During fast charge, the cell is charged at a duty

factor of 0.484 and receives an effective charge current of 0.484A. In terms of C-rate, this is 484mA/1700mAh =

0.285°C (or C/3.5). During precharge and top-off, the duty factor is 0.125 (i.e., 1/8), for an effective average

current of 125mA, corresponding to a C-rate of 125/1700 = 0.073C (or C/13.6). Similarly, in maintenance mode, the

duty factor is 0.0156 (i.e., 1/64) and the C-rate is 15.6/1700 = 0.0092 ( or C/109). The C-rates for charging 3

different cell capacities using a 500mA and a 1000mA current source are shown in Table 4.

13 of 14

DS2711/DS2712: Loose Cell NiMH Charger

Table 4. PARALLEL CONFIGURATION, EACH CELL

MODE CURRENT LIMIT 500mA CURRENT LIMIT 1000mA

Cell Capacity 900mAH 1700mAH 2200mAH 900mAH 1700mAH 2200mAH

Fast C/3.72 C/7.02 C/9.08 C/1.86 C/3.51 C/4.54

Precharge/Top-Off C/14.4 C/27.2 C/35.2 C/7.20 C/13.6 C/17.6

Maintenance C/115 C/218 C/282 C/57.6 C/109 C/141

Series and Single Cell Charging Example:

In the series and single-cell modes, the effective fast charge current is equal to 0.969 times the regulated current

limit and the top-off current is 0.25 times the regulated current. The maintenance mode is identical to the parallel

charging rate, that is, 1/64 times the regulated current. The C-rates for charging 3 different cell capacities using a

500mA and a 1000mA current source are shown in the following table.

Table 5. SERIES CONFIGURATION, EACH CELL

MODE CURRENT LIMIT 500mA CURRENT LIMIT 1000mA

Cell Capacity 900mAH 1700mAH 2200mAH 900mAH 1700mAH 2200mAH

Fast C/1.86 C/3.51 C/4.54 C/0.93 C/1.75 C/2.27

Precharge/Top-Off C/7.20 C/13.6 C/17.6 C/3.60 C/6.80 C/8.80

Maintenance C/115 C/218 C/282 C/57.6 C/109 C/141

LED1 and LED2 Outputs, MODE-Select Input

Open-drain outputs LED1 and LED2 pull low to indicate charge status. When inactive, the outputs are high

impedance. LED1 displays the status for the cell monitored by VP1 and LED2 displays the status for the cell

monitored by VP2.

The LED pins drive low in three “blink” patterns to annunciate the charge status. Table 6 summarizes the LED

operation in each display mode (DM0, DM1, DM2) for each charge condition. In parallel mode, LED1 indicates the

status of the cell whose positive terminal is connected to VP1 and LED2 indicates the status of the cell whose

positive terminal is connected to VP2. In series mode, LED1 indicates the charge status for both cells since they

are charged in series.

Table 6. DISPLAY PATTERNS BY DISPLAY MODE AND CHARGE ACTIVITY

DISPLAY MODE CHARGE ACTIVITY

PRE/FAST/TOP-

OFF

CHARGING

0.80s Low

0.16s High-Z

MAINTENANCE FAULT

0.80s Low

0.16s High-Z

Low

DMSEL PIN

DM0

DM1

DM2

High-Z = High Impedance

NO

BATTERY

Low High-Z Low

Float High-Z Low High-Z

High High-Z

Package Information

For the latest package outline information, go to www.maxim-ic.com/DallasPackInfo.

14 of 14

0.48s Low

0.48s High-Z

0.16s Low

0.16s High-Z

0.16s Low

0.16s High-Z

Loading...

Loading...