Page 1

r

www.dalsemi.com

DS2480

Serial 1-Wire™ Line Drive

FEATURES

Universal, common-ground serial port to

1-WireTM line driver for MicroLAN

applications

Works with all iButtons™ and MicroLANcompatible 1-Wire slave devices

Communicates at regular and Overdriv e 1-W ire

speed and serial port data rates of 9600

(default), 19200, 57600 and 115200 bps

Supports 12V EPROM programming and stiff

5V pull-up for Crypto iButton, sensors and

EEPROM

Self-calibrating time base with ±5% tolerance

for serial and 1-Wire communication

Slew rate controlled 1-Wire pull-down and

active pull-up to accommodate long lines and

reduce radiation

User-selectable RXD/TXD polarity minimizes

component count when interfacing to 5V

based RS232 systems or directly to UARTs

Programmable 1-Wire timing and driver

characteristics accommodate a wide range of

MicroLAN configurations at regular speed

Smart protocol combines data and control

information without requiring extra pins

Compatible to optical, IR and RF to RS232

converters

Low cost 8-pin SOIC surface mount package

Operates over 4.5V to 5.5V from -40°C to

+85°C

TM

PIN ASSIGNMENT

1

GND

1-W

NC

V

DD

8-PIN SOIC

(150 MIL)

8

RXD

2

7

TXD

3

4

POL

6

V

PP

5

PIN DESCRIPTION

GND Ground

1-W 1-Wire Input/Output

NC No Connection

V

V

DD

PP

4.5 to 5.5V

Optional EPROM

Programming Voltage

POL RXD/TXD Polarity Select

TXD Serial Data from UART

RXD Serial Data to UART

ORDERING INFORMATION

DS2480S 8-pin SOIC

1 of 33 012501

Page 2

DS2480

DESCRIPTION

The DS2480 is a serial port to 1-Wire interface chip that supports standard and Overdrive speeds. It

connects directly to UARTs and 5V RS232 systems. Interfacing to RS232C (± 12V levels) requires a

passive clamping circuit and one 5V to ± 12V level translator. Internal timers relieve the host of the

burden of generating the time-critical 1-Wire communication waveforms. In contrast to the

DS9097 (E) where a full character must be sent by the host for each 1-W ire time slot, the DS2480 can

translate each character into eight 1-Wire time slots thereby increasing the data throughput

significantly. In addition, the DS2480 can be set to communicate at four different data rates including

115.2 kbps, 57.6 kbps and 19.2 kbps with 9.6 kbps being the power-on default. Command codes

received from the host’s crystal controlled UART serve as a reference to continuously calibrate the onchip timing generator. The DS2480 uses a unique protocol that merges data and control information

without requiring control pins. This approach maintains compatibility to off-the-shelf serial to

wireless converters allowing easy realization of 1-Wire media jumpers. The various control functions

of the DS2480 are optimized for MicroLAN 1-Wire networks and support the special needs of all

current 1-Wire devices including the Crypto iButton, EPROM-based Add-Only Memories, EEPROM

devices and 1-Wire Thermometers.

DETAILED PIN DESCRIPTION

PIN SYMBOL DESCRIPTION

1 GND Ground Pin: common ground reference and ground return for 1-Wire bus

2 1-W 1-Wire Input/Output Pin: 1-Wire bus with slew-rate-controlled pull-down, active

pull-up, ability to switch in VPP to program EPROM, and ability to switch in

VDD through a low-impedance path to program EEPROM, perform a

temperature conversion or operate the Crypto iButton.

3 NC No Connection Pin.

4V

5V

DD

PP

6 POL RXD/TXD Polarity Select: RXD/TXD polarity select; tied to GND for RS232

7 TXD Serial Data from UART: data input from host (inverted or true); maximum

8 RXD Serial Data to UART: signal output to host; push-pull driver with CMOS

Power Input Pin: power supply for the chip and 1-Wire pull-up voltage. 5V ±

10%; may be derived from 12V VPP with an external voltage regulator.

EPROM Programming Voltage: 12V supply input for EPROM programming; if

EPROM programming is not required, this pin must be tied to VDD. VPP must

come up before VDD.

(12V or 5V) connection, tied to V

voltage swing -0.3V to V

+ 0.3V; for logic thresholds see DC specifications.

DD

for direct connection to UART chip.

DD

compatible levels; for true ±12V RS232 systems an external level-translator

must be provided.

2 of 28

Page 3

DS2480

OVERVIEW

The DS2480 directly interfaces a 5-volts serial communication port with its lines TXD (transmit) and

RXD (receive) to a 1-Wire bus. In addition the device performs a sp eed conversion allowin g the data rate

at the communication port to be different from the 1-Wire date rate. Several parameters relating to the

1-Wire port and its timing as well as the communication speed at both the port and the 1-Wire bus are

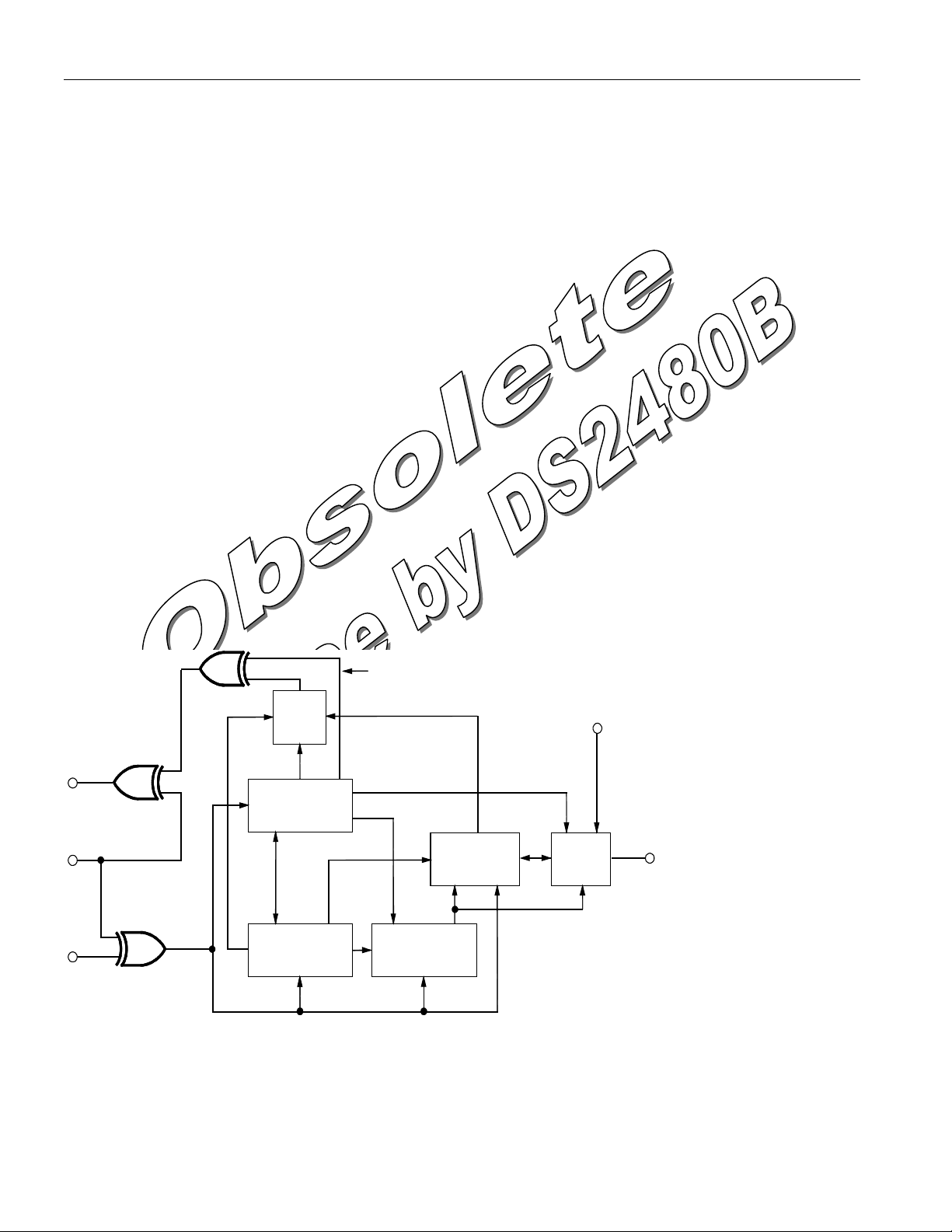

configurable. The circuit to achieve these functions is outlined in Figure 1, Block Diagram. The device

gets its input data from the serial communication port of the host computer through pin TXD. For

compatibility with active-high as well as active-low systems, the incoming signal can be inverted by

means of the polarity input POL. The polarity chosen by hard wiring the logic level of this pin is also

valid for the output pin RXD. If for minimizing the interface hardware an asymmetry between RXD and

TXD is desired, this can be achieved by setting the most significant bit of the Speed Control parameter to

a 1 (see Configuration Parameter Value Codes). With the MS bit of the speed control set to 1, the polarity

at TXD is still selected by the logic level at POL, but the polarity at RXD will be the opposite of what the

logic level at POL specifies. As data enters the core of the DS2480’s logic circuitry, it is analyzed to

separate data and command bytes and to calibrate the device’s timing generator. The timing generator

controls all speed relations of the communication interface and the 1-Wire bus as well as the waveforms

on the 1-Wire bus. Command bytes either affect the configuration setting or generate certain waveforms

on the 1-Wire bus. Data bytes are simply translated by the protocol converter into the appropriate 1-W ire

activities. Each data byte generates a return byte from the 1-Wire bus that is communicated back to the

host through the RXD pin as soon as the activity on the 1-Wire bus is completed. The 1-Wire driver

shapes the slopes of the 1-Wire wave forms, applies programming pulses or strong pull-up to 5-volts and

reads the 1-Wire bus using a non-TTL threshold to maximize the noise margin for best performance on

large 1-Wire MicroLAN networks.

DS2480 BLOCK DIAGRAM FIGURE 1

MS BIT OF SPEED CONTROL

(1 = RXD IS INVER TE D)

MUX

RXD

CONFIGURATION

REGISTER

POL

TXD

PROTOCOL

PROTOCOL

ANALYZER

ANALYZER

TIMING

GENERATOR

PROTOCOL

CONVERTER

1-WIRE

DRIVER

PP

V

1-W

3 of 28

Page 4

DS2480

DEVICE OPERATION

The DS2480 can be described as a complex state machine with two static and several dynamic states.

Two device-internal flags as well as functions assigned to certain bit positions in the command codes

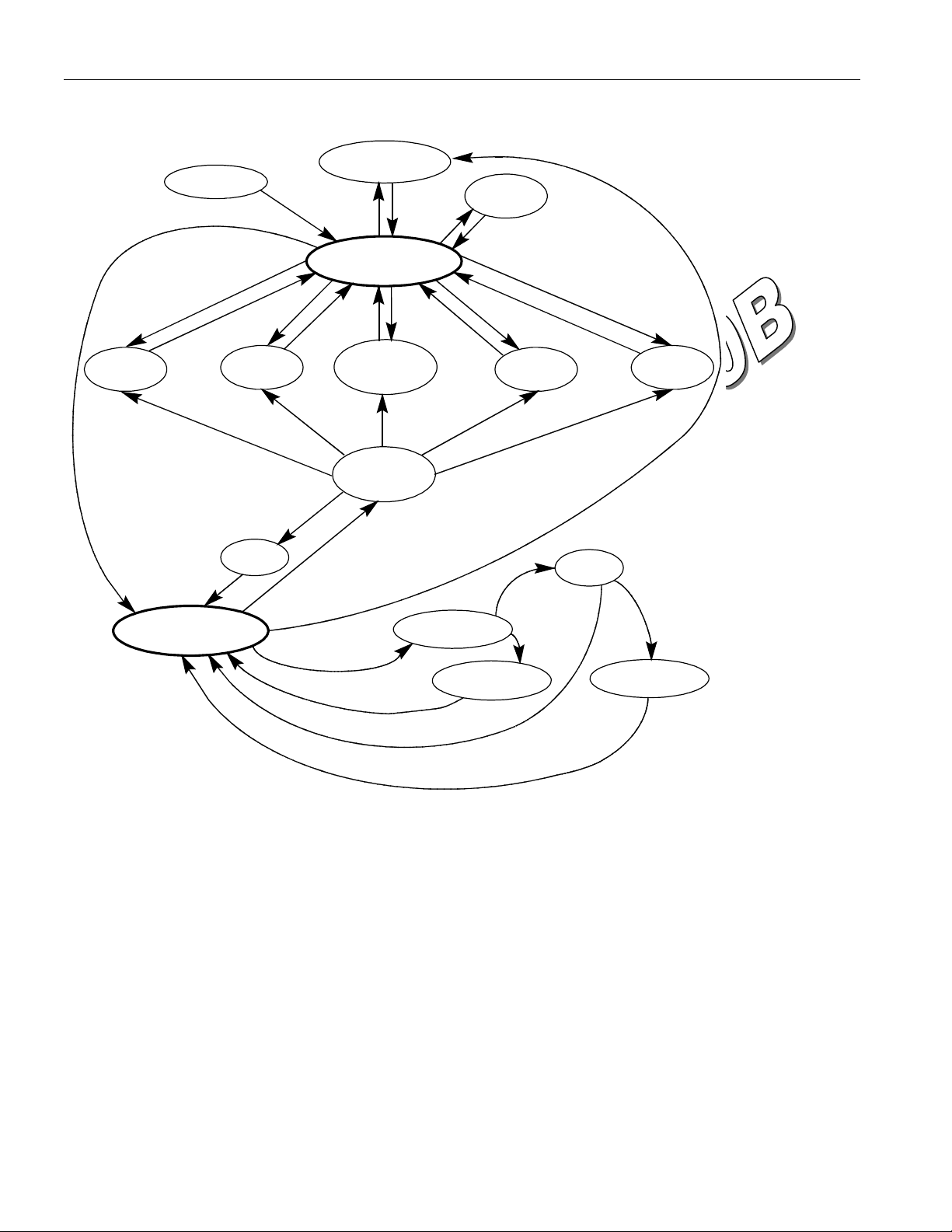

determine the behavior of the chip, as shown in the state transition diagram (Figure 2). The DS2480

requires and generates a communication protocol of 8 data bits per character, 1 stop bit and no parity. It is

permissible to use two stop bits on the TXD line. However, the DS2480 will only assert a single stop bit

on RXD. When powering up, the DS2480 performs a master reset cycle and enters the

Command Mode, which is one of the two static states. The device now expects to receive one 1-Wire

reset command on the TXD line sent by the host at a data rate of 9600 bits per second (see section

Communication Commands for details). This command byte is required solely for calibration of the

timing generator the DS2480 and is not translated into any activity on the 1-Wire bus. After this first

command byte the device is ready to receive and execute any command as described later in this

document. A master reset cycle can also be generated by means of software. This may be necessary if the

host for any reason has lost synchronization with the device. The DS2480 will perform a master reset

cycle equivalent to the power-on reset if it detects start polarity in place of the stop bit. The host has

several options to generate this condition. These include making the UART generate a break signal,

sending a NULL character at a data rate of 4800 bps and sending any character with parit y enabled and

selecting space polarity for the parity bit. As with the power-on reset, the DS2480 requires a 1-Wire reset

command sent by the host at a data rate of 9600 bps for calibration.

4 of 28

Page 5

STATE TRANSITION DIAGRAM Figure 2

K

X

A

A

A

A

A

A

V

DS2480

E1h

RESET

SOFTWARE

MASTER RESET

110XSS01

N.C.

110XSS01

111T11Q1

PULSE

TX E3h

N.C.

POWER OFF

N.C.

111T11Q1

E3h

CODE = E3h

INACTIVE

POWER

ON

COMMAND MODE

0ZZZVVV1

N.C.

CONFIGURATION

0ZZZVVV1

CHEC

MODE

RRIVAL

N.C.

N.C.

CC. OFF

T

RRIVAL

CODE

101HSS01

SEARCH

101HSS01

CCEL.

100VSSP1

100VSSP1

N.C.

TX BYTE

SINGLE BIT

FUNCTION

POWER OFF

STR. PULL-UP

RMED

DATA MODE

ALL OTHER

CODES

N.C. = UNCONDITIONAL

LEGEND: V BINARY VALUE (TYPE OF WRITE TIME SLOT)

SS 1-WIRE SPEED SELECTION CODE

P IF LOGIC 1, GENERATES STRONG PULL-UP TO 5V IMMEDIATELY FOLLOWING THE TIME SLOT

T TYPE OF PULSE; 0 = STRONG PULL-UP (5V), 1 = PROGRAMMING PULSE (12V)

Q 1 = ARM STRONG PULL-UP AFTER EVERY BYTE; 0 = DISARM

H SEARCH ACCELERATOR CONTROL; 1 = ACCELERATOR ON, 0 = ACCELERATOR OFF

ZZZ CONFIGURATION PARAMETER CODE (WRITE), 000 = READ CONFIGURATION PARAMETER

VVV CONFIGURATION PARAMETER VALUE CODE ( WRITE), CONFIGURATION PARAMETER CODE (READ)

X DON'T CARE

STR. PULL-UP NOT

ACCELERATOR

N.C.

CHECK SEARCH

PERFORM SEARCH

SEQUENCE

CC.ON

GENERATE STRONG

PULL-UP TO 5

N.C.

After the DS2480 has reached the command mode, the host can send commands such as 1-Wire Reset,

Pulse, Configuration, Search Accelerator and Single Bit functions or switch over to the secon d static state

called Data Mode. In data mode the DS2480 simply converts b ytes it receives at the TXD pin into their

equivalent 1-Wire wave forms and reports the results back to the host through the RXD pin. If the Search

Accelerator is on, each byte seen at TXD will generate a 12 -bit sequence on the 1-Wire bus (see section

Search Accelerator for detail s). If the Stron g Pull-up t o 5-volts is enabled (see Pul se command) e ach b yte

on the 1-Wire bus will be followed by a pause of predefined duration where the bus is pulled to 5-volts

via a low impedance transistor in the 1-Wire driver circuit.

5 of 28

Page 6

DS2480

While being in the Data Mode the DS2480 checks each byte received from the host fo r the reserv ed code

that is used to switch back to Command Mode. To be able to write any possible code (including the

reserved one) to the 1-Wire bus, the transition to the Command Mode is as follows: After having received

the code for switching to Command Mode, the device temporaril y enters the Che ck Mode where it waits

for the next byte. If both bytes are the same, the byte is sent once to the 1-Wire bus and the device returns

to the Data Mode. If the second byte is different from the reserved code, it will be ex ecuted as command

and the device finally enters the Command Mode. As a consequence, if the rese rved code that normally

switches to Command Mode is to be written to the 1-Wire bus, this code byte must be sent twice

(duplicated). This detail must be considered carefully when developing software drivers for the DS2480.

After having completed a memory function with a device on the 1-Wire bus it is recommended to issue a

Reset Pulse. This means that the DS2480 has to be switched to Command mode. The host then s ends the

appropriate command code and continues performing other tasks. If during this time a device arrives at

the 1-Wire bus it will generate a presence pulse. The DS2480 will recognize this unsolicited presence

pulse and notify the host by sending a byte such as XXXXXX01b. The Xs represent undefined bit values.

The fact that the host receives the byte unsolicited together with the pattern 01b in the least significant

two bits marks the bus arrival. If the DS2480 is left in Data Mode afte r completing a memory function

command it will not report any bus arrival to the host.

COMMAND CODE OVERVIEW

The DS2480 is controlled by a variety of commands. All command codes are 8 bits long. The most

significant bit of each command code distinguishes between communication and configuration

commands. Configuration commands access the configuration registers. They can write or read any of the

configurable parameters. Communication commands use data of the configuration register in order to

generate activity on the 1-Wire bus and/or (dis) arm the strong pull-up after every byte or (de) activate the

Search Accelerator without generating activity on the 1-Wire bus. Details on the command codes are

included in the State Transition diagram (Figure 2). A full explanation is given in the subsequent sections

Communication Commands and Configuration Commands.

In addition to the command codes explained in the subsequent sections the DS2480 understands the

following reserved command codes:

E1h switch to Data Mode

E3h switch to Command Mode

F1h pulse termination

Except for these reserved commands, the Search Accelerator control and the first byte after power-on

reset or master reset cycle, every legal command byte generates a response byte. The pulse termination

code triggers the response byte of the terminated pulse command. Illegal command bytes do not generate

a command response byte.

Once the device is switched back from Data Mode to Command Mode one must not repeat the E3h

command while the Command Mode is still active.

COMMUNICATION COMMANDS

The DS2480 supports four communication function commands: Reset, Single Bit, Pulse, and Search

Accelerator control. Details on the assignment of each bit of the comm and codes are shown in Table 1.

The corresponding command response bytes are detailed in Table 2. The Reset, Search Accelerator

Control and Single Bit commands include bits to select the 1-Wire communication speed (regular,

flexible regular, Overdrive). Even if a command does not generate activity on the 1-Wire bus, these bits

are latched inside the device and will take effect immediately.

6 of 28

Page 7

DS2480

COMMUNICATION COMMAND CODES TABLE 1

FUNCTION BIT 7 BIT 6 BIT 5 BIT 4 BIT 3, BIT 2 BIT 1 BIT 0

Single Bit 1 0 0 0 = write 0

1 = write 1

Search

Accelerator

Control

Reset 1 1 0 (don’t care) 00 reg. speed

Pulse 1 1 1 0 = 5V strong pull-up

1 0 1 0 = accelerator off

1 = accelerator on

See Text

1 = 12V prog. pulse

00 reg. speed

01 flex. speed

10 OD. speed

11 reg. speed

00 reg. speed

01 flex. speed

10 OD. speed

11 reg. speed

01 flex. speed

10 OD. speed

11 reg. speed

11 pulse See Text 1

See Text 1

01

01

COMMUNICATION COMMAND RESPONSE TABLE 2

FUNCTION BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

Single Bit 1 0 0 same as sent 1-Wire read back,

both bits same value

Reset 1 1 See

Text

Pulse 1 1 1 same as sent undefined

0 1 0 00 = 1-Wire shorted

01 = presence pulse

10 = alarming presence

pulse

11 = no presence pulse

(The Search Accelerator Control command does not generate a response byte.)

RESET

The Reset command must be used to begin all 1-Wire communication. The speed selection included in

the command code immediately takes effect. The response byte includes a code for the rea ction on the

1-Wire bus (bits 0 and 1) and a code for the chip revision (bits 2 to 4). If bit 5 of the response byte reads

‘1’, a programming voltage is present on the V

devices.

pin, indicating that one may try programming EPROM

PP

SINGLE BIT

The Single Bit command is used to generate a single time slot on the 1-Wire bus at the speed indicated by

bits 2 and 3. The type of the time slot (write zero or write one) is determined by the logic value of bit 4. A

read data time slot is identical to the write one time slot. Bits 0 and 1 of the response b yte transmitted b y

the DS2480 at the end of the time slot reveal the value found on the 1-Wire bus when reading.

For a time slot without a subsequent strong pull-up, bit 1 of the command must be set to 0. For a time slot

immediately followed by a strong pull-up bit 1 must be set to 1. As soon as the strong pull-up is over, the

device will send a second response byte, code EFh (read 1) or ECh (read 0), depending on the value

found on the 1-Wire bus when reading. The strong pull-up directly following the single bit is used in

conjunction with the CryptoiButton.

7 of 28

Page 8

DS2480

SEARCH ACCELERATOR CONTROL

The Search Accelerator Control command is used to set or reset the Search Accelerator control flag. Bit 4

of the command code contains the state to which the accelerator control flag is to be set. If the fl ag is set

to a 1 (on) the device translates every byte received in data mode into a 12-bit sequ ence on the 1-Wire

bus. For details on how the Search Accelerator works please refer to the section Search Accelerator

Operation. Before activating the Search Accelerator, one must make sure that the strong pull-up after

every byte is disarmed (see Pulse Command). The Search Accelerator command does not generate a

command response byte.

Although the Search Accelerator Control command itself does not generate any 1-Wire activit y, it can be

used to select the communication speed on the 1-Wire bus. The speed selection (if different from the

previous setting, e.g., from a Reset command) will take effect immediately.

PULSE

The Pulse command serves several functions that are selected by the contents of bit 1 and bit 4 of the

command code. The main functions are generating a strong pull-up to 5-volts and generating 12-volts

programming pulses for EPROM devices (if the 12-volts are available at the VPP pin). The secondary

function of the pulse command is arming and disarming a strong pull-up after every subsequent byte in

data mode. The arm/disarm function is controlled by bit 1 of the command code. Bit 4 determines

whether the device will generate a strong pull-up to 5-volts or a 12-volts programming pulse. The table

below summarizes these options.

BIT 4 BIT 1 FUNCTION

0 0 strong pull-up to 5V and disarm

1 0 12V Programming Pulse and disarm

0 1 strong pull-up to 5V and arm

1 1 12V Programming Pulse and arm

The strong pull-up to 5-volts is required to program EEPROM devices or to operate special function

devices that require a higher current for a limited time after having received a “go and convert”

command. Therefore and because it significantly reduces the ef fective d ata throu ghput on the 1-W ire bus,

the strong pull-up is disarmed most of the time. Although arming or disarming is simultaneously possible

while generating a programming pulse, this is not recommended since it is likely to destroy the DS2480 if

non-EPROM devices are connected to the 1-Wire bus. The duration of the strong pull-up or programming

pulse is determined by configuration parameters and ranges from a few microseconds up to unlimited (see

section Configuration Commands). However, unlimited duration is not allowed in conjunction with

arming the strong-pull-up after every byte. As long as the DS2480 is in Command Mode the host may

terminate a strong pull-up or programming pulse prematurely at any time by sending the command code

F1h. The response byte is generated as soon as the strong pull-up or programming pulse is over (either

because the predefined time has elapsed or due to termination). The response byte mainly returns the

command code as sent by the host, but the two least significant bits are undefined. If the strong pull-up is

armed and the device is in Data Mode, the end of the strong pull-up will be signaled as code F6h if the

most significant bit of the preceding data byte on the 1-Wire bus was a 1 and 76h otherwise. The host will

see this response byte in addition to the response on the data byte sent (see also section Wave Forms later

in this document).

8 of 28

Page 9

DS2480

SEARCH ACCELERATOR INTRODUCTION

The Search Accelerator is a logic block inside the DS2480 that allows usin g the Search ROM function

very efficiently under modern operating systems such as Windows and Windows 95/NT. Without the

DS2480 all 1-Wire port adapters have to involve the computer’s CPU for ever y single time slot or pulse

to be generated on the 1-Wire bus.

Under DOS, accessing peripherals such as the UART or parallel port is very straight forward and

therefore fast. Under Windows the situation is different and it may take several milliseconds or more to

get the first time slot generated on the 1-Wire bus. Every subsequent time slot will be generated in much

less time, since the computer simply sends out (“streams”) a long chain of bytes. This works reasonably

well when reading or writing large blocks of data.

Searching the 1-Wire bus to identify all ROM IDs of the devices connected, however, requires reading

two bits, making a decision and then writing a bit. This procedure is to be repeated 64 times to identify

and address a single device. With the overhead of modern operating systems this fairly simple process

takes a lot of time, reducing the discovery rate of devices on the 1-Wire bus from a typical value of 40 to

50 per second under DOS to less than 10 under Windows. To solve this problem the Search Accelerator

was developed.

The Search Accelerator receives from the host information on the preferred path to chose during the

execution of the Search ROM function as one contiguous chain of bytes and then translates it into the

appropriate time slots on the 1-Wire bus. In addition, the Search Accelerator reports back to the host the

ROM ID of the device actually addressed and the bit positions in which conflicts were found. (If the

ROM ID of one device has a 0 in a bit position where another device has a 1, this is called a “con flict” on

the electrical level and “discrepancy” on the logical level. See the Book of DS19x x iButton Standards for

a more detailed discussion of the Search ROM). This helps the host to select the preferred path for the

next Search ROM activity.

Since the ROM ID of all MicroLAN compatible devices is 64 bits long and a conflict may occur in any of

these bits, the total length of data reported to the host is 128 bits or 16 bytes. To avoid data overrun (if the

CPU sends data faster than it can be processed) the protocol for the Search Accelerator operation was

defined so that one has to send as many bytes as one will receive. This way the CPU sends 16 bytes for

each path and the UART guarantees the correct data timing and frees the CPU for othe r tasks while the

DS2480 performs a Search ROM function.

SE AR CH AC CELER AT OR O P ERAT ION

After the Search Accelerator is activated and the data mode is selected, the host must send 16 bytes to

complete a single Search ROM pass on the 1-Wire bus. These bytes are constructed as follows:

first byte

76543210

r

3

et cetera

16th byte

76543210

r63 x63 r62 x62 r61 x61 r60 x60

x

3

r

2

x

2

r

1

x

1

r

0

9 of 28

x

0

Page 10

DS2480

In this scheme, the index (values from 0 to 63, “n”) designates the position of the bit in the ROM ID of a

MicroLAN compatible device. The character “x” marks bits that act as filler and do not require a specific

value (don’t care bits). The character “r” marks the path to go at that particular bit in case of a conflict

during the execution of the ROM Search.

For each bit position n (values from 0 to 63) the DS2480 will generate three time slots on the 1-W ire bus.

These are referenced as:

b0 for the first time slot (read data)

b1 for the second time slot (read data) and

b2 for the third time slot (write data).

The type of time slot b2 (write 1 or write 0) is determined by the DS2480 as follows:

b2 = rn if conflict (as chosen by the host)

= b0 if no conflict (there is no alternative)

= 1 if error (there is no response)

The response the host will receive during a complete pass through a Search ROM function using the

Search Accelerator consists of 16 bytes as follows:

first byte

76543210

r’

3

d

3

r’

2

d

2

r’

1

d

1

r’

0

d

0

et cetera

16th byte

76543210

r’

63

d

63

r’

62

d

62

r’

61

d

61

r’

60

d

60

As before, the index (values from 0 to 63, “n”) designates the position of the bit in the ROM ID of a

MicroLAN compatible device. The character “d” marks the discrepancy flag in that particular bit

position. The discrepancy flag will be 1 if there is a conflict or no response in that particular bit position

and 0 otherwise. The character “r’ “ marks the actuall y chosen path at that particular bit position. The

chosen path is identical to b2 for the particular bit position of the ROM ID.

To perform a Search ROM sequence one starts with all bits rn being 0s. In case of a bus error, all

subsequent response bits r’n are 1’s until the Search Accelerator is deactivated. Thus, if r’63 and d63 are

both 1, an error has occurred during the search procedure and the last sequence has to be repeated.

Otherwise r’

(n = 0 ... 63) is the ROM code of the device that has been found and addressed.

n

For the next Search ROM sequence one re-uses the previous set rn (n = 0 ... 63) but sets rm to 1 with “m”

being the index number of the highest discrepancy flag that is 1 and sets all ri to 0 with i > m. This

process is repeated until the highest discrepancy occurs in the same bit position for two consecutive

passes.

The table below shows an example for the communication between host and DS2480 to perform one pass

through the Search ROM function using the Se arch Accelerator. After a device has been identified and

addressed, a (not specified here) memory function is executed and finally a reset pulse is generated. This

example assumes that the DS2480 was in Command Mode and that regular 1-Wire speed is used.

10 of 28

Page 11

DS2480

SEARCH ACCELERATOR USAGE EXAMPLE

Action Sequence Host TX Host RX

Generate Reset Pulse C1 C9

Set Data Mode E1 (nothing)

Search ROM command F0 (as sent)

Set Command Mode E3 (nothing)

Search Accelerator On B1 (nothing)

Set Data Mode E1 (nothing)

Send 16 bytes data response

Set Command Mode E3 (nothing)

Search Accelerator Off A1 (nothing)

Set Data Mode E1 (nothing)

Do Memory Function

Set Command Mode E3 (nothing)

Generate Reset Pulse C1 C9

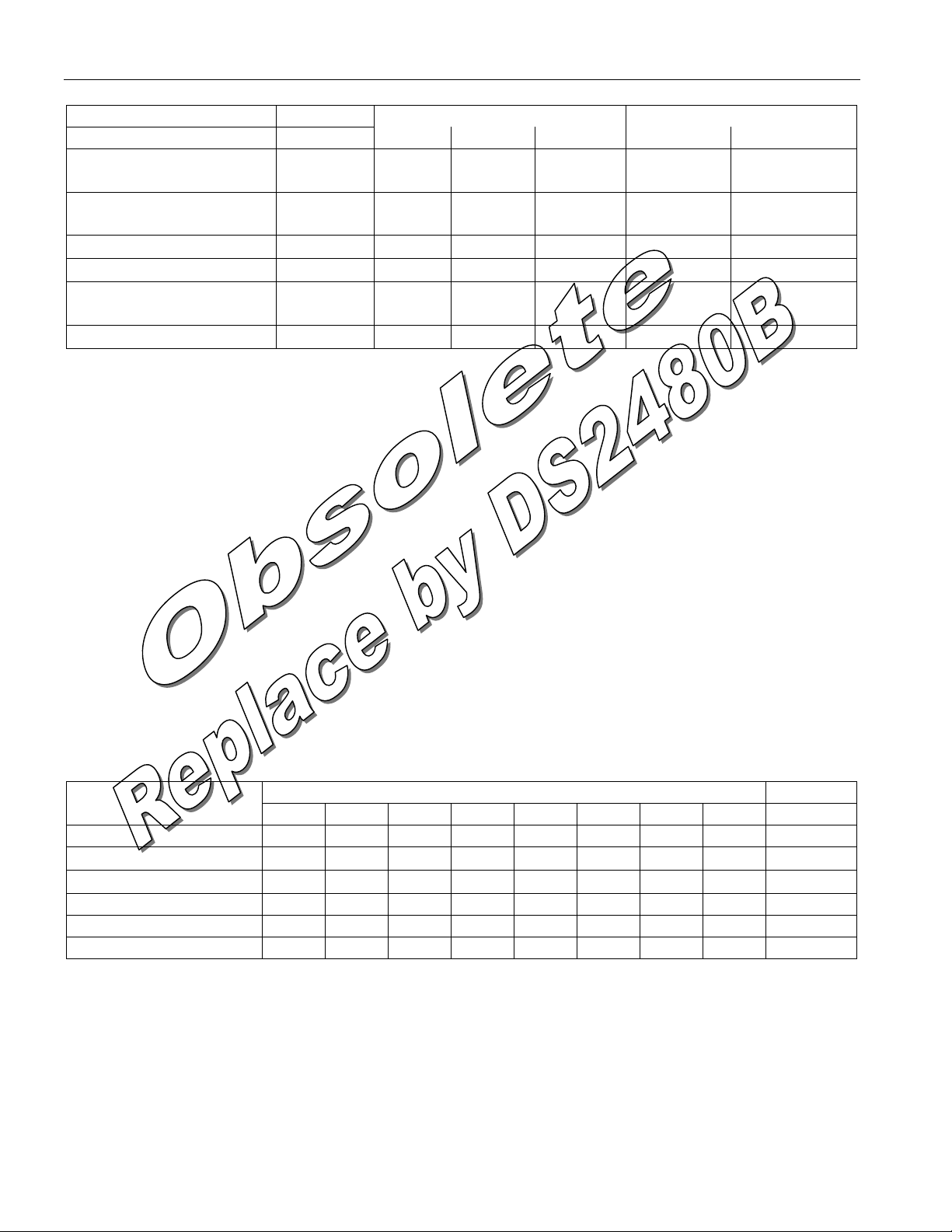

CONFIGURATION COMMANDS

The DS2480 is designed to be configurable for the varying requirements of its application. When the

device powers up and/or performs a master reset cycle, the hard-wired default configuration settings take

effect. These settings will work on a short 1-Wire bus and assume regular 1-Wire communication speed.

To change these default settings and to verify the current settings, the logic of the DS2480 supports

configuration commands. A summary of the available configuration parameters, their default settings at

regular and Overdrive speed and their applicability is shown in Table 3.

Parameters not related to the communication speed on the 1-Wire bus specify the duration of the 12-volts

programming pulse, the duration of the strong pull-up to 5-volts and the baud rate on the interface that

connects the DS2480 to the host. The remaining three parameters are used to modify the 1-Wire

communication wave forms if one selects “Flexible Speed” (see “Communication Commands” for speed

selection).

Flexible speed is implemented to improve the performance of large MicroLAN Networks. This is

accomplished by:

• limiting the slew rate on falling edges (e. g., at the beginning of time slots, to reduce ringing),

• extending the Write 1 low time (allows the current flow through the network to end slowly, to

prevent voltage spikes from inductive kickback),

• delaying the time point when reading a bit from the 1-Wire bus (gives the network more time to

stabilize, to get a higher voltage margin) and

• adding extra recovery time between Write 0 time slots (allows more energy transfer through the

network, to replenish the parasite power supply of the devices on the bus).

The latter two functions are controlled by a single parameter. Taking advantage of flexible speed requires

changing one or more of these parameters from their default values. Otherwise the waveforms will be

identical to those at regular speed.

Each configuration parameter is identified by its 3-bit parameter code and can be programmed for one of

a maximum 8 different values using a 3-bit value code. A matrix of parameter codes and value codes with

the associated physical values in shown in Table 4.

11 of 28

Page 12

DS2480

CONFIGURATION COMMAND OVERVIEW TABLE 3

Parameter Description Par. Code Configurable at Default

Regular Flexible Overdrive Reg./Flex. Overdrive

Pull-Down Slew Rate

Control

Programming Pulse

Duration

Strong Pull-up Duration 011

Write 1 low time 100

Data Sample Offset and

Write 0 Recovery Time

RS232 Baud Rate 111

The numbers given for parameter 001 (Pull-Down Slew Rate Control) are nominal values. They may vary

as specified in the Electrical Characteristics section and are almost independent of the load on the 1-Wire

bus. Information on how to select the optimum value of this parameter is given in section “Controlled

Edges”.

For the parameters 010 (Programming Pulse Duration) and 011 (Strong Pull-Up Duration) one may select

indefinite duration. This value, however, should only be selected if one is not going to switch the device

to Data Mode. As long as the device stays in Command Mode, any pulse function (programming or

strong pull-up) that uses one of these parameters can be terminated by sending the command code F1h.

Termination is not possible if the device is in Data Mode.

Parameter 111 (RS232 Baud Rate) has two functions. It selects the baud rate and allows inversion of the

signal at the RXD pin. Using one of the value codes 100 to 111 will set the polarity at RXD to the

opposite of what is defined by the logic level at the POL pin (asymmetry bit, see Figure 1). This may

reduce the component count in some applications of the device. Note that when changing the baud rate,

the DS2480 will send the command response byte at the new data rate.

A short explanation on the use of parameters 100 (Write 1 low time) and 101 (Data Sample Offset/Write

0 Recovery Time) is given in the section “Timing Diagrams” later in this document. The parameter code

110 is reserved for future extensions; one should not change the value code from its default setting.

001

010

101

√

√√ √

√√ √

√

√

√√ √

15 V/µs 15 V/µs

512 µs 512 µs

524 ms 524 ms

8 µs 1 µs

3 µs

3 µs

9.6k bits/s 9.6k bits/s

1 µs

3 µs

CONFIGURATION PARAMETER VALUE CODES Table 4

Value Codes Unit

Parameter Code 000 001 010 011 100 101 110 111

001 (PDSRC) 15 2.2 1.65 1.37 1.1 0.83 0.7 0.55 V/µs

010 (PPD) 32 64 128 256 512 1024 2048

011 (SPUD) 16.4 65.5 131 262 524 1048 2096

100 (W1LT) 8 9 10 11 12 13 14 15 µs

101 (DSO/W0RT) 345678910 µs

111 (RBR) 9.6 19.2 57.6 115.2 9.6 19.2 57.6 115.2 kbits/s

12 of 28

∞

∞

µs

ms

Page 13

DS2480

The syntax of configuration commands is very simple. Each 8-bit code word contains a 3-bit parameter

code to specify the parameter and the 3-bit value code to be selected. Bit 7 of the command code is set to

0 and bit 0 is always a 1. To read the value code of a parameter, one writes all zeros for the parameter

code and puts the parameter code in place of the parameter value code. Table 5 shows the details.

The configuration command response byte is similar to the command byte itself. Bit 0 of the response

byte is always 0. When writing a parameter, the upper 7 bits are the echo of the command code. When

reading a parameter, the current value code is returned in bit positions 1 to 3 with the upper 4 bits being

the same as sent (see Table 6).

CONFIGURATION COMMAND CODES Table 5

FUNCTION BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

Write Parameter 0 parameter code parameter value code 1

Read Parameter 0 0 0 0 parameter code 1

CONFIGURATION COMMAND RESPONSE BYTE Table 6

FUNCTION BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

Write Parameter 0 same as sent same as sent 0

Read Parameter 0 same as sent parameter value code 0

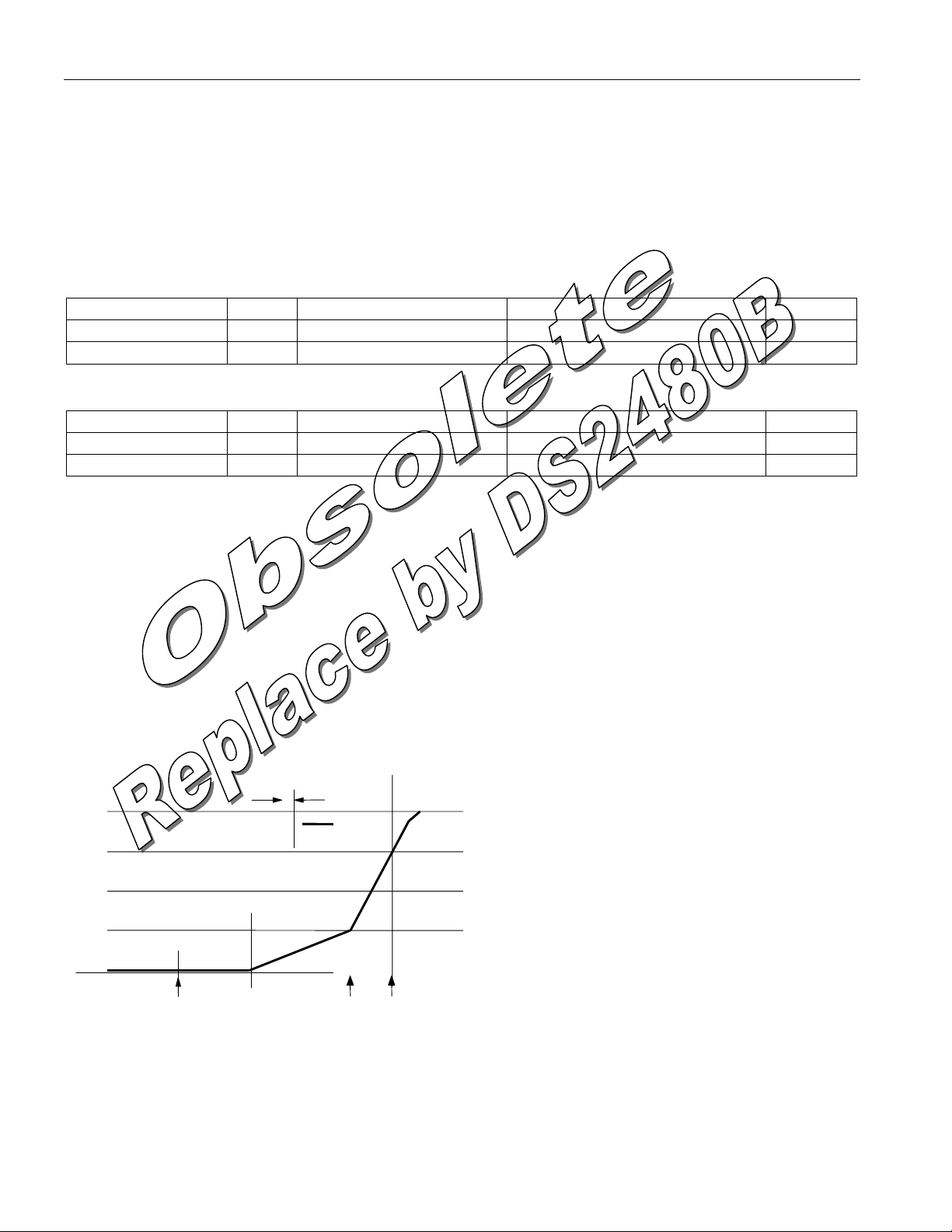

CONTROLLED EDGES

One of the tasks of the DS2480 is to actively shape the edges of the 1-Wire communication waveforms.

This speeds up the recharging of the 1-Wire bus (rising edges) and reduces ringing of long lines (falling

edges). The circuitry for shaping rising edges is always on. The slew rate of falling edges is actively

controlled only at flexible speed and requires the parameter for slew rate control being different from its

power-on default value.

ALL RISING EDGES

The active pull-up of the rising edges reduces the rise time on the 1-Wire bus significantly compared to a

simple resistive pull-up. Figure 4 shows how the DS2480 is involved in shaping a rising edge.

ACTIVE PULL-UP Figure 4

t

APUOT

5V

V

IAPTO

V

IAPO

0V

1-WIRE BUS

IS DISCHARGED

t

1

t2t

3

13 of 28

Page 14

DS2480

The circuit operates as follows: At t1 the pull-down (induced by the DS2480 or a device on the bus) ends.

From this point on the 1-Wire bus is pulled high by the weak pull-up current I

WEAKPU

provided by the

DS2480. The slope is determined by the load on the bus and the value of the pull-up current. At t2 the

voltage crosses the threshold voltage V

current I

WEAKPU

to the higher current I

ACTPU

As the voltage on the bus crosses the threshold V

(t

APUOT

), the I

current will continue to flow. After the timer is expired, the DS2480 will switch back

ACTPU

. Now the DS2480 switches over from the weak pull-up

IAPO

. As a consequence, the voltage on the bus now rises f aster.

at t3, a timer is started. As long as this timer is on

IAPTO

to the weak pull-up current.

FALLING EDGES (DS2480-INITIATED)

Whenever the DS2480 begins pulling the 1-Wire bus low to initiate a time slot, for example, it first turns

off the weak pull-up current I

WEAKPU

. Then, at regular and Overdrive speed it will generate a falling edge

at a slew rate of typically 15V/µs. This value is acceptable for short 1-Wire busses and adequate for

communication at Overdrive speed. For MicroLAN networks of more than roughly 30 meters len gth one

should always use flexible speed. One of the parameters that is adjustable at flexible speed is the slew rate

of DS2480-initiated falling edges. The effect of the slew rate control is shown in Figure 5.

SLEW RATE CONTROL Figure 5

t

F

5V

TARGET FOR

LONG LINES:

4 ± 0.5 ∝s

LOW SLEW RATE

HIGH SLEW RATE

0.8V

0V

1-WIRE BUS

IS PULLED UP

WEAK PULL-UP ENDS,

PULL-DOWN BEGINS

t

1

As extensive tests have shown, MicroLAN networks at a length of up to 300 meters will perform best if

the fall time tF is in the range of 4 ± 0.5 µs. This translates into a slew rate of approximately 1V/µs. This

slew rate is typically achieved by setting the configuration parameter 001 (Pull-Down Slew Rate Control)

to a value of 100 (see Table 4). If the actual measured fall time is longer than the target value, one should

use a value code of 011 or lower. If the fall time is shorter, one should use a value code of 101 or higher.

Once determined, the value code for the Pull-Down Slew Rate Control parameter should be stored in the

host and always be loaded into the DS2480 after apower-on or master reset cycle.

TIMING DIAGRAMS

This section explains the wave forms generated by the DS2480 on the 1-Wire bus in detail. First the

communication wave forms such as the Reset/Presence Detect Sequence and the time slots are discussed.

After that follows a detailed description of the pulse function under various conditions. The wave forms

as generated by the DS2480 may deviate slightly from specifications found in the “Book of DS19xx

iButton Standards” or in data sheets of 1-Wire slave devices. However, at a closer look one will find that

all of the timing requirements are met.

14 of 28

Page 15

DS2480

1-WIRE COMMUNICATION WAVE FORMS

One of the major features of the DS2480 is that it relieves the host from generating the timing of the

1-Wire signals and sampling the 1-Wire bus at the appropriate times. How this is done for the

reset/presence detect sequence is shown in Figure 6a. This sequence is composed of four timing

segments: the reset low time t

offset t

and a delay time t

PDT

FILL

, the short/interrupt sampling offset tSI, the presence d etect sampling

RSTL

. The timing segments tSI, t

PDT

and t

comprise the reset high time t

FILL

RSTH

where 1-Wire slave devices assert their presence or interrupt pulse. Durin g this time the DS2480 pulls the

1-Wire bus high with its weak pull-up current.

The values of all timing segments for all 1-Wire speed options are shown in the table. Since the

reset/presence sequence is slow compared to the time slots, the values for regular and flexible speed are

the same. Except for the falling edge of the presence pulse all edges are controlled b y the DS2480. The

shape of the uncontrolled falling edge is determined by the capacitance of the 1-Wire bus and the number,

speed and sink capability of the slave devices connected.

RESET/PRESENCE DETECT Figure 6a

5V

UNCONTROLLED

0V

TESTING FOR SHORT AND/OR INTERRUPT

Speed t

t

RSTL

FALLING EDGE

RSTL

RESET/PRESENCE SEQUENCE

t

t

SI

t

SI

PDT

t

RSTH

PRESENCE

PULSE

t

FILL

PRESENCE TESTING

t

PDT

IDLE

TIME

TIME

SLOT

t

FILL

t

RSTH

Regular 512 µs 8 µs 64 µs 512 µs 584 µs

Overdrive 64 µs 2 µs 8 µs 64 µs 74 µs

Flexible 512 µs 8 µs 64 µs 512 µs 584 µs

After having received the command code for generating a reset/presence sequence, the DS2480 pulls the

1-Wire bus low for t

and then lets it go back to 5-volts. The DS2480 will now wait for the

RSTL

short/interrupt sampling offset tSI to expire and then test the voltage on the 1-Wire bus to determine if

there is a short or an interrupt signal. If there is no short or interrupt (as shown in the picture), the DS2480

will wait for t

the presence test, the DS2480 will then wait for t

and test the voltage on the 1-Wire bus for a presence pulse. Regardless of the result of

PDT

to expire and then send the command response byte

FILL

to the host.

If the test for interrupt or short reveals a logic 0, the DS2480 will wait for 4096 ∝s and then test the

1-Wire bus again. If a logic 0 is detected, the 1-Wire bus is shorted and a command response byte with

the code for SHORT will be sent immediately. If a logic 1 is detected, the device will wait for t

FILL

to

expire after which it will send the command response byte with the code for an alarming presenc e pulse.

No additional testing for a presence pulse will be done. The DS2480 will perform the short/interrupt

testing as described also at Overdrive speed, although interrupt signaling is only defined for regular

speed.

The idle time following the Reset/Presence Detect sequence depends on the serial communication speed

and the host’s response time.

A Write 1 and Read Data time slot is comprised of the segments t

time slots, after the write 1 low time t

is over, the DS2480 waits for the duration of the data s ample

LOW1

LOW1

DSO

and t

. During write 1

HIGH

, t

offset and then samples the voltage at the 1-Wire bus to read the response. After this, the waiting time

t

must expire before the time slot is complete. A Write 0 time slot only consists of the two segments

HIGH1

t

LOW0

and t

REC0

.

15 of 28

Page 16

DS2480

If the network is large or heavily loaded, one should select flex ible speed and extend t

to more than

LOW1

8 µs to allow the 1-Wire bus to completely discharge. Since a large or heavily loaded network needs more

time to recharge, it is also recommended to delay sampling the bus for reading. A higher value for t

DSO

will increase the voltage margin and also provide extra energy to the slave devices when generating a

long series of write 0 time slots. However, the total of t

LOW1

+ t

should not exceed 22 µs*. Otherwise

DSO

the slave device responding may have stopped pulling the bus low when transmitting a logic 0.

The idle time between time slots within a byte or during a 12-bit sequence while the Search Accelerator is

on is zero. Between bytes, 12-bit search sequences and single bits the idle time depends on the RS232

data rate and the host’s response time. The response byte is sent to the host as soon as the l ast time slot of

a byte, 12-bit sequence or the command is completed.

WRITE 1 AND READ DATA TIME SLOT Figure 6b

5V

0V

t

LOW1

Speed t

TIME SLOT DURATION t

t

SAMPLING

LOW1

SLOT

t

DSO

Regular 8 µs 3 µs 49 µs 60 µs

Overdrive 1 µs 1 µs 8 µs 10 µs

Flexible 8 to 15 µs 3 to 10 µs 49 µs 60 to 74 µs

IDLE

TIME

NEXT

T.S.

t

HIGH1

t

SLOT

*

WRITE 0 TIME SLOT Figure 6c

REC0

IDLE

TIME

NEXT

T.S.

t

SLOT

*

5V

0V

t

RECO

Speed t

t

LOW0

*t

LOW0

Regular 57 µs 3 µs 60 µs

Overdrive 7 µs 3 µs 10 µs

Flexible 57 µs 3 to 10 µs 60 to 67 µs

*In a 5-volts environment (± 1-volt, full temperature range) the tolerance of the internal time base of

1-Wire slave devices is much narrower than what it is when operated at the minimum voltage of 2.8 volts.

Therefore, the timing generated by the DS2480 is in compliance with the requirements of all MicroLANcompatible 1-Wire devices.

16 of 28

Page 17

DS2480

PULSE WAVE FORMS, DISARMED

The pulse command can be used to generate a strong pull-up to 5-volts and a 12-volts programming

pulse, respectively. The duration of the pulse is predefined if the parameter value code of par ameter 010

(Programming Pulse Duration) and parameter 011 (Strong Pull-Up Duration), has a value from 000 to

110 (see Table 4). Figures 7a and 7b show the timing of a pulse with predefined duration, which should

be considered the normal case. If an infinite duration is chosen (parameter value code 111), the host must

terminate the pulse command, as shown in Figures 7c and 7d. All versions of Figure 7 assume that bit 1

of the pulse command is 0, i.e., disarmed mode. See section Communication Commands, Pulse, for more

details on possibilities of the pulse command.

STRONG PULL-UP TO 5V, PREDEFINED DURATION Figure 7a

IDLE

END OF PREVIOUS

5V

0V

TIME SLOT

TIME

t

t

1

2

t

SPU

t

The processing of a pulse command is essentially the same, regardless if a strong pull-up or a

programming pulse is requested. At t1 the host starts sending the pulse command byte. At t2 the DS2480

has received the command and immediately generates the pulse. The pulse ends at t3 and the DS2480

sends out the command response byte to inform the host that the command is completed. The idle time

between t1 and t2 is determined by the time to transmit the command byte at the selected baud rate. The

idle time between t3 and t4 is comprised of the time to transmit the response byte, plus the response time

of the host plus the time to transmit the command and/or data to generate the next time slot.

IDLE

TIME

3

BEGIN OF NEXT

TIME SLOT

t

4

12V PROGRAMMING PULSE, PREDEFINED DURATION Figure 7b

12V

END OF PREVIOUS

5V

0V

TIME SLOT

IDLE

TIME

t

2

A correct programming pulse can only be generated if the 12-volts programming voltage is available at

the Vpp pin of the DS2480. The slew rate of the rising and falling edge of the programming pulse (“steep

slopes”) is not actively controlled by DS2480. For EPROM programming, only a single slave device

should be connected to the 1-Wire bus and the cable must to be short, not to exceed a few meters. One

should not attempt generating a programming pulse with a non-EPROM device on the bus; this may

damage the device as well as the DS2480. Certain applications may require a duration for a stron g pullup or programming pulse that cannot be realized using one of the predefined values. Selecting infinite

duration allows the host to generate pulses of any length. As a consequence, however, the host becomes

responsible to actively control the duration of the pulse. Failing to do so may require a power-on reset or

master reset cycle of the DS2480. For this reason, infinite duration should only be used if absolutely

necessary. The time to end a pulse of infinite duration strongly depends on the baud rate of the

STEEP SLOPES

t

PP

IDLE

TIME

t

3

BEGIN OF NEXT

TIME SLOT

t

4

17 of 28

Page 18

DS2480

communication between host and DS2480. Neglecting the response time of the host, the minimum pulse

durations are: 86.8 µs at 115.2 kbps, 173.6 µs at 57.6 kbps, 520 µs at 19.2 kbps and 1.04 ms at 9.6 kbps.

STRONG PULL-UP TO 5V, INFINITE DURATION Figure 7c

END OF PREVIOUS

5V

0V

TIME SLOT

IDLE

TIME

t

1

t

2

STRONG PULL-UP ON

t

3

As before, processing the command is essentially the same, regardless if it is for a strong pull-up or a

programming pulse. At t1 the host starts sending the pulse command byte. At t2 the DS2480 has received

the command and immediately activates the strong pull-up or switches in the 12V programming voltage.

To end the pulse, the DS2480 must receive a termination command, code F1h, which occurs at t3. The

termination command does not generate a response byte. The DS2480 will immediately end the pulse and

send out the response byte of the pulse command. The idle time between t1 and t2 is determined by the

time to transmit the command byte at the selected baud rate. The idle time between t3 and t4 is comprised

of the time to transmit the pulse response byte, plus the response time of the host plus the time to transmit

the command and/or data to generate the next time slot.

IDLE

TIME

BEGIN OF NEXT

TIME SLOT

t

4

12V PROGRAMMING PULSE, INFINITE DURATION Figure 7d

12V

END OF PREVIOUS

5V

0V

TIME SLOT

IDLE

TIME

t

2

STEEP SLOPES

PROGRAMMING VOLTAGE

IS APPLIED

IDLE

TIME

t

3

BEGIN OF NEXT

TIME SLOT

t

4

PULSE WAVE FORM, ARMED

As explained in section Communication Commands, bit 1 of the pulse command allows the arming of a

strong pull-up to 5-volts if the bit is set to 1. If the strong pull-up is armed and the device is switched to

data mode, there will be a strong pull-up immediately following every byte on the 1-Wire bus. This mode

is implemented to provide extra energy when writing to EEPROM devices or to do a temperature

conversion with the DS1920 Temperature iButton, for example. These devices need a strong pull-up

immediately after the power-consuming activity has been initiated by a command code.

To arm the strong pull-up, one usually generates a “dummy” pulse with bit 1 being 1 while the device is

in command mode. To save time, the dummy pulse may immediately be terminated by sending the

termination command, code F1h. Then one switches to data mode and sends a command code that makes

one or more slaves on the 1-Wire bus require extra energy. After the command execution is finished, one

switches back to command mode and disarms the strong pull-up by generating another dumm y pulse. A

complete temperature conversion sequ ence that shows the use of the armed pulse is included i n Section

“Software DriverExamples”.

18 of 28

Page 19

DS2480

STRONG PULL-UP TO 5-VOLTS, ARMED, PREDEFINED DURATION Figure 8

END OF 8th

TIME SLOT

5V

0V

t

SPU

IDLE

TIME

BEGIN OF NEXT

TIME SLOT

t

1

t

2

t

3

Figures 8 shows the timing of the strong pull-up in data mode. At t1 the 8th time slot of the byte sent to

the 1-Wire bus is completed. Without any delay the DS2480 now activates the strong pull-up and

simultaneously starts sending the data response byte to the host. At t

DS2480 sends a pulse response byte to the host. The idle time between t

the strong pull-up ends and the

2

and t3 is comprised of the time

2

to transmit the pulse response byte, plus the response time of the host plus the time to transmit the

command and/or data to generate the next time slot.

Since in data mode the pulse termination command is not applicable, the duration of the strong pull-up

must be limited. See Table 4, parameter 011 (Strong Pull-Up Duration) for details. Selecting infinite

duration will require a power-on or master reset cycle to get the DS2480 back to communicating with the

host.

SINGLE BIT WITH STRONG PULL-UP

Similar to the pulse command the Single Bit command also allows generating a strong pull-up

immediately following a time slot. The strong pull-up of the Single Bit command, however, is controlled

directly by bit 1 of the command code and therefore needs not be armed. Since the DS2480 remains in

command mode when using the Single Bit command, any duration of the strong pull-up including infinite

may be selected. Figure 9 shows the timing of the Single Bit command with the immediately following

strong pull-up. Strong pull-up immediately following a single time slot is implemented to support the

DS1954 CryptoiButton. After having received the command code to run a pro gram, the CryptoiButton

sends out an acknowledge bit and then starts the microcomputer to run the firmware program for a

predefined time.

SINGLE BIT WITH STRONG PULL-UP, PREDEFINED DURATION Figure 9a

IDLE

TIME

2

BEGIN OF NEXT

ACTIVITY

t

3

5V

0V

END OF PREVIOUS

TIME SLOT

t

1

t

SPU

t

For predefined duration (Figure 9a) the timing is as follows: At t1 the time slot is completed. Now the

DS2480 activates the strong pull-up and simultaneously starts sending the response byte of the Single Bit

command to the host. At t2 the strong pull-up ends and the DS2480 sends out a pulse response byte. The

idle time between t2 and t3 is comprised of the time to transmit the pulse response byte, plus the response

time of the host plus the time to transmit the command and/or data to generate the next time slot. For

infinite duration (Figure 9b) the strong pull-up also begins immediately after the time slot is completed.

To end the strong pull-up, the DS2480 must receive a termination command, code F1h, which occurs at

. The termination command does not generate a response byte. The DS2480 will then immediately end

t

2

19 of 28

Page 20

DS2480

the strong pull-up and send out a pulse response byte. Everything else is the same as with predefined

duration.

SINGLE BIT WITH STRONG PULL-UP, INFINITE DURATION Figure 9b

END OF PREVIOUS

5V

0V

STRONG PULL-UP ON

IDLE

TIME

BEGIN OF NEXT

ACTIVITY

t

1

t

2

t

3

The minimum duration of a strong pull-up of infinite duration strongly depends on the baud rate of the

communication between host and DS2480. The host must first receive the response byte of the single-bit

command, react to it and then transmit the termination command. Neglecting the hosts response time, the

shortest duration of an infinite strong pull-up therefore is173.6 µs at 115.2 kbps, 347.2 µs at 57.6 kbps,

1.04 ms at 19.2 kbps and 2.08 ms at 9.6 kbps.

SOFTWARE DRIVER EXAMPLES

The DS2480 requires a software driver that translates the activities to be generated on the 1-Wire bus into

the appropriate commands. The examples below cover typical situations, such as reading the ROM,

writing to the scratchpad of a Memory iButton, reading the memory of a Memory iButton, programming

an Add-Only iButton EPROM and performing a temperature conversion with the Temperature iButton

DS1920. An example for the use of the Search Accelerator is included in the description of the Search

Accelerator, earlier in this document. The DS2480 command codes used in these examples are valid for

regular speed and will work properly on short 1-Wire busses (< 10 meters). The response b yte on the

reset command assumes a normal presence pulse, no alarm or short. The DS2480 includes a 1-byte

buffer that stores a byte received from the host while the previous byte is being translated into activity on

the 1-Wire bus. For this reason the host may send another byte even without having received the response

byte. Sending bytes faster than they can be translated into 1-Wire activities may result in loss of data

and/or synchronization and therefore should be avoided.

READ ROM SEQUENCE

Action Sequence Host TX Host RX

Generate Reset Pulse C1 C9

Set data mode E1 (nothing)

Read ROM Command 33 (as sent)

Read ROM ID (8 bytes) FF (x8) ROM ID

Set command mode E3 (nothing)

Generate Reset Pulse C1 C9

20 of 28

Page 21

WRITE SCRATCHPAD SEQUENCE

Write 2 bytes to scratchpad at memory locations 16h and 17h

Action Sequence Host TX Host RX

Generate Reset Pulse C1 C9

Set data mode E1 (nothing)

Skip ROM Command CC CC

Write Scratchpad Cmd. 0F (as sent)

Starting Address TA1 16 (as sent)

Starting Address TA2 00 (as sent)

Write to the Scratchpad (2 bytes) (as sent)

Set command mode E3 (nothing)

Generate Reset Pulse C1 C9

READ MEMORY SEQUENCE

Read 8 bytes from memory address 0040h

Action Sequence Host TX Host RX

Generate Reset Pulse C1 C9

Set data mode E1 (nothing)

Skip ROM Command CC (as sent)

Read Memory Command F0 (as sent)

Starting Address TA1 40 (as sent)

Starting Address TA2 00 (as sent)

Read 8 bytes of data FF (x8) data

Set command mode E3 (nothing)

Generate Reset Pulse C1 C9

DS2480

WRITE EPROM SEQUENCE (DS2505)

Write memory starting at address 40h

Action Sequence Host TX Host RX

Set Vpp dur. = 512====∝∝∝∝s

Generate Reset Pulse C1 C9

Set data mode E1 (nothing)

Skip ROM Command CC (as sent)

Write Memory Command 0F (as sent)

Starting Address TA1 40 (as sent)

Starting Address TA2 00 (as sent)

*** Send data byte (data) (as sent)

Receive CRC16 FF (x2) CRC16

Set command mode E3 (nothing)

Generate Program Pulse FD response

Set data mode E1 (nothing)

Read written byte FF (data)

Go to *** to write the next byte or end the sequence as shown below.

Set command mode E3 (nothing)

Generate Reset Pulse C1 C9

29 28

21 of 28

Page 22

DS2480

TEMPERATURE CONVERSION SEQUENCE

Action Sequence Host TX Host RX

Set pull-up dur. = 524 ms 39 38

Generate Reset Pulse C1 C9

Set data mode E1 (nothing)

Skip ROM Command CC (as sent)

Set command mode E3 (nothing)

Arm strong pull-up EF (nothing)

Terminate pulse F1 response

Set data mode E1 (nothing)

Convert Temperature 44 (as sent)

Wait for pulse response (nothing) response

Set command mode E3 (nothing)

Disarm strong pull-up ED (nothing)

Terminate pulse F1 response

Generate Reset Pulse C1 C9

HARDWARE APPLICATION EXAMPLES

This section discusses five typical application scenarios of the DS2480. When directly designed into a

new product, the device can be connected as shown in Figure 10a. The ci rcuit becomes more complex if

a 1-Wire bus is to be interfaced to a port that provides and expects inverted signals, but does not

necessarily meet the RS232C (± 12-volts) standard (Figure 10b).

UART DIRECT Figure 10a

UART

OR ∝C

SIN (RXD)

SOUT (TXD)

LM

+/(-) 5V RS232 Figure 10b

POWER

STEALING

DTR

RTS

RXD

TXD

GND

LM

UART

OR ∝C

DRIVER/

LEVEL SHIFTER

1

0

1

STOP0

VOLTAGE

REGULATOR

STOP

5V

12V

(5V)

5V

SEE TEXT

12V

(5V)

V

PP

RXD

TXD

V

DD

DS2480

GND

V

PP

RXD

DS2480

TXD

GND

V

DD

POL

1-WIRE BUS

1-W

RETURN

POL

1-W

1-WIRE BUS

RETURN

22 of 28

Page 23

DS2480

The signals DTR and RTS provide the power to operate the DS2480. The resistor in the TXD line and the

Schottky diode limit the negative voltage at the TXD pin of the DS2480 to 0.3 volts maximum. The

resistor is typically 4.7 kΩ. If the inverting driver is current-limited to 1 mA the resistor is not required.

From the DS2480’s perspective, this circuit will work with inverted signals of ± 5-volts as well as 0 to

5-volts. Depending on the voltage levels the host expects, it may be necessary to generate a negative

voltage on the RXD line. Figure 10c shows how this can be accomplished for a true RS232C system.

+ 12V RS232 Figure 10c

5V

POWER

STEALING

DTR

RTS

UART

OR ∝C

RXD

2.7 k

TXD

1∝

GND

In the interface to a true RS232C system (± 12-volts, Figure 10c) the power for the DS2480 is stolen from

DTR and RTS. The software must make sure that at least one of these signals constantly provides the

12-volts operating voltage. The 6.8 kΩ resistor and the 4.7 volts Zener diode in the TXD line limit the

positive voltage at the TXD pin of the DS2480. The Schottky diode limits the negative voltage to

0.3 volts maximum. The Schottky diode in series with the capacitor forms a parasitic supply to gener ate

the negative bias for the host’s receive channel. The positive signal is switched in through the P-channel

MOSFET that connects to the RXD output of the DS2480. In this circuit diagram the MOSFET switches

the RXD line to +5-volts, which normally is sufficient for RS232Csystems. Switching to 12-volts is also

possible, but requires a P-channel transistor with a different threshold voltage. The signal inversion

caused by the transistor is compensated through the DS2480 by using a value code of 100, 101, 110 or

111 for the RS232 baud rate setting.

VOLTAGE

REGULATOR

6.8 k

4.7V

S

D

SEE TEXT

STOP

BSS110

0

LM

1

12V

(5V)

V

PP

RXD

TXD

V

DD

DS2480

GND

POL

1-WIRE BUS

1-W

RETURN

23 of 28

Page 24

DS2480

UART DIRECT OPTO ISOLATED Figure 10d

The circuit in Figure 10d is essentially the same as in Figure 10a. The main difference is the optoisolation. The characteristics of the opto-isolators are not very critical. Using a different t ype will affect

the values of the resistors that limit the current through the LEDs and bias the photo transistors.

+ 5 TO 12V RS232 OPTO ISOLATED Figure 10e

The circuit in Figure 10e combines the true RS232C interface with opto-isolation. The energy to power

the LED in the TXD channel and to provide the positive voltage for the host’s RXD input is stolen from

DTR and RTS. The negative voltage for the RXD input is taken from the TXD line through a parasitic

supply consisting of a Schottky diode in series with a capacitor. The HCPL-2202 opto-isolator has a

totem pole output that allows switching in positive as well as negative voltage. The +5-volts are sufficient

for most RS232C systems. Switching in 12-volts requires a opto-isolator with different voltage

characteristics. In the schematic the HCPL-2202 opto-isolator is sourced by the RXD pin of the DS2480.

It can as well be connected the traditional way where the DS2480 sinks the current through the LED.

This, however, causes a signal inversion that has to be compensated through the DS2480 by using a value

code of 100, 101, 110 or 111 for the RS232 baud rate setting. Using other t ypes of opto-isolators than

shown in the schematic will at least require changing the values of the resistors.

24 of 28

Page 25

DS2480

RS232 DATA TIMING RXD LINE Figure 11

t

FR

START

BIT 0

t

RR

BIT 1 BIT 2 BIT 3 BIT 4 BIT 5 BIT 6 BIT 7 STOP

T

R

(DIAGRAM DRAWN FOR POL = 5V)

10 T

R

RECEIVE DELAY TIMING Figure 12

BIT 6 BIT 7 STOP

TXD

INPUT SAMPLING 8.5TR9.5T

R

(DIAGRAM DRAWN FOR POL = 5V)

START

RXD

RS232 DATA TIMING TXD LINE Figure 13

BIT 0 BIT 1 BIT 2 BIT 3 BIT 4 BIT 5 BIT 6 BIT 7 STOP

T

T

V

V

IL

IH

1.5 T

R

2.5 TR3.5 TR4.5 TR5.5 TR6.5 TR7.5 TR8.5 TR9.5 T

TT = 1/BAUD RATE OF UART

DIAGRAM DRAWN FOR POL = 5V)

10 T

T

TR = 1/BAUD RATE OF DEVICE

BIT

t

t

IDLER

IDLET

R

25 of 28

Page 26

FUNCTION AND SPEED MATRIX Table 7

1-Wire Speed

Baud Rate Regular Flexible Overdrive Function

9600 bps

√√ √

√√ √

19200 bps X X

√

X

57600 bps X X

XX

√

√

√

√

115200 bps X X X Search

XX

√

Search

Command/Data

Search

Command/Data

Search

Command/Data

Command/Data

DS2480

√ t

X not recommended unless t

is guaranteed by the UART; no precautions necessary

IDLET

IDLET

TXD LINE ASYMMETRY Figure 14

is controlled by the host through a wait function

26 of 28

Page 27

DS2480

ABSOLUTE MAXIMUM RATINGS*

Voltage on 1-W to Ground -0.5V to +14.0V

Voltage on RXD, TXD, POL to Ground -0.5V to +7.0V

Operating Temperature -40°C to +85°C

Storage Temperature -55°C to +125°C

Soldering Temperature See J-STD-020A Specification

* This is a stress rating only and functional operation of the device at these or any other conditions above

those indicated in the operation sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods of time may affect reliability.

DC ELECTRICAL CHARACTERISTICS (VDD = 4.5V to 5.5V;-40°C to 85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Supply Voltage V

Programming Voltage V

Operating Current I

Idle Current on V

PP

I

Active Pull-up Timer Threshold V

Active Pull-up On Threshold V

1-Wire Input High V

1-Wire Input Low V

TXD/POL input resistor R

TXD/POL input levels V

TXD/POL input levels V

1-Wire weak pull-up current I

1-Wire active pull-up current I

Strong pull-up voltage drop

∆V

@ 10 mA load on 1-W

Programming voltage drop

∆V

@ 10 mA load on 1-W

RXD sink current @ 0.4V I

RXD source current @ VDD-0.4V I

Power On Reset Trip Point V

VPP Sensor Trip Point V

CC

PP

DD

PP

IAPTO

IAPO

IH1

IL1

I

IH

IL

WEAKPU

ACTPU

STRPU

PROG

OLR

OHR

POR

PPTRIP

4.5 5.0 5.5 V

11.75 12.25 V 1

3.0 5.0 mA

20 µA 2

VDD-1.4 VDD-1.1 V

0.95 1.2 V

3.4 V

1.8 V

30

kΩ

3

2.7 V

0.8 V

1.5 3.0 5.0 mA

915 mA

0.6 V 4

0.24 V 5

6mA

-4 mA

3.3 V

9.5 V

27 of 28

Page 28

DS2480

CAPACITANCES (tA = 25°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

TXD/POL input capacitance C

1-Wire input capacitance C

IN

IN1

5pF

10 pF

AC ELECTRICAL CHARACTERISTICS (VDD = 4.5V to 5.5V;-40°C to 85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

UART Bit Time T

Device Bit Time T

Fall Time RXD t

Rise Time RXD t

Transmit Idle Time t

Receive Idle Time t

Asymmetry t

Arrival Response Time t

Master Reset Time t

Active Pull-Up on Time t

Response Time t

T

R

FR

RR

IDLET

IDLER

ASYM

ARR

MR

APUOT

RESP

8.68 104 µs 6

8.68 104 µs 6, 7

820ns8

13 27 ns 8

0µs9

t

IDLET

µs

1µs10

4.4 52 µs 11

104 µs 12

0.5 2.0 µs 13

8.68 + ∆ 104 + ∆

µs 11, 14

NOTES:

1. VPP - ∆V

2. Applies only if a 12.0V supply is connected. If VPP and VDD are tied together, current is less than

1 µA.

3. Input load is to GND.

4. Voltage difference between VDD and 1-W.

5. Voltage difference between VPP and 1-W.

6. 8.68 µs (115.2 kbps), 52 µs (19.2 kbps), 17.36 µs (57.6 kbps), 104 µs (9.6 kbps).

7. Nominal values; tolerance = ±5%.

8. At VCC = 5.0V and 100 pF load to GND.

9. See Table 7, Function and Speed Matrix.

10. Independent of baud rate.

11. Minimum at 115.2 kbps, maximum at 9.6 kbps.

12. The master reset cycle is complete after t

13. Minimum value at Overdrive speed; maximum value at regular speed.

14. ∆=is the time to complete the activity on the 1-Wire bus; values range from 0 (configuration

command) up to5130 µs (alarming presence pulse)

must be within 11.5 to 12.0V.

PROG

is over.

MR

28 of 28

Loading...

Loading...