Page 1

r

www.maxim-ic.com

DS2450

1-Wire Quad A/D Converte

FEATURES

Four high-impedance inputs to measure

analog voltages over the 1-Wire® bus

User programmable input range (2.56V,

5.12V), resolution (1 to 16 bits) and alarm

thresholds

5V, single supply operation

Very low power: 2.5 mW active, 25 μW idle

Built-in multidrop controller allows multiple

DS2450’s to be identified and operated on a

common 1-Wire bus

Responds to Conditional Search if the analog

voltage crosses the alarm thresholds

Channels not used as analog input can serve

as open drain digital outputs for closed-loop

control

Directly connects to a single port pin of a

microprocessor and communicates at up to

16.3k bits per second

Overdrive mode boosts communication speed

to 142k bits per second

On-chip 16-bit CRC-generator for

safeguarding data transfers

Unique, factory-lasered and tested 64-bit

registration number (8-bit family code + 48bit serial number 8-bit CRC tester) assures

absolute traceability because no two parts are

PIN ASSIGNMENT

V

NC

DATA

GND AIN-A

1

2

3

4

8-PIN SOIC (208 MIL)

8

AIN-D

AIN-C

7

6

AIN-B

5

PIN DESCRIPTION

VCC 4.5 to 5.5V

NC Do Not Connect

DATA 1-Wire Bus

GND Ground

AIN-A Analog Input A

AIN-B Analog Input B

AIN-C Analog Input C

AIN-D Analog Input D

ORDERING INFORMATION

DS2450S 8-pin SOIC

DS2450S/T&R 8-pin SOIC Tape-and-Reel

DS2450S+ 8-pin SOIC

DS2450S+T&R 8-pin SOIC Tape-and-Reel

+ Indicates lead-free compliance.

1-Wire is a registered trademark of Dallas Semiconductor.

alike

8-bit family code specifies device

communication requirements to bus master

Operating temperature range from -40°C to

+85°C

Compact, low cost 8-pin SOIC surface mount

package

DESCRIPTION

The DS2450 1-Wire Quad A/D Converter is based on a successive-approximation analog to digital

converter with a four to one analog multiplexer. Each input channel has its own register set to store the

input voltage range, resolution, and alarm threshold values as well as flags to enable participation of the

device in the conditional search if the input voltage leaves the specified range. Two alarm flags for each

channel indicate if the voltage measured was too high or too low without requiring the bus master to do

1 of 24 112706

Page 2

DS2450

the comparison. Each A/D conversion is initiated by the bus master. A channel not used as analog input

can serve as a digital open-drain output. After disabling the input the bus master can directly switch on or

off the open-drain transistor at the selected channel. All device settings are stored in SRAM and kept

non-volatile while the device gets power either through the 1-Wire bus or through its VCC pin. After

powering up, a power-on reset flag signals the bus master the need to restore the device settings before

the regular operation can resume. All device registers and conversion read-out registers are organized as

three 8-byte memory pages similar to the Status Memory of a DS2505/6 device. An on-chip CRC16

generator protects the communication against transmission errors when reading through the end of a

memory page as well as when writing individual bytes.

OVERVIEW

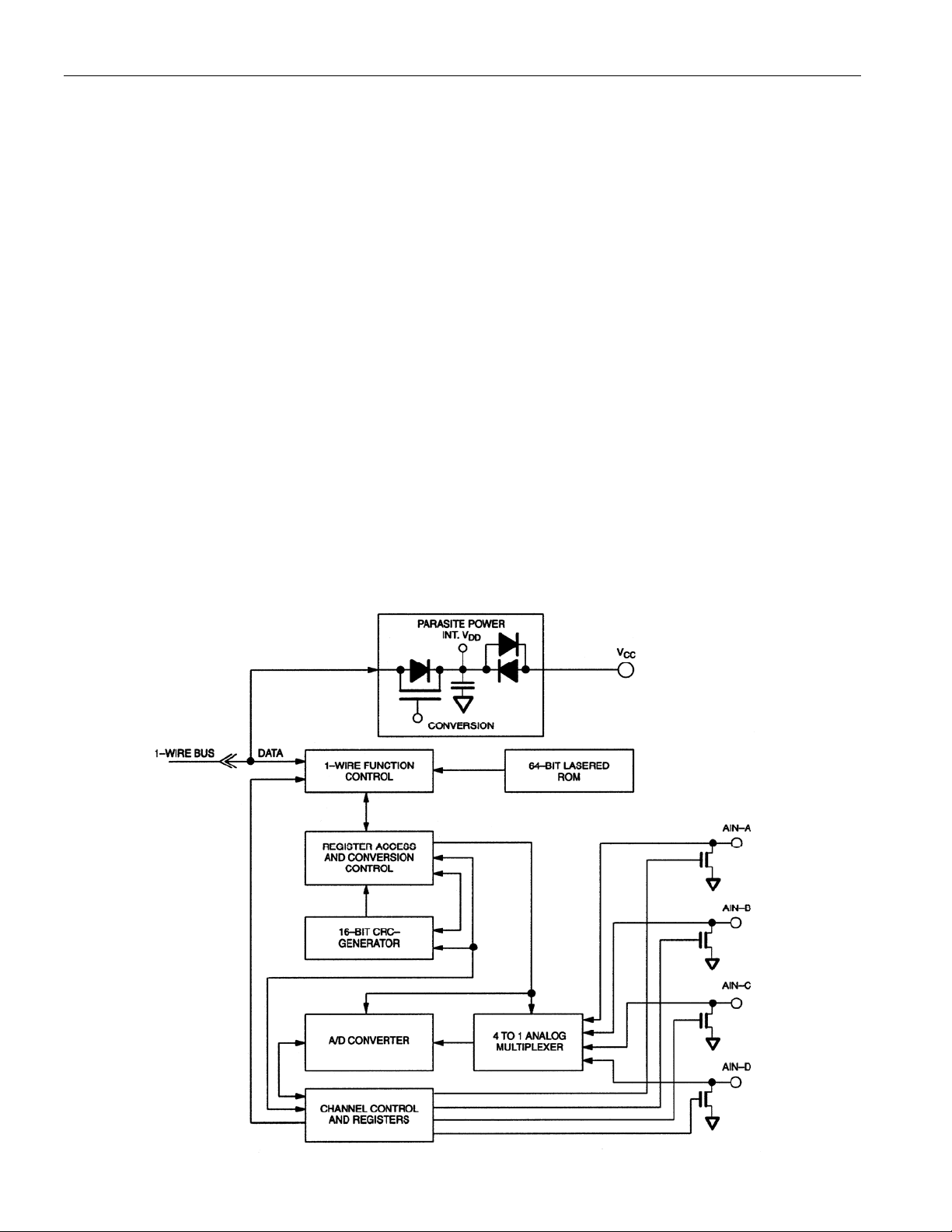

The block diagram in Figure 1 shows the major function blocks of the device. The DS2450 contains a

factory-lasered registration number that includes a unique 48-bit serial number, an 8-bit CRC, and an 8bit family code (20H). The 64-bit ROM portion of the DS2450 not only creates an absolutely unique

electronic identification for the device itself but also is a means to locate and address the device in order

to exercise its control functions.

The device gets its power either from the 1-Wire bus or through its VCC pin. Without a VCC supply the

device stores energy on an internal capacitor during periods where the signal line is high and continues to

operate off of this “parasite” power source during the low times of the 1-Wire line until it returns to high

to replenish the parasite (capacitor) supply. This, however, provides sufficient energy only for

communication. To perform an A/D conversion a strong pullup of the 1-Wire bus to 5V or a VCC supply

is required.

DS2450 BLOCK DIAGRAM Figure 1

2 of 24

Page 3

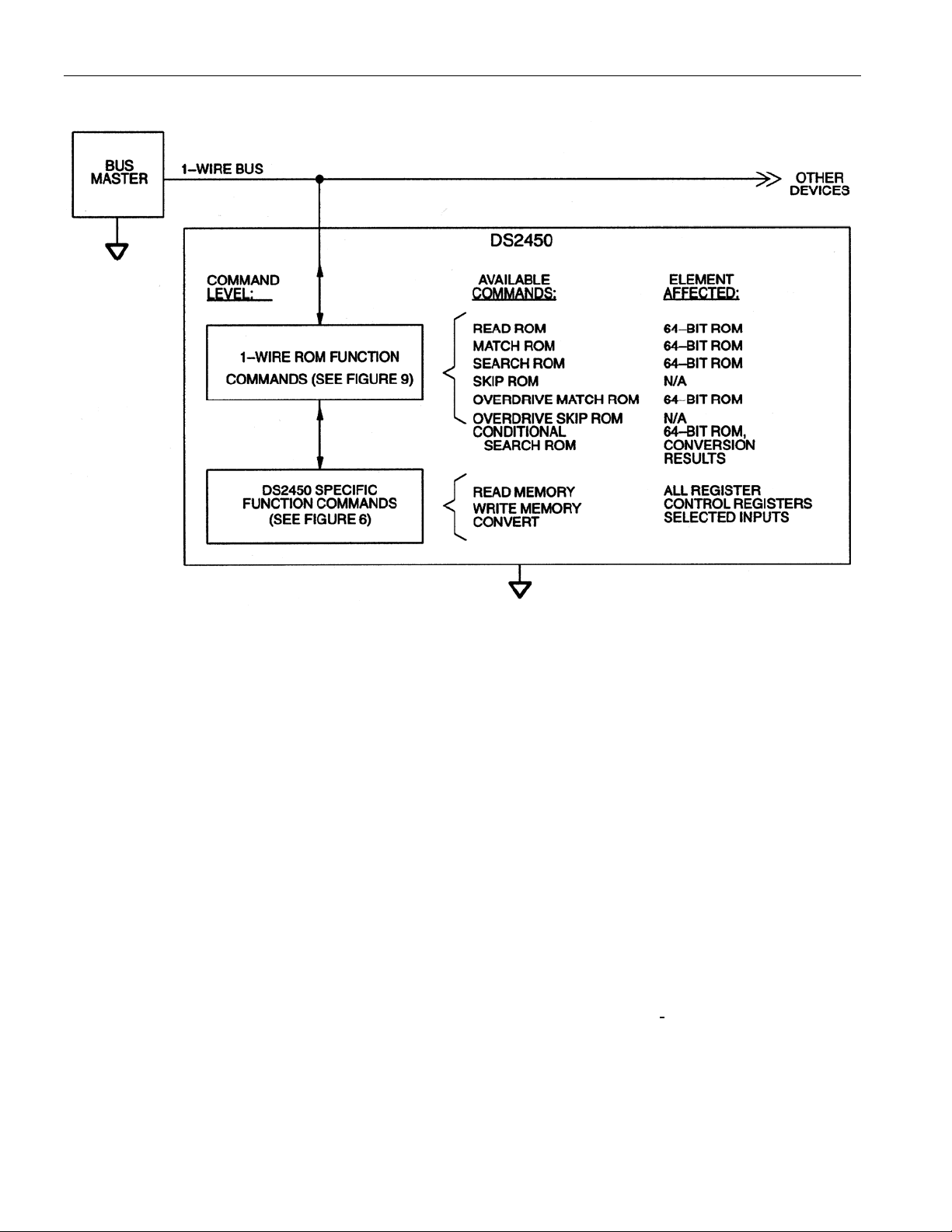

HIERARCHICAL STRUCTURE FOR 1-WIRE PROTOCOL Figure 2

DS2450

The DS2450 uses the standard Dallas Semiconductor 1-Wire protocol for data transfers. Communication

to and from the DS2450 requires a single bi-directional line that is typically a port pin of a

microcontroller. The hierarchical structure of the 1-Wire protocol is shown in Figure 2. The 1-Wire bus

master must first provide one of the seven ROM Function Commands, 1) Read ROM, 2) Match ROM, 3)

Search ROM, 4) Conditional Search ROM, 5) Skip ROM, 6) Overdrive-Skip ROM or 7) OverdriveMatch ROM. Upon completion of an overdrive ROM command byte executed at standard speed, the

device will enter Overdrive mode where all subsequent communication occurs at a higher speed. The

protocol required for these ROM function commands is described in Figure 9. After a ROM function

command is successfully executed, the memory and control functions become accessible and the master

may provide any one of the available commands. The protocol for these commands is described in Figure

6. All data is read and written least significant bit first.

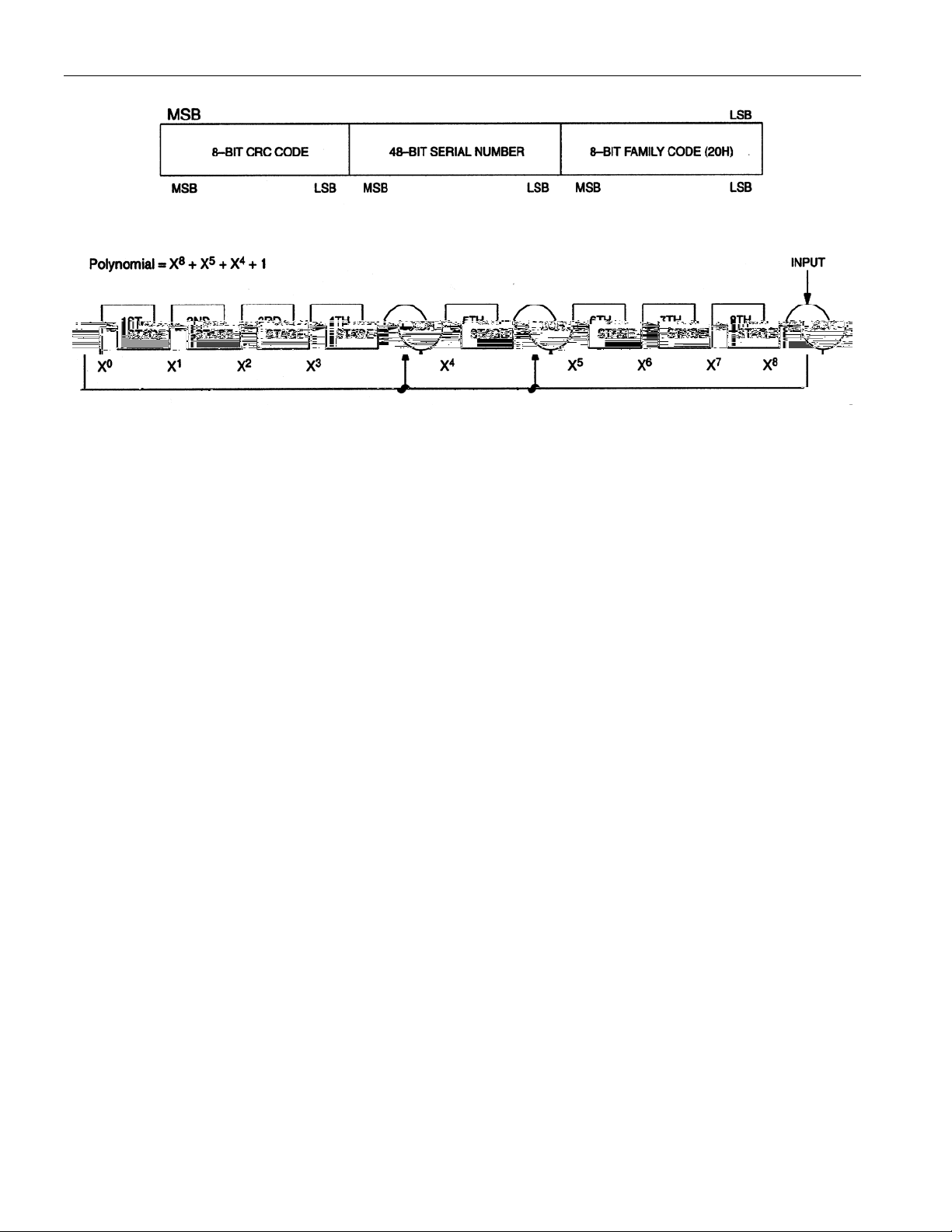

64-BIT LASERED ROM

Each DS2450 contains a unique ROM code that is 64 bits long. The first eight bits are a 1-Wire family

code. The next 48 bits are a unique serial number. The last eight bits are a CRC of the first 56 bits. (See

Figure 3.) The 1-Wire CRC is generated using a polynomial generator consisting of a shift register and

XOR gates as shown in Figure 4. The polynomial is X

Dallas 1-Wire Cyclic Redundancy Check is available in the Book of DS19xx i

shift register acting as the CRC accumulator is initialized to zero. Then starting with the least significant

bit of the family code, one bit at a time is shifted in. After the 8th bit of the family code has been entered,

then the serial number is entered. After the 48

register contains the CRC value. Shifting in the eight bits of CRC should return the shift register to all

zeros.

8

+ X5 + X4 + 1. Additional information about the

ButtonTM Standards. The

th

bit of the serial number has been entered, the shift

3 of 24

Page 4

DS2450

64-BIT LASERED ROM Figure 3

1-WIRE CRC-GENERATOR Figure 4

DEVICE REGISTERS

All registers of the DS2450 are mapped into a linear memory range of 24 adjacent bytes organized as

three 8-byte pages. The first page, called conversion read-out, contains the memory area where the chipinternal logic places the results of a conversion for the bus master to read. Starting with channel A at the

lowest address, each channel has an area of 16 bits assigned for the c

4 of 24

Page 5

DS2450

The next bits, OC (output control) and OE (enable output) control the alternate use of a channel as output.

For normal operation as analog input the OE bit of a channel needs to be 0, rendering the OC bit to a

don’t care. With OE set to 1, a 0 for OC will make the channel’s output transistor conducting, a 1 for OC

will switch the transistor off. With a pullup resistor to a positive voltage, for example, the OC bit will

directly translate into the voltage equivalent of its logic state. Enabling the output does not disable the

analog input. Conversions remain possible, but will result in values close to 0 if the transistor is

conducting.

The IR bit in the second byte of a channel’s control and status memory selects the input voltage range.

With IR set to 0, the highest possible conversion result is reached at 2.55V. Setting IR to 1 requires an

input voltage of 5.10V for the same result. The next bit beyond IR has no function. It will always read 0

and cannot be changed to 1.

The next two bits, AEL alarm enable low and AEH alarm enable high, control whether the device will

respond to the Conditional Search command (see ROM Functions) if a conversion results in a value

higher (AEH) than or lower (AEL) than the channel’s alarm threshold voltage as specified in the alarm

settings. The alarm flags AFL (low) and AFH (high) tell the bus master whether the channel’s input

voltage was beyond the low or high threshold at the latest conversion. These flags are cleared

automatically if a new conversion reveals a non-alarming value. They can alternatively be written to 0 by

the bus master without a conversion.

The next bit of a channel’s control and status memory always reads 0 and cannot be changed to 1. The

POR bit (power on reset) is automatically set to 1 as the device performs a power-on reset cycle. As long

as this bit is set the device will always respond to the Conditional Search command in order to notify the

bus master that the control and threshold data is no longer valid. After powering-up the POR bit needs to

be written to 0 by the bus master. This may be done together with restoring the control and threshold

data. It is possible for the bus master to write the POR bit to a 1. This will make the device participate in

the conditional search but will not generate a reset cycle. Since the POR bit is related to the device and

not channel-specific the value written with the most recent setting of an input range or alarm enable

applies. The power-on default setting for the control/status data is 08h for the first and 8Ch for the

second byte of each channel.

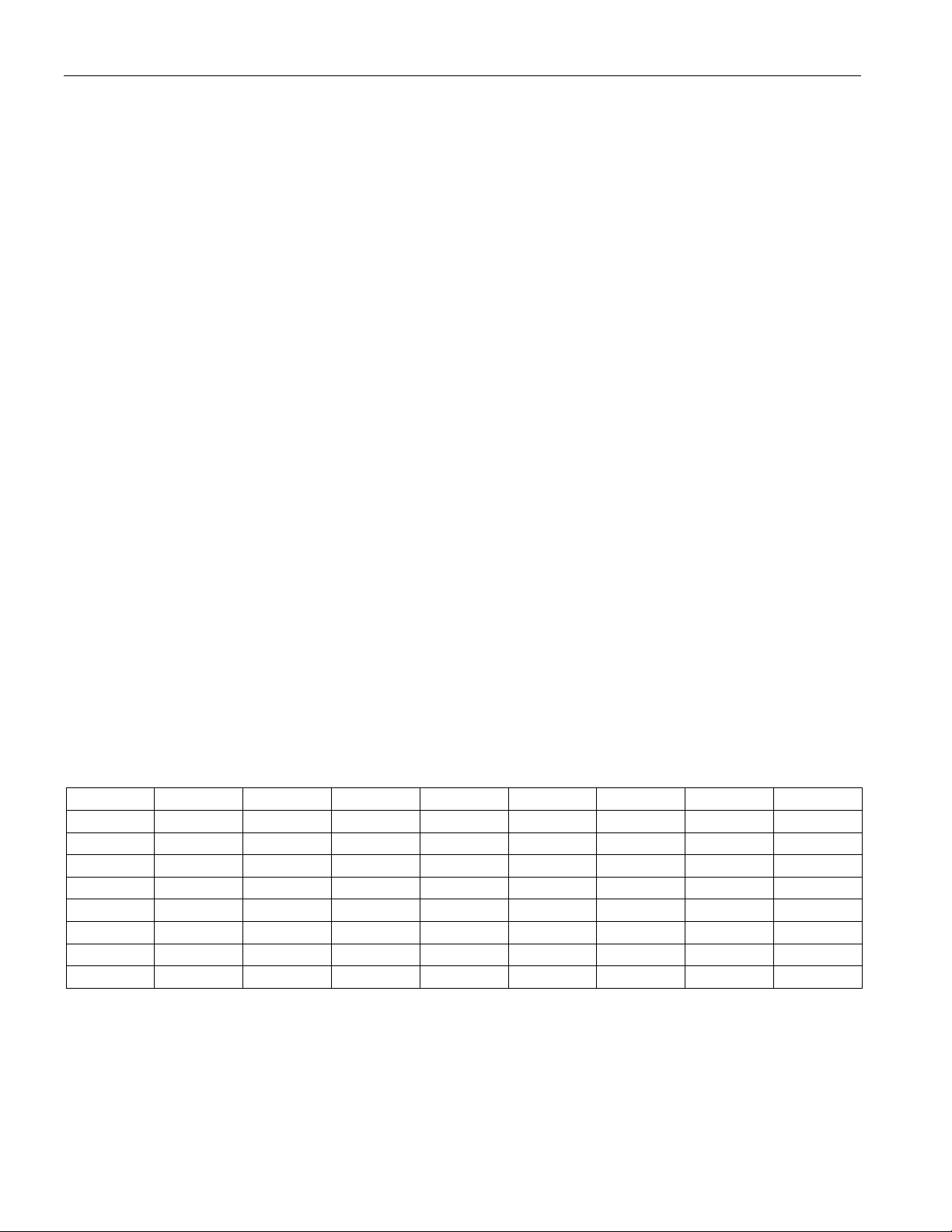

MEMORY MAP PAGE 1, CONTROL/STATUS DATA Figure 5b

Address bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

08

09

0A

0B

0C

0D

0E

0F

OE-A OC-A 0 0 RC3-A RC2-A RC1-A RC0-A

POR 0 AFH-A AFL-A AEH-A AEL-A 0 IR-A

OE-B OC-B 0 0 RC3-B RC2-B RC1-B RC0-B

POR 0 AFH-B AFL-B AEH-B AEL-B 0 IR-B

OE-C OC-C 0 0 RC3-C RC2-C RC1-C RC0-C

POR 0 AFH-C AFL-C AEH-C AEL-C 0 IR-C

OE-D OC-D 0 0 RC3-D RC2-D RC1-D RC0-D

POR 0 AFH-D AFL-D AEH-D AEL-D 0 IR-D

5 of 24

Page 6

DS2450

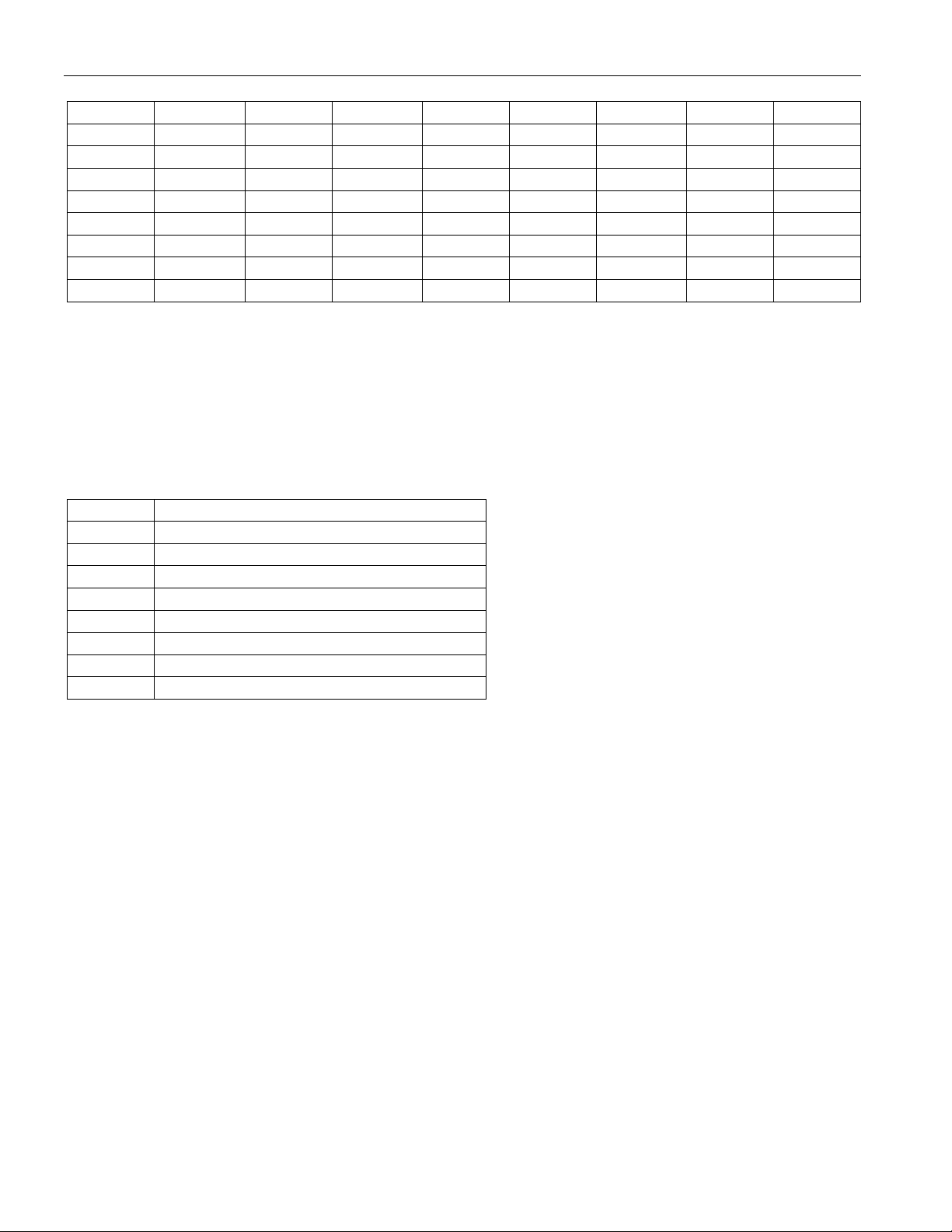

MEMORY MAP PAGE 2, ALARM SETTINGS Figure 5c

Address bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

10

11

12

13

14

15

16

17

MSBL-A A A A A A A LSBL-A

MSBH-A A A A A A A LSBH-A

MSBL-B B B B B B B LSBL-B

MSBH-B B B B B B B LSBH-B

MSBL-C C C C C C C LSBL-C

MSBH-C C C C C C C LSBH-C

MSBL-D D D D D D D LSBL-D

MSBH-D D D D D D D LSBH-D

The registers for the alarm threshold voltages of each channel are located in memory page 2 with the low

threshold being at the lower address (Figure 5c). The power-on default thresholds are 00h for low alarm

and FFh for high alarm. The alarm settings are always eight bits. For a resolution higher or equal to

eight bits the alarm flag will be set if the eight most significant bits of the conversion result yield a

number higher than stored in the high alarm register (AFH) or lower than stored in the low alarm register

(AFL). For a resolution lower than eight bits the least significant bits of the alarm registers are ignored.

MEMORY MAP PAGE 3, Factory Calibration, VCC Control Byte Figure 5d

Address

18

19

1A

1B

1C

1D

1E

1F

Factory Calibration (do not change)

Factory Calibration (do not change)

Factory Calibration (do not change)

Factory Calibration (do not change)

Set to 40 hex if VCC powered

Factory Calibration (do not change)

Factory Calibration (do not change)

Factory Calibration (do not change)

There is a fourth memory page in the address range of 18 to 1F used during calibration at the factory.

This memory page is accessible to the user through the Read Memory and Write Memory commands.

Changing the data of this page arbitrarily will de-calibrate the A/D converter or make the device

nonfunctional until it undergoes a power-on reset. If the device is VCC powered the analog circuitry

must be kept permanently active by writing a value of 40 hex to memory address 1C after power-up.

This also eliminates the offset time otherwise needed with each CONVERT command. See the

description of the CONVERT command for details.

FUNCTION COMMANDS

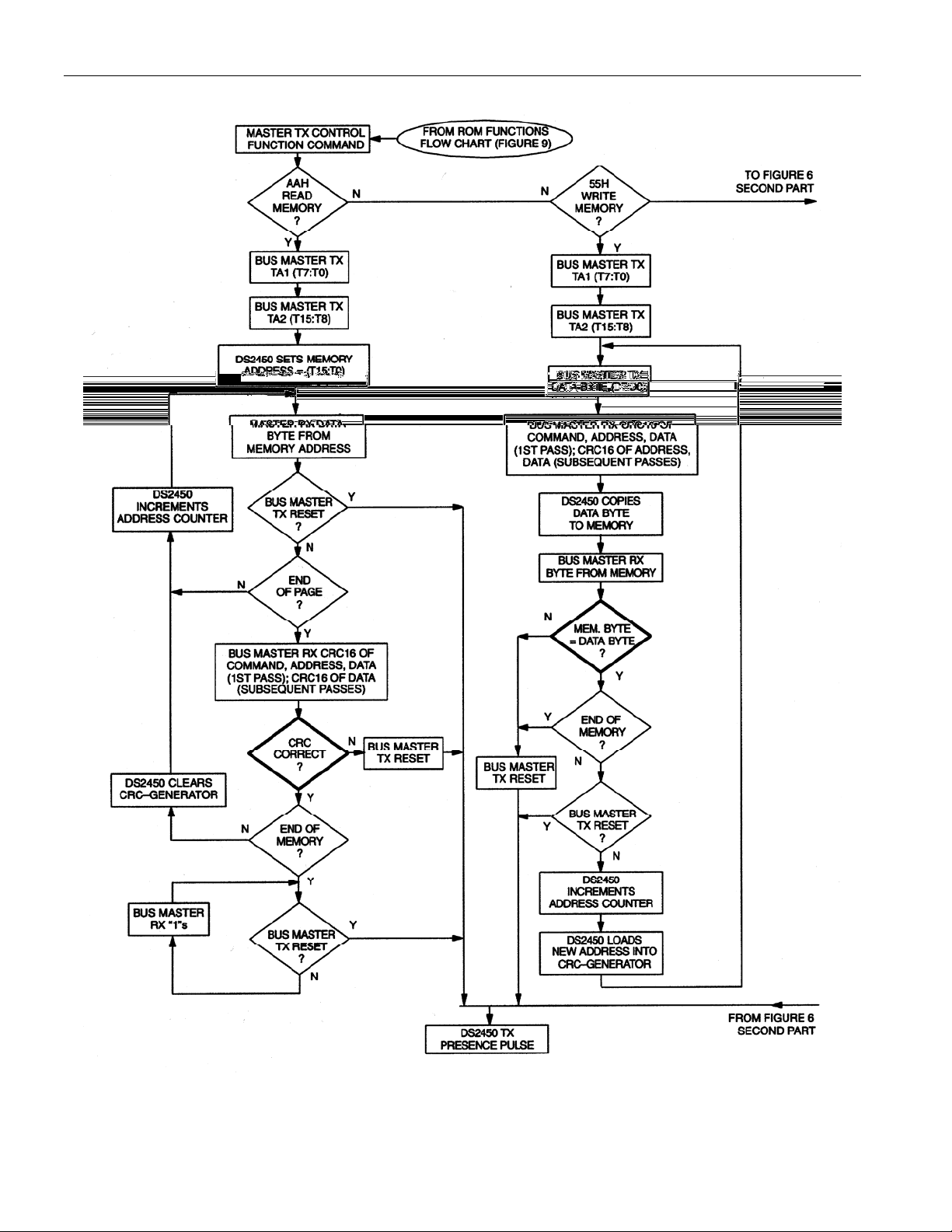

The Function Command Flow Chart (Figure 6) describes the protocols necessary for accessing the device

registers. Since the memory map of the DS2450 is small compared to the 16-bit addressing capabilities

the 11 most significant bits of the address will be forced to 0 before they enter the CRC-generator. The

communication between master and DS2450 takes place either at regular speed (default, OD = 0) or at

Overdrive Speed (OD = 1). If not explicitly set into Overdrive mode the device assumes regular speed.

6 of 24

Page 7

DS2450

READ MEMORY [AAH]

The Read Memory command is used to read conversion results, control/status data and alarm settings.

The bus master follows the command byte with a two byte address (TA1=(T7:T0), TA2=(T15:T8)) that

indicates a starting byte location within the memory map. With every subsequent read data time slot the

bus master receives data from the DS2450 starting at the supplied address and continuing until the end of

an eight-byte page is reached. At that point the bus master will receive a 16-bit CRC of the command

byte, address bytes and data bytes. This CRC is computed by the DS2450 and read back by the bus

master to check if the command word, starting address and data were received correctly. If the CRC read

by the bus master is incorrect, a Reset Pulse must be issued and the entire sequence must be repeated.

Note that the initial pass through the Read Memory flow chart will generate a 16-bit CRC value that is the

result of clearing the CRC-generator and then shifting in the command byte followed by the two address

bytes, and finally the data bytes beginning at the first addressed memory location and continuing through

to the last byte of the addressed page. Subsequent passes through the Read Memory flow chart will

generate a 16-bit CRC that is the result of clearing the CRC-generator and then shifting in the new data

bytes starting at the first byte of the next page.

WRITE MEMORY [55H]

The Write Memory command is used to write to memory pages 1 and 2 in order to set the channelspecific control data and alarm thresholds. The command can also be used to write the single control byte

on page 3 at address 1Ch. The bus master will follow the command byte with a two byte starting address

(TA1=(T7:T0), TA2=(T15:T8)) and a data byte of (D7:D0). A 16-bit CRC of the command byte, address

bytes, and data byte is computed by the DS2450 and read back by the bus master to confirm that the

correct command word, starting address, and data byte were received. Now the DS2450 copies the data

byte to the specified memory location. With the next eight time slots the bus master receives a copy of

the same byte but read from memory for verification. If the verification fails, a Reset Pulse should be

issued and the current byte address should be written again.

If the bus master does not issue a Reset Pulse and the end of memory was not yet reached, the DS2450

will automatically increment its address counter to address the next memory location. The new two-byte

address will also be loaded into the 16-bit CRC-generator as a starting value. The bus master will send

the next byte using eight write time slots. As the DS2450 receives this byte it also shifts it into the CRCgenerator and the result is a 16-bit CRC of the new data byte and the new address. With the next sixteen

read time slots the bus master will read this 16-bit CRC from the DS2450 to verify that the address

incremented properly and the data byte was received correctly. Following the CRC the master receives

the byte just written as read from the memory. If the CRC or read-back byte is incorrect, a Reset Pulse

should be issued in order to repeat the Write Memory command sequence.

Note that the initial pass through the Write Memory flow chart will generate a 16-bit CRC value that is

the result of shifting the command byte into the CRC-generator, followed by the two address bytes, and

finally the data byte. Subsequent passes through the Write Memory flow chart due to the DS2450

automatically incrementing its address counter will generate a 16-bit CRC that is the result of loading (not

shifting) the new (incremented) address into the CRC-generator and then shifting in the new data byte.

The decision to continue after having received a bad CRC or if the verification fails is made entirely by

the bus master. Write access to the conversion read-out registers is not possible. If a write attempt is

made to a page 0 address the device will follow the Write Memory flow chart correctly but the

verification of the data byte read back from memory will usually fail. The Write Memory command

sequence can be ended at any point by issuing a Reset Pulse.

7 of 24

Page 8

FUNCTION COMMAND FLOW CHART Figure 6

DS2450

8 of 24

Page 9

FUNCTION COMMAND FLOW CHART Figure 6 (continued)

DS2450

9 of 24

Page 10

DS2450

CONVERT [3CH]

The Convert command is used to initiate the analog to digital conversion for one or more channels at the

resolution specified in memory page 1, control/status data. The conversion takes between 60 and 80 μs

per bit plus an offset time of maximum 160 μs every time the convert command is issued. For four

channels with 12-bit resolution each, as an example, the convert command will not take more than

4x12x80 μs plus 160 μs offset, which totals 4 ms. If the DS2450 gets its power through the VCC pin, the

bus master may communicate with other devices on the 1-Wire bus while the DS2450 is busy with A/D

conversions. If the device is powered entirely from the 1-Wire bus, the bus master must instead provide a

strong pullup to 5V for the estimated duration of the conversion in order to provide sufficient energy.

The conversion is controlled by the input select mask (Figure 7a) and the read-out control byte (Figure

7b). In the input select mask the bus master specifies which channels participate in the conversion. A

channel is selected if the bit associated to the channel is set to 1. If more than one channel is selected, the

conversion takes place one channel after another in the sequence A, B, C, D, skipping those channels that

are not selected. The bus master can read the result of a channel’s conversion before the conversion of all

the remaining selected channels is completed. In order to distinguish between the previous result and the

new value the bus master uses the read-out control byte. This byte allows presetting the conversion readout registers for each selected channel to all 1’s or all 0’s. If the expected result is close to 0 then one

should preset to all 1’s or to all 0’s if the conversion result will likely be a high number. In applications

where the bus master can wait until all selected channels are converted before reading, a preset of the

read-out registers is not necessary. Note that for a channel not selected in the input select mask, the

channel’s read-out control setting has no effect. If a channel constantly yields conversion results close to

0 the channel’s output transistor may be conducting. See section Device Registers for details.

INPUT SELECT MASK (CONVERSION COMMAND) Figure 7a

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

“don’t care” D C B A

READ-OUT CONTROL (CONVERSION COMMAND) Figure 7b

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Set D Clear D Set C Clear C Set B Clear B Set A Clear A

Set Clear Explanation

0 0 no preset, leave as is

0 1 preset to all 0’s

1 0 preset to all 1’s

1 1 (illegal code)

Following the Convert command byte the bus master transmits the input select mask and the read-out

control byte. Now the bus master reads the CRC16 of the command byte, select mask and control byte.

The conversion will start no earlier than 10 μs after the most significant bit of the CRC is received by the

bus master.

With a parasitic power supply the bus master must activate the strong pullup within this 10 μs window for

a duration that is estimated as explained above. After that, the data line returns to an idle high state and

communication on the bus can resume. The bus master would normally send a reset pulse to exit the

Convert command. Read data time slots generated after the strong pullup has ended but before issuing a

reset pulse should result in all 1’s if the conversion time was calculated correctly.

10 of 24

Page 11

DS2450

With VCC power supply the bus master may either send a reset pulse to exit the Convert command or

continuously generate read data time slots. As long as the DS2450 is busy with conversions the bus

master will read 0’s. After the conversion is completed the bus master will receive 1’s instead. Since in a

open-drain environment a single 0 overwrites multiple 1’s the bus master can monitor multiple devices

converting simultaneously and immediately knows when the last one is ready. As in the parasitically

powered scenario the bus master finally has to exit the Convert command by issuing a rest pulse.

1-WIRE BUS SYSTEM

The 1-Wire bus is a system which has a single bus master and one or more slaves. In all instances the

DS2450 is a slave device. The discussion of this bus system is broken down into three topics: hardware

configuration, transaction sequence, and 1-Wire signaling (signal types and timing). A 1-Wire protocol

defines bus transactions in terms of the bus state during specific time slots that are initiated on the falling

edge of sync pulses from the bus master. For a more detailed protocol description, refer to Chapter 4 of

the Book of DS19xx iButton Standards.

HARDWARE CONFIGURATION

The 1-Wire bus has only a single line by definition; it is important that each device on the bus be able to

drive it at the appropriate time. To facilitate this, each device attached to the 1-Wire bus must have open

drain or 3-state outputs. The 1-Wire port of the DS2450 is open drain with an internal circuit equivalent

to that shown in Figure 8. A multidrop bus consists of a 1-Wire bus with multiple slaves attached. At

regular speed the 1-Wire bus has a maximum data rate of 16.3k bits per second. The speed can be

boosted to 142k bits per second by activating the Overdrive Mode. The 1-Wire bus requires a pullup

resistor of approximately 5kΩ at regular speed or maximum 2.2kΩ at Overdrive speed for

communication. During A/D conversions the bus master must provide a strong pullup to 5V to supply

sufficient energy if the DS2450 is powered entirely from the 1-Wire bus.

The idle state for the 1-Wire bus is high. If for any reason a transaction needs to be suspended, the bus

MUST be left in the idle state if the transaction is to resume. If this does not occur and the bus is left low

for more than 16 μs (Overdrive Speed) or more than 120 μs (regular speed), one or more devices on the

bus may be reset.

HARDWARE CONFIGURATION Figure 8

SEE TEXT

11 of 24

Page 12

DS2450

TRANSACTION SEQUENCE

The protocol for accessing the DS2450 via the 1-Wire port is as follows:

Initialization

ROM Function Command

Memory/Convert Function Command

Transaction/Data

INITIALIZATION

All transactions on the 1-Wire bus begin with an initialization sequence. The initialization sequence

consists of a reset pulse transmitted by the bus master followed by presence pulse(s) transmitted by the

slave(s). The presence pulse lets the bus master know that the DS2450 is on the bus and is ready to

operate. For more details, see the “1-Wire Signaling” section.

ROM FUNCTION COMMANDS

Once the bus master has detected a presence, it can issue one of the seven ROM function commands. All

ROM function commands are eight bits long. A list of these commands follows (refer to flowchart in

Figure 9):

Read ROM [33H]

This command allows the bus master to read the DS2450’s 8-bit family code, unique 48-bit serial

number, and 8-bit CRC. This command can only be used if there is a single DS2450 on the bus. If more

than one slave is present on the bus, a data collision will occur when all slaves try to transmit at the same

time (open drain will produce a wired-AND result). The resultant family code and 48-bit serial number

will result in a mismatch of the CRC.

MATCH ROM [55H]

The match ROM command, followed by a 64-bit ROM sequence, allows the bus master to address a

specific DS2450 on a multidrop bus. Only the DS2450 that exactly matches the 64-bit ROM sequence

will respond to the following memory/convert function command. All slaves that do not match the 64-bit

ROM sequence will wait for a reset pulse. This command can be used with a single or multiple devices

on the bus.

SKIP ROM [CCH]

This command can save time in a single drop bus system by allowing the bus master to access the

memory/ convert functions without providing the 64-bit ROM code. If more than one slave is present on

the bus and a read command is issued following the Skip ROM command, data collision will occur on the

bus as multiple slaves transmit simultaneously (open drain pulldowns will produce a wired-AND result).

SEARCH ROM [F0H]

When a system is initially brought up, the bus master might not know the number of devices on the 1Wire bus or their 64-bit ROM codes. The Search ROM command allows the bus master to use a process

of elimination to identify the 64-bit ROM codes of all slave devices on the bus. The search ROM process

is the repetition of a simple 3-step routine: read a bit, read the complement of the bit, then write the

desired value of that bit. The bus master performs this simple, 3-step routine on each bit of the ROM.

After one complete pass, the bus master knows the contents of the ROM in one device. The remaining

number of devices and their ROM codes may be identified by additional passes. See Chapter 5 of the

Book of DS19xx i

example.

12 of 24

Button Standards for a comprehensive discussion of a Search ROM, including an actual

Page 13

DS2450

CONDITIONAL SEARCH [ECH]

The Conditional Search ROM command operates similarly to the Search ROM command except that only

devices fulfilling the specified condition will participate in the search. The DS2450 will respond to the

Conditional Search command if a channel’s alarm enable flags AEH and/or AEL are set and the

conversion results in a value outside the range specified by the channel’s alarm threshold voltages. See

section Device Registers for details. The Conditional Search ROM provides an efficient means for the

bus master to determine devices on a multidrop system that have to signal an important event, such as a

voltage leaving the tolerance band. After each pass of the Conditional Search that successfully

determined the 64-bit ROM for a specific device on the multidrop bus, that particular device can be

individually accessed as if a Match ROM had been issued since all other devices will have dropped out of

the search process and are waiting for a reset pulse.

OVERDRIVE SKIP ROM [3CH]

On a single-drop bus this command can save time by allowing the bus master to access the

memory/convert functions without providing the 64-bit ROM code. Unlike the normal Skip ROM

command the Overdrive Skip ROM sets the DS2450 in the Overdrive Mode (OD = 1). All

communication following this command has to occur at Overdrive Speed until a reset pulse of minimum

480 μs duration resets all devices on the bus to regular speed (OD = 0).

When issued on a multidrop bus this command will set all Overdrive-supporting devices into Overdrive

mode. To subsequently address a specific Overdrive-supporting device, a reset pulse at Overdrive speed

has to be issued followed by a Match ROM or Search ROM command sequence. This will speed up the

time for the search process. If more than one slave supporting Overdrive is present on the bus and the

Overdrive Skip ROM command is followed by a read command, data collision will occur on the bus as

multiple slaves transmit simultaneously (open drain pulldowns will produce a wired-AND result).

Overdrive Match ROM [69H]

The Overdrive Match ROM command, followed by a 64-bit ROM sequence transmitted at Overdrive

Speed, allows the bus master to address a specific DS2450 on a multidrop bus and to simultaneously set it

in Overdrive Mode. Only the DS2450 that exactly matches the 64-bit ROM sequence will respond to the

subsequent memory function command. Slaves already in Overdrive mode from a previous Overdrive

Skip or Match command will remain in Overdrive mode. All overdrive-capable slaves will return to

regular speed at the next Reset Pulse of minimum 480 μs duration. The Overdrive Match ROM

command can be used with a single or multiple devices on the bus.

13 of 24

Page 14

ROM FUNCTIONS FLOW CHART Figure 9

DS2450

14 of 24

Page 15

ROM FUNCTIONS FLOW CHART Figure 9 (continued)

DS2450

15 of 24

Page 16

DS2450

USAGE EXAMPLE (set-up section)

There is a single VCC powered DS2450 on the 1-Wire bus. Set-up channel D for 12 bits, 5.12V range and

alarm thresholds of 2.0V (64h) and 3.0V (96h) (increment 20 mV) and convert the input voltage; turn on

the channel A output if low alarm occurs and the channel B output if high alarm occurs, respectively.

MASTER MODE DATA (LSB FIRST) COMMENTS

TX Reset

RX Presence Presence Pulse

TX CCh Issue “Skip ROM” Command

TX 55h Issue “Write Memory” Command

TX 08h TA1, beginning address

TX 00h TA2, address = 0008h

TX C0h data byte (address 0008) CH-A

RX <CRC16> CRC of command, address, data byte

RX C0h read-back for simple verification

TX 00h next data byte (address 0009h)

RX <CRC16> CRC of address, data byte

RX 00h read-back for simple verification

TX C0h data byte (address 000A) CH-B

RX <CRC16> CRC of address, data byte

RX C0h read-back for simple verification

TX 00h next data byte (address 000Bh)

RX <CRC16> CRC of address, data byte

RX 00h read-back for simple verification

TX C0h data byte (address 000C) CH-C*

RX <CRC16> CRC of address, data byte

RX C0h read-back for simple verification

TX 00h next data byte (address 000Dh)

RX <CRC16> CRC of address, data byte

RX 00h read-back for simple verification

TX 0Ch data byte (address 000E) CH-D

RX <CRC16> CRC of address, data byte

RX 0Ch read-back for simple verification

TX 0Dh next data byte (address 000Fh)

RX <CRC16> CRC of address, data byte

RX 0Dh read-back for simple verification

Continued on the next page.

*In a multi-drop environment it takes less time to set-up an unused channel rather than skipping it.

Reset Pulse (480 - 960 μs)

16 of 24

Page 17

DS2450

USAGE EXAMPLE (set-up continued, conversion, read flags)

MASTER MODE DATA (LSB FIRST) COMMENTS

TX Reset

RX Presence Presence Pulse

TX CCh Issue “Skip ROM” Command

TX 55h Issue “Write Memory” Command

TX 16h TA1, beginning address

TX 00h TA2, address = 0016h

TX 64h data byte (address 0016) CH-D

RX <CRC16> CRC of command, address, data byte

RX 64h read-back for simple verification

TX 96h next data byte (address 0017h)

RX <CRC16> CRC of address, data byte

RX 96h read-back for simple verification

TX Reset

RX Presence Presence Pulse

TX CCh Issue “Skip ROM” Command

TX 3Ch Issue “Convert” Command

TX 08h input select mask CH-D

TX 40h read-out control byte

RX <CRC16> CRC of command, mask, control byte

RX <multiple data bytes> continue reading until byte is FFh

TX Reset

RX Presence Presence Pulse

TX CCh Issue “Skip ROM” Command

TX Aah Issue “Read Memory” Command

TX 0Fh TA1, beginning address

TX 00h TA2, address = 000Fh

RX <data byte> status data* CH-D

RX <CRC16> CRC of command, address, data byte

Continued on the next page.

*The status data byte includes the channel D alarm flags AFH and AFL which are used to control the

channel A and B outputs (see next page).

Reset Pulse (480 - 960 μs)

Reset Pulse (480 - 960 μs)

Reset Pulse (480 - 960 μs)

17 of 24

Page 18

DS2450

USAGE EXAMPLE (control channel A and channel B outputs)

MASTER MODE DATA (LSB FIRST) COMMENTS

TX Reset

Reset Pulse (480 - 960 μs)

RX Presence Presence Pulse

TX CCh Issue “Skip ROM” Command

TX 55h Issue “Write Memory” Command

TX 08h TA1, beginning address

TX 00h TA2, address = 0008h

TX 80h if AFL = 1 / C0h if

data byte (address 0008) CH-A

AFL = 0

RX <CRC16> CRC of command, address, data byte

RX <data byte> read-back for simple verification

TX 00h next data byte (address 0009h)*

RX <CRC16> CRC of address, data byte

RX 00h read-back for simple verification

TX 80h if AFH = 1 / C0h if

data byte (address 000A) CH-B

AFH = 0

RX <CRC16> CRC of address, data byte

RX <data byte> read-back for simple verification

TX Reset

Reset Pulse (480 - 960 μs)

RX Presence Presence Pulse

*In a multi-drop environment it takes less time to perform a non-changing write cycle rather than

skipping a byte.

1-WIRE SIGNALING

The DS2450 requires strict protocols to ensure data integrity. The protocol consists of four types of

signaling on one line: reset sequence with reset pulse and presence pulse, Write 0, Write 1 and Read Data.

All these signals except presence pulse are initiated by the bus master. The DS2450 can communicate at

two different speeds, regular speed and Overdrive Speed. If not explicitly set into the Overdrive mode,

the DS2450 will communicate at regular speed. While in Overdrive mode the fast timing applies to all

wave forms.

The initialization sequence required to begin any communication with the DS2450 is shown in Figure 10.

A Reset Pulse followed by a Presence Pulse indicates the DS2450 is ready to send or receive data given

the correct ROM command and memory function command. The bus master transmits (TX) a reset pulse

, minimum 480 μs at regular speed, 48 μs at Overdrive Speed). The bus master then releases the

(t

RSTL

line and goes into receive mode (RX). The 1-Wire bus is pulled to a high state via the pullup resistor.

After detecting the rising edge on the data pin, the DS2450 waits (t

at Overdrive speed) and then transmits the Presence Pulse (t

, 60-240 μs at regular speed, 8-24 μs at

PDL

Overdrive Speed).

A Reset Pulse of 480 μs or longer will exit the Overdrive Mode returning the device to regular speed. If

the DS2450 is in Overdrive Mode and the Reset Pulse is no longer than 80 μs the device will remain in

Overdrive Mode.

,15-60 μs at regular speed, 2-6 μs

PDH

18 of 24

Page 19

DS2450

INITIALIZATION PROCEDURE “RESET AND PRESENCE PLUSES” Figure 10

*IN ORDER NOT TO MASK INTERRUPT SIGNALING BY OTHER DEVICES ON THE 1-WIRE BUS, t

SHOULD ALWAYS BE LESS THAN 960 μs

**INCLUDES RECOVERY TIME

RSTL

+ tR

READ/WRITE TIME SLOTS

The definitions of write and read time slots are illustrated in Figure 11. All time slots are initiated by the

master driving the data line low. The falling edge of the data line synchronizes the DS2450 to the master

by triggering a delay circuit in the DS2450. During write time slots, the delay circuit determines when

the DS2450 will sample the data line. For a read data time slot, if a “0” is to be transmitted, the delay

circuit determines how long the DS2450 will hold the data line low overriding the 1 generated by the

master. If the data bit is a “1”, the device will leave the read data time slot unchanged.

READ/WRITE TIME DIAGRAM Figure 11

Write-one Time Slot

19 of 24

Page 20

READ/WRITE TIMING DIAGRAM Figure 11 (continued)

Write-zero Time Slot

Read-data Time Slot

DS2450

20 of 24

Page 21

DS2450

CRC HARDWARE DESCRIPTION AND POLYNOMIAL Figure 12

CRC-GENERATION

With the DS2450 there are two different types of CRCs (Cyclic Redundancy Checks). One CRC is a 8bit type and is stored in the most significant byte of the 64-bit ROM. The bus master can compute a CRC

value from the first 56 bits of the 64-bit ROM and compare it to the value stored within the DS2450 to

determine if the ROM data has been received error-free by the bus master. The equivalent polynomial

function of this CRC is X8 + X5 + X4 + 1. This 8-bit CRC is received in the true (non inverted) form

when reading the ROM of the DS2450. It is computed once at the factory and lasered into the ROM.

The other CRC is a 16-bit type, generated according to the standardized CRC16 polynomial function X16

+ X15 + X2 + 1. This CRC is used to safeguard data when reading from or writing to the device’s

memory. It is the same type of CRC as is used with NV RAM based iButtons to safeguard data packets

of the iButton File Structure. In contrast to the 8-bit CRC, the 16-bit CRC is always returned in the

complemented (inverted) form. A CRC-generator inside the DS2450 chip (Figure 12) will calculate a

new 16-bit CRC at every situation shown in the command flow chart of Figure 6.

The DS2450 provides this CRC value to the bus master to validate the transfer of command, address, and

data to and from the bus master. When reading the memory, the 16-bit CRC is transmitted when the end

of each 8-byte memory page is reached. At the initial pass through the Read Memory flow chart the 16bit CRC will be generated by clearing the CRC-generator, shifting in the command byte, low address,

high address and the data bytes beginning at the first addressed memory location and continuing until the

last byte of the addressed memory page is reached. Subsequent passes through the Read Memory flow

chart will generate a 16-bit CRC that is the result of clearing the CRC-generator and then shifting in the

new data bytes starting at the first byte of the next page and continuing until the last byte of the page is

reached.

When writing to the DS2450, the bus master receives a 16-bit CRC to verify the correctness of the data

transfer before the device copies the data byte to its memory. With the initial pass through the Write

Memory flow chart the 16-bit CRC will be generated by clearing the CRC-generator, shifting in the

command, address low, address high and the data byte. Subsequent passes through the Write Memory

flow chart due to the DS2450 automatically incrementing its address counter will generate an 16-bit CRC

that is the result of loading (not shifting) the new (incremented) address into the CRC-generator and then

shifting in the new data byte.

For more details on generating CRC values including example implementations in both hardware and

software, see the Book of DS19xx i

Button Standards.

21 of 24

Page 22

TRANSFER CHARACTERISTIC

DS2450

INCREMENT AND MINIMUM FULL SCALE INPUT VOLTAGE VERSUS

RESOLUTION

Range = 2.56V Range = 5.12V

Resolution

2 bits 640 1.60 1280 3.20

3 bits 320 2.08 640 4.16

4 bits 160 2.32 320 4.64

5 bits 80 2.44 160 4.88

6 bits 40 2.50 80 5.00

7 bits 20 2.53 40 5.06

8 bits 10 2.545 20 5.09

9 bits 5 2.5525 10 5.105

10 bits 2.5 2.5563 5 5.1125

11 bits 1.25 2.5581 2.5 5.1163

12 bits 0.625 2.5591 1.25 5.1181

13 bits 0.313 2.5595 0.625 5.1191

14 bits 0.156 2.5598 0.313 5.1195

15 bits 0.078 2.5599 0.156 5.1198

16 bits 0.039 2.5599 0.078 5.1199

In the shaded areas the accuracy is less than the resolution. The conversion results may include random

noise.

1 LS bit equivalent

input voltage(mV)

minimum full scale

input voltage (V)

1 LS bit equivalent

input voltage (mV)

minimum full scale

input voltage (V)

22 of 24

Page 23

DS2450

ABSOLUTE MAXIMUM RATINGS*

Voltage on DATA to Ground -0.5V to +7.0V

Operating Temperature -40°C to +85°C

Storage Temperature -55°C to +125°C

Soldering Temperature See J-STD-020 Specification

* This is a stress rating only and functional operation of the device at these or any other conditions above

those indicated in the operation sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods of time may affect reliability.

DC ELECTRICAL CHARACTERISTICS (-40°C to +85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Supply Voltage VCC 4.5 5.0 5.5 V 10

Logic 1 V

Logic 0 V

Output Logic Low @ 4 mA V

Output Logic High V

Input Load Current I

Operating Current I

Quiescent Current I

IH

IL

OL

OH

L

CC

CCQ

2.2 V 1

-0.3 +0.8 V 1

0.4 V 1

V

PUP

5

6.0 V 1, 2

μA

3

0.5 mA 7

20

μA

8

CAPACITANCE (tA= 25°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

I/O (1-Wire) C

Analog Input C

IN/OUT

AIN

100 800 pF 5

50 pF

RESISTANCES (tA= 25°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Analog Input Z

0.5 1.5

AIN

MΩ

AC ELECTRICAL CHARACTERISTICS REGULAR SPEED (-40°C to +85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Time Slot t

Write 1 Low Time t

Write 0 Low Time t

Read Low Time t

Read Data Valid t

Release Time t

Read Data Setup tSU 1

Recovery Time t

Reset Time High t

Reset Time Low t

Presence Detect High t

Presence Detect Low t

60 120

SLOT

1 15

LOW

60 120

LOW0

1 15

LOWR

exactly 15

RDV

RELEASE

0 15 45

1

REC

480

RSTH

480

RSTL

15 60

PDH

60 240

PDL

μs

μs

μs

μs

μs

μs

μs

μs

μs

μs

μs

μs

4

6

23 of 24

Page 24

DS2450

AC ELECTRICAL CHARACTERISTICS

OVERDRIVE SPEED (-40°C to +85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Time Slot t

Write 1 Low Time t

Write 0 Low Time t

Read Low Time t

Read Data Valid t

Release Time t

Read Data Setup tSU 1

Recovery Time t

Reset Time High t

Reset Time Low t

Presence Detect High t

Presence Detect Low t

6 16

SLOT

1 2

LOW1

6 16

LOW0

1 2

LOWR

Exactly 2

RDV

RELEASE

0 1.5 4

1

REC

48

RSTH

48 80

RSTL

2 6

PDH

8 24

PDL

μs

μs

μs

μs

μs

μs

μs

μs

μs

μs

μs

μs

4

AC ELECTRICAL CHARACTERISTICS (-40°C to +85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Sample & Hold Aperture tSH 20

Equivalent Input Noise V

Total Conversion Error N

t.b.d.

INOISE

ERR

± 1/2

LSB 9

μV

RMS

μs

NOTES:

1. All voltages are referenced to ground.

2. V

= external pullup voltage.

PUP

3. Input load is to ground.

4. Read data setup time refers to the time the host must pull the 1-Wire bus low to read a bit. Data is

guaranteed to be valid within 1 μs of this falling edge.

5. Capacitance on the data pin could be 800 pF when power is first applied. If a 5 kΩ resistor is used to

pull up the data line to V

, 5 μs after power has been applied the parasite capacitance will not affect

PUP

normal communications.

6. The reset low time (t

) should be restricted to a maximum of 960 μs, to allow interrupt signaling,

RSTL

otherwise, it could mask or conceal interrupt pulses.

7. Measured with V

= 5.0V supply and 1-Wire input open.

CC

8. Measured with VCC = 5.0V supply, 1-Wire input open and analog circuitry inactive.

9. At 8-bit resolution regardless of range and temperature; includes offset, non-linearity and noise. Out

of range is denoted by an all zeros reading. Input voltage at or near minimum and maximum input

range may include additional non-linearity error.

10. VCC or 1-Wire pullup voltage must ramp to 4.5V or higher at least 1µs before voltage can be applied

to analog inputs. This can be achieved through low-pass filtering of the analog input voltage.

REVISION HISTORY

Pages changed at Rev 071906: 1, 2, 6, 7, 23, 24

Pages changed at Rev 112706: 1, 7, 23, 24

24 of 24

Loading...

Loading...