Page 1

General Description

The DS1862 is a closed-loop laser-driver control IC with

built-in digital diagnostics designed for XFP MSA. The

laser control function incorporates average power control (APC) and allows extinction ratio control though a

temperature indexed look-up table (LUT). The DS1862

monitors up to seven analog inputs, including temperature and monitor diode (MD) current, which are used to

regulate the laser bias current and extinction ratio.

Warning and alarm thresholds can be programmed to

generate an interrupt if monitored signals exceed tolerance. Calibration is also provided internally using independent gain and offset scaling registers for each of

the monitored analog signals. Settings such as programmed calibration data are stored in password-protected EEPROM memory. Programming is accomplished

through an I

2

C-compatible interface, which can also be

used to access diagnostic functionality.

Applications

Laser Control and Monitoring 10Gbps Optical

Transceiver Modules (XFP)

Laser Control and Monitoring

Digital Diagnostics in Optical Transmission

Features

♦ Implements XFP MSA Requirements for Digital

Diagnostics, Serial ID, and User Memory

♦ I2C-Compatible Serial Interface

♦ Automatic Power Control (APC)

♦ Extinction Ratio Control with Look-Up Table

♦ Seven Monitored Channels for Digital Diagnostics

(Five Basic Plus Two Auxiliary)

♦ Internal Calibration of Monitored Channels

(Temp, V

CC2/3

, Bias Current, Transmitted, and

Received Power)

♦ Programmable Quick-Trip Logic for Turning

Off Laser for Eye Safety

♦ Access to Monitoring and ID Information

♦ Programmable Alarm and Warning Thresholds

♦ Operates from 3.3V or 5V Supply

♦ 25-Pin CSBGA, 5mm x 5mm Package

♦ Internal or External Temperature Sensor

♦ -40°C to +100°C Operating Temperature Range

♦ One 8-Bit Buffered DAC

DS1862

XFP Laser Control and Digital Diagnostic IC

______________________________________________

Maxim Integrated Products

1

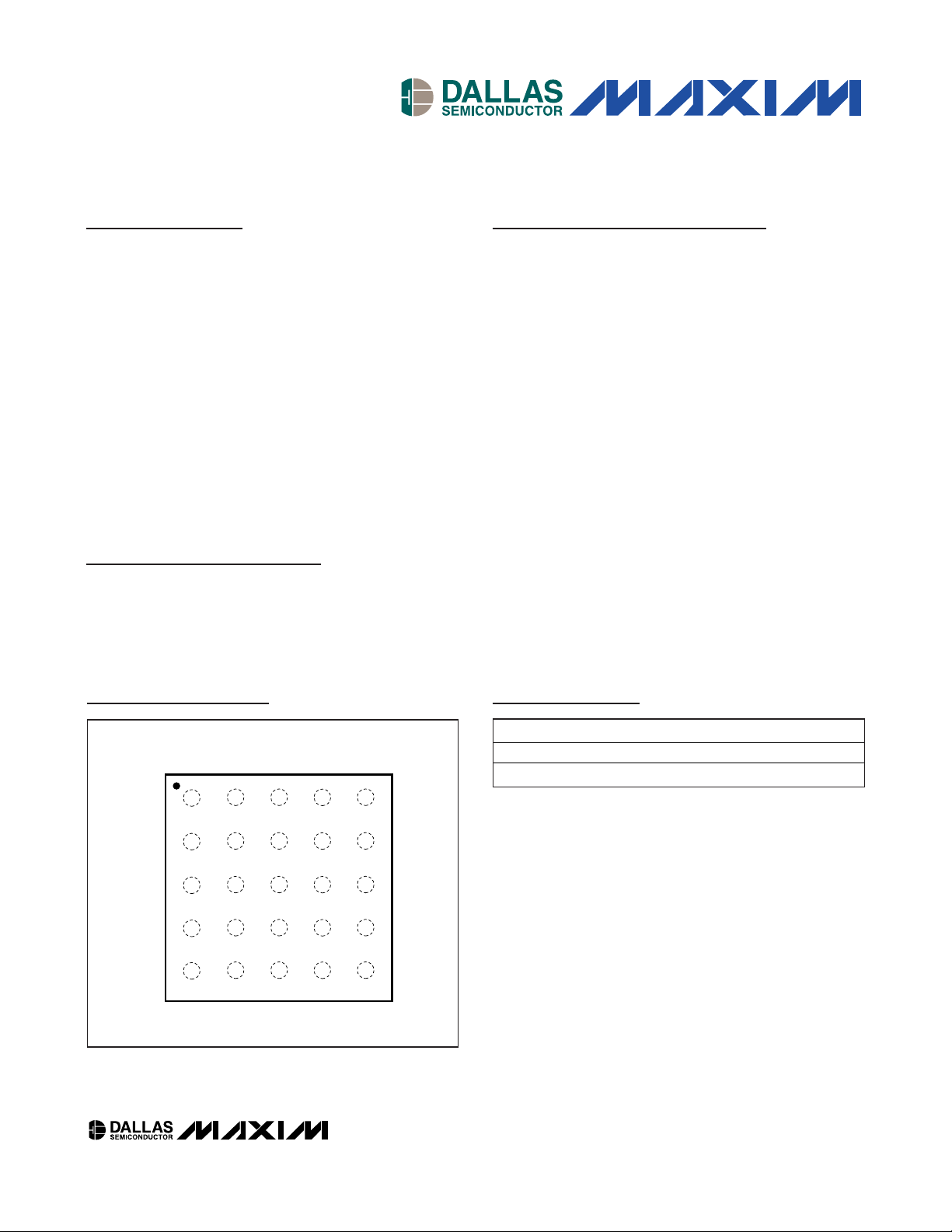

Pin Configuration

Rev 1; 12/07

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

+

Denotes lead-free package.

Ordering Information

Typical Operating Circuit appears at end of data sheet.

TOP VIEW

A

B

C

D

E

1

2345

CSBGA (5mm x 5mm)

PART TEMP RANGE PIN-PACKAGE

DS1862B -40°C to +100°C 25 CSBGA (5mm x 5mm)

DS1862B+ -40°C to +100°C 25 CSBGA (5mm x 5mm)

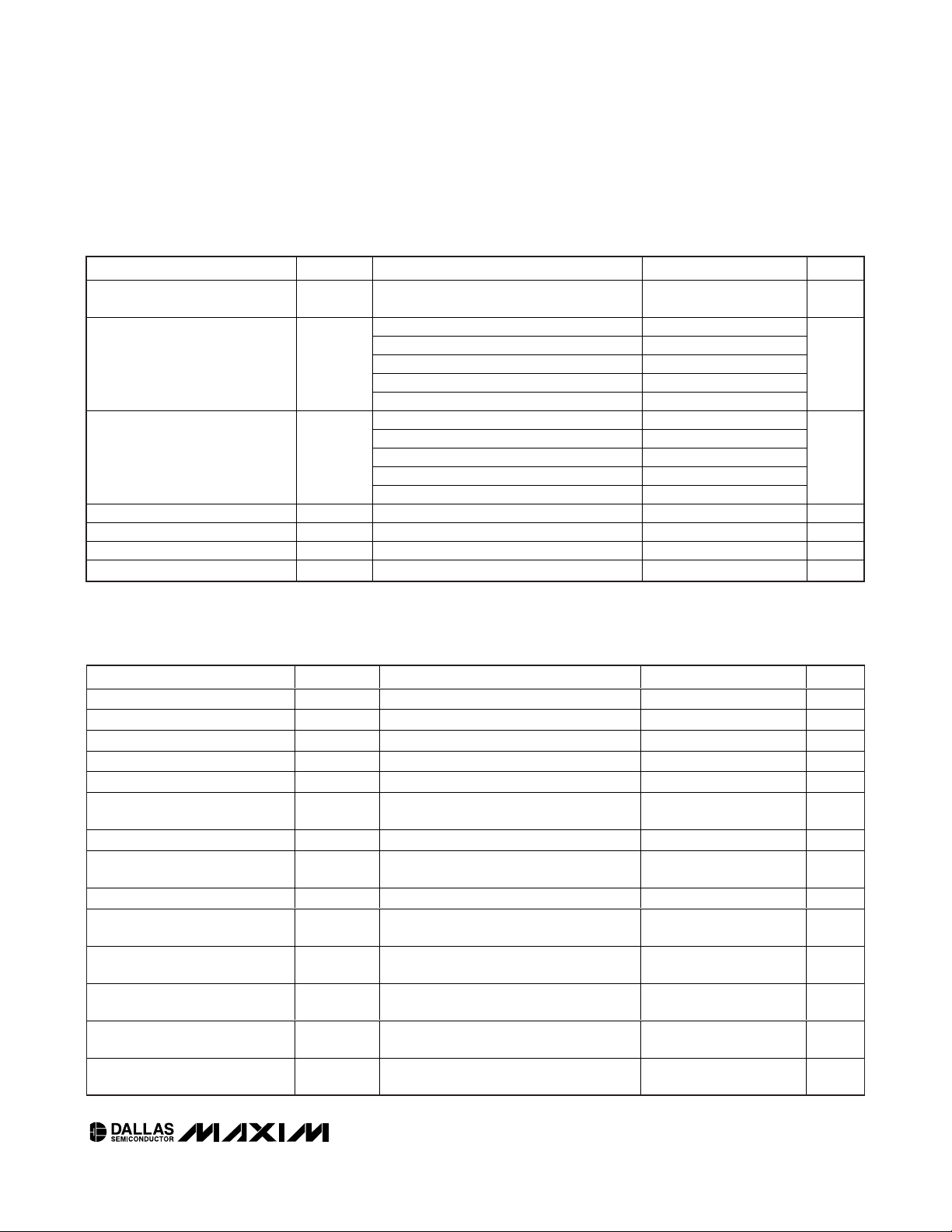

Page 2

DS1862

XFP Laser Control and Digital Diagnostic IC

2 _____________________________________________________________________

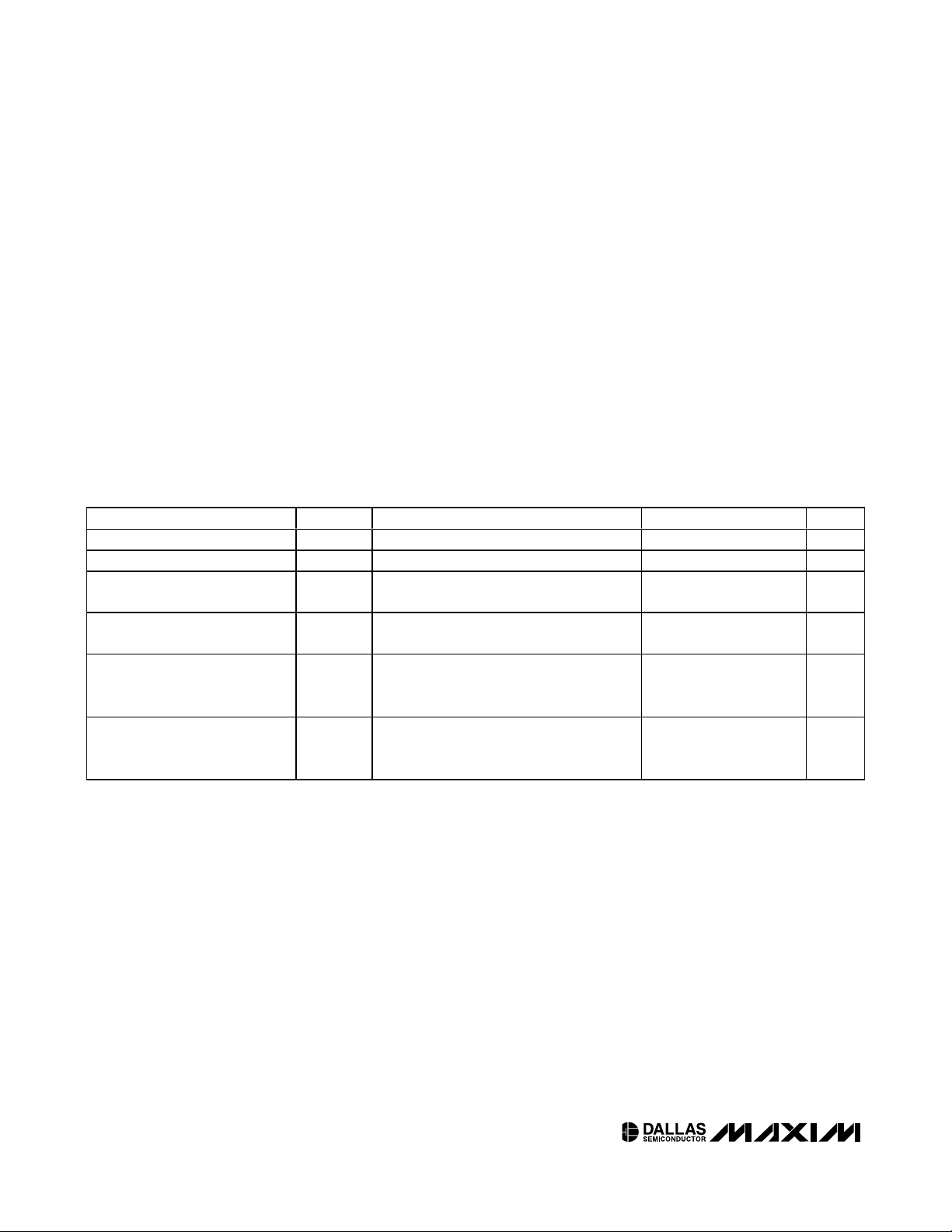

ABSOLUTE MAXIMUM RATINGS

RECOMMENDED OPERATING CONDITIONS

(V

CC3

= +2.9V to +5.5V, TA= -40°C to +100°C, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage on Any Open-Drain Pin

Relative to Ground.............................................-0.5V to +6.0V

Voltage on MOD-DSEL, SDA, SCL, FETG, THRSET, TX-D,

AUX1MON, AUX2MON, IBIASMON,

RSSI, BIASSET, MODSET, EN1,

and EN2 ............-0.5V to (V

CC3

+ 0.5V), not to exceed +6.0V

Voltage on SC-RX-LOS, SC-RX-LOL, RX-LOS, SC-TX-LOS,

MOD-NR, EN1,

and EN2 ............-0.5V to (V

CC2

+ 0.5V), not to exceed +6.0V

Operating Temperature Range .........................-40°C to +100°C

EEPROM Programming Temperature Range .........0°C to +70°C

Storage Temperature Range .............................-55°C to +125°C

Soldering Temperature...................See J-STD-020 Specification

Main Supply Voltage V

Secondary Supply Voltage V

High-Level Input Voltage

(SDA, SCL)

Low-Level Input Voltage

(SDA, SCL)

High-Level Input Voltage

(TX-D, MOD-DESEL,

P-DOWN/RST) (Note 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC3

CC2

V

V

V

(Note 1) +2.9 +5.5 V

V

not to exceed V

CC2

IIH (max) = 10µA

IH

IIL (max) = -10µA

IL

IIH (max) = 10µA 2

IH

(Note 2) +1.6 +3.6 V

CC3

0.7 x

V

CC3

GND -

0.3

V

CC3

0.3 x

V

V

CC3

+

0.5

CC3

+

0.3

V

V

V

Low-Level Input Voltage

(TX-D, MOD-DESEL,

P-DOWN/RST) (Note 3)

V

IIL (max) = -10µA -0.3 +0.8 V

IL

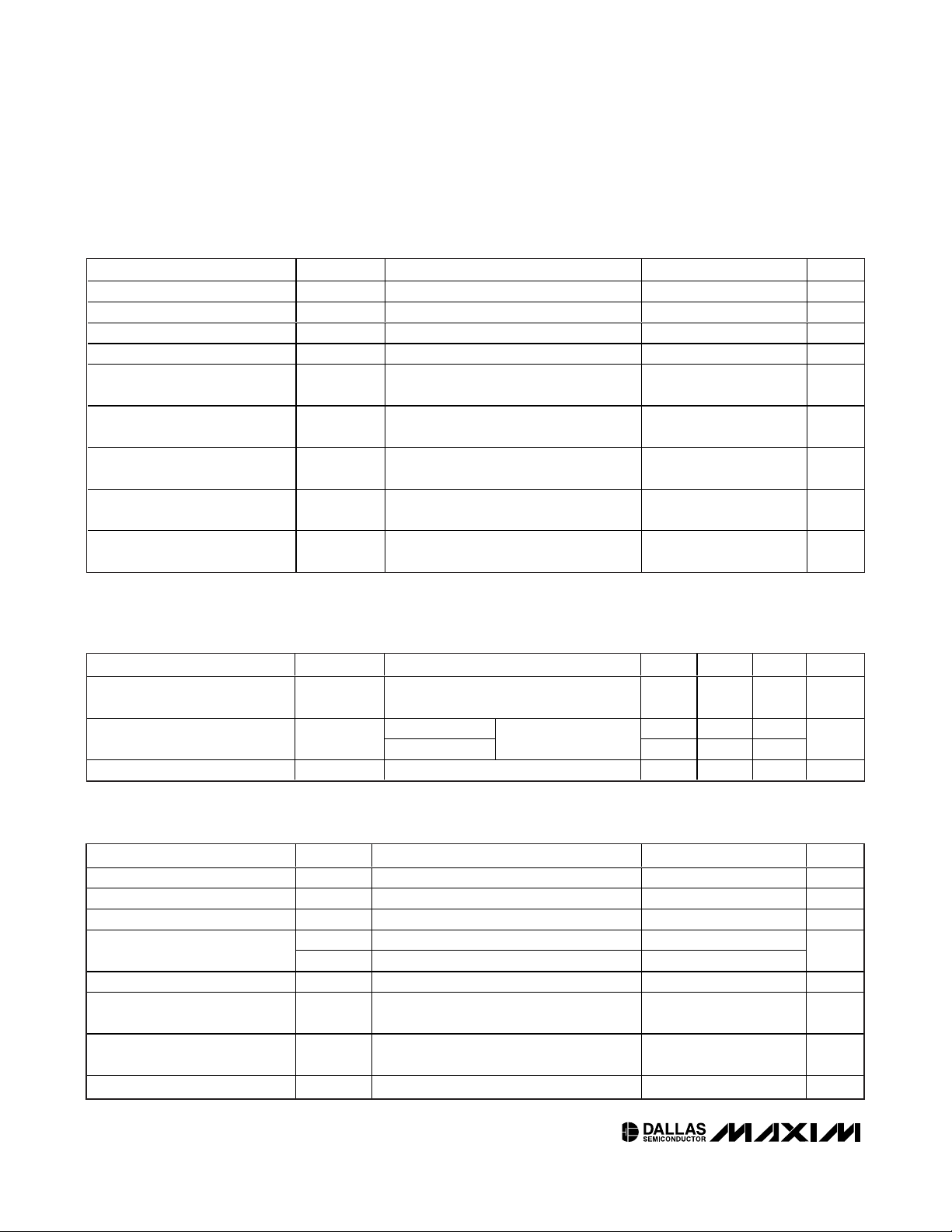

Page 3

DS1862

XFP Laser Control and Digital Diagnostic IC

_____________________________________________________________________ 3

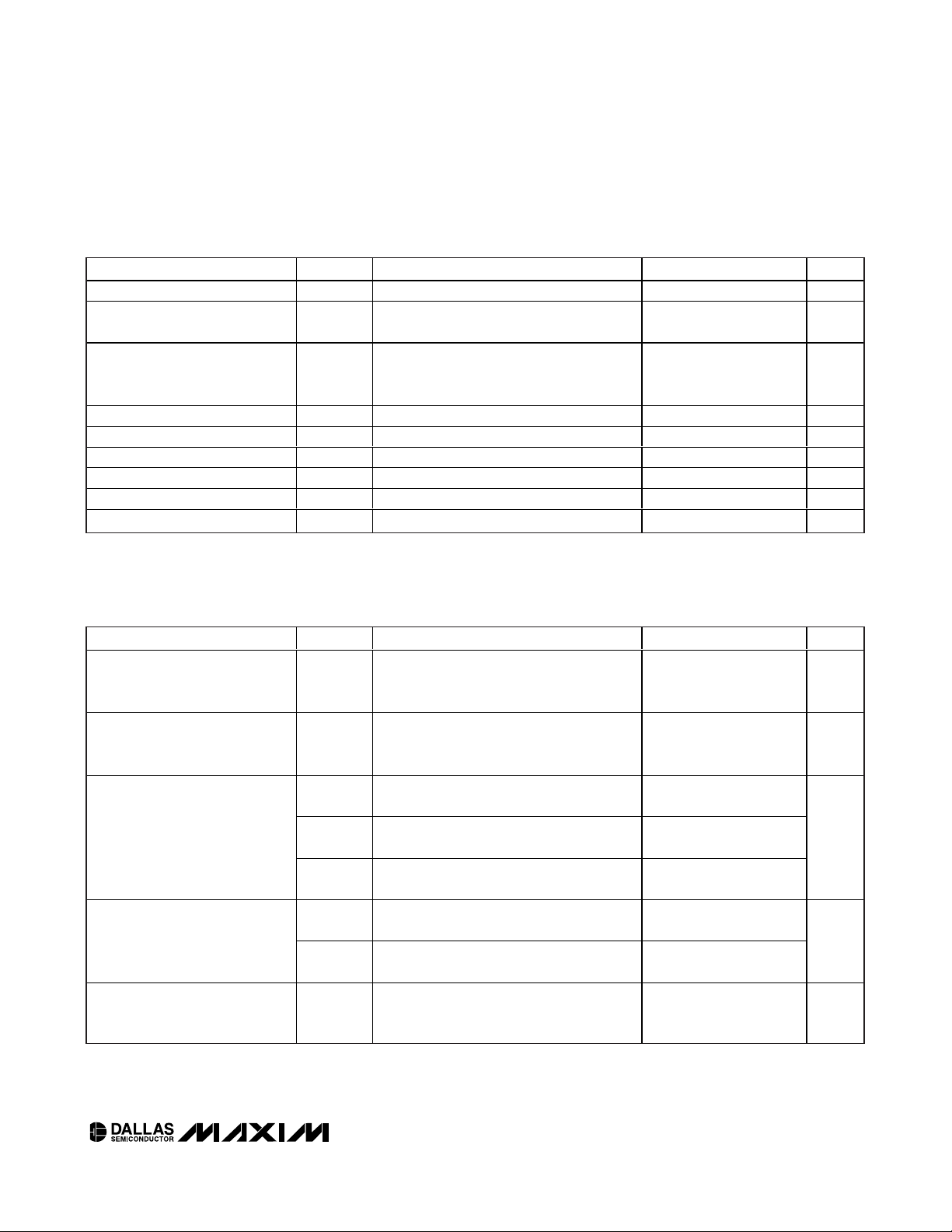

DC ELECTRICAL CHARACTERISTICS

(V

CC3

= +2.9V to +5.5V, V

CC2

= +1.6V to +3.6V, TA= -40°C to +100°C, unless otherwise noted.)

DC ELECTRICAL CHARACTERISTICS—INTERFACE SIGNALS TO SIGNAL CONDITIONERS

(V

CC2

= +1.6V to +3.6V, V

CC3

= +2.9V to +5.5V, TA= -40°C to +100°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Current I

High-Level Output Voltage

(FETG)

CC3

V

OH

P-DOWN/RST = 1 3 5 mA

V

-

IOH (max) = -2mA

CC3

0.5

V

Low-Level Output Voltage

(MOD-NR, INTERRUPT, SDA,

V

OL

IOL (max) = 3mA 0 0.4 V

and FETG)

Resistor (Pullup) R

I/O Capacitance C

Leakage Current I

Leakage Current (SCL, SDA) I

PU

I/O

L

L

(Note 4) 10 pF

91215kΩ

-10 +10 µA

-10 +10 µA

Digital Power-On Reset POD 1.0 2.2 V

Analog Power-On Reset POA 2.0 2.6 V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

High-Level Input Voltage

(SC-RX-LOS, SC-RX-LOL,

and SC-TX-LOS)

V

IIH (max) = 100µA

IH

0.7 x

V

CC2

V

CC2

0.1

+

V

Low-Level Input Voltage

(SC-RX-LOS, SC-RX-LOL,

and SC-TX-LOS)

High-Level Output Voltage

(EN1 and EN2)

Low-Level Output Voltage

(EN1, EN2, and RX-LOS)

Leakage Current

(SC-RX-LOS, SC-RX-LOL

and SC-TX-LOS, RX-LOS)

0.3 x

V

CC2

0.40

V

V

V

V

V

OH2

OH3

V

IL

OH

OL

OL2

I

L

IIL (max) = -100µA 0

V

-

V

V

CC2

0.2

CC2

0.4

CC2

0.2

-

-

IOH (max) = -0.7mA

V

= 2.5V to 3.6V

CC2

I

(max) = -2mA

OH

V

= 1.6V

CC2

I

(max) = -0.7mA

OH

IOL (max) = 0.7mA 0.20

V

= 2.5V to 3.6V

CC2

(max) = 2mA

I

OL

-10 +10 µA

V

V

V

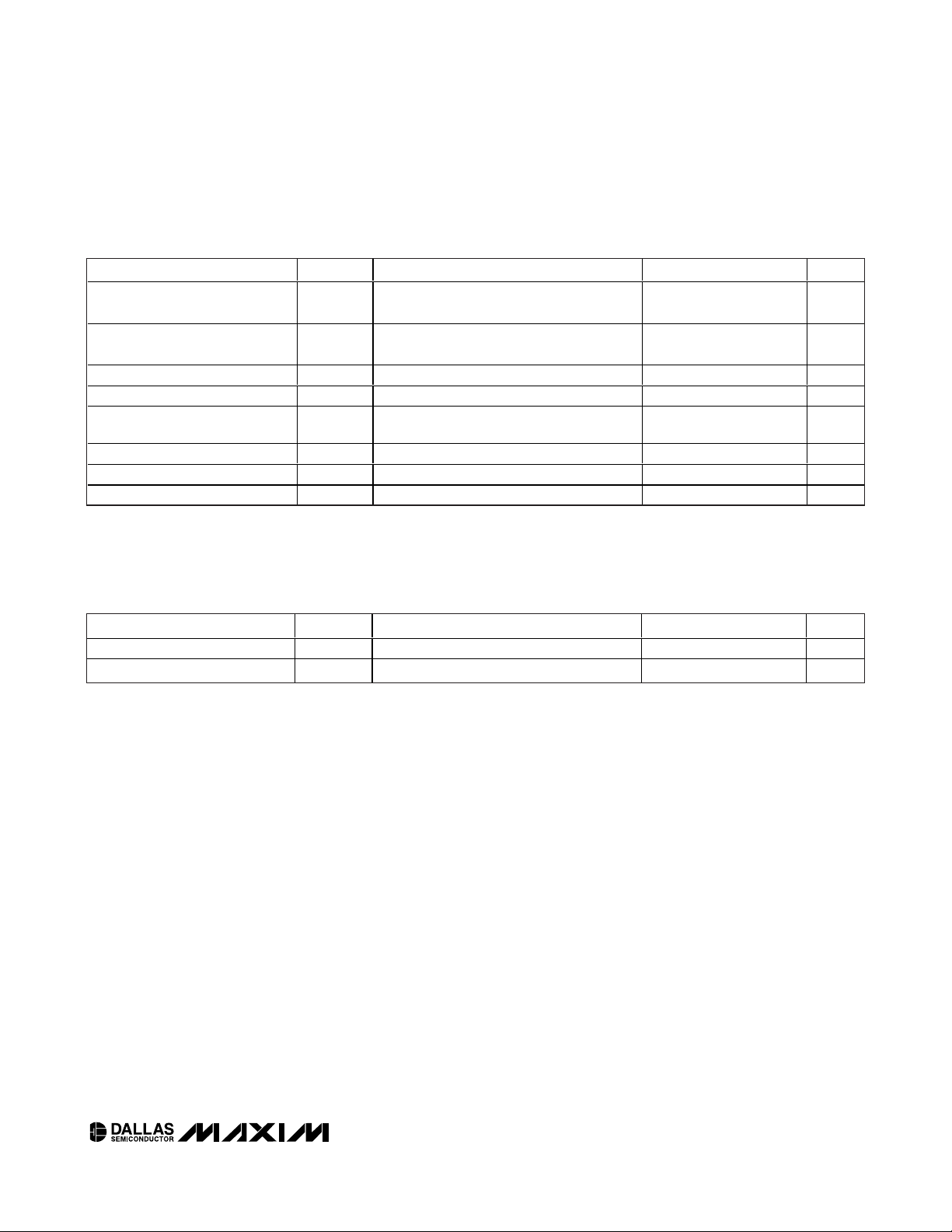

Page 4

DS1862

XFP Laser Control and Digital Diagnostic IC

4 _____________________________________________________________________

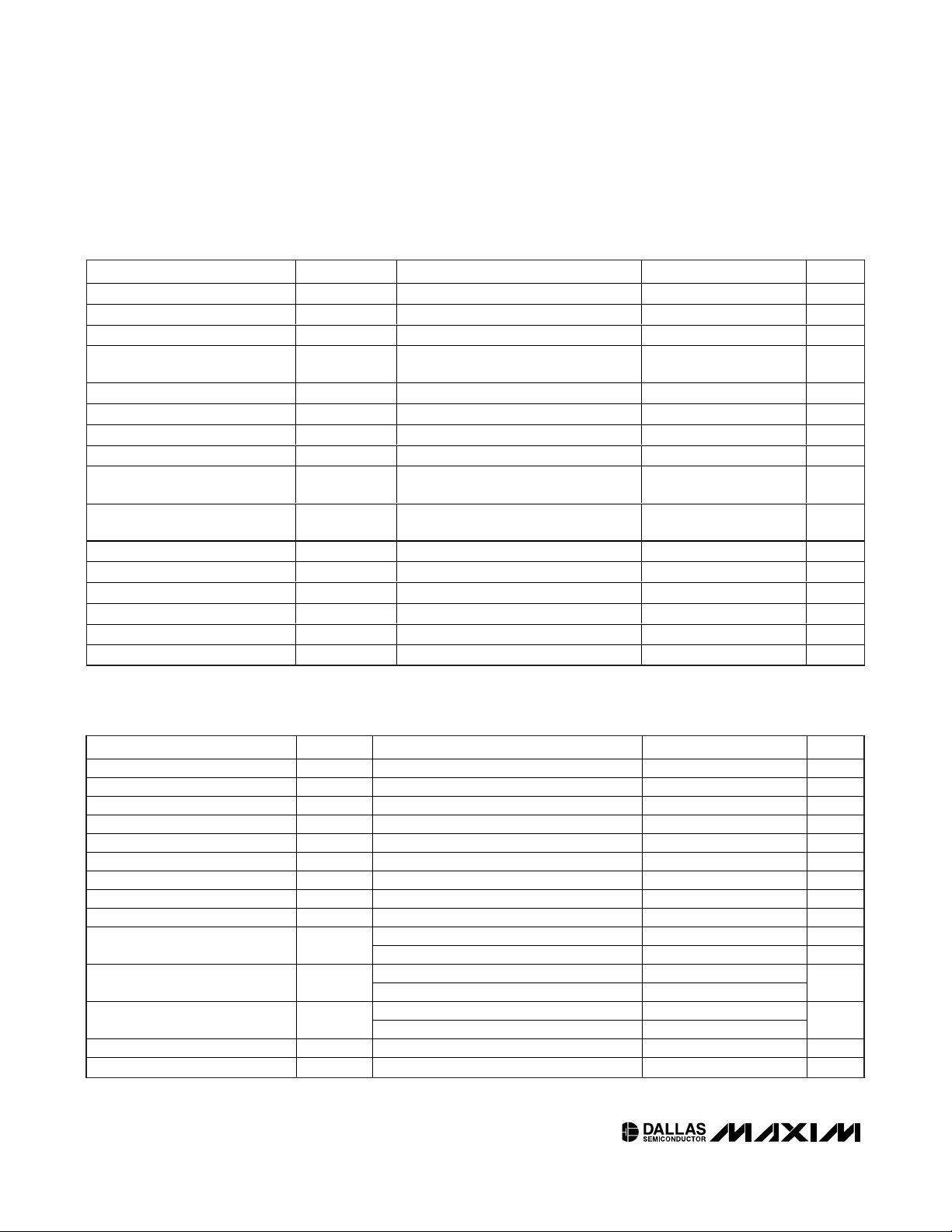

I2C AC ELECTRICAL CHARACTERISTICS

(V

CC3

= +2.9V to +5.5V, TA= -40°C to +100°C, unless otherwise noted.)

ANALOG OUTPUT CHARACTERISTICS

(V

CC3

= +2.9V to +5.5V, V

CC2

= +1.6V to +3.6V, TA= -40°C to +100°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCL Clock Frequency f

Clock Pulse-Width Low t

Clock Pulse-Width High t

Bus Free Time between STOP

and START Conditions

Start Hold Time t

Start Setup Time t

Data in Hold Time t

Data in Setup Time t

Rise Time of Both SDA and

SCL Signals

Fall Time of Both SDA and

SCL signals

STOP Setup Time t

MOD-SEL Setup Time t

MOD-SEL Hold Time t

Aborted Sequence Bus Release t

C ap aci ti ve Load for E ach Bus Li ne C

EEPROM Write Time t

SCI

LOW

HIGH

t

BUF

HD:SDA

SU:SDA

HD:DAT

SU:DAT

t

R

t

F

SU:STO

H os t_sel e ct_set up

Host_select_hold

MOD-DE SEL _Ab ort

B

W

(Note 5)

(Note 5)

(Note 5) 400 pF

≤ 4-Byte write (Note 6) 16 ms

0 400 kHz

1.3 µs

0.6 µs

1.3 µs

0.6 µs

0.6 µs

0 0.9 µs

100 ns

20 +

0.1C

B

20 +

0.1C

B

0.6 µs

2ms

10 µs

300 ns

300 ns

2ms

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I

BIASSET

I

I

I

Voltage on I

V

V

V

(Off-State Current) I

BIASSET

MODSET

MODSET

(Off-State Current) I

and I

BIASSET

THRSET

Drift Across temperature (Note 8) -5 +5 %

THRSET

Capacitance load C

THRSET

APC Calibration Accuracy +25°C 25 µA

APC Temp Drift

I

DNL

BMD

I

INL

BMD

I

Voltage Drift 1.2 %/V

BMD

I

FS Accuracy 1.5 %

BMD

I

BIASSET

Shutdown ±10 ±100 nA

Shutdown ±10 ±100 nA

(Note 7) 0.7 3.0 V

= 100µA 50 1000 mV

MODSET

BIASSET

I

MODSET

MODSET

V

MAX

V

THRSETIMAX

THRSET

0.200mA to 1.5mA -5 +5 %

50µA to 200µA 12 µA

Sink, SRC_SNK_B = 0 -0.9 +0.9

Source, SRC_SNK_B = 1 -0.9 +0.9

Sink, SRC_SNK_B = 0 -4.0 +4.0

Source, SRC_SNK_B = 1 -4.0 +4.0

0.01 1.50 mA

0.01 1.20 mA

1nF

LSB

LSB

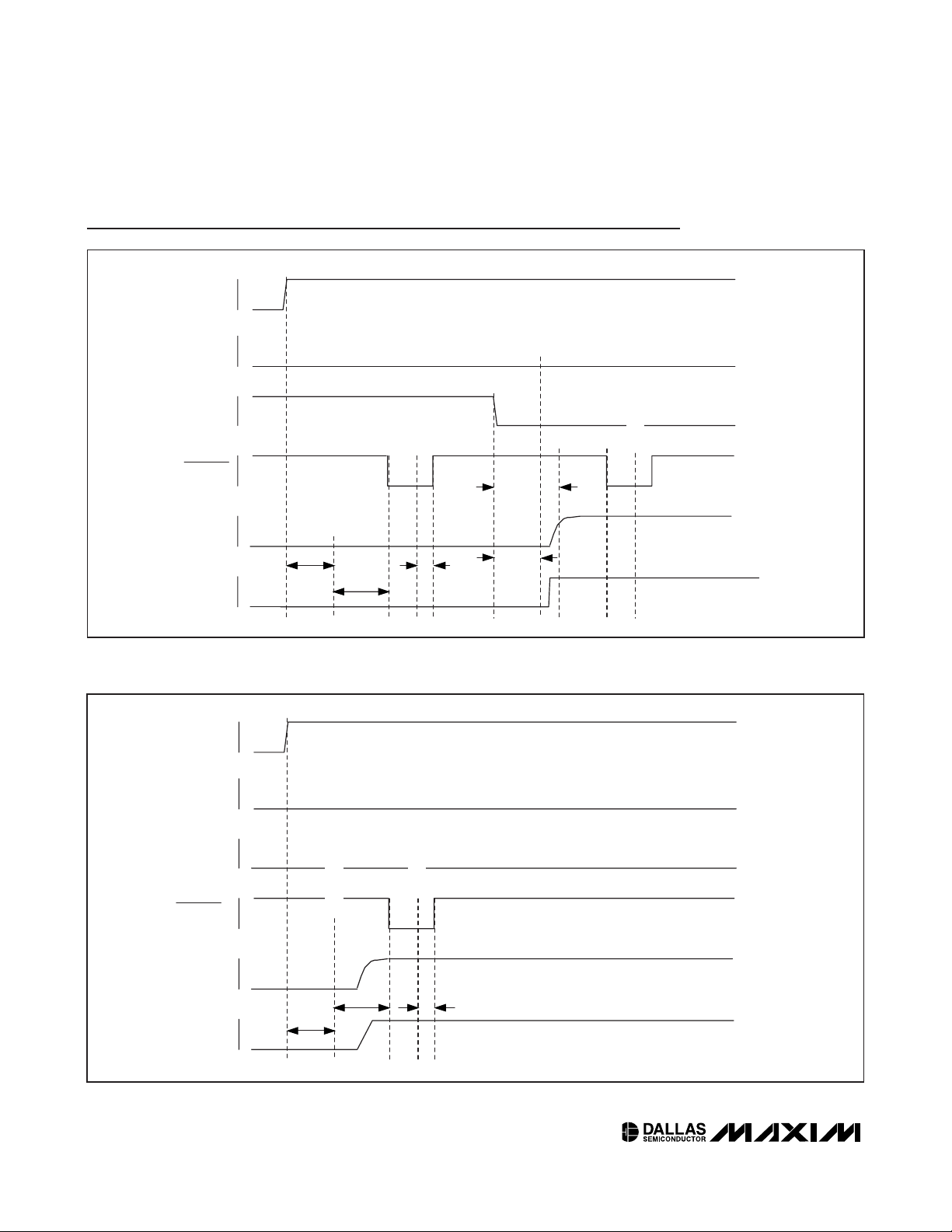

Page 5

DS1862

XFP Laser Control and Digital Diagnostic IC

_____________________________________________________________________ 5

AC ELECTRICAL CHARACTERISICS—XFP CONTROLLER

(V

CC3

= +2.9V to +5.5V, V

CC2

= +1.6V to +3.6V, TA= -40°C to +100°C, unless otherwise noted.)

ANALOG OUTPUT CHARACTERISTICS (continued)

(V

CC3

= +2.9V to +5.5V, V

CC2

= +1.6V to +3.6V, TA= -40°C to +100°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I

MODSET

Accuracy

+25°C

I

MODSET

= 0.04mA to 1.2mA

75µA range -0.9 +0.9

150µA range -0.9 +0.9

I

MODSET

DNL

300µA range -0.9 +0.9

600µA range -0.9 +0.9

1200µA range -0.9 +0.9

75µA range -1.5 +1.5

150µA range -1.5 +1.5

I

MODSET

INL

300µA range -1.0 +1.0

600µA range -1.0 +1.0

1200µA range -1.0 +1.0

I

I

I

APC Bandwidth IMD / I

Temp Drift 5%

MODSET

Voltage Drift 1.2 %/V

MODSET

FS Accuracy 1.5 %

MODSET

= 1 (Note 4) 6 10 30 kHz

APC

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Time to Initialize t

TX-D Assert Time t

TX-D Deassert Time t

P-DOWN/RST Assert Time t

P-DOWN/RST Deassert Time t

MOD-DESEL Deassert Time t

INTERRUPT Assert Delay t

INTERRUPT Deassert Delay t

MOD-NR Assert Delay t

MOD-NR Deassert Delay t

RX-LOS Assert Time t

RX-LOS Deassert Time t

P-DOWN/RST Reset Time t

Shutdown Time t

V

INIT

OFF

ON

PDR-ON

PDR-OFF

MOD-DESEL

INT-ON

INT-OFF

MOD-NR-ON

MOD-NR-OFF

LOS-ON

LOS-OFF

RESET

FAULT

within ±5% of nominal 30 200 ms

CC3

IBIAS and IMOD below 10% of nominal 5 µs

IBIAS and IMOD above 90% of nominal 1 ms

IBIAS and IMOD below 10% of nominal 100 µs

IBIAS and IMOD above 90% of nominal 200 ms

Time until proper response to I2C

communication

Time from fault to interrupt assertion 100 ms

Time from read (clear flags) to interrupt

deassertion

Time from fault to MOD-NR assertion 0.5 ms

Time from read (clear flags) to MOD-NR

deassertion

Time from SC-RX-LOS assertion to

RX-LOS assertion

Time from SC-RX-LOS deassertion to

RX-LOS deassertion

Time from P-DOWN/RST assertion to

initial reset

Time from fault to I

and I

below 10%

BMD

BIASSET

, I

MODSET

-1.5 +1.5 %

LSB

LSB

2ms

500 µs

0.5 ms

100 ns

100 ns

10 µs

,

30 µs

Page 6

DS1862

XFP Laser Control and Digital Diagnostic IC

6 _____________________________________________________________________

AC ELECTRICAL CHARACTERISICS—SOFT* CONTROL AND STATUS

(V

CC3

= +2.9V to +5.5V, V

CC2

= +1.6V to +3.6V, TA= -40°C to +100°C, unless otherwise noted.)

*

All SOFT timing specifications are measured from the falling edge of “STOP” signal during I2C communication.

ANALOG INPUT CHARACTERISTICS

(V

CC3

= +2.9V to +5.5V, TA= -40°C to +100°C, unless otherwise noted.)

A/D INPUT VOLTAGE MONITORING (IBIASMON, AUX2MON, AUX1MON, RSSI, BMD)

(V

CC3

= +2.9V to +5.5V, TA= -40°C to +100°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Soft TX-D Assert Time t

Soft TX-D Deassert Time t

Soft P-DOWN/RST Assert Time t

Soft P-DOWN/RST Deassert Time t

Soft MOD-NR Assert Delay

Soft MOD-NR Deassert Delay

Soft RX_LOS Assert Time t

Soft RX_LOS Deassert Time t

Analog Parameter data Ready

(DATA-NR)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I

Configurable Source or

BMD

Sink (+/-)

I

Voltage (I

BMD

I

Input Resistance R

BMD

- 0µA) V

BMD

OFF_Soft

ON_Soft

PDR-ON_Soft

PDR-OFF_Soft

t

MOD-NR-ON

_Soft

t

MOD-NR-OFF

_Soft

LOS-ON_Soft

LOS-OFF_Soft

BMD

BMD

IBIAS and IMOD below 10% of nominal 50 ms

IBIAS and IMOD above 90% of nominal 50 ms

IBIAS and IMOD below 10% of nominal 50 ms

IBIAS and IMOD above 90% of nominal 200 ms

Time from fault to MOD-NR assertion 50 ms

Time from read (clear flags) to MOD-NR

deassertion

Time from SC-RX-LOS assertion to

RX-LOS assertion

Time from SC-RX-LOS deassertion to

RX-LOS deassertion

Source mode 2.0

Sink mode

I

range 0 to 1.5mA

BMD

0.05 1.50 mA

1.2

400 550 700 Ω

50 ms

50 ms

50 ms

500 ms

V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Input Resolution ΔV

Supply Resolution ΔV

Input/Supply Accuracy A

Update Rate

Input/Supply Offset V

Full-Scale Input (I

RSSI)

Full-Scale Input (AUX1MON,

AUX2MON, and V

BMD (Monitor) (TX-P) FS setting 1.5 mA

BIASMON

CC2/3

and

)

MON

CC2/3

CC

t

FRAME1

t

FRAME2

OS

At factory setting 0.25 0.5 %FS

AUX1MON and AUX2MON disabled 48 52

All channels enabled 64 75

(Note 4) 0 5 LSB

At factory setting 2.4875 2.5 2.5125 V

At factory setting

(Note 9)

6.5208 6.5536 6.5864 V

610 µV

1.6 mV

ms

Page 7

DS1862

XFP Laser Control and Digital Diagnostic IC

_____________________________________________________________________ 7

FAST ALARMS AND VCCFAULT CHARACTERISTICS

(V

CC3

= +2.9V to +5.5V, V

CC2

= +1.6V to +3.6V, TA= -40°C to +100°C, unless otherwise noted.)

Note 1: All voltages are referenced to ground. Current into IC is positive, out of the IC is negative.

Note 2: Secondary power supply is used to support optional variable power-supply feature of the XFP module. If V

CC2

is not used,

(i.e., signal conditioners using 3.3V supply) V

CC2

should be connected to the V

CC3

.

Note 3: Input signals (i.e., TX-D, MOD-DESEL, and P-DOWN/RST have internal pullup resistors.

Note 4: Guaranteed by design. Simulated over process and 50µA < I

BMD

< 1500µA.

Note 5: C

B

—total capacitance of one bus line in picofarads.

Note 6: EEPROM write begins after a stop condition occurs.

Note 7: This is the maximum and minimum voltage on the MODSET and BIASSET pins required to meet accuracy and drift specifi-

cations.

Note 8: For V

THRSET

, offset may be as much as 10mV.

Note 9: This is the uncalibrated offset provided by the factory; offset adjustment is available on this channel.

Note 10: % FS refers to calibrated FS in case of internal calibration, and uncalibrated FS in the case of external calibration.

Uncalibrated FS is set in the factory and specified in this data sheet FS (factory). Calibrated FS is set by the user, allowing

a change in any monitored channel scale.

Note 11: See the

Monitor Channels

section for more detail or V

CC2

and V

CC3

selection.

NONVOLATILE MEMORY CHARACTERISTICS

(V

CC3

= +2.9V to +5.5V, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

HIGHBIAS and TX-P Threshold

FS

V

Fault Asserted

CC2/3

Falling Edge Delay

QT Temperature Coefficient -3 +3 %

QT Voltage Coefficient 0.5 %/V

QT FS Trim Accuracy (4.2V,

+25°C)

QT Accuracy (Trip) (INL) -2 0 +2 LSB

QT Voltco 0.5 %/V

QT Tempco 1.5 3 %

(Note 10) 2.48 2.5 2.52 mA

↓ V

CC2/3

(Note 11)

75 ms

2.480 2.500 2.520 mA

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Endurance (Write Cycle) +70°C 50k Cycles

Endurance (Write Cycle) +25°C 200k Cycles

Page 8

DS1862

XFP Laser Control and Digital Diagnostic IC

8 _____________________________________________________________________

Timing Diagrams

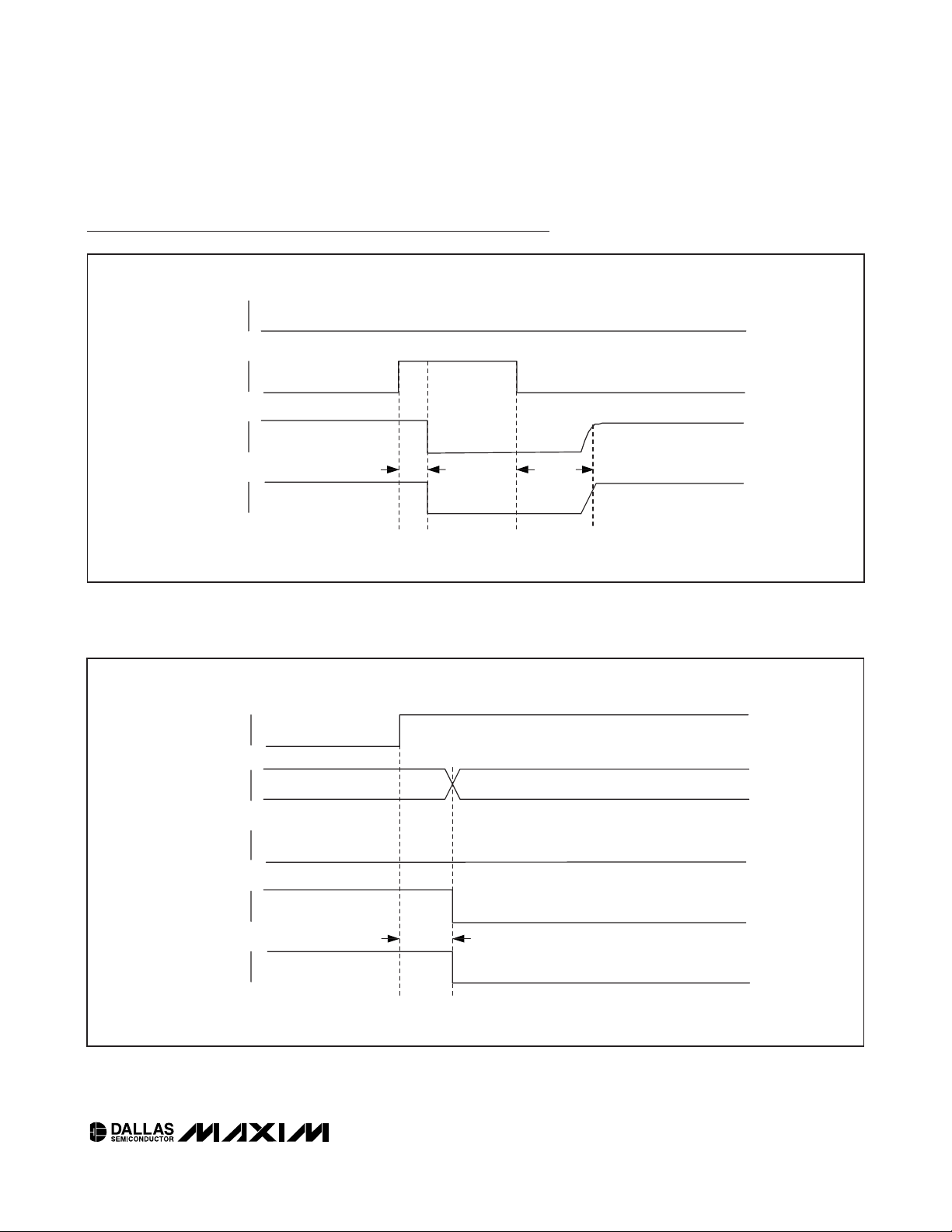

Figure 1. Power-On Initialization with P-DOWN/RST Asserted and TX-D/SOFT-TX-D Not Asserted

Figure 2. Power-On Initialization with P-DOWN/RST Not Asserted and TX-D/SOFT-TX-D Not Asserted (Normal Operation)

VCC > V

POA

TX-D

P-DOWN/RST

INTERRUPT

I

BIASSET

I

MODSET

READ-FLAGS

RESET-DONE

t

INIT

t

INIT ON

t

INIT OFF

t

PDR-OFF

t

INIT

RESET-DONE

VCC > V

POA

TX-D

READ-FLAGS

P-DOWN/RST

READ-FLAGS

INTERRUPT

I

BIASSET

I

MODSET

RESET-DONE

t

INIT ON

t

INIT

t

INIT OFF

Page 9

DS1862

XFP Laser Control and Digital Diagnostic IC

_____________________________________________________________________ 9

Timing Diagrams (continued)

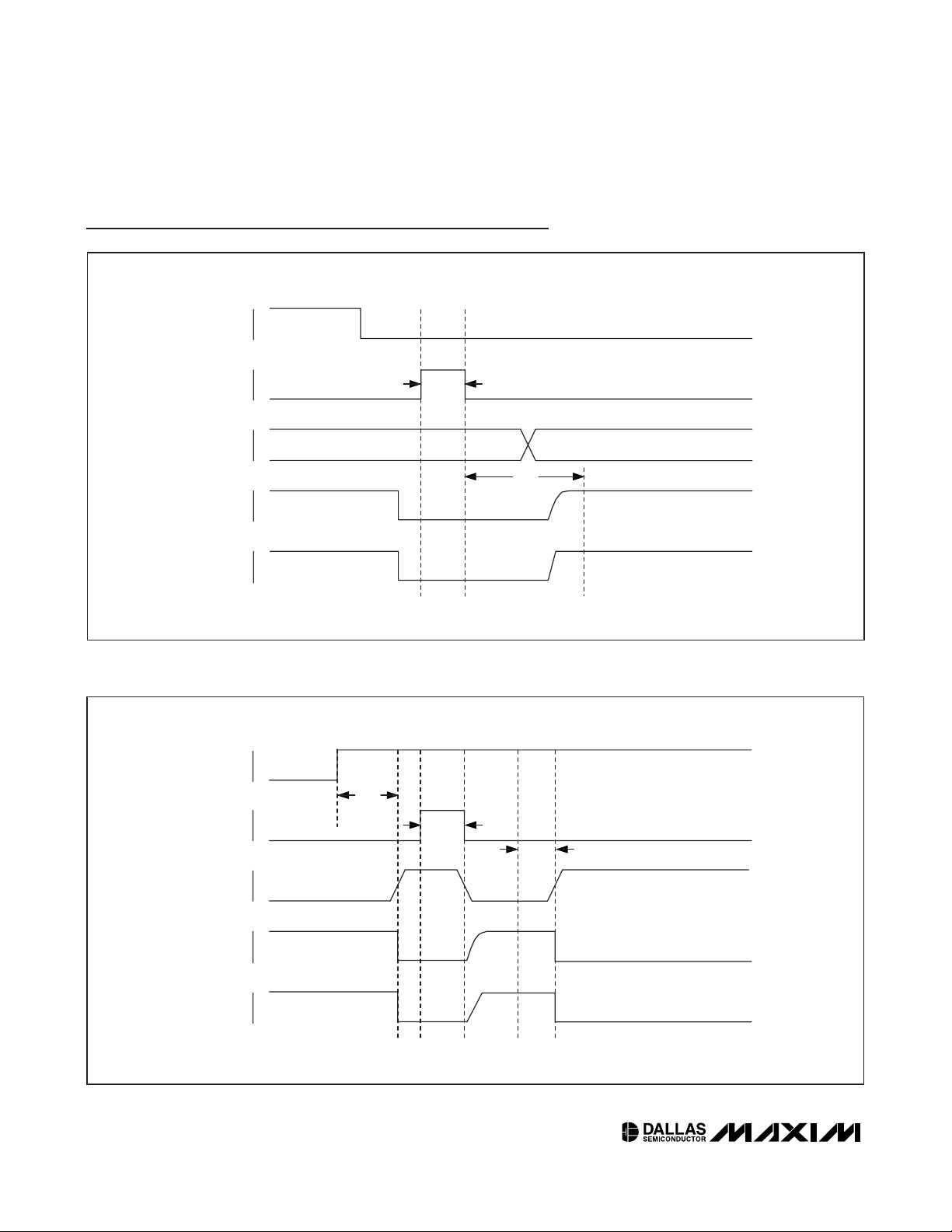

Figure 3. TX-D Timing During Normal Operation

Figure 4. Detection of Safety Fault Condition

TX-F

TX-D

I

BIASSET

I

MODSET

t

OFF

t

ON

OCCURRENCE

OF FAULT

FETG

TX-D

I

BIASSET

I

MODSET

t

FAULT

Page 10

DS1862

XFP Laser Control and Digital Diagnostic IC

10 ____________________________________________________________________

Figure 5. Successful Recovery from Transient Safety Fault Condition Using P-DOWN/RST

Figure 6. Unsuccessful Recovery from Transient Safety Fault Condition

Timing Diagrams (continued)

OCCURRENCE

OF FAULT

t

P-DOWN/RST

FETG

I

BIASSET

I

MODSET

RESET

t

INIT

RESET-DONE

OCCURRENCE

OF FAULT

P-DOWN/RST

FETG

(FETG_POL = 1)

I

BIASSET

I

MODSET

t

FAULT

t

RESET

RESET-DONE

t

FAULT

Page 11

DS1862

XFP Laser Control and Digital Diagnostic IC

____________________________________________________________________ 11

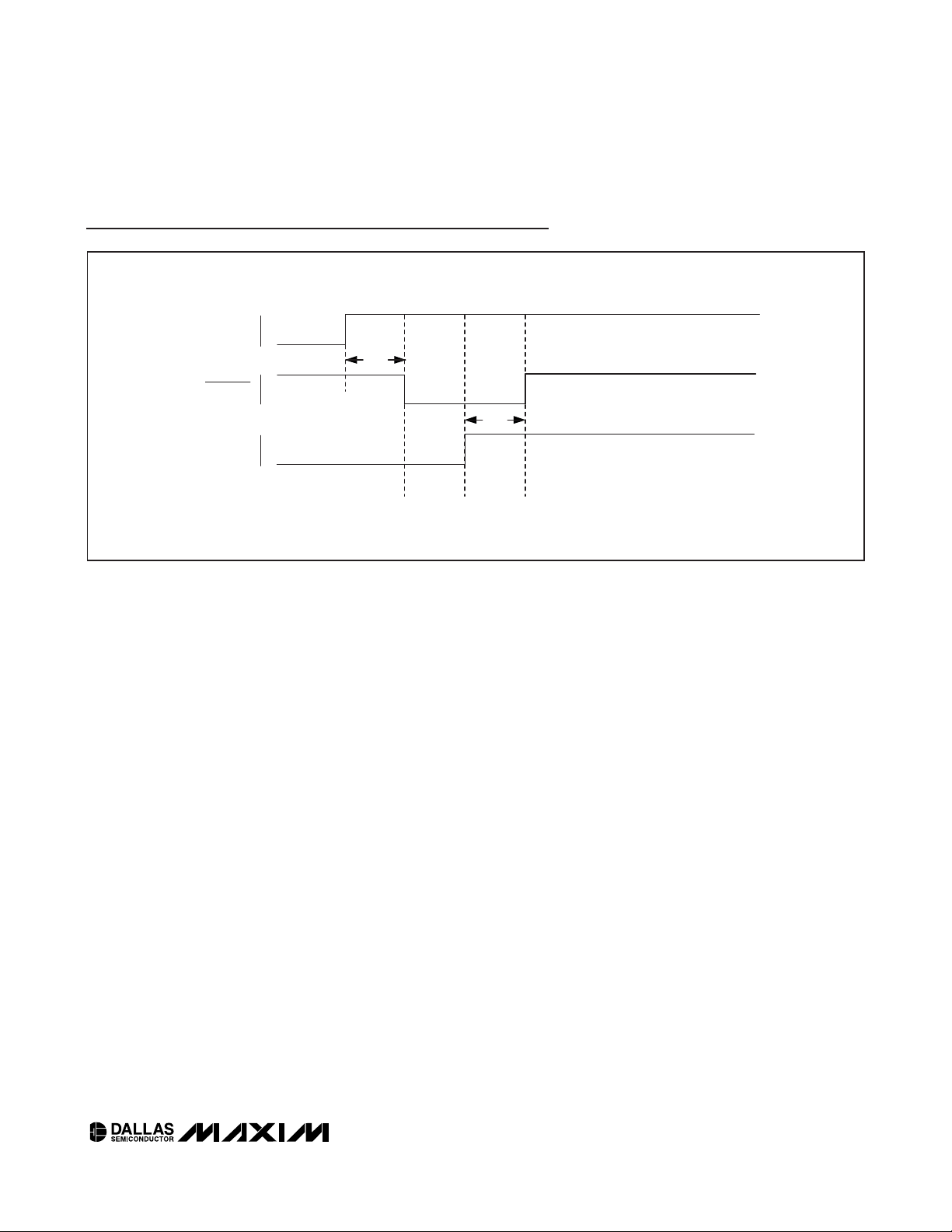

Figure 7. Monitor Channel Fault Timing

Timing Diagrams (continued)

OCCURRENCE

OF MONITOR

CHANNEL FAULT

INTERRUPT

READ FLAGS

t

INIT_ON

t

INIT_OFF

Page 12

DS1862

XFP Laser Control and Digital Diagnostic IC

12 ____________________________________________________________________

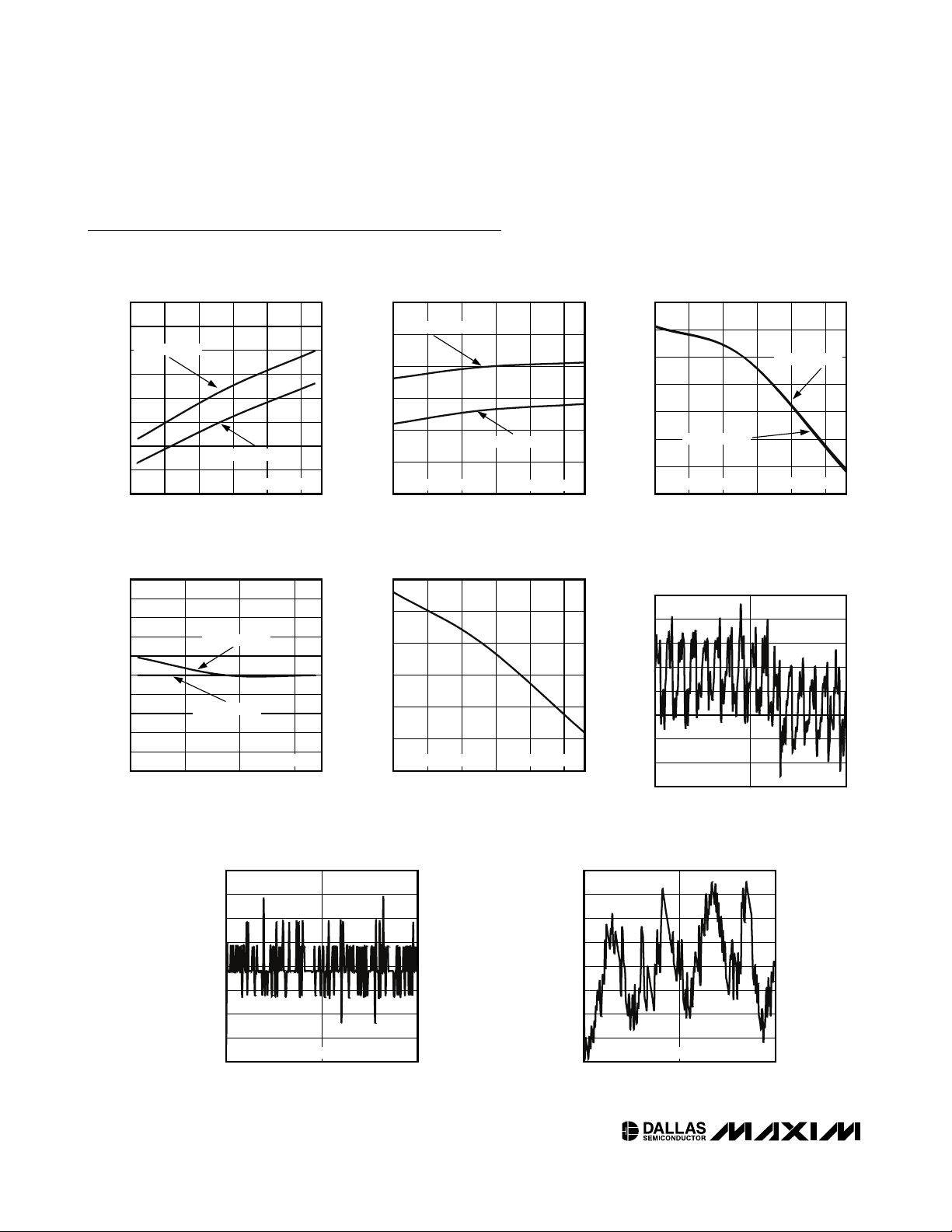

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

SUPPLY CURRENT vs. SUPPLY VOLTAGE

DS1862 toc01

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (mA)

5.34.83.3 3.8 4.3

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

2.0

2.8

SRC_SINK_B = 1

SRC_SINK_B = 0

I

BMD

= 499.479μA

SUPPLY CURRENT vs. TEMPERATURE

DS1862 toc02

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

8560-15 10 35

3.0

3.5

4.0

4.5

5.0

5.5

6.0

-40

SRC_SINK_B = 1

SRC_SINK_B = 0

I

BMD

= 499.479μA

V

CC3

= 5.5V, V

CC2

= 1.6V

I

BMD

DRIFT vs. TEMPERATURE

DS1862 toc03

TEMPERATURE (°C)

I

BMD

DRIFT (%)

8560-15 10 35

-2.5

-1.5

-2.0

-1.0

-0.5

0

0.5

1.0

-40

SRC_SINK_B = 1

SRC_SINK_B = 0

I

BMD

= 499.479μA

V

CC3

= 5.5V, V

CC2

= 1.6V

I

BMD

DRIFT vs. SUPPLY VOLTAGE

DS1862 toc04

SUPPLY VOLTAGE (V)

I

BMD

DRIFT (%)

5.23.6 4.4

-1.0

0

-0.2

0.2

-0.6

-0.8

-0.4

0.4

0.6

0.8

1.0

2.8

SRC_SINK_B = 1

SRC_SINK_B = 0

I

BMD

= 499.479μA

I

MODSET

DRIFT vs. TEMPERATURE

DS1862 toc05

TEMPERATURE (°C)

I

MODSET

DRIFT (%)

85-15 10 35 60

-2.0

-1.5

-1.0

-0.5

0

0.5

1.0

-40

I

BMD

= 499.479μAV

CC3

= 5.5V, V

CC2

= 1.6V

INTEGRAL NONLINEARITY

OF QUICK TRIPS

DS1862 toc06

CODE (0–255)

ERROR (LSB)

256128

-0.8

-0.2

0

-0.6

-0.4

0.2

0.4

0.6

0.8

0

DIFFERENTIAL NONLINEARITY

OF I

MODSET

DS1862 toc07

CODE (0–255)

ERROR (LSB)

256128

-0.20

-0.05

0

-0.15

-0.10

0.05

0.10

0.15

0.20

0

FSR = 75μA

V

CC3

= 4.2V, V

CC2

= 1.6V

INTEGRAL NONLINEARITY

OF I

MODSET

DS1862 toc08

CODE (0–255)

ERROR (LSB)

256128

-0.20

-0.05

0

-0.15

-0.10

0.05

0.10

0.15

0.20

0

FSR = 75μAV

CC3

= 4.2V, V

CC2

= 1.6V

Page 13

DS1862

XFP Laser Control and Digital Diagnostic IC

____________________________________________________________________ 13

Pin Description

NAME

DESCRIPTION

Power-Down/Reset Input. This multifunction pin is pulled high internally. See the Power-Down/Reset Pin

section for additional information.

Signal Conditioner Receiver Loss-of-Signal Input. This pin is an active-high input with LVCMOS/LVTTL

voltage levels.

Signal Conditioner Receiver Loss-of-Lock Input. This pin is an active-high input with LVCMOS/LVTTL

voltage levels.

THRSET

Threshold Set Output. This pin is a programmable voltage source that can be used for Rx signal

conditioner.

V

CC2

1.8V Power-Supply Input

RX-LOS

Receiver Loss-of-Signal. This open-drain output indicates when there is insufficient optical power.

SCL

I2C Serial-Clock Input

FETG

FET Gate Output. This pin can drive an external FET gate associated with safety fault disconnect.

RSSI

Received Power Signal Input

MODSET

Modulation Current Output. This pin is only capable of sinking current.

TX-D

Transmit Disable Input. This pin has an internal pullup resistor.

SDA

I2C Serial-Data Input/Output

EN1

Enable 1 Output. Functional control for signal conditioners.

EN2

Enable 2 Output. Functional control for signal conditioners.

BIASSET

Bias Current Output. This pin is only capable of sinking current.

Interrupt. This open-drain output pin indicates a possible operational fault or critical status condition to the

host.

MOD-NR

Indicating Module Operational Fault. Open-drain output. This pin indicates the status of the MOD-NR flag.

Aux1 Monitor Input. This pin can be used to measure any voltage quantity.

Aux2 Monitor Input. This pin can be used to measure any voltage quantity or external temperature sensor.

BMD

Monitor Diode Current Input. This pin is capable of sourcing or sinking current.

GND

Ground

Module Deselect Input. This pin must be pulled low to enable I2C communication. This pin is pulled high

internally.

IBIASMON

Bias Monitor Input. This pin can be used to monitor the voltage across the laser.

Signal Conditioner Transmitter Loss-of-Signal. This pin is an active-high input with LVCMOS/LVTTL

voltage levels.

V

CC3

3.3V or 5V Power-Supply Input

PIN

P-DOWN/RST A1

SC-RX-LOS A2

SC-RX-LOL A3

A4

A5

B1

B2

B3

B4

B5

INTERRUPT D1

AUX1MON D3

AUX2MON D4

MOD-DESEL E2

SC-TX-LOS E4

C1

C2

C3

C4

C5

D2

D5

E1

E3

E5

Page 14

DS1862

XFP Laser Control and Digital Diagnostic IC

14 ____________________________________________________________________

Block Diagram

V

CC2

V

CC3

IBIASMON

AUX2MON

RSSI

AUX1MON

BMD

V

CC3

V

CC2

MOD-DESEL

SDA

SCL

RX-LOS

V

CC3

I

BMD

R

PU

TEMPERATURE

I TO V

V

V

CC2

I2C

INTERFACE

SENSOR

CC3

TX-P

ADDRESS

DATA BUS

R/W

ADDRESS

R/W

DATA BUS

MUX

ALARM AND

WARNING

THRESHOLDS

GAIN

ADC 13 BIT

ALARM FLAGS

WARNING FLAGS

MASKING BITS

LOWER MEMORY

TABLE-SELECT BYTE

ALARM AND

WARNING

THRESHOLDS

RIGHT

OFFSET

SHIFTING

MEASURED DATA

SERIAL ID

TABLE

01h

DATA

COMPARATORS

TABLE

EEPROM

BIAS AND

MODULATION

ENABLE

I

BMD

02h

WARNING

FLAGS

ALARM

FLAGS

CONTROL

SIGNALS

TEMPERATURE

INTERRUPT

MASKING BITS

MISC

TABLE

03h

LUT

CONTROLED

WITH

LUT

INT

DS1862

TABLE

04h

MODULE

CONFIG

A

EXT(IBMD

TABLE

THRSET

)

HIGH-BIAS QT

V

05h

CC3

INTERRUPT

THRSET

MODSET

A

BIASSET

INT

SC-RX-LOS

SC-RX-LOL

SC-TX-LOS

EN1

EN2

MOD-NR

GND

LOGIC

HIGH-BIAS ALARM THRESHOLD

I

BIASSET

TX-P

HIGH TX_P ALARM THRESHOLD

LOW TX_P ALARM THRESHOLD

TX-P

TX-F

V

OR V

CC2

SOFT TX-D

HIGH-BIAS ALARM

HIGH TX_P ALARM

LOW TX_P ALARM

CC3

STARTUP

INITIALIZATION

AND

LASER SAFETY

SHUTDOWN

BLOCK

R

PU

BIAS AND MOD

ENABLE

R

PU

TX-D

P-DOWN/RST

FETG

Page 15

DS1862

XFP Laser Control and Digital Diagnostic IC

____________________________________________________________________ 15

Detailed Description

The DS1862’s block diagram is described in detail

within the following sections and memory map/memory

description.

Automatic Power Control (APC)

The DS1862’s APC is accomplished by closed-loop

adjustment of the bias current (BIASSET) until the feedback current (BMD) from a photodiode matches the

value determined by the APC registers. The relationship between the APC register and I

BMD

is given by:

I

BMD

= 5.859µA x APCC<7:0> +

(1.464µA x APCF<1:0>)

where APCC<7:0> is the 8-bit value in Table 04h, byte

84h that controls the coarse BMD current and

APCF<1:0> is the 2-bit value that controls the fine BMD

current.

The BMD pin appears as a voltage source in series with

two resistors. The overall equivalent resistance of the

BMD input pin can be closely approximated by the plot

in Figure 8. The voltage that appears on the BMD pin,

assuming no external current load, is 1.2V if BMD is in

sink-current mode (SRC_SINK_B = 0) or 2.0V if BMD is

set to source current (SRC_SINK_B = 1). This allows the

photodiode to be referenced to either V

CC3

or GND.

When the control loop is at steady state, the BMD current

setting matches the current that is measured by the I

BMD

voltage across the internal resistance. During a transient

period, the DS1862 adjusts the current drive on the

BIASSET pin to bring the loop into steady state. The

DS1862 is designed to support loop gains of 1/20 to 10.

On power-up, the BMD current ramps up to the previously saved current setting in EEPROM APC registers.

While operating, the DS1862 monitors the BMD current.

If it begins to deviate from the desired (set) I

BMD

value,

then, again, the current on the BIASSET pin is adjusted

to compensate.

Extinction Ratio Control

Look-Up Table (LUT)

The DS1862 uses a temperature indexed look-up table

(LUT) to control the extinction ratio. The MODSET pin is

capable of sinking current based on the 8-bit binary

value that is controlling it. The DS1862 also features a

user-configurable current range to increase extinction

ratio resolution. Five current ranges, as described in

Table 1, are available to control the current entering

MODSET.

Figure 8. Approximate Model of the BMD Input

Table 1. Selectable Current Ranges for

MODSET

LUT CURRENT RANGE

TABLE 04h, BYTE 86h<2:0>

000 0 to 75

001 0 to 150

010 0 to 300

011 0 to 600

100 0 to 1200

CURRENT RANGE

(µA)

BMD RESISTANCE vs. BMD SUPPLY CURRENT

600

584

565

546

(Ω)

527

BMD

R

508

489

470

0

0

(mA)

I

BMD

I

BMD

VOLTAGE

BMD

R

BMD

V

BMD

1.501.250.25 0.50 0.75 1.00

NOTE: V

CONTROLLED BY THE

SRC_SINK BIT IN

BMD

TABLE 04h

IS

Page 16

DS1862

XFP Laser Control and Digital Diagnostic IC

16 ____________________________________________________________________

If the largest current range is selected, the maximum

value of FFh (from LUT) corresponds to a 1200µA sink

current. Regardless of current range, the MODSET

value always consists of 256 steps, including zero.

I

MODSET

can be controlled automatically with the temperature-based look-up table, or by three other manual

methods.

Automatic temperature addressed look-up is accomplished by an internal or external temperature sensor

controlling an address pointer. This pointer indexes

through 127 previously loaded 8-bit current values

stored in the LUT. Each one of the 127 temperature

slot locations corresponds to a 2°C increment over

the -40°C to +102°C temperature range. Any temperature above or below these points causes the code in

the first or last temperature slot to be indexed. Both the

internal temperature sensor and an external sensor

connected to AUX2MON are capable of providing a

signal to control the extinction ratio automatically with

an indexed LUT. Table 2 illustrates the relationship

between the temperature and the memory locations in

the LUT.

Automatic and manual control of MODSET is controlled

by two bits: TEN and AEN that reside in Table 04h, Byte

B2h. By default (from factory) TEN and AEN are both

set, causing complete automatic temperature-based

look-up. If TEN and/or AEN are altered, then the

DS1862 is set to one of the manual modes. Table 3

describes manual mode functionality.

Table 2. Temperature Look-Up Table

Table 3. Truth Table for TEN and AEN Bits

TEMPERATURE (°C)

< -40 80h

-40 80h

-38 81h

-36 82h

——

+96 C4h

+98 C5h

+100 C6h

+102 C7h

> +102 C7h

CORRESPONDING LOOK-UP

TABLE ADDRESS

TEN AEN DS1862 LUT FUNCTIONALITY

Manual mode that allows users to write a value

directly to the LUT Value register (Table 04h,

00

01

10

11

Byte B1h) to drive MODSET. While in this mode,

the LUT index pointer register is not being

updated, and no longer drives the LUT Value

register.

Manual mode that allows users to write a value

directly to the LUT Value register (Table 04h,

Byte B1h) to drive MODSET. While in this mode,

the LUT index pointer register is still being

updated, however it no longer drives the LUT

Value register.

Manual mode that allows users to write a value to

the LUT index pointer (Table 04h, Byte B0), then

the DS1862 updates the LUT Value register

(Table 04h, Byte B1h) based on the user’s index

pointer.

Automatic mode (factory default). This mode

automatically indexes the LUT based on

temperature, placing the resulting LUT address

in the LUT index pointer register (Table 04h, Byte

B0h). Then the MODSET setting is transferred

from that LUT address to the LUT Value register

(Table 04h, Byte B1h). Lastly the I

to the new MODSET code.

MODSET

is set

Page 17

DS1862

XFP Laser Control and Digital Diagnostic IC

____________________________________________________________________ 17

Monitor Channels

The DS1862 has seven monitored voltage signals that

are polled in a round-robin multiplexed sequence and

are updated with the frame rate, t

FRAME

. All channels

are read as 16-bit values, but have 13-bit resolution,

and with the exception of temperature measurements,

all channels are stored as unsigned values. The resulting

16-bit value for all monitored channels, except internal

temperature, is calculated by internally averaging the

analog-to-digital result 8 times. The resulting internal

temperature monitor channel is averaged 16 times. See

the

Internal Calibration

section for a complete descrip-

tion of each channel’s method(s) of internal calibration.

The AUX1MON, AUX2MON, and V

CC2/3

monitor channels are optional and can be disabled. This feature

allows for shorter frame rate for the essential monitor

channels. Channels that can not be disabled are: internal temperature, BMD, RSSI, and IBIASMON. A table of

full-scale (FS) signal values (using factory internal calibration without right shifting) and the resulting FS code

values for all seven channels is provided below.

Measuring Temperature—Internal or External

The DS1862 is capable of measuring temperature on

three different monitor channels: internal temperature

sensor, AUX1MON, and AUX2MON. Only the internal

temperature and AUX2MON channels are capable of

indexing the LUT to control the extinction ratio. To use

an external temperature sensor on AUX2MON, the

TEMP_INT/EXT bit in Table 04h, Byte 8Bh, must be set.

While AUX2MON controls the extinction ratio, the internal temperature sensor does not stop running; despite

extinction ratio control by AUX2MON, it is this internal

temperature signal that continues to control the status

of temperature flags. Also when TEMP_INT/EXT = 1, the

internal temperature clamps at -40°C and +103.9375°C,

and when TEMP_INT/EXT = 0 it clamps at -120°C and

+127.984°C. AUX2MON, however, does have its own flag

to indicate an out-of-tolerance condition and assert the

INTERRUPT pin.

Both AUX1MON and AUX2MON can be used to measure temperature as a function of voltage on their

respective pins. They can be enabled by selecting

either 0h or 4h from Table 5. Internal (or external) calibration may be required to transmute the input voltage

to the desired two’s-complement digital code, readable

from the result registers in lower memory, Bytes 6Ah,

6Bh and 6Ch, 6Dh.

Measuring V

CC2/3

The DS1862 has the flexibility to internally measure

either V

CC2

or V

CC3

to monitor supply voltage. V

CC2

or

V

CC3

is user selectable by the V

CC2/3

_Sel bit in Table

01h, Byte DCh. To remove V

CC2/3

from the round-robin

monitor update scheme, despite having V

CC2

or V

CC3

selected to be monitored, the Reserve_EN bit in Table

04h, Byte 8Bh can be programmed to a 0. The analog

power-on-reset flag, POA, indicates the status of V

CC3

power supply. Even though POA seems to behave similarly to V

CC2/3

monitor channel, it is completely sepa-

rate and has no connection.

Measuring APC and Laser Parameters—BMD,

IBIASMON, RSSI

BMD and BIASSET are used to control and monitor the

laser functionality. Regardless of the set BMD current in

the APC register, the DS1862 measures BMD pin current and uses this value not only to adjust the current

on the BIASSET pin, but also to monitor TX-P as well.

The IBIASMON pin is used to input a voltage signal to

the DS1862 that can be used to monitor the bias current through the laser. This monitor channel does not

drive the HIGHBIAS quick-trip (QT) alarms for safety

Table 4. Monitor Channel FS and LSB Detail

RESERVE_EN V

00V

01V

10V

11V

CC2/3_Sel

RESULT

result not enabled.

CC2/3

result not enabled.

CC2/3

is being measured.

CC3

is being measured.

CC2

SIGNAL +FS SIGNAL +FS (hex) -FS SIGNAL -FS (hex) LSB

Temperature 127.984°C 7FF8 -120°C 8800 0.0625°C

V

CC2/3

IBIASMON 2.4997V FFF8 0V 0000 38.147µV

RSSI 2.4997V FFF8 0V 0000 38.147µV

AUX1MON 6.5528V FFF8 0V 0000 38.147µV

AUX2MON 6.5528V FFF8 0V 0000 38.147µV

BMD (TX-P) 1.5mA FFF8 0mA 0000 22.888nA

6.5528V FFF8 0V 0000 100µV

Page 18

DS1862

XFP Laser Control and Digital Diagnostic IC

18 ____________________________________________________________________

fault functionality, current on the BIASSET pin is monitored by the DS1862 to control the HIGHBIAS quick

trip. Similar to TX-P, the RSSI pin is used to measure

the received power, RX-P.

Measuring Voltage Quantities

using AUX1MON and AUX2MON

AUX1MON and AUX2MON are auxiliary monitor inputs

that may be used to measure additional parameters.

AUX1/2MON feature a user-selectable register that

determines the measured value’s units (i.e., voltage,

current, or temperature). In addition to indicating units,

some of the 4-bit op-codes, in Table 5, also place the

part in special modes used for alarms and faults internally. Whichever units’ scale is selected, the DS1862 is

only capable of measuring a positive voltage quantity,

therefore internal or external calibration may be

required to get the binary value to match the measured

quantity. A table of acceptable units and/or their corresponding user-programmable 4-bit op-code is provided below.

Alarms and Warning Flags

Based on Monitor Channels

All of the monitor channels feature alarm and warning

flags that are asserted automatically as user-programmed thresholds are internally compared with monitor channel results. Flags may be set, which, if not

masked, will generate an interrupt on the INTERRUPT

pin or generate a safety fault. Whenever V

CC2/3

,

AUX2MON, AUX1MON, RSSI, and internal temperature

go beyond their threshold trip points and the corresponding mask bit is 0, an interrupt is generated on the

INTERRUPT pin and a corresponding warning or alarm

flag is set. Similarly, a safety fault occurs whenever

BMD or BIASSET go beyond threshold trip points.

When this happens, the FETG pin immediately asserts

and BIASSET and MODSET currents are shut down.

Monitor Channel Conversion Example

Table 6 provides an example of how a 16-bit ADC code

corresponds to a real life measured voltage using the

factory-set calibration on either RSSI or IBIASMON. By

factory default, the LSB is set to 38.147µV.

To calculate V

CC2

, V

CC3

, AUX1MON, or AUX2MON,

convert the unsigned 16-bit value to decimal and multiply by 100µV.

To calculate the temperature (internal), treat the two’scomplement value binary number as an unsigned binary number, then convert it to decimal and divide by

256. If the result is grater than or equal to 128, subtract

256 from the result.

Temperature: high byte = -128°C to +127°C signed;

low byte = 1/256°C.

Table 5. AUX1/2MON Functionality

Selection (Unit Selection)

Table 6. A/D Conversion Example

Table 7. Temperature Bit Weights

VALUE

0000b Auxiliary monitoring not implemented

0001b

0010b Reserved

0011b

0100b

0101b Laser wavelength

0110b

0111b

1000b

1001b

1010b + 5V sup p l y cur r ent ( 16- b i t val ue i s cur r ent i n 0.1m A)

1101b

1110b

1111b

DESCRIPTION OF AUX1/2MON INTENDED USE

(UNITS OF MEASURE)

APD bias voltage (16-bit value is voltage in units of

10mV)

TEC current (mA), (16-bit value is current in units of

0.1mA)

Laser temperature (same encoding as module

temperature)

+5V supply voltage (encoded as primary voltage

monitor)

+3.3V supply voltage (encoded as primary voltage

monitor)

+1.8V supply voltage (encoded as primary voltage

monitor) (V

-5.2V supply voltage (encoded as primary voltage

monitor)

+3.3V supply current (16-bit value is current in

0.1mA)

+1.8V supply current (16-bit value is current in

0.1mA)

-5.2V supply current (16-bit value is current in

0.1mA)

CC2

)

MSB (BIN) LSB (BIN) VOLTAGE (V)

11000000 00000000 1.875

10000000 10000000 1.255

S262

-1

2

-2

2

5

-3

2

4

2

-4

2

3

2

-5

2

2

2

1

2

———

0

2

Page 19

DS1862

XFP Laser Control and Digital Diagnostic IC

____________________________________________________________________ 19

Internal Calibration

The DS1862 has two means for scaling an analog input

to a digital result. The two devices alter the gain and

offset of the signal to be calibrated. All of the inputs

except internal temperature have unique registers for

both the gain and the offset that can be found in Table

04h. See the table below for a complete description of

internal calibration capabilities including right-shifting

for all monitor channels.

To scale a specific input’s gain and offset, the relationship between the analog input and the expected digital

result must be known. The input that would produce a

corresponding digital result of all zeroes is the null

value (normally this input is GND). The input that would

produce a corresponding digital result of all ones is the

full-scale (FS) value minus one LSB. The FS value is

also found by multiplying an all ones digital value by

the weighted LSB. For example, a digital reading is 16

bits long, assume that the LSB is known to be 50µV,

then the FS value would be 216x 50µV = 3.2768V.

A binary search can be used to find the appropriate

gain value to achieve the desired FS of the converter.

Once the gain value is determined, then it can be

loaded into the appropriate channels’ Gain register.

This requires forcing two known voltages on to the

monitor input pin. For best results, one of the forced

voltages should be the NULL input and the other

should be 90% of FS. Since the LSB of the least significant bit in the digital reading register is known, the

expected digital results are also known for both the null

and FS value inputs. Figure 9 describes the hysteresis

built into the DS1862’s LUT functionality.

With the exception of BMD, which can source or sink

current, all monitored channels are high impedance

and are only capable of directly measuring a voltage. If

other measured quantities are desired, such as: light,

frequency, power, current etc., they must be converted

to a voltage. In this situation the user is not interested in

voltage measurement on the monitored channel, but

the measurement of the desired parameter. Only the

relationship between the indirect measured quantity

(light, frequency, power, current, etc.) to the expected

digital result must be known.

An example of gain scaling using the recommended

binary search procedure is provided with the following

pseudo-code.

To help will the computation, two integers need to be

defined: count 1 and count 2. CNT1 = NULL / LSB and

CNT2 = 90%FS / LSB. CLAMP is the largest result that

can be accommodated.

Table 8. Temperature Conversion

Examples

Table 9. Internal Calibration Capabilities

Figure 9. Look-Up Table Hysteresis

MSB (BIN) LSB (BIN) TEMPERATURE (°C)

01000000 00000000 +64

01000000 00001000 +64.03215

01011111 00000000 +95

11110110 00000000 -10

11011000 00000000 -40

SIGNAL

Temperature — x —

V

CC2/3

IBIASMON x x x

RSSI (RX-P) x x x

AUX1MON x x x

AUX2MON x x x

BMD (TX-P) x x x

INTERNAL

SCALING

xx—

INTERNAL

OFFSET

RIGHT-

SHIFTING

M6

M5

M4

M3

MEMORY LOCATION

M2

M1

2 4 6 8 10 12

DECREASING

TEMPERATURE

INCREASING

TEMPERATURE

TEMPERATURE (°C)

Page 20

DS1862

XFP Laser Control and Digital Diagnostic IC

20 ____________________________________________________________________

/* Assume that the Null input is 0.5V. */

/* In addition, the requirement for LSB is 50µV. */

FS = 65536 * 50e-6; /* 3.2768 */

CNT1 = 0.5 / 50e-6; /* 10000 */

CNT2 = 0.90*FS / 50e-6; /* 58982 */

/* Thus the NULL input of 0.5V and the 90% of FS input

is 2.94912V. */

set the trim-offset-register to zero;

set Right-Shift register to zero (Typically zero.

See the

Right-Shifting

section);

gain_result = 0h;

CLAMP = FFF8h/2^(Right_Shift_Register);

For n = 15 down to 0

begin

gain_result = gain_result + 2^n;

Force the 90% FS input (2.94912V);

Meas2 = read the digital result from the part;

If Meas2 >= CLAMP then

gain_result = gain_result - 2^n;

Else

Force the NULL input (0.5V);

Meas1 = read the digital result from the part;

if (Meas2 - Meas1) > (CNT2 - CNT1) then

gain_result = gain_result - 2^n;

end;

Set the gain register to gain_result;

The gain register is now set and the resolution of the

conversion will best match the expected LSB. The next

step is to calibrate the offset of the DS1862. With the

correct gain value written to the gain register, again

force the NULL input to the monitor pin. Read the digital result from the part (Meas1). The offset value is

equal to negative value of Meas1.

The calculated offset is now written to the DS1862 and

the gain-and offset-scaling procedure is complete.

Right-Shifting A/D Conversion Result

(Scalable Dynamic Ranging)

Right-shifting is a digital method used to regain some

of the lost ADC range of a calibrated system. If rightshifting is enabled, by simply loading a non-zero value

into the appropriate Right-Shifting Register, then the

DS1862 shifts the calibrated result just before it is

stored into the monitor channels’ register. If a system is

calibrated so the maximum expected input results in a

digital output value of less than 7FFFh (50% of FS),

then it is a candidate for using the right-shifting

method.

If the maximum desired digital output is less than

7FFFh, then the calibrated system is using less than 1/2

the ADC’s range. Similarly, if the maximum desired digital output is less than 1FFFh, then the calibrated system is only using 1/8th the ADC’s range. For example, if

an applied maximum analog signal yields a maximum

digital output less than 1FFCh, then only 1/8th of the

ADC’s range is used. Right-shifting improves the resolution of the measured signal as part of internal calibration. Without right-shifting, the 3 MS bits of the ADC will

never be used. In this example, a value of 3 for the

right-shifting maximizes the ADC range and a larger

gain setting must be loaded to achieve optimal conversion. No resolution is lost since this is a 13-bit converter

that is left justified. The value can be right-shifted 3

times without losing any resolution. The following table

describes when the right-shifting method can be effectively used.

Table 10. Right-Shifting Selection

OFFSET REGISTER

_

=

MEAS

()

−

11

⎡

⎢

4

⎣

⎤

⎥

⎦

OUTPUT RANGE USED WITH

ZERO RIGHT-SHIFTS

0h .. FFFFh 0

0h .. 7FFFh 1

0h .. 3FFFh 2

0h .. 1FFFh 3

0h .. 0FFFh 4

NUMBER OF RIGHT-

SHIFTS NEEDED

Page 21

DS1862

XFP Laser Control and Digital Diagnostic IC

____________________________________________________________________ 21

Warning and Alarm Logic Based on

AUX1/2MON, V

CC2/3

, Temp, RX-P,

and IBIASMON

The DS1862 is capable of generating an alarm and/or

warning whenever an analog monitored channel goes

out of a user-defined tolerance. Temperature, bias current (based on IBIASMON), receive power (based on

RSSI), AUX1MON, AUX2MON, and V

CC2/3

, are moni-

tored channels that generate latched flags. See the figure below for more detail pertaining to AUX1MON and

AUX2MON. Flags are latched into a high state the first

time a monitored channel goes out of the defined operating window and for each monitored signal there is a

Mask bit that can be set to prevent the corresponding

alarm or warning flag from being set. Once a flag is set,

it is cleared by simply reading its memory location.

Figure 10. AUX1/2 Monitor Logic

AUX1MON (PIN)

THRESHOLD

AUX2MON (PIN)

THRESHOLD

AUX1MON

(APD MODE)

AUX2MON

(APD MODE)

ADC

ADC

LATCH

AUX1/2MON LOGIC

C

C

MASK BIT

LATCHED-APDSUPPLY-FAULT

4-BIT UNIT SELECT

AUX1MON

(TEC MODE)

AUX2MON

(TEC MODE)

AUX1MON

AUX2MON

*COMPARATOR LOGIC IS

DUPLICATED FOR HIGH

AND LOW ALARMS AND

WARNINGS.

LATCHED-TECFAULT

LATCH

AUX1MON

(LASER WL MODE)

AUX2MON

(LASER WL MODE)

AUX1MON

MODE)

(V

EE5

AUX2MON

MODE)

(V

EE5

AUX1MON

MODE)

(V

CC2

AUX2MON

MODE)

(V

CC2

AUX1MON

MODE)

(V

CC5

AUX2MON

(V

CC5

AUX1MON

(V

CC3

AUX2MON

(V

CC3

ANY FLAG

MODE)

MODE)

MODE)

BIT

LATCH

LATCH

LATCHED-V

LATCHED-V

INTERRUPT (PIN)

CC5

CC3

LATCH

LATCH

LATCH

LATCHEDWAVELENGH-UL

LATCHED-V

LATCHED-V

EE5

CC2

CORRESPONDING MASK

Page 22

DS1862

XFP Laser Control and Digital Diagnostic IC

22 ____________________________________________________________________

Warning and Alarm Logic Based on

Signal Conditioners

The DS1862 also has flags that are set by certain logical

conditions on signal conditioner (SC) pins: SC-RX-LOL,

SC-RX-LOS, SC-TX-LOS. Similarly, for each latched

signal conditioner flag there are also mask bits that are

capable of preventing the alarm or warning flag from

causing an INTERRUPT pin to assert. Again, flags are

cleared automatically whenever their memory address

is read. See Figure 11 for more detail.

Quick-Trip Logic and FETG

Shutdown Functionality

In addition to alarms and warnings, the DS1862 also

has quick-trip (QT) functionality (sometimes referred to

as fast alarms) that is capable of shutting down the

LASER with the FETG pin in conjunction with shutting

down I

MODSET

and I

BIASSET

. I

BMD

and I

BIASSET

currents are measured and are compared with userdefined trip points to set the quick-trip flags: QT LOW

TX-P, QT HIGH TX-P, and QT HIGH BIAS. These flags

are also capable of being masked to prevent FETG

from being asserted when an out-of-tolerance condition

is detected. FETG is not asserted by setting the TX-D

pin, SOFT TX-D, or P-DOWN/RST pin to a high state,

however, I

MODSET

, and I

BIASSET

will shut down. See

Figure 12 for more detail.

Figure 11. Signal Conditioner and Other Logic

SIGNAL CONDITIONER AND MISCELLANEOUS LOGIC

HIGH TX-P

LOW TX-P

HIGH BIAS

SC-RX-LOS

(PIN)

SC-RX-LOL

(PIN)

LATCH

LATCH

LATCHED-TX-FAULT

LATCHED-RX-NR

SC-TX-LOS

(PIN)

LATCHED-TX-FAULT

P-DOWN/RST

(PIN)

TIMER

LATCHED-TX-NR

LATCH

LATCHED-RESET-DONE

LATCHLATCH

SC-RX-LOS

(PIN)

SC-RX-LOL (PIN)

TX-FAULT

VCC2-FAULT

LATCHEDRX-LOS

LATCH

MOD-NR (PIN)

*OPEN DRAIN

ANY FLAG

ANY MASK BIT

RX-LOS (PIN)

*OPEN DRAIN

LATCHEDMOD-NR

LATCH

SC-RX-LOL

(PIN)

INTERRUPT (PIN)

LATCHED

RX-CDR-NL

Page 23

DS1862

XFP Laser Control and Digital Diagnostic IC

____________________________________________________________________ 23

The polarity of the FETG pin can also be reversed by

setting the FETG_POL bit. Once a safety fault has

occurred, the FETG pin and all of the attendant flags can

only be reset by pulsing the P-DOWN/RST pin high for the

reset time, t

RESET

, or by toggling the P-DOWN/RST bit in

Byte 6Eh, bit 4. See the

Power-Down/Reset Pin

section for

more details.

Power-Down/Reset Pin

The P-DOWN/RST pin is a multifunction input pin that

resets and/or powers down the DS1862. Since the pin is

internally pulled up, its normal state is released, which

corresponds to power-down mode. If the P-DOWN/RST

pin is released, or driven high, the DS1862 responds by

shutting down the MODSET and BIASSET currents.

Once the pin is pulled low, operation continues (if not

inhibited by a safety fault). Besides powering down the

DS1862, a high-going pulse with minimum reset time,

t

RESET

, can be applied to the P-DOWN/RST pin. This is

necessary to restart the DS1862, especially if it is in a

safety shutdown condition and needs to be restarted

after the safety condition has been rectified. See the

timing diagrams for proper pin timing.

Power-Down Functionality

During power-down mode I

BIASSET

and I

MODSET

drop

below 10µA, effectively shutting down the laser. FETG

is not asserted and safety faults do not occur during

this period. During power-down, I2C communication is

still active, but the signal conditioner pins EN1 and EN2

are noncontrollable and automatically change to the

states: EN1 = 1 and EN2 = 0. Other internal flags/signals that are based on the signal conditioner inputs still

reflect the status on the signal conditioner pins during

power-down. For example, RX-LOS still reflects the status of SC-RX-LOS, and MOD-NR still reflects the logical

states for the signal conditioner pins. Similarly, it is possible for FETG to be asserted, even though the BIASSET

and MODSET currents are shut down. However, during

power-down and a short period, t

PDR-OFF

, during powerup, TX-P Low flag is ignored (internally automatically

masked out) and does not contribute to FETG’s logic.

Figure 12. Safety Fault and Shutdown Logic

SHUTDOWN LOGIC

LATCHED-TX-FAULT

LATCH

BMD (PIN)

(TX-P CURRENT)

ADC

THRESHOLD

QT LOW

TX-P FLAG

LOW TX-P MASK

BMD (PIN)

(TX-P CURRENT)

BIASSET (PIN)

(BIASSET CURRENT)

SOFT TX-D

P-DOWN/RST (PIN)

TX-D (PIN)

SAFETY FLAG

SOFT P-DOWN/RST

ADC

THRESHOLD

ADC

THRESHOLD

HIGH TX-P MASK

BIAS HIGH MASK

SHUTDOWN

FLAG

QT HIGH

TX-P FLAG

QT BIAS

HIGH FLAG

QT LOW TX-P FLAG

QT HIGH TX-P FLAG

QT BIAS HIGH FLAG

FETG_POL

FETG_POL

DRIVE A P-CHANNEL SWITCH

0

DRIVE A N-CHANNEL SWITCH

1

SAFETY FLAG

LATCH

FETG (PIN)

Page 24

DS1862

XFP Laser Control and Digital Diagnostic IC

24 ____________________________________________________________________

During an asserted period of P-DOWN/RST (DS1862 in

power-down), and V

CC3

is cycled, the DS1862 remains

in power-down mode upon power-up. While in powerdown mode the INTERRUPT pin does not assert. Once

V

CC3

has returned, the reset done flag asserts after the

interrupt assert delay, t

INIT ON

.

Reset Functionality

Besides powering down the DS1862, the P-DOWN/RST

pin also functions to reset the DS1862. After a highgoing pulse of time t

RESET

, several events occur within

the DS1862. First, MODSET and BIASSET currents shut

down and are then reinstated. Second, between the rising edge of the reset pulse and the assertion of the

reset-done flag (t

INIT

), the low TX-P flag is ignored and

does not cause FETG to trip. After time t

INIT,

the low

TX-P flag becomes functional. Also, at this time, the

reset-done flag is asserted, causing an interrupt to be

generated. If there are no faults before t

INIT

, then no

interrupts are asserted on the INTERRUPT pin.

If V

CC3

is powered up while P-DOWN/RST is high, then

the reset-done flag must be cleared twice. The first time

the reset-done flag is generated by V

CC3

powering up,

the second time reset-done is generated by a falling

edge on P-DOWN/RST. If V

CC3

is continuously powered while P-DOWN/RST is low then only one resetdone flag needs to be cleared. See the timing

diagrams for graphical detail.

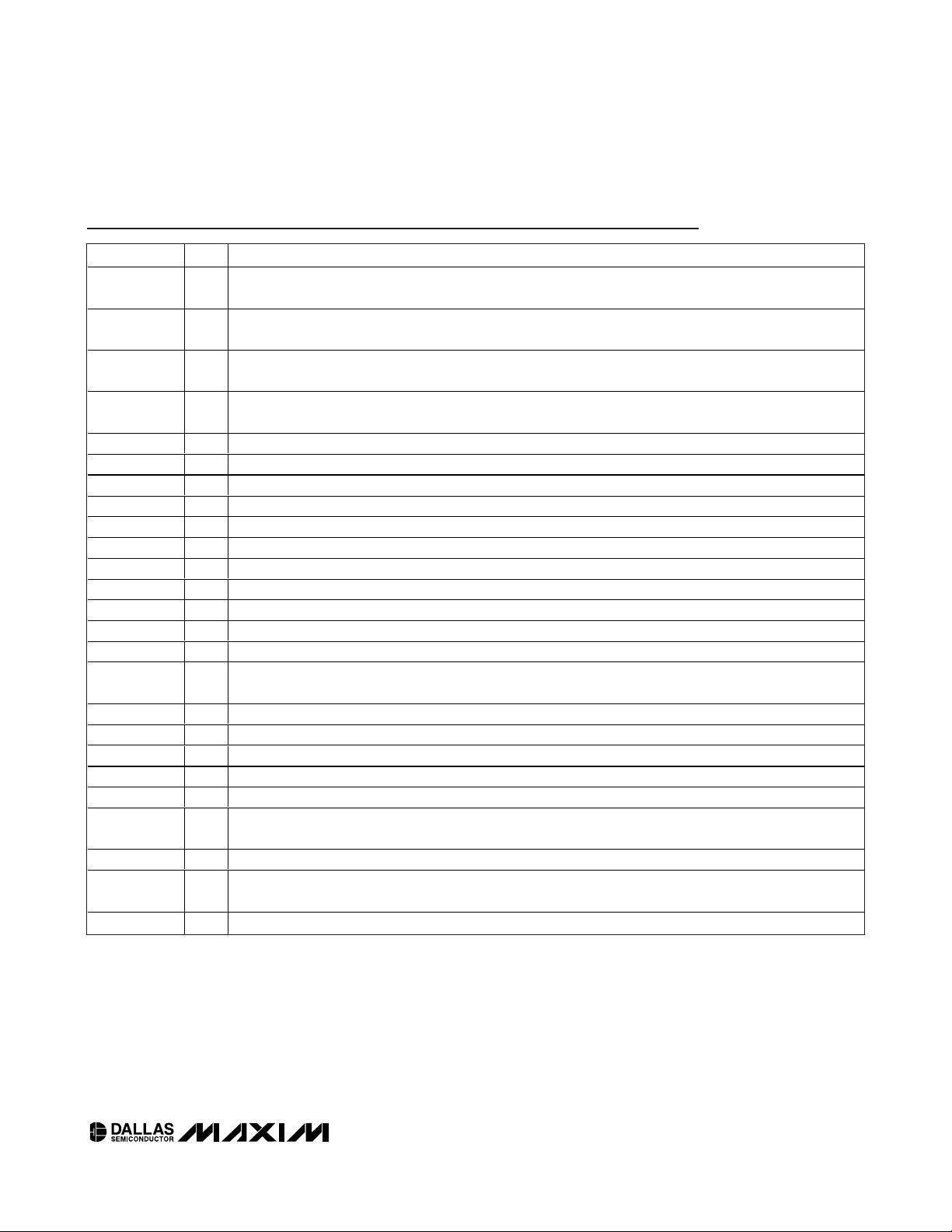

DS1862 Memory Map

Memory Organization

The DS1862 features six separate memory tables that

are internally organized into four byte rows. The Lower

Memory is addressed from 00h to 7Fh and contains

alarm and warning thresholds, flags, masks, several

control registers, password entry area (PE), and the

Table Select byte. Table 01h primarily contains user

EEPROM as well as several control bytes for various

functions. Table 02h is strictly user EEPROM that is protected by a host password. Table 03h is strictly used

for controlling the extinction ratio with an LUT. Table

04h is a multifunction space that contains internal calibration values for monitored channels, LUT index pointers, and miscellaneous control bytes. Table 05h is

factory programmed and stores SCALE values for use

with suggested external temperature sensors. Also, one

byte in Table 05h controls the THRSET voltage source

and is completely accessible without any password

protection. See the Memory section for a more complete detail of each byte’s function, as well as Table 11

for read/write permissions for each Byte. Many nonvolatile memory locations (listed within the

Detailed

Register Description

section) are actually SRAMShadowed EEPROM, which are controlled by the SEEB

bit in Table 4, Byte B2h.

The DS1862 incorporates SRAM-shadowed EEPROM

memory locations for key memory addresses that may

be rewritten many times. By default the Shadowed

EEPROM Bit, SEEB, is not set and these locations act

as ordinary EEPROM. By setting SEEB, these locations begin to function like SRAM cells, which allow an

infinite number of write cycles without concern of wearing out the EEPROM. This also eliminates the requirement for the EEPROM write time, tWR. Because

changes made with SEEB enabled do not affect the

EEPROM, these changes are not retained through

power cycles. The power-up value is the last value written with SEEB disabled. This function can be used to

limit the number of EEPROM writes during calibration or

to change the monitor thresholds periodically during

normal operation helping to reduce the number of times

EEPROM is written. The Memory Map description indicates which locations are shadowed-EEPROM.

Page 25

DS1862

XFP Laser Control and Digital Diagnostic IC

____________________________________________________________________ 25

Figure 13. General View of DS1862 Memory Organization

Register Map

Table 11. Permission Table

DEC hex

00

127 7F

128 80

2

C SLAVE ADDRESS A0h

I

00h

LOWER MEMORY

DIGITAL DIAGNOSTIC

FUNCTIONS

PASSWORD ENTRY (PWE)

(4 BYTES)

TABLE SELECT BYTE

TABLE 01h

TABLE 00h

XFP MSA

SERIAL ID DATA

7Fh

80h

TABLE 02h

USER EEPROM DATA

80h 80h80h

MODULATION DAC

LUT

C7h

TABLE 04hTABLE 03h

CONTROL AND

CONFIGURATION

TABLE

(72 BYTES)

80h

OPTIONAL SCALE VALUES

AND THRSET CONTROL

BBh

TABLE 05h

87h

DC220 MISC CONTROL BITS

255 FF

FFh

PERMISSION READ WRITE

At least one byte in this row is different than

<0>

<1> ALL ALL

<2> ALL MODULE

<3> ALL HOST

<4> MODULE MODULE

<5> ALL FACTORY

<6> NEVER HOST

<7> NEVER MODULE

the rest of the bytes, so look at each byte

separately for permissions.

FFh

Page 26

DS1862

XFP Laser Control and Digital Diagnostic IC

26 ____________________________________________________________________

*

V

CC2/3

are in reserved locations.

LOWER MEMORY (00H–7FH)

A D DR ESS

( h ex )

<0,2>

00

<2>

08

<2>

10

38

70

78

18

20

28

30

40

48

50

58

60

68

<2>

<2>

<2>

<2>

<0,2>

<1>

<1>

<1>

<1>

<1>

<1>

<0,1>

<0,1>

BYTE

BYTE 0/8 BYTE 1/9 BYTE 2/A BYTE 3/B BYTE 4/C BYTE 5/D BYTE 6/E BYTE 7/F

Reserved Reserved Reserved Reserved Reserved Reserved SRAM SRAM

Temp/Res/Bias/

TxP Alarm

Temp/Res/Bias/

TxP Mask

Reserved Reserved Reserved Reserved POA Reserved PEC_EN Host PW

Host PW Host PW Host PW PWE (MSB) PWE (LSB) Table Select

BYTE/WORD

(hex)

01 Signal Cond

50

51

52

53

54

55

56

WORD 0 WORD 1 WORD 2 WORD 3

EE Signal Cond Temp Alarm Hi Temp Alarm Lo Temp Warn Hi

Temp Warn Lo V

V

Warn Lo* Bias Alarm Hi Bias Alarm Lo Bias Warn Hi

CC3

Alarm Hi* V

CC3

Alarm Lo* V

CC3

Bias Warn Lo TX-P Alarm Hi TX-P Alarm Lo TX-P Warn Hi

TX-P Warn Lo RX-P Alarm Hi RX-P Alarm Lo RX-P Warn Hi

RX-P Warn Lo Aux1 Alarm Hi Aux1 Alarm Lo Aux1 Warn Hi

Aux1 Warn Lo Aux2 Alarm Hi Aux2 Alarm Lo Aux2 Warn Hi

Aux2 Warn Lo EE EE Reserved Reserved Reserved Reserved

SRAM SRAM SRAM SRAM SRAM SRAM SRAM SRAM

RxP/Aux1/Aux2/

Res Alarm

RxP/Aux1/Aux2/

Res Mask

Temp Value V

Temp/Res/Bias/

TxP Warn

Temp/Res/Bias/

TxP Mask

CC2/3

RxP/Aux1/Aux2/

Res Warn

RxP/Aux1/Aux2/

Res Mask

Tx/Rx Misc

Flags

Rx/Rx Misc

Mask

Apd/Tec/

Wave/Res Flags

Apd/Tec/Wave/

Res Mask

V

CC5/3/2

Alarm Flags

V

CC5/3/2/

Alarm Mask

Value* Bias Value TX-P Value

RX-P Value Aux1 Value Aux2 Value GCS1 GCS0

EXPANDED BYTES

Bit7 Bit6* Bit5 Bit4 Bit3 Bit2 Bit1 Bit0**

NAME

<1>

<1>

<1>

<1>

<1>

<1>

<1>

<1>

bit14bit13bit12bit11bit10bit9bit8bit7bit6bit5bit4bit3bit2bit1bit

bit

15

EE EE EE EE EE EN2 Value EN1 Value Lock-T1-221

L-HI-TEMP-ALL-LO-TEMP-

AL

L-HI-RX-P-AL

L-HI-TEMP-W

L-LO-RX-P-ALL-HI-AUX1-ALL-LO-AUX1-ALL-HI-AUX2-ALL-LO-AUX2-

L-LO-TEMP-

W

Reserved Reserved L-HI-BIAS-AL

Reserved Reserved L-HI-BIAS-W L-LO-BIAS-W L-HI-TX-P-W L-LO-TX-P-W

L-HI-RX-P-W L-LO-RX-P-W L-HI-AUX1-W

L-LO-AUX1-

W

L-HI-AUX2-W

L-LO-BIAS-

AL

AL

L-LO-AUX2-

W

L-HI-TX-P-AL

Reserved Reserved

Reserved Reserved

L-TX-NR L-TX-F L-TX-CDR-NL L-RX-NR L-RX-LOS L-RX-CDR-NL L-MOD-NR

L-APD-SUP-F L-TEC-F L-WAVE-NL Reserved Reserved Reserved Reserved Reserved

L-HI-V

CC5

-AL

L-LO–V

AL

CC5-

L-HI-V

CC3

-AL

L-LO–V

AL

CC3

L-HI-V

CC2

-AL

L-LO–V

AL

CC2-

L-HI-V

CC3

Vee

Vee

EE5

Warn Hi*

V

CC5/3/2

Warn Flags

V

CC5/3/2

Warn Mask

L-LO-TX-

L-RESET-

L-LO-V

-AL

P-AL

DONE

AL

Vee

/Vee

EE5

0

-

Page 27

DS1862

XFP Laser Control and Digital Diagnostic IC

____________________________________________________________________ 27

*

Bit 6 and Bit 3 of Byte 6Eh are masked by Bit 6 and Bit 5 of Byte DDh in Table 01h, respectively.

**

Bit 0 of Address 01h can be written only if Bit 0 of Byte DDh in Table 01h is set.

BYTE

(hex)

57

58

59

5A

5B

5C

5D

5E

5F

6E

6F

74

BYTE/WORD

NAME bit

<1>

<1>

<1>

<1>

<1>

<1>

<1>

<1>

<1>

<1>

<1>

POA <1>

77 Host PW

78 Host PW

79 Host PW

7A Host PW

7B PWE

7C PWE

7D PWE

7E PWE

7F Table Select

<6>

<6>

<6>

<6>

<6>

<6>

<6>

<6>

Bit7 Bit6* Bit5 Bit4 Bit3 Bit2 Bit1 Bit0**

bit14bit13bit12bit11bit10bit9bit8bit7bit6bit5bit4bit3bit2bit1bit

15

L-HI-V

CC5

HI-TEMP-AL

MASK

HI-RX-P-AL

MASK

HI-TEMP-W

MASK

HI-RX-P-W

MASK

TX-NR MASK TX-F MASK

APD-SUP-F

MASK

HI-V

-AL

CC5

MASK

HI-V

CC5

MASK

TX-D SOFT TX-D MOD-NR P-DOWN/RST

TX-NR TX-F TX-CDR-NL RX-NR RX-CDR-NL Reserved Reserved Reserved

POA Reserved Reserved Reserved Reserved Reserved Reserved Reserved

31

2

23

2

15

2

7

2

31

2

23

2

15

2

7

2

<1>

7

2

-W L-LO-V

LO-TEMP-AL

LO-RX-P-AL

LO-TEMP-W

LO-RX-P-W

TEC-F MASK

LO-V

-W

LO-V

EXPANDED BYTES (CONTINUED)

CC5

MASK

MASK

MASK

MASK

CC5

MASK

CC5

MASK

30

2

22

2

14

2

6

2

30

2

22

2

14

2

6

2

6

2

-W L-HI-V

HI-AUX1-AL

HI-AUX1-W

TX-CDR-NL

-AL

HI-V

-W

HI-V

WAVE-NL

-W L-LO-V

CC3

Reserved Reserved

LO-AUX1-AL

MASK

MASK

Reserved Reserved

LO-AUX1-W

MASK

MASK

MASK

CC3

MASK

CC3

MASK

29

2

21

2

13

2

5

2

29

2

21

2

13

2

5

2

5

2

-AL

MASK

RX-NR MASK

Reserved Reserved Reserved Reserved Reserved

LO-V

MASK

-W

LO-V

MASK

CC3

2

2

2

2

2

2

2

2

2

CC3

28

20

12

28

20

12

CC3

-AL

-W

4

4

4

-W L-HI-V

HI-BIAS-AL

MASK

HI-AUX2-AL

MASK

HI-BIAS-W

MASK

HI-AUX2-W

MASK

RX-LOL

MASK

HI-V

MASK

HI-V

MASK

SOFT

P-DOWN

CC2

CC2

CC2

27

2

19

2

11

2

2

27

2

19

2

11

2

2

2

3

3

3

-W L-LO-V

LO-BIAS-AL

LO-AUX2-AL

LO-BIAS-W

LO-AUX2-W

RX-CDR-NL

-AL

LO-V

-W

LO-V

CC2

MASK

MASK

MASK

MASK

MASK

CC2

MASK

CC2

MASK

-W L-HI-V

EE5

HI-TX-P-AL

MASK

Reserved Reserved

HI-TX-P-W

MASK

Reserved Reserved

MOD-NR

MASK

-AL

HI-V

-AL

EE5

MASK

-W

HI-V

-W

EE5

MASK

-W L-LO-V

INTERRUPT RX-LOS DATA-NR

26

2

18

2

10

2

2

2

26

2

18

2

10

2

2

2

2

2

25

2

17

2

9

2

1

2

25

2

17

2

9

2

1

2

1

2

-W

EE5

LO-TX-P-AL

MASK

LO-TX-P-W

MASK

RESET-

DONE MASK

LO-V

-AL

EE5

MASK

LO-V

-W

EE5

MASK

24

2

16

2

8

2

0

2

24

2

16

2

8

2

0

2

0

2

0

Page 28

DS1862

XFP Laser Control and Digital Diagnostic IC

28 ____________________________________________________________________

Note: Byte DDh <6:5> of Table 01h enables bit 6 and bit 3 of Byte 6Eh in the lower memory.

TABLE 01H (SERIAL ID MEMORY)

ADDRESS

(hex)

<2>

80

<2>

88

<2>

90

<2>

98

<2>

A0

<2>

A8

<2>

B0

<2>

B8

<2>

C0

<2>

C8

<2>

D0

<2>

D8

<2>

E0

<2>

E8

<2>

F0

<2>

F8

BYTE

(hex)

DC

DD

DE

BYTE/WORD

NAME

<2>

<2>

LO Mem EN Reserved

<2>

AUX1/2 UNIT SEL AUX1-SEL 23AUX1-SEL 22AUX1-SEL 21AUX1-SEL 20AUX2-SEL 23AUX2-SEL 22AUX2-SEL 21AUX2-SEL 2

EE EE EE EE EE EE EE EE EE

WORD 0 WORD 1 WORD 2 WORD 3

Byte 0/8 Byte 1/9 Byte 2/A Byte 3/B Byte 4/C Byte 5/D Byte 6/E Byte 7/F

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE V

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EE EE EE EE EE EE EE EE

EXPANDED BYTES

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

bit14bit13bit12bit11bit10bit9bit8bit7bit6bit5bit4bit3bit2bit1bit

bit

15

Reserved Reserved Reserved Reserved Reserved Reserved Reserved V

Enable 6Eh,

bit 6

Enable 6Eh,

bit 3

Reserved Reserved Reserved Reserved LOCK-bit

CC2/3

_Sel

LO Mem 6Eh

enable

AUX1/2 Unit

Select

EE

CC2/3

0

_Sel

0

TABLE 02H (HOST USER MEMORY)

ADDRESS

(hex)

<3>

80–FF

WORD 0 WORD 1 WORD 2 WORD 3

Byte 0/8 Byte 1/9 Byte 2/A Byte 3/B Byte 4/C Byte 5/D Byte 6/E Byte 7/F

EE EE EE EE EE EE EE EE

TABLE 03H (MODSET LOOK-UP TABLE)

ADDRESS

(hex)

<4>

80–87

<4>

88–BF

<4>

C0–C7

WORD 0 WORD 1 WORD 2 WORD 3

Byte 0/8 Byte 1/9 Byte 2/A Byte 3/B Byte 4/C Byte 5/D Byte 6/E Byte 7/F

EE,

< -40°C

EE,

-40°C

EE,

-38°C

EE,

-36°C

EE,

-34°C

————————

EE,

+88°C

EE,

+90°C

EE,

+92°C

EE,

+94°C

EE,

+96°C

EE,

-32°C

EE,

+98°C

EE,

-30°C

EE,

+100°C

EE,

-28°C

EE, > +102°C

Page 29

DS1862

XFP Laser Control and Digital Diagnostic IC

____________________________________________________________________ 29

ADDRESS

(hex)

<4>

80

<4>

88

<4>

90

<4>

98

Scale MS B RX-P

<4>

A0

<4>

A8

Offset MSB RX-P

<4>

B0

<7>

B8

BYTE

(hex)

81

82

83

84

85

86

87

8B

B2

ONF

B4

B8

B9

BA

BB

TABLE 04H (CONTROL AND CONFIG) (80H–BBH)

WORD 0 WORD 1 WORD 2 WORD 3

Byte 0/8 Byte 1/9 Byte 2/A Byte 3/B Byte 4/C Byte 5/D Byte 6/E Byte 7/F

Reserved

Quic k trip TX-P

high

Bia s shift,

TX-P shift

Quic k trip

TX-P low

Reserved Reserved

Scale

LSB RX-P

Offset MSB

temp

Offset

LSB temp

Offset

LSB RX-P

LUT INDEX

pointer

Module PWD

setting

LUT value LUT_conf Reserved DAC status Reserved Reserved Reserved

Module PWD

setting

RX-P shift

AUX1 shift

QT high bia s

setting

Scale MSB

V

CC3

Scale

MSB AUX1

Offset MSB

V

CC3

Offset MSB

AUX1

Module PWD

setting

AUX2 shift

Reserved

Control

Regi ster 2

Scale LSB

V

CC3

Scale

LSB AUX1

Offset

LSB V

CC3

Offset

LSB AUX1

Module PWD

setting

APC

course setting

APC

fine setting

LUT current

range

Reserved Reserved Reserv ed Reserved

Scale MSB

BIAS

Scale

MSB AUX2

Offset

MSB Bias

Offset MSB

AUX2

Scale

LSB BIAS

Scale LSB

AUX2

Offset LSB

BIAS

Offset LSB

AUX2

Scale

MSB TX-P

Reserved Reserved

Offset MSB