Page 1

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

______________________________________________ Maxim Integrated Products 1

For pricing delivery, and ordering information please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

General Description

The DS1859 dual, temperature-controlled, nonvolatile

(NV) variable resistors with three monitors consists of

two 50kΩ or two 20kΩ, 256-position, linear, variable

resistors; three analog monitor inputs (MON1, MON2,

MON3); and a direct-to-digital temperature sensor. The

device provides an ideal method for setting and temperature-compensating bias voltages and currents in

control applications using minimal circuitry. The variable resistor settings are stored in EEPROM memory

and can be accessed over the 2-wire serial bus.

Applications

Optical Transceivers

Optical Transponders

Instrumentation and Industrial Controls

RF Power Amps

Diagnostic Monitoring

Features

♦ SFF-8472 Compatible

♦ Five Monitored Channels (Temperature, VCC,

MON1, MON2, MON3)

♦ Three External Analog Inputs (MON1, MON2, MON3)

That Support Internal and External Calibration

♦ Scalable Dynamic Range for External Analog Inputs

♦ Internal Direct-to-Digital Temperature Sensor

♦ Alarm and Warning Flags for All Monitored

Channels

♦ Two 50kΩ or Two 20kΩ, Linear, 256-Position,

Nonvolatile Temperature-Controlled Variable

Resistors

♦ Resistor Settings Changeable Every 2°C

♦ Access to Monitoring and ID Information

Configurable with Separate Device Addresses

♦ 2-Wire Serial Interface

♦ Two Buffers with TTL/CMOS-Compatible Inputs and

Open-Drain Outputs

♦ Operates from a 3.3V or 5V Supply

♦ Operating Temperature Range of -40°C to +95°C

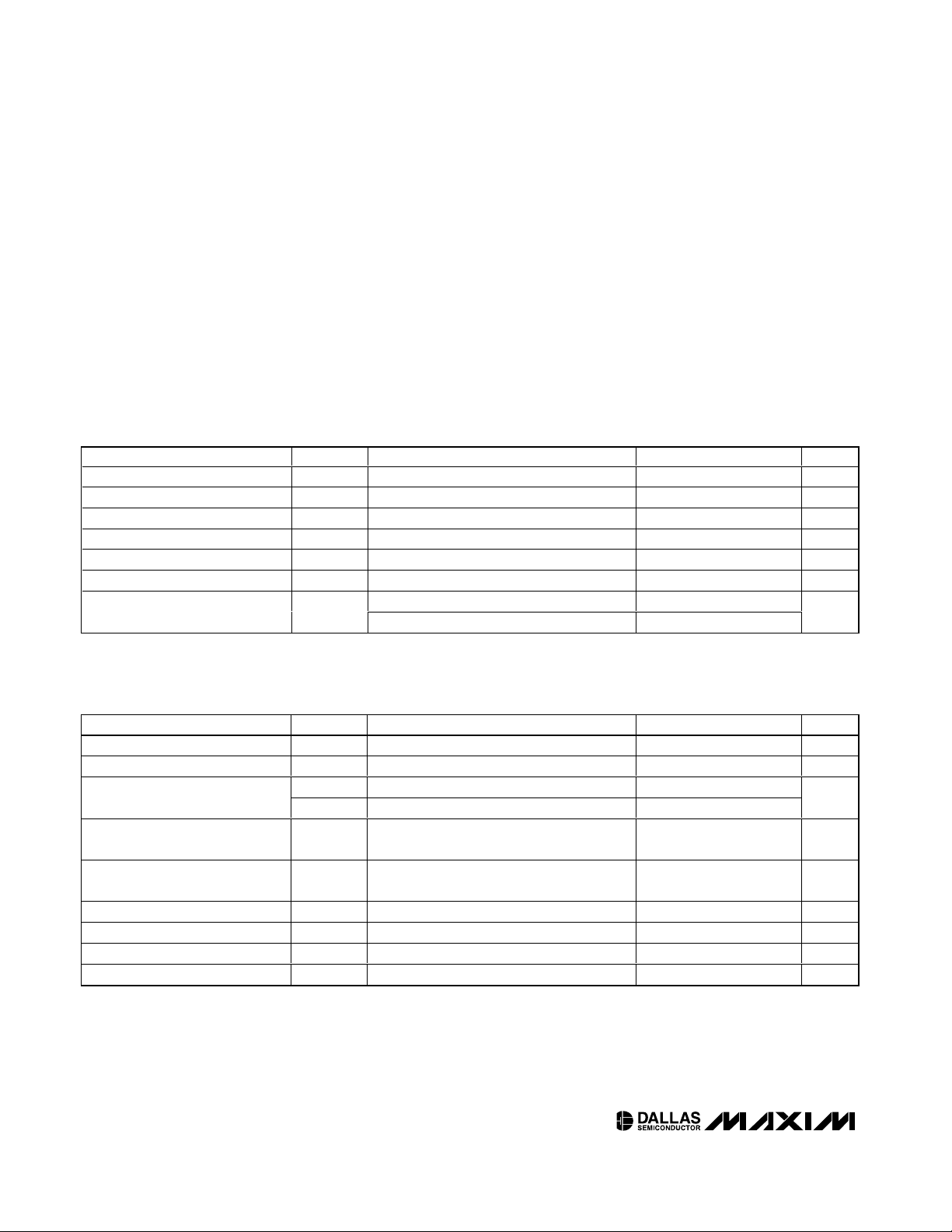

Ordering Information

Rev 4; 2/06

EVALUATION KIT

AVAILABLE

PART

RESISTANCE

PIN-PACKAGE

DS1859B-020 20kΩ 16 CSBGA

DS1859B-020+ 20kΩ 16 CSBGA

DS1859B-050 50kΩ 16 CSBGA

DS1859B-050+ 50kΩ 16 CSBGA

A

TOP VIEW

B

C

D

1

CSBGA (4mm x 4mm)

1.0mm PITCH

TSSOP

324

MON3

OUT1IN2

MON1

L0GND

WPEN

L1

H0SDA

OUT2

H1

V

CC

SCLIN1

MON2

DS1859

SDA

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

SCL

OUT1

IN1

OUT2

IN2

WPEN

GND

V

CC

H1

L1

H0

L0

MON3

MON2

MON1

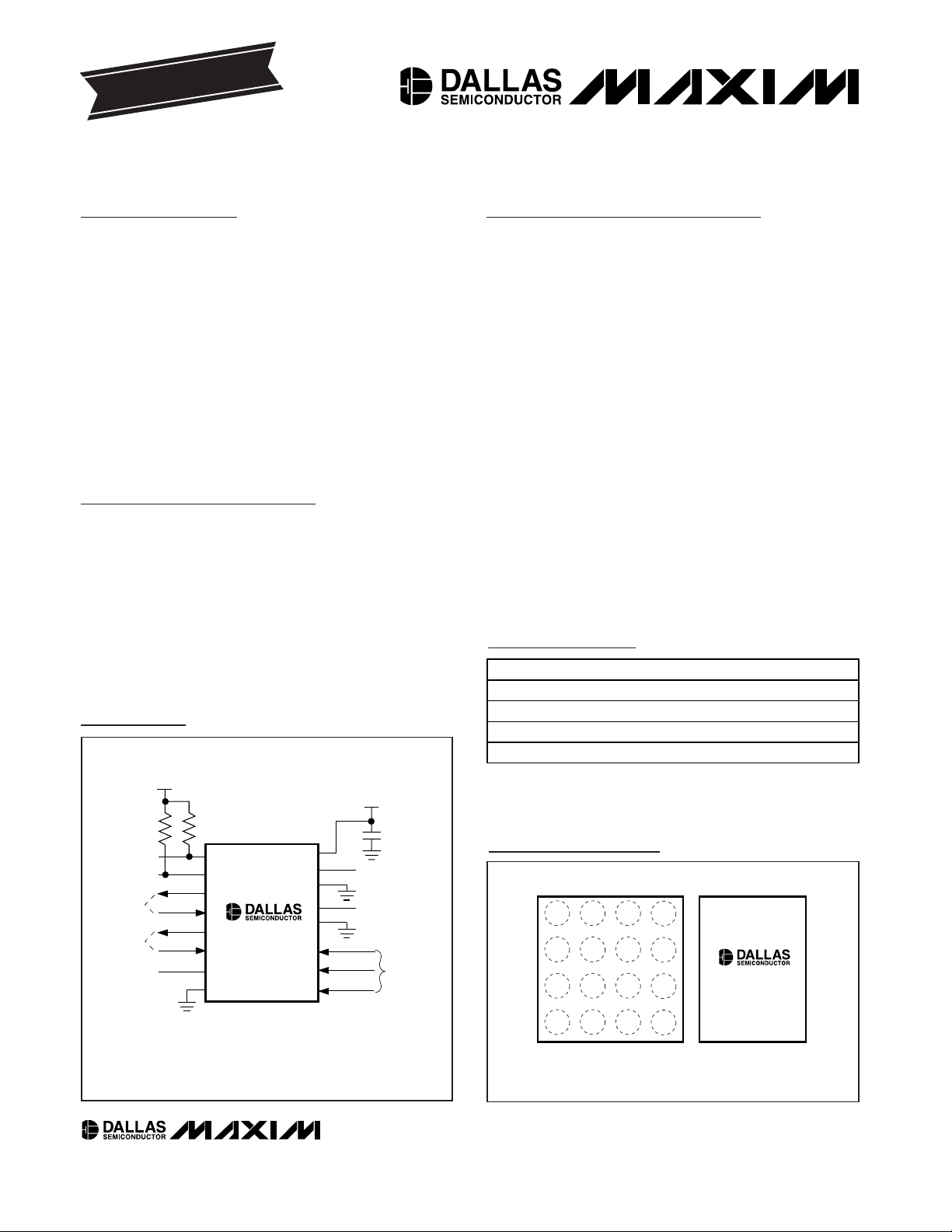

Pin Configurations

DS1859

SDA

1

2

3

4

5

6

7

8

16

0.1µF

15

14

13

12

11

10

9

SCL

OUT1

IN1

OUT2

IN2

WPEN

GND

V

CC

H1

L1

H0

L0

MON3

MON2

MON1

GROUND TO

DISABLE WRITE

PROTECT

Rx POWER*

DIAGNOSTIC

INPUTS

TO LASER

MODULATION

CONTROL

TO LASER BIAS

CONTROL

DECOUPLING

CAP

Tx POWER*

Tx BIAS*

*SATISFIES SFF-8472 COMPATIBILITY

V

CC

VCC = 3.3V

4.7kΩ4.7kΩ

Tx-FAULT

LOS

2-WIRE

INTERFACE

Typical Operating Circuit

+Denotes lead-free package.

Ordering Information continued at end of data sheet.

Page 2

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

2 _____________________________________________________________________

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Supply Voltage V

CC

(Note 1)

5.5 V

V

IH

(Note 2)

V

V

IL

(Note 2)

V

Resistor Inputs (L0, L1, H0, H1)

V

Resistor Current I

RES

-3 +3 mA

High-Z Resistor Current I

ROFF

0.1 µA

Input logic 1

Input Logic Levels (IN1, IN2)

Input logic 0 0.9

V

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage Range on VCCRelative to Ground ...........-0.5V to +6.0V

Voltage Range on Inputs Relative

to Ground* ................................................-0.5V to V

CC

+ 0.5V

Voltage Range on Resistor Inputs Relative

to Ground* ................................................-0.5V to V

CC

+ 0.5V

Current into Resistors............................................................5mA

Operating Temperature Range ...........................-40°C to +95°C

Programming Temperature Range .........................0°C to +70°C

Storage Temperature Range .............................-55°C to +125°C

Soldering Temperature .......................................See IPC/JEDEC

J-STD-020A

RECOMMENDED DC OPERATING CONDITIONS

(TA= -40°C to +95°C, unless otherwise noted.)

PARAMETER

CONDITIONS

UNITS

Supply Current I

CC

(Note 3) 1 2 mA

Input Leakage I

IL

nA

V

OL1

3mA sink current 0 0.4

Low-Level Output Voltage

(SDA, OUT1, OUT2)

V

OL2

6mA sink current 0 0.6

V

Full-Scale Input (MON1, MON2,

MON3)

At factory setting

(Note 4)

2.5

V

Full-Scale VCC Monitor

At factory setting

(Note 5)

V

I/O Capacitance C

I/O

10 pF

WPEN Pullup R

WPEN

40 65 100 kΩ

Digital Power-On Reset POD

2.2 V

Analog Power-On Reset POA

2.6 V

DC ELECTRICAL CHARACTERISTICS

(VCC= 2.85V to 5.5V, TA= -40°C to +95°C, unless otherwise noted.)

*Not to exceed 6.0V.

Input Logic 1 (SDA, SCL, WPEN)

Input Logic 0 (SDA, SCL, WPEN)

2.85

0.7 x Vcc VCC + 0.3

-0.3 +0.3 x V

-0.3 VCC + 0.3

0.001

1.5

CC

SYMBOL

MIN TYP MAX

-200 +200

2.4875

6.5208 6.5536 6.5864

1.0

2.0

2.5125

Page 3

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

_____________________________________________________________________ 3

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Thermometer Error T

ERR

-40°C to +95°C

°C

DIGITAL THERMOMETER

(VCC= 2.85V to 5.5V, TA= -40°C to +95°C, unless otherwise noted.)

PARAMETER

CONDITIONS

UNITS

EEPROM Writes +70°C

NONVOLATILE MEMORY CHARACTERISTICS

(VCC= 2.85V to 5.5V)

PARAMETER

CONDITIONS

Input Resolution

µV

Supply Resolution ∆V

CC

1.6 mV

Input/Supply Accuracy

(MON1, MON2, MON3, V

CC

)

A

CC

At factory setting

% FS

Update Rate for MON1, MON2,

MON3, Temp, or V

CC

t

frame

30 45 ms

Input/Supply Offset

(MON1, MON2, MON3, V

CC

)

V

OS

(Note 14) 0 5 LSB

ANALOG VOLTAGE MONITORING

(VCC= 2.85V to 5.5V, TA= -40°C to +95°C, unless otherwise noted.)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Position 00h Resistance (50kΩ)T

A

= +25°C

1.0

kΩ

Position FFh Resistance (50kΩ)T

A

= +25°C 40 50 60 kΩ

Position 00h Resistance (20kΩ)T

A

= +25°C

kΩ

Position FFh Resistance (20kΩ)T

A

= +25°C 16 20 24 kΩ

Absolute Linearity (Note 6) -2 +2 LSB

Relative Linearity (Note 7) -1 +1 LSB

Temperature Coefficient (Note 8) 50

ANALOG RESISTOR CHARACTERISTICS

(VCC= 2.85V to 5.5V, TA= -40°C to +95°C, unless otherwise noted.)

SYMBOL

∆VMON 610

0.65

0.20 0.40 0.55

MIN TYP MAX UNITS

0.25 0.5

1.35

ppm/°C

(full scale)

SYMBOL

MIN TYP MAX

50,000

±3.0

Page 4

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

4 _____________________________________________________________________

PARAMETER

CONDITIONS

UNITS

Fast mode (Note 9) 0 400

SCL Clock Frequency f

SCL

Standard mode (Note 9) 0 100

kHz

Fast mode (Note 9) 1.3

Bus Free Time Between STOP and

START Condition

t

BUF

Standard mode (Note 9) 4.7

µs

Fast mode (Notes 9, 10) 0.6

Hold Time (Repeated)

START Condition

Standard mode (Notes 9, 10) 4.0

µs

Fast mode (Note 9) 1.3

LOW Period of SCL Clock t

LOW

Standard mode (Note 9) 4.7

µs

Fast mode (Note 9) 0.6

HIGH Period of SCL Clock t

HIGH

Standard mode (Note 9) 4.0

µs

Fast mode (Notes 9, 11, 12) 0 0.9

Data Hold Time

Standard mode (Notes 9, 11, 12) 0

µs

Fast mode (Note 9)

Data Setup Time

Standard mode (Note 9)

ns

Fast mode (Note 9) 0.6

START Setup Time

Standard mode (Note 9) 4.7

µs

Fast mode (Note 13)

300

Rise Time of Both SDA and SCL

Signals

t

R

Standard mode (Note 13)

ns

Fast mode (Note 13)

300

Fall Time of Both SDA and SCL

Signals

t

F

Standard mode (Note 13)

300

ns

Fast mode 0.6

Setup Time for STOP Condition

Standard mode 4.0

µs

Capacitive Load for Each Bus Line

C

B

(Note 13) 400 pF

EEPROM Write Time t

W

(Note 14) 10 20 ms

AC ELECTRICAL CHARACTERISTICS

(VCC= 2.85V to 5.5V, TA= -40°C to +95°C, unless otherwise noted. See Figure 6.)

Note 1: All voltages are referenced to ground.

Note 2: I/O pins of fast-mode devices must not obstruct the SDA and SCL lines if V

CC

is switched off.

Note 3: SDA and SCL are connected to V

CC

and all other input signals are connected to well-defined logic levels.

Note 4: Full Scale is user programmable. The maximum voltage that the MON inputs read is approximately Full Scale, even if the volt-

age on the inputs is greater than Full Scale.

Note 5: This voltage defines the maximum range of the analog-to-digital converter voltage, not the maximum V

CC

voltage.

Note 6: Absolute linearity is the difference of measured value from expected value at DAC position. The expected value is a

straight line from measured minimum position to measured maximum position.

Note 7: Relative linearity is the deviation of an LSB DAC setting change vs. the expected LSB change. The expected LSB change

is the slope of the straight line from measured minimum position to measured maximum position.

Note 8: See the Typical Operating Characteristics.

Note 9: A fast-mode device can be used in a standard-mode system, but the requirement t

SU:DAT

> 250ns must then be met. This

is automatically the case if the device does not stretch the LOW period of the SCL signal. If such a device does stretch the

LOW period of the SCL signal, it must output the next data bit to the SDA line t

RMAX

+ t

SU:DAT

= 1000ns + 250ns = 1250ns

before the SCL line is released.

SYMBOL

MIN TYP MAX

t

HD:STA

t

HD:DAT

t

SU:DAT

t

SU:STA

t

SU:STO

100

250

20 + 0.1C

20 + 0.1C

20 + 0.1C

20 + 0.1C

B

B

B

B

1000

Page 5

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

_____________________________________________________________________ 5

Note 10: After this period, the first clock pulse is generated.

Note 11: The maximum t

HD:DAT

only has to be met if the device does not stretch the LOW period (t

LOW

) of the SCL signal.

Note 12: A device must internally provide a hold time of at least 300ns for the SDA signal (see the V

IH MIN

of the SCL signal) to

bridge the undefined region of the falling edge of SCL.

Note 13: C

B

—total capacitance of one bus line, timing referenced to 0.9 x VCCand 0.1 x VCC.

Note 14: Guaranteed by design.

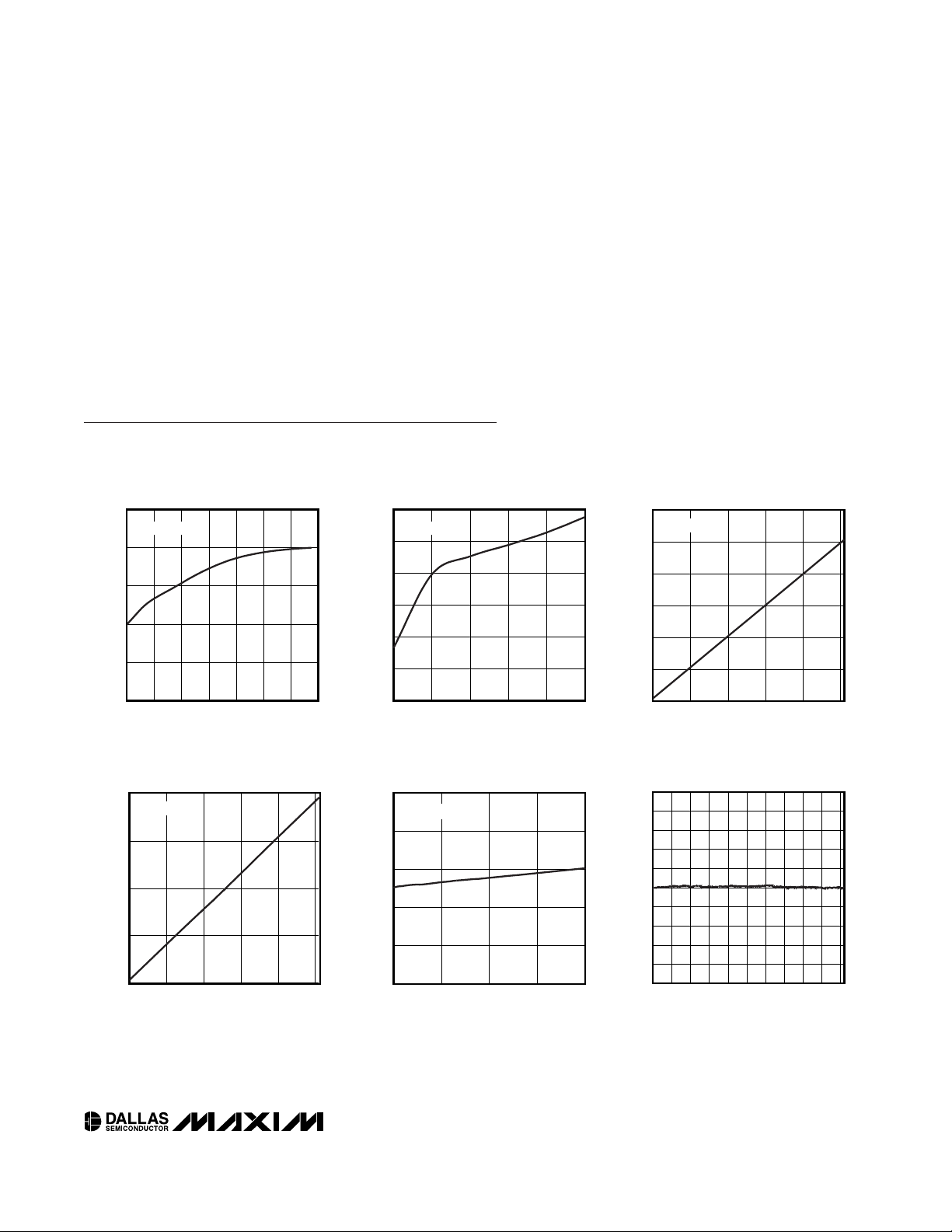

Typical Operating Characteristics

(VCC= 5.0V, TA= +25°C, for both 50kΩ and 20kΩ versions, unless otherwise noted.)

TEMPERATURE (°C)

40 60 80200-20

560

600

640

680

720

520

-40 100

SUPPLY CURRENT vs. TEMPERATURE

DS1859 toc01

SUPPLY CURRENT (µA)

SDA = SCL = V

CC

SUPPLY CURRENT vs. VOLTAGE

DS1859 toc02

VOLTAGE (V)

SUPPLY CURRENT (µA)

5.04.54.03.5

450

500

550

600

650

700

400

3.0 5.5

SDA = SCL = V

CC

RESISTANCE vs. SETTING

DS1859 toc03

SETTING (DEC)

RESISTANCE (kΩ)

20015010050

10

20

30

40

50

60

0

0 250

50kΩ VERSION

RESISTANCE vs. SETTING

DS1859 toc04

SETTING (DEC)

RESISTANCE (kΩ)

20015010050

5

10

15

20

0

0 250

20kΩ VERSION

ACTIVE SUPPLY CURRENT

vs. SCL FREQUENCY

DS1859 toc05

SCL FREQUENCY (kHz)

ACTIVE SUPPLY CURRENT (µA)

300200100

600

640

680

720

760

560

0 400

SDA = V

CC

RESISTOR 0 INL (LSB)

DS1859 toc06

SETTING (DEC)

RESISTOR 0 INL (LSB)

225200150 17550 75 100 12525

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0 250

Page 6

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

6 _____________________________________________________________________

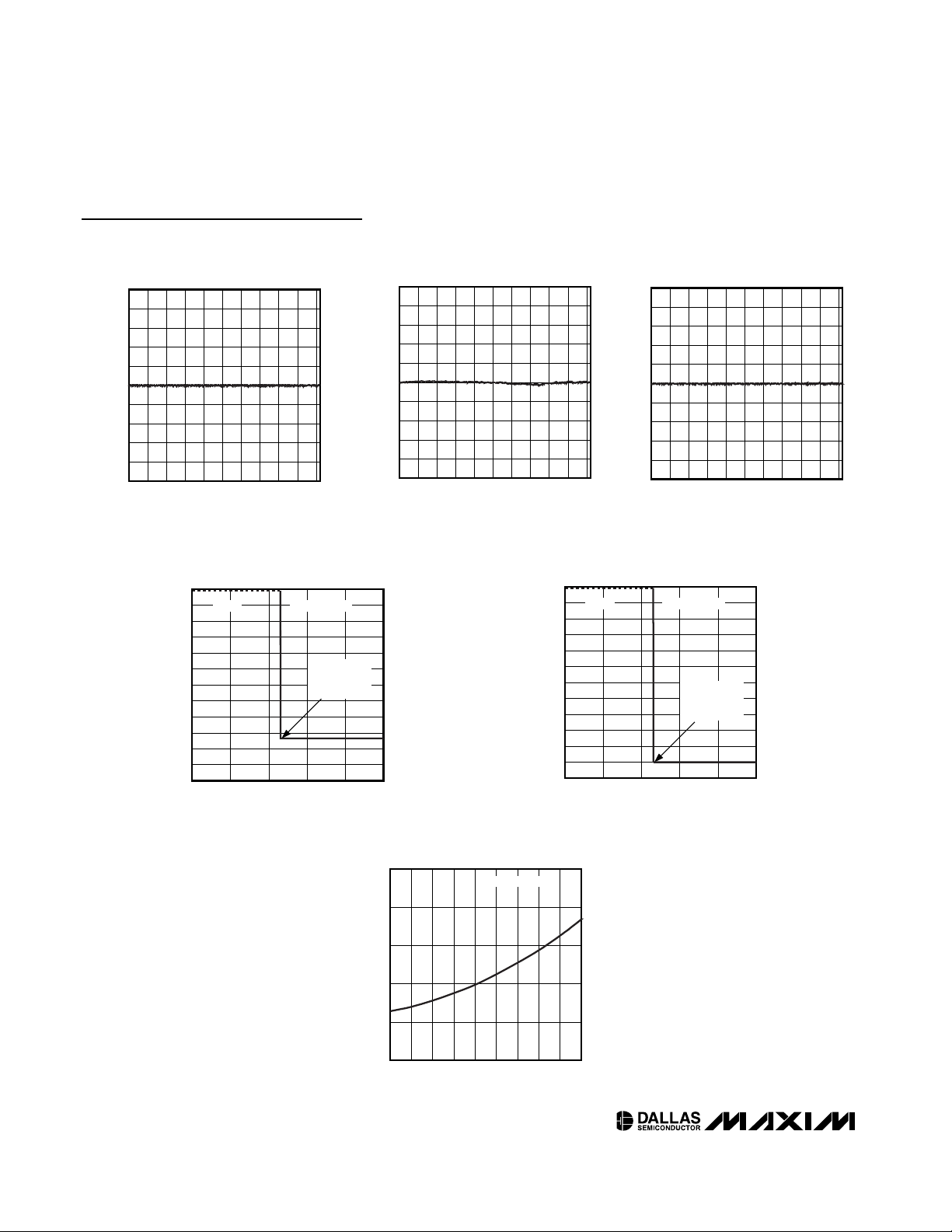

Typical Operating Characteristics (continued)

(VCC= 5.0V, TA= +25°C, for both 50kΩ and 20kΩ versions, unless otherwise noted.)

RESISTOR 0 DNL (LSB)

DS1859 toc07

SETTING (DEC)

RESISTOR 0 DNL (LSB)

225200150 17550 75 100 12525

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0 250

RESISTOR 1 INL (LSB)

DS1859 toc08

SETTING (DEC)

RESISTOR 1 INL (LSB)

225200150 17550 75 100 12525

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0 250

RESISTOR 1 DNL (LSB)

DS1859 toc09

SETTING (DEC)

RESISTOR 1 DNL (LSB)

225200150 17550 75 100 12525

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0 250

POSITION 00h RESISTANCE

vs. TEMPERATURE

DS1859 toc12

TEMPERATURE (°C)

RESISTANCE (kΩ)

20 35 50 65 805-10-25

0.96

0.97

0.98

0.99

1.00

0.95

-40 95

50kΩ VERSION

RESISTANCE

vs. POWER-UP VOLTAGE

DS1859 toc11

POWER-UP VOLTAGE (V)

RESISTANCE (kΩ)

2341

30

20

40

50

60

70

80

90

100

110

120

0

10

05

PROGRAMMED

RESISTANCE

(80h)

>1MΩ 20kΩ VERSION

RESISTANCE

vs. POWER-UP VOLTAGE

DS1859 toc10

POWER-UP VOLTAGE (V)

RESISTANCE (kΩ)

2341

30

20

40

50

60

70

80

90

100

110

120

0

10

05

PROGRAMMED

RESISTANCE

(80h)

>1MΩ 50kΩ VERSION

Page 7

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

_______________________________________________________________________________________ 7

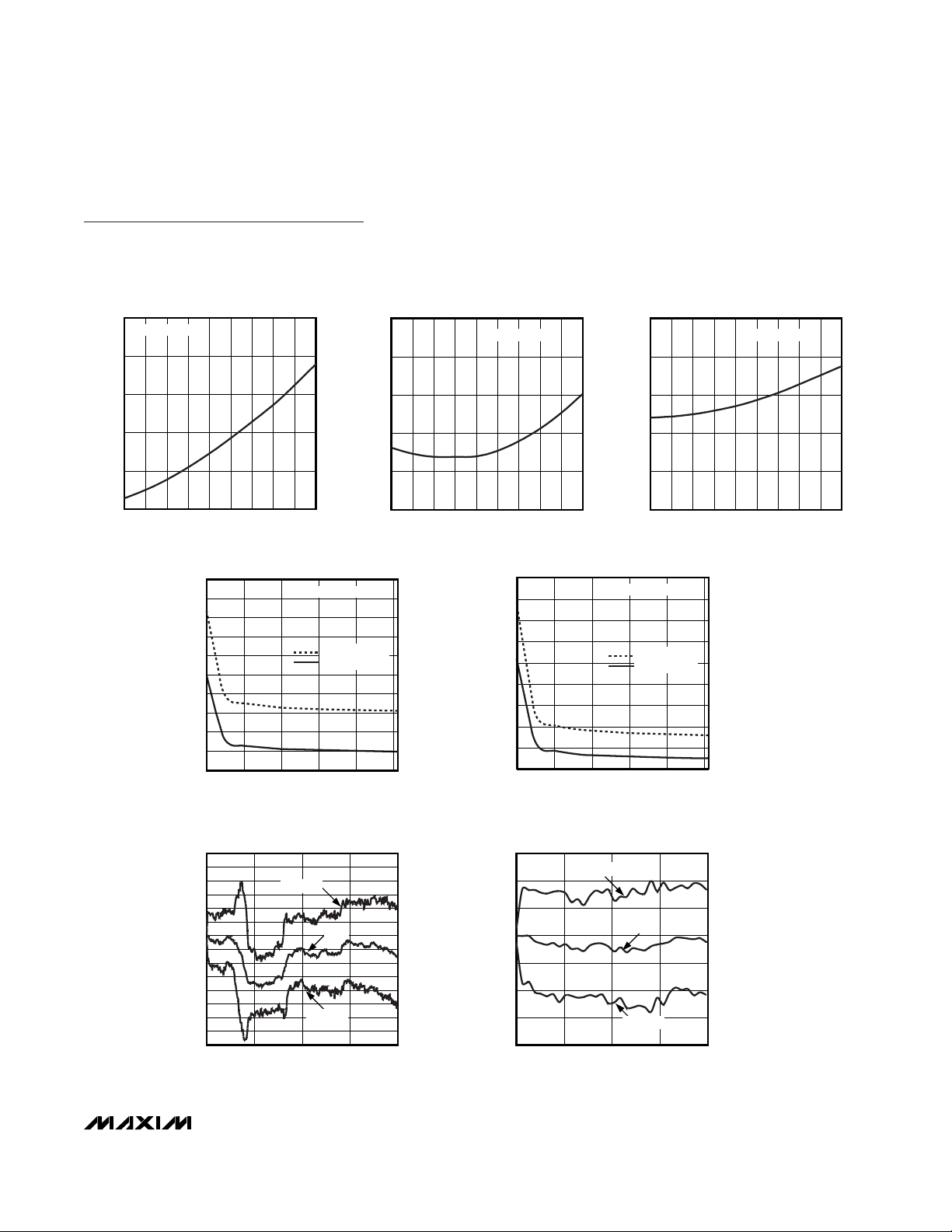

Typical Operating Characteristics (continued)

(VCC= 5.0V, TA= +25°C, for both 50kΩ and 20kΩ versions, unless otherwise noted.)

POSITION FFh RESISTANCE

vs. TEMPERATURE

DS1859 toc14

TEMPERATURE (°C)

RESISTANCE (kΩ)

80655035205-10-25

51.20

51.40

51.60

51.80

52.00

51.00

-40 95

50kΩ VERSION

POSITION FFh RESISTANCE

vs. TEMPERATURE

DS1859 toc15

TEMPERATURE (°C)

RESISTANCE (kΩ)

80655035205-10-25

19.20

19.40

19.50

19.80

20.00

19.00

-40 95

20kΩ VERSION

TEMPERATURE COEFFICIENT vs. SETTING

DS1859 toc16

SETTING (DEC)

TEMPERATURE COEFFICIENT (ppm/°C)

20015010050

100

50

0

-50

150

200

250

300

350

400

-100

0 250

50kΩ VERSION

+25°C TO +95°C

+25°C TO -40°C

TEMPERATURE COEFFICIENT vs. SETTING

DS1859 toc17

SETTING (DEC)

TEMPERATURE COEFFICIENT (ppm/°C)

20015010050

100

0

200

300

400

500

600

700

800

-100

0 250

+25°C TO +95°C

+25°C TO -40°C

20kΩ VERSION

LSB ERROR vs. FULL-SCALE INPUT

DS1859 toc18

NORMALIZED FULL SCALE (%)

LSB ERROR

755025

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

-8

0 100

+3 SIGMA

-3 SIGMA

MEAN

LSB ERROR vs. FULL-SCALE INPUT

DS1859 toc19

NORMALIZED FULL SCALE (%)

LSB ERROR

9.3756.2503.125

-3

-2

-1

0

1

2

3

-4

0 12.500

+3 SIGMA

-3 SIGMA

MEAN

POSITION 00h RESISTANCE

vs. TEMPERATURE

DS1859 toc13

TEMPERATURE (°C)

RESISTANCE (kΩ)

80655035205-10-25

0.34

0.35

0.36

0.37

0.38

0.33

-40 95

20kΩ VERSION

Page 8

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

8 _____________________________________________________________________

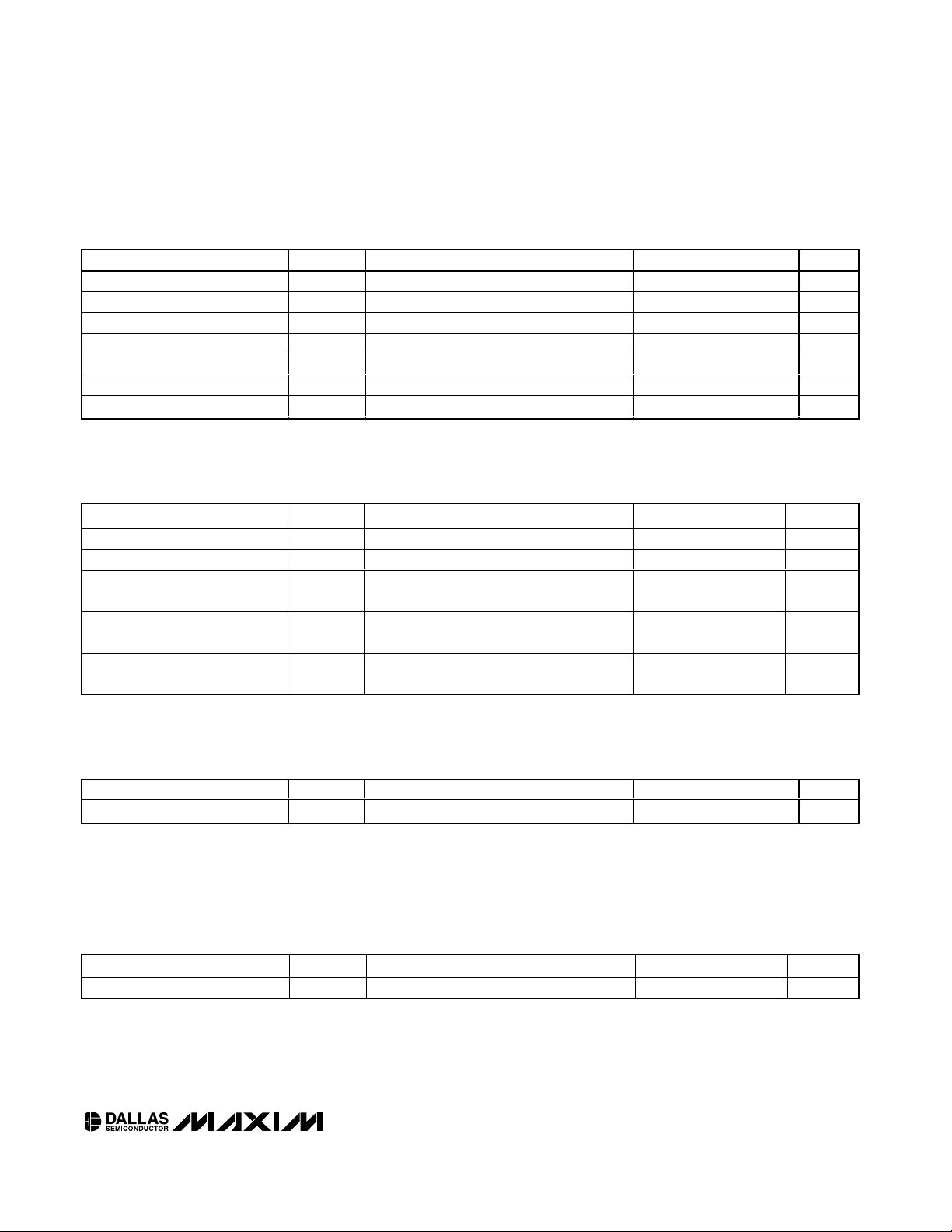

Detailed Description

The user can read the registers that monitor the VCC,

MON1, MON2, MON3, and temperature analog signals.

After each signal conversion, a corresponding bit is set

that can be monitored to verify that a conversion has

occurred. The signals also have alarm and warning flags

that notify the user when the signals go above or below

the user-defined value. Interrupts can also be set for

each signal.

The position values of each resistor can be independently programmed. The user can assign a unique

value to each resistor for every 2°C increment over the

-40°C to +102°C range.

Two buffers are provided to convert logic-level inputs

into open-drain outputs. Typically, these buffers are

used to implement transmit (Tx) fault and loss-of-signal

(LOS) functionality. Additionally, OUT1 can be asserted

in the event that one or more of the monitored values

go beyond user-defined limits.

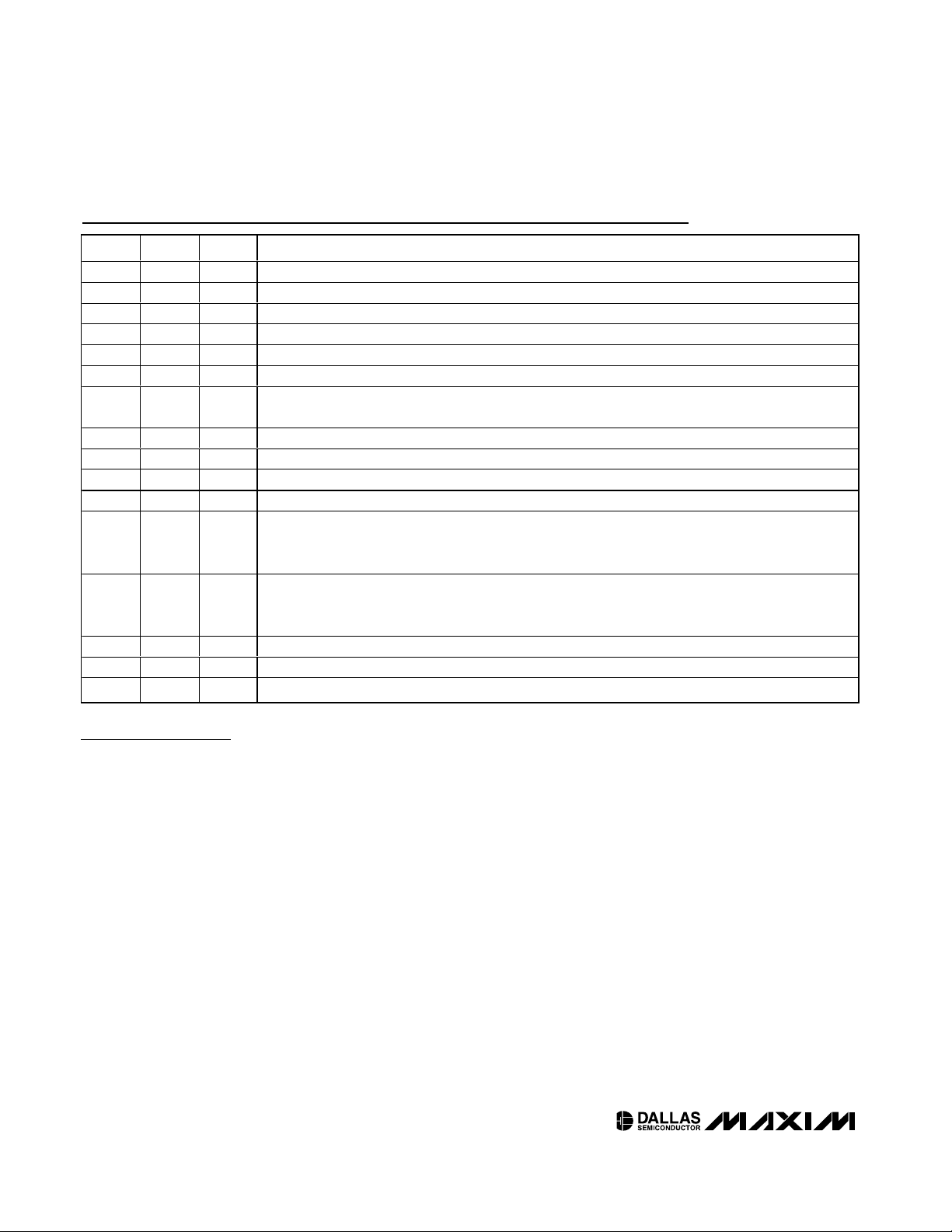

PIN

FUNCTION

1B2

2-Wire Serial Data I/O Pin. Transfers serial data to and from the device.

2A2SCL 2-Wire Serial Clock Input. Clocks data into and out of the device.

3C3

Open-Drain Buffer Output

4A1IN1 TTL/CMOS-Compatible Input to Buffer

5B1

Open-Drain Buffer Output

6C2IN2 TTL/CMOS-Compatible Input to Buffer

7C1

Write Protect Enable. The device is not write protected if WPEN is connected to ground. This pin has

an internal pullup (R

WPEN

). See Table 6.

8D1

Ground

9D3

External Analog Input

10 D4

External Analog Input

11 C4

External Analog Input

12 D2 L0

Low-End Resistor 0 Terminal. It is not required that the low-end terminals be connected to a potential

less than the high-end terminals of the corresponding resistor. Voltage applied to any of the resistor

terminals cannot exceed the power-supply voltage, V

CC

, or go below ground.

13 B3 H0

High-End Resistor 0 Terminal. It is not required that the high-end terminals be connected to a

potential greater than the low-end terminals of the corresponding resistor. Voltage applied to any of

the resistor terminals cannot exceed the power-supply voltage, V

CC

, or go below ground.

14 B4 L1 Low-End Resistor 1 Terminal

15 A4 H1 High-End Resistor 1 Terminal

16 A3 V

CC

Supply Voltage

Pin Description

BALL NAME

SDA

OUT1

OUT2

WPEN

GND

MON1

MON2

MON3

Page 9

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

_____________________________________________________________________ 9

DEVICE

ADDRESS

AD (AUXILIARY DEVICE ENABLE A0h)

MD (MAIN DEVICE ENABLE)

DEVICE ADDRESS

ADDRESS

ADDRESS

ADDRESS

R/W

R/W

TxF

DATA BUS

R/W

TxF

RxL

LOS

ADEN ADFIX

SDA

SCL

IN1

OUT1

2-WIRE

INTERFACE

MINT

INV1

Tx FAULT

IN2

MON2

MON1

MON3

V

CC

GND

WPEN

OUT2

INV2

EEPROM

128 x 8 BIT

00h-7Fh

STANDARDS

PROT

AUX

AD

ADDRESS

TABLE

SELECT

R/W

EEPROM

72 x 8 BIT

80h-C7h

TABLE 02

RESISTOR 0

LOOK-UP

TABLE

PROT

MAIN

MD

EEPROM

96 x 8 BIT

00h-5Fh

LIMITS

SRAM

32 x 8 BIT

60h-7Fh

NOT PROTECTED

PROT

MAIN

MD

TEMP INDEX

ALARM FLAGS

WARNING FLAGS

MUX

CTRL

MEASUREMENT

ADDRESS

TABLE

SELECT

R/W

EEPROM

72 x 8 BIT

80h-C7h

TABLE 03

RESISTOR 1

LOOK-UP

TABLE

PROT

MAIN

MD

TEMP INDEX

R

WPEN

MONITORS LIMIT

HIGH

MONITORS LIMIT

LOW

TABLE SELECT

TEMP INDEX

MINT (BIT)

INTERNAL

TEMP

V

CC

MUX

ADC

12-BIT

INTERNAL

CALIBRATION

A/D

CTRL

V

CC

V

CC

PROT AUX

PROT MAIN

MPEN

APEN

COMPARATOR

MEASUREMENT

ALARM FLAGS

WARNING FLAGS

MONITORS LIMIT LOW

MONITORS LIMIT HIGH

COMP CTRL

INTERRUPT

MINT

TABLE 01

EEPROM

16 x 8 BIT

80h-8Fh

VENDOR

PROT

MAIN

MD R/W

DEVICE ADDRESS

ADDRESS

TABLE SELECT

MASKING (TMP, V

CC

, MON1, MON2, MON3)

ADFIX (BIT)

ADEN (BIT)

MPEN (BIT)

APEN (BIT)

INV2 (BIT)

INV1 (BIT)

RESISTOR 0

50kΩ OR 20kΩ FULL SCALE

256 POSITIONS

L0

H0

REGISTERREGISTER

RESISTOR 1

50kΩ OR 20kΩ FULL SCALE

256 POSITIONS

L1

H1

RIGHT

SHIFTING

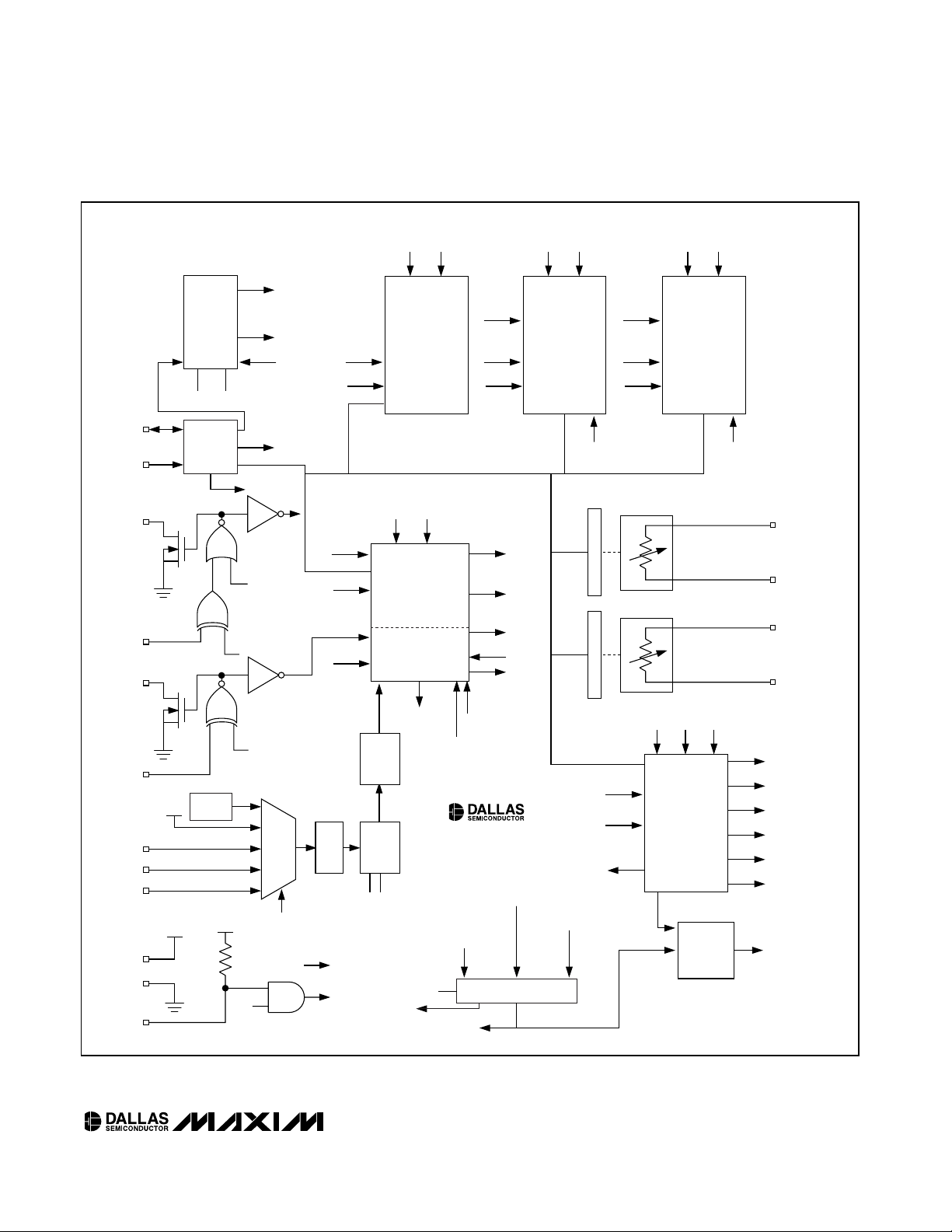

DS1859

Figure 1. Block Diagram

Page 10

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

10 ____________________________________________________________________

Monitored Signals

Each signal (VCC, MON1, MON2, MON3, and temperature) is available as a 16-bit value with 12-bit accuracy

(left-justified) over the serial bus. See Table 1 for signal

scales and Table 2 for signal format. The four LSBs

should be masked when calculating the value.

For the 20kΩ version, the 3 LSBs are internally masked

with 0s.

The signals are updated every frame rate (t

frame

) in a

round-robin fashion.

The comparison of all five signals with the high and low

user-defined values are done automatically. The corresponding flags are set to 1 within a specified time of

the occurrence of an out-of-limit condition.

Calculating Signal Values

The LSB = 100µV for VCC, and the LSB = 38.147µV for

the MON signals when using factory default settings.

To calculate VCC, convert the unsigned 16-bit value to

decimal and multiply by 100µV.

To calculate MON1, MON2, or MON3, convert the

unsigned 16-bit value to decimal and multiply by

38.147µV.

To calculate the temperature, treat the two’s complement value binary number as an unsigned binary number, then convert to decimal and divide by 256. If the

result is greater than or equal to 128, subtract 256 from

the result.

Temperature: high byte: -128°C to +127°C signed; low

byte: 1/256°C.

SIGNAL

+FS

+FS

-FS

-FS

(hex)

Temperature

-128°C 8000

V

CC

0V 0000

MON1

0V 0000

MON2

0V 0000

MON3

0V 0000

Table 1. Scales for Monitor Channels at

Factory Setting

SIGNAL FORMAT

V

CC

Unsigned

MON1 Unsigned

MON2 Unsigned

MON3 Unsigned

Temperature Two’s complement

Table 2. Signal Comparison

TEMPERATURE

(°C)

CORRESPONDING LOOK-UP

TABLE ADDRESS

<-40 80h

-40 80h

-38 81h

-36 82h

-34 83h

——

+98 C5h

+100 C6h

+102 C7h

>+102 C7h

Table 3. Look-up Table Address for

Corresponding Temperature Values

2

8

2

0

Monitor/VCCBit Weights

Temperature Bit Weights

Monitor Conversion Example

VCCConversion Examples

Temperature Conversion Examples

SIGNAL

127.984°C 7FFC

6.5528V FFF8

2.4997V FFF8

2.4997V FFF8

2.4997V FFF8

(hex)

SIGNAL

MSB (BIN) LSB (BIN) VOLTAGE (V)

11000000 00000000 1.875

10000000 10000000 1.255

S262

-1

2

-2

2

5

4

2

-3

2

-4

2

3

2

-5

2

2

2

-6

2

1

2

-7

2

0

2

-8

2

MSB 2

LSB 2

15214213212211210

7

MSB (BIN) LSB (BIN) VOLTAGE (V)

10000000 10000000 3.29

11000000 11111000 4.94

6

2

5

2

9

2

4

3

2

2

2

2

1

2

MSB (BIN) LSB (BIN) TEMPERATURE (°C)

01000000 00000000 64

01000000 00001111 64.059

01011111 00000000 95

11110110 00000000 -10

11011000 00000000 -40

Page 11

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

____________________________________________________________________ 11

Variable Resistors

The value of each variable resistor is determined by

a temperature-addressed look-up table, which can

assign a unique value (00h to FFh) to each resistor for

every 2°C increment over the -40°C to +102°C range

(see Table 3). See the Temperature Conversion section

for more information.

The variable resistors can also be used in manual

mode. If the TEN bit equals 0, the resistors are in manual mode and the temperature indexing is disabled. The

user sets the resistors in manual mode by writing to

addresses 82h and 83h in Table 01 to control resistors

0 and 1, respectively.

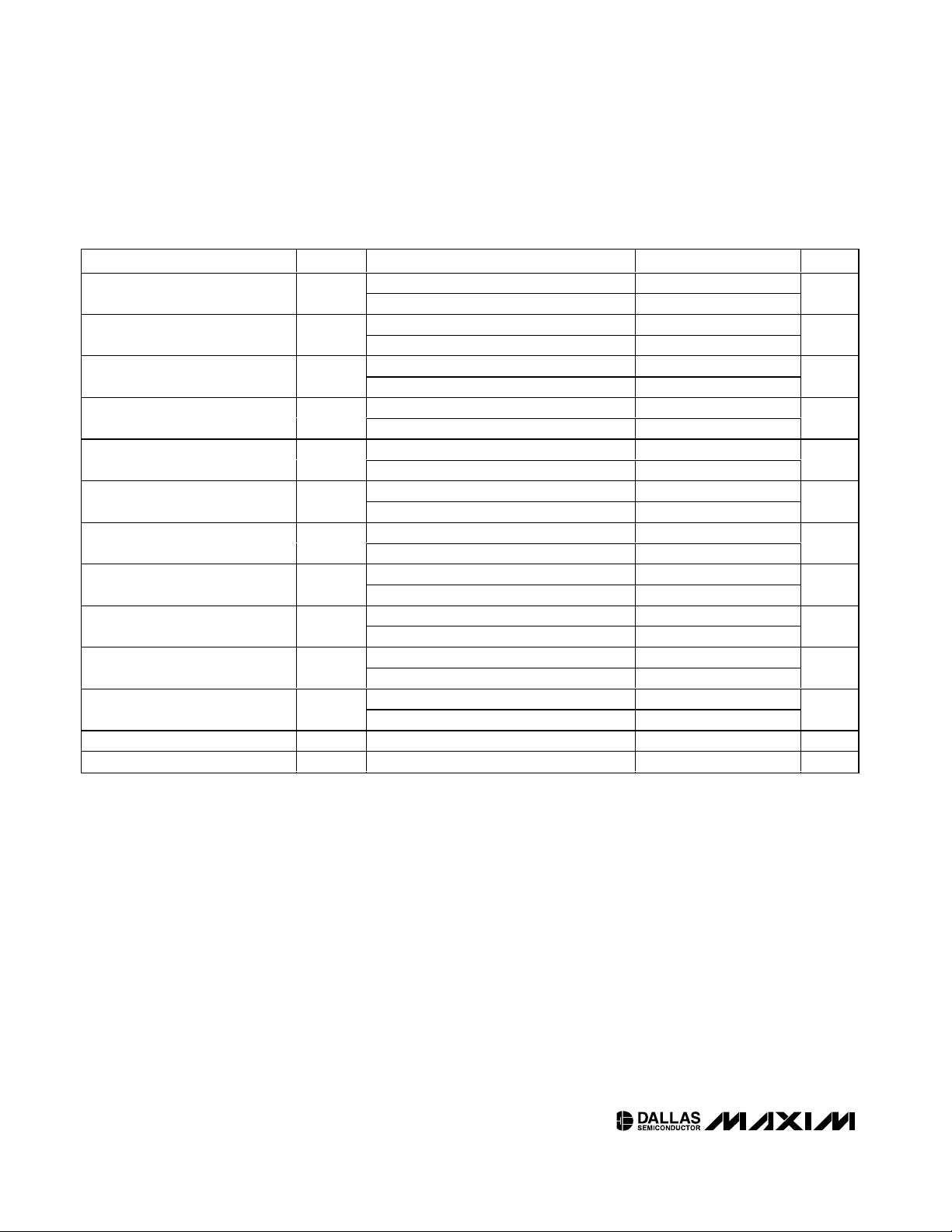

Memory Description

Main and auxiliary memories can be accessed by two

separate device addresses. The Main Device address

is A2h (or value in Table 01 byte 8Ch, when ADFIX = 1)

and the Auxiliary Device address is A0h. A user option

is provided to respond to one or two device addresses.

This feature can be used to save component count in

SFF applications (Main Device address can be used)

or other applications where both GBIC (Auxiliary

Device address can be used) and monitoring functions

are implemented and two device addresses are needed. The memory blocks are enabled with the corresponding device address. Memory space from 80h and

ADEN

(ADDRESS

ENABLE)

NO. OF SEPARATE

DEVICE

ADDRESSES

ADDITIONAL

INFORMATION

02See Figure 2

1

See Figure 3

Table 4. ADEN Address Configuration

ADEN ADFIX

AUXILIARY

MAIN ADDRESS

00A0h A2h

01A0h

EEPROM

(Table 01, 8Ch)

10N/A A2h

11N/A

EEPROM

(Table 01, 8Ch)

Table 5. ADEN and ADFIX Bits

MAIN

DEVICE

MON LOOK-UP

TABLE CONTROL

R0 LOOK-UP

TABLE

AUXILIARY

DEVICE

0

DEC

0

95

96

127

128

143

199

MEMORY PARTITION WITH ADEN BIT = 0

EN

EN

EN

5Fh

60h

EN

SEL

EN

SEL

7Fh 7Fh

80h

80h

C7h

F0h

FFh

RESERVED

8Fh

TABLE SELECT

MAIN DEVICE ENABLE

AUXILIARY DEVICE ENABLE

DECODER

0

F0h

FFh

RESERVED

R1 LOOK-UP

TABLE

EN

SEL

80h

C7h

TABLE 03TABLE 02TABLE 01

Figure 2. Memory Organization, ADEN = 0

1 (Main Device only)

ADDRESS

Page 12

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

12 ____________________________________________________________________

above is accessible only through the Main Device

address. This memory is organized as three tables. The

desired table can be selected by the contents of memory location 7Fh, Main Device. The Auxiliary Device

address has no access to the tables, but the Auxiliary

Device address can be mapped into the Main Device’s

memory space as a fourth table. Device addresses are

programmable with two control bits in EEPROM.

ADEN configures memory access to respond to different device addresses (see Tables 4 and 5).

The default device address for EEPROM-generated

addresses is A2h.

If the ADEN bit is 1, additional 128 bytes of EEPROM

are accessible through the Main Device, selected as

Table 00 (see Figure 3). In this configuration, the

Auxiliary Device is not accessible. APEN controls the

protection of Table 00 regardless of ADEN’s setting.

ADFIX (address fixed) determines whether the Main

Device address is determined by an EEPROM byte

(Table 01, byte 8Ch, when ADFIX = 1). There can be

up to 128 devices sharing a common 2-wire bus, with

each device having its own unique device address.

WPEN

MPEN PROTECT MAIN

0X No

X0 No

11 Yes

Table 6. Main Device

APEN

WPEN PROTECT AUXILIARY

0

XNo

1

X Yes

Table 7. Auxiliary Device

MAIN

DEVICE

MON LOOK-UP

TABLE CONTROL

R0 LOOK-UP

TABLE

AUXILIARY

DEVICE

80h

DEC

0

95

96

127

128

143

199

255

EN

EN

EN

5Fh

60h

EN

SEL

EN

SEL

FFh

7Fh

80h

80h

C7h

F0h

FFh

RESERVED

8Fh

TABLE SELECT

TABLE 00

MAIN DEVICE ENABLE

DECODER

0

F0h

FFh

RESERVED

R1 LOOK-UP

TABLE

EN

SEL

80h

C7h

TABLE 03TABLE 02TABLE 01

MEMORY PARTITION WITH ADEN BIT = 1

Figure 3. Memory Organization, ADEN = 1

Page 13

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

____________________________________________________________________ 13

MEMORY LOCATION

(hex)

EEPROM/SRAM

R/W

DEFAULT SETTING

(hex)

NAME OF LOCATION FUNCTION

00 to 7F EEPROM

00 Standards Data —

Auxiliary Device

MEMORY

LOCATION

(hex)

EEPROM/

SRAM

DEFAULT

(hex)

FUNCTION

00 to 01 EEPROM

00

Contains upper limit settings for temperature.

If the limit is violated, an alarm flag in Main

Device byte 70h is set.

02 to 03 EEPROM

00

Contains lower limit settings for temperature. If

the limit is violated, an alarm flag in Main

Device byte 70h is set.

04 to 05 EEPROM

00

Contains upper limit settings for temperature.

If the limit is violated, a warning flag in Main

Device byte 74h is set.

06 to 07 EEPROM

00

Contains lower limit settings for temperature. If

the limit is violated, a warning flag in Main

Device byte 74h is set.

08 to 09 EEPROM

00

Contains upper limit settings for VCC. If the

limit is violated, an alarm flag in Main Device

byte 70h is set.

0A to 0B EEPROM

00

Contains lower limit settings for VCC. If the

limit is violated, an alarm flag in Main Device

byte 70h is set.

0C to 0D EEPROM

00

Contains upper limit settings for VCC. If the

limit is violated, a warning flag in Main Device

byte 74h is set.

0E to 0F EEPROM

00

Contains lower limit settings for VCC. If the

limit is violated, a warning flag in Main Device

byte 74h is set.

10 to 11 EEPROM

00

Contains upper limit settings for MON1. If the

limit is violated, an alarm flag in Main Device

byte 70h is set.

Main Device

Note: SRAM defaults are power-on defaults. EEPROM defaults are factory defaults.

Register Map

A description of the registers is below. The registers

are read only (R) or read/write (R/W). The R/W registers

are writable only if write protect has not been asserted

(see the Memory Description section).

Bytes designated as "Reserved" have been set aside

for added functionality in future revisions of this device.

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

SETTING

NAME OF LOCATION

TMPlimhi (MSB to LSB)

TMPlimlo (MSB to LSB)

TMPwrnhi (MSB to LSB)

TMPwrnlo (MSB to LSB)

VCClimhi (MSB to LSB)

VCClimlo (MSB to LSB)

VCCwrnhi (MSB to LSB)

VCCwrnlo (MSB to LSB)

MON1limhi (MSB to LSB)

Page 14

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

14 ____________________________________________________________________

MEMORY

LOCATION

(hex)

EEPROM/

SRAM

R/W

DEFAULT

(hex)

NAME OF LOCATION

FUNCTION

12 to 13 EEPROM

00

Contains lower limit settings for MON1. If the

limit is violated, an alarm flag in Main Device

byte 70h is set.

14 to 15 EEPROM

00

MON1wrnhi

(MSB to LSB)

Contains upper limit settings for MON1. If the

limit is violated, a warning flag in Main Device

byte 74h is set.

16 to 17 EEPROM

00

MON1wrnlo

(MSB to LSB)

Contains lower limit settings for MON1. If the

limit is violated, a warning flag in Main Device

byte 74h is set.

18 to 19 EEPROM

00

Contains upper limit settings for MON2. If the

limit is violated, an alarm flag in Main Device

byte 70h is set.

1A to 1B EEPROM

00

Contains lower limit settings for MON2. If the

limit is violated, an alarm flag in Main Device

byte 70h is set.

1C to 1D EEPROM

00

MON2wrnhi

(MSB to LSB)

Contains upper limit settings for MON2. If the

limit is violated, a warning flag in Main Device

byte 74h is set.

1E to 1F EEPROM

00

MON2wrnlo

(MSB to LSB)

Contains lower limit settings for MON2. If the

limit is violated, a warning flag in Main Device

byte 74h is set.

20 to 21 EEPROM

00

Contains upper limit settings for MON3. If the

limit is violated, an alarm flag in Main Device

byte 71h is set.

22 to 23 EEPROM

00

Contains lower limit settings for MON3. If the

limit is violated, an alarm flag in Main Device

byte 71h is set.

24 to 25 EEPROM

00

MON3wrnhi

(MSB to LSB)

Contains upper limit settings for MON3. If the

limit is violated, a warning flag in Main Device

byte 75h is set.

26 to 27 EEPROM

00

MON3wrnlo

(MSB to LSB)

Contains lower limit settings for MON3. If the

limit is violated, a warning flag in Main Device

byte 75h is set.

28 to 37 EEPROM — — Reserved —

38 to 5F EEPROM

— Memory —

60 to 61 SRAM R —

Measured TMP

(MSB to LSB)

Digitized measured value for temperature.

See Table 1.

62 to 63 SRAM R —

Measured V

CC

(MSB to LSB)

Digitized measured value for V

CC

.

See Table 1.

64 to 65 SRAM R —

Measured MON1

(MSB to LSB)

Digitized measured value for MON1.

See Table 1.

66 to 67 SRAM R —

Measured MON2

(MSB to LSB)

Digitized measured value for MON2.

See Table 1.

Main Device (continued)

SETTING

R/W

MON1limlo (MSB to LSB)

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

MON2limhi (MSB to LSB)

MON2limlo (MSB to LSB)

MON3limhi (MSB to LSB)

MON3limlo (MSB to LSB)

Page 15

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

____________________________________________________________________ 15

MEMORY

LOCATION

(hex)

EEPROM/

SRAM

DEFAULT

(hex)

FUNCTION

68 to 69 SRAM R —

Measured MON3

(MSB to LSB)

Digitized measured value for MON3.

See Table 1.

6A to 6D SRAM — — Reserved —

6E SRAM — — Logic states —

Bit 7 — R X HIZSTA

Resistor status bit. A high indicates that both

resistors are in high-impedance mode. A low

indicates that both resistors are operating

normally.

6—

0 HIZCO

Resistor control bit. Setting this bit high

causes both resistors to go into a highimpedance state.

5——X X —

4——X X —

3——X X —

2—RX TXF

This status bit is high when OUT1 is high,

assuming there is an external pullup resistor

on OUT1.

1—RX RXL

This status bit is high when OUT2 is high,

assuming there is an external pullup resistor

on OUT2.

0—RX RDYB

This status bit goes high when V

CC

has fallen

below the POA level.

6F SRAM — — Conversion updates —

Bit 7 —

0 TAU

This bit goes high after a temperature and

address update has occurred for the

corresponding measurement in bytes 60h to

61h. This bit can be written to a 0 by the user

and monitored to verify that a conversion has

occurred.

6—

0V

CC

U

This bit goes high after a V

CC

update has

occurred for the corresponding measurement

in bytes 62h to 63h. This bit can be written to

a 0 by the user and monitored to verify that a

conversion has occurred.

5—

0 MON1U

This bit goes high after a MON1 update has

occurred for the corresponding measurement

in bytes 64h to 65h. This bit can be written to

a 0 by the user and monitored to verify that a

conversion has occurred.

Main Device (continued)

R/W

R/W

R/W

SETTING

NAME OF LOCATION

R/W

R/W

Page 16

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

16 ____________________________________________________________________

MEMORY

LOCATION

(hex)

EEPROM/

SRAM

R/W

DEFAULT

(hex)

NAME OF LOCATION

FUNCTION

4—

0 MON2U

This bit goes high after a MON2 update has

occurred for the corresponding measurement

in bytes 66h to 67h. This bit can be written to

a 0 by the user and monitored to verify that a

conversion has occurred.

3——0 MON3U

This bit goes high after a MON3 update has

occurred for the corresponding measurement

in bytes 68h to 69h. This bit can be written to

a 0 by the user and monitored to verify that a

conversion has occurred.

2——0 — —

1——0 — —

0——0 — —

70 SRAM R Alarm flags —

Bit 7 — — — TMPhi

This alarm flag goes high when the upper limit

of the temperature setting is violated.

6——— TMPlo

This alarm flag goes high when the lower limit

of the temperature setting is violated.

5——— V

CC

hi

This alarm flag goes high when the upper limit

of the V

CC

setting is violated.

4——— V

CC

lo

This alarm flag goes high when the lower limit

of the V

CC

setting is violated.

3——— MON1hi

This alarm flag goes high when the upper limit

of the MON1 setting is violated.

2——— MON1lo

This alarm flag goes high when the lower limit

of the MON1 setting is violated.

1——— MON2hi

This alarm flag goes high when the upper limit

of the MON2 setting is violated.

0——— MON2lo

This alarm flag goes high when the lower limit

of the MON2 setting is violated.

71 SRAM R — Alarm flags —

Bit 7 — — — MON3hi

This alarm flag goes high when the upper limit

of the MON3 setting is violated.

6——— MON3lo

This alarm flag goes high when the lower limit

of the MON3 setting is violated.

5——— X —

4——— X —

Main Device (continued)

SETTING

R/W

Page 17

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

____________________________________________________________________ 17

MEMORY

LOCATION

(hex)

EEPROM/

SRAM

R/W

DEFAULT

(hex)

NAME OF LOCATION

FUNCTION

3——— X —

2——— X —

1——— X —

0——— MINT

A mask of all flags located in Table 01 byte

88h determines the value of MINT. MINT is

maskable to 0 if no interrupt is desired by

setting Table 01 byte 88h to 0.

72 to 73 SRAM — — Reserved —

74 SRAM R — Warning flags —

Bit 7 — — — TMPhi

This warning flag goes high when the upper

limit of the temperature setting is violated.

6——— TMPlo

This warning flag goes high when the lower

limit of the temperature setting is violated.

5——— V

CC

hi

This warning flag goes high when the upper

limit of the V

CC

setting is violated.

4——— V

CC

lo

This warning flag goes high when the lower

limit of the V

CC

setting is violated.

3——— MON1hi

This warning flag goes high when the upper

limit of the MON1 setting is violated.

2——— MON1lo

This warning flag goes high when the lower

limit of the MON1 setting is violated.

1——— MON2hi

This warning flag goes high when the upper

limit of the MON2 setting is violated.

0——— MON2lo

This warning flag goes high when the lower

limit of the MON2 setting is violated.

Main Device (continued)

SETTING

Page 18

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

18 ____________________________________________________________________

MEMORY

LOCATION

(hex)

EEPROM/

SRAM

R/W

DEFAULT

(hex)

NAME OF LOCATION

FUNCTION

75 SRAM R — Warning Flags —

Bit 7 — — 0 MON3hi

This warning flag goes high when the upper

limit of the MON3 setting is violated.

6——0 MON3lo

This warning flag goes high when the lower

limit of the MON3 setting is violated.

5——0 X —

4——0 X —

3——0 X —

2——0 X —

1——0 X —

76 to 7E SRAM — — Reserved —

7F SRAM

— Table select —

Bit 7 — — 0 X —

6——0 X —

5——0 X —

4——0 X —

3——0 X —

2——0 X —

1——0

0——0

Table select bits

Set bits = 00 to select Table 00, set bits = 01

to select Table 01, set bits = 10 to select

Table 02, set bits = 11 to select Table 03.

Main Device (continued)

SETTING

R/W

Page 19

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

____________________________________________________________________ 19

MEMORY

LOCATION

(hex)

EEPROM/

SRAM

R/W

DEFAULT

SETTING

(hex)

NAME OF

LOCATION

FUNCTION

80 SRAM R/W Mode —

Bit 7 — — 0 X —

6——0 X —

5——0 X —

4——0 X —

3——0 X —

2——0 X —

1——1 TEN

If TEN = 0, the resistors can be controlled manually. The

user sets the resistor in manual mode by writing to

addresses 82h and 83h in Table 01 to control resistors 0

and 1, respectively.

0——1 AEN

AEN = 0 is a test mode setting and provides manual

control of the temperature index (Table 01, address 81h).

81 SRAM R —

Temperature

index

This byte is the temperature-calculated index used to

select the address of resistor settings in the look-up

tables (Tables 02 and 03, addresses 80h through C7h).

82 SRAM R/W FF Resistor 0 Resistor 0 position values from 00h to FFh.

83 SRAM R/W FF Resistor 1 Resistor 1 position values from 00h to FFh.

84 to 87 SRAM — — Reserved —

88

R/W

This byte configures a maskable interrupt, determining

which event asserts a buffer 1 output (MINT set to 1, see

register 89h in Table 01). If any combination of

temperature, V

CC

, MON1, MON2, or MON3 is desired to

generate an interrupt, the corresponding bits are set to 1.

If interrupt generation is not desired, set all bits to 0.

Bit 7 — — 1 TMP —

6——1 V

CC

—

5——1 MON1 —

4——1 MON2 —

3——1 MON3 —

2——0 X —

1——0 X —

0——0 X —

89

R/W Configuration —

Bit 7 — — 0 X —

6——0 X

Table 01h

EEPROM

EEPROM

Interrupt enable

Page 20

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

20 ____________________________________________________________________

MEMORY

LOCATION

(hex)

EEPROM/

SRAM

R/W

DEFAULT

SETTING

(hex)

NAME OF

LOCATION

FUNCTION

5——0 ADEN

Controls if the device responds to one or two device

addresses (see the Memory Description section and

Table 5).

4——0 ADFIX

Controls the means by which Main and Auxiliary Device

addresses are set (see the Memory Description section

and Table 5).

3——0 APEN

Controls auxiliary write protect. See the Memory

Description section.

2——0 MPEN

Controls main write protect. See the Memory Description

section.

1——0 INV1

Configures buffer 1 with OUT1 = MINT +

(INV1 [XOR] IN1).

0——0 INV2 Configures buffer 2 with OUT2 = INV2 [XOR] IN2.

8A to 8B

—— Reserved

8C

R/W A2

Contains Main Device address if the bit ADFIX = 1. If

ADFIX = 0, then address A2h is used.

8D

—— Reserved —

8E

R/W

Contains bits used to perform right shift operations on the

A/D output converter. See the Right Shift A/D Conversion

Result section.

7——0 —

6——0 MON1

2

Right Shift Control MSB

5——0 MON1

1

4——0 MON1

0

Right Shift Control LSB

3——0 —

2——0 MON2

2

Right Shift Control MSB

1——0 MON2

1

0——0 MON2

0

Right Shift Control LSB

8F

R/W

Contains bits used to perform right shift operations on the

A/D output converter. See the Right Shift A/D Conversion

Result section.

7——0 —

6——0 MON3

2

Right Shift Control MSB

5——0 MON3

1

4——0 MON3

0

Right Shift Control LSB

3——0 —

2——0 —

1——0 —

0——0 —

Table 01h (continued)

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

Device address

Page 21

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

____________________________________________________________________ 21

MEMORY

LOCATION

(hex)

EEPROM/

SRAM

R/W

DEFAULT

SETTING

(hex)

NAME OF

LOCATION

FUNCTION

90 to 91

—0 Reserved

92 to 93

R/W Gain Cal V

CC

Gain registers for internal calibration. See the Internal

Calibration section.

94 to 95

R/W

96 to 97

R/W

98 to 99

R/W

9A to 9F

— Reserved

A0 to A1

— Reserved

A2 to A3

R/W

Offset registers for internal calibration.

See the Internal Calibration section.

A4 to A5

R/W

A6 to A7

R/W

A8 to A9

R/W

AA to AD

— Reserved

AE to AF

R/W

Factory

Offset calibration for temperature calibrated at factory.

Table 01h (continued)

MEMORY

LOCATION

(hex)

EEPROM/

SRAM

R/W

DEFAULT

SETTING

(hex)

NAME OF LOCATION FUNCTION

80 to C7

R/W FF Resistor 0 Temp LUT Look-up table for Resistor 0.

F0 to F7

—— Reserved —

F8 to FF

R

Factory

Resistor 0 Cal Constants

Calibration constants for Resistor 0.

(See Table 8)

Table 02h

MEMORY

LOCATION

(hex)

EEPROM/

SRAM

R/W

DEFAULT

SETTING

(hex)

NAME OF LOCATION FUNCTION

80 to C7

R/W FF Resistor 1 Temp LUT Look-up table for Resistor 1.

F0 to F7

—— Reserved —

F8 to FF

R

Factory

Resistor 1 Cal Constants

Calibration constants for Resistor 1.

(See Table 8)

Table 03h

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

EEPROM

Programmed

Gain Cal Mon1

Gain Cal Mon2

Gain Cal Mon3

Offset Cal V

Offset Cal Mon1

Offset Cal Mon2

Offset Cal Mon3

Offset Cal Tmp

CC

EEPROM

EEPROM

EEPROM

EEPROM

Programmed

Programmed

Page 22

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

22 ____________________________________________________________________

Programming the Look-up Table (LUT)

The following equation can be used to determine which

resistor position setting, 00h to FFh, should be written in

the LUT to achieve a given resistance at a specific temperature.

α = 3.852357 for the 20kΩ resistor

α = 4.5680475 for the 50kΩ resistor

R = the resistance desired at the output terminal

C = temperature in degrees Celsius

u, v, w, x

1

, x0, y, and z are calculated values found in the

corresponding look-up tables. The variable x from the

equation above is separated into x1(the MSB of x) and x

0

(the LSB of x). Their addresses and LSB values are given

below. Resistor 0 variables are found in Table 1, and

Resistor 1 variables are found in Table 2.

When shipped from the factory, all other memory locations in the LUTs are programmed to FFh.

Table 8. Calibration Constants

Internal Calibration

The DS1859 has two methods for scaling an analog

input to a digital result. The two methods are gain and

offset. Each of the inputs (V

CC

, MON1, MON2, and

MON3) has a unique register for the gain and the offset

found in Table 01h, 92h to 99h, and A2h to A9h.

To scale the gain and offset of the converter for a specific input, you must first know the relationship between

the analog input and the expected digital result. The

input that would produce a digital result of all zeros is

the null value (normally this input is GND). The input

that would produce a digital result of all ones is the fullscale (FS) value. The FS value is also found by multiplying an all-ones digital answer by the weighted LSB

(e.g., since the digital reading is a 16-bit register, let us

assume that the LSB of the lowest weighted bit is

50µV, then the FS value is 65,535 x 50µV = 3.27675V).

A binary search is used to scale the gain of the converter. This requires forcing two known voltages to the

input pin. It is preferred that one of the forced voltages

is the null input and the other is 90% of FS. Since the

LSB of the least significant bit in the digital reading register is known, the expected digital results are also

known for both inputs (null/LSB = CNT1 and 90%FS/

LSB = CNT2).

The user might not directly force a voltage on the input.

Instead they have a circuit that transforms light, frequency, power, or current to a voltage that is the input

to the DS1859. In this situation, the user does not need

to know the relationship of voltage to expected digital

result but instead knows the relationship of light, frequency, power, or current to the expected digital result.

pos R C

Ru v C w C

xyC zC

α, α,

•• •

•• •

()

=

−+ −

()

+−

()

()

+−

()

+−

()

−

125 25

125 25

2

2

M6

M5

M4

M3

M2

M1

246810 12

TEMPERATURE (°C)

MEMORY LOCATION

INCREASING

TEMPERATURE

DECREASING

TEMPERATURE

Figure 4. Look-Up Table Hysteresis

ADDRESS (Hex)

VARIABLE LSB

F8 u 2

0

F9 v 20E-6

FA w 100E-9

FB x

1

2

1

FC x

0

2

-7

FD y 2E-6 (signed)

FE z 10E-9

FF Reserved —

Page 23

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

____________________________________________________________________ 23

An explanation of the binary search used to scale the

gain is best served with the following example pseudocode:

/* Assume that the Null input is 0.5V. */

/* In addition, the requirement for LSB is 50µV. */

FS = 65535 x 50E-6; /* 3.27675 */

CNT1 = 0.5 / 50E-6; /* 10000 */

CNT2 = 0.90 x FS / 50E-6; /* 58981.5 */

/* Thus the null input 0.5V and the 90% of FS input is

2.949075V. */

Set the trim-offset-register to zero;

Set Right-Shift register to zero (typically zero.

See Right-Shifting section);

gain_result = 0h;

Clamp = FFF8h/2^(Right_Shift_Register);

For n = 15 down to 0

begin

gain_result = gain_result + 2^n;

Force the 90% FS input (2.949075V);

Meas2 = read the digital result from

the part;

If Meas2 >= Clamp then

gain_result = gain_result – 2^n;

Else

Force the null input (0.5V);

Meas1 = read the digital result from

the part;

if (Meas2 – Meas1) > (CNT2 –

CNT1) then

gain_result = gain_result – 2^n;

end;

Set the gain register to gain_result;

The gain register is now set and the resolution of the

conversion will best match the expected LSB. The next

step is to calibrate the offset of the DS1859. With the

correct gain value written to the gain register, again

force the null input to the pin. Read the digital result

from the part (Meas1). The offset value is equal to the

negative value of Meas1.

The calculated offset is now written to the DS1859 and

the gain and offset scaling is now complete.

Right-Shifting A/D Conversion Result

(Scalable Dynamic Ranging)

The right-shifting method is used to regain some of the

lost ADC range of a calibrated system. If a system is

calibrated such that the maximum expected input

results in a digital output value of less than 7FFFh (1/2

FS), then it is a candidate for using the right-shifting

method.

If the maximum desired digital output is less than 7FFFh,

then the calibrated system is using less than 1/2 of the

ADC’s range. Similarly, if the maximum desired digital

output is less than 1FFFh, then the calibrated system is

only using 1/8 of the ADC’s range. For example, if using

a zero for the right-shift during internal calibration and

the maximum expected input results in a maximum digital output less than 1FFCh, only 1/8 of the ADC’s range is

used. If left like this, the three MS bits of the ADC will

never be used. In this example, a value of 3 for the rightshifting will maximize the ADC range. No resolution is

lost since this is a 12-bit converter that is left justified.

The value can be right-shifted four times without losing

resolution. Table 9 shows when the right-shifting method

can be used.

Memory Protection

Memory access from either device address can be

either read/write or read only. Write protection

is accomplished by a combination of control bits in

EEPROM (APEN and MPEN in configuration register

89h) and a write-protect enable (WPEN) pin. Since the

WPEN pin is often not accessible from outside the module, this scheme effectively allows the module to be

locked by the manufacturer to prevent accidental writes

by the end user.

Separate write protection is provided for the Auxiliary

and Main Device address through distinct bits APEN

and MPEN. APEN and MPEN are bits from configuration register 89h, Table 01. Due to the location, the

APEN and MPEN bits can only be written through the

Offset gister h

Meas

XOR h_Re =−

[]

4000

1

2

4000

OUTPUT RANGE USED

WITH ZERO RIGHT-SHIFTS

NUMBER OF

RIGHT-SHIFTS NEEDED

0h .. FFFFh 0

0h .. 7FFFh 1

0h .. 3FFFh 2

0h .. 1FFFh 3

0h .. 0FFFh 4

Table 9. Right Shifting

Page 24

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

24 ____________________________________________________________________

Main Device address. The control of write privileges

through the Auxiliary Device address depends on the

value of APEN. Care should be taken with the setting of

MPEN, once set to a 1, assuming WPEN is high.

Access through the Main Device is thereafter denied

unless WPEN is taken to a low level. By this means,

inadvertent end-user write access can be denied.

Main Device address space 60h to 7Fh is SRAM and is

not write protected by APEN, MPEN, or WPEN. For

example, the user may reset flags set by the device.

Note that in single device mode (ADEN bit = 1), APEN

determines the protection level of Table 00, independent of WPEN.

The write-protect operation, for both Main and Auxiliary

Devices, is summarized in Tables 6 and 7.

Temperature Conversion

The direct-to-digital temperature sensor measures temperature through the use of an on-chip temperature

measurement technique with an operating range from

-40°C to +102°C. Temperature conversions are initiated

upon power-up, and the most recent conversion is

stored in memory locations 60h and 61h of the Main

Device, which are updated every t

frame

. Temperature

conversions do not occur during an active read or write

to memory.

The value of each resistor is determined by the temperature-addressed look-up table. The look-up table assigns

a unique value to each resistor for every 2°C increment

with a 1°C hysteresis at a temperature transition over the

operating temperature range (see Figure 4).

Power-Up and Low-Voltage Operation

During power-up, the device is inactive until V

CC

exceeds the digital power-on-reset voltage (POD). At this

voltage, the digital circuitry, which includes the 2-wire

interface, becomes functional. However, EEPROMbacked registers/settings cannot be internally read

(recalled into shadow SRAM) until VCCexceeds the analog power-on-reset voltage (POA), at which time the

remainder of the device becomes fully functional. Once

VCCexceeds POA, the RDYB bit in byte 6Eh of the Main

Device memory is timed to go from a 1 to a 0 and indicates when analog-to-digital conversions begin. If V

CC

ever dips below POA, the RDYB bit reads as a 1 again.

Once a device exceeds POA and the EEPROM is

recalled, the values remain active (recalled) until VCCfalls

below POD.

For 2-wire device addresses sourced from EEPROM

(ADFIX = 1), the device address defaults to A2h until V

CC

exceeds POA and the EEPROM values are recalled. The

Auxiliary Device (A0h) is always available within this volt-

age window (between POD and the EEPROM recall)

regardless of the programmed state of ADEN.

Furthermore, as the device powers up, the V

CC

lo alarm

flag (bit 4 of 70h in Main Device) defaults to a 1 until the

first VCCanalog-to-digital conversion occurs and sets or

clears the flag accordingly.

2-Wire Operation

Clock and Data Transitions: The SDA pin is normally

pulled high with an external resistor or device. Data on

the SDA pin may only change during SCL-low time

periods. Data changes during SCL-high periods will

indicate a START or STOP condition depending on the

conditions discussed below. See the timing diagrams

in Figures 5 and 6 for further details.

START Condition: A high-to-low transition of SDA with

SCL high is a START condition that must precede any

other command. See the timing diagrams in Figures 5

and 6 for further details.

STOP Condition: A low-to-high transition of SDA with

SCL high is a STOP condition. After a read or write

sequence, the stop command places the DS1859 into a

low-power mode. See the timing diagrams in Figures 5

and 6 for further details.

Acknowledge: All address and data bytes are transmitted through a serial protocol. The DS1859 pulls the

SDA line low during the ninth clock pulse to acknowledge that it has received each word.

Standby Mode: The DS1859 features a low-power

mode that is automatically enabled after power-on,

after a STOP command, and after the completion of all

internal operations.

Device Addressing: The DS1859 must receive an 8-bit

device address following a START condition to enable

a specific device for a read or write operation. The

address is clocked into this part MSB to LSB. The

address byte consists of either A2h or the value in

Table 01 8Ch for the Main Device or A0h for the

Auxiliary Device, then the R/W bit. This byte must

match the address programmed into Table 01 8Ch or

A0h (for the Auxiliary Device). If a device address

match occurs, this part will output a zero for one clock

cycle as an acknowledge and the corresponding block

of memory is enabled (see the Memory Organization

section). If the R/W bit is high, a read operation is initiated. If the R/W is low, a write operation is initiated (see

the Memory Organization section). If the address does

not match, this part returns to a low-power mode.

Page 25

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

____________________________________________________________________ 25

Write Operations

After receiving a matching address byte with the R/W

bit set low, if there is no write protect, the device goes

into the write mode of operation (see the Memory

Organization section). The master must transmit an 8bit EEPROM memory address to the device to define

the address where the data is to be written. After the

byte has been received, the DS1859 transmits a zero

for one clock cycle to acknowledge the address has

been received. The master must then transmit an 8-bit

data word to be written into this address. The DS1859

again transmits a zero for one clock cycle to acknowledge the receipt of the data. At this point, the master

must terminate the write operation with a STOP condition. The DS1859 then enters an internally timed write

process twto the EEPROM memory. All inputs are disabled during this byte write cycle.

Page Write

The DS1859 is capable of an 8-byte page write. A page

is any 8-byte block of memory starting with an address

evenly divisible by eight and ending with the starting

address plus seven. For example, addresses 00h

through 07h constitute one page. Other pages would

be addresses 08h through 0Fh, 10h through 17h, 18h

through 1Fh, etc.

A page write is initiated the same way as a byte write,

but the master does not send a STOP condition after

the first byte. Instead, after the slave acknowledges the

data byte has been received, the master can send up

to seven more bytes using the same nine-clock

sequence. The master must terminate the write cycle

with a STOP condition or the data clocked into the

DS1859 will not be latched into permanent memory.

The address counter rolls on a page during a write. The

counter does not count through the entire address

space as during a read. For example, if the starting

address is 06h and 4 bytes are written, the first byte

goes into address 06h. The second goes into address

07h. The third goes into address 00h (not 08h). The

fourth goes into address 01h. If more than 9 bytes or

more are written before a STOP condition is sent, the

first bytes sent are overwritten. Only the last 8 bytes of

data are written to the page.

Acknowledge Polling: Once the internally timed write

has started and the DS1859 inputs are disabled,

acknowledge polling can be initiated. The process

involves transmitting a START condition followed by the

device address. The R/W bit signifies the type of operation that is desired. The read or write sequence will only

be allowed to proceed if the internal write cycle has

completed and the DS1859 responds with a zero.

Read Operations

After receiving a matching address byte with the R/W bit

set high, the device goes into the read mode of operation. There are three read operations: current address

read, random read, and sequential address read.

Current Address Read

The DS1859 has an internal address register that maintains the address used during the last read or write

STOP

CONDITION

OR REPEATED

START

CONDITION

REPEATED IF MORE BYTES

ARE TRANSFERRED

ACK

START

CONDITION

ACK

ACKNOWLEDGEMENT

SIGNAL FROM RECEIVER

ACKNOWLEDGEMENT

SIGNAL FROM RECEIVER

SLAVE ADDRESS

MSB

SCL

SDA

R/W

DIRECTION

BIT

12 678 9 12 893–7

Figure 5. 2-Wire Data Transfer Protocol

Page 26

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

26 ____________________________________________________________________

operation, incremented by one. This data is maintained

as long as VCCis valid. If the most recent address was

the last byte in memory, then the register resets to the

first address.

Once the device address is clocked in and acknowledged by the DS1859 with the R/W bit set to high, the

current address data word is clocked out. The master

does not respond with a zero, but does generate a

STOP condition afterwards.

Single Read

A random read requires a dummy byte write sequence to

load in the data byte address. Once the device and data

address bytes are clocked in by the master and acknowledged by the DS1859, the master must generate another

START condition. The master now initiates a current

address read by sending the device address with the

R/W bit set high. The DS1859 acknowledges the device

address and serially clocks out the data byte.

Sequential Address Read

Sequential reads are initiated by either a current

address read or a random address read. After the master receives the first data byte, the master responds

with an acknowledge. As long as the DS1859 receives

this acknowledge after a byte is read, the master can

clock out additional data words from the DS1859. After

reaching address FFh, it resets to address 00h.

The sequential read operation is terminated when the

master initiates a STOP condition. The master does not

respond with a zero.

The following section provides a detailed description of

the 2-wire theory of operation.

2-Wire Serial-Port Operation

The 2-wire serial-port interface supports a bidirectional

data transmission protocol with device addressing. A

device that sends data on the bus is defined as a transmitter, and a device that receives data as a receiver.

The device that controls the message is called a master. The devices that are controlled by the master are

slaves. The bus must be controlled by a master device

that generates the serial clock (SCL), controls the bus

access, and generates the START and STOP conditions. The DS1859 operates as a slave on the 2-wire

bus. Connections to the bus are made through the

open-drain I/O lines SDA and SCL. The following I/O

terminals control the 2-wire serial port: SDA, SCL.

Timing diagrams for the 2-wire serial port can be found

in Figures 5 and 6. Timing information for the 2-wire

serial port is provided in the AC Electrical

Characteristics table for 2-wire serial communications.

The following bus protocol has been defined:

◆ Data transfer may be initiated only when the bus is

not busy.

◆ During data transfer, the data line must remain

stable whenever the clock line is high. Changes in

SDA

SCL

t

HD:STA

t

LOW

t

HIGH

t

R

t

F

t

BUF

t

HD:DAT

t

SU:DAT

REPEATED

START

t

SU:STA

t

HD:STA

t

SU:STO

t

SP

STOP START

Figure 6. 2-Wire AC Characteristics

Page 27

DS1859

Dual, Temperature-Controlled Resistors with

Internally Calibrated Monitors

____________________________________________________________________ 27

the data line while the clock line is high will be

interpreted as control signals.

Accordingly, the following bus conditions have been

defined:

Bus not busy: Both data and clock lines remain high.

Start data transfer: A change in the state of the data

line from high to low while the clock is high defines a

START condition.

Stop data transfer: A change in the state of the data

line from low to high while the clock line is high defines

the STOP condition.

Data valid: The state of the data line represents valid

data when, after a START condition, the data line is stable for the duration of the high period of the clock signal.

The data on the line can be changed during the low period of the clock signal. There is one clock pulse per bit of

data. Figures 5 and 6 detail how data transfer is accomplished on the 2-wire bus. Depending on the state of the

R/W bit, two types of data transfer are possible.

Each data transfer is initiated with a START condition

and terminated with a STOP condition. The number of

data bytes transferred between START and STOP conditions is not limited and is determined by the master

device. The information is transferred byte-wise and

each receiver acknowledges with a ninth bit.

Within the bus specifications, a standard mode

(100kHz clock rate) and a fast mode (400kHz clock

rate) are defined. The DS1859 works in both modes.

Acknowledge: Each receiving device, when addressed,

is obliged to generate an acknowledge after the byte

has been received. The master device must generate an

extra clock pulse, which is associated with this acknowledge bit.

A device that acknowledges must pull down the SDA line

during the acknowledge clock pulse in such a way that

the SDA line is a stable low during the high period of the

acknowledge-related clock pulse. Setup and hold times

must be taken into account. A master must signal an end

of data to the slave by not generating an acknowledge bit

on the last byte that has been clocked out of the slave. In

this case, the slave must leave the data line high to

enable the master to generate the STOP condition.

1) Data transfer from a master transmitter to a

slave receiver. The first byte transmitted by the

master is the command/control byte. Next follows

a number of data bytes. The slave returns an

acknowledge bit after each received byte.

2) Data transfer from a slave transmitter to a mas-

ter receiver. The master transmits the first byte

(the command/control byte) to the slave. The

slave then returns an acknowledge bit. Next follows a number of data bytes transmitted by the

slave to the master. The master returns an

acknowledge bit after all received bytes other

than the last byte. At the end of the last received

byte, a not acknowledge can be returned.

The master device generates all serial clock pulses and

the START and STOP conditions. A transfer is ended with

a STOP condition or with a repeated START condition.

Since a repeated START condition is also the beginning

of the next serial transfer, the bus is not released.

The DS1859 can operate in the following three modes:

1) Slave Receiver Mode: Serial data and clock are

received through SDA and SCL, respectively. After

each byte is received, an acknowledge bit is transmitted. START and STOP conditions are recognized as the beginning and end of a serial transfer.

Address recognition is performed by hardware

after the slave (device) address and direction bit

have been received.

2) Slave Transmitter Mode: The first byte is

received and handled as in the slave receiver

mode. However, in this mode the direction bit

indicates that the transfer direction is reversed.

Serial data is transmitted on SDA by the DS1859,

while the serial clock is input on SCL. START and

STOP conditions are recognized as the beginning

and end of a serial transfer.

3) Slave Address: Command/control byte is the first

byte received following the START condition from

the master device. The command/control byte

consists of 4-bit control code. They are used by

the master device to select which of eight possible devices on the bus is to be accessed. When

reading or writing to the DS1859, the deviceselect bits must match one of two valid device

addresses, 00h or the address registered in Table

01 location 8Ch. The last bit of the command/control byte (R/W) defines the operation to be performed. When set to a ‘1’ a read operation is

selected, and when set to a ‘0’ a write operation is

selected. The slave address can be set by the

EEPROM. Following the START condition, the

DS1859 monitors the SDA bus checking the

device type identifier being transmitted. Upon

receiving the 1010 control code, the appropriate

device address bits, and the read/write bit, the