Page 1

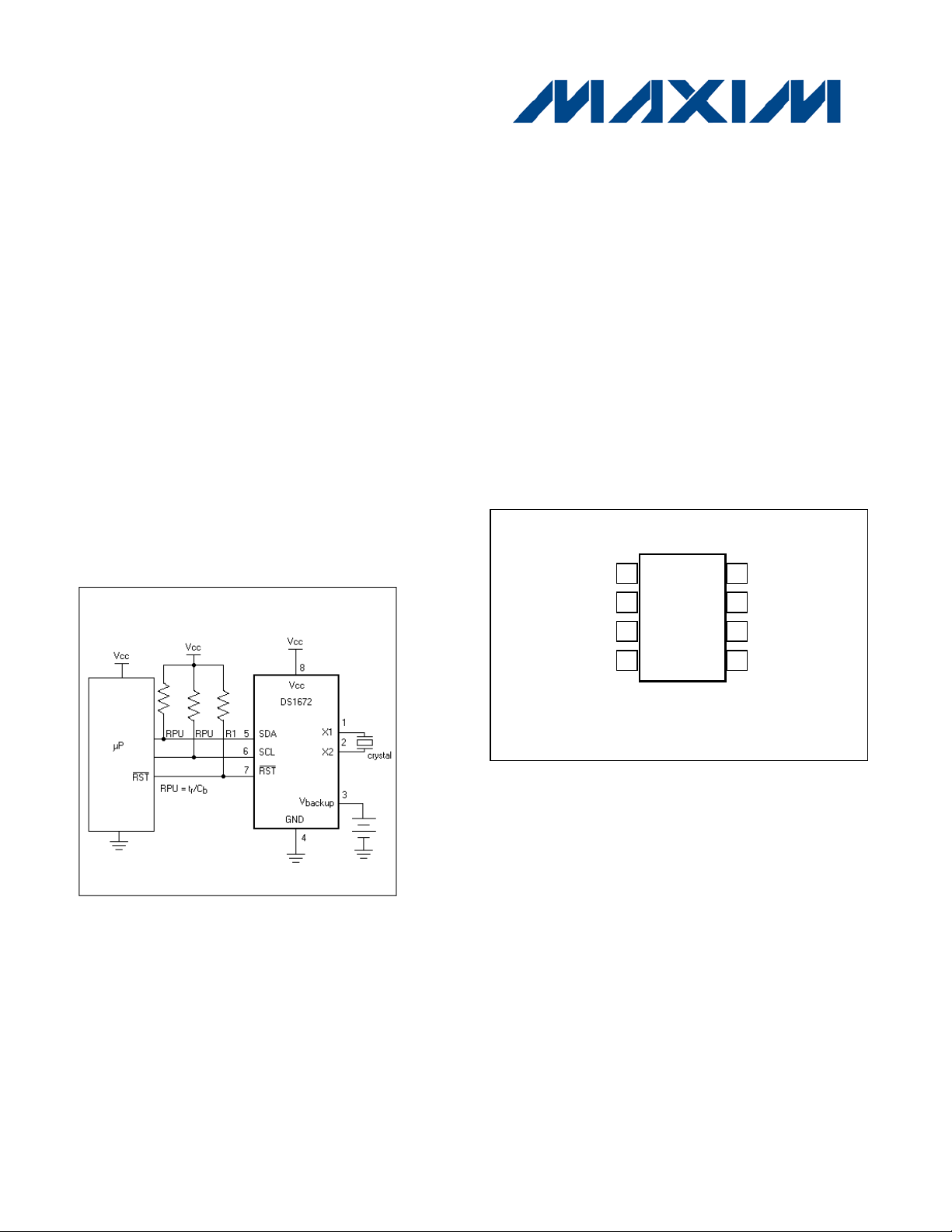

TYPICAL OPERATING CIRCUIT

PDIP

µ

TOP VIEW

1

2 3 4 8 7 6 5

VCC

RST

SCL

SDA

X1

X2

V

BACKUP

GND

DS1672

DS1672

I2C 32-Bit Binary Counter RTC

19-6032; Rev 9/11

GENERAL DESCRIPTION

The DS1672 incorporates a 32-bit counter and

power-monito ring funct ions. The 32-bit counter

is designed to count seconds and can be used to

derive time-of-day, week, month, month, and

year by using a software a lgorithm. A p re c is io n,

temperature-compensated reference and

comparator circuit monitors the status of VCC.

When an out-of-tolerance condition occurs, an

inte r na l powe r -fail signal is generated that for ces

the reset to the active stat e. When VCC r eturns to

an in-tolerance cond ition, the reset signal is kept

in the active state for a period of time to allow

the power supply and processor to stabilize.

FEATURES

32-Bit Counter

I2C Serial Interface

Automatic Power -Fail Detect and Switch

Circuitry

Power-Fail Res e t Output

Low-Voltage Oscillator Operat ion

(1.3V min)

Trickle-C harge Capability

Underwriters Labor at or ies (UL) Recog nized

-40°C to +85°C Operating Range

PIN CONFIGURATION

.

SO

SOP

1 of 15

Page 2

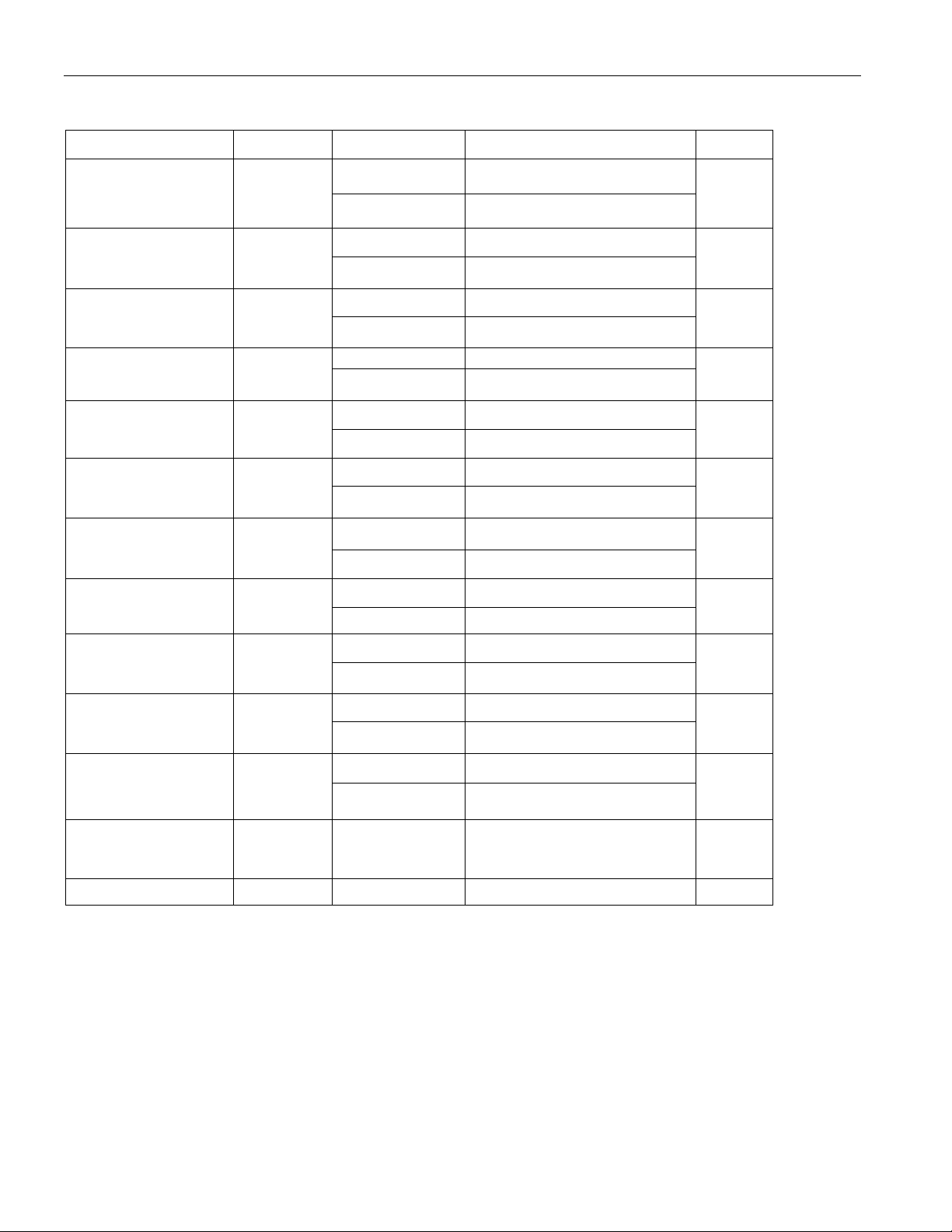

ORDERING INFORMATION

8 SO (150 mils)/Tape

and Reel

8 SO (150 mils)/Tape

and Reel

1672

rr -2

1672

rr -3

1672

rr -33

8 µSOP(3mm)/Tape

and Reel

1672

rr -33

PART TEMP RANGE VOLTAGE (V) PIN-PACKAGE TOP MARK*

DS1672-2+ -40°C to +85°C 2.0 8 PDIP (300 mils) DS1672-2

DS1672-3+ -40°C to +85°C 3.0 8 PDIP (300 mils) DS1672-3

DS1672-33+ -40°C to +85°C 3.3 8 PDIP (300 mils) DS1672-33

DS1672S-2+ -40°C to +85°C 2.0 8 SO (150 mils) D1672-2

DS1672S-3+ -40°C to +85°C 3.0 8 SO (150 mils) D1672-3

DS1672S-33+ -40°C to +85°C 3.3 8 SO (150 mils) D167233

DS1672

DS1672S-3+T&R -40°C to +85°C 3.0

DS1672S-33+T&R -40°C to +85°C 3.3

DS1672U-2+ -40°C to +85°C 2.0

DS1672U-3+ -40°C to +85°C 3.0

DS1672U-33+ -40°C to +85°C 3.3

8 µSOP(3mm)

8 µSOP(3mm)

8 µSOP(3mm)

DS1672U-33+T&R -40°C to +85°C 3.3

+ Denotes a lead-free/RoHS-compliant de vice.

* A “+” anywh er e on the top mark deno t es a lea d-free device. rr = 2-digit alphanumeric revision code.

D1672-3

D167233

2 of 15

Page 3

DS1672

DS1672-2

VCC

1.8

2.0

5.5

DS1672-3

VCC

2.7

3.0

5.5

DS1672-33

VCC

2.97

3.3

5.5

Logic 1

VIH

0.7 x VCC

V

CC

+ 0.5

V

Logic 0

VIL

-0.5

+0.3 x VCC

V

Backup Supply Voltage

V

BACKUP

1.3

3.0

3.63

V

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Active Supply Current

I

-2: VCC = 2.2V

600

µA

-3: VCC = 3.3V

-33: VCC = 3.63V

Standby C urrent

I

-2: VCC = 2.2V

500

µA

-3: VCC = 3.3V

-33: VCC = 3.63V

Power-F ail Vo ltage

VPF

-2:

2.70

2.88

2.97

V

-3:

2.45

2.60

2.70

-33:

1.58

1.70

1.80

V

BACKUP

L eakage Curre n t

I

BACKUPLKG

25

50

nA

Logic 0 Output (Note 4)

IOL

VOL = 0.4V

3

mA

Logic 0 Output (Note 4,

IOL

VCC > 2 V; VOL = 0.4V

3

mA

VCC < 2 V; VOL = VCC

* 0.2

ABSOLUTE MAXIMUM RATINGS

Voltage Range on Any Pin Relat ive to Ground……………………………………………..-0.5V to +6.0V

Operating Temperature Range (noncondensing) ...…………………………………………-40°C to +85°C

Storage Temperature Range……………………………………………………………….-55°C to +125°C

Soldering Temperature (reflow)………………………………………….…………………. +260°C

Lead Temperature (soldering, 10s) ……………………………………………………………….. +260°C

This is a stress rating only and functional operation of the device at these or any other conditions beyond those indicated in the operation

sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods of time can affect device

reliability.

RECOMMENDED OPERATING CONDITIONS

(TA = -40°C to +85°C) (Note 1)

PARAMETER SYMBOL MIN TYP MAX UNITS

Supply

Voltage

Note 1: All voltages referenced to ground.

DC ELECTRICAL CHARACTERISTICS

(V

(Note 2)

(Note 3)

CCMIN

< VCC < V

CCMAX, TA

= -40°C to +85°C.) (Note 1)

CCA

CCS

V

DS1672-2 Onl y)

Note 1: All voltages referenced to ground.

Note 2: I

Note 3: I

Note 4: SDA and RST.

specified with SCL clocking at max frequency (400kHz), trickle charger disabled.

CCA

specified with VCC = V

CCS

and SDA, SCL = V

CCTYP

, tr ickle charger disabled.

CCTYP

3 of 15

Page 4

DC ELECTRICAL CHARACTERISTICS

V

BACKUP

Cu rrent (Oscillator On)

I

BACKUPOSC

0.425

1

µA

V

BACKUP

Current (Oscillator Off)

I

BACKUP

200

nA

Nomi nal Frequency

fO

32.768

kHz

Series Resistanc e

ESR

45

kΩ

Load Capacitance

CL 6 pF

(VCC = 0V, TA = -40°C to +85°C.) (Note 5)

PARAMETER SYMBOL MIN TYP MAX UNITS

Note 5: Using the recommended crystal on X1 and X2.

CRYSTAL SPECIFICATIONS

PARAMETER SYMBOL MIN TYP MAX UNITS

*The crystal, traces, and crystal input pins should be isolated from RF generating signals. Refer to Application Note 58: Crystal

Considerations for Dallas Real -Time Clocks for additional specifications

*

DS1672

4 of 15

Page 5

AC ELECTRICAL CHARACTERISTICS

Bus Free T ime

START Condition

Hold Time

Condition (Note 6 )

Fast mode

1.3

Setup Time for a

Condition

Rise T ime of B oth

Signals (Note 10)

Fall Time of Both

Signals (Note 10)

Ca pacitive Load for

(Note 10)

(VCC = 0V, TA = -40°C to +85°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DS1672

SCL Clock

Frequency

Bet ween a STOP a nd

(R epeated) STA RT

LOW Peri od of SCL

Clock

HIGH Period of SCL

Clock

Repea ted ST ART

Data Hol d Time

(Notes 7, 8)

Data Setup Time

(Note 9)

f

SCL

t

BUF

t

HD:STA

t

LOW

t

HIGH

t

SU:STA

t

HD:DAT

t

SU:DAT

Fast mode 100 400

Standard mod e 100

Fast mode 1.3

Standard mod e 4.7

Fast mode 0.6

Standard mod e 4.0

Standard mod e 4.7

Fast mode 0.6

Standard mod e 4.0

Fast mode 0.6

Standard mod e 4.7

Fast mode 0 0.9

Standard mod e 0

Fast mode 100

Standard mod e 250

kHz

µs

µs

µs

µs

µs

µs

ns

Fast mode 20 + 0.1CB 300

SDA and SC L

SDA and SC L

t

tF

R

Standard mod e 1000

Fast mode 20 + 0.1C

300

B

Standard mod e 300

Setup Time for STOP

Condition

Each Bus Line

I/O Capacitance C

Note 6: After this period, the first clock pulse is generated.

Note 7: A device must internally provide a hold time of at least 300ns for the SDA signal (referenced to the V

order to br i dge the undefined r egion of the fallin g edge of SC L.

Note 8:The maximum t

Note 9: A fast-mode device can be used in a standard-mode system, but the requirement t

automatically be the case if the device does not stretch the LOW period of the SCL signal. If such a device does stretch the LOW

period of the SCL signal, it must output the next data bit to the SDA line t

line is relea sed.

Note 10: C

–Total capacitance of one bus line in pF.

B

HD:DAT

t

SU:STO

CB 400 pF

I/O

has only to be met if the device does not stretch the LOW period (t

Fast mode 0.6

Standard mod e 4.0

10 pF

) of th e SCL sign al.

LOW

≥ to 250ns must then be met. This will

SU:DAT

m ax + t

R

= 1000 + 250 = 1250ns before the SCL

SU:DAT

ns

ns

µs

of the SCL signal) in

IHMIN

5 of 15

Page 6

POWER-UP/POWER-DOWN CHARACTERISTICS

VCC Detec t to RST (VCC Rising)

(Note 11)

SCL

START

SDA

STOP

t

BUF

REPEATED

START

t

HD:STA

t

LOW

t

HD:STA

t

HD:DAT

t

SU:DAT

t

HIGH

t

SU:STA

t

F

t

SU:STO

OUTPUTS

VCC

V

PF(max)

INPUTS

HIGH IMPEDANCE

RST

DON'T CARE

VALID

RECOGNIZED

RECOGNIZED

VALID

t

RPD

V

PF(min)

tF

tPD

tR

t

RPU

(TA = -40°C to +85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS

DS1672

VCC Detec t to RST (VCC Falling) t

VCC Fa ll Time; V

PF(MAX)

VCC Ri se Tim e; V

Note 11: If the EOSC bit in the control register is set to logic 1, t

PF(MIN)

to V

to V

tF 300

PF(MIN)

tR 0

PF(MAX)

10 µs

RPD

t

250 ms

RPU

is equal to 250ms plus the startup time of the crystal oscillator.

RPU

µs

µs

Warning: Negative undershoots below –0.3V while the part is in battery-backed mode can cause

loss of data.

Figure 1. Ti m i ng Dia gr am

Figure 2. Power-Up/Power-Down Timing

6 of 15

Page 7

PIN DESCRIPTION

Connections for Standard 32.768kHz Quartz Crystal. The internal oscillator

co nnected to the exte rnal oscillator s igna l and t he X2 p in is left uncon nect ed.

Battery Input for Any Standard 3V L ithiu m Cel l or Ot her E nergy Source.

of Acceptability” at www.maxim-ic.com/qa/info/ul.

Serial-Data Input/O utput. SDA is the input/out put pin for the I2C s er ial

interface. The SDA pin is open dra in and requires an external pullup resistor.

I2C Serial-Clock Input. SCL is used to synchronize data movement on the

serial interface and requ ires an ext er nal pullup r es i stor.

Active-Lo w Reset Output. It functions as a micro processor reset signal. This

Power pin for Primary Po w er Supply. W hen VCC is applie d with in no rmal

VCC is belo w VPF, reads and writes are inhibited.

Figure 3. Recommended Layout for Crystal

LOCAL GROUND PLANE (LAYER 2)

CRYSTAL

X1

X2

GND

PIN NAME FUNCTION

circuitry is designed for operation with a crystal having a specified load

capacitance (CL) o f 6pF. For more information about crysta l select ion and

1, 2 X1, X2

crystal layout considerations, refer to Application Note 58: Crystal

Considerations with Dallas Real-Time Clocks. The DS1672 can also be driven

by an external 32.768kHz oscillator. In this configuration, the X1 pin is

Battery voltage must be held between 1.3V and 3.63V for proper operation.

Diodes placed in series between t he power source and the V

3 V

BACKUP

result in improper operation. If a backup supply is not required, V

be grounded. UL recognized to ensure against reverse charging curr ent whe n

used in conjunct ion with a lithium battery (charger disabled). S ee “Cond it io ns

4 GND Ground.

5 SDA

BACKUP

DS1672

pin ma y

BACKUP

must

6 SCL

7 RST

8 VCC

pin is an open-drain output and requires an external pullup resistor.

limits, the device is fully access ib le and dat a can b e wr itten and read. When

7 of 15

Page 8

DS1672

PARAMETER

SYMBOL

MIN

TYP

MAX

UNITS

NOTES

Nominal Frequency

FO

32.768

kHz

Series Resistance

ESR

45

kΩ

Load Capacitance

CL 6 pF

32-Bit Counter

(4 Bytes)

I2C Interface

Power Control

Address Register

Control Logic

1Hz

V

CC

V

BACKUP

GND

SCL

SDA

Control

Trickle Charger

X1 X2

RST

Dallas

Semiconductor

DS1672

C

L

C

L

N

Oscillator

and

divider

Detailed Description

The DS1672 provides a 32-bit co unter that inc reme nts onc e-per-second. The counter data is accessible

via an I2C serial interface. A precision, temperature-compensated, voltage reference and comparator

cir cu it mo nit or s VCC. Whe n VCC drops below VPF, RST becomes act ive and the interface is d isa bled t o

prevent data corruption. The device switches to the backup supply input, which maintains oscillator and

counter operation while VCC is absent . When VCC r ises above VPF, RST remains low for a period of time

(t

) to allow VCC to stabilize.

RPU

The block diagram in Figure 4 shows the main elements of the DS1672. As shown, communications to

and from the DS1672 occur ser ially o ver a I2C, bid irect ional bus. T he DS1672 o perat es as a s lave dev ice

on the I2C bus. Access is obtained by implementing a START condition and providing a device

identificat ion code fo llowed by a register add ress. Subseque nt reg isters can be accessed seque nt ially unt il

a STOP condition is executed.

Figure 4. Block Diagram

Oscillator Circuit

The DS1672 uses an external 32.768kHz crysta l. The oscillator circu it does not require any external

resistors or capac itor s to o per at e. Table 1 specifies severa l cr yst al parameters for the external crysta l.

Figure 4 shows a functional sc hematic of the oscillator circuit. If using a cr ystal with the specif ied

characterist ics, the startup time is usually less than one second.

Table 1. Crystal Specifications*

* The crystal, traces, and crystal input pins should be isolated from RF gen erating signals. Refer to Application Note 58:

Clock Accur acy

The accuracy o f the clock is dependent upon the accuracy o f the crystal and the accurac y of the match

between the capacitive load of the oscillator circuit and the capacitive load for which the crystal was

8 of 15

Page 9

DS1672

ADDRESS

B7

B6

B5

B4

B3

B2

B1

B0

FUNCTION

00h

LSB

Counter Byte 1

01h

Counter Byte 2

02h

Counter Byte 3

03h

MSB Counter Byte 4

04h

EOSC

Control

05h

TCS

TCS

TCS

TCS

DS

DS

RS

RS

Trick le Ch arger

READ/WRITE

ACCESS

RST

VCC < VPF, VCC < V

BACKUP

No

Active

V

BACKUP

VCC < VPF, VCC > V

BACKUP

No

Active

VCC

VCC > VPF, VCC < V

BACKUP

Yes

Inactive

VCC

VCC > VPF, VCC > V

BACKUP

Yes

Inactive

VCC

trimmed. Additional error will be added by crystal frequency drift caused by temperature shifts. External

circuit noise coup led into the oscillator circuit may result in the clock running fast . Refer to Application

Note 5: “Crystal Considerations with Dallas Real-Time Clocks” for detailed information.

Address Map

The counter is accessed by reading or writing the first 4 bytes of the DS1672 (00h–03h) . The co ntrol

register and t rick le charger are ac cessed by r eadin g o r writ ing the appr op riate r egister b ytes as illustr at ed

in Table 2. If the master co ntinues to send or request more d ata after the address pointer has reached 05h,

the address pointer w ill wrap aro und to location 00h.

Table 2. Reg isters

Power Control

The device is fully accessible and data can be written and ready only when VCC is greater than VPF.

Ho weve r, whe n VCC falls below VPF, (point at which write prot ection occurs) t he internal clock reg ister s

are blocked from any access. If VPF is less than V

V

BACKUP

VCC to V

the V

wh en VCC drops below VPF. I f VPF is great er than V

BACKUP

BACKUP

w hen VCC drops below V

BACKUP

so u rce u ntil VCC is r etu rned to nominal levels (see Table 3).

. Oscillato r and counter operation a re maint ained fro m

BACKUP

, the device power is switched from VCC to

BACKUP

, the device power is switched from

Table 3. Power Control

SUPPLY CONDITION

POWERED BY

Oscillator Control

The EOSC b it ( bit 7 o f the contro l register) co ntrols the osc illator when in back-up mode. This bit when

set to log ic 0 will st art the oscillator . When this bit is set to a logic 1, the oscillator is stopped and the

DS1672 is placed into a low-power standby mode (I

powered by V

the oscil lat o r is alwa ys on regardless of the stat us of the EOSC bit ; ho w e ver, the counter

CC,

BACKUP

) whe n in ba ck-up mode. When the DS1672 is

is incremented only when EOSC is a logic 0.

Microprocessor Monitor

A temperature-compensated comparator circuit monitors the level of VCC. Whe n VCC fa lls to the p owe rfail trip point, the RST signal (open drain) is pulled active, and read/write access is inhibited. When VCC

ret ur ns to no minal le ve ls , the RST signal is k ept in the active state for t

supply and microp rocessor to st abilize. Note, however, t hat if the EOSC bit is set to a logic 1 (to disable

the o scillator during write protection), the reset signal will be kept in an active state for t

startup time of the oscillator.

(typically) to allow the power

RPU

plus the

RPU

9 of 15

Page 10

DS1672

X X X X 0 0 X X Disabled

X X X X 1 1 X X Disabled

X X X X X X 0 0 Disabled

1 0 1 0 0 1 0

1

No diode, 250Ω resistor

1 0 1 0 1 0 0

1

One diode, 250Ω resistor

1 0 1 0 0 1 1

0

No diode, 2kΩ resistor

1 0 1 0 1 0 1

0

One diode, 2kΩ resistor

1 0 1 0 0 1 1

1

No diode, 4kΩ resistor

1 0 1 0 1 0 1

1

One diode, 4kΩ resistor

0 0 0 0 0 0 0 0 Initial defa ult va lue--disabled

Trickle Charger

The trickle charger is controlled by the trickle charge register. The simplified schematic of Figure 5

shows the basic components o f the t r ickle charger. T he tr ickle c harge se lect (T CS) b it (bits 4–7) co nt rols

the select ion of the t rickle charger. In order to prevent accidenta l enabling, only a patt ern on 1010 will

enable the tr ickle charger. Al l ot her patt erns will disable the trickle charger. The DS1672 powers up with

the trickle charger disabled. The diode select (DS) bits (bits 2, 3) select whether or not a diode is

connected between VCC and V

BACKUP

The RS bits (bits 0, 1 ) se lect whet her a resistor is connected bet ween VCC and V

of the resistor is. The resist or selected by the resisto r select (RS) bits and the diode select ed by the diode

select (DS) bits are as follows:

TCS TCS TCS TCS DS DS RS RS FUNCTION

. If DS is 01, no diode is selected o r if DS is 10, a diode is select ed.

BACKUP

and what the value

Warning: The resistor value of 250Ω must not be selected whenever V

is greater

CC

than 3.63V.

Diode and resisto r se lect ion is deter mined by the user according to the maximum current des ired for

battery or super cap charg ing. The maximum c harging current can be calculated as illustrated in the

following exa mple. Assume t ha t a syste m power supply of 3V is applied to VCC and a super cap is

connected to V

bet ween V

and V

CC

BACKUP

As the super cap changes, the vo ltage drop between VCC and V

charge current w ill decrease.

. Also assume that the trickle charger has been e nabled with a diode and resistor R2

BACKUP

. T he maximum current I

I

= (5.0V - diode drop) / R1 ≈ (5.0V - 0.6V) / 2kΩ ≈ 2.2mA

MAX

would, t herefore, be ca lculated as follows:

MAX

BACKUP

will decrease and, therefore, the

10 of 15

Page 11

DS1672

1 OF 16 SELECT

NOTE: ONLY 1010 ENABLES

1 OF 2

SELECT

1 OF 3

SELECT

TCS

TCS

TCS

TCS

DS

DS

RS

RS

BIT 7

BIT 6

BIT 5

BIT 4

BIT 3

BIT 2

BIT 1

BIT 0

250Ω

R1

R2

TRICKLE CHARGE REGISTER

TCS =

TRICKLE CHARGER SELECT

DS =

DIODE SELECT

RS =

RESISTOR SELECT

VCC

V

2kΩ

R3

4k

Figure 5. Programmable Trickle Charger

BACKUP

Ω

2

I

C Serial Data Bus

The DS1672 supports a bidirectional I2C bus and data transmission proto col. A device that sends dat a

onto the bus is de fined as a tr ansmitt er and a devi ce rece iving dat a as a rece iver. T he device that contr ols

the message is c a lled a master. The de vices t hat are co ntro lled by t he mast er are s laves. T he bus must be

controlled by a master device that generates t he se rial clock (SCL), controls the bus a ccess, and ge nerates

the START and STOP conditions. The DS1672 operates as a s lave on the I2C bus. Connections to the bus

are made via the open-drain I/O lines SDA and SCL. Within the bus specifications, a standard mode

(100kHz maximum clock rate) and a fast mode (400kHz maximum clock rate) are defined. The DS1672

op erat es in bo th mo des.

The fo llo w in g bus protocol has been defined (Figure 6):

Data transfe r may be initiated only w hen the bus is not busy.

During data tr ansfer, the dat a line must r emain stable whenever the clock line is HIGH. Changes i n

the dat a lin e whi le the clock line is high will be interpret ed as contro l signals.

Accordingly, the follow ing bus condition s have been defined:

Bus not busy: Both data and clock lines remain HIGH.

Start data transfer: A change in the state of the data line fro m high to low, while the clock line is

high, defines a START condit ion.

Stop data transfer: A change in the state o f the data line from low t o high, while the clock line i s

high, defines a STOP condition.

11 of 15

Page 12

DS1672

Data valid: The st ate of the data l ine represents valid dat a when, after a ST ART condition, the

data line is stable for t he duration o f the high perio d of the clock signal. T he data o n the line must

be changed during the low period of the clock signal. There is one clock pulse per bit o f data.

Each data transfer is initiated with a START condition and terminated with a STOP condition.

The number of data bytes transferred between the START a nd t he ST OP conditions is not limited,

and is determined by the master device. The information is transferred byte-wise and each

receiver acknowledges with a ninth bit. Within the I2C bus specifications a standard mode

(100kHz clock rate) and a fast mode (400kHz clock rate) are defined.

Acknowledge: Each receiving device, when addressed, is obliged to generate an acknowledge

after the reception of each byte. The master device must generate an extra clock pulse that is

associated with th is acknow ledge bit.

A device that acknowledges must pull do wn the SDA line during the acknowledge clock pulse in

such a way that t he SDA line is stab le LOW during t he HIGH period o f the acknow ledge related

clock pulse. O f co urse, setup and ho ld t imes must be t aken into acco unt. A mast er must signa l an

end of data to the slave by not generating an acknowledge bit on the last byte that has been

clocked out of the slave. In this case, the slave must leave the dat a line HIGH to enable t he master

to generate the STOP co nd ition.

Figures 7 and 8 detail how data tr ansfer is acco mplished on the I2C bus. Depending upon the state of the

R/W bit, two types of data t r ansfer are possible:

1) Data transfer from a master transmitter to a slave receiver. The first byte transmitted by the

master is the s lave address. Ne xt follows a number of data bytes. The slave ret urns an acknow ledge

bit after each received byte.

2) Data transfer from a slave transmitter to a master receive r. The first byte (the slave addr ess) is

transmitted by t he master. T he slave then retur ns an acknowledge bit. Next fo llows a number of data

bytes transmitted b y the slave to the master . The master ret urns an acknowledge bit after all received

bytes other than the last byte. At t he end of the last rece ived byte, a “not acknowledge” is returned.

The master device generates all of the serial clock pulses and the START and STOP conditions. A

tr ansfer is e nded wit h a ST OP c ond itio n or with a repeat ed START condition. Since a rep eated START

co ndit ion is also the beginning of the next serial t ransfer, the bus will not be released.

The DS1672 can operate in the following two modes:

1) Slave receiver mode (DS1672 write mode): Serial data and clock are received through SDA and

SCL. After each byte is received, an acknowledge bit is t r ansmitted . S T ART and STOP conditions are

recognized as the beginning and end of a serial transfer. Address recognition is performed by

hardware after reception of the slave address and d irection bit (Figure 7). T he slave addr ess byte is t he

first byte received after the START condition is generated by the master. The slave address byte

contains the 7-bit DS1672 address, which is 1101000, followed by the direction bit (R/W), wh ich fo r

a write is a 0. After receiving and decoding the slave address byte the DS1672 outputs an

acknowledge on the SDA line. After the DS1672 acknowledges the slave address + write bit, the

master transmits a word address to the DS1672. This will set the register pointer o n the DS1672, wit h

the DS1672 ack nowledging t he transfer. T he master ma y then t ransmit zero or more bytes of data,

12 of 15

Page 13

DS1672

MSB

slave address

R/W

direction

bit

SDA

SCL

START

CONDITION

1 2 6 7 8 9

1 2 8 9

STOP CONDITION

OR

REPEATED

START CONDITION

3 - 8

acknowledgement

signal from receiver

acknowledgement

signal from receiver

ACK ACK

repeated if more bytes

are transferred

with the DS1672 acknowledging each byte received. The register pointer will increment after each

byte is transferred. The mast er will generate a stop condition to terminate the dat a wr ite.

2) Slave transmitter mode (DS1672 read mode): The first byte is rece ived and handled as in the slave

receiver mode. However, in this mode, the direction bit will indicate that the transfer direction is

reversed. Ser ia l data is t ransmitted o n SDA by the DS1 672 while the serial clock is input on SCL.

START and STOP co nditions are recognized as t he beginning and e nd of a serial transfer (Figure 8) .

The slave address byte is t he first byte received after the START condition is generated by the master.

The slave address byte contains the 7-bit DS1672 address, which is 1101000, followed by the

d ire ct io n bit ( R/ W), which for a read is a 1. After rece iving and decod ing the slave address byte the

DS1672 outputs an acknowledge on the SDA line. The DS1672 then begins to transmit data starting

with the register address pointed to by the register pointer. If the register pointer is not written to

before the init iation of a read mode the first add ress that is read is the last o ne stored in the reg ister

pointer. The DS1672 must r eceive a “not ackno wledge” to end a read.

Figure 6. Data Transfer on I2C Serial Bus

Figure 7. Data Write: Slave Receiver Mode

<Slave Address> <Word Address (n)> <Data(n) <Data(n+1)> <Data(n+X)>

<RW>

AXXXXXXXXA1101000S 0 XXXXXXXX A XXXXXXXX A XXXXXXXX A P

S - START

A - ACKNOWLEDGE

P - STOP

R/W - READ/WRITE O R DI RECTION BIT ADDRESS = D0H

DATA TRANSFERRED

(X+1 BYTES + ACKNOWLEDGE)

13 of 15

Page 14

DS1672

PACKAGE

THETA-JA

THETA-JC

8 PDIP (300 mi ls )

110°C/W

40°C/W

8 SO (150 mils)

128.4°C/W

36°C/W

8 µSOP (3mm)

206.3°C/W

42°C/W

8 PDIP (300 mi ls )

P8+1

21-0043

—

8 SO (150 mils)

S8+5

21-0041

90-0096

8 µSOP (3mm)

U8+1

21-0036

90-0092

Figure 8. Data Read: Slave Transmitter Mode

<Slave Address> <Data(n)> <Data(n+1) <Data(n+2)> <Data(n+X)>

S - START

A - ACKNOWLEDGE

P - STOP

A - NOT ACKNOWLEDGE

R/W - READ/WRITE O R DI RECTION BIT ADDRESS = D1H

<RW>

AXXXXXXXXA1101000S 1 XXXXXXXX A XXXXXXXX A XXXXXXXX A P

(X+1 BYTES + ACKNOWLEDGE); NOTE: LAST DATA BYTE IS

FOLLOWED BY A NOT ACKNO WLEDGE (A) SIGNAL)

DATA TRANSFERRED

THERMAL INFORMATION

PACKAGE INFORMATION

For the latest package outline inf ormation and land patterns (footprints), go to www.maxim-ic.com/packages. Note

that a “+”, “#”, or “-“ in the package code i ndic ates RoHS status only. Package drawings may show a different suffix

character, but t he dr awing per tains to the package regardless of RoHS status.

PACKAGE TYPE PACK AGE CODE OUTLIN E N O . LAND PATTERN NO.

14 of 15

Page 15

REVISION HISTORY

REVISION

DATE

PAGES

CHANGED

Updated the Ordering Information, Absolute Maximum Ratings,

Information, and Package Information

DS1672

DESCRIPTION

9/11

Recommended Operating Conditions, DC Electrical Characteristics, AC

Electrical Characteristics, Pin Description, Trickle Charger, Thermal

2, 3, 5, 7,

10, 15

15 of 15

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied. Maxim

reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2011 Maxim Integrated Products Maxim is a registered tr ademark of Ma xi m I nt egrated Pr oduc ts , Inc .

Loading...

Loading...