Page 1

DS1340

I2C RTC with Trickle Charger

________________________________________________________________

Maxim Integrated Products

1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

General Description

The DS1340 is a real-time clock (RTC)/calendar that is

pin compatible and functionally equivalent to the ST

M41T00, including the software clock calibration. The

device additionally provides trickle-charge capability

on the V

BACKUP

pin, a lower timekeeping voltage, and

an oscillator STOP flag. Block access of the register

map is identical to the ST device. Two additional registers, which are accessed individually, are required for

the trickle charger and flag. The clock/calendar provides seconds, minutes, hours, day, date, month, and

year information. A built-in power-sense circuit detects

power failures and automatically switches to the backup supply. Reads and writes are inhibited while the

clock continues to run. The device is programmed serially through an I2C bidirectional bus.

Applications

Portable Instruments

Point-of-Sale Equipment

Medical Equipment

Telecommunications

Features

♦ Enhanced Second Source for the ST M41T00

♦ Available in a Surface-Mount Package with an

Integrated Crystal (DS1340C)

♦ Fast (400kHz) I2C Interface

♦ Software Clock Calibration

♦ RTC Counts Seconds, Minutes, Hours, Day, Date,

Month, and Year

♦ Automatic Power-Fail Detect and Switch Circuitry

♦ Trickle-Charge Capability

♦ Low Timekeeping Voltage Down to 1.3V

♦ Three Operating Voltage Ranges (1.8V, 3V, and 3.3V)

♦ Oscillator Stop Flag

♦ Available in 8-Pin µSOP or SO Packages

♦ Underwriters Laboratories (UL) Recognized

Ordering Information

4

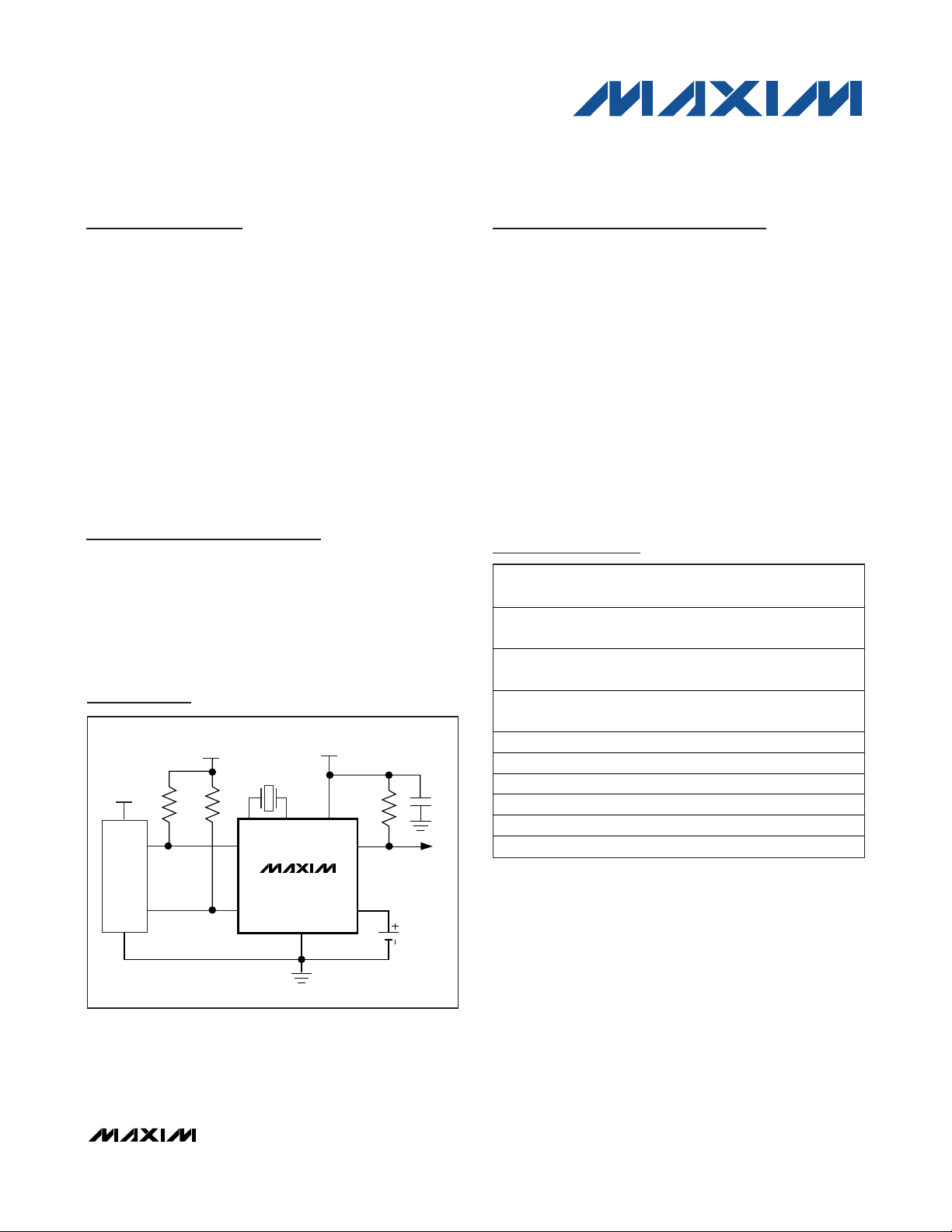

CPU

V

CC

V

CC

V

CC

5

6

8

12

SDA

SCL

GND

X2X1

V

CC

C1

R

PU

R

PU

CRYSTAL

FT/OUT

V

BACKUP

3

7

R

PU

= tR / CB

DS1340

Typical Operating Circuit

PART TEMP RANGE

PINPACKAGE

TOP MARK

†

DS1340Z-18+ -40°C to +85°C

8 SO

(0.150in)

D1340-18

DS1340Z-3+ -40°C to +85°C

8 SO

(0.150in)

DS1340-3

DS1340Z-33+ -40°C to +85°C

8 SO

(0.150in)

D134033

DS1340U-18+ -40°C to +85°C 8 μSOP 1340 -18

DS1340U-3+ -40°C to +85°C 8 μSOP 1340 -3

DS1340U-33+ -40°C to +85°C 8 μSOP 1340 -33

DS1340C-18# -40°C to +85°C 16 SO DS1340C-18

DS1340C-3# -40°C to +85°C 16 SO DS1340C-3

DS1340C-33# -40°C to +85°C 16 SO DS1340C-33

Pin Configurations appear at end of data sheet.

+

Denotes a lead(Pb)-free/RoHS-compliant package.

#

Denotes a RoHS-compliant device that may include lead(Pb)

that is exempt under RoHS requirements. The lead finish is

JESD97 category e3, and is compatible with both lead-based

and lead-free soldering processes.

†

A "+" anywhere on the top mark denotes a lead(Pb)-free device.

A "#" denotes a RoHS-compliant device.

19-5578; Rev 7; 8/11

Page 2

DS1340

I2C RTC with Trickle Charger

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

RECOMMENDED DC OPERATING CONDITIONS

(VCC= V

CC MIN

to V

CC MAX

, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VCC= 3.3V, TA= +25°C, unless

otherwise noted.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage Range on VCCPin Relative to Ground .....-0.3V to +6.0V

Voltage Range on SDA, SCL, and FT/OUT

Relative to Ground..................................-0.3V to (V

CC

+ 0.3V)

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range .............................-55°C to +125°C

Lead Temperature (soldering, 10s) .................................+260°C

Soldering Temperature (reflow) .......................................+260°C

Supply Voltage (Note 2) V

Input Logic 1 (SDA, SCL) VIH (Note 2) 0.7 x VCC V

Input Logic 0 (SDA, SCL) VIL (Note 2) -0.3 +0.3 x VCC V

Supply Voltage, Pullup

(FT/OUT, SDA, SCL), V

Bac kup Supply Voltage (Note 2) V

Trickle-Charge Current-Limiting

Resistors

Power-Fail Voltage (Note 2) V

Input Leakage (SCL, CLK) ILI -1 +1 μA

I/O Leakage (SDA, FT/OUT) ILO -1 +1 μA

SDA Logic 0 Output I

FT/OUT Logic 0 Output I

Active Supply Current (Note 7) I

Standby Current (Note 8) I

V

BACKUP

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Lea kage Current I

DS1340-18 1.71 1.8 5.5

DS1340-3 2.7 3.0 5.5

DS1340-33 2.97 3.3 5.5

(Note 2) 5.5 V

DS1340-18 1.3 3.7

DS1340-3 1.3 3.7

DS1340-33 1.3 5.5

DS1340-18 1.51 1.6 1.71

DS1340-3 2.45 2.6 2.7

DS1340-33 2.70 2.88 2.97

VCC > 2V; VOL = 0.4V 3.0

1.7V < VCC < 2V; VOL = 0.2 x VCC 3.0

VCC > 2V; VOL = 0.4V 3.0

1.7V < VCC < 2V; VOL = 0.2 x VCC 3.0

1.3V < VCC < 1.7V; VOL = 0.2x VCC 250 μA

DS1340-18; VCC = 1.89V 72 150

DS1340-3; VCC = 3.3V 108 200

DS1340-33; VCC = 5.5V 192 300

DS1340-18; VCC = 1.89V 60 100

DS1340-3; VCC = 3.3V 81 125

DS1340-33; VCC = 5.5V 100 150

= 3.7V 100 nA

CC

= 0V

CC

V

PU

BACKUP

R1 (Notes 3, 4) 250

R2 (Note 5) 2000

R3 (Note 6) 4000

PF

OLSDA

OLSQW

CCA

CCS

BACKUPLKG VBACKUP

+ 0.3 V

CC

V

V

V

mA

mA

μA

μA

Page 3

DS1340

I2C RTC with Trickle Charger

_______________________________________________________________________________________ 3

DC ELECTRICAL CHARACTERISTICS

(VCC= 0V, V

BACKUP

= 3.7V, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

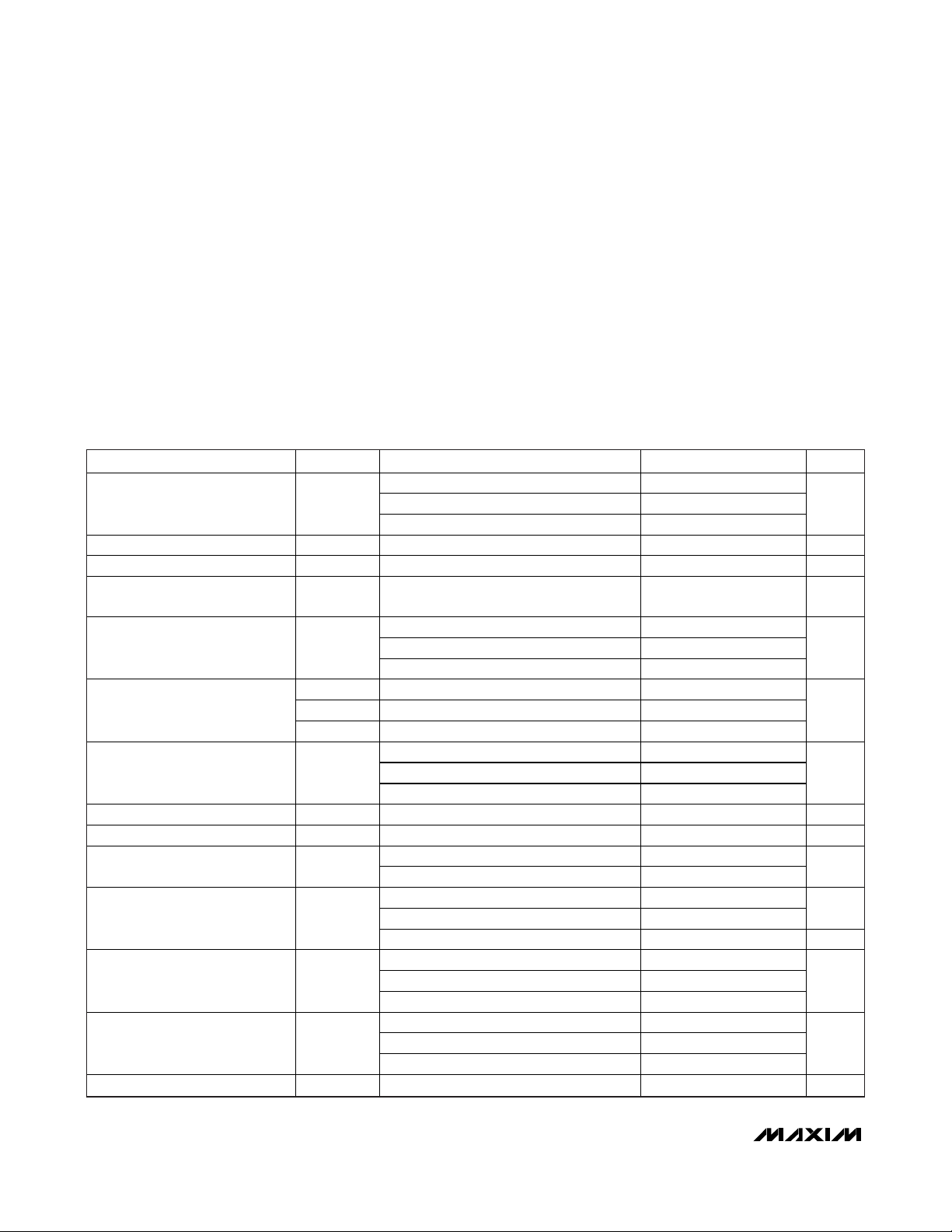

AC ELECTRICAL CHARACTERISTICS

(VCC= V

CC MIN

to V

CC MAX

, TA= -40°C to +85°C, unless otherwise noted.) (Notes 1,14, Figure 1)

V

BACKUP

V

BACKUP

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Current

Data-Retention Current I

I

BACKUP1

I

BACKUP2

I

BACKUP3

BACKUPDR

OSC ON, FT = 0 (Note 9) 800 1150

OSC ON, FT = 1 (Note 9) 850 1250

OSC ON, FT = 0, V

= +25°C (Notes 9, 10)

T

A

OSC OFF 25.0 100 nA

SCL Clock Frequenc y f

Bus Free Time Between STOP

and START Condition s

Hold Time (Repeated) START

Condition (Note 11)

Low Period of SCL Clock t

High Period of SCL Clock t

Data Hold Time (Notes 12, 13) t

Data Setup Time (Note 14) t

START Setup Time t

Rise T ime of SDA and SCL

Signals (Note 15)

Fall Time of SDA and SCL

Signals (Note 15)

Setup Time for STOP Condition t

Capacitive Load for Each Bus

Line

I/O Capacitance (SCL, SDA) C

Pulse Width of Spikes that Must

be Suppressed by the Input

Filter

Oscillator Stop Flag (OSF) Delay t

PARAMETER SYMBOL CONDITIONS MIN TYP MA X UNITS

SCL

t

BUF

t

HD: STA

LOW

HIGH

HD:DAT

SU:DAT

SU:STA

t

R

t

SU:STO

C

I/O

t

SP

OSF

Standard mode 0 100

Fast mode 100 400

Standard mode 4.7

Fast mode 1.3

Standard mode 4.0

Fast mode 0.6

Standard mode 4.7

Fast mode 1.3

Standard mode 4.0

Fast mode 0.6

Standard mode 0 0.9

Fast mode 0 0.9

Standard mode 250

Fast mode 100

Standard mode 4.7

Fast mode 0.6

Standard mode 20 + 0.1CB 1000

Fast mode 20 + 0.1CB 300

Standard mode 20 + 0.1CB 300

F

Fast mode 20 + 0.1CB 300

Standard mode 4.7

Fast mode 0.6

(Note 15) 400 pF

B

10 pF

Fast mode 30 ns

(Note 16) 100 ms

BACKUP

= 3.0V,

nA

800 1000

kHz

μs

μs

μs

μs

μs

ns

μs

ns

ns

μs

Page 4

DS1340

I2C RTC with Trickle Charger

4 _______________________________________________________________________________________

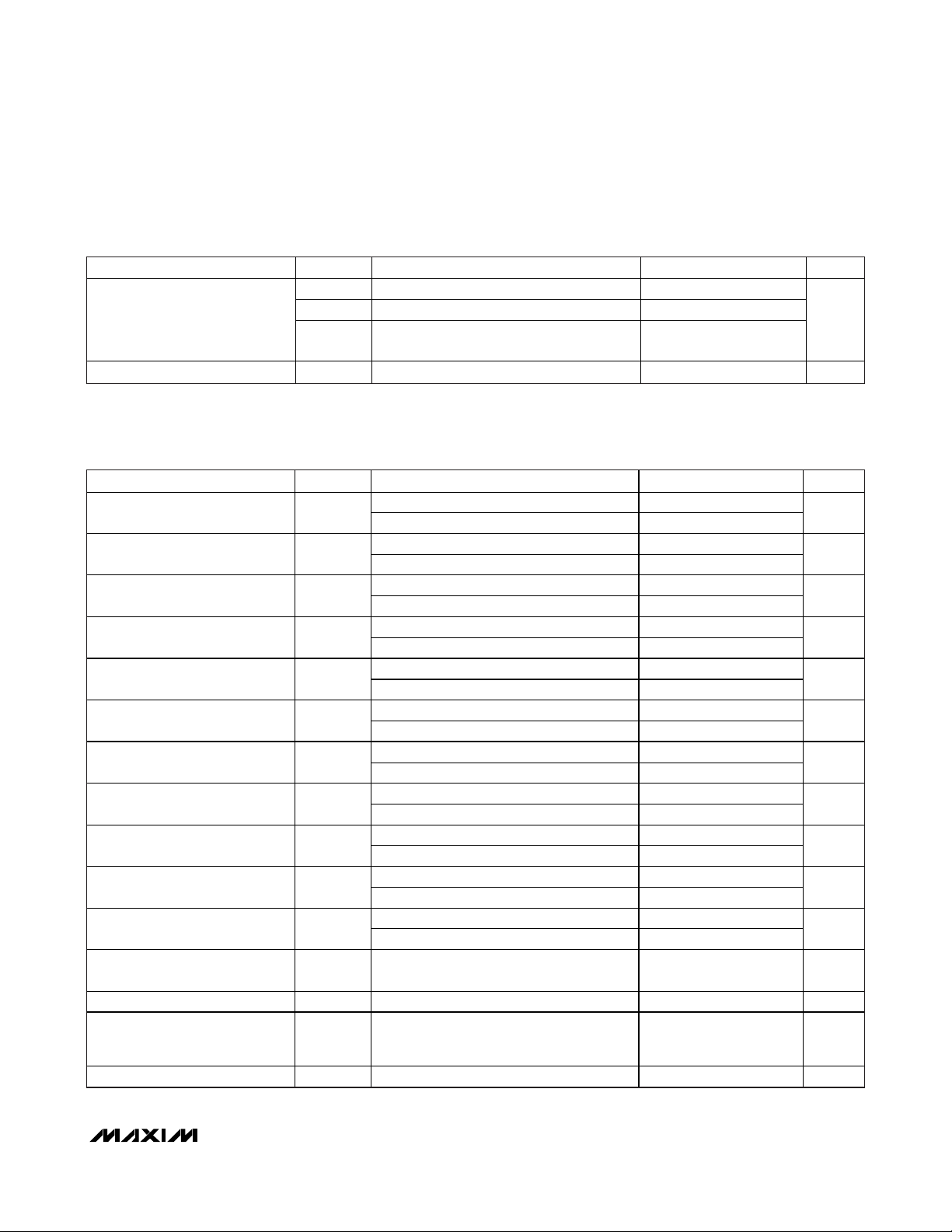

POWER-UP/POWER-DOWN CHARACTERISTICS

(TA= -40°C to +85°C) (Figure 2)

WARNING: Under no circumstances are negative undershoots, of any amplitude, allowed when device is in battery-backup mode.

Note 1: Limits at -40°C are guaranteed by design and not production tested.

Note 2: All voltages are referenced to ground.

Note 3: Measured at V

CC

= typ, V

BACKUP

= 0V, register 08h = A5h.

Note 4: The use of the 250Ω trickle-charge resistor is not allowed at V

CC

> 3.63V and should not be enabled.

Note 5: Measured at V

CC

= typ, V

BACKUP

= 0V, register 08h = A6h.

Note 6: Measured at V

CC

= typ, V

BACKUP

= 0V, register 08h = A7h.

Note 7: I

CCA

—SCL clocking at max frequency = 400kHz.

Note 8: Specified with I

2

C bus inactive.

Note 9: Measured with a 32.768kHz crystal attached to the X1 and X2 pins.

Note 10: Limits at +25°C are guaranteed by design and not production tested.

Note 11: After this period, the first clock pulse is generated.

Note 12: A device must internally provide a hold time of at least 300ns for the SDA signal (referred to as the V

IH(MIN)

of the SCL

signal) to bridge the undefined region of the falling edge of SCL.

Note 13: The maximum t

HD:DAT

only has to be met if the device does not stretch the low period (t

LOW

) of the SCL signal.

Note 14: A fast-mode device can be used in a standard-mode system, but the requirement t

SU:DAT

≥ to 250ns must be met. This

is automatically the case if the device does not stretch the low period of the SCL signal. If such a device does stretch the

low period of the SCL signal, it must output the next data bit to the SDA line t

R MAX

+ t

SU:DAT

= 1000 + 250 = 1250ns

before the SCL line is released.

Note 15: C

B

—total capacitance of one bus line in pF.

Note 16: The parameter t

OSF

is the period of time the oscillator must be stopped for the OSF flag to be set over the 0V ≤ VCC≤

V

CCMAX

and 1.3V ≤ V

BAT

≤ 3.7V range.

Note 17: This delay applies only if the oscillator is enabled and running. If the oscillator is disabled or stopped, no power-up delay

occurs.

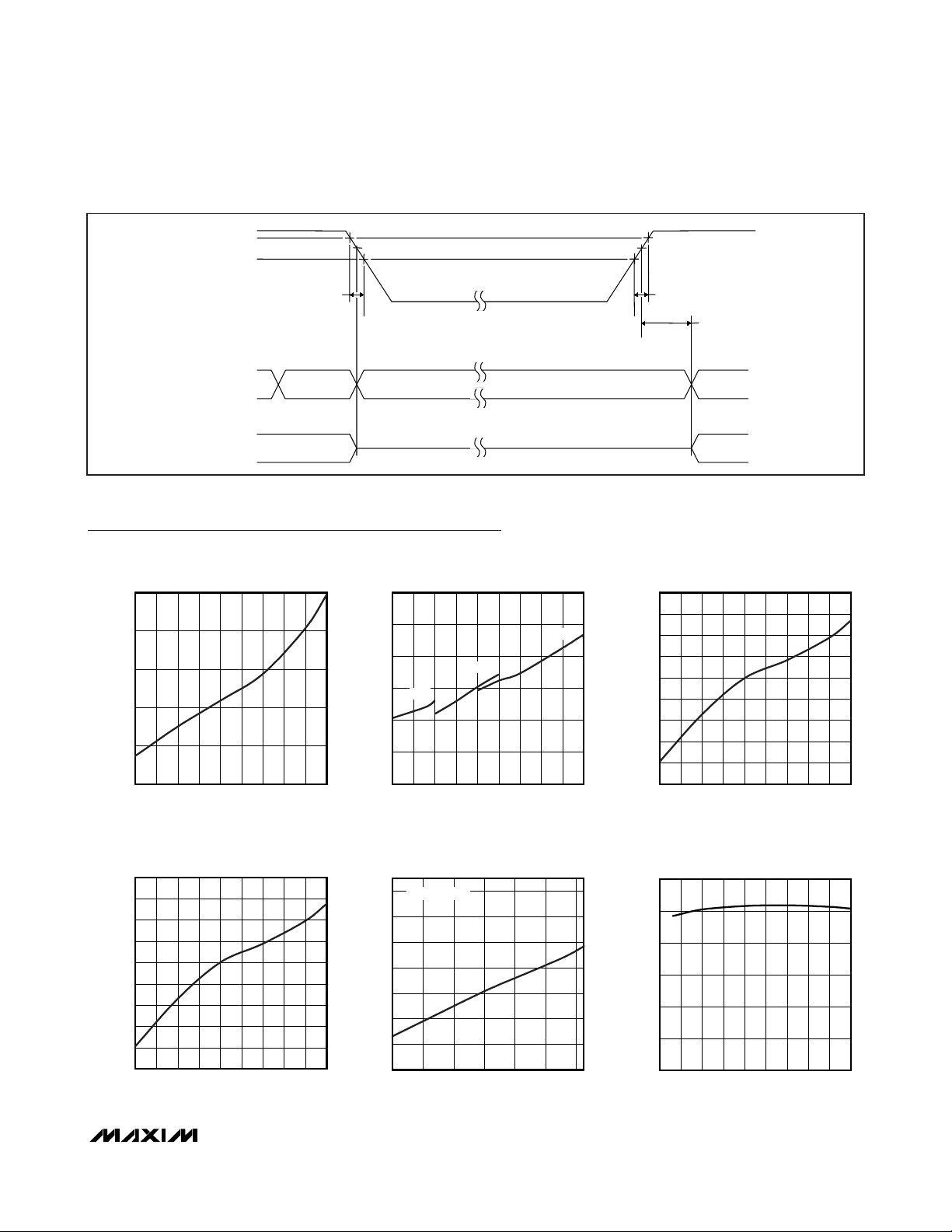

Figure 1. Data Transfer on I2C Serial Bus

Recovery at Power-Up t

VCC Fall Time; V

V

PF(MIN)

VCC Rise Time; V

V

PF(MAX)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

REC

PF(MIN)

to

to

t

VCCF

t

VCCR

PF(MAX)

(Note 17) 2 ms

300 µs

0µs

SDA

t

BUF

t

LOW

SCL

t

HD:STA

STOP START REPEATED

NOTE: TIMING IS REFERENCED TO V

IL(MAX)

AND V

IH(MIN)

t

R

t

HD:DAT

.

t

HIGH

t

F

t

SU:DAT

START

t

SU:STA

t

HD:STA

t

SP

t

SU:STO

Page 5

DS1340

I2C RTC with Trickle Charger

_______________________________________________________________________________________ 5

Figure 2. Power-Up/Power-Down Timing

Typical Operating Characteristics

(VCC= +3.3V, TA= +25°C, unless otherwise noted.)

I

CCSA

vs. VCC FT = 0

DS1340 toc01

VCC (V)

SUPPLY CURRENT (μA)

5.04.54.03.53.02.52.01.5

50

100

150

200

250

0

1.0 5.5

25

50

75

100

125

150

0

I

CCS

vs. VCC FT = 0

DS1340 toc02

VCC (V)

SUPPLY CURRENT (μA)

5.04.54.03.53.02.52.01.51.0 5.5

-1.8V

-3.0V

-3.3V

I

BACKUP1

(FT = 0) vs. V

BACKUP

DS1340 toc03

450

500

550

600

650

700

750

800

850

400

V

BACKUP

(V)

SUPPLY CURRENT (nA)

5.04.54.03.53.02.52.01.51.0 5.5

I

BACKUP2

(FT = 1) vs. V

BACKUP

DS1340 toc04

450

500

550

600

650

700

750

800

850

400

V

BACKUP

(V)

SUPPLY CURRENT (nA)

5.04.54.03.53.02.52.01.51.0 5.5

I

BACKUP3

vs. TEMPERATURE

DS1340 toc05

TEMPERATURE (°C)

SUPPLY CURRENT (nA)

6040-20 0 20

500

550

600

650

700

750

800

850

-40 80

V

BACKUP

= 3.0V

OSCILLATOR FREQUENCY vs. SUPPLY VOLTAGE

(FT x 64)

DS1340 toc06

V

BACKUP

(V)

FREQUENCY (Hz)

5.04.54.03.53.02.52.01.5

32768.1

32768.2

32768.3

32768.4

32768.5

32768.6

32768.0

1.0 5.5

V

CC

V

V

INPUTS

OUTPUTS

PF(MAX)

PF(MIN)

RECOGNIZED RECOGNIZED

VALID

V

t

F

PF

DON'T CARE

HIGH-Z

V

PF

t

R

t

REC

VALID

Page 6

DS1340

I2C RTC with Trickle Charger

6 _______________________________________________________________________________________

Detailed Description

The DS1340 is a low-power clock/calendar with a trickle

charger. Address and data are transferred serially

through a I2C bidirectional bus. The clock/calendar provides seconds, minutes, hours, day, date, month, and

year information. The date at the end of the month is

automatically adjusted for months with fewer than 31

days, including corrections for leap year. The DS1340

has a built-in power-sense circuit that detects power failures and automatically switches to the backup supply.

Power Control

The power-control function is provided by a precise,

temperature-compensated voltage reference and a

comparator circuit that monitors the VCClevel. The

device is fully accessible and data can be written and

read when VCCis greater than VPF. However, when V

CC

falls below VPF, the internal clock registers are blocked

from any access. If V

PF

is less than V

BACKUP

, the

device power is switched from VCCto V

BACKUP

when

VCCdrops below VPF. If VPFis greater than V

BACKUP

,

the device power is switched from VCCto V

BACKUP

Pin Description

Table 1. Power Control

PIN

816

1 — X1

2 — X2

3 14 V

4 15 GND Ground

5 16 SDA

6 1 SCL

7 2 FT/OUT

8 3 V

— 4–13 N.C. No Connection. Mu st be connected to ground.

NAME FUNCTION

Connections for a Standard 32.768kHz Quartz Crystal. The internal oscillator circuitry is designed for

operation with a crystal having a specified load capacitance (C

oscillator and can optionally be connected to an external 32.768kHz oscillator. The output of the

internal oscillator, X2, is left unconnected if an external oscillator is connected to X1.

Connect ion for a Secondary Power Supply. For the 1.8V and 3V dev ices, V

between 1.3V and 3.7V for proper operation. D iodes p laced in series between the supply and the input

BACKUP

CC

pin may result in improper operation. V

This pin can be connected to a primary cell such as a lithium coin cell. Additionally, this pin can be

connected to a rechargeable cell or a super cap when used with the trickle-charge feature. UL recognized to

ensure against reverse charging when used with a lithium battery (www.maxim-ic.com/qa/info/ul).

Serial Data Input/Output. SDA is the data input/output for the I

drain and requires an e xternal pullup resistor.

Serial Clock Input. SCL is the clock input for the I

movement on the serial interface.

Frequency Test/Output. This pin is u sed to output either a 512H z signal or the va lue of the OUT bit.

When the FT bit is logic 1, the FT/OUT pin toggles at a 512Hz rate. When the FT bit i s logic 0, the

FT/OUT pin reflects the value of the OUT bit. This open-drain pin requires an external pullup resistor,

and operates with e ither V

the voltage on V

Primary Power Supply. When vo ltage is applied within normal limits, the device is fully accessib le and

data can be written and read. When a backup supply is connected to the device and V

reads and writes are inhibited. However, the timekeeping function continues unaffected by the lower

input voltage.

. If not used, this pin can be left unconnected.

CC

CC

or V

BACKUP

applied. The pul lup vo ltage can be up to 5.5V, regardless of

BACKUP

) of 12.5pF. X1 is the input to the

L

must be held

BACKUP

can be as h igh a s 5.5V on the 3.3V device.

2

C serial interface. The SDA pin is open

2

C interface and is used to synchronize data

is below VPF,

CC

SUPPLY CONDITION

VCC < VPF,

V

< V

CC

VCC < VPF,

V

> V

CC

VCC > VPF,

V

< V

CC

VCC > VPF,

V

> V

CC

BACKUP

BACKUP

BACKUP

BACKUP

READ/WRITE

ACCESS

No V

No V

Yes V

Yes V

POW ERE D

BY

BAT

CC

CC

CC

Page 7

DS1340

I2C RTC with Trickle Charger

_______________________________________________________________________________________ 7

when VCCdrops below V

BACKUP

. The registers are

maintained from the V

BACKUP

source until VCCis

returned to nominal levels (Table 1). After VCCreturns

above VPF, read and write access is allowed t

REC

.

Oscillator Circuit

The DS1340 uses an external 32.768kHz crystal. The

oscillator circuit does not require any external resistors

or capacitors to operate. Table 2 specifies several crystal parameters for the external crystal. Figure 3 shows a

functional schematic of the oscillator circuit. If using a

crystal with the specified characteristics, the startup

time is usually less than one second.

Clock Accuracy

The initial clock accuracy depends on the accuracy of

the crystal and the accuracy of the match between the

capacitive load of the oscillator circuit and the capacitive load for which the crystal was trimmed. Additional

error is added by crystal frequency drift caused by

temperature shifts. External circuit noise coupled into

the oscillator circuit can result in the clock running fast.

Figure 4 shows a typical PC board layout for isolating

the crystal and oscillator from noise. Refer to

Application Note 58: Crystal Considerations with Dallas

Real-Time Clocks

(www.maxim-ic.com/RTCapps) for

detailed information.

DS1340C Only

The DS1340C integrates a standard 32,768Hz crystal

into the package. Typical accuracy with nominal V

CC

and +25°C is approximately +15ppm. Refer to

Application Note 58 for information about crystal accuracy vs. temperature.

Operation

The DS1340 operates as a slave device on the serial

bus. Access is obtained by implementing a START

condition and providing a device identification code followed by data. Subsequent registers can be accessed

sequentially until a STOP condition is executed. The

device is fully accessible and data can be written and

read when VCCis greater than VPF. However, when

VCCfalls below VPF, the internal clock registers are

blocked from any access. If VPFis less than V

BACKUP

,

the device power is switched from VCCto V

BACKUP

when VCCdrops below VPF. If VPFis greater than

V

BACKUP

, the device power is switched from VCCto

V

BACKUP

when VCCdrops below V

BACKUP

. The regis-

ters are maintained from the V

BACKUP

source until V

CC

is returned to nominal levels. The functional diagram

(Figure 5) shows the main elements of the serial RTC.

Table 2. Crystal Specifications*

*

The crystal, traces, and crystal input pins should be isolated

from RF generating signals. Refer to

Application Note 58:

Crystal Considerations for Dallas Real-Time Clocks

for addi-

tional specifications.

Figure 3. Oscillator Circuit Showing Internal Bias Network

Figure 4. Layout Example

PARAMETER SYMBOL MIN TYP MAX UNITS

Nominal

Frequency

Series Resistance ESR 80 kΩ

Load Capacitance C

f

O

L

32.768 kHz

12.5 pF

RTC

C

1

L

X1

CRYSTAL

2

C

L

X2

COUNTDOWN

CHAIN

RTC

REGISTERS

LOCAL GROUND PLANE (LAYER 2)

X1

CRYSTAL

X2

GND

Page 8

DS1340

Address Map

Table 3 shows the DS1340 address map. The RTC registers are located in address locations 00h to 06h, and

the control register is located at 07h. The trickle-charge

and flag registers are located in address locations 08h

to 09h. During a multibyte access of the timekeeping

registers, when the address pointer reaches 07h—the

end of the clock and control register space—it wraps

around to location 00h. Writing the address pointer to

the corresponding location accesses address locations

08h and 09h. After accessing location 09h, the address

pointer wraps around to location 00h. On a I2C START,

STOP, or address pointer incrementing to location 00h,

the current time is transferred to a second set of registers. The time information is read from these secondary

registers, while the clock may continue to run. This

eliminates the need to reread the registers in case the

main registers update during a read.

Clock and Calendar

The time and calendar information is obtained by reading the appropriate register bytes. Table 3 shows the

RTC registers. The time and calendar data are set or

initialized by writing the appropriate register bytes. The

contents of the time and calendar registers are in the

I2C RTC with Trickle Charger

8 _______________________________________________________________________________________

Table 3. Address Map

X = Read/Write bit

Note: Unless otherwise specified, the state of the registers is not defined when power is first applied.

Figure 5. Functional Diagram

X1

C

L

C

L

POWER

CONTROL

SERIAL

INTERFACE

AND ADDRESS

REGISTER

"C" VERSION ONLY

V

CC

V

BACKUP

SCL

SDA

X2

FT/OUT

CIRCUIT

CONTROL

LOGIC

512Hz

1Hz

MUX/

BUFFER

CLOCK AND

CALENDAR

REGISTERS

USER BUFFER

(7 BYTES)

N

32,768Hz

DIVIDER AND

CALIBRATION

DS1340

ADDRESS BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0 FUNCTION RANGE

00H EOSC 10 Seconds Seconds Seconds 00–59

01H X 10 Minutes Minutes Minutes 00–59

02H CEB CB 10 Hours Hours Century/Hours 0–1; 00–23

03H X X X X X Day Day 01–07

04H X X 10 Date Date Date 01–31

05H X X X 10 Month Month Month 01–12

06H 10 Year Year Year 00–99

07H OUT FT S CAL4 CAL3 CAL2 CAL1 CAL0 Control —

08H TCS3 TCS2 TCS1 TCS0 DS1 DS0 ROUT1 ROUT0 Trickle Charger —

09H OSF 0 0 0 0 0 0 0 Flag —

Page 9

binary-coded decimal (BCD) format. The day-of-week

register increments at midnight. Values that correspond

to the day of week are user-defined but must be

sequential (i.e., if 1 equals Sunday, then 2 equals

Monday, and so on). Illogical time and date entries

result in undefined operation. Bit 7 of register 0 is the

enable oscillator (EOSC) bit. When this bit is set to 1,

the oscillator is disabled. When cleared to 0, the oscillator is enabled. The initial power-up value of EOSC is

0. The clock can be halted whenever the timekeeping

functions are not required, minimizing V

BAT

current

(I

BACKUPDR

) when VCCis not applied.

Location 02h is the century/hours register. Bit 7 and bit

6 of the century/hours register are the century-enable

bit (CEB) and the century bit (CB). Setting CEB to logic

1 causes the CB bit to toggle, either from a logic 0 to a

logic 1, or from a logic 1 to a logic 0, when the years

register rolls over from 99 to 00. If CEB is set to logic 0,

CB does not toggle.

When reading or writing the time and date registers,

secondary (user) buffers are used to prevent errors

when the internal registers update. When reading the

time and date registers, the user buffers are synchronized to the internal registers on any START or STOP

and when the register pointer rolls over to zero. The

time information is read from these secondary registers

while the clock continues to run. This eliminates the

need to reread the registers in case the internal registers update during a read.

The divider chain is reset whenever the seconds register is written. Write transfers occur on the acknowledge

from the DS1340. Once the divider chain is reset, to

avoid rollover issues, the remaining time and date registers must be written within one second.

Special-Purpose Registers

The DS1340 has three additional registers (control,

trickle charger, and flag) that control the RTC, trickle

charger, and oscillator flag output.

Control Register (07h)

Bit 7: Output Control (OUT). This bit controls the output level of the FT/OUT pin when the FT bit is set to 0. If

FT = 0, the logic level on the FT/OUT pin is 1 if OUT = 1

and 0 if OUT = 0. The initial power-up OUT value is 1.

Bit 6: Frequency Test (FT). When this bit is 1, the

FT/OUT pin toggles at a 512Hz rate. When FT is written

to 0, the OUT bit controls the state of the FT/OUT pin.

The initial power-up value of FT is 0.

Bit 5: Calibration Sign Bit (S). A logic 1 in this bit indicates positive calibration for the RTC. A 0 indicates

negative calibration for the clock. See the

Clock

Calibration

section for a detailed description of the bit

operation. The initial power-up value of S is 0.

Bits 4 to 0: Calibration Bits (CAL4 to CAL0). These

bits can be set to any value between 0 and 31 in binary

form. See the

Clock Calibration

section for a detailed

description of the bit operation. The initial power-up

value of CAL0–CAL4 is 0.

Trickle-Charger Register (08h)

The simplified schematic in Figure 6 shows the basic

components of the trickle charger. The trickle-charge

select (TCS) bits (bits 4–7) control the selection of the

trickle charger. To prevent accidental enabling, only a

DS1340

I2C RTC with Trickle Charger

_______________________________________________________________________________________ 9

Figure 6. Trickle Charger Functional Diagram

BIT 7

BIT 6

TCS3

V

CC

BIT 5

TCS2

TCS1

1 OF 16 SELECT

NOTE: ONLY 1010b

ENABLES CHARGER

TCS0

BIT 4

BIT 3

DS1

1 OF 2

SELECT

BIT 2

DS0

BIT 1

ROUT1

SELECT

1 OF 3

BIT 0

ROUT0

TCS

= TRICKLE-CHARGER SELECT

0-3

= DIODE SELECT

DS

0-1

= RESISTOR SELECT

TOUT

0-1

250Ω

2kΩ

4kΩ

R1

R2

R3

V

BACKUP

Page 10

DS1340

pattern on 1010 enables the trickle charger. All other

patterns disable the trickle charger. The trickle charger

is disabled when power is first applied. The diodeselect (DS) bits (bits 2, 3) select whether or not a diode

is connected between VCCand V

BACKUP

. If DS is 01,

no diode is selected; if DS is 10, a diode is selected.

The ROUT bits (bits 0, 1) select the value of the resistor

connected between VCCand V

BACKUP

. Table 3 shows

the resistor selected by the resistor select (ROUT) bits

and the diode selected by the diode select (DS) bits.

Warning: The ROUT value of 250Ω must not be select-

ed whenever VCCis greater than 3.63V.

The user determines diode and resistor selection

according to the maximum current desired for battery

or super cap charging (Table 4). The maximum charging current can be calculated as illustrated in the following example.

Assume that a 3.3V system power supply is applied to

VCCand a super cap is connected to V

BACKUP

. Also

assume that the trickle charger has been enabled with

a diode and resistor R2 between VCCand V

BACKUP

.

The maximum current I

MAX

would therefore be calculat-

ed as follows:

I

MAX

= (3.3V - diode drop) / R2 ≈ (3.3V - 0.7V) /

2kΩ≈1.3mA

As the super cap charges, the voltage drop between

VCCand V

BACKUP

decreases and therefore the charge

current decreases.

Flag Register (09h)

Bit 7: Oscillator Stop Flag (OSF). A logic 1 in this bit

indicates that the oscillator has stopped or was

stopped for some time period and may be used to

judge the validity of the clock and calendar data. This

bit is edge triggered and is set to logic 1 when the

internal circuitry senses that the oscillator has transitioned from a normal run state to a STOP condition. The

following are examples of conditions that can cause the

OSF bit to be set:

1) The first time power is applied.

2) The voltages present on VCCand V

BACKUP

are insufficient to support oscillation.

3) The EOSC bit is set to 1, disabling the

oscillator.

4) External influences on the crystal (e.g., noise,

leakage).

The OSF bit remains at logic 1 until written to logic 0. It

can only be written to logic 0. Attempting to write OSF

to logic 1 leaves the value unchanged.

Bits 6 to 0: All other bits in the flag register read as 0

and cannot be written.

Clock Calibration

The DS1340 provides a digital clock calibration feature

to allow compensation for crystal and temperature variations. The calibration circuit adds or subtracts counts

from the oscillator divider chain at the divide-by-256

stage. The number of pulses blanked (subtracted for

negative calibration) or inserted (added for positive calibration) depends upon the value loaded into the five

calibration bits (CAL4–CAL0) located in the control register. Adding counts speeds the clock up and subtracting counts slows the clock down.

The calibration bits can be set to any value between 0

and 31 in binary form. Bit 5 of the control register, S, is

the sign bit. A value of 1 for the S bit indicates positive

calibration, while a value of 0 represents negative calibration. Calibration occurs within a 64-minute cycle.

The first 62 minutes in the cycle can, once per minute,

I2C RTC with Trickle Charger

10 ______________________________________________________________________________________

Table 4. Trickle-Charge Register

TCS3 TCS2 TCS1 TCS0 DS1 DS0 ROUT1 ROUT0 FUNCTION

X X X X 0 0 X X Disabled

X X X X 1 1 X X Disabled

XXXXXX00Disabled

1 0 1 0 0 1 0 1 No diode, 250Ω resistor

1 0 1 0 1 0 0 1 One diode, 250Ω resistor

1 0 1 0 0 1 1 0 No diode, 2kΩ resistor

1 0 1 0 1 0 1 0 One diode, 2kΩ resistor

1 0 1 0 0 1 1 1 No diode, 4kΩ resistor

1 0 1 0 1 0 1 1 One diode, 4kΩ resistor

0 0 0 0 0 0 0 0 Power-on reset value

Page 11

have a one-second interval where the calibration is performed. Negative calibration blanks 128 cycles of the

32,768Hz oscillator, slowing the clock down. Positive

calibration inserts 256 cycles of the 32,768Hz oscillator,

speeding the clock up. If a binary 1 is loaded into the

calibration bits, only the first two minutes in the 64minute cycle are modified. If a binary 6 is loaded, the

first 12 minutes are affected, and so on. Therefore,

each calibration step either adds 512 or subtracts 256

oscillator cycles for every 125,829,120 actual 32,678Hz

oscillator cycles (64 minutes). This equates to

+4.068ppm or -2.034ppm of adjustment per calibration

step. If the oscillator runs at exactly 32,768Hz, each of

the 31 increments of the calibration bits would represent +10.7 or -5.35 seconds per month, corresponding

to +5.5 or -2.75 minutes per month.

For example, if using the FT function, a reading of

512.01024Hz would indicate a +20ppm oscillator frequency error, requiring a -10(00 1010) value to be

loaded in the S bit and the five calibration bits.

Note: Setting the calibration bits does not affect the frequency test output frequency. Also note that writing to

the control register resets the divider chain.

I

2

C Serial Data Bus

The DS1340 supports a bidirectional I2C bus and data

transmission protocol. A device that sends data onto

the bus is defined as a transmitter and a device receiving data as a receiver. The device that controls the

message is called a master. The devices that are controlled by the master are slaves. A master device that

generates the serial clock (SCL), controls the bus

access, and generates the START and STOP conditions must control the bus. The DS1340 operates as a

slave on the I

2

C bus. Connections to the bus are made

through the open-drain I/O lines SDA and SCL. Within

the bus specifications a standard mode (100kHz max

clock rate) and a fast mode (400kHz max clock rate)

are defined. The DS1340 works in both modes.

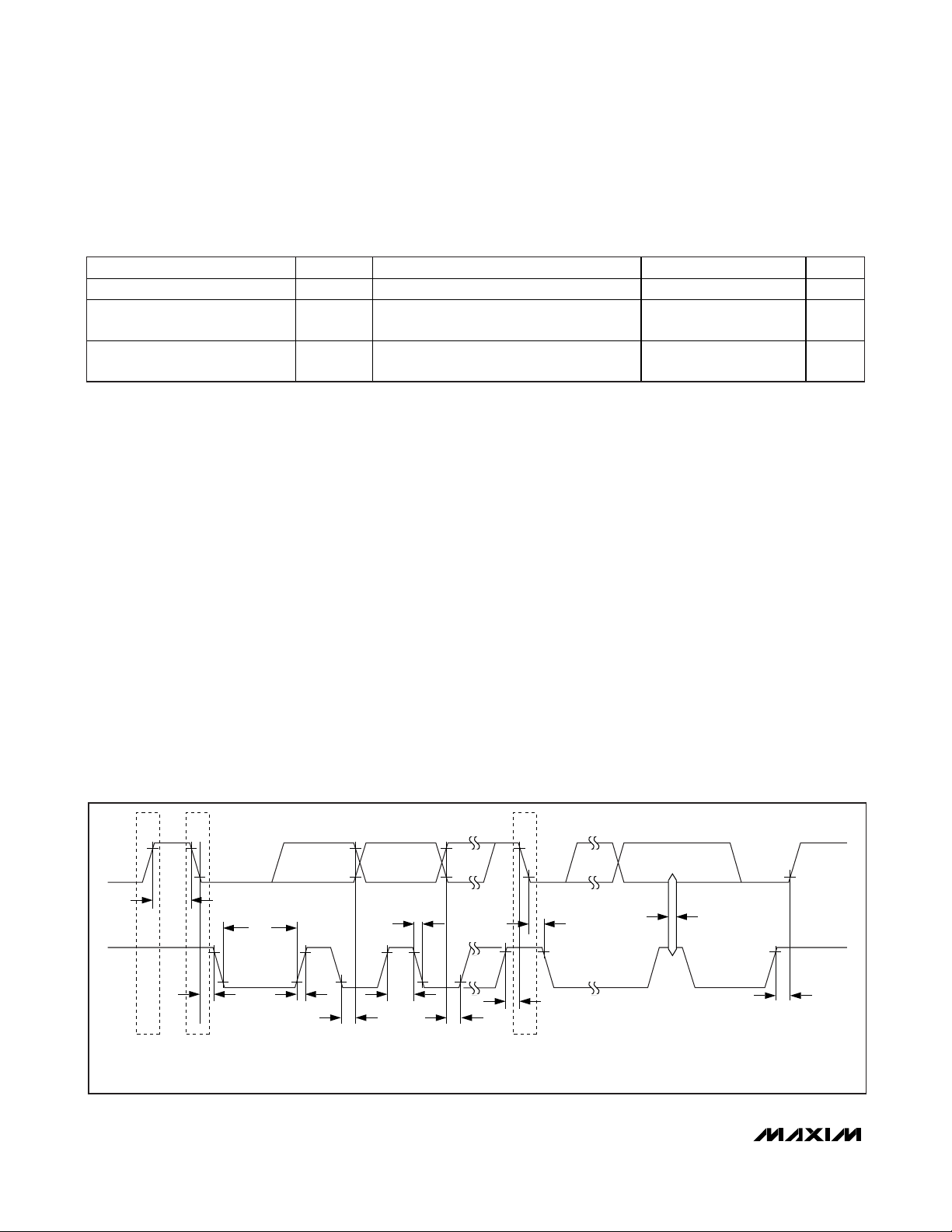

The following bus protocol has been defined (Figure 7):

• Data transfer can be initiated only when the bus is

not busy.

• During data transfer, the data line must remain

stable whenever the clock line is high. Changes in

the data line while the clock line is high are interpreted as control signals.

Accordingly, the following bus conditions have been

defined:

Bus not busy: Both data and clock lines remain

high.

START data transfer: A change in the data line’s

state from high to low, while the clock line is high,

defines a START condition.

STOP data transfer: A change in the data line’s

state from low to high, while the clock line is high,

defines a STOP condition.

Data valid: The data line’s state represents valid

data when, after a START condition, the data line is

stable for the duration of the high period of the

clock signal. The data on the line must be changed

during the low period of the clock signal. There is

one clock pulse per bit of data.

Each data transfer is initiated with a START condition and terminated with a STOP condition. The

number of data bytes transferred between the

START and STOP conditions is not limited, and is

DS1340

I2C RTC with Trickle Charger

______________________________________________________________________________________ 11

Figure 7. I2C Data Transfer Overview

MSB FIRST MSB LSB MSB LSB

SDA

SLAVE

ADDRESS

SCL

IDLE

START

CONDITION

1–7 8 9 1–7 8 9 1–7 8 9

R/W ACK ACKDATA ACK/

REPEATED IF MORE BYTES

ARE TRANSFERRED

DATA

NACK

STOP CONDITION

REPEATED START

Page 12

DS1340

I2C RTC with Trickle Charger

12 ______________________________________________________________________________________

determined by the master device. The information

is transferred byte-wise and each receiver

acknowledges with a ninth bit.

Acknowledge: Each receiving device, when

addressed, is obliged to generate an acknowledge after the reception of each byte. The master

device must generate an extra clock pulse that is

associated with this acknowledge bit.

A device that acknowledges must pull down the

SDA line during the acknowledge clock pulse in

such a way that the SDA line is stable low during

the high period of the acknowledge-related clock

pulse. Setup and hold times must be taken into

account. A master must signal an end of data to

the slave by not generating an acknowledge bit on

the last byte that has been clocked out of the

slave. In this case, the slave must leave the data

line high to enable the master to generate the

STOP condition.

Figures 8 and 9 detail how data transfer is accomplished on the I2C bus. Depending upon the state of

the R/W bit, two types of data transfer are possible:

Data transfer from a master transmitter to a

slave receiver. The first byte transmitted by the

master is the slave address. Next follows a number of data bytes. The slave returns an acknowledge bit after each received byte.

Data transfer from a slave transmitter to a master receiver. The master transmits the first byte (the

slave address). The slave then returns an acknowledge bit. Next follows a number of data bytes transmitted by the slave to the master. The master

returns an acknowledge bit after all received bytes

other than the last byte. At the end of the last

received byte, a not acknowledge is returned.

The master device generates all the serial clock

pulses and the START and STOP conditions. A

transfer is ended with a STOP condition or with a

repeated START condition. Since a repeated

START condition is also the beginning of the next

serial transfer, the bus is not released.

The DS1340 can operate in the following two modes:

Slave Receiver Mode (Write Mode): Serial data

and clock are received through SDA and SCL.

After each byte is received, an acknowledge bit is

transmitted. Start and STOP conditions are recognized as the beginning and end of a serial transfer. Hardware performs address recognition after

reception of the slave address and direction bit.

The slave address byte is the first byte received

after the master generates the START condition.

The slave address byte contains the 7-bit DS1340

address, which is 1101000, followed by the direction bit (R/W), which is 0 for a write. After receiving

and decoding the slave address byte, the DS1340

outputs an acknowledge on SDA. After the

DS1340 acknowledges the slave address + write

bit, the master transmits a word address to the

DS1340. This sets the register pointer on the

DS1340, with the DS1340 acknowledging the

transfer. The master can then transmit zero or

more bytes of data, with the DS1340 acknowledging each byte received. The register pointer increments after each data byte is transferred. The

master generates a STOP condition to terminate

the data write.

Slave Transmitter Mode (Read Mode): The first

byte is received and handled as in the slave

receiver mode. However, in this mode, the direction bit indicates that the transfer direction is

reversed. The DS1340 transmits serial data on

SDA while the serial clock is input on SCL. Start

and STOP conditions are recognized as the beginning and end of a serial transfer. Hardware performs address recognition after reception of the

slave address and direction bit. The slave address

byte is the first byte received after the master generates the START condition. The slave address

byte contains the 7-bit DS1340 address, which is

1101000, followed by the direction bit (R/W),

which is 1 for a read. After receiving and decoding

the slave address byte, the DS1340 outputs an

acknowledge on SDA. The DS1340 then begins to

transmit data starting with the register address

pointed to by the register pointer. If the register

pointer is not written to before the initiation of a

read mode, the first address that is read is the last

one stored in the register pointer. The DS1340

must receive a not acknowledge to end a read.

Page 13

DS1340

I2C RTC with Trickle Charger

______________________________________________________________________________________ 13

<SLAVE

Figure 8. Data Write—Slave Receiver Mode

Figure 9. Data Read—Slave Transmitter Mode

Figure 10. Data Write/Read (Write Pointer, Then Read)—Slave Receive and Transmit

ADDRESS> <R/W> <WORD ADDRESS (n)> <DATA (n)> <DATA (n + 1)>

S - START

A - ACKNOWLEDGE (ACK)

P - STOP

R/W - READ/WRITE OR DIRECTION BIT ADDRESS

MASTER TO SLAVE SLAVE TO MASTER

<DATA (n + X)

AXXXXXXXXA1101000S 0 XXXXXXXX A XXXXXXXX A XXXXXXXX A P

DATA TRANSFERRED

(X + 1 BYTES + ACKNOWLEDGE)

...

<SLAVE

ADDRESS> <R/W> <DATA (n)> <DATA (n + 1)> <DATA (n + 2)>

S - START

A - ACKNOWLEDGE (ACK)

P - STOP

A - NOT ACKNOWLEDGE (NACK)

R/W - READ/WRITE OR DIRECTION BIT ADDRESS

MASTER TO SLAVE SLAVE TO MASTER

<SLAVE

ADDRESS>

<DATA (n)> <DATA (n + 1)> <DATA (n + 2)> <DATA (n + X)>

AXXXXXXXX XXXXXXXX A XXXXXXXX A XXXXXXXX A P

S - START

Sr - REPEATED START

A - ACKNOWLEDGE (ACK)

P - STOP

A - NOT ACKNOWLEDGE (NACK)

R/W - READ/WRITE OR DIRECTION BIT ADDRESS

<DATA (n + X)>

AXXXXXXXXA1101000S 1 XXXXXXXX A XXXXXXXX A XXXXXXXX A P

DATA TRANSFERRED

(X + 1 BYTES + ACKNOWLEDGE)

NOTE: LAST DATA BYTE IS FOLLOWED BY A NACK.

<SLAVE

<R/W><R/W> <WORD ADDRESS (n)>

ADDRESS>

AXXXXXXXXA1101000 1101000S Sr0 A1

...

...

MASTER TO SLAVE SLAVE TO MASTER

DATA TRANSFERRED

(X + 1 BYTES + ACKNOWLEDGE)

NOTE: LAST DATA BYTE IS FOLLOWED BY A NACK.

Page 14

DS1340

I2C RTC with Trickle Charger

14 ______________________________________________________________________________________

Chip Information

PROCESS: CMOS

SUBSTRATE CONNECTED TO GROUND

Thermal Information

Theta-JA: 170°C/W (0.150in SO)

Theta-JC: 40°C/W (0.150in SO)

Theta-JA: 221°C/W (µSOP)

Theta-JC: 39°C/W (µSOP)

Theta-JA: 89.6°C/W (0.300in SO)

Theta-JC: 24.8°C/W (0.300in SO)

Handling, PC Board Layout,

and Assembly

The DS1340C package contains a quartz tuning-fork

crystal. Pick-and-place equipment may be used, but

precautions should be taken to ensure that excessive

shocks are avoided. Exposure to reflow is limited to 2

times maximum. Ultrasonic cleaning should be avoided

to prevent damage to the crystal.

Avoid running signal traces under the package, unless

a ground plane is placed between the package and the

signal line. All N.C. (no connect) pins must be connected to ground.

Moisture-sensitive packages are shipped from the factory dry-packed.Handling instructions listed on the package label must be followed to prevent damage during

reflow. Refer to the IPC/JEDEC J-STD-020 standard for

moisture-sensitive device (MSD) classifications.

1

2

3

4

8

7

6

5

V

CC

FT/OUT

SCL

SDA

V

BACKUP

GND

X2

X1

TOP VIEW

SO, μSOP

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

SCL

SDA

GND

V

BACKUP

N.C.

N.C.

N.C.

N.C.

N.C.

SO (300 mils)

FT/OUT

V

CC

N.C.

N.C.

N.C.

N.C.

N.C.

DS1340

DS1340C

Pin Configurations

PACKAGE

TYPE

PACKAGE

CODE

OUTLINE NO.

LAND

PATTERN NO.

8 SO (150 mils) S8+2

21-0041

90-0096

8 µSOP U8+1

21-0036

90-0092

16 SO (300 mils) W16#H2

21-0042 90-0107

Package Information

For the latest package outline information and land patterns

(footprints), go to www.maxim-ic.com/packages

. Note that a

“+”, “#”, or “-” in the package code indicates RoHS status only.

Package drawings may show a different suffix character, but

the drawing pertains to the package regardless of RoHS status.

Page 15

DS1340

I2C RTC with Trickle Charger

______________________________________________________________________________________ 15

Revision History

REVISION

NUMBER

0 6/03

1 7/04

2 12/04

3 11/05 Updated the Ordering Information tab le to correct lead-free/RoHS packages. 1

4 3/06

5 8/08

REVISION

DATE

DESCRIPTION

Initial release. —

Changed “2-wire” to “I2C” throughout the data sheet.

Added UL recognition info bullet to the Features section and to the V

description.

Added the “I/O Capacitance (SCL, SDA)” parameter (C

Characteri st ics table.

Added “SDA, SCL” and “V

and changed the sy mbol from “V

Conditions table; in the DC Electr ica l Characteristics table, changed the “Oscillator

Current” parameter to “V

Added the integrated-crystal and lead-free package s to the Ordering Information table;

added the integrated-crystal packages to the Features, P in Configurations, Pin

Description.

In Table 1, added increased crystal ESR with increased suppl y min imum voltage

requirement.

Added the DS1340C Only sect ion. 7

Updated Figure 5 to al so show the “C Version” crysta l. 7

Added the Handling, PC Board Layout, and Assembly section. 12

Added the integrated-crystal package Theta-JA and Theta- JC informat ion to the

Thermal Information sect ion.

In the General Description section, indicated that the time and date function continues

while powered by V

Updated the Typical Operating Circuit by removing pin numbers and adding a b ypas s

capacitor.

In the Pin Description, updated the V

should be placed between the battery and pin and added the UL link; changed the

V

description.

CC

Added the Power Control section and new Table 1. 6

In the Handling, PC Board Layout, and Assembl y section, added solder reflow

information for the RoHS SO package.

Added Package Information table. 14

Removed leaded part numbers from the Ordering Information table. 1

Removed the t

In the Typical Operating Characterist ic s section, updated/changed the “FT vs.

V

In the Pin Description, added pullup vo ltage information to the SDA, SCL, and FT/OUT

descriptions.

Updated Figure 5. 8

In the Clock and Calendar section, added text explaining the use of EOSC to halt the

oscillator.

Replaced Figure 7 with an updated version; changed Figures 8 and 9 and added

Figure 10 with more comprehensive I

” graph to “OSCILLATOR FREQUENCY vs. SUPPLY VOLTAGE (FT x 64).”

BACKUP

BACKUP

parameter and RST waveform from Figure 2. Replaced t

RPU

= 0V” to the “Supply Voltage, Pullup (FT/OUT)” parameter

CC

BACKUP

” to “VPU” in the Recommended DC Operating

IH

Current.”

.

description to indicate that no diodes

BACKUP

2

C figures.

) to the AC Electrical

I/O

BACKUP

RST

pin

with t

REC

.

PAGES

CHANGED

All

1, 6

2

3

1, 6

6

13

1

1

6

13

5

5

6

9

13

Page 16

DS1340

I2C RTC with Trickle Charger

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2011 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Revision History (continued)

REVISION

NUMBER

6 10/10

7 8/11

REVISION

DATE

DESCRIPTION

Updated the top mark information in the Ordering Information table. 1

Updated the soldering information in the Absolute Maximum Ratings sect ion. 2

Updated the SDA and SCL pin descriptions in the Pin Description table. 6

Increased ESR from 45,60k (max) to 80k (max) in Table 2.

Updated the Package Information table. 14

Raised V

provide wide vo ltage functiona l operation; reorganized the EC tables and note s

l im it s for the -18 and -3 version s from 1.89V and 3.3V to 5.5V to

CC(MAX)

PAGES

CHANGED

7

2, 3

Loading...

Loading...