Page 1

General Description

The DS1086 EconOscillator™ is a programmable clock

generator that produces a spread-spectrum (dithered)

square-wave output of frequencies from 260kHz to

133MHz. The selectable dithered output reduces radiated-emission peaks by dithering the frequency 2% or

4% below the programmed frequency. The DS1086 has

a power-down mode and an output-enable control for

power-sensitive applications. All the device settings are

stored in nonvolatile (NV) EEPROM memory allowing it

to operate in stand-alone applications.

Applications

Printers

Copiers

PCs

Computer Peripherals

Cell Phones

Cable Modems

Features

o User-Programmable Square-Wave Generator

o Frequencies Programmable from 260kHz to

133MHz

o 2% or 4% Selectable Dithered Output

o Glitchless Output-Enable Control

o 2-Wire Serial Interface

o Nonvolatile Settings

o 5V Supply

o No External Timing Components Required

o Power-Down Mode

o 10kHz Master Frequency Step Size

o EMI Reduction

DS1086

Spread-Spectrum EconOscillator

________________________________________________________________

Maxim Integrated Products

1

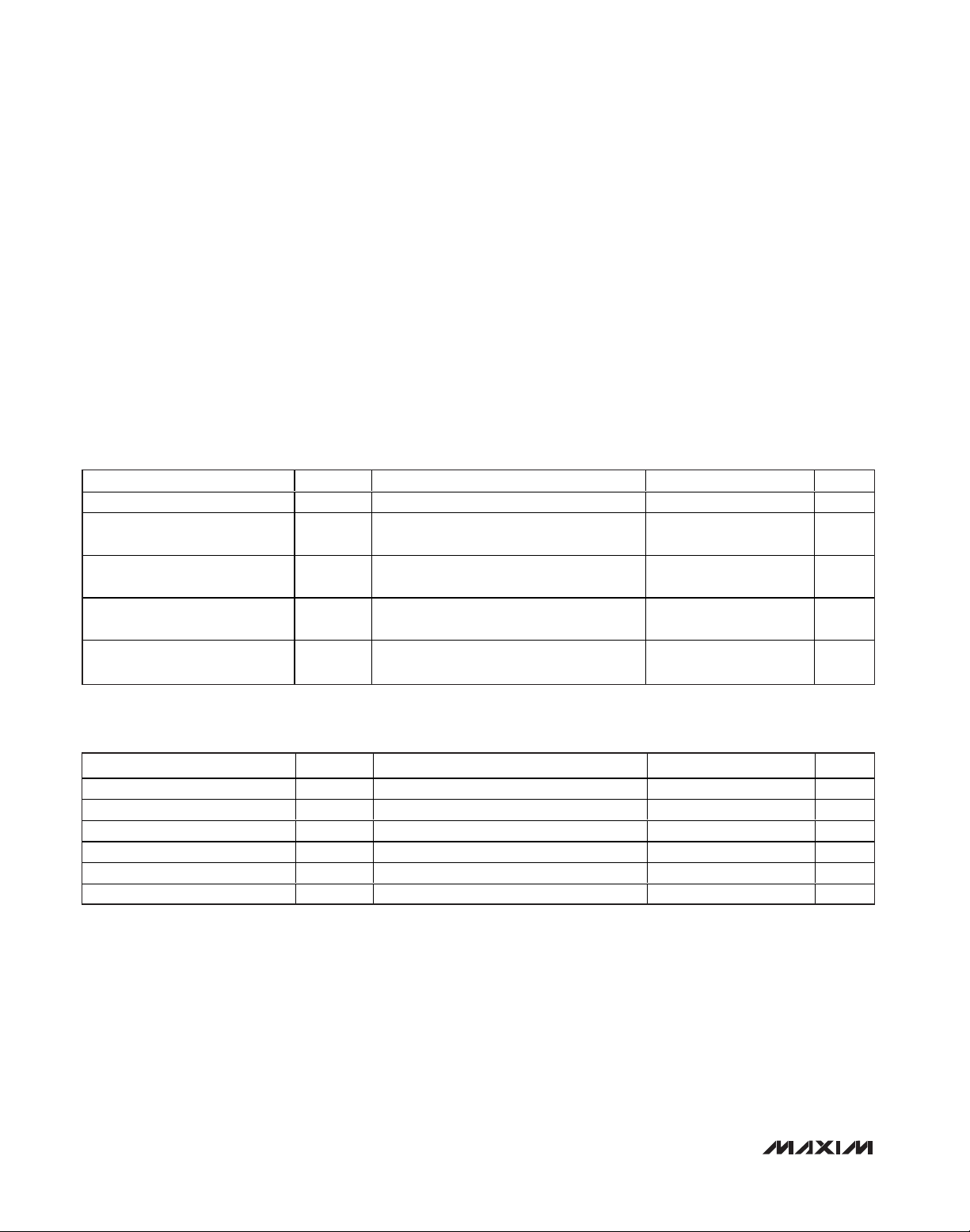

Pin Configuration

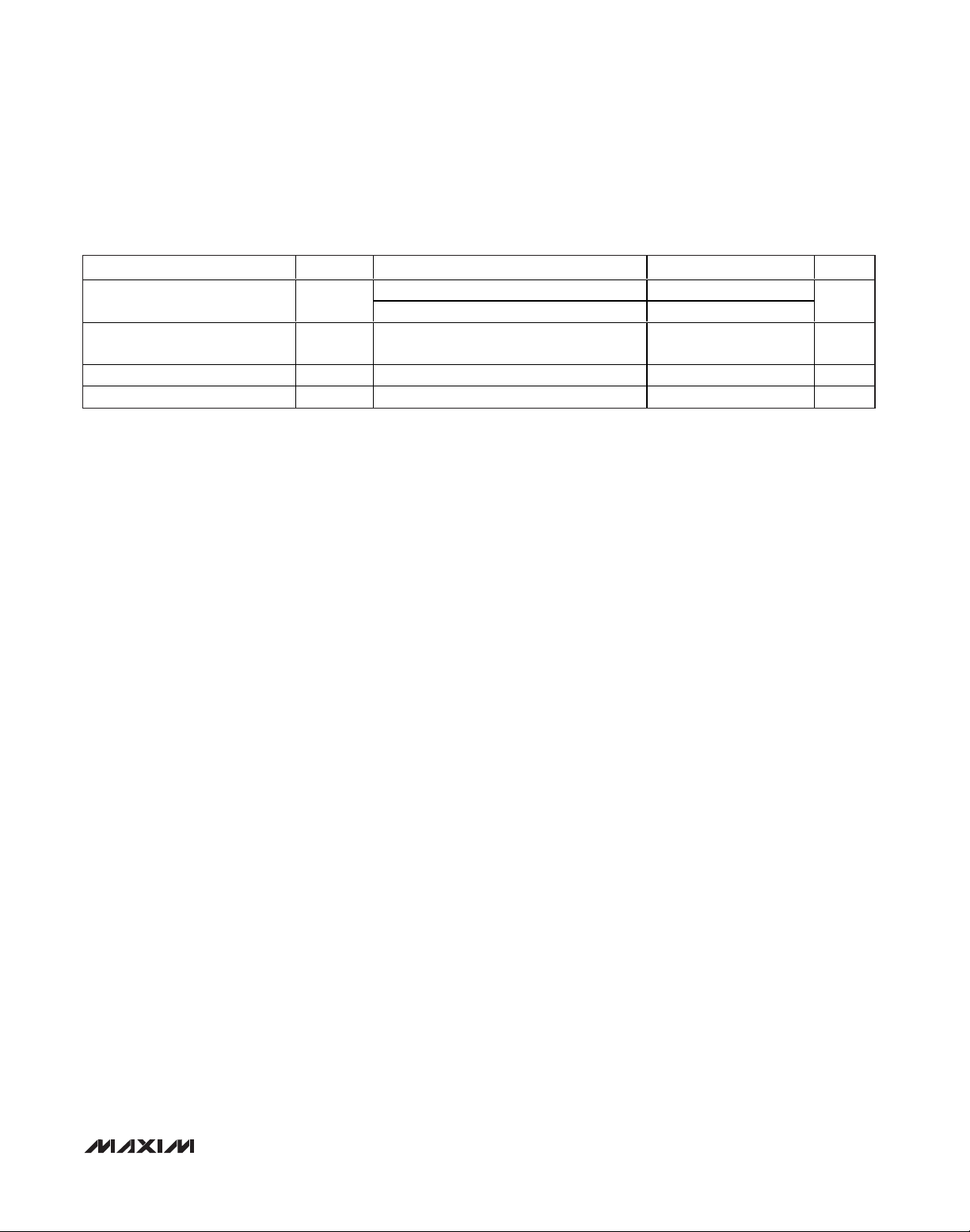

Ordering Information

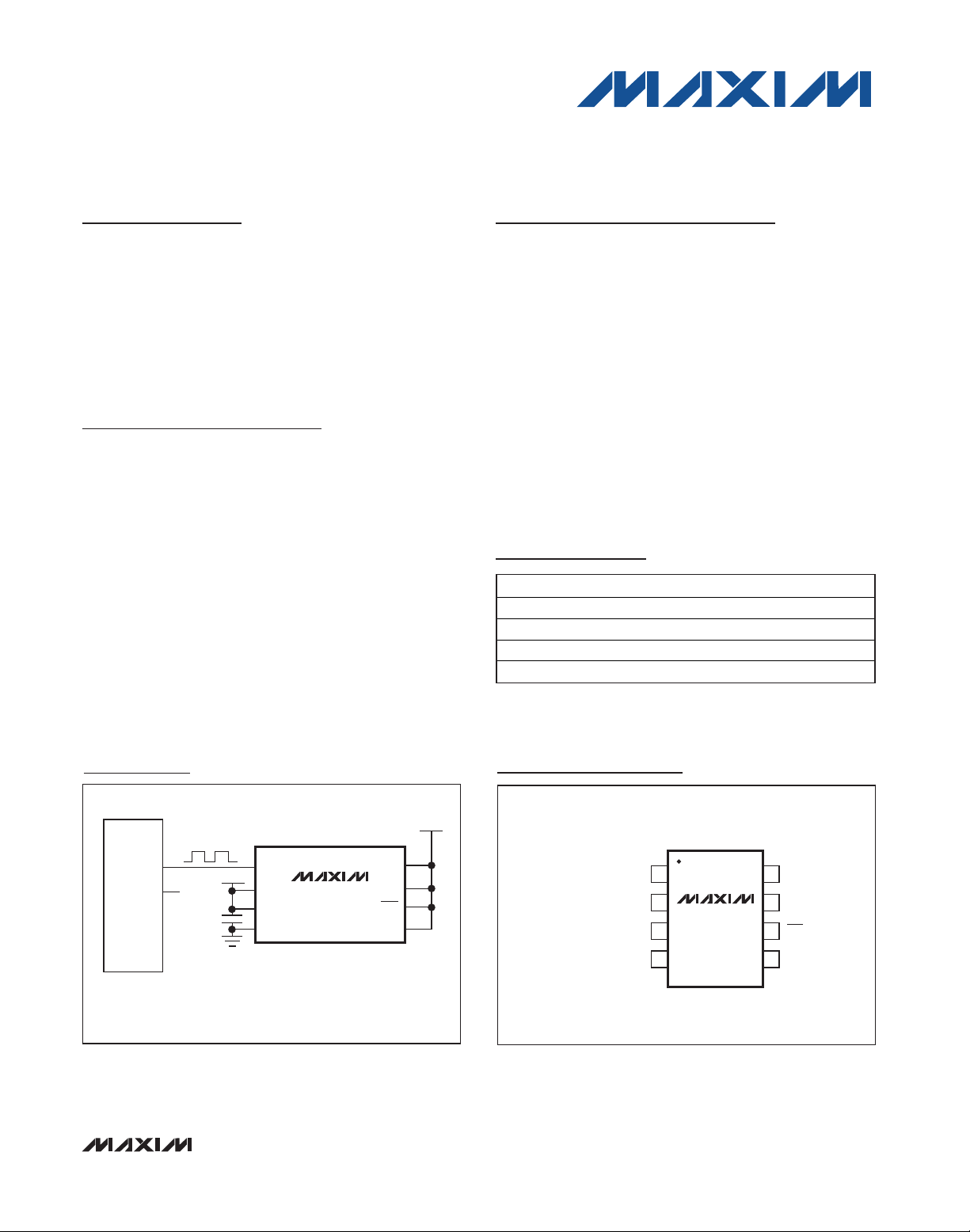

Typical Operating Circuit

19-6224; Rev 2; 3/12

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Note: Contact the factory for custom settings.

+

Denotes a lead(Pb)-free/RoHS-compliant package.

PART TEMP RANGE PIN-PACKAGE

DS1086U 0°C to +70°C 8 µSOP

DS1086U+ 0°C to +70°C 8 µSOP

DS1086Z 0°C to +70°C 8 SO

DS1086Z+ 0°C to +70°C 8 SO

EconOscillator is a trademark of Maxim Integrated Products, Inc.

MICRO-

PROCESSOR

XTL1/OSC1

XTL2/OSC2

*SDA AND SCL CAN BE CONNECTED DIRECTLY HIGH IF THE DS1086 NEVER NEEDS

TO BE PROGRAMMED IN-CIRCUIT, INCLUDING DURING PRODUCTION TESTING.

DITHERED 260kHz TO

133MHz OUTPUT

OUT

V

CC

N.C.

DECOUPLING CAPACITORS

(0.1µF and 0.01µF)

SPRD

V

CC

GND

DS1086

SCL*

SDA*

PDN

V

CC

OE

TOP VIEW

OUT

V

1

2

DS1086

3

CC

4

µSOP/SO

87SCL

SDASPRD

PDN

6

OEGND

5

Page 2

DS1086

Spread-Spectrum EconOscillator

2 _______________________________________________________________________________________

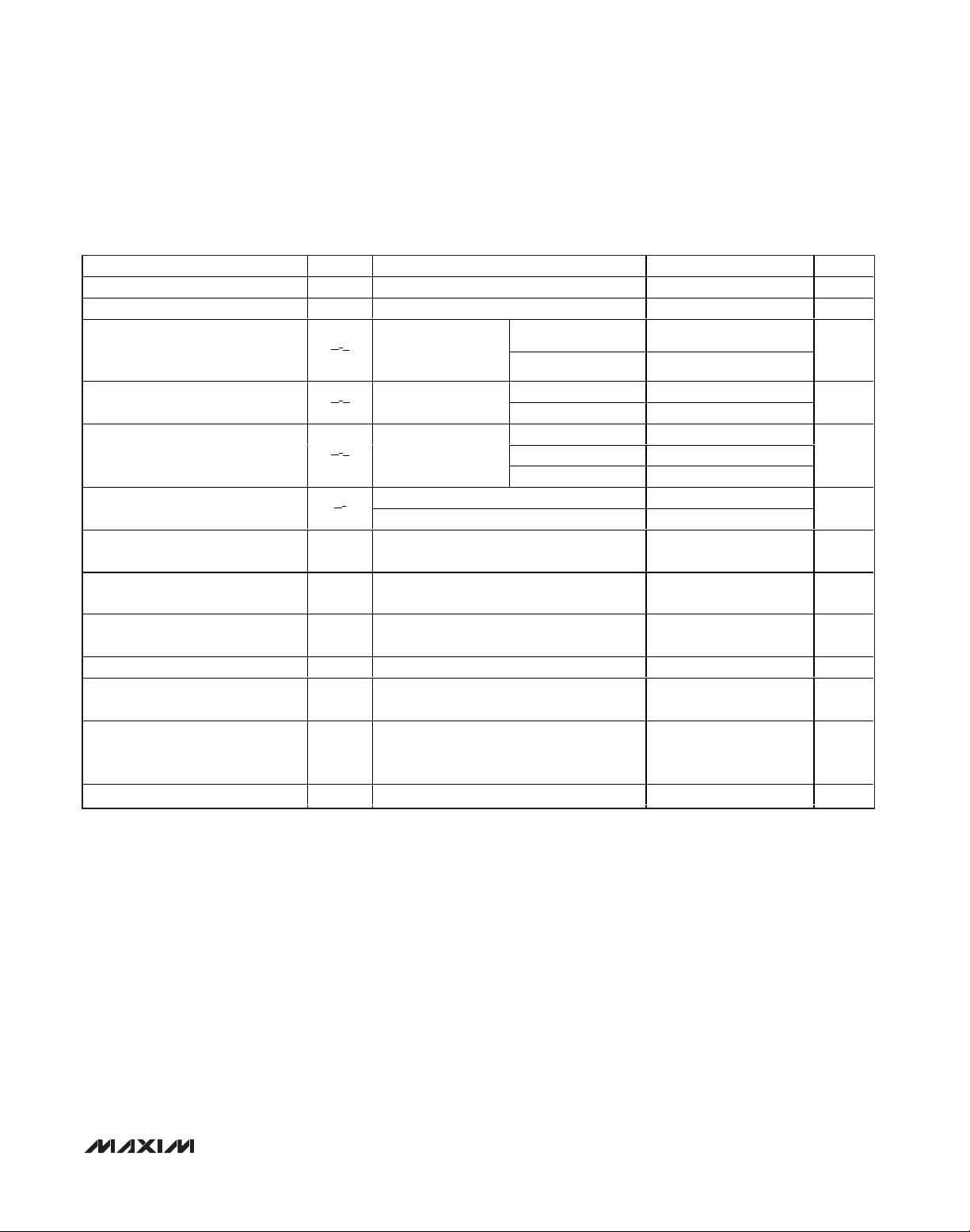

ABSOLUTE MAXIMUM RATINGS

RECOMMENDED DC OPERATING CONDITIONS

(VCC= 5V ±5%, TA= 0°C to +70°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

DC ELECTRICAL CHARACTERISTICS

(VCC= 5V ±5%, TA= 0°C to +70°C.)

Voltage on VCCRelative to Ground ......................-0.5V to +6.0V

Voltage on SPRD, PDN, OE, SDA,

SCL Relative to Ground (See Note 1).......-0.5 to (V

CC

+ 0.5V)

Continuous Power Dissipation (T

A

= +70°C)

µSOP (derate 4.5mW/°C above +70°C)........................362mW

SO (derate 5.9mW/°C above +70°C).........................470.6mW

Junction Temperature......................................................+150°C

Operating Temperature Range...............................0°C to +70°C

Storage Temperature Range .............................-55°C to +125°C

Soldering Temperature (reflow)

Lead(Pb)-free................................................................+260°C

Containing lead(Pb) .....................................................+240°C

Note 1: This voltage must not exceed 6.0V.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage V

High-Level Input Voltage

(SDA, SCL)

Low-Level Input Voltage

(SDA, SCL)

High-Level Input Voltage

(SPRD, PDN, OE)

Low-Level Input Voltage

(SPRD, PDN, OE)

CC

V

V

V

V

(Note 1) 4.75 5.00 5.25 V

IH

IL

IH

IL

0.7 x

V

CC

-0.3

2

-0.3 0.8 V

VCC +

0.3

0.3 x

V

CC

V

CC

0.3

+

V

V

V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

High-Level Output Voltage (OUT) V

Low-Level Output Voltage (OUT) V

High-Level Input Current I

Low-Level Input Current I

Supply Current (Active)

Standby Current (Power-Down) I

OH

OL

IH

IL

I

CC

CCQ

IOH = -4mA, VCC = min 2.4 V

IOL = 4mA 0.4 V

VCC = 5.25V 1 µA

VIL = 0V -1 µA

CL = 15pF (output at default frequency) 35 mA

Power-down mode 35 µA

Page 3

DS1086

Spread-Spectrum EconOscillator

_______________________________________________________________________________________ 3

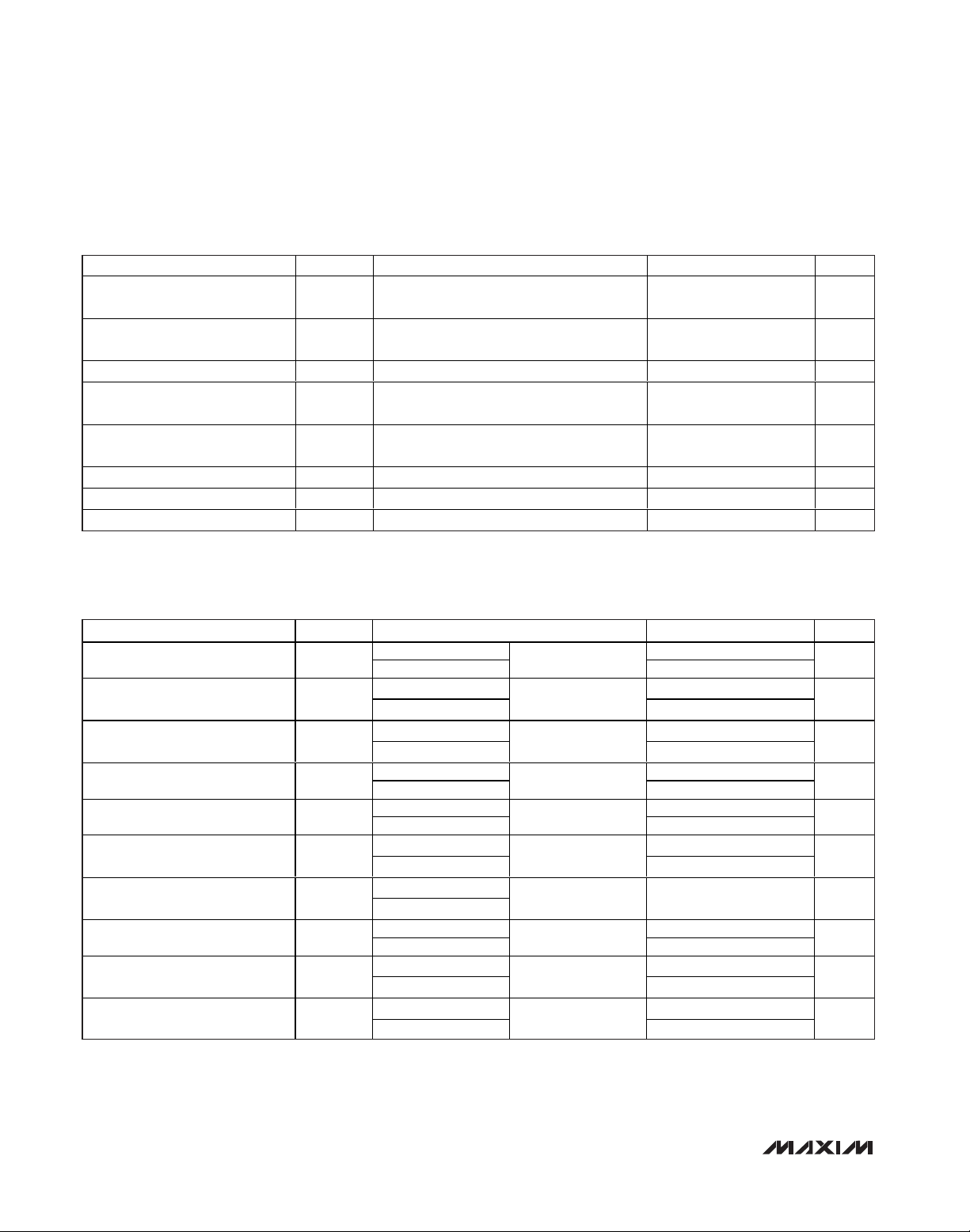

MASTER OSCILLATOR CHARACTERISTICS

(VCC= 5V ±5%, TA= 0°C to +70°C.)

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS

Master Oscillator Range f

Default Master Oscillator Frequency f

Master Oscillator Frequency

Tolerance

Voltage Frequency Variation

Dither Frequency Range

Integral Nonlinearity of Frequency

DAC

DAC Step Size

DAC Span

DAC Default Factory default register setting 500 decimal

Offset Step Size

Offset Default OS

Dither Rate f0/4096 Hz

OSC

INL Entire range (Note 7) -0.4 +0.4 %

(Note 2) 66 133 MHz

0

VCC = 5V,

∆ f

0

T

= +25°C

f

∆

f

∆

f

∆

f

A

0

(Notes 3,17)

f

Over voltage range,

V

0

f

T

0

f

0 Prescaler bit J0 = 0 (Note 6) 4

= +25°C (Note 4)

T

A

Over temperature

range, V

(Note 5)

Prescaler bit J0 = 1 (Note 6) 2

∆ between two consecutive DAC values

(Note 8)

Frequency range for one offset setting

(see Table 2)

∆ between two consecutive offset values

(see Table 2)

Factory default OFFSET register setting

(5 LSBs) (see Table 2)

CC

= 5V

Default frequency (f0) -0.75 +0.75

DAC step size -0.75 +0.75

Default frequency -0.75 +0.75

DAC step size -0.75 +0.75

Default frequency -0.5 +0.5

133MHz -0.5 +0.5Temperature Frequency Variation

66MHz -1.0 +1.0

97.1 MHz

10 kHz

10.24 MHz

5.12 MHz

RANGE

(5 LSBs of

RANGE register)

%

%

%

%

hex

Page 4

DS1086

Spread-Spectrum EconOscillator

4 _______________________________________________________________________________________

AC ELECTRICAL CHARACTERISTICS

(VCC= 5V ±5%, TA= 0°C to +70°C.)

p

AC ELECTRICAL CHARACTERISTICS: 2-WIRE INTERFACE

(VCC= 5V ±5%, TA= 0°C to +70°C.)

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS

Frequency Stable After Prescaler

Change

Frequency Stable After DAC or

Offset Change

Power-Up Time t

Enable of OUT After Exiting

Power-Down Mode

OUT High-Z After Entering

Power-Down Mode

Load Capacitance C

Output Duty Cycle (OUT) 40 60 %

PDN Rise/Fall Time 1µs

+ t

or

t

stab

t

pdn

(Note 9) 0.2 1 ms

(Note 10) 0.1 0.5 ms

stab

(Note 11) 15 50 pF

L

1 Period

500 µs

0.1 ms

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS

SCL Clock Frequency f

Bus Free Time Between a STOP

and START Condition

Hold Time (Repeated) START

Condition

LOW Period of SCL t

HIGH Period of SCL t

Setup Time for a Repeated

START

Data Hold Time t

Data Setup Time t

Rise Time of Both SDA and SCL

Signals

Fall Time of Both SDA and SCL

Signals

SCL

t

BUF

t

HD:STA

LOW

HIGH

t

SU:STA

HD:DAT

SU:DAT

t

R

t

F

Fast mode 400

Standard mode

Fast mode 1.3

Standard mode

Fast mode 0.6

Standard mode

Fast mode 1.3

Standard mode

Fast mode 0.6

Standard mode

Fast mode 0.6

Standard mode

Fast mode

Standard mode

Fast mode 100

Standard mode

Fast mode 20 + 0.1C

Standard mode

Fast mode 20 + 0.1C

Standard mode

(Note 12)

(Note 12)

(Notes 12, 13)

(Note 12)

(Note 12)

(Note 12)

(Notes 12, 14, 15) 0 0.9 µs

(Note 12)

(Note 16)

(Note 16)

4.7

4.0

4.7

4.0

4.7

250

20 + 0.1C

20 + 0.1C

B

B

B

B

100

300

1000

300

1000

kHz

µs

µs

µs

µs

µs

ns

ns

ns

Page 5

DS1086

Spread-Spectrum EconOscillator

_______________________________________________________________________________________ 5

AC ELECTRICAL CHARACTERISTICS: 2-WIRE INTERFACE (continued)

(VCC= 5V ±5%, TA= 0°C to +70°C.)

Note 1: All voltages are referenced to ground.

Note 2: DAC and OFFSET register settings must be configured to maintain the master oscillator frequency within this range.

Correct operation of the device is not guaranteed if these limits are exceeded.

Note 3: This is the absolute accuracy of the master oscillator frequency at the default settings.

Note 4: This is the change that is observed in master oscillator frequency with changes in voltage from nominal voltage at

T

A

= +25°C.

Note 5: This is the percentage frequency change from the +25°C frequency due to temperature at V

CC

= 5V. The maximum temperature change varies with the master oscillator frequency setting. The minimum occurs at the default master oscillator

frequency (f

default

). The maximum occurs at the extremes of the master oscillator frequency range (66MHz or 133MHz)

(see Figure 2).

Note 6: The dither deviation of the master oscillator frequency is unidirectional and lower than the undithered frequency.

Note 7: The integral nonlinearity of the frequency adjust DAC is a measure of the deviation from a straight line drawn between the

two endpoints of a range. The error is in percentage of the span.

Note 8: This is true when the prescaler = 1.

Note 9: Frequency settles faster for small changes in value. During a change, the frequency transitions smoothly from the original

value to the new value.

Note 10: This indicates the time elapsed between power-up and the output becoming active. An on-chip delay is intentionally

introduced to allow the oscillator to stabilize. t

stab

is equivalent to approximately 512 master clock cycles and therefore

depends on the programmed clock frequency.

Note 11: Output voltage swings can be impaired at high frequencies combined with high output loading.

Note 12: A fast-mode device can be used in a standard-mode system, but the requirement t

SU:DAT

> 250ns must then be met.

This is automatically the case if the device does not stretch the LOW period of the SCL signal. If such a device does

stretch the LOW period of the SCL signal, it must output the next data bit to the SDA line at least t

R MAX

+ t

SU:DAT

=

1000ns + 250ns = 1250ns before the SCL line is released.

Note 13: After this period, the first clock pulse is generated.

Note 14: A device must internally provide a hold time of at least 300ns for the SDA signal (referred to as the V

IH MIN

of the SCL sig-

nal) in order to bridge the undefined region of the falling edge of SCL.

Note 15: The maximum t

HD:DAT

need only be met if the device does not stretch the LOW period (t

LOW

) of the SCL signal.

Note 16: C

B

—total capacitance of one bus line, timing referenced to 0.9 x VCCand 0.1 x VCC.

Note 17: Typical frequency shift due to aging is ±0.5%. Aging stressing includes Level 1 moisture reflow preconditioning (24hr

+125°C bake, 168hr 85°C/85%RH moisture soak, and 3 solder reflow passes +240 +0/-5°C peak) followed by 1000hr

max V

CC

biased 125°C HTOL, 1000 temperature cycles at -55°C to +125°C, 96hr 130°C/85%RH/5.5V HAST and 168hr

121°C/2 ATM Steam/Unbiased Autoclave.

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS

Setup Time for STOP t

Capacitive Load for Each Bus

Line

NV Write-Cycle Time t

Input Capacitance C

SU:STO

C

WR

Fast mode 0.6

Standard mode 4.0

(Note 16) 400 pF

B

I

5pF

10 ms

µs

Page 6

Typical Operating Characteristics

(VCC= 5.0V, TA= 25°C, unless otherwise noted)

DS1086

Spread-Spectrum EconOscillator

6 _______________________________________________________________________________________

SUPPLY CURRENT vs. TEMPERATURE

DS1086 toc01

TEMPERATURE (°C)

CURRENT (mA)

605030 402010

11

12

13

14

15

16

17

18

19

20

10

070

SUPPLY CURRENT vs. VOLTAGE

DS1086 toc02

VOLTAGE (V)

CURRENT (mA)

5.155.054.954.854.75 5.25

11

12

13

14

15

16

17

18

19

20

10

SUPPLY CURRENT vs. PRESCALER

DS1086 toc03

PRESCALER

CURRENT (mA)

200150100500250

11

12

13

14

15

16

17

18

19

20

10

5.25V

5.0V

4.75V

SUPPLY CURRENT vs. PRESCALER

DS1086 toc04

PRESCALER

CURRENT (mA)

200150100500250

11

12

13

14

15

16

17

18

19

20

10

70°C, 25°C, AND 0°C

SUPPLY CURRENT vs. TEMPERATURE

WITH OE = 0

DS1086 toc05

TEMPERATURE (°C)

CURRENT (mA)

605030 402010

1

2

3

4

5

6

7

8

9

10

0

070

SUPPLY CURRENT vs. TEMPERATURE

WITH PDN = 0

DS1086 toc06

TEMPERATURE (°C)

CURRENT (µA)

605030 402010

1

2

3

4

5

6

7

8

9

10

0

070

FREQUENCY PERCENT CHANGE

vs. SUPPLY VOLTAGE

DS1086 toc07

VOLTAGE (V)

FREQUENCY PERCENT CHANGE FROM 5V

5.155.054.954.85

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

4.75 5.25

FREQUENCY PERCENT CHANGE

vs. TEMPERATURE

DS1086 toc08

TEMPERATURE (°C)

FREQUENCY PERCENT CHANGE FROM 25°C

605030 402010

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

070

Page 7

DS1086

Spread-Spectrum EconOscillator

_______________________________________________________________________________________ 7

Pin Description

Processor-Controlled Mode

Stand-Alone Mode

Figure 1. Clock Spectrum Dither Comparison

Figure 2. Temperature Variation Over Frequency

PIN NAME FUNCTION

1 OUT Oscillator Output

2 SPRD Dither Enable. When the pin is high, the dither is enabled. When the pin is low, the dither is disabled.

3VCCPower Supply

4 GND Ground

5OE

6 PDN

7 SDA

8 SCL

CLOCK SPECTRUM COMPARISON

(9kHz BW, PEAK DETECT)

0

CRYSTAL OSC

-5

-10

-15

DS1086 4% DITHER

-20

-25

-30

RELATIVE AMPLITUDE (dBm)

-35

-40

90 95

Output Enable. When the pin is high, the output buffer is enabled. When the pin is low, the output is

disabled but the master oscillator is still on.

Power-Down. When the pin is high, the master oscillator is enabled. When the pin is low, the master

oscillator is disabled (power-down mode).

2-Wire Serial Data. This pin is for serial data transfer to and from the device. The pin is open drain

and can be wire-OR’ed with other open-drain or open-collector interfaces.

2-Wire Serial Clock. This pin is used to clock data into the device on rising edges and clock data out

on falling edges.

MAXIMUM TEMPERATURE VARIATION

vs. MASTER FREQUENCY

2.0

DS1086 NO DITHER

FREQUENCY (MHz)

DS1086 fig01

9491 9392

1.5

1.0

0.5

0

-0.5

-1.0

FREQUENCY % CHANGE FROM 25°C

-1.5

-2.0

66.00 133.00

82.75 116.2599.50

FREQUENCY (MHz)

DS1086 fig02

V

DITHERED 260kHz TO

133MHz OUTPUT

V

CC

DECOUPLING CAPACITORS

(0.1µF and 0.01µF)

OUT

SPRD

V

GND

DS1086

CC

4.7kΩ 4.7kΩ

SCL

SDA

V

PDN

OE

CC

MICRO-

PROCESSOR

XTL1/OSC1

2-WIRE

CC

INTERFACE

XTL2/OSC2

*SDA AND SCL CAN BE CONNECTED DIRECTLY HIGH IF THE DS1086 NEVER NEEDS

TO BE PROGRAMMED IN-CIRCUIT, INCLUDING DURING PRODUCTION TESTING.

DITHERED 260kHz TO

133MHz OUTPUT

OUT

V

CC

N.C.

DECOUPLING CAPACITORS

(0.1µF and 0.01µF)

SPRD

V

GND

DS1086

CC

SCL*

SDA*

PDN

V

CC

OE

Page 8

DS1086

Spread-Spectrum EconOscillator

8 _______________________________________________________________________________________

Detailed Description

A block diagram of the DS1086 is shown in Figure 3.

The internal master oscillator generates a square wave

with a 66MHz to 133MHz frequency range. The frequency of the master oscillator can be programmed

with the DAC register over a two-to-one range in 10kHz

steps. The master oscillator range is larger than the

range possible with the DAC step size, so the OFFSET

register is used to select a smaller range of frequencies

over which the DAC spans. The prescaler can then be

set to divide the master oscillator frequency by 2

x

(where x equals 0 to 8) before routing the signal to the

output (OUT) pin.

A programmable triangle-wave generator injects an offset element into the master oscillator to dither its output

2% or 4%. The dither is controlled by the J0 bit in the

PRESCALER register and enabled with the SPRD pin.

The maximum spectral attenuation occurs when the

prescaler is set to 1. The spectral attenuation is

reduced by 2.7dB for every factor of 2 that is used in

the prescaler. This happens because the prescaler’s

divider function tends to average the dither in creating

the lower frequency. However, the most stringent spectral emission limits are imposed on the higher frequencies where the prescaler is set to a low divider ratio.

The external control input, OE, gates the clock output

buffer. The PDN pin disables the master oscillator and

turns off the clock output for power-sensitive applications*. On power-up, the clock output is disabled until

power is stable and the master oscillator has generated

512 clock cycles. Both controls feature a synchronous

enable that ensures there are no output glitches when

the output is enabled, and a constant time interval (for a

given frequency setting) from an enable signal to the

first output transition.

The control registers are programmed through a 2-wire

interface and are used to determine the output frequency and settings. Once programmed into EEPROM,

since the register settings are NV, the settings only

need to be reprogrammed if it is desired to reconfigure

the device.

*

Factory default setting. OS is the integer value of the 5 LSBs

of the RANGE register.

Table 1. Register Summary

X0= Don’t care, reads as zero.

X

1

= Don’t care, reads as one.

X

X

= Don’t care, reads indeterminate.

X = Don’t care.

Table 2. Offset Settings

*

The power-down command must persist for at least two out-

put frequency cycles plus 10µs for deglitching purposes.

REGISTER ADDR MSB BINARY LSB

PRESCALER 02h X

DAC HIGH 08h b9 b8 b7 b6 b5 b4 b3 b2 01111101b R/W

DAC LOW 09h b1 b0 X

OFFSET 0Eh X

ADDR 0Dh X

RANGE 37h X

WRITE EE 3Fh NO DATA

OFFSET FREQUENCY RANGE (MHz)

OS - 6 61.44 to 71.67

OS - 5 66.56 to 76.79

OS - 4 71.68 to 81.91

OS - 3 76.80 to 87.03

OS - 2 81.92 to 92.15

OS - 1 87.04 to 97.27

OS* 92.16 to 102.39

OS + 1 97.28 to 107.51

OS + 2 102.40 to 112.63

OS + 3 107.52 to 117.75

OS + 4 112.64 to 122.87

OS + 5 117.76 to 127.99

OS + 6 122.88 to 133.11

X

1

X

1

X

1

X

X

X

1

X

1

X

1

X

X

J0 P3 P2 P1 P0 11100000b R/W

X

X

0

b4 b3 b2 b1 b0 1 1 1 - - - - - b R/W

1

X

1

b4 b3 b2 b1 b0 x x x - - - - - b R

X

X

0

WC A2 A1 A0 11110000b R/W

1

X

0

X

0

X

0

0

FACTORY

DEFAULT

00000000b R/W

——

ACCESS

Page 9

DS1086

Spread-Spectrum EconOscillator

_______________________________________________________________________________________ 9

The output frequency is determined by the following

equation:

where:

min frequency of selected OFFSET range

is the

lowest frequency (shown in Table 2 for the corresponding offset).

DAC value

is the value of the DAC register (0 to 1023).

Prescaler

is the value of 2xwhere x = 0 to 8.

See the

Example Frequency Calculations

section for a

more in-depth look at using the registers.

________________Register Definitions

The DS1086 registers are used to determine the output

frequency and dither amount. A summary of the registers is shown in Table 1. Using the default register settings below, the default output frequency is 97.1MHz.

See the

Example Frequency Calculations

section for an

example on how to determine the register settings for a

desired output frequency.

PRESCALER Register

The PRESCALER register controls the prescaler (bits P3

to P0) and dither (bit J0). The prescaler divides the master oscillator frequency by 2xwhere x can be from 0 to 8.

Any prescaler value entered that is greater than 8

decodes as 8. The dither applied to the output is controlled with bit J0. When J0 is high, 2% peak dither is

selected. When J0 is low, 4% peak dither is selected.

DAC HIGH/DAC LOW Register

The 2-byte DAC register sets the frequency of the master

oscillator to a particular value within the current offset

range. Each step of the DAC changes the master oscillator frequency by 10kHz. The first byte is the MSB (DAC

HIGH) and the second byte is the LSB (DAC LOW).

OFFSET Register

The OFFSET register determines the range of frequencies

that can be obtained for a given DAC setting. The factory

default offset is copied into the RANGE register so the

user can access the default offset after making changes

to the OFFSET register. See Table 2 for OFFSET ranges.

Correct operation of the device is not guaranteed outside the range 66MHz to 133MHz.

SDA

Figure 3. DS1086 Block Diagram

(1)

SCL

V

CC

2-WIRE

INTERFACE

EEPROM CONTROL

REGISTERS

DAC

OFFSET

ADDR

RANGE

PRESCALER

DS1086

DAC

FREQUENCY

CONTROL VOLTAGE

PDN

DITHER

CONTROL

OE

SPRD

GND

TRIANGLE WAVE

GENERATOR

DITHER SIGNAL

( )

MIN FREQUENCY OF SELECTED OFFSET RANGE

( )

+×10

f

OUTPUT

=

DAC VALUE kHz STEP SIZE

PRESCALER

VOLTAGE-CONTROLLED

OSCILLATOR

MASTER

OSCILLATOR

PRESCALER

BY 1, 2, 4...256

OUTPUT

OUT

Page 10

DS1086

Spread-Spectrum EconOscillator

10 ______________________________________________________________________________________

ADDR Register

The A0, A1, A2 bits determine the 2-wire slave address.

The WC bit determines if the EEPROM is to be written

to after register contents have been changed. If

WC = 0 (default), EEPROM is written automatically after

a WRITE EE command. If WC = 1, the EEPROM is only

written when the WRITE EE command is issued. In

applications where the register contents are frequently

written, the WC bit should be set to 1. Otherwise, it is

necessary to wait for an EEPROM write cycle to complete between writing to the registers. This also prevents wearing out the EEPROM. Regardless of the

value of the WC bit, the value of the ADDR register is

always written immediately to EEPROM. When the

WRITE EE command has been received, the contents

of the registers are written into the EEPROM, thus locking in the register settings.

RANGE Register

This read-only register contains a copy of the factoryset offset (OS). This value can be read to determine the

default value of the OFFSET register when programming a new master oscillator frequency.

WRITE EE Command

This command is used to write data from RAM to

EEPROM when the WC bit in ADDR register is 1. See

the

ADDR Register

section for more details.

Example Frequency Calculations

Example #1:

Calculate the register values needed to

generate a desired output frequency of 11.0592MHz.

Since the desired frequency is not within the valid master oscillator range of 66MHz to 133MHz, the prescaler

must be used. Valid prescaler values are 2

x

where x

equals 0 to 8 (and x is the value that is programmed

into the P3 to P0 bits of the PRESCALER register).

Equation 1 shows the relationship between the desired

frequency, the master oscillator frequency, and the

prescaler.

By trial and error, x is incremented from 0 to 8 in

Equation 2, finding values of x that yield master oscillator frequencies within the range of 66MHz to 133MHz.

Equation 2 shows that a prescaler of 8 (x = 3) and a

master oscillator frequency of 88.4736MHz generates

our desired frequency. In terms of the device register, x

= 3 is programmed in the lower four bits of the

PRESCALER register. Writing 03h to the PRESCALER

register sets the PRESCALER to 8 (and 4% peak

dither). Be aware that the J0 bit also resides in the

PRESCALER register.

f

MASTER OSCILLATOR

= f

DESIRED

x prescaler = f

DESIRED

x 2

X

f

MASTER OSCILLATOR = 11.0592MHz x 23= 88.4736MHz

Once the target master oscillator frequency has been

calculated, the value of offset can be determined.

Using Table 2, 88.4736MHz falls within both OS - 1 and

OS - 2. However, choosing OS - 1 would be a poor

choice since 88.4736MHz is so close to OS - 1’s minimum frequency. On the other hand, OS - 2 is ideal

since 88.4736MHz is very close to the center of

OS - 2’s frequency span. Before the OFFSET register

can be programmed, the default value of offset (OS)

(2)

(3)

Figure 4. 2-Wire Data Transfer Protocol

f

MASTER OSCILLATOR

f

DESIRED

f

MASTER OSCILLATOR

prescaler

X

2

==

SDA

MSB

SCL

START

CONDITION

SLAVE ADDRESS

12 678 9 12 8 93–7

R/W

DIRECTION

BIT

ACKNOWLEDGEMENT

SIGNAL FROM RECEIVER

ACK

ACKNOWLEDGEMENT

SIGNAL FROM RECEIVER

REPEATED IF MORE BYTES

ARE TRANSFERRED

ACK

OR REPEATED

STOP

CONDITION

START

CONDITION

Page 11

DS1086

Spread-Spectrum EconOscillator

______________________________________________________________________________________ 11

must be read from the RANGE register (last five bits). In

this example, 12h (18 decimal) was read from the

RANGE register. OS - 2 for this case is 10h (16 decimal). This is the value that is written to the OFFSET register.

Finally, the two-byte DAC value needs to be determined. Since OS - 2 only sets the range of frequencies,

the DAC selects one frequency within that range as

shown in Equation 3.

f

MASTER OSCILLATOR = (MIN FREQUENCY OF SELECTED OFFSET

RANGE) + (DAC value x 10kHz)

Valid values of DAC are 0 to 1023 (decimal) and 10kHz

is the step size. Equation 4 is derived from rearranging

Equation 3 and solving for DAC.

Since the two-byte DAC register is left justified, 655 is

converted to hex (028Fh) and bit-wise shifted left six

places. The value to be programmed into the DAC register is A3C0h.

In summary, the DS1086 is programmed as follows:

PRESCALER = 03h (4% peak dither) or 13h (2% peak

dither)

OFFSET = OS - 2 or 10h (if range was read as 12h)

DAC = A3C0h

Notice that the DAC value was rounded. Unfortunately,

this means that some error is introduced. In order to

calculate how much error, a combination of Equation 1

and Equation 3 is used to calculate the expected output frequency. See Equation 5.

The expected output frequency is not exactly equal to the

desired frequency of 11.0592MHz. The difference is

450Hz. In terms of percentage, Equation 6 shows that the

expected error is 0.004%. The expected error assumes

typical values and does not include deviations from the

typical as specified in the electrical tables.

Example #2:

Calculate the register values needed to

generate a desired output frequency of 100MHz.

Since the desired frequency is already within the valid

master oscillator frequency range, the prescaler is set

to divide by 1, and hence, PRESCALER = 00h (for 4%

peak dither) or 10h (for 2% peak dither).

f

MASTER OSCILLATOR

= 100.0MHz x 20= 100.0MHz

Next, looking at Table 2, OS + 1 provides a range of

frequencies centered around the desired frequency. In

order to determine what value to write to the OFFSET

register, the RANGE register must first be read.

Assuming 12h was read in this example, 13h (OS + 1)

is written to the OFFSET register.

Finally, the DAC value is calculated as shown in

Equation 8.

The result is then converted to hex (0110h) and then

left-shifted, resulting in 4400h to be programmed into

the DAC register.

In summary, the DS1086 is programmed as follows:

PRESCALER = 00h (4% peak dither) or 10h (2% peak

dither)

OFFSET = OS + 1 or 13h (if RANGE was read as 12h)

DAC = 4400h

(4)

(8)

(7)

(6)

(5)

(9)

f

DAC VALUE

DAC VALUE

(

MASTER OSCILLATOR

MIN FREQUENCY OF SELECTED

=

(. . )

88 4736 81 92

=

=≈

. ( )

655 36 655

OFFSET RANGE

)

kHz STEP SIZE

10

MHz MHz

−

kHz STEP SIZE

10

decimal

−

MIN FREQUENCY OF SELECTED OFFSET

(

RANGE DAC VALUE x kHz STEP SIZE

) ( )

f

OUTPUT

=

f

OUTPUT

+

prescaler

MHz x kHz

(. ) ( )

81 92 655 10

=

MHz

.

88 47

8

.

=

11 05875

10

+

8

MHz

=

%

ERROR

EXPECTED

%

ERROR

EXPECTED

×= ×=

100

ff

DESIRED EXPECTED

=

=

11 0592

−

f

DESIRED

. .

MHz MHz

11 0592 11 05875

450

.

−

.

11 0592

Hz

.%

MHz

MHz

100 0 004

×

100

DAC VALUE

MHz MHz

(. . )

100 0 97 28

10

−

kHz STEP SIZE

. ( )=

=

272 00

decimal

97 28 272 10

MHz kHz

f

OUTPUT

(. ) ( )

=

100 0

.

1

MHz

+×

0

2

.

=

100 0

MHz

=

Page 12

DS1086

Spread-Spectrum EconOscillator

12 ______________________________________________________________________________________

Since the expected output frequency is equal to the

desired frequency, the calculated error is 0%.

_______2-Wire Serial Port Operation

2-WIRE SERIAL DATA BUS

The DS1086 communicates through a 2-wire serial

interface. A device that sends data onto the bus is

defined as a transmitter, and a device receiving data

as a receiver. The device that controls the message is

called a "master." The devices that are controlled by the

master are "slaves." A master device that generates the

serial clock (SCL), controls the bus access, and generates the START and STOP conditions must control the

bus. The DS1086 operates as a slave on the 2-wire

bus. Connections to the bus are made through the

open-drain I/O lines SDA and SCL.

The following bus protocol has been defined (see

Figures 4 and 6):

• Data transfer can be initiated only when the bus is

not busy.

• During data transfer, the data line must remain

stable whenever the clock line is HIGH. Changes

in the data line while the clock line is high are

interpreted as control signals.

Accordingly, the following bus conditions have been

defined:

Bus not busy: Both data and clock lines remain HIGH.

Start data transfer: A change in the state of the data

line, from HIGH to LOW, while the clock is HIGH,

defines a START condition.

Stop data transfer: A change in the state of the data

line, from LOW to HIGH, while the clock line is HIGH,

defines the STOP condition.

Data valid: The state of the data line represents valid

data when, after a START condition, the data line is stable for the duration of the HIGH period of the clock signal. The data on the line must be changed during the

LOW period of the clock signal. There is one clock

pulse per bit of data.

Figure 6. 2-Wire AC Characteristics

Figure 5. Slave Address

MSB

1 0 1 1 A2 A1 A0 R/W

SDA

SCL

STOP START

DEVICE

IDENTIFIER

t

BUF

t

t

HD:STA

LOW

DEVICE

ADDRESS

t

R

t

HD:DAT

LSB

READ/WRITE BIT

t

F

t

HIGH

t

SU:DAT

REPEATED

START

t

SU:STA

t

HD:STA

t

SP

t

SU:STO

Page 13

Each data transfer is initiated with a START condition

and terminated with a STOP condition. The number of

data bytes transferred between START and STOP conditions is not limited, and is determined by the master

device. The information is transferred byte-wise and

each receiver acknowledges with a ninth bit.

Within the bus specifications a regular mode (100kHz

clock rate) and a fast mode (400kHz clock rate) are

defined. The DS1086 works in both modes.

Acknowledge: Each receiving device, when

addressed, is obliged to generate an acknowledge

after the byte has been received. The master device

must generate an extra clock pulse that is associated

with this acknowledge bit.

A device that acknowledges must pull down the SDA

line during the acknowledge clock pulse in such a way

that the SDA line is stable LOW during the HIGH period

of the acknowledge-related clock pulse. Of course,

setup and hold times must be taken into account. When

the DS1086 EEPROM is being written to, it is not able to

perform additional responses. In this case, the slave

DS1086 sends a not acknowledge to any data transfer

request made by the master. It resumes normal operation when the EEPROM operation is complete.

A master must signal an end of data to the slave by not

generating an acknowledge bit on the last byte that has

been clocked out of the slave. In this case, the slave

must leave the data line HIGH to enable the master to

generate the STOP condition.

Figures 4, 5, 6, and 7 detail how data transfer is

accomplished on the 2-wire bus. Depending upon the

state of the R/W bit, two types of data transfer are possible:

1) Data transfer from a master transmitter to a slave

receiver. The first byte transmitted by the master is

the slave address. Next follows a number of data

bytes. The slave returns an acknowledge bit after

each received byte.

2) Data transfer from a slave transmitter to a master

receiver. The first byte (the slave address) is transmitted by the master. The slave then returns an

acknowledge bit. Next follows a number of data

bytes transmitted by the slave to the master. The

master returns an acknowledge bit after all

received bytes other than the last byte. At the end

of the last received byte, a not acknowledge is

returned.

The master device generates all of the serial clock

pulses and the START and STOP conditions. A transfer

is ended with a STOP condition or with a repeated

START condition. Since a repeated START condition is

also the beginning of the next serial transfer, the bus is

not released.

The DS1086 can operate in the following two modes:

Slave receiver mode: Serial data and clock are

received through SDA and SCL. After each byte is

received, an acknowledge bit is transmitted. START

and STOP conditions are recognized as the beginning

and end of a serial transfer. Address recognition is performed by hardware after reception of the slave

address and direction bit.

Slave transmitter mode: The first byte is received and

handled as in the slave receiver mode. However, in this

mode, the direction bit indicates that the transfer direction is reversed. Serial data is transmitted on SDA by

the DS1086 while the serial clock is input on SCL.

START and STOP conditions are recognized as the

beginning and end of a serial transfer.

Slave Address

Figure 5 shows the first byte sent to the device. It

includes the device identifier, device address, and the

R/W bit. The device address is determined by the

ADDR register.

Registers/Commands

See Table 1 for the complete list of registers/commands and Figure 7 for an example of using them.

__________Applications Information

Power-Supply Decoupling

To achieve the best results when using the DS1086,

decouple the power supply with 0.01µF and 0.1µF

high-quality, ceramic, surface-mount capacitors.

Surface-mount components minimize lead inductance,

which improves performance, and ceramic capacitors

tend to have adequate high-frequency response for

decoupling applications. These capacitors should be

placed as close to pins 3 and 4 as possible.

Stand-Alone Mode

SCL and SDA cannot be left floating when they are not

used. If the DS1086 never needs to be programmed incircuit, including during production testing, SDA and

SCL can be tied high. The SPRD pin must be tied either

high or low.

DS1086

Spread-Spectrum EconOscillator

______________________________________________________________________________________ 13

Page 14

DS1086

Spread-Spectrum EconOscillator

14 ______________________________________________________________________________________

Chip Information

SUBSTRATE CONNECTED TO GROUND

Figure 7. 2-Wire Transactions

Package Information

For the latest package outline information and land patterns

(footprints), go to www.maxim-ic.com/packages

. Note that a

“+”, “#”, or “-” in the package code indicates RoHS status only.

Package drawings may show a different suffix character, but

the drawing pertains to the package regardless of RoHS status.

PACKAGE

TYPE

PACKAGE

CODE

OUTLINE NO.

LAND

PATTERN NO.

8 µSOP U8-1

21-0036

90-0092

8 SO S8-4

21-0041

90-0096

TYPICAL 2-WIRE WRITE TRANSACTION

MSB

10 1

START

DEVICE IDENTIFIER

EXAMPLE 2-WIRE TRANSACTIONS (WHEN A0, A1, AND A2 ARE ZERO)

A) SINGLE BYTE WRITE

-WRITE OFFSET REGISTER

LSB

1

A2*

ADDRESS

DEVICE

START

R/WA0*A1*

READ/

WRITE

B0h

MSB LSB

SLAVE

b7 b6 b5 b4 b3 b2 b1 b0

ACK

COMMAND/REGISTER ADDRESS

0Eh

SLAVE

ACK

00001110

SLAVE

ACK

DATA

OFFSET10110000

MSB LSB

SLAVE

SLAVE

b7 b6 b5 b4 b3 b2 b1 b0

ACK

ACK

SLAVE

STOP

ACK

DATA

SLAVE

ACK

STOP

B) SINGLE BYTE READ

-READ OFFSET REGISTER

C) TWO BYTE WRITE

-WRITE DAC REGISTER

D) TWO BYTE READ

-READ DAC REGISTER

*THE ADDRESS DETERMINED BY A0, A1, AND A2 MUST

MATCH THE ADDRESS SET IN THE ADDR REGISTER.

START

START

START

B0h

B0h

B0h

SLAVE

ACK

SLAVE

ACK

SLAVE

ACK

10110000

10110000

10110000 10110001

0Eh

00001110

08h

00001000

08h

00001000

SLAVE

ACK

SLAVE

ACK

SLAVE

ACK

REPEATED

START

DATA

DAC MSB

REPEATED

START

B1h

10110001

SLAVE

ACK

B1h

DAC LSB

SLAVE

ACK

DATA

SLAVE

ACK

DATA

OFFSET

SLAVE

ACK

DATA

DAC MSB

MASTER

NACK

STOP

MASTER

ACK

STOP

DAC LSB

DATA

MASTER

NACK

STOP

Page 15

DS1086

Spread-Spectrum EconOscillator

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time. The parametric values (min and max limits) shown in

the Electrical Characteristics table are guaranteed. Other parametric values quoted in this data sheet are provided for guidance.

15

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2012 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Revision History

REVISION

NUMBER

0 10/02 Initial release

1 9/03

2 3/12

REVISION

DATE

DESCRIPTION

Corrected the dither rate in the Ma ster Oscillator Characteristics tab le; updated

Table 2

Updated the Ordering Information, Absolute Maximum Ratings, and Package

Informat ion

PAGES

CHANGED

3, 8

1, 2, 14

Loading...

Loading...