Page 1

78M6618 PDU1 Evaluation Board

User Manual

November 2011

Rev 3

UM_6618_022

Page 2

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit

patent licenses are implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408- 737- 7600

2011 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products.

Page 3

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

Table of Contents

1 Introduction.................................................................................................................................... 5

1.1 Package Contents................................................................................................................. 5

1.2 System Requirements ........................................................................................................... 5

1.3 Safety and ESD Notes .......................................................................................................... 6

1.4 Firmware Demo Code Introduction ........................................................................................ 6

1.5 Testing the Evaluation Board Prior to Shipping ...................................................................... 6

2 Installation ..................................................................................................................................... 7

2.1 USB Connection and Driver Installation ................................................................................. 8

2.2 Connecting the External DC Supply ...................................................................................... 8

2.3 Confirm COM Port Mapping .................................................................................................. 9

2.4 Verify Serial Connection to the PC ...................................................................................... 10

2.5 Connect the AC Source and Load ....................................................................................... 12

3 Circuit Description and Theory of Operation ............................................................................. 13

3.1 78M6618 ............................................................................................................................ 13

3.2 Voltage Regulators ............................................................................................................. 13

3.3 Input Signal Conditioning .................................................................................................... 14

3.4 Relay Control ...................................................................................................................... 14

3.5 Theory of Operation ............................................................................................................ 14

3.5.1 78M6618 Operation ................................................................................................... 14

3.5.2 Voltage and Current Measurement ............................................................................ 14

4 In-Circuit Emulator (ICE) Adaptor ............................................................................................... 17

5 Schematics, Bill of Materials, and PCB Layouts ........................................................................ 18

5.1 78M6618 PDU1 Evaluation Board Schematics .................................................................... 18

5.2 78M6618 PDU1 Evaluation Board Bill of Materials .............................................................. 22

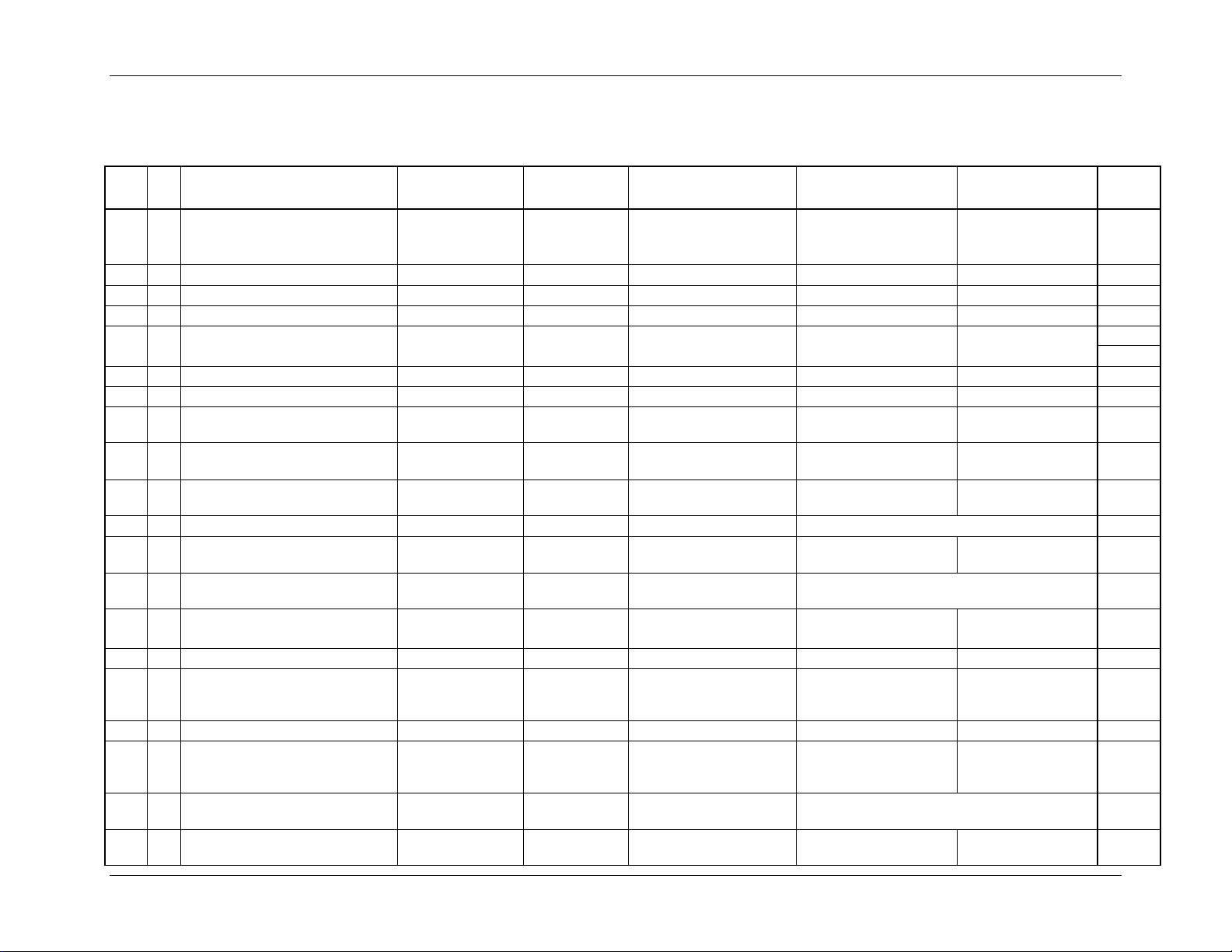

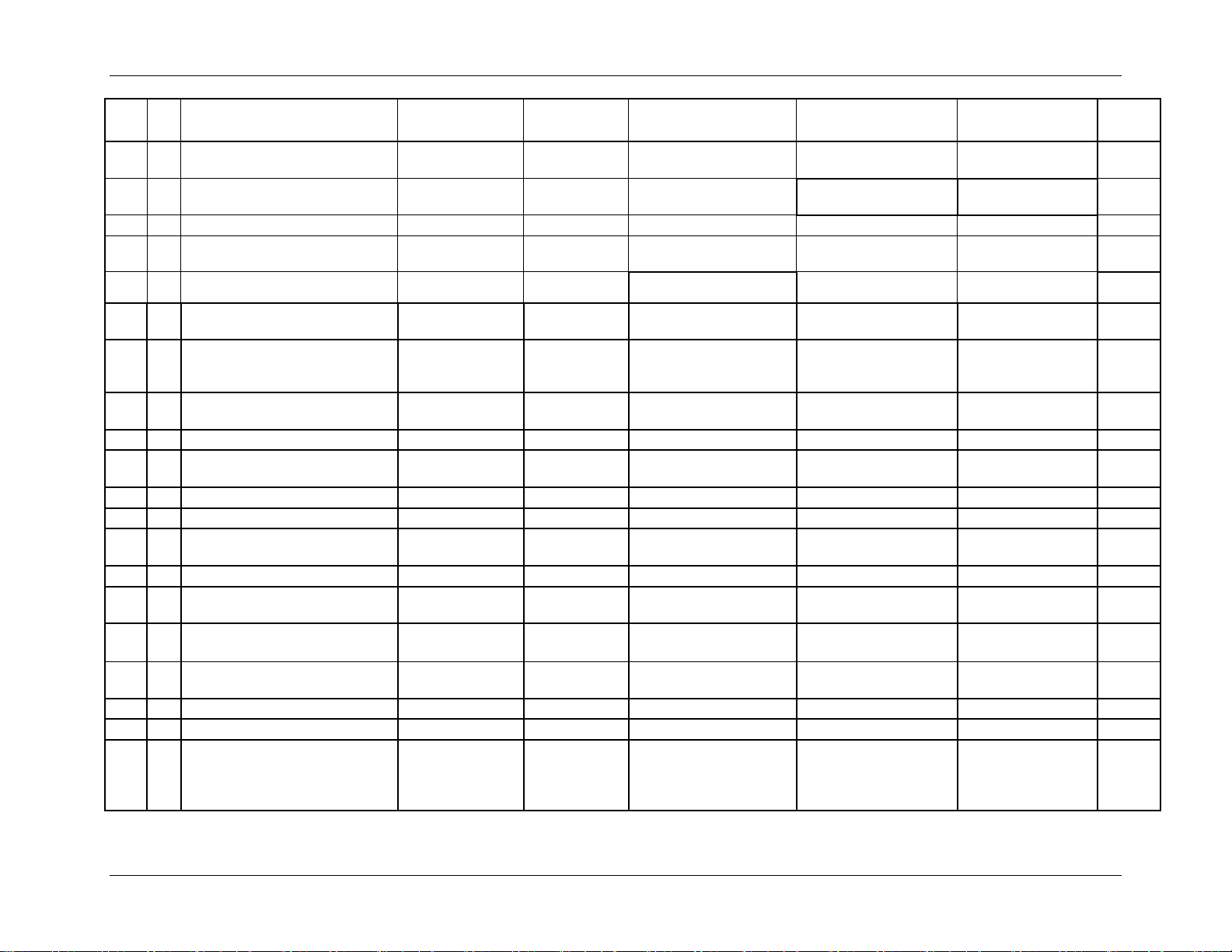

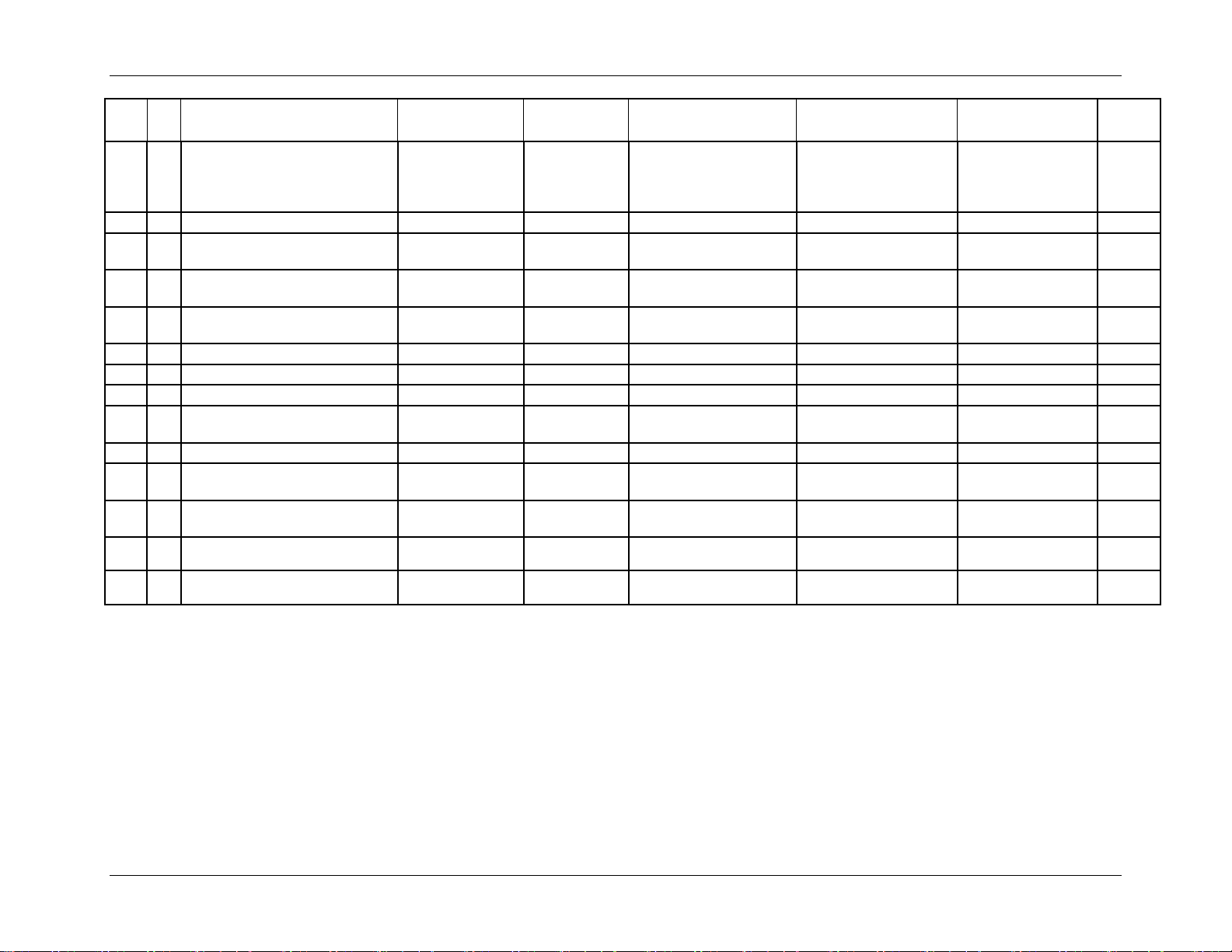

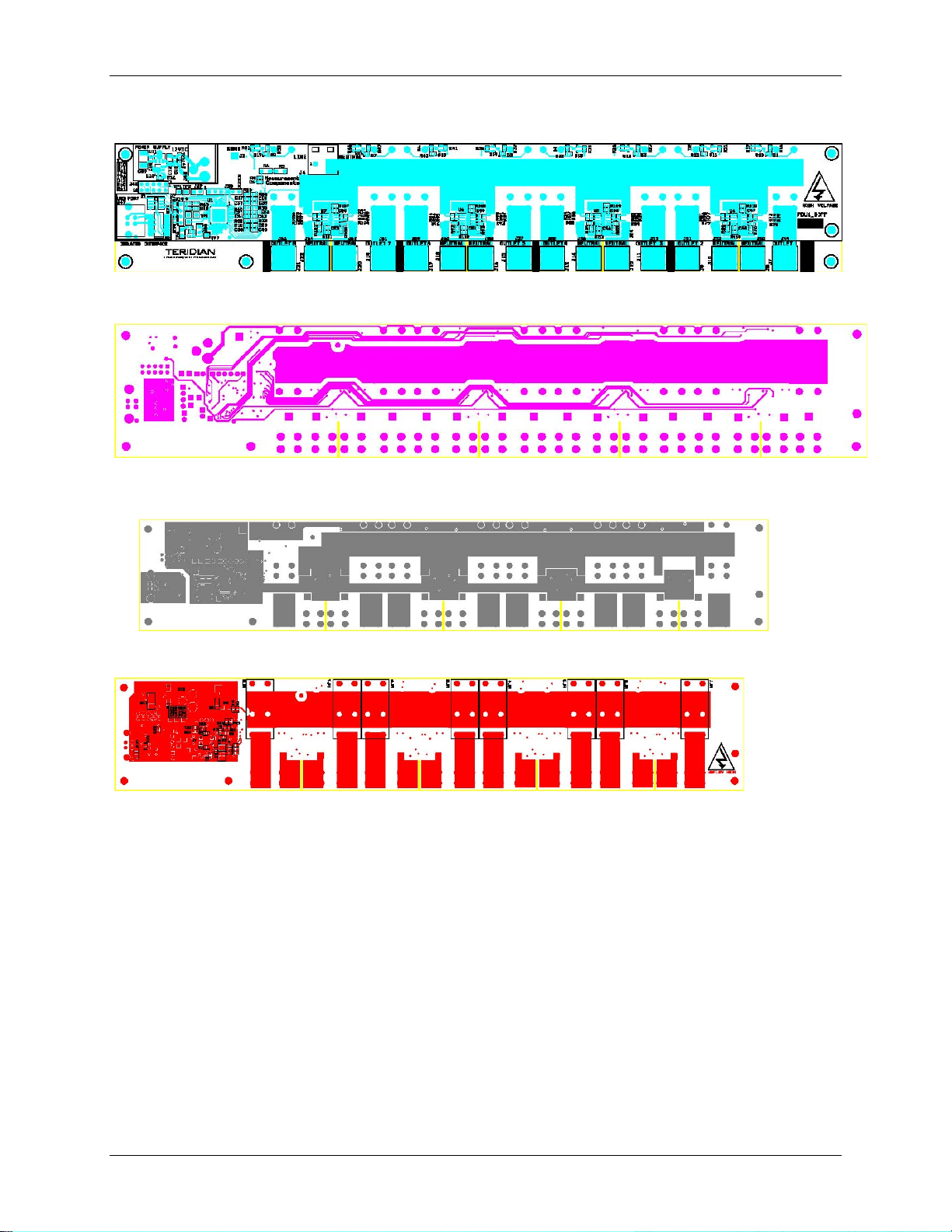

5.3 78M6618 PDU1 Evaluation Board PCB Layouts.................................................................. 25

6 Ordering Information ................................................................................................................... 26

7 Contact Information ..................................................................................................................... 26

Appendix A - 78M6618 PDU1 Board with CTs .................................................................................... 27

A.1 78M6618 PDU-CT Evaluation Board ................................................................................... 27

A.2 78M6618 PDU-CT Evaluation Board Schematics ................................................................ 28

A.3 78M6618 PDU-CT Evaluation Board Bill of Materials .......................................................... 32

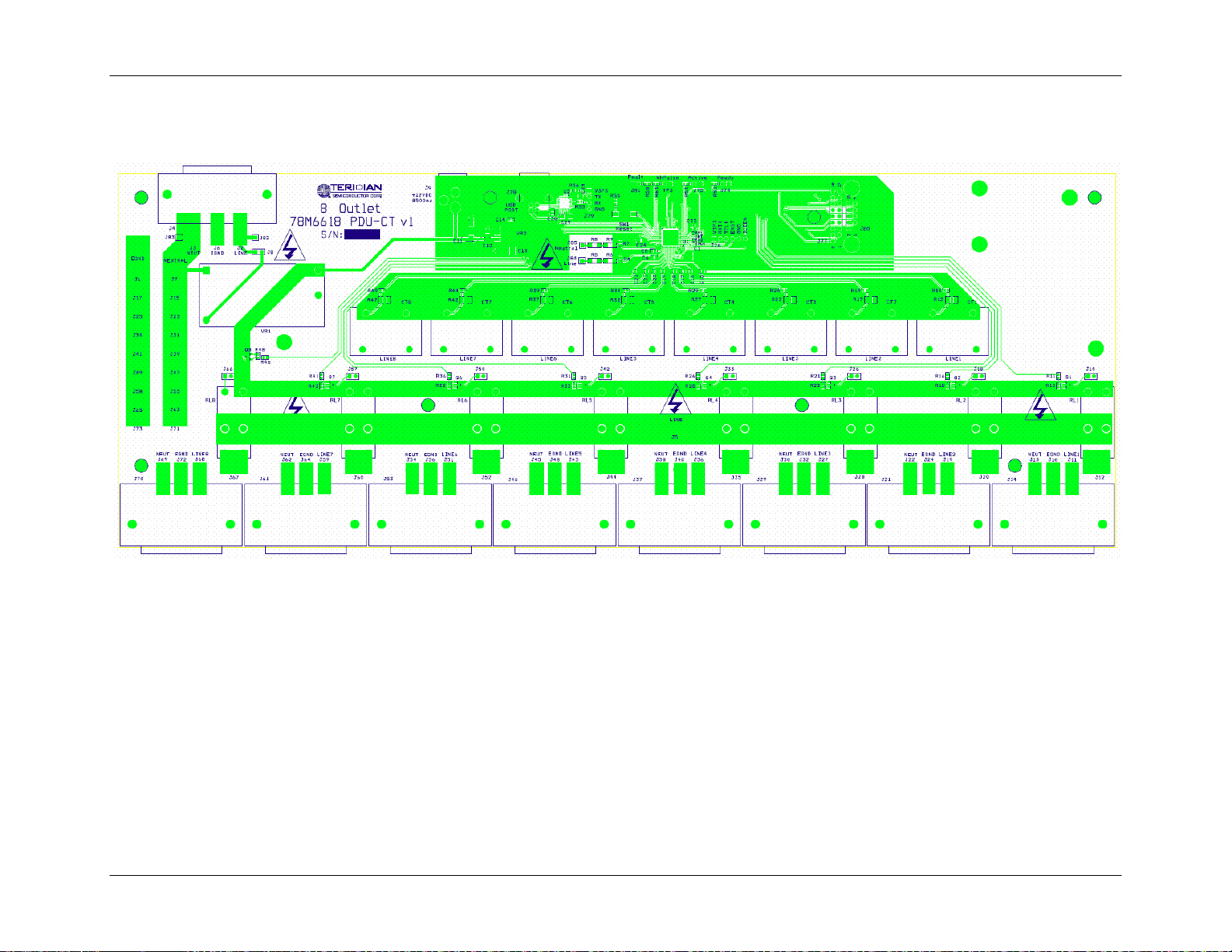

A.4 78M6618 PDU-CT Evaluation Board PCB Layouts .............................................................. 34

Appendix B – 78M6618 PDU1 Version 1 (Single-Ended Shunt) ......................................................... 36

Revision History .................................................................................................................................. 37

Rev 3 3

Page 4

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

Figures

Figure 1: 78M6618 PDU1 Connections .................................................................................................... 7

Figure 2: Serial Port Verification Screen ................................................................................................. 12

Figure 3: Differential PDU Block Diagram............................................................................................... 13

Figure 4: PCB Parasitic Resistance ....................................................................................................... 15

Figure 5: Differential Amplifier and Current Sense Resistor .................................................................... 15

Figure 6: Detail View of Differential Amplifiers ........................................................................................ 16

Figure 7: ICE Adaptor ............................................................................................................................ 17

Figure 8: 78M6618 ICE Adaptor Attachment .......................................................................................... 17

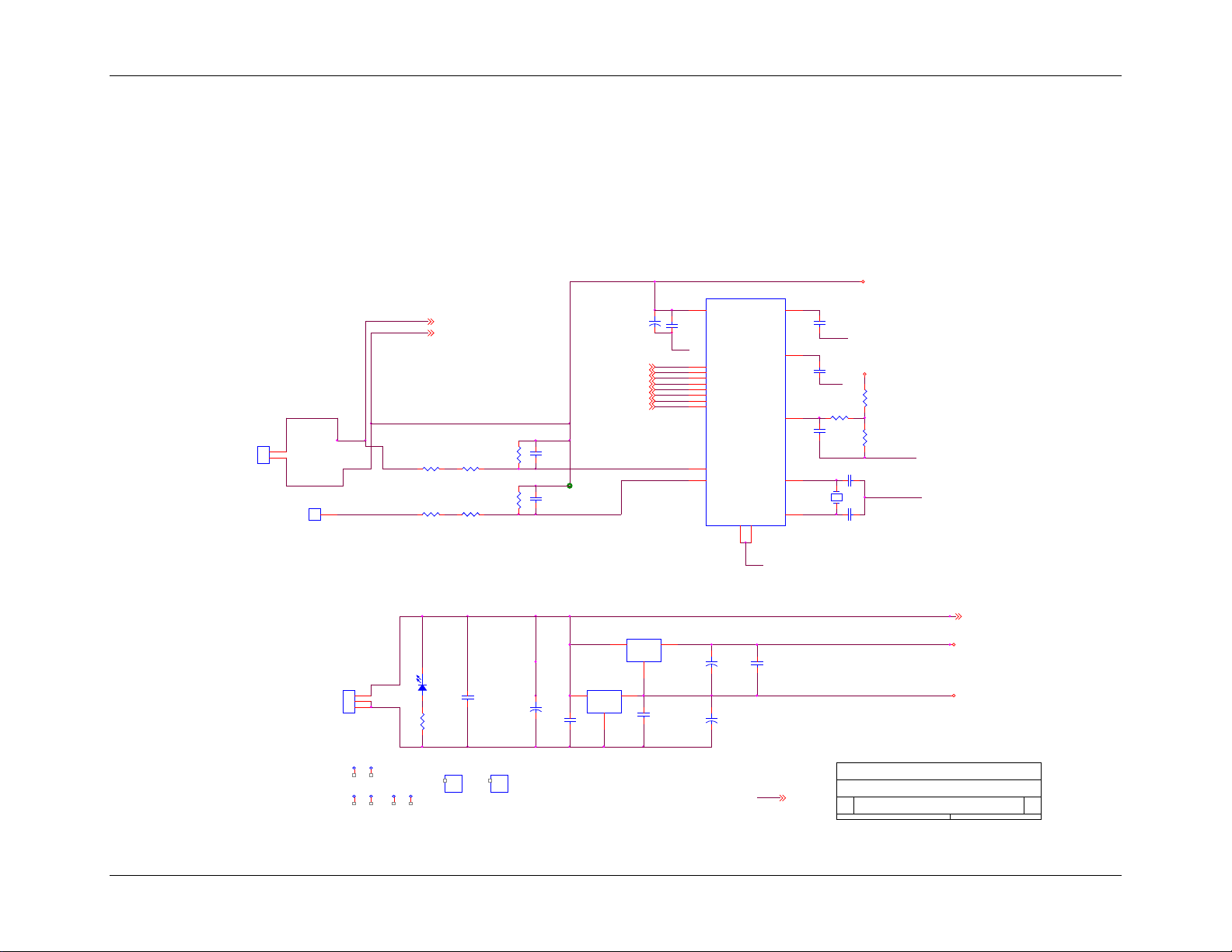

Figure 9: 78M6618 PDU1 Evaluation Board Electrical Schematic (1 of 4) ............................................... 18

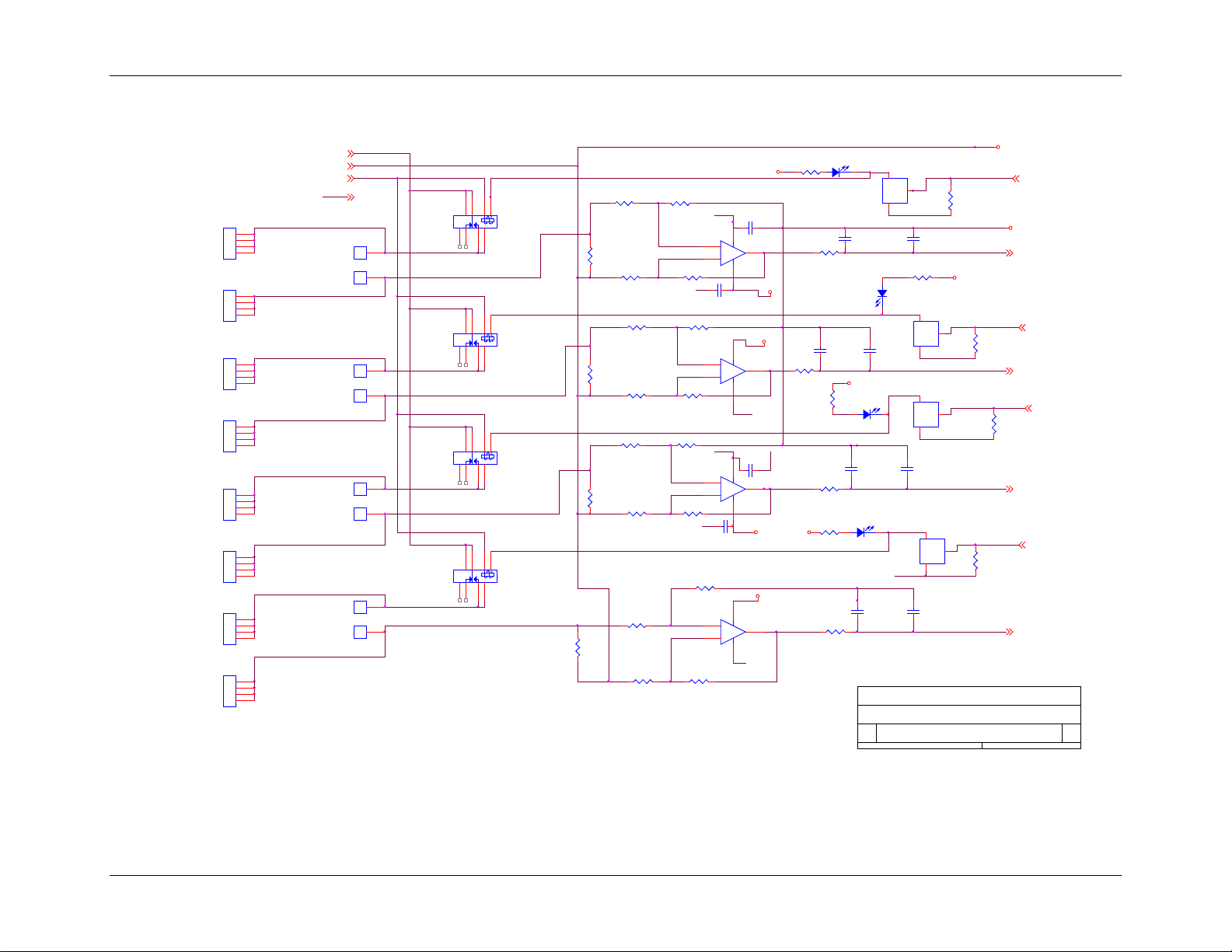

Figure 10: 78M6618 PDU1 Evaluation Board Electrical Schematic (2 of 4) ............................................. 19

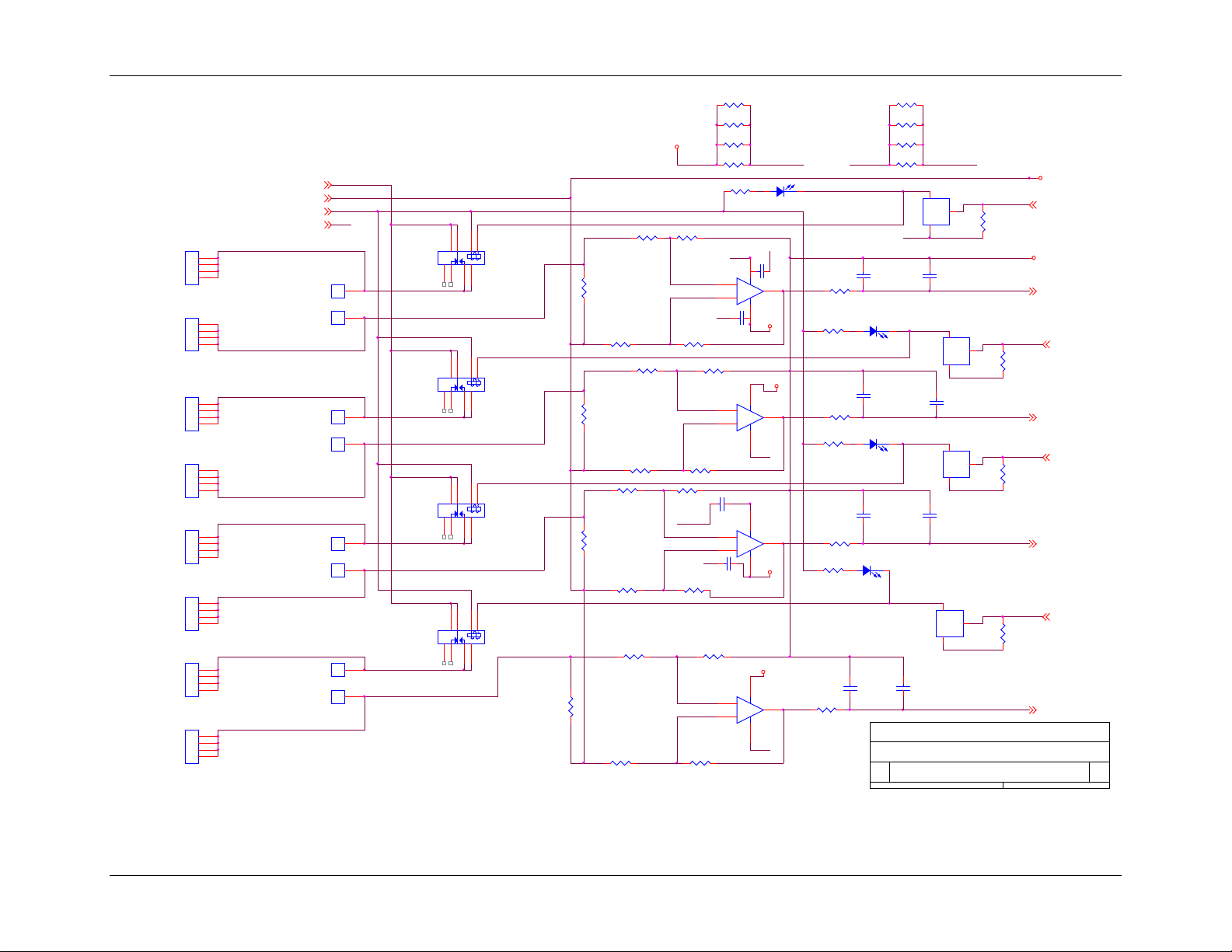

Figure 11: 78M6618 PDU1 Evaluation Board Electrical Schematic (3 of 4) ............................................. 20

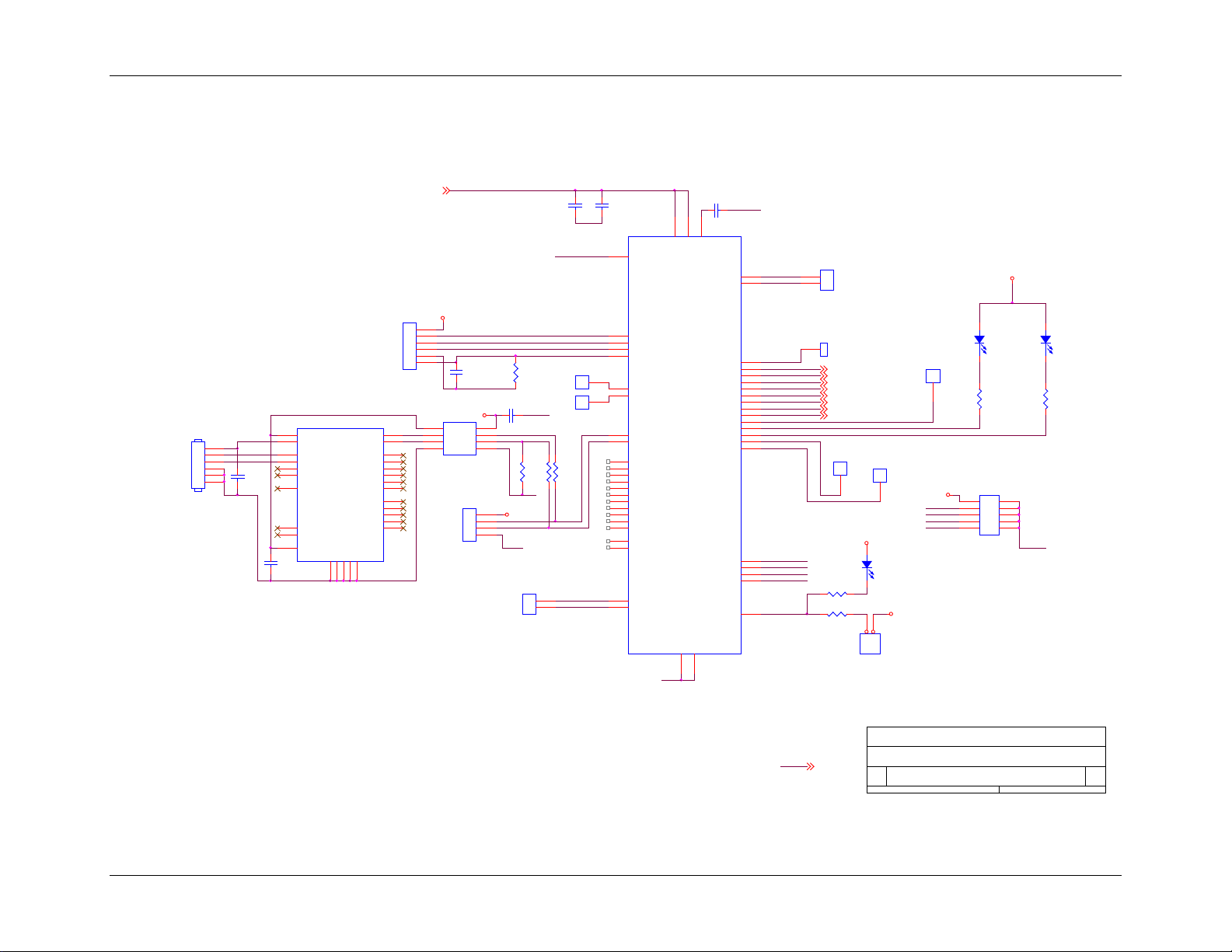

Figure 12: 78M6618 PDU1 Evaluation Board Electrical Schematic (4 of 4) ............................................. 21

Figure 13: 78M6618 PDU1 Evaluation Board PCB Top View ................................................................. 25

Figure 14: 78M6618 PDU1 Evaluation Board PCB Power View.............................................................. 25

Figure 15: 78M6618 PDU1 Evaluation Board PCB GND View ................................................................ 25

Figure 16: 78M6618 PDU1 Evaluation Board PCB Bottom View ............................................................ 25

Figure 17: 78M6618 PDU-CT Evaluation Board ..................................................................................... 27

Figure 18: 78M6618 PDU-CT Evaluation Board Electrical Schematic (1 of 4) ......................................... 28

Figure 19: 78M6618 PDU-CT Evaluation Board Electrical Schematic (2 of 4) ......................................... 29

Figure 20: 78M6618 PDU-CT Evaluation Board Electrical Schematic (3 of 4) ......................................... 30

Figure 21: 78M6618 PDU-CT Evaluation Board Electrical Schematic (4 of 4) ......................................... 31

Figure 22: 78M6618 PDU-CT Evaluation Board PCB Top View.............................................................. 34

Figure 23: 78M6618 PDU-CT Evaluation Board PCB Bottom View......................................................... 35

Tables

Table 1: COM Port Setup Parameters .................................................................................................... 10

Table 2: 78M6618 PDU1 Evaluation Board Bill of Materials ................................................................... 22

Table 3: 78M6618 PDU-CT Evaluation Board Bill of Materials ................................................................ 32

4 Rev 3

Page 5

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

Teridian is a trademark of Maxim Integrated Products, Inc.

Windows and Windows XP are r egistered trademarks of M icrosoft Corp.

1 Introduction

The Teridian™ 78M6618 PDU1 evaluation board is an example of a low-cost power distribution unit

(PDU) utilizing the 78M6618 system-on-chip (SoC). The 78M6618 monitors the AC line voltage and eight

load currents, and controls switching of eight internal load relays. The embedded firmware calculates the

RMS line voltage and RMS load currents, watts, VAs, VARs, and power factor. The real-time data is

transmitted to a PC via a USB interface for display in a Windows

The 78M6618 UART interface is used as the communications link to an on-board isolated USB interface

IC.

®

-based graphical user interface (GUI).

Included with the 78M6618 PDU1 is a Windows-based GUI for simplified access to the following

measurement data and controls:

• RMS voltage and current

• Real, apparent, and reactive power and power factor

• Accumulated energy usage and expense tracking

• Line frequency

• Minimum and peak parameter tracking

• Alarm indicators

• Programmable alarm thresholds

• Internal load relay (16A) control

This document describes the evaluation board with “78M6618 PDU1_DIFF” imprinted on the board. This

board is a complete replacement for (and obsoletes) the earlier 78M6618 PDU1 evaluation board.

Refer to the GUI User Guide for information about the GUI.

1.1 Package Contents

The 78M6618 PDU1 evaluation kit includes:

• 78M6618 PDU1_DIFF evaluation board

• Universal AC to 12 V DC power supply with international plug adapters

• ICE Adaptor board

• USB A/B cable

1.2 System Requirements

The 78M6618 PDU1 GUI requires use of a PC with the following features:

• PC (1 GHz, 1 GB) with Microsoft Windows 7, Windows XP® or Win2000, equipped with USB port

• Minimum 1024 x 768 video display resolution

Rev 3 5

Page 6

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

1.3 Safety and ESD Notes

EXERCISE CAUTION WHEN LIVE AC VOLTAGES ARE PRESENT!

Standard ESD precautions must be taken when handling electronic equipment. The

78M6618 PDU1 contains ESD protected interfaces.

Do not connect test equipment, ICE emulators or external development boards directly to the

78M6618 hardware. Damage to the 78M6618 PDU1 and external equipment will occur due to the

78M6618’s “high side” reference topology. The 78M6618’s V3P3 (i.e., “high side”) is connected

directly to Neutral (Earth Ground) and the ground is 3.3V below neutral, creating a ground

reference disparity with any properly grounded external equipment. Also, reversing the line and

neutral connections at the inlet would place the board’s ground reference at the AC line voltage.

Always use the isolated USB interface for connecting to a PC. Contact the factory for instructions

on connecting other types of test equipment.

The board components and firmware settings are designed to operate with the following nominal AC

electrical ranges:

Voltage Current Line Frequency

110-240 VAC 20A Max 46-64 Hz

1.4 Firmware Demo Code Introduction

The Firmware Demo Code provides the following features:

• Basic energy measurement data such as Watts, Volts, current, VAR, VA, phase angle, power factor,

accumulated energy, frequency, date/time, and various alarm statuses.

• Control of alarm thresholds, calibration coefficients, temperature compensation, etc.

There are two means to facilitate performance evaluation between the user at the PC host and the

firmware code in the 78M6618 PDU1 evaluation board:

• The graphical user interface (GUI). For information about the GUI, refer to the GUI User Guide.

• The Command Line Interface (CLI) via HyperTerminal or comparable terminal emulator on a different

operating system. For information about the CLI, see the Firmware Description Document.

The 78M6618 PDU1 evaluation board is shipped with demonstration code loaded in the 78M6618 device

and included on the CD. The code revision can be verified by entering the command >i via the command

line interface. Firmware for the Demo Unit can be updated using either the Teridian TFP2 or an in-circuit

emulator such as Signum Systems ADM51 (

www.signum.com ).

1.5 Testing the Evaluation Board Prior to Shipping

Before every 78M6618 PDU1 evaluation board is shipped, the following procedures have been performed

at the factory:

• Full Calibration – Precise energy source equipment is used to calibrate the current and voltage. The

temperature is also calibrated at the same time.

• Accuracy Test – This “bench” level test ensures the energy measurement accuracy is within +/-0.5%.

6 Rev 3

Page 7

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

Outlet 2

Outlet 8

Outlet 7

DC Power Plug

(J48)

AC Inlet (J4)

Outlet 6

Outlet 4

Outlet 5

Outlet 3

Outlet 1

Connect the USB Port

(J47) to the Host PC

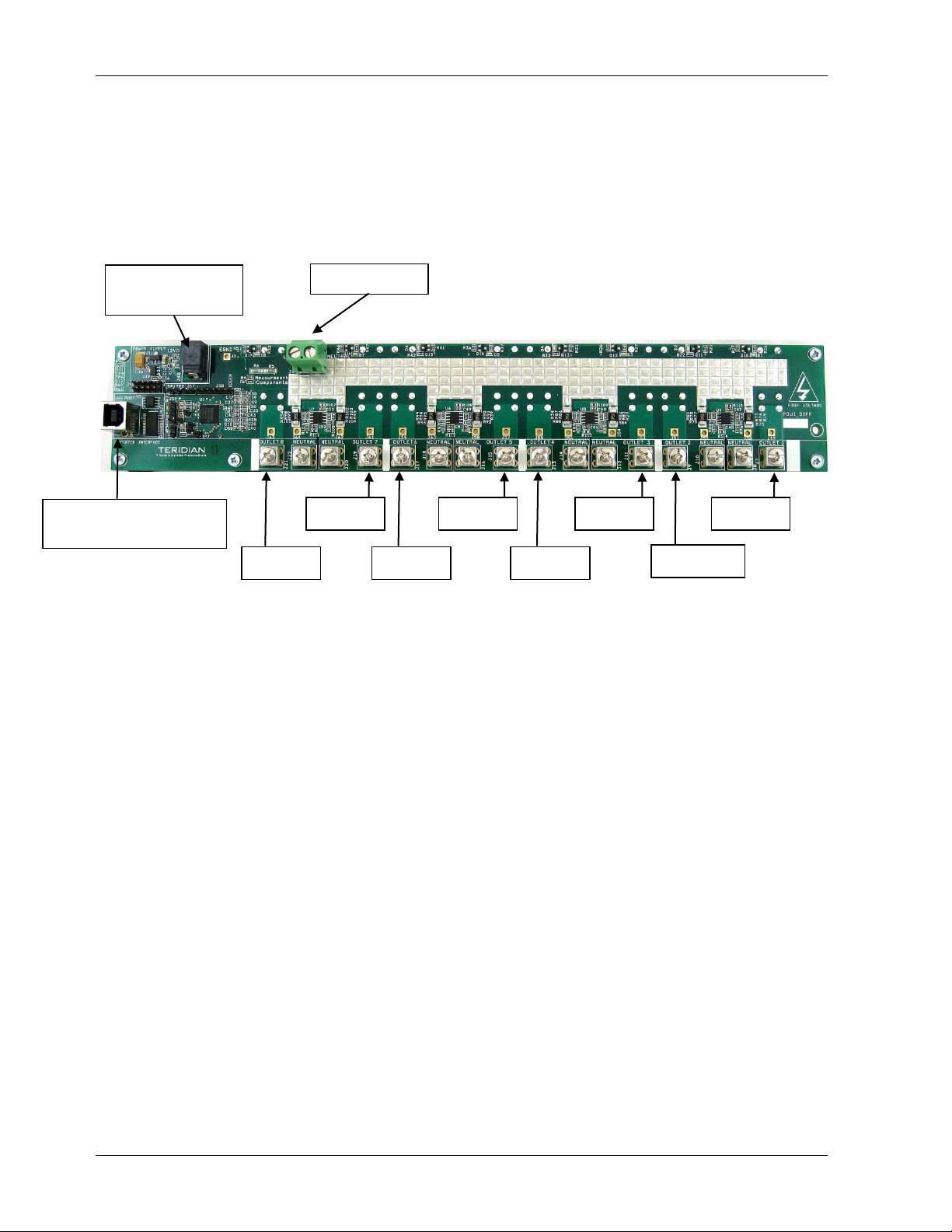

2 Installation

Figure 1 shows the basic connections to the 78M6618 PDU1 Evaluation Board. DC power is supplied to

the PDU1 through the DC power jack (J48). The USB cable provides an electrically isolated

communications link between the host PC and the PDU1 as well as power to the USB controller on the

Evaluation Board. The AC input to the PDU is connected via the terminal block J4. The PDU1 has eight

outlets that connect to the loads to be measured. Screw terminals are provided to make the line and

neutral connections to the loads.

Figure 1: 78M6618 PDU1 Connections

Rev 3 7

Page 8

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

2.1 USB Connection and Driver Installation

This evaluation kit includes an isolated USB interface for serial communications with a PC. The FTDI USB

controller IC FT232R performs the USB functions. The FTDI Windows driver presents a virtual COM port

for enabling serial communications. Control of the 78M6618-PDU-1 can be managed using either a

terminal emulation program or using the supplied Windows Dashboard GUI. The FTDI Windows driver is

a certified driver for Windows 2000 and XP.

Because the USB interface is USB powered, the USB driver installation can be completed with no other

DC power supplied to the evaluation board.

1. Connect a USB AB cable between the host PC and the evaluation board.

2. Upon attaching the 78M6618-PDU-1 to the PC, the Found New Hardware Wizard automatically

launches and installs the appropriate driver files. If your PC does not find the FTDI driver files on its

local hard disk drive, locate and reference the FTDI USB Driver and Utilities subdirectory on the CD.

The FT232R controller is powered from the USB cable and is active even when no AC power is

applied to the 78M6618-PDU-1.

Note: If an older FTDI driver has been previously installed, it is recommended to remove the older

version before installing this newer FTDI driver. Execute the ftdiClean.exe utility from the FTDI

USB Driver and Utilities subdirectory.

For FTDI driver support on other operating systems, please check FTDI’s website at

(http://www.ftdichip.com/FTDrivers.htm).

2.2 Connecting the External DC Supply

An external DC supply is provided for operation of the evaluation board. Follow these steps to connect

the 78M6618 PDU1 with the external DC supply:

1. Select the appropriate plug for the AC adapter and snap it into place.

2. Connect the DC cable of the 12V AC adapter to J48.

3. Plug the AC adapter into an appropriate outlet.

8 Rev 3

Page 9

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

PDU-1 COM Port:

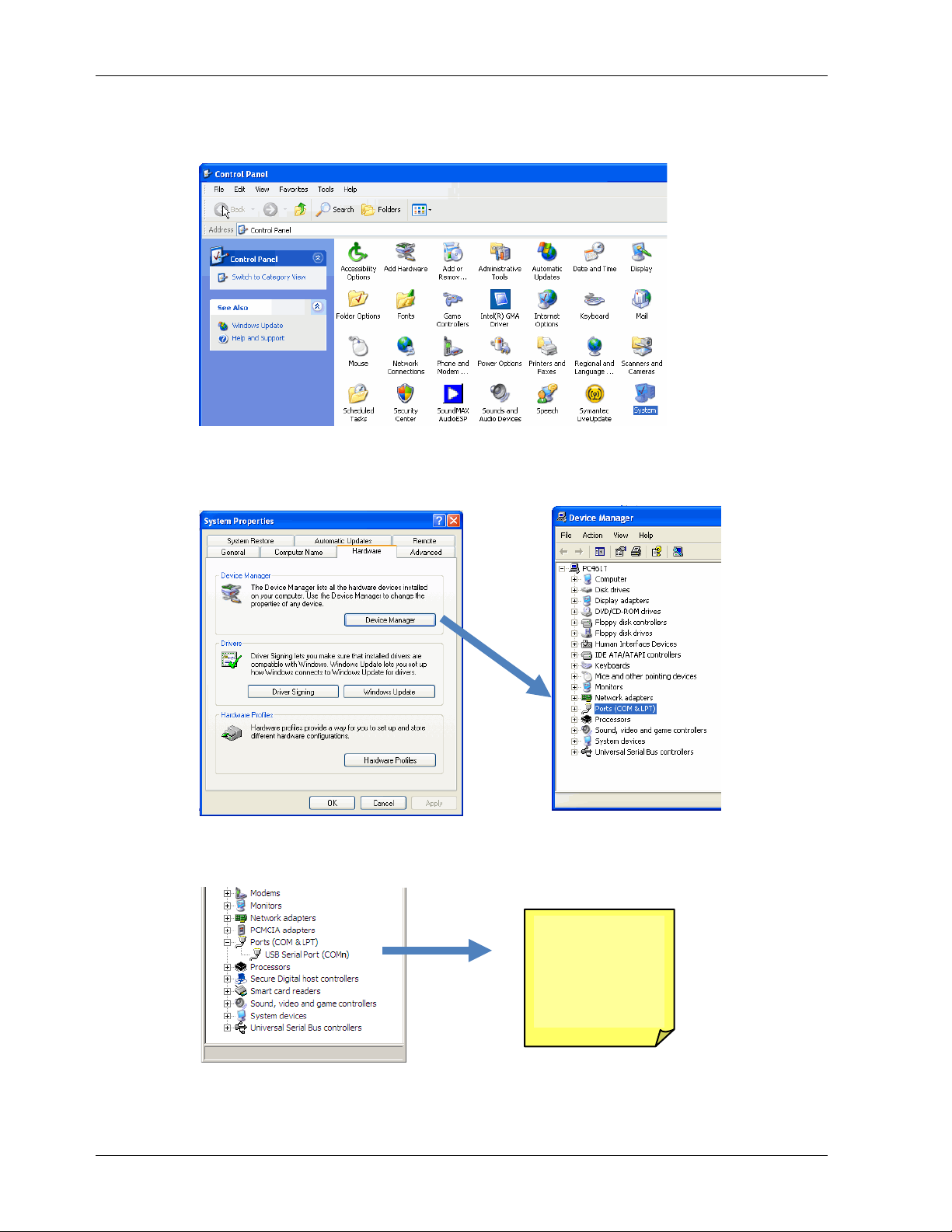

2.3 Confirm COM Port Mapping

1. Launch the Control Panel and click on the System icon.

2. The System Properties screen appears. Click on the Hardware tab. Click on Device Manager.

Under Ports (COM & LPT), look for the USB Serial Port assignment.

3. Take note of the COM port assignment for the USB Serial Port.

Rev 3 9

Page 10

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

Select

COM Port

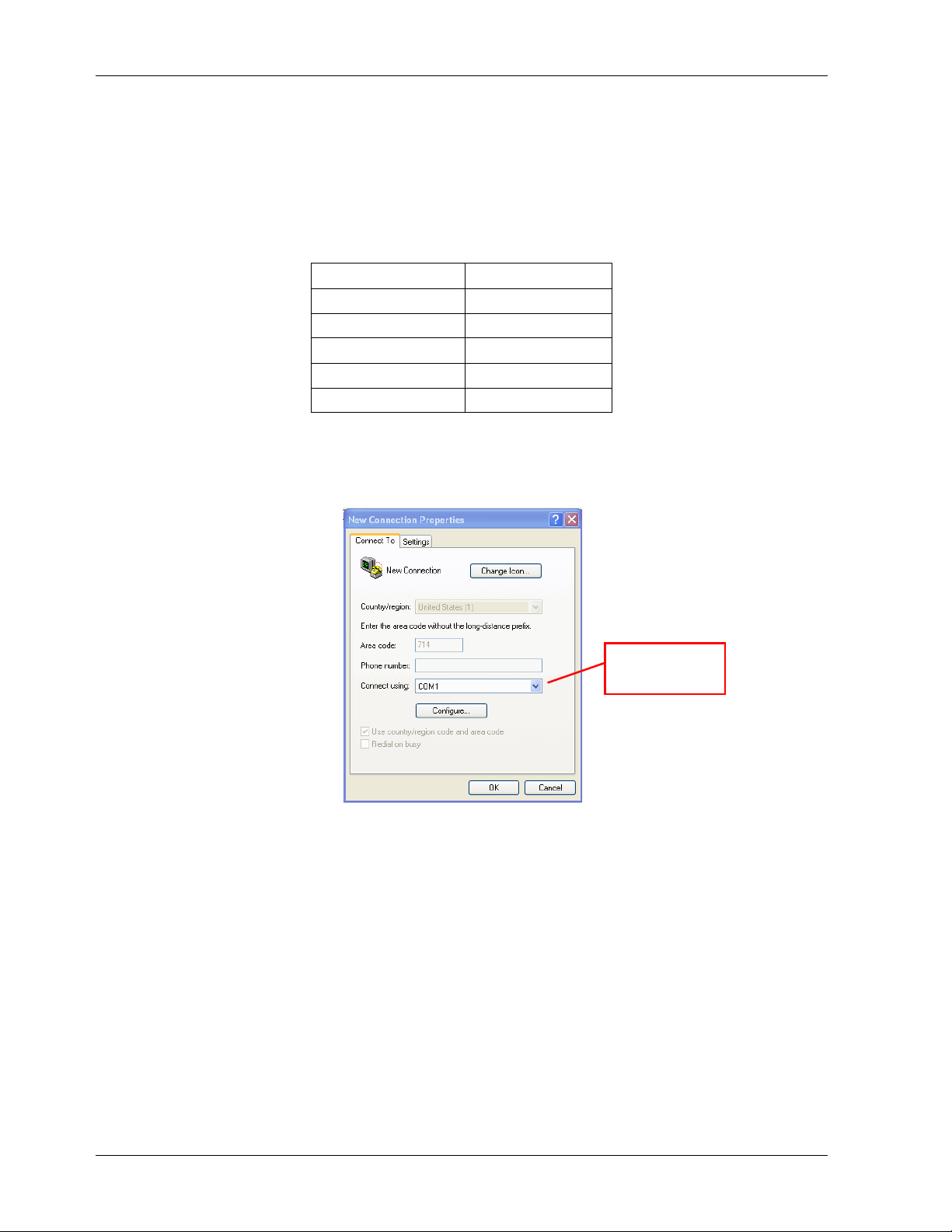

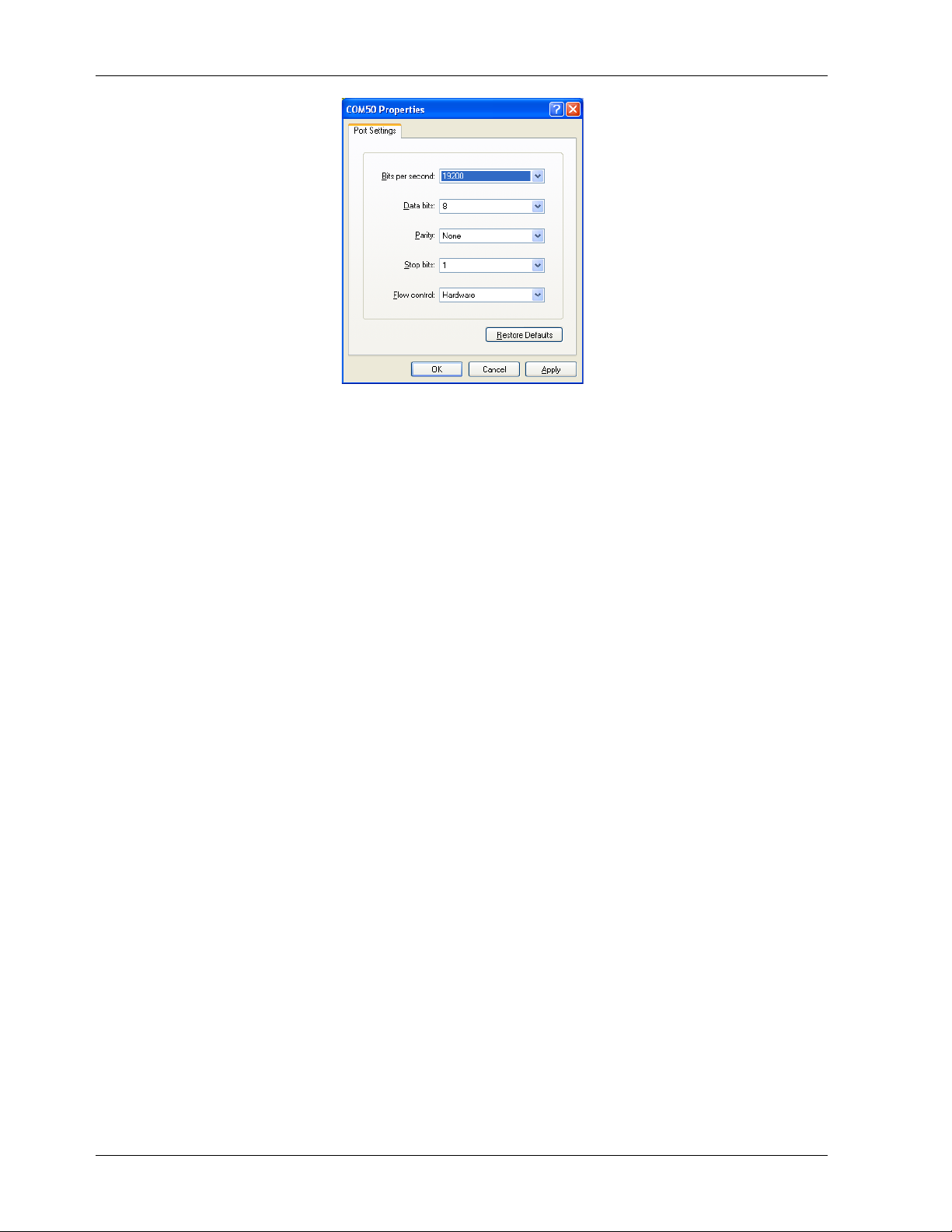

2.4 Verify Serial Connection to the PC

After connecting the USB cable from the 78M6618-PDU-1 to the host PC and powering the PDU board

with the 12VDC adapter, start the HyperTerminal application (or another suitable communication

program) to create a session using the communication parameters shown in Table 1. The firmware

installed in your board may use a different COM port setup than what is shown here. Refer to the

Firmware Description Document provided with your board for the correct setup for your firmware.

Table 1: COM Port Setup Parameters

Setup Parameter 78M6618

Port speed (baud) 38400

Data bits 8

Parity None

Stop bits 1

Flow control None

HyperTerminal can be found in Windows by selecting Start All Programs Accessories

Communications HyperTerminal. The connection parameters are configured by selecting File

Properties. The New Connection Properties menu appears.

Select the appropriate COM port and click Configure. The COMn Properties menu appears.

10 Rev 3

Page 11

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

Note that port parameters can only be adjusted when the connection is not active. It may be necessary to

click the Disconnect Button (shown below) to disconnect the port.

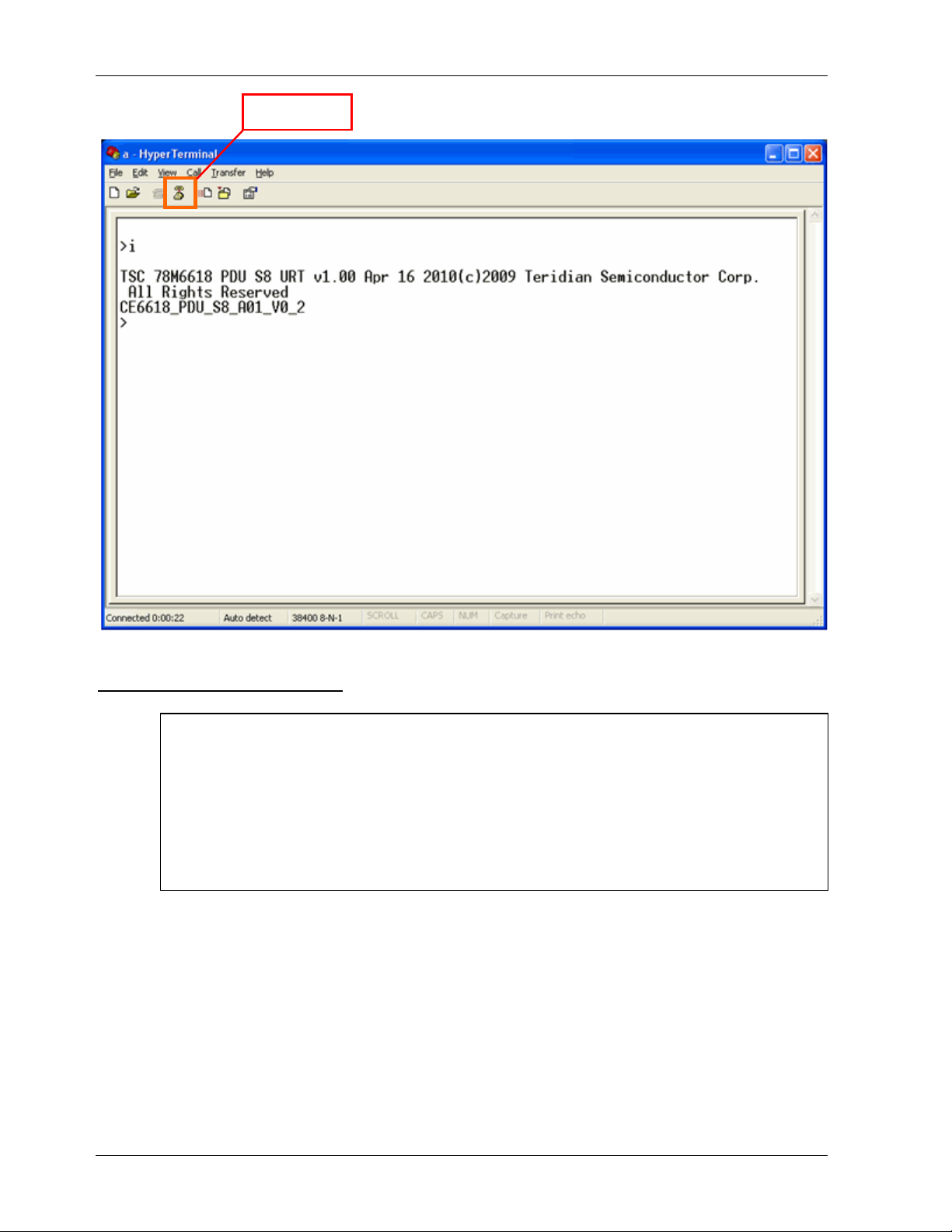

When the terminal emulation program has connected to the correct USB COM port, verify operation of the

PDU by pressing the “Enter” key on the PC. The evaluation board should respond with a “>” prompt. You

should also be able to identify the firmware version programmed into your board

If communication is not established with the evaluation board, check the following:

1. Make sure that 12VDC is supplied to the board through J48.

2. Make sure that the terminal emulation program is using the correct COM port.

3. Check the serial port configuration against the configuration given in the Firmware Description

Document.

Rev 3 11

Page 12

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

If the FTDI device driver did not install properly, there would be no assigned COM port

Disconnect

Figure 2: Serial Port Verification Screen

FTDI COM Port Trouble-Shooting

number for the FTDI controller. Repeat the USB Driver Installation, see Section 2.1.

Microsoft Windows may associate a Ball Point device to the FTDI USB controller. When this

occurs a FTDI device COM port assignment is available via HyperTerminal but there is no

communications data. Verify if a Ball Point device has been added to the “Human Interface

Devices” via the Device manager. Refer to Section 2.3 for access to the Device Manager. If

a Ball Point device exists, delete it and unplug and replug the evaluation board’s USB cable.

2.5 Connect the AC Source and Load

Connect the desired AC source to the terminal block J4. Be sure to observe the correct connections for

line and neutral as they are designated on the silk screen. Terminal block J4 accepts bare wires size

24AWG to 10AWG. Be sure to select wire gauge appropriate to the total load to be applied to the board,

and make sure that the screws are tightened for good electrical connection and wire retention.

The loads to be controlled and metered are connected to the screw terminals J7-J22 that are located on

the bottom edge of the board. These terminals can accept bare wire, or spade terminals or ring terminals

that are capable of accepting a 6-32 screw. The individual terminals are rated to carry a maximum current

of 15A. As with the AC inlet connection, be sure to observe proper connection to the AC line (labeled

Outlet n) and AC neutral.

12 Rev 3

Page 13

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

Low Pass

Filter

LOAD

Series

Regulators

V6P6

V3P3

+12V

GND

Low Pass

Filter

Differential

Amplifier

+

-

Relay

Driver

+12VDC

12VDC

Return

(One of 8 channels)

Voltage Sense

Resistors

Current

Sense

Resostor

78M6618

I Input

V input

V3P3

DIO

AC LINE

AC

NEUTRAL

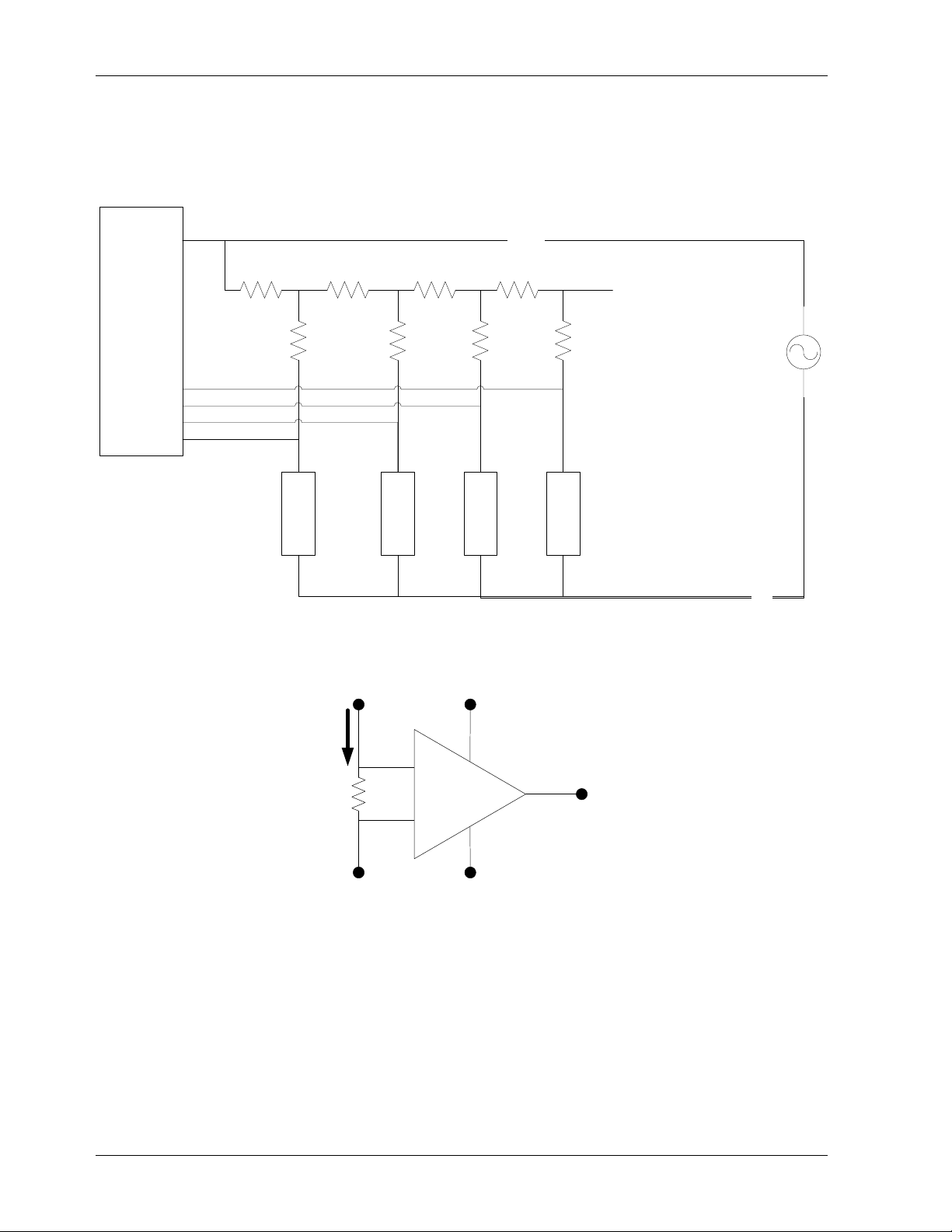

3 Circuit Description and Theory of Operation

Figure 3 shows a block diagram of the PDU1 Evaluation Board. For simplicity, only one of the 8 identical

channels is shown.

Figure 3: Differential PDU Block Diagram

The main functional blocks of the evaluation board are the 78M6618 energy measurement SoC, voltage

regulators, input signal conditioning, and relay control.

3.1 78M6618

The 78M6618 is a highly integrated IC for energy monitoring and measurement. The key features of the

78M6618 include:

• A 21-bit delta sigma analog to digital converter (ADC) with 10 multiplexed analog inputs

• A 32-bit digital signal processor core (Compute Engine, or CE)

• An 8-bit microprocessor core

• 128 Kbytes flash memory

• 32,768 kHz oscillator

• Up to 19 general-purpose digital I/O pins (DIO).

For detailed information on the 78M6618, refer to the 78M6618 Data Sheet.

3.2 Voltage Regulators

The evaluation board is powered by an external 12VDC source. The on-board relays for switching power

to the 8 outlets are powered directly from the 12V supply. Linear regulators are used to provide the 3.3V

supply for the 78M6618 and external logic and a 6.6V supply for the operational amplifiers that are used

to amplify the voltage from the current sense resistors.

Rev 3 13

Page 14

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

3.3 Input Signal Conditioning

Input signal conditioning includes the voltage divider used to reduce the AC line voltage to a level that can

be measured by the 78M6618, the differential amplifiers that are used to remove common-mode voltage

from the input signals to the ADC current channels, and the low-pass filters that block high-frequency

signal content from the ADC inputs.

3.4 Relay Control

Power to each of the 12 outlets on the board is switched by a relay. The relays are individually controlled

by digital I/O (DIO) lines from the 78M6618. Do to the type of relay driver circuit used on this board, the

firmware Relay Config register (0x0210) is set equal to 2. This inverts the relay driver input polarity.

3.5 Theory of Operation

Before describing the operation of the PDU, it may be helpful to make note of some of the characteristics

of the 78M6618 and the board design.

1. The reference for the 78M6618’s ADC is its positive power supply (V3P3), not ground.

2. The 78M6618’s 3.3V power supply is directly connected to the neutral side of the AC power source.

As a result, the 78M6618’s ground reference is actually 3.3V below the AC neutral.

3.5.1 78M6618 Operation

The analog multiplexer at the front end of the delta-sigma ADC sequentially presents the signals at the 10

analog input pins to the ADC, which converts them to digital words which are presented to the 32-bit

compute engine (CE). The CE performs filtering and calculates RMS voltage and current, line frequency,

real power and reactive power. The CE transfers its results to the 80515 MPU at the end of each

accumulation interval. The accumulation interval, which is the period over which RMS voltage, current

and power are calculated, is determined by the firmware loaded into the 78M6618’s internal flash, and

may be between 200 milliseconds and 1 second. The 80515 MPU performs some scaling of the CE

results, calculates some additional values, and manages the communication with an external host via its

integrated UART. The MPU also controls the operation of the CE.

3.5.2 Voltage and Current Measurement

As previously described, the reference voltage for the 78M6618 ADC is 3.3V. The valid input range for

the ADC is 3.3V ±250 mV. A 250 mV signal corresponds to full scale on the ADC. A voltage divider is

used to scale the line voltage to the ±250 mV range of the ADC. The voltage divider consists of 2 1 MΩ

resistors and one 750 Ω resistor. The ADC measures the voltage across the 750Ω resistor, which is

0.0375% of the line voltage. With this ratio, the ADC can measure line voltages up to 667V

corresponds to a sinusoidal voltage input of ~471 V

limits the frequency content of the input signal to around 4,500 Hz.

The PDU uses current sense resistors, also known as shunt resistors, to sense the current flowing in the

neutral or return of each outlet. The value of the current sense resistor is selected to scale the voltage

drop across the resistor to the input range of the ADC. The sense resistors must also have low resistance

values in order to keep voltage drop and power dissipation to acceptable levels. The 78M6618’s ADC has

single ended inputs referenced to V3P3. The PCB traces that are used for the line and neutral buses on

the PDU board have resistances that are of the same magnitude or greater than that of the acceptable

shunts. This parasitic resistance appears between the reference end of the sense resistors and the ADCs

reference point, as illustrated by Figure 4. If the sense resistors are corrected directly to the ADC inputs

as shown in Figure 5, it is impossible to separate the voltage across the sense resistors from the voltage

across the parasitic resistance in the PCB. Because of this, current flowing in one outlet will affect the

voltage at the ADC current measurement inputs for other channels, resulting in channel-to-channel

crosstalk. To eliminate this problem, differential amplifiers are used between the current sense resistors

and the ADC current measurement inputs, as shown in Figure 5. The differential amplifier is biased to

provide an output centered at 3.3V, and rejects the voltage drop due to the PCB resistance, which

appears as common mode voltage at the amplifier inputs, so that the signal presented at the ADC input is

. An RC low-pass filter at the input to the ADC

RMS

PEAK

, which

14 Rev 3

Page 15

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

RshuntRshunt

Rshunt

Load

Load

Load

Load

78M6618

Runknown Runknown

Runknown Runknown

AC

Line

Neutral

Rshunt

ADC

Reference

Current

Sense

Inputs

Differential

Amplifier

-

+

Current

Sense

Resostor

AC Return

from load

AC Neutral

V6P6

GND

To LPF

and ADC

Input

Load Current

due only to the voltage drop across the current sense resistor. An additional advantage of using the

differential amplifier is that it is possible to use lower value sense resistors by increasing the gain of the

differential amplifier. The PDU evaluation board uses 500 µΩ sense resistors, with an amplifier gain of 10.

With this configuration, a peak current of 50A results in full-scale input to the ADC. This allows the PDU to

measure 16A loads with a crest factor slightly greater than 3.

Figure 4: PCB Parasitic Resistance

The layout of the feedback networks for the differential amplifiers is critical to provide true differential

Figure 5: Differential Amplifier and Current Sense Resistor

operation and to avoid noise pickup due to the high voltages and currents present on the PDU1 board.

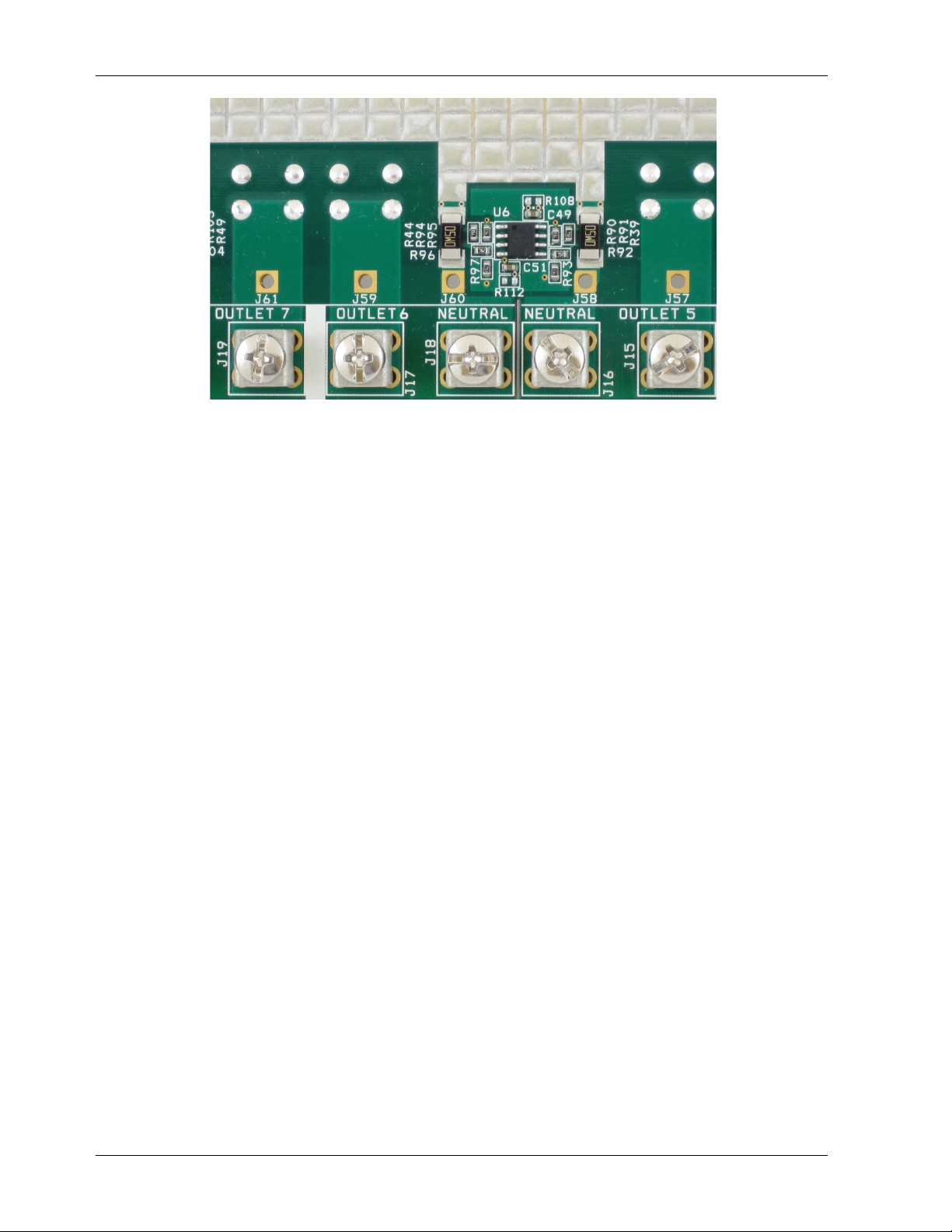

Figure 6 shows a detail view of the current sense resistors, the dual op amp, and their feedback

networks.

Rev 3 15

Page 16

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

Figure 6: Detail View of Differential Amplifiers

The op amps and their feedback networks are laid out to minimize the interconnect distance between the

current sense resistors and the op amp inputs. They are also located above a V3P3 plane to minimize

electrical noise pickup. For more detailed information on PCB layout, refer to the application note

Designing a Differential Power Distribution Unit Using the 78M6618.

16 Rev 3

Page 17

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

4 In-Circuit Emulator (ICE) Adaptor

The 78M6618’s firmware (stored in internal flash memory) can be updated to accommodate program

enhancements. Use the Signum ADM51 or the Teridian TFP2 to download new firmware to the 78M6618.

The supplied ICE Adaptor is required to interface the flat ribbon cable (provided with the ADM51 or TFP2)

to the 78M6618 evaluation board.

Figure 7: ICE Adaptor

Figure 3 shows how to attach the ICE Adaptor to the 78M6618 evaluation board. Please make note of the

orientation of the ICE Adaptor as to how it attaches to the 78M6618 evaluation board (V3P3 ICE Adaptor

pin connects to the +V Evaluation Board pin).

Figure 8: 78M6618 ICE Adaptor Attachment

Disconnect the 78M6618 evaluation board from live AC voltages before connecting the

ADM51 or TFP2. An Earth ground disparity and high AC voltages are present on the

78M6618 evaluation board when it is connected to the AC outlet. Equipment damage to

the 78M6618, ADM51/TFP2 and attached PC may occur when live AC voltages are

present on the 78M6618 evaluation board. Refer to the 78M661x Safety Precautions

Applications Note for additional information.

It is recommended to always use the supplied flat ribbon cable. Do not use discrete wires in place of the

flat ribbon. Poor signal integrity will cause flash memory programming errors. Additional adaptors and flat

ribbon cables can be ordered through Maxim.

Rev 3 17

Page 18

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

x

XIN

LINEV

LINE 2,3

NEUTRAL 2,3

R6

1M 0.1%

1206W

R5

1M 0.1%

1206W

MS 660-RN732BTTD1004B25

+

C2

10uF 25V

DigiKey 478-1762-1-ND

1812

C6

1000pF

0603

XOU T

R9

1M 0.1%

1206W

U10

78L33

IN3OUT

1

GND

2

J48

5VEXT

RAPC712A

MS 502-RAPC712X

1

2

3

C8

1000pF

0603

U11

78L33

IN3OUT

1

GND

2

OUTCUR83

Title

Size Document Number Rev

Date: Sheet

of

Power Distribution U nit 8 Outlet Dif ferential C urrent Single Phase

TERIDIAN SEMICONDUCTOR CORP.

B

1 4Tuesday, May 10, 2011

C36

1uF

0603

D9

Red LED

.

R106

11K

LOGO2

1

TERIDIAN

LOGO1

1

Warning

R8

1M 0.1%

1206W

MS 660-RN732BTTD1004B25

MT1 MT2

C14

1uF

0603

GND

J3

CON1

1

Black

White

Green

GND

DigiKey 160-1181-6-ND

GND

GND

V3P3

C15

0.1uF

0603

C12

1uF 20V

1206P

3.3V below

Neutral

V3P3

connected t o

NEUTRAL

EGND

External wire to

J2 center point

12 VDC Input

+

C30

10uF 25V

DigiKey 478-1762-1-ND

1812

OUTCUR22

C7

33pF

0603

C9

9pF

0603

Y1

32.768KHz

CM200S

535-9166-1-ND

14

GND

OUTCUR32

V3P3

OUTCUR53

+12VDC

OUTCUR42

OUTCUR73

MT4MT3 MT5

OUTCUR63

MT6

3.3V above Neutral (V3P3)

V6P6

GND

Tyco 640454-2

GND

To Relays

V3P3

OUTCUR12

C1

0.1uF

0603

C4

NC

0603

+/-178mVrms

V3P3

V3P3

V1

R2

2K

0603

V2P5

EGNDV

VREF

C5

100pF

0603

+/-250mVpp

R3

20.0K 1%

0603

C3

0.1uF

0603

R1

16.9K 1%

0603

GND

LINE

U1-1

78M6618-68QFN

QFN68

V2P5

48

V3P3A

51

IA

61

IB

60

ID

58

IC

59

VREF

62

IF

56

IE

57

IG

55

V1

63

GNDA1

50

IH

54

VA

53

VB

52

XIN

66

XOU T

68

GNDA2

65

R4

750 0.1%

0603

+

C35

10uF 25V

DigiKey 478-1762-1-ND

1812

R7

750 0.1%

0603

J4

terminal block

1

2

NEUTRAL

A98275-ND

+

C13

220uF 25V lo imp

UUDB

MS 647-UUD1E221MNL

All things ref erenced to V3P3 f or 78M6618

Note: SMA GND shield is -3.3V relativ e to Neutral (Earth GND )

V3P3 connected t o NEUTRAL for Saf ety due to SMA GND shield

5 Schematics, Bill of Materials, and PCB Layouts

This section includes the schematics, bill of materials and PCB layouts for the 78M6618 PDU1 evaluation board.

5.1 78M6618 PDU1 Evaluation Board Schematics

18 Rev 3

Figure 9: 78M6618 PDU1 Evaluation Board Electrical Schematic (1 of 4)

Page 19

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

Egnd/Green

Neutral/White

Line/Black

NUD3112LT1GOSCT-ND

Neutral/White

Line/Black

Egnd/Green

R17

10K

0603

Neutral1/W hite

-

+

U4B

MAX4494/SO

7

5

6

8 4

R21

10K

0603

Neutral2/W hite

Neutral3/W hite

Neutral4/W hite

R73

75K

0603

-

+

U4A

MAX4494/SO

1

3

2

4 8

R74

7.5K

0603

GND

RLY2

R75

7.5K

0603

R76 75K

0603

Line/Black

Neutral/White

Egnd/Green

V6P6

GND

J50

CON1

1

J49

CON1

1

Q11

NUD3112/ SOT

C46

0.1UF

0603

NEUTRAL

J52

CON1

1

J51

CON1

1

J54

CON1

1

J53

CON1

1

GND

J55

CON1

1

J56

CON1

1

NEUTRAL1,3

V3P3

C47

0.1UF

0603

+12VDC

R83

7.5K

0603

R82

75K

0603

R85

75K

0603

R84

7.5K

0603

GND

GND

Q13

NUD3112/ SOT

C37

.047uF

0603

OUTCUR1

RELAY1 4

V6P6

RELAY2 4

GND

V3P3

C38

.047uF

0603

R26

10K

0603

Q12

NUD3112/ SOT

+12VDC

GND

D1

LED

OUTCUR2

J7

CON4

STERM

MS 534-8191

1

2

3

4

R78

7.5K

0603

R77

75K

0603

R79

7.5K

0603

R80 75K

0603

Q10

NUD3112/ SOT

R81

.0005

2512P

MS 66-ULR25R006FLF TR

Title

Size Doc ument Number Rev

Date: Sheet

of

Power Distribution U nit 8 Outlet Dif ferent ial Current Single Phase

TERIDIAN SEMICONDUCTOR CORP.

B

2 4Tuesday, May 10, 2011

C39

.047uF

0603

J8

CON4

STERM

MS 534-8191

1

2

3

4

LINE

NEUTRAL

OUTL ET3

OUTL ET2

OUTL ET1

OUTL ET4

RLY4

RLY3

R19

.0005

2512P

MS 66-ULR25R006FLF TR

D2

LED

C18

1000pF

0603

C19

1000pF

0603

RL4

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

5

4

1

2

6

7

8

RL1

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

5

4

1

2

6

7

8

J9

CON4

STERM

MS 534-8191

1

2

3

4

RL2

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

54

1

2

6

7

8

R27

2K

0603

R30

750

0603

RL3

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

54

1

2

6

7

8

R22

2K

0603

C20

1000pF

0603

R32

2K

0603

R35

750

0603

R29

.0005

2512P

MS 66-ULR25R006FLF TR

R20

750

0603

J10

CON4

STERM

MS 534-8191

1

2

3

4

R34

.0005

2512P

MS 66-ULR25R006FLF TR

R25

750

0603

R16

2K

0603

C17

1000pF

0603

D3

LED

V3P3

V3P3

LINE1,3

OUTCUR3 1

OUTCUR2 1

OUTCUR1 1

OUTCUR3

OUTCUR4 1

.

RELAY3 4

LED, Green

LED, Green

-

+

U5A

MAX4494/SO

1

3

2

4 8

J11

CON4

STERM

MS 534-8191

1

2

3

4

C45

0.1UF

0603

C48

0.1UF

0603

V3P3

J12

CON4

STERM

MS 534-8191

1

2

3

4

D4

LED

C40

.047uF

0603

J13

CON4

STERM

MS 534-8191

1

2

3

4

-

+

U5B

MAX4494/SO

7

5

6

8 4

J14

CON4

STERM

MS 534-8191

1

2

3

4

+12VDC1,3

OUTCUR4

V6P6

GND

+12VDC

R31

10K

0603

+12VDC

GND

V3P3

RELAY4

4

V6P6

R86

75K

0603

R88

7.5K

0603

R87

7.5K

0603

R89

75K

0603

Egnd/Green

Neutral/White

Line/Black

DigiKey 475-1409-1-ND

Rev 3 19

Figure 10: 78M6618 PDU1 Evaluation Board Electrical Schematic (2 of 4)

Page 20

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

-

+

U7A

MAX4494/SO

1

3

2

4 8

C52

0.1UF0603

R42

2K

0603

R102

75K

0603

R104

7.5K

0603

R103

7.5K

0603

R105

75K

0603

-

+

U7BMAX4494/SO

7

5

6

8 4

GND

R47

2K

0603

GND

Q15

NUD3112/ SOT

R52

2K

0603

RLY6

RELAY6 4

NEUTRAL

V6P6

GND

RLY7

Q16

NUD3112/ SOT

RLY8

R108NC

GND

Neutral/White

Line/Black

Neutral1/ White

Egnd/Green

Egnd/Green

Neutral/White

Line/Black

Neutral1/ White

Egnd/Green

Neutral/White

Line/Black

Neutral1/ White

R109NC

GND

Egnd/Green

Neutral/White

Line/Black

Neutral1/ White

V6P6

R36

10K

0603

RELAY7 4

R110NC

R46

10K

0603

Title

Size Document N umber Rev

Date: Sheet

of

Power Distribut ion Unit 8 Outlet Dif ferent ial Current Single Phase

TERIDIAN SEMICONDUCTOR CORP.

B

3 4Wednesday , May 11, 2011

NEUTRAL1,2

LINE

NEUTRAL

OUTL ET5

RELAY8 4

OUTL ET8

OUTL ET7

OUTL ET6

GND

R39

2512P

MS 66-ULR25R006F LFTR

R54

.0005

2512P

MS 66-ULR25R006F LFTR

C22

1000pF

0603

R55

750

0603

RL5

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

54

1

2

6

7

8

R45

750

0603

RL8

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

54

1

2

6

7

8

RL6

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

54

1

2

6

7

8

C24

1000pF

0603

C21

1000pF

0603

R40

750

0603

R49

.0005

2512P

MS 66-ULR25R006F LFTR

R50

750

0603

GND

R37

2K

0603

R44

.0005

2512P

MS 66-ULR25R006F LFTR

C23

1000pF

0603

RL7

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

5412

6

7

8

V3P3

LINE1,2

OUTCUR6 1

OUTCUR5 1

NUD3112LT1GOSCT-ND

OUTCUR8 1

OUTCUR7 1

.

DigiKey 475-1409-1-ND

LED, Green

LED, Green

J58

CON1

1

R98

7.5K

R100

7.5K

0603

R99

75K

R101

75K

0603

V6P6

V6P6

R91

7.5K

0603

R90

75K

0603

R92

7.5K

0603

J60

CON1

1

J59

CON1

1

J62

CON1

1

J61

CON1

1

J64

CON1

1

J63

CON1

1

NEUTRAL

C41

.047uF

0603

GND1,3

RELAY5 4

V3P3

OUTCUR5

J57

CON1

1

V6P6

Q17

NUD3112/ SOT

C49

0.1UF

0603

V3P3

C42

.047uF

0603

J15

CON4

STERM

MS 534-8191

1

2

3

4

C43

.047uF

0603

J16

CON4

STERM

MS 534-8191

1

2

3

4

C44

.047uF

0603

J17

CON4

STERM

MS 534-8191

1

2

3

4

C50

0.1UF

0603

R41

10K

0603

V3P3

J18

CON4

STERM

MS 534-8191

1

2

3

4

GND

OUTCUR6

J19

CON4

STERM

MS 534-8191

1

2

3

4

R94

7.5K

0603

R96

7.5K

0603

R95

75K

0603

R97

75K

0603

J20

CON4

STERM

MS 534-8191

1

2

3

4

C51

0.1UF0603

R107NC

J21

CON4

STERM

MS 534-8191

1

2

3

4

Q14

NUD3112/ SOT

R51

10K

0603

R93

75K

0603

R111NC

R113NC

R112NC

R114NC

J22

CON4

STERM

MS 534-8191

1

2

3

4

NEUTRAL

GND

OUTCUR7

D5

LED

-

+

U6AMAX4494/SO

1

3

2

4 8

NEUTRAL

D6

LED

D7

LED

OUTCUR8

-

+

U6B

MAX4494/SO

7

5

6

8 4

D8

LED

RLY5

+12VDC1, 3

Figure 11: 78M6618 PDU1 Evaluation Board Electrical Schematic (3 of 4)

20 Rev 3

Page 21

Title

Size Document N umber Rev

Date: Sheet

of

Power Distribut ion Unit 8 Outlet Dif ferent ial Current Single Phase

TERIDIAN SEMICONDUCTOR CORP.

B

4 4Tuesday , May 10, 2011

R61

10K

0603

TP3

SIP100P2

Wh

1

2

DigiKey 475-1409-1-ND

Pulse Output

V3P3

TP6

TP

TPWW

1

.

PCLK

GND

MISO

PWRUP

TRXCE

CSN

no connect

TXEN

MOSI

CD

DR

SCKDIO4

DIO5

DIO43

DIO19

DIO16

DIO17

DIO18

DIO1

DIO2

DIO3

no connect

no connect

PacketPowerOneNetSM BusJ37

Pins

SMBALTRB

SMBTXLOB

SMBCLOCK

SMBRXD

no connect

SLE

CE

no connect

no connect

SMBCKHDB DATAIO

DATACLK

INT

SCLK

SREAD

SDATA

GND

GND

PSDI

D10

READY

TP1

TP

TPWW

1

V3P3

TP7

TP

TPWW

1

DIO3

PSDO

D11

LED

TP2

TP

TPWW

1

GND

GND

PCSZ

RELAY3 2

C27

1uF

810-C1608X5R1C105M

0603

C25

0.1uF

0603

UTX

GND

J40

SPI1

DIP100P10

1 2

3 4

5 6

7

8

9 10

RELAY5 3

R62

470

0603

R15

470

0603

V3P3

RELAY2 2

D12

Red LED

DIO17

RELAY7 3

DIO18

V3P3

RELAY4 2

GND

GND

V3P3

RELAY6 3

C26

0.1uF

0603

LED, GrnLED, Y el

GNDGND

DIO6

U2

28-LD SSOP

28-SSOP

768-1007-1-ND

VCC

20

USBDM

16

USBDP

15

VCCIO

4

NC1

8

RESETB

19

OSCI

27

RXD

5

RTS

3

CTS

11

DTR

2

DSR

9

RI

6

CBUS0

23

TXD

1

OSCO

28

CBUS1

22

CBUS2

13

CBUS3

14

CBUS4

12

3V3OUT

17

AGND25GND1

7

GND218GND3

21

TEST

26

NC2

24

DCD

10

DIO16

GNDGND

GND

DIO19

J66

CON2

1

2

DIO43

NEUTRAL1,2

DIO4

DigiKey 160-1181-6-ND

URX

R58

330

0603

C29

1000pF

0603

TCLK

RXT X

J47

USB-B

USBBV

MS 806-KUSBVX-BSIN-W

1

2

3

4

5

6

ACTIVE

ICE inputs become

ERST

when ICEE low

LCD seg driv ers

V3P3

J38

ICE

SIP100P6

1

2

3

4

5

6

ICEEN

USBDM

USB5V

V3P3

USBRX

can source upto 50ma

U2 internal 3. 3V LDO

USBDP

USBTX

U3

ADUM3201

ADUM3201

ADUM3201ARZ-ND

VOA

2

V1

1

ND1

4

V2

8

VIA

7

G2

5

VIB3VOB

6

USB3V

C31

4.7uF

1206P

USBGND

C32

0.1uF

0603

Mouser 571-1487588-2

1.5M A/B Whit e Cable

ADI TX/RX data interf ace

DIO1

DIO2

GND

DIO5

PCLK

SCL

PSDI

SDA

J67

CON2

1

2

SDI

CLK

PSDO

Must use iso lated USB hub

CSZ

SDO

PCSZ

CSZ

SDO

SDI

CLK

LED, Red

R60

470

0603

V3P3

C28

R57

R56

SW1

Optional Res et Switch

1000pF

1K

1K

EVQ-PJX05M Panasonic

J39

DEBUG

SIP100P4

1

2

3

4

TP4

TEST POINT

1

R59

10K

0603

R71

0

0603

C33

0.1uF

0603

RELAY1 2

RELAY8 3

TP5

TP

TPWW

1

DigiKey 160-1184-1-ND

I2C Master

for

EEPROM

Internal s lave SPI cont roller

U1-2

78M6618-68QFN

QFN68

SEG12

30

SEG2

21

SEG17

34

SEG16

33

RESET

49

SEG18

35

V3P3D

9

ERXTX/SEG9

4

SDCK/D IO4/SEG24

37

SDATA/DIO5/ SEG25

38

ERST/SEG11

1

ETCLK/SEG10

2

DIO13/SEG33

29

SEG15

32

RX

46

SEG1

20

SEG7

26

SEG8

27

TX

7

SEG0

19

VBAT

47

COM1

18

COM0

17

CKTEST/SEG19

10

DIO17/SEG37

14

PSDI/SEG6

25

DIO18/SEG38

15

TEST

67

SEG14

31

PCSZ/SEG5

13

PSDO/SEG4

12

PCLK/SEG3

8

GNDD1

3

ICEE

36

V3P3SYS

11

WPULSE/D IO6/SEG26

39

DIO8/SEG28

42

DIO9/SEG29

43

DIO10/SEG30

44

DIO11/SEG31

45

DIO43/SEG63

28

DIO14/SEG34

22

DIO15/SEG35

23

DIO16/SEG36

24

TMUXOU T

6

DIO7/SEG27

40

OPTX/DIO2

5

OPRX/DIO1

64

DIO3

16

DIO19/SEG39

41

SM Bus Address

Alternate

bit-bang SPI

interf ace

R72

0

0603

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

Figure 12: 78M6618 PDU1 Evaluation Board Electrical Schematic (4 of 4)

Rev 3 21

Page 22

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

MS - Mouser

C1,C3,C15,C25,C26,C32,C33,

2 3 C2,C30,C35

10µF 25V

2312

399-3734-1-ND

T491C106K025AT

KEMET

Yes

3 1 C4

0603

DNP

—

—

—

4 1 C5

100pF

0603

445-1281-1-ND

C1608C0G1H101J

TDK Corporation

Yes

Yes

Yes

6 1 C7

33pF

0603

399-1055-1-ND

C0603C330J5GACTU

KEMET

Yes

7 1 C9

9pF

0603

445-5046-1-ND

C1608C0G1H090C

TDK Corporation

Yes

CC1206KKX7R8BB10

5

220µF 25V lo

imp

GRM188R61E105KA1

2D

11 1 C31

4.7µF

1206

399-4630-1-ND (1206)

T491A475M025AT

KEMET

Yes

C37,C38,C39,C40,C41,C42,

C43,C44

GRM188F51H473ZA0

1D

OSRAM Opto

Semiconductors

15 1 D10

Yellow LED

0603

160-1184-1-ND

LTST-C190YKT

Lite-On Inc.

Yes

J3,J49,J50,J51,J52,J53,J54,

J62,J63,J64

17 1 J4

TERM BLOCK

Through Hole

A98275-ND

796740-2

TE Connectivity

Yes

J7,J8,J9,J10,J11,J12,J13,J14,

Sullins Connector

Solutions

Sullins Connector

Solutions

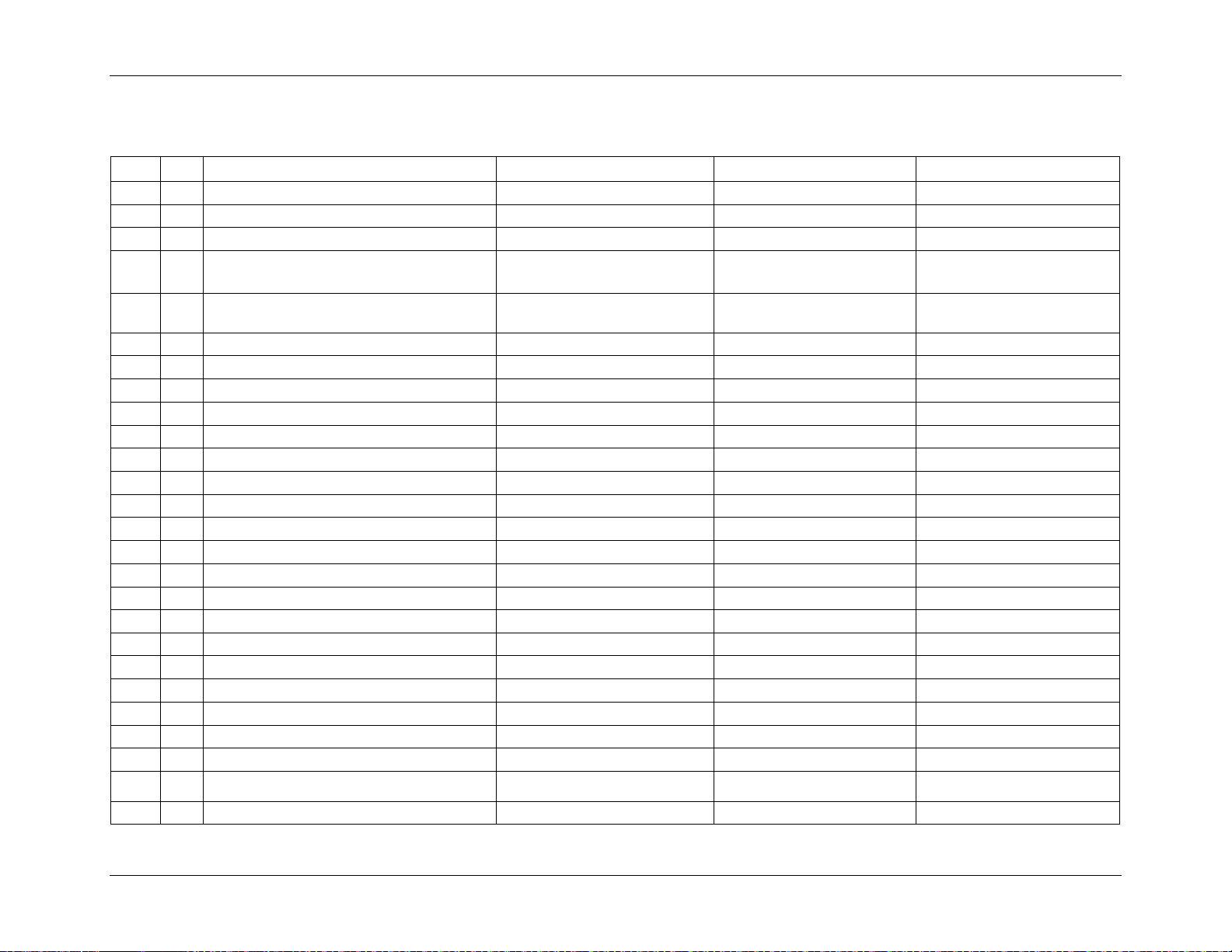

5.2 78M6618 PDU1 Evaluation Board Bill of Materials

Table 2: 78M6618 PDU1 Evaluation Board Bill of Materials

Item Qty Reference Part

1 15

5 11

8 1 C12

9 1 C13

10 3 C14,C27,C36

12 8

13 9 D1,D2,D3,D4,D5,D6,D7,D8,D11 Green LED 0603 475-1409-1-ND LG Q971-KN-1

C45,C46,C47,C48,C49,C50,

C51,C52

C6,C8,C17,C18,C19,C20,C21,

C22,C23,C24,C29

0.1µF 0603 399-5089-1-ND C0603C104K5RACTU KEMET Yes

1000pF 0603 445-1298-1-ND C1608X7R2A102K TDK Corporation

1µF 25V

1µF (0603)

.047µF

PCB

Footprint

1206 311-1356-1-ND

SMD 493-2278-1-ND UUD1E221MNL1GS Nichicon Yes

0603 490-3897-1-ND

0603 490-1567-1-ND

Digi-Key

Part Number Manufacturer RoHS

Yageo Yes

Murata Yes

Murata Yes

Yes

14 2 D9,D12 Red LED 0603 160-1181-6-ND LTST-C190CKT Lite-On Inc. Yes

16 17

18 16

19 1 J38 ICE Through Hole S1011E-36-ND PBC36SAAN

20 1 J39 DEBUG Through Hole S1011E-36-ND PBC36SAAN

J55,J56,J57,J58,J59,J60,J61,

J15,J16,J17,J18,J19,J20,J21,

J22

22 Rev 3

CON1 Through Hole DNP — — —

CON4 Through Hole MS 534-8191 8191

Keystone

Electronics

Yes

Yes

Yes

Page 23

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

Digi-Key

Sullins Connector

Solutions

MS 806-KUSBVX-

BS1N-B

23 1 J48

RAPC712A

Through Hole

MS 502-RAPC712X

RAPC712X

Switchcraft

Yes

Sullins Connector

Solutions

Sullins Connector

Solutions

INDCT

DRVR

RL1,RL2,RL3,RL4,RL5,RL6,RL

16A 12V SPDT

29 1 R1

16.9K 1%

0603

P16.9KHCT-ND

ERJ-3EKF1692V

Panasonic

Yes

R2,R16,R22,R27,R32,R37,R42,

R47,R52

31 1 R3

20.0K 1%

0603

P20.0KHCT-ND

ERJ-3EKF2002V

Panasonic

Yes

32 2 R4,R7

750 0.1%

0603

P750YCT-ND

ERA-3YEB751V

Panasonic

Yes

MS 660-

RN732BTTD1004B25

34 3 R15,R60,R62

470

0603

P470GCT-ND

ERJ-3GEYJ471V

Panasonic

Yes

R17,R21,R26,R31,R36,R41,R4

6,R51,R59,R61

R19,R29,R34,R39,R44,R49,R5

MS 66-

ULRB22512R0005FL

R20,R25,R30,R35,R40,R45,R5

38 1 R58

330

0603

P330HCT-ND

ERJ-3EKF3300V

Panasonic

Yes

39 2 R71,R72 0 0603

P0.0GCT-ND

ERJ-3GEY0R00V

Panasonic

Yes

Item Qty Reference Part

21 1 J40 SPI1 Through Hole S2011E-36-ND PBC36DAAN

22 1 J47 USB-B Through Hole

24 2 J66,J67 CON2 Through Hole S1011E-36-ND PBC36SAAN

25 2 LOGO1,LOGO2 Logo Silkscreen — — — —

26 5 TP1,TP2,TP5,TP6,TP7 TP Through Hole S1011E-36-ND PBC36SAAN

27 8

28 8

30 9

33 4 R5,R6,R8,R9 1M 0.1% 1206

Q10,Q11,Q12,Q13,Q14,Q15,Q

16,Q17

7,RL8

LOAD/RELAY

Low Profile

2K 0603 P2.0KGCT-ND ERJ-3GEYJ202V Panasonic Yes

PCB

Footprint

SOT-23-3

Through Hole 255-1446-ND ALZ12F12 Panasonic Yes

MS - Mouser

NUD3112LT1GOSCT-

ND

Part Number Manufacturer RoHS

806-KUSBVX-BS1N-B Kycon Yes

NUD3112LT1G ON Semiconductor Yes

RN732BTTD1004B25 KOA Speer Yes

Yes

Yes

Yes

35 10

36 8

37 8

40 16

4,R81

0,R55

R73,R76,R77,R80,R82,R85,

R86,R89,R90,R93,R95,R97,

R99,R101,R102,R105

Rev 3 23

10K 0603 P10.0KHCT-ND ERJ-3EKF1002V Panasonic Yes

0.0005 2512

750 0603 P750GCT-ND ERJ-3GEY0R00V Panasonic Yes

75K 0603 RG16P75.0KBCT-ND RG1608P-753-B-T5 Susumu Yes

ULRB2R0005FLFSLT

FSLT

IRC Yes

Page 24

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

Digi-Key

42 1 R106

11K

0603

P11KGCT-ND

ERJ-3GEYJ113V

Panasonic

Yes

R107,R108,R109,R110,R111,

Sullins Connector

Solutions

Sullins Connector

Solutions

46 1 U1

78M6618-68QFN

68-QFN — —

Maxim

Yes

47 1 U2

FTDI 28-SSOP

28-SSOP

768-1007-1-ND

FT232RL-REEL

FTDI

Yes

48 1 U3

ADUM3201

8-SOIC

ADUM3201ARZ-ND

ADUM3201ARZ

Analog Devices

Yes

ROHM

Semiconductor

50 2 U10,U11

78L33

SOT-89-3

497-1200-1-ND

L78L33ACUTR

STMicroelectronics

Yes

Abracon

Corporation

Keystone

Keystone

Electronics

B&F Fastener

Supply

Item Qty Reference Part

R74,R75,R78,R79,R83,R84,

41 16

43 8

44 1 TP3 Wh Through Hole S1011E-36-ND PBC36SAAN

45 1 TP4 TEST POINT Through Hole S1011E-36-ND PBC36SAAN

49 4 U4,U5,U6,U7 OP AMP 8-SOIC LM2904MXCT-nd LM2904MX

51 1 Y1 32.768KHz 4-SOJ 535-9166-1-ND ABS25-32.768KHZ-T

52 6 MT1,MT2,MT3,MT4,MT5,MT6 STANDOFFS Through Hole MS 534-1809 1809

53 6 standoff bumpers RUBBER N/A MS 534-720 720

R87,R88,R91,R92,R94,R96,

R98,R100,R103,R104

R112,R113,R114

7.5k 0603 RG16P7.5KBCT-ND RG1608P-752-B-T5 Susumu Yes

2.5k 0603 DNP — — —

PCB

Footprint

MS - Mouser

Part Number Manufacturer RoHS

Electronics

Yes

Yes

Yes

Yes

Yes

Yes

54 12 # 4 screws for stand offs Screws Through Hole H346 PMS 440 0050 PH

24 Rev 3

Yes

Page 25

UM_6612_016 78M6618 PDU1 Evaluation Board User Manual

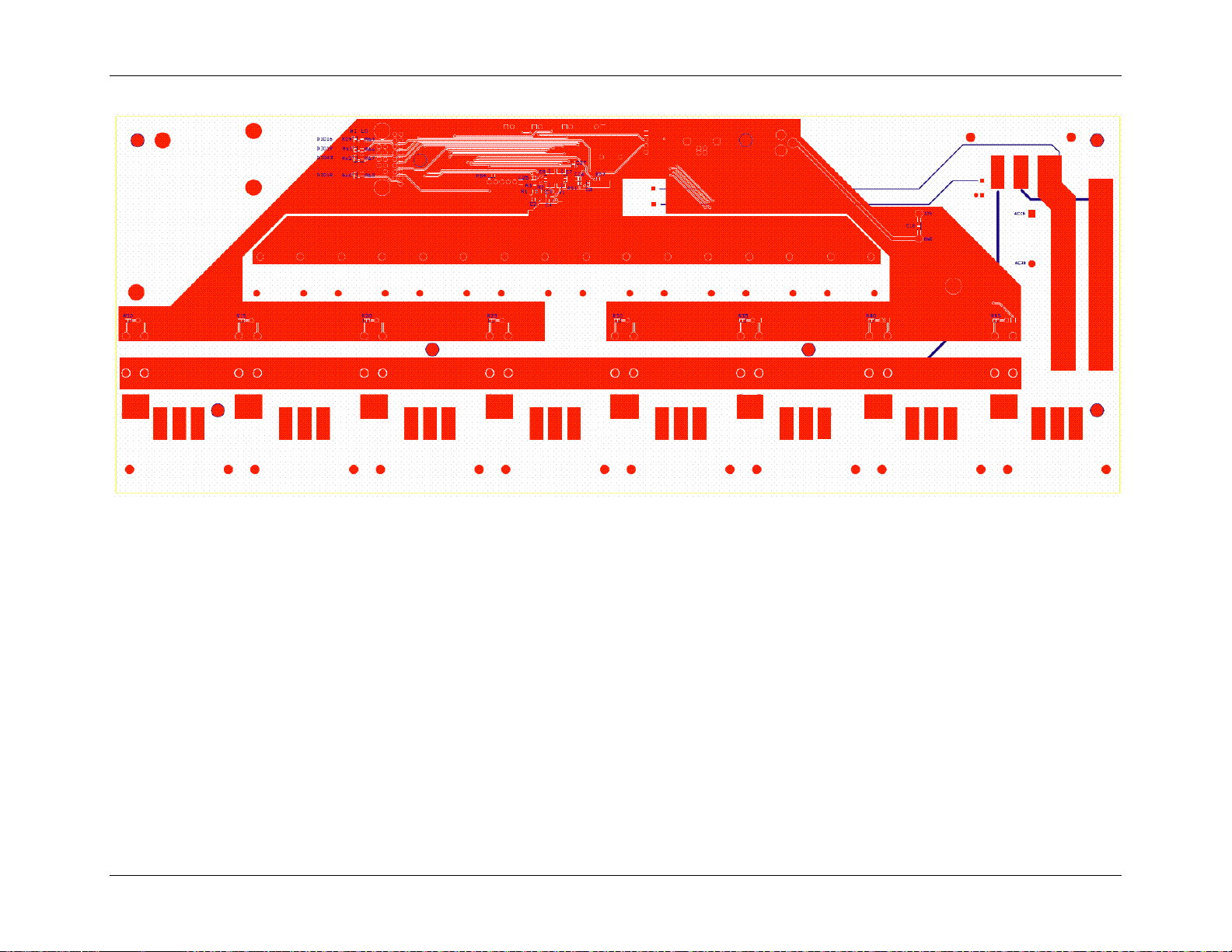

5.3 78M6618 PDU1 Evaluation Board PCB Layouts

Figure 13: 78M6618 PDU1 Evaluation Board PCB Top View

Figure 14: 78M6618 PDU1 Evaluation Board PCB Power View

Figure 15: 78M6618 PDU1 Evaluation Board PCB GND View

Figure 16: 78M6618 PDU1 Evaluation Board PCB Bottom View

Rev 3 25

Page 26

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

Part Description

Order Number

6 Ordering Information

78M6618 PDU1 Evaluation Board 78M6618-PDU-1

7 Contact Information

For more information about Maxim products or to check the availability of the 78M6618, contact technical

support at

www.maxim-ic.com/support.

26 Rev 3

Page 27

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

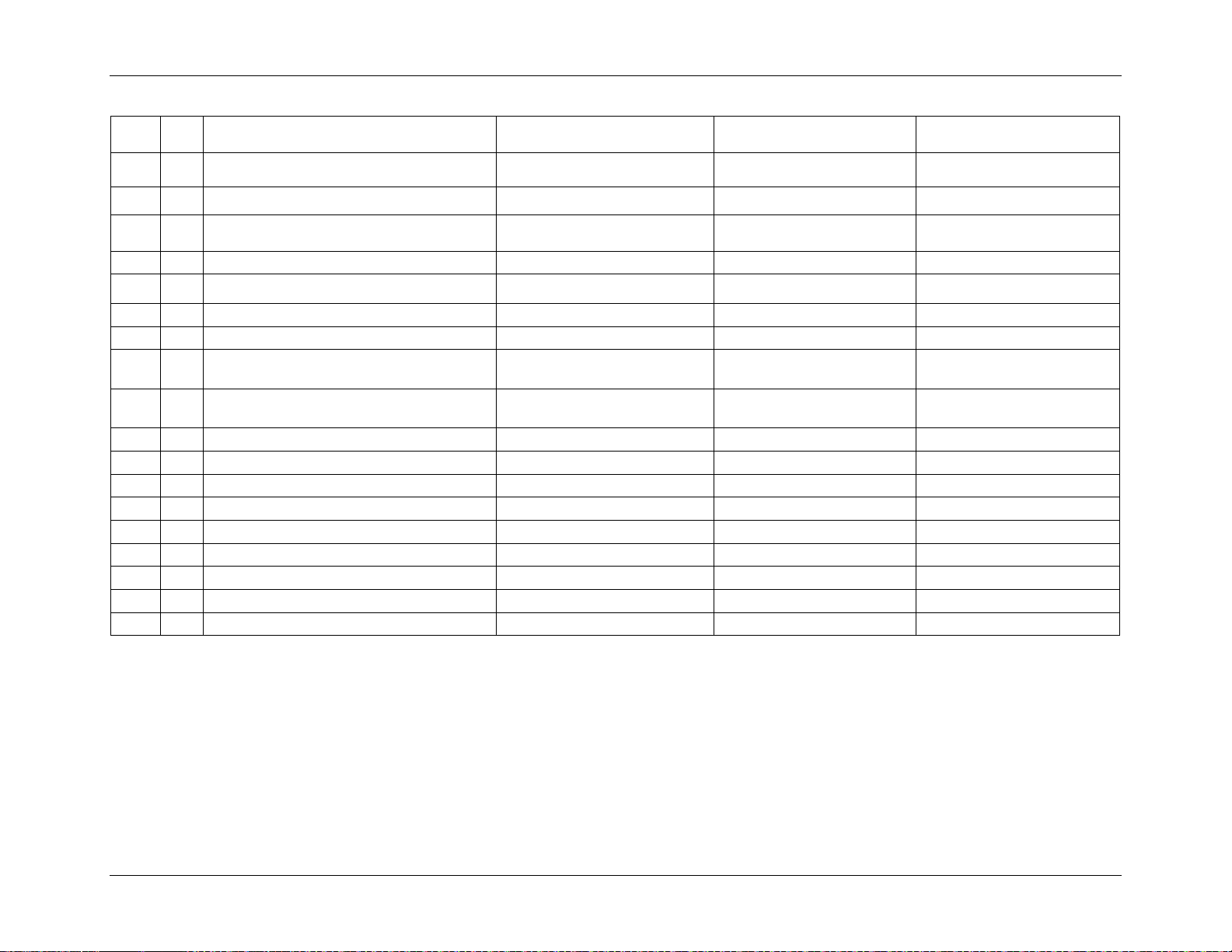

Appendix A - 78M6618 PDU1 Board with CTs

This appendix includes the photograph, schematics, bill of materials, and layout images for a comparable 78M6618 PDU1 evaluation board using

current transformers (CTs) in place of current shunt resistors. The information on this board is provided as reference only and is not available for

purchase.

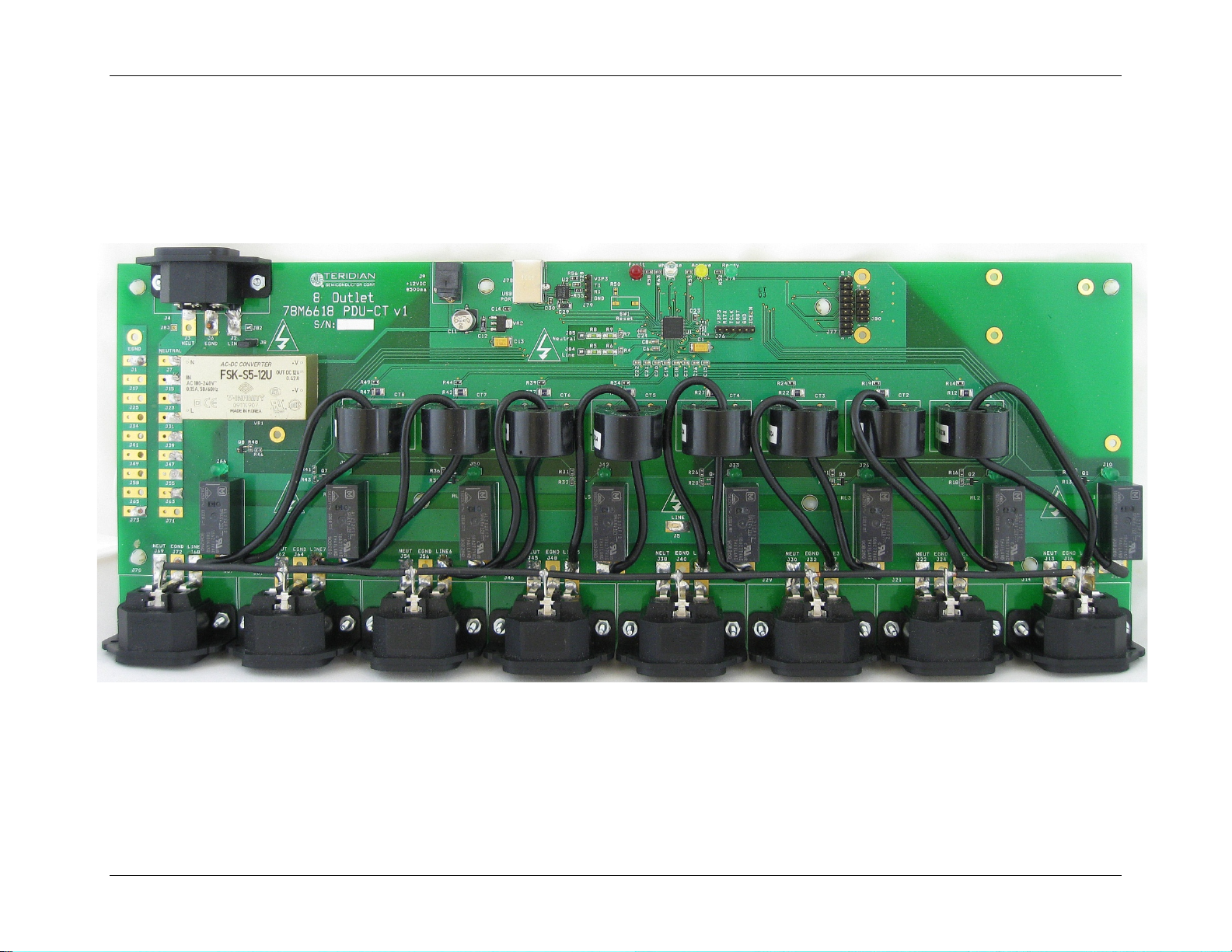

A.1 78M6618 PDU-CT Evaluation Board

Figure 17: 78M6618 PDU-CT Evaluation Board

Rev 3 27

Page 28

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

OUTCUR2

XIN

LINEV

LINE

OUTCUR3

NEUTRAL

R6

1M 0.1%

1206W

R5

1M 0.1%

1206W

MS 660-RN732BTTD1004B25

OUTCUR4

+

C1

10uF 25V

DigiKey 478-1762-1-ND

1812

C6

1000pF

0603

XOU T

R9

1M 0.1%

1206W

OUTCUR5

C8

1000pF

0603

OUTCUR6

OUTCUR7

OUTCUR8

MT3

MS 561-PS500A

Title

Size Document Number Rev

Date: Sheet

of

PDUCTV1 1

Power Distribution U nit 8 Outlet Single Phase with C Ts

TERIDIAN SEMICONDUCTOR CORP.

B

1 4Monday, March 01, 2010

GND

MT5

MS 561-PS500A

EGND

MT11

MS 561-PS500A

MT4

MS 561-PS500A

MT12

MS 561-PS500A

MT6

MS 561-PS500A

MT2

MS 561-PS500A

GND

.

LOGO2

1

TERIDIAN

J8

SIP100P2

Weco Tst

1

2

LOGO1

1

Warning

R8

1M 0.1%

1206W

MS 660-RN732BTTD1004B25

MT7

MT10

MT9MT8

LOGO6

1

Neutral/White

Line/Black

Egnd/Green

Black

White

Green

V3P3

+12VDC

C10

0.1uF

0603

J82

CON1

SIP100P1

1

EGND

C12

1uF 20V

1206P

C14

1uF

0603

LOGO3

1

J5

ACTERM

K1287

MS 534-1287-ST

1

2

LOGO4

1

LOGO5

1

+

C13

10uF 25V

DigiKey 478-1762-1-ND

1812

J9

Weco Tst

RAPC712A

MS 502-RAPC712

1

2

3

VR1

FSKS5-12V

FSKS5

102-1471-ND

GND

4

AC1

1

AC2

2

+12V

5

GND

C7

33pF

0603

C9

9pF

0603

Y1

32.768KHz

CM200S

535-9166-1-ND

1

4

J4

AC Inlet

PX0580

MS 562-PX0580/PC

1

2

3 VR2

+3.3V 500mA

MS 511-LD1117S33C

SOT223

VOUT

2

VIN

3

TAB

4

GND

1

V3P3

J2

CON1

SIPW2

1

MT13

MT16MT14

MT15

J1

ACTERM

K1287

MS 534-1287-ST

1

2

J3

CON1

SIPW2

1

GND

V3P3

LINE

To Relays

V3P3

OUTCUR1

C2

0.1uF

0603

C4

NC

0603

+/-178mVrms

V3P3

J6

CON1

SIPW2

1

V1

R2

2K

0603

GND

GND

V2P5

GND

NEUTV

GND

VREF

GND

C5

100pF

0603

+/-250mVpp

R3

20.0K 1%

0603

C3

0.1uF

0603

R1

16.9K 1%

0603

GND

U1-1

78M6618-68QFN

QFN68

V2P5

48

V3P3A

51

IA

61

IB

60

ID

58

IC

59

VREF

62

IF

56

IE

57

IG

55

V1

63

GNDA1

50

IH

54

VA

53

VB

52

XIN

66

XOU T

68

GNDA2

65

R4

750 0.1%

0603

J83

CON1

SIP100P1

1

J7

ACTERM

K1287

MS 534-1287-ST

1

2

R7

750 0.1%

0603

J84

CON1

SIP100P1

1

J85

CON1

SIP100P1

1

NEUTRAL

+

C11

220uF 25V lo imp

UUDB

MS 647-UUD1E221MNL

MT1

MS 561-PS500A

A.2 78M6618 PDU-CT Evaluation Board Schematics

Figure 18: 78M6618 PDU-CT Evaluation Board Electrical Schematic (1 of 4)

28 Rev 3

Page 29

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

R15

2K

0603

J18

SIP100P2

LED

1

2

Q1

NPN 500m a 30V

SOT23T

MS 512 -MMBTA13

GND

R20

2K

0603

J26

SIP100P2

LED

1

2

V3P3

J33

SIP100P2

LED

1

2

R25

2K

0603

RLY2

RELAY2

RLY3

RLY4

Neutral/White

Line/Black

Egnd/Green

Egnd/Green

Neutral/White

Line/Black

Q2

NPN 500m a 30V

SOT23T

MS 512 -MMBTA13

GND

R16

1K

0603

R18

10K

0603

Egnd/Green

Neutral/White

Line/Black

Egnd/Green

Neutral/White

Line/Black

RELAY3

Q3

NPN 500m a 30V

SOT23T

MS 512 -MMBTA13

GND

R23

10K

0603

R21

1K

0603

R17

4.99 1%

1210

MS 660-SR732ETTE4R99F

V3P3

CT2

CT020P2A

CT020P2A

Oswell

Title

Size Document N umber Rev

Date: Sheet

of

PDUCTV1

1

Power Distribut ion Unit 8 Outlet Single Phase with C Ts

TERIDIAN SEMICONDUCTOR CORP.

B

2 4Monday, March 01, 2010

OUTCUR4

NEUTRAL

+12VDC

+12VDC

+12VDC

+12VDC

LINE

NEUTRAL

OUTL ET1

RELAY4

OUTL ET4

OUTL ET3

OUTL ET2

EGND

Q4

NPN 500m a 30V

SOT23T

MS 512 -MMBTA13

GND

R26

1K

0603

R28

10K

0603

C16

1000pF

0603

R29

750

0603

RL1

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

5412

6

7

8

R19

750

0603

RL4

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

54

1

2

6

7

8

RL2

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

5412

6

7

8

V3P3

R22

4.99 1%

1210

MS 660-SR732ETTE4R99F

C18

1000pF

0603

C15

1000pF

0603

R14

750

0603

CT3

CT020P2A

CT020P2A

Oswell

R24

750

0603

R10

2K

0603

J10

SIP100P2

LED

1

2

C17

1000pF

0603

RL3

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

54

126

7

8

V3P3

LINE

+12VDC

OUTCUR2

OUTCUR1

OUTCUR4

OUTCUR3

.

EGND

MS 604-WP1503GD

LED, Green

V3P3

R27

4.99 1%

1210

MS 660-SR732ETTE4R99F

MS 604-WP1503GD

LED, Green

CT4

CT020P2A

CT020P2A

Oswell

OUTCUR2

OUTCUR3

OUTCUR1

J21

AC Outlet

PX0675

MS 562-PX0675/PC

1

2

3

J22

CON1

SIPW2

1

J19

CON1

SIPW2

1

J24

CON1

SIPW2

1

J29

AC Outlet

PX0675

MS 562-PX0675/PC

1

2

3

J30

CON1

SIPW2

1

J27

CON1

SIPW2

1

J32

CON1

SIPW2

1

J37

AC Outlet

PX0675

MS 562-PX0675/PC

1

2

3

J38

CON1

SIPW2

1

J36

CON1

SIPW2

1

J40

CON1

SIPW2

1

J11

CON1

SIPW2

1

J13

CON1

SIPW2

1

J14

AC Outlet

PX0675

MS 562-PX0675/PC

1

2

3

J16

CON1

SIPW2

1

J12

ACTERM

K1287

MS 534-1287-ST

1

2

J17

ACTERM

K1287

MS 534-1287-ST

1

2

J15

ACTERM

K1287

MS 534-1287-ST

1

2

J23

ACTERM

K1287

MS 534-1287-ST

1

2

J20

ACTERM

K1287

MS 534-1287-ST

1

2

J25

ACTERM

K1287

MS 534-1287-ST

1

2

J31

ACTERM

K1287

MS 534-1287-ST

1

2

J28

ACTERM

K1287

MS 534-1287-ST

1

2

J34

ACTERM

K1287

MS 534-1287-ST

1

2

R13

10K

0603

R11

1K

0603

RELAY1

J35

ACTERM

K1287

MS 534-1287-ST

1

2

J39

ACTERM

K1287

MS 534-1287-ST

1

2

J41

ACTERM

K1287

MS 534-1287-ST

1

2

R12

4.99 1%

1210

MS 660-SR732ETTE4R99F

CT1

CT020P2A

CT020P2A

Oswell

RLY1

Figure 19: 78M6618 PDU-CT Evaluation Board Electrical Schematic (2 of 4)

Rev 3 29

Page 30

78M6618 PDU1 Evaluation Board User Manual UM_6618_022

Title

Size Document N umber Rev

Date: Sheet

of

PDUCTV1

1

Power Distribut ion Unit 8 Outlet Single Phase with C Ts

TERIDIAN SEMICONDUCTOR CORP.

B

3 4Monday, March 01, 2010

OUTCUR8

OUTL ET5

+12VDC

+12VDC

+12VDC

+12VDC

LINE

NEUTRAL

OUTL ET7

OUTL ET6

EGND

OUTL ET8

RLY6

RLY5

OUTCUR5

RLY8

RLY7

OUTCUR7

OUTCUR6

GND

V3P3

V3P3

V3P3

V3P3

GND

GND

GND

J50

SIP100P2

LED

1

2

J66

SIP100P2

LED

1

2

R47

4.99 1%

1210

MS 660-SR732ETTE4R99F

J58

ACTERM

K1287

MS 534-1287-ST

1

2

C20

1000pF

0603

J73

ACTERM

K1287

MS 534-1287-ST

1

2

J59

CON1

SIPW2

1

R41

1K

0603

RL5

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

5412

6

7

8

C21

1000pF

0603

RL8

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

54

1

2

6

7

8

CT7

CT020P2A

CT020P2A

Oswell

J43

CON1

SIPW2

1

R46

1K

0603

R37

4.99 1%

1210

MS 660-SR732ETTE4R99F

Q7

NPN 500m a 30V

SOT23T

MS 512 -MMBTA13

RL6

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

5412

6

7

8

CT5

CT020P2A

CT020P2A

Oswell

J47

ACTERM

K1287

MS 534-1287-ST

1

2

RL7

16A 12V SPDT Low Profile

ALZ

255-1446-ND

3

5412

6

7

8

J60

ACTERM

K1287

MS 534-1287-ST

1

2

R44

750

0603

Q8

NPN 500m a 30V

SOT23T

MS 512 -MMBTA13

R40

2K

0603

R36

1K

0603

J45

CON1

SIPW2

1

J70

AC Outlet

PX0675

MS 562-PX0675/PC

1

2

3

J51

CON1

SIPW2

1

R33

10K

0603

J69

CON1

SIPW2

1

R42

4.99 1%

1210

MS 660-SR732ETTE4R99F

J55

ACTERM

K1287

MS 534-1287-ST

1

2

Q6

NPN 500m a 30V

SOT23T

MS 512 -MMBTA13

J71

ACTERM

K1287

MS 534-1287-ST

1

2

R49

750

0603

J48

CON1

SIPW2

1

J65

ACTERM

K1287

MS 534-1287-ST

1

2

C22

1000pF

0603

J42

SIP100P2

LED

1

2

R45

2K

0603

R35

2K

0603

J72

CON1

SIPW2

1

R32

4.99 1%

1210

MS 660-SR732ETTE4R99F

J61

AC Outlet

PX0675

MS 562-PX0675/PC

1

2

3

R43

10K

0603

J44

ACTERM

K1287

MS 534-1287-ST

1

2

J62

CON1

SIPW2

1

R34

750

0603

J64

CON1

SIPW2

1

R48

10K

0603

J53

AC Outlet

PX0675

MS 562-PX0675/PC

1

2

3

CT8

CT020P2A

CT020P2A

Oswell

R39

750

0603

Q5

NPN 500m a 30V

SOT23T

MS 512 -MMBTA13

R38

10K

0603

J49

ACTERM

K1287

MS 534-1287-ST

1

2

J46

AC Outlet

PX0675

MS 562-PX0675/PC

1

2

3

J57

SIP100P2

LED

1

2

J67

ACTERM

K1287

MS 534-1287-ST

1

2

J52

ACTERM

K1287

MS 534-1287-ST

1

2

J54

CON1

SIPW2

1

J68

CON1

SIPW2

1

C19

1000pF

0603

J63

ACTERM

K1287

MS 534-1287-ST

1

2

J56

CON1

SIPW2

1

R30

2K

0603

R31

1K

0603

CT6

CT020P2A

CT020P2A

Oswell

V3P3

LINE

+12VDC

OUTCUR7

OUTCUR6

OUTCUR5

RELAY6

RELAY5

EGND

OUTCUR8

NEUTRAL

RELAY8

RELAY7

Line/Black

Egnd/Green

Neutral/White

Line/Black

Egnd/Green

Neutral/White

Line/Black

Egnd/Green

Neutral/White

Line/Black

MS 604-WP1503GD

LED, Green

MS 604-WP1503GD

LED, Green

.

Egnd/Green

Neutral/White

Figure 20: 78M6618 PDU-CT Evaluation Board Electrical Schematic (3 of 4)

30 Rev 3

Page 31

UM_6618_022 78M6618 PDU1 Evaluation Board User Manual

Title

Size Document N umber Rev

Date: Sheet

of

PDUCTV1 1

Power Distribut ion Unit 8 Outlet Single Phase with C Ts

TERIDIAN SEMICONDUCTOR CORP.

B

4 4Monday, March 01, 2010

V3P3

R63

10K

0603

TP3

SIP100P2

Wh

1

2

Pulse Output

V3P3

.

PCLK

MISO

PWRUP

TRXCE

CSN

no connect

TXEN

MOSI

CD

DR

SCKDIO4

DIO5

DIO43

DIO19

DIO16

DIO17

DIO18

DIO1

DIO2

DIO3

no connect

no connect

PacketP owerOneNetSM BusJ37

Pins

SMBALTRB

SMBTXLOB

SMBCLOCK

SMBRXD

no connect

SLE

CE

no connect

no connect

SMBCKHDB DATAIO

DATACLK

INT

SCLK

SREAD

SDATA

GND

GND

PSDI

V3P3

TP1

TP

TPWW

1

V3P3

DIO3

PSDO

GND

TP2

TP

TPWW

1

PCSZ

GND

C23

1uF

810-C1608X5R1C105M

0603

RESET

R51

0

0603

C25

0.1uF

0603

C26

NC

0603

UTX

SW1

NC

EP11

R50

NC

0603

J80

SPI1

DIP100P10

1 2

3 4

5 6

7 8

9 10

R52

470

0603

R53

470

0603

V3P3

DIO17

DIO18

V3P3

GND

V3P3

C24

0.1uF

0603

LED, Grn

GND

LED, Y el

DIO5

DIO43

DIO19

DIO3

DIO16

V3P3

OneNet

interf ace to

ADF7025

DIO2

DIO1

J77

ONENET

DIP100P18

1 2

3

45

6

7

8

9 10

11 12

13

14

15

16

17 18

DIO4

GNDGND

DIO6

GND

DIO16

GNDGND

DIO19

GND

R64

NC

0603

DIO43

DIO4

GND

R59

NC

0603

URX

R65

NC

0603

R60

NC

0603

R66

NC

0603

R67

NC

0603

R54

330

0603

R61

NC

0603

GNDGND

C27

1000pF

0603

TCLK

RXT X

J78

USB-B

USBB

MS 154-2442-E

1

2

3

4

5

6

ICE input s become

ERST

when ICEE low

LCD seg drivers

V3P3

J76

ICE

SIP100P6

1

2

3

4

5

6

ICEEN

U2

FT232QFN32

FTQFN32

MS 895-FT232RQ

VCC

19

USBDM

15

USBDP

14

VCCIO

1

NC1

5

RESETB

18

OSCI

27

RXD

2

RTS

32

CTS

8

DTR

31

DSR

6

RI

3

CBUS0

22

TXD

30

OSCO

28

CBUS1

21

CBUS2

10

CBUS3

11

CBUS4

9

3V3OUT

16

AGND24GND1

4

GND217GND320TEST

26

NC2

12

DCD

7

NC3

13

NC4

25

NC5

29

NC6

23

USBDM

USB5V

R62

NC

0603

USBDP

C29

4.7uF

1206P

C30

0.1uF

0603

Mouser 571-1487588-2

1.5M A/B Whit e Cable

GND

ADI TX/RX data interface

DIO1

DIO2

GND

GNDGND

DIO5

DIO17

PCLK

SCL

DIO18

PSDI

J74

SIP100P2

READY

MS 604-WP1503GD

1

2

SDA

DIO43

SDI

CLK

PSDO

J75

SIP100P2

ACTIVE

MS 604-WP1503YD

1

2

CSZ

SDO

PCSZ

CSZ

SDO

SDI

CLK

C28

0.1uF

0603

J81

SIP100P2

FAULT

MS 604-WP1503ID

1

2

LED, Red

R58

470

0603

V3P3

C28

R57

R56

SW1

Optional Res et Switch

1000pF

1K

1K

EVQ-PJX05M Panasonic

V3P3

J79

DEBUG

SIP100P4

1

2

3

4

DIO16

R57

10K

0603

DIO18

R55

0

0603

RELAY1

RELAY5

RELAY4

RELAY3

RELAY2

RELAY8

RELAY7

RELAY6

GNDGND

DIO19

I2C Master

for

EEPROM

Internal s lave SPI cont roller

U1-2

78M6618-68QFN

QFN68

SEG12

30

SEG2

21

SEG17

34

SEG16

33

RESET

49

SEG18

35