Page 1

General Description

The MAX11800–MAX11803 low-power touch-screen controllers operate from a single supply of 1.70V to 3.6V, targeting power-sensitive applications such as handheld

equipment. The devices contain a 12-bit SAR ADC and a

multiplexer to interface with a resistive touch-screen

panel. A digital serial interface provides communications.

The MAX11800–MAX11803 include digital preprocessing

of the touch-screen measurements, reducing bus loading

and application-processor resource requirements. The

included smart interrupt function generator greatly

reduces the frequency of interrupt servicing to the

devices. The MAX11800–MAX11803 enter low-power

modes automatically between conversions to save power,

making the devices ideal for portable applications.

The MAX11800/MAX11801 offer two modes of operation:

direct and autonomous. Direct mode allows the application processor to control all touch-screen controller activity. Autonomous mode allows the MAX11800/MAX11801

to control touch-screen activity, thereby freeing the

application processor to perform other functions. In

autonomous mode, the devices periodically scan the

touch screen for touch events without requiring hostprocessor intervention. This can be used to reduce system power consumption. An on-chip FIFO is used during

autonomous mode to store results, increasing effective

data throughput and lower system power.

The MAX11800–MAX11803 support data-tagging,

which records the type of measurement performed; X,

Y, Z1, or Z2, and the type of touch event; initial touch,

continuing touch, or touch release.

The MAX11800/MAX11802 support the SPI™ serial bus.

The MAX11801/MAX11803 support the I2C serial bus.

The MAX11800–MAX11803 are available in 12-pin TQFN

and 12-pin WLP packages, and are specified over the

-40°C to +85°C (extended) and -40°C to +105°C (automotive) temperature ranges.

Applications

Features

♦ 4-Wire Touch-Screen Interface

♦ X/Y Coordinate and Touch Pressure Measurement

♦ Ratiometric Measurement

♦ 12-Bit SAR ADC

♦ Single 1.7V to 3.6V Supply

♦ Two Operating Modes—Direct and Autonomous

♦ Data Tagging Provides Measurement and Touch

Event Information

♦ Data Filtering Provides Noise Reduction

♦ Aperture Mode Provides Spatial Filtering

♦ Digital Processing Reduces Bus Activity and

Interrupt Generation

♦ Programmable Touch-Detect Pullup Resistors

♦ Auto Power-Down Control for Low-Power

Operation

♦ 25MHz SPI Interface (MAX11800/MAX11802)

♦ 400kHz I

2

C Interface (MAX11801/MAX11803)

♦ 1.6mm x 2.1mm, 12-Pin WLP and 4mm x 4mm,

12-Pin TQFN

♦ Low-Power Operation

343µW at VDD= 1.7V, 34.4ksps

888µW at VDD= 3.3V, 34.4ksps

♦ ESD Protection

±4kV HBM

±8kV HBM (X+, X-, Y+, Y-)

±1kV CDM

±200V MM

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive

Touch-Screen Controllers with I2C/SPI Interface

________________________________________________________________

Maxim Integrated Products

1

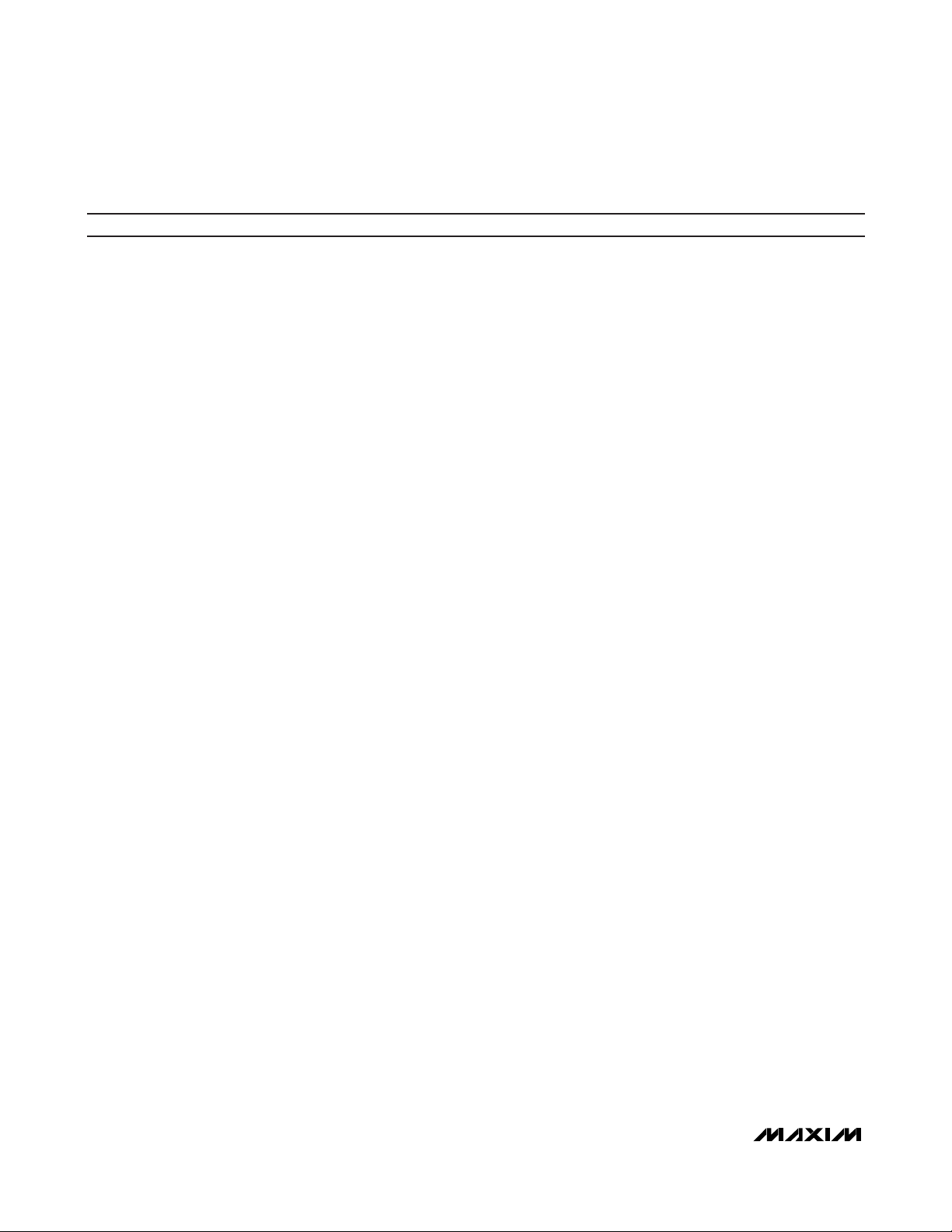

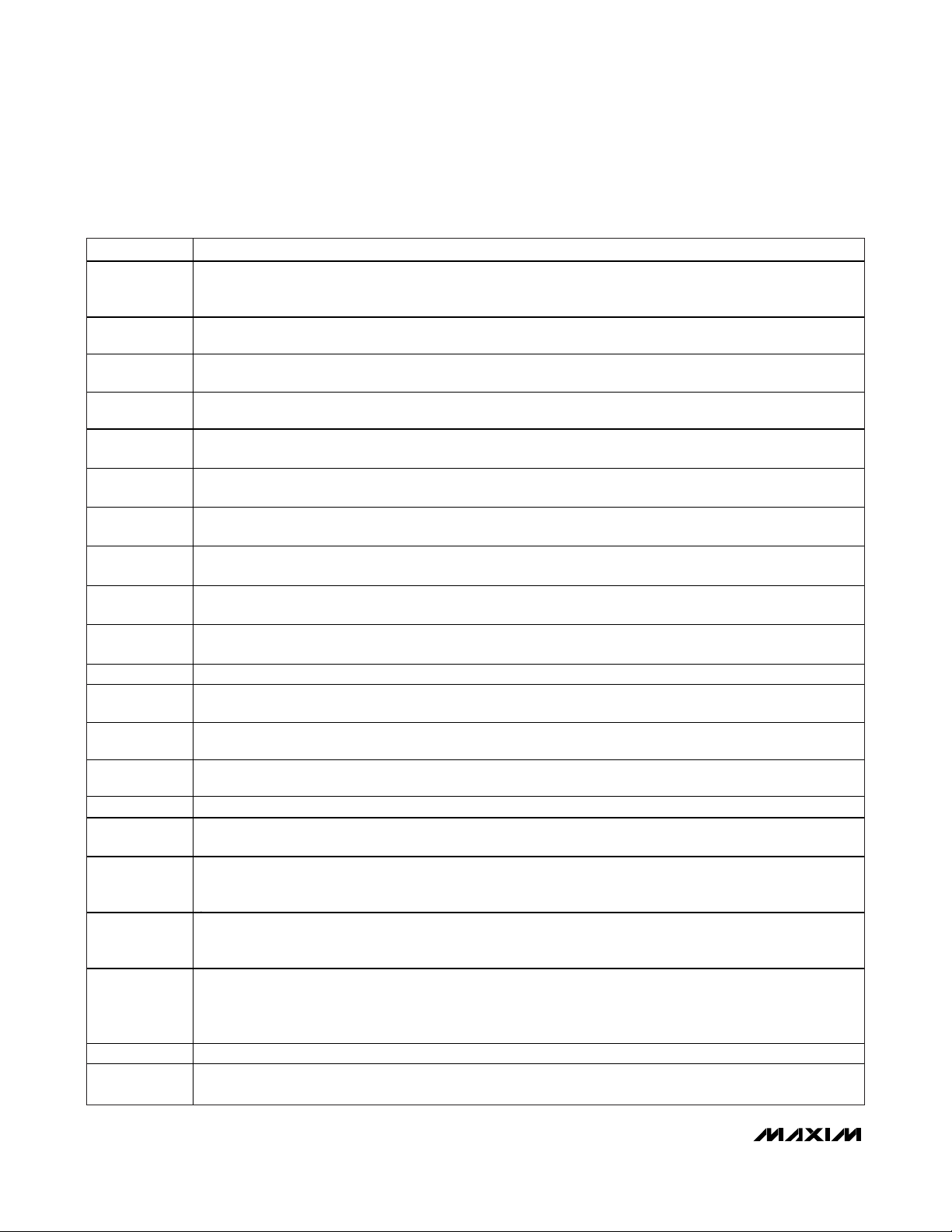

Ordering Information

19-4711; Rev 3; 10/10

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

PART TEMP RANGE PIN-PACKAGE

MAX11800ETC+ -40°C to +85°C 12 TQFN-EP*

MAX11800GTC/V+ -40°C to +105°C 12 TQFN-EP*

MAX11800EWC+T -40°C to +85°C 12 WLP

MAX11801ETC+ -40°C to +85°C 12 TQFN-EP*

MAX11801GTC/V+ -40°C to +105°C 12 TQFN-EP*

MAX11801EWC+T -40°C to +85°C 12 WLP

MAX11802ETC+ -40°C to +85°C 12 TQFN-EP*

MAX11802EWC+T -40°C to +85°C 12 WLP

MAX11803ETC+ -40°C to +85°C 12 TQFN-EP*

MAX11803EWC+T -40°C to +85°C 12 WLP

Typical Operating Circuits and Pin Configurations appear

at end of data sheet.

+

Denotes a lead(Pb)-free/RoHS-compliant package.

/V denotes an automotive qualified part.

T = Tape and reel.

*

EP = Exposed pad.

Mobile Communication

Devices

PDAs, GPS Receivers,

Personal Navigation

Devices, Media Players

Portable Instruments

POS Terminals

Handheld Games

Automotive Center

Consoles

SPI is a trademark of Motorola, Inc.

Page 2

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

2 _______________________________________________________________________________________

TABLE OF CONTENTS

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

I

2

C Timing Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

SPI Timing Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Typical Operating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Functional Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Detailed Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Position Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Pressure Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Touch-Detect Modes and Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

PUR and PUF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Idle Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Features Available in the MAX11800–MAX11803 Averaging Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Combined Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Data Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Low-Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Features Available in the MAX11800/MAX11801 Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Autonomous Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Aperture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Panel Setup, Measurement, and Scan Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Direct Conversion Mode Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Interrupt Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Panel Setup Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Panel Measurement Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Combined Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Auxiliary Measurement Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Autonomous Conversion Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Measurement Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Combined Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Delayed Touch Detection During Mode Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

FIFO Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Clearing FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

FIFO Data Block Readback Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

FIFO Data Word Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Block Readback Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Clearing Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Aperture Modes and Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Aperture Range Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

FIFO Aperture Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Applications Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Using Aperture Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Page 3

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

_______________________________________________________________________________________ 3

TABLE OF CONTENTS (continued)

Examples of Using Aperture Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

SPI Communication Sequence (MAX11800/MAX11802) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

SPI Configuration Register Write (MAX11800/MAX11802) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

SPI Configuration or Result Register Read (MAX11800/MAX11802) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

SPI Conversion Command (MAX11800/MAX11802) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

I

2

C-Supported Sequence (MAX11801/MAX11803) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Bit Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

START and STOP Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Early STOP Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Slave Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

I

2

C Register Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Acknowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Write Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Read Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Streamlined I

2

C Read Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

I

2

C Conversion and Measurement Commands (MAX11801/MAX11803) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Command and Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

User-Accessible Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Status and Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Data Readback Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Autonomous Conversion Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Direct Conversion Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Panel Setup and Measurement Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

User Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

General Status Register (0x00) (Read Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

General Configuration Register (0x01) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Measurement Resolution Configuration Register (0x02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Measurement Averaging Configuration Register (0x03) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

ADC Sampling Time Configuration Register (0x04) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Panel Setup Timing Configuration Register (0x05) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Delayed Conversion Configuration Register (0x06) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Touch-Detect Pullup Timing Configuration Register (0x07) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Autonomous Mode Timing Configuration Register (0x08) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Aperture Configuration Register (0x09) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Auxiliary Measurement Configuration Register (0x0A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Operating Mode Configuration Register (0x0B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

MAX11800/MAX11802 Typical Operating Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

MAX11801/MAX11803 Typical Operating Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Pin Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Chip Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Package Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Page 4

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

4 _______________________________________________________________________________________

Figure 1. I2C Timing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Figure 2. SPI Timing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

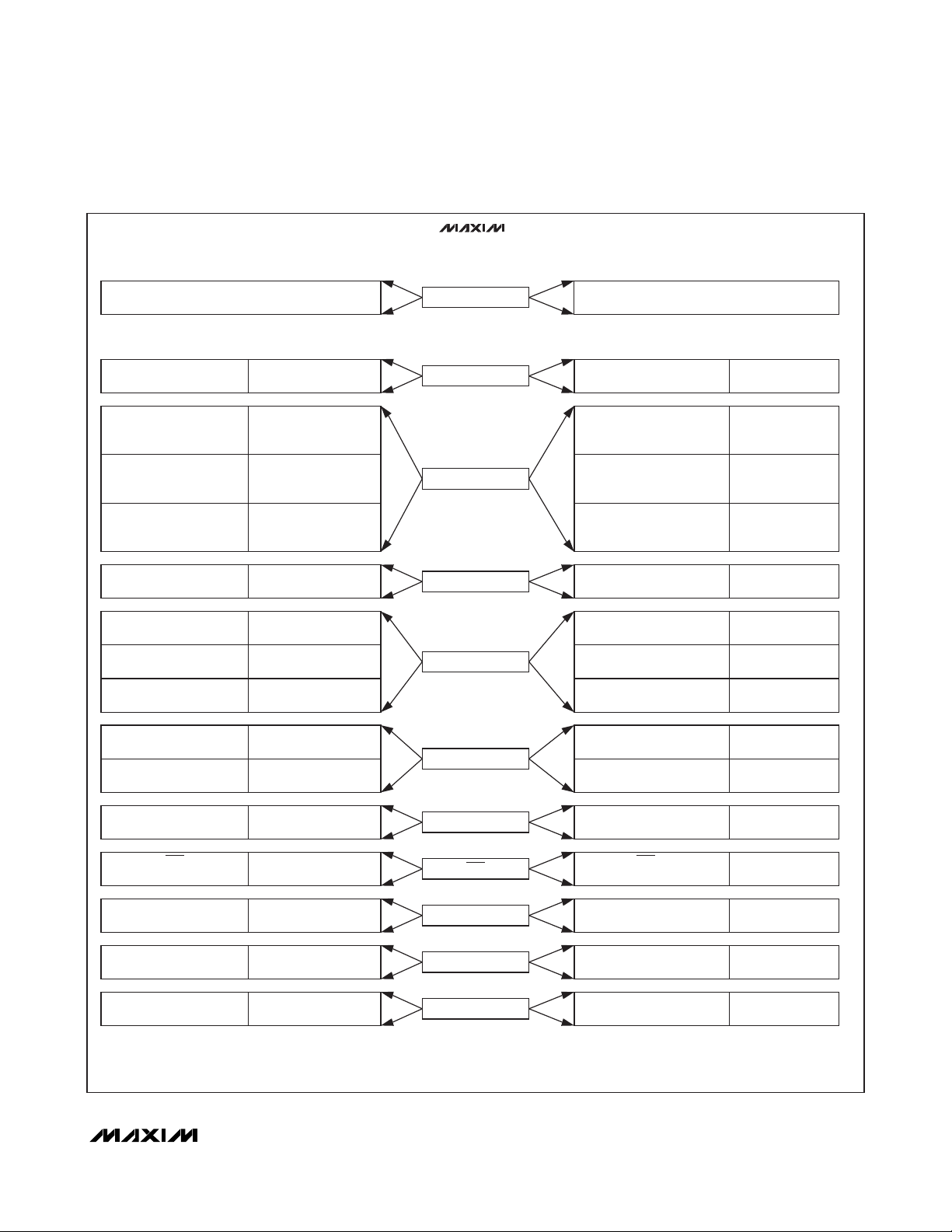

Figure 3a. MAX11800/MAX11801 Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

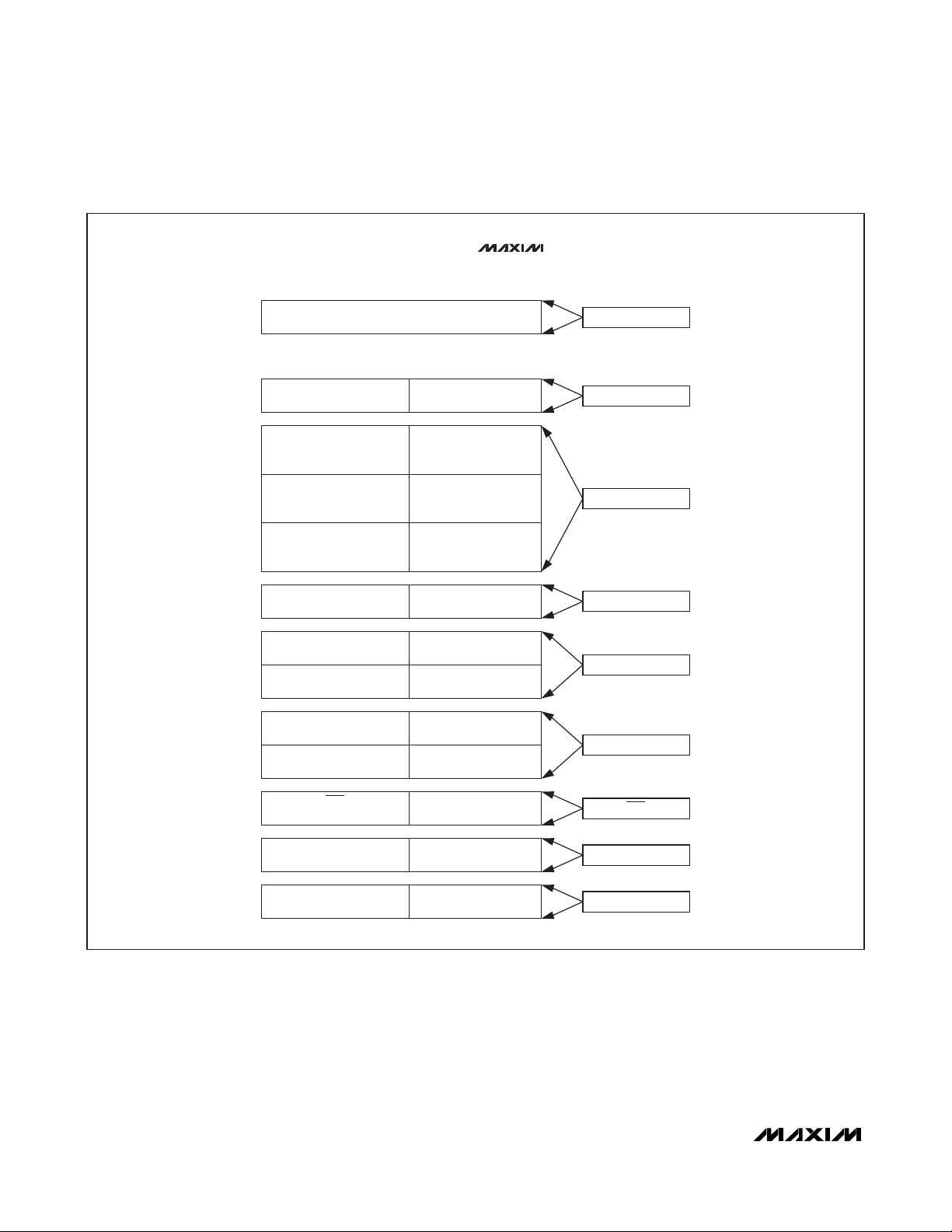

Figure 3b. MAX11802/MAX11803 Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 4. Position Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 5. Pressure Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 6. Touch-Detection Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 7. Touch-Detection Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Figure 8. State Machine Transitions (Direct Conversion Mode)—MAX11800–MAX11803 . . . . . . . . . . . . . . . . . . . . .25

Figure 9. Continuous Interrupt Mode (Direct Conversion Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Figure 10. Edge Interrupt Mode (Direct Conversion Mode)—MAX11800–MAX11803 . . . . . . . . . . . . . . . . . . . . . . . .27

Figure 11. Command and Measurement Flow (DCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 12. Panel Setup and Measurement Commands—MAX11800–MAX11803 . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 13. Combined Commands—MAX11800–MAX11803 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Figure 14. State Machine Transitions––Autonomous Conversion Mode—MAX11800/MAX11801 . . . . . . . . . . . . . . .31

Figure 15. Clear-on-Read Interrupt Operation—MAX11800/MAX11801 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Figure 16. Aperture Usage Example Waveforms—MAX11800/MAX11801 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Figure 17. SPI Single Configuration Register Write Sequence—MAX11800/MAX11802 . . . . . . . . . . . . . . . . . . . . . .38

Figure 18. SPI Multiple Configuration Register Write Sequence—MAX11800/MAX11802 . . . . . . . . . . . . . . . . . . . . .38

Figure 19. SPI Single-Byte Register Read Sequence—MAX11800/MAX11802 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Figure 20. SPI Multiple-Byte Register Read Sequence—MAX11800/MAX11802 . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 21. SPI Conversion Command—MAX11800/MAX11802 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 22. 2-Wire Interface Timing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Figure 23. START, STOP, and Repeated START Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Figure 24. Acknowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Figure 25. I

2

C Single Write Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Figure 26. I2C Multiple Write Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Figure 27. Basic Single Read Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Figure 28. I

2

C Multiple Read Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Figure 29. I2C Streamlined Read Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Figure 30. I

2

C Conversion and Measurement Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

LIST OF FIGURES

Page 5

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

_______________________________________________________________________________________ 5

LIST OF TABLES

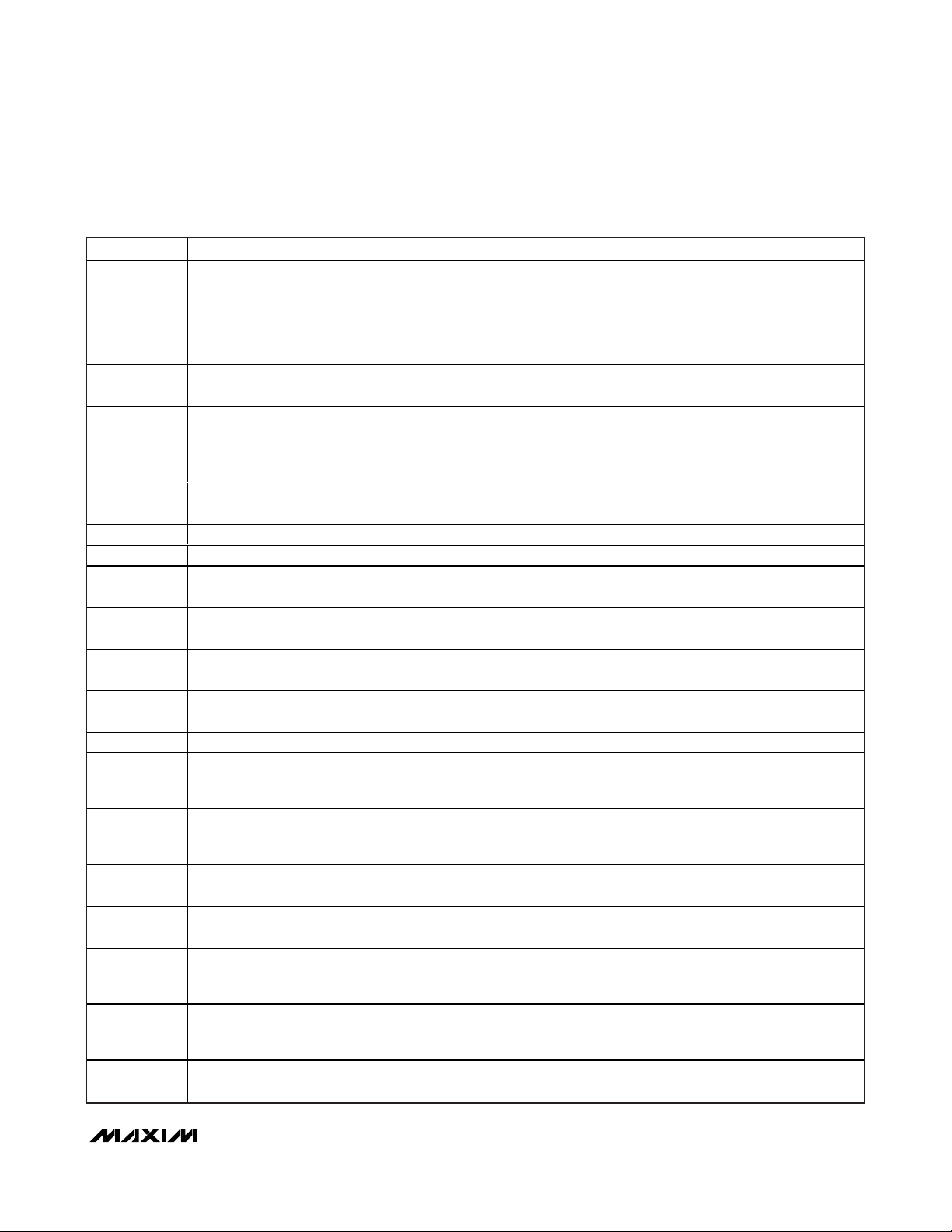

Table 1. Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Table 2. Operating Modes, Conditions, and Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Table 3. Summary of Physical Panel Settings for Supported Measurement Types . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Table 4. Median Averaging Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Table 5. Data Word Structure (All Direct Conversion Modes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Table 6. Measurement and Event Tags (Continuous Interrupt Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Table 7. Measurement and Event Tags (Edge Interrupt Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Table 8. Panel Setup Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Table 9. Panel Measurement Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Table 10. FIFO Data Block Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table 11. FIFO Data Word Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 12. FIFO Data Measurement Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 13. FIFO Event Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 14. Readback and FIFO Contents with Aperture Mode Enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Table 15. Readback and FIFO Contents with Aperture Mode Disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Table 16. SPI Command and Data Format: 8 Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Table 17. I

2

C Command and Data Format: 8 Bits Plus ACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Table 18. Status and Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table 19. Data Readback Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table 20. Conversion Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Table 21. Measurement Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Page 6

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

6 _______________________________________________________________________________________

Table 1. Terminology

TERM DEFINITION

Panel,

Touch Sc re en,

Touch Panel

TSC

X+

X-

Y+

Y-

R

TOUCH

Z1

Z2

AUX

AD C Analog-to-Digital Convert er: Circuit used to transform analog information into a form suitable for digital operations.

AP

AVG

MAF

SAF Straight Averaging Filter: The SAF takes the average of an entire sample set.

TDM

DCM

ACM

PSU

PM C Panel Measurement Command: Individual measurements of X or Y position and Z1 or Z2 pressure measurements.

CMC

Resistive Touch Sensor: Panel, or touch screen, or touch panel are used interchangeably to denote the

resistive touch sensor.

Touch-Sc reen Controller: Devices attached to a touch screen that provide the interface between an

application processor (AP) and touch screen.

X Position Positive I/O: Analog I/O from resistive touch screen. See Figure 4 for configuration and

measurement details.

X Position Negative I/O: Analog I/O from resisti ve touch screen. See F igure 4 for configuration and

measurement details.

Y Position Positive I/O: Analog I/O from resistive touch screen. See Figure 4 for configuration and measurement

details.

Y Position Negative I/O: Analog I/O from resisti ve touch screen. See F igure 4 for configuration and

measurement details.

Touch Resistance: Represents the resistance between the X and Y planes of a resistive touch screen during a

touch e vent.

Z1 Measurement: A resist ive touch-screen measurement to determine the resistance between the two planes

within the panel sensor during a touch event (R

Z2 Measurement: A resist ive touch-screen measurement to determine the resistance between the two planes

within the panel sensor during a touch event (R

Auxiliary Input: Analog input to the MAX11800–MAX11803 that can be used to monitor external conditions

such as battery voltage or temperature.

Application Processor: An external microcontroller or microprocessor that interfaces to and controls the

general operation of the MAX11800–MAX11803.

Averaging Mode: The abil ity to average consecutive measurement results to reduce noise from switch

bounce, power-supply ripple, and incomplete settling.

Median Averaging Filter: The MAF first removes the minimum and maximum samples before taking the

average of the remaining sample set.

Touch-Detect Mode: An untimed mode that monitors the panel for a touch using a user-selectable panel

pullup resistor of either 50k or 100k.

Direct Conversion Mode: A mode of operation in which the AP request s indi vidual panel setup and

convers ion operations or automated combinations of measurement s (X and Y, X and Y and Z1, or X and Y and

Z1 and Z2). The AP maintains control over the initiation of panel setup, measurements, and the sampling

Autonomous Conver sion Mode: A mode of operation in which the MAX11800/MAX11801 idle in TDM until a

touch event occurs. After a touch is detected, the MAX11800/MAX11801 begin an automated sequence of

measurements determined by the user conf iguration regi ster s.

Panel Setup Command: User-programmable modes for the purpose of allowing the panel suffic ient time to

settle, prior to the start of measurement s. PSU commands conf igure the on-chip multiplexer in preparation to

perform either X, Y, Z1, or Z2 measurements. Durations can either be specified and managed by the

MAX11800–MAX11803 (in ACM and DCM) or managed by the AP (in DCM).

Combined Measurement Command: Combination s of PMCs (X and Y, X and Y and Z1, or X and Y and Z1 and

Z2) offered by the MAX11800–MAX11803 and executed in series to reduce AP bus and interrupt activity.

). See Figure 5 for configuration and measurement details.

TOUCH

). See Figure 5 for configuration and measurement details.

TOUCH

Page 7

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

_______________________________________________________________________________________ 7

Table 1. Terminology (continued)

TERM DEFINITION

First-In First-Out Memory: The MAX11800–MAX11803 contain a 1024-bit FIFO that is used to store conversion

FIFO

Scan

Scan Block

Timed Scan

Untimed Scan Untimed Scan: A scan or scan block operation that is controlled by the AP. This only applies to DCM.

TAG

ETAG Event Tag: Data tags indicating the panel touch status observed during a measurement.

MTAG Measurement Tag: Data tag indicating the type of measurement read back by the AP (either X, Y, Z1, or Z2).

TIRQ

EINT

CINT

CORINT

APER Aperture Mode: Available in ACM only. Reduces data writes to the FIFO by spatially filtering measurement data.

CONT

LPM

PUR

PUF

SAR ADC

I2C

SPI

results when operating in autonomous conversion mode. FIFO depth indicates the number of words (16-bit

quantity) in the FIFO.

Scan: Generally, a single sequence of operations performed in DCM or ACM. The operations could include a

panel setup operation, followed by a panel measurement operation, or a combined measurement operation.

Scan Block: Generally, a sequence of multiple operations performed in DCM or ACM. The operations could

include panel-setup operations, panel-measurement operations, or combined measurement operations.

Timed Scan: A scan or scan block operation that uses the on-chip oscillator and timer. The timer is controlled

through the configuration registers and represents an array of fixed (time) quantities that are user selectable

(MAX11800/MAX11801).

D a t a Ta g : Infor m ati on ap p end ed to the end of an AD C conver si on r esul t. Tag s i nd i cate the typ e of m easur em ent and

touch status associ ated w i th each p anel ob ser vati on. S ee the d efi ni ti ons for E TAG and M TAG ( al so i n Tab l e 1) .

Touch Interrupt Request: Active-low interrupt, indicating that a touch is present (CINT) or has been initiated

(EINT) in DCM, or that new data is available in the FIFO in ACM.

Edge Interrupt Mode: Indicates, through TIRQ, that a touch has been initiated (EINT) in DCM. The duration that

TIRQ is low is user programmable.

Continuous Interrupt Mode: Indicates, through TIRQ, that a touch is present (CINT) in DCM. TIRQ goes low to

indicate the presence of a touch and stays low until the touch event ceases.

Clear-on-Read Interrupt Mode: Used in ACM only. TIRQ goes low to indicate the presence of new FIFO data. The

interrupt is cleared when the data is read by the AP (MAX11800/MAX11801).

C o n t i n u o u s B i t : An op ti on i n D C M to r etur n the MAX11800–MAX11803 to a p anel setup ( w ai t) m od e ( P S U ) after a

conver si on, r ather than a r etur n to TD M ( r ecom m end ed onl y for ap p l i cati ons w i th ver y l ong p anel settl i ng ti m es and

r eq uest contr ol l i ng thei r ow n aver ag i ng ) . The conti nuous b i t r esi d es i n b i t 0 ( R0) of the P S U an

Low-Power Mode: An idle mode used in DCM/EINT or ACM modes, when a touch is detected at the conclusion of

the last measurement. This indicates a new measurement needs to be requested or scheduled (the touch-detect

pullup is not engaged to save power).

Pullup Rough: A fast pullup mode, which uses the main X+ switch in parallel with the on-chip resistive pullup

(50kΩ/100kΩ) to quickly slew the touch panel capacitances. R

Pullup Fine: A slow (fine) pullup mode, which uses the on-chip resistive pullup to slew the touch-panel

capacitances to their final values (R

Successive Approximation Register ADC: An analog-to-digital converter that converts a continuous analog

waveform into a discrete digital representation through a binary search through all possible quantization levels

before finally converging upon a digital output for each conversion.

Inter-Integrated Circuit: A multimaster serial computer bus that is used to attach low-speed peripherals to other

components using two bidirectional open-drain lines, serial data (SDA) and serial clock (SCL), pulled up with

resistors.

Serial Peripheral Interface: A serial interface in which a master device supplies clock pulses to exchange data

serially with a slave over two data wires (master-slave and slave-master).

= 50kΩ or 100kΩ) typical and is required for all applications.

PUF

≤ 10Ω typical.

PUR

d P M C r eg i ster s.

Page 8

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

8 _______________________________________________________________________________________

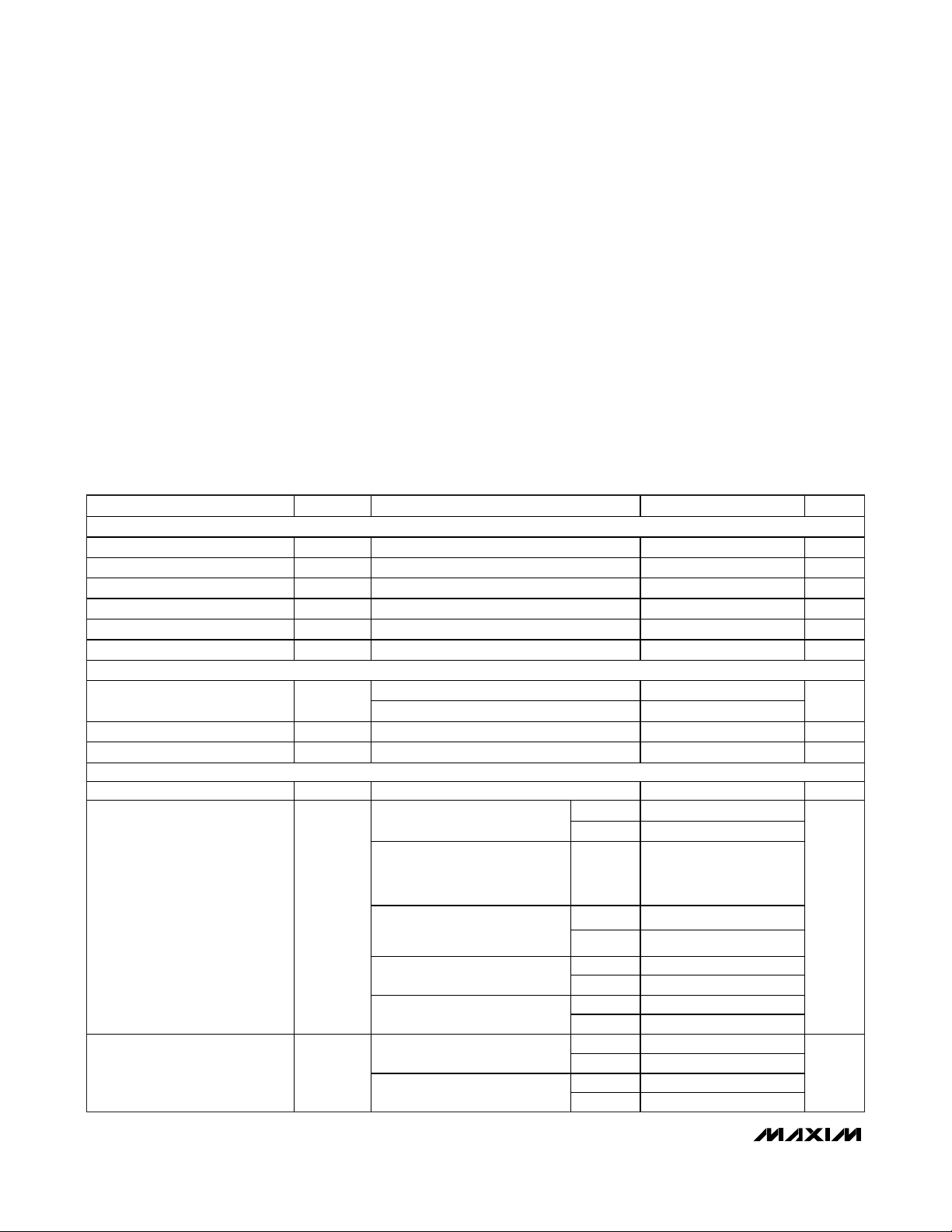

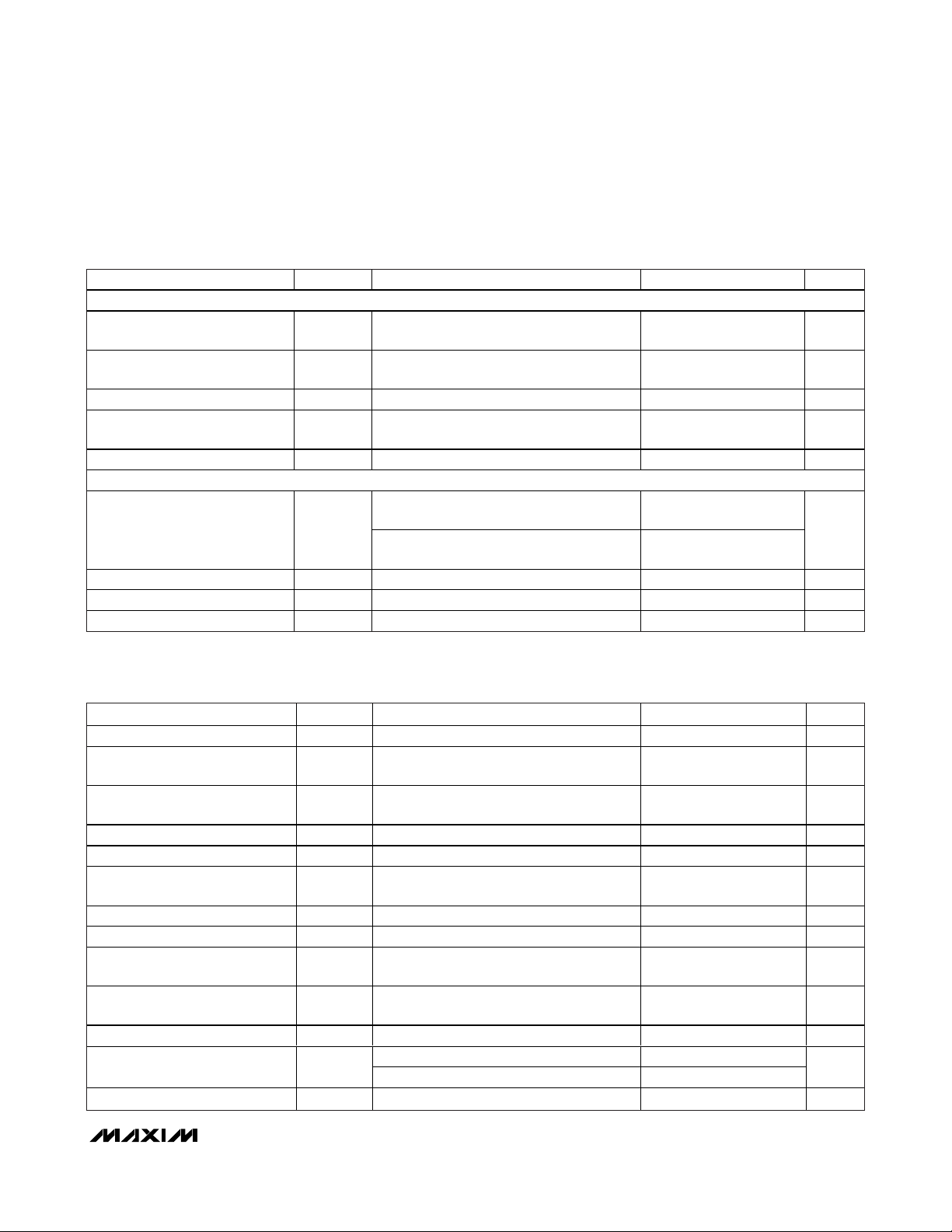

ELECTRICAL CHARACTERISTICS

(VDD= 1.7V to 3.6V, TA= -40°C to +85°C (MAX11800E–MAX11803E), TA= -40°C to +105°C (MAX11800G/MAX11801G), unless otherwise noted. Typical values are at T

A

= +25°C and V

DD

= 3.3V, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDto GND...........................................................-0.3V to +4.0V

X+, X-, Y+, Y-, AUX, TIRQ to GND ........................-0.3V to +4.0V

SCL, CLK, SDA, DIN, A0, CS, A1, DOUT to GND.-0.3V to +4.0V

Maximum Current into Any Pin .........................................±50mA

Continuous Power Dissipation (T

A

= +70°C)

12-Pin TQFN (derate 24.4mW/°C above +70°C) ....1951.2mW

12-Pin WLP (derate 6.5mW/°C above +70°C) ..........518.8mW

Operating Temperature Ranges

MAX1180_E_ _..................................................-40°C to +85°C

MAX1180_G_ _ ...............................................-40°C to +105°C

Storage Temperature Range .............................-65°C to +150°C

Junction Temperature......................................................+150°C

Lead Temperature (excluding WLP, soldering, 10s) .......+300°C

Soldering Temperature (reflow) .......................................+260°C

ABSOLUTE MAXIMUM RATINGS

Note 1: All WLP devices are 100% production tested at TA= +25°C. Specifications over temperature limits are guaranteed by

design and characterization.

ADC

ADC Re so lution No miss ing codes 10 11 Bits

Differentia l Nonlinearity DNL 12-bit resolution ±1.5 LSB

Integral Nonlinearity INL 12-bit resolution ±1.5 LSB

Offset Error ±2 LSB

Gain Error ±4 LSB

Throughput 105 ksps

TOUCH SENSORS (X+, X-, Y+, Y-, AUX)

Switch On-Resistance

Switch Driver Current 100ms pulse 50 mA

Input Voltage Range 0 VDD V

POWER SUPPLY (VDD)

Supply Voltage VDD 1.7 3.6 V

Supply Current

Power Consumption

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

VDD = 1.7V 7

V

= 3.3V 5

DD

Power-down mode. Al l digital

inputs static.

TDM. All digital inputs static.

Does not inc lude panel

currents when touched.

Timed LPM. All digital inputs

static. Does not include panel

currents when touched.

AUX conversions at 34.4ksps

equivalent rate, SPI

AUX conversions at 34.4ksps

equivalent rate, I

AUX conversions at 34.4ksps

equivalent rate, SPI

AUX conversions at 34.4ksps

equivalent rate, I

1.7V 0.2

3.6V 2

3.6V 7

1.7V 9

3.3V 16

1.7V 216

3.3V 273 550

2

C

2

C

1.7V 202

3.3V 269 550

1.7V 367

3.3V 901

1.7V 343

3.3V 888

μW

μA

Page 9

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

_______________________________________________________________________________________ 9

ELECTRICAL CHARACTERISTICS (continued)

(VDD= 1.7V to 3.6V, TA= -40°C to +85°C (MAX11800E–MAX11803E), TA= -40°C to +105°C (MAX11800G/MAX11801G), unless otherwise noted. Typical values are at T

A

= +25°C and V

DD

= 3.3V, unless otherwise noted.)

I2C TIMING CHARACTERISTICS

(VDD= 1.7V to 3.6V, TA= -40°C to +85°C (MAX11801E and MAX11803E), TA= -40°C to +105°C (MAX11801G), unless otherwise

noted. Typical values are at T

A

= +25°C and VDD= 3.3V, unless otherwise noted. See Figure 1.)

DIGITAL INPUTS (SDA, DIN, SCL, CLK, A0, CS, A1)

Input Logic-High Voltage V

Input Logic-Low Voltage VIL

Input Leakage Current IIN VIN = 0V or VDD -1 +1 μA

Input Hystere sis V

Input Capacitance 6 pF

DIGITAL OUTPUTS (SDA, DOUT, TIRQ)

Output Logic-High V

Output Logic-Low—TIRQ, DOUT VOL I

Output Logic-Low—SDA VOL I

TIRQ Pullup Res istor 125 k

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IH

HYS

OH

0.7 x

V

DD

DOUT, I

TIRQ, CMOS conf iguration,

I

SOURCE

= 1mA 0.4 V

SINK

= 3mA 0.4 V

SINK

SOURCE

= 1mA

= 1mA

0.9 x

V

DD

0.9 x

V

DD

V

0.3 x

V

0.5 x

V

DD

DD

V

V

V

Serial-Clock Frequency f

Bus Free Time t

Hold Time for START Condition t

SCL Pulse-Width Low t

SCL Pulse-Width High t

Setup Time for Repeated START

(Sr) Condition

Data Hold Time t

Data Setup Time t

SDA and SCL Rise/Fall Time t

SDA and SCL Fall Time t

Setup Time for STOP Condition t

Bus Capacitance Allowed C

Pulse Width of Suppressed Spike t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCL

BUF

HD;STA

LOW

HIGH

t

SU;STA

HD;DAT

SU;DAT

R, tF

TF

SU;STO

SP

Bus free time between STOP and START

condition

After this period, the first clock pulse is

generated

Receiving

Transmitting

VDD = 1.7V to 2.7V 10 100

B

VDD = 2.7V to 3.6V 10 400

0 400 kHz

1.3 μs

0.6 μs

1.3 μs

0.6 μs

0.6 μs

0 900 ns

100 ns

20 +

/10

C

B

20 +

C

/10

B

0.6 μs

300 ns

250 ns

50 ns

pF

Page 10

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

10 ______________________________________________________________________________________

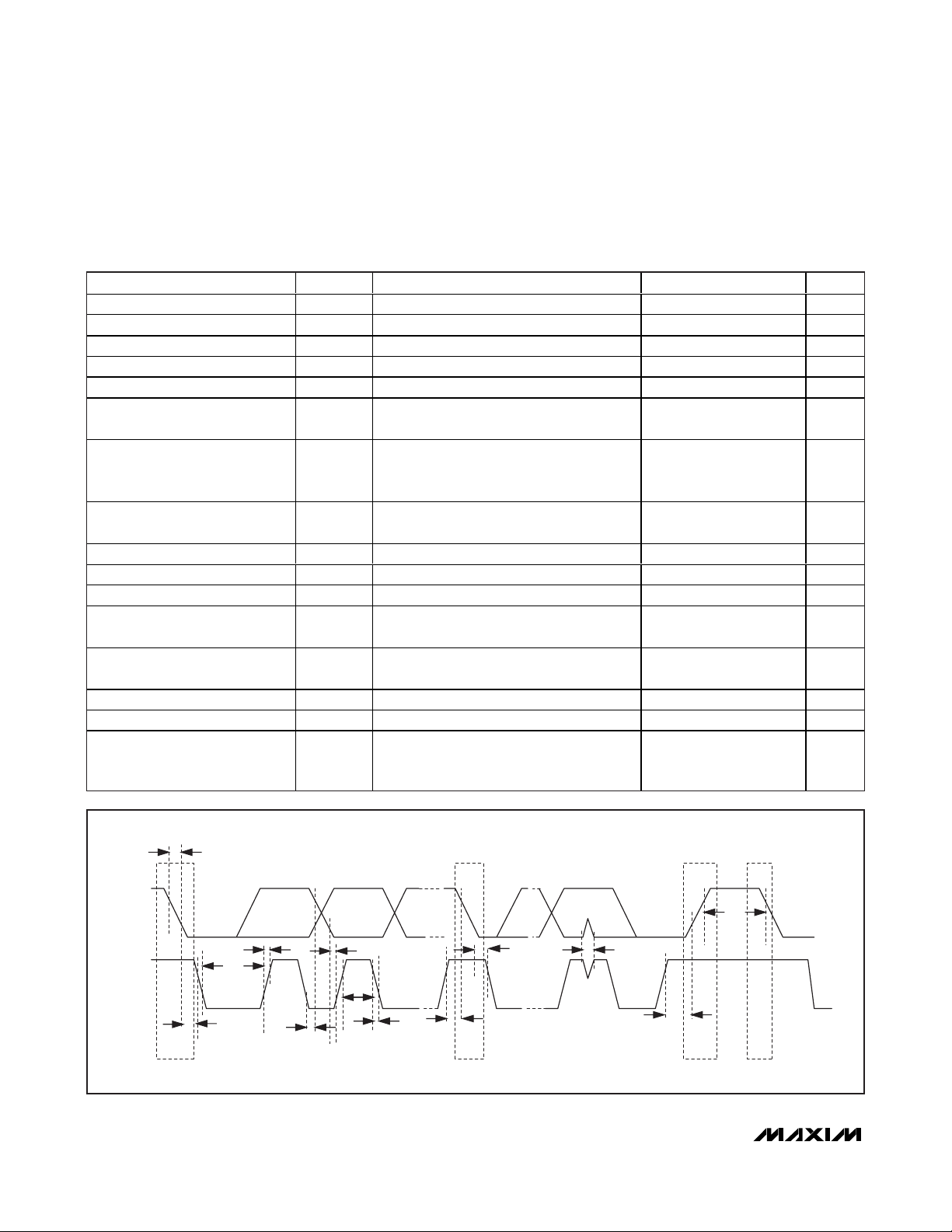

SPI TIMING CHARACTERISTICS

(VDD= 1.7V to 3.6V, TA= -40°C to +85°C (MAX11800E and MAX11802E), TA= -40°C to +105°C (MAX11800G), unless otherwise

noted. Typical values are at T

A

= +25°C and VDD= 3.3V, unless otherwise noted. See Figure 2.)

Figure 1. I2C Timing Diagram

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CLK Frequency f

CLK Period t

CLK Pulse-Width High t

CLK Pulse-Width Low t

CS Low to 1st CLK Rise Setup t

CS Low After 0th CLK Rise Hold t

CS High to 17th CLK Setup t

CLK

CP

CH

CL

CSS0

CSH0

To prevent a 0th CLK read from being taken

as a 1st read in a free-running application

To prevent a 17th CLK read from being

CSS1

recognized by the device in a free-running

application

25 MHz

40 ns

18 ns

18 ns

18 ns

0ns

18 ns

CS High After 16th CLK Falling

Edge Hold

CS Pulse-Width High t

DIN to CLK Setup t

DIN Hold After CLK t

DOUT Transition Valid After CLK

Rise

DOUT Remains Valid After CLK

Rise

DOUT Valid Before CLK Rise t

CS Rise to DOUT Disable t

CLK Rise to DOUT Enable t

t

CSH1

CSW

DS

DH

t

DOT

t

DOH

DO1

DOD

DOE

Output transition time 25 ns

Output hold time 3 ns

t

= tCP - t

DO1

C

LOAD

C

LOAD

regard to 8th

transition time with regard to 8th CLK read.

t

F

SDA

SCL

t

LOW

t

R

t

HIGH

t

SU;DAT

0ns

18 ns

25 ns

0ns

DOT

10 ns

= 20pF 40 ns

= 20pF. Minimum = hold time with

CLK read. Maximum =

t

SP

t

HD;STA

325ns

t

BUF

t

S

HD;STA

t

HD;DAT

t

t

F

SU;STA

Sr

t

SU;STO

P

S

Page 11

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

______________________________________________________________________________________ 11

Figure 2. SPI Timing Diagram

t

CLK

t

CSS0

DS

t

DH

1

t

CSH0

CS

0

t

CP

t

CH

t

CL

89

t

SCH1

t

CSW

t

CSS1

16

DIN

DOUT

SPI WRITE OPERATION

CS

CLK

DIN

DOUT

SPI READ OPERATION

XA6 A5 A4 A3 A2 A1

HIGH-Z

t

CSS0

1

A6

X

HIGH-Z

t

DS

t

DH

A5 A4 A3

W

A0

t

CP

t

t

CL

CH

A1

A2

A0

D7

t

DOE

t

DO1

89

X

R

D7

D6 D5 D4

t

DOH

X

X

D5

D6

D3

X

D4 D3

D1 D0

D2

X

XXX

D2 D1 D0

t

DO0

16

HIGH-Z

Page 12

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

12 ______________________________________________________________________________________

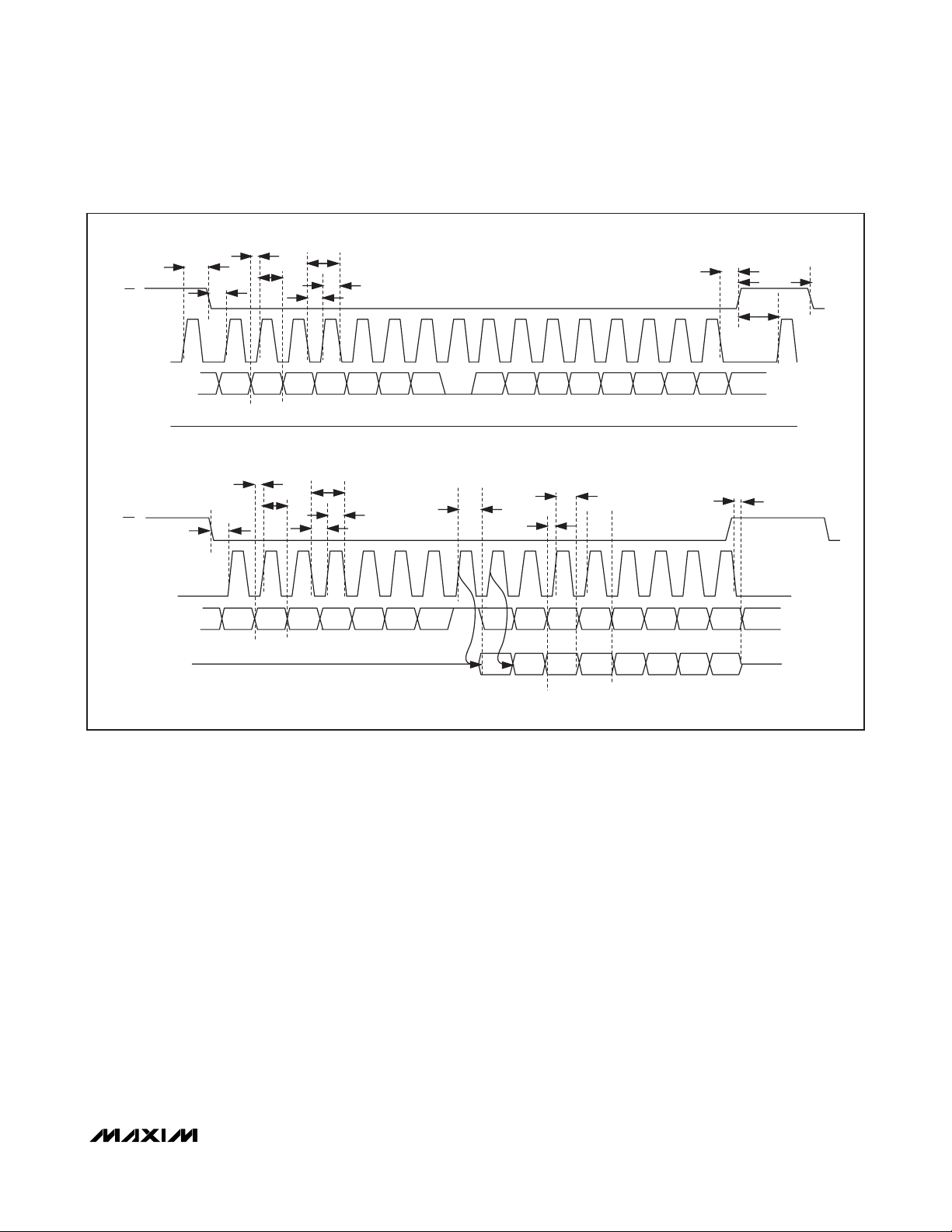

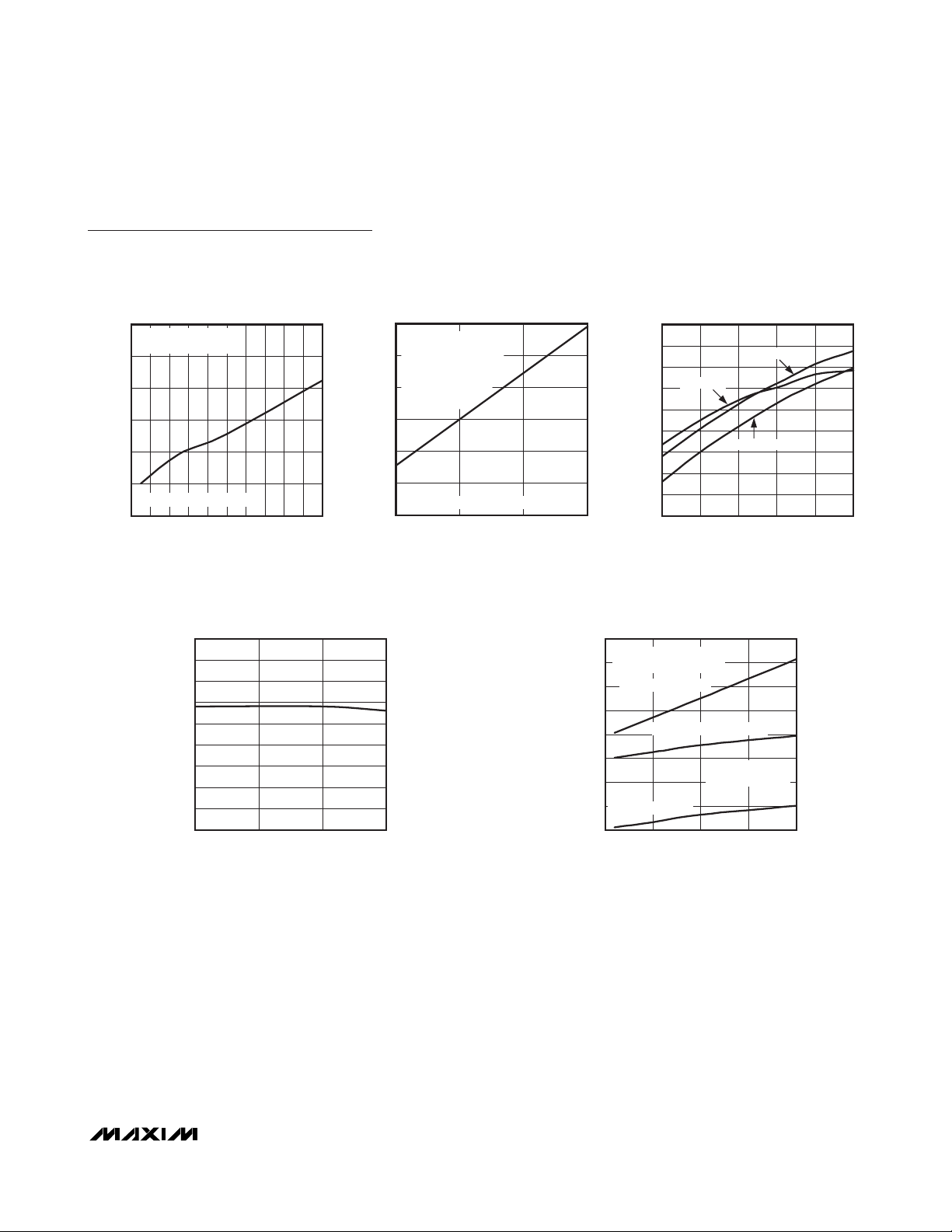

Typical Operating Characteristics

(VDD= 1.8V at TA= -40°C to +85°C (TA= -40°C, TA= 0°C, TA= +25°C, and TA= +85°C), 12-bit mode, all measurements using

noncontinuous AUX input. SPI = 10MHz and I

2

C = 400kHz, unless otherwise noted. Resistive touch-screen panel (X+ to X- = 608Ω,

Y+ to Y- = 371Ω).)

AVERAGE SUPPLY CURRENT

vs. SAMPLING RATE

90

AUTONOMOUS MODE

80

MAX11800

MAX11801

70

60

50

40

30

SUPPLY CURRENT (FA)

20

DATA TAKEN WITH

10

RESISTIVE TOUCH

SENSOR

0

0 200

SAMPLING RATE (cps)

cps = COORDINATES

PER SECOND

180160120 14040 60 80 10020

AVERAGE SUPPLY CURRENT

vs. SAMPLING RATE

5

DIRECT EDGE

INTERRUPT MODE

4

3

2

1

0

0 200

cps = COORDINATES PER SECOND

SAMPLING RATE (cps)

MAX11800 toc01

AVERAGE SUPPLY CURRENT

vs. SAMPLING RATE

5

DIRECT CONTINUOUS

INTERRUPT MODE

4

3

2

SUPPLY CURRENT (FA)

1

0

0 200

cps = COORDINATES PER SECOND

SAMPLING RATE (cps)

MAX11800 toc02

SUPPLY CURRENT (FA)

18016014012010080604020

18016014012010080604020

MAX11800 toc03

0.40

0.36

0.32

0.28

0.24

0.20

0.16

0.12

0.08

POWER-DOWN SUPPLY CURRENT (µA)

0.04

0

-40 85

vs. TEMPERATURE

TEMPERATURE (NC)

8

MAX11800 toc04

603510-15

7

6

(I)

ON

R

X+

5

X-

4

3

1.6 3.6

CHANGE IN ADC GAIN

vs. TEMPERATURE

4

SUPPLY CURRENT IN POWER-DOWN

3

2

1

0

-1

DELTA FROM +25NC (LSB)

-2

-3

-4

-40 110

TEMPERATURE (NC)

8050-10 20

MAX11800 toc07

SWITCH RESISTANCE

vs. SUPPLY VOLTAGE

Y+

Y-

VDD (V)

SWITCH RESISTANCE

vs. TEMPERATURE

7

6

MAX11800 toc05

5

(I)

4

ON

R

3

2

3.22.82.42.0

1

-40 85

Y+

MAX11800 toc06

X+

Y-

X-

603510-15

TEMPERATURE (NC)

CHANGE IN ADC OFFSET

vs. TEMPERATURE

4

3

2

1

0

-1

DELTA FROM +25NC (LSB)

-2

-3

-4

-40 110

TEMPERATURE (NC)

8050-10 20

MAX11800 toc08

Page 13

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

______________________________________________________________________________________

13

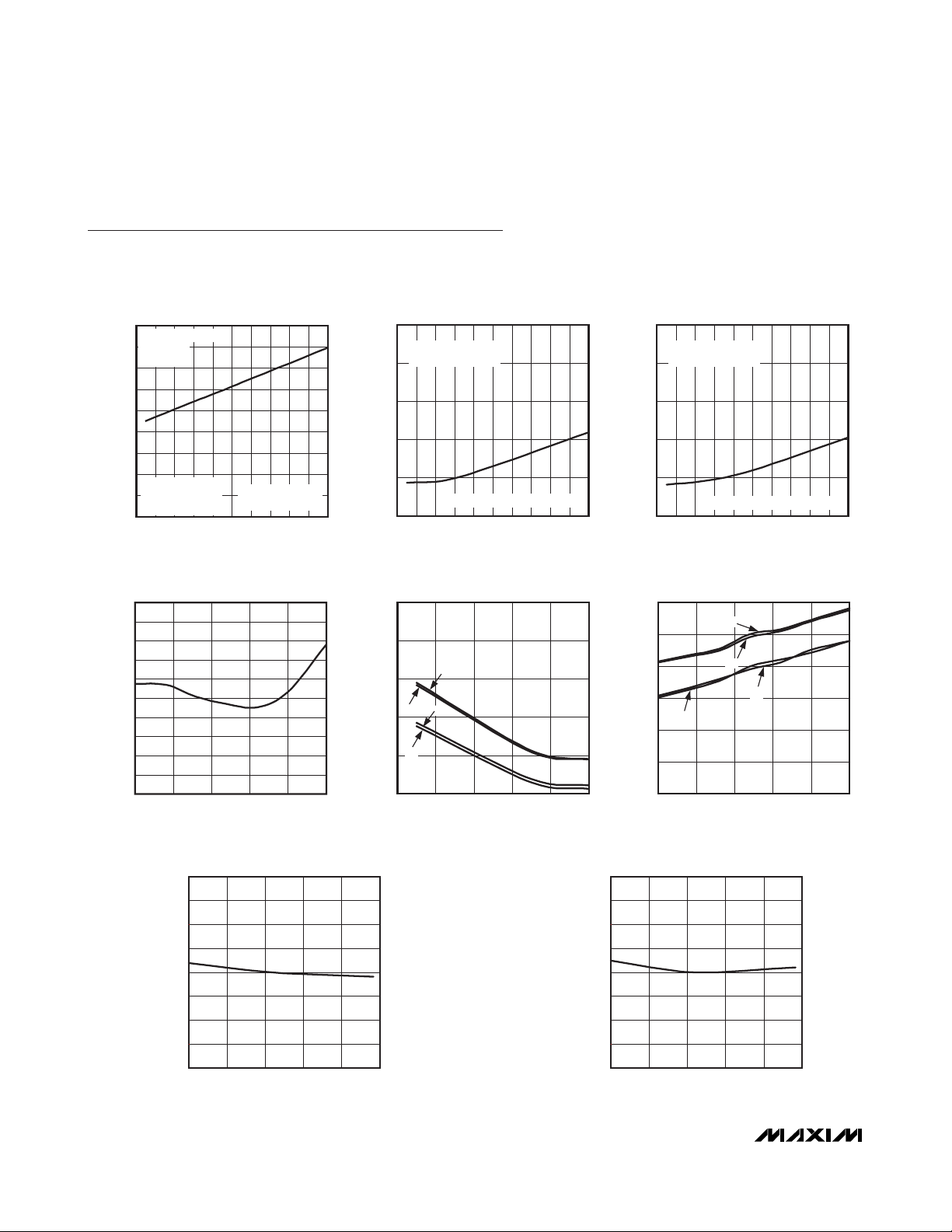

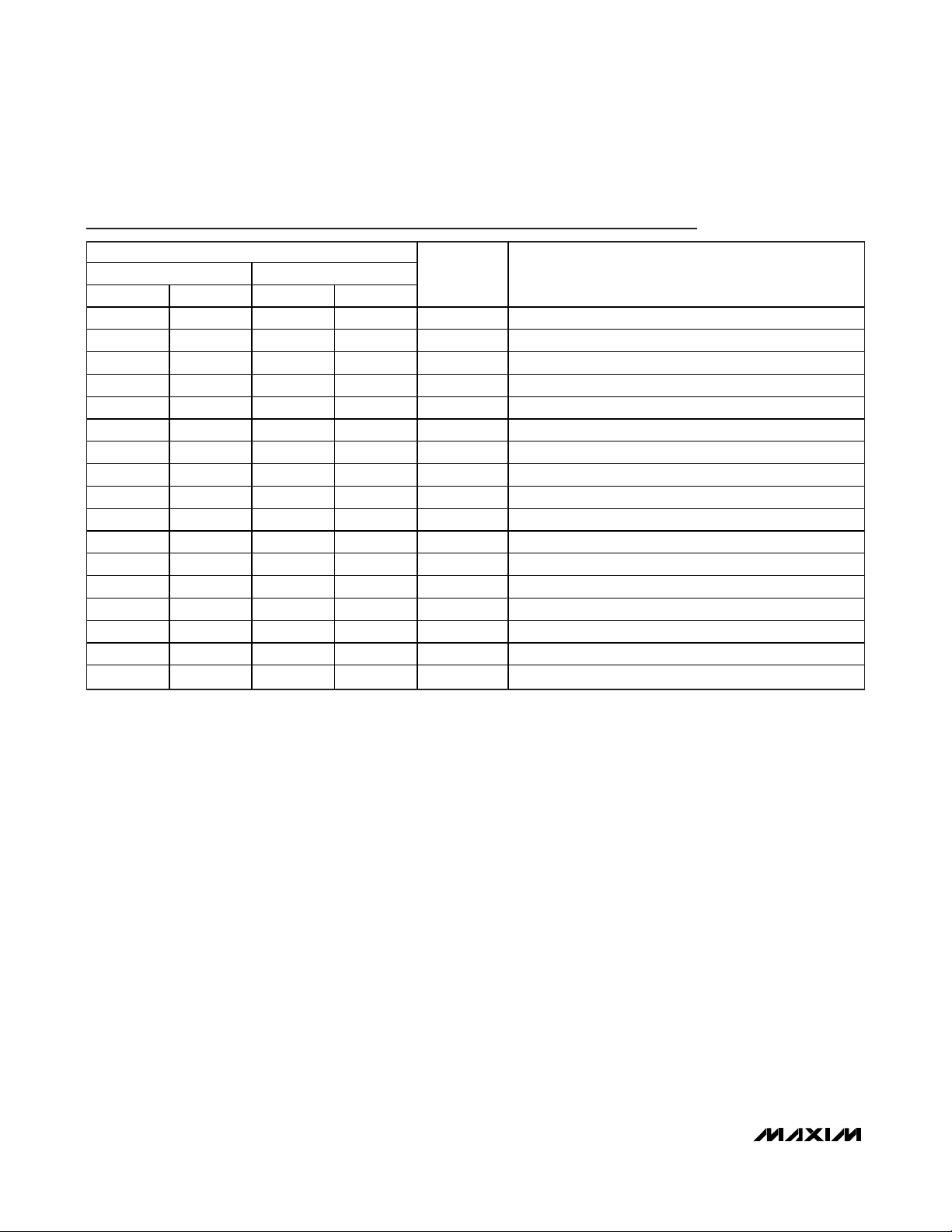

Typical Operating Characteristics (continued)

(VDD= 1.8V at TA= -40°C to +85°C (TA= -40°C, TA= 0°C, TA= +25°C, and TA= +85°C), 12-bit mode, all measurements using

noncontinuous AUX input. SPI = 10MHz and I

2

C = 400kHz, unless otherwise noted. Resistive touch-screen panel (X+ to X- = 608Ω,

Y+ to Y- = 371Ω).)

AVERAGE SUPPLY CURRENT

vs. SAMPLING RATE

3.0

DIRECT CONVERSION

MODE—AUXILIARY INPUT

2.5

2.0

1.5

1.0

SUPPLY CURRENT (FA)

0.5

sps = SAMPLES PER SECOND

0

0 200

SAMPLING RATE (sps)

18016014012010080604020

INTERNAL OSCILLATOR CLOCK

FREQUENCY vs. SUPPLY VOLTAGE

2.08

2.06

2.04

2.02

2.00

1.98

1.96

1.94

1.92

INTERNAL OSCILLATOR CLOCK FREQUENCY (MHz)

1.90

1.8 3.6

VDD (V)

MAX11800 toc09

AVERAGE SUPPLY CURRENT

vs. SAMPLING RATE

120

AUXILIARY INPUT DATA

SAMPLED AT 1ksps AND

100

2ksps WITH EIGHT AND

16 SAMPLES

80

AVERAGING

ENABLED

60

40

SUPPLY CURRENT (FA)

20

0

ksps = KILO-SAMPLES PER SECOND

832

EQUIVALENT SAMPLING RATE (ksps)

2416

2.08

2.06

MAX11800 toc10

2.04

2.02

2.00

1.98

1.96

1.94

1.92

INTERNAL OSCILLATOR CLOCK FREQUENCY (MHz)

1.90

INTERNAL OSCILLATOR CLOCK

FREQUENCY vs. TEMPERATURE

V

DD

V

= 1.8V

DD

V

= 3.6V

DD

-40 85

TEMPERATURE (NC)

POWER CONSUMPTION

vs. SAMPLE RATE

160

DATA TAKEN WITH

140

MAX11800 toc12

3.02.4

*MAX11800/MAX11801

RESISTIVE TOUCH SENSOR

AUTONOMOUS MODE*

120

100

80

60

40

POWER CONSUMPTION (FW)

20

0

0 200

DIRECT CONTINUOUS MODE

cps = COORDINATES

PER SECOND

DIRECT EDGE MODE

SAMPLE RATE (cps)

15010050

= 3.0V

603510-15

MAX11800 toc13

MAX11800 toc11

Page 14

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

14 ______________________________________________________________________________________

Pin Description

PIN

MAX11800/MAX11802 MAX11801/MAX11803

TQFN-E P WL P TQFN- EP WLP

1 A4 1 A4 X+ X+ Channel Input/Output

2 B4 2 B4 VDD Power Supply. Bypass VDD to GND with a 1μF capacitor.

3 B3 3 B3 GND Ground

4 C4 4 C4 X- X- Channel Input/Output

5 C3 5 C3 Y- Y- Channel Input/Output

6 C2 6 C2 TIRQ Active-Low Touch Interrupt Output

7 C1 — —- DIN SPI Serial Data Input

8 B1 — — CLK SPI Serial Data Cloc k Input

9 A1 — — CS SPI Chip-Select Input

10 B2 — — DOUT SPI Data Output

11 A2 11 A2 AUX Auxiliary Input

12 A3 12 A3 Y+ Y+ Channel Input/Output

— — 7 C1 SDA I2C Serial Data Bus Input/Output

— — 8 B1 SCL I2C Serial Data Clock Input

— — 9 A1 A0 I2C Address Input Bit 0

— — 10 B2 A1 I2C Address Input Bit 1

— — — — EP Exposed Pad (TQFN only). Connected to ground.

NAME FUNCTION

Page 15

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

______________________________________________________________________________________ 15

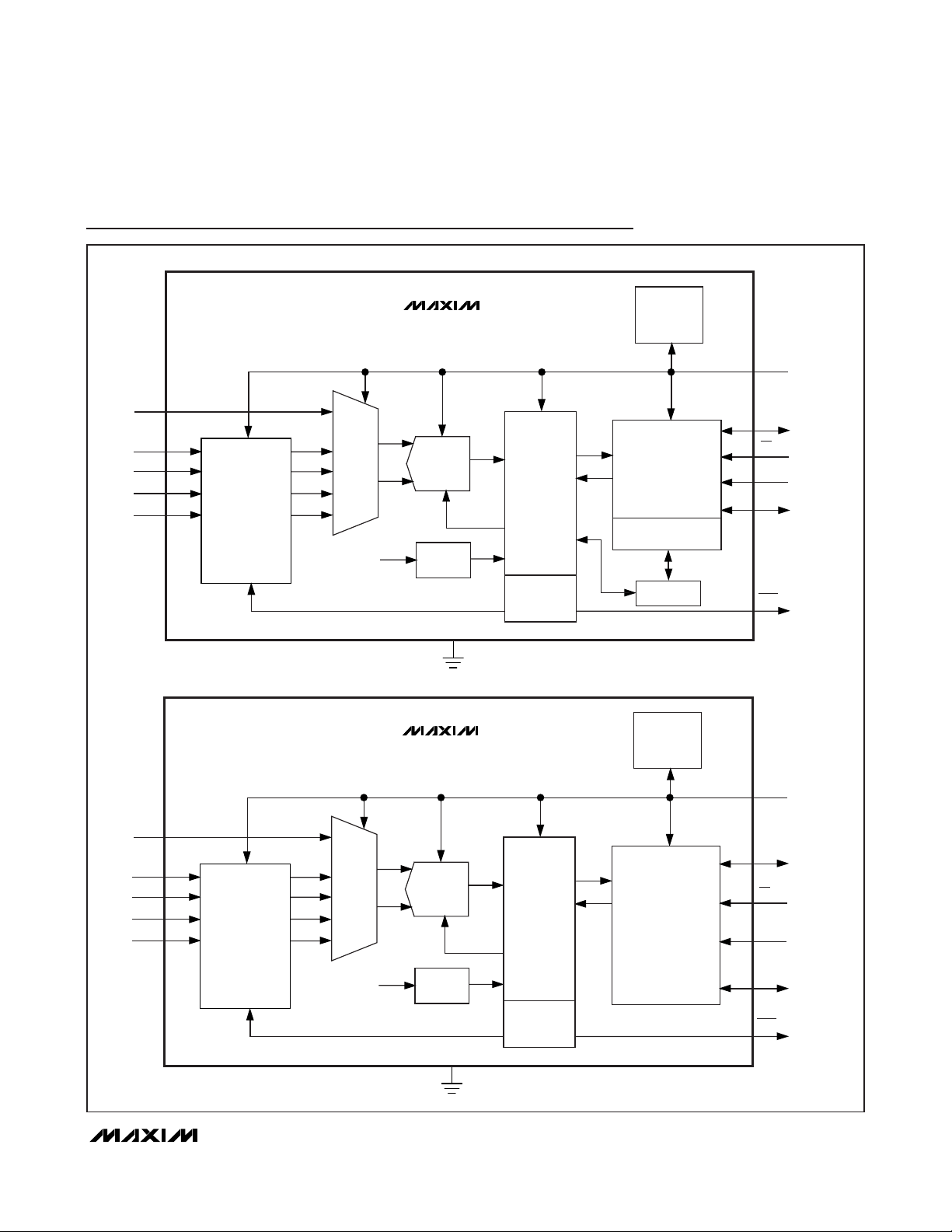

Functional Diagrams

AUX

POWER

MAX11800/MAX11801

X+

X-

Y+

Y-

TOUCHSCREEN

INTERFACE

MUX

SAR

ADC

LOGIC

CORE

V

DD

INTERNAL

CLOCK

INTERRUPT

GENERATION

ENGINE

GND

AND

BIAS

SERIAL INTERFACE

PHYSICAL LAYER

(ANALOG INTERFACE)

SIF

PHY

AUTONOMOUS

MODE ENGINE

FIFO

V

DD

DOUT (A1)

CS (A0)

CLK (SCL)

DIN (SDA)

TIRQ

AUX

POWER

MAX11802/MAX11803

X+

X-

Y+

Y-

TOUCHSCREEN

INTERFACE

MUX

SAR

ADC

LOGIC

CORE

V

DD

INTERNAL

CLOCK

INTERRUPT

GENERATION

ENGINE

GND

AND

BIAS

SERIAL INTERFACE

PHYSICAL LAYER

(ANALOG INTERFACE)

SIF

PHY

V

DD

DOUT (A1)

CS (A0)

CLK (SCL)

DIN (SDA)

TIRQ

Page 16

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

16 ______________________________________________________________________________________

Detailed Description

The MAX11800–MAX11803 contain standard features

found in a typical resistive touch-screen controller as

well as advanced features found only on Maxim touchscreen controllers. Standard features included in the

MAX11800–MAX11803 are:

• 4-wire touch-screen interface

• X/Y coordinate measurement

• Touch pressure measurement

• Direct conversion operation—requires direct AP

involvement

• Single commands—AP initiates all activity, one

command at a time

• Ratiometric measurement

• 12-bit SAR ADC

• Single 1.7V to 3.6V supply

• Programmable touch-detect pullup—50kΩ or

100kΩ

• Auto power-down control for low-power operation

Advanced features found in the MAX11800/MAX11801

include:

• Autonomous conversion operation—minimal AP

involvement

• On-chip FIFO—buffers up to 16 consecutive mea-

surements

• Data tagging—records measurement and touch-

event information

• Filtering—reduces noise using straight or median

averaging

• Aperture mode—provides spatial filtering

• Combined commands—multiple operations per-

formed with a single AP command

• User-programmable acquisition modes

• Programmable interrupt output drive

Advanced features found in the MAX11802/MAX11803

include:

• Data tagging—records measurement and touch

event information

• Filtering—reduces noise using straight or median

averaging

• Combined commands—multiple operations performed with a single AP command

• User-programmable acquisition modes

• Programmable interrupt output drive

The MAX11800/MAX11801 operate in one of two toplevel modes: direct conversion mode (DCM) or

autonomous conversion mode (ACM). Direct conversion mode requires the AP to initiate all activity to and

from the MAX11800/MAX11801. DCM is the operating

mode that most standard resistive touch-screen controllers use. ACM allows the MAX11800/MAX11801 to

perform measurements automatically and inform the AP

when they are complete, reducing data transfers on the

serial bus as well as generating fewer interrupt

requests. The MAX11802/MAX11803 operate in DCM

only. DCM requires the AP to initiate all activity to and

from the MAX11802/MAX11803. DCM is the operating

mode that most standard resistive touch-screen controllers use.

Both DCM and ACM support averaging, data tagging,

and combined commands. Certain commands and

operations are only available in DCM, while others are

only available in ACM. See Figures 3a and 3b and

Table 2 for details.

Position Measurements

Position measurements determine either the X or Y

coordinates of the point of contact on the panel sensor.

Allow adequate time for the panel to settle when switching between X and Y measurements. Figure 4 shows

the physical setup of the panel when performing position measurements.

The element R

TOUCH

represents the resistance between

the X and Y planes of the panel sensor. R

TOUCH

does

not contribute to the error when performing position

measurements. R

TOUCH

affects the panel settling time

required between each valid measurement.

The panel end-to-end resistance in the direction of

measurement determines the power applied across the

panel. The panel dissipates power in the X elements

when performing an X direction measurement and dissipates power in the Y elements when performing a Y

direction measurement.

Page 17

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

______________________________________________________________________________________ 17

Figure 3a. MAX11800/MAX11801 Operation Modes

MAX11800/MAX11801

OPERATION MODES

DIRECT CONVERSION MODE

CONFIGURATION REGISTER 0x0B BITS[6:5] = 00

CONFIGURATION

REGISTERS

PANEL TIMING

0x05

N/A

N/A

AUX

0x0A

AVERAGING METHOD

0x03, 0x0B

EDGE INTERRUPT MODE

0x01

CONTINUOUS INTERRUPT MODE

0x01

N/A N/A

EVENT TAG (ETAG)

(FIFO NOT USED)

MEASUREMENT TAG (MTAG)

(FIFO NOT USED)

AND READBACK COMMANDS

DATA READBACK: 0x52–0x59

DATA READBACK: 0x52–0x59

DATA READBACK: 0x5A–0x5B

DATA READBACK: 0x52–0x59 FIFO READBACK: 0x50

DATA READBACK: 0x52–0x59

SETUP, MEASUREMENTS,

PANEL SETUP

0x69–0x6F

COMBINED MEASUREMENT

MEASUREMENT: 0x70–0x75

PANEL MEASUREMENT

MEASUREMENT: 0x78–0x7F

AUX MEASUREMENT

MEASUREMENT: 0x76–0x77

N/A

N/A N/A N/A

N/A N/A N/A

OPERATION MODE

PANEL SETUP

MEASUREMENTS

AVERAGING

INTERRUPTS

DATA TAGGING

AUTONOMOUS CONVERSION MODE

CONFIGURATION REGISTER 0x0B BITS[6:5] = 01, 10, 11

CONFIGURATION

REGISTERS

PANEL TIMING (1)

0x05

COMBINED MEASUREMENT

0x0B

N/A N/A

N/A N/A

AVERAGING METHOD (1)

0x03, 0x0B

CLEAR-ON-READ

INTERRUPT (1)

EVENT TAG (ETAG)

(USES FIFO)

MEASUREMENT TAG (MTAG)

(USES FIFO)

SETUP, MEASUREMENTS,

AND READBACK COMMANDS (2)

N/A

MEASUREMENT: N/A

FIFO READBACK: 0x50

N/A

N/A

FIFO READBACK: 0x50

N/A N/A

TIRQ

0x01

ADC RESOLUTION AND TIMING

0x02, 0x04, 0x06

PUR AND PUF TIMING

0x07

N/A

NOTE 1: THE CONFIGURATION REGISTERS MUST BE SET UP PRIOR TO ENTERING AUTONOMOUS MODE. THESE REGISTERS CANNOT BE ALTERED WHILE AUTONOMOUS MODE IS ACTIVE.

NOTE 2: COMMANDS RECEIVED WHILE AUTONOMOUS MODE IS ACTIVE ARE IGNORED (EXCEPT READBACK COMMANDS). DURING AUTONOMOUS MODE ALL SCAN ACTIVITIES ARE

CONTROLLED BY THE MAX11800/MAX11801, BASED ON THE SETTINGS OF THE CONFIGURATION REGISTERS. ALL MEASUREMENT RESULTS ARE STORED IN THE ON-CHIP FIFO.

N/A N/A

N/A N/A

N/A N/A

N/A N/A

APERTURE

TIRQ

ADC

TDM TIMING

AUTONOMOUS TIMING

APERTURE SETTING (1)

0x09, 0x0B

TIRQ (1)

0x01

ADC RESOLUTION AND TIMING (1)

0x02, 0x04, 0x06

PUR AND PUF TIMING (1)

0x07

TINT AND SCANP TIMING (1)

0x08

N/A

Page 18

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

18 ______________________________________________________________________________________

Figure 3b. MAX11802/MAX11803 Operation Modes

MAX11802/MAX11803

OPERATION MODES

DIRECT CONVERSION MODE

CONFIGURATION

REGISTERS

PANEL TIMING

0x05

N/A

N/A

AUX

0x0A

AVERAGING METHOD

0x03, 0x0B

EDGE INTERRUPT MODE

0x01

CONTINUOUS INTERRUPT MODE

0x01

EVENT TAG (ETAG)

(FIFO NOT USED)

MEASUREMENT TAG (MTAG)

(FIFO NOT USED)

SETUP, MEASUREMENTS,

AND READBACK COMMANDS

PANEL SETUP

0x69–0x6F

COMBINED MEASUREMENT

MEASUREMENT: 0x70–0x75

DATA READBACK: 0x52–0x59

PANEL MEASUREMENT

MEASUREMENT: 0x78–0x7F

DATA READBACK: 0x52–0x59

AUX MEASUREMENT

MEASUREMENT: 0x76–0x77

DATA READBACK: 0x5A–0x5B

N/A

N/A

N/A

DATA READBACK: 0x52–0x59

DATA READBACK: 0x52–0x59

OPERATION MODE

PANEL SETUP

MEASUREMENTS

AVERAGING

INTERRUPTS

DATA TAGGING

TIRQ

0x01

ADC RESOLUTION AND TIMING

0x02, 0x04, 0x06

PUR AND PUF TIMING

0x07

N/A

N/A

N/A

TIRQ

ADC

TDM TIMING

Page 19

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

______________________________________________________________________________________ 19

Pressure Measurements

Z1 and Z2 measurements determine the resistance

between the two planes within the panel sensor during

a touch (R

TOUCH

). Depending on the known physical

properties of the panel, one of two equations extract the

value of R

TOUCH

, providing information about the pressure and area of the touch applied to the panel. Allow

adequate time for the panel to settle when switching

between position and pressure measurements. Figure 5

shows the physical setup of the panel when performing

pressure measurements.

Z1 and Z2 measurements allow observation of the voltage on either side of the effective R

TOUCH

resistance.

With both Z1 and Z2 measurements available, compute

R

TOUCH

as follows:

If only a Z1 measurement is available, compute

R

TOUCH

as follows:

The power applied across the panel during pressure

measurements is greatly dependent on R

TOUCH

and

the physical position of the touch. The maximum power

dissipation in the panel during a pressure measurement

is approximately PZ= V

DD

2

/R

TOUCH

. This maximum

Table 2. Operating Modes, Conditions, and Options

1

In ACM, the choices are limited to X and Y scan, or X and Y and Z1 scan, or X and Y and Z1 and Z2 scan.

2

In DCM, MTAG is always used. For DCM with CONT = 0, the following ETAGs are used: 00 = touch present (data valid), 10 = no

touch present (data may be invalid), 11 = measurement in progress (data invalid). For DCM with CONT = 1, the panel cannot be

scanned for a touch because panel setup switches are configured in a measurement mode; therefore, ETAG = 00 is used if a measurement is not in progress, or ETAG = 11 if a measurement is in progress.

3

A separate configuration register for delay time, sampling time, averaging, and ADC resolution settings configures the AUX input.

Figure 5. Pressure Measurements

Figure 4. Position Measurements

⎞

−

1

⎟

⎠

Y

POSITION

N

2

BIT

COR

INT

YY

OPERATION

MODE

DCM

MAX11800–

PUR

PSU PMC CMC TDM LPM AVG FIFO APER

CONT MTAG ETAG

PUF

Yes Yes Yes Yes No Yes No No Yes Yes Yes

2

Yes 2Yes Yes Yes No

X, Y,

Z1, Z2

EINT CINT

MAX11803

ACM

MAX11800/

1

Yes

Yes 1 Yes 1 Yes Yes Yes Yes Yes Yes No Yes Yes Yes No No Yes

MAX11801

AUX No Yes 3 No No — Yes 3No No No No No No No No No No

RR

TOUCH XPLATE

=

TOUCH

RX

⎛

XPLATE POSITION

=

⎜

N

⎝

BITX

2

R

XZ

⎛

⎜

⎝

2

⎞

⎛

⎟

⎜

⎠

⎝

POSITION

N

2

N

BI

TTZ

Z

1

⎞

⎛

2

⎟

⎜

⎠

BITX

11

−

⎝

Z

1

R

YPLATE

⎛

⎜

⎝

⎞

−−

⎟

⎠

⎞

⎟

⎠

ADC

INPUT

PANEL

R

TOUCH

X-

X POSITION MEASUREMENT

Y+

Y-

X+

V

DD

PANEL

R

X-

Y POSITION MEASUREMENT

TOUCH

ADC

INPUT

V

Y+

DD

Y-

X+

PANEL

R

TOUCH

X-

Z1 PRESSURE MEASUREMENT

ADC

INPUT

X+

V

Y+

DD

PANEL

R

TOUCH

Y-

X-

Z2 PRESSURE MEASUREMENT

V

Y+

DD

ADC

INPUT

Y-

X+

Page 20

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

20 ______________________________________________________________________________________

power dissipation condition is observed when the point

of contact is in the top left corner of the panel sensor.

The planar end-to-end resistance included in the current path is minimal at this location. Keep the averaging

and panel settling durations to the minimum required

by the application when pressure measurements are

required. Table 3 summarizes the physical panel settings for supported measurement types.

Touch-Detect Modes and Options

Figure 6 shows the internal circuitry in the

MAX11800–MAX11803 used to detect the presence of

a touch on the panel. The selection of the pullup resistance value (RTD= touch-detect resistance) and the

durations of the rough pullup interval (PUR = lowimpedance pullup) and fine pullup interval (PUF = highimpedance pullup) are user-defined.

The MAX11800–MAX11803 revert to the low-power

panel setup when placed in touch-detect mode (TDM).

Figure 6 shows the active panel drive switches (YMSW

and XPSW are omitted for simplicity). TSW is a dedicated pullup switch used in TDM. TSW is also used during

PUF and TDM. XPSW is activated during PUR periods.

TDRSEL allows the selection of an internal pullup resistor value of either 50kΩ or 100kΩ.

The X and Y touch-screen plates create an open circuit

with no current flow in the panel when the panel is not

being touched. In this case, TOUCH (see Figure 6) is

low. When a touch causes contact between the panel X

and Y plates, a current path is created and TOUCH is

pulled high, as long as R

PX

+ RPY(the sum of panel

end-to-end resistance) is much lower than RTD. Typical

open-circuit panel plate resistances range from 200Ω

to 1000Ω.

The MAX11800–MAX11803 enter high-impedance

pullup mode (50kΩ or 100kΩ) when the panel is not

being touched. The device is idle in this mode until a

touch is detected. The YMSW and TSW transistors are

on, and the XPSW and PSW transistors are off. With no

touch present, the Y- input of the TSC is at ground and

the X+ input is at V

DD

- VTN, where VTNis the threshold

voltage of the TSW nMOS device. This is a low-power

mode in which no current is consumed until a panel

touch occurs. When a touch is present on the panel,

the touch-screen controller (TSC) X+ input is pulled low

by the touch panel plate resistance and the YMSW transistor. This causes TOUCH to assume a logic-high and

the devices either issue the TIRQ interrupt for direct

conversion modes (MAX11800–MAX11803) or begin

self-timed scans for autonomous conversion mode

(MAX11800/MAX11801).

The value of the user-defined RTDdepends on the

characteristics of the panel. To ensure reliable

detection values, worst-case panel resistance must

be checked against RTD. The interaction between

RTDand the panel (or external noise rejecting)

capacitance determines how quickly the panel can

be switched from measurement modes back to

touch monitoring mode without reporting false

touches or erroneous tags due to panel settling.

Panel touch status is also required to tag data from a

completed scan and measurement operation. Following

each scan operation, the panel must be returned to

TDM to determine if the panel is still being touched and

if the data obtained during the scan operation should

be considered valid. This operation is required since

the panel cannot be monitored for the presence of a

touch during the scan and measurement procedure.

The MAX11800–MAX11803 must return to TDM after

completing a measurement and making a decision on

the touch status of the panel. The measurement procedure is only completed upon resolution of the touch status and when data is tagged and available for

readback. The characteristics of the return to TDM and

Table 3. Summary of Physical Panel Settings for Supported Measurement Types

Note: The ADC input is fully differential with the negative input internally connected to GND. The MAX11800–MAX11803 control

access to the PUR, PUF, TDM, and LPM, which do not require setup procedures.

U

indicates unconnected node.

MODE X+ X- Y+ Y- REF+ REF-

XVDDGND ADC_IN U X+ X-

Y ADC_IN U V

Z1 ADC_IN GND V

Z2 U GND V

PUR VDD (10Ω) U U GND U —

V

through

TDM or PUF

LPMUUUUU—

DD

50kΩ or 100kΩ

U U GND U —

DD

DD

DD

GND Y+ Y-

UY+X-

ADC_IN Y+ X-

Page 21

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

______________________________________________________________________________________ 21

the timing of the decision are configurable through the

touch-detect pullup timing configuration register (0x07).

Program the MAX11800–MAX11803 in the context of

the application to maximize power efficiency and

achieve the desired scan throughput.

PUR and PUF

PUR is a fast pullup mode, which uses the main X+

switch in parallel with the resistive pullup to quickly slew

the panel capacitance. PUF uses only the touch-detect

pullup resistor, RTD. PUR and PUF serve the same function as TDM, but are timed so that the panel can settle

after completing measurements and before rendering

any decisions on the touch status of the panel.

Use the optional PUR mode to reduce the time to tag

data by momentarily placing the panel in a low-impedance (< 10Ω) pullup mode instead of using the available 50kΩ/100kΩ touch-detection pullup resistors. This

operation forces the monitored TSC input high during

the PUR interval. Once the PUR interval expires, a PUF

interval must be allowed so that the panel can recover

and pull the TSC input low in case a touch is present.

The purpose of the PUR mode is to reduce the time

required to determine touch status by avoiding long

pullup time constants caused by high-capacitance

touch panels and the high-impedance on-chip pullup

resistors (RTD). When a touch is present during PUR

intervals, the current through the low-impedance pullup

(XPSW) and panel combination is significantly higher

than that observed in the PUF mode. The durations in

the PUR mode should be matched to the panel characteristics and the desired scan throughput rates to minimize power dissipation.

While use of the PUR mode is optional, the PUF period

is required for all applications. The PUF interval allows

the panel to resettle following scan or optional PUR

intervals. When a touch is not present, the panel capacitance settles toward V

DD

through the internal pullup

switch and a portion of the panel resistance (with the

optional PUR mode disabled). When a touch is present,

the panel capacitance settles toward ground through a

portion of the panel resistance, ideally significantly

lower than the selected pullup impedance, RTD. Allow

enough recovery time for settling through the panel

resistance when using a PUR mode. Figure 7 illustrates

the touch-detection operations.

Idle Modes

Once the PUF period expires, the preceding measurement data is tagged and made available for readback.

The MAX11800–MAX11803 transition to an appropriate

mode depending on the conversion and interrupt mode

selected.

Features Available in the

MAX11800–MAX11803 Averaging Modes

The MAX11800–MAX11803 contain a programmable

averaging filter. When enabled, this feature allows collecting 4, 8, or 16 consecutive samples for each measurement type requested. The number of the samples

for each measurement type is controlled by configuration register 0x03. Averaging can be assigned to each

measurement type. For example, X and Y measurements can use an average of 16 samples, while Z measurements can use one or four samples to save power.

The AUX depth is selected in configuration register

0x0A.

The MAX11800–MAX11803 can be configured to perform one of two statistical operations. One option is a

median averaging filter (MAF). The MAF first removes

the lowest and highest values before averaging the

remaining sample set. The second filter type is a

straight averaging filter (SAF), which takes the average

of the entire sample set. Both filter types and

position/pressure averaging are controlled by configuration register 0x0B. Table 4 presents the details of the

median averaging operations of the MAX11800–

MAX11803. For the MAX11800/MAX11801, averaging is

supported in both direct conversion mode and

autonomous conversion mode. The MAX11802/

MAX11803 support only direct conversion mode.

Figure 6. Touch-Detection Circuitry

V

DD

PSW

TDRSEL

RTD RTD

Y+

XPSW

PUR

X-

PANEL

X+

Y-

YMSW

PUR, PUF, TDM

TSW

PUR, PUF, TDM

TOUCH

(TO MAX11800/

MAX11801 LOGIC)

MAX11800–

MAX11803

Page 22

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

22 ______________________________________________________________________________________

Figure 7. Touch-Detection Operations

FAST PULLUP TOUCH DETECTION (NOTE: INCREASED CURRENT IN PUR MODE DURING TOUCH)

DIGITAL WAVEFORM

(OPTIONAL)

MEASUREMENT COMPLETE—

DATA IS KNOWN

ANALOG WAVEFORM

V

DD

TSC INPUT

INITIAL INPUT VOLTAGE

DETERMINED BY LAST SCAN

ACTIVITY

NORMAL TOUCH DETECTION (NOTE: NO PUR PERIOD; ALLOW LONG PULLUP TIMES)

DIGITAL WAVEFORM

POWER ASSISTED PULLUP PERIOD (10Ω) PANEL IS ALLOWED TO RESETTLE BEFORE

FORCED FAST PULLUP USING

10Ω SWITCH

DATA VALIDITY IS DETERMINED

(DATA IS TAGGED)

PUF MODESCAN MODE

DETERMINING DATA VALIDITY

TIME

DATA VALIDITY IS DETERMINED

(DATA IS TAGGED)

TOUCH DETECTPUR MODE

IS THERE A TOUCH?

YES = LPM.

NO = TDM.

TOUCH NOT PRESENT: TSC INPUT

REMAINS HIGH

TOUCH PRESENT:

TSC INPUT PULLED LOW

TOUCH DETECTPUF MODESCAN MODE

MEASUREMENT COMPLETE—

DATA IS KNOWN

ANALOG WAVEFORM

V

DD

TSC INPUT

INITIAL INPUT VOLTAGE

DETERMINED BY LAST SCAN

ACTIVITY

PANEL IS ALLOWED TO RESETTLE BEFORE DETERMINING DATA VALIDITY

(THROUGH 50kΩ/100kΩ PULLUP)

TOUCH NOT PRESENT:

TSC INPUT PULLED HIGH THROUGH 50kΩ/100kΩ PULLUP

TOUCH PRESENT:

TSC INPUT PULLED LOW BY PANEL

TIME

IS THERE A TOUCH?

YES = LPM.

NO = TDM.

Page 23

MAX11800–MAX11803

Low-Power, Ultra-Small Resistive Touch-Screen

Controllers with I2C/SPI Interface

______________________________________________________________________________________ 23

Combined Commands

Combined commands reduce AP interaction with the

MAX11800–MAX11803 by allowing multiple measurements. For example, the MAX11800–MAX11803 can be

instructed to provide X and Y data, or X and Y and Z1

data, or X and Y and Z1 and Z2 data using a single

command.

Data Tagging

In direct conversion modes, all measurement data is

contained in a 16-bit word. X, Y, Z1, and Z2 information

is stored independently. Each word consists of 12 bits

of measurement data plus a 2-bit measurement type

(MTAG) and a 2-bit event tag (ETAG). The measurement tag identifies whether the data represents an X, Y,

Z1, or Z2 result. The event tag indicates the point at

which the data is sampled (initial, midpress, or release)

during the touch event. When trying to read a result that

is pending, the entire data stream is read back as

FFFFh and the event tag as 11b, indicating that the corresponding measurement is in progress and that the

data stream is to be ignored. For combined commands,

all data locations requested by the command are

marked FFFFh, pending the completion of the entire

command and the proper tagging of the data. See

Table 5.

Direct conversion modes do not use the internal FIFO

or support the aperture function (see the

Aperture

Modes and Options

section). Each measurement type

uses a single location in the (16-bit) memory. The AP

must retrieve the data from the last requested measurement before moving on to the next measurement of the

type.

Auxiliary measurement data is not tagged because it is

not related to panel operation. Auxiliary measurement

data is stored and read back identically to the other

direct conversion data. The tag locations for auxiliary

measurement data are always set to 0000b, unless the