Page 1

TITOLO

MT SERIES ACTUATORS

Aluminum rack and pinion

pneumatic actuators

Max-Air Technology, Inc. 751 Hoff Rd O’Fallon, Missouri 63366

Tel: +1.636.272.4934 Toll Free: 888.842.9998 Fax: 636.272.4937

www.maxairtech.com E-mail: info@maxairtech.com

1

Page 2

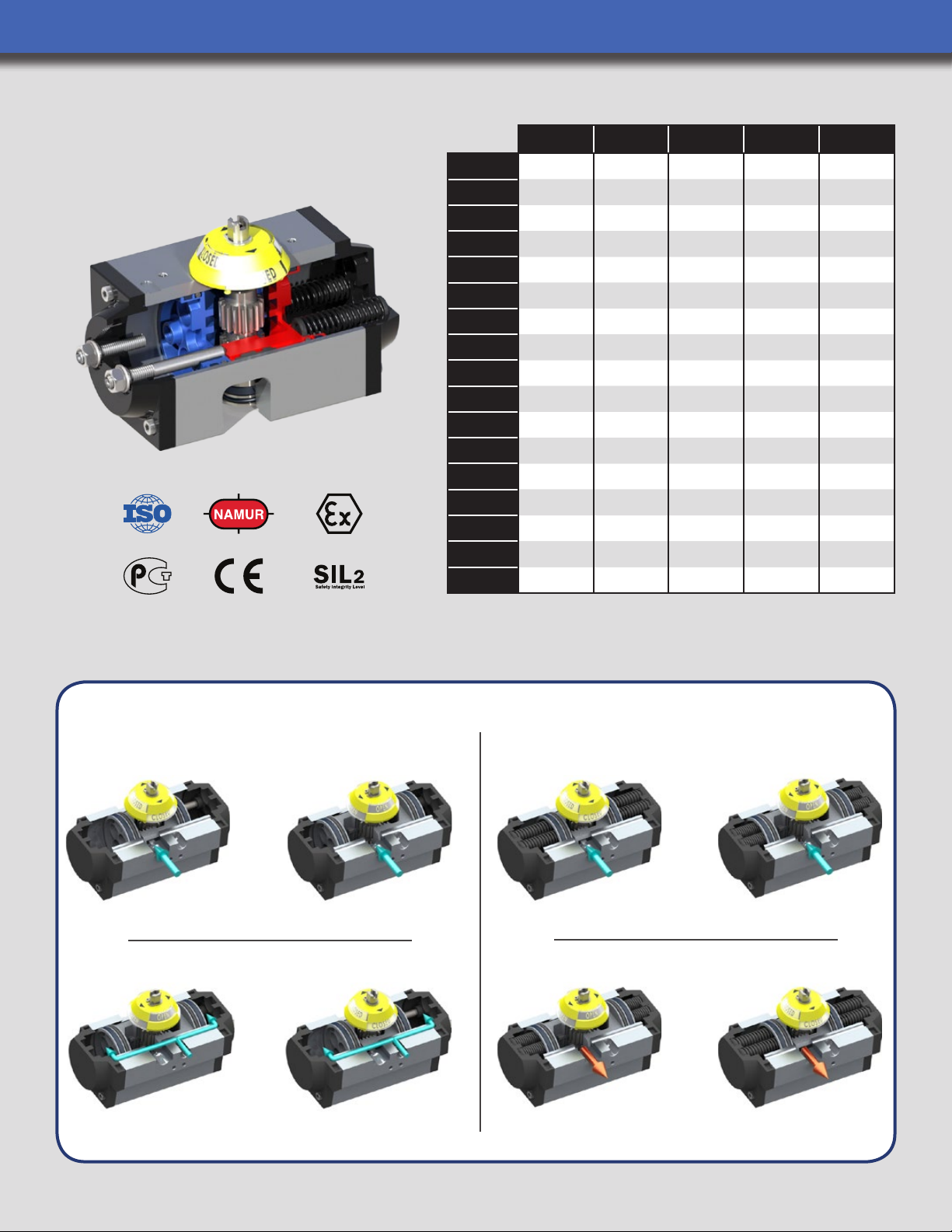

FEATURES & BENEFITS

COMPACT DESIGN

The MAX-AIR rack & pinion pneumatic actuator produces

linear torque output in a compact design utilizing the same

body and end caps for double-acting and spring-return

units.

NAMUR MOUNTING

Namur VDI/VDE 3845 and ISO 5211 dimensions on all

sizes. No special blocks are required to mount solenoid

valves, limit switches or positioners.

DEGREE OF TRAVEL

The standard angle of rotation is 90°. Additional travel

rotations through 180° are available. For sizes from MT08

through MT66, Max-Air actuators feature dual travel stops

that provide ± 10° stroke rotation on both the opening and

closing phases of the actuator stroke. 110° of travel in a

standard 90° actuator!

MULTIPLE OUTPUT SHAFTS

The female pinion drive is standard with a double-square

output drive, and optional with a double-D drive, keyed

drive and designs to meet your specific requirements.

HIGH-CYCLE BEARINGS

Shaft bearings isolate the pinion gear from the housing

and support the shaft for high-cycle applications. Many

competitive manufacturers do not provide this critical

feature.

RUGGED TOOTH DESIGN

The pinion teeth are engaged the full length and stroke of

the piston. The pinion height allows manual override without

needing to remove the indicator.

HIGH VISIBILITY POSITION INDICATION

External open/close indicator as standard, available for all

rotations.

HIGH CYCLE-LIFE WEAR PADS

Pistons incorporate double wear pads (skates) to separate

the rack from the actuator wall and serve as both guide and

wear bearings.

SAFE PRE-LOADED SPRING CARTRIDGES

Epoxy-coated special steel springs are pre-loaded with nonmetallic materials. The stainless steel end-cap fasteners

are extra long to allow for spring relaxation. All parts are

corrosion-resistant.

ALTERNATIVE OPERATING MEDIA

Air pressure operation from 2.8 to 10 Bar (40 to 150 PSI).

Water, nitrogen and compatible hydraulic fluids may also be

used to power the actuator.

STAINLESS STEEL FASTENERS

All external fasteners are corrosion-resistant stainless steel.

HONED BORE FOR HIGH CYCLE-LIFE

Extruded aluminum body is internally machined and honed

to exact specifications. Honing prevents dry spots from

forming within the actuator bore and therefore eliminates

premature seal failure —a critical aspect to long cycle-life.

All internal and external surfaces are hard anodized for

corrosion resistance, with all units permanently lubricated

at the factory.

TRACEABILITY

All units are externally marked with a progressive traceable

serial number.

QUALITY ASSURANCE

100% of all units are factory pressure and leak tested, and

individually boxed for shipment.

BEST WARRANTY IN THE INDUSTRY

Max-Air products are covered by our unlimited cycle-life

warranty. Contact your representative for more details.

ACCESSORIES

Max-Air offers a wide range of adapters for many different

types of valves—including butterfly valves, ball valves and

plug valves—as well as a variety of pneumatic and electric

automation accessories suitable for diverse industrial

environments.

Please call for details.

Introducing Lock Mesh™

Max-Air Technology’s high performance Teon ® infused stainless

steel mesh coating, introduced as our “Lock Mesh™” coating

combines the strength and corrosion resistance of stainless

steel with the technological advancements of infused PTFE.

2

Page 3

DOUBLE ACTING TORQUES

40 PSIG 60 PSIG 80 PSIG 100 PSIG 120 PSIG

MT04

MT12

MT08

MT16

MT17

MT21

MT26

MT31

MT36

MT41

MT46

MT51

MT56

MT61

MT66

MT71

MT76

*All torques in inch pounds (in-lbs)

40 60 80 100 120

62 94 125 156 187

110 147 207 259 295

137 206 275 344 412

180 270 360 450 540

250 375 500 625 750

375 562 750 937 1125

500 750 1000 1250 1500

800 1200 1600 2000 2400

1000 1500 2000 2500 3000

1562 2344 3125 3906 4687

2250 3375 4500 5625 6750

3000 4500 6000 7500 9000

4550 6825 9100 11375 13650

6000 9000 12000 15000 18000

11750 17625 23500 29375 35250

15750 23625 31500 39375 47250

START TO

OPEN

START TO

CLOSE

OPERATION REFERENCE DIAGRAM

SPRING RETURNDOUBLE ACTING

OPENING PHASE

AIR IN #4 = PISTONS OPEN

CLOSING PHASE

OPEN

CLOSED START TO

START TO

OPEN

AIR IN #4 = PISTONS OPEN (SPRINGS COMPRESS)

CLOSE

OPENING PHASE

CLOSING PHASE

OPEN

CLOSED

AIR IN #2 = PISTONS CLOSED

Double Acting Operation is also known as “Air to Open, Air to Close” or “Air to Air”.

3

AIR FAILURE = PISTONS CLOSE (SPRINGS RELAX)

Page 4

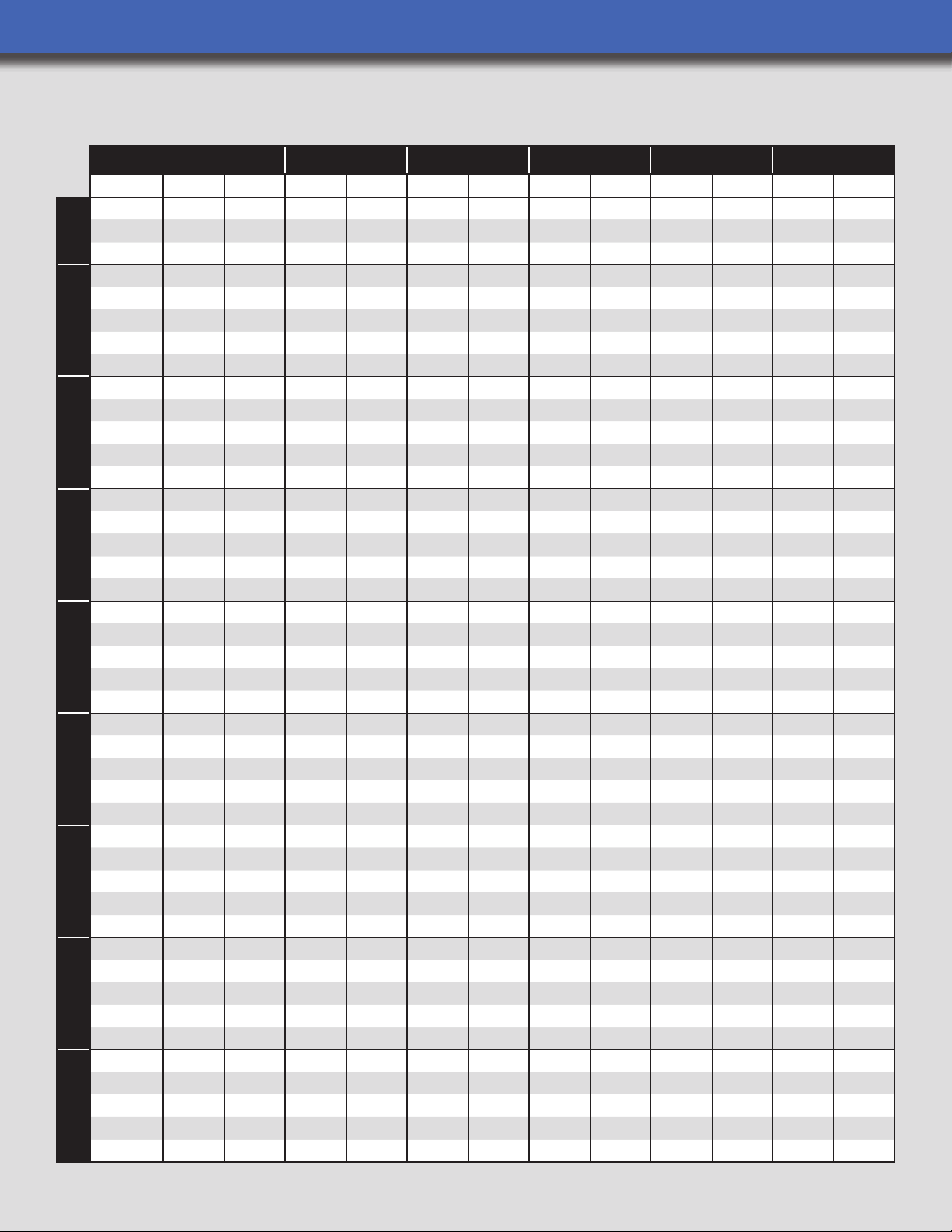

SPRING RETURN TORQUES MT12-MT41

POS.1

CLOSING TORQUE

POS. 2 OPENING TORQUE

(SPRING) 40 PSIG 60 PSIG 80 PSIG 100 PSIG 120 PSIG

#Springs Start End Start End Start End Start End Start End Start End

1+1 33 22 40 29 72 61 103 92 134 123 165 154

2+2 66 44 – – 50 28 81 59 112 90 143 121

MT12

3+3 99 66 – – – – 58 27 90 66 121 88

1+1 33 20 90 78 127 115 187 175 239 227 275 263

2+2 65 40 70 45 107 82 167 142 219 194 255 230

3+3 98 60 50 13 87 50 147 110 199 162 235 198

MT08

4+4 130 80 – – 67 17 127 77 179 129 215 165

5+5 163 100 – – – – 107 45 159 97 195 133

2+2 75 53 84 62 153 131 222 200 291 269 359 337

3+3 11 2 81 56 25 125 94 194 163 263 232 331 300

4+4 150 107 – – 99 56 168 125 237 194 305 262

MT16

5+5 187 134 – – 72 19 141 88 210 157 278 225

7+5 224 160 – – – – 115 51 184 120 252 188

2+2 93 64 11 6 87 206 177 296 267 386 357 476 447

3+3 139 96 84 41 174 131 264 221 354 3 11 444 401

4+4 185 128 – – 142 85 232 175 322 265 412 355

MT17

5+5 232 160 – – 110 38 200 128 290 218 380 308

7+5 278 192 – – – – 168 82 258 172 348 262

2+2 122 92 158 128 283 253 408 378 533 503 658 628

3+3 184 138 11 2 66 237 191 362 316 487 441 612 566

4+4 245 184 66 5 191 130 316 255 441 380 566 505

MT21

5+5 307 230 – – 145 68 270 193 395 318 520 443

7+5 369 278 – – 97 6 222 131 347 256 472 381

2+2 196 124 251 179 438 366 626 554 813 741 1001 929

3+3 294 185 190 81 377 268 565 456 752 643 940 831

4+4 392 247 – – 315 170 503 358 690 545 878 733

MT26

5+5 490 309 – – 253 72 441 260 628 447 816 635

7+5 588 372 – – – – 378 162 565 349 753 537

2+2 251 187 313 249 563 499 813 749 1063 999 1313 1249

3+3 376 280 220 124 470 374 720 624 970 874 1220 1124

4+4 502 374 – – 376 248 626 498 876 748 1126 998

MT31

5+5 627 467 – – 283 123 533 373 783 623 1033 873

7+5 753 560 – – – – 440 247 690 497 940 747

2+2 412 306 494 388 894 788 1294 1188 1694 1588 2094 1988

3+3 617 461 339 183 739 583 1139 983 1539 1383 1939 1783

4+4 824 614 – – 586 376 986 776 1396 1176 1786 1576

MT36

5+5 1029 767 – – 433 171 833 571 1233 971 1633 1371

7+5 1236 921 – – – – 679 364 1079 764 1479 1164

2+2 505 371 629 495 1129 995 1629 1495 2129 1995 2629 2495

3+3 757 566 444 243 944 743 1444 1243 1944 1743 2444 2243

4+4 1011 741 – – 759 289 1259 989 1759 1489 2259 1989

MT41

5+5 1263 929 – – 572 237 1072 737 1572 1237 2072 1737

7+5 1516 1113 – – – – 887 484 1387 984 1887 1484

*All torques in inch pounds (in-lbs). Spring Return Actuators are also known as “Air to Open, Spring to Close” or “Air to Spring”.

*Actuator drawings may be downloaded at www.maxairtech.com

4

Page 5

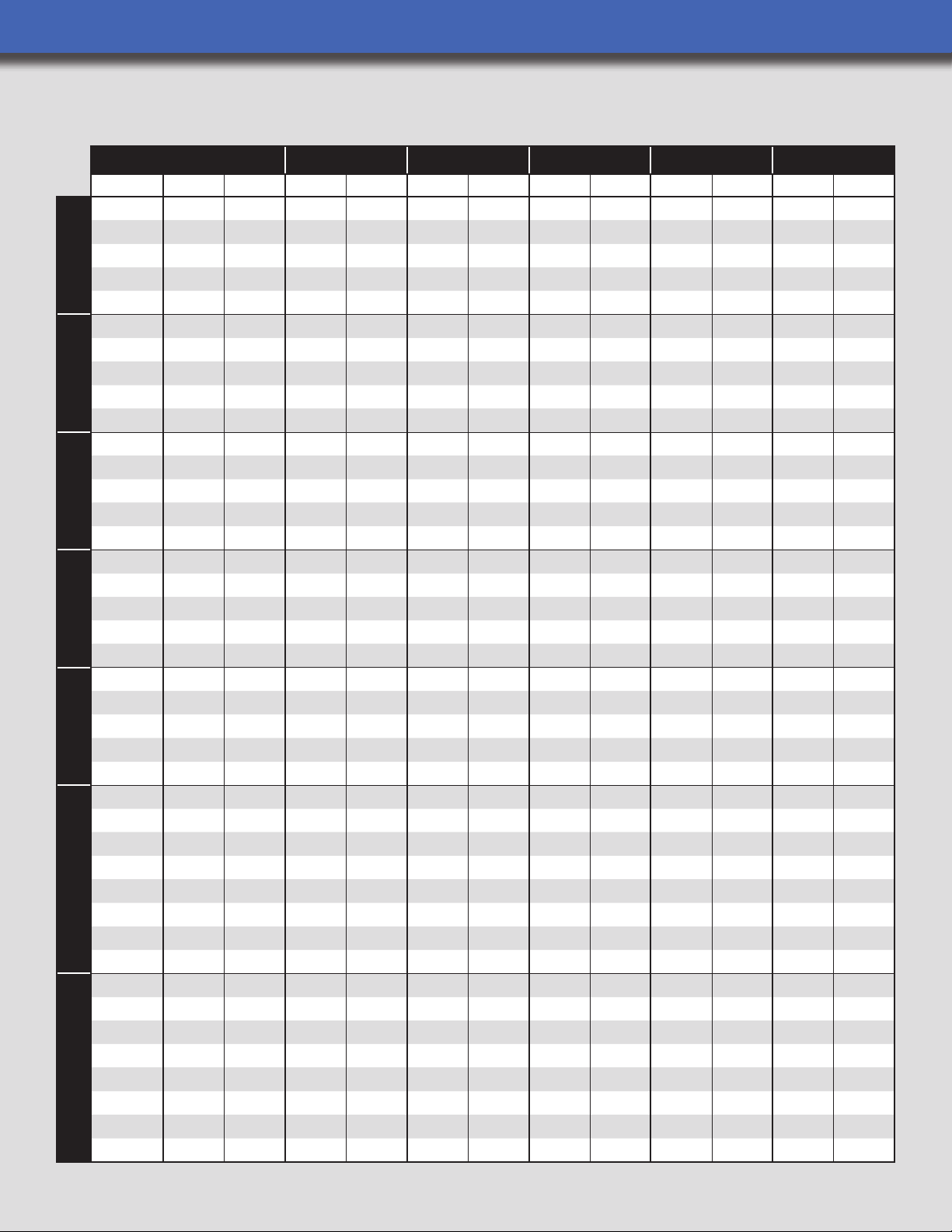

SPRING RETURN TORQUES MT46-MT76

POS.1

CLOSING TORQUE

POS. 2 OPENING TORQUE

(SPRING) 40 PSIG 60 PSIG 80 PSIG 100 PSIG 120 PSIG

#Springs Start End Start End Start End Start End Start End Start End

2+2 890 560 1002 672 1784 1454 2565 2235 3346 3016 4127 3797

3+3 1334 840 722 228 1504 1010 2285 1791 3066 2572 3847 3353

4+4 1779 1120 – – 1224 565 2005 1346 2786 2127 3567 2908

MT46

5+5 2224 1399 – – 945 120 1726 901 2507 1682 3288 2463

7+5 2669 1679 – – – – 1446 456 2227 1237 3008 2018

2+2 1101 869 1381 1149 2506 2274 3631 3399 4756 4524 5881 5649

3+3 1652 1304 946 598 2071 1723 3196 2848 4321 3973 5446 5098

4+4 2203 1738 512 47 1637 1172 2762 2297 3887 3422 5012 4547

MT51

5+5 2754 2173 – – 1202 621 2327 1749 3452 2871 4577 3996

7+5 3303 2607 – – 768 72 1893 1197 3018 2322 4143 3447

2+2 1487 1055 1945 1513 3445 3013 4945 4513 6445 6013 7945 7513

3+3 2231 1583 1417 769 2917 2269 4417 3769 5917 5269 7417 6769

4+4 2974 2111 889 26 2389 1526 3889 3026 5389 4526 6889 6026

MT56

5+5 3718 2638 – – 1862 782 3362 2282 4862 3782 6362 5282

7+5 4462 3166 – – 1334 38 2834 1538 4334 3038 5834 4538

2+2 2146 1711 2839 2404 5114 4679 7389 6954 9664 9229 11939 11504

3+3 3220 2566 1984 1330 4259 3605 6534 5880 8809 8155 11084 10430

4+4 4293 3422 1128 257 3403 2532 5678 4807 7953 7082 10228 9657

MT61

5+5 5366 4277 – – 2548 1459 4823 3734 7098 6009 9373 8284

7+5 6438 5133 – – 1692 387 3967 2662 6242 4937 8517 7212

2+2 2810 2084 3916 3190 6916 6190 9916 9190 12916 12190 15916 15190

3+3 4215 3126 2874 1785 5874 4785 8874 7785 11874 10785 14874 13785

4+4 5619 4269 1831 381 4831 3381 7831 6381 10831 9381 13831 12381

MT66

5+5 7024 5211 – – 3789 1976 6789 4976 9789 7976 12789 10976

7+5 8430 6252 – – – – 5748 3570 8748 6570 11748 9570

1+1 2123 1534 10216 9627 16091 15502 21966 21377 27841 27252 33716 33127

2+2 4247 3068 8682 7503 14557 13378 20432 19253 26307 25128 32182 31003

3+3 6370 4602 7148 5380 13023 11255 18898 17130 27773 23005 30648 28880

4+4 8493 6136 5614 3257 11489 9132 17364 15007 23239 20882 29114 26757

5+5 10617 7670 – – 9955 7008 15830 12883 21705 18758 27580 24633

MT71

6+6 12740 9204 – – 8421 4885 14296 10760 20171 16635 26046 22510

7+7 14863 10737 – – – – 12763 8637 18638 14512 24513 20387

8+8 16987 12271 – – – – 11229 6513 17104 12388 22979 18263

1+1 2843 1784 13966 12907 21841 20782 29716 28657 37591 36532 45466 44407

2+2 5686 3569 12181 10064 20056 17939 27931 25814 35806 33689 43681 41564

3+3 8530 5353 10397 7220 18272 15095 26147 22970 34022 30845 41897 38720

4+4 11373 7137 8613 4377 16488 12252 24363 20127 32238 28002 40113 35877

5+5 14216 8922 – – 14703 9409 22578 17284 30453 25159 38328 33034

MT76

6+6 17059 10706 – – 12919 6566 20794 14441 28669 22316 36544 30191

7+7 19902 12490 – – – – 19010 11598 26885 19473 34760 27348

8+8 22746 14275 – – – – 17225 8754 25100 16629 32975 24504

*All torques in inch pounds (in-lbs)

*Actuator drawings may be downloaded at www.maxairtech.com

5

Page 6

HOW TO ORDER

A

A - SPECIAL COATING

ENP = Electroless

Nickel Plated

LMC = LockMesh

Coated

EPOXY = Epoxy

Coated

Omit if N/A

*Note: 1) Not all combinations available, and special

solutions not shown are possible. Please call factory for

details. 2) Max-Air Technology reserves the right to change

or modify products without prior notice & without incurring

any obligation to make such changes on products previously

or subsequently sold.

Important: It is imperative that the air supply pressure

is properly veried when sizing actuators, and to ensure

all supply lines are properly sized to deliver adequate

volume to the actuator, for proper operation.

.

B

B - SPECIAL PINION

DD = Double-D

KYWY = Keyway

Omit if N/A

.

C = SERIES

MT

C D

SAMPLE PART NUMBERS

D = SIZE

04

12

08

16

17

21

26

31

36

41

46

51

56

61

66

71

76

.

E

E - CONFIGURATION

DA = Double-Acting

S2 = 2+2 Springs

S3 = 3+3 Springs

S4 = 4+4 Springs

S5 = 5+5 Springs

S7x5 = 7+5 Springs

F - MOUNTING

F04

F03-F05

F04-F07

F05-F07

F07-F10

F10-F12

F10-F14

F16

(UT SERIES ONLY)

F04/3.25

F12/3.25

5.00/3.25

.

F

.

G - OUTPUT DRIVE

CH11 = 11mm DSQ

CH14 = 14mm DSQ

CH17 = 17mm DSQ

CH22 = 22mm DSQ

CH27 = 27mm DSQ

CH36 = 36mm DSQ

CH46 = 46mm DSQ

.500x.375

.560x.375

.625x.438

.750x.500

.875x.625

1.181x.866

18x10mm

14x22mm

22x14mm

25x19mm

Call for keyway

Other options available

G

H - SPECIAL SEALS

SLT = Super Low Temp

LT = Low Temp

Standard Temp (Omit)

HT = Elevated Temp

.

H

MT26.S4.F05-F07.CH17

SIZE = 26

CONFIGURATION = 4+4 Springs

MOUNTING = F05-F07

OUTPUT DRIVE = 17mm DSQ

ACTUATOR REFERENCE TABLE

Drive (mm) Drive (in) Standard ISO Pattern Optional ISO Pattern

MT04

MT12

MT08

MT16

MT17

MT21

MT26

MT31

MT36

MT41

MT46

MT51

MT56

MT61

MT66

MT71

MT76

9 0.354 F03 -

11 0.433 F04 F03/F05

11 0.433 F03/F05 F04

14 0.551 F05/F07 F04/F07

14 0.551 F05/F07 -

17 0.670 F05/F07 -

17 0.670 F05/F07 -

17 0.670 F05/F07 -

22 0.866 F07/F10 -

22 0.866 F07/F10 -

22 0.866 F07/F10 -

27 1.063 F10/F12 -

27 1.063 F10/F12 -

36 1.417 F10/F14 F10/F12

36 1.417 F10/F14 F10/F12

46 1.811 F16 F14

46 1.811 F16 -

EPOXY.MT31.S5.F05-F07.CH17

SPECIAL COATING = EPOXY

SIZE = 31

CONFIGURATION = 5+5 Springs

MOUNTING = F05-F07

OUTPUT DRIVE = 17mm DSQ

6

Page 7

AIR CONSUMPTION / WEIGHTS / WARRANTY

Double Acting Spring Return

Weight (lbs) Air Consumption (cu-in) Weight (lbs) Air Consumption (cu-in)

MT04

MT12

MT08

MT16

MT17

MT21

MT26

MT31

MT36

MT41

MT46

MT51

MT56

MT61

MT66

MT71

MT76

*Note: Spring return weights consider actuator tted with max number of springs possible. Air consumption is normalized at standard temperature and pressure.

1.06 4.03 NA NA

2.00 13.50 2.18 8.00

2.76 15.26 3.00 6.10

3.52 25.60 3.94 11.20

4.22 34.30 4.75 15.60

5.17 44.40 6.00 18.10

7.1 5 68.70 8.30 30.00

9.13 88.90 10.74 40.60

14.60 153.10 17.80 75.00

17.20 190.60 20.90 100.00

24.20 275.00 29.90 115.60

35.30 425.00 42.00 181.30

44.10 565.50 53.80 256.30

61.50 881.30 83.10 343.80

84.50 1037.50 105.60 443.80

147.30 1694.00 182.90 600.00

179.90 1963.00 216.10 731.00

STANDARD WARRANTY INFORMATION

Max-Air Technology provides the following warranty regarding products manufactured by it. THE WARRANTY STATED HEREIN IS EXPRESSELY IN LIEU OF ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR INPLIED, OR STATUTORY, INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTY OF FITNESS FOR

A PARTICULAR PURPOSE. Max-Air Technology warrants its products to be free from defects in materials and workmanship when these products are used for the purpose for

which they were designed and manufactured. Max-Air Technology does not warrant its products against chemical or stress corrosion or against any other failure other than from

defects in materials or workmanship. The warranty period is for twelve (12) months from installation date or eighteen (18) months from shipment date, whichever date comes

first. Any claims regarding this warranty must be in writing and received by Max-Air Technology before the last effective date of the warranty period. Upon Max-Air Technology

receipt of a warranty claim, Max-Air Technology reserves the right to inspect the product(s) in question at either the field location or at Max-Air Technology Manufacturing plant.

If, after inspection of the product(s) in question, Max-Air Technology determines that the purchaser’s claim is covered by this warranty, Max-Air Technology’s sole liability and the

purchaser’s sole remedy under this warranty is limited to the refunding of the purchase price or repair or replacement thereof a Max-Air Technology option. Max-Air Technology will

not be liable for any repairs, labor, material or other expenses that are not specifically authorized in writing by Max-Air Technology, and in no event shall Max-Air Technology be

liable for any direct or consequential damages arising out of any defect from any cause whatsoever. If any Max-Air Technology product is modified or altered at any location other

than Max-Air Technology – St. Louis (Missouri) or Max-Air Technology – Sesto San Giovanni (Milan) ITALY without the express written authorization of Max-Air Technology are

not covered by this warranty. The warranty for such products shall be subject only to the warranty relief, if any, provided by the suppliers and/or manufacturers of such products.

UNLIMITED CYCLE LIFE WARRANTY

Max-Air Technology, Inc. provides the following unlimited cycle life warranty regarding products manufactured by Max-Air Technology, Inc. of O’Fallon, Missouri and Emme

Technology S.r.l. of Sesto San Giovanni, Italy, a.k.a. the “Max-Air Group”. This warranty includes all aluminum rotary rack and pinion actuators which are manufactured by the

Max-Air Group and brand labeled for marketing purposes for other companies and business entities, and applies only to those items which are clearly identified as Max-Air brand

labeled products. The warranty stated herein is expressly in lieu of all other warranties and representations, expressed or implied, or statutory, including, without limitation, the

implied warranty of fitness for a particular purpose. Max-Air Technology warrants it products to be free from defects in materials and workmanship when these products are

used for the purpose for which they were designed and manufactured. Max-Air Technology does not warrant its products against chemical or stress corrosion or against any

other failure other than from defects in materials or workmanship. The warranty period is for twelve (12) months from installation date or eighteen (18) months from shipment

date, whichever date comes first. Any claims regarding this warranty must be in writing and received by Max-Air Technology before the last effective date of the warranty period.

Upon receipt of a warranty claim, Max-Air Technology reserves the right to inspect the product(s) in question at either the field location or at a Max-Air designated facility. If,

after the inspection of the product(s) in question, Max-Air Technology determines that the purchaser’s claim is covered by this warranty, Max-Air Technology’s sole liability and

the purchaser’s sole remedy under this warranty is limited to the refunding of the purchase price or repair or replacement thereof, at the sole discretion of Max-Air Technology.

Max-Air Technology will not be liable for any repairs, labor, material, or other expenses that are not specifically authorized in writing by Max-Air Technology, and in no event shall

Max-Air Technology be liable for any direct or consequential damages arising out of any defect from any cause whatsoever. If any Max-Air Technology products are modified

or altered in any way, without the expressed written consent of Max-Air Technology, the products will not be covered by this warranty. Max-Air Technology further warrants

its aluminum rotary rack and pinion pneumatic actuator products to be free from seal failure for the life of the product when such product(s) are used for the purpose in which

they are designed. This warranty extension shall be known as the ‘Unlimited Cycle Life Warranty’ and provides that in the event of seal failure outside the standard warranty

time period, Max-Air Technology will inspect and repair the product(s) in question free of charge. If during the inspection, Max-Air Technology, or its authorized service repair

center, finds that failure was caused by the introduction of foreign debris into the internal operating mechanism of the pneumatic actuator, and/or finds that failure was caused

by end user modification, then the warranty extension shall be null and void. The unlimited cycle life warranty does not cover the freight charges to and from an authorized

Max-Air Technology service repair center, regardless if warranty coverage is applicable or not. Warranty coverage provides for replacement of all wear bearing parts, and other

components if necessary as determined by Max-Air Technology or its authorized service repair center. Max-Air Technology reserves the right to end this warranty extension at

anytime at its sole discretion, and without notification.

7

Page 8

MT04 EXPLODED VIEW

Blue = Items sold in the skates and

wear bearings repair kit

Red = Items sold in the o-ring repair kit

18

17

3

6

5

8

14

11

21

1

2

4

IMPORTANT SPECIAL FEATURE!

The MAX-AIR MT04 is designed so that standard NAMUR mount

solenoid valves can be connected horizontally. This is a MAX-AIR

EXCLUSIVE feature.

13

15

16

10

9

7

22

19

5

4

23

3

25

1

24

20

# DESCRIPTION MATERIALS

1 End Cap Bolts AISI 304 Stainless Steel

2 Left End Cap Die Cast Aluminum Epoxy Coated

6 Left Piston Anodized Aluminum

8 Actuator Body Extruded Aluminum (6063 or 6005)

9 Upper Pinion Washer Technopolymer

10 Pinion Snap Ring AISI 304 Stainless Steel

11 Pinion Nickel Plated Carbon Steel

16 Indicator Inserts Technopolymer

17 Indicator Technopolymer

18 Indicator Screw AISI 304 Stainless Steel

19 Right Piston Anodized Aluminum

20 Travel Stop AISI 304 Stainless Steel

21 Travel Stop AISI 304 Stainless Steel

22 Right End Cap Die Cast Aluminum Epoxy Coated

24 Travel Stop Nuts AISI 304 Stainless Steel

NOTE

The MT04 is the smallest actuator in our MT lineup. The MT04 is only

available in double-acting conguration, and Standard Buna Seals.

# DESCRIPTION MATERIALS

4 Piston Wear Bearing Technopolymer

7 Piston Skate Technopolymer

13 Upper Pinion Bearing Technopolymer

# DESCRIPTION MATERIALS

3 End Cap O-Ring BUNA-N

5 Piston O-Ring BUNA-N

14 Upper Pinion O-Ring BUNA-N

15 Lower Pinion O-Ring BUNA-N

23 Travel Stop Washers AISI 304 Stainless Steel

25 Travel Stop O-Rings BUNA-N

8

Page 9

MT04 & MT12 TECHNICAL DATA

.787

.205

.394

.315

.472

2x 1/8" NPT

4x #10-32x.315

.945

(NAMUR)

1.260

(NAMUR)

.157

M6x.470

4x #10-32x.315

.984

1.969

3.94

2.00

1.56

.98

2.75

.783

.43

.02

1.10

Beacon

Indicator

(Removable)

#10-32" UNFx.394

.354

.354

1.417

ISO F03

INCHES

IN

DIMENSIONS

3845

VDI/VDE

NAMUR

AND

3337

DIN-1521

ISO

O

T

DIMENSIONS

TECHNICAL DATA

MT04

M

I

H

A

B

C

D

F

L

MT04

MT12

*Only available in Double Acting conguration, and with Standard Buna-N Seals (-4°F to 176°F).

MT12

A B C D F I L M F05 F03/F04 DSQ ISO 5211

2.64 1.57 0.47 2.80 0.49 0.87 4.69 0.394

#10-32x.394

#10-32x.394 — F04

¼"-20x.394

11 mm

(0.433in)

9

F03/F05

Page 10

MT12 EXPLODED VIEW

Blue = Items sold in the skates and

wear bearings repair kit

Red = Items sold in the o-ring repair kit

18

2

1

5

3

6

7

8

14

11

10

13

12

17

16

9

7

19

5

3

2

1

15

# DESCRIPTION MATERIALS

1 End Cap Bolts AISI 304 Stainless Steel

2 Left End Cap Die Cast Aluminum Epoxy Coated

6 Left Piston Anodized Aluminum

8 Actuator Body Extruded Aluminum (6063 or 6005)

9 Upper Pinion Washer Technopolymer

10 Pinion Snap Ring AISI 304 Stainless Steel

11 Pinion Nickel Plated Carbon Steel

16 Open/Closed Indicator Technopolymer

17 Indicator Window Technopolymer

18 Indicator Snap Ring AISI 304 Stainless Steel

19 Travel Stop Piston Anodized Aluminum

# DESCRIPTION MATERIALS

7 Piston Skate Technopolymer

12 Lower Pinion Bearing Technopolymer

13 Upper Pinion Bearing Technopolymer

# DESCRIPTION MATERIALS

3 End Cap O-Ring BUNA-N

5 Piston O-Ring BUNA-N

14 Upper Pinion O-Ring BUNA-N

15 Lower Pinion O-Ring BUNA-N

SPECIAL NOTE

The second smallest actuator in our lineup, the MT12 actuator is designed without dual travel stop adjustments to save space, while at the same time

offered in both DA (double-acting) and SR (spring-return) congurations. Available only in Standard Buna-N Seals (-4°F to 176°F).

10

Page 11

MT08 - MT66 EXPLODED VIEW

1

2

3

6

Blue = Items sold in the skates and

wear bearings repair kit

18

Red = Items sold in the o-ring repair kit

17

7

4

5

14

8

11

12

15

# DESCRIPTION MATERIALS

1 End Cap Bolts AISI 304 Stainless Steel

2 Left End Cap Die Cast Aluminum Epoxy Coated

6 Left Piston Anodized Aluminum

8 Actuator Body Extruded Aluminum (6063 or 6005)

9 Upper Pinion Washer Technopolymer

10 Pinion Snap Ring AISI 304 Stainless Steel

11 Pinion Nickel Plated Carbon Steel

16 Open/Closed Indicator Technopolymer

17 Indicator Window Technopolymer

18 Indicator Snap Ring AISI 304 Stainless Steel

19 Travel Stop Piston Anodized Aluminum

20 Closed Travel Stop AISI 304 Stainless Steel

21 Open Travel Stop AISI 304 Stainless Steel

22 Travel Stop End Cap Die Cast Aluminum Epoxy Coated

24 Travel Stop Nuts AISI 304 Stainless Steel

16

10

9

19

13

5

4

7

21

22

20

3

1

# DESCRIPTION MATERIALS

4 Piston Wear Bearing Technopolymer

7 Piston Skate Technopolymer

12 Lower Pinion Bearing Technopolymer

13 Upper Pinion Bearing Technopolymer

# DESCRIPTION MATERIALS

3 End Cap O-Ring BUNA-N

5 Piston O-Ring BUNA-N

14 Upper Pinion O-Ring BUNA-N

15 Lower Pinion O-Ring BUNA-N

23 Travel Stop O-Rings BUNA-N

23

24

SERVICE CODE DESCRIPTION

Super Low Temperature SLT

Severe Cold LT

Standard STD

Elevated Temperature HT

For super low temperatures down to -67°F, special super low temperature seals and lubricant must

be used.

For temperatures below -4°F down to -49°F, special low temperature seals and lubricant must be

used.

Actuators come standard with BUNA-N seals, which are good for normal temperature ranges of -4°F

to 176°F.

For elevated temperatures up to 300°F, VITON® seals are available. Typical VITON® installations

are good for 300°F continuous and 350°F cyclic.

11

Page 12

MT08 - MT66 TECHNICAL DATA

1.18

K

E

G

J

F

A

45°

DSQ

B

A

H

90°

0.157 0.157

DETAIL C:

Top Pinion

C

D

I

A

X

W

SECTION A-A:

Valve Connection

ISO 5211 Flange

M

#10-32 x.315

0.56

1/4" NPT

C

B

L

#10-32 x.315

DETAIL B:

SV Connection

1.26

0.95

3.15

1.18

*Double-D and keyway drive options available. Contact Max-Air for details.

A B C D E F G H I L M J K W X DSQ ISO 5211

2.64 1.57 0.47 2.80 1.77 0.49 0.06 1.85 0.87 4.69 0.394

MT12

2.76 1.62 0.47 2.68 1.70 0.65 0.06 2.07 1.02 6.30 0.394

MT08

3.19 1.85 0.47 3.19 1.75 0.75 0.08 2.44 1.30 6.50 0.394

MT16

3.19 1.85 0.47 3.19 1.75 0.75 0.08 2.44 1.30 7.76 0.394 1.97

MT17

3.78 2.13 0.55 3.86 1.77 0.75 0.08 3.01 1.38 6.70 0.394 1.97

MT21

3.78 2.13 0.55 3.86 1.77 0.75 0.08 3.01 1.38 9.41 0.394 1.97

MT26

4.49 2.44 0.77 4.61 1.73 0.91 0.08 3.56 1.59 9.06 0.551 1.97

MT31

5.16 2.60 0.77 6.06 1.77 1.18 0.12 3.76 1.59 9.69 0.551 2.76

MT36

5.16 2.60 0.77 6.06 1.77 1.18 0.12 3.76 1.77 11.42 0.551 2.76

MT41

5.71 2.87 1.10 6.63 1.77 1.18 0.12 3.88 2.22 13.81 0.787 2.76

MT46

7.13 3.58 1.10 7.95 1.73 1.57 0.12 4.33 2.13 14.21 0.787 4.02

MT51

7.13 3.58 1.10 7.95 1.73 1.57 0.12 4.90 2.62 16.46 0.787 4.02

MT56

9.13 4.49 1.10 10.12 1.77 1.97 0.16 6.32 3.15 17.48 0.787 4.02

MT61

9.13 4.49 1.10 10.12 1.77 1.97 0.16 6.32 3.15 19.76 0.787 4.02

MT66

1.42 #10-32x.394 1.969

1.65 #10-32x.394 — — F04

1.42 #10-32x.315 1.969

1.65 #10-32x.315 — — F04

1.97

¼"-20x.394

1.65 #10-32x.394 F04/F07

¼"-20x.394

¼"-20x.512

¼"-20x.512

¼"-20x.512

5

/16"-18x.512

5

/16"-18x.512

5

/16"-18x.512

3

3

3

3

Note*: Dimensions subject to change without notice. Dimensions in inches unless otherwise noted.

/8"-16x.709

/8"-16x.709

/8"-16x.709

/8"-16x.709

2.756

2.756

2.756

2.756

2.756

4.016

4.016

4.016

4.921

4.921

4.921

5.512

4.921

5.512

¼"-20x.394

¼"-20x.394

5

/16"-18x.512

5

/16"-18x.512

5

/16"-18x.512

5

/16"-18x.512

5

/16"-18x.512

3

/8"-16x.709

3

/8"-16x.709

3

/8"-16x.709

½"-13x.787

½"-13x.787

½”-13x.787

5

/8"-11x.984

½”-13x.787

5

/8”-11x.984

Note: Envelope dimensions shown, see individual cutsheets for dimensional details.

11 mm

11 mm

14 mm

14 mm F05/F07

17 mm F05/F07

17 mm F05/F07

17 mm F05/F07

22 mm F07/F10

22 mm F07/F10

22 mm F07/F10

27 mm F10/F12

27 mm F10/F12

36 mm

36 mm

F03/F05

F03/F05

F05/F07

F10/F12

F10/F14

F10/F12

F10/F14

12

Page 13

MT71 - MT76 EXPLODED VIEW

26

23

21

1

2

6

3

27

18

17

16

27

Blue = Items sold in the skates and

wear bearings repair kit

Red = Items sold in the o-ring repair kit

19

5

4

22

1

4

5

8

14

9

11

# DESCRIPTION MATERIALS

1 End Cap Bolts AISI 304 Stainless Steel

2 Left End Cap Die Cast Aluminum Epoxy Coated

6 Left Piston Anodized Aluminum

8 Actuator Body Extruded Aluminum (6063 or 6005)

10 Pinion Snap Ring AISI 304 Stainless Steel

11 Pinion Nickel Plated Carbon Steel

16 Open/Closed Indicator Technopolymer

17 Indicator Window Technopolymer

18 Indicator Snap Ring AISI 304 Stainless Steel

19 Right Piston Anodized Aluminum

20 Travel Stop, Open AISI 304 Stainless Steel

21 Travel Stop, Closed AISI 304 Stainless Steel

22 Right End Cap Die Cast Aluminum Epoxy Coated

26 Travel Stop Nut AISI 304 Stainless Steel

27 Lifting Eyelets Forged Stainless Steel

7

25

15

10

Note*: Now available with bi-directional travel stops, +/-10° Adjustment.

3

23

# DESCRIPTION MATERIALS

4 Piston Wear Bearing Technopolymer

7 Piston Skates Technopolymer

9 Upper Pinion Bearing Technopolymer

25 Lower Pinion Bearing Technopolymer

# DESCRIPTION MATERIALS

3 End Cap O-Ring BUNA-N

5 Piston O-Ring BUNA-N

14 Upper Pinion O-Ring BUNA-N

15 Lower Pinion O-Ring BUNA-N

23 Travel Stop O-Rings BUNA-N

20

26

SERVICE CODE DESCRIPTION

Super Low Temperature SLT

Severe Cold LT

Standard STD

Elevated Temperature HT

For super low temperatures down to -67°F (-55°C), special super low temperature seals and

lubricant must be used.

For temperatures below -4°F (-20°C) down to -49°F (-45°C), special low temperature seals and

lubricant must be used.

Actuators come standard with BUNA-N seals, which are good for normal temperature ranges of -4°F

(-20°C) to 176°F (80°C).

For elevated temperatures up to 300°F, VITON® seals are available. Typical VITON® installations

are good for 300°F (149°C) continuous and 350°F (177°C) cyclic.

13

Page 14

MT71 & MT76 TECHNICAL DATA

J K

M

L

D

A

B

F

H

I

C

J K

M

L

D

A

B

F

H

I

C

MT71

*Double-D and keyway drive options available. Contact Max-Air for details.

A B C D E F G H I L M J K DSQ ISO 5211

12.99 6.50 1.10 12.99 2.17 2.45 0.20 6.22 4.13 22.83 1.417

MT71

12.99 6.50 1.10 12.99 2.17 2.45 0.20 6.22 5.51 26.69 1.417 6.496

MT76

MT76

5.512

6.496

5

/8”-11x1.260

3

/4”-10x1.260

3

/4”-10x1.260

46 mm

46 mm F16

F14

F16

*Double-D and keyway drive options available. Contact Max-Air for details.

14

Page 15

MATERIAL & COATING REFERENCE

Increased Corrosion Resistance

Aluminum:

Hard Anodized

(Standard)

Material / Coating

Silver-gray with a matte

appearance

Appearance

Good general corrosion

properties in most

“natural” environments

with pH from 4.5 to 8.5.

Good resistance to salt

air environments. The

coating is extremely

hard and resistant to

General Properties

abrasion.

Aluminum:

Anodized w/

Polyamide Epoxy

Coating

Black with a

medium gloss nish

This epoxy coating

is a relatively thick

coating which creates

a barrier against many

of the chemicals which

anodizing alone cannot

adequately resist. It

will resist more acidic

or basic environments

than anodizing alone.

Aluminum:

Electroless Nickel

Infused

Medium gloss

silver nish

Uniformly thick coating

with essentially

no porosity and a

reasonably high

hardness. The coating is

pure, tough, hard, and

resistant to many types

of corrosion media.

Aluminum: Teon

Infused SS Mesh

“Lock MeshTM”*

Coating

Dark Grey nish

This coating provides

complete surface

coverage and exhibits

excellent corrosion

resistance properties

in a wide variety of

applications. In addition,

it is FDA approved for

food contact.

Stainless Steel:

ASTM A351

Grade CF8M

Silver; low to medium

gloss unless polished

304 and 316 stainless

steel are the most

commonly used

alloys. Both have good

corrosion resistance

but 316 is generally

considered superior,

however more

expensive.

Lowest Cost Moderate Cost Moderately High Cost Moderately High Cost Highest Cost

Relative Cost

Good general corrosion

resistance, particularly

in salt or alkaline

Highly acidic or basic

environments

will break down the

coating.

Performance Limitations

*See Lock Mesh Product Bulletin 20130305-RO for technical details.

environments. Limited

resistance to acids.

Surface chalking will

occur when exposed

to UV radiation.

Also suitable for low

concentrations of

caustic washdown

solutions.

The coating will provide

enhanced corrosion

protection in very acidic

environments but will

not withstand attack

from strong alkaline

media. Also suitable

for low to medium

concentrations of

caustic washdown

solutions.

15

These coatings

are resistant to any

environment into which

an actuator would be

installed. Provided the

integrity of the surface

is intact, the coating can

resist a broad array of

chemical environments

at temperatures ranging

from sub- zero to 350°

F.

Although stainless steel

does offer enhanced

corrosion resistance,

it also is dramatically

higher in both cost

and weight. The weight

differential will often

necessitate the use

of special support

bracketry.

Corrosion resistance is

superior.

Page 16

TITOLO

The Best Way To Automate Your Process

Your nearest Max-Air dealer can be found at:

NORTH AMERICA

Max-Air Technology, Inc.

751 Hoff Rd

O’Fallon, Missouri 63366

United States of America

Tel: +1.636.272.4934

Toll Free: 888.842.9998

Fax: 636.272.4937

EUROPE

Emme Technology, Srl.

Via Di Vittorio, 307/27

20099 Sesto San Giovanni

Milan, Italy

Tel: +39.02.2626.2174

Fax: +39.02.2622.0777

16

Rev. May 6, 2015

R05062015

Loading...

Loading...