A I R C O N D I T I O N I N G

TECHNICAL MANUAL

Serie/Series/Serie/Série/ Serie

Emissione/Issue/misión

Émission/ Ausgabe

MI26A MI35A MI53A

08.18

Catalogo/Catalogue/Catálogo/Brochure/ Katalog

Sostituisce/Supersedes/Remplaza

Remplace/ Ersetzt

MTE01111F0520-00

-

HYDRONIC HIGH WALL

D18

Hydronic Highwall

Contents

1. Introduction ......................................................................... 2

2. Nomenclature .............................................................. 2

3. Product Schedule ....................................................... 3

4. External Appearance .................................................. 3

5. Features....................................................................... 4

6. Specifications ............................................................. 5

7. Dimension ................................................................... 7

8. Service Spaces ........................................................... 7

9. Wiring Diagrams ......................................................... 8

10. Capacity Tables ........................................................ 9

11. Sound Levels .......................................................... 13

12. Exploded View ........................................................ 14

13. Installation ............................................................... 16

14. Controller ................................................................ 29

Hydronic Highwall

2 Introduction

1. Introduction

Fan coil unit is a kind of compound device which assemble fan and heat-exchang coil together. Fan coil with

fresh air supply system is a main type of center air-conditioner syste m, so it is an important compo nent of AC

devices. Fan coil unit has concealed type and exposed type. A cooling (heating) supply system usually

consists of fan coil termin als an d c hilled water system (heat ed w at er system).

Maxa fan coil is designed and manufactured on the base of advanced technology, and utilize qualified

galvanized iron as material. Due to its supper-thin design, it has such advantages: beautiful outlook, space

saving, easy installation, etc. And the most obvious advantage is that it can decrease the outlet air Tempdifference as low as possible to make room more comfortable, as well as don’t decrease cooling capacity

output. For the large air flow v olume design, it can increase r oom ventilati on frequency, supply more flesh air,

and balance room te mperature distribution. Bene fiting fro m adopt ion of adv an ced mat eria l and t echno lo gy, it

can effectively decrease t he running no ise and keep running smoothly. With the advantages above, it can be

widely applied in market, hospital, office build ing, hotel, airport, etc.

2. Nomenclature

M I – 26 A

Cooling capacity (2,6 kW)

Chilled Water Fan Coil Unit

Maxa

Hydronic Highwall

Product Schedule 3

3. Product Schedule

Model Type

Air volume

(CFM)

Power supply

MI35A

Wall mounted

250

220~240V-1Ph-50Hz MI35A 400

MI53A 500

4. External Appearance

Hydronic Highwall

4 Features

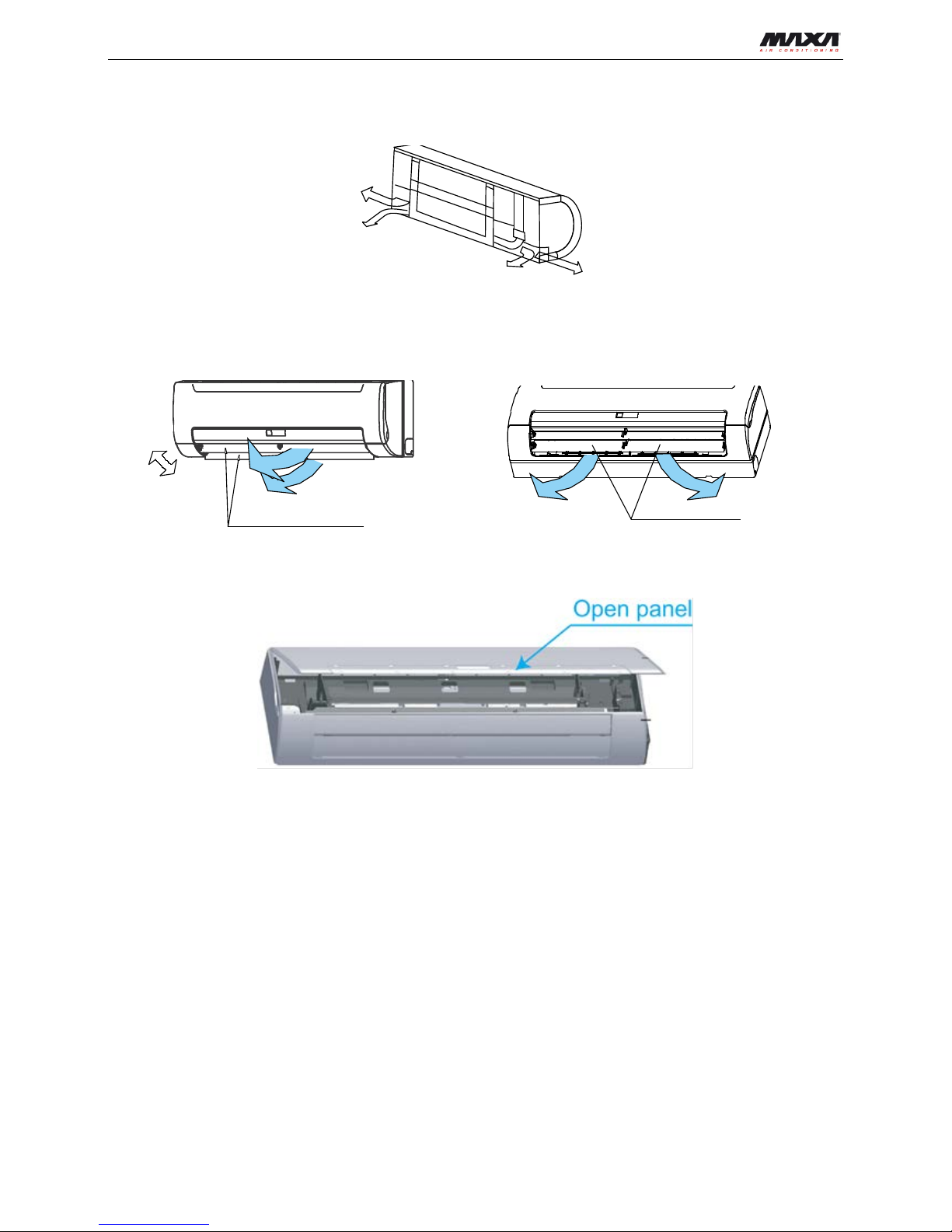

5. Features

New panel supplies more choic e f or cust oms.

Multi-connection outlet pipe method: left/right/rear, more flexible for inst allation.

Wind direction adjustment can be in horizontal and vertica l way for auto swing louver

Built-in 3-way electromagnetic valve.

Easy maintenance has been r ealized as the front panel can be r emoved for easy access.

Remote controller with LCD di splay is standard, wired contr oller and central controller ar e opt ional.

Four-speed motor with super high speed reserved for mor e choice.

Right piping

Left piping

Right back piping

Left back piping

Horizontal a

ir deflector

Vertical air deflector

Hydronic Highwall

Specifications 5

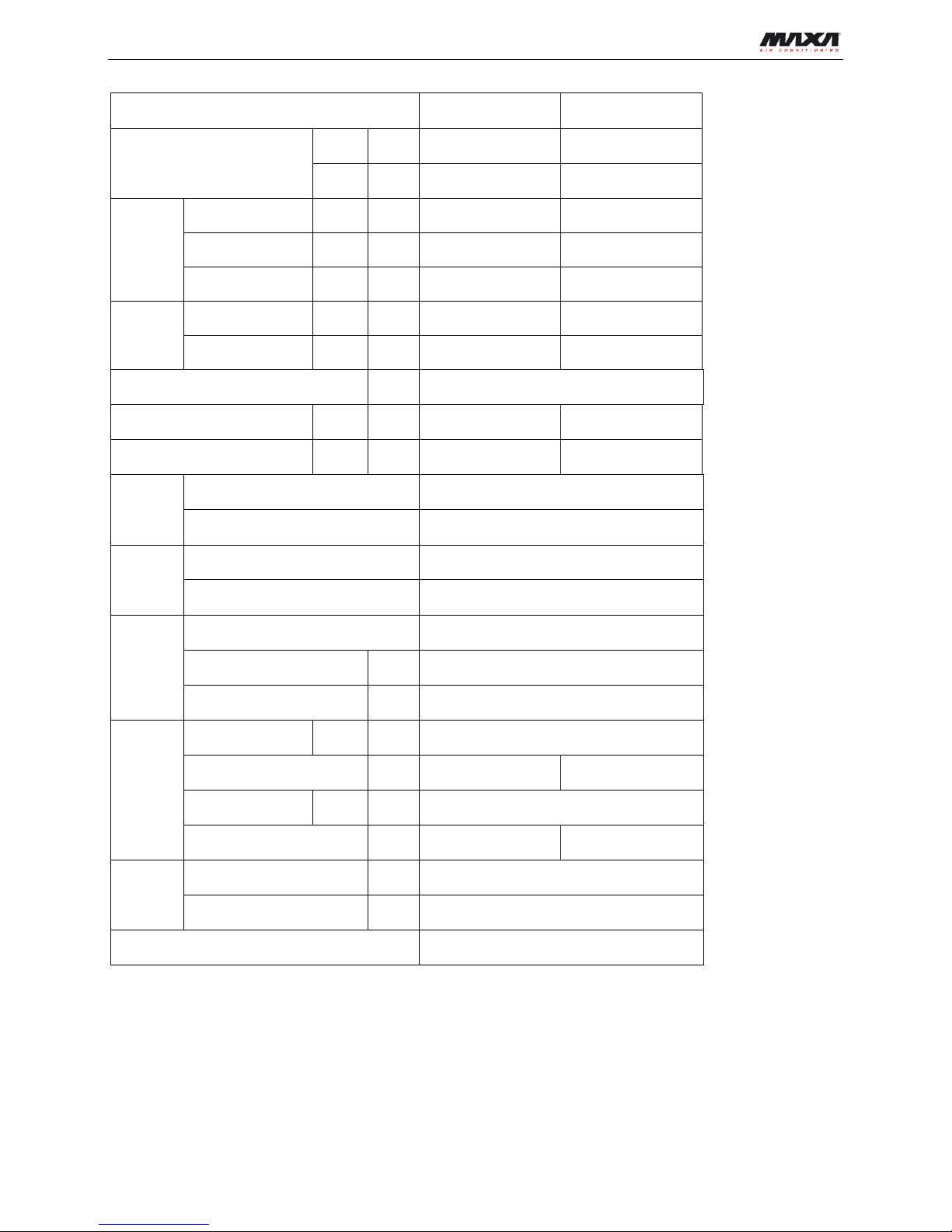

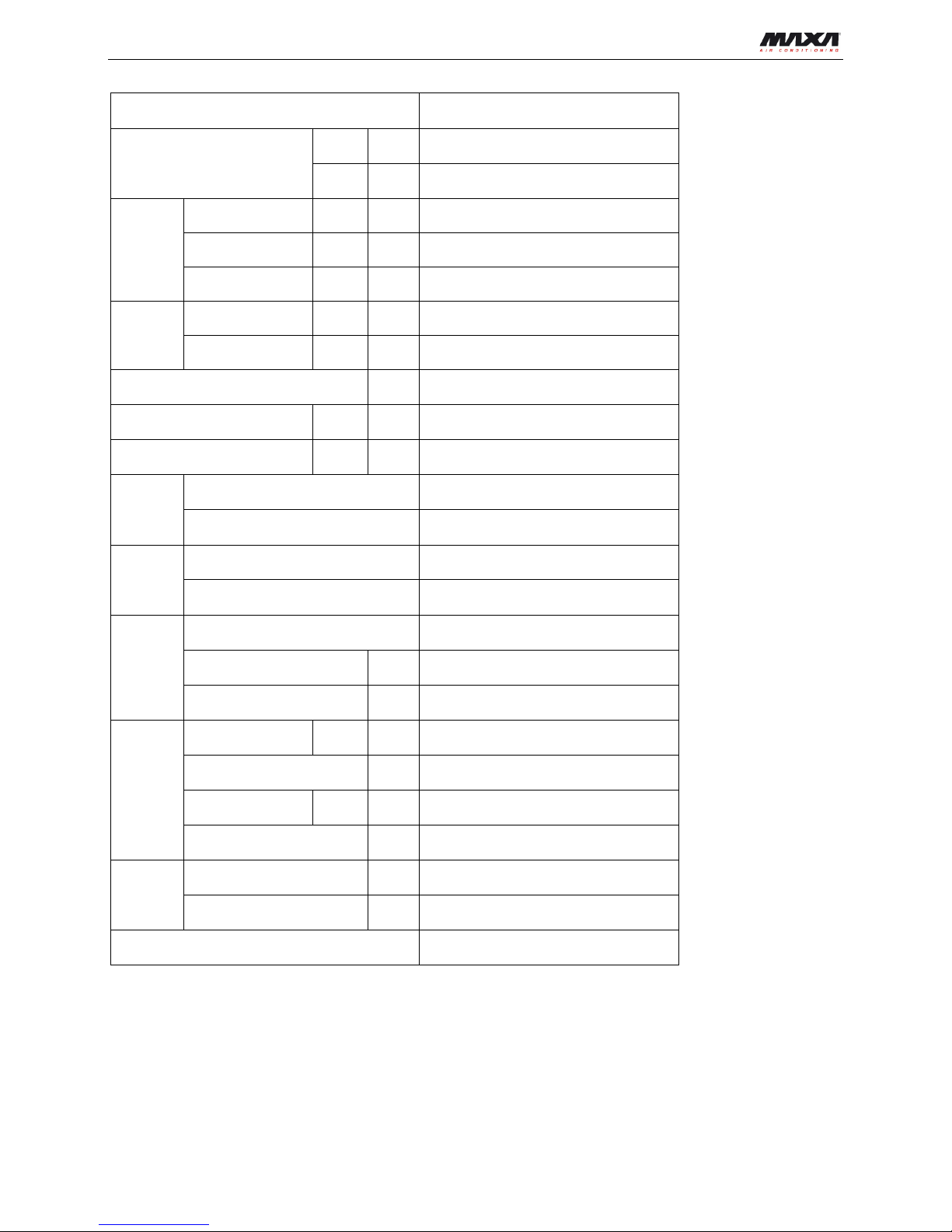

6. Specifications

Model

MI26A MI35A

Air flow

H/M/L m3/h 425/360/320 680/580/510

H/M/L CFM 250/210/190 400/340/300

Cooling

Capacity H/M/L kW 2.63/2.41/2.16 3.28/2.83/2.41

Water flow rate H l/h 452 564

Water pressure drop H kPa 29.4 43.5

Heating

Capacity H/M/L kW 3.36/3.1/2.79 4.37/3.73/3.17

Water pressure drop H kPa 27.3 40.8

Power supply

V/ph/Hz

220-240/1/50

Power input

H W 24 40

Sound pressure

level H/M/L dB(A) 30/24/20 37/31/26

Fan motor

Type Low noise 4-speed fan motor

Quantity 1

Fan

Type Cross-flow fan

Quantity 1

Coil

Row 2

Max. Working pressure Mpa 1.6

Diameter mm Φ7

Body

Dimensions W×H×D mm 915×230×290

Net weight kg 13 13.3

Packing W×H×D mm 1020×315×390

Gross weight kg 16.3 16.7

Pipe

connection

Water inlet/outlet pipe Inch G3/4"

Drain pipe mm ODΦ20

Controller

R51/E (standard)

Note:

1. H: high speed; M: medium speed; L: low speed

2. Cooling Conditions: entering water 7°C, temperature rise 5°C, entering air temperat ure 27°C DB,19°CWB.

Heating Conditions: entering water 50°C, enter air temperature 20°C, the same water flow as the cooling conditions.

3. Noise is tested in semi-anechoic test room.

Hydronic Highwall

6 Specifications

Specifications

Model

MI42A

Air flow

H/M/L m3/h 850/720/640

H/M/L CFM 500/420/380

Cooling

Capacity H/M/L kW 4.25/3.85/3.32

Water flow rate H l/h 731

Water pressure drop H kPa 31.8

Heatin

g

Capacity H/M/L kW 5.81/5.17/4.43

Water pressure drop H kPa 30.2

Power supply

V/ph/Hz

220-240/1/50

Power input

H W 50

Sound pressure level

H/M/L dB(A) 39/33/28

Fan motor

Type Low noise 4-speed fan motor

Quantity 1

Fan

Type Cross-flow fan

Quantity 1

Coil

Row 2

Max. Working pressure Mpa 1.6

Diameter mm Φ7

Body

Dimensions W×H×D mm 1072×230×315

Net weight kg 15.8

Packing W×H×D mm 1180×315×415

Gross weight kg 19.4

Pipe

connection

Water inlet/outlet pipe Inch G3/4"

Drain pipe mm ODΦ20

Controller

R51/E (standard)

Note:

1. H: high speed; M: medium s peed; L: low speed

2. Cooling Conditions: entering water 7°C, temperature rise 5°C, entering air temperat ure 27°C DB,19°CWB.

Heating Conditions: entering water 50°C, enter air temperature 20°C, the same water flow as the cooling conditions.

3. Noise is tested in semi-anechoic test room.

Hydronic Highwall

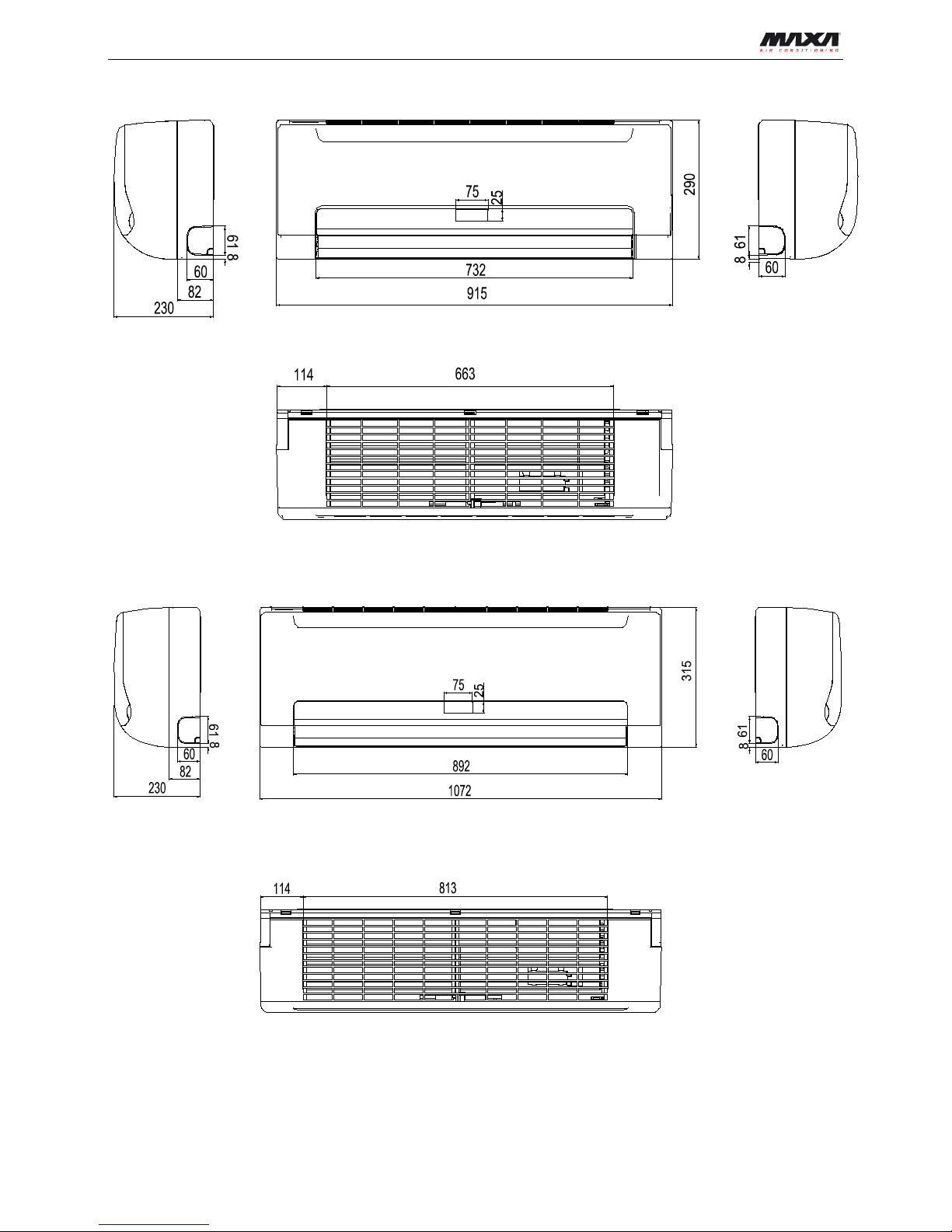

Dimensioni

7

7. Dimensioni

MI26A MI35A

MI53A

Hydronic Highwall

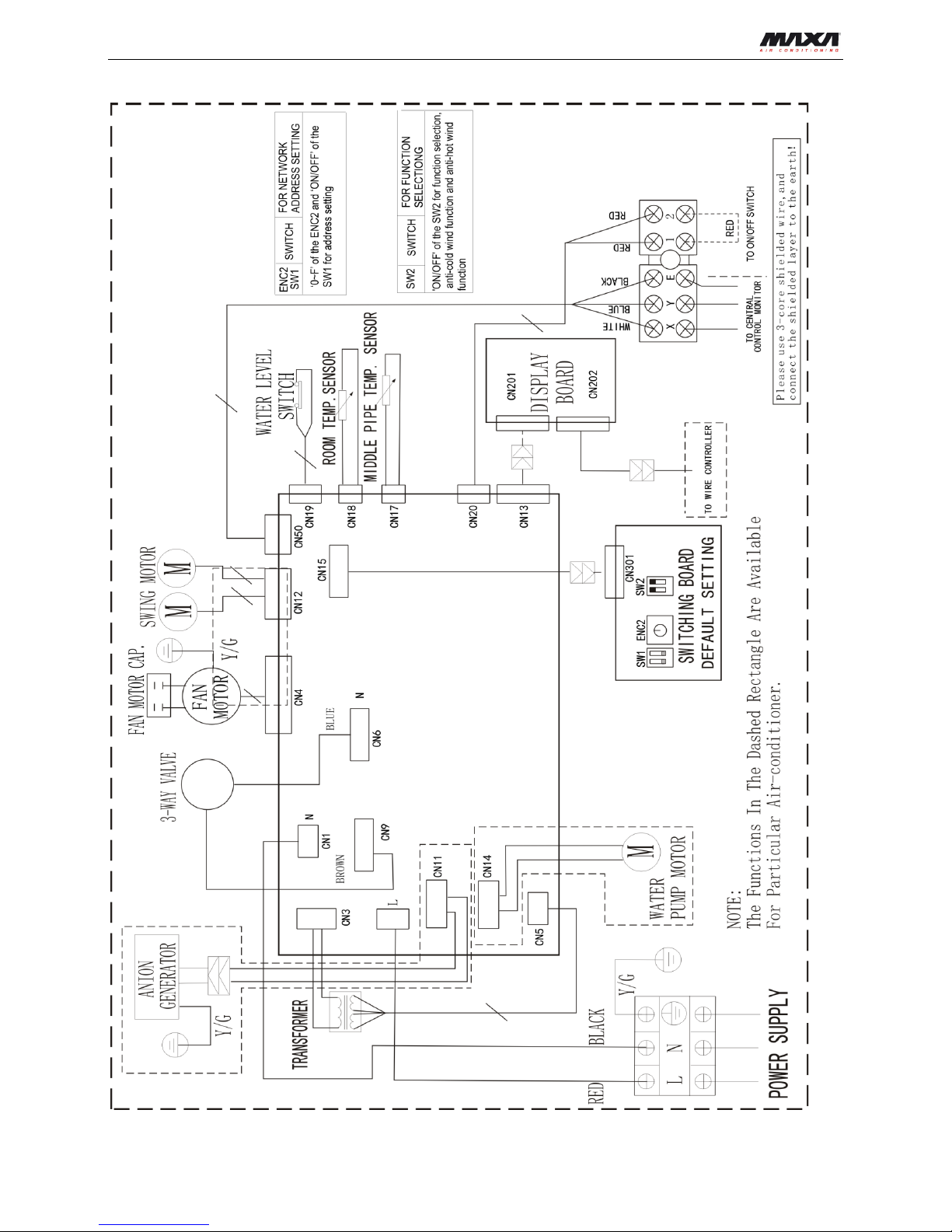

8 Wiring Diagrams

8. Wiring Diagrams

Hydronic Highwall

Capacity Tables 9

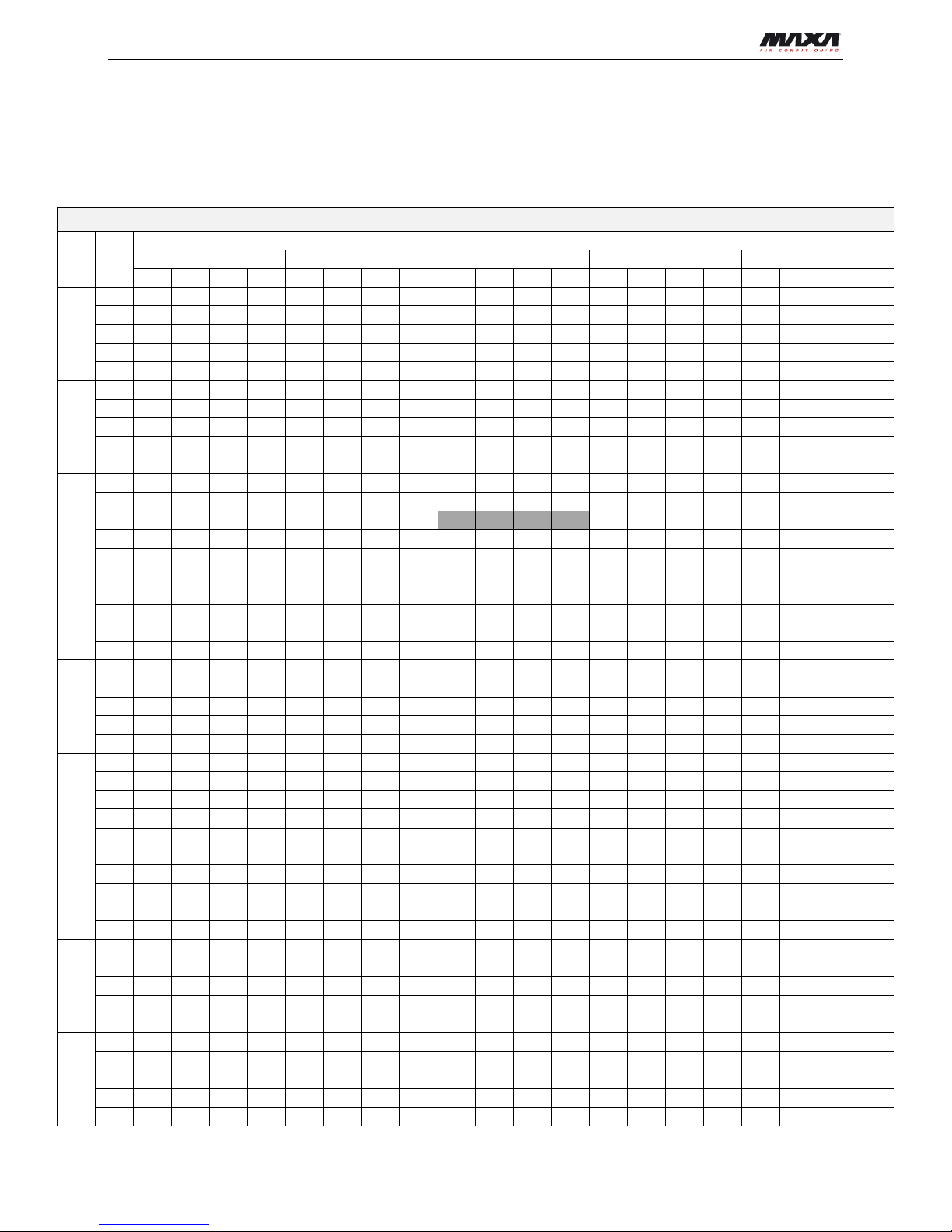

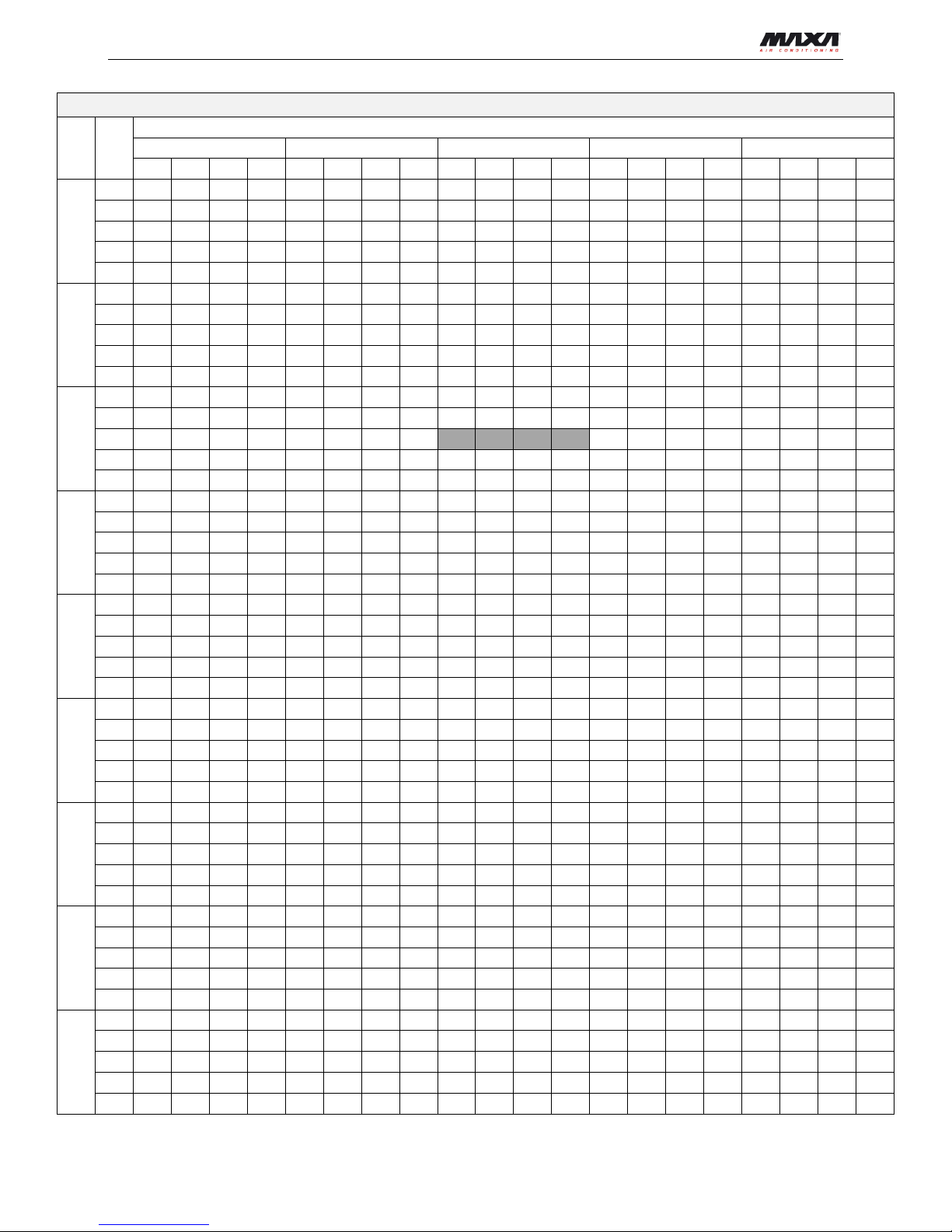

10. Capacity Tables

Cooling Capacity:

Remark: EWT: Enter Water Temp. (℃); Δt: Temperature Difference (℃)

DB: Dry Bulb Temp. (℃); WB: Wet Bulb Temp. (℃);

TC: Total Cooling Capacity (kW); SC: Sensible Cooling Capacity (kW);

WF: Water Flow (m

3

/h); WPD: Water Pressure Drop (kPa)

MI26A

EWT Δt

Air inlet condition

DB:21 WB:15

DB:26.7 WB:19.4

DB:27 WB:19

DB:29 WB:21

DB:33 WB:25

TC

SC

WF

WPD

TC

SC

WF

WPD

TC

SC

WF

WPD

TC

SC

WF

WPD

TC

SC

WF

WPD

5

3

2.17

1.58

0.62

55.8

3.35

2.02

0.96

132.6

3.28

2.11

0.94

127.2

3.67

1.92

1.05

158.7

4.93

2.39

1.41

287.4 4 2.05

1.49

0.44

27.8

3.22

1.96

0.69

68.9

3.17

2.05

0.68

66.7

3.52

1.86

0.76

82.4

4.78

2.32

1.03

151.9 5 1.89

1.43

0.33

15.2

3.08

1.89

0.53

40.4

3.02

1.98

0.52

38.8

3.39

2.93

0.58

48.7

4.63

2.28

0.80

91.1

6

1.73

1.37

0.25

8.8

2.94

1.84

0.42

25.6

2.89

1.91

0.41

24.6

3.24

1.72

0.46

30.9

4.52

2.20

0.65

60.2

7

1.55

1.28

0.19

5.2

2.80

1.75

0.34

17.0

2.74

1.85

0.34

16.2

3.10

1.65

0.38

20.8

4.36

2.13

0.54

41.3 6 3

1.97

1.49

0.56

45.6

3.16

1.94

0.91

118.0

3.09

2.02

0.89

112.7

3.48

1.84

1.00

143.0

4.74

2.32

1.36

265.7 4 1.83

1.42

0.39

22.1

3.04

1.87

0.65

61.2

2.96

1.95

0.64

58.3

3.34

1.78

0.72

74.1

4.59

2.24

0.99

140.0

5

1.69

1.35

0.29

12.1

2.89

1.80

0.50

35.5

2.83

1.90

0.49

34.1

3.21

1.71

0.55

43.7

4.44

2.16

0.76

83.8

6

1.51

1.29

0.22

6.8

2.75

1.75

0.39

22.3

2.69

1.83

0.39

21.3

3.05

1.63

0.44

27.4

4.33

2.09

0.62

55.2 7 1.33

1.20

0.16

3.8

2.61

1.67

0.32

14.7

2.54

1.78

0.31

14.0

2.91

1.56

0.36

18.4

4.17

2.05

0.51

37.8 7 3

1.76

1.40

0.50

36.5

2.95

1.84

0.85

102.9

2.89

1.94

0.83

98.5

3.28

1.75

0.94

126.6

4.52

2.20

1.29

240.8

4

1.61

1.34

0.35

17.3

2.83

1.78

0.61

53.2

2.76

1.87

0.59

50.4

3.15

1.69

0.68

65.7

4.40

2.16

0.95

128.7

5

1.46

1.28

0.25

9.0

2.69

1.72

0.46

30.7

2.63

1.81

0.45

29.4

2.99

1.62

0.52

38.1

4.25

2.09

0.73

76.8 6 1.28

1.21

0.18

4.9

2.55

1.67

0.36

19.1

2.50

1.75

0.36

18.5

2.86

1.55

0.41

24.1

4.14

2.01

0.59

50.5 7 1.11

1.11

0.14

2.7

2.41

1.59

0.30

12.6

2.33

1.69

0.29

11.8

2.71

1.48

0.33

15.9

3.98

1.94

0.49

34.4

8

3

1.54

1.32

0.44

28.0

2.75

1.76

0.79

89.4

2.69

1.85

0.77

85.2

3.08

1.65

0.88

111.8

4.33

2.13

1.24

221.0

4

1.39

1.28

0.30

12.8

2.63

1.70

0.57

45.9

2.55

1.81

0.55

43.2

2.93

1.60

0.63

57.0

4.17

2.05

0.90

115.7 5 1.23

1.20

0.21

6.4

2.50

1.63

0.43

26.5

2.42

1.73

0.42

24.9

2.80

1.54

0.48

33.4

4.06

1.97

0.70

70.1 6 1.10

1.10

0.16

3.6

2.33

1.58

0.33

16.1

2.29

1.67

0.33

15.5

2.66

1.46

0.38

21.0

3.91

1.94

0.56

45.1

7

0.96

0.96

0.12

2.0

2.20

1.51

0.27

10.5

2.13

1.61

0.26

9.8

2.49

1.40

0.31

13.5

3.77

1.86

0.46

30.9

9

3

1.32

1.25

0.38

20.5

2.56

1.69

0.73

77.2

2.49

1.77

0.71

73.0

2.87

1.57

0.82

97.4

4.14

2.05

1.19

202.0 4 1.20

1.20

0.26

9.5

2.41

1.62

0.52

38.7

2.34

1.72

0.50

36.4

2.72

1.51

0.59

49.3

3.98

1.97

0.86

105.5 5 1.10

1.07

0.19

5.2

2.28

1.56

0.39

22.2

2.21

1.66

0.38

20.8

2.59

1.45

0.45

28.6

3.87

1.90

0.67

63.7

6

0.97

0.97

0.14

2.8

2.13

1.50

0.31

13.4

2.06

1.61

0.29

12.5

2.46

1.38

0.35

17.8

3.71

1.86

0.53

40.6

7

0.79

0.79

0.10

1.4

1.97

1.43

0.24

8.4

1.91

1.53

0.23

7.9

2.28

1.32

0.28

11.3

3.58

1.79

0.44

27.8

10

3

1.16

1.16

0.33

15.9

2.35

1.60

0.67

64.9

2.25

1.70

0.65

59.8

2.67

1.49

0.77

84.3

3.95

1.94

1.13

183.9 4 1.07

1.07

0.23

7.6

2.20

1.54

0.47

32.2

2.13

1.65

0.46

30.0

2.52

1.43

0.54

42.0

3.78

1.90

0.81

95.1

5

0.95

0.95

0.16

3.9

2.06

1.49

0.35

18.0

1.97

1.59

0.34

16.5

2.38

1.37

0.41

24.1

3.67

1.83

0.63

57.1

6

0.82

0.82

0.12

2.0

1.92

1.42

0.27

10.8

1.83

1.53

0.26

9.9

2.23

1.30

0.32

14.6

3.51

1.78

0.50

36.3 7 0.52

0.52

0.06

0.6

1.75

1.36

0.21

6.6

1.67

1.48

0.20

6.0

2.08

1.23

0.26

9.4

3.35

1.71

0.41

24.4

11

3

1.02

1.02

0.29

12.4

2.12

1.53

0.61

52.9

2.04

1.62

0.59

49.2

2.46

1.41

0.70

71.2

3.72

1.86

1.07

163.7

4

0.94

0.94

0.20

5.8

1.98

1.47

0.43

26.2

1.91

1.56

0.41

24.1

2.32

1.35

0.50

35.7

3.57

1.81

0.77

84.7

5

0.81

0.81

0.14

2.8

1.83

1.42

0.32

14.3

1.75

1.53

0.30

13.0

2.17

1.29

0.37

20.0

3.46

1.75

0.59

50.8 6 0.65

0.65

0.09

1.2

1.67

1.36

0.24

8.2

1.61

1.46

0.23

7.6

2.01

1.22

0.29

11.9

3.30

1.70

0.47

32.1 7 0.44

0.44

0.05

0.4

1.49

1.31

0.18

4.8

1.43

1.43

0.18

4.5

1.85

1.15

0.23

7.4

3.15

1.63

0.39

21.5

12

3

0.90

0.90

0.26

9.6

1.89

1.45

0.54

42.3

1.80

1.57

0.52

38.4

2.23

1.33

0.64

58.8

3.51

1.79

1.01

145.8

4

0.80

0.80

0.17

4.2

1.75

1.40

0.38

20.4

1.67

1.51

0.36

18.4

2.10

1.27

0.45

29.3

3.37

1.73

0.72

75.3 5 0.69

0.69

0.12

2.0

1.60

1.35

0.28

10.9

1.52

1.46

0.26

9.8

1.95

1.21

0.33

16.1

3.24

1.67

0.56

44.5 6 0.41

0.41

0.06

0.5

1.42

1.31

0.20

6.0

1.41

1.38

0.20

5.9

1.78

1.15

0.26

9.4

3.08

1.62

0.44

28.0

7

0.34

0.34

0.04

0.3

1.26

1.26

0.15

3.4

1.30

1.30

0.16

3.7

1.62

1.08

0.20

5.7

2.93

1.56

0.36

18.6

13

3

0.78

0.78

0.22

7.1

1.65

1.39

0.47

32.3

1.56

1.51

0.45

28.7

2.01

1.26

0.58

47.8

3.29

1.72

0.94

127.8 4 0.66

0.66

0.14

2.9

1.51

1.34

0.33

15.2

1.46

1.43

0.31

14.2

1.87

1.20

0.40

23.2

3.15

1.65

0.68

65.9 5 0.48

0.48

0.08

1.0

1.35

1.32

0.23

7.8

1.37

1.37

0.23

7.9

1.72

1.14

0.30

12.6

3.01

1.59

0.52

38.5

6

0.32

0.32

0.05

0.3

1.23

1.23

0.18

4.5

1.27

1.27

0.18

4.8

1.55

1.08

0.22

7.1

2.85

1.55

0.41

24.0

7

0.24

0.24

0.03

0.1

1.12

1.12

0.14

2.7

1.17

1.17

0.14

3.0

1.36

1.02

0.17

4.0

2.71

1.48

0.33

15.9

Hydronic Highwall

10 Capacity Tables

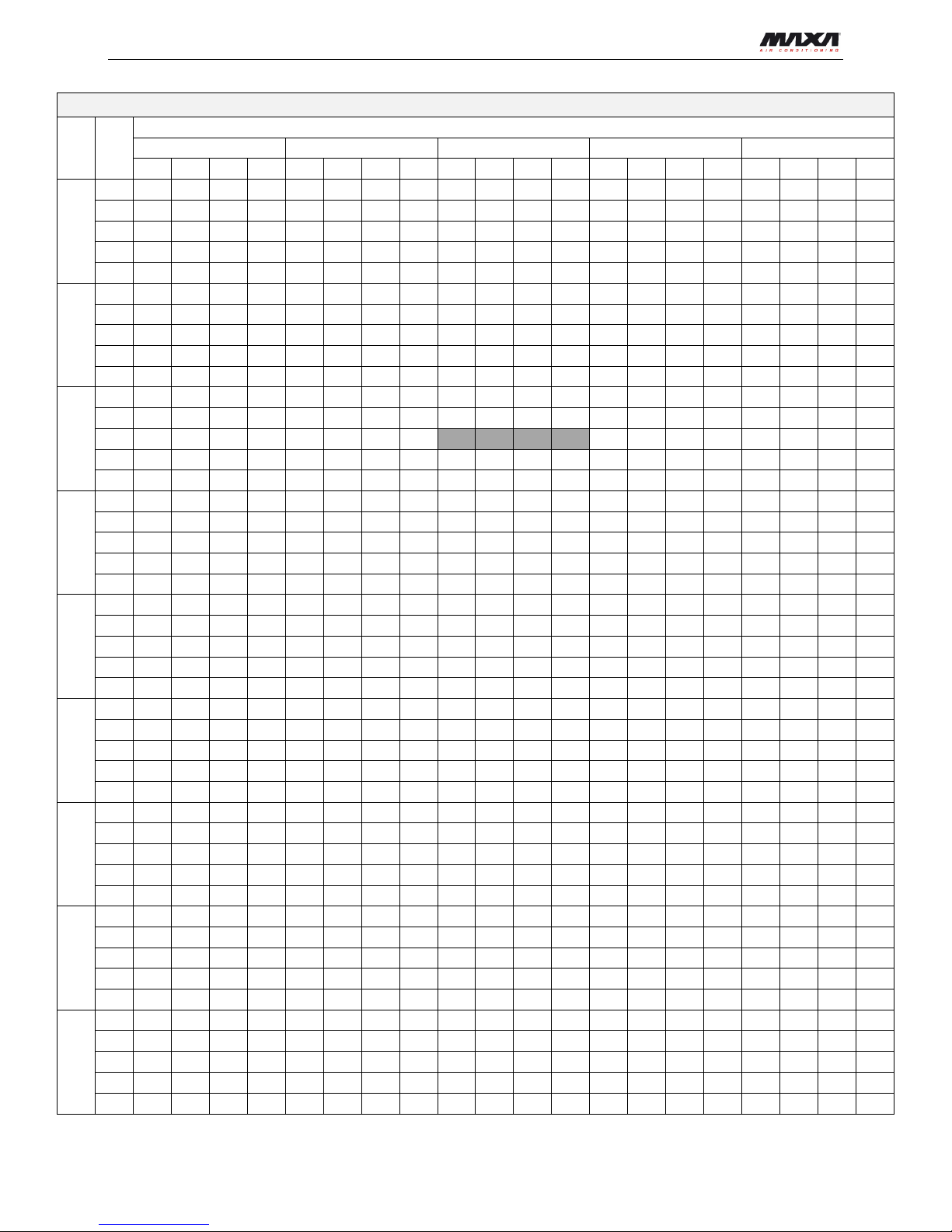

Cooling capacity table

MI35A

EWT Δt

Air inlet condition

DB:21 WB:15 DB:26.7 WB:19.4 DB:27 WB:19 DB:29 WB:21 DB:33 WB:25

TC SC WF WPD TC SC WF WPD TC SC WF WPD TC SC WF WPD TC SC WF WPD

5

3 2.71 1.97 0.78 82.6 4.18 2.52 1.20 196.2 4.09 2.63 1.17 188.3 4.57 2.40 1.31 234.8 6.15 2.98 1.76 425.2

4 2.55 1.86 0.55 41.1 4.02 2.44 0.86 102.0 3.95 2.55 0.85 98.7 4.39 2.32 0.94 121.9 5.96 2.89 1.28 224.7

5 2.36 1.78 0.41 22.5 3.84 2.36 0.66 59.7 3.77 2.47 0.65 57.4 4.22 3.65 0.73 72.1 5.77 2.84 0.99 134.8

6 2.15 1.70 0.31 13.0 3.67 2.29 0.53 37.9 3.60 2.39 0.52 36.4 4.04 2.15 0.58 45.8 5.63 2.75 0.81 89.1

7 1.93 1.60 0.24 7.7 3.49 2.18 0.43 25.2 3.41 2.30 0.42 24.0 3.87 2.06 0.48 30.8 5.44 2.65 0.67 61.1

6

3 2.45 1.86 0.70 67.5 3.94 2.42 1.13 174.6 3.85 2.52 1.10 166.7 4.34 2.29 1.24 211.6 5.92 2.89 1.70 393.1

4 2.28 1.77 0.49 32.7 3.79 2.33 0.81 90.6 3.70 2.44 0.79 86.3 4.17 2.22 0.90 109.6 5.73 2.79 1.23 207.2

5 2.10 1.68 0.36 17.9 3.60 2.25 0.62 52.5 3.53 2.37 0.61 50.4 4.00 2.13 0.69 64.7 5.54 2.70 0.95 124.0

6 1.89 1.61 0.27 10.0 3.43 2.18 0.49 33.1 3.35 2.28 0.48 31.5 3.80 2.04 0.54 40.6 5.40 2.60 0.77 81.7

7 1.66 1.50 0.20 5.7 3.25 2.08 0.40 21.8 3.17 2.22 0.39 20.7 3.63 1.95 0.45 27.2 5.21 2.56 0.64 55.9

7

3 2.19 1.74 0.63 53.9 3.68 2.30 1.06 152.3 3.60 2.42 1.03 145.7 4.08 2.18 1.17 187.4 5.63 2.75 1.61 356.3

4 2.01 1.68 0.43 25.6 3.53 2.22 0.76 78.8 3.44 2.34 0.74 74.6 3.92 2.11 0.84 97.3 5.49 2.70 1.18 190.4

5 1.82 1.60 0.31 13.4 3.35 2.14 0.58 45.4 3.28 2.26 0.56 43.5 3.73 2.02 0.64 56.4 5.30 2.60 0.91 113.6

6 1.60 1.51 0.23 7.2 3.18 2.08 0.46 28.3 3.12 2.18 0.45 27.3 3.56 1.93 0.51 35.7 5.16 2.51 0.74 74.7

7 1.39 1.39 0.17 4.0 3.01 1.98 0.37 18.6 2.91 2.11 0.36 17.4 3.37 1.85 0.41 23.5 4.97 2.41 0.61 51.0

8

3 1.92 1.65 0.55 41.5 3.43 2.20 0.98 132.3 3.35 2.30 0.96 126.1 3.84 2.06 1.10 165.5 5.40 2.65 1.55 327.0

4 1.73 1.60 0.37 19.0 3.28 2.13 0.71 68.0 3.18 2.25 0.68 63.9 3.65 2.00 0.79 84.3 5.21 2.56 1.12 171.2

5 1.53 1.50 0.26 9.5 3.11 2.04 0.54 39.2 3.02 2.16 0.52 36.9 3.50 1.92 0.60 49.5 5.06 2.46 0.87 103.7

6 1.38 1.38 0.20 5.3 2.91 1.97 0.42 23.8 2.85 2.08 0.41 22.9 3.32 1.83 0.48 31.0 4.88 2.41 0.70 66.7

7 1.20 1.20 0.15 3.0 2.74 1.88 0.34 15.5 2.66 2.01 0.33 14.5 3.11 1.75 0.38 19.9 4.70 2.32 0.58 45.7

9

3 1.64 1.56 0.47 30.3 3.19 2.10 0.91 114.3 3.10 2.21 0.89 107.9 3.58 1.96 1.03 144.2 5.16 2.56 1.48 298.9

4 1.49 1.49 0.32 14.0 3.01 2.03 0.65 57.2 2.92 2.14 0.63 53.9 3.40 1.89 0.73 73.0 4.97 2.46 1.07 156.0

5

1.38

1.33

0.24

7.7

2.85

1.94

0.49

32.8

2.76

2.07

0.47

30.8

3.23

1.80

0.56

42.3

4.83

2.37

0.83

94.2

6 1.21 1.21 0.17 4.1 2.66 1.87 0.38 19.9 2.57 2.00 0.37 18.5 3.06 1.72 0.44 26.3 4.62 2.31 0.66 60.0

7 0.98 0.98 0.12 2.0 2.46 1.78 0.30 12.5 2.38 1.91 0.29 11.6 2.85 1.64 0.35 16.7 4.47 2.23 0.55 41.2

10

3 1.45 1.45 0.42 23.6 2.93 1.99 0.84 96.1 2.81 2.13 0.80 88.5 3.33 1.86 0.96 124.7 4.92 2.41 1.41 272.1

4 1.33 1.33 0.29 11.2 2.75 1.92 0.59 47.6 2.65 2.05 0.57 44.4 3.14 1.78 0.67 62.2 4.72 2.37 1.01 140.7

5 1.19 1.19 0.20 5.7 2.57 1.86 0.44 26.6 2.46 1.99 0.42 24.4 2.97 1.70 0.51 35.7 4.57 2.28 0.79 84.5

6 1.02 1.02 0.15 2.9 2.39 1.77 0.34 16.0 2.28 1.91 0.33 14.6 2.78 1.62 0.40 21.7 4.37 2.22 0.63 53.7

7 0.65 0.65 0.08 0.9 2.18 1.70 0.27 9.8 2.08 1.84 0.26 8.9 2.60 1.54 0.32 13.9 4.18 2.13 0.51 36.0

11

3 1.28 1.28 0.37 18.3 2.64 1.90 0.76 78.3 2.55 2.03 0.73 72.8 3.06 1.76 0.88 105.3 4.64 2.32 1.33 242.1

4 1.17 1.17 0.25 8.6 2.48 1.84 0.53 38.7 2.38 1.95 0.51 35.7 2.89 1.68 0.62 52.8 4.45 2.26 0.96 125.3

5 1.01 1.01 0.17 4.1 2.29 1.77 0.39 21.1 2.18 1.90 0.38 19.2 2.70 1.60 0.46 29.5 4.31 2.18 0.74 75.2

6 0.80 0.80 0.12 1.8 2.08 1.69 0.30 12.2 2.00 1.82 0.29 11.3 2.51 1.52 0.36 17.7 4.11 2.13 0.59 47.5

7 0.54 0.54 0.07 0.6 1.86 1.63 0.23 7.1 1.79 1.79 0.22 6.6 2.31 1.43 0.28 11.0 3.92 2.04 0.48 31.8

12

3 1.13 1.13 0.32 14.3 2.36 1.81 0.68 62.7 2.25 1.95 0.64 56.8 2.78 1.66 0.80 87.0 4.38 2.23 1.26 215.7

4 0.99 0.99 0.21 6.2 2.19 1.75 0.47 30.2 2.08 1.89 0.45 27.3 2.62 1.59 0.56 43.3 4.20 2.16 0.90 111.3

5

0.86

0.86

0.15

3.0

2.00

1.69

0.34

16.1

1.89

1.83

0.33

14.5

2.43

1.51

0.42

23.8

4.04

2.08

0.69

65.9

6 0.52 0.52 0.07 0.7 1.77 1.63 0.25 8.8 1.76 1.72 0.25 8.7 2.22 1.43 0.32 13.9 3.84 2.03 0.55 41.5

7 0.43 0.43 0.05 0.4 1.57 1.57 0.19 5.1 1.62 1.62 0.20 5.4 2.02 1.34 0.25 8.4 3.65 1.95 0.45 27.5

13

3 0.97 0.97 0.28 10.6 2.06 1.73 0.59 47.8 1.95 1.88 0.56 42.5 2.51 1.57 0.72 70.7 4.10 2.14 1.18 189.1

4 0.83 0.83 0.18 4.3 1.89 1.67 0.41 22.5 1.82 1.79 0.39 21.0 2.33 1.49 0.50 34.3 3.93 2.06 0.84 97.5

5 0.60 0.60 0.10 1.4 1.68 1.65 0.29 11.5 1.70 1.70 0.29 11.7 2.14 1.42 0.37 18.6 3.75 1.98 0.65 57.0

6 0.40 0.40 0.06 0.4 1.53 1.53 0.22 6.6 1.59 1.59 0.23 7.1 1.94 1.34 0.28 10.5 3.56 1.93 0.51 35.6

7 0.29 0.29 0.04 0.2 1.40 1.40 0.17 4.0 1.46 1.46 0.18 4.4 1.69 1.27 0.21 5.9 3.37 1.85 0.41 23.5

Hydronic Highwall

Capacity Tables 11

Cooling capacity table

MI53A

EWT Δt

Air inlet condition

DB:21 WB:15 DB:26.7 WB:19.4 DB:27 WB:19 DB:29 WB:21 DB:33 WB:25

TC SC WF WPD TC SC WF WPD TC SC WF WPD TC SC WF WPD TC SC WF WPD

5

3 3.51 2.55 1.01 60.4 5.42 3.26 1.55 143.4 5.30 3.40 1.52 137.6 5.92 3.11 1.70 171.6 7.97 3.86 2.29 310.8

4 3.31 2.41 0.71 30.1 5.21 3.16 1.12 74.6 5.12 3.31 1.10 72.1 5.69 3.01 1.22 89.1 7.73 3.74 1.66 164.3

5 3.05 2.31 0.53 16.4 4.98 3.05 0.86 43.7 4.88 3.20 0.84 42.0 5.47 4.73 0.94 52.7 7.48 3.68 1.29 98.6

6 2.79 2.21 0.40 9.5 4.76 2.97 0.68 27.7 4.67 3.09 0.67 26.6 5.23 2.78 0.75 33.5 7.30 3.56 1.05 65.1

7 2.50 2.07 0.31 5.6 4.53 2.83 0.56 18.4 4.42 2.99 0.54 17.6 5.01 2.67 0.62 22.6 7.05 3.43 0.87 44.7

6

3 3.18 2.40 0.91 49.4 5.11 3.13 1.46 127.6 4.99 3.27 1.43 121.9 5.62 2.97 1.61 154.7 7.67 3.74 2.20 287.4

4 2.95 2.29 0.63 23.9 4.91 3.02 1.05 66.2 4.79 3.16 1.03 63.1 5.40 2.87 1.16 80.1 7.42 3.62 1.60 151.5

5 2.72 2.18 0.47 13.1 4.67 2.91 0.80 38.3 4.58 3.07 0.79 36.9 5.18 2.76 0.89 47.3 7.18 3.50 1.23 90.6

6 2.45 2.09 0.35 7.3 4.45 2.83 0.64 24.2 4.34 2.95 0.62 23.0 4.92 2.64 0.71 29.7 6.99 3.37 1.00 59.8

7 2.15 1.94 0.26 4.2 4.21 2.70 0.52 15.9 4.11 2.87 0.50 15.2 4.70 2.53 0.58 19.9 6.75 3.31 0.83 40.9

7

3 2.84 2.26 0.81 39.4 4.77 2.98 1.37 111.3 4.67 3.13 1.34 106.5 5.29 2.82 1.52 137.0 7.30 3.56 2.09 260.5

4 2.61 2.17 0.56 18.7 4.58 2.88 0.98 57.6 4.45 3.03 0.96 54.5 5.08 2.73 1.09 71.1 7.11 3.50 1.53 139.2

5 2.35 2.07 0.41 9.8 4.34 2.77 0.75 33.2 4.25 2.93 0.73 31.8 4.84 2.62 0.83 41.2 6.87 3.37 1.18 83.1

6 2.07 1.96 0.30 5.3 4.12 2.69 0.59 20.7 4.04 2.82 0.58 20.0 4.62 2.50 0.66 26.1 6.68 3.25 0.96 54.6

7 1.80 1.80 0.22 2.9 3.89 2.57 0.48 13.6 3.77 2.74 0.46 12.7 4.37 2.40 0.54 17.2 6.44 3.13 0.79 37.2

8

3 2.49 2.14 0.71 30.3 4.45 2.85 1.27 96.7 4.34 2.99 1.24 92.2 4.97 2.67 1.43 121.0 6.99 3.43 2.00 239.0

4 2.24 2.07 0.48 13.9 4.25 2.75 0.91 49.7 4.12 2.92 0.89 46.7 4.73 2.59 1.02 61.7 6.75 3.31 1.45 125.2

5 1.99 1.94 0.34 7.0 4.04 2.64 0.69 28.7 3.91 2.80 0.67 27.0 4.53 2.48 0.78 36.2 6.56 3.19 1.13 75.8

6 1.78 1.78 0.26 3.9 3.77 2.56 0.54 17.4 3.70 2.70 0.53 16.7 4.31 2.37 0.62 22.7 6.32 3.13 0.91 48.8

7 1.56 1.56 0.19 2.2 3.55 2.44 0.44 11.3 3.44 2.61 0.42 10.6 4.03 2.27 0.50 14.6 6.10 3.01 0.75 33.4

9

3 2.13 2.02 0.61 22.1 4.13 2.72 1.18 83.6 4.02 2.86 1.15 78.9 4.64 2.54 1.33 105.4 6.68 3.31 1.92 218.5

4 1.93 1.93 0.42 10.3 3.90 2.62 0.84 41.8 3.78 2.77 0.81 39.4 4.40 2.45 0.95 53.3 6.44 3.19 1.38 114.1

5

1.78

1.73

0.31

5.6

3.69

2.51

0.64

24.0

3.58

2.68

0.61

22.5

4.19

2.34

0.72

30.9

6.26

3.07

1.08

68.9

6 1.56 1.56 0.22 3.0 3.45 2.42 0.49 14.5 3.32 2.59 0.48 13.5 3.97 2.23 0.57 19.2 5.99 3.00 0.86 43.9

7 1.28 1.28 0.16 1.5 3.19 2.31 0.39 9.1 3.08 2.48 0.38 8.5 3.69 2.13 0.45 12.2 5.79 2.89 0.71 30.1

10

3 1.88 1.88 0.54 17.2 3.79 2.58 1.09 70.2 3.64 2.75 1.04 64.7 4.32 2.40 1.24 91.2 6.38 3.13 1.83 198.9

4 1.72 1.72 0.37 8.2 3.56 2.48 0.76 34.8 3.43 2.66 0.74 32.4 4.07 2.31 0.87 45.5 6.11 3.07 1.31 102.8

5 1.54 1.54 0.26 4.2 3.32 2.40 0.57 19.5 3.18 2.58 0.55 17.8 3.85 2.21 0.66 26.1 5.92 2.96 1.02 61.8

6 1.32 1.32 0.19 2.1 3.10 2.30 0.44 11.7 2.96 2.48 0.42 10.7 3.60 2.10 0.52 15.8 5.67 2.88 0.81 39.3

7 0.84 0.84 0.10 0.6 2.83 2.20 0.35 7.2 2.69 2.39 0.33 6.5 3.37 1.99 0.41 10.2 5.42 2.76 0.67 26.3

11

3 1.66 1.66 0.47 13.4 3.42 2.47 0.98 57.3 3.30 2.62 0.95 53.2 3.97 2.28 1.14 77.0 6.02 3.01 1.72 177.0

4 1.51 1.51 0.33 6.3 3.21 2.38 0.69 28.3 3.08 2.53 0.66 26.1 3.75 2.18 0.81 38.6 5.77 2.93 1.24 91.6

5 1.31 1.31 0.23 3.0 2.96 2.29 0.51 15.4 2.83 2.47 0.49 14.1 3.50 2.08 0.60 21.6 5.59 2.83 0.96 55.0

6 1.04 1.04 0.15 1.3 2.70 2.20 0.39 8.9 2.59 2.35 0.37 8.2 3.25 1.97 0.47 12.9 5.33 2.75 0.76 34.7

7 0.71 0.71 0.09 0.4 2.40 2.12 0.30 5.2 2.32 2.32 0.28 4.8 2.99 1.86 0.37 8.0 5.08 2.64 0.62 23.2

12

3 1.46 1.46 0.42 10.4 3.06 2.35 0.88 45.8 2.91 2.53 0.84 41.5 3.61 2.15 1.03 63.6 5.68 2.89 1.63 157.7

4 1.29 1.29 0.28 4.6 2.83 2.27 0.61 22.1 2.69 2.45 0.58 19.9 3.39 2.05 0.73 31.6 5.44 2.80 1.17 81.4

5

1.11

1.11

0.19

2.2

2.59

2.19

0.45

11.8

2.45

2.37

0.42

10.6

3.15

1.96

0.54

17.4

5.23

2.70

0.90

48.2

6 0.67 0.67 0.10 0.5 2.30 2.12 0.33 6.5 2.28 2.23 0.33 6.3 2.88 1.85 0.41 10.2 4.98 2.62 0.71 30.3

7 0.55 0.55 0.07 0.3 2.04 2.04 0.25 3.7 2.10 2.10 0.26 4.0 2.62 1.74 0.32 6.2 4.73 2.52 0.58 20.1

13

3 1.26 1.26 0.36 7.7 2.67 2.24 0.77 35.0 2.52 2.43 0.72 31.1 3.25 2.03 0.93 51.7 5.32 2.78 1.52 138.3

4 1.07 1.07 0.23 3.2 2.45 2.16 0.53 16.5 2.36 2.32 0.51 15.3 3.02 1.93 0.65 25.0 5.09 2.67 1.09 71.3

5 0.77 0.77 0.13 1.1 2.18 2.13 0.38 8.4 2.21 2.21 0.38 8.6 2.78 1.84 0.48 13.6 4.86 2.57 0.84 41.6

6 0.52 0.52 0.07 0.3 1.99 1.99 0.28 4.8 2.05 2.05 0.29 5.2 2.51 1.74 0.36 7.7 4.61 2.50 0.66 26.0

7 0.38 0.38 0.05 0.1 1.82 1.82 0.22 3.0 1.89 1.89 0.23 3.2 2.20 1.64 0.27 4.3 4.37 2.40 0.54 17.2

Hydronic Highwall

12 Capacity Tables

Cooling capacity modification coefficient table:

Speed

MI26A

MI35A

MI42A

TC SC TC SC TC SC

High 1 1 1 1 1 1

Mid

0.92

0.9

0.86

0.83

0.91

0.86

Low

0.82

0.8

0.73

0.7

0.78

0.75

Heating Capacity:

Remark:

Δt: Temperature Difference (℃) ; TH: Total Heating Capacity (kW);

WF: Water Flow (m

3

/h); WPD: Water Pressure Drop (kPa)

MI26A

Δt

Air inlet temp. (20℃ DB)

Water in let temp. (℃)

35 40 45 50 55 60 65 70

TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD

10

1.15

0.10

1.2 1.80

0.15

2.8 2.49

0.21

5.4 3.14

0.27

8.7 3.80

0.33

12.6 4.46

0.38

17.5 5.11

0.44

22.9 5.75

0.49

29.0

8

1.27

0.14

2.2 1.98

0.21

5.4 2.65

0.28

9.6 3.31

0.36

15.0 3.94

0.42

21.3 4.58

0.49

28.8 5.23

0.56

37.4 5.87

0.63

47.2

6

1.47

0.21

5.3 2.14

0.31

11.2 2.78

0.40

18.8 3.45

0.49

29.0 4.10

0.59

41.0 4.74

0.68

54.9 5.35

0.77

69.7 6.03

0.86

88.6

MI35A

Δt

Air inlet temp. (20℃ DB)

Water in let temp. (℃)

35 40 45 50 55 60 65 70

TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD

10

1.49

0.13

2.1 2.34

0.20

5.1 3.25

0.28

9.7 4.10

0.35

15.5 4.95

0.43

22.7 5.82

0.50

31.3 6.66

0.57

41.0 7.50

0.65

52.0

8

1.66

0.18

4.0 2.58

0.28

9.6 3.46

0.37

17.3 4.31

0.46

26.8 5.14

0.55

38.2 5.98

0.64

51.6 6.82

0.73

67.1 7.66

0.82

84.7

6

1.92

0.28

9.5 2.80

0.40

20.1 3.62

0.52

33.7 4.50

0.65

52.0 5.35

0.77

73.5 6.19

0.89

98.4 6.98

1.00

124.9 7.87

1.13

158.9

MI42A

Δt

Air inlet temp. (20℃ DB)

Water in let temp. (℃)

35 40 45 50 55 60 65 70

TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD TH WF WPD

10

1.99

0.17

1.6 3.13

0.27

3.9 4.33

0.37

7.5 5.46

0.47

11.9 6.60

0.57

17.4 7.76

0.67

24.1 8.88

0.76

31.5

10.00

0.86

40.0

8

2.21

0.24

3.1 3.44

0.37

7.4 4.61

0.50

13.3 5.75

0.62

20.7 6.85

0.74

29.4 7.97

0.86

39.7 9.09

0.98

51.7

10.21

1.10

65.1

6

2.56

0.37

7.3 3.73

0.53

15.4 4.83

0.69

25.9 6.00

0.86

40.0 7.13

1.02

56.5 8.25

1.18

75.7 9.30

1.33

96.1

10.49

1.50

122.3

Heating capacity modification coefficient table :

Speed

MI26A

MI35A

MI42A

TH TH TH

High 1 1

1

Mid

0.92

0.85

0.89

Low

0.83

0.73

0.76

Hydronic Highwall

Sound Levels 13

Altitude modification coefficient table:

Altitude (m)

TC

SC

TH

500

0.98

0.95

0.95

1000

0.97

0.91

0.91

1500

0.95

0.86

0.86

2000

0.94

0.82

0.82

2500

0.93

0.78

0.78

3000

0.91

0.74

0.7

11. Sound Levels

Test condition

Unit Number Model

Sound pressure level under three speeds of fan (dB(A))

H M L

1 MI26A 30 24 20

3 MI35A 37 31 26

4 MI53A 39 33 28

Hydronic Highwall

14 Ex ploded V iew

12. Exploded View

MI26A MI35A

No. Part Name Quantity

No. Part Name Quantity

1 Filter 2 14 Louver 1

2 Evaporator I 1 15 Panel dalle 1

3 Evaporator II 1 16 Panel 1

4 Evaporator Ⅲ 1 17 Panel frame ass'y 1

5 Coil temp sensor 1 18 Stepper motor 2

6 Evaporate connect board 1 19 Screw cover 3

7 Display board ass'y 1 20 Pipe clamp 1

8 Motor 1 21 Drainage pan 1

9 Base pan assembly 1 22 Bearing base 1

10 Motor spud 2 23 Evaporator left clapboard 1

11 E-part box ass'y 1 24 W ater inlet pip e ass'y 1

11.1 Dial code switch box cover 1 25 Water outlet pipe ass'y 1

11.2 Electric control box seat 1 26 Three-way valve 1

11.3 E-Part box cover 1 27 Control wire for 3-Ways valve 1

11.4 Electric control box soleplate 1 28 Outlet screw pipe ass'y 1

11.5 Electric control box side board ass'y 1 29 Inlet screw pipe ass'y 1

11.6 Dial code switch board ass'y 1 30 Discharge valve 1

11.7 Main controller ass'y 1 31 Cross fan 1

11.8 Transformer 1 32 Base pan holder 1

11.9 Wire joint 1 33 Formaldehyde killer 1

11.10 Wire joint, 3p 1 34 Room Temperature Sensor Ass'y 1

11.11 Motor capacitor 1 35 Network matching wire 1

12 Air outlet frame mount ass'y 1 36 Remote controller 1

13 Louver board 1 37 Remote controller holder ass'y 1

Hydronic Highwall

Exploded View 15

MI53A

No. Part Name Quantity

No. Part Name Quantity

1 Filter 2 14 Air outlet frame mount ass'y 1

2 Evaporator I 1 15 Louver board 1

3 Evaporator II 1 16 Louver 1

4 Evaporator Ⅲ 1 17 Panel dalle 1

5 Coil temp sensor 1 18 Panel 1

6 Evaporate connect board 1 19 Stepper motor 2

7 Cross fan 1 20 Screw cover 3

8 Display board ass'y 1 21 Pipe clamp 1

9 Motor 1 22 Drainage pan 1

10 Base pan assembly 1 23 Bearing base 1

11 Motor spud 2 24 Water inlet pipe ass'y 1

12 Panel frame ass'y 1 25 Water outlet pip e ass'y 1

13 E-part box ass'y 1 26 Three-way valve 1

13.1 Dial code switch box cover 1 27 Control wire for 3-Ways valve 1

13.2 Electric control box seat 1 28 Outlet screw pipe ass'y 1

13.3 E-Part box cover 1 29 Inlet screw pipe ass'y 1

13.4 Electric control box soleplate 1 30 Discharge valve 1

13.5 Electric control box side board ass'y

1 31 Evaporator left clapboard 1

13.6 Dial code switch board ass'y 1 32 Base pan holder 1

13.7 Main controller ass'y 1 33 Formaldehyde killer 1

13.8 Transformer 1 34 Room Temperature Sensor Ass'y

1

13.9 Motor capacitor 1 35 Network matching wire 1

13.10 Wire joint, 3p 1 36 Remote controller 1

13.11 Wire joint 1 37 Remote controller holder ass'y 1

Hydronic Highwall

16 Installation

13. Installation

13.1 Precautions

Be sure to be in conformity with the local, national and international laws and regulations.

Read "PRECAUTIONS" c ar ef ul ly before installation.

The following precautions include important safty it ems. O bserve them and never forget.

Keep the installation manual in a handy place for future refere nce.

Before out from factory, FAN COIL UNIT ( AIR UNITS) has passed Fan Co il Overpressure Resi stant Test,

Statically and Dynamically Balanced Adjustment, Noise Test, Air (cool) Volume Test, Electric Property

Test, Outline Quality Detection.

The safety precautions listed here are divided into two categories. In either case, important safety

information is listed which mu st be r ead carefully.

Warning: Failure to observe a warning may result in death.

Caution: Failure to observe a caution may resu lt in injury or damage to the equipment.

After completing the installation, make sure that the unit operates properly during the start-up operation.

Please instruct the custo mer on how to operate the unit and keep it maintained.

Warning:

Be sure only trained and qualified service personnel to install, repair or service the equipment.

Improper installation, repair, and maintenance may result in electric shocks, short-circuit, leaks, fire or

other damage to the equipme nt .

Install according to the installation instructions strictly.

If installation is defective, it will cause water leakage, electrical shock and fire.

When installing the unit in a small room, take measures against to keep refrigerant concentration

from exceeding allowable safety limits in the event of refrigerant leakage.

Contact the place of purchase for more information. Excessive refrigerant in a closed ambient can lead

to oxygen deficiency.

Use the attached accessories parts and specified parts for installation.

Otherwise, it will cause the s et t o fall, w at er leakage, electrical shock and fire.

The appliance must be installed 2.3m above floor.

The appliance shall not be installed in the laundry.

Before obtaining access to terminals, all supply circuits must be disconnected.

The appliance must be positioned so that the plug is accessible.

The enclosure of the appliance shall be marked by word, or by symbols, with the direction of the

fluid flow.

For electrical work, follow the local national wiring standard, regulation the installation

instructions. An independent circuit and single outlet must be used.

If electrical circuit capacity is not enough or defect in electr i cal w ork, it will cause electrical shock fire.

Use the specified cable and connect tightly and clamp the cable so that no external force will be

acted on the terminal.

If connection or fixing is not per fe ct , it will cause heat-up or fire at t he connection.

Wiring routing must be properly arranged so that control board cover is fixed properly.

If control board cover is not fixed perfectly, it will cause heat-up at connection point of terminal, fire or

electrical shock.

If the supply cord is damaged, it must be replaced by the manufacture or its service agent or a

similarly qualified person in order to avoid a hazard.

An all-pole disconnection switch having a contact separation of at least 3mm in all poles should

be connected in fixed wiring.

Hydronic Highwall

Installation 17

When carrying out piping connection, take care not to let air substances go into refrigeration

cycle.

Otherwise, it will cause lower capacity, abnormal high pr essure in the refrigeration cy cl e.

Do not modify the length of the power supply cord or use of extension cord, and do not share

the single outlet with other electrical appliances.

Otherwise, it will cause fire or electrical shock.

If the water leaks during installation, ventilate the area immediately.

After completing the installation work, check that the water does not leak.

The cool water in the unit is not lower than 3 ℃, hot wat er is not higher than 70℃. Water in the unit must

clean, air quality must meet t o the standard of PH=6.5~7.5.

Caution:

Ground the air conditioner.

Do not connect the ground wire to gas or wat er pipes , lightnin g rod or te lephone gr ound wire.I ncompl ete

grounding may result in elect r ic shocks.

Be sure to install an earth leakage breaker.

Failure to install an earth lea kage br eaker may result in electric shocks.

Connect the outdoor unit wires, and then connect the indoor unit wires.

You are not allowed to connect the air conditioner with the power source until wiring and piping the air

conditioner is done.

While following the installation instructions, install drain piping in order to ensure proper

drainage and insulate piping in order to prevent condensation.

Improper drain piping may result in water leakage and property damage.

Install the indoor and outdoor units, power supply wiring and connecting wires at least 1 meter

away from televisions or radios in order to prevent image interference or noise.

Depending on the radio w aves, a distance of 1 meter may not b e sufficient enough to elimin ate the noise.

This appliance is not intended for use by persons (including children) with reduced

physical,sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the appliance by a person responsible

for their safety.

Don't install the air conditioner in the following locations:

There is petrolatum existing.

There is salty air surrounding (ne ar the coast).

There is caustic gas (the sul fid e, for example) existing in t he air (near a hot spring).

The Volt vibrates violently (in the factor ies).

In buses or cabinets.

In kitchen where it is full of oil gas.

There is strong electroma gnet ic w ave existing.

There are inflammable ma terials or gas.

There is acid or alkaline liqui d evaporating.

Other special conditions.

Hydronic Highwall

18 Installation

13.2 Accessory

Name Shape Quantity Function

1. Screw ST3.9x25 for installation board

3 Secure the installation board

2. Plastic expanded tube

3

3. Wrapping tape

1

4. Drain pipe

1

5. Wall conduit cover

1

6. Remote controller

(including operation manual)

1

7. Frame

1 Hold the remote controller

8. Mounting screw (ST2.9 x 10-C-H)

2 Insulation the holder of remote controller

9. Alkaline dry batteries (AM4)

2

10. Owner's manual

1

11. Installation manual

1

12. seel gasket

4 For connecting water pipe

13.3 Remote controller installation

Never throw or beat the contr oller.

Before installation, operate the remote controller t o det ermine its location in a recept i on r ange.

Keep the remote controller at least 1m apart fro m the nearest TV set or ster eoequipment. ( it is necessary

to prevent image disturba nc es or noise interferences.)

Do not install the remote controller in a place exposed to direct sunlight or close to a heating source,

such as a stove.

Note that the positive and negative poles are right positions whe n loading batteries.

This information is subject to change s due t o technological improv em ent without further notices.

Hydronic Highwall

Installation 19

13.4 Indoor unit installation

13.4.1 Installation place

Installation in t he followi ng places may c ause trouble . If it is unavoidable, please consult with t he local de aler.

A place f ul l of m achine oil.

A salin e pla c e such as coast.

A place f ul l of s ul fide gas such as hot-spring r esor t .

Places where there are high frequency machines such as wireless equipment, welding machine, and

medical facility.

A place t her e i s no c ombustive gases and volati le matter.

A place of special environmental conditions.

Indoor unit installation place

A place w her e is no obstacle near the inlet and outlet area.

A place w hi c h can bear the indoor unit.

A place w hi c h is c onvenient to maintenance.

A place w hi c h pr ovides the space around the indoor unit as required r ight i n t he diagram.

There is strong electroma gnet ic w ave existing.

A place w hi c h is far from heat, steam and infla m mable gas.

13.4.2 Drilling a hole and mounting installation board

Installation Board and Its Direction (unit: mm)

MI26A/MI35A type MI42A type

Fix the installation board.

Install the installation board horizontally on structural parts on the wall with the spaces provided around

the plate.

In case of brick, concrete or similar type walls, make 5mm dia. holes on the wall. Insert clip anchors for

Remote

controller

CANCEL

LOCK

SET TEMPERATURE(°C)

AUTO

COOL

DRY

HEAT

FAN

HIGH

MED

LOW

TE M P

MODE

SWING TIMER

RESET

ON/OFF

FAN

SPEED

VENT

ECO NO MI C

RUN NI NG

Remote controller

holder

Mounting screw B

ST2.9x10-C-H

460

25

290

915

mounting board of indoor unit

the shape of indoor unit

730

316

1070

36

mounting board of indoor unit

the shape of indoor unit

Hydronic Highwall

20 Installation

appropriate mounting screws.

Fix the installation board on t he w all.

Right installation

False installation

Drilling a hole

Determine the pipe hole position using t he instal lation board, and drill th e pipe hole (N95mm) s o it slants

slightly downward.

Always use a wall hole condu it w hen piercing metal lath, ply w ood or metal plate.

13.4.3 Connective and drain pipe installation

Drain pipe installation

Run the drain hose sloping dow nward. Do not install the dr ai n hose as illustrated below.

When connection extended drain hose, i nsulate the connecting par t of extended drain hose with a shield

pipe.

Connection pipe installation

mounting

board

of indoor unit

horizontal line

Tow Screw

Tow Screw

mounting

board

ofindoorunit

horizontal line

mounting

board

of indoor unit

horizontal line

Do not form a rise

Do not put the hose

end into water

Shield pipe

Wall

Drain hose

Extended drain hose

Hydronic Highwall

Installation 21

For the left-hand and rear-left-hand piping, install the piping as shown. Bend the connective pipe to be

laid at 43mm height or less from the wall.

Fix the end of the connectiv e pipe. (Re fer to Tightening Connection in WATER PIPING INST ALLATION)

Cautions:

Connect the indoor unit first, then the outdoor unit. Bend and arrange t he pipe carefully.

Do not allow the piping to let out fro m the back of the indoor unit .

Be careful not to let the drain hose slack.

Insulate both of the auxiliary piping.

Banding the drain hose under t he auxiliary pipe.

Piping and bandaging

Wind the connective cable, drain hose and wiring with tape securely, evenly as shown below.

Because the condensed water from rear of the indoor unit is gathered in Pond Box and is piped out of

room. Do not put anything else in the box.

13.4.4 Indoor unit installation

Pass the piping through the hol e in the w all.

Put the claw at the back of the indoor unit on the hook of the installation board, move the Indoor Unit

from side to side to see that it is secur ely hooked.

Piping can easily lift the indoor unit by the cushioning material between the i ndoor unit an d the wall. Get

Right piping

Left piping

Right back piping

Left back piping

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

34

Indoor unit outline

Connective pipe

Connective

cable

Drain hose

Connective

pipe

Pipe room

Pond box

Wrapping belt

Indoor unit

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

Hydronic Highwall

22 Installation

it out after finish piping.

Push the lower part of the Indoor Unit up to t he wall, and then move the Indoor Unit fro m side to side, up

and down to check if it is hooked securely.

13.5 Water pipe installation

Connection of the water pipe sho uld be done by professiona ls. Double-span should be use d when connecting

pipes of Indoor Unit.

At the first debugging, complet ely expel air from coils via expelling valve.

13.6 Wiring chart

The wiring diagram please refers to chapter 8.

Cautions:

The reserved function is indicat ed in broken line table, users can select it when necessary.

An all-pole disconnection device which has at least 3mm separation distance in all pole and a residual

current device (RCD) with the rating of above 10mA shall be incorporated in the fixed wiring according

to the national rule.

The appliance shall be installe d in a c cor dance with national wiring regulations.

Take out the faceplate, and then dismantle the display cover

Individual connect the power cord and signal line, adjust the dial switch.

hook

Cushioning

material

3-way valve

(4.ports)

discharge

valve

conector

faceplate

display cover plate

Hydronic Highwall

Installation 23

13.6.1 Terminal Board Diagram

Note: The air-conditio ner s can connect with Central Control Monitor (CCM). B efore operation, please wiring

correctly and set system address and network addre s s of indoor units.

Single phase indoor unit

Power supply 220-240V/1 ph/50Hz

Circuit breaker/fuse (A) 15/15

Indoor unit power wiring

Below 20m Twisted pairwire 2.5 mm

2

Below 50m Twisted pairwire 6 mm2

Ground wiring (mm2) 2.5

Please adopt the shielded t w ist ed-pair wire, and connect the shielded layer to E

The reserved wire control function is indicated in broken line table, users can purchase the wire controller

when necessary.

13.6.2 Network address setting

the wire holder of power

cord(three-position)

the wire holder of signal line

(five-position)

display cover plate

dial switch

INDOOR UNIT POWER

220-240V

~

50Hz

XT1

Y/G

DER

KCALB

L N

DER

KCALB

DER

KCALB

ETIHW

KCALB

EULB

1 2

X Y

E

DER

TO Timer

To Central Control Monitor

(CCM)COMM. BUS

XT3

DER

WIRE CONTROLLER

To wire controller

DISPLAY BOARD

Hydronic Highwall

24 Installation

Every air-conditioner in network has only one net work address to distinguish each other. Ad dress code of airconditioner in LAN is set by code switch on Network Inter fac e M odule (NIM), and the set range is 0-63.

Functions of anti-cold wind and anti-hot wind

13.7 Troubleshooting

ON

1

2

ON

1

2

ON

1

2

ON

1

2

SW1

ENC2

~

~

~

~

Toggle switch set

Network address

code

00~15

16~31

32~47

48-63

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

ON

1

2

ON

1

2

ON

1

2

ON

1

2

SW2

Toggle switch set

Function selection

Anti-cold wind OFF,

Anti-hot wind OFF

Anti-cold wind OFF,

Anti-hot wind ON

Anti-cold wind ON,

Anti-hot wind OFF

Anti-cold wind ON,

Anti-hot wind ON

Hydronic Highwall

Installation 25

Malfunction code Malfunction

EE

Water-level alarm malfunction

E2

T2 evaporator sensor malfunction

E3

T1 evaporator sensor malfunction

OK

OK

EE: Water-level alarm malfunction

Exist

OK

Water-level switch connecting

wire between switch and main

board gets loose

Reconnect and ensure

that the connection is

reliable.

There is something wrong

with the water-level sw itch

Exist

Replace switch

Chip fault, or chip foot sheds off, or chip is

inverted (correct mode is s emicircular bent

alignment)

Error

Reinstall chip, or install other chip

with same model on the faulty unit,

to check whether there is

something wrong with chip.

Mainboard error:

For example, getting wet

Replace mainboard

OK

Hydronic Highwall

26 Installation

OK

OK

E2: T2 evaporator sensor malfunction

Exist

OK

T2 Connecting wire between s ensor

and mainboard gets loose

Reconnect and ensure that the

connection is reliable.

Temperature sensor is short-

circuited or punctured

Exist

Replace sensor

Chip fault, or chip foot sheds off, or chip is

inverted (correct mode is semicircular bent

alignment)

Error

Reinstall chip, or insta ll other chip w ith same

model on the faulty unit, to check whether

there is something wrong with chip.

Mainboard error:

For example, getting wet

Replace mainboard

OK

OK

OK

E3: T1 evaporator sensor malfunction

Exist

OK

T1 Connecting wire between sensor

and mainboard gets loose

Reconnect and ensure that the

connection is reliable.

Temperature sensor is short-

circuited or punctured

Exist

Replace sensor

Chip fault, or chip foot sheds off, or chip is

inverted (correct mod e is semi circular bent

alignment)

Error

Reinstall chip, or install other chip

with same model on the faulty unit,

to check whether there is

something wrong with chip.

Mainboard error:

For example, getting wet

Replace mainboard

OK

Hydronic Highwall

Installation 27

13.7.1 Troubles and causes of air conditioner

If one of the following malfunctio ns occur, stop operation, shut off the power, and contact with your dealer.

The operation lamp is flashin g r api dly (twice every second)

This lamp is still flashing rapidly after turn off the pow er and t ur n on again.

Remote controller receives malfunction or the button does not work well.

A safet y device such as a fuse, a breaker frequently actuates.

Water leaks from indoor unit.

Other malfunctions.

Solution

Clean the heat exchanger.

Clean the air filter.

Eliminate all dirties and make air

smooth.

Close doors and windows.

Make curtains in order to shelter from

sunshine.

Reduce heat source.

AC cooling capacity reduces (normal).

Sympt

oms Causes

Unit does not start

Air flowing normally but

completely can't cooling

Low cooling effect

Low heating effect

Power failure.

Power switch is off.

Fuse of power switch may have burned.

Batteries of remote controller exhausted

or other problem of controller.

Temperature is not set correctly.

Indoor unit heat exchanger is dirty.

The air filter is dirty.

Inlet of indoor units is blocked.

Doors and windows are open

Sunlight directly shine.

Too much heat resource.

Outdoor temp. is too high.

Wait for the comeback of power.

Switch on the power.

Replace the fuse.

Replace the batteries or check the

controller.

Set the temperature properly.

Use heating device.

Close doors and windows.

Outdoor temperature is lower than 7 C .

Doors and windows not completely

closed.

Hydronic Highwall

28 Installation

13.7.2 Troubles and causes of remote controller

Before asking for serving or r epairing, check the following poi nt s .

Symptoms

Causes

The fan speed can not be

changed.

Check whether the MODE

indicated on the display is

"AUTO"

When the automatic mode is

selected, the air conditioner will

automatically change the fan

speed.

The remote controller signal is

not transmitted even when

the ON/OFF button is pushed.

Check whether the batteries

in the remote controller are

exhausted.

The power supply is off.

No receiving tone sounds

from the indoor unit even

when the ON/OFF button is

pressed.

Check whether the signal

transmitter of the remote

controller is properly directed

to the infrared signal receiver

of the indoor unit when the

ON/OFF button is pressed.

Directly transmit the signal transmitter of

the remote controller to the

infrared signal receiver of the

indoor unit, and then repeatly

push the ON/OFF button twice.

The indication on the display

disappears after a lapse of

time.

Check whether the timer

operation has come to an

end when the TIMER OFF

is indicated on the display.

The air conditioner operation will

stop up to the set time

The TIMER ON indicator

goes off after a lapse of

certain time.

Check whether the timer

operation is started when

the TIMER ON is indicated

on the display.

Up to the set time, the

air conditioner will automatically

start and the appropriate

indicator will go off.

The TEMP. indicator does

not come on.

Check whether the MODE

indicated on the display is

FAN ONLY

The temperature cannot be set during

FAN mode.

Solution

Protection against hot wind in

cooling mode.

Reduce the temperature of inlet in

cooling mode rise the temperature of

inlet in heating mode.

Protection against cold wind in

heating mode.

Hydronic Highwall

Controller 29

14. Controller

14.1 Standard Controller : Remote Controller R51/E

14.1.1 Specifications

Model R51/E

Rated Voltage 3.0V

Lowest Voltage of CPU Emitting Signal 2.0V

Reaching Distance 8m (when using 3.0 voltage, it can get 11m)

Environment Temperature Range -5℃~60℃

14.1.2 Performance Features

1. Operating Mode: COOL、HEAT、DRY、FAN and AUTO.

2. Timer Setting Function i n 24 hour s.

3. Indoor Temperature Se t t ing Ra nge : 17℃~30℃.

4. LCD display for all functions.

5. Compatible with the former R11.

14.1.3 Function Buttons Introduction

1. TEMP DOWN Button: Push the TEMP DOWN button to decrease t he indoor temperature sett ing or t o

adjust the timer in a counter-clockwise direction.

2. MODLE SELECT Button: Each time you push the button, a mode is selected in a sequ ence that goes

from AUTO, COOL, DRY, HE A T and FAN as the following figure indicates:

3. SWING Button: Push this switch button to change the louver angle.

Hydronic Highwall

30 Controller

4. RESET Button: When the RESET button is pushed, all of the current settings are cancelled a nd t he

control will return to the initial settings.

5. ECONOMIC RUNNING Button: Push this button to go into the Energy-Saving operation mode.

6. LOCK Button: Push this button to lock in all the current settings. To release settings, push aga in.

7. CANCEL Button: Push this button to cancel the TIMER settings.

8. TIMER Button: This but t on is used to preset the time ON (st ar t to operate) and the time OFF (turn off

the operation)

9. ON/OFF Button: Push this but t on t o s t ar t t he unit operation. Push the button again to stop the unit

operation.

10. FAN SPEED Button: This button is used for setting fan speed in the sequence that goes fr om AUTO,

LOW, MED to HIGH, and then bac k to Auto.

11. TEMP UP Button: Push this button to increase the indoor temperature setting or t o adjust t he t imer in a

counter-clockwise direction.

12. VENT Button: Pus h this button to set the ventilating mode. The ventilating m ode w ill operate in the

following sequence:

14.1.4 Indicators Introduction

1. TRANSMISSION Indicator: This indicator lights when remote controller transmits signals to indoor unit.

2. MODE Display: Shows the current operation mode - AUTO, COOL, DRY or HE AT. HE AT on ly av ailab le

for heat pump model.

3. HEAT PUMP ONLY- LOCK display is displayed by pushing the LOCK button. Push the LOCK button

again to clear display.

4. TIMER Display: This display area shows the settings of TIMER. That is, if only the starting time of

operation is set, it will display the TI M ER ON. If only the turning off time of operation is set, it will display

the TIMER OFF. If both operation s are set , it will sho w TIMER ON OFF which indicates y ou hav e chosen

to set both the starting time and o ff ti me.

5. FAN Display: When the FAN button is pushed, this signal ind icat or lights.

6. Digital Display Area: This area will show the temperat ure, and if in the TIME R mode, it will show the ON

and OFF settings of the TIM ER.

NOTE: All items are shown in the Fig for the purpose of clear presentation, But during the actual operation

only the relative functional item s ar e shown on the display panel.

14.1.5 Operational Guidelines

14.1.5.1 Operating the Remote Controller

Display Panel

AUTO

COOL

DRY

HEAT

1 6

2

3 4

5

FAN

HIGH

MED

LOW

Hydronic Highwall

Controller 31

Install / Replace Batteries: The Remote Controller uses t w o alkaline dry batteries(R03/Ir03X2).

1. To install batteries, slide back the cover of the battery compartment and install the batteries according to

the directions (+and -) shown on the Remote Controller.

2. To replace the old batteries , use t he same method as mentioned above.

Note :

1. When replacing batteries, do not use old batteries or a different type battery. This may cause the remote

controller to malfunction.

2. If you do not use the remote controller for several weeks remove the batteries. Otherwise battery leakage

may damage the remote controller.

3. The average battery life under normal use is about 6 months.

4. Replace the batteries when ther e is no answering beep from the indoor unit or if the Tran smission Indicator

light fails to appear.

14.1.5.2 Automatic Operation

When the Air Conditioner is ready for use, switch on the power and the OPERATION indicator lamp on the

display panel of the indoor unit st ar ts flashing.

1. Use the MODE select button t o select AUTO.

2. Push the TEMP button to set the desired room temperature. The most comfortable temperature settings

are between 21℃ to 28℃.

3. Push the ON/OFF button to start the air conditioner. The OPERATION lamp on the display panel of the

indoor unit lights. The operating mode of AUTO FAN SPEED is automatically set and there are no

indicators shown on the display panel of the remote controller.

4. Push the ON/OFF butto n again to stop the unit.

Note :

1. In the AUTO mode, the air conditioner can logically choose the mode of COOL, FAN, HEAT and DRY by

sensing the difference between the actual ambient room temperature and the set temperature on the

remote controller..

2. If the AUTO mode is not comfortable for you , the desired mode can be selected manually.

14.1.5.3 COOL, HEAT, and FAN ONLY Operation

1. If the AUTO mode is not comfortable, you may manually override the settings by using COOL, DRY,

HEAT(HEAT PUMP units only), or FAN ONLY modes.

2. Push the TEMP button to set the desired room temperature. When in COOLING mode, the most

comfortable settings are 21℃ or above. When in HEATING mode, t he most c omfortabl e settings are 2 8℃

or below.

3. Push the FAN SPEED to select t he FA N mode of AUTO, HIGH, MED or LOW.

4. Push the ON/OFF butt on. The operation lamp l ights and the air conditio ner st arts to run according to your

settings.

5. Push the ON/OFF butto n again to stop.

Note :

The FAN ONLY mode cannot be used to control the temperature. While in this mode, only steps 1、3 and 4

may be performed.

14.1.5.4 Dry Operation

1. Push the MODE button t o select DRY.

2. Push the TEMP button to set the desired temperature from 21℃ to 28℃.

3. Push the ON/OFF butt on. The operat ion la mp l ight s and the air conditioner star ts to run in th e D RY mode.

4. Push the ON/OFF button again to stop the unit.

Note :

Due to the difference of the set temperat ure of the unit and the act ual indoor temperature, t he Air Conditioner

Hydronic Highwall

32 Controller

when in DRY mode will automatically operate many ti mes w ithout running the COOL and F AN mo de.

14.1.5.5 Time Operation

PUSH TIMER button to set the on and off times of the unit.

1. To set the STARTING time.

1.1 Please push the CANCEL butt on to cancel any former settings.

1.2 Push the TIMER button. The remote controller will show the TIMER and the signal "h" is shown on the

display panel. The control is now r eady to reset the TIMER ON to st ar t the operation.

1.3 Push the TEMP button ( or ) to set desired unit START time .

1.4 After setting the TIMER there will be a one-half second delay before the remote controller transmits the

signal to the Air Conditioner. Then, after approximately another 2 seconds, the set temperature will reappear on the digital display.

2. To set the STOPPING time.

2.1 Please press the CANCEL but t on to cancel any former settings.

2.2 Push the TIMER button and the remote controller will show the last set time for the START operation

and the signal "h" will be shown on the display panel. You are now ready to re-adjust the TIMER OFF to

stop the operation.

2.3 Push the TEMP button to cancel the TIMER ON setting. The d igital area will show "00".

2.4 Push the TIMER button and the remot e controller will show the last set time for t he STOP operation and

the signal "h" will be shown on the display panel. You are now ready to reset the time of the STOP

operation.

2.5 Push the TEMP button ( or ) to set the time you want to stop the operation.

2.6 After setting the TIMER there will be a one-half second delay before the remote controller transmits the

signals to the Air Conditioner. Then after approximately another 2 seconds, the set temperature will reappear on the digital display.

3. Set the STARTING & STOPPING time

3.1 Please press the CANCEL but t on to cancel any former settings.

3.2 Push the TIMER button and the remote controller will show the last setting time for START operation

and the signal "h" will be shown on the display panel. You are now ready to readjust the TIMER ON to

start the operation.

3.3 Push the TEMP button ( or ) to set the time you want to start the operati on.

3.4 Push the TIMER button and the remot e controller will show the last set tim e for STOP operation and the

signal "h" will be shown on the display panel. Y ou are now ready to reset the time of the STOP oper ation.

3.5 Push the TEMP button ( or ) to set the time you want to stop the operation.

3.6 After setting the TIMER there will be a one-half second delay before the remote controller transmits the

signal to the Air Conditioner. Then, after approximately another 2 seconds ,the set temperature will reappear on the digital display.

Note :

1. Please reset the TIMER aft er cancelling the former time set tings.

2. The setting time is relative time. That is the time set is based on t he delay of the current time.

14.2 Optional Controller

Hydronic Highwall

Controller 33

14.2.1 Central Controller: WGC3

Hydronic Highwall

34 Controller

Hydronic Highwall

Controller 35

Liquid crystal matrix display description:

1. The liquid crystal matrix is composed of 4*64 grids, and each grid is co m posed of two blocks of

different sizes (as shown in t he above figure).

2. The matrix includes horizontal coordinates 00-15 on the upper side and vertical coordinat es 00+ , 16+,

32+ and 48+ on the left

Side, which indicate the addr ess of the indoor unit. The sum of the horizontal coordinate and t he

vertical coordinate of the grid is the address of the grid. Each grid cor r esponds to an indoor unit of this

address.

3. One grid is composed of two blocks of different sizes. The status

Indication table is as follow s:

Status

Object

Constantly on Slow blink

Fast blink

Big black block In-service Selected

Out of service

Small black block Power on

Fault of indoor unit Power off

LCD display description

1. Description of the standby page

1) The LCD displays the standby page, 60 air con ditioners are in service, of which 28 are powered on

and 32 off.

2) In the matrix, the big dots of (00, 16+) and (15,32+) are luminous, and the small dot s ar e not luminous.

It indicates the 32 air conditioner s with the addresses from 16 to 47 are powered off.

3) In the matrix, the big and small dots of (09, 48+) and (12, 48+) are not lumino us. I t indicates the four air

conditioners with the addr esses from 57 to 60 are outside the net w ork.

4) All other big and small dots in the matrix are luminous. It indicates all other a ir conditioners are in the

network and powered on.

5) The address of the air conditioner is sum of the coordinates. For example, t he addr ess of (09, 48+) is

09+48=57.

6) The centralized controller keypad is loc ked, and the centralized contro ll er communicates with the

computer normally.

Hydronic Highwall

36 Controller

Query page description

1) The LCD displays the query page, and the air co nditioner with the address o f 08 is being queried.

Mode of the air conditioner with the address 01 is: Cooling, str ong air, swing on, indoor tem per at ur e

22°C, set temperature 20°C, c ooling mode “lock”.

2) In the matrix, only the big and small black dots at ( 00, 00+) and (01, 00+) are lumin ous. I t indicates the

in-service and power-on status of the air conditioner s w it h t he addr esses of 00 and 01.

3) The centralized controller communicates with the computer nor ma lly .

Setting page description

1) The LCD displays the setting page, and qu er ie s the air conditioner with the ad dres s of 08. The mode of

the air conditioner with the addr ess 08 is: Cooling, strong air, swi ng on, i ndoor temperature 28°C, set

temperature 22°C, cooling .

2) In the matrix, only the big black dots from (08, 00+ ) to (16, 00+) are luminous. It indicates the air

conditioners with the addr esses from 08 to 16 are in service.

3) The centralized controller communic at es with the computer normally.

Fault page display descript ion

1) Query the air conditioner with the address o f 08 in the query page. The air conditi oner with the address

of 08 is faulty, and the fault code is 08. T he big black dot below (08, 0+) blin ks.

2) In the matrix, only the big and small black dots from (00, 00+) to (16, 15+) illu m inate. It indicates the in-

service status of the air condit i oners with the addresses o f 00 an d 01.

3) The centralized controller communic at es with the computer normally.

I dati riportati nella presente documentazione sono solamente

indicativi. Il costruttore si riserva la facoltà di apportare in qualsiasi

momento tutte le modifiche ritenute necessarie.

The data indicated in this manual are purely indicative. The

manufacturer reserves the right to modify the data whenever it is

considered necessary.

Via S. G. LAvoratore 24 (Loc. La Macia)

37040 Arcole

Verona - Italy

Tel. +39 - 045.76.36.585

Fax +39 - 045.76.36.551

www.maxa.it

e-mail: info@advantixspa.it

A I R C O N D I T I O N I N G

Loading...

Loading...