Page 1

TECHNICAL MANUAL 2013

SPLIT LIGHT MULTI DC INVERTER

MODELS

Indoor units Outdoor units

BDLM26A2 BD2M53A3

BDLM36A2 BD3M98A3

BDLM53A2

This manual has been created for informative purpose. The company declines every responsibility for the results of projecting or installation based on the explanations and the technical specifications

given in this manual. Is besides forbidden the reproduction under any form of the texts and of the figures contained in this manual.

Page 2

Serie / Series / Serie / Serie

TECHNICAL MANUAL

SPLIT LIGHT MULTI DC

Emissione / Issue

Ausgabe / Emission

03 - 2013

Catalogo / Catalogue / Katalog / Catalogue

Sostituise / Supersade

Ersetzt / Remplace

04 - 2011

MTE01028D2820-01

3

Page 3

INDICE

1. Specifics.....................................................................................................................................5

1.1 Indoor units specific.................................................................................................................. 5

1.2 Outdoor units specifics ............................................................................................................. 6

1.3 Noise criteria curve tables for both models ..............................................................................7

2. Outlines and dimensions ............................................................................................................ 7

2.1 Indoor unit ................................................................................................................................7

2.2 Outdoor unit .............................................................................................................................8

3. Refrigerant circuit ....................................................................................................................... 9

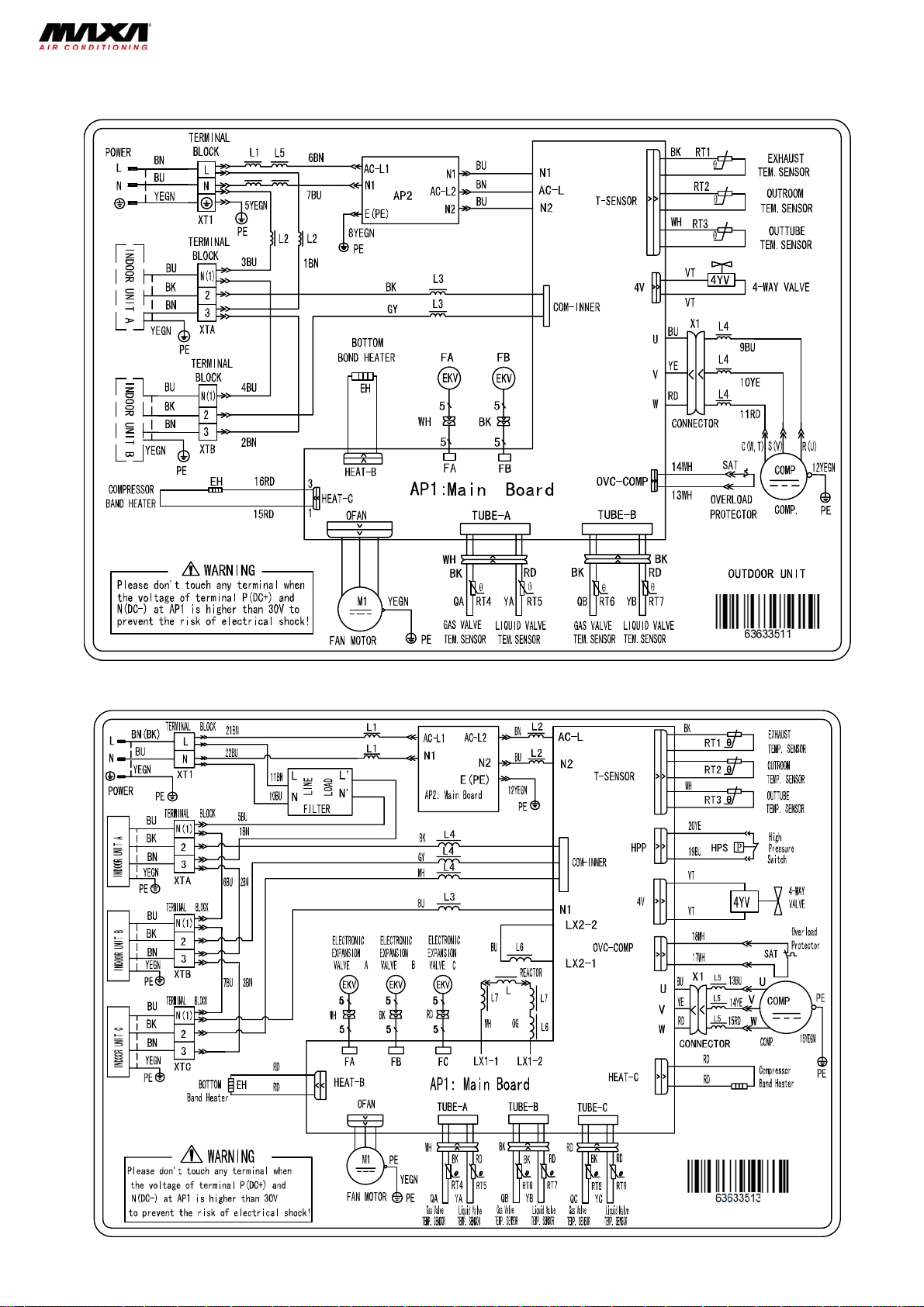

4. Electrical diagram.....................................................................................................................10

4.1 Indoor units ............................................................................................................................10

4.2 Outdoor unit ...........................................................................................................................11

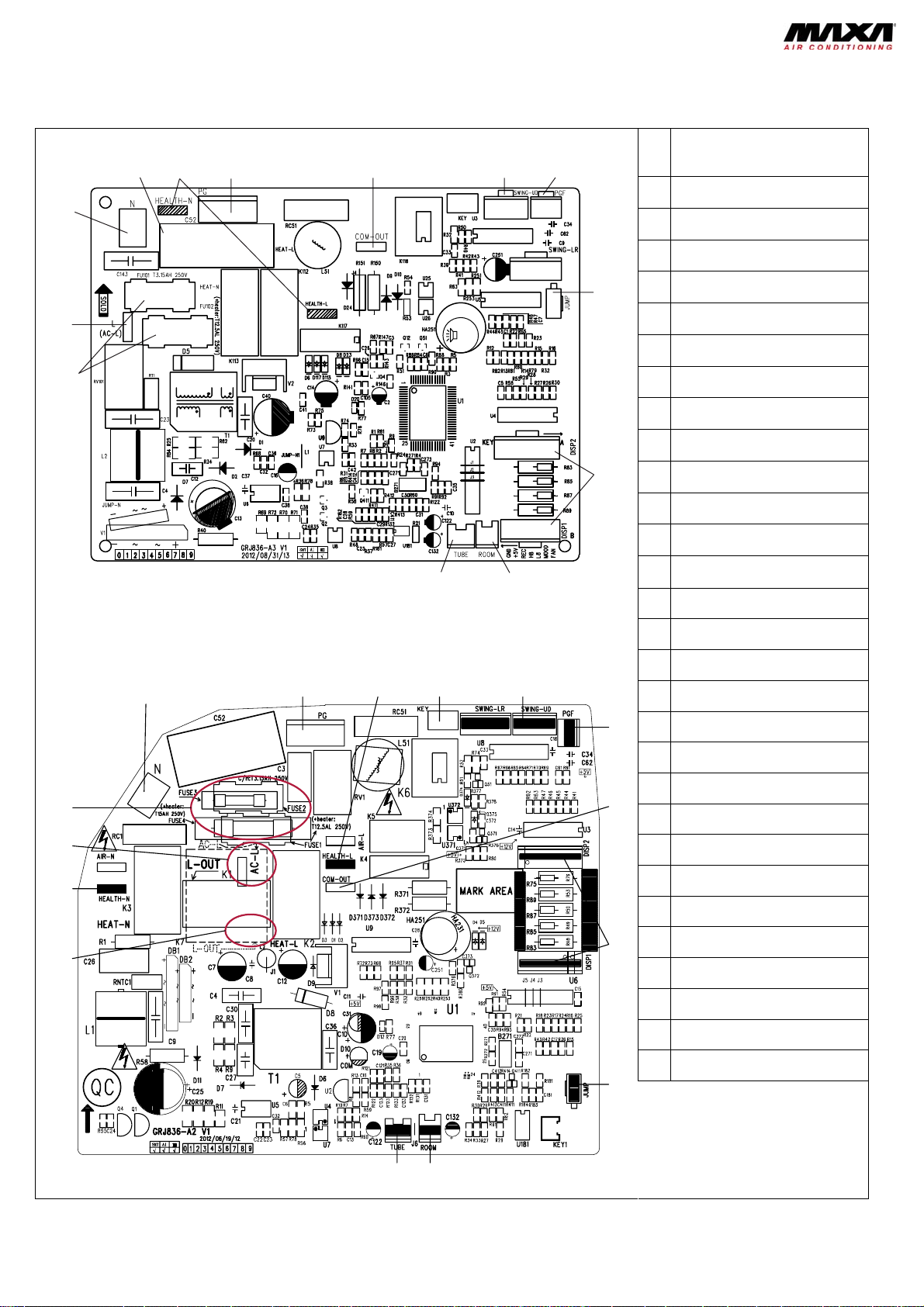

5. Printed circuit ...........................................................................................................................12

5.1 Indoor units ............................................................................................................................12

5.2 Indoor units ............................................................................................................................13

6. Control functions ...................................................................................................................... 14

6.1. Temperature Parameters ...................................................................................................... 14

6.2. Basic functions ...................................................................................................................... 14

6.3. Others ................................................................................................................................... 14

6.4. Displayer ...............................................................................................................................15

7. Outdoor units Operation ........................................................................................................... 17

7.1. Temperature parameters....................................................................................................... 17

7.2. System basic function ........................................................................................................... 17

8. Troubleshooting .......................................................................................................................20

8.1. Malfunction Display of Indoor Unit.........................................................................................20

8.2. How to Check simply the main part....................................................................................... 21

8.3 Malfunction Display of Outdoor Units ..................................................................................... 26

8.4 Malfunction checking and elimination..................................................................................... 27

Appendix.....................................................................................................................................36

Appendix 1: Resistance Table of Ambient Temperature Sensor for Indoor and Outdoor Units(15K).......................... 36

Appendix 2: Resistance Table of Outdoor and Indoor Tube Temperature Sensors(20K) ........................................... 37

Appendix 3: Resistance Table of Outdoor Discharge Temperature Sensor(50K)........................................................ 38

4

Page 4

1. Specifics

1.1. Outdoor units specifics

Models

Power supply

Capacity

Power input kW 1,5(0,5~2,5) 2,15(0,6~4,5)

Cooling

Absorbed current A 6,8 10,9

S.E.E.R. W/W 5,60-A+ 5,10-A

Capacity

Power input kW 1,5(0,5~2,7) 2,28(0,8~3,9)

Heating

Absorbed current A 6,8 11,4

S.C.O.P. W/W 3,80-A 3,80-A

Compressor trademark

Compressor model QXA-B141zF030A QXAS-D23zX090B

Compressor type

Compressor oil

Comp. oil charge L

L.R.A.

Compressor RLA A 7,2

Compressor input

Compressor capacity

Comp. Overload protector 1NT11L-6233

Throttling method

Starting method

Working temp range °C

Condenser material Aluminum fin-copper tube

Rows-Fin Gap

Coil length (l) x height (H) x coil width (L) mm 851 x 660 x 38,1

Fan motor apeed rpm 880/700/500

Output of fan motor W

Fan Motor RLA A 0,56

Outdoor unit

Fan motor capacitor μF 4

Outdoor air flow volume m3/h 2600/2300/1600

Fan type-piece

Fan diameter mm

Defrosting method

Climate type

Isolation

Moisture protection

Permissible excessive operating pressure for the discharge side Mpa

Permissible excessive operating pressure for the suction side

Sound pressure level

Sound power level

Outline dimension mm 963 x 700 x 396 1001 x 790 x 427

Packing dimension mm 1029 x 458 x 750 1083 x 488 x 855

Net / Gross weight kg 50/55 96/74

Refrigerant charge kg R410A / 1,40

Max. connection pipe length (for each indoor unit)

Difference in livel m 10 10

Gas additional charge g/m

pipe

Pipe out.

Connection

diameter

Operating temperature °C

Liquid

Gas Inch 3/8 1/2

V- Ph, Hz 230V 220 ~ 240V , 50Hz

kW 5,0(2,0~6,3) 7,0(2,0~10,0)

Btu/h 17,0(6,9~21,5) 24,2(6,8~34,1)

kW 5,6(2,5~6,6) 8,5(3,2~11,0)

Btu/h 19,1(8,5~22,6) 29,0(10,9~37,5)

ZHUHAI LANDA COMPRESSOR CO. LTD

W 1440

4320

Electronic expansion valve

mm 2-1.4

MPa 2,5

dB(A) 56/53/50 58/54/52

dB(A) 66/63/60 68/64/62

m ≤20 ≤20

Inch 1/4 1/4

BD2M53A3 BD3M98A3

DC inverter Rotary

RB68EP

0,39 0,95

11,5

2550

7250

Transducer starting

-15°C ≤ T ≤ 48°C

982,2 x 748 x 38,1

690/600/500

60

0,6

3,5

3300/2900/2400

Axial fan –1

520 552

Automatic defrost

T1

I

IP24

4,3

R410A / 2,2

1/4

3/8

-15 ~ 48

5

Page 5

0

[

]

1.2 Indoor units specifics

MODELS BDLM26A2 BDLM36A2 BDLM53A2

Power supply

Total capacity

Power input W 10 10

Cooling

Absorbed current A 0,04 0,04

Total capacity

Power input W 10 10

Heating

Absorbed current A 0,04 0,04

Air flow volume

Dehumidifying volume l/h 0,6

Fan motor speed (SH/M/L) (r/min) 1320/1200/1100/950 1280/1080/1000/920

Fan Motor Capacitor μF 1 1

Fan motor full load Amp (FLA) A 0,144 0,22

Output of fan motor W 10 20

Motor model FN10A-PG FN20J-PG

Fan type-piece

Diameter-Length mm Ø85 X 596 Ø92 X 645

Evaporator

Pipe diameter

Row-Fin gap mm 2-1,5 2-1,4

Indoor Coil

Coil length (l)xheight (H)xcoil width (L)

Swing motor model MP24AA

Output of swing motor W 1,5 1,5

Fuse

Indoor sound level (H/M/L) dB(A) 39/34/28 40/35/30

Dimension (W/D/H) mm 790X174X265 845X180X275

Dimension of package (W/D/H) mm 870x248X355 918x258X370

Net weight/Gross weight

Liquid pipe

Gas pipe (to indoor unit)

(SH/H/M/L)**

(m3/h)

V-Ph, Hz

kW 2.600 3.500

Btu/h 8,8 11,9

kW 2.800 3.800

Btu/h 9,5 12,9

500 630

Cross flow fan – 1

Aluminum fin-copper tube

mm Ø7

mm 581X267X25,4 690X267X25,4

A PCB 3,15A

kg 9/11 10/12,5

mm Ø6 Ø6

mm Ø9,52 Ø9,52

The data of specifications are subject to change without prior notice. Please refer to the actual data specified on the

nameplate of the unit.

220 ~ 240V ○,1, 50Hz

230V

1,4

5.300

18,0

55

0,3

5.800

19,7

55

0,3

850

1,8

1420/1250/1150/105

1,5

0,31

20

FN20V-PG

Ø98 X 710

2-1,4

715×304,8x25,4

MP28VB

2,0

43/40/35

940/200/298

1013X288X395

13/16

Ø6

Ø12,7

Note: Test conditions:

Standard condition

Dry bulb temp. °C Wet bulb temp. °C Dry bulb temp. °C Wet bulb temp. °C

Indoor side state Outdoor side state

Rated cooling 27 19 35 24

Max. cooling 32 23 48 26

Min. cooling 21 15 18 -

Rated heating 20 15 7 6

Max heating 27 - 24 18

Min. heating 20 15 -15 -16

3) Microphone at a distance of 1m from the unit.

Approximate calculation from Sound Pressure Level to Sound Power Level:

*1.0*1.0

LL

21

- Average Sound Pressure Level

L

: Sound pressure level of front test point.

1P

L

: Sound pressure level of side test point for indoor unit

2P

- Approximate Sound Power Lever

L =10*lg

p

LL =

+10.

pW

+

PP

LL .

21,PP

.

1010(*2/1

6

Page 6

1.3 Noise criteria curve tables for both models

60

50

40

30

Noice/dB(A)

20

10

0

Low Middle High Super High

Indoor Fan Motor Rotating Speed

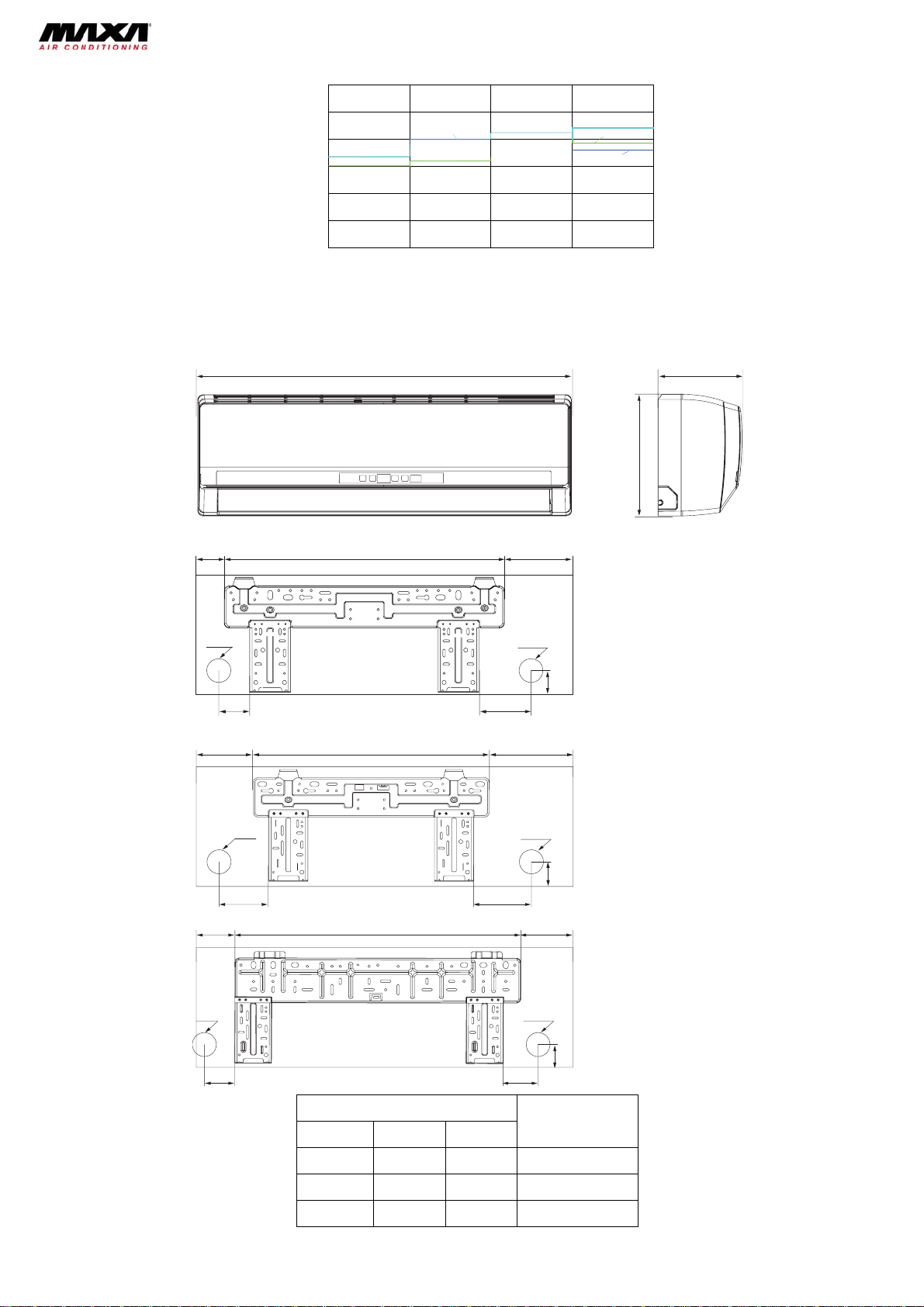

2. Outlines and dimensions

2.1 Indoor units

W

BDLM53A2

BDLM36A2

BDLM26A2

D

H

36

Φ55

Φ55

69

85

941506

BDLM26A2

09K Units

Φ55

40

8704

172542131

BDLM3A2

12K Units

Φ55

50

19469452

BDLM53A2

18K Units

Φ55

Φ55

61183

45

Dimension (mm)

Models

W H D

790 265 174 BDLM26A2

845 275 180 BDLM36A2

940 298 200 BDLM53A2

7

Page 7

8

92341

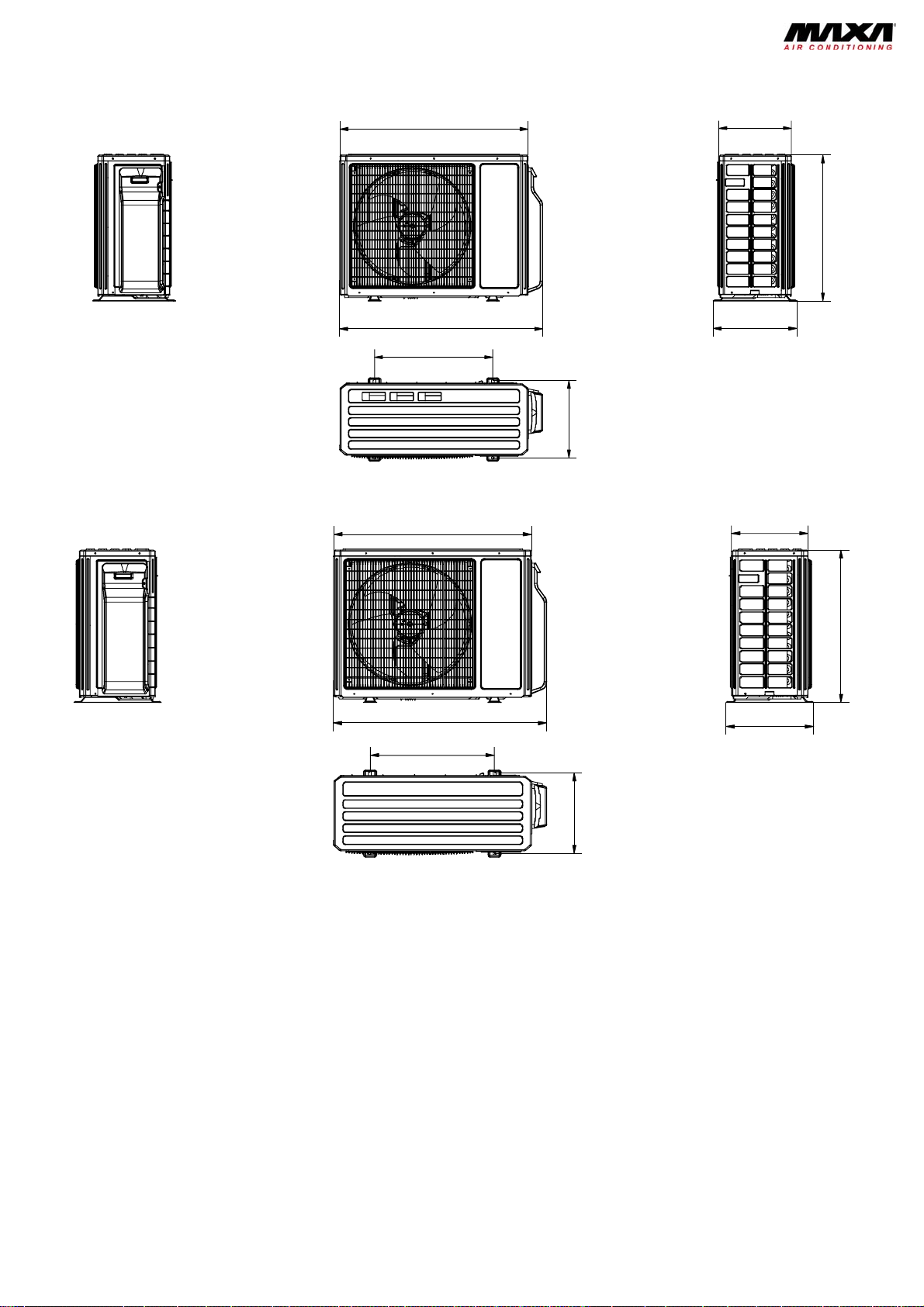

2.2 Outdoor units

a) BD2M53A3

560

700

396963

368

Unit:mm

b) BD3M98A3

924 370

1001

610

427

399

Unit:mm

790

8

Page 8

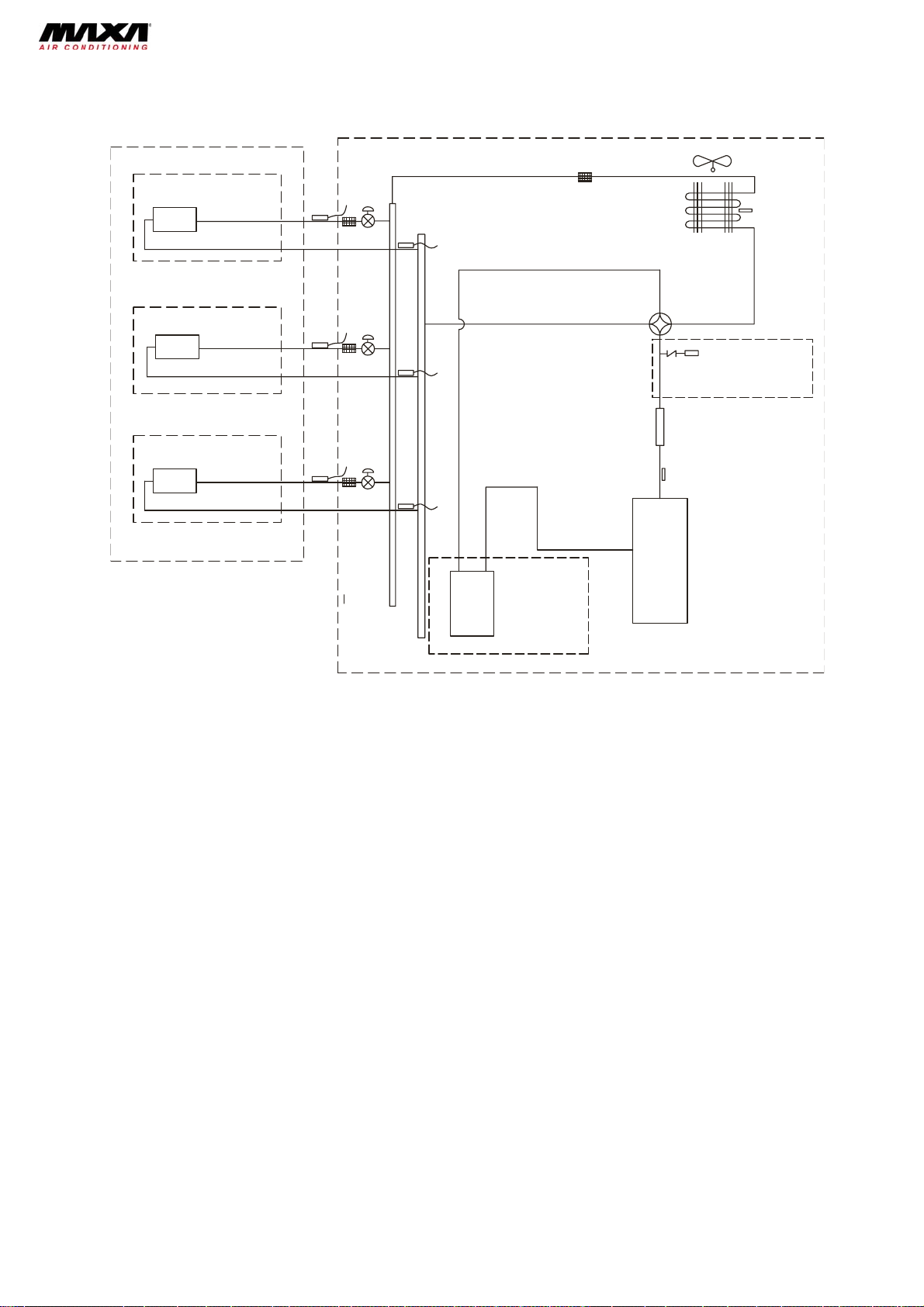

3. Refrigerant circuit

indoor

A heat exchanger

B heat exchanger

C heat exchanger

A3

B3

C3

filter

filter

filter

outdoor

filter

A

1

A2

B

1

B2

C

1

C2

outdoor heat exchanger

fan

4-way valve

SP

high pressure switch

Note: N ot available for 14K/1 8K

model

discharge silencer

discharge temperature

sensor

inverter comp resso r

gas -liquid separator

Note: N ot available for 1 4K/18K m od el

A1:A-unit electronic expansion valve A2:A-unit gas pipe temperature sensor A3:A-unit liquid pipe temperature sensor

B1:B-unit electronic expansion valve B2:B-unit gas pipe temperature sensor B3:B-unit liquid pipe temperature sensor

C1:C-unit electronic expansion valve C2:C-unit gas pipe temperature sensor C3:C-unit liquid pipe temperature sensor

D1:D-unit electronic expansion valve D2:D-unit gas pipe temperature sensor D3:D-unit liquid pipe temperature sensor

9

Page 9

4. Electrical diagram

4.1 Indoor units

BDLM26A2, BDLM36A2

TUBE

TEM.SENSOR

0

RT2

TUBE

CAP

JUMP

DISP1

RECEIVERAND

DISPLAY BOARD

DISP2

AP1

ROOM

TEM.SENSOR

0

RT1

ROOM

AP2

SWING-UD

M2

SWING

MOTOR

HEALTH-N

BU

COO L PLASMA

GENER ATOR

FAN

MOTOR

M1

PG

COM-OUT

HEALTH-L

PGF

AC-L

RD

N

1BU

3BK

2BN

4YEGN

EVAPORATOR

XT

N(1)

2

3

PE

OUTDOOR UNIT

BU

BK

BN

YEGN

BDLM53A2

NOTE:The parts with broken line is applicable

to the models with COOL PLASMA GENERATOR

TUBE

TEMP.SENSOR

0

RT2

TUBE

ROOM

TEMP.SENSOR

0

RT1

ROOM

CAP

AP2

JUMP

DISP1

DISP2

SWING-UD

FAN MOTOR

M1

PG

PGF

N

COM-OUT

AC-L

HEALTH-NHEALTH-L

1BU

3BK

2BN

XT

N(1)

2

3

4YEGN

PE

EVAPORATOR

BU

BK

BN

YEGN

OUTDOOR UNIT

M2

AP1

RECEIVER AND

DISPLAY BOARD

SWING

MOTOR

RD

COO L PLASMA

GENER ATOR

(optional)

BU

10

Page 10

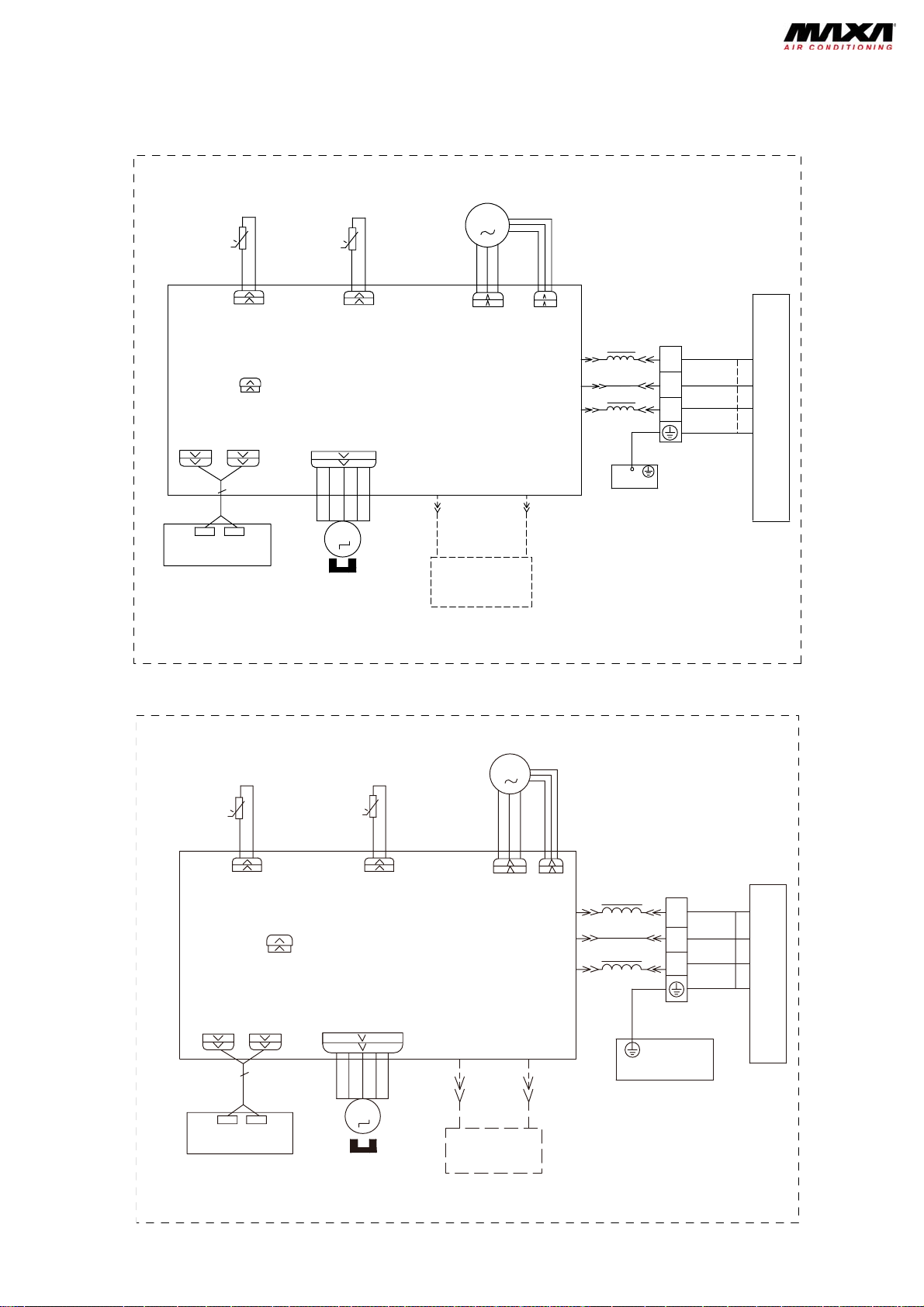

4.2 Outdoor unit

BD2M53A3

BD3M98A3

11

Page 11

r

r

5. Printed circuits

5.1 Indoor units

Models: BDLM26A2, BDLM36A2

Top View

2

1

13

Model: BDLM53A2

Top View

1

853764

1112

234 5

9

10

No Part name

Power supply live wire connector

1

Power supply neutral wire

2

connector

Fan capacitor

3

Health function terminal

4

(optional)

5 Indoor fan wire terminal

Indoor and outdoor unit

6

communication wire terminal

Up & down swing control

7

terminal

Indoor fan feedback terminal

8

Jumper cap

9

Display panel terminal

10

Indoor ambient temperature

11

sensor

Indoor pipe temperature sensor

12

Protective tube

13

No Part name

1 Interface of neutral wire

2 Interface of PG motor

Interface of health function live

3

wire

6

4 Interface of auto button

5 Interface of up and down swing

6 Interface of PG feedback

15

14

13

12

1011

7

8

9

Interface of indoor and outdoor

7

unit communication

Interface of display

8

9 Interface of jumper cap

Interface of ambient temperature

10

senso

Interface of tube temperature

11

senso

Power supply interface of outdoor

12

live wire

Interface of heath function neutral

13

wire

14 Interface of live wire

15 Interface of fuse

12

Page 12

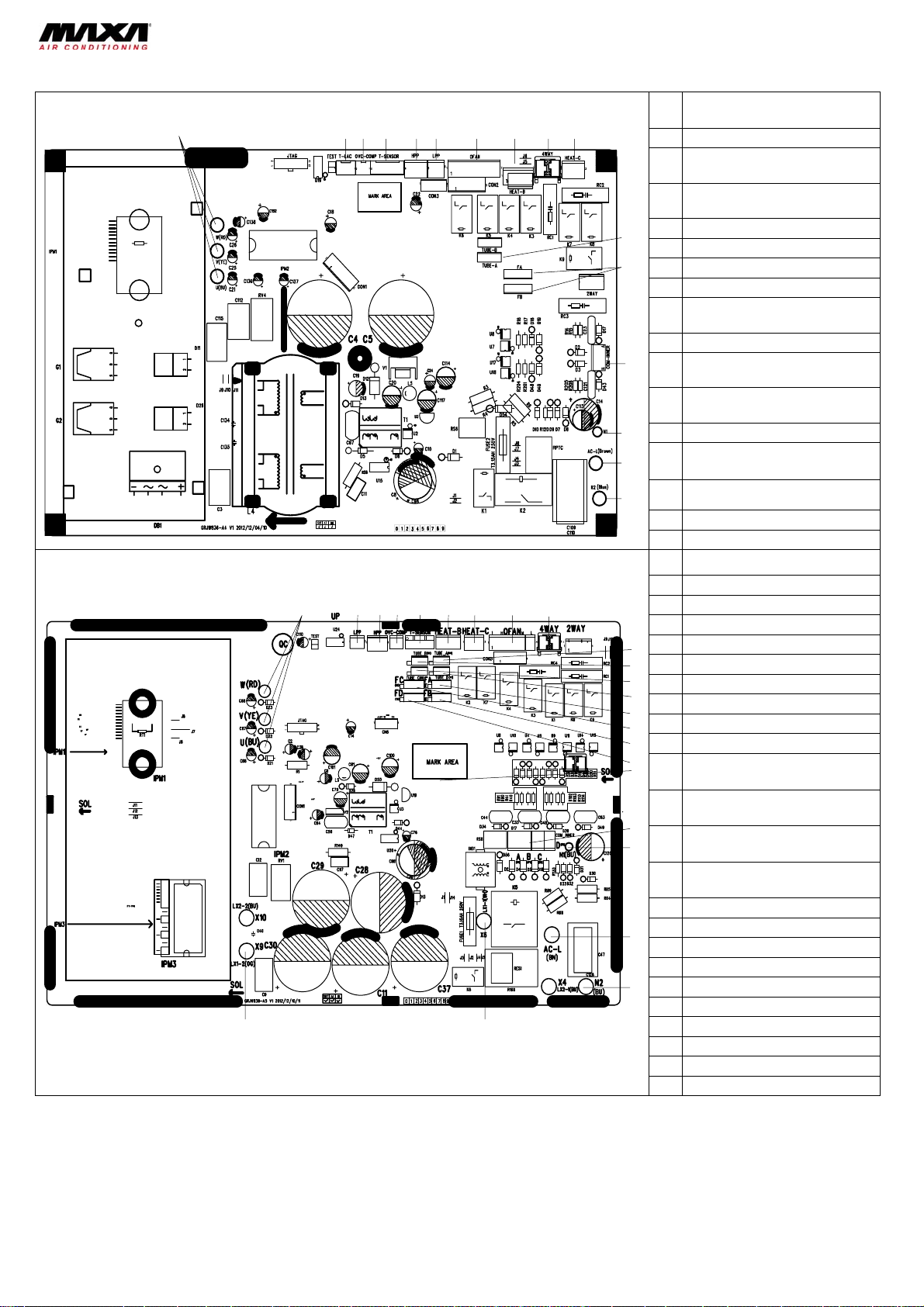

5.2 Outdoor units

3

516

71819

Model: BD2M53A3

1

Models: BD3M98A3

23

23 4 56 7 8 9 10

1

123456 879

22

No Part name

Compressor terminal

1

Temp. sensor terminal of low

2

ambient temp. cooling

Compressor overload protection

3

terminal

4 Outdoor temp. sensor terminal

11

5 High pressure protection terminal

12

13

14

15

16

10

11

12

1

14

1

1

20

21

Low pressure protection terminal

6

Outdoor fan terminal

7

Terminal of chassis electric

8

heating belt

4-way valve terminal

9

Terminal of compressor electric

10

heating belt

Temp sensor terminal of gas

11

valve and liquid valve

Electric expansion valve terminal

12

Terminal of IDU and ODU

13

communication wire

Terminal of communication

14

neutral wire

Live wire terminal

15

Neutral wire terminal

16

No Part name

1 Compressor terminal

High pressure protection

2

3 Low pressure protection

Compressor overload protection

4

5 Outdoor temp. sensor terminal

6 Terminal chassis electric heater

7 Terminal of comp. electric heater

Outdoor fan terminal

8

9 4-way valve terminal

Unit A liquid valve and gas valve

10

temp. sensor

Unit B liquid valve and gas valve

11

temp. sensor

Unit C liquid valve and gas valve

12

temp. sensor

Unit D liquid valve and gas valve

13

temp. sensor

14 Unit A electronic expansion valve

15 Unit B electronic expansion valve

16 Unit C electronic expansion valve

17 Unit D electronic expansion valve

Communication wire with indoor

18

19 Communication neutral wire

20 Live wire

21 Neutral wire

22 Reactor 1

23 Reactor 2

13

Page 13

6. Control functions

6.1. Temperature Parameters

• Indoor ambient temperature (Tin_amb.)

• Evaporator tube temperature (T

Setting temperature (T

set)

Note: The following function manual, the temperature unit is centigrade, if there is Fahrenheit, there will be

T(°F)=T(°Cx1.8+32.

6.2. Basic functions

6.2.1 Cooling mode

1. Temperature can be set in the range of 16 ~ 30°C.

2. The unit will firstly run at high fan speed for 8s and then switch to preset fan speed.

3. When error of outdoor unit occurs or the unit stops for protection, indoor unit will keep its original operating state.

6.2.2 Dehumidifying mode

1. Temperature can be set in the range of 16 ~ 30°C.

2. The unit will firstly run at high fan speed for 8s and then switch to low fan speed.

3. When error of outdoor unit occurs or the unit stops for protection, indoor unit will keep its original operating state.

6.2.3 Fan mode

1. The unit will firstly run at high fan speed for 8s and then switch to preset fan speed.

2. When error of outdoor unit occurs or the unit stops for protection, indoor unit will keep its original operating state.

6.2.4 Heating mode

1. Temperature can be set in the range of 16 ~ 30°C.

2. If compress stops at required temperature point, indoor fan will run by blowing residual heat.

3. If compress under heating mode stops for error, indoor fan will run by blowing residual heat.

4. Function of blowing residual heat:

Indoor fan switching into low speed will stops after 1 min delay.

5. Anti-cold air

After heating compressor runs, indoor fan runs according to the following conditions:

If compressor runs within 90s and T

above, indoor fan will run at low speed. After 3 min at low speed or T

running, indoor fan won't stop. Once at preset fan speed, it won't forcibly return to low speed.

6.2.5 AUTO mode

1) When T

2) When T

3) When 18°C < T

in_amb. ≥ 25°C, the unit runs under cooling mode, Tset = 25°C.

in_amb. ≤ 18°C, the unit runs under heating mode, Tset = 18°C. And it runs under fan.

in_amb. < 25°C, the unit keeps its original operating state. If first energization, it runs under fan mode.

6.3. Others

6.3.1 Buzzer

The air conditioner will send out Hua alert

6.3.2 Auto Button

When turn off the unit, press this button, the whole unit will run at auto mode, indoor fan motor will run in auto fan speed,

turn on the swing. At unit turns on, press the Auto button that the unit will turns off.

6.3.3 Auto fan speed control

Under Cool, Heat, Fan modes, indoor fan will accord to the ambient temperature select High, Mid, Low three speeds, the

dehumidifying mode auto fan speed is low. The switch of each fan mode should be 3.5mins.

6.3.4 Timer function

The common setting for Timer:

a) Timer on: At unit off, can set up the Timer On function, when Timer On act, the controller will run at original setting

mode, the Timer interval is 0.5hr, setting range is 0.5-24hrs.

in_tube)

in_tube < 35°C, indoor fan won't run. When Tin_tube ≥ 35°C or compressor run for 90s

in_tube ≥ 40°C, indoor fan runs at preset speed. Once

when it is energized or receives a control command.

14

Page 14

b) Timer off: At unit on, can set up the Timer Off function, when Timer Off act, the unit will turn off, the Timer interval is

0.5hr, setting range is 0.5-24hrs.

Hours setting for Timer:

a) Timer on: If unit is running then to set up the Timer On, the unit will go on running, if the unit is off to set up the Timer

On, when Timer On acts, the unit will run at the presetting modes.

b) Timer off: If unit is off then to set up the Timer Off, when setting the Timer off, the unit stand by, if unit is turned on to

set up Timer Off, when the Timer Off act, the system will stop to work.

c) Timer change: When unit is running in Timer mode, by operate the On/Off of remote controller to turn on or turn off the

unit, can reset up the Timer function, the unit will run at the mode of last setting.

If unit is running, at the same time to set up Timer On and Timer Off, the system will keep the present setting status, after

the Timer On. When system is running, at the same time to set up Timer On and Timer Off, the unit will keep the current

presetting working status, if Timer Off act, the unit will stop working.

When unit is stop running, at the same time to set up the Timer On and Timer Off, the unit will keep stop running, until

Timer On act, the unit will start to work, after this when Timer On of every day act, it will run at presetting modes, when

Timer Off act, the unit will stop to work.

If the setting for the Timer Off and Timer On are the same, the Timer Off will act.

6.3.5 Memory function

Contents of memory: Modes, Up and Down Swing, Light, Setting Temp. Setting fan speed, Common setting for Timer

(Hours will not memorized). After Timer Off, when re-power on, the unit will automatically turn on and run at memorized

contents.

There is no Timer Setting in the remote control order that the unit will memorize the remote control order of last setting

and it will run at that mode.

6.3.5 I Feel function

When controller received the orders that the controller will work according to ambient temperature which is sent by remote

control (Except Defrost and Anti-cool wind, it will still adopt the air conditioner self ambient sensor sampling value), the

remote control in every 10mins, to send the ambient temperature value to controller. 11mins later, the controller haven’t

received the ambient temperature value from the remote control that the air conditioner will run itself ambient temperature.

If there is no setting function that the ambient temperature will adopt the AC sensor sampling value. Power off will not

memorize this function.

6.3.7 TURBO function

Only in Cool or Heat mode, the Turbo setting is available, when controller received this order, the indoor fan will run at

super high, sent the outdoor unit Turbo signal and sent the high fan speed.

6.4. Displayer

6.4.1 Basic display

(1) After powered on, the displaying failure will fully displayed then only power indicator light on.

(2) Remote control to turn on the unit, the running indicator and cooling indicator will light on. Heat mode: the running

indicator and heating indicator will light on. In dehumidifying mode, running indicator and dehumidifying indicator light on.

Fan mode, running indicator light on. Auto mode: running indicator and actual running mode indicator will light on.

(3) If turns off the Light button, that all display will be turned off (still valid at unit off).

(4) After set up the SLEEP function, the displayer will keep original displaying status that is Sleep function will not affect

the light on and off.

6.4.2 Forcible Defrosting Function

When the unit is in Heat mode and set temperature is 16°C, press “+, -, +, -, +, -,” successively for 5s, and the indoor unit

will enter forcible defrosting setting and send the signal to the outdoor unit.

When the indoor unit receives forcible defrosting signal from the outdoor unit, it will exit forcible defrosting setting.

15

Page 15

6.4.3 Refrigerant Recovery Function

Enter refrigerant recovery mode: turn on the unit within 5 min after energization and at 16°C cooling mode. Press remote

controller light off button successively for 3 times within 3s and the unit will enter refrigerant recovery mode, displaying Fo.

The signal will be sent to the outdoor unit.

Exit refrigerant recovery mode: during refrigerant recovery, if any signal from remote controller is received or refrigerant

recovery lasts for 25min, it will exit this mode.

Action of entering refrigerant recovery mode: the indoor fan will operate in Cool mode. The fan speed is high and set

temperature is 16°C. The horizontal louver will be at the smallest angle.

Action of exit refrigerant recovery mode: the indoor fan will operate according to the last remote control setting.

6.4.4 Pre-operation Function

When Cool mode at 30°C is set, press “-, +, -, +, -, +” successively for 3s, it will enter pre-operation mode. The signal will

be sent to the outdoor unit.

Pre-operation mode: it performs cooling operation (indoor fan does not operate) and display “dd”. After exiting preoperation mode, the indoor unit will stop displaying “dd”. If the signal of “wrong wire connection or expansion valve

malfunction” is received, “dn” will be displayed.

6.4.5 Mode Conflict

When the mode of started unit is different from that of operating unit, the indoor unit will display mode conflict code “E7”.

16

Page 16

7. Outdoor units Operation

7.1. Temperature parameters

¾ Outdoor ambient sensor temperature (Tout_amb.)

¾ Outdoor heat exchanger tube sensor temperature (T

¾ Setting temperature (T

set)

7.2. System basic function

7.2.1 Cool mode

7.2.1.1 Heat mode transfers to Cool mode

(1) Compressor stops.

(2) Four-way valve delayed 2mins power off.

7.2.1.2 Cool operation and stop running condition

(1) When T

(2) When the capacity requirement is 0 (Cool and unit stops).

Note: Unit off, fan is the same as Cool and unit will stop.

7.2.1.3 Outdoor fan motor control

Outdoor fan unit start up (stop-turn on), firstly run at high speed for 3 mins, then according to control logic adjust, when

compressor stop, outdoor fan will stop after 1min delay.

(1) To turn on one indoor unit: when T

When T

(2) To turn on two indoor units: when T

run at high speed.

Note: When only one unit is turned on, to increase turn on one indoor unit dual unit, outdoor fan will run at high speed for

3min, then according to control logic adjust.

7.2.1.4 Four-way valve control

In this mode, four-way valve off (cannot electrify)

7.2.1.5 Control logic in detail

According to the difference of indoor unit evaporator inlet and outlet temperature (called “actual overheat degree”) and

goal overheat degree to confirm indoor unit expansion valve open degree.

7.2.1.6 Anti-freezing protection under Cool mode

If satisfied with the anti-freezing protection condition, system will enter into anti-freezing protection status, if only single

unit anti-freezing protection act, the indoor unit capacity preset as 0; if all the unit start anti-freezing protection, the

compressor will stop, outdoor fan will stop after 60s delay. If arrive at anti-freeze condition, finish anti-freezing.

7.2.2 Dehumidifying mode

Under this mode, outdoor fan, compressor start up is the same with control condition and Cool modes.

7.2.3 Heat mode

7.2.3.1 Cool mode transfers to Heat mode

(1) Compressor stops running.

(2) Four-way valve delays 2mins will electrified; same disposal procedure under each protection.

7.2.3.2 Heat operation and stop running condition

(1) When T

on).

(2) In Heat mode unit will stop

7.2.3.3 Fan motor control

Outdoor unit start up (Stop --Turn on) firstly will run at high speed for 3 mins, it will accord to control logic to adjust, if

compressor stop running, outdoor fan will stop after 1 min delay. Outdoor fan control logic: There will be at least 80s for

each modes switch.

7.2.3.4 Four-way valve control

in_amb - Tset ≥ 0.5°C, cooling operation will run (Cool mode starts up and arrive at the temperature of unit on).

out_amb <25°C, outdoor fan will run at low fan speed.

out_amb ≥ 25°C, outdoor unit will run at high speed.

out_amb <18°C, outdoor fan will run at low speed; when Tout_amb≥18°C, outdoor fan

in_amb ≤ (Tset +3) ± 0.5°C, heating operation will run (Heat mode starts up and arrive at the temperature of unit

out_tube)

17

Page 17

In this mode, four-way valve electrify.

Note:

In each mode, after protection and unit stop, modes switch or unit off, 4-way valve will power off after 2 minutes delay.

7.2.3.5 Defrosting under Heat mode

Under Heat mode, there is intelligent defrosting.

7.2.3.6 Heating Turbo function

When outdoor unit received heating mode Turbo function from the indoor unit, at this time, outdoor unit add certain

frequency running.

7.2.4 Fan mode

When outdoor unit main mode transfer from Cool (Dehumidify) or Heat mode to Fan mode, compressor stop running,

outdoor fan will stop running after 1min delay.

7.2.5 Electric heat control target

7.2.5.1 Compressor electric heat belt control

After powered on, if T

After compressor started up or T

If -5°C < T

out_amb, compressor electric heat belt will keep original status.

7.2.5.2 Chassis electric heating cord control (optional)

From entering into Defrosting to Defrosting finish, within compressor started up 3 minutes, if ambient temp. is very low,

chassis electric heating belt work; if ambient temperature is very high, it will not work.

7.2.6 System protection function

7.2.6.1 Indoor unit modes confliction protection

If indoor unit presetting is different, will accord to the following condition for running: will accord to the first entering indoor

unit mode for the fiducial mode, to compare with other indoor unit modes to judge whether confliction happen or not.

1) Cool (Dehumidify) conflict with Heat mode: some indoor unit received the outdoor unit mode confliction signal later, this

indoor unit will turn off, memorize unit off status.

2) Fan and Heat confliction: some indoor unit received outdoor unit mode confliction signal later, this indoor unit will turn

off, memorize unit off status.

7.2.6.2 Air exhaust temperature protection

If continuously 6 times, air exhaust temperature protection happened, the compressor cannot resume to run. If need to

power off and re-power on can resume. (if compressor running time exceed 7mins, the protection time will clear 0.)

7.2.6.3 Communication malfunction

If continuously 3mins hasn’t received the correct signal of indoor unit and within 10s, cannot receive the correct signal

from the drive board that is the communication malfunction, outdoor unit will stop running, auto heating or heating mode,

blow surplus heat, in other modes, indoor unit will run at presetting fan speed.

7.2.6.4 Power module protection and module overheat protection

Mode protection acts, compressor stop running, after compressor stopped 3mins, will automatically resume to running

status, if protection times continuously happened 6 times (if compressor running time exceed 7mins, the protection times

will clear 0), unit turned off and sent wrong signal to indoor unit, cannot resume running status; It is need to re-power on

can resume to run.

7.2.6.5 Compressor overcurrent protection

If detected the whole unit current value exceeded the determinative value, compressor stopped 3mins later, it will

automatically resume to running status, protection times exceeds 6 times (if compressor running time is more than 7min,

that the protection times will clear to 0), unit will turn of sent wrong signal to indoor unit, cannot automatically resume to

run. At this time, it is need to power off and re-power on can resume.

7.2.6.6 Sensor malfunction detection

Outdoor: at unit standby, do not test outdoor each sensor malfunction, unit turned on and compressor continuously run

for 3mins later, start to detect air exhaust sensor malfunction; Defrosting (or heating oil return) finished, within 10mins, do

out_amb. ≤ -5°C and compressor hasn’t start up, electric heat belt will start to work.

out_amb.> -3°C, the electric heat belt will stop to work;

18

Page 18

not detect outdoor tube sensor malfunction; Other outdoor sensors after unit turned on start to detect malfunction, outdoor

each sensor continuously 30s does not in the temperature upper limit or down limit will alarm.

Indoor: Under any status to test indoor each sensor malfunction, continuously 30s does not during the temperature upper

and down limit, will alarm.

Upper and lower limits of temperature sensors

Indoor ambient sensor (sensor with 15K resistance and connected with a 15K resistance) ≤ -40°C

Indoor inlet tube sensor (sensor with 20K resistance and connected with a 20K resistance) ≤ -40°C

Indoor central tube sensor (sensor with 20K resistance and connected with a 20K resistance) ≤ -40°C

Indoor outlet tube sensor (sensor with 20K resistance and connected with a 20K resistance) ≤ -40°C

Outdoor ambient sensor (sensor with 15K resistance and connected with a 15K resistance) ≤ -40°C

Outdoor tube temperature sensor (sensor with 20K resistance and connected with a 20K resistance) ≤ -40°C

Outdoor air exhaust sensor (sensor with 50K resistance and connected with a 15K resistance)

≥ 142°C

≥ 136°C

≥ 136°C

≥ 136°C

≥ 142°C

≥ 136°C

≤ -26°C ≥ 140°C

7.2.6.7 Anti-high temperature protection under Heat mode

If detected some indoor unit tube temperature is very high, that the indoor unit will stop running after arrived at preset

temperature, if tube temperature resumed, the compressor will resume to run.

7.2.6.8 Compressor delay protection

Due to each protection, malfunction arrived at the temperature, after compressor stopped running, when restart up, there

will be 3mins delay, power off exception.

7.2.6.9 Compressor high-pressure protection

After high-pressure protection malfunction happened, if continuously detected compressor high-pressure switch closed, it

need to power off, then re-power on, the whole unit will resume to run.

7.2.6.10 Compressor overload protection

If detected the compressor overload switch act, it will run at indoor temperature arrive at presetting temperature condition,

the unit will stop and display corresponding malfunction, compressor stopped for 3mins above and compressor overload

switch reset, the whole unit will automatically resume to running status. Protection times exceeds 6 times (if compressor

continuously running time exceed 7min, that the protection times will clear 0) without automatically response, it need to

power off and re-power on for resume.

7.2.6.11 Demagnetization current protection

When detected demagnetization current value is larger than regulative value, compressor will stop running.

7.2.6.12 Compressor startup

Compressor start up at 30 Hz frequency, after start up, according to whole unit capacity requirement rise frequency

running. During raise up to the target frequency, each protection condition (including frequency raise condition and current

protection condition) will act.

7.2.6.13 PFC act

After outdoor unit sent turn on order to drive board, PFC will turn on at once, after 3s the compressor will start up after

compressor stop running, PFC will stop working at once.

19

Page 19

8. Troubleshooting

8.1. Malfunction Display of Indoor Unit

a) Malfunction display requirement

When there are several malfunctions, they will be displayed circularly.

b) Malfunction display method

(1) Hardware malfunction: immediate display; refer to “malfunction display table”;

(2) Operation state: immediate display; refer to “malfunction display table”;

(3) Other malfunctions: it is displayed after the compressor stops for 200s; refer to “malfunction display table”. Note: when

the compressor is restarted, the malfunction display delay time (200s) is cleared.

(4) When the unit is under limit frequency or frequency drop state, the display can be controlled via remote controller.

c) Malfunction display control

The indicator lamp and dual 8 nixie tube displays shall be synchronized. That is when the indicator lamp blinks, the dual 8

nixie tube displays the corresponding malfunction code.

d) Display control via remote controller

Enter display control: press light button successively for 6 times within 3s to display the corresponding malfunction code;

Exit display control: pressing light button successively for 6 times within 3s or after display is shown for 5min, the display

will terminate.

Malfunction name

Zero detection circuit error

Jumper terminal error protection

No feedback of indoor fan motor

Short/open circuit of the indoor ambient temp. sensor

Short/open circuit of the indoor evaporator

Inlet tube sensor malfunction

Outlet tube sensor malfunction

Short/open circuit of the of the IPM module temp. sensor

Short/open circuit of the outdoor ambient temp. sensor

Short / open circuit of the temperature sensor at the inlet of

the condenser coil.

Short/open circuit of the outdoor tube sensor.

Short/open circuit of the temperature sensor at the outlet of

the condenser coil

Exhaust sensor open or short circuit

Communication error between the indoor and outdoor units

Compressor phase current error

Compressor demagnetization protection

PN voltage drop protection (DC link voltage drop error)

IPM high temperature protection

Refrigerant-lacking or blockage protection

Capacitor charge error

Refrigerant system high pressure protection

Refrigerant system low pressure protection (reserved)

Compressor thermal overload protection

Fault in matching

Loading EEPROM error

AC current detect circuit error

Outdoor DC fan motor malfunction

Mode conflict

Refrigerant recovery mode

Blow mode

Defrosting or oil return in heating

Compressor start-up failure

Compressor discharge high temperature protection

Anti-high temperature protection

AC over-current protection

Overload protection

Compressor desynchronizing

Compressor phase failure / phase-inverse protection

IPM module protection

"88" Display

U8

C5

H6

F1

F2

b5

b7

P7

F3

A5

F4

A7

F5

E6

U1

HE

U3

P8

F0

PU

E1

E3

H3

LP

EE

U5

L3

E7

Fo

Lc

E4

E8

E5

P5

H7

Ld

H5

RUN " "

Flash 17 times

Flash 15 times

Flash 11 times

Flash 6 times

Flash once

Flash 3 times

Flash 19 times

Flash 7 times

Quick flash Quick flash

Flash 4 times /

Flash 8 times

Flash 5 times

Indoor Unit Indicating Lamps

COOL " "

/ Flash once

/ Flash twice

Flash 19 times

Flash 22 times

Flash 18 times

Flash 3 times

Flash 4 times

Flash 5 times

Flash 12 times

Flash 14 times

Flash 20 times

Flash 19 times

Flash 10 times

Flash 17 times

Flash 3 times

Flash 15 times

Flash 13 times

Flash 11 times

Flash 15 times

Flash 7 times

Flash 11 times

Flash 5 times

ON for 0,5s and

OFF for 10s

HEAT " "

ON for 0,5s and

OFF for 10s

20

Page 20

Over voltage protection for PN

DC bus-bar high voltage protection

PFC protection

The four-way valve is abnormal

"88" Display state under test state: minimum cooling(heating)-P0; middle cooling(heating)-P3 Nominal cooling(heating)-P1;

maximum cooling(heating)–P2; Corresponding indicator lamp will be on for 0.3s and off for 0.3s

PL

PH

HC

U7

Flash 21 times

Flash 11 times

Flash 6 times

Flash 20 times

8.2. How to Check simply the main part

8.2.1 U8 Malfunction

Possible causes:

1. The controller diagnoses incorrectly due .to instant energization after de-energized while the capacitor discharges slowly;

2. Malfunction of the zero-cross detection circuit of the mainboard.

See the flow chart below:

“U8” is displayed on the unit.

Re-energize 1 minute after de-erergization

Is “U8” still displayed?

The zero-cross detection circuit of the mainboard

is defined abnormal. Replace the mainboard.

No

The unit returns to normal.

Conclusion: U8 is displayed due to

instant energization after de-energization

while the capacitor discharges slowly.

Malfunction is eliminated.

8.2.2. C5 Malfunction

Possible causes:

1. There is no jumper cap on the controller;

2. Jumper cap is not inserted properly and tightly;

3. Jumper cap is damaged;

4. Controller is damaged.

See the flow chart below:

C5 is displayed on the unit.

Is there jumper cap on the controller? Install a matching jumper cap.

No

Is there jumper cap inserted incorrectly or improperly?

Replace the jumper cap

Yes

No

No

No

Is the malfunction eliminated?

Yes

Re-insert the jumper cap.

Is the malfunction eliminated?

Yes

Is the malfunction eliminated?

Yes

The mainboard is defined abnormal; replace it

No

Yes

End

21

Page 21

8.2.3 H6 Malfunction

Possible causes:

1. Fan motor is locked;

2. The feedback terminal of PG motor is not connected tightly;

3. The control terminal of PG motor is not connected tightly;

4. Motor is damaged;

5. Malfunction of the rotation speed detection circuit of the mainboard.

See the flow chart below:

“H6” is displayed on the unit.

Stir the fan blade with a tool when

the unit is DE-ENERGIZED.

No

Yes

No

Is the wiring terminal of PG motor loose?

Yes

No

No

Stir the fan blade by hand when

the unit is DE-ENERGIZED to see

if the blade rotate smoothly?

No

Energize and retart up the unit, test if the

voltage between on contral terminal

board for PG motor is more than 50V

within 1 min after the louvers are opened

No

No

Yes

No

Measure the voltage of this terminal

to neutral wire on the mainboard

No

Replace the mainboard

with the same model

Tighten the screw; reassemble the

blade, motor and shaft bearing rubber

base sub-assy to make sure there is no

foreign object between them

Is the malfunction eliminated?

Insert the wiring terminal of indoor fan

Is the malfunction eliminated?

Reinstall the motor and the blade

to make it rotate smoothly.

Is the malfunction eliminated?

Is the motor startup

No

Replace the PG motor

Is the malfunction eliminated?

Yes

End

Yes

Yes

Yes

Yes

Yes

22

Page 22

8.2.4. F1/F2 Malfunction

C5 is displayed on the unit.

Is there jumper cap on the mainbaord? Install a matching jumper cap.

Is the jumper cap inserted incorrectly or improperly?

Replace the jumper cap

Yes

No

No

The mainboard is defined abnormal; replace it

Is the malfunction eliminated?

No

End

No

No

Is the malfunction eliminated?

Yes

Re-insert the jumper cap.

Is the malfunction eliminated?

Yes

The jumper cap

Yes

Yes

23

Page 23

8.2.5 E6 Malfunction Inspection

1. Check if connection wire between indoor and outdoor units and wire inside the unit are connected well.

2. Check if mainboard of indoor or outdoor unit is damaged.

Communication malfunction of some indoor units

De-energize the unit and check if the connecting

wire of indoor and outdoor unit and wiring of

electric box are correct.

No

Is wire connected correctly?

Yes

Connect wires according

to the wiring diagram

Is malfunction removed?

No

De-energize the unit. Change the communication cable

of indoor units. Energize the unit and wait for 3 min

No

Does the broken-down indoor unit resume normal?

Yes

Replace mainboard of outdoor unit

Replace the broken-down mainboard of the indoor unit

End

Yes

24

Page 24

Communication malfunction of all indoor units

De-energize the unit and check if the

connecting wire of indoor and outdoor unit

and wiring of electric box are correct.

Yes

Is wire connected correctly?

De-energize the unit. Check if the

connecting wire between outdoor

mainbaord and filter plate is correct.

Yes

Is wire connected correctly?

Yes

Is connecting wire damaged?

Check if there is power input between

neutral wire and live wire of outdoor unit.

No

Is there power input?

Yes

Replace mainboard of outdoor unit

Does communication resume normal?

Yes

End

No

Connect wires according

to the wiring diagram

No

No

Connect wires according

to the wiring diagram

Yes

Replace the connecting wire

Replace filter plate of outdoor unit

No

Replace mainboard of indoor unit

Is malfunction removed?

No

Is malfunction removed?

No

Is malfunction removed?

No

Is malfunction removed?

No

Yes

Yes

Yes

Yes

25

Page 25

8.3 Malfunction Display of Outdoor Units

When several malfunctions occur at the same time, they will be displayed in circulation and every malfunction is displayed

for 5s.

No Malfunction description LED1 LED2 LED3 LED4

0 Normal stop ○ ○ ○ ○

1 Compressor run ● ○ ○ ○

2 Compressor overload protection ◙ ○ ○ ○

3 Discharge protection ○ ● ○ ○

4 Outdoor unit overload protection ● ● ○ ○

5 High pressure protection ◙ ● ○ ○

6 Over current protection ○ ◙ ○ ○

7 IMP protection ● ◙ ○ ○

8 IMP over heating protection ◙ ◙ ○ ○

9 PFC protection (including PFC overheating protection) ○ ○ ● ○

10 Phase current protection ● ○ ● ○

11 Over voltage protection ◙ ○ ● ○

12 Insufficient voltage protection ○ ● ● ○

13 Start failure ● ● ● ○

14 Compressor desynchronizing ◙ ● ● ○

15 Compressor phase-lacking protection ○ ◙ ● ○

16 Compressor phase current detection malfunction ● ◙ ● ○

17 Memory chip mistake ◙ ◙ ● ○

18 DC power supply circuit-short ○ ○ ◙ ○

19 Defrosting ● ○ ◙ ○

20 Oil return ◙ ○ ◙ ○

21 Complete unit frequency restriction protection ○

22 Complete unit frequency dropping protection ●

23 Unit A frequency restriction or frequency dropping protection ◙

24 Unit B frequency restriction or frequency dropping protection ○ ◙ ◙ ○

25 Unit C frequency restriction or frequency dropping protection ● ◙ ◙ ○

26 Unit D frequency restriction or frequency dropping protection ◙ ◙ ◙ ○

27 Outdoor ambient temperature sensor protection ◙ ○ ○ ●

28 Outdoor tube temperature sensor protection ● ○ ○ ●

29 Discharge temperature sensor protection ◙ ○ ○ ●

30 IPM thermal resistance malfunction ○ ● ○ ●

31 Unit A liquid pipe temperature sensor malfunction ● ● ○ ●

32 Unit A gas pipe temperature sensor malfunction ◙ ● ○ ●

33 Unit B liquid pipe temperature sensor malfunction ○ ◙ ○ ●

34 Unit B gas pipe temperature sensor malfunction ● ◙ ○ ●

35 Unit C liquid pipe temperature sensor malfunction ◙ ◙ ○ ●

36 Unit C gas pipe temperature sensor malfunction ○ ○ ● ●

37 Unit D liquid pipe temperature sensor malfunction ● ○ ● ●

38 Unit D gas pipe temperature sensor malfunction ◙ ○ ● ●

39 Unit A mode conflict ○ ● ● ●

40 Unit B mode conflict ● ● ● ●

41 Unit C mode conflict ◙ ● ● ●

42 Unit D mode conflict ○ ◙ ● ●

43 Communication failure with Unit A ● ◙ ● ●

44 Communication failure with Unit B ◙ ◙ ●

45 Communication failure with Unit C ○ ○ ◙

46 Communication failure with Unit D ● ○ ◙

47 Unit A freeze protection ◙ ○

48 Unit B freeze protection ○ ●

49 Unit C freeze protection ● ●

50 Unit D freeze protection ◙ ●

51 Unit A overheating prevention protection ○ ◙

52 Unit B overheating prevention protection ● ◙

53 Unit C overheating prevention protection ◙ ◙ ◙ ●

54 Unit D overheating prevention protection ○ ○

55 Unit A communication wire misconnection or expansion valve malfunction ● ○

56 Unit B communication wire misconnection or expansion valve malfunction ◙ ○

57 Unit C communication wire misconnection or expansion valve malfunction ○ ●

58 Unit D communication wire misconnection or expansion valve malfunction ● ●

● ◙

● ◙

● ◙

◙

●

◙

●

◙

●

◙

●

◙

●

◙

●

○

○

○

○

○

○

○

○

●

●

●

◙

◙

◙

◙

◙

Note: ○: off, ●: on, ◙: blink

26

Page 26

8.4 Malfunction checking and elimination

Note: Discharge the position in below pictures with discharge resistance after open the top cover and check if the voltage is

below 20V with universal meter, then begin to check.

BD2M53A3

BD3M98A3

27

Page 27

(1) IPM protection malfunction

Main checking point

● If the input voltage of the unit is within normal range?

● If the connection wire of compressor is connected well? Is it loose?

● If the connection sequence is correct?

● If the resistance of compressor coil is normal?

● If the isolation of compressor coil with copper pipe is good?

● If the unit is overloaded?

● If the heat radiation of the unit is good?

● If the refrigerant charge is suitable?

Energize the unit

Please check:

1. if the indoor and outdoor heat exchanges are dirty, if there

is obstacle to affect the radiation;

2. if the indoor and outdoor fans are running normally;

3. if the pressure of the system is too high;

4. if the refrigerant is too much which causes the high level of

pressure;

If the above cases are existed?

Yes

No

If the wire of compressor is connected

well and correctly?

Yes

Test the resistance between

the three phases

Test the isolation impedance between the three

phases of the compressor and the copper pipe

If the resistance is normal?

Yes

No

Reconnect the wire of the

compressor according to the

correct wiring method

No

Correct according to the service

manual and then energize the

unit to operate

Yes

If the resistance is above 500M ?

Replace the compressor

No

Malfunction is eliminated

No

Yes

Replace the outdoor mainboard

End

28

Page 28

(2) PFC protection malfunction

Main checking points:

● If the power supply is normal;

● Check if the connection wire of induction is connected well and if the induction is broken;

Flow chart:

Start

Check If the power supply is normal

Power supply is abnormal

No

Check if the outdoor induction is broken

Yes

Turn on the unit after the

power supply resumes to

normal situation

The induction is broken

Yes

Replace the induction

Replace the outdoor mainboard

No

(3) Capacity charging malfunction

Main checking points:

● If the mainboard is broken;

● If the wiring of the is broken

End

No

Malfunction is eliminated

Yes

Energize the unit and wait for 1min

Test the voltage between the two ends of the electrolytic

capacitor with the DC shift of the universal meter

The voltage is above 100V

No

Check if the induction wiring is

loose or the induction is cut off

Yes

The detection circuit of

the outdoor mainboard

has malfunction

Replace the outdoor

mainboard

The induction is cut off

or the wiring is loose

No No

Replace the outdoor mainboard

Replace the induction or

Yes Yes

reconnect the loose wire

Malfunction is eliminated

End

29

Page 29

(4) Anti-high temperature and overload malfunction Main checking points:

● If the outdoor ambient temperature is within the normal range;

● If the outdoor fan is running normally;

● If the indoor and outdoor radiation environment is good;

If the outdoor ambient temperature

is above 53°C

If the indoor and outdoor radiation is insufficient

If the outdoor fan is working normally

Replace outdoor mainboard

(5) T emper ature sensor malfunction

Main checking points:

● If the temperature sensor is damaged or broken;

● If the terminal of the temperature sensor is loosened or not connected;

● If the mainboard is broken;

Flow chart:

Check whether the wiring terminal between

temperature sensor and controller is

loosened or poorly contacted?

Check whether the temperature sensor

is normal according to resistance table

Start

No

No

Yes

End

Start

No

Yes

Replace the controller

with the same model

End

Yes

Yes

No

It is a normal protection, please

operate the unit after the outdoor

ambient temperature has changed

Improve the radiation environment of the unit

Check if the terminal of the fan is

connected well, if the fan is broken

Replace fan capacitor

Replace outdoor fan

Yes

No

No

Insert the temperature

sensor tightly

Eliminate the malfunction

Replace the temperature

sensor with the same model

No

Eliminate the malfunction

Yes

Yes

30

Page 30

(6) Start failure malfunction

Main checking points:

● If the connection wire of the compressor is connected properly;

● If the stop duration of the compressor is sufficient;

● If the compressor is broken;

● If the refrigerant charging amount is too much;

Energize and start the unit

No

If the stop duration of the

compressor is longer than 3min

Yes

If the connection wire of the compressor

is connected well and correctly

Yes

No

If the refrigerant charging

amount is too much

Yes

Charge the refrigerant according

to the service manual

Eliminate the malfunction

No

The stop duration of the

unit is not enough, the

high and low pressure of

the system is not

balanced, restart it after

3min

Replace the outdoor mainboard

No

Eliminate the malfunction

Replace the compressor

End

Yes

Yes

Reconnect the connection wire

No

of the compressor according to

the wiring diagram

No

Energize and start the unit

Yes

31

Page 31

(7) Communication malfunction

Main checking points:

● If the connection wire between the indoor unit and outdoor unit is connected well, if the wires inside the unit is

connected well;

● If the indoor mainboard or outdoor main board is broken;

Communication malfunction

of some indoor units

De-energize, check the

connection wire of indoor

and outdoor unit and the

wire of the electric box is

connected correctly

Connected correctly

Yes

De-energize, change the

communication wire of the

well communicated indoor

unit and malfunction

indoor unit, then energize

the unit and wait for 3min

The malfunction indoor

unit resumes normal

No

Replace the mainboard of

the malfunction indoor unit

End

No

Yes

Reconnect according

to the wiring diagram

Replace outdoor

mainboard

Eliminate the malfunction

No

Yes

32

Page 32

All the indoor units appear

communication malfunction

De-energize, check the connection

wire of indoor and outdoor unit and

the wire of the electric box is

connected correctly

Connected correctly?

Yes

De-energize, check if the

connection wire between the

outdoor mainboard and the

filter board according to the

wiring diagram

Connected correctly?

Yes

The connection wire is broken?

No

Check if there is power input

between the neutral wire and live

wire of the outdoor mainboard

There is power input?

Yes

Replace the outdoor mainboard

Resume communication?

Yes

End

No

No

No

No

Reconnect according

to the wiring diagram

Reconnect according

to the wiring diagram

Replace the

connection wire

Replace the filter board

of the outdoor unit

Replace indoor mainboard

Eliminate the malfunction

Eliminate the malfunction

No

Eliminate the malfunction

No

Eliminate the malfunction

No

Yes

Yes

Yes

Yes

33

Page 33

(8) Compressor overload, discharge protection malfunction

Main checking points:

● If the electric expansion valve is connected well or it is broken;

● If there is refrigerant leakage;

● If the overload protector is broken;

If the overload protector is

connected well?

No

Check the resistance between the

two ends of the overload protector

in ambient temperature, if the

resistance is below 1k

If the wiring of the electric

expansion valve is connected well?

Check the coil of the electric

expansion valve, replace it if it is

Replace the overload

protector

Eliminate the malfunction

Check the refrigerant status, if there

is refrigerant leakage, recharge it

according to the service manual

Eliminate the malfunction

Replace outdoor mainboard

Noted: the detection method of the coil of the electric expansion valve: there is five pieces of the coil of the electric

expansion valve, the resistance of one of them (the leftmost or the rightmost one) is almost the same as the resistance of

other terminal (within 100 Ohm). Judge the condition of the electronic expansion valve through detecting this resistance.

Start

End

Yes

Yes

No

No

Yes

Yes

No

No

Reconnect according

to the wiring diagram

34

Page 34

(9) Compressor desynchronizing malfunction

Main checking points:

● If the pressure of the system is too high;

● If the electric expansion valve is working normally or it is broken;

● If the radiation of the unit is good;

The unit appears desynchronizing

as soon as energizing and starting

The stop duration of the

compressor is longer than 3min?

No

The wiring of the compressor is

connected properly?

Yes

No

Reconnect the wire properly

Yes

No

Eliminate the malfunction

The electric expansion valve

is broken?

No

Replace the electric expansion valve

Yes

No

Eliminate the malfunction

Replace outdoor mainboard

Eliminate the malfunction

No

Yes

Replace the compressor

End

Yes

Yes

35

Page 35

Appendix

Appendix 1: Resistance Table of Ambient Temperature Sensor for Indoor and Outdoor Units (15K)

Temp. (°C) Resistance (kΩ) Temp. (°C) Resistance (kΩ) Temp. (°C) Resistance (kΩ) Temp. (°C) Resistance (kΩ)

-19 138.1 20 18.75 59 3.848 98 1.071

-18 128.6 21 17.93 60 3.711 99 1.039

-17 121.6 22 17.14 61 3.579 100 1.009

-16 115 23 16.39 62 3.454 101 0.98

-15 108.7 24 15.68 63 3.333 102 0.952

-14 102.9 25 15 64 3.217 103 0.925

-13 97.4 26 14.36 65 3.105 104 0.898

-12 92.22 27 13.74 66 2.998 105 0.873

-11 87.35 28 13.16 67 2.896 106 0.848

-10 82.75 29 12.6 68 2.797 107 0.825

-9 78.43 30 12.07 69 2.702 108 0.802

-8 74.35 31 11.57 70 2.611 109 0.779

-7 70.5 32 11.09 71 2.523 110 0.758

-6 66.88 33 10.63 72 2.439 111 0.737

-5 63.46 34 10.2 73 2.358 112 0.717

-4 60.23 35 9.779 74 2.28 113 0.697

-3 57.18 36 9.382 75 2.206 114 0.678

-2 54.31 37 9.003 76 2.133 115 0.66

-1 51.59 38 8.642 77 2.064 116 0.642

0 49.02 39 8.297 78 1.997 117 0.625

1 46.6 40 7.967 79 1.933 118 0.608

2 44.31 41 7.653 80 1.871 119 0.592

3 42.14 42 7.352 81 1.811 120 0.577

4 40.09 43 7.065 82 1.754 121 0.561

5 38.15 44 6.791 83 1.699 122 0.547

6 36.32 45 6.529 84 1.645 123 0.532

7 34.58 46 6.278 85 1.594 124 0.519

8 32.94 47 6.038 86 1.544 125 0.505

9 31.38 48 5.809 87 1.497 126 0.492

10 29.9 49 5.589 88 1.451 127 0.48

11 28.51 50 5.379 89 1.408 128 0.467

12 27.18 51 5.197 90 1.363 129 0.456

13 25.92 52 4.986 91 1.322 130 0.444

14 24.73 53 4.802 92 1.282 131 0.433

15 23.6 54 4.625 93 1.244 132 0.422

16 22.53 55 4.456 94 1.207 133 0.412

17 21.51 56 4.294 95 1.171 134 0.401

18 20.54 57 4.139 96 1.136 135 0.391

19 19.63 58 3.99 97 1.103 136 0.382

36

Page 36

Appendix 2: Resistance Table of Outdoor and Indoor Tube Temperature Sensors(20K)

Temp.(°C) Resistance(kΩ) Temp. (°C) Resistance(kΩ) Temp.(°C) Resistance(kΩ) Temp. (°C) Resistance(kΩ)

-19 181.4 20 25.01 59 5.13 98 1.427

-18 171.4 21 23.9 60 4.948 99 1.386

-17 162.1 22 22.85 61 4.773 100 1.346

-16 153.3 23 21.85 62 4.605 101 1.307

-15 145 24 20.9 63 4.443 102 1.269

-14 137.2 25 20 64 4.289 103 1.233

-13 129.9 26 19.14 65 4.14 104 1.198

-12 123 27 18.13 66 3.998 105 1.164

-11 116.5 28 17.55 67 3.861 106 1.131

-10 110.3 29 16.8 68 3.729 107 1.099

-9 104.6 30 16.1 69 3.603 108 1.069

-8 99.13 31 15.43 70 3.481 109 1.039

-7 94 32 14.79 71 3.364 110 1.01

-6 89.17 33 14.18 72 3.252 111 0.983

-5 84.61 34 13.59 73 3.144 112 0.956

-4 80.31 35 13.04 74 3.04 113 0.93

-3 76.24 36 12.51 75 2.94 114 0.904

-2 72.41 37 12 76 2.844 115 0.88

-1 68.79 38 11.52 77 2.752 116 0.856

0 65.37 39 11.06 78 2.663 117 0.833

1 62.13 40 10.62 79 2.577 118 0.811

2 59.08 41 10.2 80 2.495 119 0.77

3 56.19 42 9.803 81 2.415 120 0.769

4 53.46 43 9.42 82 2.339 121 0.746

5 50.87 44 9.054 83 2.265 122 0.729

6 48.42 45 8.705 84 2.194 123 0.71

7 46.11 46 8.37 85 2.125 124 0.692

8 43.92 47 8.051 86 2.059 125 0.674

9 41.84 48 7.745 87 1.996 126 0.658

10 39.87 49 7.453 88 1.934 127 0.64

11 38.01 50 7.173 89 1.875 128 0.623

12 36.24 51 6.905 90 1.818 129 0.607

13 34.57 52 6.648 91 1.736 130 0.592

14 32.98 53 6.403 92 1.71 131 0.577

15 31.47 54 6.167 93 1.658 132 0.563

16 30.04 55 5.942 94 1.609 133 0.549

17 28.68 56 5.726 95 1.561 134 0.535

18 27.39 57 5.519 96 1.515 135 0.521

19 26.17 58 5.32 97 1.47 136 0.509

37

Page 37

Appendix 3: Resistance Table of Outdoor Discharge Temperature Sensor(50K)

Temp.(°C) Resistance(kΩ) Temp.(°C) Resistance(kΩ) Temp.(°C) Resistance(kΩ) Temp.(°C) Resistance(kΩ)

-29 853.5 10 98 49 18.34 88 4.754

-28 799.8 11 93.42 50 17.65 89 4.609

-27 750 12 89.07 51 16.99 90 4.469

-26 703.8 13 84.95 52 16.36 91 4.334

-25 660.8 14 81.05 53 15.75 92 4.204

-24 620.8 15 77.35 54 15.17 93 4.079

-23 580.6 16 73.83 55 14.62 94 3.958

-22 548.9 17 70.5 56 14.09 95 3.841

-21 516.6 18 67.34 57 13.58 96 3.728

-20 486.5 19 64.33 58 13.09 97 3.619

-19 458.3 20 61.48 59 12.62 98 3.514

-18 432 21 58.77 60 12.17 99 3.413

-17 407.4 22 56.19 61 11.74 100 3.315

-16 384.5 23 53.74 62 11.32 101 3.22

-15 362.9 24 51.41 63 10.93 102 3.129

-14 342.8 25 49.19 64 10.54 103 3.04

-13 323.9 26 47.08 65 10.18 104 2.955

-12 306.2 27 45.07 66 9.827 105 2.872

-11 289.6 28 43.16 67 9.489 106 2.792

-10 274 29 41.34 68 9.165 107 2.715

-9 259.3 30 39.61 69 8.854 108 2.64

-8 245.6 31 37.96 70 8.555 109 2.568

-7 232.6 32 36.38 71 8.268 110 2.498

-6 220.5 33 34.88 72 7.991 111 2.431

-5 209 34 33.45 73 7.726 112 2.365

-4 198.3 35 32.09 74 7.47 113 2.302

-3 199.1 36 30.79 75 7.224 114 2.241

-2 178.5 37 29.54 76 6.998 115 2.182

-1 169.5 38 28.36 77 6.761 116 2.124

0 161 39 27.23 78 6.542 117 2.069

1 153 40 26.15 79 6.331 118 2.015

2 145.4 41 25.11 80 6.129 119 1.963

3 138.3 42 24.13 81 5.933 120 1.912

4 131.5 43 23.19 82 5.746 121 1.863

5 125.1 44 22.29 83 5.565 122 1.816

6 119.1 45 21.43 84 5.39 123 1.77

7 113.4 46 20.6 85 5.222 124 1.725

8 108 47 19.81 86 5.06 125 1.682

9 102.8 48 19.06 87 4.904 126 1.64

38

Page 38

39

Page 39

Page 40

Via Gettuglio Mansoldo

(Loc. La Macia) 37040 Arcole

Verona, Italy

Tel. +39 - 045.76.36.585 r.a.

Fax +39 - 045.76.36.551 r.a.

www.maxa.it

e-mail: maxa@maxa.it

Loading...

Loading...