MAXA BDLM26A2, BDLM36A2, BD2M53A3, BD3M98A3, BDLM53A2 Technical Manual

TECHNICAL MANUAL 2013

SPLIT LIGHT MULTI DC INVERTER

MODELS

Indoor units Outdoor units

BDLM26A2 BD2M53A3

BDLM36A2 BD3M98A3

BDLM53A2

This manual has been created for informative purpose. The company declines every responsibility for the results of projecting or installation based on the explanations and the technical specifications

given in this manual. Is besides forbidden the reproduction under any form of the texts and of the figures contained in this manual.

Serie / Series / Serie / Serie

TECHNICAL MANUAL

SPLIT LIGHT MULTI DC

Emissione / Issue

Ausgabe / Emission

03 - 2013

Catalogo / Catalogue / Katalog / Catalogue

Sostituise / Supersade

Ersetzt / Remplace

04 - 2011

MTE01028D2820-01

3

INDICE

1. Specifics.....................................................................................................................................5

1.1 Indoor units specific.................................................................................................................. 5

1.2 Outdoor units specifics ............................................................................................................. 6

1.3 Noise criteria curve tables for both models ..............................................................................7

2. Outlines and dimensions ............................................................................................................ 7

2.1 Indoor unit ................................................................................................................................7

2.2 Outdoor unit .............................................................................................................................8

3. Refrigerant circuit ....................................................................................................................... 9

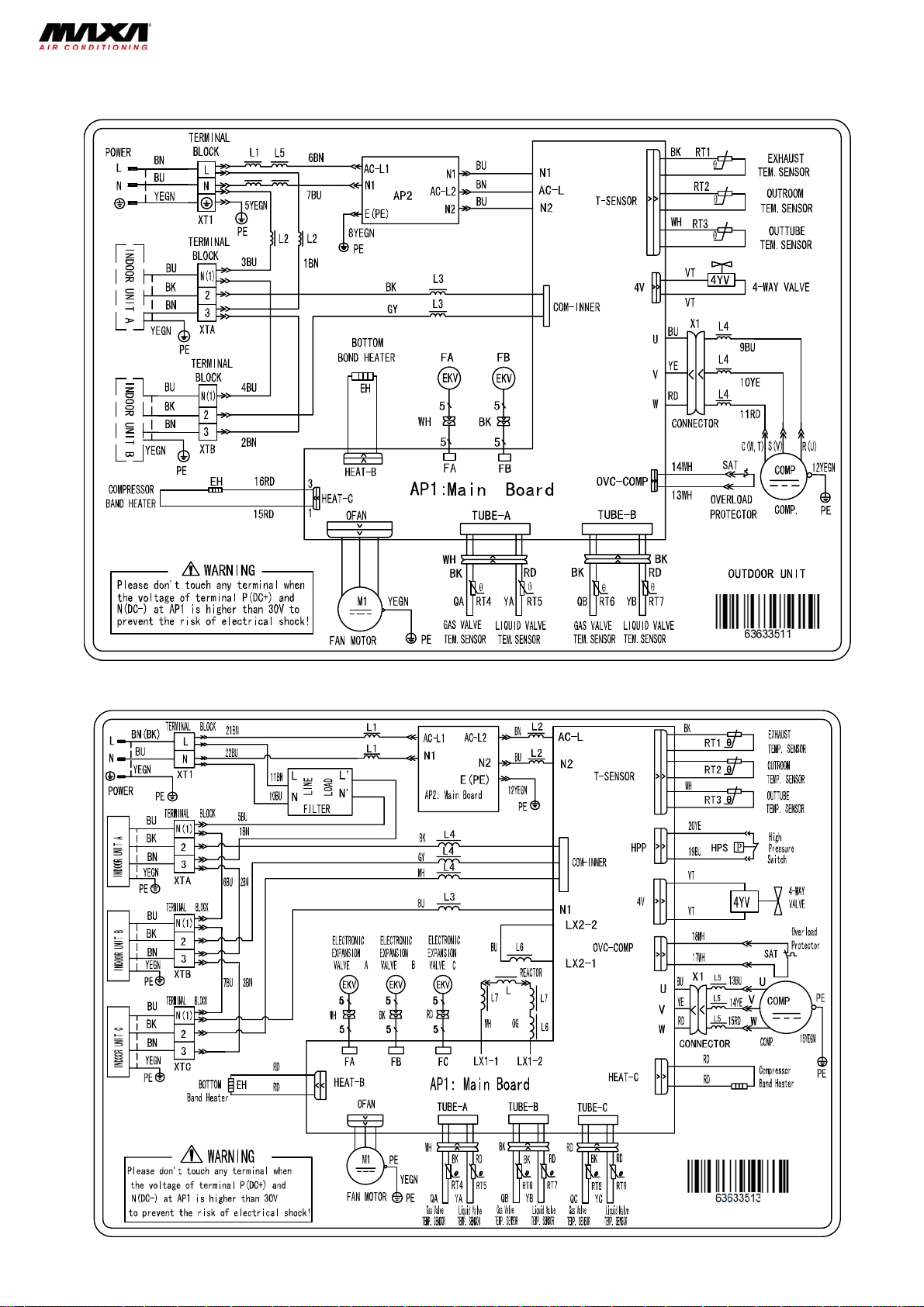

4. Electrical diagram.....................................................................................................................10

4.1 Indoor units ............................................................................................................................10

4.2 Outdoor unit ...........................................................................................................................11

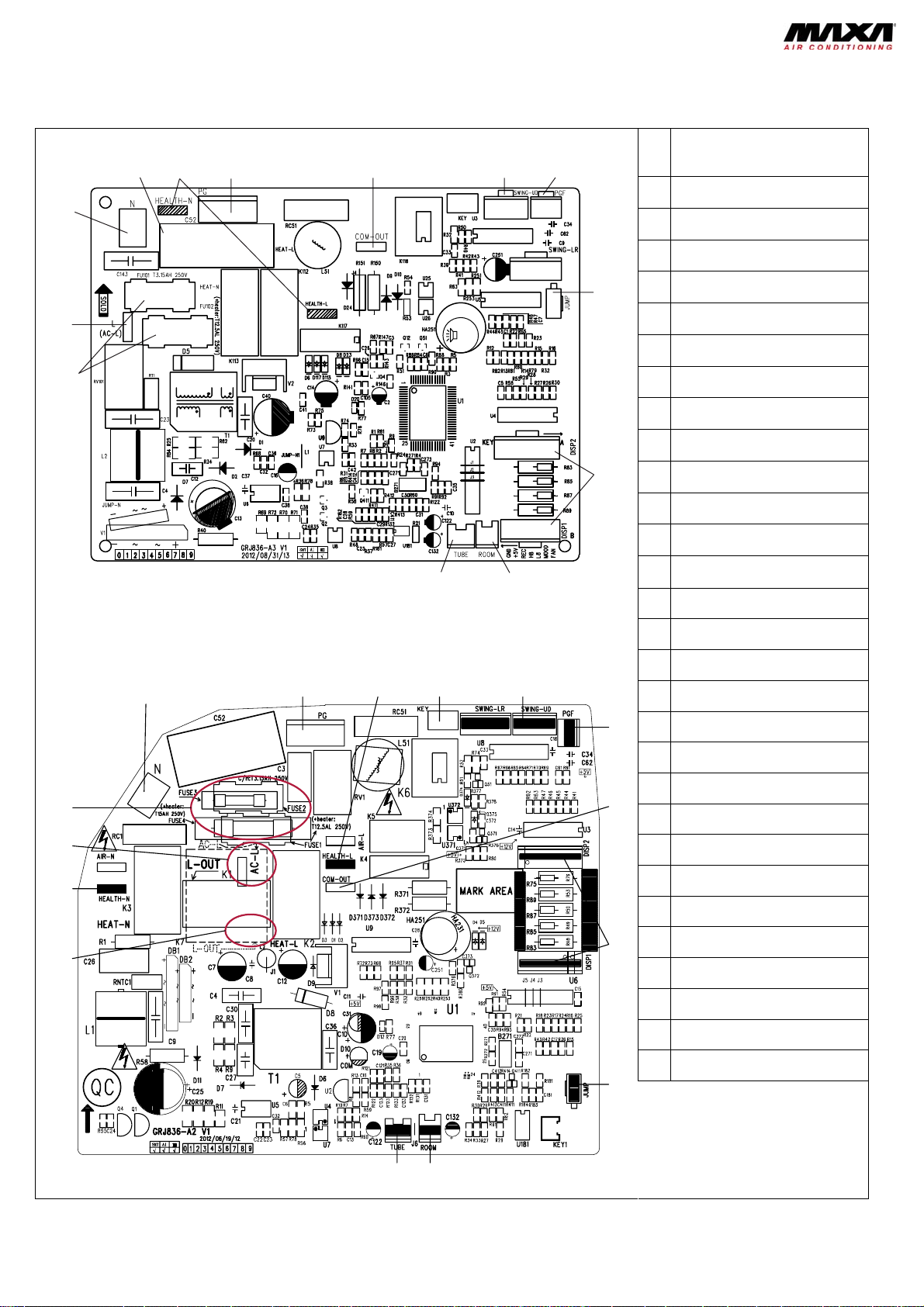

5. Printed circuit ...........................................................................................................................12

5.1 Indoor units ............................................................................................................................12

5.2 Indoor units ............................................................................................................................13

6. Control functions ...................................................................................................................... 14

6.1. Temperature Parameters ...................................................................................................... 14

6.2. Basic functions ...................................................................................................................... 14

6.3. Others ................................................................................................................................... 14

6.4. Displayer ...............................................................................................................................15

7. Outdoor units Operation ........................................................................................................... 17

7.1. Temperature parameters....................................................................................................... 17

7.2. System basic function ........................................................................................................... 17

8. Troubleshooting .......................................................................................................................20

8.1. Malfunction Display of Indoor Unit.........................................................................................20

8.2. How to Check simply the main part....................................................................................... 21

8.3 Malfunction Display of Outdoor Units ..................................................................................... 26

8.4 Malfunction checking and elimination..................................................................................... 27

Appendix.....................................................................................................................................36

Appendix 1: Resistance Table of Ambient Temperature Sensor for Indoor and Outdoor Units(15K).......................... 36

Appendix 2: Resistance Table of Outdoor and Indoor Tube Temperature Sensors(20K) ........................................... 37

Appendix 3: Resistance Table of Outdoor Discharge Temperature Sensor(50K)........................................................ 38

4

1. Specifics

1.1. Outdoor units specifics

Models

Power supply

Capacity

Power input kW 1,5(0,5~2,5) 2,15(0,6~4,5)

Cooling

Absorbed current A 6,8 10,9

S.E.E.R. W/W 5,60-A+ 5,10-A

Capacity

Power input kW 1,5(0,5~2,7) 2,28(0,8~3,9)

Heating

Absorbed current A 6,8 11,4

S.C.O.P. W/W 3,80-A 3,80-A

Compressor trademark

Compressor model QXA-B141zF030A QXAS-D23zX090B

Compressor type

Compressor oil

Comp. oil charge L

L.R.A.

Compressor RLA A 7,2

Compressor input

Compressor capacity

Comp. Overload protector 1NT11L-6233

Throttling method

Starting method

Working temp range °C

Condenser material Aluminum fin-copper tube

Rows-Fin Gap

Coil length (l) x height (H) x coil width (L) mm 851 x 660 x 38,1

Fan motor apeed rpm 880/700/500

Output of fan motor W

Fan Motor RLA A 0,56

Outdoor unit

Fan motor capacitor μF 4

Outdoor air flow volume m3/h 2600/2300/1600

Fan type-piece

Fan diameter mm

Defrosting method

Climate type

Isolation

Moisture protection

Permissible excessive operating pressure for the discharge side Mpa

Permissible excessive operating pressure for the suction side

Sound pressure level

Sound power level

Outline dimension mm 963 x 700 x 396 1001 x 790 x 427

Packing dimension mm 1029 x 458 x 750 1083 x 488 x 855

Net / Gross weight kg 50/55 96/74

Refrigerant charge kg R410A / 1,40

Max. connection pipe length (for each indoor unit)

Difference in livel m 10 10

Gas additional charge g/m

pipe

Pipe out.

Connection

diameter

Operating temperature °C

Liquid

Gas Inch 3/8 1/2

V- Ph, Hz 230V 220 ~ 240V , 50Hz

kW 5,0(2,0~6,3) 7,0(2,0~10,0)

Btu/h 17,0(6,9~21,5) 24,2(6,8~34,1)

kW 5,6(2,5~6,6) 8,5(3,2~11,0)

Btu/h 19,1(8,5~22,6) 29,0(10,9~37,5)

ZHUHAI LANDA COMPRESSOR CO. LTD

W 1440

4320

Electronic expansion valve

mm 2-1.4

MPa 2,5

dB(A) 56/53/50 58/54/52

dB(A) 66/63/60 68/64/62

m ≤20 ≤20

Inch 1/4 1/4

BD2M53A3 BD3M98A3

DC inverter Rotary

RB68EP

0,39 0,95

11,5

2550

7250

Transducer starting

-15°C ≤ T ≤ 48°C

982,2 x 748 x 38,1

690/600/500

60

0,6

3,5

3300/2900/2400

Axial fan –1

520 552

Automatic defrost

T1

I

IP24

4,3

R410A / 2,2

1/4

3/8

-15 ~ 48

5

0

[

]

1.2 Indoor units specifics

MODELS BDLM26A2 BDLM36A2 BDLM53A2

Power supply

Total capacity

Power input W 10 10

Cooling

Absorbed current A 0,04 0,04

Total capacity

Power input W 10 10

Heating

Absorbed current A 0,04 0,04

Air flow volume

Dehumidifying volume l/h 0,6

Fan motor speed (SH/M/L) (r/min) 1320/1200/1100/950 1280/1080/1000/920

Fan Motor Capacitor μF 1 1

Fan motor full load Amp (FLA) A 0,144 0,22

Output of fan motor W 10 20

Motor model FN10A-PG FN20J-PG

Fan type-piece

Diameter-Length mm Ø85 X 596 Ø92 X 645

Evaporator

Pipe diameter

Row-Fin gap mm 2-1,5 2-1,4

Indoor Coil

Coil length (l)xheight (H)xcoil width (L)

Swing motor model MP24AA

Output of swing motor W 1,5 1,5

Fuse

Indoor sound level (H/M/L) dB(A) 39/34/28 40/35/30

Dimension (W/D/H) mm 790X174X265 845X180X275

Dimension of package (W/D/H) mm 870x248X355 918x258X370

Net weight/Gross weight

Liquid pipe

Gas pipe (to indoor unit)

(SH/H/M/L)**

(m3/h)

V-Ph, Hz

kW 2.600 3.500

Btu/h 8,8 11,9

kW 2.800 3.800

Btu/h 9,5 12,9

500 630

Cross flow fan – 1

Aluminum fin-copper tube

mm Ø7

mm 581X267X25,4 690X267X25,4

A PCB 3,15A

kg 9/11 10/12,5

mm Ø6 Ø6

mm Ø9,52 Ø9,52

The data of specifications are subject to change without prior notice. Please refer to the actual data specified on the

nameplate of the unit.

220 ~ 240V ○,1, 50Hz

230V

1,4

5.300

18,0

55

0,3

5.800

19,7

55

0,3

850

1,8

1420/1250/1150/105

1,5

0,31

20

FN20V-PG

Ø98 X 710

2-1,4

715×304,8x25,4

MP28VB

2,0

43/40/35

940/200/298

1013X288X395

13/16

Ø6

Ø12,7

Note: Test conditions:

Standard condition

Dry bulb temp. °C Wet bulb temp. °C Dry bulb temp. °C Wet bulb temp. °C

Indoor side state Outdoor side state

Rated cooling 27 19 35 24

Max. cooling 32 23 48 26

Min. cooling 21 15 18 -

Rated heating 20 15 7 6

Max heating 27 - 24 18

Min. heating 20 15 -15 -16

3) Microphone at a distance of 1m from the unit.

Approximate calculation from Sound Pressure Level to Sound Power Level:

*1.0*1.0

LL

21

- Average Sound Pressure Level

L

: Sound pressure level of front test point.

1P

L

: Sound pressure level of side test point for indoor unit

2P

- Approximate Sound Power Lever

L =10*lg

p

LL =

+10.

pW

+

PP

LL .

21,PP

.

1010(*2/1

6

1.3 Noise criteria curve tables for both models

60

50

40

30

Noice/dB(A)

20

10

0

Low Middle High Super High

Indoor Fan Motor Rotating Speed

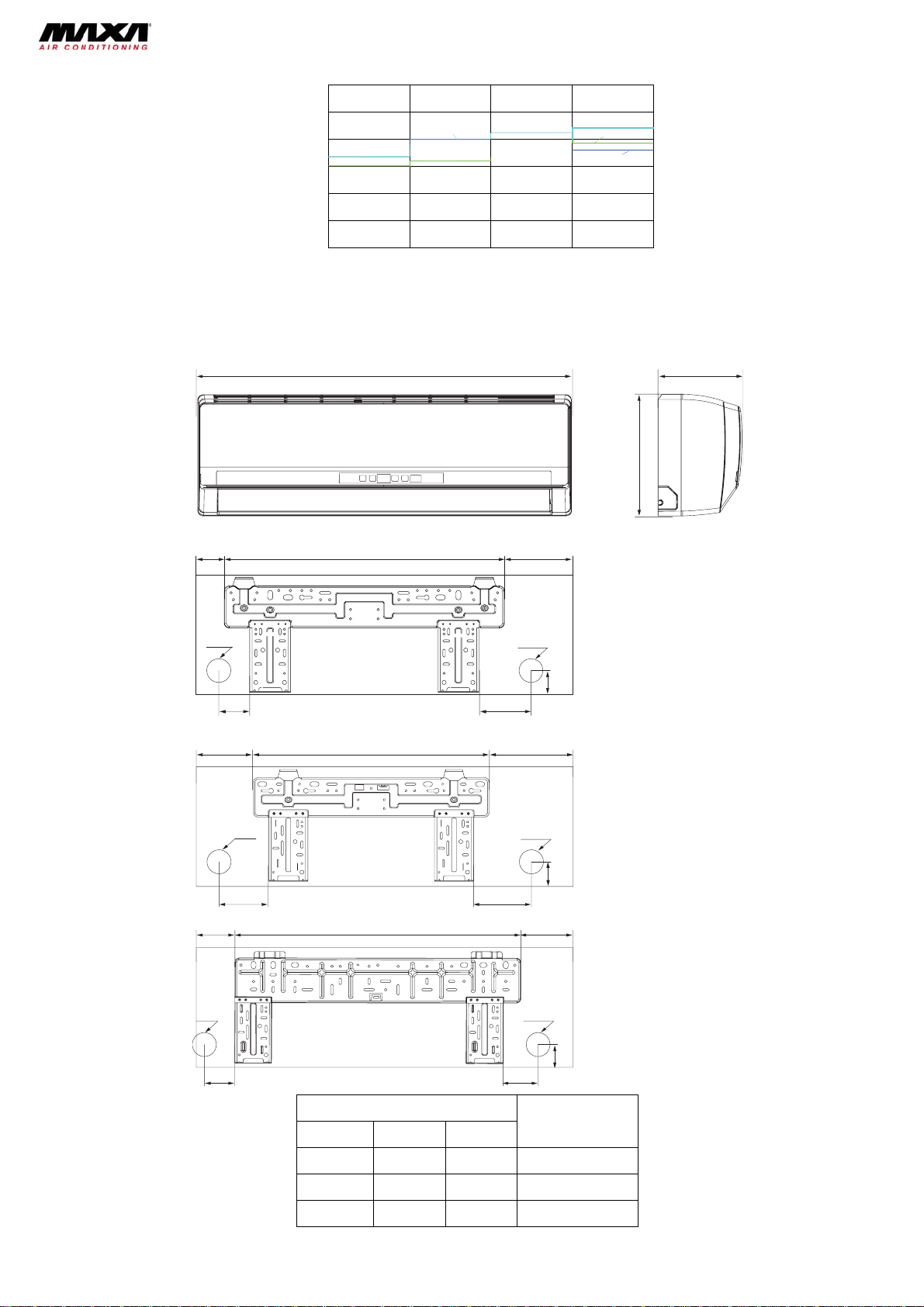

2. Outlines and dimensions

2.1 Indoor units

W

BDLM53A2

BDLM36A2

BDLM26A2

D

H

36

Φ55

Φ55

69

85

941506

BDLM26A2

09K Units

Φ55

40

8704

172542131

BDLM3A2

12K Units

Φ55

50

19469452

BDLM53A2

18K Units

Φ55

Φ55

61183

45

Dimension (mm)

Models

W H D

790 265 174 BDLM26A2

845 275 180 BDLM36A2

940 298 200 BDLM53A2

7

8

92341

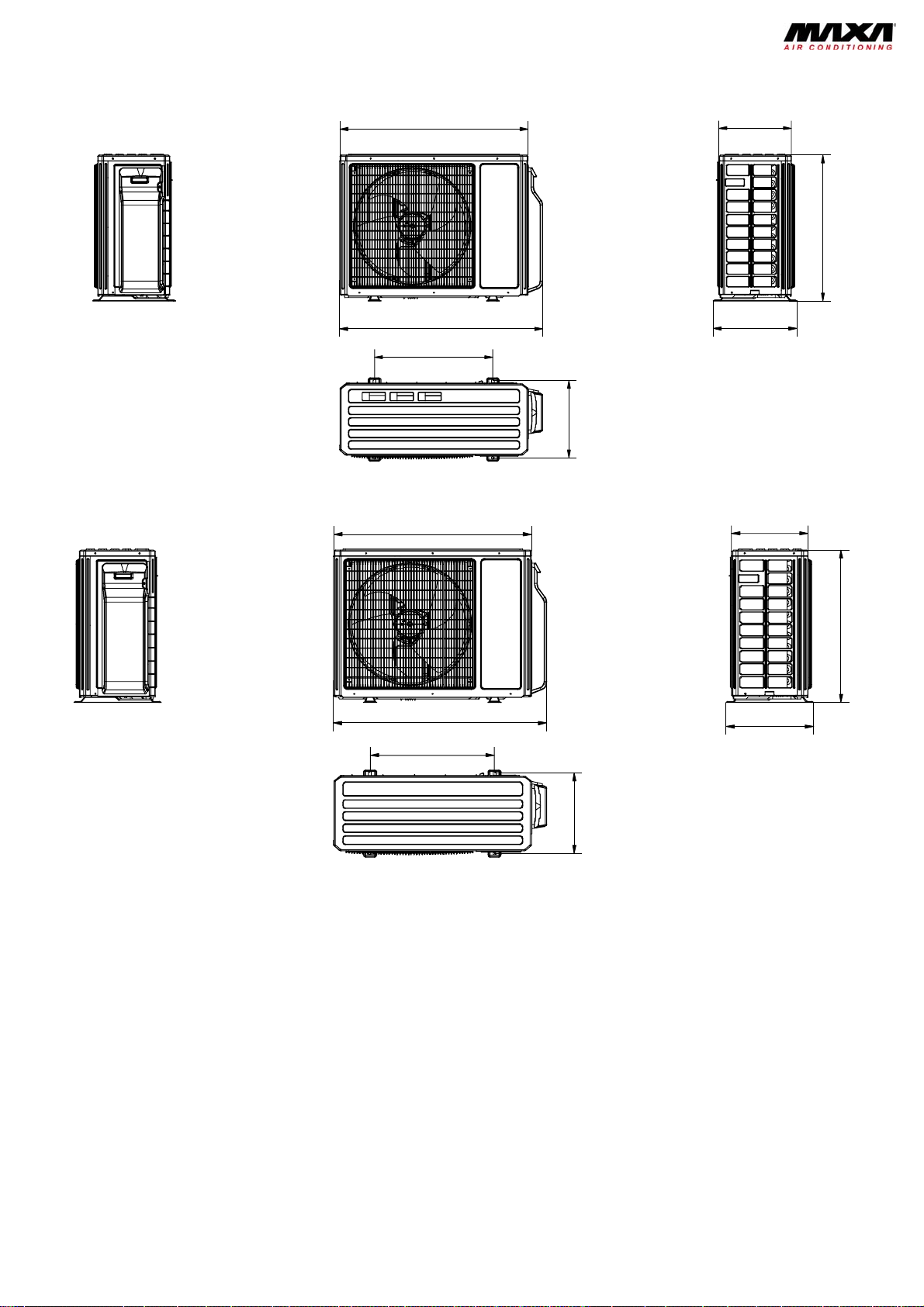

2.2 Outdoor units

a) BD2M53A3

560

700

396963

368

Unit:mm

b) BD3M98A3

924 370

1001

610

427

399

Unit:mm

790

8

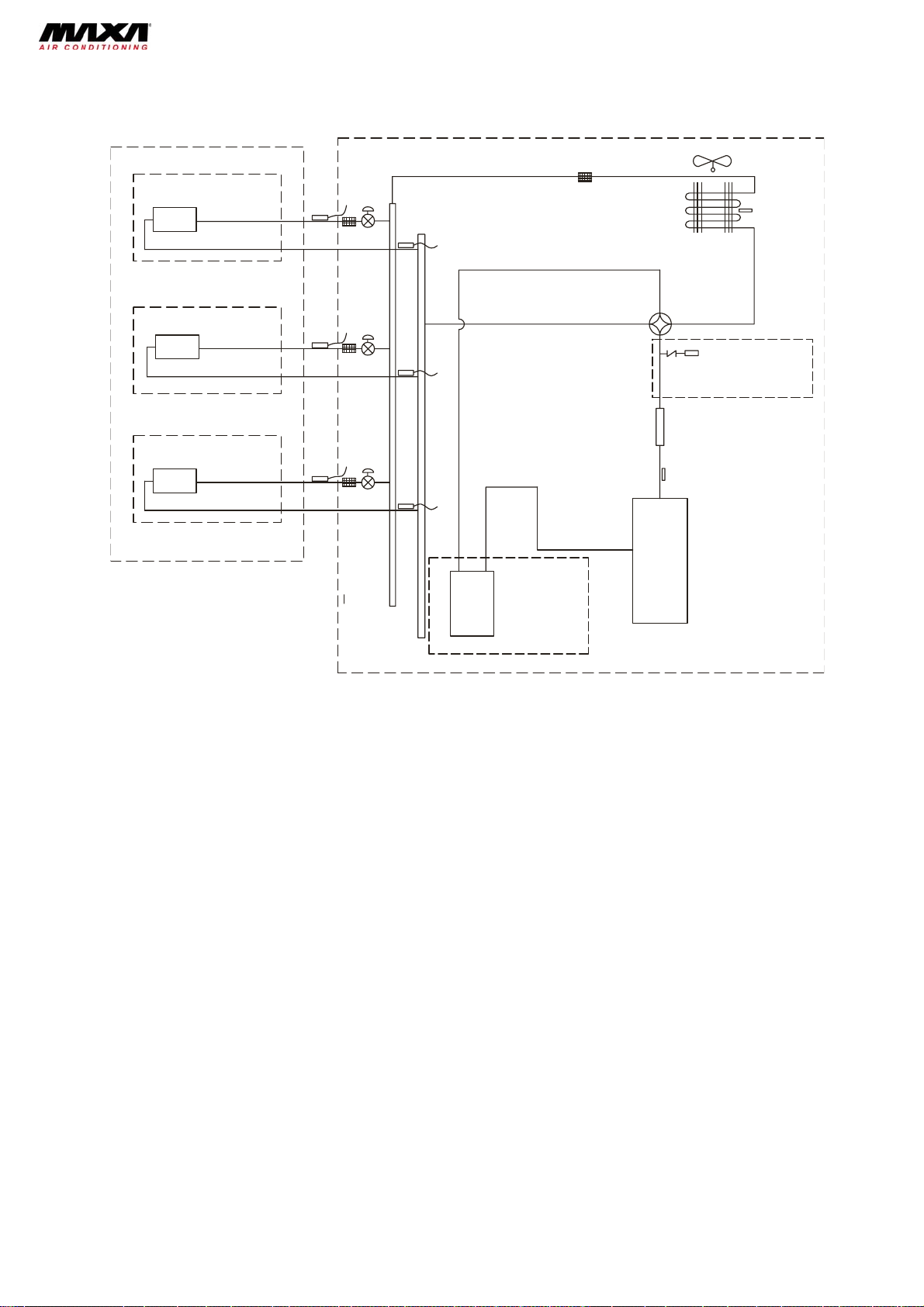

3. Refrigerant circuit

indoor

A heat exchanger

B heat exchanger

C heat exchanger

A3

B3

C3

filter

filter

filter

outdoor

filter

A

1

A2

B

1

B2

C

1

C2

outdoor heat exchanger

fan

4-way valve

SP

high pressure switch

Note: N ot available for 14K/1 8K

model

discharge silencer

discharge temperature

sensor

inverter comp resso r

gas -liquid separator

Note: N ot available for 1 4K/18K m od el

A1:A-unit electronic expansion valve A2:A-unit gas pipe temperature sensor A3:A-unit liquid pipe temperature sensor

B1:B-unit electronic expansion valve B2:B-unit gas pipe temperature sensor B3:B-unit liquid pipe temperature sensor

C1:C-unit electronic expansion valve C2:C-unit gas pipe temperature sensor C3:C-unit liquid pipe temperature sensor

D1:D-unit electronic expansion valve D2:D-unit gas pipe temperature sensor D3:D-unit liquid pipe temperature sensor

9

4. Electrical diagram

4.1 Indoor units

BDLM26A2, BDLM36A2

TUBE

TEM.SENSOR

0

RT2

TUBE

CAP

JUMP

DISP1

RECEIVERAND

DISPLAY BOARD

DISP2

AP1

ROOM

TEM.SENSOR

0

RT1

ROOM

AP2

SWING-UD

M2

SWING

MOTOR

HEALTH-N

BU

COO L PLASMA

GENER ATOR

FAN

MOTOR

M1

PG

COM-OUT

HEALTH-L

PGF

AC-L

RD

N

1BU

3BK

2BN

4YEGN

EVAPORATOR

XT

N(1)

2

3

PE

OUTDOOR UNIT

BU

BK

BN

YEGN

BDLM53A2

NOTE:The parts with broken line is applicable

to the models with COOL PLASMA GENERATOR

TUBE

TEMP.SENSOR

0

RT2

TUBE

ROOM

TEMP.SENSOR

0

RT1

ROOM

CAP

AP2

JUMP

DISP1

DISP2

SWING-UD

FAN MOTOR

M1

PG

PGF

N

COM-OUT

AC-L

HEALTH-NHEALTH-L

1BU

3BK

2BN

XT

N(1)

2

3

4YEGN

PE

EVAPORATOR

BU

BK

BN

YEGN

OUTDOOR UNIT

M2

AP1

RECEIVER AND

DISPLAY BOARD

SWING

MOTOR

RD

COO L PLASMA

GENER ATOR

(optional)

BU

10

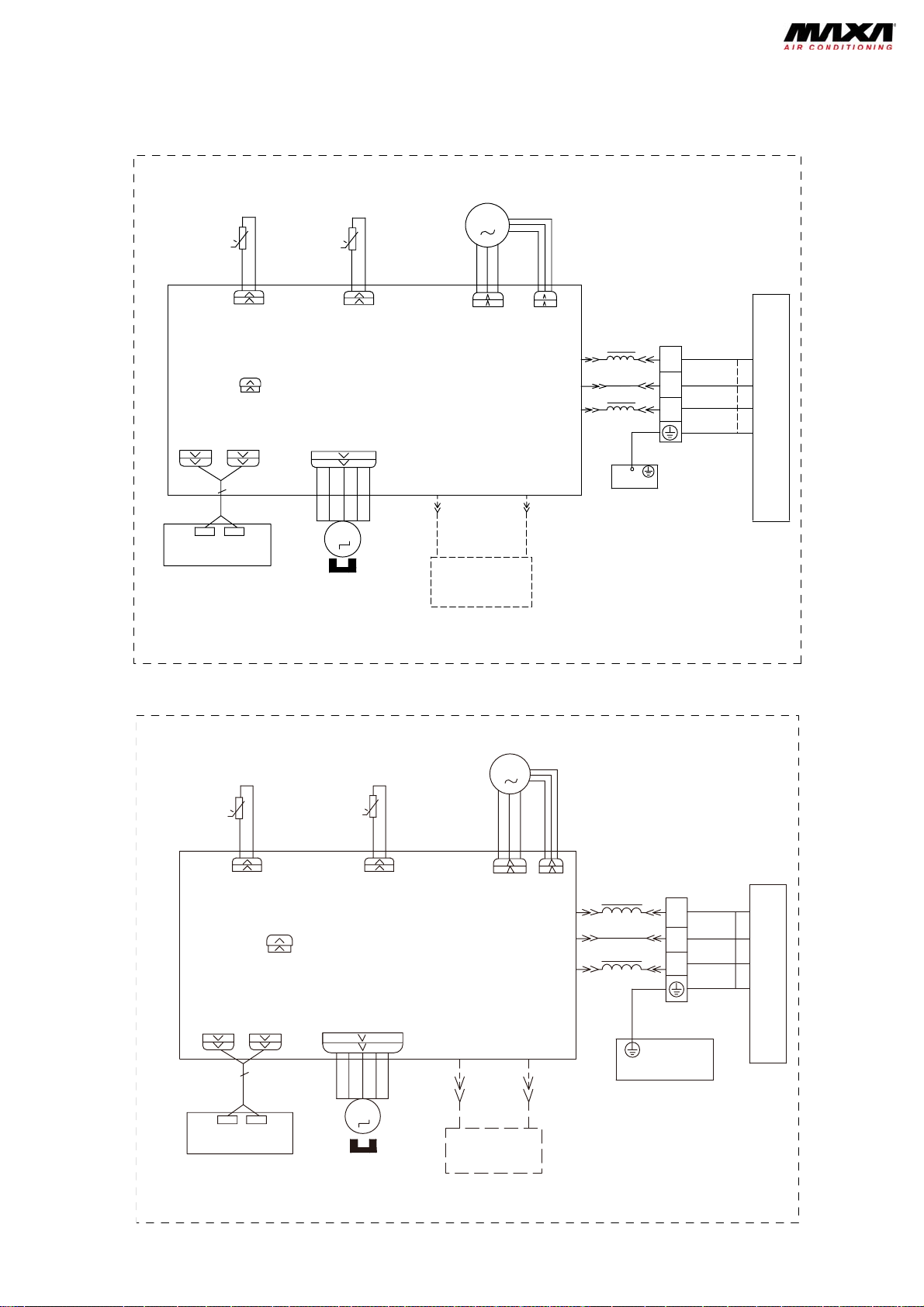

4.2 Outdoor unit

BD2M53A3

BD3M98A3

11

r

r

5. Printed circuits

5.1 Indoor units

Models: BDLM26A2, BDLM36A2

Top View

2

1

13

Model: BDLM53A2

Top View

1

853764

1112

234 5

9

10

No Part name

Power supply live wire connector

1

Power supply neutral wire

2

connector

Fan capacitor

3

Health function terminal

4

(optional)

5 Indoor fan wire terminal

Indoor and outdoor unit

6

communication wire terminal

Up & down swing control

7

terminal

Indoor fan feedback terminal

8

Jumper cap

9

Display panel terminal

10

Indoor ambient temperature

11

sensor

Indoor pipe temperature sensor

12

Protective tube

13

No Part name

1 Interface of neutral wire

2 Interface of PG motor

Interface of health function live

3

wire

6

4 Interface of auto button

5 Interface of up and down swing

6 Interface of PG feedback

15

14

13

12

1011

7

8

9

Interface of indoor and outdoor

7

unit communication

Interface of display

8

9 Interface of jumper cap

Interface of ambient temperature

10

senso

Interface of tube temperature

11

senso

Power supply interface of outdoor

12

live wire

Interface of heath function neutral

13

wire

14 Interface of live wire

15 Interface of fuse

12

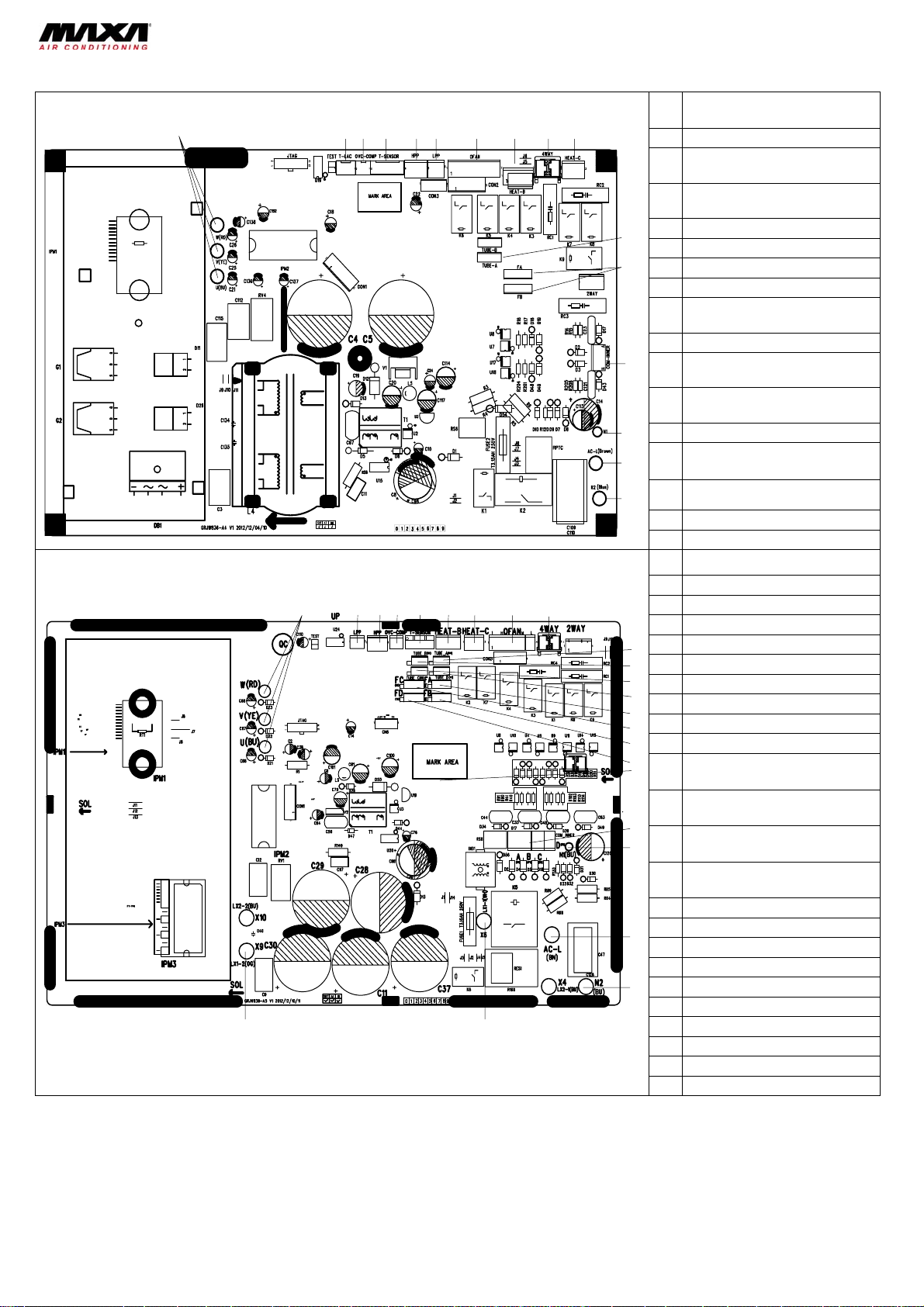

5.2 Outdoor units

3

516

71819

Model: BD2M53A3

1

Models: BD3M98A3

23

23 4 56 7 8 9 10

1

123456 879

22

No Part name

Compressor terminal

1

Temp. sensor terminal of low

2

ambient temp. cooling

Compressor overload protection

3

terminal

4 Outdoor temp. sensor terminal

11

5 High pressure protection terminal

12

13

14

15

16

10

11

12

1

14

1

1

20

21

Low pressure protection terminal

6

Outdoor fan terminal

7

Terminal of chassis electric

8

heating belt

4-way valve terminal

9

Terminal of compressor electric

10

heating belt

Temp sensor terminal of gas

11

valve and liquid valve

Electric expansion valve terminal

12

Terminal of IDU and ODU

13

communication wire

Terminal of communication

14

neutral wire

Live wire terminal

15

Neutral wire terminal

16

No Part name

1 Compressor terminal

High pressure protection

2

3 Low pressure protection

Compressor overload protection

4

5 Outdoor temp. sensor terminal

6 Terminal chassis electric heater

7 Terminal of comp. electric heater

Outdoor fan terminal

8

9 4-way valve terminal

Unit A liquid valve and gas valve

10

temp. sensor

Unit B liquid valve and gas valve

11

temp. sensor

Unit C liquid valve and gas valve

12

temp. sensor

Unit D liquid valve and gas valve

13

temp. sensor

14 Unit A electronic expansion valve

15 Unit B electronic expansion valve

16 Unit C electronic expansion valve

17 Unit D electronic expansion valve

Communication wire with indoor

18

19 Communication neutral wire

20 Live wire

21 Neutral wire

22 Reactor 1

23 Reactor 2

13

Loading...

Loading...