Max TA116/21-13, TA116/22-9, TA116/22-9(CE), TA116/21-13(CE) Maintenance Manual

TA116/21-13(CE)

TA116/22-9(CE)

FINE WIRE STAPLER

PNEUMATIC STAPLER

PNEUMATISCHER HEFTER

AGRAFEUSE ONEUMATIQUE

GRAFFATRICE PNEUMATICA

MÁQUINA GRAPADORA NEUMÁTICA

OPERATING and MAINTENANCE MANUAL

BETRIEBSANLEITUNG

MANUEL D’UTILISATION et D’ENTRETIEN

MANUALE DI FUNZIONAMENTO E MANUTENZIONE

MANUAL DE OPERACIONES Y MANTENIMIENTO

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY WARNING

AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

WARNING

LESEN SIE VOR INBETRIEBNAHME DES GERÄTES DIE GEBRAUCHS- UND SICHERHEITSHINWEISE. BITTE BEWAHREN SIE DIE GEBRAUCHS- UND SICHERHEITSHINWEISE AUF, DAMIT SIE AUCH SPÄTER EINGESEHEN WERDEN KÖNNEN.

ACHTUNG

AVANT D’UTILISER CET OUTIL, LIRE CE MANUEL ET LES CONSIGNES DE SECURITE

AFIN DE GARANTIR UN FONCTIONNEMENT SUR.

CONSERVER CE MANUEL EN LIEU SUR AVEC L’OUTIL AFIN DE POUVOIR LE CON-

AVERTISSEMENT

ATTENZIONE

SULTER ULTERIEUREMENT.

PRIMA DI USARE QUESTA MACCHINA, STUDIARE IL MANUALE PER PRENDERE ATTO

DEGLI AVVERTIMENTI E DELLE ISTRUZIONIPER LA SICUREZZA.

TENERE QUESTE ISTRUZIONI INSIEME ALLO STRUMENTO PER CONSULTAZIONI FUTURE.

PARA EVITAR GRAVES DAÑOS PERSONALES O EN LA PROPIEDAD.

ANTES DE EMPLEAR LA HERRAMIENTA, LEER CON ATENCIÓN Y COMPRENDER LOS

SIGUIENTES INSTRUCCIONES DE SEGURIDAD.

ATENCIÓN

ENGLISH

OPERATING and MAINTENANCE MANUAL

INDEX

1. SAFETY INSTRUCTIONS ..................................................3

2. SPECIFICATIONS AND TECHNICAL DATA ....................6

3. AIR SUPPLY AND CONNECTIONS ..................................6

4. INSTRUCTIONS FOR OPERATION ..................................7

5. MAINTENANCE..................................................................9

6. STORAGE ..........................................................................9

7. TROUBLE SHOOTING/REPAIRS......................................9

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY WARNING AND INSTRUCTIONS.

WARNING

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

1. SAFETY INSTRUCTIONS

WARNING

TO AVOID SEVERE PERSONAL INJURY OR PROPERTY

DAMAGE

BEFORE USING THE TOOL, READ CAREFULLY AND UNDERSTAND THE FOLLOWING "SAFETY INSTRUCTIONS". FAILURE TO FOLLOW WARNINGS COULD

RESULT IN DEATH OR SERIOUS INJURY.

PRECAUTIONS ON USING THE TOOL

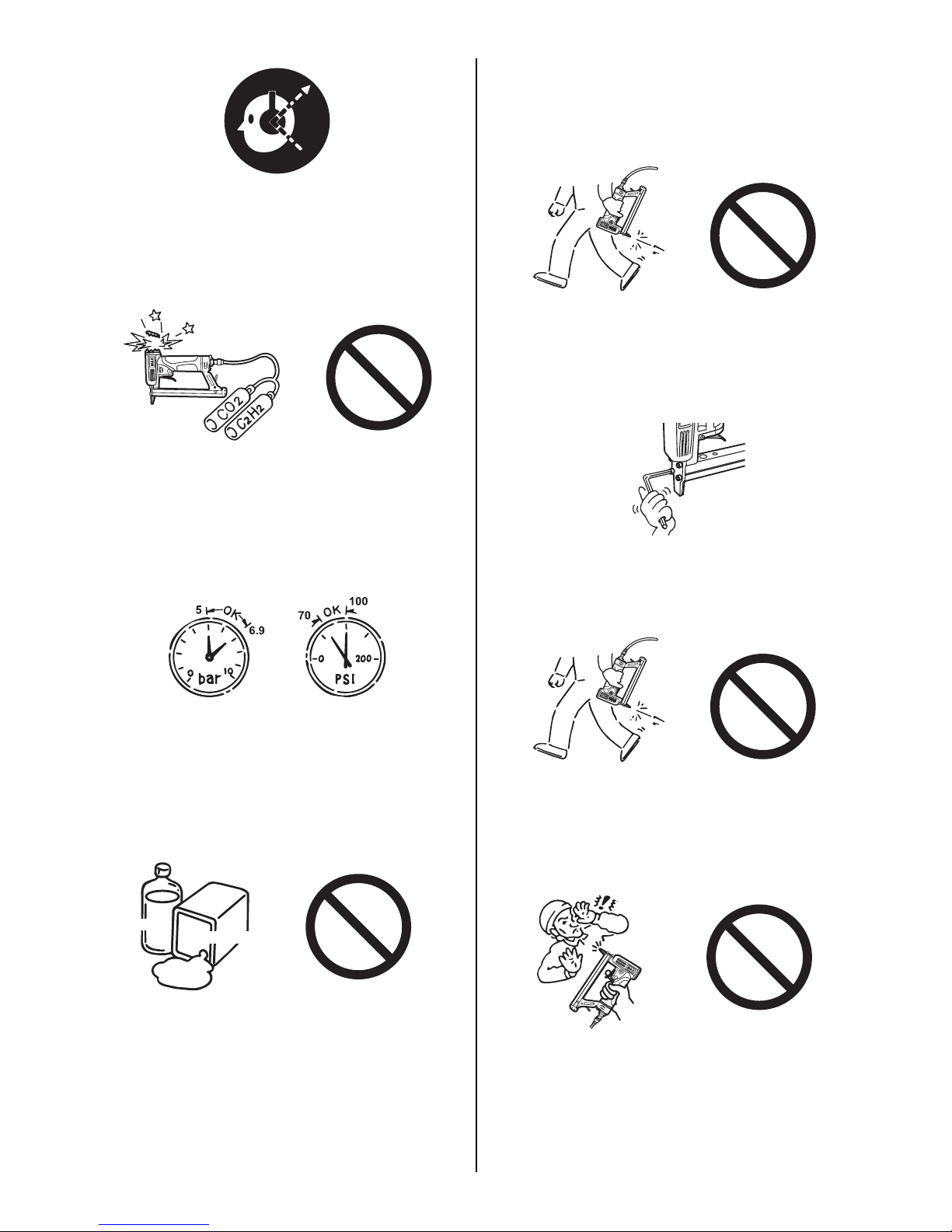

1. WEAR SAFETY GLASSES OR GOGGLES

Danger to the eyes always exists due to the possibility of

dust being blown up by the exhausted air or of a fastener flying up due to the improper handling of the tool. For these

reasons, safety glasses or goggles shall always be worn

when operating the tool.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment must conform to

the requirements of Council Directive 89/686/EEC of 21

DEC. 1989 (the American National Standards Institute,

ANSI Z87.1) and provide both frontal and side protection.

The employer is responsible to enforce the use of eye protection equipment by the tool operator and all other personnel in the work area.

NOTE: Non-side shielded spectacles and face shields

alone do not provide adequate protection.

3

2. EAR PROTECTION MAY BE REQUIRED IN SOME ENVIRONMENTS

As the working condition may include exposure to high

noise levels which can lead to hearing damage, the employer and user should ensure that any necessary hearing protection is provided and used by the operator and others in

the work area.

3. DO NOT USE ANY POWER SOURCE EXCEPT AN AIR

COMPRESSOR

The tool is designed to operate on compressed air. Do not

operate the tool on any other highpressure gas, combustible gases (e.g., oxygen, acetylene, etc.) since there is the

danger of an explosion. For this reason, absolutely do not

use anything other than an air compressor to operate the

tool.

7. DO NOT USE A WRONG FITTINGS

The connector on the tool must not hold pressure when air

supply is disconnected. If a wrong fitting is used, the tool

can remain charged with air after disconnecting and thus

will be able to drive a fastener even after the air line is disconnected, possibly causing injury.

8. DISCONNECT THE AIR SUPPLY AND EMPTY THE

MAGAZINE WHEN THE TOOL IS NOT IN USE

Always disconnect the air supply from the tool and empty

the magazine when operation has been completed or suspended, when unattended, moving to a different work area,

adjusting, disassembling, or repairing the tool, and when

clearing a jammed fastener.

9. INSPECT SCREW TIGHTNESS

Loose or improperly installed screws or bolts cause accidents and tool damage when the tool is put into operation.

Inspect to confirm that all screws and bolts are tight and

properly installed prior to operating the tool.

4. OPERATE WITHIN THE PROPER AIR PRESSURE

RANGE

The tool is designed to operate within an air pressure range

of 5 to 6.9 bar (70 to 100 p.s.i.).

The pressure should be adjusted to the type of the work being fastened. The tool shall never be operated when the operating pressure exceeds 6.9 bar (100 p.s.i.).

Never connect the tool to air pressure which potentially exceeds 13.8 bar (200 p.s.i.) as the tool can burst.

Thinner

Gasoline

5. DO NOT OPERATE THE TOOL NEAR A FLAMMABLE

SUBSTANCE

Never operate the tool near a flammable substance (e.g.,

thinner, gasoline, etc.). Volatile fumes from these substances could be drawn into the compressor and compressed together with the air and this could result in an explosion.

6. NEVER USE THE TOOL IN AN EXPLOSIVE ATMOSPHERE

Sparks from the tool may ignite atmospheric gases, dust or

other combustible materials.

10. DO NOT TOUCH THE TRIGGER UNLESS YOU INTEND

TO DRIVE A FASTENER

Whenever the air supply is connected to the tool, never

touch the trigger unless you intend to drive a fastener into

the work. It is dangerous to walk around carrying the tool

with the trigger pulled, and this and similar actions should

be avoided.

11. NEVER POINT THE DISCHARGE OUTLET TOWARD

YOURSELF AND OTHER PERSONNEL

If the discharge outlet is pointed toward people, serious accidents may be caused when misfiring. Be sure the discharge outlet is not pointed toward people when connecting

and disconnecting the hose, loading and unloading the fasteners or similar operations.

4

Loading...

Loading...