Page 1

SN890CH/34, SN890CH/28, SN890RH

and

SN890RH-R

PNEUMATIC NAILER

CLOUEUSE PNEUMATIQUES

CLAVADORAS NEUMATICAS PARA

PEINES DE CLAVO

OPERATING and MAINTENANCE MANUAL

MANUEL D’UTILISATION et D’ENTRETIEN

MANUAL DE OPERACIONES Y MANTENIMIENTO

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY

WARNING AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

AVANT D’UTILISER CET OUTIL, LIRE CE MANUEL ET LES CONSIGNES DE

SECURITE AFIN DE GARANTIR UN FONCTIONNEMENT SUR.

CONSERVER CE MANUEL EN LIEU SUR AVEC L’OUTIL AFIN DE POUVOIR LE

CONSULTER ULTERIEUREMENT.

PARA EVITAR GRAVES DAÑOS PERSONALES O EN LA PROPIEDAD.

ANTES DE EMPLEAR LA HERRAMIENTA, LEER CON ATENCIÓN Y

COMPRENDER LOS SIGUIENTES INSTRUCCIONES DE SEGURIDAD.

WARNING:

AVERTISSEMENT:

ATENCIÓN:

Page 2

2

DEFINITIONS OF SIGNAL WORDS

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

NOTE: Emphasizes essential information.

DÉFINITIONS DES DIFFÉRENTS DEGRÉS D’ AVERTISSEMENTS

AVERTISSEMENT Indique une situation éventuellement dangereuse qui, si elle n’est pas contournée,

pourrait provoquer la mort ou des blessure sérieuses.

ATTENTION Indique une situation éventuellement dangereuse qui, si elle n’est pas contournée,

pourrait provoquer des blessures légères à moyennement sérieuses.

REMARQUE Souligne des informations importantes.

DEFINICIÓN DE LAS INDICACIONES DE ADVERTENCIA

¡

ATENCIÓN! Indica una situación potencialmente peligrosa que podría causar la muerte o graves

lesiones si no se evita.

¡

PRECAUCIÓN! Indica una situación potencialmente peligrosa que podría causar lesiones menos

graves o leves si no se evita.

NOTA: Resalta informaciones importantes.

INDEX INDEX INDICE

ENGLISH Page 3 to 15 Page

FRANÇAIS Page 17 to 29 Page

ESPAÑOL Page 31 to 43 Page

Page 3

3

ENGLISH

SN890CH/34, SN890CH/28,

SN890RH and SN890RH-R

PNEUMATIC NAILER

INDEX

1. SAFETY INSTRUCTIONS

……………

4

2. SPECIFICATIONS &

TECHNICAL DATA

……………………

7

3. AIR SUPPLY AND CONNECTIONS

…

9

4.

INSTRUCTIONS FOR OPERATION…10

5. MAINTAIN FOR PERFORMANCE

…

15

6. STORING

……………………………

15

7. TROUBLESHOOTING/REPAIRS

……

15

OPERATING and MAINTENANCE MANUAL

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY WARNING

AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

WARNING:

Page 4

4

1. SAFETY INSTRUCTIONS

PRECAUTIONS ON USING THE TOOL

1. WEAR SAFETY GLASSES OR GOGGLES

Danger to the eyes always exists due to the possibility of dust being blown up by the exhausted air

or of a fastener flying up due to the improper handling of the tool. For these reasons, safety glasses

or goggles shall always be worn when operating the tool.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment

must conform to the requirements of the American National Standards Institute, ANSI Z87.1 (Council

Directive 89/686/EEC of 21 DEC. 1989) and provide both frontal and side protection.

The employer is responsible to enforce the use of eye protection equipment by the tool operator

and all other personnel in the work area.

NOTE: Non-side shielded spectacles and face shields alone do not provide adequate protection.

2. EAR PROTECTION MAY BE REQUIRED IN SOME ENVIRONMENTS

As the working condition may include exposure to high noise levels which can lead to hearing

damage, the employer and user should ensure that any necessary hearing protection is provided and

used by the operator and others in the work area.

3. DO NOT USE ANY POWER SOURCE EXCEPT AN AIR COMPRESSOR

The tool is designed to operate on compressed air. Do not operate the tool on any other highpressure

gas, combustible gases (e.g., oxygen, acetylene, etc.) since there is the danger of an explosion. For

this reason, absolutely do not use anything other than an air compressor to operate the tool.

4. OPERATE WITHIN THE PROPER AIR PRESSURE RANGE

The tool is designed to operate within an air pressure range of 70 to 100 p.s.i. (5 to 7 bar.)

The pressure should be adjusted to the type of the work being fastened. The tool shall never be

operated when the operating pressure exceeds 120 p.s.i. (8 bar.)

Never connect the tool to air pressure which potentially exceeds 200 p.s.i. (14 bar) as the tool can

burst.

5. DO NOT OPERATE THE TOOL NEAR A FLAMMABLE SUBSTANCE

Never operate the tool near a flammable substance (e.g., thinner, gasoline, etc.). Volatile fumes from

these substances could be drawn into the compressor and compressed together with the air and this

could result in an explosion.

6. DO NOT USE A WRONG FITTINGS

The connector on the tool must not hold pressure when air supply is disconnected. If a wrong fitting

is used, the tool can remain charged with air after disconnecting and thus will be able to drive a

fastener even after the air line is disconnected, possibly causing injury.

7. DISCONNECT THE AIR SUPPLY AND EMPTY THE MAGAZINE WHEN THE TOOL IS NOT

IN USE

Always disconnect the air supply from the tool and empty the magazine when operation has been

completed or suspended, when unattended, moving to a different work area, adjusting,

disassembling, or repairing the tool, and when clearing a jammed fastener.

WARNING:

TO AVOID SEVERE PERSONAL INJURY OR PROPERTY DAMAGE

BEFORE USING THE TOOL, READ CAREFULLY AND UNDERSTAND THE FOLLOWING

“SAFETY INSTRUCTIONS”. FAILURE TO FOLLOW WARNINGS COULD RESULT IN DEATH OR

SERIOUS INJURY.

5

7

70

100

Page 5

5

8. INSPECT SCREW TIGHTNESS

Loose or improperly installed screws or bolts cause accidents and tool damage when the tool is put

into operation. Inspect to confirm that all screws and bolts are tight and properly installed prior to

operating the tool.

9. DO NOT TOUCH THE TRIGGER UNLESS YOU INTEND TO DRIVE A FASTENER

Whenever the air supply is connected to the tool, never touch the trigger unless you intend to drive

a fastener into the work. It is dangerous to walk around carrying the tool with the trigger pulled, and

this and similar actions should be avoided.

10. NEVER POINT THE DISCHARGE OUTLET TOWARD YOURSELF AND OTHER PERSONNEL

If the discharge outlet is pointed toward people, serious accidents may be caused when misfiring.

Be sure the discharge outlet is not pointed toward people when connecting and disconnecting the

hose, loading and unloading the fasteners or similar operations.

11. USE SPECIFIED FASTENERS (SEE PAGE 7)

The use of fasteners other than specified fasteners will cause the tool malfunction. Be sure to use

only specified fasteners when operating the tool.

12. PLACE THE DISCHARGE OUTLET ON THE WORK SURFACE PROPERLY

Failure to place the discharge outlet of the nose in a proper manner can result in a fastener flying

up and is extremely dangerous.

13. KEEP HANDS AND BODY AWAY FROM THE DISCHARGE OUTLET

When loading and using the tool, never place a hand or any part of body in fastener discharge area

of the tool. It is very dangerous to hit the hands or body by mistake.

14. DO NOT DRIVE FASTENERS CLOSE TO THE EDGE AND CORNER OF THE WORK AND THIN

MATE RIAL

The workpiece is likely to split and the fastener could fly free and hit someone.

15. DO NOT DRIVE FASTENERS ON TOP OF OTHER FASTENERS

Driving fasteners of the top of other fasteners may cause deflection fasteners which could cause

injury.

16. REMOVING THE FASTENERS AFTER COMPLETING OPERATION

If fasteners are left in the magazine after the completion of operation, there is the danger of a serious

accident occurring prior to the resumption of operation, should the tool be handled carelessly, or

when connecting the air fitting. For this reason, always remove all fasteners remaining in the

magazine after completion of the operation.

17. CHECK OPERATION OF THE CONTACT TRIP MECHANISM FREQUENTLY IN CASE OF

USING A CONTACT TRIP TYPE TOOL

Do not use the tool if the trip is not working correctly as accidental driving of a fastener may result.

Do not interfere with the proper operation of the contact trip mechanism.

Page 6

6

18. WHEN USING THE TOOL OUTSIDE OR ELEVATED PLACE

When fastening roofs or similar slanted surface, start fastening at the lower part and gradually work

your way up. Fastening backward is dangerous as you may loose your foot place.

Secure the hose at a point close to the area you are going to drive fasteners. Accidents may be

caused due to the hose being pulled inadvertently or getting caught.

19. NEVER USE THE TOOL IF ANY PORTION OF THE TOOL CONTROLS (e.g., TRIGGER, CONTACT

ARM) IS INOPERABLE, DISCONNECTED, ALTERED OR NOT WOKING PROPERLY

20. NEVER ACTUATE THE TOOL INTO FREE SPACE

This will avoid any hazard caused by free flying fasteners and excessive strain of the tool.

21. ALWAYS ASSUME THAT THE TOOL CONTAINS FASTENERS

22. RESPECT THE TOOL AS A WORKING IMPLEMENT

23. NO HORSEPLAY

24. NEVER LOAD THE TOOL WITH FASTENERS WHEN ANY ONE OF THE OPERATING CONTROLS

(e.g., TRIGGER, CONTACT ARM) IS ACTIVATED

OBSERVE THE FOLLOWING GENERAL CAUTION IN ADDITION TO

THE OTHER WARNINGS CONTAINED IN THIS MANUAL

•

Do not use the tool as a hammer.

•

Always carry the tool by the handle, never carry the tool by the air hose.

•

The tool must be used only for the purpose it was designed.

•

Never remove, tamper with the operating controls (e.g., TRIGGER, CONTACT ARM)

•

Keep the tool in a dry place out of reach of children when not in use.

•

Do not use the tool without Safety Warning label.

•

Do not modify the tool from original design or function without approval by MAX CO., LTD.

Page 7

7

2. SPECIFICATIONS AND TECHNICAL DATA

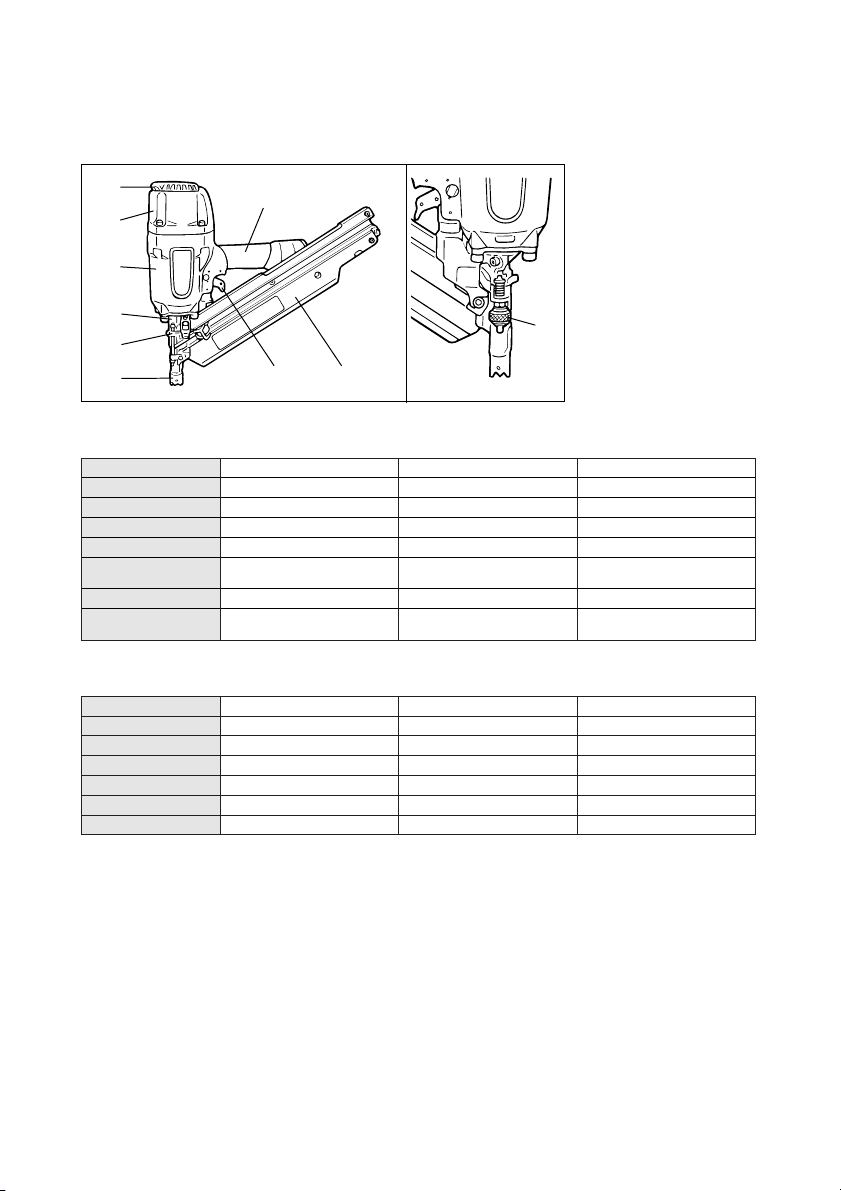

1. NAME OF PARTS

q

Frame

w

Cylinder Cap

e

Contact Arm

r

Nose

t

Magazine

y

Trigger

u

Grip

i

Exhaust Cover

o

Adjustment dial

!0

Door

i

u

w

q

r

e

!0

y t

o

PRODUCT NO. SN890CH/34 SN890CH/28 SN890RH, SN890RH-R

HEIGHT 14-3/4˝ (374 mm) 14-3/4˝ (374 mm) 14-1/8˝ (359.2 mm)

WIDTH 4˝ (102 mm) 4˝ (102 mm) 4˝ (102 mm)

LENGTH 17˝ (436 mm) 16-7/8˝ (429 mm) 21-3/8˝ (542 mm)

WEIGHT 8.0 lbs. (3.63 kg) 8.0 lbs. (3.63 kg) 8.0 lbs. (3.63 kg)

RECOMMENDED

70 to 100 p.s.i. (5 to 7 bar) 70 to 100 p.s.i. (5 to 7 bar) 70 to 100 p.s.i. (5 to 7 bar)

OPERATING PRESSURE

LOADING CAPACITY 90 Nails 75 Nails 64 Nails

AIR CONSUMPTION

1.78

Rat 90 p.s.i. (6 bar) 1.78Rat 90 p.s.i. (6 bar) 1.78Rat 90 p.s.i. (6 bar)

operating pressure operating pressure operating pressure

PRODUCT NO. SN890CH/34 SN890CH/28 SN890RH, SN890RH-R

NAIL LENGTH 2˝ to 3-1/2˝ (50 to 90 mm) 2˝ to 3-1/2˝ (50 to 90 mm) 2˝ to 3-1/2˝ (50 to 90 mm)

SHANK DIAMETER .113˝ to .148˝ (2.9 to 3.8 mm) .113˝ to .130˝ (2.9 to 3.3 mm) .113˝ to .148˝ (2.9 to 3.8 mm)

SHANK TYPE Smooth, Ring, Screw Smooth, Ring, Screw Smooth, Ring, Screw

HEAD DIAMETER .256˝ to .303˝ (6.5 to 7.7 mm) .275˝ to .303˝ (7.0 to 7.7 mm) .267˝ to .295˝ (6.8 to 7.5 mm)

COLLATION ANGLE 34 degree 28 degree 21 degree

HEAD Clipped head Clipped head Full round head

2. TOOL SPECIFICATIONS

TOOL AIR FITTINGS:

This tool uses a 3/8˝ N.P.T. male plug. The inside diameter should be .39˝ (9.9mm) or larger. The fitting must be capable of

discharging tool air pressure when disconnected from the air supply.

RECOMMENDED OPERATING PRESSURE:

70 to 100 p.s.i. (5 to 7 bar). Select the operating air pressure within this range for best fastener performance.

DO NOT EXCEED 120 p.s.i. (8 bar).

3. FASTENER SPECIFICATIONS

Page 8

8

4. TECHNICAL DATA

q

NOISE

A-weighted single-event ------ LWA, 1s, d 96.34 dB

sound power level

A-weighted single-event ------ LpA, 1s, d 87.68 dB

emission sound pressure

level at work station

These values are determined and documented in accordance to EN12549 : 1999.

w

VIBRATION

Vibration characteristic value = 5.18 m/s

2

These values are determined and documented in accordance to ISO 8662-11.

This value is a tool-related characteristic value and does not represent the influence to the hand-arm-system when using the tool.

An influence to the hand-arm-system when using the tool will for example depend on the gripping force, the contact pressure

force, the working direction, the adjustment of mains supply, the workpiece, the workpiece support.

5. APPLICATIONS

*Floor and wall framing

*Subflooring

*Roof and wall sheathing

*Fencing

Page 9

9

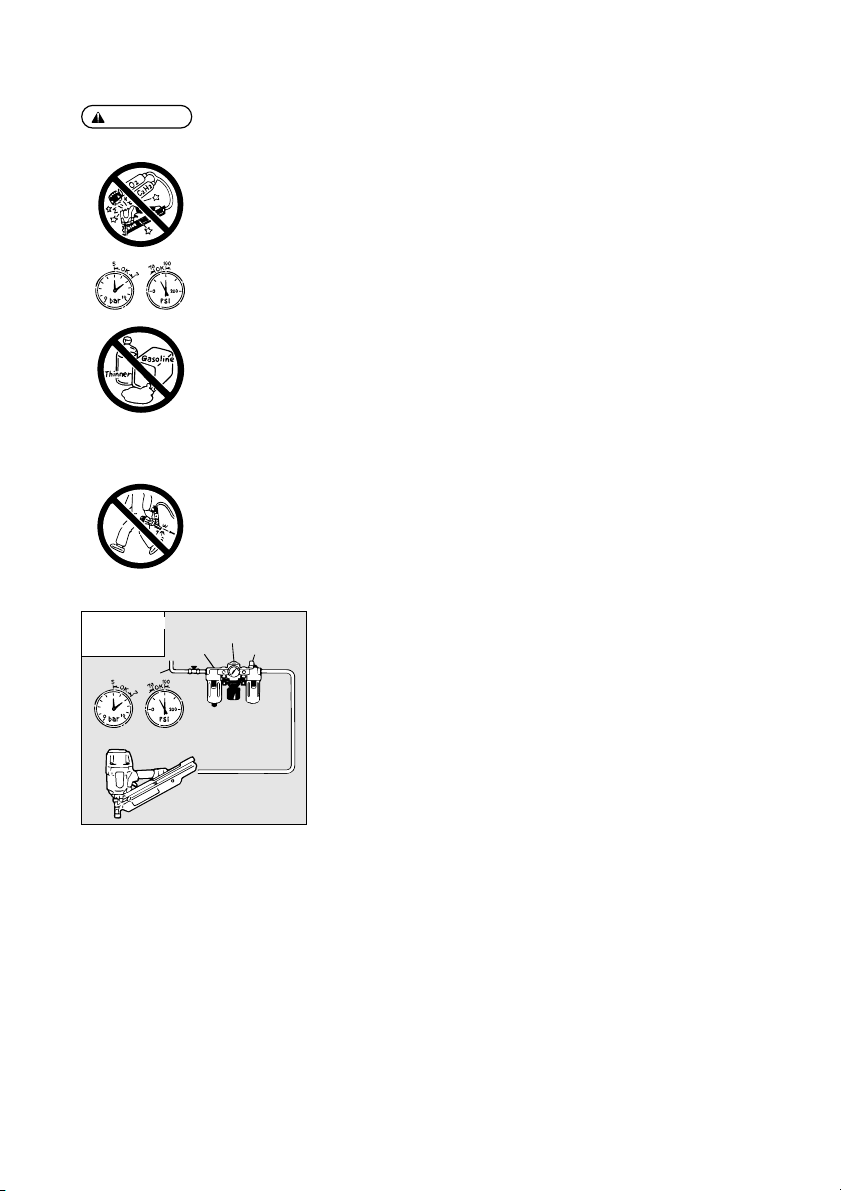

WARNING:

3. AIR SUPPLY AND CONNECTIONS

Read section titled “SAFETY INSTRUCTIONS”.

DO NOT USE ANY POWER SOURCE EXCEPT AN AIR COMPRESSOR

The tool is designed to operate on compressed air. Do not operate the tool on any other highpressure

gas, combustible gases (e.g., oxygen, acetylene, etc.) since there is the danger of an explosion. For this

reason, absolutely do not use anything other than an air compressor to operate the tool.

OPERATE WITHIN THE PROPER AIR PRESSURE RANGE

The tool designed to operate within an air pressure range of 70 to 100 p.s.i. (5 to 7 bar.)

The pressure should be adjusted to the type of the work being fastened. The tool shall never be

operated when the operating pressure exceeds 120 p.s.i. (8 bar.)

DO NOT OPERATE THE TOOL NEAR A FLAMMABLE SUBSTANCE

Never operate the tool near a flammable substance (e.g., thinner, gasoline, etc.). Volatile fumes from

these substances could be drawn into the compressor and compressed together with the air and this

could result in an explosion.

DO NOT USE A WRONG FITTINGS

The connector on the tool must not hold pressure when air supply is disconnected. If a wrong fitting is

used, the tool can remain charged with air after disconnecting and thus will be able to drive a fastener

even after the air line is disconnected, possibly causing injury.

DISCONNECT THE AIR SUPPLY AND EMPTY THE MAGAZINE WHEN THE TOOL IS NOT IN USE

Always disconnect the air supply from the tool and empty the magazine when operation has been

completed or suspended, when unattended, moving to a different work area, adjusting, disassembling,

or repairing the tool, and when clearing a jammed fastener.

FITTINGS: Install a male plug on the tool which is free flowing and which will release

air pressure from the tool when disconnected from the supply source.

HOSES: Hose has a min. ID of 1/4˝ (6 mm) and max. length of no more than 17˝ (5

meters).

The supply hose should contain a fitting that will provide “quick disconnecting” from

the male plug on the tool.

SUPPLY SOURCE: Use only clean regulated compressed air as a power source for

the tool.

3-PIECE AIRSET (Air filter, Regulator, Oiler):

Refer to TOOL SPECIFICATIONS for setting the correct operating pressure for the

tool.

NOTE:

A filter will help to get the best performance and minimum wear from the tool because dirt and water in

the air supply are major causes of wear in the tool.

Frequent, but not excessive, lubrication is required for the best performance. Oil added thru the air line

connection will lubricate the internal parts.

[

[

AIR SUPPLY & CONNECTIONS

AIR SUPPLY & CONNECTIONS

Air compressor

Air hose

Used at 70 to 100 p.s.i. (5 to 7 bar)

Air filter

3-piece airset

]

]

Regulator

Oiler

Page 10

10

WARNING:

WARNING:

4. INSTRUCTIONS FOR OPERATION

Read section titled “SAFETY INSTRUCTIONS”.

1. BEFORE OPERATION

q

Wear Safety Glasses or Goggles.

w

Do not connect the air supply.

e

Inspect screw tightness.

r

Check operation of the contact arm & trigger if moving smoothly.

t

Connect the air supply.

y

Check the air-leakage. (The Tool must not have the air-leakage.)

u

Hold the Tool with finger-off the trigger, then push the contact arm against the work-piece. (The tool

must not operate.)

i

Hold the Tool with contact arm free from work-piece and pull the trigger. (The Tool must not operate.)

o

Disconnect the air supply.

2. OPERATION

Wear safety glasses or goggles danger to the eyes always exists due to the possibility of dust being

blown up by the exhausted air or of a fastener flying up due to the improper handling of the tool. For

these reasons, safety glasses or goggles shall always be worn when operating the tool.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment

must conform to the requirements of the American National Standards Institute, ANSI Z87.1 (Council

Directive 89/686/EEC of 21 DEC. 1989) and provide both frontal and side protection.

The employer is responsible to enforce the use of eye protection equipment by the tool operator and all

other personnel in the work area.

NOTE: Non-side shielded spectacles and face shields alone do not provide adequate protection.

Keep hands and body away from the discharge outlet when driving the fasteners because of dangerous

of hitting the hands or body by mistake.

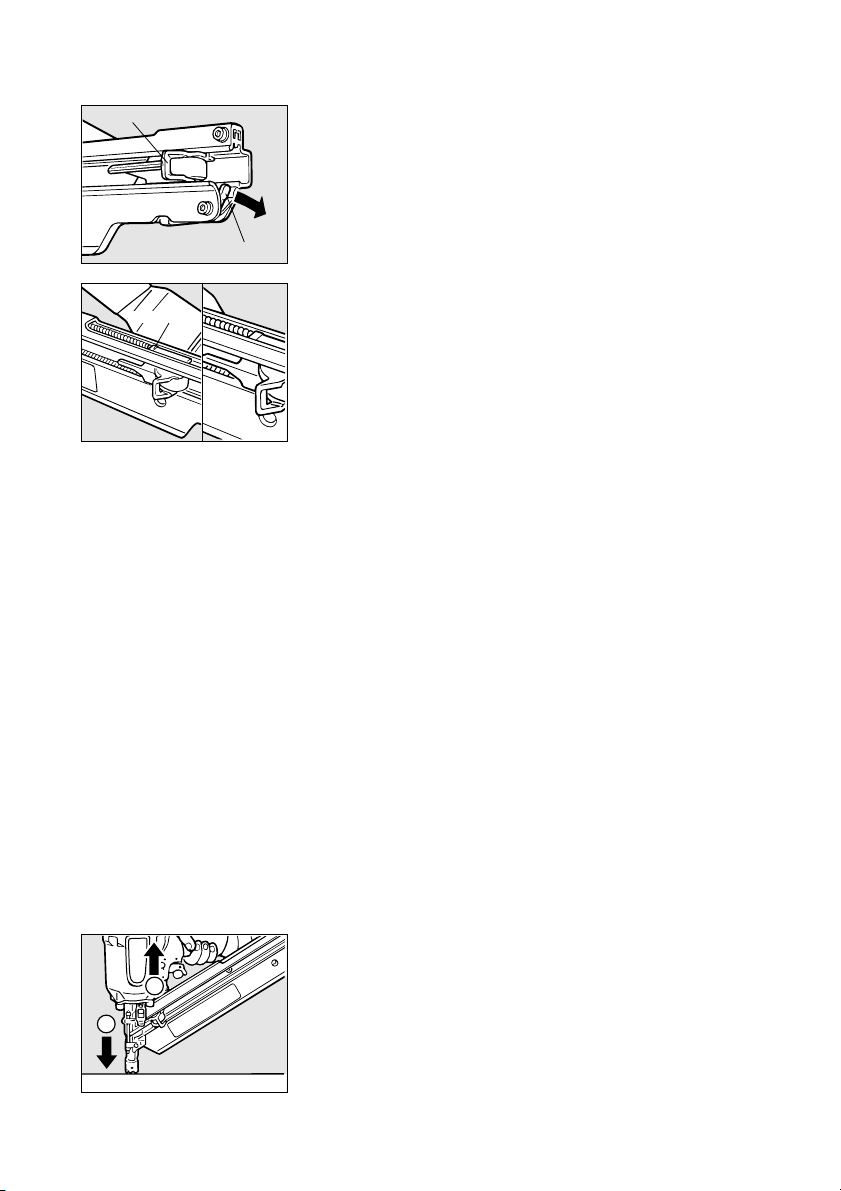

NAIL LOADING

q

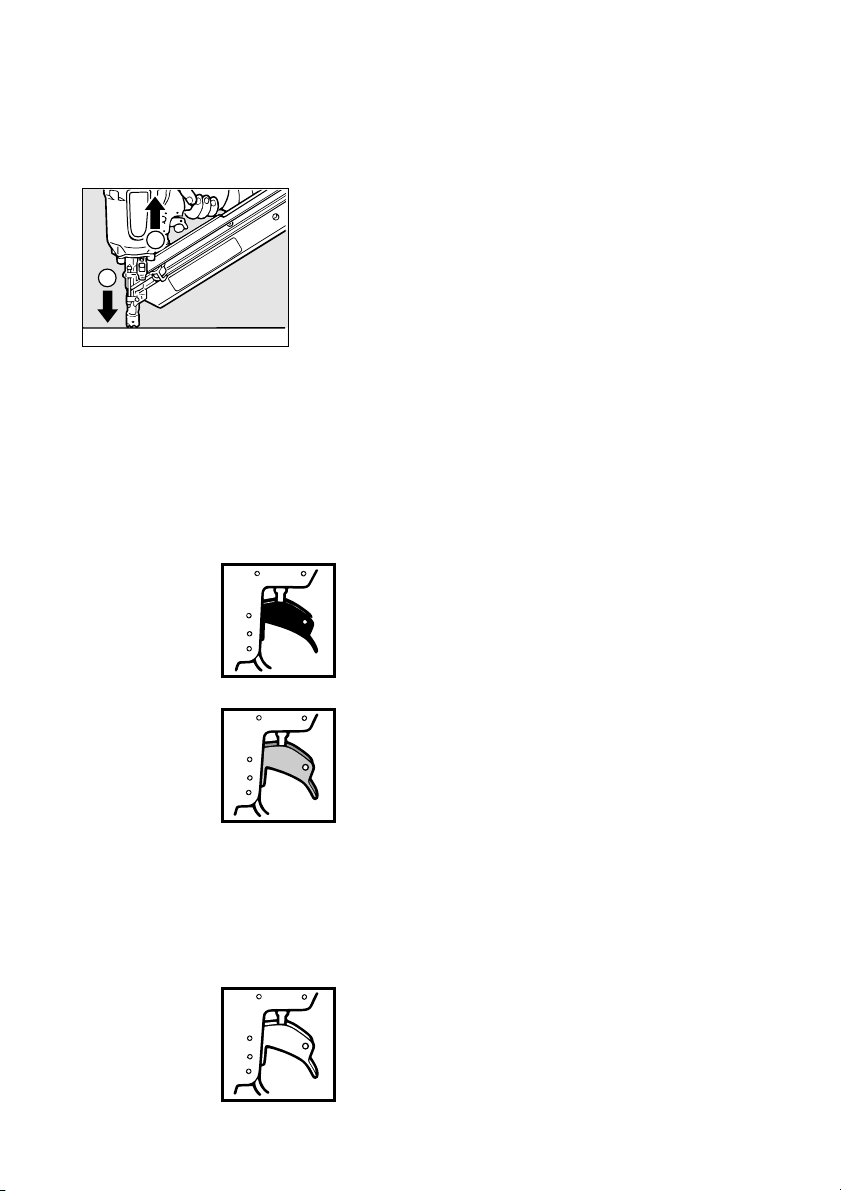

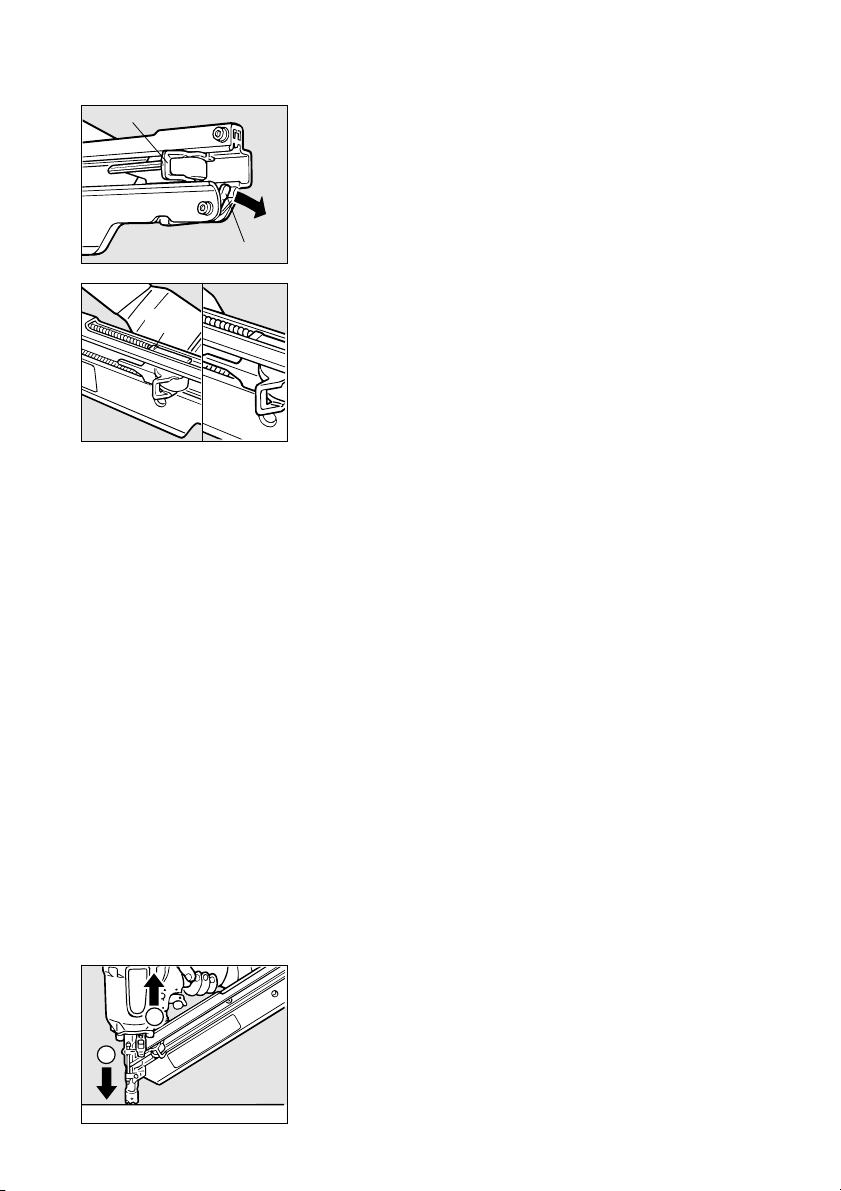

Pull the pusher back until it is engaged with the pusher hook.

w

Insert a strip of nails into the top of magazine.

Pusher hook

Magazine

Nails

Pusher

Page 11

11

e

Release the pusher hook as pulling the pusher. Slide the pusher against the nails.

NOTE:

Be sure that tip of the pusher is located above the last nail’s head as shown.

TEST OPERATION

q

Adjust the air pressure at 70 p.s.i. (5 bar) and connect the air supply.

w

Without touching the trigger, depress the contact arm against the work-piece.

Pull the trigger. (The tool must fire the fastener.)

e

With the tool off the work-piece, pull the trigger.

Then depress the contact arm against the work-piece.

(The tool must fire the fastener.)

r

Adjust the air pressure as much as the lowest possible according to the diameters and length of

fastener and the hardness of work-piece.

Pusher hook

Pusher

Tip of the pusher

PROCEDURE

q

Hold the trigger.

w

Depress the contact arm.

DRIVING FASTENERS

CONTACT TRIP MODEL w/ANTI-DOUBLE FIRE MECHANISM

The anti-double fire mechanism (US patent 5597106, UK patent 2286790) is installed on this tool.

The common operating procedure on “Contact Trip” tools is for the operator to contact the work to

actuate the trip mechanism while keeping the trigger pulled, thus driving a fastener each time the work is

contacted. This will allow rapid fastener placement on many jobs, such as sheathing, decking and pallet

assembly. All pneumatic tools are subject to recoil when driving fasteners. The tool may bounce,

releasing the trip, and if unintentionally allowed to re-contact the work surface with the trigger still

actuated (finger still holding trigger pulled) an unwanted second fastener will be driven.

CONTACT FIRE OPERATION

For contact fire operation, hold the trigger and depress the contact arm against the work surface.

1

2

Page 12

12

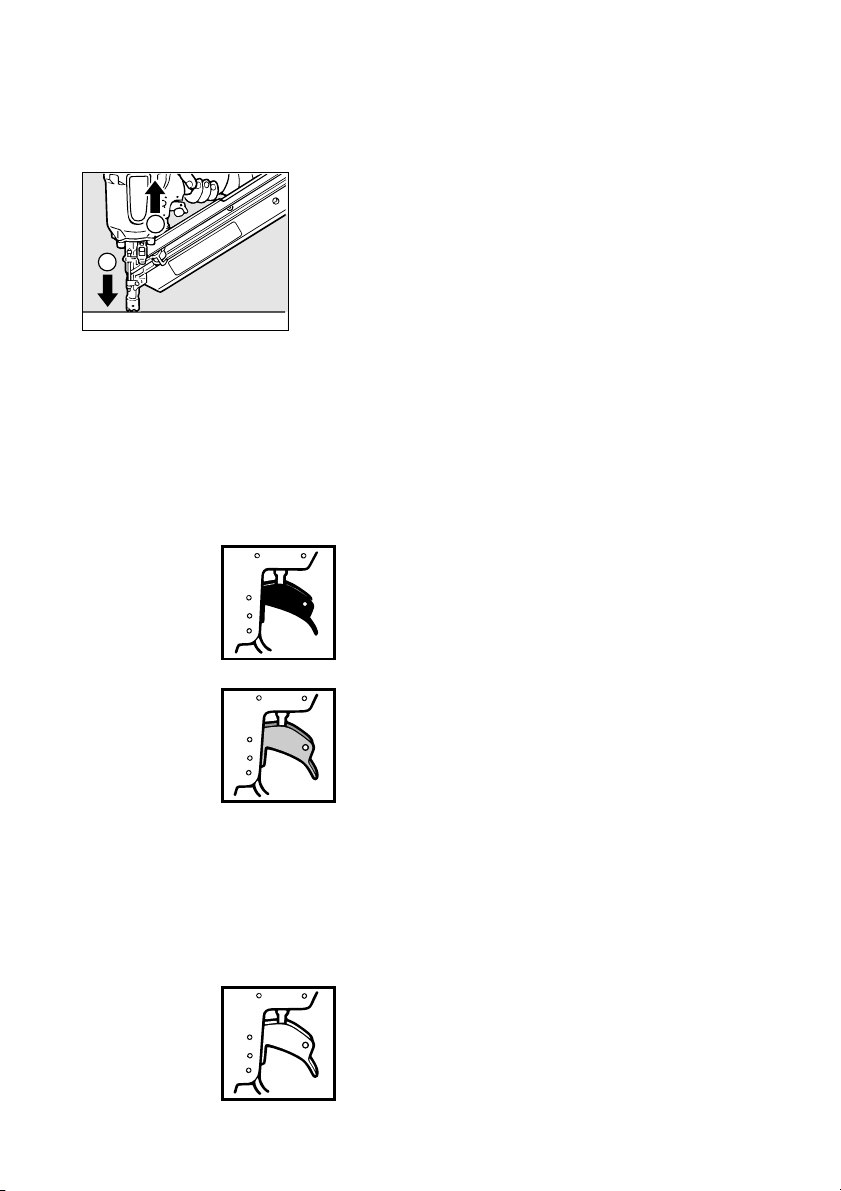

SEQUENTIAL TRIP

The Sequential Trip requires the operator to hold the tool against the work before pulling the trigger. This

makes accurate fastener placement easier, for instance on framing, toe nailing and crating applications.

The Sequential Trip allows exact fastener location without the possibility of driving a second fastener

on recoil, as described under “Contact Trip”.

The Sequential Trip Tool has a positive safety advantage because it will not accidentally drive a

fastener if the tool is contacted against the work-or anything else-while the operator is holding the

trigger pulled.

SEQUENTIAL TRIP

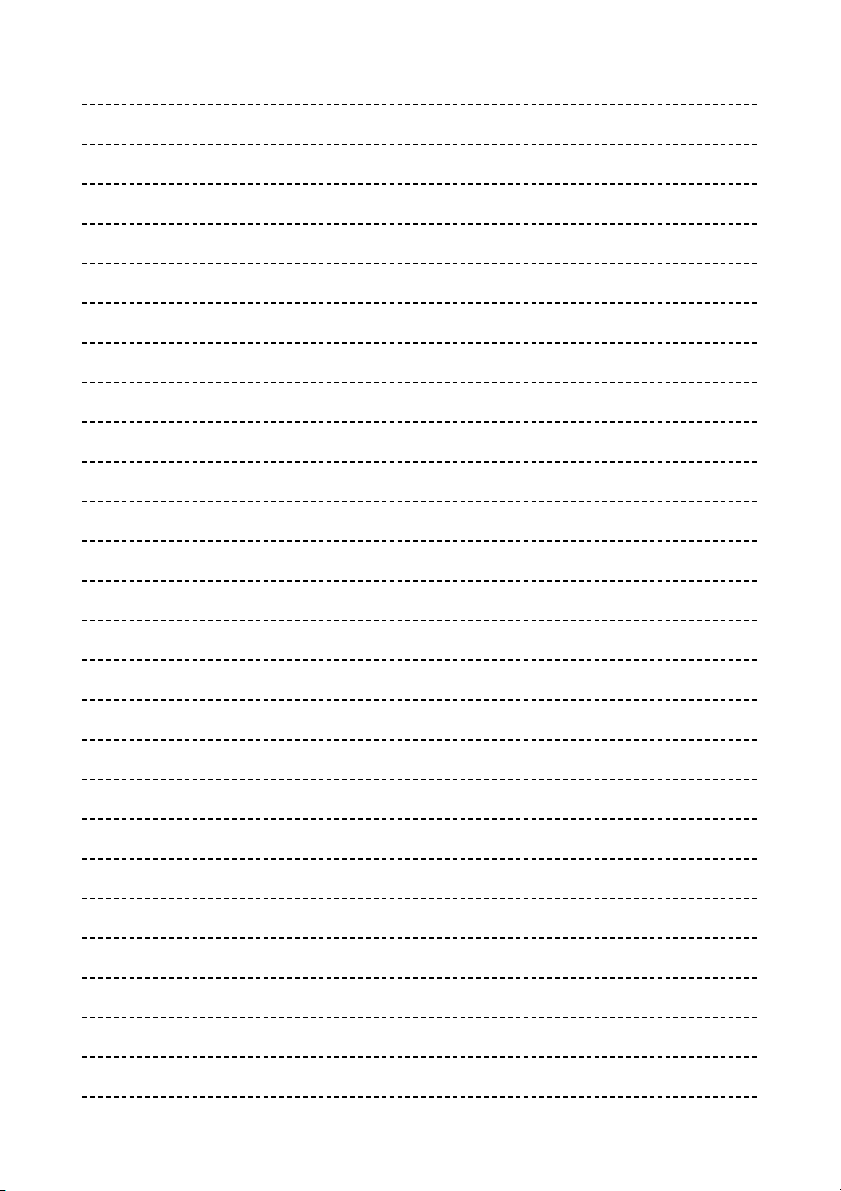

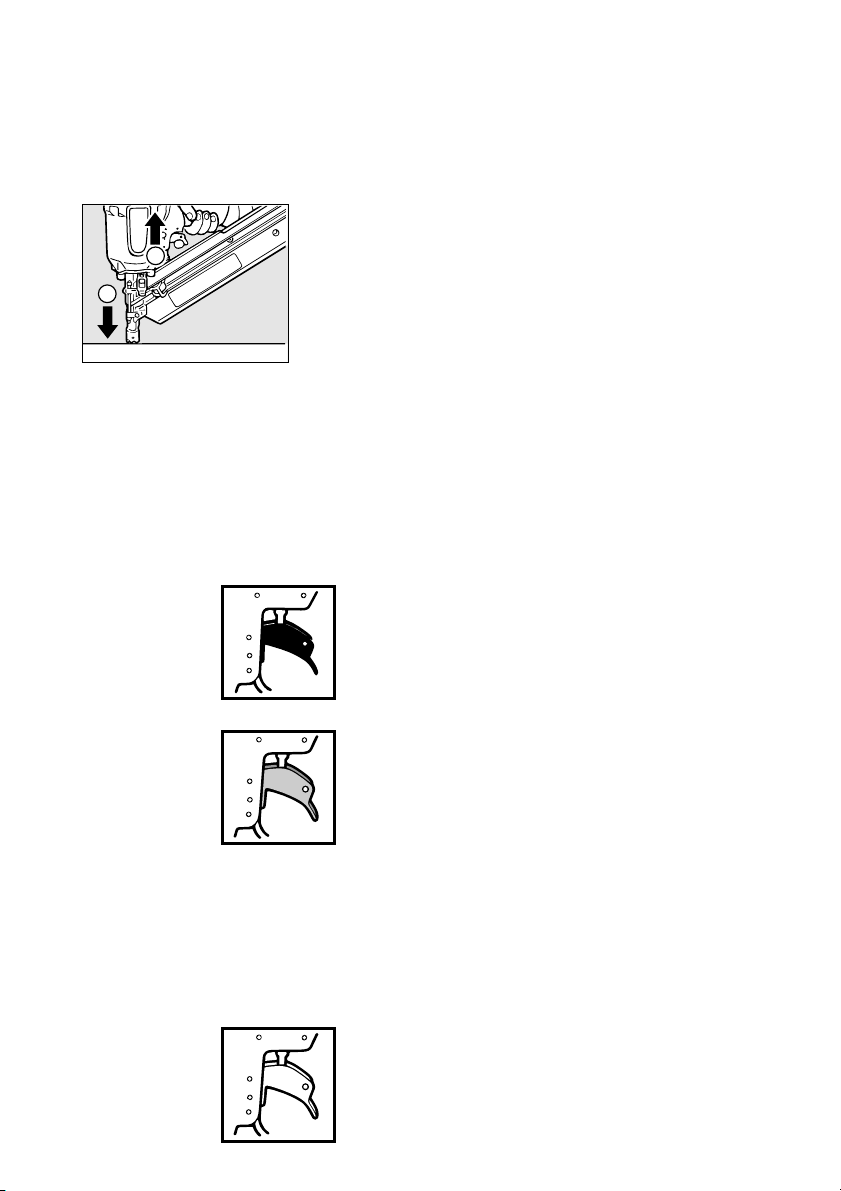

Identified by ORANGE TRIGGER.

PROCEDURE

q

Depress the contact arm.

w

Pull the trigger.

SINGLE FIRE OPERATION (ANTI-DOUBLE FIRE MECHANISM)

For single fire operation, depress the contact arm against the work surface and pull the trigger. Tool can

not fire a second nail until the trigger is released and tool can cycle.

MODEL IDENTIFICATION

CONTACT TRIP

The common operating procedure on “Contact Trip” tools is for the operator to contact the work to

actuate the trip mechanism while keeping the trigger pulled, thus driving a fastener each time the work

is contacted. This will allow rapid fastener placement on many jobs, such as sheathing, decking and

pallet assembly.

All pneumatic tools are subject to recoil when driving fasteners. The tool may bounce, releasing the trip,

and if unintentionally allowed to recontact the work surface with the trigger still actuated (finger still

holding trigger pulled) an unwanted second fastener will be driven.

CONTACT TRIP

Identified by BLACK TRIGGER.

CONTACT TRIP WITH ANTI-DOUBLE FIRE MECHANISM

(US patent 5597106, UK patent 2286790)

Identified by RED TRIGGER.

2

1

Page 13

13

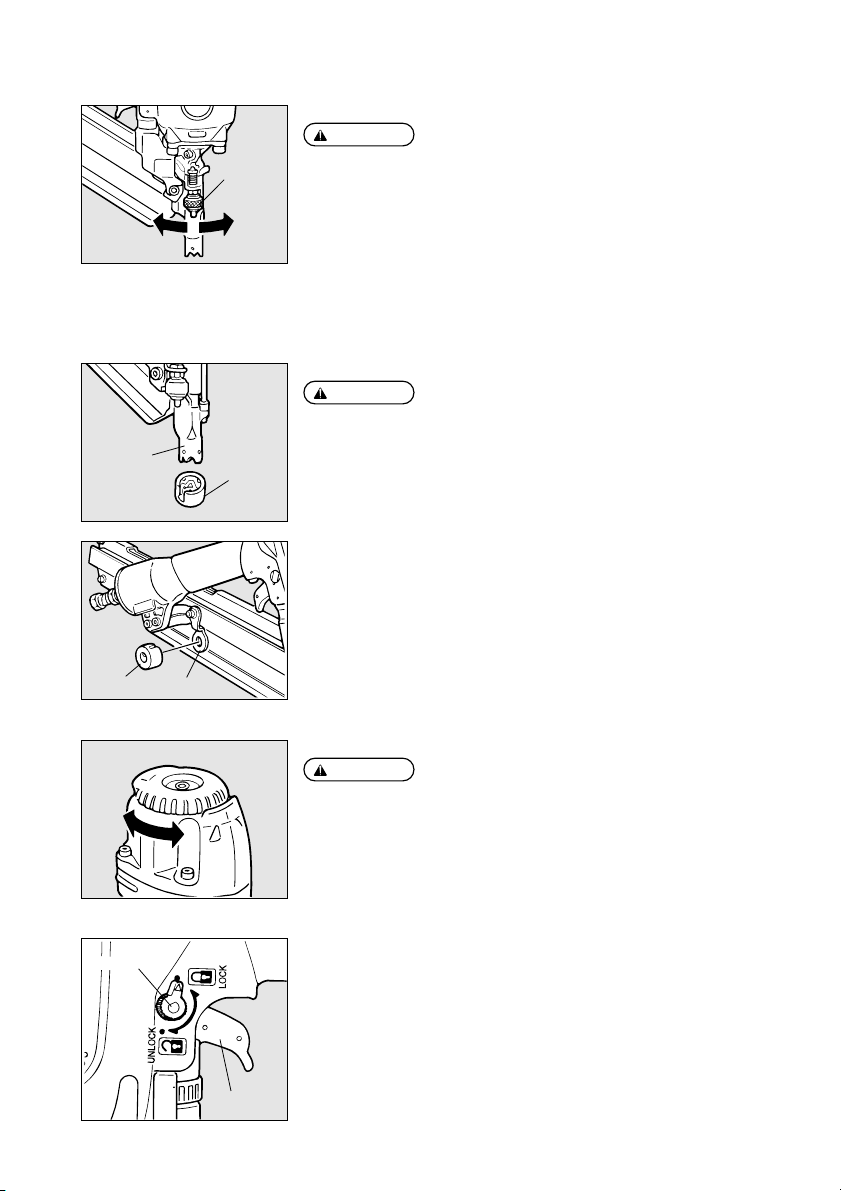

DRIVING DEPTH ADJUSTMENT

ALWAYS disconnect air supply before making adjustment.

The driving depth adjustment is made by adjusting the contact arm “B”.

q

With air pressure set, drive a few nails into a representative material sample to

determine if adjustment is necessary.

w

If adjustment is required, disconnect air supply.

e

Refer to the mark on the contact arm for direction to turn the adjustment dial.

r

Re-connect air supply.

DIRECTIONAL EXHAUST COVER

ALWAYS disconnect air supply before rotating the exhaust cover.

Direction of the exhaust air is changeable by rotating exhaust cover by hand.

CONTACT TIP (OPTION)

ALWAYS disconnect air supply before attaching / detaching the contact tip.

Attach the contact tip on the tip of contact arm “B”, when driving nails to a soft material.

The contact tip can be kept at the tail hanger when not using.

WARNING:

WARNING:

WARNING:

Adjustment dial

Deeper Shallow

Contact arm “B”

Contact tip

Tail hanger

Contact tip

TRIGGER LOCK MECHANISM

The tool is equipped with a trigger lock mechanism. Push and rotate the trigger LOCK

to the trigger UNLOCK position before driving nails.

Trigger lock dial

Trigger

Page 14

14

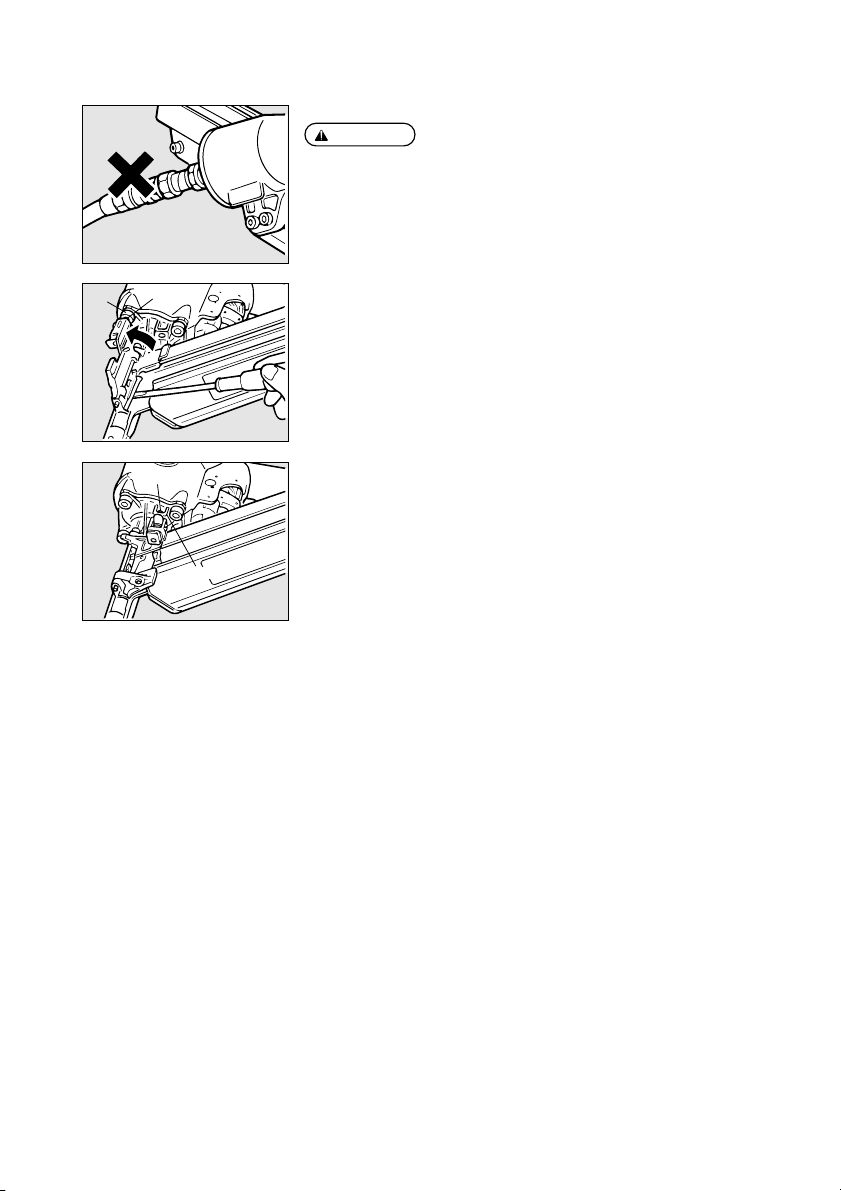

REMOVING JAMMED NAILS

ALWAYS disconnect air supply before removing jammed nails.

WARNING:

q

Take out the nails from the inside of the magazine.

w

Open the door. Put the door latch pin into a bolt hole.

e

Remove nails that are jammed inside the nose by using a punch or slotted screw

driver.

r

After removing the nails, close the door and make sure that the latch pin has been

certainly fit into the pin holder.

Bolt

Latch pin

Latch pin

Pin holder

Page 15

15

5. MAINTAIN FOR PERFORMANCE

q

DO NOT FIRE THE NAILER WHEN IT IS EMPTY

w

USE A 3-PIECE AIRSET

Failure to use a 3-piece airset allows the moisture and dirt inside compressor to pass into the tool

directly. This causes rust and wear, and results in a poor operating performance. The hose length

between airset and tool should be no longer than 5 m since a longer length results in a reduction in air

pressure.

e

USE RECOMMENDED OIL

The velocite or turbine oil should be used to lubricate the tool. Upon completion of operations, place 2

or 3 drops of oil into the air plug inlet with the jet oiler. (Recommended Oil : ISO VG32)

r

INSPECT AND MAINTAIN DAILY OR BEFORE OPERATION

Disconnect air supply and empty the magazine when inspecting or maintaining the tool.

(1) Drain air line filter and compressor

(2) Keep lubricator filled in air 3-pieces set

(3) Clean filter element of air 3-pieces set

(4) Tighten all screws

(5) Keep contact arm moving smoothly

6. STORING

q

When not in use for an extended period, apply a thin coat of the lubricant to the steel parts to avoid

rust.

w

Do not store the tool in a cold weather environment. Keep the tool in a warm area.

e

When not in use, the tool should be stored in a warm and dry place. Keep out of reach of children.

r

All quality tools will eventually require servicing or replacement of parts because of wear from the

normal use.

7. TROUBLE SHOOTING/REPAIRS

The troubleshooting and/or repairs shall be carried out only by the MAX CO., LTD. authorised distributors

or by other specialists.

WARNING:

Supplement to the operating instruction

According to the European Norm EN 792-13 the regulation is valid from 01.01.2001 that all fastener

driving tools with contact actuation must be marked with the symbol “Do not use on scaffoldings,

ladders” and they shall not be used for specific application for example:

* when changing one driving location to another involves the use of scaffoldings, stairs, ladders or

ladder alike constructions e.g. roof laths,

* closing boxes or crates,

* fitting transportation safety systems e.g. on vehicles and wagons.

Page 16

16

Page 17

17

FRANÇAIS

SN890CH/34, SN890CH/28,

SN890RH and SN890RH-R

CLOUEUSE PNEUMATIQUES

INDEX

1. CONSIGNES DE SECURITE

………

18

2.

CARACTERISTIQUES TECHNIQUES

ET ACCESSOIRES

…………………

21

3.

ALIMENTATION EN AIR COMPRIME

ET CONNEXIONS

……………………

23

4. INSTRUCTIONS D’EMPLOI

………

24

5. ENTRETIEN

…………………………

29

6. STOCKAGE

…………………………

29

7. REPARATION

………………………

29

MANUEL D’UTILISATION et D’ENTRETIEN

AVANT D’UTILISER CET OUTIL, LIRE CE MANUEL ET LES CONSIGNES DE SECURITE

AFIN DE GARANTIR UN FONCTIONNEMENT SUR.

CONSERVER CE MANUEL EN LIEU SUR AVEC L’OUTIL AFIN DE POUVOIR LE

CONSULTER ULTERIEUREMENT.

AVERTISSEMENT:

Page 18

18

1. CONSIGNES DE SECURITE

PRECAUTIONS D’EMPLOI DE L’OUTIL

1. PORTER DES VERRES DE SECURITE OU DES LUNETTES DE PROTECTION

Il existe toujours un risque de danger pour les yeux provoqué par les poussières soufflées par l’air

échappé ou par la projection en l’air de l’élément de fixation due à une manipulation inadéquate de

l’outil. Pour cette raison, des verres de sécurité ou des lunettes de protection doivent toujours être

portées pendant l’utilisation de l’outil. L’employeur et/ou l’utilisateur doit s’assurer qu’un équipement

de protection des yeux approprié est porté. L’équipement de protection des yeux doit assurer la

protection frontale et latérale à la fois.

L’employeur se doit d’obliger l’opérateur d’outil et l’ensemble du personnel présent sur le lieu de

travail à porter des lunettes de protection des yeux.

REMARQUE: Des lunettes sans blindage latéral et des équipements de protection de la face seuls

n’assurent pasune protection appropriée. Directive européenne 89/686/CEE du 21 décembre 1989.

2. DANS CERTAINS ENVIRONNEMENTS UNE PROTECTION AUDITIVE PEUT ETRE EXIGEE

Etant donné que les conditions de travail peuvent entraîner une exposition à des niveaux de bruit

élevés qui peuvent provoquer des dommages d’audition, l’employeur et l’utilisateur doivent s’assurer

qu’un équipement de protection auditive est mis àdisposition et utilisé par l’opérateur et les autres

personnes se trouvant sur le lieu de travail.

3. NE PAS UTILISER D’AUTRE SOURCE D’ALIMENTATION QU’UN COMPRESSEUR D’AIR

L’outil est concu pour fonctionner avec de l’air comprimé Ne pas utiliser l’outil avec d’autres gaz

sous haute pression, des gaz combustibles (ex. l’oxygène, l’acétylène, etc.), car il y a risque

d’explosion. Par conséquent, ne rien utiliser d’autre que le compresseur d’air pour faire fonctionner

cet outil.

4. RESPECTER LA PLAGE DE PRESSION D’AIR APPROPRIEE POUR L’UTILISATION

L’outil est concu pour fonctionner dans une plage de pression de 70 à 100 p.s.i. (5 à 7 bar).

La pression doit être ajustée au type de pièce à clouer. L’outil ne doit jamais être utilisé lorsque la

pression de fonctionnement dépasse 120 p.s.i. (8 bar).

Ne jamais brancher d’outil sur l’alimentation en air comprimé dont la pression peut éventuellement

dépasser 200 p.s.i. (14 bars), l’outil risquant d’exploser.

5. NE PAS UTILISER L’OUTIL PRES D’UNE SUBSTANCE INFLAMMABLE

Ne jamais utiliser l’outil près d’une substance inflammable (ex. diluant, de l’essence, etc.). Les

fumées volatiles de ces substances peuvent être attirées dans le compresseur, comprimées en

même temps avec l’air, cela risquant de produire une explosion.

6. NE PAS UTILISER DES ELEMENTS DE FIXATION INADEQUATS

Le connecteur sur l’outil ne doit pas retenir la pression lorsque l’admission d’air est débranchée. Si

une fixation non appropriée est utilisée, l’outil peut rester chargé d’air après le débranchement et

sera ainsi capable d’enfoncer un élément de fixation même après le débranchement de l’arrivée

d’air, provoquant ainsi des dommages éventuels.

7. COUPER L’ALIMENTATION EN AIR COMPRIME ET VIDER LE MAGASIN LORSQUE L’OUTIL

N’EST PAS UTILISE

Veillez à toujours débrancher l’arrivée d’air de l’outil et à vider le magasin en fin de travail ou

lorsque le travail est suspendu, lorsque l’outil est laissé sans surveillance, est déplacé vers un autre

lieu de travail, réglé, démonté ou réparé, ou encore lorsque vous dégagez un fermoir.

AVERTISSEMENT:

AFIN D’EVITER DES DOMMAGES CORPORELS OU MATERIELS

AVANT D’UTILISER L’OUTIL, LIRE ATTENTIVEMENT CE MANUEL ET PRENDRE

CONNAISSANCE DES “CONSIGNES DE SECURITE” SUIVANTES. LE MANQUEMENT AUX

CONSIGNES DE MISE EN GARDE PEUT ENTRAÏNER LA MORT OU DES BLESSURES GRAVES.

5

7

70

100

Page 19

19

8. CONTROLER LE SERRAGE DES VIS

Des vis ou des boulons desserrés ou incorrectement installés peuvent provoquer des accidents et

endommager l’outil lorsqu’il est mis en service. Contrôler et vérifier que tous les vis et boulons sont

bien serrés et correctement installés avant d’utiliser l’outil.

9. NE PAS TOUCHER LE DECLENCHEUR SAUF POUR ENFONCER UN ELEMENT DE FIXATION

Chaque fois que l’arrivée d’air est connectée à l’outil, ne jamais toucher le déclencheur sauf si on

a l’intention d’enfoncer des éléments de fixation dans la pièce. ll est dangereux de porter l’outil tout

en marchant avec le déclencheur enclenché. Ceci, ainsi que des actions similaires doivent être

évités.

10. NE JAMAIS DIRIGER L’ORIFICE DE REFOULEMENT VERS VOUS OU VERS UNE AUTRE

PERSONNE

En cas de râté, les personnes qui se trouveraient dans la trajectoire de l’orifice de refoulement

risquent d’être grièvement blessées. Lorsque vous branchez ou débranchez le tuyau, montez ou

démontez les fermoirs ou effectuez une intervention quelconque, vérifiez toujours que l’orifice de

refoulement n’est orienté vers personne.

11. UTILISER LES ELEMENTS DE FIXATION APPROPRIÉS

L’utilisation d’éléments de fixation autres que ceux spécifiés provoque le mauvais fonctionnement

de l’outil. Sassurer d’utiliser uniquement les éléments de fixation appropriés avec l’outil.

12. PLACER CORRECTEMENT LA SORTIE DE DÉCHARGE SUR LA SURFACE DE TRAVAIL

Si l’on oublie de placer la sortie de décharge du nez de façon appropriée, on risque d’avoir comme

conséquence un détachement violent de l'attache vers le haut et ceci est extrêmement dangereux.

13. ELOIGNER VOTRE CORPS ET VOS MAINS DU NEZ DE L’APPAREIL

Lors du chargement et de l’utilisation de l’outil, ne jamais placer votre main ou une partie de votre

corps dans la zone de décharge de l’élément de fixation de l’outil.

14. NE PAS APPLIQUER LES ELEMENTS DE FIXATION PRES DU BORD DE LA PIECE ET SUR UN

MATERIAU MINCE

La pièce a tendance à éclater et l’élément de fixation risque de sauter et de heurter quelqu’un. Faire

attention lors de la fixation d’un matériau mince ou près des bords et des coins de la pièce.

15. NE PAS ENFONCER DES POINTES OU AGRAFES SUR D’AUTRES ELEMENTS DE FIXATION

Le fait d’enfoncer des éléments de fixation par dessus d’autres éléments de fixation risque de

provoquer un éclatement de ces élément qui pourrait provoquer des blessures.

16. RETRAIT DES PROJECTILES APRES LA FIN DE L’OPERATION

Si les projectiles sont laissés dans le magasin après la fin de l’opération, il y a danger d’accident

grave qui risque de se produire avant la reprise de l’opération, au cas où l’outil est manipulé

négligemment ou lors du branchement de la fixation d’air. Par conséquent, toujours enlever tous les

projectiles restant dans le changeur après la fin de l’opération.

17. VERIFIER FREQUEMMENT LE FONCTIONNEMENT DU MECANISME DE DECLENCHEMENT AU

COUP À COUP EN CAS D’UTILISATION D’UN OUTIL DE TYPE A DECLENCHEMENT AU COUP À

COUP

Ne pas utiliser l’outil si le déclencheur ne fonctionne pas correctement, car un enfoncement

accidentel d’un projectile de fixation risque de se produire. Ne pas gêner le fonctionnement correct

du mécanisme de déclenchement au coup à coup.

Page 20

20

18. UTILISATION DE L’OUTIL A L’EXTERIEUR OU SUR UN ENDROIT SURELEVE

Pour fixer un toit, ou une surface similaire inclinée, commencer la fixation sur la partie inférieure et

exécuter le travail en montant progressivement. ll est dangereux de faire des fixations en reculant,

car on risque de perdre pied en glissant.

Fixer le tuyau à un point près de la zone où les éléments de fixation doivent être enfoncés. Des

accidents risquent de se produire à cause d’un tuyau coincé ou tiré par inadvertance.

19. NE JAMAIS UTILISER L’OUTIL SI N’IMPORTE QUELLE PARTIE DES COMMANDES D’OUTIL

(PAR EXEMPLE, DÉCLENCHEUR, BRAS DE CONTACT) EST INOPÉRABLE, DÉBRANCHÉE,

CHANGÉE OU NE FONCTIONNANT PAS CORRECTEMENT

20. NE JAMAIS LANCER LES POINTES DANS UN ESPACE LIBRE

Les pointes voltigeant dans l’air présentent un certain danger;

21. TOUJOURS PRÉSUMER QUE L’OUTIL EST MUNIS DE FERMOIRS

22. CONSIDEREZ L’OUTIL COMME UN INSTRUMENT DE TRAVAIL

23. NE FAITES PAS DE GESTES BRUSQUES

24. NE JAMAIS MONTER LES FERMOIRS SUR L’OUTIL LORSQU’UNE COMMANDE (DÉTENTE

OU BRAS DE CONTACT par exemple) EST ACTIVÉE

RESPECTER LES PRECAUTIONS GENERALES SUIVANTES EN

PLUS DES AUTRES AVERTISSEMENTS DECRITS DANS CE MANUEL

•

Ne pas utiliser l’outil comme un marteau.

•

Toujours porter l’outil par la poignée, ne jamais porter l’outil par tuyau d’air.

•

L’outil doit être utilisé uniquement pour l’usage préconisé.

•

Ne jamais retirer ou altérer les commandes (DÉTENTE OU BRAS DE CONTACT par exemple).

•

Conserver l’outil dans un endroit sec, hors de portée des enfants, lorsqu’il n’est pas utilisé.

•

Ne pas utiliser l’outil sans l’étiquette de sécurité.

•

Ne pas modifier la conception originale ou les caractéristiques de l’outil sans le consentement de

MAX CO. LTD.

Page 21

21

2. CARACTERISTIQUES TECHNIQUES ET ACCESSOIRES

1. NOM DES PIÈCES

PIECES DE RACCORDEMENT D’AIR COMPRIME

Cet appareil est équipé d’une prise mâle avec filet extérieur de 9.5 mm pouce. Le diamètre intérieur devrait être de 9.9 mm au

moins. Le raccord doit permettre de décharger l’air comprimé de l’appareil lorsque l’alimentation en air comprimé est interrompue.

PRESSION DE SERVICE RECOMMANDEE:

De 70 à 100 p.s.i. (5 à 7 bars). Régler l’air comprimé à l’intérieur de cette plage pour garantir la meilleure performance possible de

fixation.

LA PRESSION DE SERVICE NE DOIT PAS DEPASSER 120 p.s.i. (8 BARS)

q

Boîtier

w

Couvercle de cylindre

e

Barre de contact

r

Nez

t

Magasin

y

Levier de commande

u

Poignée

i

Capot d’aspiration

o

Disque de reglage

!0

Porte

2. SPÉCIFICATIONS DE L’OUTIL

Produit No. SN890CH/34 SN890CH/28 SN890RH, SN890RH-R

Hauteur 374 mm 374 mm 359.2 mm

Largeur 102 mm 102 mm 102 mm

Longeur 436 mm 429 mm 542 mm

Poids 3.63 kg (8.0 lbs.) 3.63 kg (8.0 lbs.) 3.63 kg (8.0 lbs.)

Pression de service

de 70 à 100 p.s.i. (5 à 7 bars) de 70 à 100 p.s.i. (5 à 7 bars) de 70 à 100 p.s.i. (5 à 7 bars)

recommandée

Capacite de charge 90 Pointes 75 Pointes 64 Pointes

Consommation en air

1.78Rpour une pression de service de 1.78Rpour une pression de service de 1.78Rpour une pression de service de

comprimé

90 p.s.i. (6 bars) 90 p.s.i. (6 bars) 90 p.s.i. (6 bars)

3. SPÉCIFICATS DU MATÉRIEL DE FIXATION

Produit No. SN890CH/34 SN890CH/28 SN890RH, SN890RH-R

Longueur de pointe 50 à 90 mm 50 à 90 mm 50 à 90 mm

Diamètre de tige 2.9 à 3.8 mm 2.9 à 3.3 mm 2.9 à 3.8 mm

Type de queue

Tige droite, annulaire, Tige droite, annulaire, Tige droite, annulaire,

filetée filetée filetée

Diamètre de tête 6.5 à 7.7 mm 7.0 à 7.7 mm 6.8 à 7.5 mm

Angle de fixation 34 degrés 28 degrés 21 degrés

Tête Tête taillée Tête taillée Tête complètement ronde

i

w

q

r

!0

e

u

o

y t

Page 22

22

5. APPLICATIONS

*Pose de plinthes au sol et mur

*Pose de faux-fonds

*Revêtement de doit et mur

*Cloisonnage

4. CARACTÉRISTIQUES TECHNIQUES

q

BRUIT

Niveau de puissance sonore pulsée par rapport à la courbe A ------------ LWA, 1s, d 96.34 dB

Niveau de pression acoustique pulsée par rapport à la courbe A --------- LpA, 1s, d 87.68 dB

au poste de travail

Ces valeurs out été calculées et documentées, en conformité avec EN12549: 1999.

w

VIBRATIONS

Valeur caractéristique de vibration = 5.18 m/s

2

Ces valeurs sont déterminées et documentées conformément à la norme ISO 8662-11.

Cette valeur représente une valeur caractéristique connexe à l’outil et non l’influence au système main-bras lorsque l’on utilise

l’outil. Une influence au système main-bras lorsque l’on utilise l’outil dépendra, par exemple, de la force de saisie, la force de

pression de contact, la direction de fonctionnement, le réglage de l’air principale, le lieu de travail, le support d’objets de travail.

Page 23

23

AVERTISSEMENT:

3. ALIMENTATION EN AIR COMPRIME ET CONNEXIONS

Lire le paragraphe intitulé “CONSIGNES DE SECURITE”.

NE PAS UTILISER UNE AUTRE SOURCE D’ALIMENTATION EXCEPTE UN COMPRESSEUR D’AIR

L’outil est conçu pour fonctionner avec de l’air comprimé Ne pas utiliser l’outil avec d’autres gaz sous

haute pression, des gaz combustibles(ex. l’oxygène, l’acétylène, etc.), car il y a risque d’explosion. Par

conséquent, ne rien utiliser d’autre que le compresseur d’air pour faire fonctionner cet l’outil.

RESPECTER LA PLAGE DE PRESSION D’AIR APPROPRIEE POUR L’UTILISATION

L’outil est concu pour fonctionner dans une plage de pression de 70 à 100 p.s.i. (5 à 7 bar).

La pression doit être ajustée au type de pièce à clouer. L’outil ne doit jamais être utilisé lorsque la

pression de fonctionnement dépasse 120 p.s.i. (8 bar).

NE PAS UTILISER L’OUTIL PRES D’UNE SUBSTANCE INFLAMMABLE

Ne jamais utiliser l’outil près d’une substance inflammable (ex. un diluant, de l’essence, etc.). Les

fumées volatiles de ces substances peuvent être attirées dans le compresseur, être comprimées en

même temps que l’air et une explosion risque de se produire.

NE PAS UTILISER DES PROJECTILES INADEQUATS

Le raccord de l’outil ne doit pas retenir la pression lorsque l’admission d’air est débranchée. Si un

projectile non approprié est utilisé, l’outil peut rester chargé d’air après le débranchement et sera ainsi

capable d’enfoncer un projectile même après le débranchement de d’air, provoquant ainsi des

dommages éventuels.

COUPER L’ALIMENTATION EN AIR COMPRIME ET VIDER LE MAGASIN LORSQUE L’OUTIL

N’EST PAS UTILISE

Veillez à toujours débrancher l’arrivée d’air de l’outil et à vider le magasin en fin de travail ou lorsque le

travail est suspendu, lorsque l’outil est laissé sans surveillance, est déplacé vers un autre lieu de travail,

réglé, démonté ou réparé, ou encore lorsque vous dégagez un fermoir.

FIXATIONS: Installer le raccord mâle sur l’outil, qui est à flux libre et qui relâche la

pression d’air de l’outil lorsqu’il est débranché de la source d’alimentation.

TUYAUX: Le diamètre intéreur du tuyau doit être de 6 mm (1/4˝) min. et d’une

longueur maximale de 5 metres (17˝).

Le tuyau d’alimenttation doit avoir une fixation qui assure un “débranchement

rapide” de la fiche mâle sur l’outil.

SOURCE D’ALIMENTATION: Utiliser uniquement l’air comprimé régulé comme

source d’alimentation pour l’outil.

ENSEMBLE DE REGULATION (Filtre à air, mano-detendeur, graisseur):

Se référer aux SPECIFICATIONS DE L’OUTIL pour le réglage de la pression de

fonctionnement appropriée pour l’outil.

REMARQUE:

Un filtre assure une meilleure performance et un minimum d’usure de l’outil, parce que l’encrassement

et l’eau dans l’arrivée d’air sont les sources principales d’usure de l’outil. Des graissages fréquents,

mais non excéssifs sont nécessaires pour conserver la meilleure performance. L’huile ajoutée à travers

le raccord de ligne d’air lubrifie les pièces internes.

[

ARRIVEE D’AIR ET RACCORDEMENTS

Regulateur

Tuyau

Pression 70 à 100 p.s.i. (5 à 7 bar)

Regulateur

Filtre

Graisseur

Ensemble de regulation

]

Page 24

24

4. INSTRUCTIONS D’EMPLOI

Lire le paragraphe intitulé “CONSIGNES DE SECURITE”.

1. AVANT DE TRAVAILLER:

q

Mettre les lunettes de protection.

w

Ne pas encore brancher l’alimentation en air comprimé.

e

Vérifier la bonne assise des vis.

r

Vérifier le fonctionnement de la barre de contact et s’assurer que le levier de commande se déplace

librement.

t

Brancher l’alimentation en air comprimé.

y

Rechercher l’éventuelle présence d’une fuite d’air. (L’appareil ne doit pas avoir de fuite d’air.)

u

Tenir l’outil (ne pas mettre de doigt sur le levier de commande) et appuyer la barre de contact contre

la pièce à fixer. (L’outil ne doit pas fonctionner.)

i

Tenir l’outil en sorte que la barre de contact ne repose pas sur la pièce à fixer et appuyer sur le levier

de commande. (L’outil ne doit pas fonctionner.)

o

COUPER L’ALIMENTATION EN AIR COMPRIME ET VIDER LE MAGASIN LORSQUE L’OUTIL

N’EST PAS UTILISE.

2. TRAVAILLER

Porter des verres de securite ou des lunettes de protection. Il existe toujours un risque de danger pour

les yeux provoqué par les poussières soufflées par l’air échappé ou par la projection en l’air l’élément de

fixation due à une manipulation inadéquate de l’outil. Pour cette raison, des verres de sécurité ou des

lunettes de protection doivent toujours être portées pendant l’utilisation de l’outil. L’employeur et/ou

l’utilisateur doit s’assurer qu’un équipement de protection des yeux approprié est porté. L’équipement de

protection des yeux doit assurer la protection frontale et latérale à la fois.

L’employeur se doit d’obliger l’opérateur d’outil et l’ensemble du personnel présent sur le lieu de travail

à porter des lunettes de protection des yeux.

REMARQUE: Des lunettes sans blindage latéral et des équipements de protection de la face seuls

n’assurent pas une protection appropriée. Directive européenne 89/686/CEE du 21 décembre 1989.

Veillez à tenir les mains et le reste du corps hors de portée de l’ouverture de sortie pendant l’agrafage/le

pointage pour éviter de toucher accidentellement les mains ou le corps.

AVERTISSEMENT:

AVERTISSEMENT:

MISE EN PLACE D’UNE BOBINE DE POINTES

q

Tirer la coulisse de pointes vers l’arrière jusqu’ à ce qu’elle s’enclenche dans l’arrêt.

w

Mettre une bande de pointes dans le haut du magasin.

Arrêt

Magasin

Pointes

Coulisse de pointes

Page 25

25

TEST

q

Régler l’air comprimé sur 70 p.s.i. (5 bars) et brancher l’alimentation en air comprimé.

w

Appuyer la barre de contact contre la pièce à fixer sans cependant toucher au levier de commande.

Appuyer ensuite sur le levier de commande. (L’outil doit tirer la pointe.)

e

Appuyer sur le levier de commande, l’outil ne devant pas toucher la pièce à fixer. Appuyer ensuite

la barre de contact contre la pièce à fixer. (L’outil doit tirer la pointe.)

r

Régler l’air comprimé sur la pression la plus faible possible en fonction du diamètre et de la longueur

des pointes ainsi que de la dureté de la pièce à fixer.

e

Relâcher l’arrêt tout en tirant sur la coulisse de pointes pour l’approcher des pointes.

REMARQUE:

La pointe de la coulisse doit, comme l’indique le schéma, se trouver audessus de la tête

de la dernière pointe.

PROCEDE

q

Tenir le dispositif de déclenchement.

w

Enfoncer le bras de contact.

ATTACHE POUR ENFONCEMENT

MODELE DE DECLENCHEMENT A CONTACT avec MECANISME ANTI DOUBLE TIR SEQUENTIEL.

Le mécanisme de tir anti-double (brevet US 5597106, brevet UK 2286790) est installé sur cet outil. Le

mode opératoire commun sur les outils avec “déclenchement à contact” est prévu pour que l’opérateur

puisse actionner le dispositif de déclenchement, en entrant en contact avec la pièce de travail, tout en

maintenant le dispositif de déclenchement tiré, enfonçant ainsi une attache chaque fois que la pièce de

travail entre en contact. Ceci permettra un placement rapide des attaches, dans beaucoup de travaux,

comme travaux pour engainer, pontage et assemblage de palettes. Tous les outils pneumatiques sont

sujets au recul, lorsque l’on enfonce des attaches. L’outil peut rebondir, en libérant le déclenchement,

et s’il est entré par mégarde nouveau en contact avec la surface de travail, et avec le dispositif de

déclenchement encore actionné (avec votre doigt maintenant le dispositif de déclenchement tiré), une

deuxième attache non désirée sera enfoncée.

OPERATION DE TIR A CONTACT

Pour l’opération de tir de contact, maintenir le dispositif de déclenchement et enfoncer le bras de

contact contre la surface de la pièce de travail.

Arrêt

Coulisse de pointes

Extrémité pointue

de la coulisse

1

2

Page 26

26

PROCEDE

q

Enfoncer le bras de contact.

w

Tenir le dispositif de déclenchement.

OPERATION DE TIR SIMPLE (ANTI DOUBLE TIR SEQUENTIEL)

Pour l’opération de tir simple, enfoncer le bras de contact contre la surface de la pièce de travail et tirer

le dispositif de déclenchement. L’outil ne peut pas tirer un deuxième clou, tant que le dispositif de

déclenchement n’est pas libéré et l’outil peut tourner.

DECLENCHEMENT DE TIR SEQUENTIEL

Il faut, poru le déclenchement séquentiel, que l’appareil touche l’ouvrage avant que l’on ne déclenche

le levier de commande. Cette technique permet de positionner la pointe/l’agrafe avec précision sans

risquer que le recul ne libère une 2e pointe/agrafe.

Les appareils à déclenchement séquentiel présentent les avantages suivants en matière de sécurité: il

n’y a aucun déclenchement accidentel si l’appareil entre en contact avec l’ouvrage ou autre objet

lorsque l’on appuie sur le levier de commande.

DECLENCHEMENT DE TIR SEQUENTIEL

Identifié par la DÉTENTE ORANGE.

IDENTIFICATION DES DIFFERENTES MODELES

DECLENCHEMENT PAR CONTACT

Le fonctionnement normal des appareils avec déclenchement par contact prévoit que l’opérateur touche

l’ouvrage avec l’appareil pour déclencher un tir tout en maintenant le levier de commande appuyeé. De

cette facon, chaque contact de l’outil avec l’ouvrage enfonce une pointe/une agrafe. Dans de nombreux

cas cette méthode permet de pointer/agrafer rapidement. Tous les outils pneumatiques de tir d’attaches

sont sujets à un recul. L’appareil peut, éventuellement, actionner le déclenchement par contact lors d’un

éventuel impact; si cela entraîne un nouveau contact accidentel de l’appareil avec la surface à fixer

alors que le levier de commande est encore appuyé, un deuxième tir sera déclenché involontairement.

DECLENCHEMENT PAR CONTACT

Identifié par la DÉTENTE LEVLER.

MODELE DE DECLENCHEMENT A CONTACT avec MECANISME ANTI

DOUBLE TIR SEQUENTIEL. (brevet US 5597106, brevet UK 2286790)

Identifié par la DÉTENTE ROUGE.

2

1

Page 27

27

REGLAGE DE LA PROFONDEUR D’INSERTION

TOUJOURS déconnecter l’alimentation d’air avant d’effectuer le réglage.

Le réglage de la profondeur d’insertion s’effectue en réglant le barre de contact “B”.

q

Avec la pression d’air réglée, enfoncer quelques clous dans un échantillon de

matériau typique pour déterminer si le réglage est nécessaire.

w

Si le réglage est nécessaire, déconnecter l’alimentation d’air.

e

Le repère placé sur la barre de contact indique le sens dans lequel il faut tourner le

disque de réglage.

r

Connecter de nouveau l’alimentation d’air.

CAPOT D’ASPIRATION ROTATIF

TOUJOURS couper l’arrivée en air comprimé avant de tourner le capot d’aspiration.

Deux types de fonctionnement pour cette série

Il est possible de modifier la direction d’aspiration de l’air en tournant à la main le capot

d’aspiration.

AVERTISSEMENT:

AVERTISSEMENT:

CAPUCHON DE CONTACT (OPTION)

TOUJOURS déconnecter l’alimentation d’air avant de fixer / détacher le cappuchon

de contact.

Fixer le cappuchon de contact sur le barre de contact “B”, lorsque l’on insère les clous

dans un matériau souple.

AVERTISSEMENT:

Disque de

réglage

Plus profond Plus haut

Le cappuchon de contact peut être maintenu au support de queue lorsqu’il n’est pas

utilisé.

Barre de contact

“B”

Cappuchon de

contact

Suspension

de queue

Cappuchon de

contact

MODE D’EMPLOI DU MECANISME DE BLOCAGE DU D’ÉCLENCHEUR

Cet appareil est équipé d’un mécanisme de blocage du déclencheur. Appuyer sur le

loquet de blocage et le tourner afin de le libérer avant d’utiliser l’appareil.

Blocage de

la commande

Levier de

commande

(BLOQUE)

(DEBLOQUE)

Page 28

28

q

Enlever les clous de l’intérieur du magasin.

w

Ouvrir la porte. Mettre la goupille de verrou de la porte dans un trou de boulon.

e

Enlever les clous qui sont bloqués à l’intérieur du nez en utilisant un poinçon ou

tournevis encoché.

r

Après enlèvement des clous, fermer la porte et s’assurer que la goupille a été bien

adaptée dans le support de la goupille.

Boulon

Goupille de verrou

Goupille

Support de goupille

ENLEVEMENT DES CLOUS BLOQUES

TOUJOURS débrancher l’alimentation en air avant d’enlever les clous bloqués.

AVERTISSEMENT:

Page 29

29

5. ENTRETIEN

q

NE PAS FAIRE FONCTIONNER LA CLOUEUSE LORSQU’ELLE EST VIDE

w

UTILISER UN ENSEMBLE DE REGULATION

Le fait de ne pas utiliser un ensemble de régulation, permet l’entrée de l’humidité et l’encrassement à

l’intérieur du compresseur qui passe directement dans la cloueuse. Cela crée une formation de rouille

et provoque l’usure conduisant à une mauvaise performance pendant l’utilisation. La longueur du tuyau

entre le regulateur et la cloueuse ne doit pas dépasser 6 m, étant donné qu’une longueur supérieure

réduit la pression d’air.

e

UTILISER UNE HUILE RECOMMANDEE

L’huile de turbine fluide doit être utilisée pour lubrifier la cloueuse. Après la fin des opérations, placer

2 ou 3 gouttes d’huile dans l’entrée d’air de graisseur à jet. (ISO VG32)

r

VERIFIER ET ENTRETENIR L’OUTIL TOUS LES JOURS OU AVANT CHAQUE UTILISATION.

Couper l’alimentation en air comprimé et vider le magasin avant toute vérification ou mesure

d’entretien de l’outil.

(1) Vider le filtre de la conduite d’air et le compresseur.

(2) Veiller à ce que le graisseur soit toujours plein dans l’unité d’air comprimé à trois éléments.

(3) Nettoyer l’élément filtrant de l’unité d’air comprimé à trois éléments.

(4) Bien serrer toutes les vis.

(5) Faire en sorte que la barre de contact grade sa liberté de mouvement.

6. STOCKAGE

q

Si l’outil doit rester inutilisé pendant un certain temps, appliquer une mince couche de lubrifiant sur

les pièces en acier pour éviter l’apparition de rouille.

w

Ne pas entreposer l’outil dans un endroit exposé au froid. Le conserver dans un endroit chaud.

e

Si l’outil reste inutilisé, il faut le conserver dans un endroit chaud et sec. Le mettre hors de portée des

enfants.

r

Même les outils de qualité peuvent éventuellement nécessiter des mesures d’entretien ou le

remplacement de pièces en raison de l’usure normale.

7. REPARATION

Le dépistage de dérangements et/ou les réparations ne doivent être réalisés que par des distributeurs

autorisés de la société MAX CO.,LTD. ou tout autre spécialiste qui respectera les informations

contenues ici.

AVERTISSEMENT:

SuppIément au mode d’emploi

Selon Ia norme européenne EN 792-13 le réglement suivant est valable du 1.1.2001, que toutes

machines à enfoncer les fixations équipées de commande par contact doivent être marquées avec le

symbole ,,Ne pas utiliser sur des échafaudages ou e’chelles,, et elles ne seront pas utilisées pour

utilisations spécifiques, par example:

* en cours de déplacement d’ un lieu d’ enfoncement à l’autre sur des échafaudages, escaliers,

échelles ou constructions de même qu ‘ êchelles comme p.e. lattis du toit

* pour fermer des boîtes ou des caisses

* pour fixer des systèmes d’arrimages p.e. sur véhicules ou wagons.

Page 30

30

Page 31

31

ESPAÑOL

SN890CH/34, SN890CH/28,

SN890RH and SN890RH-R

CLAVADORAS NEUMATICAS

PARA PEINES DE CLAVO

INDICE

1.

INSTRUCCIONES DE SEGURIDAD…32

2.

DATOS TECNICOS Y ACCESORIOS…35

3. EL SUMINSTRO DE AIRE Y

CONEXIONES

………………………

37

4. INSTRUCCIONES PARA EL

SERVICIO

……………………………

38

5. MANTENIMIENTO

…………………

43

6. ALMACENAMIENTO

………………

43

7. SUBSANACION DE AVERIAS

……

43

MANUAL DE OPERACIONES MANTENIMIENTO

PARA EVITAR GRAVES DAÑOS PERSONALES O EN LA PROPIEDAD.

ANTES DE EMPLEAR LA HERRAMIENTA, LEER CON ATENCIÓN Y COMPRENDER

LOS SIGUIENTES INSTRUCCIONES DE SEGURIDAD.

ATENCIÓN:

Page 32

32

1. INSTRUCCIONES DE SEGURIDAD

PRECAUCIONES PARA EMPLEAR LA HERRAMIENTA

1. UTILIZAR GAFAS DE SEGURIDAD

Debido a la presencia de polvo en el aire, o el mal uso de la herramienta, siempre existe peligro a

los ojos. Por estas razones, se deben utilizar siempre las gafas de seguridad cuando se maneja la

herramienta. El usuario debe asegurarse de que se emplea la protección adecuada. La protección

debe estar de acuerdo con los requisitos de la “American National Standards Institute, ANSI Z87.1”

y debe aportar protección frontal y lateral.

El empleador es responsable de implementar el uso del equipo de protección de ojos para el

operador de herramienta y otro personal en el área de trabajo.

OBSERVAR: Las gafas sin protección lateral y sin blindaje de cara, no proporcionan la protección

adecuada. Directiva del Consejo 89/686/CEE del 21 de Diciembre de 1989.

2. EN ALGUNOS CIRCUNSTANCIAS PUEDE SER NECESARIO LA PROTECCIÓN DE OÍDOS

El usuario puede ser expuesto a un nivel alto de ruido, lo cual puede causar daños al oído. El usuario

debería asegurarse de que se emplea la protección necesaria, y de que sea empleado por los demás

trabajadores en la zona de trabajo.

3. NO UTILIZAR NINGUNA FUENTE DE ENERGÍA SALVO UN COMPRESOR DE AIRE

La herramienta esta designada para funcionar con aire comprimido. No utilizar la herramienta con

ningún otro gas de alta presión, gases combustibles (por ejemplo, oxigeno, acetileno, etc.) ya que

existe el peligro de una explosión. Por esta razón, es imprescindible que no se utilice otra cosa que

un compresor de aire para manejar la herramienta.

4. UTILIZAR DENTRO DEL LIMITE PRECISO DE PRESIÓN DE AIRE

La herramienta esta designada para funcionar dentro de limite de presión de aire de 70 a 100 p.s.i.

(5 a 7 bar).

La presión debería ser adaptada a la clase de trabajo indicado. La herramienta no debería ser

manejada cuando la presión sobrepasa 120 p.s.i. (8 bar).

No conecte la herramienta nunca a una alimentación de aire comprimido cuya presión pueda

superar posiblemente los 200 p.s.i. (14 bares), ya que la herramienta podría reventar.

5. NO MANEJAR LA HERRAMIENTA CERCA DE SUSTANCIAS INFLAMABLES

Nunca manejar la herramienta cerca de sustancias inflamables (por ejemplo aguarrás, gasolina, etc.)

Gases volátiles de estas sustancias, pueden ser arrastradas dentro del compresor y el aire

comprimido puede provocar una explosión.

6. NO UTILIZAR ACCESORIOS IMPROPIOS

El enchufe de la herramienta no debe contener presión, cuando el suministro de aire este

desconectado. Si se utiliza un accesorio impropio, la herramienta puede quedarse cargada con aire

despuès de desconectar, de este modo seguira funcionando incluso despuès de haber

desconectado el suministro de aire, con la posibilidad de causar daños.

7. MIENTRAS LA HERRAMIENTA NO ESTE EN USO, DESCONECTE LA ALIMENTACION DE

AIRE COMPRIMIDO Y VACIE EL CARGADOR

Siempre desconecte el suministro de aire desde la herramienta y vacíe el cartucho, cuando la

operación ha sido completada o está suspendida, cuando permanece sin atender, cambiando a

una área de trabajo diferente, ajustando, desarmando o reparando la herramienta, y al despejar un

afianzador atascado.

ATENCIÓN:

PARA EVITAR GRAVES DAÑOS PERSONALES O EN LA PROPIEDAD.

ANTES DE EMPLEAR LA HERRAMIENTA, LEER CON ATENCIÓN Y COMPRENDER LOS

SIGUIENTES INSTRUCCIONES DE SEGURIDAD. EL NO CUMPLIMIENTO DE LAS ADVERTENCIAS

SIGUIENTES PUEDE RESULTAR EN SERIAS LESIONES Y AUN LA MUERTE.

5

7

70

100

Page 33

33

8. COMPROBAR LA TENSIÓN DEL TORNILLO

Los tornillos flojos o mal instalados pueden causar accidentes y daños a la herramienta, cuando se

utiliza. Compruebe que todos los tornillos estèn apretados y bien instalados antes de utilizar la

herramienta.

9. NO TOCAR EL DISPARADOR AL MENOS QUE TENGA INTENCIÓN DE UTILIZARLO

Cuando el suministro de aire este conectado a la herramienta, no tocar nunca el disparador al menos

que tenga intención de utilizarlo. Es peligroso llevar la herramienta con disparador echado, y esto

debe ser evitado.

10. NUNCA APUNTE LA SALIDA DE DESCARGA HACIA UD. MISMO Y OTRO PERSONAL

Si la salida de descarga es apuntada hacia personas, pueden ocasionarse serios accidentes

cuando se dispara equivocadamente. Asegúrese de que la salida de descarga no está apuntada

hacia las personas cuando conecta y desconecta la manguera, carga y descarga los afianzadores

u operaciones similares.

11. UTILIZAR GRAPAS ESPECIFICAS

El uso de grapas que no sean las especificas pueden causar la mala función de la herramienta.

Asegurarse de utilizar únicamente grapas especificas.

12. PONGA CORRECTAMENTE EL ENCHUFE DE DESCARGA EN LA SUPERFICIE DE TRABAJO

Si se olvida de poner el enchufe de descarga de la nariz de manera apropiada, se puede causar

una separación violenta del sujetador para arriba y esto es extremadamente peligroso.

13. MANTENER LAS MANOS Y EL CUERPO ALEJADOS DE LA SALIDA DE DESCARGA

Al cargar y usar la herramienta no colocar ni la mano ni ninguna parte del cuerpo sobre la salida de

descarga, ya que puede resultar muy peligroso.

14. NO GRAPAR JUNTO AL BORDE DE LAS SUPERFICIES O MATERIALES FINOS

Es probable que la superficie se divida y la grapa podría saltar y dañar a alguien. Tener cuidado a

la hora de grapar materiales finos y los bordes y las esquinas de las superficies.

15. NO GRAPAR SOBRE OTRAS GRAPAS

Grapando encima de otras grapas puede causar desvío, lo cual puede causar daños.

16. QUITAR LAS GRAPAS DESPUÉS DE COMPLETAR LA OPERACIÓN

Si se dejan las grapas puestas despuès de completar la operación, existe el peligro de un accidente

grave, si se maneja la herramienta de forma descuidada, o en la hora de conectar las instalaciones

de aire. Por esta razón es imprescindible quitar todas las grapas que sobran despuès de completar

la operación.

17. COMPROBAR LA OPERACIÓN MECANISMO DE CONTACTO CON FRECUENCIA EN CASO DE

UTILIZAR UNA HERRAMIENTA DE TIPO “TRIP” CONTACTO

No utilizar la herramienta si “trip” no funciona correctamente, ya que puede grapar sin querer. No

tocar la operación propia del mecanismo “trip” contacto.

Page 34

34

18. LA UTILIZACIÓN DE LA HERRAMIENTA AL AIRE LIBRE O EN SITIOS ELEVADOS

A la hora de grapar tejados o otras superficies inclinados, empezar en la parte baja y poco a poco

subir. Grapar hacia atrás es peligroso ya que se puede resbalar. Asegurar la manguera cerca de la

zona donde se va a grapar. Accidentes pueden resultar debido a que la manguera se enganche.

19. NUNCA UTILICE LA HERRAMIENTA SI CUALQUIER PORCIÓN DE LOS CONTROLES DE LA

HERRIAMENTA (POR EJEMPLO, DISPARADOR, BRAZO DE CONTACTO) ES INOPERABLE,

DESCONECTADA, ALTERADA O NO OPERA CORRECTAMENTE

20. NO CLAVE NUNCA EN EL AIRE

De lo contrario, existe peligro por los clavos que salen disparados, y la herramienta sufre un

sobreesfuerzo innecesario.

21. SUPONGA SIEMPRE QUE LA HERRAMIENTA CONTIENE LOS AFIANZADORES

22. RESPECTO A LAS HERRAMIENTAS COMO UN ELEMENTO DE TRABAJO

23. NO JUEGUE HACIENDO BROMAS

24. NUNCA CARGUE LA HERRAMIENTA CON LOS AFIANZADORES CUANDO CUALQUIERA DE

LOS CONTROLES DE OPERACIÓN (ej.: DISPARADOR, BRAZO DE CONTACTO) SE

ENCUENTRA ACTIVADO

OBSERVAR LAS SIGUIENTES ADVERTENCIAS

•

No utilizar la herramienta como martillo

•

Siempre llevar la herramienta por el mango, nunca por la manguera de aire

•

La herramienta debe ser utilizada únicamente para el propósito a que fue designada

•

Nunca retire, fuerce los controles de operación (ej.: DISPARADOR, BRAZO DE CONTACTO).

•

Guardar la herramienta en sitios secos y mantener fuera del alcance de niños

•

No utilizar la herramienta sin la etiqueta de Aviso de Segurided

•

No modificar la herramienta del diseño original función sin la aprobación de MAX CO

Page 35

35

2. DATOS TECNICOS Y ACCESORIOS

1. DENOMINACIÓN DE LAS PIEZAS

PIEZAS DE CONEXION PARA EL AIRE COMPRIMIDO

Este aparato está equipado con una boquilla de empalme con rosca exterior de 9.5 mm. El diámetro interior debería ser de mín.

9.9 mm. La pieza de empalme debe permitir la descarga de presión del aparato en caso de interrupción de la alimentación de aire

comprimido.

PRESION DE SERVICIO RECOMENDADA:

70 a100 p.s.i. (5 a 7 bares). Para garantizar el rendimiento óptimo del clavador, la presión del aire debe ser regulada dentro de este

campo.

LA PRESION DE SERVICIO NO DEBE SUPERAR LOS 120 p.s.i. (8 BARES).

q

Carcasa

w

Tapa del cilindro

e

Brazo de contacto

r

Pico del clavador

t

Cargador

y

Disparador

u

Asa o mango

i

Campana de aspiración

o

Disco de ajuste

!0

Puerta

2. DATOS TÉCNICOS DE LA HERRAMIENTA

N° de producto SN890CH/34 SN890CH/28 SN890RH, SN890RH-R

Alto 374 mm 374 mm 359.2 mm

Ancho 102 mm 102 mm 102 mm

Largo 436 mm 429 mm 542 mm

Peso 3.63 kg (8.0 lbs.) 3.63 kg (8.0 lbs.) 3.63 kg (8.0 lbs.)

Presión de servicio

70-100 p.s.i. (5-7 bares) 70-100 p.s.i. (5-7 bares) 70-100 p.s.i. (5-7 bares)

recomendada

Capacidad de carga 90 Clavo 75 Clavo 64 Clavo

Consumo de aire 1.78Rcon una presion de 1.78Rcon una presion de 1.78Rcon una presion de

comprimido servicio de 90 p.s.i. (6 bares) servicio de 90 p.s.i. (6 bares) servicio de 90 p.s.i. (6 bares)

3. DATOS TÉCNICOS DE LOS CLAVOS

N° de producto SN890CH/34 SN890CH/28 SN890RH, SN890RH-R

Lonaitud de los clavos 50-90 mm 50-90 mm 50-90 mm

Diámetro del vástago 2.9-3.8 mm 2.9-3.3 mm 2.9-3.8 mm

Tipo de codolo

Vástago recto, Vástago recto, Vástago recto,

Vástago anular, Vástago Vástago anular, Vástago Vástago anular, Vástago

Diámetro del cabezal 6.5-7.7 mm 7.0-7.7 mm 6.8-7.5 mm

Ángulo de clavado 34 grados 28 grados 21 grados

Cabeza Cabeza acortada Cabeza acortada

Cabeza completamente redonda

i

w

q

r

!0

e

u

o

y t

Page 36

36

5. CAMPOS DE APLICACIÓN

*Encofrado de pisos y paredes

*Revestimiento de pisos

*Revestimiento de techos y paredes

*Vallado

4. DATOS TÉCNICOS

q

NIVEL DE RUIDO

Nivel de potencia acústica por impulsos A ------ LWA, 1s, d 96.34 dB

Nivel de intensidad acústica por impulsos A ---- Lp A, 1s, d 87.68 dB

en el puesto de trabajo

La determinación y documentación de estos valores se realiza según EN12549: 1999.

w

VIBRACIONES

Indice de vibraciones = 5.18 m/s

2

Estos valores se determinan y se documentan de acuerdo con ISO 8662-11.

Este valor es un valor característico relacionado a la herramienta y no representa la influencia al sistema mano-brazo al usar la

herramienta. Una influencia al sistema mano-brazo cuando se usa la herramienta, por ejemplo, dependerá de la fuerza de

agarre, la fuerza de presión de contacto, la dirección de trabajo, el ajuste del suministro de aire principal, el lugar de trabajo, el

soporte de los objetos de trabajo.

Page 37

37

ATENCIÓN:

3. EL SUMINISTRO DE AIRE Y CONEXIONES

Lea el apartado con el título “INSTRUCCIONES PARA LA SEGURIDAD”.

NO UTILIZAR NINGUNA OTRA FUENTE DE ENERGÍA SALVO UN COMPRESOR DE AIRE

La herramienta esta designada para funcionar con aire comprimido. No utilizar la herramienta con

ningún otro gas de alta presión, gases combustibles (por ejemplo, oxigeno, acetileno, etc.) ya que existe

el peligro de una explosión. Por esta razón, es imprescindible que no se utilice otra cosa que un

compresor de aire para manejar la harramienta.

OPERAR DENTRO DEL LIMITE CORRECTO DE PRESIÓN DE AIRE

La herramienta esta designada para funcionar dentro de limite de presión de aire de 70 a 100 p.s.i.

(5 a 7 bar).

La presión debería ser adaptada a la clase de trabajo indicado. La herramienta no debería ser manejada

cuando la presión sobrepasa 120 p.s.i. (8 bar).

NO UTILIZAR LA HERRAMIENTA CERCA DE SUSTANCIAS INFLAMABLES

Nunca manejar herramienta cerca de sustancias inflamables (por ejemplo, aguarrás, gasolina, etc.).

Gases volátiles de estas sustancias pueden ser arrastradas dentro del compresor de aire y el aire

comprimido puede provocar una explosión.

NO UTILIZAR ACCESORIOS IMPROPIOS

El conector de herramienta no debe contener presión cuando el suministro de aire este desconectado.

Si se utiliza un accesorio impropio, la herramienta puede quedarse cargada con aire despuès de

desconectar, de este modo seguira funcionando incluso despuès de haber desconectado el suministro

de aire, con la posibilidad de causar daños.

MIENTRAS LA HERRAMIENTA NO ESTE EN USO, DESCONECTE LA ALIMENTACION DE

AIRE COMPRIMIDO Y VACIE EL CARGADOR

Siempre desconecte el suministro de aire desde la herramienta y vacíe el cartucho, cuando la operación

ha sido completada o está suspendida, cuando permanece sin atender, cambiando a una área de trabajo

diferente, ajustando, desarmando o reparando la herramienta, y al despejar un afianzador atascado.

ACCESORIOS: Instalar un enchufe macho a la herramienta, lo cual permite una

corriente libre, y suelta presión de la herramienta cuando se desconecta de la

fuente de suministro.

MANGUERAS: La manguera tiene un mínimo de 6 mm (1/4˝) y máximo de 5 matros

(17˝) de largo.

Debe existir en la manguera un accesorio que permite “desconectar rapido” del

enchufe macho.

FUENTE DE SUMINISTRO: Utilizar únicamente aire comprimido regularizado limpio

como fuente de energía para la herramienta.

CONJUNTO DE 3 PIEZAS (Filtro de Aire, Regulador, Deposito de Aceite):

Ver especificaciones de la herramienta para ajustar la presión de operación

adecuada para la herramienta.

OBSERVAR:

El uso de un filtro mejora el funcionamiento y reduce el desgaste de la herramienta, ya que la suciedad

y el agua en el suministro de aire son las causas principales del desgaste de la herramienta.

Es necesario engrasar pero no excesivamente para obtener un perfecto funcionamiento. El aceite que

se añade a la conexión de suministro de aire engrasa las partes internas.

[

EL SUMINISTRO DE AIRE Y CONEXIONES

Compresor de Aire

Aire Mangueras

Presión 70 to 100 p.s.i. (5 to 7 bar)

Regulador

Filtro de Aire

Conjunto de 3 piezas

Deposito de

Acceite

]

Page 38

38

4. INSTRUCCIONES PARA EL SERVICIO

Lea el apartado con el título “INSTRUCCIONES PARA LA SEGURIDAD”.

1. ANTES DE LA PUESTA EN SERVICIO

q

Póngase gafas protectoras.

w

No conecte todavía el aire comprimido.

e

Compruebe los tornillos en cuanto a su firme asiento.

r

Compruebe el funcionamiento del brazo de contacto y la marcha fácil del disparador.

t

Conecte el aire comprimido.

y

Compruebe la herramienta en cuanto a fugas de aire. (No deben existir fugas de aire.)

u

Sujete la herramienta (sin colocar el dedo en el disparador) y apriete el brazo de contacto contra la

pieza. (La herramienta no debe funcionar.)

i

Mantenga la herramienta de modo que el brazo de contacto no esté aplicado contra la pieza, y

accione el disparador. (La herramienta no debe funcionar.)

o

Mientras la hirramienta no este en uso, desconecte la alimentacion de aire comprimido y vacie el

cargador.

2. SERVICIO

Utilizar gafas de seguridad. Debido a la presencia de polvo en el aire, o el mal uso de la herramienta,

siempre existe peligro a los ojos. Por estas razones, se deben utilizar siempre las gafas de seguridad

cuando se maneja la herramienta. El usuario debe asegurarse de que se emplea la protección

adecuada. La protección debe estar de acuerdo con los requisitos de la “American National Standards

Institute, ANSI Z87.1”. Directiva del Consejo 89/686/CEE del 21 de Diciembre de 1989 y debe aportar

protección frontal y lateral.

El empleador es responsable de implementar el uso del equipo de protección de ojos para el operador

de herramienta y otro personal en el área de trabajo.

OBSERVAR: Las gafas sin protección lateral y sin blindaje de cara, no proporcionan la protección

adecuada.

Durante el proceso de grapar/clavar, las manos y el cuerpo deben mantenerse alejados del orificio de

salida ya que existe el riesgo de que puedan ser heridos accidentalmente.

ATENCIÓN:

ATENCIÓN:

COLOCAR UN ROLLO DE CLAVOS

q

Retirar el empujador de clavo hacia atrás hasta que enclave en trinquete.

w

Colocar una tira de clavos desde arriba en el cargador.

Trinquete

Cargador

Clavos

Empujador de clavo

Page 39

39

PRUEBA DE FUNCIONAMIENTO

q

Ajuste la presión del aire a 70 p.s.i. (5 bares) y conecte el aire comprimido.

w

Sin tocar el disparador, apriete el brazo de contacto contra la pieza. Accione el disparador.

(La herramienta debe disparar el clavo.)

e

Accione el disparador sin que la herramienta esté aplicada contra la pieza. A continuación, apriete

el brazo de contacto contra la pieza. (La herramienta debe disparar el clavo.)

r

Ajuste la presión del aire al valor más bajo posible en función del diámetro y la longitud de los clavos,

así como en función de la dureza de la pieza.

e

Desbloquear el trinquete y tirar al mismo tiempo del empujador de clavo. Deslizar el

empujador de clavo hasta los clavos.

NOTA:

Tal como muestra la figura, la punta del empujador debe encontrarse por encima de la

cabeza del último clavo.

PROCEDIMIENTO

q

Mantener el disparador.

w

Presione el brazo del contacto.

SUJETADORES PARA INTRODUCCIÓN

MODELO DE TRINQUETE DE CONTACTO con MECANISMO de DISPARO ANTI-DOBLE

El mecanismo de disparo anti-doble (patente US 5597106, patente UK 2286790) está instalado en esta

herramienta. El procedimiento de funcionamiento común en las herramientas de “trinquete de contacto”

es para que el operador pueda entrar en contacto con la pieza de trabajo, para actuar el mecanismo de

trinquete, mientras que se mantiene el disparador tirado, accionando así un sujetador cada vez que se

entra en contacto con la pieza de trabajo. Esto permitirá una colocación rápida del sujetador, en muchos

tipos de trabajos, tales como forro, trabajos de puentes y montaje de plataforma. Todas las herramientas

neumáticas están sujetadas a rebote, al clavar los sujetadores. La herramienta puede rebotar,

disparando el trinquete, y si está contactando involuntariamente otra vez la superficie de la pieza de

trabajo, con el disparador todavía actuado (con su dedo todavía manteniendo el disparador tirado), un

segundo sujetador indeseado será clavado.

OPERACIÓN DEL DISPANO DE CONTACTO

Para la operación del disparo de contacto, mantener el disparador y presione el brazo del contacto

contra la superficie de la pieza de trabajo.

Trinquete

Empujador de clavo

Punta del

empujador

1

2

Page 40

40

PROCEDIMIENTO

q

Presione el brazo del contacto.

w

Tire del disparador.

OPERACIÓN SIMPLE DE DISPARO (MECANISMO DE DISPARO ANTI-DOBLE)

Para la operación simple de disparo, presione el brazo del contacto contra la superficie de la pieza de

trabajo y tire del disparador.

La herramienta no puede disparar un segundo clavo, hasta que se libere el disparador y la herramienta

puede girar.

DISPARO SECUENCIAL

En caso de realizar un disparo secuencial, es necesario tocar la pieza con el aparato antes de apretar

la palanca de accionamiento. Esta técnica de disparo permite emplazar exactamente el clavo/la grapa

sin que exista la posibilidad de aplicar un segundo clavo/una segunda grapa con el retroceso del

apataro.

Los apatatos con disparo secuencial ofrecen las siguientes ventajas a nivel de seguridad: no se puede

producir un disparo accidental al tocar la pieza u otro objeto con el apataro, estando apretada la

palanca de accionamiento.

DISPARO SECUENCIAL

Visible por el DISPARADOR ANARANJADO.

IDENTIFICACION DE LOS MODELOS

ACCIONAMIENTO POR CONTACTO

El funcionamiento normal de los aparatos con accionamiento por contacto prevé que, para efectuar un

disparo,el operario toque la pieza con el aparato mientras mantiene apretada la palanca de

accionamiento. De esta forma, se aplica un clavo/una grapa cada vez que se toca la pieza. En muchos