Page 1

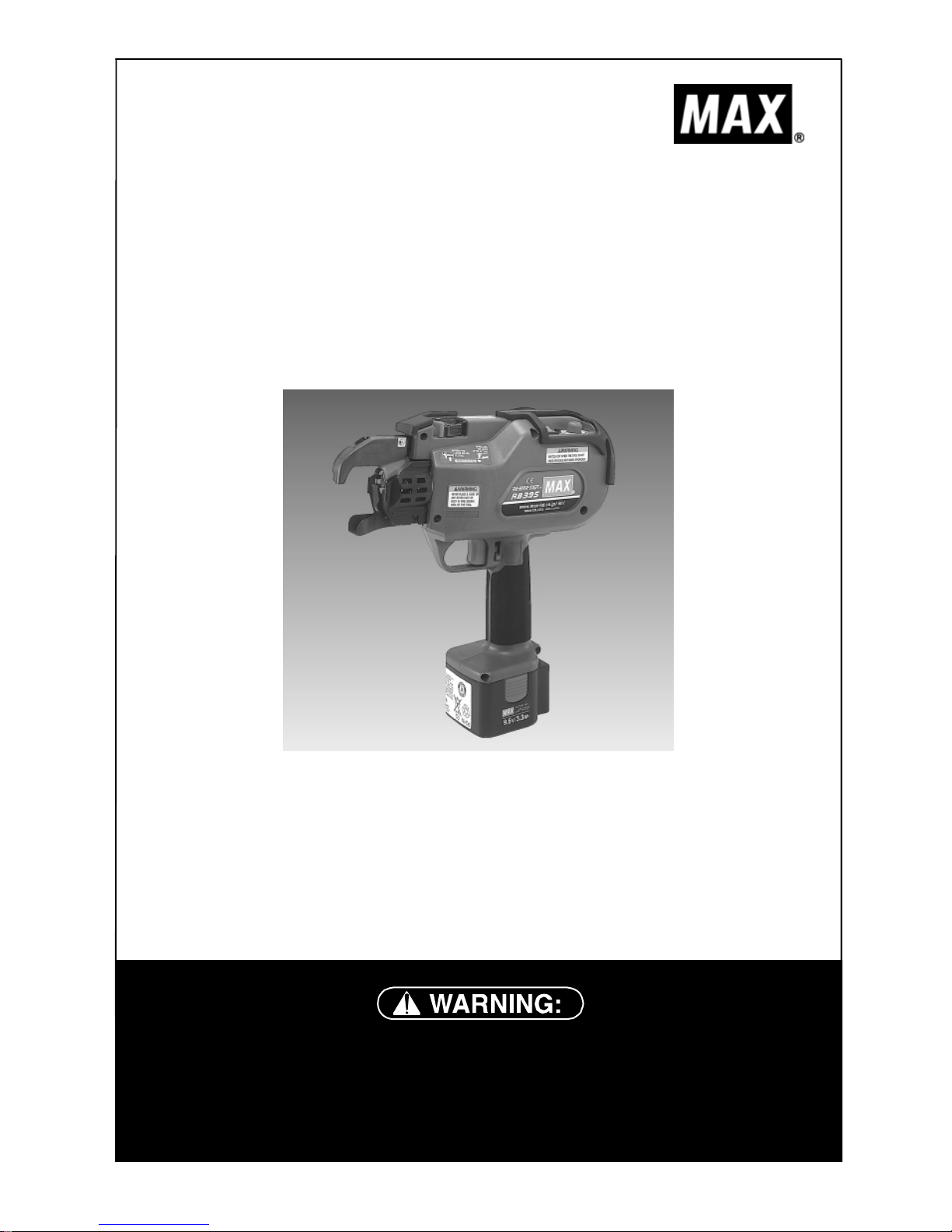

RB515, RB395, RB215

RE・BAR-TIER

RE・BAR TYING TOOL

OPERATING and MAINTENANCE MANUAL

.

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY WARNING

AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

Page 2

INDEX

ENGLISH Page 3 to 20 Page

DEFINITIONS OF SIGNAL WORDS

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTE : Emphasizes essential information.

2

Page 3

RB515, RB395, RB215

RE・BAR-TIER

INDEX

1. SPECIFICATIONS & TECHNICAL DATA.. 4

2. SAFETY INSTRUCTIONS......................... 6

3. SAFETY FEATURES............................... 10

4. BATTERY INSTRUCTIONS......................11

5. OPERATING INSTRUCTIONS ................ 14

6. MAINTENANCE....................................... 20

7. STORAGE................................................ 20

8. TROUBLESHOOTING/REPAIRS

OPERATING and MAINTENANCE MANUAL

ENGLISH

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY WA RNING

AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

3

Page 4

1. SPECIFICATIONS AND TECHNICAL DATA

1. NAME OF PARTS

Arm

Main switch

LED

Pack cap

Tie-Wire

Reel holder

Curl guide

Latch

Grip

Trigger

Trigger lock

Reel stopper

Torque and wrap dial (RB515)

Torque dial (RB395)

Feed dial (RB215)

Release stopper

Release lever

Window

Battery pack (JP409)

Terminal

Battery pack (JP409)

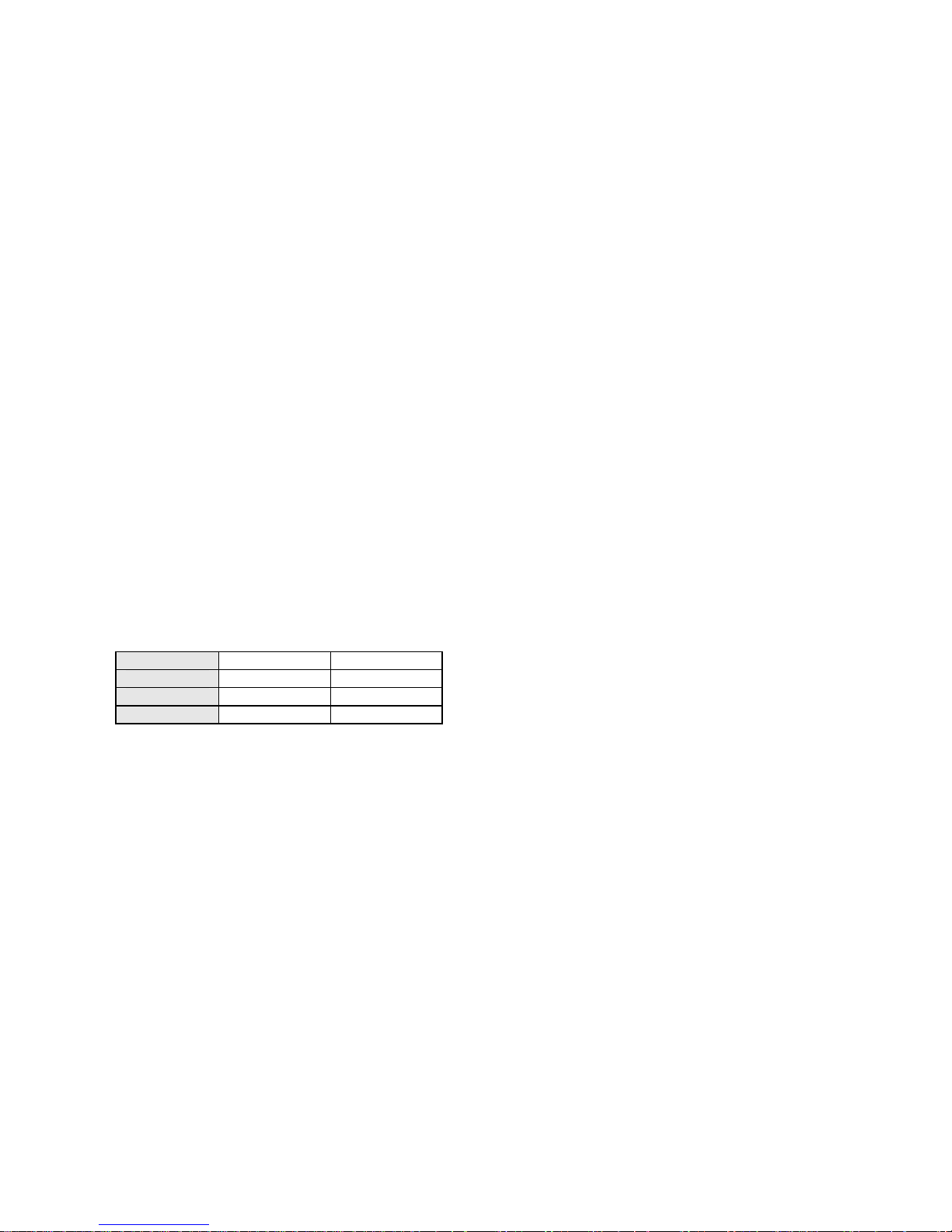

2. TOOL SPECIFICATIONS 3. WIRE SPECIFICATIONS

NAME MAX TIE-WIRE

MODEL

TW897

DIAMETER

0.8 mm

LENGTH

95 m/coil

RB515 (3 wraps / tie) Approx. 90 ties/coil

RB515 (4 wraps / tie) Approx. 75 ties/coil

RB395 Approx. 120 ties/coil

TIES PER COIL

RB215 Approx. 180~210 ties/coil

TIES PER CHARGE

Approx. 360 ties/charge

PRODUCT NO. RB515 RB395 RB215

WEIGHT

2.4 kg 2.4 kg 2.4 kg

HEIGHT

295 mm 296 mm 296 mm

WIDTH

102 mm 103 mm 103 mm

LENGTH

306 mm 290 mm 276 mm

WRAPS PER TIE

3 or 4 wraps/tie 3 wraps / tie

BATTERY

Ni-Cd 9.6V (JP409)

RECHARGE TIME

25 minutes

ACCESSORIES

Battery pack JP409 (2pcs.)

Carrying case

BATTERY CHARGER:

Use only an authorized Battery charger, Panasonic Charger EY0230B.

4

Page 5

4. TECHNICAL DATA

① NOISE

A-weighted single-event ------ LWA, 1s, d 93.6 dB

sound power level

A-weighted single event ------ LpA, 1s, d 88.5 dB

emission sound pressure

level at work station

These values are determined and documented in accordance to EN12549 : 1999.

② VIBRATION

Vibration characteristic value = 0.97 m/s2

These values are determined and documented in accordance to ISO 8662-11.

This value is a tool-related characteristic value and does not represent the influence to the hand-arm-system when using the tool.

An influence to the hand-arm-system when using the too l will, for example, depend on the gripping force, the contact pressure

force, the working direction, the adjustment of main supply, the workpiece, the workpiece support.

③ RADIATED EMISSION 30-1000 MHZ

Class B

5. APPLICATIONS

*Precast plants

*Commercial buildings

*Foundations

*Road & bridge

6. APPLICABLE BAR SIZES

Minimum Maximum

RB515

D16 × D16 D22 × D25

RB395

D10 × D10 D16 × D19

RB215

Mesh × mesh D10 × D10

5

Page 6

2. SAFETY INSTRUCTIONS

TO AVOID SEVERE PERSONAL INJURY OR PROPERTY DAMAGE

BEFORE USING THE TOOL, READ CAREFULLY AND UNDERSTAND THE FOLLOWING

”SAFETY INSTRUCTIONS”:

PRECAUTIONS ON USING THE TOOL

This equipment is a tool for use in tying re-bars. Using this equipment for other applications or in ways not

specified in the manual may lead to serious accident. Be sure to strictly observe the items written in this

manual. Persons not concerned with the work, particularly children, should be kept away from the work site

and should not be allowed to touch this equipment.

1. WEAR SAFETY GLASSES OR GOGGLES

The employer and the user must make sure that proper eye protection is worn when the tool is being

used. Eye protection equipment must conform to the requirements of the American National Standards

Institute, ANSI Z87.1 (Council Directive 89/686/EEC of 21 DEC. 1989) and it must provide frontal and

side protection.

NOTE: Nonside-shielded spectacles and face shields alone do not provide adequate protection.

2. EAR PROTECTION MAY BE REQUIRED IN SOME ENVIRONMENTS

Because working conditions may include exposure to high noise levels that could lead to hearing

damage, the employer and the user should make sure that necessary hearing protection is provided and

used by the operator and others in the work area.

3. DON’T ALLOW CHILDREN NEAR THE TOOL

Allow no bystanders, especially children, near the tool during its operation.

4. DON’T USE THE TOOL IN THE RAIN, WHERE WATER IS SPLASHING, IN A WET PLACE, OR

IN A DAMP PLACE

Using the tool in these or similar conditions will increase the risk of electric shock.

5. INSPECT THE PARTS BEFORE MOUNTING THE BATTERY PACK

●Examine the screws to make sure they are securely tightened.

Incomplete tightening may result in an accident or breakage. If a screw is loose, retighten it

completely.

●Inspect parts for damage.

Parts will wear over periods of use. Look also for missing and defective parts and for parts of poor

quality. If a part must be replaced or repaired, purchase the replacement part at an authorized MAX

Co., Ltd. distributor.

Use only genuine authorized replacement parts.

6. BE SURE TO SET THE MAIN SWITCH TO OFF, TO LOCK THE TRIGGER, AND DETACH THE

BATTERY PACK WHEN CHANGING THE BATTERY PACK, WHEN REPLACING OR ADJUSTING

THE TIE-WIRE, WHEN ABNORMALITIES OCCUR, AND WHEN THE EQUIPMENT IS NOT BEING

USED

Leaving the equipment switched on in these situations may cause breakdowns or damage.

6

Page 7

7. KEEP FINGERS AND BODY PARTS CLEAR OF THE FEEDER ARM AND CURL GUIDE AT ALL

TIMES

Failure to do so may result in serious injury.

8. KEEP FINGERS AND BODY PARTS AWAY FROM THE TIE-WIRE REEL WHEN TOOL IS IN

OPERATION

Failure to do so may result in serious injury.

9. DON’T POINT THE TOOL AT ANYONE

Personal injury may r esult i f the tool catch es an oper ator or a ny one w or king near him. While working with

the tool, be extremely careful not to bring hands, legs, and other body parts near the arm of the tool.

10. WHEN THE TOOL IS NOT IN OPERATION KEEP YOUR FINGERS OFF THE TRIGGER

Failure to do so may cause accidental tying, leading to serious injury.

11. NEVER OPERATE THE TOOL UNDER ANY ABNORMAL CONDITION

If the tool is not in good working order, or if any abnormal condition is noticed, switch it off immediately

(set the Main switch at OFF), lock the Trigger and have it examined and repaired.

12. AFTER BATTERY INSTALLATION IF THE TOOL OPERATES WITHOUT THE TRIGGER BEING

PULLED OR THE OPERATOR NOTICES UNUSUAL HEAT, SMELL, OR SOUND, DISCONTINUE

OPERATION

Failure to do so may lead to serious injury. Return to dealer for safety inspection.

13. NEVER MODIFY THE TOOL

Modifying the tool will impair performance and operatin g safety. Any modification may lead to serio us

injury and void the tool warranty.

14. MAINTAIN THE TOOL IN GOOD OPERATING CONDITION

To secure operating safety and ensure top performance, keep the tool free of wear and damage. Also

keep the tool’s handgrip dry and clean, especially free of oil and grease.

7

Page 8

15. USE ONLY THE AUTHORIZED BATTERY PACK

Use only an authorized JP battery pack. If the tool is connected to a power supply other than the

authorized pack, such as a rechargeable battery, a dry cell, or a storage battery for use in automobiles,

the tool may be damaged, break down, overheat, or even catch on fire. Don’t connect this tool to any

power supply except the authorized JP battery pack.

16. TO ENSURE MAXIMUM PERFORMANCE, FULLY CHARGE THE BATTERY BEFORE USE

A new battery pack or one not used for extended periods may have self-discharged and thus may need

recharging to restore it to a fully charged condition. Before operating the tool, make sure to charge the

Battery pack with the designated MAX Battery charger JC524H.

17. BATTERY CHARGING PRECAUTION

① Use only authorized battery charger Panasonic Battery charger EY0230B and Battery Pack

JP409

Failure to do so may cause the Battery to overheat or catch fire leading to serious injury.

② Charge the Battery only to an AC 230V wall socket

Failure to do so may result in overheating, or inadequate charging possibly causing serious injury.

③ Never use a transformer

④ Never connect the Battery charger to an engine generator direct-current power supply

The charger will break down or be damaged from burning.

⑤ Avoid charging the Battery pack in the rain, in a damp place, or where water is splashing

Charging a damp or wet Battery pack will cause an electric shock or a short circuit that may lead to

damage from burning and even the tool catching on fire.

⑥ Don’t touch the power cord or plug with a wet hand or glove

This may cause injury from electric shock.

⑦ Don’t put a cloth or any other cover on the Battery charger while the Battery pack is being

charged

This will cause overheating and damage from burning, or the Charger may even catch fire.

8

Page 9

⑧ Keep the Battery pack and Battery charger away from heat and flames

⑨ Do not charge the Battery pack near flammable materials

⑩ Charge the Battery pack in a well ventilated place

Avoid charging the Battery pack where it will be in direct sunlight.

⑪ Charge the Battery pack in a temperature range of 0°C (32°F) to 40°C (104°F)

⑫ Avoid continual use of the Battery charger

Rest the Charger for 15 minutes between charges to avoid functional trouble with the unit.

⑬ Any objects that block the ventilation holes or Battery pack receptacle may cause electric

shock or functional troubles

Operate the charger free of dust or other foreign materials.

⑭ Handle the power cord carefully

Don’t carry the Battery charger by its power cord. Don’t use the power cord to disconnect it from a

wall socket; this will damage the cord and break the wires or cause a short circuit. Don’t let the power

cord contact sharp edged tools, hot materials, oil, or grease. A damaged cord must be repaired or

replaced.

⑮ Put a pack cap on the terminal of the Battery pack

When the Battery pack is not in use, put a pack cap on its terminal to prevent short circuits.

⑯ Don’t let the terminal (metal component) of the Battery pack short-circuit

A short circuit in the terminal will generate a large current, causing to overheat the Battery pack and

become damaged.

18. WEAR SAFETY GROVES WHILE OPERATING THE TOOL

The finish tie has sharp edges. To avoid serious injuries, be careful not to touch the sharp edges. MAX

recommends wearing safety groves while operating the tool.

9

Page 10

3. SAFETY FEATURES

In order to ensure safety during operation, the RB395 has the following safety features.

● Prior to using the tool, make sure that the safety features function properly. If they do not, avoid

using the tool.

● Trigger Lock

The Trigger can be locked preventing the tool from operating for safety. Always

keep the Trigger locked when not in use.

Trigger

Trigger lock

Unless you are at tying work, set the trigger lock to the posi tion of LOCK and re move a battery pa ck. When

you start tying work, set it to the position of UNLOCK.

Pull to the left slightly and upward to UNLOCK.

● Curl Guide

When the Curl Guide is op ene d, it will em it a b eep in g sou nd a nd t he to o l doe s no t

operate.

Curl Guide

10

Page 11

4. BATTERY INSTRUCTIONS

1 Charging

● Before removing the Battery pack from the tool, set the Main switch at OFF

and lock the Trigger.

① A Pack cap that is used to prevent short circuits must be removed from the

terminal of the Battery pack.

When charging the Batt ery pa ck, remo ve it by pu shin g on its la tc hes f rom both side s

while firmly holding the grip of the tool.

② Plug the charger into a 230V wall socket.

The red light, a current-carrying indicator, will flash on and off.

Charger

Pack cap

Latch

Battery pack

Red charging lamp

Orange

standby lamp

When the orange standby light is lit

When the Battery pack is hot (after continuous use or exposure to direct sunlight) the Charger will

automatically switch to standby to protect the Battery. The orange standby light will blink until the Battery’s

temperature lowers to a safe level, The Battery will then be charged automatically.

When the Battery pack is at low temperature

When the Battery pa ck is at low temperature, its charging is automatica lly suspended until its temperat ure

increases, in order to protect it, even if it is set in the Charger.

Leave the Battery pack at normal temperature in the room for some time, and then, charge it again.

11

Page 12

When the orange standby light blinks

This indicates the Battery cannot be charged. Unplug the Charger and check the charging receptacle. If there

are any foreign objects, remove them with a soft dry cloth. If the orange light still blinks or there are no foreign

objects, there may be a problem with the battery or charger. Return to dealer for service.

③ Charge the Battery pack.

Battery pack

Red charging

lamp

Charger

Orange

standby lamp

1. Fully insert the Battery into the receptacle on the Charger until it sits securely on

the bottom.

2. Cha rgin g will start automatically and will be indicated by the red charging light.

3. Charging time is approximately 25 minutes. This will vary by temperature and

source voltage.

4. For batteries those are at low temper atures ( 5°C (41°F) or lower) or batteries that

have not been used for ex tended p eriods, cha rg ing time mus t be ex t ended l ong er.

When charging at low tem peratures, the red charging light will flash every 2 .5

seconds.

Regarding tying times per charge, a brand-new battery ties approximately 400 times per charge. The tying

times per charge will be decreased gradually by repeated re-charge until the Battery becomes unusable. The

tying times per charge depend on temperature and the Battery condition.

Tips for maximum Battery life

① If you repeatedly charge the Battery before fully using it, it will memorize an additional charging capacity

as its maximum charge. This phenomenon is called “Memory Effect”. If this happens, the Battery’s

capacity will be decreased, even if it is fully charged. In order to prevent the memory effect, charge the

battery only after the tying speed slows down considerably.

② Use two Battery packs alternately.

To extend Battery life, alternate between the two batteries provided.

12

Page 13

Battery pack breakdowns

If the following conditions occur, bring the Battery and Charger to your dealer.

● If the red charging lamp does not flash when the charger plug is inserted into an AC 230V main power

source outlet (When the battery pack is not inserted in the charger.)

● If neither the red charging lamp nor the orange standby lamp lights or flashes when the battery pack is

inserted in the charger.

● If the orange standby lamp does not change to the red charging lamp even for more than 1 hour.

● If the red charging lamp does not change from constant to flashing light even after more than 30 minutes

have passed since starting charging. (Except during low temperature charging.)

Service Life of the Battery Pack

If any condition described below is observed, the battery pack is at the end of its service life. Replace it with a

new one.

● Although the battery pack has been properly charged ( fully charged) , a great drop i n hour s of use has been

noticed.

Don’t charge the battery pack when this happens. If the motor’s rotational speed slows down, the

power of the battery pack is cons idered t o be nea rly depleted. Using the tool more will cause it to over

discharge, resulting in a shortened service life of the battery pack and also in functional trouble of the

tool’s main body.

Don’t use a battery pack when its service life is finished.

This will cause functional trouble in the tool’s main body. Also charging a battery pack that is out of

service life will lead to functional trouble in the battery charger.

Recycling a NiCad Battery

The MAX battery pack uses a NiCad battery, it may be illegal to dispose of this battery into the municipal

waste system. Check with your local soli d waste officials for details in your ar ea for r ecy cl ing opti ons or proper

disposal.

When disposing of the battery pack, make sure to put a pack cap on its terminal (with insulating tape

securing it) to prevent short circuits.

Preventing the Battery Pack from Becoming Inactive

When the tool is purcha sed, or whe n it is not used fo r extended periods (mor e than two mont hs), the ba ttery

pack must be charged for 24 hours to reach top performance.

13

Page 14

5. OPERATING INSTRUCTIONS

1 How to set the Tie-Wire

● Be sure to set the Main switch to off, to lock the Trigger, and detach the

Battery pack.

① Press the Release Lever of this equipment, and confirm that the Release Lever is

caught in the Release Stopper.

② Peel off the tape fix ing Tie-Wire by about 5cm (2”). Stretch out the tip of the w ound

Tie-Wire.

BE SURE TO USE ONLY THE SPECIFIED TIE-WIRE (MAX TW897).

The use of binding wire that has not been specified may cause breakdown of this

equipment. Therefore, be sure only to use the specified MAX TW897. Do not use

binding wire that has become rusted, since the use of rusted wire will cause

equipment breakdown.

③ Push the reel stopper to release the reel holder.

④ Set the Tie-Wire in the tool by matching the side of the Tie-Wire as shown in the

picture.

Then push the Reel Holder.

⑤ Insert the tip of the stretched out Tie-Wire into the wire guide.

● The tip of the Tie-Wire should be straightened out to allow it to pass through

the wire guide.

When mounting the Tie-Wire, the wire may become jammed inside the

machine if the wire tip is bent.

Release Stopper

Release Lever

Tie-Wire

Reel stopper

Feeding gears

Reel holder

Pipe

Wire guide

Reel holder

Tie-Wire

14

Page 15

Arm

If the window is dirty and the pipe position can not be confirmed

Open the window and wipe off the dirty on the inside of the window with a soft cloth,

etc. Close the window again after cleaning to ensure that foreign objects will not be

able to enter the machine.

⑥ Keep inserting the Tie-Wire into the pipe until the tip of the wire comes out from the

Arm part within 5 mm (1/4”) or the wire hits the dead end.

⑦ Release the release stopper, and confirm that the release lever has returned to its

original position and that the feeding gears are clamping the Tie-Wire. This

completes the Tie-Wire mounting operation.

Tie-Wire

Release stoppe

r

Feeding gears

Release lever

Tie-Wire

⑧ Remove the tape from the tie-wire completely.

⑨ Remove slack from wire spool.

Make sure the Tie-Wire does not get caught behind the wire spool. This could lead

to jamming.

● When setting the main switch to ON, absolutely do not bring your fingers

close to the binding part and rotating part of the tip.

● Do not switch the main switch ON and OFF in rapid succession, since this

operation will cause machine breakdowns.

● Do not touch the Tie-Wire during the binding work (while the machine is

operating).

⑩ Mount the battery pack on the tool’s main body until a click is heard. Turn the Main

Switch on. Tool feeds the wire about 50 mm (2”) RB215, RB395, 100 mm (4”)

RB515 and cuts the wire automatically. Remove the cut end of the wire with pliers.

⑪ Unlock the Trigger before using the tool.

Trigger lock

Trigger

15

Page 16

2 How to remove the Tie-Wire

● Be sure to turn the Main switch OFF, lock the Trigger, and remove the Battery

pack.

① Press the release lever, and confirm that the release lever is caught in the release

stopper.

Release Stopper

Release Lever

Wire guide

Tie-Wire

Tie-Wire

Reel stopper

② Remove the Tie-Wire.

③ Push the reel stopper to release the holder and remove the Tie-Wire.

④ Mount the new Tie-Wire. (Refer to the Tie-Wire mounting method explanation.)

When the Tie-Wire runs out of binding wire

There should be around 30 mm ( 1-1/8”) of the Tie-Wire left at end of the spool. This s houl d be disch arged w i th

the old spool and be replaced with a new one.

16

Page 17

RB515

3 Tension and wrap adjustment

① Be sure to turn the

Main switch OFF,

to lock the Trigger

and detach the

Battery pack.

② This dial allows

you to set 3 wraps

/ tie or 4 wraps / tie

and also you can

adjust the torque.

To increase the

tension, turn it in

the clockwise.

To decrease the

tension, turn it in

the

counterclockwise.

RB395

3 Tension adjustment

① Be sure to turn the

Main switch OFF,

to lock the Trigger

and detach the

Battery pack.

② This dial allows

you to adjust wire

tension torque

slightly.

To increase the

tension, turn it in

the clockwise.

To decrease the

tension, turn it in

the

counterclockwise.

③ Insert the charged battery pack into the tool until a click is heard.

Main switch

● When setting the main switch to ON, absolutely do not bring your hand

close to the binding part or rotating part of the tip.

④ Set the Trigger Lock to UNLOCK and turn on the main switch.

The Tie-Wire is fed automatically to the arm unit and set in the required position.

⑤ Test the tool again to check the tie strength.

⑥ If the tie strength is not appropriate, repeat procedures ①~⑤.

Battery pack

Main switch

Battery pack

LOW

Torque dial

HIGH

Torque and wrap dial

LOW

HIGH

Battery pack

Reinforcing bars Over-tightened

Appropriate

17

Page 18

RB215

3 Wire length adjustment

Battery pack

Edge part

Edge part

Feed dial

Main switch

Battery pack

HIGHLOW

① Be sure to turn the main switch OFF, to lock the trigger and detach the battery

pack.

② The feed dial is a mechanism to adjust feed rate of the Tie-Wire. When the edge

part length is not appropriate after binding, use this dial to adjust it.

③ Mount the battery pack on the tool’s main body insert the charged battery pack on

to the main unit until a click is heard.

● When setting the main switch to ON, absolutely do not bring your hand

close to the binding part or rotating part of the tip.

④ Set the Trigger Lock to UNLOCK and turn on the main switch.

The Tie-Wire is fed automatically to the arm unit and set in the required position.

⑤ Test the tool again to check the tie strength.

18

Page 19

4 For proper tightness

45°

① Tilt the tool 45° angle to the crossed re-bars.

② Apply the tool perpendicularly to the surface of crossed re-bars.

During tool operation

● Do not move the tool during tying operation until the tool stops tying automatically.

③ Tie in alternate direction.

④ Cross tie.

Bent the tail of first tie before making second tie.

⑤ When you need extra tightness, place re-bars at the top of the Arm part.

Arm

A

rm

Re-bars

19

Page 20

6. MAINTAINANCE

① Regularly inspect the tool

In order to maintain the performance of the tool, periodically clean up and inspect the tool.

② Do not lubricate the equipment

Absolutely do not lubricate this equipment. Applying lubrication will rem ove the grease inside of the tool,

and cause problem on tool.

7. STORAGE

Do not store the tool in a cold weather environment. Keep the tool in a warm area.

When not in use, the tool should be stored in a warm and dry place. Keep out of reach of children. All quality

tools will eventually require servicing or rep lacement of parts because of wear from normal us e.

REMOVE REEL OF TIE-WIRE

When you have finished the Tie-Wire, remove the Tie-Wire from the tool.

STORE THE TOOL

When you have finished the Tie-Wire or whe n the tool will no t be used for a while, switch

off the tool, make sure the motor has stopped, lock the trigger, and remove the battery

pack, With a pack cap installed on the pack's terminal to prevent short circuits tool,

attachments, and accessories should be stored in a well-ventilated dry place where the

temperature will not exceed 50 °C (122°F). The storage area must be locked and out of

the reach of children.

20

Page 21

21

Page 22

・ The contents of this manual may be changed without notice, as our policy is on e of continuous

improvement.

Temel Insaat Makina San ve Tic. Ltd. Sti. Ankara

Tel: 312-342 5250 Telefaks: 312-342 5282

[

]

www.temelltd.com.tr

www.temelinsaat.com

★070323-00/00

MADE IN JAPAN

22

Loading...

Loading...