Page 1

REBAR TYING TOOL

ATADORA DE ARMADURAS DE REFUERZO

OUTIL DE LIGATURE DE BARRES

RB441T

INSTRUCTION MANUAL AND SAFETY INSTRUCTIONS

MANUAL DE INSTRUCCIONES E INSTRUCCIONES DE SEGURIDAD

MODE D'EMPLOI ET CONSIGNES DE SÉCURITÉ

INDEX

ÍNDICE

SOMMAIRE

ENGLISH Page 2 to 18

ESPAÑOL Página 19 a 34

FRANÇAIS Page 35 à 50

Before using the tool, read and understand tool labels and manual. Failure to

follow warnings could result in serious injury. Keep these instructions with the

tool for future reference.

Lea y comprenda las etiquetas y el manual de la herramienta antes de usarla.

El incumplimiento de las advertencias puede provocar lesiones graves.

Conserve estas instrucciones junto con la herramienta para futuras consultas.

Veillez à lire et bien comprendre les étiquettes et le manuel avant d'utiliser cet

outil. Tout manquement au respect des avertissements peut entraîner des

blessures graves. Conservez ces instructions avec l'outil pour toute

consultation ultérieure.

WARNING

ADVERTENCIA

AVERTISSEMENT

Page 2

2

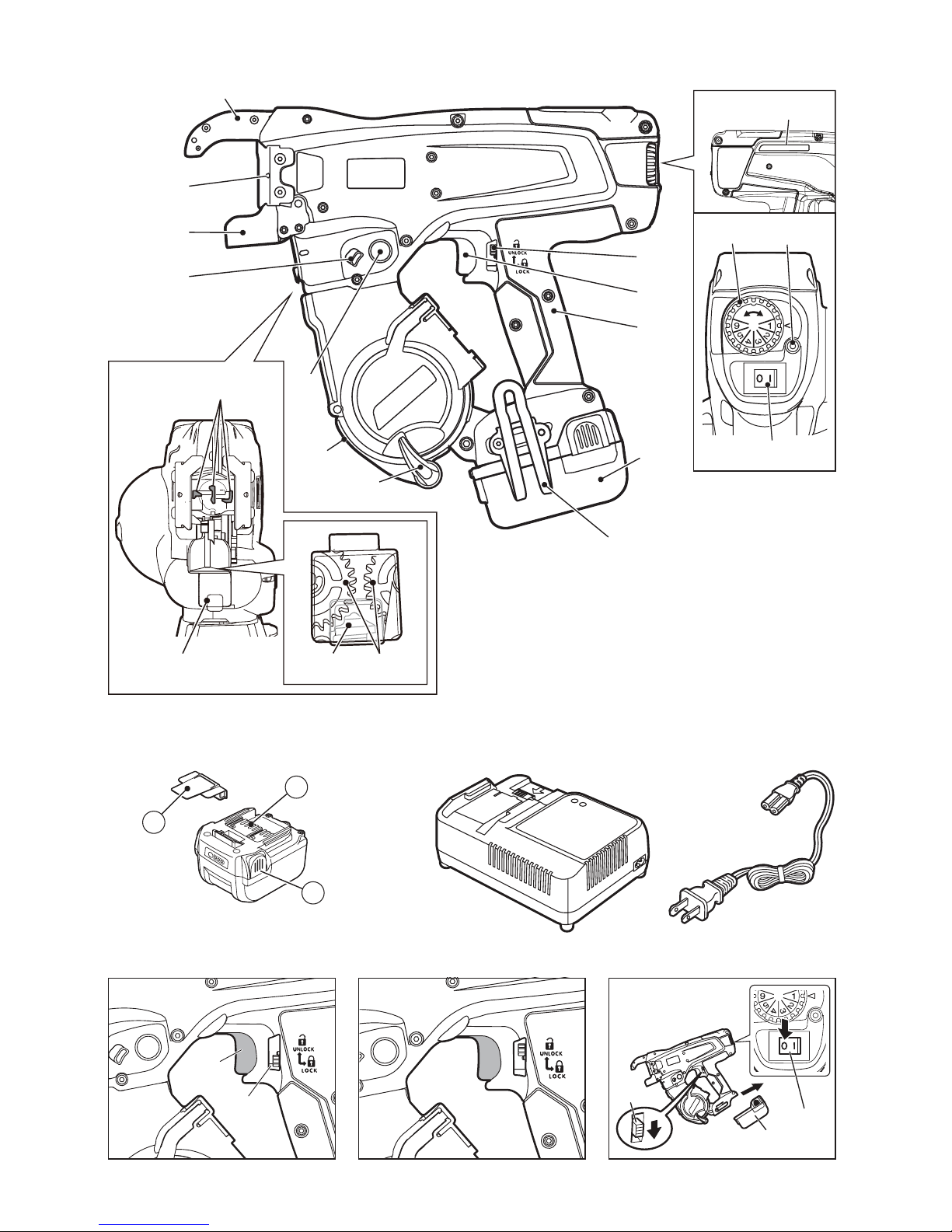

LOCK

⑤

⑳

⑮

⑬

⑭

④

②

②

⑦

⑥

③

③

Fig.1

22

21

23

⑫

①

⑨

⑩

⑪

⑧

Fig.4

Fig.2 Fig.3

Fig.5 Fig.6

⑯

⑰

⑱

⑲

②

⑤

⑮

2

Page 3

3

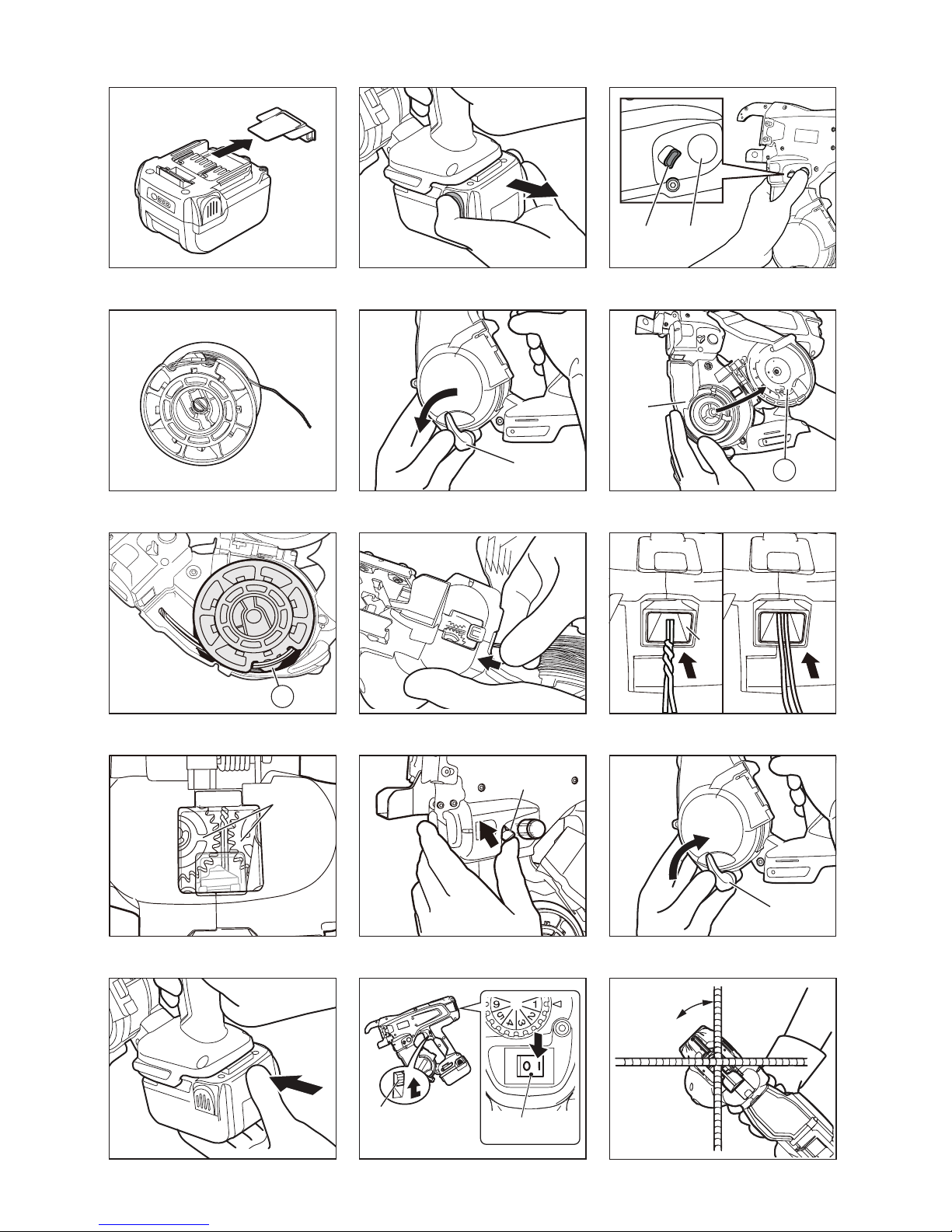

Fig.7 Fig.8 Fig.9

Fig.10 Fig.11 Fig.12

Fig.13

Fig.14 Fig.15

Fig.16 Fig.17 Fig.18

Fig.19 Fig.20 Fig.21

⑨

UNLOCK

⑮

45°

⑥

⑥

PUSH

⑨ ⑧

⑦

24

②

⑱

⑲

25

3

Page 4

4

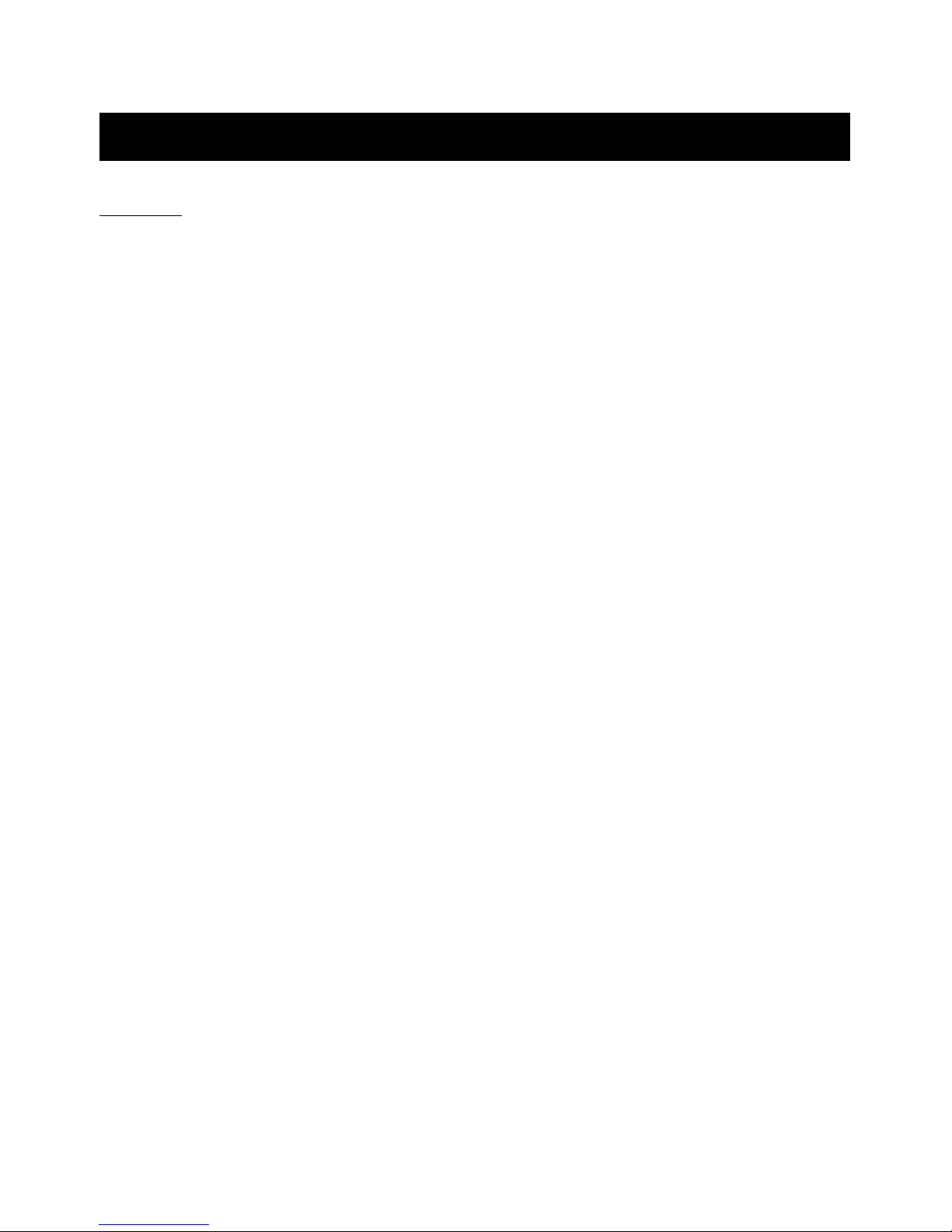

⑬

Fig.22 Fig.23 Fig.24

Fig.25

Fig.26 Fig.27

Fig.28 Fig.29

Fig.32

Fig.30

Fig.31

⑪

⑪

⑳

4

Page 5

5

INDEX

1. NAME OF PARTS......................................................................... 6

2. LIST OF CONTENTS.................................................................... 6

3. GENERAL POWER TOOL SAFETY WARNINGS ....................... 7

4. RB441T SAFETY FEATURES...................................................... 9

5. TOOL SPECIFICATIONS AND TECHNICAL DATA.................. 11

6. TECHNICAL DATA..................................................................... 12

7. PRODUCTION YEAR ................................................................. 12

8. WIRE SPECIFICATION .............................................................. 13

9. APPLICATIONS.......................................................................... 13

10. APPLICABLE REBAR SIZE....................................................... 13

11. BATTERY INSTRUCTIONS........................................................ 14

12. OPERATING INSTRUCTIONS ................................................... 15

13. STORAGE................................................................................... 17

14. WARNING BUZZERS AND PROCEDURES TO FOLLOW ....... 18

DEFINITIONS OF SIGNAL WORDS

WARNING: Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION: Indicates a hazardous situation which, if not avoided, could result in minor or moderate

injury.

NOTICE: Indicates a property damage message.

ENGLISH

INSTRUCTION MANUAL AND SAFETY INSTRUCTIONS

Original instructions

Page 6

6

1. NAME OF PARTS

Fig.1

Fig.2

Fig.3

Refer to the JC925 operating and maintenance manual.

Fig.12

Fig.13

2. LIST OF CONTENTS

• MAX Rebar Tying tool / RB441T

• Lithium ion Battery pack / JPL91440A

• Lithium ion Battery charger / JC925

•Power cord

• INSTRUCTION MANUAL AND SAFETY INSTRUCTIONS (This book)

1 Arm

2 Trigger lock

3 Trigger

4 Grip

5 Battery pack

6 Magazine stopper

7 Magazine

8 Release button

9 Release stopper

0 Curl guide

a Center mark

b Serial number

c Torque dial

d LED

e Main switch

f Hook

g Window

h Feeding gear

i Wire guide

j Belt hook

k Pack cap

l Terminal

m Latch

n Magazine cover

o Holding slot

Page 7

7

3. GENERAL POWER TOOL

SAFETY WARNINGS

1. WORK AREA SAFETY

• Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

• Do not operate power tools in

explosive atmospheres, such as in the

presence of flammable liquids, gases

or dust. Power tools create sparks which

may ignite the dust or fumes.

• Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose

control.

2. ELECTRICAL SAFETY

• Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs with

earthed (grounded) power tools.

Unmodified plugs and matching outlets

will reduce risk of electric shock.

• Avoid body contact with earthed or

grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the

cord for carrying, pulling or

unplugging the power tool. Keep cord

away from heat, oil, sharp edges or

moving parts. Damaged or entangled

cords increase the risk of electric shock.

•

When operating a power tool outdoors,

use an extension cord suitable for

outdoor use.

Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

• If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected

supply. Use of an RCD reduces the risk

of electric shock.

3. PERSONAL SAFETY

•

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication.

A moment

of inattention while operating power tools

may result in serious personal injury.

• Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate conditions

will reduce personal injuries.

• Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or

battery pack, picking up or carrying

the tool. Carrying power tools with your

finger on the switch or energising power

tools that have the switch on invites

accidents.

• Remove any adjusting key or wrench

before turning the power tool on.

A wrench or a key left attached to a

rotating part of the power tool may result

in personal injury.

• Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

• Dress properly. Do not wear loose

clothing or jewelry. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

• If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used. Use of

dust collection can reduce dust-related

hazards.

4. POWER TOOL USE AND CARE

• Do not force the power tool. Use the

correct power tool for your

application. The correct power tool will

do the job better and safer at the rate for

which it was designed.

READ ALL SAFETY WARNINGS AND ALL

INSTRUCTIONS.

Failure to follow the warnings and instructions

may result in electric shock, fire and/or

serious injury. Save all warnings and

instructions for future reference. The term

"power tool" in the warnings refers to your

mains-operated (corded) power tool or

battery-operated (cordless) power tool.

WARNING

Page 8

8

• Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the

switch is dangerous and must be

repaired.

• Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive

safety measures reduce the risk of

starting the power tool accidentally.

• Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

• Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power

tool's operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

• Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5. BATTERY TOOL USE AND CARE

• Recharge only with the charger

specified by the manufacturer. A

charger that is suitable for one type of

battery pack may create a risk of fire when

used with another battery pack.

• Use power tools only with specifically

designated battery packs. Use of any

other battery packs may create a risk of

injury and fire.

• When battery pack is not in use, keep

it away from other metal objects, like

paper clips, coins, keys, nails, screws

or other small metal objects, that can

make a connection from one terminal

to another. Shorting the battery terminals

together may cause burns or a fire.

• Under abusive conditions, liquid may

be ejected from the battery; avoid

contact. If contact accidentally occurs,

flush with water. If liquid contacts

eyes, additionally seek medical help.

Liquid ejected from the battery may cause

irritation or burns.

6. SERVICE

•

Have your power tool serviced by a

qualified repair person using only

identical replacement parts.

This will

ensure that the safety of the power tool is

maintained.

• Do not use the power tool in the rain, where

water is splashing, in a wet place, or in a

damp place. Using the tool in these or similar

conditions will increase the risk of electric

shock, dangerous malfunction, and

overheating.

• DO NOT DISPOSE OF BATTERY PACKS/

BATTERIES INTO FIRE OR WATER. Battery

packs/batteries should be collected, recycled

or disposed of in an environmental-friendly

manner.

• PROTECT THE BATTERY AGAINST HEAT,

ALSO AGAINST CONTINUOUS SUN

IRRADIATION AND FIRE. There is danger of

explosion.

• CHARGE THE BATTERY PACK IN A

TEMPERATURE RANGE 41°F (5°C) TO

104°F (40°C).

• The product you have purchased is

powered by a Li-ion battery which is

recyclable. At the end of its useful life,

under various state and local laws, it is

illegal to dispose of this battery into your

municipal waste stream. Please call 1-8008-BATTERY for information on how to

recycle this battery.

Page 9

9

4. RB441T SAFETY

FEATURES

1. INSPECT THE PARTS BEFORE

MOUNTING THE BATTERY PACK

• Examine the screws to make sure they are

securely tightened.

Incomplete tightening may result in an

accident or breakage. If a screw is loose,

retighten it completely.

• Inspect parts for damage.

Parts will wear over periods of use. Look

also for missing and defective parts and for

parts of poor quality. If a part must be

replaced or repaired, purchase the

replacement part at the dealer where the

tool was purchased or MAX CO., LTD.

authorized distributors.

Use only genuine authorized replacement

parts.

2. SET THE MAIN SWITCH (FIG.6.e) AT

"OFF", THE TRIGGER LOCK (FIG.6.2)

AT "LOCK" AND REMOVE THE BATTERY

PACK (FIG.6.5), WHEN CHANGING THE

BATTERY PACK, REPLACING OR

ADJUSTING THE TIEWIRE,

ABNORMALITIES OCCUR, AND THE

TOOL IS NOT BEING USED

Leaving the tool switched on in these

situations may cause breakdowns or

damage.

3. KEEP FINGERS AND BODY PARTS

CLEAR BETWEEN THE ARM AND CURL

GUIDE AT ALL TIMES (FIG.23)

Failure to do so may result in serious injury.

4. KEEP FINGERS AND BODY PARTS

AWAY FROM THE TIEWIRE WHEN TOOL

IS IN OPERATION

Failure to do so may result in serious injury.

5. DO NOT POINT THE TOOL AT ANYONE

Personal injury may result if the tool catches

an operator or anyone working near him/her.

While working with the tool, be extremely

careful not to bring hands, legs, and other

body parts near the arm of the tool.

6. WHEN THE TOOL IS NOT IN OPERATION

KEEP YOUR FINGERS OFF THE

TRIGGER

Failure to do so may cause accidental tying,

leading to serious injury.

7. NEVER OPERATE THE TOOL UNDER

ANY ABNORMAL CONDITION

If the tool is not in good working order, or if

any abnormal condition is noticed, switch it off

immediately (set the Main switch at "OFF"),

lock the Trigger and have it examined and

repaired.

8. AFTER BATTERY INSTALLATION IF THE

TOOL OPERATES WITHOUT THE

TRIGGER BEING PULLED OR THE

OPERATOR NOTICES UNUSUAL HEAT,

SMELL, OR SOUND, DISCONTINUE

OPERATION

Failure to do so may lead to serious injury.

Return to dealer for safety inspection.

9. NEVER MODIFY THE TOOL

Modifying the tool will impair performance and

operating safety. Any modification may lead to

serious injury and void the tool warranty.

10. MAINTAIN THE TOOL IN GOOD

OPERATING CONDITION

To secure operating safety and ensure top

performance, keep the tool free of wear and

damage. Also keep the tool's hand grip dry

and clean, especially free of oil and grease.

11. USE ONLY THE AUTHORIZED BATTERY

PACK

If the tool is connected to a power supply

other than the authorized pack, such as a

rechargeable battery, a dry cell, or a storage

battery for use in automobiles, the tool may

be damaged, break down, overheat, or even

catch on fire. Do not connect this tool to any

power supply except the authorized battery

pack.

12. TO ENSURE MAXIMUM PERFORMANCE,

FULLY CHARGE THE BATTERY BEFORE

USE

A new battery pack or one not used for

extended periods may have self-discharged

and thus may need recharging to restore it to

a fully charged condition. Before operating

the tool, make sure to charge the Battery pack

with the designated MAX Battery charger.

13. BATTERY CHARGING PRECAUTION

13-1 Use only MAX Battery charger and

MAX Battery pack.

Failure to do so may cause the Battery

to overheat or catch fire leading to

serious injury.

Page 10

10

13-2 Charge the Battery from an AC 120V

wall sockets.

Failure to do so may result in

overheating, or inadequate charging

possibly causing serious injury.

13-3 Never use a transformer.

13-4 Never connect the Battery charger to

an engine generator direct-current

power supply.

The charger will break down or be

damaged from burning.

13-5 Avoid charging the Battery pack in

the rain, in a damp place, or where

water is splashing.

Charging a damp or wet Battery pack

will cause an electric shock or a short

circuit that may lead to damage from

burning and even the tool catching on

fire.

13-6 Do not touch the power cord or plug

with a wet hand or glove.

This may cause injury from electric

shock.

13-7 Do not put a cloth or any other cover

on the Battery charger while the

Battery pack is being charged.

This will cause overheating and

damage from burning, or the Charger

may even catch fire.

13-8 Keep the Battery pack and Battery

charger away from heat and flames.

13-9 Do not charge the Battery pack near

flammable materials.

13-10 Charge the Battery pack in a well

ventilated place.

Avoid charging the Battery pack where

it will be in direct sunlight.

13-11 Charge the Battery pack in a

temperature range of 41°F (5°C) to

104°F (40°C).

13-12 Avoid continual use of the Battery

charger.

Rest the Charger for 15 minutes

between charges to avoid functional

trouble with the unit.

13-13 Any objects that block the

ventilation holes or Battery pack

receptacle may cause electric shock

or functional troubles.

Operate the charger free of dust or

other foreign materials.

13-14 Handle the power cord carefully.

Do not carry the Battery charger by its

power cord. Do not use the power cord

to disconnect it from a wall socket; this

will damage the cord and break the

wires or cause a short circuit. Do not let

the power cord contact sharp edged

tools, hot materials, oil, or grease. A

damaged cord must be repaired or

replaced.

13-15 Do not charge non rechargeable

batteries with this charger.

13-16 This charger is not intended for use

by children or disabled persons

without supervisor.

13-17 Children should be supervised to

ensure that they do not play with the

charger.

13-18 Put a Pack cap (Fig.2.k) on the

Terminal (Fig.2.l) of the Battery

pack.

When the Battery pack is not in use, put

a Pack cap on its Terminal to prevent

short circuits.

13-19 Do not let the Terminal (metal

component) of the Battery pack

short-circuit.

A short circuit in the Terminal will

generate a large current, causing to

overheat the Battery pack and become

damaged.

13-20 Do not leave or store the tool in a

vehicle or in direct sunlight during

summer. Leaving the tool in high

temperature conditions may cause

the Battery pack to deteriorate.

13-21 Do not store a fully discharged

Battery pack. If a fully discharged

Battery pack is removed from the

system and left for a long period of

time, it may become damaged.

Recharge the battery immediately

when it has been discharged.

14. WEAR SAFETY GLOVES WHILE

OPERATING THE TOOL

The finish tie has sharp edges. To avoid

serious injures, be careful not to touch the

sharp edges.

15. PRIOR TO USING THE TOOL

(Fig.4 and 5) Make sure that the safety

features function properly. If they do not,

avoid using the tool.

Page 11

11

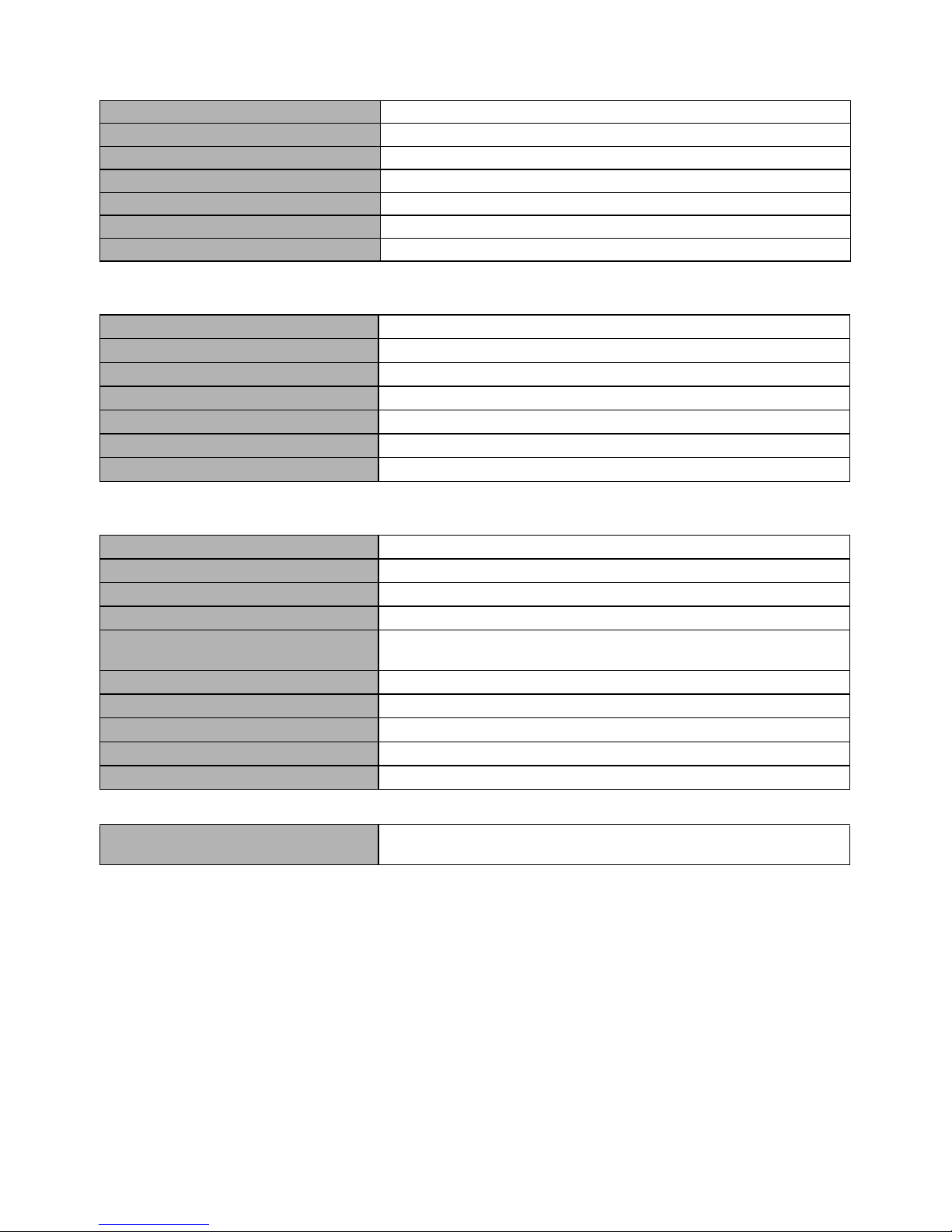

5. TOOL SPECIFICATIONS AND TECHNICAL DATA

<BATTERY CHARGER>

<BATTERY PACK>

PRODUCT DESCRIPTION MAX Rebar Tying tool “TWINTIER”

PRODUCT NO. RB441T

DIMENSIONS (Battery pack included) (H)11-1/2" (295mm) x (W)4-7/8" (125mm) x (L)13" (330mm)

WEIGHT (Battery pack included) 5.6lbs (2.5kg)

BATTERY Lithium ion Battery pack / JPL91440A

OPERATING TEMPERATURE 14°F to 104°F (-10°C to 40°C)

HUMIDITY 80% RH or less

PRODUCT DESCRIPTION Lithium ion Battery charger

PRODUCT NO. JC925

INPUT AC120V 60Hz 2.6A 160W

OUTPUT DC14.4V 7.5A, DC18V 5.4A, DC25.2V 4.5A

WEIGHT 3.3lbs (1.5kg)

OPERATING TEMPERATURE RANGE 41°F to 104°F (5°C to 40°C)

OPERATING HUMIDITY RANGE 80% RH or less

PRODUCT DESCRIPTION Lithium ion Battery pack

PRODUCT NO. JPL91440A

NOMINAL VOLTAGE DC14.4V (3.6V x 4cells)

NOMINAL CAPACITY 3.9Ah (3,900mAh)

CHARGING TIME Quick charging – Approx. 33min.(Approx. 90% of capacity)

Full charging – Approx. 45min.(100% of capacity)

ACCESSORIES Pack cap

WEIGHT 1.1lbs (0.5kg)

CHARGING TEMPERATURE 41°F to 104°F (5°C to 40°C)

OPERATINGTEMPERATURE RANGE 32°F to 104°F (0°C to 40°C)

OPERATING HUMIDITY RANGE 80% RH or less

TIES PER CHARGE Approx. 4,000 ties (*under the following conditions: normal temperature,

unused, full-charged battery and #4 x #4 (13mm x 13mm) rebars)

Page 12

12

6. TECHNICAL DATA

6-1 NOISE

Measured value according to EN 60745:

A-weighted sound pressure level (LpA): 79 dB

Uncertainty (KpA):3dB

A-weighted sound power level (LWA): 79 dB

Uncertainty (KWA):3dB

6-2 VIBRATION

Measured value according to EN 60745:

Vibration total values (ah): 0.5 m/s

2

Uncertainty (K): 0.1 m/s

2

• The declared vibration emission value has been measured in accordance with the standard test method and may

be used for comparing one tool with another.

• The declared vibration emission value may also be used in a preliminary assessment of exposure.

• The vibration emission during actual use of the power tool can differ from the declared emission value depending

on the ways in which the tool is used.

• Be sure to identify safety measures to protect the operator that are based on an estimation of exposure in the

actual conditions of use (taking account of all parts of the operating cycle such as the times when the tool is

switched off and when it is running idle in addition to the trigger time).

6-3 RADIATED EMISSION 30-1000 MHZ Class A

This is a class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

6-4 Overvoltage category - category 1 according to IEC 60664-1

6-5 Pollution degree - degree 4 according to IEC 60664-1

6-6 Design guidelines – Machinery directive annex 1, EN60745-1, EN60745-2-18

7. PRODUCTION YEAR

This product bears production number in the body (Fig.1.b). The two digits of the number from left

indicates the production year.

WARNING

WARNING

(Example)

17526035D

Year 2017

Page 13

13

8. WIRE SPECIFICATION

*RB441T is not compatible with TW898 series or TW1525 series.

9. APPLICATIONS

• Precast concrete panel

• Building foundation

• Commercial building

• Road & Bridge

• Floor heating pipe

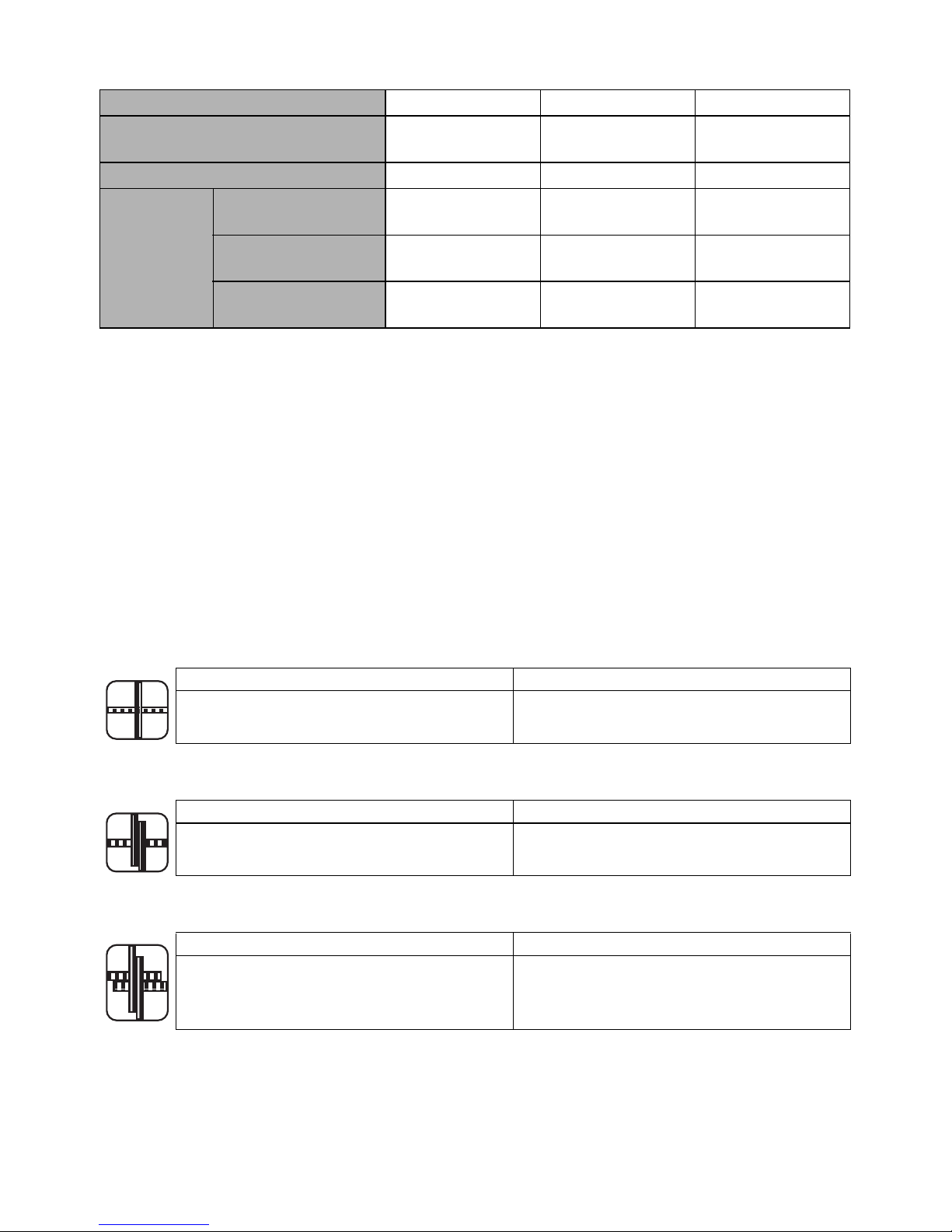

10.APPLICABLE REBAR SIZE

■ 2 rebars combination

■ 3 rebars combination

■ 4 rebars combination

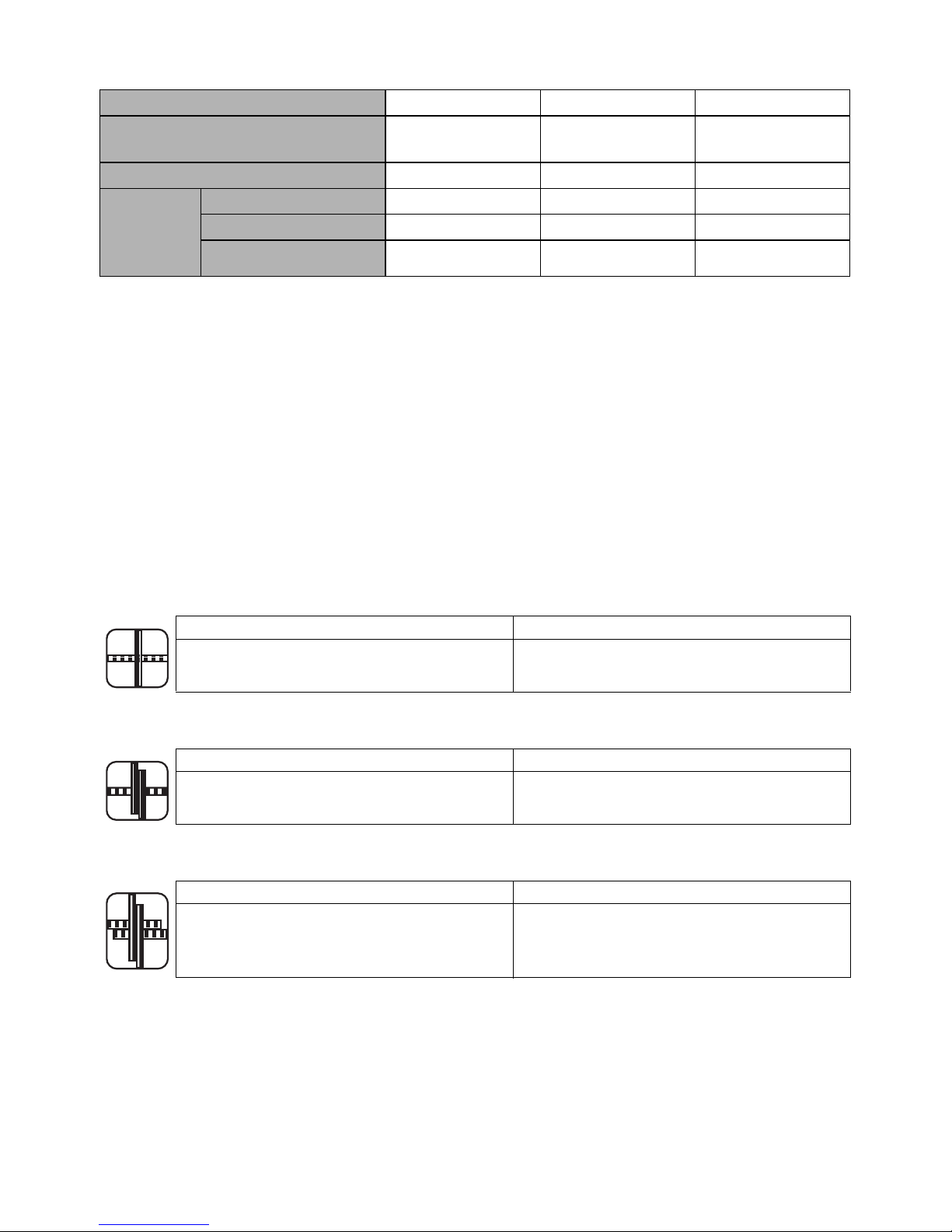

TIEWIRE TW1061T TW1061T-PC TW1061T-EG

TYPE OF WIRE

Annealed wire Poly-coated wire

Electro-galvanized

wire

DIAMETER 19GA (1.0mm) 19GA (1.1mm) 19GA (1.0mm)

TIES/COIL

#3 × #3 (10 mm × 10 mm)

Approx. 265 ties Approx. 230 ties Approx. 265 ties

#4 × #4 (13 mm × 13 mm)

Approx. 240 ties Approx. 210 ties Approx. 240 ties

#7 × #5 × #5

(22 mm × 16 mm × 16 mm)

Approx. 170 ties Approx. 150 ties Approx. 170 ties

Minimum Maximum

#3 × #3 (10mm × 10mm)

#7 × #7 (22mm × 22mm)

#8 × #6 (25mm × 19mm)

Minimum Maximum

#3 × #3 × #3 (10mm × 10mm × 10mm)

#7 × #5 × #5 (22mm × 16mm × 16mm)

#8 × #4 × #4 (25mm × 13mm × 13mm)

Minimum Maximum

#3 × #3 × #3 × #3

(10mm × 10mm × 10mm × 10mm)

#5 × #5 × #4 × #4

(16mm × 16mm × 13mm × 13mm)

Page 14

14

11.BATTERY INSTRUCTIONS

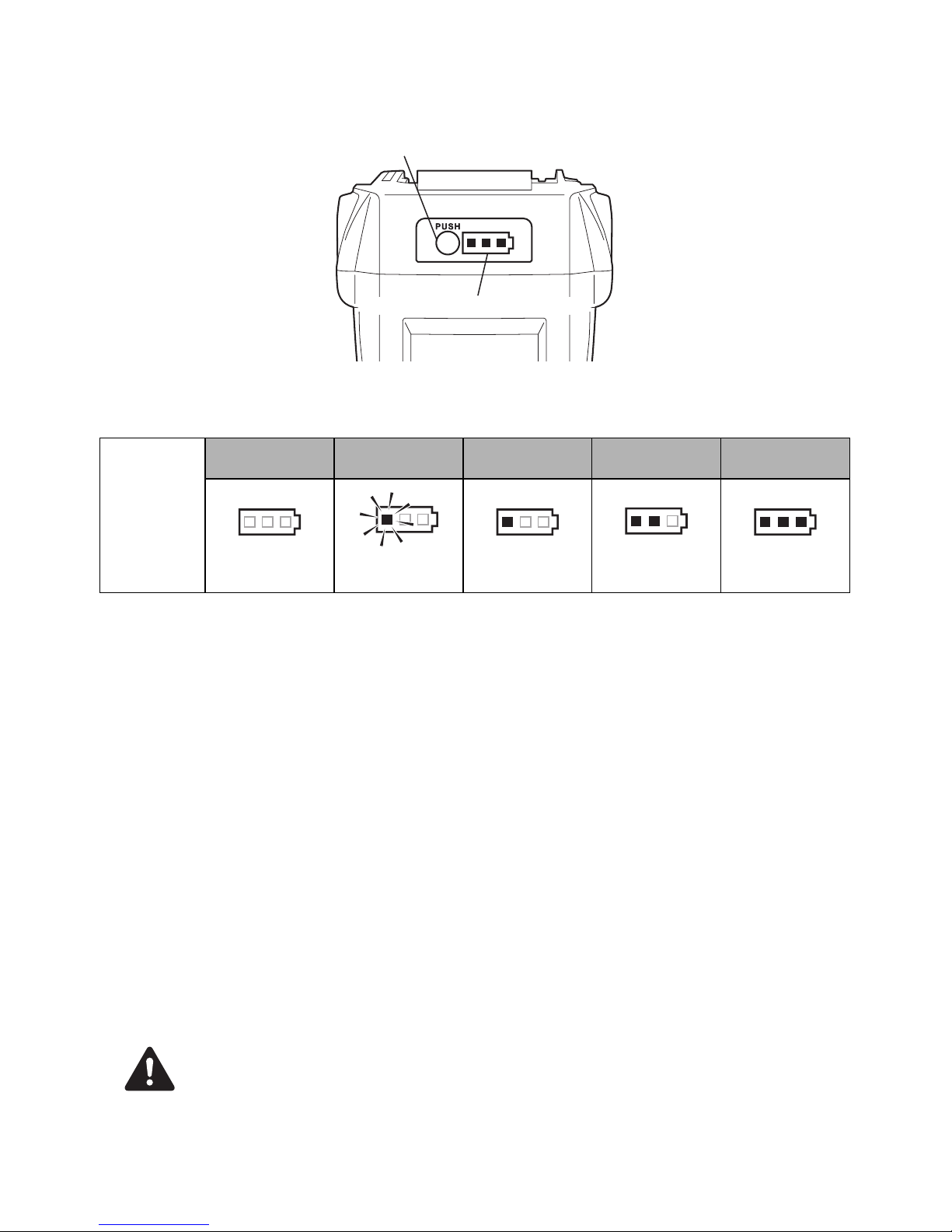

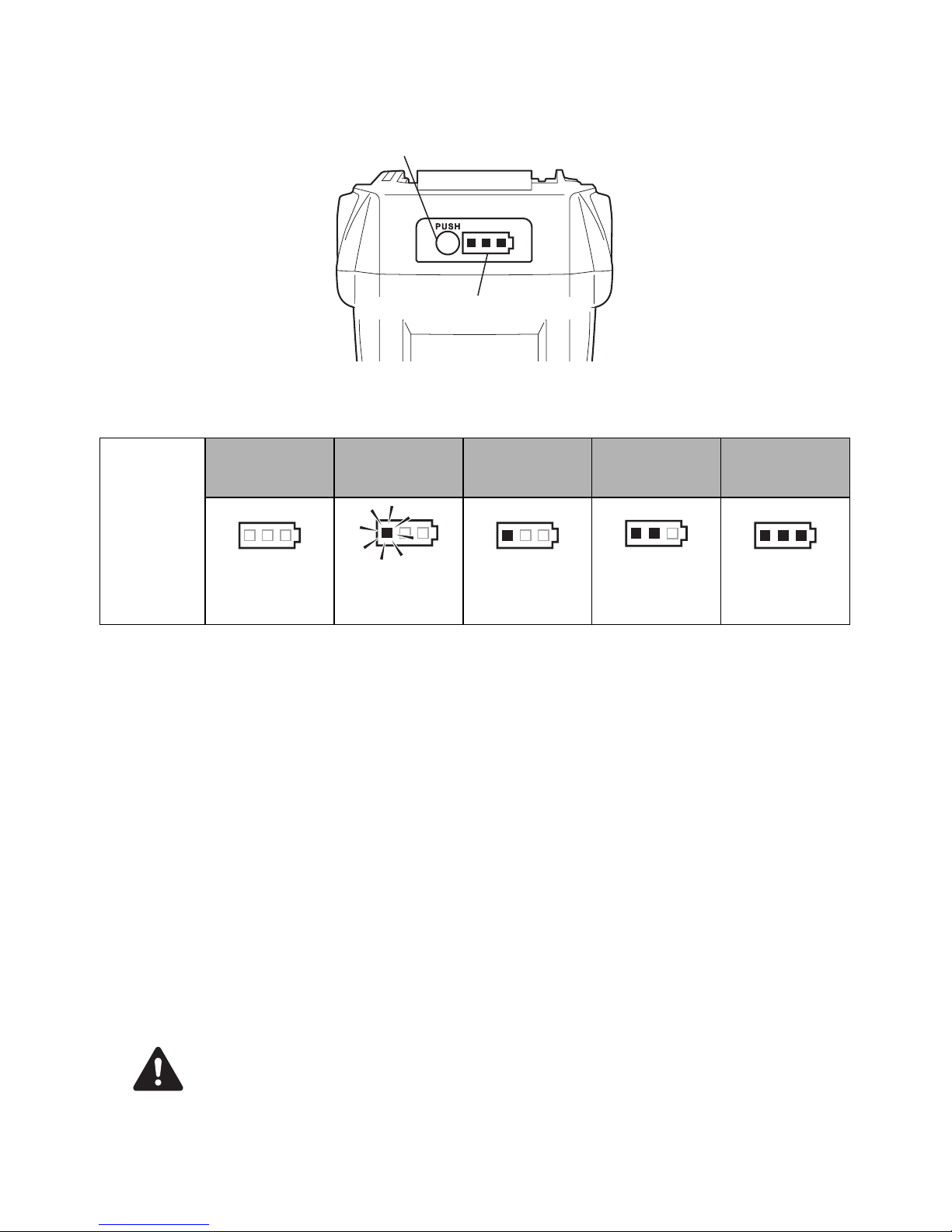

About the Battery Level Indicator

(1) To check the battery level (excluding while charging or while operating the charging

tool), press the Battery level check button.

(2) The Battery level gauge is on according to the battery level.

Service Life of the Battery pack

If any condition described below is observed, the Battery pack is at the end of its service life. Replace it

with a new one.

Although the Battery pack has been properly charged (fully charged), a great drop in tying time has been

noticed.

• Do not charge the Battery pack when this happens. If the motor’s rotational speed slows down,

the power of the Battery pack is considered to be nearly depleted. Using the tool more will

cause it to overdischarge, resulting in a shortened service life of the Battery pack and also in

functional trouble of the tool’s main body.

• Do not use a Battery pack when its service life is finished.

This will cause functional trouble in the tool’s main body. Also charging a Battery pack that is

out of service life will lead to functional trouble in the Charger.

Recycling a Li-ion Battery

The MAX battery pack uses a Li-ion battery, it may be illegal to dispose of this Battery into the municipal

waste system. Check with your local solid waste officials for details in your area for recycling options or

proper disposal.

When disposing of the Battery pack, make sure to put a Pack cap on its Terminal (with insulating

tape securing it) to prevent short circuits.

Battery level

gauge

Battery level:

0%

Battery level:

about 0 to 10%

Battery level:

about 10 to 40%

Battery level:

about 40 to 70%

Battery level:

about 70 to 100%

All indicators

OFF

One red

indicator blinks

One red

indicator ON

Two red

indicators ON

Three red

indicators ON

Battery level check button

Battery level gauge

NOTICE

CAUTION

Page 15

15

12. OPERATING INSTRUCTIONS

1. How to set the Tiewire

(Fig.6) Set the Main switch (e) at "OFF", the

Trigger lock (2) at "LOCK" and remove the

Battery pack (5).

• Be careful not to drop or give a strong

impact to the Tiewire. It may cause the

damage and the malfunction of the tool.

• Beware of the tip of the wire when you pick

up the Tiewire. It might cause an injury.

1-1 (Fig.9) Press the Release button (8) of this

tool, and confirm that the Release button is

caught in the Release stopper (9).

1-2 (Fig.10) Stretch out the tip of the wound

Tiewire.

BE SURE TO USE ONLY THE SPECIFIED

TIEWIRE (MAX TW1061T Series).

The use of binding wire that has not been

specified may cause breakdown of this tool.

Therefore, be sure only to use the specified MAX

TW1061T series.

RB441T is not compatible with TW898 series or

TW1525 series.

DO NOT USE RUSTY WIRE.

The use of the rusty wire may cause functional

trouble of the tool.

1-3 (Fig.11) Rotate the Magazine stopper (6)

45° counterclockwise.

1-4 (Fig.12,13) Open the Magazine cover (n)

and set the Tiewire in the Magazine (7) with

the Holding slot (o) side of the reel facing

up.

1-5 (Fig.14) Grasp the tool with the left hand,

hold the tip of the wire with the right hand,

and remove the wire from the Holding slot.

The 2 wire tips of new Tiewire are twisted.

1-6 (Fig.15) Straighten out the tip of the wire,

and insert the twisted wire into the Wire

guide (i) parallel.

1-7 (Fig.16) Confirm through the Window that

the twisted part of wire has reached past two

Feeding gears (h).

1-8 (Fig.17) Press the Release stopper (9) up,

and confirm that the Release button has

been raised up.

1-9 (Fig.18) Close the Magazine cover and

rotate the Magazine stopper 45° clockwise.

If the Window is dirty

Open the Window (Fig.1.g) and wipe off the dirt

on the inside of the Window with a cloth. Close

the Window again after cleaning to ensure that

foreign objects will not be able to enter the tool.

2. How to operate RB441T

(Fig.6) Set the Main switch (e) at "OFF", the

Trigger lock (2) at "LOCK" and remove the

Battery pack (5).

2-1 (Fig.19) Mount the Battery pack on the tool's

main body until a click is heard.

2-2 (Fig.20) When Main switch (e) is turned

"ON", the Hook (Fig.1.f) of the tip rotates

automatically for initializing, absolutely do

not bring your fingers close to any rotating

and moving part. Set the Main switch at "ON"

and the trigger lock (2) at "UNLOCK".

2-3 (Fig.21) Tilt the tool 45° angle to the crossed

rebars.

2-4 (Fig.22) Align the Center mark (a) to the

center of the crossed rebars.

2-5 Once pull the Trigger, the tool automatically

completes a series of tying actions (feeding,

cutting, gripping and tying).

• (Fig.23) When the Main switch (Fig.1.e) is

turned "ON", the Hook (Fig.1.f) of the tip

rotates automatically for initializing,

absolutely do not bring your fingers close

to any rotating and moving part.

• Do not touch any rotating and moving part

such as hook of the tip or the Tiewire

during the tying work (while the machine is

operating).

3. How to remove the Tiewire

(Fig.6) Set the Main switch (e) at "OFF", the

Trigger lock (2) at "LOCK" and remove the

Battery pack (5).

3-1 (Fig.9) Press the Release button (8) of the

tool and confirm that the Release button is

caught in the Release stopper (9).

CAUTION

NOTICE

WARNING

Page 16

16

3-2 (Fig.11) Rotate the Magazine stopper (6) to

open the Magazine cover.

3-3 (Fig.24) Remove the Tiewire from the

Magazine.

3-4 (Fig.25) Remove the wire with the plastic

piece from the Wire guide.

4. When the Tiewire runs out

(Fig.26) The plastic piece comes off when it is used

up normally, and can be discarded separately as

plastic and metal wire. (About 8" (20cm) remains

after normal use)

(Fig.6) Set the Main switch (e) at "OFF", the

Trigger lock (2) at "LOCK" and remove the Battery

pack (5).

5. Tension adjustment

(Fig.27.c) This dial allows you to adjust wire

tension torque slightly. To increase the tension,

turn it in the counterclockwise. To decrease the

tension, turn it in the clockwise.

6. Auto Power-off feature

This tool has "Auto Power-off" feature, which

saves the power consumption of the Battery

when the tool is not operated.

If the tool is not operated for 30 minutes, the tool

is automatically turned off. When the power is

turned off automatically, turn the Main switch

OFF and ON again to operate the tool.

7. For proper tightness

7-1 (Fig. 21) Tilt the tool 45° angle to the crossed

rebars.

7-2 (Fig.22) Align the Center mark (a) to the

center of the crossed rebars.

7-3 (Fig.28) Apply the tool perpendicularly to the

surface of the crossed rebars.

During tool operation

Do not move the tool during tying operation until

the tool stops tying automatically.

7-4 (Fig.29) Tie in alternate direction.

7-5 (Fig.30) Cross tying.

Bent the knot of the first tie before making

the second tying.

8. How to reload previously used

Tiewire

(Fig.31) Without twisting the 2 wires, insert them

into the Wire guide (i).

9. (Fig.32) How to set and remove

the belt hook to the tool

The belt hook can be installed either on the right

or the left side of the tool.

Installing/Removing the belt hook

(Installing)

Insert the belt hook into the slot on the tool.

Secure it with a screw.

(Removing)

Loosen a screw, and then remove the belt hook.

• When using the belt hook or changing the

position, set the Main switch (e) at "OFF",

the Trigger lock (2) at "LOCK" and remove

the Battery pack (5).

Failure to do so may cause the tool to start

accidentally, which may cause an accident.

• Before using the belt hook, make sure that

the hook is securely installed on the tool.

Using an improperly installed belt hook may

cause personal injury.

• Securely tighten the designated genuine

screw.

If the screw become loose due to vibration, etc.

generated by operation, the loose screw may

cause a dropping accident.

• When using the belt hook, the tool must be

hooked securely to prevent it from falling.

If the tool falls, it could result in an accident.

WARNING

Page 17

17

13.STORAGE

Do not store the tool in a cold weather

environment. Keep the tool in a warm area.

When not in use, the tool should be stored in a

warm and dry place. Keep out of reach of

children.

REMOVE REEL OF TIEWIRE

When you have finished the Tiewire, remove the

reel from the tool.

STORE THE TOOL

When you have finished tying work or when the

tool will not be used for a while, set the Main

switch (Fig.1.

e

) at "OFF", the Trigger lock

(Fig.1.

2

) at "LOCK" and remove the Battery pack

(Fig.1.

5

). The tool and accessories should be

stored in a well-ventilated dry place where the

temperature will not exceed 104°F (40°C).

The Battery pack with the Pack cap (Fig.2.

k

) to

prevent short circuits should be stored in a wellventilated dry place where the temperature will

not exceed 86°F (30°C).

Page 18

18

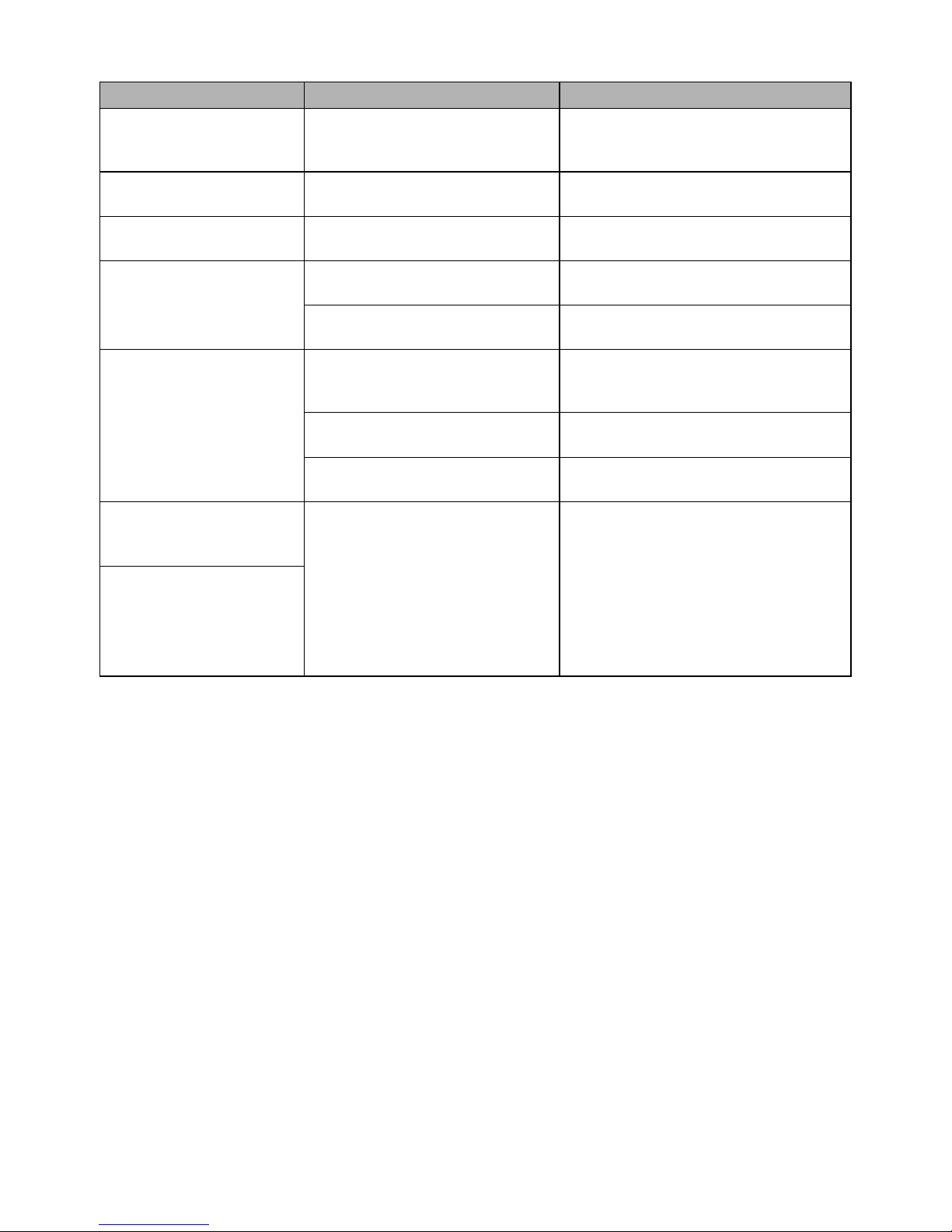

14.WARNING BUZZERS AND PROCEDURES TO FOLLOW

This tool sounds warning buzzers for the conditions described below. If the buzzer sounds, follow

procedures according to the conditions described below.

<Buzzer types and procedures to follow>

<When no buzzer sounds but malfunction is suspected>

• If the conditions described below occur, set the Main switch (Fig.1.e) at "OFF", the Trigger

lock (Fig.1.

2

) at "LOCK" and remove the Battery pack (Fig.1.5) before following procedures.

• Do not touch the tying or rotating parts at the tip when setting the Main switch at "ON" under

any circumstances.

Buzzer types Possible cause Procedures to follow

Once (Pi, pi, pi...)

Wire is jammed in the Hook

(Fig.1.f)

Check whether the wire or anything else

is caught in the Hook

Motor is hot Let the tool rest and cool down

Twice (Pipi, pipi, pipi...)

Low battery Charge the Battery pack

Battery pack is not fully inserted Insert the Battery pack properly

Three times

(Pipipi, pipipi, pipipi...)

Tiewire is used up Replace with a new Tiewire

Tiewire is jammed

Open the Magazine cover (Fig.12.n)

and fix the jammed wire

Continuous high pitched

beep (Piii...)

Curl guide (Fig.1.0) is open Confirm supported rebar diameters

Single-short and

continuous high & low

pitched chime

(Pipo / Pii poh Pii poh...)

Internal structure; defect in internal

driving mechanism

Immediately discontinue operation and

set the Main switch (Fig.6.e) at "OFF",

the Trigger lock (Fig.6.2) at "LOCK"

and remove the Battery pack (Fig.6.5)

before consulting. Then contact the

dealer where the tool was purchased or

MAX CO., LTD. authorized distributors.

Symptom Possible cause Procedures to follow

Main switch is "ON" but

does not work

Dead battery

Switch to a new battery and confirm

whether it works

Product does not

function

Auto Power-off feature operated

Try switching the Main switch (Fig.1.e)

from OFF to ON

Tying is not proper Wire is touching rebars while tying Tie so that wire is not touching rebars

Twisted off

Rebar size is not applicable Use with supported rebars diameters

Tension adjustment dial is too tight

Adjust tension adjustment dial

(Fig.1.c)

Tension is too loose

The tied section is not on the

Center mark (Fig.22.a)

Align the Center mark to the center of

the crossed rebars and pull the trigger

Rebar size is not applicable Use with supported rebar diameters

Tension adjustment dial is too

loose

Adjust tension adjustment dial tighter

(Fig.1.c)

Tie form is notably

deformed

Worn or broken parts

Immediately discontinue operation and

set the Main switch (Fig.6.e) at "OFF",

the Trigger lock (Fig.6.2) at "LOCK"

and remove the Battery pack (Fig.6.5)

before consulting. Then contact the

dealer where the tool was purchased or

MAX CO., LTD. authorized distributors.

Increased frequency of

jamming

WARNING

Page 19

19

ÍNDICE

1. NOMBRE DE LAS PIEZAS ........................................................ 20

2. LISTA DE CONTENIDOS ........................................................... 20

3. ADVERTENCIAS GENERALES DE SEGURIDAD SOBRE

LA HERRAMIENTA ELÉCTRICA............................................... 21

4. ADVERTENCIAS DE SEGURIDAD RELATIVAS A LA

RB441T ....................................................................................... 23

5. DATOS TÉCNICOS Y ESPECIFICACIONES DE LA

HERRAMIENTA.......................................................................... 26

6. DATOS TÉCNICOS .................................................................... 27

7. AÑO DE PRODUCCIÓN ............................................................. 27

8. ESPECIFICACIONES DEL ALAMBRE ...................................... 28

9. APLICACIONES ......................................................................... 28

10. TAMAÑO DE ARMADURA APLICABLE ................................... 28

11. INSTRUCCIONES DE LA BATERÍA.......................................... 29

12. INSTRUCCIONES DE FUNCIONAMIENTO............................... 30

13. ALMACENAMIENTO.................................................................. 32

14. ALARMAS ACÚSTICAS Y PROCEDIMIENTOS A SEGUIR ..... 33

DEFINICIONES DE LAS SEÑALES INDICATIVAS

ADVERTENCIA: indica una situación peligrosa que, si no se evita, puede provocar lesiones graves o

incluso la muerte.

PRECAUCIÓN: indica una situación peligrosa que, si no se evita, puede provocar lesiones leves o

moderadas.

AVISO: indica un mensaje relativo a posibles daños materiales.

ESPAÑOL

MANUAL DE INSTRUCCIONES E INSTRUCCIONES DE SEGURIDAD

Traducción de las

instrucciones originales

Page 20

20

1. NOMBRE DE LAS PIEZAS

Fig.1

Fig.2

Fig.3

Consulte el manual de funcionamiento y mantenimiento del cargador JC925.

Fig.12

Fig.13

2. LISTA DE CONTENIDOS

• Atadora de armaduras de refuerzo MAX / RB441T

• Paquete de baterías de ion litio / JPL91440A

• Cargador de baterías de ion litio / JC925

• Cable de alimentación eléctrica

• MANUAL DE INSTRUCCIONES E INSTRUCCIONES DE SEGURIDAD (este libro)

1 Brazo

2 Seguro del disparador

3 Disparador

4 Empuñadura

5 Paquete de baterías

6 Bloqueador del

compartimento de bobina

7 Compartimento de bobina

8 Botón de desbloqueo

9 Bloqueo

0 Guía de curvado

a Marca central

b Número de serie

c Disco selector del par

d LED

e Interruptor principal

f Gancho

g Ventanilla

h Engranaje de alimentación

i Guía del alambre

j Gancho para cinturón

k Tapa del paquete

l Terminal

m Cierre

n Cubierta del

compartimento de bobina

o Ranura de sujeción

Page 21

21

3. ADVERTENCIAS

GENERALES DE SEGURIDAD

SOBRE LA HERRAMIENTA

ELÉCTRICA

1. SEGURIDAD EN LA ZONA DE TRABAJO

• Mantenga la zona de trabajo limpia y

bien iluminada. Las zonas de trabajo

abarrotadas u oscuras propician los

accidentes.

• No utilice la herramienta eléctrica en

atmósferas explosivas, como por

ejemplo en presencia de líquidos

inflamables, gases o polvo. Las

herramientas eléctricas generan chispas

que pueden prender fuego al polvo o a los

humos.

• Mantenga alejados a los niños y a los

curiosos mientras utiliza la

herramienta eléctrica. Las distracciones

pueden hacerle perder el control.

2. SEGURIDAD ELÉCTRICA

• Los enchufes de las herramientas

eléctricas deben guardar

correspondencia con la toma de

corriente. Nunca modifique el enchufe

de ninguna manera. No utilice ningún

enchufe adaptador con las

herramientas eléctricas conectadas a

tierra. Los enchufes sin modificaciones y

en correspondencia con las tomas de

corriente reducirán el riesgo de descarga

eléctrica.

•

Evite el contacto corporal con las

superficies conectadas a tierra, como

tuberías, radiadores, estufas y neveras.

Si su cuerpo está conectado a tierra el

riesgo de descarga eléctrica es mayor.

• No exponga las herramientas

eléctricas a la lluvia o la humedad. La

entrada de agua a una herramienta

eléctrica aumentará el riesgo de

descarga eléctrica.

• Trate el cable con cuidado. No lo use

nunca para trasladar, arrastrar o

desenchufar la herramienta eléctrica.

Mantenga el cable alejado del calor, el

aceite, los bordes cortantes y las

piezas móviles. Los cables dañados o

enredados aumentan el riesgo de

descarga eléctrica.

•

Cuando use una herramienta eléctrica

en el exterior, hágalo utilizando un

cable de extensión adecuado.

El uso de

un cable adecuado para utilización en el

exterior reduce el riesgo de descarga

eléctrica.

•

Si la utilización de una herramienta

eléctrica en un lugar mojado es

inevitable, use un dispositivo de

corriente residual (RCD) con suministro

protegido.

La utilización de un RCD

reduce el riesgo de descarga eléctrica.

3. SEGURIDAD PERSONAL

•

Cuanto utilice una herramienta eléctrica

permanezca alerta, preste atención a lo

que hace y aplique el sentido común. No

utilice una herramienta eléctrica si está

cansado o bajo los efectos de drogas,

bebidas alcohólicas o medicamentos.

Un

instante de descuido durante la utilización

de herramientas eléctricas puede provocar

graves lesiones personales.

•

Use equipo de protección personal. Use

siempre protección ocular.

El equipo de

protección, como máscara antipolvo,

zapatos de seguridad antideslizantes,

casco y protección auditiva, utilizado en las

condiciones apropiadas reducirá el riesgo

de lesiones personales.

• Prevenga la puesta en marcha

accidental. Antes de conectar la

herramienta a la red de alimentación

eléctrica y/o al paquete de baterías,

recogerla o trasladarla, asegúrese de

que el interruptor esté en la posición

"off" ("desconectado"). El traslado de

las herramientas eléctricas con el dedo

en el interruptor o con el interruptor en la

posición "on" propicia los accidentes.

• Antes de poner en marcha la

herramienta retire de la misma toda

llave de ajuste o llave inglesa.

Una llave inglesa o llave de ajuste sujeta

a una pieza giratoria de la herramienta

eléctrica puede provocar lesiones

personales.

LEA TODAS LAS INSTRUCCIONES Y

ADVERTENCIAS DE SEGURIDAD.

Si no respeta las advertencias e instrucciones,

pueden producirse descargas eléctricas,

incendios y/o lesiones graves.

Conserve

todas las advertencias e instrucciones

para futuras consultas.

El término

"herramienta eléctrica" indicado en las

advertencias se refiere a la herramienta

conectada (mediante cables) a la red eléctrica

o accionada por batería (inalámbrica).

ADVERTENCIA

Page 22

22

•

Utilice la herramienta sin extralimitarse.

Manténgase en todo momento en

equilibrio, con los pies bien apoyados

en el suelo.

De este modo podrá controlar

mejor la herramienta eléctrica en

situaciones imprevistas.

• Vístase adecuadamente. No use ropa

holgada ni joyas. Mantenga el cabello,

la ropa y los guantes alejados de las

piezas móviles. Las prendas holgadas,

las joyas o el cabello largo pueden quedar

atrapados en las piezas móviles.

• Si la herramienta tiene dispositivos

para recogida y extracción de polvo,

asegúrese de que están conectados y

se utilizan adecuadamente. El uso del

dispositivo de recogida de polvo puede

reducir los peligros relacionados con el

mismo.

4. UTILIZACIÓN Y CUIDADO DE LA

HERRAMIENTA ELÉCTRICA

• No fuerce la herramienta eléctrica. Use

la herramienta eléctrica adecuada a

sus necesidades. La herramienta

eléctrica adecuada hará mejor el trabajo y

de manera más segura a la velocidad

para la que fue diseñada.

• No use la herramienta eléctrica si el

interruptor no conmuta entre las

posiciones "on" ("conectado") y "off"

("desconectado"). Toda herramienta

eléctrica que no puede controlarse con el

interruptor es peligrosa y debe repararse.

• Desconecte el enchufe de la red

eléctrica y/o el paquete de baterías de

la herramienta antes de guardarla o de

realizar ajustes o cambios de

accesorios. Estas medidas de seguridad

preventivas reducen el riesgo de puesta

en marcha accidental de la herramienta

eléctrica.

• Guarde las herramientas eléctricas

fuera de uso alejadas del alcance de

los niños y no deje que las utilicen

personas no familiarizadas con las

mismas o con estas instrucciones. El

uso de herramientas eléctricas por

personas que carecen de la formación

necesaria resulta peligroso.

• Realice el mantenimiento de las

herramientas eléctricas. Compruebe

que las piezas móviles estén bien

alineadas y sujetas, y que ninguna

pieza esté dañada o en un estado que

pueda afectar al funcionamiento de la

herramienta eléctrica. Si detecta

alguna avería, haga reparar la

herramienta eléctrica antes de usarla.

El mantenimiento deficiente de las

herramientas eléctricas provoca muchos

accidentes.

• Mantenga las herramientas de corte

afiladas y limpias. Las herramientas de

corte adecuadamente mantenidas y con

los bordes afilados tienen menos

probabilidades de atascarse y son más

fáciles de controlar.

• Use la herramienta eléctrica, los

accesorios, las piezas, etc. de acuerdo

con estas instrucciones, teniendo en

cuenta las condiciones de trabajo y la

tarea que debe realizar. El uso de la

herramienta eléctrica para trabajos que

no sean los previstos podría provocar una

situación peligrosa.

5. UTILIZACIÓN Y CUIDADO DE LA

BATERÍA DE LA HERRAMIENTA

• Recargue la batería únicamente con el

cargador especificado por el

fabricante. Un cargador apto para un

determinado tipo de paquete de baterías

puede provocar riesgo de incendio si se

utiliza con otro tipo de paquete de

baterías.

• Use las herramientas eléctricas sólo

con los paquetes de batería diseñados

específicamente. El uso de cualquier

otro paquete de baterías puede provocar

riesgo de lesiones e incendio.

• Cuando el paquete de baterías esté

fuera de uso, manténgalo alejado de

otros objetos metálicos, como clips

para papeles, monedas, llaves, clavos,

tornillos u otros objetos metálicos

pequeños que pueden establecer la

conexión entre un terminal y otro. La

unión de los terminales de baterías puede

causar quemaduras o provocar un

incendio.

• En condiciones de uso inadecuadas la

batería puede proyectar líquido, cuyo

contacto es necesario evitar. Si

accidentalmente entra en contacto con

dicho líquido, lávese bien con agua. Si

el líquido entra en contacto con los

ojos, lávese con agua y acuda al

médico. El líquido proyectado por la

batería puede causar irritación o

quemaduras.

6. REPARACIÓN

•

La reparación de la herramienta eléctrica

debe confiarse a un técnico cualificado

que utilice únicamente las piezas de

recambio originales.

De esta manera se

garantizará la seguridad de la herramienta

eléctrica.

Page 23

23

• No use la herramienta eléctrica bajo la

lluvia, donde haya salpicaduras de agua, o

en un lugar húmedo o mojado. La utilización

de la herramienta en esas condiciones o

similares aumentará el riesgo de descarga

eléctrica, avería peligrosa y recalentamiento.

• NO ARROJE LAS BATERÍAS O PAQUETES

DE BATERÍAS AL FUEGO O AL AGUA. Las

baterías o paquetes de baterías deben

recogerse, reciclarse o eliminarse de una

manera que no afecte al medio ambiente.

• PROTEJA LA BATERÍA CONTRA EL

CALOR, LA IRRADIACIÓN SOLAR

CONTINUA Y EL FUEGO. Hay peligro de

explosión.

• CARGUE EL PAQUETE DE BATERÍAS EN

UN INTERVALO DE TEMPERATURA DE

41°F (5°C) A 104°F (40°C).

• El producto que ha adquirido funciona con

una batería de ion litio que es reciclable.

Cuando llegue al final de su vida útil, y

según la normativa estatal y local, es ilegal

eliminar la batería en el sistema ordinario

de residuos municipales. Llame al 1-800-8BATTERY para obtener información sobre

cómo reciclar la batería.

4. ADVERTENCIAS DE

SEGURIDAD RELATIVAS

A LA RB441T

1. REVISE LAS PIEZAS ANTES DE MONTAR

EL PAQUETE DE BATERÍAS

• Compruebe que los tornillos están bien

ajustados.

Un ajuste insuficiente puede provocar un

accidente o una avería en la herramienta.

Si un tornillo está flojo, vuelva a apretarlo

a fondo.

• Revise las piezas para comprobar que no

presentan daños.

Las piezas se deterioran con el uso.

Compruebe también que no faltan piezas

y que no son defectuosas o de mala

calidad. Si hay alguna pieza que deba

reemplazarse o repararse, diríjase al

proveedor donde compró la herramienta o

a un distribuidor autorizado por MAX CO.,

LTD.

Use únicamente las piezas de recambio

originales autorizadas.

2. COLOQUE EL INTERRUPTOR

PRINCIPAL (FIG.6.e) EN LA POSICIÓN

"OFF" ("DESCONECTADO"), COLOQUE

EL SEGURO DEL DISPARADOR

(FIG.6.2) EN LA POSICIÓN "LOCK"

("BLOQUEADO") Y EXTRAIGA EL

PAQUETE DE BATERÍAS (FIG.6.5)

CUANDO CAMBIE EL PAQUETE DE

BATERÍAS, SUSTITUYA O AJUSTE EL

ALAMBRE DE AMARRE, SE PRODUZCA

CUALQUIER ANOMALÍA O LA

HERRAMIENTA ESTÉ FUERA DE USO

Si se deja la herramienta activada en esas

situaciones, pueden producirse lesiones o

averías.

3. MANTENGA LOS DEDOS Y EL CUERPO

APARTADOS DEL BRAZO Y DE LA GUÍA

DE CURVADO EN TODO MOMENTO

(FIG.23)

El incumplimiento de esta advertencia

puede provocar lesiones graves.

4. MANTENGA LOS DEDOS Y EL CUERPO

APARTADOS DEL ALAMBRE DE

AMARRE CUANDO LA HERRAMIENTA

ESTÉ EN FUNCIONAMIENTO

El incumplimiento de esta advertencia

puede provocar lesiones graves.

Page 24

24

5. NO APUNTE A NADIE CON LA

HERRAMIENTA

Si la herramienta atrapa al operario o a

alguien que esté trabajando cerca de él

podría provocarle lesiones. Cuando trabaje

con la herramienta, tenga sumo cuidado de

no acercar las manos, las piernas u otras

partes del cuerpo al brazo de la misma.

6. CUANDO LA HERRAMIENTA NO ESTÉ

EN FUNCIONAMIENTO, QUITE LOS

DEDOS DEL DISPARADOR

El incumplimiento de esta advertencia

puede ocasionar el accionamiento

accidental de la herramienta y provocar

lesiones graves.

7. NUNCA HAGA FUNCIONAR LA

HERRAMIENTA EN CONDICIONES

ANÓMALAS

Si la herramienta no está en buenas

condiciones de funcionamiento, o si observa

alguna anomalía, desconéctela

inmediatamente (coloque el interruptor

principal en la posición "OFF"), bloquee el

disparador y haga que la revisen y la

reparen.

8. DESPUÉS DE LA INSTALACIÓN DE LA

BATERÍA, SI LA HERRAMIENTA SE

PONE EN MARCHA SIN ACCIONAR EL

DISPARADOR O SI EL OPERARIO

ADVIERTE UN CALENTAMIENTO, OLOR

O SONIDO INUSUALES, DEBE

INTERRUMPIRSE EL FUNCIONAMIENTO

El incumplimiento de esta advertencia

puede provocar lesiones graves. Lleve la

herramienta al distribuidor para que reciba

una inspección de seguridad.

9. NUNCA MODIFIQUE LA HERRAMIENTA

La modificación de la herramienta incidirá

negativamente en el rendimiento y en la

seguridad de funcionamiento. Cualquier

modificación de la herramienta puede

provocar lesiones graves y dar lugar a la

anulación de la garantía.

10. MANTENGA LA HERRAMIENTA EN

BUENAS CONDICIONES DE

FUNCIONAMIENTO

Para garantizar un funcionamiento seguro y

el máximo rendimiento, proteja a la

herramienta de las averías y el desgaste.

Además, mantenga limpia y seca la

empuñadura de la herramienta,

especialmente sin aceite o grasa.

11. USE ÚNICAMENTE EL PAQUETE DE

BATERÍAS AUTORIZADO

Si está conectada a una fuente de energía

que no es el paquete autorizado, como por

ejemplo una batería recargable, una pila

seca o un acumulador para automóviles, la

herramienta puede resultar dañada, sufrir

averías, recalentarse o incluso incendiarse.

No conecte esta herramienta a ninguna

fuente de energía que no sea el paquete de

baterías autorizado.

12. PARA GARANTIZAR EL MÁXIMO

RENDIMIENTO, CARGUE POR

COMPLETO LA BATERÍA ANTES DE

USARLA

Un paquete de baterías nuevo o que ha

estado en desuso durante un período

prolongado puede haberse descargado; en

ese caso, es necesario volver a cargarlo al

máximo de su capacidad. Antes de poner en

funcionamiento la herramienta, asegúrese de

cargar el paquete de baterías con el cargador

de baterías de MAX especificado.

13. PRECAUCIÓN PARA LA CARGA DE LA

BATERÍA

13-1 Use únicamente el cargador de

baterías de MAX y el paquete de

baterías de MAX.

El incumplimiento de esta indicación

puede provocar el recalentamiento o el

incendio de la batería, lo cual

ocasionaría lesiones graves.

13-2 Cargue la batería en un enchufe de

pared de 120 V CA.

El incumplimiento de esta indicación

puede provocar recalentamiento o una

carga inadecuada, lo cual posiblemente

ocasionaría lesiones graves.

13-3 Nunca use un transformador.

13-4 Nunca conecte el cargador de

baterías al suministro eléctrico de

corriente continua de un grupo

electrógeno.

El cargador se incendiará y sufrirá

averías o daños.

13-5 Evite cargar el paquete de baterías

bajo la lluvia, en un lugar húmedo o

donde haya salpicaduras de agua.

La carga del paquete de baterías en un

lugar mojado o húmedo provocará una

descarga eléctrica o un cortocircuito

que puede causar quemaduras e

incluso incendiar la herramienta.

Page 25

25

13-6 No toque el cable de alimentación ni

el enchufe con las manos o los

guantes húmedos.

La descarga eléctrica podría causarle

lesiones.

13-7 No cubra el cargador de baterías con

un paño u otro objeto mientras se

carga el paquete de baterías.

Si lo hace, el cargador podría

recalentarse y provocarle quemaduras

e incluso incendiarse.

13-8 Mantenga el paquete de baterías y el

cargador de baterías alejados del

calor y las llamas.

13-9 No cargue el paquete de baterías

cerca de materiales inflamables.

13-10 Cargue el paquete de baterías en un

lugar bien ventilado.

Evite cargar el paquete de baterías en

un lugar en el que esté expuesto a la luz

solar directa.

13-11 Cargue el paquete de baterías en un

intervalo de temperatura de 41°F

(5°C) a 104°F (40°C).

13-12 Evite el uso continuo del cargador de

baterías.

Deje descansar al cargador durante 15

minutos entre una y otra carga para

evitar problemas de funcionamiento en

la unidad.

13-13 Todo objeto que bloquee los

orificios de ventilación o el

receptáculo del paquete de baterías

puede provocar descarga eléctrica o

problemas de funcionamiento.

Haga funcionar el cargador sin que

tenga polvo u otros materiales

extraños.

13-14 Manipule con cuidado el cable de

alimentación.

No traslade el cargador de baterías

sujetándolo por el cable de

alimentación. No tire del cable de

alimentación para desconectarlo del

enchufe de pared; el cable resultará

dañado y se romperán los hilos o se

producirá un cortocircuito. No deje que

el cable de alimentación entre en

contacto con herramientas de bordes

afilados, materiales calientes, aceite o

grasa. Si el cable está dañado es

necesario repararlo o cambiarlo.

13-15 No use este cargador para cargar

baterías no recargables.

13-16 Los niños y las personas

discapacitadas no pueden usar este

cargador sin supervisión.

13-17 Es necesario vigilar a los niños para

asegurarse de que no jueguen con el

cargador.

13-18 Ponga la tapa (Fig.2.k) sobre el

terminal (Fig.2.l) del paquete de

baterías.

Cuando el paquete de baterías no esté

en uso, coloque la tapa sobre el

terminal para evitar cortocircuitos.

13-19 No permita que se produzcan

cortocircuitos en el terminal

(componente metálico) del paquete

de baterías.

Un cortocircuito en el terminal generará

un exceso de corriente que recalentará

al paquete de baterías provocándole

daños.

13-20 Durante el verano, no deje ni guarde

la herramienta en un vehículo o

expuesta a la luz solar directa. Si la

herramienta está en un lugar con

temperaturas elevadas, el paquete

de baterías puede deteriorarse.

13-21 No guarde un paquete de baterías

completamente descargado. Un

paquete de baterías completamente

descargado y retirado del sistema

puede resultar dañado si no se

utiliza durante un tiempo

prolongado. Cuando la batería se

haya descargado, recárguela

inmediatamente.

14. USE GAFAS DE SEGURIDAD MIENTRAS

UTILIZA LA HERRAMIENTA

El amarre de acabado tiene bordes

cortantes. Para evitar lesiones graves, tenga

cuidado de no tocar los bordes cortantes.

15. ANTES DE USAR LA HERRAMIENTA

(Fig.4 y 5) Asegúrese de que los dispositivos

de seguridad funcionan correctamente. En

caso contrario, evite usar la herramienta.

Page 26

26

5. DATOS TÉCNICOS Y ESPECIFICACIONES DE LA

HERRAMIENTA

<CARGADOR DE BATERÍAS>

<PAQUETE DE BATERÍAS>

DESCRIPCIÓN DEL PRODUCTO Atadora de armaduras de refuerzo MAX "TWINTIER"

N° DE PRODUCTO RB441T

DIMENSIONES

(paquete de baterías incluido)

(Alto) 11-1/2" (295 mm) x (Ancho) 4-7/8" (125 mm) x (Largo) 13" (330 mm)

PESO (paquete de baterías incluido) 5,6 lbs (2,5 kg)

BATERÍA Paquete de baterías de ion litio / JPL91440A

TEMPERATURA DE FUNCIONAMIENTO 14°F a 104°F (-10°C a 40°C)

HUMEDAD 80% HR o menos

DESCRIPCIÓN DEL PRODUCTO Cargador de baterías de ion litio

N° DE PRODUCTO JC925

ENTRADA CA 120 V 60 Hz 2,6 A 160 W

SALIDA CC 14,4 V 7,5 A, CC 18 V 5,4 A, CC 25,2 V 4,5 A

PESO 3,3 lbs (1,5 kg)

INTERVALO DE TEMPERATURA DE

FUNCIONAMIENTO

41°F a 104°F (5°C a 40°C)

INTERVALO DE HUMEDAD DE

FUNCIONAMIENTO

80% HR o menos

DESCRIPCIÓN DEL PRODUCTO Paquete de baterías de ion litio

N° DE PRODUCTO JPL91440A

VOLTAJE NOMINAL CC 14,4 V (3,6 V x 4 celdas)

CAPACIDAD NOMINAL 3,9 Ah (3.900 mAh)

TIEMPO DE CARGA Carga rápida: aprox. 33 min (aprox. 90% de capacidad)

Carga completa: aprox. 45 min (100% de capacidad)

ACCESORIOS Tapa del paquete

PESO 1,1 lbs (0,5 kg)

TEMPERATURA DE CARGA 41°F a 104°F (5°C a 40°C)

INTERVALO DE TEMPERATURA DE

FUNCIONAMIENTO

32°F a 104°F (0°C a 40°C)

INTERVALO DE HUMEDAD DE

FUNCIONAMIENTO

80% HR o menos

AMARRES POR CARGA Aprox. 4.000 amarres (*en las siguientes condiciones: temperatura

normal, batería no usada y completamente cargada, y armaduras de

#4 x #4 (13mm x 13mm))

Page 27

27

6. DATOS TÉCNICOS

6-1 NIVEL DE RUIDO

Valor medido según la norma EN 60745:

Nivel de presión acústica ponderado A (LpA): 79 dB

Incertidumbre (KpA): 3 dB

Nivel de potencia acústica ponderado A (LWA): 79 dB

Incertidumbre (KWA): 3 dB

6-2 VIBRACIÓN

Valor medido según la norma EN 60745:

Valores de vibración totales (ah): 0,5 m/s

2

Incertidumbre (K): 0,1 m/s

2

• El valor declarado de emisión de vibraciones ha sido medido de acuerdo con un método de ensayo normalizado

y puede utilizarse para comparar una herramienta con otra.

• El valor declarado de emisión de vibraciones también puede usarse en una evaluación preliminar de exposición.

• La emisión de vibraciones durante el uso real de la herramienta eléctrica puede diferir del valor de emisión

declarado dependiendo de las formas en que se utilice la herramienta.

• Asegúrese de establecer medidas de seguridad que protejan al operario y que se basen en una estimación de

la exposición en las condiciones reales de uso (teniendo en cuenta todos los posibles estados de la herramienta

en el ciclo de operación: cuando está apagada, cuando está encendida pero en reposo, y cuando está

accionada).

6-3 EMISIÓN RADIADA 30-1.000 MHZ Clase A

Este es un producto de clase A. En un entorno doméstico, puede producir interferencias radioeléctricas, en cuyo

caso el usuario deberá adoptar las medidas oportunas.

6-4 Categoría de sobretensión: categoría 1 según IEC 60664-1

6-5 Grado de contaminación: grado 4 según IEC 60664-1

6-6 Directivas de diseño: Directiva de Maquinaria Anexo 1, EN 60745-1, EN 60745-2-18

7. AÑO DE PRODUCCIÓN

Este producto lleva el número de producción en el cuerpo (Fig.1.b). Los dos primeros dígitos de la

izquierda indican el año de producción.

ADVERTENCIA

ADVERTENCIA

(Ejemplo)

17526035D

Año 2017

Page 28

28

8. ESPECIFICACIONES DEL ALAMBRE

* La RB441T no es compatible con la serie TW898 ni con la serie TW1525.

9. APLICACIONES

• Paneles de hormigón prefabricado

• Cimientos de edificios

• Edificios comerciales

• Carreteras y puentes

• Tuberías de calefacción por suelo radiante

10.TAMAÑO DE ARMADURA APLICABLE

■ Combinación de 2 armaduras

■ Combinación de 3 armaduras

■ Combinación de 4 armaduras

ALAMBRE DE AMARRE TW1061T TW1061T-PC TW1061T-EG

TIPO DE ALAMBRE

Alambre recocido

Alambre bañado en

poliéster

Alambre

electrogalvanizado

DIÁMETRO 19GA (1,0 mm) 19GA (1,1 mm) 19GA (1,0 mm)

AMARRES

POR

BOBINA

#3 × #3 (10 mm × 10 mm)

Aprox. 265

amarres

Aprox. 230

amarres

Aprox. 265

amarres

#4 × #4 (13 mm × 13 mm)

Aprox. 240

amarres

Aprox. 210

amarres

Aprox. 240

amarres

#7 × #5 × #5

(22 mm × 16 mm × 16 mm)

Aprox. 170

amarres

Aprox. 150

amarres

Aprox. 170

amarres

Mínimo Máximo

#3 × #3 (10 mm × 10 mm)

#7 × #7 (22 mm × 22 mm)

#8 × #6 (25 mm × 19 mm)

Mínimo Máximo

#3 × #3 × #3 (10 mm × 10 mm × 10 mm)

#7 × #5 × #5 (22 mm × 16 mm × 16 mm)

#8 × #4 × #4 (25 mm × 13 mm × 13 mm)

Mínimo Máximo

#3 × #3 × #3 × #3

(10 mm × 10 mm × 10 mm × 10 mm)

#5 × #5 × #4 × #4

(16 mm × 16 mm × 13 mm × 13 mm)

Page 29

29

11.INSTRUCCIONES DE LA BATERÍA

Acerca del indicador de nivel de la batería

(1) Para comprobar el nivel de la batería (excepto mientras está cargando o funcionando

con la herramienta de carga), pulse el botón de comprobación del nivel de la batería.

(2) El indicador de nivel de la batería se ilumina según el nivel de la batería.

Vida útil del paquete de baterías

Si se observa alguna de las situaciones que se describen a continuación, el paquete de baterías está

en el final de su vida útil. Cámbielo por uno nuevo.

Aunque el paquete de baterías se ha cargado correctamente (plenamente cargado), se observa una

importante reducción del tiempo de amarre.

• Cuando esto suceda, no cargue el paquete de baterías. Si la velocidad de rotación del motor

se desacelera, se considera que la energía del paquete de baterías está a punto de agotarse.

El uso de la herramienta aumentará la descarga excesiva acortando la vida útil del paquete de

baterías y provocando problemas funcionales del cuerpo principal de la herramienta.

• No use un paquete de baterías caducado.

Si lo hace, el cuerpo principal del aparato sufrirá problemas funcionales. Cargar un paquete de

baterías caducado también provocará problemas funcionales en el cargador de baterías.

Reciclado de una batería de ion litio

El paquete de baterías de MAX utiliza una batería de ion litio; puede ser ilegal eliminar esta batería en

el sistema de residuos municipales. Consulte las disposiciones vigentes en su zona para el reciclado y

la eliminación correcta de este tipo de producto.

Cuando proceda a eliminar el paquete de baterías, asegúrese de poner la tapa en el terminal

(asegurada con cinta aislante) para evitar cortocircuitos.

Indicador de

nivel de la

batería

Nivel de la

batería:

0%

Nivel de la

batería:

aprox. 0 a 10%

Nivel de la

batería:

aprox. 10 a 40%

Nivel de la

batería:

aprox. 40 a 70%

Nivel de la

batería:

aprox. 70 a 100%

Todos los

indicadores

APAGADOS

Un indicador

rojo

intermitente

Un indicador

rojo

ENCENDIDO

Dos indicadores

rojos

ENCENDIDOS

Tres indicadores

rojos

ENCENDIDOS

Botón de comprobación de nivel de la batería

Indicador de nivel de la batería

AVISO

PRECAUCIÓN

Page 30

30

12. INSTRUCCIONES DE

FUNCIONAMIENTO

1. Cómo instalar el alambre de amarre

(Fig.6) Coloque el interruptor principal (e)

en la posición "OFF" ("DESCONECTADO"),

coloque el seguro del disparador (2) en la

posición "LOCK" ("BLOQUEADO") y extraiga

el paquete de baterías (5).

• Vigile que el alambre de amarre no se caiga

o reciba un golpe fuerte. Ello podría podría

provocar daños o averías en la

herramienta.

• Tenga cuidado con la punta del alambre

cuando manipule el alambre de amarre.

Podría provocarle lesiones.

1-1 (Fig.9) Presione el botón de desbloqueo (8)

de la herramienta y confirme que dicho

botón queda asegurado en el bloqueo (9).

1-2 (Fig.10) Tire de la punta del alambre de

amarre expuesto.

ASEGÚRESE DE USAR ÚNICAMENTE EL

ALAMBRE DE AMARRE ESPECIFICADO

(SERIE TW1061T de MAX).

El uso de un alambre de amarre que no sea el

especificado puede provocar averías en la

herramienta. Por lo tanto, asegúrese de usar

únicamente la serie TW1061T de MAX

especificada.

La RB441T no es compatible con la serie TW898

ni con la serie TW1525.

NO UTILICE ALAMBRE OXIDADO.

El uso de alambre oxidado puede provocar

problemas de funcionamiento en la herramienta.

1-3 (Fig.11) Gire el bloqueador del compartimento

de bobina (

6

) 45° hacia la izquierda.

1-4 (Fig.12, 13) Abra la cubierta del

compartimento de bobina (n) e instale el

alambre de amarre en el compartimento (7)

de modo que el lado de la ranura de sujeción

(o) de la bobina quede orientado hacia

arriba.

1-5 (Fig.14) Agarre la herramienta con la mano

izquierda, sujete la punta del alambre con la

mano derecha, y extraiga el alambre por la

ranura de sujeción.

Las dos puntas de alambre del nuevo alambre

de amarre están trenzadas.

1-6 (Fig.15) Estire la punta del alambre e

introduzca el alambre trenzado a lo largo de

la guía del alambre (i).

1-7 (Fig.16) Confirme a través de la ventanilla

que la parte trenzada del alambre ha pasado

por los dos engranajes de alimentación (h).

1-8 (Fig.17) Presione el bloqueo (9) hacia

arriba y confirme que el botón de

desbloqueo se ha elevado.

1-9 (Fig.18) Cierre la cubierta del compartimento

de bobina y gire el bloqueador del

compartimento 45° hacia la derecha.

Si la ventanilla está sucia

Abra la ventanilla (Fig.1.g) y elimine la

suciedad del interior de la ventanilla con un

paño. Después de limpiar, cierre de nuevo la

ventanilla para asegurarse de que ningún

material extraño penetre en la herramienta.

2. Cómo utilizar la RB441T

(Fig.6) Coloque el interruptor principal (e)

en la posición "OFF" ("DESCONECTADO"),

coloque el seguro del disparador (2) en la

posición "LOCK" ("BLOQUEADO") y extraiga

el paquete de baterías (5).

2-1 (Fig.19) Introduzca el paquete de baterías

en el cuerpo principal de la herramienta

hasta oír un clic.

2-2 (Fig.20) Cuando el interruptor principal (e)

está en posición "ON" ("CONECTADO"), el

gancho (Fig.1.f) de la punta gira

automáticamente para inicializarse. No

acerque los dedos a ninguna pieza giratoria

o móvil bajo ninguna circunstancia. Coloque

el interruptor principal en la posición "ON"

("CONECTADO") y el seguro del disparador

(2) en la posición "UNLOCK"

("DESBLOQUEADO").

2-3 (Fig.21) Incline la herramienta en un ángulo

de 45° respecto de las armaduras

entrecruzadas.

2-4 (Fig.22) Alinee la marca central (a) con el

centro de las armaduras entrecruzadas.

2-5 Cuando se acciona el disparador, la

herramienta completa automáticamente una

serie de acciones de amarre (alimentación,

corte, sujeción y amarre).

PRECAUCIÓN

AVISO

Page 31

31

• (Fig.23) Cuando el interruptor principal

(Fig.1.e) está en posición "ON"

("CONECTADO"), el gancho (Fig.1.f) de la

punta gira automáticamente para

inicializarse. No acerque los dedos a

ninguna pieza giratoria o móvil bajo

ninguna circunstancia.

• No toque ninguna pieza giratoria o móvil,

como el gancho de la punta o el alambre de

amarre, durante el trabajo de amarre

(mientras la herramienta está en

funcionamiento).

3. Cómo extraer el alambre de amarre

(Fig.6) Coloque el interruptor principal (e)

en la posición "OFF" ("DESCONECTADO"),

coloque el seguro del disparador (2) en la

posición "LOCK" ("BLOQUEADO") y extraiga

el paquete de baterías (5).

3-1 (Fig.9) Presione el botón de desbloqueo (8)

de la herramienta y confirme que dicho

botón queda asegurado en el bloqueo (9).

3-2 (Fig.11) Gire el bloqueador del

compartimento de bobina (6) para abrir la

cubierta del compartimento.

3-3 (Fig.24) Extraiga el alambre de amarre del

compartimento de bobina.

3-4 (Fig.25) Extraiga el alambre con la pieza de

plástico de la guía del alambre.

4. Cuando el alambre de amarre se

agota

(Fig.26) La pieza de plástico se desprende

cuando el alambre se agota, y puede

desecharse por separado como plástico y

alambre metálico (quedan unos 8" (20 cm) tras

un uso normal).

(Fig.6) Coloque el interruptor principal (e) en la

posición "OFF" ("DESCONECTADO"), coloque

el seguro del disparador (2) en la posición

"LOCK" ("BLOQUEADO") y extraiga el paquete

de baterías (5).

5. Ajuste de la tensión

(Fig.27.c) El disco selector le permite ajustar

ligeramente el par de tensión del alambre. Para

aumentar la tensión, gírelo hacia la izquierda.

Para disminuir la tensión, gírelo hacia la derecha.

6. Función de desconexión

automática

Esta herramienta tiene una función de

"Desconexión automática" que ahorra

consumo de energía de la batería cuando la

herramienta no está en funcionamiento.

Si la herramienta está sin funcionar durante 30

minutos, se desconecta automáticamente.

Cuando el suministro eléctrico se interrumpa

automáticamente, coloque el interruptor

principal en la posición "OFF"

("DESCONECTADO") y luego vuelva a colocarlo

en la posición "ON" ("CONECTADO") para

poner en funcionamiento la herramienta.

7. Para una tensión correcta

7-1 (Fig.21) Incline la herramienta en un ángulo

de 45° respecto de las armaduras

entrecruzadas.

7-2 (Fig.22) Alinee la marca central (a) con el

centro de las armaduras entrecruzadas.

7-3 (Fig.28) Coloque la herramienta

perpendicularmente a la superficie de las

armaduras entrecruzadas.

Durante el funcionamiento de la herramienta

No mueva la herramienta durante la operación

de amarre hasta que deje de funcionar

automáticamente.

7-4 (Fig.29) Amarre en dirección alterna.

7-5 (Fig.30) Amarre entrecruzado.

Antes de realizar el segundo amarre, doble

el nudo del primero.

8. Cómo instalar de nuevo un

alambre de amarre previamente

usado

(Fig.31) Introduzca los dos alambres en la guía

del alambre (i) sin trenzarlos.

9. (Fig.32) Cómo colocar y extraer el

gancho para cinturón de la

herramienta

El gancho para cinturón puede colocarse tanto

en el lado derecho como en el izquierdo de la

herramienta.

Montaje/Desmontaje del gancho para cinturón

(Montaje)

Inserte el gancho para cinturón en la ranura de

la herramienta. Fíjelo con un tornillo.

ADVERTENCIA

Page 32

32

(Desmontaje)

Afloje el tornillo y, a continuación, desmonte el

gancho para cinturón.

• Cuando utilice el gancho para cinturón o

cambie la posición, coloque el interruptor

principal (e) en la posición "OFF"

("DESCONECTADO"), coloque el seguro

del disparador (2) en la posición "LOCK"

("BLOQUEADO") y extraiga el paquete de

baterías (5).

De no observar esta instrucción, la

herramienta podría ponerse en marcha

accidentalmente y provocar un accidente.

• Antes de usar el gancho para cinturón,

asegúrese de que el gancho está

correctamente montado en la herramienta.

El uso de un gancho para cinturón montado

incorrectamente podría provocar lesiones

personales.

• Apriete firmemente el tornillo original

especificado.

Si el tornillo se afloja a causa de la vibración o

de otros movimientos generados durante el

funcionamiento, el tornillo flojo puede provocar

una caída accidental de la herramienta.

• Cuando utilice el gancho para cinturón, la

herramienta debe engancharse de forma

segura para que no se caiga.

Si la herramienta se cae, podría provocar un

accidente.

13.ALMACENAMIENTO

No guarde la herramienta en lugares fríos.

Manténgala en un lugar templado.

Cuando no la utilice, guarde la herramienta en

un lugar templado y seco. Manténgala fuera del

alcance de los niños.

EXTRAIGA LA BOBINA DE ALAMBRE DE

AMARRE

Al finalizar la operación de amarre con alambre,

extraiga la bobina de la herramienta.

GUARDE LA HERRAMIENTA