Max RB515, RB395, RB215 Maintenance Manual

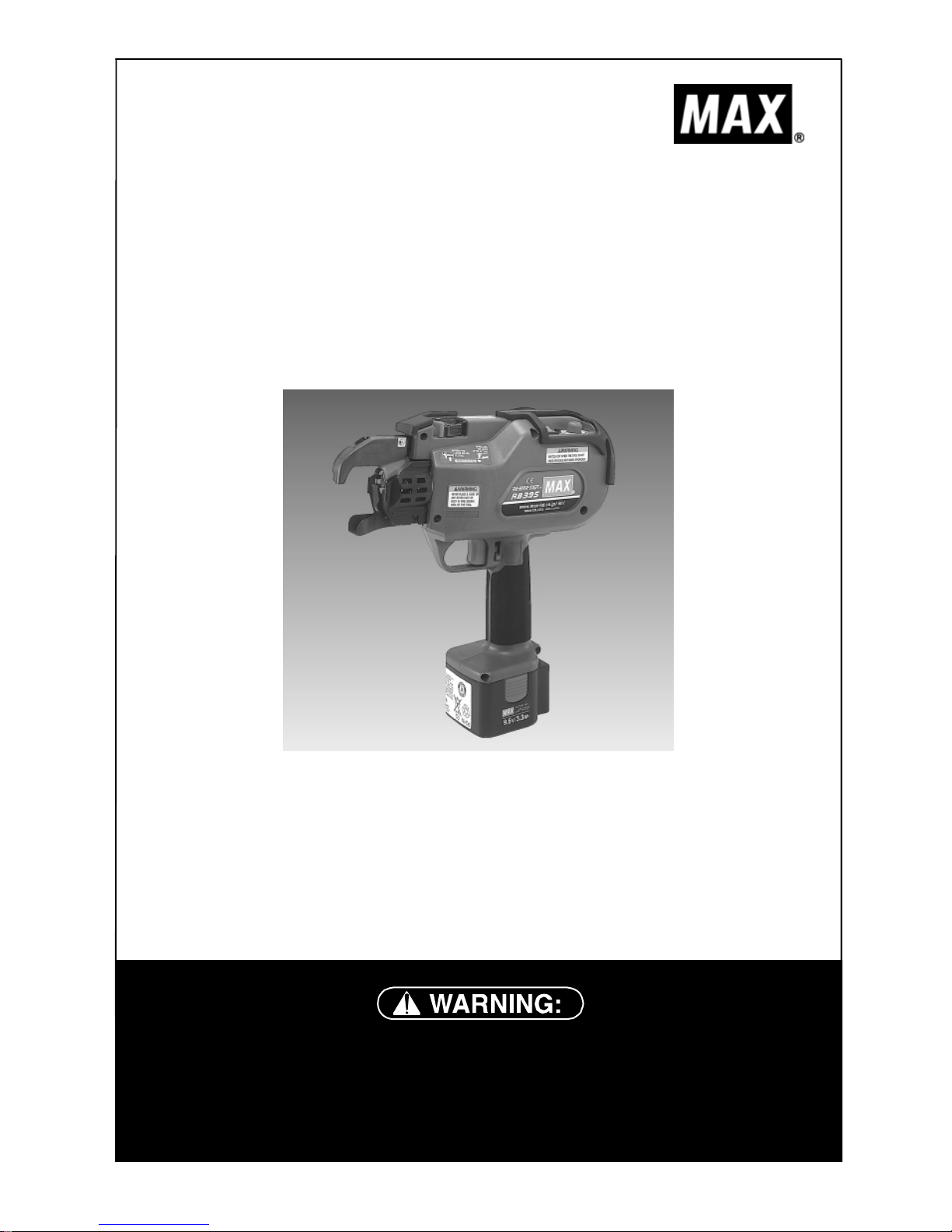

RB515, RB395, RB215

RE・BAR-TIER

RE・BAR TYING TOOL

OPERATING and MAINTENANCE MANUAL

.

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY WARNING

AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

INDEX

ENGLISH Page 3 to 20 Page

DEFINITIONS OF SIGNAL WORDS

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTE : Emphasizes essential information.

2

RB515, RB395, RB215

RE・BAR-TIER

INDEX

1. SPECIFICATIONS & TECHNICAL DATA.. 4

2. SAFETY INSTRUCTIONS......................... 6

3. SAFETY FEATURES............................... 10

4. BATTERY INSTRUCTIONS......................11

5. OPERATING INSTRUCTIONS ................ 14

6. MAINTENANCE....................................... 20

7. STORAGE................................................ 20

8. TROUBLESHOOTING/REPAIRS

OPERATING and MAINTENANCE MANUAL

ENGLISH

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY WA RNING

AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

3

1. SPECIFICATIONS AND TECHNICAL DATA

1. NAME OF PARTS

Arm

Main switch

LED

Pack cap

Tie-Wire

Reel holder

Curl guide

Latch

Grip

Trigger

Trigger lock

Reel stopper

Torque and wrap dial (RB515)

Torque dial (RB395)

Feed dial (RB215)

Release stopper

Release lever

Window

Battery pack (JP409)

Terminal

Battery pack (JP409)

2. TOOL SPECIFICATIONS 3. WIRE SPECIFICATIONS

NAME MAX TIE-WIRE

MODEL

TW897

DIAMETER

0.8 mm

LENGTH

95 m/coil

RB515 (3 wraps / tie) Approx. 90 ties/coil

RB515 (4 wraps / tie) Approx. 75 ties/coil

RB395 Approx. 120 ties/coil

TIES PER COIL

RB215 Approx. 180~210 ties/coil

TIES PER CHARGE

Approx. 360 ties/charge

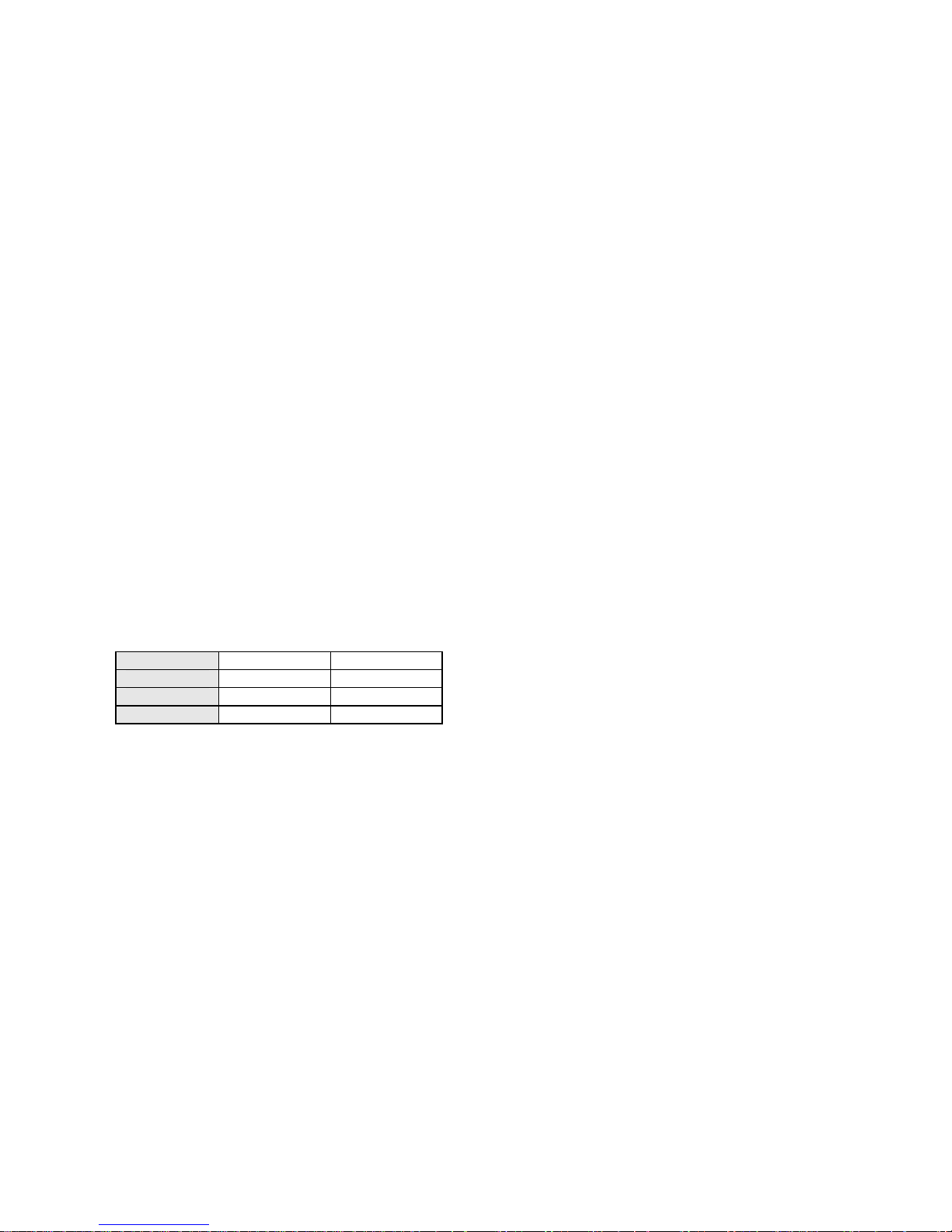

PRODUCT NO. RB515 RB395 RB215

WEIGHT

2.4 kg 2.4 kg 2.4 kg

HEIGHT

295 mm 296 mm 296 mm

WIDTH

102 mm 103 mm 103 mm

LENGTH

306 mm 290 mm 276 mm

WRAPS PER TIE

3 or 4 wraps/tie 3 wraps / tie

BATTERY

Ni-Cd 9.6V (JP409)

RECHARGE TIME

25 minutes

ACCESSORIES

Battery pack JP409 (2pcs.)

Carrying case

BATTERY CHARGER:

Use only an authorized Battery charger, Panasonic Charger EY0230B.

4

4. TECHNICAL DATA

① NOISE

A-weighted single-event ------ LWA, 1s, d 93.6 dB

sound power level

A-weighted single event ------ LpA, 1s, d 88.5 dB

emission sound pressure

level at work station

These values are determined and documented in accordance to EN12549 : 1999.

② VIBRATION

Vibration characteristic value = 0.97 m/s2

These values are determined and documented in accordance to ISO 8662-11.

This value is a tool-related characteristic value and does not represent the influence to the hand-arm-system when using the tool.

An influence to the hand-arm-system when using the too l will, for example, depend on the gripping force, the contact pressure

force, the working direction, the adjustment of main supply, the workpiece, the workpiece support.

③ RADIATED EMISSION 30-1000 MHZ

Class B

5. APPLICATIONS

*Precast plants

*Commercial buildings

*Foundations

*Road & bridge

6. APPLICABLE BAR SIZES

Minimum Maximum

RB515

D16 × D16 D22 × D25

RB395

D10 × D10 D16 × D19

RB215

Mesh × mesh D10 × D10

5

2. SAFETY INSTRUCTIONS

TO AVOID SEVERE PERSONAL INJURY OR PROPERTY DAMAGE

BEFORE USING THE TOOL, READ CAREFULLY AND UNDERSTAND THE FOLLOWING

”SAFETY INSTRUCTIONS”:

PRECAUTIONS ON USING THE TOOL

This equipment is a tool for use in tying re-bars. Using this equipment for other applications or in ways not

specified in the manual may lead to serious accident. Be sure to strictly observe the items written in this

manual. Persons not concerned with the work, particularly children, should be kept away from the work site

and should not be allowed to touch this equipment.

1. WEAR SAFETY GLASSES OR GOGGLES

The employer and the user must make sure that proper eye protection is worn when the tool is being

used. Eye protection equipment must conform to the requirements of the American National Standards

Institute, ANSI Z87.1 (Council Directive 89/686/EEC of 21 DEC. 1989) and it must provide frontal and

side protection.

NOTE: Nonside-shielded spectacles and face shields alone do not provide adequate protection.

2. EAR PROTECTION MAY BE REQUIRED IN SOME ENVIRONMENTS

Because working conditions may include exposure to high noise levels that could lead to hearing

damage, the employer and the user should make sure that necessary hearing protection is provided and

used by the operator and others in the work area.

3. DON’T ALLOW CHILDREN NEAR THE TOOL

Allow no bystanders, especially children, near the tool during its operation.

4. DON’T USE THE TOOL IN THE RAIN, WHERE WATER IS SPLASHING, IN A WET PLACE, OR

IN A DAMP PLACE

Using the tool in these or similar conditions will increase the risk of electric shock.

5. INSPECT THE PARTS BEFORE MOUNTING THE BATTERY PACK

●Examine the screws to make sure they are securely tightened.

Incomplete tightening may result in an accident or breakage. If a screw is loose, retighten it

completely.

●Inspect parts for damage.

Parts will wear over periods of use. Look also for missing and defective parts and for parts of poor

quality. If a part must be replaced or repaired, purchase the replacement part at an authorized MAX

Co., Ltd. distributor.

Use only genuine authorized replacement parts.

6. BE SURE TO SET THE MAIN SWITCH TO OFF, TO LOCK THE TRIGGER, AND DETACH THE

BATTERY PACK WHEN CHANGING THE BATTERY PACK, WHEN REPLACING OR ADJUSTING

THE TIE-WIRE, WHEN ABNORMALITIES OCCUR, AND WHEN THE EQUIPMENT IS NOT BEING

USED

Leaving the equipment switched on in these situations may cause breakdowns or damage.

6

7. KEEP FINGERS AND BODY PARTS CLEAR OF THE FEEDER ARM AND CURL GUIDE AT ALL

TIMES

Failure to do so may result in serious injury.

8. KEEP FINGERS AND BODY PARTS AWAY FROM THE TIE-WIRE REEL WHEN TOOL IS IN

OPERATION

Failure to do so may result in serious injury.

9. DON’T POINT THE TOOL AT ANYONE

Personal injury may r esult i f the tool catch es an oper ator or a ny one w or king near him. While working with

the tool, be extremely careful not to bring hands, legs, and other body parts near the arm of the tool.

10. WHEN THE TOOL IS NOT IN OPERATION KEEP YOUR FINGERS OFF THE TRIGGER

Failure to do so may cause accidental tying, leading to serious injury.

11. NEVER OPERATE THE TOOL UNDER ANY ABNORMAL CONDITION

If the tool is not in good working order, or if any abnormal condition is noticed, switch it off immediately

(set the Main switch at OFF), lock the Trigger and have it examined and repaired.

12. AFTER BATTERY INSTALLATION IF THE TOOL OPERATES WITHOUT THE TRIGGER BEING

PULLED OR THE OPERATOR NOTICES UNUSUAL HEAT, SMELL, OR SOUND, DISCONTINUE

OPERATION

Failure to do so may lead to serious injury. Return to dealer for safety inspection.

13. NEVER MODIFY THE TOOL

Modifying the tool will impair performance and operatin g safety. Any modification may lead to serio us

injury and void the tool warranty.

14. MAINTAIN THE TOOL IN GOOD OPERATING CONDITION

To secure operating safety and ensure top performance, keep the tool free of wear and damage. Also

keep the tool’s handgrip dry and clean, especially free of oil and grease.

7

Loading...

Loading...