Page 1

PASJ30(CE)

CORDLESS PRUNING SHEARS

AKKU-GARTENSCHERE

CISAILLES A ELAGER SANS FIL

CESOIA DA POTATURA A BATTERIA

PODADERA INALÁMBRICA

MANUALE DI FUNZIONAMENTO E MANUTENZIONE

MANUAL DE OPERACIONES Y MANTENIMIENTO

WARNING

WARNUNG

AVERTISSEMENT

ATTENZIONE

ADVERTENCIA

OPERATING AND MAINTENANCE MANUAL

BETRIEBSANLEITUNG

MANUEL D'UTILISATION ET D'ENTRETIEN

Original Language English

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY WARNING

AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

LESEN SIE VOR INBETRIEBNAHME DES GERÄTES DIE GEBRAUCHS- UND SICHERHEITSHINWEISE.BITTE BEWAHREN SIE DIE GEBRAUCHS- UND SICHERHEITSHINWEISE AUF, DAMIT SIE AUCH SPÄTER EINGESEHEN WERDEN KÖNNEN.

AVANT D’UTILISER CET OUTIL, LIRE CE MANUEL ET LES CONSIGNES DE SÉCURITÉ AFIN DE

GARANTIR UN FONCTIONNEMENT SÛR.

CONSERVER CE MANUEL EN LIEU SÛR AVEC L’OUTIL AFIN DE POUVOIR LE CONSULTER

ULTÉRIEUREMENT.

PRIMA DI USARE QUESTA MACCHINA, STUDIARE IL MANUALE PER PRENDERE ATTO DEGLI

AVVERTIMENTI E DELLE ISTRUZIONIPER LA SICUREZZA.

TENERE QUESTE ISTRUZIONI INSIEME ALLO STRUMENTO PER CONSULTAZIONI FUTURE.

ANTES DE UTILIZAR ESTA HERRAMIENTA, LEA DETENIDAMENTE ESTE MANUAL PARA

FAMILIARIZARSE CON LAS ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD.

CONSERVE ESTAS INSTRUCCIONES JUNTO CON LA HERRAMIENTA PARA FUTURAS CONSULTAS.

Page 2

INDEX INHALTSVERZEICHNIS TABLE DES MATIÈRES INDICE ÍNDICE

ENGLISH Page 9 to 28

DEUTSCH Page 29 to 48

FRANÇAIS Page 49 to 68

ITALIANO Page 69 to 88

ESPAÑOL Page 89 to 108

EC DECLARATION OF CONFORMITY Page 111

www.max-europe.com

DEFINITIONS OF SIGNAL WORDS

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

NOTE: Emphasizes essential information.

DEFINITIONEN DER HINWEISBEZEICHNUNGEN

WARNUNG: Zeigt eine eventuell gefährliche Situation an, die den Tod oder schwere

Verletzungen zur Folge haben könnte, wenn sie nicht vermieden wird.

VORSICHT: Zeigt eine eventuell gefährliche Situation an, die leichte oder mittelschwere

Verletzungen zur Folge haben könnte, wenn sie nicht vermieden wird.

HINWEIS: Hebt wichtige Informationen hervor.

DÉFINITIONS DES DIFFÉRENTS DEGRÉS D’ AVERTISSEMENTS

AVERTISSEMENT: Indique une situation éventuellement dangereuse qui, si elle n’est pas

contournée, pourrait provoquer la mort ou des blessure sérieuses.

ATTENTION:

REMARQUE: Souligne des informations importantes.

DEFINIZIONE DELLE INDICAZIONI DI AVVERTIMENTO

ATTENZIONE: Indica l’eventualità che possa verificarsi una situazione pericolosa, la quale se

AVVERTENZA: Indica l’eventualità che possa verificarsi una situazione pericolosa, la quale se

NOTA: Evidenzia informazioni importanti.

DEFINICIÓN DE LAS INDICACIONES DE ADVERTENCIA

ADVERTENCIA: Indica una situación potencialmente peligrosa que podría causar la muerte o

PRECAUCIÓN: Indica una situación potencialmente peligrosa que podría causar lesiones menos

NOTA: Resalta informaciones importantes.

Indique une situation éventuellement dangereuse qui, si elle n’est pas contournée,

pourrait provoquer des blessures légères à moyennement sérieuses.

non viene evitata, può risultare letale o provocare gravi lesioni.

non viene evitata, può provocare lesioni di lieve o media entità.

graves lesiones si no se evita.

graves o leves si no se evita.

2

Page 3

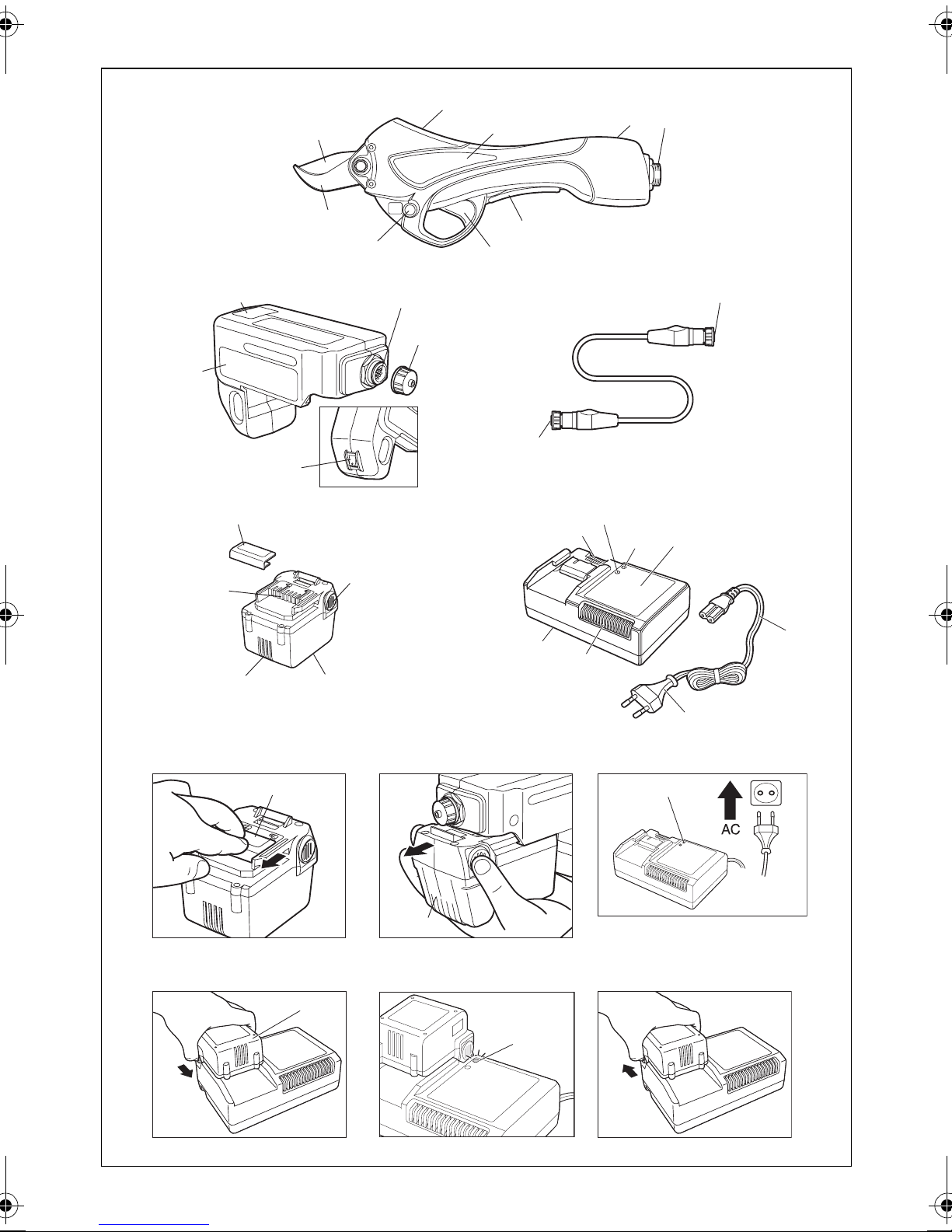

Fig.A/Abb.A

1

3

50

51

7

2

4

Fig.B/Abb.B Fig.C/Abb.C

8

10

6

5

9

52

12

11

Fig.D/Abb.D Fig.E/Abb.E

14

13

15

21

1716

18

22

20

19

12

53

24

Fig.F/Abb.F Fig.G/Abb.G Fig.H/Abb.H

13

19

25

Fig.I/Abb.I Fig.J, K, L/Abb.J, K, L Fig.M/Abb.M

25

19

23

3

Page 4

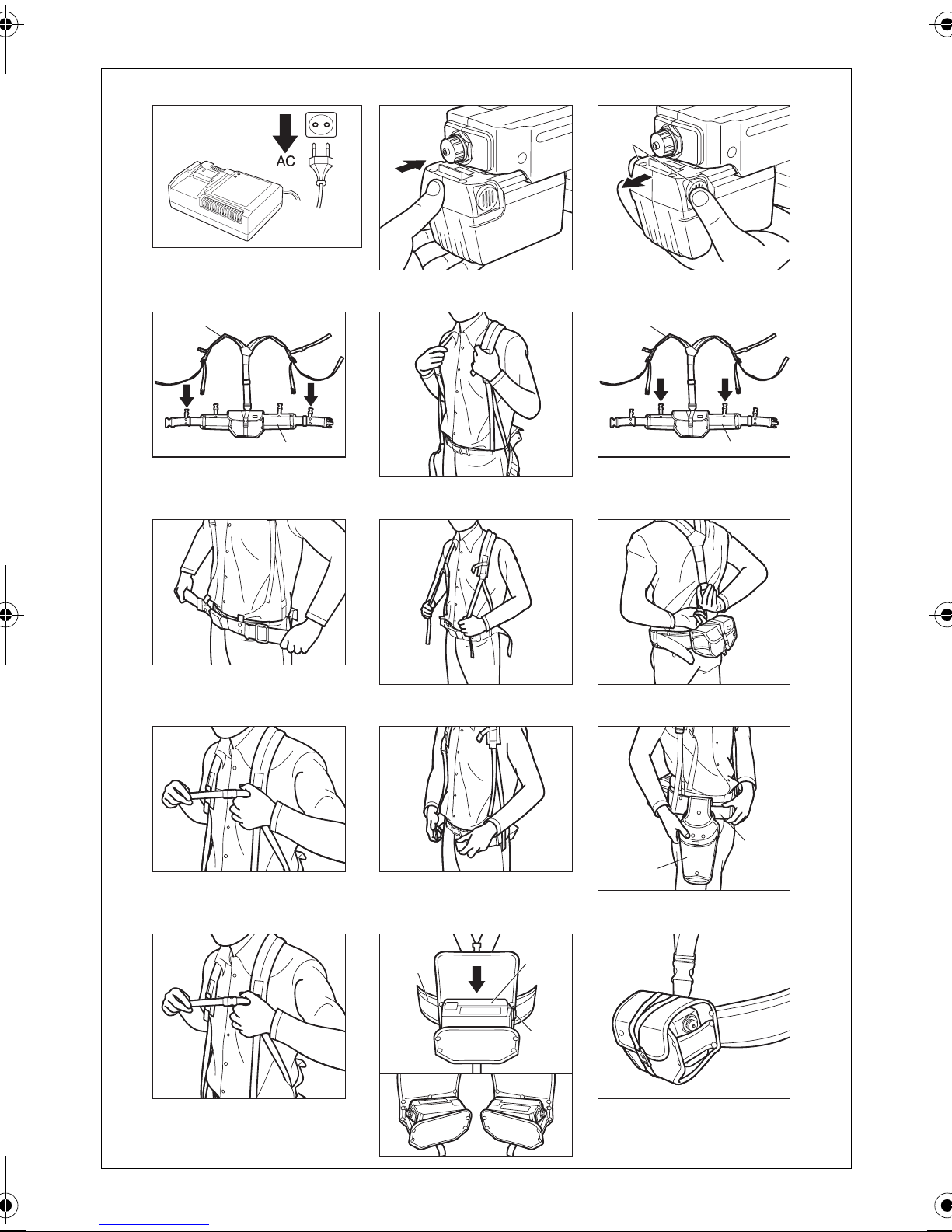

Fig.N/Abb.N Fig.O/Abb.O Fig.P/Abb.P

15

Fig.Q/Abb.Q Fig.R/Abb.R Fig.S/Abb.S

26

26

27

Fig.T/Abb.T Fig.U/Abb.U Fig.V/Abb.V

Fig.W/Abb.W Fig.X/Abb.X Fig.Y/Abb.Y

27

Fig.Z/Abb.Z Fig.AA/Abb.AA Fig.AB/Abb.AB

28

27

34

29

30

RL

4

Page 5

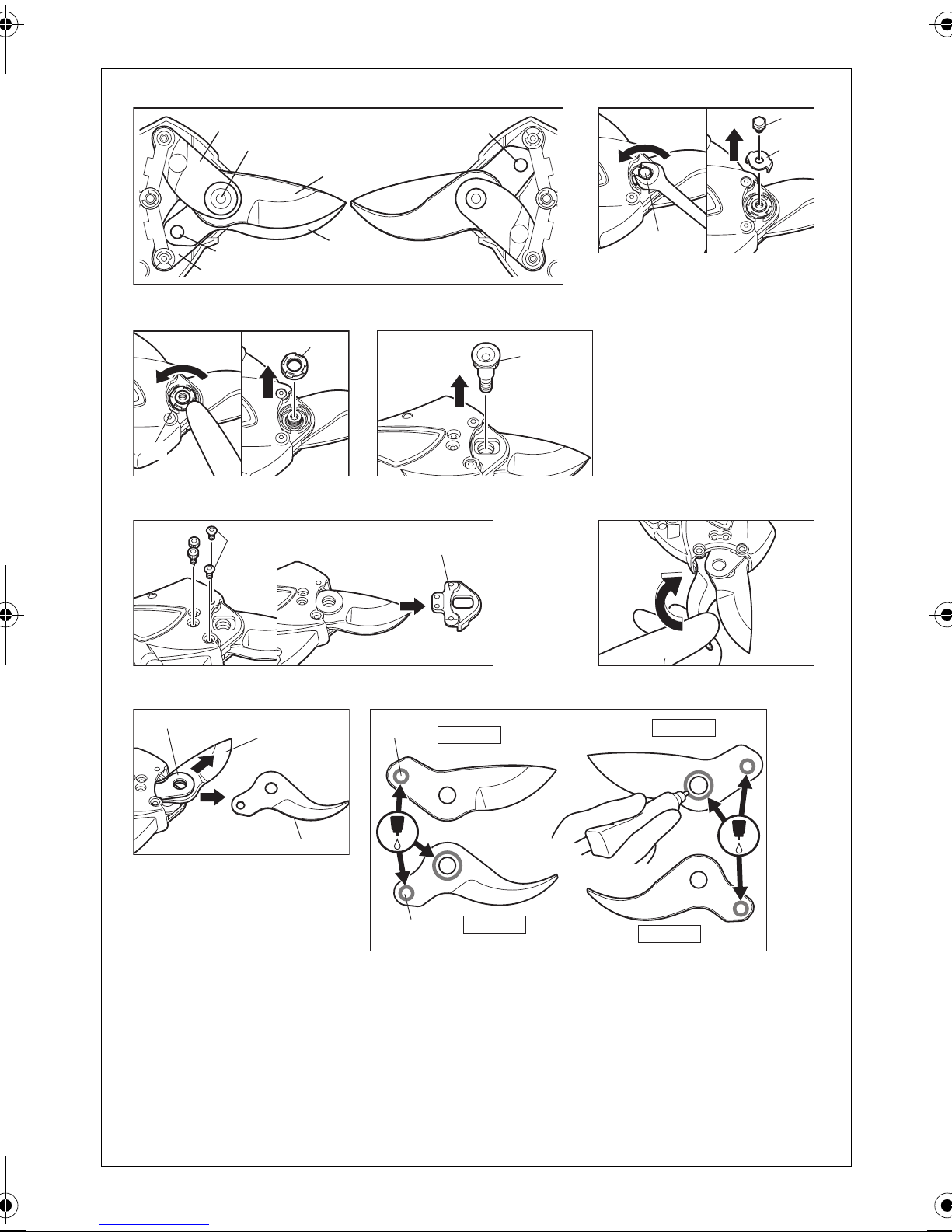

Fig.AC/Abb.AC Fig.AD/Abb.AD

Fig.AE/Abb.AE

Fig.AF/Abb.AF

Fig.AI/Abb.AI

33

10

9

29

10

26

3231

Fig.AG/Abb.AG Fig.AH/Abb.AH

11

Fig.AJ/Abb.AJ

Fig.AK/Abb.AK

10

12

3

6

5

4

Fig.AL/Abb.AL Fig.AM/Abb.AM

34

Fig.AN/Abb.AN

a bb

6

5

5

Page 6

Fig.AO/Abb.AO

Fig.AP/Abb.AP

35

36

39

1

37

2

40

38

Fig.AQ/Abb.AQ

Fig.AR/Abb.AR

42

36

42

Fig.AS/Abb.AS Fig.AT/Abb.AT

43

44

40

41

Fig.AU/Abb.AU

35

Fig.AV/Abb.AV

1

45

1

1’

2

46

2

2’

6

Page 7

Fig.AW/Abb.AW Fig.AX/Abb.AX

Fig.AY/Abb.AY

37

45

Fig.AZ/Abb.AZ

C D

35

39

Fig.BA/Abb.BA

36

44

Fig.BB/Abb.BB

Fig.BC/Abb.BC

42

Fig.BE/Abb.BE

44

Fig.BD/Abb.BD

40

41

40

7

Page 8

Fig.BF/Abb.BF

Fig.BG/Abb.BG Fig.BH/Abb.BH

1

47

Fig.BI/Abb.BI

36

47

49

1

2

36

48

8

Page 9

ENGLISH

OPERATING AND MAINTENANCE MANUAL

INDEX

1. GENERAL POWER TOOL SAFETY WARNINGS.............9

2. PRUNING SHEARS SAFETY WARNINGS .....................12

3. SPECIFICATIONS AND TECHNICAL DATA ..................14

4. CHARGING METHOD ......................................................17

5. PREPARATION FOR USE ...............................................20

6. HOW TO REPLACE BLADES ......................................... 23

7. MAINTENANCE PROCEDURE........................................24

8. HOW TO READ CONTROL BOX AND SHEAR LAMPS .. 26

9. SIMPLIFIED OPERATION CHART ..................................28

1. GENERAL POWER TOOL

SAFETY WARNINGS

WARNING

READ ALL SAFETY WARNINGS AND ALL

INSTRUCTIONS.

Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious injury. Save all warnings and instruc-

tions for future reference. The term "power

tool" in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1. WORK AREA SAFETY

• Keep work area clean and well lit. Clut-

tered or dark areas invite accidents.

• Do not operate power tools in explosive

atmospheres, such as in the presence

of flammable liquids, gases or dust.

Power tools create sparks which may ignite the dust or fumes.

• Keep children and bystanders away

while operating a power tool. Distrac-

tions can cause you to lose control.

2. ELECTRICAL SAFETY

• Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce risk

of electric shock.

• Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is

an increased risk of electric shock if your

body is earthed or grounded.

• Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric shock.

9

Page 10

• Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges and moving

parts. Damaged or entangled cords in-

crease the risk of electric shock.

•

When operating a power tool outdoors,

use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor

use reduces the risk of electric shock.

• Do not use the power tool in the rain,

where water is splashing, in a wet

place, or in a damp place. Using the tool

in these or similar conditions will increase

the risk of electric shock, dangerous malfunction, and overheating. If operating a

power tool in a damp location is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

3. PERSONAL SAFETY

•

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication.

A moment of

inattention while operating power tools may

result in serious personal injury.

• Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection, hand protector used for appropriate

conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energizing power tools

that have the switch on invites accidents.

• Remove any adjusting key or wrench

before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result in a

personal injury.

• Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in unexpected situations.

• Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

• If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and

properly used. Use of dust collection can

reduce dust-related hazards.

4. POWER TOOL USE AND CARE

• Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job better

and safer at the rate for which it was designed.

• Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the

switch is dangerous and must be repaired.

• Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

• Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

10

Page 11

• Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool's operation. If damaged, have the power

tool repaired before use. Many accidents

are caused by poorly maintained power

tools.

• Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

• Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for oper-

ations different from those intended could

result in a hazardous situation.

5. BATTERY TOOL USE AND CARE

• DO NOT DISPOSE OF BATTERY

PACKS/BATTERIES INTO FIRE OR WATER. Battery packs/batteries should be

collected, recycled or disposed of in an environmental-friendly manner.

• PROTECT THE BATTERY AGAINST

HEAT, ALSO AGAINST CONTINUOUS

SUN IRRADIATION AND FIRE. There is

danger of explosion.

•

DO NOT DISPOSE OF POWER TOOLS

INTO HOUSEHOLD WASTE.

According to

the European Guideline 2002/96/EC for

Waste Electrical and Electronic Equipment

and its implementation into national right,

power tools that are no longer usable must

be collected separately and disposed of in

an environmentally correct manner.

• The MAX battery pack uses a Li-ion battery, it may be illegal to dispose of this battery into the municipal waste system.

Check with your local solid waste officials

for details in your area for recycling options

or proper disposal.

• Recharge only with the charger specified by the manufacturer. A charger that

is suitable for one type of battery pack may

create a risk of fire when used with another

type of battery pack.

• Use power tools only with specifically

designated battery packs. Use of any

other battery packs may create a risk of injury and fire.

• When battery pack is not in use, keep it

away from other metal objects, like paper clips, coins, keys, nails, screws or

other small metal objects, that can

make a connection from one terminal to

another. Shorting the battery terminals to-

gether may cause burns or a fire.

• Under abusive conditions, liquid may

be ejected from the battery; avoid contact. If contact accidentally occurs,

flush with water. If liquid contacts eyes,

additionally seek medical help. Liquid

ejected from the battery may cause irritation or burns.

• CHARGE THE BATTERY PACK IN A

TEMPERATURE RANGE 5°C (41°F) TO

40°C (104°F)

6. SERVICE

11

•

Have your power tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the

safety of the power tool is maintained.

Page 12

2. PRUNING SHEARS SAFETY WARNINGS

1. BE SURE TO KEEP HANDS AWAY FROM

THE TRIGGER SWITCH AND DETACH

THE BATTERY PACK WHEN REPLACING

OR ADJUSTING THE BLADES, WHEN

ABNORMALITIES OCCUR, AND WHEN

THE EQUIPMENT IS NOT BEING USED

Leaving the Battery pack installed in these

situations may cause breakdowns or damage.

2. HOLD TOOL BY INSULATED GRIPS

WHEN PERFORMING AN OPERATION,

BECAUSE THE TOOL'S BLADES MAY

CONTACT HIDDEN "LIVE" WIRE

Contacting with a "live" wire may make exposed metal parts of the tool "electrified" and

shock the operator. Failure to do so may result in serious injury.

3. DO NOT POINT THE TOOL AT ANYONE

Personal injury may result if the tool catches

an operator or anyone working near him.

While working with the tool, be extremely

careful not to bring hands, legs, and other

body parts near the Blades of the tool.

4. NEVER MODIFY THE TOOL

Modifying the tool will impair performance

and operating safety. Any modification may

lead to serious injury and void the tool warranty.

5. THIS APPLIANCE IS NOT INTENDED FOR

USE BY PERSONS (INCLUDING CHILDREN) WITH REDUCED PHYSICAL, SENSORY OR MENTAL CAPABILITIES, OR

LACK OF EXPERIENCE AND KNOWLEDGE,UNLESS THEY HAVE BEEN GIVEN

SUPERVISION OR INSTRUCTION CONCERNING USE OF THE APPLIANCE BY A

PERSON RESPONSIBLE FOR THEIR

SAFETY.

Children should be supervised to ensure that

they do not play with the appliance.

6. MINORS SHOULD NEVER BE ALLOWED

TO OPERATE THE TOOL; IT SHOULD

NEVER BE LEFT UNATTENDED AND

WHEN NOT IN USE SHOULD BE STORED

IN A LOCKED PLACE OUT OF THE

REACH OF CHILDREN.

8. DON’T LEAVE THE MACHINE IN RAIN OR

WET LOCATIONS.

9. KEEP BYSTANDERS WELL AWAY FROM

YOUR WORK AREA.

10. BE CAREFUL NOT TO CATCH FOREIGN

MATTER BETWEEN THE BLADES.

If the blades are jammed with foreign matter,

immediately switch off the machine.

Then remove the foreign matter from the

blades.

11. TAKE CARE, AVOID CUTTING ELECTRICAL WIRES THAT MAY BE HIDDEN.

12. KEEP HANDS AWAY FROM MOVING

PARTS

13. KEEP YOUR FREE HAND AWAY FROM

THE CUTTING AREA.

Never touch the blades. They are very sharp

and you may cut yourself.

14. BE VIGILANT WHEN OPERATING TO ENSURE THAT THE FINGERS ON THE

HAND USED TO HOLD OR MOVE TWIGS

TO BE PRUNED ARE NOT EXPOSED TO

THE CUTTING BLADE.

15. USE ONLY THE AUTHORIZED BATTERY

PACK

Use only MAX JPL925 battery pack. If the

tool is connected to a power supply other

than the authorized pack, such as a rechargeable battery, a dry cell, or a storage

battery for use in automobiles, the tool may

be damaged, break down, overheat, or even

catch on fire. Do not connect this tool to any

power supply except the MAX JPL925 battery pack.

16. TO ENSURE MAXIMUM PERFORMANCE,

FULLY CHARGE THE BATTERY BEFORE

USE

A new battery pack or one not used for extended periods may have self-discharged

and thus may need recharging to restore it to

a fully charged condition. Before operating

the tool, make sure to charge the Battery

pack with the designated MAX Battery

charger JC928.

7. DON’T USE THE MACHINE OR PERFORM

BATTERY CHARGING OPERATIONS IN

THE RAIN.

12

Page 13

17. BATTERY CHARGING PRECAUTION

• Use only MAX Battery charger JC928

and Battery Pack JPL925.

Failure to do so may cause the Battery to

overheat or catch fire leading to serious injury.

• Charge the Battery from AC between

100V and 240V wall sockets.

Failure to do so may result in overheating,

or inadequate charging possibly causing

serious injury.

• Never use a transformer.

• Never connect the Battery charger to an

engine generator direct-current power

supply.

The charger will break down or be damaged from burning.

• Avoid charging the Battery pack in the

rain, in a damp place, or where water is

splashing.

Charging a damp or wet Battery pack will

cause an electric shock or a short circuit

that may lead to damage from burning and

even the tool catching on fire.

• Do not touch the power cord or plug

with a wet hand or glove.

This may cause injury from electric shock.

• Do not put a cloth or any other cover on

the Battery charger while the Battery

pack is being charged.

This will cause overheating and damage

from burning, or the Charger may even

catch fire.

• Keep the Battery pack and Battery

charger away from heat and flames.

• Do not charge the Battery pack near

flammable materials.

• Charge the Battery pack in a well venti-

lated place.

Avoid charging the Battery pack where it

will be in direct sunlight.

•

Charge the Battery pack in a temperature range of 5°C (41°F) to 40°C (104°F).

• Avoid continual use of the Battery

charger.

Rest the Charger for 15 minutes between

charges to avoid functional trouble with the

unit.

• Any objects that block the ventilation

holes or Battery pack receptacle may

cause electric shock or functional troubles.

Operate the charger free of dust or other

foreign materials.

• Handle the power cord carefully.

Do not carry the Battery charger by its

power cord. Do not use the power cord to

disconnect it from a wall socket; this will

damage the cord and break the wires or

cause a short circuit. Do not let the power

cord contact sharp edged tools, hot materials, oil, or grease. A damaged cord must

be repaired or replaced.

• Do not charge non rechargeable batteries with this charger.

• This charger is not intended for use by

children or disabled persons without

supervisor.

• Children should be supervised to ensure that they do not play with the

charger.

• Put a pack cap on the terminal of the

Battery pack.

When the Battery pack is not in use, put a

pack cap on its terminal to prevent short

circuits.

Keep it away from other metal objects,

such as clips, coins, keys, nails, screws or

other small metal objects, that can make a

connection from one terminal to another.

• Do not leave or store the tool in a vehicle or in direct sunlight during summer.

Leaving the tool in high temperature

conditions may cause the battery pack

to deteriorate.

• Do not store a fully discharged battery

pack. If a fully discharged battery pack

is removed from the system and left for

a long period of time, it may become

damaged. Recharge the battery immediately when it has been discharged.

13

Page 14

3. SPECIFICATIONS AND TECHNICAL DATA

1. NAME OF PARTS(SEE Fig.A-BI)

1 UPPER BLADE

2 LOWER BLADE

3LED LAMP

4 TRIGGER LOCK LEVER

Fig.A

Fig.B

Fig.C 12 CABLE TERMINAL

Fig.D

Fig.E

5 TRIGGER

6 SWITCH LEVER

7TERMINAL

50

NAME LABEL (SPECIFICATION LABEL)

51 WARNING LABEL

8LED LAMP

9 TERMINAL CAP

10 TERMINAL

11 POWER SWITCH

52 SPECIFICATION/WARNING LABEL

13 BATTERY CAP

14 BATTERY TERMINAL

15 LATCH

16 VENTILATOR SLITS

17 SPECIFICATION / WARNING LABEL

18 BATTERY PACK ENTRY POINT

LED LAMP (RED/GREEN) CHARGING

19

STATUS INDICATOR LAMP

LED LAMP (ORANGE) CHARGING

20

STATUS INDICATOR LAMP

21 SPECIFICATION / WARNING LABEL

22 VENTILATOR SLITS

23 CE(VDE) POWER PLUG

24 POWER CORD

53 WARNING LABEL

Fig.G 25 BATTERY PACK

Fig.Q

Fig.AA

Fig.AD

Fig.AF 33 ARM BAND

Fig.AL 34 HOLSTER

Fig.AO

Fig.AP

Fig.AQ 42 BLADE HOLDER

Fig.AS

Fig.AV

Fig.BF

Fig.BI

26 SUSPENDER

27 WEST BELT

28 WEST PAD

29 CONTROL BOX

30 TERMINAL OF THE CONTROL BOX

31 PROJECTION OF THE TERMINAL

32 CONVEX OF THE TERMINAL

35 BLADE ARM FOR UPPER BLADE

36 SHAFT

37 PIN FOR LOWER BLADE

38 BLADE ARM FOR LOWER BLADE

39 PIN FOR UPPER BLADE

40 BOLT 5X8

41 WASHER

43 BOLT 4X6 (4PCS.)

44 ALUMINUM BASE

45 HOLE

46 HOLE

47 SHARPENER

48 GREASE SUMP

49 GREASE IN TUBE

2. TOOL SPECIFICATION<TOOL>

PRODUCT NO. PASJ30(CE)

WEIGHT 0.9Kg(2.0lb)

HEIGHT 120mm(4-7/8")

WIDTH 50mm(2")

LENGTH 330mm(13-1/8")

RATED VOLTAGE / BATTERY 25.2V, Li-ion Battery pack JPL925

MOTOR Brushless DC Motor

OPERATING TEMPERATURE -10°C to 40°C (14°F to 104°F)

OPERATING HUMIDITY 80% RH or less

MAXIMUM CUTTING CAPACITY 30mm/15mm diameter

14

Page 15

<BATTERY CHARGER>

PRODUCT NAME MAX lithium ion battery charger

PRODUCT CODE JC928(CE)

INPUT AC100-240V 50/60Hz 1.62-0.68A

OUTPUT

WEIGHT 1.6Kg

OPERATING TEMPERATURE RANGE -10°C to 40°C (14°F to 104°F)

OPERATING HUMIDITY 80% RH or less

DC 7.2/10.8/14.4V 7A

DC 18/21.6/25.2/28.8V 3.9A

<BATTERY PACK>

PRODUCT NAME MAX lithium ion battery pack

PRODUCT NO. JPL925

BATTERY TYPE Lithium ion battery

NOMINAL VOLTAGE DC25.2 V

NOMINAL CAPACITY 3.0 Ah (3,000 mAh)

CHARGING TIME

(USE WITH JC928(CE))

ACCESSORIES Pack cap (For preventing short circuit)

WEIGHT 0.9 Kg

CHARGING TEMPERATURE 5°C to 40°C (41°F to 104°F)

OPERATING TEMPERATURE -10°C to 40°C (14°F to 104°F)

OPERATING HUMIDITY 80% RH or less

Quick charging - Approximately 45 minutes (Apprx. 90% of capacity)

Full charging - Approximately 54 minutes at 20°C (100% of capacity)

<CONTROL BOX>

PRODUCT NAME control box for 25.2v battery pack

NOMINAL VOLTAGE DC25.2V

RATED VOLTAGE/BATTERY 25.2V, Li-ion Battery pack JPL925

ACCESSORIES Connector cap (For preventing short circuit)

WEIGHT 0.4Kg/1.3Kg (With Battery)

SIZE (L) × (H) × (W) (L)181mm × (H)129mm × (W)84mm (With Battery)

15

Page 16

3. TECHNICAL DATA

1 NOISE

A-weighted single-event ------ LWA, 74.81 dB

sound power level

A-weighted single event ------ LpA, 63.81 dB

emission sound pressure

level at work station

Uncertainty (K): 3 dB

These values are determined and documented in accordance to EN60745-1.

2 VIBRATION

Vibration characteristic value - 0.0321 m/s

Uncertainty (K): 1.5 m/s

2

2

These values are determined and documented in accordance to EN ISO 5349-1 and EN ISO 5349-2.

This value is a tool-related characteristic value and does not represent the influence to the handarm-system when using the tool. An influence to the hand-arm-system when using the tool will, for

example, depend on the gripping force, the contact pressure force, the working direction, the adjustment of main supply, the workpiece, the workpiece support.

3 RADIATED EMISSION 30-1000 MHZ

Class B

4 Overvoltage category

category I according to IEC 60664-1

5 Pollution degree

degree 4 according to IEC 60664-1

6 Design guidelines

Machinery directive Annex I, EN 60745-1, EN 60745-2-8

EMI :EN 55014-1 RFP EN 61000-6-3 RE

EMS :EN 55014-2 CATEGORY IV EN 61000-4-2/-3/-4/-6

4. ABOUT PRODUCTION YEAR

This product bears production number in the body. The two digits of the number from left indicates

the production year.

(Example)

10826035D

Year 2010

<Standard accessories>

● JPL925 (Battery), 1 piece ● JC928 (Rapid charger), 1 unit

● Control box, 1 unit ● Connection cable, 1 piece

● Battery holder (with holster and arm band), 1 piece ● Hex wrench, 2 piece

● Spanner, 1 piece ● Safety glasses, 1 pair ● Sharpener, 1 piece

● Instruction manual, 1 copy ● Carry case, 1 piece

<Main uses>

● Pruning fruit trees

• Please note that the main functions, shapes and other features in the above specifications are subject

to change for purposes of improvement.

16

Page 17

4. CHARGING METHOD

WARNING

• Charge at the specified voltage.

Be sure to charge using a AC100V - 240V wall

socket. Charging with a other voltage other

than that specified cannot only cause problems but is also dangerous.

• Never charge with an engine generator or a

DC power supply.

This can not only cause a problem but also can

also result in abnormal heating and fire.

• Use a standard wall socket.

The charger must be securely plugged into a

wall socket. The power plug must not be loose

or be able to come out easily. Use of a wall

socket that does not allow the power plug to be

inserted securely may result in an accident

caused by overheating. If that is a possibility,

use another wall socket.

• Keep the pack cap on the battery pack

whenever it is not being used.

∗ Initial state of battery pack

The battery pack is not fully charged when you

purchase it. Correctly charge the battery pack

using the charger before use.

CAUTION

• In its initial state, the battery pack, although

not fully charged, can be used to operate

the machine when it is attached. Be careful

not to operate the trigger switch inadvertently.

• When installing or removing the battery

pack in the control box, check that the power switch of the control box is turned off.

1 (Fig. F) Remove the pack cap, which cov-

ers the battery pack terminal area, used

to prevent short circuiting.

(Fig. G) When the battery pack is used once

and installed in the control box, remove the

pack from the machine first.

(See P 20, How to remove the battery pack.)

2 (Fig. H) Plug the charger power cord into

a AC100V - 240V wall socket.

The red LED lamp blinks and a pip sounds

twice to indicate that the power is on.

3 Charge the battery pack.

(1) (Fig. I) Slide the battery pack firmly until it

reaches the end of the battery pack installation port of the charger.

(2) (Fig. J) If the battery pack is connected to the

charger, charging starts automatically.

The red LED lamp lights up and a pip sounds

once to indicate that the battery is being

charged.

(3) When the battery pack has been rapid-

charged, the red indicator LED lamp will start

to blink green.

(Fig. K) When the green LED lamp blinks, a

beep will sound for approximately two seconds. At this point, the battery has been recharged to approximately 90% capacity.

The rapid charging process takes approximately 45 minutes. (However, the recharging time and capacity will charge slightly

depending on the ambient temperature and

power voltage)

(Fig. L) You can use the battery pack when

rapid charging is complete. However, if you

leave the battery pack on the charger, charging will continue. When the battery is fully

charged (to 100% capacity), the green LED

lamp lights up (and a beep will sound for approximately two seconds).

4 (Fig. M) After you have charged the bat-

tery pack, remove it from the charger.

5 (Fig. N) Unplug the charger power cord

from the wall socket.

17

Page 18

INDICATION OF QUICK CHARGER LAMPS

Charger LED lamp Buzzer sound Recharging status

Red lamp blinks.

It blinks every second.

The power cord is plugged

into the receptacle.

Two short beeps (Pi, pi)

The charger is

powered.

The charger power cord is plugged

into a wall socket.

Red lamp lights.

It remains lit.

The green lamp blinks.

It blinks every second.

The green lamp lights up.

It remains lit.

The red lamp lights up.

The orange lamp lights up.

They remain lit.

The orange lamp lights up.

It remains lit.

The orange lamp blinks.

It blinks quickly (0.1 sec

ON and 0.1 sec OFF).

The battery pack is mounted.

One short beep (Pi)

The battery has been recharged.

A long beep for approx. 2

seconds (Piii...)

Fully recharged.

A long beep for approx. 2

seconds (Piii...)

— Protective charging

— Standby

Not possible to recharge.

Short continuous beeps for

approx. 10 seconds

(Pi, pi, pi, pi,...)

The battery is being recharged.

The battery has

been recharged.

Battery is "fully" recharged.

Not possible to recharge.

Quick recharging continues.

The battery has been recharged to approx. 90% of its capacity.

If you leave the battery pack on the

charger, recharging will continue.

Recharged to 100% capacity.

The battery is recharged with a low

current to protect the charger and battery.

If the temperature of the battery pack

is too high: Battery recharging starts

automatically when the temperature

drops below the limit.

If the temperature of the battery pack

is too low: Place the battery pack in a

room temperature location for a while,

then retry recharging it.

Unable to recharge the battery.

The battery pack slot is contaminated,

or the battery pack has failed.

∗ For batteries those are at low temperatures (10°C (50°F) or lower), charging time must be extended

longer.

18

Page 19

CAUTION

• When the orange LED lamp blinks and short beeps keep sounding for approximately 10 seconds: Charging failed

You cannot charge the battery. If this occurs, first unplug the power cord from the wall socket. Next,

remove the battery pack from the charger, and check whether any foreign substances have entered

the terminals of the battery pack or charger. If any foreign substances are found, remove them using

a soft material.

If no foreign substances are found, or if the orange LED lamp is still blinking even after foreign substances have been removed, the battery pack may have expired, or the battery pack or charger may

be malfunctioning. If you have an extra battery pack, use it. If the orange LED lamp still blinks, return

the battery pack and charger to your dealer for inspection or repair.

• When a fully charged battery pack is set on the charger again, the red LED lamp may light up,

but this is not a failure. The lamp will soon turn green, indicating that the battery is fully

charged.

• The charger has a cooling fan that may start working due to the temperature of the battery pack

and charger. The fan stops working when the temperature drops.

• Certain ambient temperature conditions or the battery pack may prolong the charging time.

• Charging several battery packs continuously may prolong the average charging time.

• Once charging is completed, allow the charger to rest for approximately five minutes before

charging again.

• In the following cases, return the battery pack and charger to your dealer for inspection or repair, since they may be faulty.

− When the power cord is plugged into a AC100V - 240V wall socket, the red LED lamp does not blink.

(with the battery pack not set.)

− When the battery pack is connected to the charger, the red or orange LED lamp does not light or

blink.

− When the battery pack is hot and the orange LED lamp lights up, the red LED lamp does not light up

60 or more minutes have elapsed.

− When the red LED lights up, it does not start blinking green after 90 or more minutes have elapsed.

19

Page 20

5. PREPARATION FOR USE

1. Installing or removing the battery

pack

WARNING

• When installing or removing the battery

pack in the control box, check that the

power switch of the control box is

turned off.

• Make sure that the battery pack is correctly installed in the control box before

use.

An incorrectly installed battery pack may

fall off during operation, which may result in

personal injury.

• Keep the connector cap on the control

box whenever it is not being used.

(Fig. O) To install the battery pack, first align the

slot on the battery pack with the slot on the control box, then slide it in the direction of the arrow

until it clicks securely in place.

(Fig. P) To remove the battery pack from the

control box, press the latches at both sides and

slide the pack straight forward in the direction of

the arrow, while holding the hollow part on the

control box side with your other hand.

2. Preparation for use

1 (Fig.Q Fig.S) Attach the front side of the

suspender to the waist belt.

There are two points on the belt for attaching

the suspender. Choose the one of your liking.

2 (Fig.R) Put your arm through the sus-

pender.

3 (Fig.T) Secure the waist belt, pull it to the

right and left to adjust the length so that

it fits properly.

4 (Fig.U Fig.V) Adjust the length of the sus-

pender belt so that it fits properly.

5 (Fig.W) Secure the chest belt and adjust

the length so that it fits properly.

6 (Fig.X) After adjusting the suspender and

belts, remove the waist belt and chest

belt, and set the battery holder down.

7 Install the battery pack in the control box.

3. Installation method

1 (Fig. AA) Store the control box containing

the battery pack into the battery holder so

that the terminal of the control box is on

the same side as your dominant hand.

Store the control box with the LED lamps

facing upward.

2 (Fig.AB) Firmly fasten the control box

storage section of the battery holder using the buckle.

3 (Fig.AC) Remove the connector cap,

which covers the control box terminal area, used to prevent short circuiting.

4 (Fig.AD) Connect the connecting cable to

the control box terminals and tighten the

screws of the terminals on the connecting cable side.

∗ You can connect either terminal at the

right and left ends of the connecting cable.

∗ The terminal on the control box side

has a projection while the connecting

cable side has a hollow. Connect the

cable so that they will fit with each other.

For a simplified control box chart, see page 26.

5 (Fig.AE) Putting on the battery holder

Hold the bottom of the connecting cable terminal at the unconnected end with the hand

that you will use to hold the shears, taking

care not to touch the inside of the terminal.

Carry the battery holder on your back as you

would carry a rucksack.

(Fig.Y) Fit the holster on the waist belt and

(Fig.Z) buckle the waist belt, suspender and

chest belt.

If you use a purchased waist bag in addition

to the battery holder, adjust the bottom of the

battery holder to the top of the waist bag belt

so that you can easily put on and take off the

battery holder.

∗ Take care that the connecting cable

does not get between your body and

the shoulder band of the battery pack.

6 (Fig.AF) Putting on the arm band

Put the arm band on your upper arm as

shown in the figure, and fix the connecting

cable.

7 (Fig.AG) Connecting the machine and

connecting cable

Insert the connecting cable terminal into the

machine terminal and turn it to the right to

connect it securely.

20

Page 21

∗ Similarly to when connecting the con-

trol box, match the hollow and projection of the connecting cable and

machine.

4. Switch operation

CAUTION

Before connecting the control box

• Check that you cannot pull the trigger

unless you depress the switch lever.

• Check that the trigger returns when you

depress the switch lever and pull and release the trigger.

If the switch lever or trigger does not operate correctly, it could result in an accident.

1 (Fig.AH) Turn on the power switch of the

control box.

∗ When the switch is turned on

The red LED lamp of the shears slowly

blinks.

Check that the machine is standing by and

that the green LED lamp blinks slowly.

At this time, one to three of the green LED

lamps on the top of the control box light up.

− The three green LED lamps indicate the

battery charge level. If all of the three

LED lamps are lit up, the battery is

charged sufficiently. If only one green

LED lamp is blinking, charge the battery.

• If the red LED lamp of the shears lights up

There is a problem. Check the cause of the

problem by inspecting the LED lamps on the

control box.

− If one or more red LED lamps lights up or

blinks, there is a problem. The cause of the

problem can be checked by inspecting the

lighting and blinking patterns of the red LED

lamps. For an explanation of the patterns,

see "HOW TO READ CONTROL BOX AND

SHEAR LAMPS" on p 26.

2 (Fig.AI) Release the trigger lock lever of

the shears.

• When the blades are closed

While depressing the trigger and switch lever, push the trigger lock lever in the direction of the arrow to release the lock.

• When the blades are open

Push the trigger lock lever in the direction

of the arrow to release the lock.

3 (Fig.AJ) Hold down the switch lever of the

shears.

If the switch lever is depressed, the buzzer

sounds for a short time. If the switch lever is

not released, the buzzer sounds for a long

time. When the blades open and the blinking

green LED lamp of the shears lights up, the

machine is ready.

If the blades do not open, release the switch

lever, and then hold it down again.

∗ If you depress the trigger, the blades do

not open. Hold down the switch lever

with the trigger released.

∗ If the green LED lamp of the shears

blinks quickly, the battery is not

charged sufficiently. Charge the battery.

4 (Fig.AK) If the trigger is pulled ( ) with

the switch lever depressed, the blades

move in the closing directions. If the trigger is not released, the blades stop at the

closed positions.

If the trigger is released ( ), the blade

moves in the direction of the opening and

stops at the fully open positions.

The blades open and close according to the

extent the trigger is pulled.

5. How to switch the opening angle

of the blades

This machine can cut twigs of diameters up

to 30 mm, but you can change the maximum

diameter to 15 mm by switching the opening

angle of the blades.

1 (Fig.AJ) Press the switch lever twice and

then release it.

2 Hold the switch lever with the trigger

pulled for two seconds until the buzzer

sounds.

∗ Do steps 1 and 2 within five seconds of

each other.

3 If the buzzer does not sound, release the

switch lever and the trigger. One second

later, repeat steps 1 and 2.

Every time you do the operations above, the

maximum diameter changes from 30 mm to 15

mm and vice-versa.

• When it is unnecessary to switch the open-

ing angle of the blades

1 Press the switch lever five times.

2 Disconnect the connection cable from

the shears.

21

Page 22

3 When the buzzer sounds from the control

box, turn off the power.

4 Operate the switch as explained in "4.

Switch operation" on page 21. After that,

the opening angle of the blades cannot

be switched over.

∗ If you need to switching the opening angle

of blades, perform steps 1 to 4 again.

6. How to store the shears in the holster

(Fig. AL) Turn off the power switch of the

control box while pulling the trigger (with the

blades closed)

∗ While the blades are closed, check that the

lamp of the shears is turned off.

WARNING

• When storing the shears in the holster,

be sure to close its blades.

If the machine is stored while its blades are

open, you may be injured and the holster

may be broken.

∗ If the trigger lock lever is locked with the

trigger pulled (with the blades closed),

the blades are kept closed even if the

trigger is released after that.

To open the blades again, release the

trigger lock lever while depressing the

trigger and switch lever.

7. Pruning method

WARNING

• Use safety glasses.

Wear safety glasses when using the machine. Otherwise you run the risk of eye

damage due to flying chips.

(Fig. AM) When pruning, cut twigs one by one

between the upper and lower blades.

(This machine can cut twigs with a diameter of

up to approximately 30 mm. When the opening

angle of the blades is changed, the diameter can

be up to about 15 mm.)

∗ If the battery charge level is low, the ma-

chine may not be able to cut twigs.

∗ The machine may not be able to cut twigs,

depending on the dryness of the wood or

other factors.

When stopping work, lock the trigger lock lever

with the blades closed or turn off the power

switch of the control box, and then store the

shears in the holster.

∗ If the machine is not used for five minutes,

it is set in the standby mode automatically.

When starting work again, release the trigger lock lever. Then, hold down the switch

lever. After the buzzer sounds, you can restart pruning work.

∗ If the machine is not used for 60 minutes,

the power is turned off automatically.

∗ When starting the work again, turn the

switch off, and then turn it on again. Then,

hold down the switch lever. After the buzzer sounds, you can re-start pruning work.

When you have finished pruning, turn off the

power of the control box with the blades closed,

disconnect the connecting cable, remove the

battery pack from the control box, fit the pack cap

to the battery pack, and store the machine in a

dry location that is not affected by high temperature and that is away from children.

22

Page 23

MOTOR PROTECTION FUNCTION

This machine has a circuit that stops the machine when the motor becomes hot.

If the motor stops, stop using the machine, turn

off the power switch, wait until the motor cools

down, and then start the work again.

• Notification that the machine stopped because of motor high temperature

The buzzer sounds and the two at both ends of

the three lamps on the control box blink in red

and the center one goes off.

6. HOW TO REPLACE BLADES

WARNING

• When replacing the blades, be sure to

turn off the power switch of the control

box with the blades open, and disconnect the connecting cable from both the

control box and the machine.

• When replacing the blades, be sure to

wear gloves.

CAUTION

• Avoid using the machine in a way in

which the motor protection function operates on a frequent basis.

This can cause the motor to heat up or experience other problem.

8. If a twig is caught in blades

If a twig is caught in the blades (cannot be cut by

the cutting action), release the trigger. Releasing

the trigger moves the blades in the opening direction.

If the twig is still caught in the blades after releasing the trigger, do not move the machine to the

sides but move it slowly in up and down with the

trigger released to free the twig from the blades.

To reuse the machine after removing the twig,

release the switch lever again. After that, the machine can be used as normal.

WARNING

• If the blades break and scatter, workers

may sustain injuries that lead to loss of

eyesight or other serious injuries.

(Fig.AN) Do not move the blades in a lateral direction since the trigger may break and

the blades may be crushed.

a: Correct usage method

b: Lateral movement during the cutting ac-

tion that can break the blades

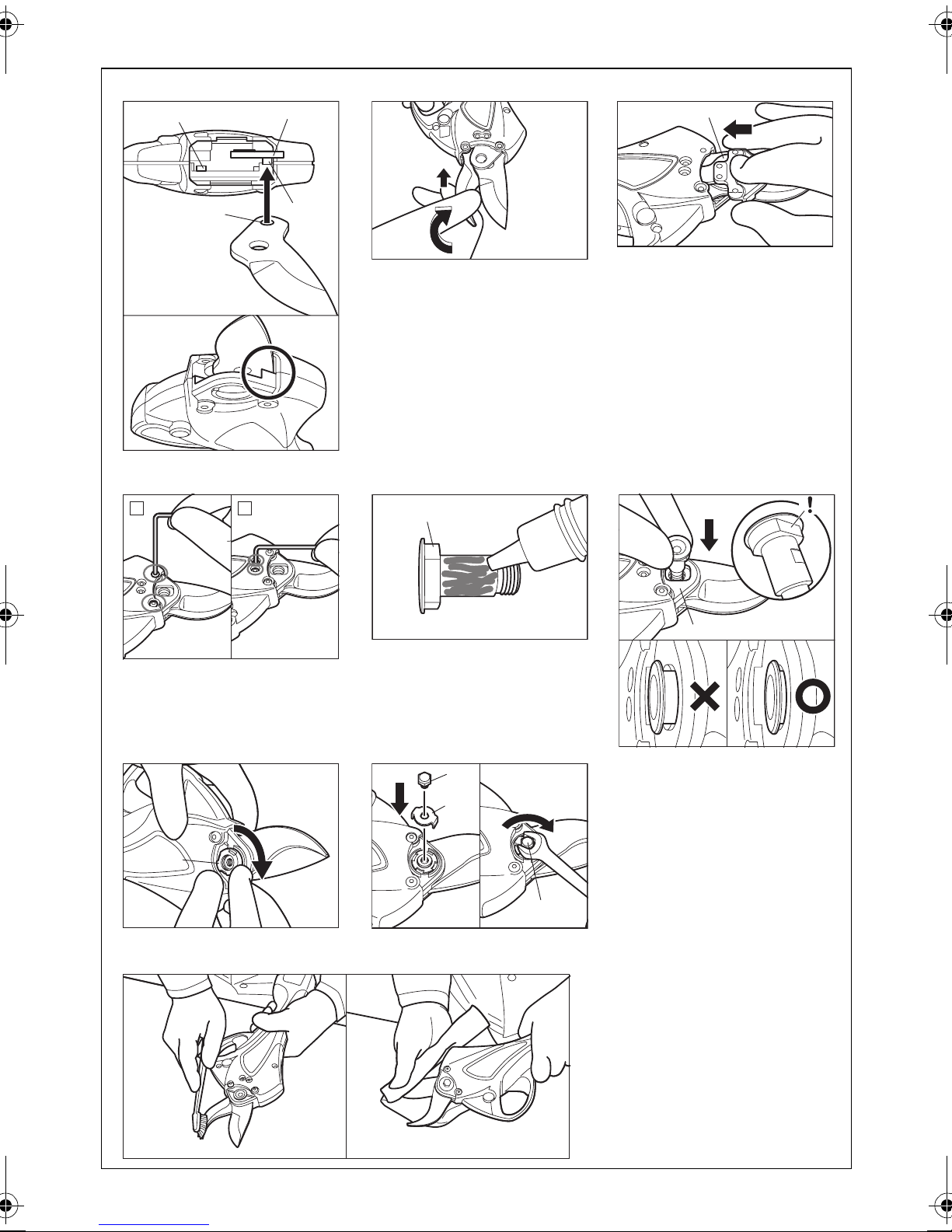

[STRUCTURE AROUND SHAFT] (FIG.

AO)

1. How to remove blades

1 (Fig.AP) Loosen the hex bolt with the at-

tached hex spanner to remove the hex

bolt and washer.

2 (Fig.AQ) Use your hand to rotate the

blade holder in the direction of the arrow

and remove it.

3 (Fig.AR) Reverse the machine and pull

out the shaft.

4 (Fig.AS) Remove the four hex socket

head bolts with the attached hex wrench

to remove the aluminum base.

∗ When removing the bolts, take care not

to injure your hand on the blades.

5 (Fig.AT)Move the lower blade to the left

as shown in the figure, turn it clockwise

and remove it from the pin of the blade

arm for lower blade.

∗ Be sure to wear gloves when removing

the lower blade. Touching blade with

bare hands may cause injury.

6 (Fig.AU) Pull out the lower blade. Move

the upper blade into the space after the

lower blade is pulled out and pull out the

upper blade.

2. How to install blades

1 (Fig.AV) Apply grease to the upper and

lower blades.

2 (Fig.AW) Insert the hole of the upper

blade to the pin of the blade arm for the

upper blade.

23

Page 24

3 (Fig.AX)Insert the lower blade into the

shears. Turn the lower blade clockwise

as inserted into the shears and insert the

hole on the lower blade over the pin of the

blade arm for lower blade.

4 After inserting the upper and lower

blades over the pins of the blade arms,

pull the upper and lower blades, and confirm that they do not detach.

∗ If the blades detach, they are not insert-

ed over the pins of the blade arms properly. In such a case, reinsert them.

5 (Fig.AY) Insert the aluminum base be-

tween the blade and the machine and adjust the hole for the hex socket head bolt.

∗ If the blades are open too wide, the alu-

minum base floats and cannot be installed.

6 (Fig.AZ) Tighten the four hex socket head

bolts using the attached hex wrench.

∗ Tighten bolt "a" holding the short end

of the L-wrench, and tighten bolt "b"

holding the long end of the wrench.

(To stabilize the tightening force)

7 (Fig.BA) Apply the attached grease all

around the shaft.

8 (Fig. BB) Insert the shaft in the shaft hole.

Insert the shaft so that its flat face will be

matched with the hole of the aluminum

base.

∗ If it is difficult to insert the shaft, swing

the lower blade in both vertical and lateral directions.

9 (Fig.BC) While holding the shaft to pre-

vent it from coming out, install the blade

holder by rotating it with your hand.

∗ Tighten the blade holder firmly until

you cannot rotate it any more without

using a tool.

0 (Fig.BD) Install the washer and be sure to

tighten the hex bolt using the attached

wrench.

7. MAINTENANCE PROCEDURE

WARNING

• When inspecting or servicing, be sure to

turn off the switch of the control box and

disconnect the connecting cable from the

machine.

If you inspect or service the machine with the

connecting cable connected, an unexpected

accident may occur.

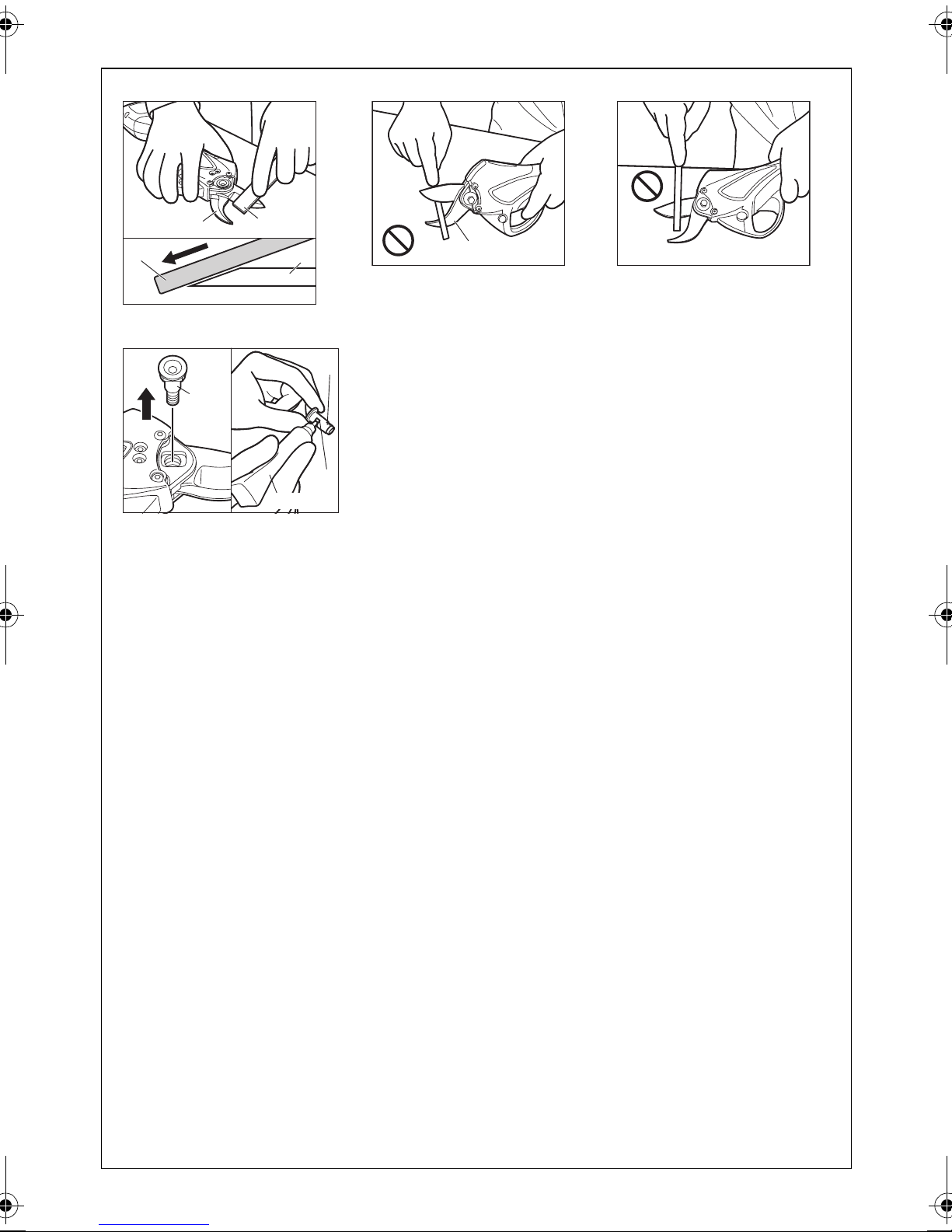

1 How to maintain blades

(Fig.BE) After working, remove dirt from both

sides of the blades using a hard brush and wipe

them with wet cloth for storage.

If the blades are not maintained, the friction of

the blades will increase and the usage time after

one charge is shortened.

The lives of the blades will also be shortened.

2 How to sharpen blades

(Fig.BF) How to sharpen upper blade

Match the flat side of the grindstone to the angle

of the blade edge, press it in the direction of the

arrow and sharpen the entire blade edge.

CAUTION

• (Fig.BG) Do not sharpen the lower

blade.

CAUTION

• (Fig.BH) Do not sharpen the reverse

side of the blade.

After carrying out the above process, connect

the machine to the control box and check its operation.

If the upper and lower blades are operating correctly, the replacement work is completed.

If the blades do not operate correctly, remove

and install them again according to the procedure in "HOW TO REPLACE BLADES" (P 23). If

the machine still does not operate correctly, return it to your dealer for inspection or repair.

3 How to apply grease

Apply grease to the shaft at the rate of once

a month or so.

(Fig.BI) Apply the grease evenly to the shaft

and grease sump.

For information about how to remove the

shaft, see "HOW TO REPLACE BLADES",

Step 1 and 2 (P 23).

24

Page 25

4 Cautions when not using the machine for

long periods

When not using the machine for long periods, remove the battery pack from the control box and charge it fully. Fit the pack cap

to the battery pack, and store the machine in

a dry location where it will not be affected by

high temperatures.

The battery pack will discharge even if it is

not used, although at a very slow rate. If the

battery is kept at a low charge level for a long

period, it will become unusable.

Even if you do not use the machine for a long

period, charge the battery once every six

months or so.

5 Never modify or carry out repair work on

this machine

If this machine is modified, it will not operate

optimally and may become a safety risk.

Therefore, do not modify it under any circumstances.

6 Periodic inspection of the machine

To maintain the machine's performance, carry out cleaning and inspection.

25

Page 26

8. HOW TO READ CONTROL BOX AND SHEAR LAMPS

[LAMP ON THE CONTROL BOX]

Normal state (Lamp is green)

Lamp alternately

Normal (Green)

State of lamp

: Lit up

: Blinking

: OFF

Contents of

display

Remedy

Battery charge

level is full

Use the machine.

If the battery charge level is low, the machine may not be

able to cut twigs.

Battery charge

level is medium

If an error or problem occurs (Lamp is red)

Battery charge

level is low

Battery needs to

be charged

Charge the battery.

blinks between red

and green

Maintenance period

Return the tool to your

dealer for repair.

State of lamp

: Lit up

: Blinking

: OFF

Contents of

display

Remedy

Error (Blinking red)

Battery pack

charge level is low

Stop using the

machine, charge

the battery, then

start the operation

again.

Motor temperature is high

Stop using the

machine, wait until the motor cools

down, then start

the operation

again.

Blades were locked

during cutting action

Release the trigger

and switch lever. If the

twig is still caught in

the blades, open the

blades, taking care

not to swing the machine laterally.

No power is supplied

to the machine

Turn off the power,

and turn it on again after confirming the connection of the

connecting cable terminals. If the display

does not disappear,

the machine has a

problem.

Circuit trouble

If the red lamp lights

up (remains on), turn

the power on again. If

the red lamp still lights

up after that, stop using the machine and

consult your dealer.

Problem

(Light up red)

26

Page 27

[LAMP ON THE SHEARS]

Normal state (Lamp is green)

Normal (Green)

State of lamp

: Lit up

: Blinking

: OFF

Contents of display Standby Battery needs to be charged

If the machine is not used for five min-

Remedy

utes, it is set in the standby mode.

When using again, hold down the

switch lever.

If an error or problem occurs (Lamp is red)

State of lamp

: Lit up

: Blinking

: OFF

Contents of display Error No power is supplied

Check the contents of the error with

Remedy

the control box.

Slow blinking Quick blinking

Charge the battery.

Error (Red) Lamp off

Check the power supply of the control

box and the connecting cable to ensure there is a secure connection and

no breakage.

Lamp alternately blinks between

red and green

Maintenance period

Return the tool to your dealer for repair.

• Maintenance period

The machine counts the number of times that the blades lock under strong load.

This count is used to notify users that it is time for maintenance.

Servicing may be needed even if maintenance is not indicated on the machine.

27

Page 28

9. SIMPLIFIED OPERATION CHART

Turn on the power switch.

The buzzer makes a "pip" sound.

The shears do not operate. (They

are in the standby mode.)

Depress the switch lever.

The buzzer makes a "pip" sound.

If you keep depressing (holding

down) the switch lever, the buzzer

makes a "peep" sound and the

blades open.

* If the trigger lock lever has been

applied with the trigger pulled, release the lock to open blades.

∗ LED indicates when the battery is

fully charged.

Shears LED

The green LED

starts slowly blinking.

Shears LED

The Green LED

stops blinking and

stays light.

Control box LED

The green LED

lights up.

Control box LED

The green LED

lights up.

Start the work again

Turn off the power

switch once.

Start the work again

Pull/release the trigger while depressing the switch lever.

The blades move according to the

operation of the trigger.

If the trigger is pulled, the blades

close. If the trigger is released, the

Shears LED

The green LED

lights up.

blades open.

Do not operate the trigger for five minutes.

The buzzer makes a "peep" sound.

Then, the blades do not move even

if the trigger is pulled.

(The machine is returned to the

standby mode.)

Shears LED

The green LED

starts slowly blinking.

Do not operate the trigger for 60 minutes.

The buzzer makes a "peep" sound.

Then, the blades do not move even

if the trigger is pulled. (The power is

turned off.)

Shears LED

The green LED

stops blinking slowly and turns OFF.

Control box LED

The green LED

lights up.

Control box LED

The green LED

lights up.

Control box LED

OFF

28

Loading...

Loading...