Max Megatron 1400HP, Megatron 2200, Megatron 1400, Megatron 2200HP, Megatron FAST Quick Install Manual

...Page 1

CONFORMS TO UL STD 325

UL CLASS - I, II, III, IV

CERTIFIED TO CAN/CSA STD

C22.2 NO. 247

Quick Install Guide for

Megatron

Swing Gate Operator

SAFETY SENSORS REQUIRED

High

Pr

ofile

1400HP

2200HP

2200HP PLUS

Residential / Commercial

Brushless DC

Swing Gate Operators

Made in USA

1400

2200

2200 PLUS

FAST

FAST PLUS

4009963

Version 10

www.max.us.com

Page 2

Table of Contents

Quick Install Guide

1. Operator Placement

2. Arm Position

3. Release Handle Clamp

4. AC Input Power

5. Ground Operator

6. Set Opening Direction and ID Plug

7. Limit Switch Adjustment

8. Entrapment Protection Wiring

9. Learn Gate Positions

10. Adjust ERD Reverse Sensor

11. Loops & Loop Detectors

12. Matrix 1 Settings

13. Wiring Opening Device Options

Dual Gate Operators Wiring

1

2

3

4

5

5

6

7-8

8

9

9

10

10

11

Troubleshooting

USB Black Box Port

Test Edge 1 Entrapment sensor

Gate Cycling Troubleshooting

Matrix 1 LED Troubleshooting

MC-200 LED Troubleshooting

BC-7 Module LED Troubleshooting

Commonly Used Safety Sensor Wiring

Megatron specifications

UL 325 Class of Operation - Class I, II, III, IV

Gate Type - Vehicular Swing Gate

Input AC Power/Amps - Switchable: 115VAC / 6 Amp, 1 phase

or 230VAC / 2 Amp, 1 phase

Motor - 24VDC Brushless (equivalent to 1 HP AC motor)

Operating Temperature: -4°F to 158°F (-20°C to 70°C)

Cycles per Hour AC Input Power - Continuous

Battery Back-Up Cycles (BC-7 Battery Module-7 Amp/Hr

Batteries fully charged): - Approximately 450 cycles

NOTE: The number of gate cycles using ONLY battery back-up power will vary depending on the

weight of the gate, the gate length, the operating condition of the gate hardware, temperature and

the amount of charge the batteries have at the beginning of the battery power only operation.

Max Gate Weight / Length:

- MAX Megatron 1400 and 1400HP - 1400lbs @ 15 ft or 1200 lbs @ 20 ft

- MAX Megatron 2200 and 2200HP - 2200lbs @ 15 ft or 1500 lbs @ 20 ft

- MAX Megatron 2200 PLUS and 2200HP PLUS - 2500lbs @ 15 ft or 1800 lbs @ 20 ft

- MAX Megatron FAST - 1200lbs @ 12 ft gate per operator

- MAX Megatron FAST PLUS - 1600lbs @ 12 ft gate per operator

NOTE: The MAX Megatron FAST and FAST PLUS are ONLY available for installation on bi-parting gates

(dual operators). A single gate operator CANNOT be used.

25.2”

High Profile

1400HP

2200HP

2200HP PLUS

26.6”

12

12

13

14-15

16

17

18-21

29.9”

24.5”

16.8”

90° Opening Time:

- MAX Megatron 1400/1400HP/2200/2200HP/2200 PLUS/2200HP PLUS - 16 selectable speeds

from approximately 11.5 sec to 20 sec depending on the weight and length of the gate.

- MAX Megatron FAST and FAST PLUS - 16 selectable speeds from approximately

6 sec to 14 sec depending on the weight and length of the dual gates.

Entrapment Protection:

- UL 325 Type A Inherent (ERD sensor)

- Inputs for NORMALLY CLOSED (N.C.) UL 325

Type B1 (photo cell) and Type B2 (sensing edge)

17”

2

1400

2200

2200 Plus

FAST

FAST PLUS

24.5”

18.3”

18.5”

UL 325 2016 Standard-Megatron Quick Install Rev 10

21.3”

Page 3

Quick Install Guide

for MAX Megatron

www.max.us.com

For detailed installation instructions and COMPLETE information about ALL the available options & features for

the MAX Megatron, please refer to the MAX Megatron Installation and Owners manual.

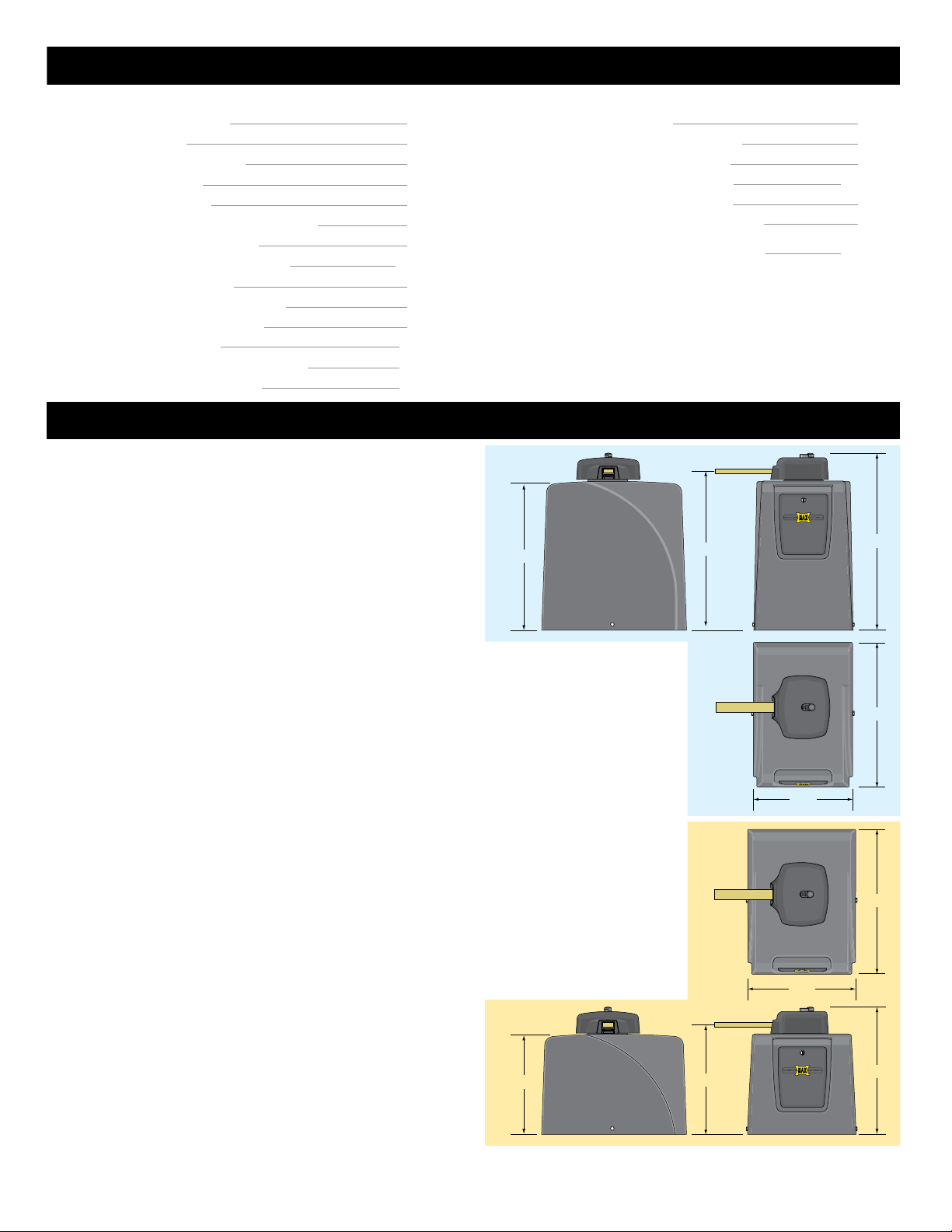

Operator Placement

1

Transmitter

CLOSING Photocell Beam can be 5” or less away from gate

CLOSED Gate

A

Long Arm

Calculations MUST be followed:

A should be at least 1/4 the gate length.

NOTE: Uphill or heavy gates - should be at least 1/3 the gate length.

B 15” minimum for open gate clearance (2” thick gate).

C distance “A” minus 17 inches (A - 17 = C).

Arm Restrictions

•

71” MAX length for arms.

• Long arm should be 90° from gate when OPEN.

• Arms should NOT be completely straight when CLOSED.

See

Arm Position on next page.

2

A

Secure gate operator

to concrete pad with

six (6) 1/2” x 3” (min)

Pivot

Point

Short Arm

1/2

sleeve anchors.

Receiver to MC-200 EDGE 1 Input

B

Concrete Pad

8”

LIMIT

LIMIT

CLOSED

OPEN

ERD

MC-200

JOG

Sensitivity

JOG

Motor Controller

Motor

GND

Cell

MATRIX

Photo

LEFT

RIGHT

Jog LT

Edge 1

Edge 2

ON-LINE

UL Entrap

Edge

OverLoad

Jog RT

5

4

1

3

POWER

MAX

2

ERD

12

16

LED ON

Edge

PhotoCell

Limit SW

13

15

14

POWER

POWER/SOLAR

IN

IN

TO MOTOR

CONTROLLER

BATTERY

BATTERY

BATTERY

MATRIX 1

PRIMARY

BACK-UP MODE

GATE

LEAVE

MAGLOCK

CLOSED

DELAY

OPEN

OPEN

PACK

IN

OPEN

LEAVE

MADE in USA

MAG

RIGHT

LEFT

1 TIME

OPEN

2Sec1.5Sec

OFF

LOCK

COM

NC

AUTOMATIC OPEN/CLOSE CONTROLS

Tamper NO

ANTI

GATE

SAFETYCENTEREXIT

TAILGATE

COM

TAMPER

GND

EXIT

OFFON

Tamper IN

CENTER

PHOTOCELL

UL

EDGE 1

SAFETY

MAX

MIN

OFF

ENTRAP

EDGE 2

CLOSE TIMER

ID PLUG

PARTIAL

MOTOR MOTION

ERROR

OPEN

ID

PLUG

UL ALARM 12V

ALARM RET

RESET

OPEN

STOPCLOSE

GND

POSITION

RECORDER

REVERSE SENSITIVITY

MAX

12VDC

GATE SPEED

MOTOR OVERLOAD

GND

OBD PORT

OPEN

BLACK BOX

GATE

MIN

NO LIMIT SWITCH /

COM

STATUS

CLAMP SLIPPING

24VDC

MAX

CLOSE

GND

LIMIT

BATTERY

SWITCH

ON-LINE

IN USE

MOTOR

ON-LINE

POWER

PRIMARY

SEC

GATE

GATE

24V

GND

PHOTOCELL

GND

STRIKE

GND

KEYPAD / RDR

GND

FIRE DEPT

GND

MAX OPEN

GND

RADIO SIG.

RADIO GND

OPEN

STOP

CLOSE

COM

GATE DISABLE

(+)

GND

(-)

(+)

GND

(-)

www.max.us.com

Made in USA

14”

8”

12” 6”6”

24”

C

Pivot

Point

30”

Concrete Pad

10”

30”

8.5”

Area

5.5”5.5”

Conduit

12”

12”

24”

UL 325 2016 Standard

ONE Entrapment protection sensor

MUST installed or operator will NOT

function. It MUST be MONITORED

and NORMALLY CLOSED (N.C.).

Beam Height:

21” Normal

27.5” Max.

Models: 1400/2200/FAST = 25”

Models: 1400HP/2200HP = 33.5”

Ground Level

Check local building codes in

your area for depth of concrete

(2 ft typical).

Models: 1400/2200/FAST = 19”

Models: 1400HP/2200HP = 27.5”

1

BATTERY

MATRIX 1

PRIMARY

BACK-UP MODE

GATE

LEAVE

MAGLOCK

CLOSED

DELAY

OPEN

OPEN

LEAVE

OPEN

MADE in USA

MAG

RIGHT

LEFT

OPEN

Photocell

PWR 24V -

ID

PLUG

12VDC

GND

24VDC

GND

EXIT

CENTER

SAFETY

GND -

RADIO SIG.

AUTOMATIC OPEN/CLOSE CONTROLS

ANTI

TAILGATE

BOARD

OFFON

MATRIX

RS-485 (+) -

RS-485 (-) -

MIN

OFF

CLOSE TIMER

POSITION

RECORDER

BLACK BOX

FIRE DEPT

GND

RADIO GND

1 TIME

OFF

2Sec1.5Sec

LOCK

COM

NC

Tamper NO

GATE

SAFETYCENTEREXIT

COM

TAMPER

GND

Tamper IN

PHOTOCELL

UL

EDGE 1

MAX

ENTRAP

EDGE 2

ID PLUG

PARTIAL

MOTOR MOTION

ERROR

OPEN

INPUTS

PACK

SWITCH

Power In

MOTOR

MOTOR

BATTERY

LIMIT

ALARM

UL ALARM 12V

ALARM RET

RESET

OPEN

STOP CLOSE

GND

REVERSE SENSITIVITY

MAX

GATE SPEED

MOTOR OVERLOAD

OBD PORT

OPEN

GATE

MIN

NO LIMIT SWITCH /

COM

STATUS

CLAMP SLIPPING

MAX

CLOSE

LIMIT

BATTERY

SWITCH

ON-LINE

IN USE

MOTOR

ON-LINE

POWER

PRIMARY

SEC

GATE

GATE

24V

GND

PHOTOCELL

GND

STRIKE

GND

KEYPAD / RDR

GND

MAX OPEN

GND

OPEN

STOP

CLOSE

COM

GATE DISABLE

(+)

GND

(-)

(+)

GND

(-)

MAX BC-7

Battery Voltage

Battery Module

EF1/2

ON/OFF

Replace

TEST

Battery IN

Battery

Battery

Battery

Error

6” Above

Ground

Conduit

UL 325 2016 Standard-Megatron Quick Install Rev 10

Page 4

2

arm position

Install arms using these guidlines:

Arm in OPEN Position Arm in CLOSE Position

Gate Closed

Long Arm

Arm in Closed

Position

Short Arm

ERD

Sensitivity

Motor

OverLoad

5

4

3

MAX

ERD

12

16

LED ON

13

15

14

POWER/SOLAR

IN

BATTERY

BATTERY

MATRIX 1

BACK-UP MODE

LEAVE

CLOSED

IN

LEAVE

MADE in USA

OPEN

AUTOMATIC OPEN/CLOSE CONTROLS

ANTI

TAILGATE

EXIT

OFFON

CENTER

SAFETY

MAX

MIN

OFF

CLOSE TIMER

PARTIAL

OPEN

ID

PLUG

POSITION

RECORDER

12VDC

GND

OBD PORT

BLACK BOX

24VDC

GND

STRIKE

FIRE DEPT

GND

MAX OPEN

GND

RADIO SIG.

RADIO GND

www.max.us.com

Gate Open

Ideal long arm position

is 90° from open gate.

JOG

JOG

LEFT

RIGHT

OPEN

1 TIME

MAX

GATE SPEED

MIN

MAX

PHOTOCELL

GND

KEYPAD / RDR

GND

LIMIT

LIMIT

CLOSED

OPEN

GND

Jog LT

Edge 1

Edge 2

Jog RT

TO MOTOR

CONTROLLER

PRIMARY

GATE

OPEN

OPEN

RIGHT

LEFT

OFF

SAFETYCENTEREXIT

MOTOR MOTION

OPEN

STOPCLOSE

REVERSE SENSITIVITY

MOTOR OVERLOAD

NO LIMIT SWITCH /

CLAMP SLIPPING

LIMIT

SWITCH

ON-LINE

MOTOR

ON-LINE

PRIMARY

SEC

GATE

GATE

GND

(+)

GND

(-)

(+)

GND

(-)

Made in USA

MC-200

Motor Controller

Cell

MATRIX

Photo

ON-LINE

Edge

UL Entrap

1

POWER

2

PhotoCellEdge

Limit SW

POWER

IN

BATTERY

MAGLOCK

DELAY

PACK

MAG

2Sec1.5Sec

LOCK

COM

NC

Tamper NO

GATE

COM

TAMPER

GND

Tamper IN

PHOTOCELL

UL

EDGE 1

ENTRAP

EDGE 2

ID PLUG

ERROR

UL ALARM 12V

ALARM RET

RESET

GND

OPEN

GATE

COM

STATUS

CLOSE

BATTERY

IN USE

POWER

24V

GND

OPEN

STOP

CLOSE

COM

GATE DISABLE

Long Arm

Positive Stop

on Long Arm

1/4” gap

IMPORTANT: DO NOT allow positive

stop on long arm to touch short arm in

closed position. Leave about a 1/4” gap.

Shor

t Arm

LIMIT

LIMIT

CLOSED

OPEN

MC-200

ERD

JOG

Sensitivity

JOG

GND

Motor Controller

Cell

Motor

MATRIX

Photo

Jog LT

Edge 1

LEFT

Edge 2

RIGHT

Jog RT

ON-LINE

Edge

UL Entrap

OverLoad

5

4

1

3

POWER

MAX

2

ERD

12

16

LED ON

PhotoCellEdge

Limit SW

13

15

14

POWER

POWER/SOLAR

IN

IN

TO MOTOR

CONTROLLER

BATTERY

BATTERY

BATTERY

PRIMARY

MATRIX 1

BACK-UP MODE

GATE

LEAVE

MAGLOCK

CLOSED

DELAY

OPEN

OPEN

PACK

IN

LEAVE

OPEN

MADE in USA

MAG

RIGHT

LEFT

OPEN

1 TIME

OFF

2Sec1.5Sec

LOCK

COM

NC

AUTOMATIC OPEN/CLOSE CONTROLS

Tamper NO

ANTI

GATE

SAFETYCENTEREXIT

TAILGATE

COM

TAMPER

GND

EXIT

OFFON

Tamper IN

CENTER

PHOTOCELL

UL

EDGE 1

SAFETY

MAX

MIN

OFF

ENTRAP

EDGE 2

CLOSE TIMER

ID PLUG

PARTIAL

MOTOR MOTION

ERROR

OPEN

ID

PLUG

UL ALARM 12V

ALARM RET

RESET

OPEN

STOPCLOSE

POSITION

GND

RECORDER

REVERSE SENSITIVITY

MAX

12VDC

GATE SPEED

MOTOR OVERLOAD

GND

OBD PORT

OPEN

BLACK BOX

GATE

MIN

NO LIMIT SWITCH /

COM

STATUS

24VDC

CLAMP SLIPPING

MAX

CLOSE

GND

LIMIT

BATTERY

SWITCH

ON-LINE

IN USE

MOTOR

POWER

ON-LINE

PRIMARY

SEC

GATE

GATE

24V

GND

PHOTOCELL

GND

STRIKE

GND

KEYPAD / RDR

GND

FIRE DEPT

GND

MAX OPEN

GND

RADIO SIG.

RADIO GND

OPEN

STOP

CLOSE

COM

GATE DISABLE

(+)

GND

(-)

(+)

GND

(-)

www.max.us.com

Made in USA

NO

Wall

Gate Open

Opening

in Wall

NEVER install the arm so arm protrudes

through an opening in the open position.

Re-Attach Arm to Operator:

Limit pin MUST fit into slot in

bottom of release handle clamp

directly under the arm when

re-attaching arm to operator.

Release Handle Clamp

Arm

Slot

Gate Bracket Assembly

DO NOT over tighten bolt

Arm MUST be level.

Arm Elbow Assembly

L

ong Arm

DO NOT over tighten bolt

BATTERY

MATRIX 1

BACK-UP MODE

LEAVE

CLOSED

LEAVE

OPEN

MADE in USA

OPEN

1 TIME

AUTOMATIC OPEN/CLOSE CONTROLS

ANTI

TAILGATE

BOARD

EXIT

OFFON

MATRIX

CENTER

RS-485 (+) -

RS-485 (-) -

PWR 24V -

SAFETY

MIN

MAX

OFF

GND -

CLOSE TIMER

PARTIAL

OPEN

ID

PLUG

ALARM

POSITION

RECORDER

12VDC

GND

OBD PORT

BLACK BOX

24VDC

GND

STRIKE

GND

KEYPAD / RDR

GND

FIRE DEPT

GND

MAX OPEN

GND

RADIO SIG.

RADIO GND

Battery Voltage

EF1/2

Positive

PRIMARY

GATE

OPEN

OPEN

RIGHT

LEFT

MOTOR MOTION

PACK

SWITCH

BATTERY

LIMIT

OPEN

MAX

GATE SPEED

MIN

MAX

LIMIT

SWITCH

ON-LINE

MOTOR

ON-LINE

PRIMARY

GATE

PHOTOCELL

GND

(+)

GND

(-)

ON/OFF

Battery

Stop

MAGLOCK

DELAY

MAG

OFF

2Sec1.5Sec

LOCK

COM

NC

Tamper NO

GATE

SAFETYCENTEREXIT

COM

TAMPER

GND

Tamper IN

PHOTOCELL

UL

EDGE 1

ENTRAP

EDGE 2

ID PLUG

ERROR

INPUTS

Power In

MOTOR

MOTOR

UL ALARM 12V

ALARM RET

RESET

STOP CLOSE

GND

REVERSE SENSITIVITY

MOTOR OVERLOAD

OPEN

GATE

NO LIMIT SWITCH /

COM

STATUS

CLAMP SLIPPING

CLOSE

BATTERY

IN USE

POWER

SEC

GATE

24V

GND

OPEN

STOP

CLOSE

COM

GATE DISABLE

(+)

GND

(-)

MAX BC-7

Battery Module

Replace

TEST

Battery IN

Battery

Battery

Error

Short Arm

Limit Pin

Limit Rings

When satisified with gate open and closed positions, weld completely

around arm tubing and gate bracket.

UL 325 2016 Standard-Megatron Quick Install Rev 10

2

Page 5

release handle clamp

YES

3

Adjustment:

IMPORTANT: Tighten the adjustment bolt until

NO SLIPPAGE occurs when handle is in the

IMPORTANT: Handle MUST be

HORIZONTAL when FIRMLY in

secure position.

SECURE HORIZONTAL position.

factory set bolt

DO NOT adjust

YES

Adjustment

Bolt

Handle in release position

olt

b

djust

a

or firm grip

f

NO

Pull

Test for Arm Slippage: When Release Handle Clamp is

in the SECURE HORIZONTAL position, Pull the end of

gate. NO slippage should occur. If it does, re-adjust bolt.

Re-Attach Arm to Operator:

Limit pin MUST fit into slot in

bottom of release handle clamp

directly under the arm when

re-attaching arm to operator.

Release Handle Clamp

Arm

Slot

LIMIT

LIMIT

CLOSED

OPEN

MC-200

ERD

JOG

Sensitivity

JOG

GND

Motor Controller

Cell

Motor

MATRIX

Photo

Jog LT

Edge 1

LEFT

Edge 2

RIGHT

Jog RT

ON-LINE

Edge

UL Entrap

OverLoad

5

4

1

3

POWER

MAX

2

ERD

12

16

LED ON

PhotoCellEdge

Limit SW

13

15

14

POWER

POWER/SOLAR

IN

IN

TO MOTOR

CONTROLLER

BATTERY

BATTERY

BATTERY

MATRIX 1

PRIMARY

BACK-UP MODE

GATE

LEAVE

MAGLOCK

CLOSED

DELAY

OPEN

OPEN

PACK

IN

OPEN

LEAVE

MADE in USA

MAG

RIGHT

LEFT

1 TIME

OPEN

2Sec1.5Sec

OFF

LOCK

COM

NC

AUTOMATIC OPEN/CLOSE CONTROLS

Tamper NO

ANTI

GATE

SAFETYCENTEREXIT

TAILGATE

COM

TAMPER

GND

EXIT

OFFON

Tamper IN

CENTER

PHOTOCELL

UL

EDGE 1

SAFETY

MAX

MIN

OFF

ENTRAP

EDGE 2

CLOSE TIMER

ID PLUG

PARTIAL

MOTOR MOTION

ERROR

OPEN

ID

PLUG

UL ALARM 12V

ALARM RET

RESET

OPEN

STOPCLOSE

POSITION

GND

RECORDER

REVERSE SENSITIVITY

MAX

12VDC

GATE SPEED

MOTOR OVERLOAD

GND

OBD PORT

OPEN

BLACK BOX

GATE

MIN

NO LIMIT SWITCH /

COM

STATUS

24VDC

CLAMP SLIPPING

MAX

CLOSE

GND

LIMIT

BATTERY

SWITCH

ON-LINE

IN USE

MOTOR

POWER

ON-LINE

PRIMARY

SEC

GATE

GATE

24V

GND

PHOTOCELL

GND

STRIKE

GND

KEYPAD / RDR

GND

FIRE DEPT

GND

MAX OPEN

GND

RADIO SIG.

RADIO GND

OPEN

STOP

CLOSE

COM

GATE DISABLE

(+)

GND

(-)

(+)

GND

(-)

www.max.us.com

Made in USA

IMPORTANT: The arm MUST NOT slip when

the gate is cycling or the gate OPEN and

CLOSE limit positions will NOT be LEARNED.

Gate speed will remain slow if gate positions

are NOT learned.

Limit Pin

Limit Rings

3

NOTE: Limit rings that have been previously

set will automatically re-align the gate’s open

and close position after release handle clamp

has been re-attached and secured.

No re-adjustment is necessary.

UL 325 2016 Standard-Megatron Quick Install Rev 10

Page 6

W

ARNIN

G

HI

GH

VO

LT

A

GE

4

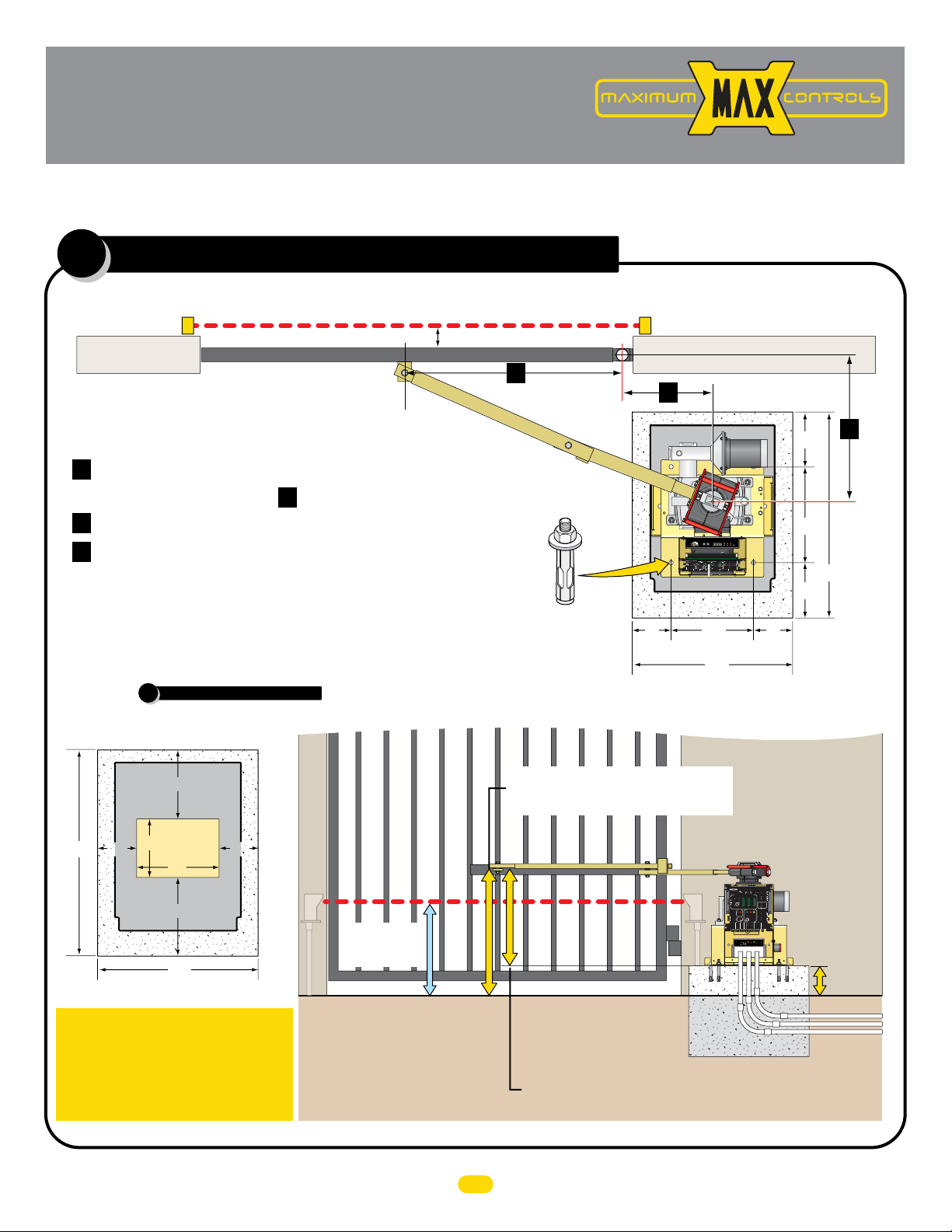

ac input power

Wire input AC power wire to the MAX Megatron Toroid box.

Choose either 115V or 230V setting on input AC power

selector switch.

CAUTION: If power selector

switch is set for 115V but

input power is actually 230 V,

7 Amp Fuse will blow.

CAUTION: Make sure circuit

breaker is OFF from incoming

AC input wire BEFORE wiring!

Input AC Power Options

Single Phase 115VAC Only

115VAC

Set to 115V

Single Phase 230VAC Only

115V

115 OR 230VAC

Power Wire

230VAC

DANGER

HIGH VOLTAGE!

Line (Black)

Neutral (White)

Chassis (Green)

Power Terminal

Input AC Power

Selector Switch

Line (Black)

Neutral (White)

Chassis (Green)

230V

Back of MAX

MAX

Toroid Box

7 Am

FU

io

ct

te

o

r

p

e

d

th

e

h

u

t

i

n

i

t

n

y w

.

l

co

n

o

use

or

f

F

f

:

o

ace

as

G

g

pl

n

e

N

i

e le

I

r

,

ne p

at

N

r

ntr

e

R

r

i

ble

co

A

si

n

and

st f

W

pour

o

fu

n

i

i

e

T:

ct

N

yp

es

ga

un

e

t

t

E

a

r

e

iqu

se

m

i

st

pro

l

i

i

r

a

SEM

l

sa

ut

é

IS

,

ct

re

T

e

t

i

a

r

R

d

n

met

ca

VE

t

o

ce

r

A

e

p

in

’

e

d

m

co

es

u

sq

i

r

êmes typ

m

les.

e

d

na

i

om

n

p

SE

ax

m

n

A

O

3

C

WER

VA

PO

5

1

1

ff

O

7 Amp Fuse

n

s

AC

IN

115

S

elec

Vo

t

Input

ltage

11

5V

A

230VA

C

or

C

MAX

Mega

t

ro

n To

r

o

id

Toroid Box

www

.

Max.US.c

o

m

AC Power

Gang Box

Power

Terminal

WARNING

!

HIGH

t

ec

VOLTAGE

sconn

before

di

power

icing unit

v

ser

Set to 230V

230V

Turn Power ON

n

o

i

t

ec

MAX

Toroid Box

st fire

WARNING

n

agai

same type and

rome

AVERT

mp

co

es d

u

q

me

ris

mê

de

na

mi

no

7 Amp

SE

FU

n

O

WER

PO

Off

urn Power ON

LEDs should light up on operator.

Battery power automatically turns ON.

T

F

:

, re

ISSEMENT:

ttre

ce

’in

s ty

les.

115VA

ntinu

r co

o

place only wit

rating

ro

p

la

, u

ie

nd

t ca

e

pe

C 3A ma

e

prot

d

th

e

h

s

of fuse.

pa

ntre les

r ne

u

ble

co

si

n

po

fu

s

ctio

e

te

r un

e

tilis

ristiqu

é

ct

ra

OPERATOR!

x

IMPORTANT: Make sure there are NO exposed bare

wires at the power terminal connection.

Turn ALL Power OFF

DO NOT

CYCLE

1 Turn OFF POWER Switch on MAX Toroid Box.

Battery power will remain ON.

2 WAIT for 15 seconds.

3 Press and HOLD (approx. 5 seconds) the

RED ON/OFF BATTERY button until MAX BC-7

LEDs turn ON, then release button. LEDs will

turn OFF. (Up to 30 sec.)

IMPORTANT: This procedure must

be followed whenever ALL power

must be turned OFF on operator.

OverLo

M

ot

or

ad

ER

S

E

e

RD

n

D

s

i

t

i

v

i

t

y

5

1

2

4

1

3

3

1

4

15

16

JOG

MA

LE

LE

F

X

D

T

O

N

J

O

R

I

G

G

HT

LT

MA

T

R

IX

1

M

AD

E

in

US

A

AU

TO

MATIC

A

N

E

XI

TA

TI

T

I

LG

AT

ON

OF

C

E

N

T

E

R

SA

F

E

T

Y

M

I

N

O

M

F

A

F

C

X

LOS

E

TI

I

D

M

ER

P

LUG

PA

RT

I

O

PE

N

1

2

VD

C

GN

D

PO

S

ITI

R

ECO

2

ON

4

VD

RD

C

G

ER

N

D

O

BD

BLACK

PO

R

T

BO

X

G.

T

O GND

RADIO SI

DEP

RADI

OPEN

IRE

F

AX

GND

M

AD / RDR

RIKE

GND

ST

YP

GND

KE

B

a

t

t

er

y

Vo

E

l

t

a

g

1

e

/

2

F

3

T

og

R

J

og

ND

1

J

G

2

ge

o

Ed

dge

E

ll

Phot

e

C

M

A

O

T

N

R

-

I

L

B

A

B

T

A

TE

C

K

U

P

L

L

E

E

A

A

V

CL

VE

E

O

O

P

SE

E

N

D

O

PEN

E

EXIT

F

PWR 24V -

AL

M

A

X

G

A

M

I

N

M

A

X

L

L

CE

O

PR

GND

PHOT

GA

GND

+)

(

O

N

/

O

FF

B

a

t

R

t

e

e

r

y

p

l

a

B

a

t

t

e

X

I

N

E

E

L

R

M

OP

1

X

GND -

T

E

I

M

T

D

N

G

c

e

r

y

d

i

m

g

1

e

i

Y

t

S

W

M

U

2

L

ot

E

n

O

D

E

P

E

N

T

I

M

E

OP

E

N

L

E

FT

/

CLO

RD

A

SE CONT

O

B

ATRI

M

RS-485 (-) -

RS-485 (+) -

TER

MO

T

O

R

M

O

P

EN

S

TOP

RE

S

P

V

E

E

RS

ED

E

M

O

T

OR

NO

LI

M

CL

I

AM

P SL

LI

M

SW

I

T

I

T

O

CH

N

L

I

N

E

M

OT

O

O

N

R

L

I

NE

ARY

E

SE

C

)

GA

-

T

(

E

)

D

+

(

N

G

)

(

MA

B

X

a

tt

e

r

y

M

T

E

S

T

B

a

t

t

B

e

a

r

y

tt

e

r

y

E

r

r

o

r

M

t

or

E

r

ap

d

g

C-20

e

C

on

P

P

h

o

t

t

O

o

r

C

ol

0

W

e

l

l

l

R

I

M

A

RY

G

A

T

E

O

P

E

R

N

I

G

HT

ROLS

S

A

M

O

TI

O

N

C

LO

S

E

SE

NS

I

T

I

VI

T

Y

OV

E

RL

O

AD

T

SWIT

CH

I

PP

/

I

NG

N

OP

OPE

OSE

ST

CL

BC

-7

o

d

u

le

I

N

er

ER

M

A

G

LO

D

C

ELA

K

OF

F

Y

1

.

5

Se

c

2

S

e

c

MAG

LO

C

K

FETYCEN

C

O

M

N

C

G

A

TE

R

A

TA

L

A

M

T

H

P

a

C

T

m

E

I

W

R

per

S

T

I

M

I

L

K

N

C

A

O

P

Y

R

E

C

T

T

O

A

B

M

S

T

U

G

P

T

N

ND

I

R

a

O

m

T

O

pe

M

r

IN

In

r

e

ow

P

P

H

U

OT

L

OC

E

LL

R

EN

TO

T

O

R

EDGE

AP

M

1

ED

G

E

2

ID

P

LU

G

ER

R

O

R

U

L

A

L

A

RM

A

LA

12

R

V

M

R

E

R

T

ES

ET

G

ND

G

ATE

S

TA

T

US

O

P

EN

C

O

M

C

LOSE

LE

B

AT

TE

R

Y

I

N

U

S

DISAB

E

E

T

P

O

COM

WER

GA

V

4

2

GND

n

o

i

t

c

e

t

o

r

p

d

the

e

h

t

i

inu

t

w

n

y

.

o

l

e

c

s

r

on

u

o

f

e

F

f

c

:

o

s

a

l

as

e

G

l

g

p

n

ep

N

e

r

e

ti

r

t

,

n

a

NI

n

e

e

R

r

o

i

ur

d r

bl

c

A

i

f

o

t

s

n

p

an

s

W

u

f

:

io

in

e

t

T

s

p

n

c

N

y

ga

u

e

t

t

E

ue

a

e

q

er

i

M

t

s

m

i

E

s

pro

i

il

a

r

a

S

l

s

é

S

ut

t

I

e

,

r

T

e

t

i

ac

t

r

R

d

e

a

E

c

m

en

V

t

o

c

r

A

e

n

p

i

’

e

d

m

p

o

y

s

t

c

e

u

es

q

s

m

i

r

.

s

mê

e

ale

d

n

i

m

o

n

mp

A

7

E

S

U

F

n

O

R

3A max

E

OW

P

5VAC

11

f

f

O

1

UL 325 2016 Standard-Megatron Quick Install Rev 10

4

Page 7

L

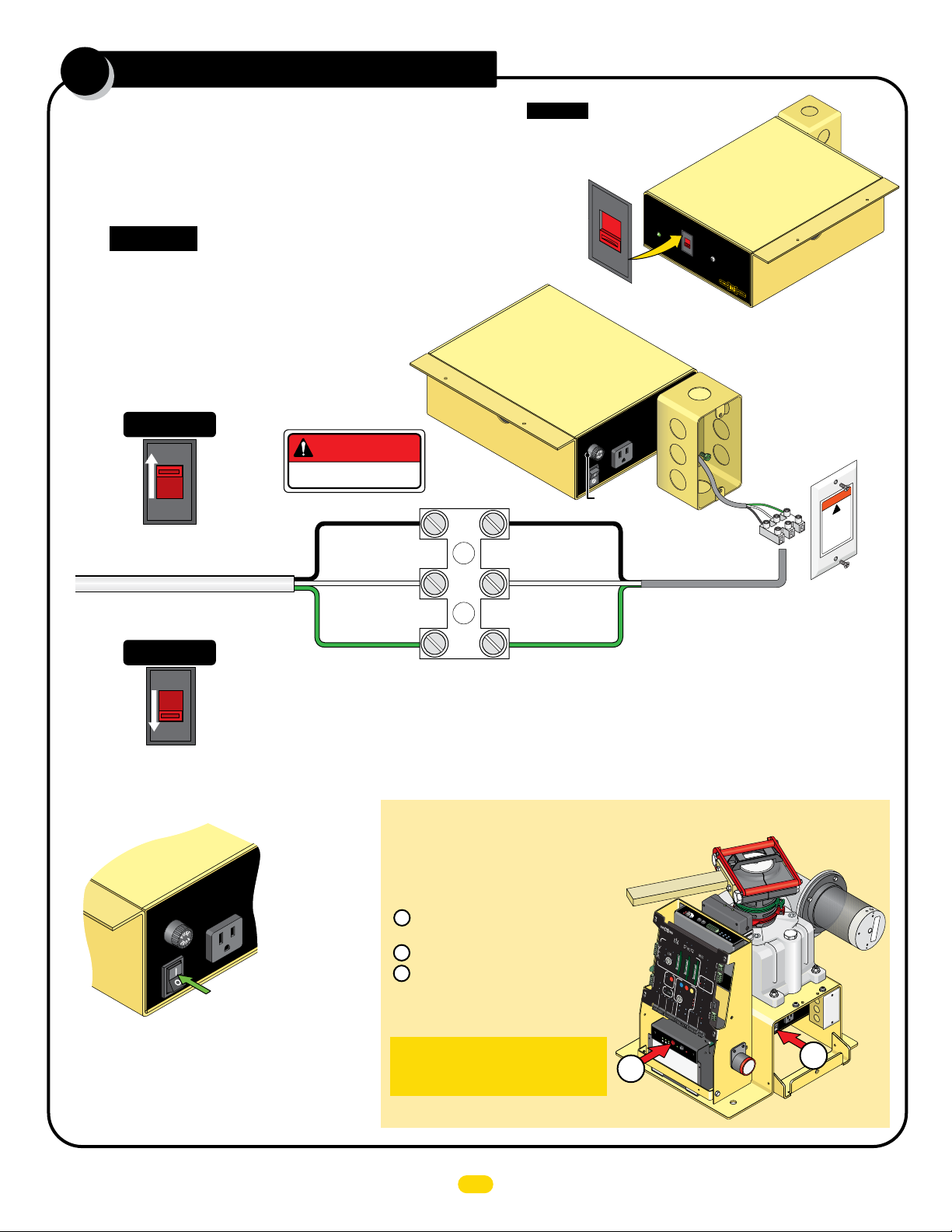

ground operator

WARNING

5

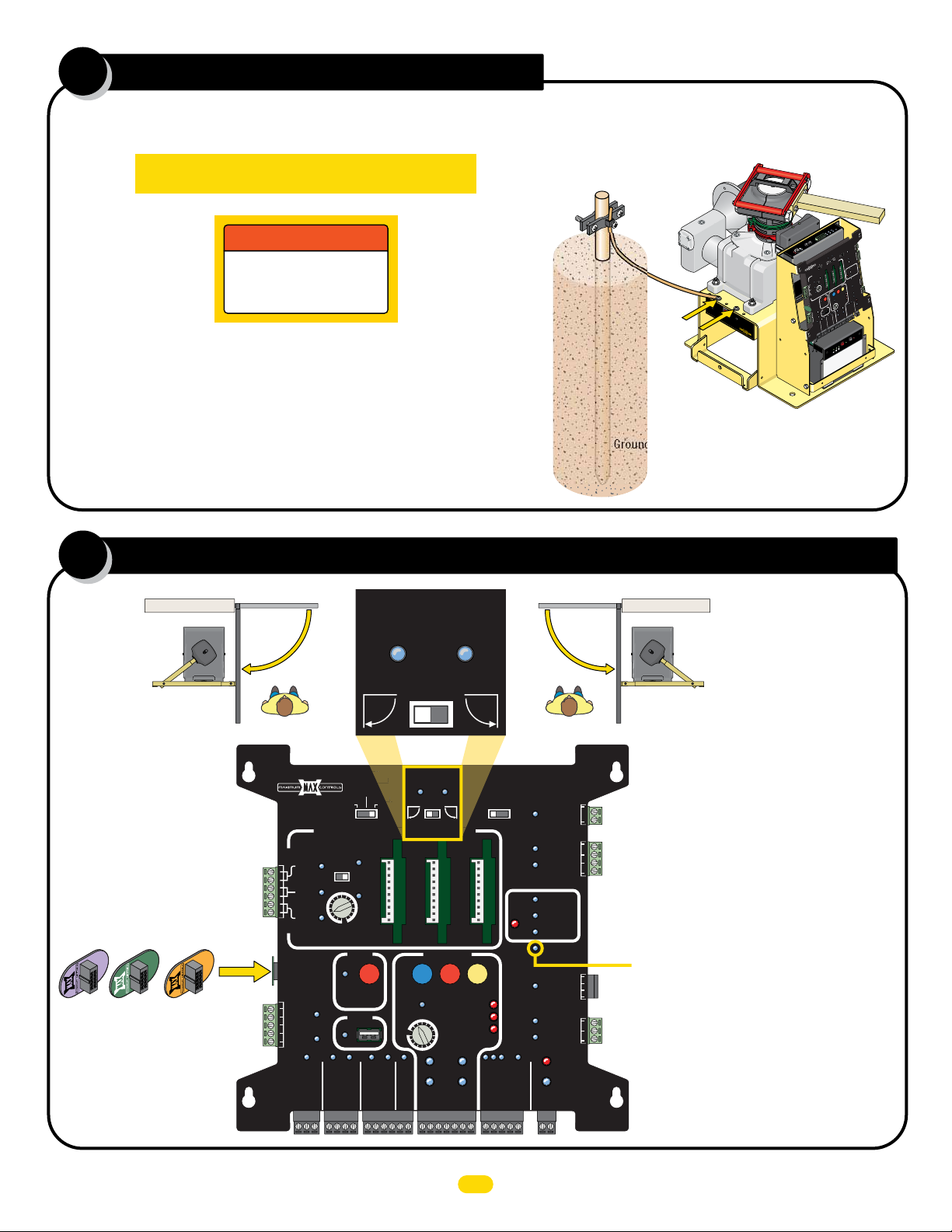

Operator MUST be Properly GROUNDED

IMPORTANT: Operator MUST be grounded in lightning

prone areas or warranty will be VOIDED!

WARNING

connect chassis

to ground rod for

lightning protection

Proper grounding of this gate operator is a requirement for LIGHTNING

PROTECTION in lightning prone areas. To be effective, ground connections

should be made with a minimum 12 AWG, 600 volt insulated wire to a

ground point within 3 feet of the gate operator. The ground point must be

at an electrical panel, a metallic cold water pipe that runs in the earth, or

a grounding rod.

NOTE: Consult city codes for AC line wiring.

Beware of existing underground services.

Ground

within 3 ft

of operator.

ssis

a

Ch

Ground

Grounding Rod

0

0

oller

r

nt

MC-2

Co

r

to

p

WER

o

a

tr

O

M

n

P

E

L

U

e

ll

g

e

d

C

E

X

to

o

E

RI

h

T

N

I

l

P

1

A

L

-

M

el

e

o

g

N

t

C

d

2

O

o

2

E

h

e

P

1

g

W

S

d

t

i

D

E

dge

im

N

L

E

T

G

R

T

g

L

o

J

og

J

G

T

JO

RIGH

G

T

O

F

J

E

L

D

ity

v

N

R

AX

ti

i

O

E

s

M

D

E

4

en

3

5

L

S

6

1

r

d

5

1

to

o

4

oa

1

L

3

M

r

2

1

1

ve

O

D

ER

B

O

A

RD

MA

TR

IX

RS-485 (+) -

RS-485 (-) -

PWR 24V -

AC

I

5

N

11

S

el

ec

V

t

ol

I

nput

t

a

115

ge

VA

230V

C

or

A

C

M

A

X

M

e

g

at

r

on

Tor

w

w

o

w

id

.M

ax

.U

S.c

o

m

GND -

M

O

G

C

A

M

C

CK

K

N

O

C

L

G

LO

A

AY

c

M

L

Se

2

Y

DE

R

c

e

A

5S

.

IM

1

F

PR

TE

F

O

O

A

N

G

r

e

p

N

M

m

E

a

O

P

T

C

T

O

H

G

I

D

R

Y

N

GN

E

ER

P

DE

T

O

N

T

O

I

T

F

E

r

A

M

L

e

B

p

m

-UP

GATE

Ta

LS

R

CK

VE

N

E

A

A

O

E

P

D

PE

B

L

E

O

M

SE

M

I

A

TR

T

T

CLO

1

N

IX 1

O

R

Y

L

T

AT

M

L

VE

E C

A

FE

E

A

S

L

N

OCE

S

T

PE

O

O

LO

H

P

1

SA

N/C

U

MO

n

i

GE

E

ER

D

T

ED

A

TO

N

M

CE

C OPE

R

TI

GE 2

D

MA

E

T

Power In

UL

EXI

UTO

G

U

A

PL

TI

AP

R

E

ID

OR

AN

NT

T

I

E

R

N

A

PUTS

G

ER

L

M

AI

O

T

TO

F

F

R

O

PA

V

CK

2

N

BA

1

O

T

S

M

T

T

WI

E

E

R

R

T

A

R

Y

C

L

H

M

A

L

I

T

XI

E

AL

AR

M

CE

I

L

P

ET

MI

R

L

S

A

T

U

RE

AL

D

N

G

N

O

I

T

MO

R

E

NT

E

F

SA

D

G

U

12

G

N

E

MOTOR

P

O

X

MA

M

O

E

C

S

N

F

I

O

M

OF

L

SE

C

Y

O

T

ER

L

C

Y

T

P

TIM

VI

I

TE

T

E

L

A

SI

A

S

STO

G

I

N

S

O

T

L

SE

R

A

TU

C

E

AD

N

S

P

O

E

R

ERY

N

L

P

E

T

E

STA

R

O

P

E

VE

REV

AT

O

O

S

B

R

U

/

O

T

N

I

O

CH

T

M

I

NG

I

SW

T

I

IPP

D

M

SL

X

ER

EE

LI

P

A

O

P

W

N

M

S

AM

CL

PO

N

ATE

O

G

I

LE

SIT

ER

B

O

P

RD

A

O

D

C

MIN

S

E

I

R

N

V

D

T

RT

I

X

G

O

M

MA

P

I

H

X

L

24

C

O

D

T

B

B

I

E

E

O

W

K

N

I

S

C

L

ATE

M

A

S

L

B

ON-

G

O

C

LO

N

OR

C

E

C

TOP

E

OT

VD

N

M

I

P

S

C

L

E

-

S

O

E

ON

T

D

A

N

G

)

D

(

N

R

G

LL

MARY

I

+)

E

(

D

C

PR

E

T

A

VD

G

4

)

R

C

D

2

(

/

N

)

D

G

D

TO

N

+

G

D

(

N

O

A

G

D

H

P

E

P

N

Y

K

EN

D

E

G

P

N

K

T

O

TRI

G

P

D

D

E

S

N

X

N

.

A

G

D

G

G

I

E D

N

M

O

S

I

R

G

I

D

F

O

I

A

D

R

A

R

7

BC-

odule

M

y

r

MAX

atte

B

N

I

ry

e

t

Bat

rror

E

T

S

E

T

ry

e

ge

t

t

e

lta

c

Ba

a

pl

Vo

y

Re

F

r

e

t

ery

t

F

t

B

t

F

Ba

a

O

A

/

/2

B

N

1

T

O

ry

T

e

t

ER

t

E

Ba

Y

I

N

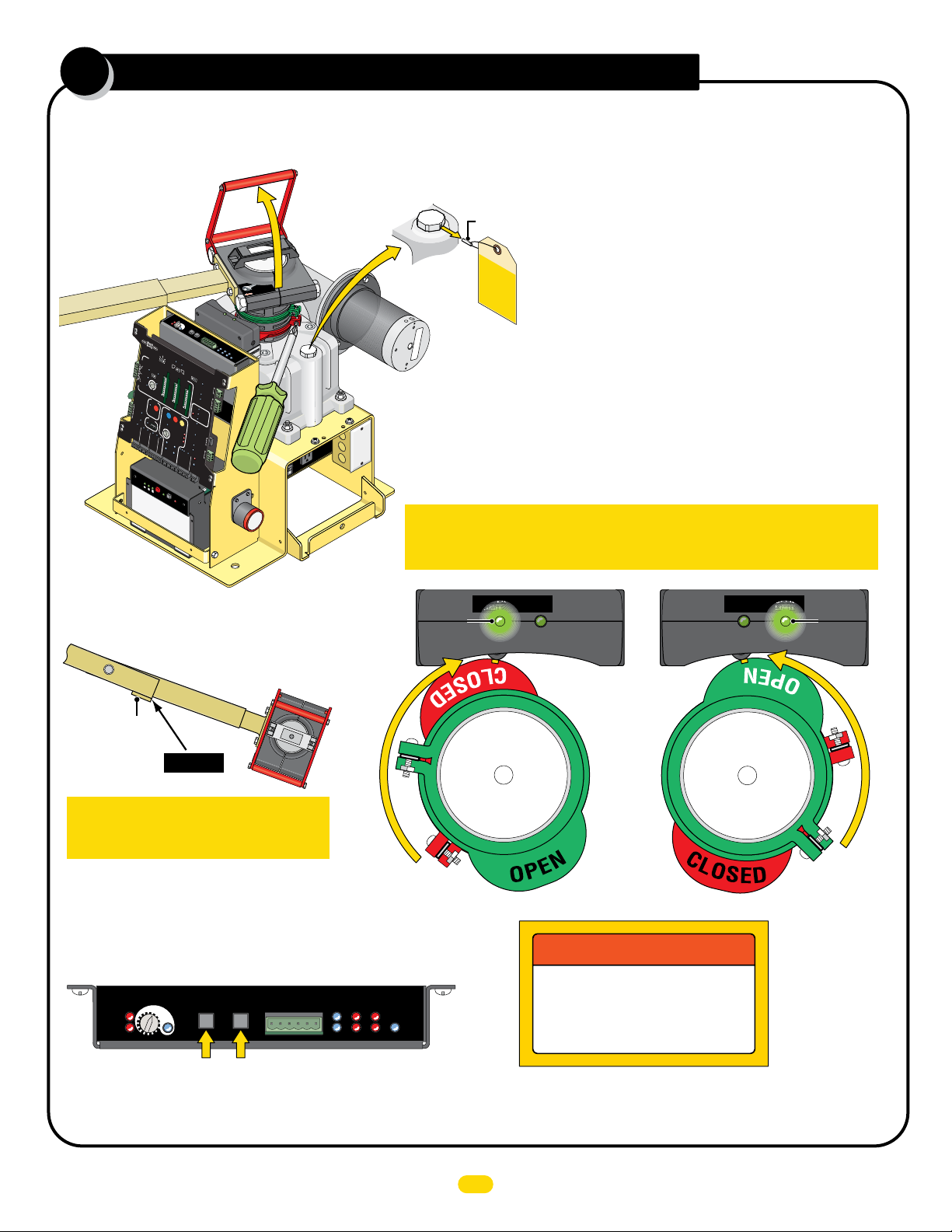

set opening direction and id plug

6

OPEN LEFT OPEN RIGHT

ID plug MUST be plugged in.

1400

1400HP

1400

MAX

MEGATRON

2200

2200HP

2200

AX

M

MEGATRON

FAST

N

ATRO

MAX

MEG

PRIMARY

GATE

PRIMARY

OPEN

LEFT

OPEN

GATE SPEED

PRIMARY

PHOTOCELL

GND

OPEN

RIGHT

GATE

OPEN

RIGHT

MOTOR MOTION

STOP CLOSE

REVERSE SENSITIVITY

MOTOR OVERLOAD

NO LIMIT SWITCH /

LIMIT

SWITCH

ON-LINE

MOTOR

ON-LINE

GATE

(+)

GND

(-)

SAFETYCENTEREXIT

CLAMP SLIPPING

SEC

GATE

(+)

GND

(-)

MAGLOCK

DELAY

OFF

OPEN

STOP

2Sec1.5Sec

GATE

TAMPER

UL

ENTRAP

GATE

STATUS

CLOSE

COM

MAG

LOCK

PHOTOCELL

UL ALARM 12V

GATE DISABLE

COM

Tamper NO

COM

Tamper IN

EDGE 1

EDGE 2

ID PLUG

ERROR

ALARM RET

RESET

OPEN

CLOSE

BATTERY

IN USE

POWER

24V

GND

NC

Dual Gate Operators NOTE: Secondary

operator will automatically be set to

GND

the opposite opening direction as the

primary gate operator.

ID Plug Error: If ID plug is NOT plugged in,

board will constantly beep and operator will

GND

COM

NOT function.

NOTE: See manual for more

information about Matrix 1 settings.

OPEN

LEFT

Set the desired opening direction.

MATRIX 1

MADE in USA

EXIT

CENTER

SAFETY

FAST

PLUG

ID

12VDC

GND

24VDC

GND

RADIO SIG.

BATTERY

BACK-UP MODE

LEAVE

CLOSED

LEAVE

OPEN

OPEN

1 TIME

AUTOMATIC OPEN/CLOSE CONTROLS

ANTI

TAILGATE

OFFON

MAX

MIN

OFF

CLOSE TIMER

PARTIAL

OPEN

POSITION

FIRE DEPT

RADIO GND

RECORDER

OBD PORT

BLACK BOX

GND

MAX OPEN

MAX

MIN

MAX

STRIKE

GND

KEYPAD / RDR

GND

GND

UL 325 2016 Standard-Megatron Quick Install Rev 10

5

Page 8

limit switch adjustment

MIT

CAUTION

7

The limit rings need to be set BEFORE the gate can be cycled or DAMAGE could occur.

Manual Release

O

Mot

ver

or

Loa

d

E

S

ER

R

e

n

D

s

i

D

ti

vi

ty

5

1

2

4

1

3

3

1

4

15

1

6

JOG

MA

LE

L

E

F

X

D

T

O

N

JOG

R

I

G

H

M

AT

R

I

X

1

M

A

D

E i

n

U

S

A

AUTOMATI

AN

E

XI

T

T

AI

L

GA

ON

C

E

NT

ER

S

A

F

E

T

Y

MI

N

OF

M

A

F

C

X

LOS

E

T

I

I

D

ME

P

R

L

U

G

P

AR

TIA

O

PE

1

2

V

D

C

GND

P

O

SI

RE

TI

2

ON

COR

4

V

D

C

DE

G

ND

O

BD

BLACK

P

O

RT

BO

X

D

N

O SIG.

I

T

D

O G

I

A

N

D

E

R

DEP

A

P

E

R

O

D

X

N

FIR

D

G

IKE

N

MA

R

G

D

PA

N

ST

Y

G

KE

Ba

t

tery Vo

E

l

t

ag

1/

e

2

F

T

o

B

B

AC

K

L

E

A

C

VE

O

P

EN

C

T

I

T

E

O

F

F

L

N

R

M

M

A

R

D

R

/

L

D

OCEL

T

O

GND

PH

GND

ON/O

F

B

F

a

ttery

J

AT

T

E

RY

-U

P MO

L

E

D

A

VE

E

L

O

S

E

D

P

R

I

MA

O

P

E

RY

N

G

1

A

T

I

T

M

E

E

O

P

E

N

L

EF

T

OP

OPE

EN

RIGHT

N/CLOSE

MA

G

LO

RD

DE

C

OA

X

I

K

O

B

L

X

F

A

F

I

CO

TR

Y

T

A

PWR 24V -

1

.

M

5

S

N

e

c

TR

RS-485 (-) -

2

RS-485 (+) -

S

e

C

O

c

E

MA

LS

NT

GND -

G

ERE

L

OCK

S

AF

E

TY

COM

G

AT

M

R

E

A

TAMPER

AL

T

a

CH

T

mp

WI

S

e

IT

r

M

LI

K

N

C

A

P

Y

R

E

C

T

OM

AT

B

G

PUTS

T

ND

IN

a

R

mp

TO

O

M

er I

N

P

MOTOR

HO

UL

T

O

C

E

MO

L

L

TION

E

NTR

E

A

D

P

GE

1

O

PE

N

E

MA

D

GE

X

STOP

2

G

I

AT

D

PL

E

C

SP

R

U

L

E

VE

O

G

ERROR

IN

E

S

RS

E

E

D

E

SE

NSI

X

M

T

UL

I

O

VIT

T

A

OR

Y

L

O

A

V

R

E

R

A

M 1

N

L

L

O

O

A

A

L

D

R

I

2

M

V

M R

CL

I

T

SW

A

M

ET

P

I

RE

T

SL

C

H

I

SE

P

/

P

I

T

N

G

G

LI

ND

G

M

AT

S

I

T

WI

E

S

TC

O

TAT

N

H

-LI

US

N

E

MO

TO

O

O

PR

N

R

PE

-

I

LI

M

N

N

AR

E

G

Y

A

C

T

OM

E

C

+)

L

SE

OS

(

ND

C

E

G

G

-)

A

T

(

E

E

B

+)

AT

(

ND

T

N

G

E

-)

R

E

E

(

Y

I

N

ISABL

S

OP

US

D

OP

O

E

M

ST

E

CL

T

P

CO

OWE

GA

R

V

D

24

GN

MAX BC-

B

a

Re

tte

p

r

y

l

ac

Mo

Battery

e

7

d

ul

e

TE

S

T

Batte

B

r

attery

y

IN

Erro

r

IMPORTANT: Remove breather

pin from gear reducer BEFORE

cycling operator.

Breather Pin

Adjust Limit Switches:

Make sure power is ON. Manually Release Arm.

1. Move gate to CLOSED position.

CAUTI

ON

t

bol

st

rip

g

adju

or firm

f

REMOVE

BEFORE

OPERATION

2. Loosen closed limit ring screw.

3. Rotate closed limit ring until closed LED lights.

4. TIGHTEN CLOSED limit ring screw

LT

g

RT

og

ND

1

J

G

2

ge

e

o

g

Ed

t

o

Ed

h

P

Cell

MA

ON-L

T

R

IX

IN

E

E

L

d

i

m

g

1

e

i

t

S

W

M

U

2

L

ot

E

n

MC-2

tr

or

E

a

d

p

g

e

C

ont

P

P

h

o

to

0

O

r

C

ol

0

WE

e

l

l

l

er

R

N

C

O

er In

w

Po

R

TO

MO

on

i

ct

te

o

r

p

the

h

t

nued

wi

nti

y

.

l

co

on

use

f

s

: For

ace

es

g of

pl

pa

l

n

e

i

e

r

t

r

,

ne

a

r

nt

e

e

our

n co

and

st fir

WARNING

p

o

:

fusibl

n

i

e

t

c

NT

e

typ

un

E

agai

r

ques

i

se

prot

me

i

st

l

i

r

a

SEM

sa

l

uti

é

e

tr

t

ract

RTIS

E

ndie,

e

ca

V

A

et

nc

i

e

d’

mprome

co

ues

sq

mes typ

i

r

ê

.

m

es

de

nominal

p

7 Am

E

x

US

F

ma

On

3A

WER

AC

PO

115V

ff

O

IMPORTANT: LEDs MUST light up when gate reaches OPEN and CLOSE

positions or operator WILL NOT learn gate positions. If gate positions are

not learned, gate cycling speed will remain SLOW during normal operation.

CLOSED

LED

lights

CLOSED

LIMIT

OPEN

LIMIT

leaving NO gap.

5. Move gate to OPEN position.

6. Loosen open limit ring screw.

7. Rotate open limit ring until open LED lights.

8. TIGHTEN OPEN limit ring screw

leaving NO gap.

IMPORTANT: Manually Secure Arm

CLOSED

OPEN

LIMIT

LIMIT

OPEN

LED

lights

Arm in Closed

Position

Short Arm

Positive Stop

on Long Arm

1/4” gap

IMPORTANT: DO NOT allow positive stop

on long arm to touch short arm in closed

position. Leave about a 1/4” gap.

“Fine Tune” Limit Rings Adjustment

ERD

Sensitivity

Motor

OverLoad

ERD

5

4

3

MAX

12

16

LED ON

13

15

14

Push and HOLD the JOG LEFT or JOG RIGHT buttons

accordingly on the MAX MC-200 motor controller to

move the gate (release the button to stop gate).

Re-adjust limit ring postions as desired.

JOG

LEFT

JOG

RIGHT

GND

Jog LT

Edge 1

Edge 2

Jog RT

Photo

MATRIX

Cell

ON-LINE

Limit SW

Edge

1

2

Edge

D

E

L

l

i

t

n

u

g

n

i

r

D

E

S

O

L

C

e

MC-200

Motor Controller

UL Entrap

POWER

PhotoCell

s

t

h

g

i

l

t

a

t

o

R

Limit Ring

Screw has

NO GAP when

tightened.

Arm in

CLOSED position

Make sure OPEN/CLOSE

limit rings are tightened

after adjustment or

slippage could occur.

CAUTION

Arm in

OPEN position

NO GAP when

R

o

Limit Ring

Screw has

tightened.

t

a

t

e

O

P

E

N

r

i

n

g

u

n

t

i

l

L

E

D

l

i

g

h

t

s

UL 325 2016 Standard-Megatron Quick Install Rev 10

6

Page 9

entrapment protection wiring

8

12 Volt Power Extension Terminal:

Entrapment protection sensor power (12V) MUST be wired to this terminal

or it will NOT be MONITORED by the gate operator.

Motor

OverLoad

ERD

ERD

Sensitivity

12

13

14

5

4

3

MAX

16

LED ON

15

JOG

LEFT

JOG

RIGHT

GND

Jog LT

Edge 1

Edge 2

Jog RT

3

2

1

EDGE 1: MONITORED CLOSE ONLY

Edge 2: LEARNED MONITORED OPEN/CLOSE

Photo Cell: LEARNED MONITORED OPEN/CLOSE

NOTE: See manual for more information about learned monitored inputs.

Typical Wiring For:

Normally Closed (N.C.)

Photo Cell to EDGE 1

Thru-Beam

PWR 12V

ity does NOT matter

olar

P

IMPORTANT: Photocells

MUST be in alignment

or fault will occur.

Reflective

Beam

flector

e

R

See pages 18-20

for specific

photocell wiring.

IMPORTANT Sensing devices MUST

be powered by MC-200 or they will

NOT be MONITORED.

12V

Ex

Terminal

RecrTrans

Power

tension

EDGE 1

CLOSING Direction ONLY

(N.C.)

GND (C)

JOG

LEFT

y

t

X

vi

A

O

ERD

M

D

nsiti

E

4

3

5

L

Se

16

r

d

15

14

3

Moto

1

12

verLoa

O

la

l

D

nsta

i

ER

n

ee

a

S

l

:

r

i

N

Vo

N:

O

AUTIO

C

NTI

E

ent Prot

TT

A

pm

a

wi

Entr

nsor Guidel

be

MC-200 Swing

Se

MUST

L NOT fu

or

L

CLO

WI

ens

LY

or

A s

at

•

sensor

RMAL

wh

oper

0

NO

20

RED

e

r

O

Wi

MC-

•

’s

/o

MONIT

ator

d.

e and

e

oper

s

dg

u

of th

E

e

ar

ng

i

ANY

MUST be

s

er

to

12V

ed

D

Rev

r

•

WR

P

be wi

TORE

NI

200

MUS

s

MO

lt wi

MC-

u

put

er

•

fa

w

in

o

or

p

ED

S

ED

U

R

N

E

U

P

•

M

U

J

PWR 12V

1

X

RS-485 (+) -

GND

MATRI

RS-485 (-) -

PWR 24V -

-

-

GND -

NOTE: Power extension

terminal is connected to 12V

power on back of MC-200.

Cell

Photo

ON-LINE

Limit SW

HT

JOG

IG

R

N

tr

s

n

i

n

o

ti

nsta

i

d’

ce

oti

ecti

s

e

in

DG

E

o

t

ed

r

on.

ti

c

n

N.C.)

(

D

E

, to

S

Y

NL

oper

O

al

s

n du

e

Ce

o

hot

ts

P

r

3 Inpu

e

us

nsors.

e

s

ain

em

r

T

cur.

oc

l

l

00

-2

C

M

ow

p

LY

N

rs

o

O

s

n

e

s

-

-

Jumper UNUSED Entrapment Protection Inputs

or a fault will occur.

MATRIX

Edge

1

2

Edge

Motor Controller

UL Entrap

POWER

PhotoCell

Normally Closed (N.C.)

Sensor Wire

GND

MC-200

Example: Inputs 2 & 3

are NOT used and

MUST be jumpered

to GND.

UL 325 2016 Standard

ONE Entrapment protection sensor MUST installed or operator will NOT

function. It MUST be MONITORED and NORMALLY CLOSED (N.C.).

GEM-104 MUST be used

10K Edge

Normally

Closed

GEM - 104

ON = Obstruction

BLINKING = Fault

MON.

PWR

PWR 12V

Power

12V

tension

Ex

Terminal

SAFETY

INPUT

200

ller

C-

ntro

M

Co

r

ER

o

W

ot

trap

M

PO

En

UL

l

l

ge

Ce

Ed

IX

to

E

TR

Pho

1

LIN

-

MA

ge

to

Cell

ON

2

Pho

1

ge

ge

D

Ed

Ed

T

GN

R

g

LT

Jo

og

J

-

-

Jog RT

Jog LT

ns.

o

ucti

llation.

ored

on

t

g

n

si

Moni

r

or

1

E

Reve

e

g

Ed

h

c

OR

s

r

ea

to

a

onitored

M

can

l

Photo

l

Cell

.

ed to

3

2

1

GN

D

ed

s

u

e

b

T

MUS

n

io

t

R 12V

W

ec

t

P

o

pr

t

12V

en

R

OR

m

W

p

P

MOT

tra

U

n

00

P

e

2

r

IN

Y

C-

e

R

M

TE

h

AT

K

B

C

wit

PA

T

I

M

I

L

H

ITC

W

S

M

R

A

L

A

2

1

-

GND

Edge 1

TS

2

Ed

SW

Limit

Entrapment Protect

3

Inputs:

e

us

n

u

2

Edge 2

N

Inputs

Photo Cell

MO

R

to

TOR

To LEA

I

t

MON

1.

ired

w

earned.

l

mpered.

ju

s

er

ev

ed

R

ir

2.

w

Edge 1

CLOSE ONLY

be

ess

Pr

ons

3.

t

but

beep is

il

unt

Learn

beeping.

by

WIL

s

D

LE

or

4.

ens

s

OTH

B

or

f

operat

s

es

Pr

5.

o learn

t

beeping

s

nput

I

er In

w

Po

MUS

p

d in

3

&

se

ITOR

input

N

ED

inputs

unus

o

y

An

ing Edge and/or

ei

to

OL

H

and

he s

t

at

heard,

M

NS

E

OP

mode la

be ON

L

C

M

on

MC

s are

or

but

OP

or

ST

ens

s

ops.

t

s

now

are

on

i

mper

ju

T

”

s

D

E

ut

N

R

A

T be “LE

MUS

:

3

be

nsors.

be

&

ST

an

2

c

be

s

MU

s

ST

hey

t

MU

s

Sensor

ORE

an

c

EF

input

B

ell

ed

o C

Phot

3.

OP

T

or

S

2

&

x 1

i

input

gins.

Matr

be

her

on

t

e

the OPEN

im

D

t

mode

arn

ame

le

N

O

I

T

O

M

R

O

OT

OSE

ated

CL

c

P

indi

.

TO

ed

t

5 min

ec

or

ON

f

det

s

t

be

h

s

L

eac

WIL

or

f

s

D

.

dual

LE

in

m

hen

5

w

-200.

hin

it

mode,

-200s

used.

learn

again w

on

t

end

and

ED.

s

ITOR

MON

MOTOR

Polarity does NOT matter

NOTE: See

manual for more

Sensing Edge

information

about sensing

edges.

See page 21 to wire

a Gate Link wireless

transmitter.

Normally Closed (N.C.) Sensing Edge to EDGE 1

EDGE 1 (N.C.)

CLOSING Direction ONLY

GND (C)

1

D

T

GN

R

g

LT

Jo

og

J

HT

JOG

IG

R

JOG

LEFT

y

t

X

vi

N

A

O

ERD

M

D

nsiti

E

4

3

5

L

Se

r

oad

Moto

verL

O

D

ER

MC-200 Swing

12

AUTIO

C

TT

A

A sensor

•

op

Wi

•

MO

op

e

r

a

Rev

•

be

MC-

•

o

p

N

U

•

U

J

MATRIX

PWR 24V -

3

1

NTI

E

Entr

ator

er

NO

e

r

NIT

ator

er

s

u

s

er

ed

r

wi

200

er

w

S

U

P

M

GND -

16

15

14

S

:

N

N:

O

pm

a

nsor Guidel

Se

MUST

L

WI

RMALLY

RED

O

MC-

’s

d.

e

E

ng

i

ANY

to

WR

P

NI

MO

in

ED

ED

R

E

1

RS-485 (+) -

RS-485 (-) -

nsta

i

e

e

r

i

Vo

e

be wir

NOT

L

sensor

20

e an

dg

of th

12V

ORE

T

MUS

ts

pu

fa

or

PWR 12V

-

ns.

o

.

ucti

tr

on

s

n

i

llati

n

o

sta

ti

n

i

la

l

d’

tice

o

n

a

l

on

ecti

Moni

or

1

E

ines

Reve

nt Prot

DG

E

o

t

Ed

ed

on.

ti

c

h

n

c

N.C.)

(

s

fu

r

ea

D

to

E

a

, to

r

S

Y

e

NL

op

CLO

O

al

s

Monitor

n du

e

can

l

Photo

l

wh

0

Ce

Cell

.

hoto

ts

P

to

or

d/

ed

3 Inpu

3

e

e us

2

b

1

GN

D

MUST

nsors.

e

in

s

D

ema

r

T

cur.

MUS

V

oc

l

l

R 12

lt wi

W

u

P

00

2

t

-

C

en

M

m

W

p

a

P

r

t

n

00

e

2

r

C-

e

M

ow

h

p

wit

LY

s

N

T

r

I

o

O

M

I

s

L

H

n

e

ITC

s

W

S

GND

M

R

A

L

A

-

-

-

HARDWiring

1

IX

TR

LIN

-

MA

to

Cell

ON

2

Pho

ge

ge

Ed

Ed

1

-

-

-

GND

Jog RT

Jog LT

ored

t

g

n

si

r

e

g

OR

ed

ed

s

u

e

b

T

n

io

ect

t

o

pr

2V

1

R

OR

OT

TS

M

U

P

IN

Y

R

TE

AT

K

B

C

PA

3

2

ller

C-200

ntro

M

Co

r

ER

o

W

ot

trap

M

PO

En

UL

l

l

ge

Ce

Ed

to

E

Pho

1

ge

on

2

i

Ed

SW

er

Limit

mp

ju

T

US

”

M

s

D

E

ut

N

Entrapment Protect

p

R

A

3

d in

Inputs:

2

se

u

n

T be “LE

u

:

MUS

3

be

3

nsors.

be

se

ST

&

2

an

&

2

c

s

be

MU

s

ITOR

ST

hey

Edge 2

t

N

Inputs

input

MU

Photo Cell

s

N

MO

Sensor

ORE

R

o

can

t

EF

ED

input

Edge 1

ell

LEA

ed

o

TOR

o C

T

I

inputs B

unus

o

t

y

3.

MON

OP

T

1.

An

or

S

ired

2

w

&

x 1

and/or Phot

i

.

input

earned.

gins

l

be

her

on Matr

t

ing Edge

e

ei

jumpered.

s

the OPEN

im

er

D

to

t

mode

ev

OL

ed

R

ir

H

arn

ame

2.

w

s

le

Edge 1

and

be

N

CLOSE ONLY

he

t

O

I

OT

at

M

heard,

Press

R

is

O

ons

3.

t

OT

M

but

beep

il

unt

CLOSE

cated

P

indi

O

in.

ST

ed

t

5 m

N

ec

E

or

ON

f

det

s

OP

t

be

h

s

L

WIL

or eac

f

s

mode la

D

.

dual

LE

in

m

be ON

Learn

hen

L

5

w

beeping.

-200.

C

hin

by

WIL

it

M

ode,

s

m

-200s

D

on

C

LE

M

4.

used.

learn

again w

ensor

s

on

OTH

t

end

B

s are

.

or

or

f

and

ED

s

OP but

or

ST

operat

TOR

s

I

ens

s

es

Pr

ops.

t

MON

5.

s

o learn

t

now

are

beeping

s

nput

I

MOTORPo

er In

w

Typical

For:

Entrapment Protection Device Locations:

Entrapment Area

Gate Closed

Beam: 5” or LESS

from CLOSED gate.

CLOSING Direction

IMPORTANT: Entrapment

Photocell ONLY

Dual Gate Operators NOTE: Connect CLOSING Direction

photocell to the PRIMARY gate operator’s MC-200.

Protection Photocells MUST be

Monitored Normally Closed Type.

IMPORTANT: Photocells

MUST be in alignment

or fault will occur.

Continued on next page.

7

CLOSING direction photocell

to MC-200 EDGE 1 input.

Run conduit

to operator

Gate Open

UL 325 2016 Standard-Megatron Quick Install Rev 10

Page 10

continued

8

Entrapment Protection Device Options and Locations:

CLOSING direction photocell to MC-200 EDGE 1 input.

Top View

Beam: 5” or LESS from CLOSED gate.

Wireless

WIRELESS NOTE: Refer to the instruction sheet that

Module

comes with the wireless module for wiring and

mounting instructions when using wireless option.

Entrapment Area

Gate Closed

Hinge AreaEnd of Gate Options

Max 10K Mini Sensing Edge (N.C.)

Conduit

Closed Gate

OPENING/CLOSING

Two Sided 10K Sensing Edge

to Edge 2 or Photo Cell input

MC-200 Edge 2 or Photo Cell input

MC-200 Edge 1 input

Closed Gate

CLOSING ONLY

One Sided

10K Sensing Edge

IMPORTANT: Sensing edges MUST be

Monitored 10K Normally Closed Type.

Dual Gate Operators NOTE: Run EACH entrapment protection sensor

to each corresponding GATE OPERATOR’S MC-200 motor controller.

See Megatron manual for more information.

Bottom of Gate

Side View

OPEN/CLOSE Sensing Edge on Bottom of Gate:

If the bottom of gate is 6” or higher above the ground,

then a 10K sensing edge should be installed.

CLOSING direction Photocell

IMPORTANT: Photocells MUST

Beam Height:

21” Normal

27.5” Max.

be in alignment or fault will occur.

Closed Gate

The hinge area may need protection

against entrapment. MAX 10K mini

sensing edge works well in this area.

(OPEN/CLOSE direction, MC-200

Edge 2 or Photo Cell input)

OPENING/CLOSING or

Closing ONLY 10K (N.C.)

Sensing Edge

6” or More

Entrapment Protection

10K Sensing Edge,

Install along entire

edge of gate.

Gate Open

Normally CLOSED (N.C.)

OPENING direction Photocell

IMPORTANT: Photocells MUST

be in alignment or fault will occur.

OPENING direction Photocell,

Install just above gate operator.

Gate Open

Area

Entrapment

learn gate positions

9

After the OPEN and CLOSED limit rings have been set, the arm is SECURE and at least ONE entrapment sensor

has been installed, put the gate in the CLOSED position:

MOTOR MOTION

1. Push OPEN button to cycle gate to open position.

Operator cycles slowly while learning position.

2. Then push CLOSE button to cycle gate to closed position.

Operator cycles slowly while learning position.

OPEN STOP CLOSE

MOTOR MOTION

OPEN STOP CLOSE

Matrix 1

Matrix 1

After gate positions have been learned, the gate will cycle at the speed set on matrix 1 “GATE SPEED” setting.

UL 325 2016 Standard-Megatron Quick Install Rev 10

8

Matrix 1

MAX

GATE SPEED

MIN

MAX

Set to MAX

Page 11

E

3

6

10

Adjust ERD Reverse sensor

The ERD Sensor - Electronic Reversing Device (Type A) MUST be adjusted for the OPEN and CLOSE gate cycles.

When the gate encounters an obstruction during the CLOSE cycle, it will reverse to the open position and PAUSE the gate.

An input command (press remote button or exit loop) is needed BEFORE the gate will reset and close again.

When the gate encounters an obstruction during the OPEN cycle, it will reverse approximately 6 inches and PAUSE the gate.

An input command (press remote button or exit loop) is needed BEFORE the gate will reset and open again.

For the ERD Sensitivity to function correctly:

• THE RELEASE HANDLE CLAMP MUST NOT SLIP when the gate encounters an obstruction.

• Limit switches must be learned BEFORE adjusting the ERD Sensitivity.

Typical Settings:

ERD

Sensitivity

5

4

3

12

16

13

14

ERD

Sensitivity

12

13

14

ERD

Sensitivity

12

13

14

11

In-Ground Loops

Connections

Loop

Exit

Loop

NOTE: See manual for

more information

about loops and

loop detectors.

LED ON

15

5

4

3

16

LED ON

15

5

4

3

16

LED ON

15

loops & loop detectors

Safety

Position 12:

• Typical gate setting.

MAX

Position 15:

• Heavy gate setting.

• Long gate setting.

MAX

Position 16:

• Uphill gate setting.

• High wind area gate setting.

MAX

CAUTION: Position 16 results in gate exerting

MAXIMUM force before reversing direction.

Safety

Loop

Safety Loops

Wired in series

PLUG