Page 1

OPERATING INSTRUCTIONS MANUAL

MANUEL D’INSTRUCTIONS D’UTILISATION

MANUAL DE INSTRUCCIONES DE FUNCIONAMIENTO

BETRIEBSANLEITUNG

MANUAL DE OPERACIONES Y MANTENIMIENTO

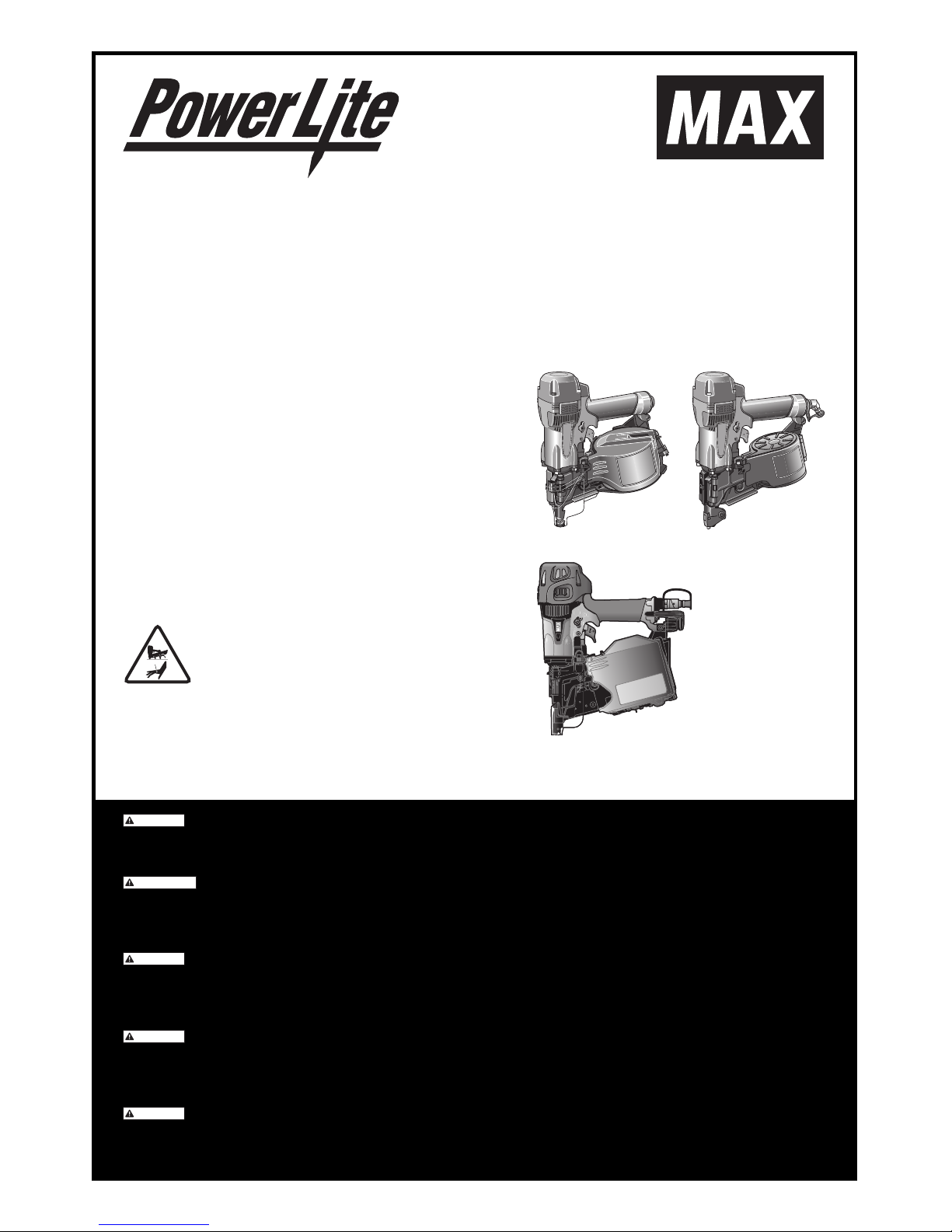

HIGH PRESSURE COIL NAILER

CLOUEUSE À BOBINE HAUTE

PRESSION

CLAVADORA DE ALTA PRESIÓN PARA

CLAVOS EN BOBINA

HOCHDRUCK-COILNAGLER

CHIODATRICE A BOBINA AD ALTA

PRESSIONE

INDEX ENGLISH Page 1 to 4

INDEX FRANÇAIS Page 5 à 9

ÍNDICE ESPAÑOL Página 10 a 14

INDEX DEUTSCH Seite 15 bis 19

INDICE ANALITICO ITALIANO Pagine da 20 a 24

Before using the tool, read and understand tool labels and Safety instruction manual and Operating

instructions manual. Failure to follow warnings could result in serious injury.

Keep these instructions with the tool for future reference.

Veillez à lire et bien comprendre les étiquettes et le Manuel d’instructions sur la sécurité et le Manuel

d’instructions d’utilisation avant d’utiliser cet outil. Tout manquement au respect des avertissements

peut entraîner des blessures graves.

Conservez ces instructions avec l’outil pour toute consultation ultérieure.

Lea y comprenda las etiquetas, el manual de instrucciones de seguridad y el manual de instrucciones

de funcionamiento de la herramienta antes de usarla. El incumplimiento de las advertencias puede

provocar lesiones graves.

Conserve estas instrucciones junto con la herramienta para futuras consultas.

Lesen Sie vor der Verwendung des Werkzeugs die Beschriftungen am Werkzeug, die

Sicherheitsanleitung und die Betriebsanleitung sorgfältig durch. Das Nichtbefolgen der Warnungen

kann zu schweren Verletzungen führen.

Bewahren Sie diese Anweisungen zum späteren Nachschlagen mit dem Werkzeug zusammen auf.

Prime di utilizzare l'utensile, leggere e comprendere le etichette e i manuali Istruzioni di sicurezza e

Istruzioni per l'uso dell'utensile. La mancata osservanza delle avvertenze potrebbe risultare in gravi

lesioni personali.

Conservare queste istruzioni insieme all'utensile per consultazioni future.

HN65(CE) HN65J(CE)

HN90F

Original Language English

WARNING

AVERTISSEMENT

ADVERTENCIA

WARNUNG

AVV ERT ENZ A

Page 2

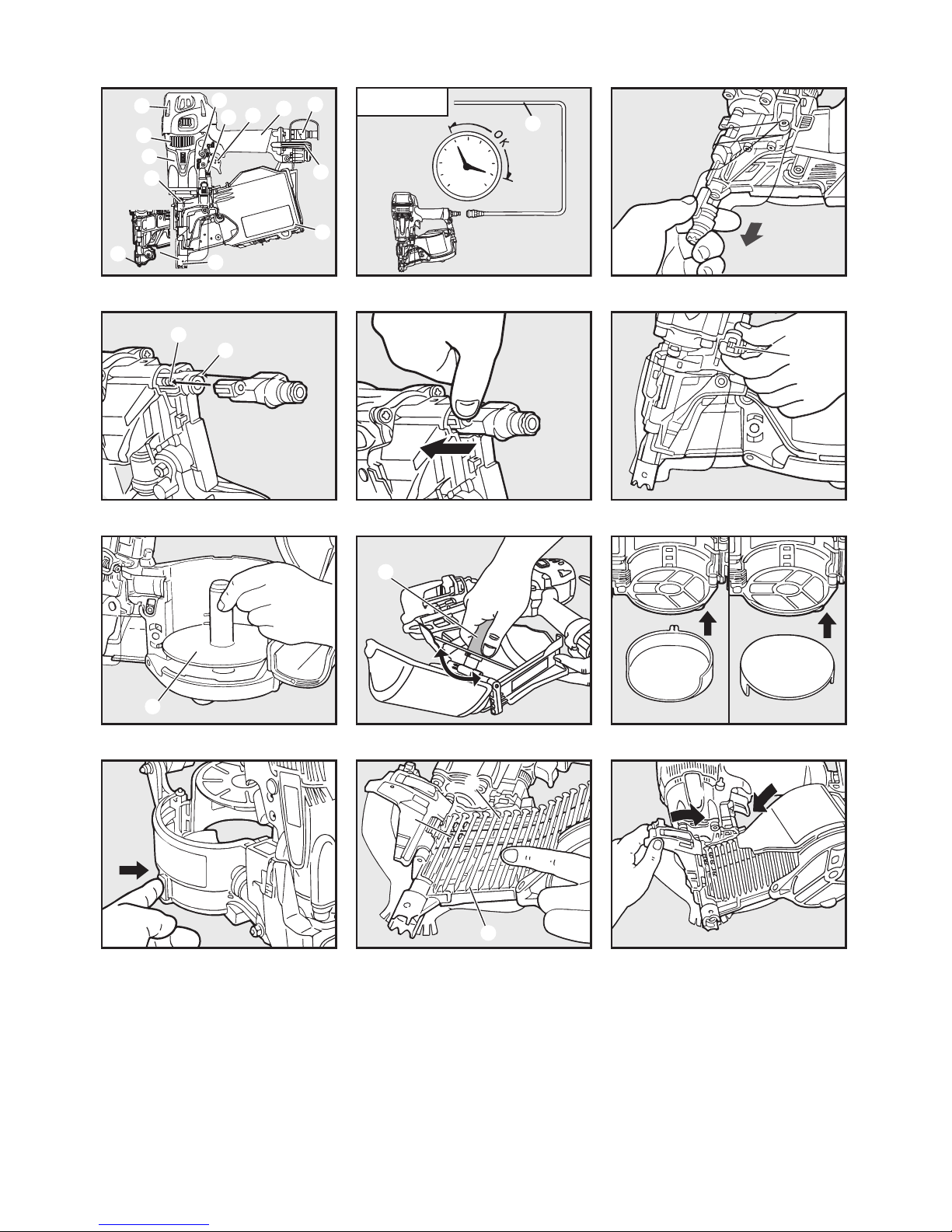

Fig.1 Fig.2 Fig.3 (HN65)

Fig.4 (HN65) Fig.5 (HN65) Fig.6

Fig.7 (HN65) Fig.8 (HN90F) Fig.9 (HN65J)

Fig.10 (HN65J) Fig.11 Fig.12

6

7

b

0

5

c

3

a

4

1

8

2

HN65J

9

170 psi

12 bar

320 psi

23 bar

2

1

1

2

1

2

3

2

40mm (1-1/2")

2

40 mm (1-1/2")65 mm (2-1/2")

5

4

6

7

8

Page 3

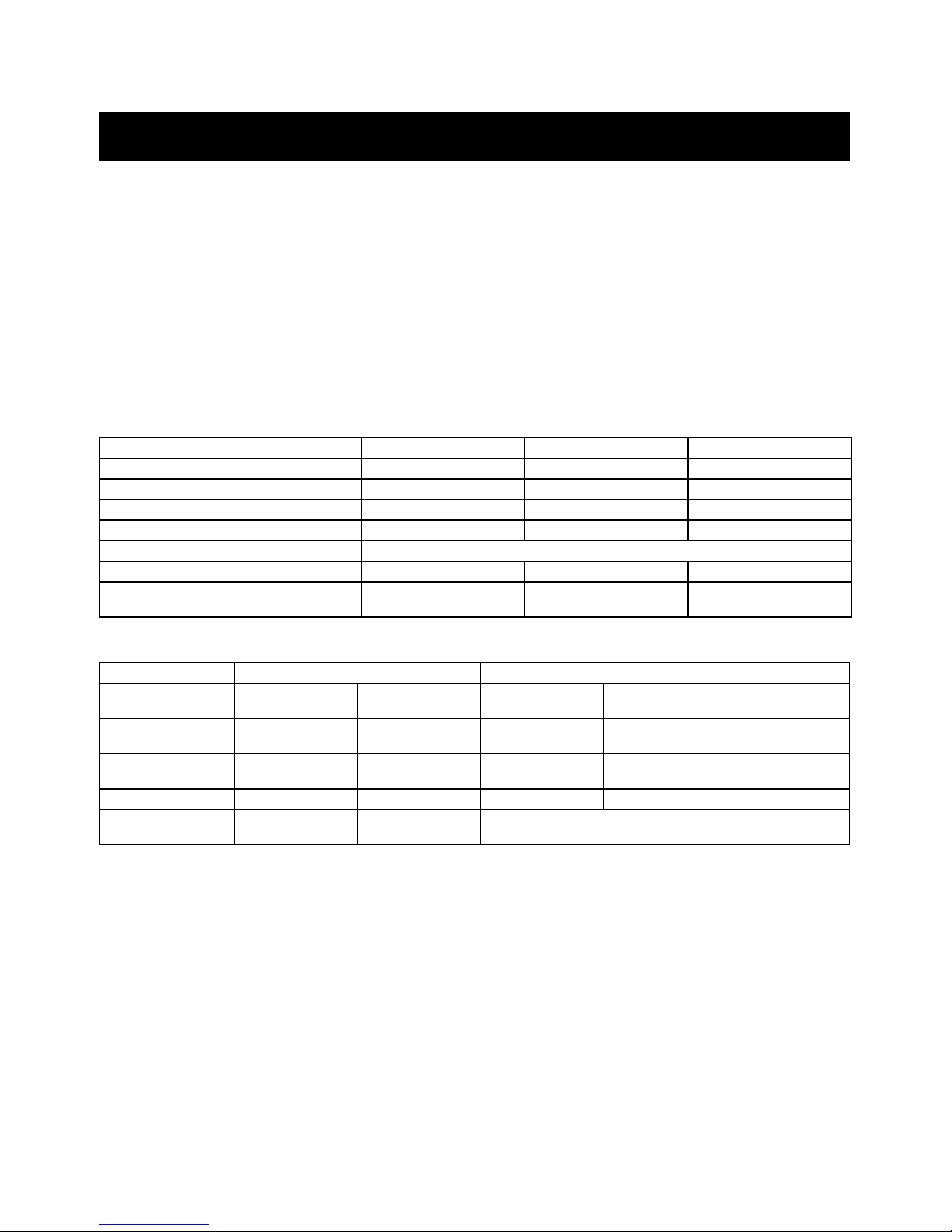

Fig.13 Fig.14 (HN65, HN90F) Fig.15 (HN90F)

Fig.16 (HN65J) Fig.17 (HN65J) Fig.18 (HN90F)

㻸㻻㻯㻷

㼁㻺㻸㻻㻯㻷

1

2

1

2

3

2

4

3

Page 4

1

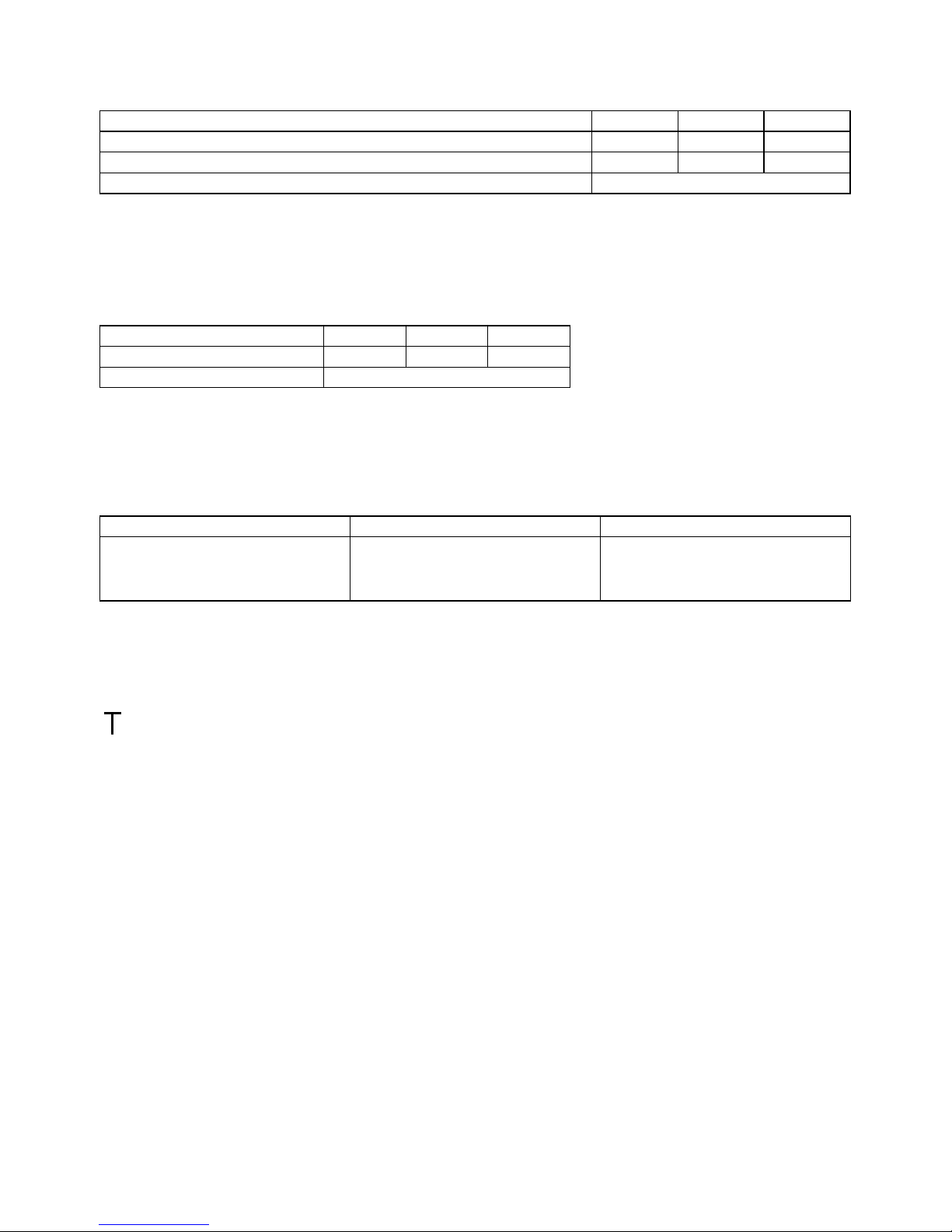

1. SPECIFICATIONS AND TECHNICAL DATA

1. NAME OF PARTS (SEE Fig.1)

2. TOOL SPECIFICATIONS

3. FASTENER SPECIFICATIONS

ENGLISH

OPERATING INSTRUCTIONS MANUAL

1 Frame 8 Exhaust Cover

2 Cylinder Cap 9 Trigger Lock Dial

3 Contact Arm 0 Plug

4 Nose a Aiming Guide Locator (HN65J)

5 Magazine b Adjust Dial

6 Trigger c Rafter Hook (HN90F)

7 Grip

PRODUCT NO. HN90F HN65 HN65J

HEIGHT 331mm 13" 301mm 11-7/8" 291mm 11-1/2"

WIDTH 126mm 5" 129mm 5" 102mm 4"

LENGTH 298mm 11-3/4" 291mm 11-1/2" 291mm 11-1/2"

WEIGHT 2.6 kg 5.7 lbs. 1.9 kg 4.3 lbs. 2.0 kg 4.4 lbs.

RECOMMENDED OPERATING PRESSURE 12 to 23 bar 170 to 320 p.s.i.

LOADING CAPACITY 300 Nails 400 Nails 100 Nails

AIR CONSUMPTION 3.4L at 18 bar / 257 p.s.i.

operating pressure

1.7L at 18 bar / 257 p.s.i.

operating pressure

1.4L at 18 bar / 257 p.s.i.

operating pressure

PRODUCT NO. HN90F HN65 HN65J

TYPE OF COLLATION

PLASTIC SHEET

COLLATED

WIRE WELDED PLASTIC SHEET

COLLATED

WIRE WELDED PLASTIC SHEET

COLLATED

NAIL LENGTH

45 to 75mm

1-3/4" to 3"

45 to 90mm

1-3/4" to 3-1/2"

32 to 65mm

1-1/4" to 2-1/2"

38 to 65mm

1-1/2" to 2-1/2"

40 to 65mm

1-1/2" to 2-1/2"

SHANK DIAMETER

2.5 to 2.9mm

.099" to .114"

2.5 to 3.8mm

.099" to .148"

2.5 to 2.9mm

.099" to .113"

2.1 to 3.3mm

.083" to .131"

3.3 to 4.1mm

.131" to .162"

SHANK TYPE Smooth, Screw Smooth, Ring, Screw Smooth, Screw Smooth, Ring, Screw Smooth

HEAD DIAMETER

5.5 to 7.7mm

.217" to .303"

6.0 to 7.7mm

.236" to .303"

5.0 to 7.0mm

.197" to .275"

7.2mm

.283"

Page 5

2

4. TECHNICAL DATA

NOISE

These values are determined and documented in accordance to EN12549:1999+A1:2008.

NOTE: These values are tool-related characteristic values and do not represent the noise generation at the point of use. Noise at the point

of use will for example depend on the working environment, the workpiece, the workpiece support, and the number of driving operations.

In addition, reference should be made to noise reduction measures.

NOTE: Workplace design can also serve to reduce noise levels, for example placing workpieces on sound-damping supports (see also ISO

11690-1).

VIBRATION

These values are determined and documented in accordance to ISO 28927-13

NOTE: The vibration emission value above is a tool-related characteristic value and does not represent the influence to the hand-arm-system when using the tool. Any influence to the hand-arm-system when using the tool will for example depend on the gripping force, the contact pressure force, the working direction, the adjustment of energy supply, the workpiece, the workpiece support.

5. APPLICATIONS

6. ABOUT PRODUCTION YEAR

This product bears production number at the lower part of the grip of the main body. The two digits of the number from left indicates the

production year.

HN90F HN65 HN65J

A-weighted single-event sound power level ------ LWA, 1s, d 93.1dB 90.0dB 89.9dB

A-weighted single-event emission sound pressure level at work station------ LpA, 1s, d 81.7dB 85.6dB 86.2dB

Uncertainty 3dB

HN90F HN65 HN65J

Vibration characteristic value 6.42 m/s

2

4.13 m/s

2

4.34 m/s2

Uncertainty 1.5 m/s

2

HN90F HN65 HN65J

∗ Floor and wall framing

∗ Subflooring

∗ Roof and wall sheathing

∗ Fencing

∗ Floor and wall framing

∗ Subflooring

∗ Roof and wall sheathing

∗ Fencing

∗ Fastening metal connectors for wood

construction.

(Example)

1 7 8 2 6 0 3 5 D

Year 2017

Page 6

3

2. AIR SUPPLY AND CONNECTIONS (Fig.2)

A. HOSES AND SUPPLY SOURCE

WHEN USING THE TOOL, BE SURE TO USE A SPECIAL AIR

COMPRESSOR AND AIR HOSE.

In order to improve its performance, it has set its working pressure

higher than the conventional nailers. To use the tool, you always

need the special air compressor 1 and the air hose 2 (MAX PowerLite Compressor and MAX PowerLite Hose).

Use of high pressure gas (for example, oxygen, acetylene, etc.)

causes abnormal combustion, possibly resulting in explosion.

Use only the special air compressor and air hose.

B. OPERATING PRESSURE:

12 to 23 bar / 170 to 320 p.s.i. Select the operating air pressure

within this range for best performance based upon the fastener

application and work surface. Using the lowest acceptable to

minimize noise, vibration and wear.

DO NOT EXCEED 23 bar / 320 p.s.i.

NOTICE:

Frequent, but not excessive, lubrication is required for the best

performance. Upon completion of operations, place 2 or 3 drops

of oil into the air plug inlet with the jet oiler.

3. INSTRUCTIONS FOR OPERATION

1. BEFORE OPERATION

1 Wear Safety Glasses or Goggles.

2 Do not connect the air supply.

3 Inspect screw tightness.

4 Check operation of the contact arm & trigger if moving

smoothly.

5 Connect the air supply.

6 Check the air-leakage. (The Tool must not have the air-

leakage.)

7 Hold the Tool with finger-off the trigger, then push the con-

tact arm against the work-piece. (The tool must not operate.)

8 Hold the Tool with contact arm free from work-piece and pull

the trigger. (The Tool must not operate.)

9 Disconnect the air supply.

2. OPERATION

ATTACHING THE CONTACT NOSE (HN65)

Attach the following contact noses depending on the nail head diameter used.

1 (Fig.3) Pull the contact nose to remove it.

2 (Fig.4,5) Aligning the rail with the contact arm, press the

contact nose as shown in the figure to fit it until it clicks.

NAIL LOADING

1 (Fig.6) Open the Magazine:

Pull up Door Latch 1 and swing Door open. Swing Magazine Cap open.

2 (Fig.7) (HN65) Check adjustment:

The Nail Support 2 can be moved up and down to four settings. To change setting pull up on the Nail Post and twist to

the correct step. The Nail Support should be adjusted correctly to the position indicated in inches and millimeters inside Magazine 3.

(Fig.8) (HN90F)

The nail support 2 can be moved up and down to four settings. The nail support moves down by turning it counterclockwise and moves up by turning it clockwise. The nail

support should be adjusted correctly to the position indicated in inches and millimeters.

(Fig.9,10) (HN65J) When using 40mm / 1-1/2" nails, attach

the nail support 2 in such a manner that a mark “40” can

been seen. When using 65mm / 2-1/2" ones, attach the nail

support 2 upside down.

To detach, push the latch on the back of the magazine with

a finger.

3 (Fig.11) Nail loading:

Place a coil of nails 4 over the Nail Post in the Magazine.

Uncoil enough nails to reach the Feed Pawl 5, and place

the second nail between the teeth on the Feed Pawl. The

nail heads fit in slot 6 on Nose.

4 (Fig. 12) Swing Magazine Cap 7 closed.

5 (Fig. 12) Close the Door 8.

Check that Door Latch 1 engages. (If it does not engage, check

that the nail heads are in the slot 6 on the Nose).

TEST OPERATION

1 Adjust the air pressure at 170 p.s.i. (12 bar) and connect the

air supply.

2 Without touching the Trigger, depress the Contact Arm

against the work-piece.

Pull the Trigger. (The tool should fire the fastener.)

3 With the tool off the work-piece, pull the Trigger.

Then depress the Contact Arm against the work-piece.

(Tool with red triggers should fire the fastener, but tool with

orange triggers should not.)

4 Adjust the air pressure as much as the lowest possible ac-

cording to the diameters and length of fastener and the

hardness of work-piece.

DRIVING FASTENERS

HN65J

This tool is assembled with FULL SEQUENTIAL TRIP.

HN65, HN90F

This tool is shipped with CONTACT TRIP WITH ANTI-DOUBLE

FIRE MECHANISM selected.

It is the responsibility of employer, tool owner or tool operator to

select the appropriate actuation system for the fastener application and training of tool operator before changing the trigger setting.

SWITCHING CONTACT TRIP WITH ANTI-DOUBLE FIRE

MECHANISM TO FULL SEQUENTIAL TRIP (Option) (HN90F,

HN65)

To change the trigger system, please contact MAX CO., LTD. authorized distributors and have them change the system.

SWITCHING FULL SEQUENTIAL TRIP (Option) TO CONTACT

TRIP WITH ANTI-DOUBLE FIRE MECHANISM (HN90F, HN65)

To change the trigger system, please contact MAX CO., LTD. authorized distributors and have them change the system.

CONTACT FIRE OPERATION (CONTACT TRIP) (HN90F,

HN65)

For contact fire operation, pull the Trigger and depress the Contact Arm against the work surface.

SINGLE FIRE OPERATION (ANTI-DOUBLE FIRE MECHANISM) (HN90F, HN65)

For single fire operation, depress the Contact Arm against the

work surface and pull the Trigger. A fastener will be driven. Release trigger. Begin again.

SINGLE FIRE OPERATION (FULL SEQUENTIAL TRIP) (For

tool with orange triggers)

For single fire operation, depress the Contact Arm against work

surface and pull trigger. A fastener will be driven. Release both

trigger and Contact Arm. Begin again.

Head Diameter Contact Nose Color

5.0 to 6.0mm

(.197" to .236")

Contact Nose S Black

6.0 to 7.0mm

(.236" to .275")

Contact Nose L Silver

Page 7

4

DRIVING DEPTH ADJUSTMENT DIAL

Adjust the driving depth by twisting the adjustment dial b as indicated below.

TRIGGER LOCK MECHANISM (Fig.13)

This tool has a Trigger Lock. The trigger should be locked at all

times until you intend to drive nail into the work surface. Push and

rotate the Trigger LOCK Dial 1 clockwise from LOCK to UNLOCK position immediately before driving nails. When fastening

is complete, push and rotate switch counterclockwise to LOCK

position.

CONTACT TIP (Fig.14) (HN90F, HN65)

Attach the Contact Tip 1 on the tip of Contact Arm 2, when driving nails to a soft material.

The Contact Tip can be kept on the Arm Cover 3 when not using.

REMOVING JAMMED NAILS (Fig.15)

• ALWAYS disconnect the air supply.

• Wear gloves when removing jams; do not use bare hands

• Confirm that you have removed all nails from nose of tool

before reconnecting to air supply.

1 Disconnect the air supply.

2 Open the tool door and remove nails from inside of the mag-

azine.

3 Insert a thin metal stick in the tool nose and hit the metal

stick with a hammer or remove the jam with a flathead

screwdriver.

4 Put back the nails on the feed pawl and close the tool door.

WHEN USING THE TOOL FOR STEEL PLATES

(HN90F, HN65)

(HN65) This tool is exclusively designed for 1.6mm / 16Ga. to

2.3mm / 13Ga. thick light gauge steel.

(HN90F) This tool is exclusively designed for 1.6mm / 16Ga. to

3.2mm / 11Ga. thick light gauge steel.

When using it, comply with the Work Standards, considering the

object condition and work site environment.

1 Select appropriate nails according to the object thickness,

seeing the Nail Selection Criteria Chart.

∗ The nails may not be driven into the object depending on its

hardness or thickness.

∗ If the object is thicker than an appropriate range of thickness,

the nails may not be driven into it because of being bent.

2 If the thickness of the light gauge steel foundations material

used is 3.2mm / 11Ga., use the 2.9mm / .113" nails for steel

plate. (HN90F)

3 Never drive the nails directly into the light gauge steel be-

cause they will fly off, endangering you.

4 Be sure to apply the discharge outlet to the object at a right

angle. If applied obliquely, the nails will fly off, endangering

you.

5 Never use the nails for the roofs (roof foundations included)

or ceilings (ceiling foundations included).

6 If the nails are driven into the steel plate too deeply, their

holding force will be extremely reduced. When working with

the tool, fully check the driven conditions.

Nail Selection Criteria

REPLACING THE AIMING GUIDE LOCATOR

(HN65J)

The aiming guide locator is worn out depending on the frequency

of use.

If the machine cannot be easily held vertically when setting the

aiming guide locator in a hole in a metal fitting, it is about time to

replace.

Replace it in the following procedure:

1 (Fig.16) Remove a rubber washer 1 with a regular

screwdriver to pull out a pin 2. Push the nail leg guide 3

to remove the aiming guide locator 4.

2

(Fig.17) Attach a new aiming guide locator, set the pin and put

back the rubber washer.

When replacing the aiming guide locator, contact the nearest

MAX CO., LTD. authorized distributor.

CHANGING THE HOOK DIRECTION (HN90F)

(Fig.18) The hook can be directed in the two direction. Remove

the hexagon socket cap screw with hexagon wrench, change the

direction, and then, put back the bolt to reassemble.

PROCEDURE

1 Pulling the Trigger and keeping it

pulled.

2 Depressing the Contact Arm.

CONTACT TRIP WITH

ANTI-DOUBLE FIRE

MECHANISM

The tool fires a nail each time when the

Contact Arm is depressed.

SEQUENTIAL TRIP The tool cannot fire a nail.

PROCEDURE

1 Depressing the Contact Arm.

2 Pulling the Trigger and keeping it

pulled.

CONTACT TRIP WITH

ANTI-DOUBLE FIRE

MECHANISM

The tool fires a nail.

The tool cannot fire a second nail until

the Trigger is released.

SEQUENTIAL TRIP The tool fires a nail.

In order to fire a second nail, you should

both release the Trigger and remove the

Contact arm from the surface.

Deep Shallow

WARNING

Tool Diameter Length

Object thickness

(Total) range

Light gauge

steel thickness

HN65

HN90F

2.5mm

(.098")

45mm

(1-3/4")

25 to 35mm

(1" to 1-3/8")

1.6 to 2.3mm

(16Ga. to

13Ga.)

50mm

(2")

30 to 40mm

(1-1/8" to 1-1/2")

57mm

(2-1/4")

35 to 45mm

(1-3/8" to 1-3/4")

65mm

(2-1/2")

45 to 55mm

(1-1/2" to 1-1/8")

HN90F

2.9mm

(.113")

45mm

(1-3/4")

25 to 35mm

(1" to 1-3/8")

1.6 to 3.2mm

(16Ga. to

11Ga.)

50mm

(2")

30 to 40mm

(1-1/8" to 1-1/2")

57mm

(2-1/4")

35 to 45mm

(1-3/8" to 1-3/4")

65mm

(2-1/2")

45 to 55mm

(1-1/2" to 1-1/8")

Wood

Object thickness

(Total) range

Penetration amount

Light gauge steel:

(HN65) 1.6mm (16Ga.) to 2.3mm

(13Ga.) thick

(HN90F) 1.6mm (16Ga.) to 3.2mm

(11Ga.) thick

∗ For the 3.2mm (11Ga.) thick light gauge steel, use the

2.9mm (.113") nails for steel plates. (HN90F)

Page 8

25

HN65(CE)

EXPLODED

VIEW AND SPARE

PARTS LIST

SCHEMA ECLATE ET

LISTE DES PIECES

DE RECHANGE

DESPIECE DE LA

MAQUINA Y LISTA

DE RECAMBIOS

EINZELTEILDAR-

STELLUNG UND

ERSATZTEILLISTE

ESPLOSO DEI

COMPONENTI ED

ELENCO DELLE

PARTI DI RICAMBIO

1

2

4

5

6

7

8

9

10

11

12

13

15

16

19

17

23

24

26

32

21

27

28

29

156

A

3

18

20

B

77

78

79

81

82

96

98

100

97

103

110

108

80

94

95

104

112

109

113

116

117

118

119

120

114

111

115

22

31

33

59

57

58

73

62

64

75

63

56

44

45

46

47

48

49

51

52

53

54

48

60

145

68

65

105

69

72

36

76

20

30

33

106

91

80

34

101

66

67

107

43

50

55

111

127

B

128

124

126

80

37

40

35

38

39

131

122

121

A

123

99

21

31

41

102

125

85

89

90

83

84

91

87

80

88

86

132

93

133

134

92

67

103

14

146

O-RING KIT

Parts marked

in included

are

the O-ring kit

147

72

158

64

71

70

48

49

51

53

56

58

48

157

159

154

155

160

52

54

57

59

148

6

74

130

129

161

Page 9

26

HN65(CE)

ITEM

NO.

PART

NO.

MATERIAL ENGLISH FRANÇAIS ESPAÑOL DEUTSCH ITALIANO

1 HN10338 Steel SCREW 5X36 VIS 5X36 TORNILLO 5X36 SCHRAUBE 5X36 VITE 5X36

2 HN11467 Aluminum CYLINDER CAP

CAPUCHON DE

CYLINDRE

TAPA DEL CILINDRO ZYLINDERDECKEL CALOTTA CILINDRO

3 HN11363 Steel, Rubber CYLINDER CAP SEAL

JOINT DE CAPUCHON DE

CYLINDRE

JUNTA ESTANCA DE

TAPA DEL CILINDRO

ZYLINDERDECKELDICHTUNG

GUARNIZIONE CALOTTA

CILINDRO

4 KK23650 Steel

COMPRESSION SPRING 3650 RESSORT À PRESSION 3650

MUELLE DE COMPRESIÓN

3650

DRUCKFEDER 3650

MOLLA DI COMPRESSIONE

3650

5 HN11364 Rubber PISTON STOP BUTÉE DE PISTON TOPE DEL PISTÓN KOLBENANSCHLAG ARRESTO PISTONE

6 HH11136 Rubber O-RING AS568-132

JOINT TORIQUE AS568132

JUNTA TÓRICA AS568132

O-RING AS568-132

GUARNIZIONE

CIRCOLARE AS568-132

7 HH19752 Rubber O-RING 1A 2X31.5

JOINT TORIQUE 1A

2X31,5

JUNTA TÓRICA 1A

2X31,5

O-RING 1A 2X31,5

GUARNIZIONE

CIRCOLARE 1A 2X31,5

8 HN11396 Polyacetal HEAD VALVE PISTON

PISTON DE

DISTRIBUTEUR AVANT

PISTÓN DE VÁLVULA DE

IMPULSIÓN

DRUCKVENTILKOLBEN

PISTONE VALVOLA DI

TESTA

9 HN11367 Aluminum HEAD VALVE GUIDE

GUIDE DE

DISTRIBUTEUR AVANT

GUÍA DE VÁLVULA DE

IMPULSIÓN

DRUCKVENTILFÜHRUNG

GUIDA VALVOLA DI

TESTA

10 HH14904 Rubber O-RING AS568-032

JOINT TORIQUE AS568032

JUNTA TÓRICA AS568032

O-RING AS568-032

GUARNIZIONE

CIRCOLARE AS568-032

11 HH11805 Rubber O-RING P22A JOINT TORIQUE P22A JUNTA TÓRICA P22A O-RING P22A

GUARNIZIONE

CIRCOLARE P22A

12 HN70108 Magnesium, Steel MAIN PISTON UNIT PISTON PRINCIPAL PISTÓN PRINCIPAL HAUPTKOLBENEINHEIT

UNITÀ PISTONE

PRINCIPALE

13 HN11370 Rubber CYLINDER SEAL JOINT DE CYLINDRE

JUNTA ESTANCA DEL

CILINDRO

ZYLINDERDICHTUNG GUARNIZIONE CILINDRO

14 EE31105 Steel PLANE WASHER 1-6 RONDELLE PLATE 1-6 ARANDELA 1-6 UNTERLEGSCHEIBE 1-6 RONDELLA PIANA 1-6

15 HH11135 Rubber O-RING 1A P31.5 JOINT TORIQUE 1A P31,5 JUNTA TÓRICA 1A P31,5 O-RING 1A P31,5

GUARNIZIONE

CIRCOLARE 1A P31,5

16 HN81140 Aluminum CYLINDER A CYLINDRE A CILINDRO "A" ZYLINDER A CILINDRO "A"

17 HH11174 Rubber O-RING 1A P35 JOINT TORIQUE 1A P35 JUNTA TÓRICA 1A P35 O-RING 1A P35

GUARNIZIONE

CIRCOLARE 1A P35

18 HN11369 Aluminum CYLINDER B CYLINDRE B CILINDRO "B" ZYLINDER B CILINDRO "B"

19 HN11384 Rubber BUMPER AMORTISSEUR AMORTIGUADOR STOSSDÄMPFER AMMORTIZZATORE

20 HN11374 Nylon EXHAUST COVER

CAPOT DE

L’ÉCHAPPEMENT

CUBIERTA DE ESCAPE ABLUFTGITTER COPERTURA SCARICO

21 HN81086 Nylon, Rubber EXHAUST COVER UNIT

UNITÉ DU CAPOT DE

L’ÉCHAPPEMENT

UNIDAD DE CUBIERTA DE

ESCAPE

ABLUFTGITTER-EINHEIT

UNITÀ COPERTURA

SCARICO

22 HN11376 Polyester FILTER B FILTRE B FILTRO "B" FILTER B FILTRO "B"

23 HN11375 Stainless steel FILTER A FILTRE A FILTRO "A" FILTER A FILTRO "A"

24 HN11361 Magnesium FRAME CHÂSSIS ARMAZÓN GEHÄUSE TELAIO

26 HN10810

Polyethylene

terephthalate

NAME LABEL A

ÉTIQUETTE NOMINATIVE AETIQUETA DE NOMBRE

"A"

NAMENSSCHILD A ETICHETTA NOME "A"

27 HN10811

Polyethylene

terephthalate

NAME LABEL B

ÉTIQUETTE NOMINATIVE BETIQUETA DE NOMBRE

"B"

NAMENSSCHILD B ETICHETTA NOME "B"

28 KK23507 Steel

COMPRESSION SPRING

3507

RESSORT À PRESSION

3507

MUELLE DE

COMPRESIÓN 3507

DRUCKFEDER 3507

MOLLA DI

COMPRESSIONE 3507

29 CN35075 Nylon TRIGGER LOCK LEVER

LEVIER DE BLOCAGE DE

LA COMMANDE

PALANCA DE SEGURO

DEL DISPARADOR

AUSLÖSESPERRHEBEL

LEVA DI BLOCCO DEL

GRILLETTO

30 FF21235 Steel ROLL PIN 3X30

GOUPILLE ÉLASTIQUE

3X30

PASADOR DE RODILLO

3X30

SPANNSTIFT 3X30 PERNO ROTANTE 3X30

31 HH11120 Rubber O-RING AS568-009

JOINT TORIQUE AS568009

JUNTA TÓRICA AS568009

O-RING AS568-009

GUARNIZIONE

CIRCOLARE AS568-009

32 HN11442 Aluminum PIPE TUBE TUBO ROHR TUBO

33 HH19127 Rubber O-RING 1A 1.5X6.6

JOINT TORIQUE 1A

1,5X6,6

JUNTA TÓRICA 1A

1,5X6,6

O-RING 1A 1,5X6,6

GUARNIZIONE

CIRCOLARE 1A 1,5X6,6

34 CN35074 Polyacetal TRIGGER LOCK DIAL

MOLETTE DE BLOCAGE

DE LA COMMANDE

DISCO DE BLOQUEO DEL

DISPARADOR

AUSLÖSESPERREEINSTELLRAD

MANOPOLA DI BLOCCO

DEL GRILLETTO

35 HN10379 Rubber GRIP COVER

REVÊTEMENT DE LA

POIGNÉE

CUBIERTA DE

EMPUÑADURA

GRIFFÜBERZUG

COPERTURA

IMPUGNATURA

36 HH14906 Rubber O-RING AS568-133

JOINT TORIQUE AS568133

JUNTA TÓRICA AS568133

O-RING AS568-133

GUARNIZIONE

CIRCOLARE AS568-133

37 TA17024

Polyacetal,

Polyethylene

END CAP FILTER KM-23

FILTRE DU CAPUCHON

D’EXTRÉMITÉ KM-23

FILTRO DE TAPÓN

TERMINAL KM-23

ENDKAPPENFILTER KM23

FILTRO PEZZO DI

CHIUSURA FINALE KM-

23

38 HH19102 Rubber O-RING 1A 2.4X31.8

JOINT TORIQUE 1A

2.4X31.8

JUNTA TÓRICA 1A

2,4X31,8

O-RING 1A 2,4X31,8

GUARNIZIONE

CIRCOLARE 1A 2,4X31,8

39 HN12037 Aluminum END CAP

CAPUCHON

D’EXTRÉMITÉ

TAPÓN TERMINAL ENDKAPPE

PEZZO DI CHIUSURA

FINALE

40 TT05416 Steel, Rubber AIR PLUG PRISE D’AIR TOMA DE AIRE LUFTSTECKER INNESTO RAPIDO ARIA

Page 10

27

41 HN10316 Rubber END PLUG CAP

CAPUCHON DE LA PRISE

D’EXTRÉMITÉ

TAPÓN TERMINAL DE

TOMA

ENDKAPPENSTOPFEN

TAPPO DI CHIUSURA

FINALE

42

43 BB40437 Steel SCREW 5X30 VIS 5X30 TORNILLO 5X30 SCHRAUBE 5X30 VITE 5X30

44 HN10820 Aluminum FEED NOZZLE BUSE DE CHARGEMENT

BOQUILLA DE

ALIMENTACIÓN

EINFÜLLSTUTZEN

UGELLO DI

ALIMENTAZIONE

45 HH19722 Rubber O-RING 1A 1.5X5 JOINT TORIQUE 1A 1,5X5 JUNTA TÓRICA 1A 1,5X5 O-RING 1A 1,5X5

GUARNIZIONE

CIRCOLARE 1A 1,5X5

46 HN10043 Steel PILOT CAP CAPUCHON PILOTE TAPÓN PILOTO PILOTKAPPE

PEZZO DI CHIUSURA

PILOTA

47 HN10018 Rubber PILOT SEAL JOINT PILOTE JUNTA ESTANCA PILOTO PILOTDICHTUNG GUARNIZIONE PILOTA

48 HH12105 Rubber O-RING 1A 1.5X12.8

JOINT TORIQUE 1A

1,5X12,8

JUNTA TÓRICA 1A

1,5X12,8

O-RING 1A 1,5X12,8

GUARNIZIONE

CIRCOLARE 1A 1,5X12,8

49 HN10016 Polyacetal

TRIGGER VALVE

HOUSING

LOGEMENT DE LA VALVE

DE DÉCLENCHEMENT

CARCASA DE VÁLVULA

DEL DISPARADOR

AUSLÖSEVENTILGEHÄUSE

ALLOGGIAMENTO

VALVOLA GRILLETTO

50 HN81098 Polyacetal, Rubber PILOT VALVE ASSY

ENSEMBLE DU

DISTRIBUTEUR PILOTE

CONJUNTO DE VÁLVULA

PILOTO

PILOTVENTILBAUGRUPPE

GRUPPO VALVOLA

PILOTA

51 HH11208 Rubber O-RING 1B P6 JOINT TORIQUE 1B P6 JUNTA TÓRICA 1B P6 O-RING 1B P6

GUARNIZIONE

CIRCOLARE 1B P6

52 HN10017 Polyacetal PILOT VALVE DISTRIBUTEUR PILOTE VÁLVULA PILOTO PILOTVENTIL VALVOLA PILOTA

53 HH11132 Rubber O-RING 1A P10A JOINT TORIQUE 1A P10A JUNTA TÓRICA 1A P10A O-RING 1A P10A

GUARNIZIONE

CIRCOLARE 1A P10A

54 KK23619 Steel

COMPRESSION SPRING

3619

RESSORT À PRESSION

3619

MUELLE DE

COMPRESIÓN 3619

DRUCKFEDER 3619

MOLLA DI

COMPRESSIONE 3619

55 HN81311

Steel, Polyacetal,

Rubber

TRIGGER VALVE STEM

ASSY

ENSEMBLE DE TIGE DE

MANŒUVRE DU

DÉCLENCHEUR

CONJUNTO DE VÁSTAGO

DE VÁLVULA DEL

DISPARADOR

AUSLÖSEVENTILSCHAFTBAUGRUPPE

GRUPPO STELO

VALVOLA GRILLETTO

56 HH19707 Rubber O-RING 1A 1.4X2.5

JOINT TORIQUE 1A

1,4X2,5

JUNTA TÓRICA 1A

1,4X2,5

O-RING 1A 1,4X2,5

GUARNIZIONE

CIRCOLARE 1A 1,4X2,5

57 HN10353 Steel, Rubber TRIGGER VALVE STEM

TIGE DE MANŒUVRE DU

DÉCLENCHEUR

VÁSTAGO DE VÁLVULA

DEL DISPARADOR

AUSLÖSEVENTILSCHAFT

STELO VALVOLA

GRILLETTO

58 HH19214 Rubber O-RING 1B 1.5X3 JOINT TORIQUE 1B 1,5X3 JUNTA TÓRICA 1B 1,5X3 O-RING 1B 1,5X3

GUARNIZIONE

CIRCOLARE 1B 1,5X3

59 HN10019 Steel TRIGGER VALVE CAP

CAPUCHON DE LA VALVE

DU DÉCLENCHEUR

TAPÓN DE VÁLVULA DEL

DISPARADOR

AUSLÖSEVENTILKAPPE

CAPPELLETTO VALVOLA

GRILLETTO

60 HN80077

Steel, Polyacetal,

Rubber

TRIGGER ASSY

ENSEMBLE DU

DÉCLENCHEUR

CONJUNTO DE

DISPARADOR

AUSLÖSER-BAUGRUPPE GRUPPO GRILLETTO

62 CN35115 Steel CONTACT LEVER A LEVIER À CONTACT A

PALANCA DE CONTACTO

"A"

KONTAKTHEBEL A LEVA Dl CONTATTO "A"

63 HS10147 Polyacetal TRIGGER DÉCLENCHEUR DISPARADOR AUSLÖSER GRILLETTO

64 FF22402 Stainless steel ROLL PIN 3X16

GOUPILLE ÉLASTIQUE

3X16

PASADOR DE RODILLO

3X16

SPANNSTIFT 3X16 PERNO ROTANTE 3X16

65 HN11399 Nylon SWITCH LEVER A

LEVIER DE

COMMUTATEUR A

PALANCA

CONMUTADORA "A"

SCHALTHEBEL A LEVA INTERRUTTORE "A"

66 HN10786 Stainless steel ARM GUIDE PLATE PLAQUE GUIDE DU BRAS

PLACA DE GUÍA DEL

BRAZO

ARMLEITBLECH

PIASTRA GUIDA

BRACCIO

67 HN10785 Rubber CONTACT BUMPER

AMORTISSEUR DE

CONTACT

AMORTIGUADOR DE

CONTACTO

KONTAKTSTOSSFÄNGER

AMMORTIZZATORE

CONTATTO

68 HS10146 Steel SWITCH LEVER B

LEVIER DE

COMMUTATEUR B

PALANCA

CONMUTADORA "B"

SCHALTHEBEL B LEVA INTERRUTTORE "B"

69 CN34500 Steel SWITCH SPRING

RESSORT DU

COMMUTATEUR

MUELLE CONMUTADOR SCHALTFEDER MOLLA INTERRUTTORE

70 KK23735 Steel

COMPRESSION SPRING

3735

RESSORT À PRESSION

3735

MUELLE DE

COMPRESIÓN 3735

DRUCKFEDER 3735

MOLLA DI

COMPRESSIONE 3735

71 KK23736 Steel

COMPRESSION SPRING

3736

RESSORT À PRESSION

3736

MUELLE DE

COMPRESIÓN 3736

DRUCKFEDER 3736

MOLLA DI

COMPRESSIONE 3736

72 KK23129 Steel

COMPRESSION SPRING

3129

RESSORT À PRESSION

3129

MUELLE DE

COMPRESIÓN 3129

DRUCKFEDER 3129

MOLLA DI

COMPRESSIONE 3129

73 HN10784 Nylon ARM GUIDE GUIDE DU BRAS GUÍA DEL BRAZO ARMFÜHRUNG GUIDA BRACCIO

74 KK23912 Steel

COMPRESSION SPRING

3912

RESSORT À PRESSION

3912

MUELLE DE

COMPRESIÓN 3912

DRUCKFEDER 3912

MOLLA DI

COMPRESSIONE 3912

75 HN10356 Steel CONTACT ARM A BRAS DE CONTACT A BRAZO DE CONTACTO "A" KONTAKTARM A

BRACCIO DI CONTATTO

"A"

76 HN10026 Polyacetal ADJUST DIAL MOLETTE DE RÉGLAGE DISCO DE AJUSTE EINSTELLRAD

MANOPOLA DI

REGOLAZIONE

77 HN11389 Nylon ADJUST SPACER

ENTRETOISE

D’AJUSTEMENT

ESPACIADOR DE AJUSTE

EINSTELLABSTANDSHALTER

DISTANZIATORE DI

REGOLAZIONE

78 HH14164 Rubber O-RING AS 568-030

JOINT TORIQUE AS 568030

JUNTA TÓRICA AS 568030

O-RING AS 568-030

GUARNIZIONE

CIRCOLARE AS 568-030

HN65(CE)

ITEM

NO.

PART

NO.

MATERIAL ENGLISH FRANÇAIS ESPAÑOL DEUTSCH ITALIANO

Page 11

28

79 HN11380 Steel NOSE BUSE NARIZ NASE PUNTA

80 EE39602 Rubber RUBBER WASHER 7

RONDELLE DE

CAOUTCHOUC 7

ARANDELA DE CAUCHO 7 GUMMISCHEIBE 7 RONDELLA DI GOMMA 7

81 BB40213 Steel SCREW 6X25 VIS 6X25 TORNILLO 6X25 SCHRAUBE 6X25 VITE 6X25

82 FF31250 Steel PARALLEL PIN 1250

GOUPILLE PARALLÈLE

1250

PERNO PARALELO 1250 ZYLINDERSTIFT 1250 PERNO PARALLELO 1250

83 CN33679 Steel DOOR LATCH VERROU DE PORTE CIERRE DE PUERTA KLAPPENVERSCHLUSS

DISPOSITIVO DI

CHIUSURA

SPORTELLINO

84 KK33353 Steel TORSION SPRING 3353

RESSORT DE TORSION

3353

MUELLE DE TORSIÓN

3353

TORSIONSFEDER 3353

MOLLA Dl TORSIONE

3353

85 HN11463 Steel RATCHET A CLIQUET A TRINQUETE "A" SPERRKLINKE A ROCCHETTO "A"

86 CN34479 Steel RATCHET B CLIQUET B TRINQUETE "B" SPERRKLINKE B ROCCHETTO "B"

87 KK23282 Steel

COMPRESSION SPRING

3282

RESSORT À PRESSION

3282

MUELLE DE

COMPRESIÓN 3282

DRUCKFEDER 3282

MOLLA DI

COMPRESSIONE 3282

88 FF41281 Steel STEP PIN 1281

BOULON À GRADINS

1281

PERNO ESCALONADO

1281

STUFENBOLZEN 1281 PERNO SCALARE 1281

89 FF41599 Steel STEP PIN 1599

BOULON À GRADINS

1599

PERNO ESCALONADO

1599

STUFENBOLZEN 1599 PERNO SCALARE 1599

90 HN11382 Steel DOOR PORTE PUERTA KLAPPE SPORTELLINO

91 EE39609 Rubber

RUBBER WASHER

1.8X6X2

RONDELLE DE

CAOUTCHOUC 1,8X6X2

ARANDELA DE CAUCHO

1,8X6X2

GUMMISCHEIBE 1,8X6X2

RONDELLA IN GOMMA

1,8X6X2

92 EE39172 Steel

PLANE WASHER

5.1X12X1.2

RONDELLE PLATE

5,1X12X1,2

ARANDELA 5,1X12X1,2

UNTERLEGSCHEIBE

5,1X12X1,2

RONDELLA PIANA

5,1X12X1,2

93 BB40427 Steel SCREW 4X8 VIS 4X8 TORNILLO 4X8 SCHRAUBE 4X8 VITE 4X8

94 BB40407 Steel SCREW 5X20 VIS 5X20 TORNILLO 5X20 SCHRAUBE 5X20 VITE 5X20

95 HN12405 Steel CONTACT BOLT BOULON DE CONTACT PERNO DE CONTACTO KONTAKTBOLZEN BULLONE DI CONTATTO

96 HH11903 Rubber O-RING 1A 1.2X4 JOINT TORIQUE 1A 1,2X4 JUNTA TÓRICA 1A 1,2X4 O-RING 1A 1,2X4

GUARNIZIONE

CIRCOLARE 1A 1,2X4

97 JJ80010 Steel U-RETAINING RING 3.2

BAGUE-U DE RETENUE

3,2

ANILLO DE RETENCIÓN

EN "U" 3,2

U-HALTERING 3,2

ANELLO DI FISSAGGIO A

"U" 3,2

98 KK29136 Steel

COMPRESSION SPRING

3952

RESSORT À PRESSION

3952

MUELLE DE

COMPRESIÓN 3952

DRUCKFEDER 3952

MOLLA DI

COMPRESSIONE 3952

99 HN70111 Steel CONTACT ARM B UNIT

UNITÉ DU BRAS DE

CONTACT B

BRAZO DE CONTACTO

“B”

KONTAKTARM-EINHEIT B

UNITÀ BRACCIO DI

CONTATTO "B"

100 HN81108 Steel, Rubber CONTACT NOSE L ASSY

ENSEMBLE DE LA BUSE

DE CONTACT L

CONJUNTO DE NARIZ DE

CONTACTO "L"

KONTAKTNASEBAUGRUPPE L

GRUPPO PUNTA DI

CONTATTO "L"

101 HN81107 Steel, Rubber CONTACT NOSE S ASSY

ENSEMBLE DE LA BUSE

DE CONTACT S

CONJUNTO DE NARIZ DE

CONTACTO "S"

KONTAKTNASEBAUGRUPPE S

GRUPPO PUNTA DI

CONTATTO "S"

102 FF31602 Steel PARALLEL PIN 1602

GOUPILLE PARALLÈLE

1602

PERNO PARALELO 1602 ZYLINDERSTIFT 1602 PERNO PARALLELO 1602

103 HN11984 Steel CHECK PAWL CLIQUET D’ARRÊT

TRINQUETE DE

RETENCIÓN

PRÜFKLINKE

NOTTOLINO DI

CONTROLLO

104 KK33221 Steel TORSION SPRING 3221

RESSORT DE TORSION

3221

MUELLE DE TORSIÓN

3221

TORSIONSFEDER 3221

MOLLA Dl TORSIONE

3221

105 KK23653 Steel

COMPRESSION SPRING

3653

RESSORT À PRESSION

3653

MUELLE DE

COMPRESIÓN 3653

DRUCKFEDER 3653

MOLLA DI

COMPRESSIONE 3653

106 KK23788 Steel

COMPRESSION SPRING

3788

RESSORT À PRESSION

3788

MUELLE DE

COMPRESIÓN 3788

DRUCKFEDER 3788

MOLLA DI

COMPRESSIONE 3788

107 KK23710 Steel

COMPRESSION SPRING

3710

RESSORT À PRESSION

3710

MUELLE DE

COMPRESIÓN 3710

DRUCKFEDER 3710

MOLLA DI

COMPRESSIONE 3710

108 FF41817 Steel STEP PIN 1817

BOULON À GRADINS

1817

PERNO ESCALONADO

1817

STUFENBOLZEN 1817 PERNO SCALARE 1817

109 HN11462 Steel FEED PAWL

CLIQUET

D’ALIMENTATION

TRINQUETE DE AVANCE VORSCHUBKLINKE

NOTTOLINO DI

ALIMENTAZIONE

110 HN11385 Nylon ARM COVER CAPOT DU BRAS CUBIERTA DE BRAZO ARMABDECKUNG COPERTURA BRACCIO

111 CC00401 Steel HEX NUT M5 ÉCROU HEXAGONAL M5 TUERCA HEXAGONAL M5 SECHSKANTMUTTER M5 DADO ESAGONALE M5

112 HH11113 Rubber O-RING 1A P9 JOINT TORIQUE 1A P9 JUNTA TÓRICA 1A P9 O-RING 1A P9

GUARNIZIONE

CIRCOLARE 1A P9

113 HN11390 Steel FEED PISTON

PISTON

D’ALIMENTATION

PISTÓN DE AVANCE VORSCHUBKOLBEN

PISTONE DI

ALIMENTAZIONE

114 HH11106 Rubber O-RING 1A P16 JOINT TORIQUE 1A P16 JUNTA TÓRICA 1A P16 O-RING 1A P16

GUARNIZIONE

CIRCOLARE 1A P16

115 KK23724 Steel

COMPRESSION SPRING

3724

RESSORT À PRESSION

3724

MUELLE DE

COMPRESIÓN 3724

DRUCKFEDER 3724

MOLLA DI

COMPRESSIONE 3724

116 KK23173 Steel

COMPRESSION SPRING

3173

RESSORT À PRESSION

3173

MUELLE DE

COMPRESIÓN 3173

DRUCKFEDER 3173

MOLLA DI

COMPRESSIONE 3173

117 CN37998 Rubber FEED PISTON STOP

ARRÊT DU PISTON

D’ALIMENTATION

TOPE DE PISTÓN DE

AVANCE

VORSCHUBKOLBENANSCHLAG

ARRESTO PISTONE DI

ALIMENTAZIONE

HN65(CE)

ITEM

NO.

PART

NO.

MATERIAL ENGLISH FRANÇAIS ESPAÑOL DEUTSCH ITALIANO

Page 12

29

118 CN35285 Steel SPRING COLLAR COLLIER A RESSORT COLLARÍN DE MUELLE FEDERTELLER COLLARE MOLLA

119 JJ22408 Stainless steel

C-RETAINING RING 24

SUS

C-BAGUE DE RETENUE 24

SUS

ANILLO DE RETENCIÓN

EN "C" 24 SUS

C-HALTERING 24 SUS

ANELLO DI FISSAGGIO A

"C" 24 SUS

120 CN37383 Nylon SPRING HOOK CROCHET À RESSORT GANCHO DE MUELLE FEDERHAKEN GANCIO MOLLA

121 KK13051 Steel TENSION SPRING 3051

RESSORT DE TENSION

3051

MUELLE TENSOR 3051 ZUGFEDER 3051

MOLLA DI

TENSIONAMENTO 3051

122 CN30601 Rubber

VIBRATION-PROOF

BLOCK

BLOC ANTIVIBRATION BLOQUE ANTIVIBRACIÓN

VIBRATIONSBESTÄNDIGER BLOCK

BLOCCO A PROVA DI

VIBRAZIONI

123 FF41287 Steel STEP PIN 1287

BOULON À GRADINS

1287

PERNO ESCALONADO

1287

STUFENBOLZEN 1287 PERNO SCALARE 1287

124 HN10805 Rubber CONTACT TIP EXTRÉMITÉ DE CONTACT PUNTA DE CONTACTO KONTAKTSPITZE PUNTA DI CONTATTO

125 CN35388 Nylon MAGAZINE MAGASIN CARGADOR MAGAZIN CARICATORE

126 HN10389 Polyacetal NAIL SUPPORT SUPPORT À CLOUS SOPORTE DE CLAVOS NAGELTRÄGER SUPPORTO CHIODI

127 CN37428 Nylon POST CAP CAPUCHON AVANT TAPA DEL POSTE PFOSTENKAPPE CAPPUCCIO COLONNINA

128 HN81401

Polyethylene

terephthalate

MAGAZINE CAP ASSY

ENSEMBLE DU CAPOT

DU MAGASIN

CONJUNTO DE TAPA DEL

CARGADOR

MAGAZINKAPPENBAUGRUPPE

GRUPPO COPERCHIO

CARICATORE

129 CN35651 Nylon MAGAZINE CAP

COUVERCLE DU

MAGASIN

TAPA DEL CARGADOR MAGAZINKAPPE

COPERCHIO

CARICATORE

130 HN12403

Polyethylene

terephthalate

WARNING LABEL

ÉTIQUETTE

D’AVERTISSEMENT

ETIQUETA DE

ADVERTENCIA

WARNSCHILD

TARGHETTA DI

AVVERTENZA

131 HN81059 MAGAZINE ASSY ENSEMBLE DU MAGASIN

CONJUNTO DE

CARGADOR

MAGAZINBAUGRUPPE GRUPPO CARICATORE

132 HN81013 Brass MAGNET ASSY

ENSEMBLE

MAGNÉTIQUE

IMÁN MAGNETBAUGRUPPE GRUPPO MAGNETE

133 HN11386 Polyvinyl Chloride DUST COVER CAPOT ANTIPOUSSIÈRE CUBIERTA ANTIPOLVO STAUBABDECKUNG

PROTEZIONE

ANTIPOLVERE

134 CN31083 Rubber DUST COVER FITTING

FIXATION DU CAPOT

ANTIPOUSSIÈRE

ELEMENTO DE FIJACIÓN

DE CUBIERTA

ANTIPOLVO

STAUBABDECKUNGVERBINDUNGSSTÜCK

RACCORDO PROTEZIONE

ANTIPOLVERE

145 HN81402 ARM GUIDE KIT KIT GUIDE DU BRAS KIT DE GUÍA DEL BRAZO ARMFÜHRUNGSKIT KIT GUIDA BRACCIO

146 HN81091 SEQUENTIAL TRIP KIT

KIT DE DÉCLENCHEMENT

SÉQUENTIEL

KIT DE DISPARO

SECUENCIAL

KIT FÜR FORTLAUFENDE

AUSLÖSUNG

KIT DI ATTIVAZIONE IN

SEQUENZA

147 HN81090 O-RING KIT KIT DE JOINT TORIQUE KIT DE JUNTA TÓRICA O-RING-KIT

KIT GUARNIZIONE

CIRCOLARE

148 HN81309 TRIGGER VALVE KIT

KIT DE MANŒUVRE DU

DÉCLENCHEUR

KIT DE VÁLVULA DEL

DISPARADOR

AUSLÖSEVENTIL-KIT KIT VALVOLA GRILLETTO

149 TA81014 STEP PIN KIT ASSY

ASSEMBLAGE KIT DU

BOULON À GRADINS

KIT DE PERNO

ESCALONADO

STUFENBOLZEN-KITBAUGRUPPE

GRUPPO KIT PERNO

SCALARE

154 HN10100 Steel CONTACT LEVER LEVIER À CONTACT PALANCA DE CONTACTO KONTAKTHEBEL LEVA Dl CONTATTO

155 KK33300 Steel TORSION SPRING 3300

RESSORT DE TORSION

3300

MUELLE DE TORSIÓN

3300

TORSIONSFEDER 3300

MOLLA Dl TORSIONE

3300

156 HN10403 Polyacetal TRIGGER DÉCLENCHEUR DISPARADOR AUSLÖSER GRILLETTO

157 HN11420 Steel ARM GUIDE PIN

GOUPILLE DU GUIDE DU

BRAS

PERNO DE GUÍA DEL

BRAZO

ARMFÜHRUNGSSTIFT PERNO GUIDA BRACCIO

158 HN11418 Nylon ARM GUIDE GUIDE DU BRAS GUÍA DEL BRAZO ARMFÜHRUNG GUIDA BRACCIO

159 HN10357 Rubber CONTACT BUMPER

AMORTISSEUR DE

CONTACT

AMORTIGUADOR DE

CONTACTO

KONTAKTSTOSSFÄNGER

AMMORTIZZATORE

CONTATTO

160 HN10401 Steel CONTACT ARM A BRAS DE CONTACT A BRAZO DE CONTACTO "A" KONTAKTARM A

BRACCIO DI CONTATTO

"A"

161 HN12632

Polyethylene

terephthalate

WARNING LABEL 2

ÉTIQUETTE

D’AVERTISSEMENT 2

ETIQUETA DE

ADVERTENCIA 2

WARNSCHILD 2

TARGHETTA DI

AVVERTENZA 2

HN65(CE)

ITEM

NO.

PART

NO.

MATERIAL ENGLISH FRANÇAIS ESPAÑOL DEUTSCH ITALIANO

Page 13

40

Page 14

41

Page 15

42

Page 16

EC DECLARATION OF CONFORMITY

We hereby declare that the product titled in this instruction manual

conforms to the essential health and safety requirements of EC Directives

as below.

Directive : Machinery Directive 2006/42/EC

Manufacturer : MAX CO., LTD.

1848, Kawai, Tamamura-machi, Sawa-gun,

Gunma, 370-1117 JAPAN

This product has been evaluated for conformity with the above directives

using the following standards.

DÉCLARATION DE CONFORMITÉ CE

Nous déclarons par la présente que le produit du titre de ce manuel

d’ instructions est conforme aux exigences essentielles de santé et de

sécurité des Directives CE décrites ci-dessous.

Directive : Directive de Mécanique 2006/42/CE

Fabricant

Ce produit a été évalué quant à sa conformité avec les directives

ci-dessus selon les normes suivantes.

Nailer

121127

DECLARACIÓN EC DE CONFORMIDAD

Por este medio declaramos que el producto mencionado en este manual

de instrucciones se encuentra en conformidad con los requerimientos de

salud y de seguridad esenciales de las Directivas CE.

Directiva : Directiva sobre Maquinaria 2006/42/CE

Fabricante

Este producto ha sido evaluado en conformidad con las directivas

antes mencionadas utilizando las normas siguientes.

EG-KONFORMITÄTSERKLÄRUNG

Wir erklären hiermit, dass das in dieser Bedienungsanleitung

beschriebene Produkt mit den maßgeblichen Gesundheits- und

Sicherheitsvorschriften der EG-Richtlinien konform ist, wie nachstehend

beschrieben.

Richtlinie : Maschinenrichtlinie 2006/42/EG

Hersteller

Dieses Produkt wurde auf seine Konformität mit den oben genannten

Richtlinien unter Verwendung der folgenden Standards überprüft.

Maschinenrichtlinie : EN ISO 12100 : 2010

EN792-13 :2000+A1 :2008

ISO11148-13

Directive de Mécanique : EN ISO 12100 : 2010

EN792-13 :2000+A1 :2008

ISO11148-13

DICHIARAZIONE DI CONFORMITÀ CE

Si dichiara qui che il prodotto riferito in questo manuale di istruzioni

risulta conforme ai requisiti di base concernenti la salute e la sicurezza,

espressi dalle direttive CE, come riportato di seguito.

Direttiva : Direttiva Macchine 2006/42/CE

Produttore : MAX CO., LTD.

1848, Kawai, Tamamura-machi, Sawa-gun,

Gunma, 370-1117 GIAPPONE

Directiva sobre maquinaria : EN ISO 12100 : 2010

EN792-13 :2000+A1 :2008

ISO11148-13

Questo prodotto è stato valutato per la conformità alle direttive

indicate sopra utilizzando gli standard seguenti.

Titolo : Direttore generale, Reparto controllo qualità,

MAX CO.,LTD.

Indirizzo

: 1848, Kawai, Tamamura-machi, Sawa-gun,

Gunma, 370-1117 GIAPPONE

Sede in Europa : MAX.EUROPE BV/Presidente della società

MAX.EUROPE Camerastraat 19,

1322 BB Almere, Olanda

Direttiva Macchine : EN ISO 12100 : 2010

EN792-13 :2000+A1 :2008

ISO11148-13

: MAX CO., LTD.

1848, Kawai, Tamamura-machi, Sawa-gun,

Gunma, 370-1117 JAPON

Agent de conformité agréé : MAXEUROPE BV/Président dans

la communauté Camerastraat 19,

1322 BB Almere, Pays-Bas

Titre : Directeur général du service Assurance

qualité et environnement, MAX CO.,LTD.

Adresse

: 1848, Kawai, Tamamura-machi, Sawa-gun,

Gunma, 370-1117 JAPON

: MAX CO., LTD.

1848, Kawai, Tamamura-machi, Sawa-gun,

Gunma, 370-1117 JAPÓN

Título : Director General del Departamento de Control

de Calidad y Medio Ambiente, MAX CO., LTD.

Dirección

: 1848, Kawai, Tamamura-machi, Sawa-gun,

Gunma, 370-1117 JAPÓN

Complier autorizado : MAX.EUROPE BV/Presidente de la comunidad

Camerastraat 19,1322 BB Almere, Paises Bajos

: MAX CO., LTD.

1848, Kawai, Tamamura-machi, Sawa-gun,

Gunma, 370-1117 JAPAN

Machinery Directive : EN ISO 12100 : 2010

EN792-13 :2000+A1 :2008

ISO11148-13

Address

Gunma, 370-1117 JAPAN

: 1848, Kawai, Tamamura-machi, Sawa-gun,

Title : Environment and Quality Assurance Dept.

General Manager, MAX CO.,LTD.

Authorized complier : MAX.EUROPE BV/President in

the community Camerastraat 19,1322 BB

Almere, The Netherlands

Position : Geschäftsführer, Abteilung für Umwelt und

Qualitätssicherung, MAX CO.,LTD.

Adresse

: 1848, Kawai, Tamamura-machi, Sawa-gun,

Gunma, 370-1117 JAPAN

Autorisierter Entsorger : MAX.EUROPE BV/Präsident in der Gemeinschaft

Camerastraat 19, 1322 BB Almere, Niederlande

HN65, HN65J, HN90F

Page 17

• The content of this manual might be changed without notice for improvement.

• Le contenu de ce manuel est sujet à modification sans préavis à des fins d’amélioration.

• El contenido de este manual puede ser cambiado sin noticia previa para mejoramiento.

• Änderungen der Betriebsanleitung zum Zwecke der Verbesserung ohne Ankündigung vorbehalten.

• I contenuti di questo manuale possono essere cambiati senza preavviso per motivi di miglioramento

del prodotto.

4100779

170818-00/01

www.max-europe.com (EUROPE Site)

www.maxusacorp.com (USA Site)

wis.max-ltd.co.jp/int/ (GLOBAL Site)

Camerastraat 19

1322 BB

Almere The Netherlands

Phone: +31-36-546-9669

FAX: +31-36-536-3985

257 East 2nd Street

Mineola, NY 11501, U.S.A.

TEL: 1-800-223-4293

FAX: (516)741-3272

Loading...

Loading...