Page 1

HN100

(

CE

)

HIGH PRESSURE FRAMING TOOL

HOCHDRUCKGESTALTENWERKZEUG

OUTIL D’ENCADREMENT À HAUTE

PRESSION

ATTREZZO PER INCORNICIATURA AD

ALTA PRESSIONE

HERRAMIENTA DE ENMARCADO DE

ALTA PRESIÓN

OPERATING and MAINTENANCE MANUAL

BETRIEBSANLEITUNG

MANUEL D’UTILISATION et D’ENTRETIEN

MANUALE DI FUNZIONAMENTO E MANUTENZIONE

MANUAL DE OPERACIONES Y MANTENIMIENTO

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY WARNING AND

INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

WARNING

LESEN SIE VOR INBETRIEBNAHME DES GERÄTES DIE GEBRAUCHS- UND SICHERHEITSHINWEISE. BITTE BEWAHREN SIE DIE GEBRAUCHS- UND SICHERHEITSHINWEISE AUF,

DAMIT SIE AUCH SPÄTER EINGESEHEN WERDEN KÖNNEN.

ACHTUNG

AVANT D’UTILISER CET OUTIL, LIRE CE MANUEL ET LES CONSIGNES DE SECURITE

AFIN DE GARANTIR UN FONCTIONNEMENT SUR.

CONSERVER CE MANUEL EN LIEU SUR AVEC L’OUTIL AFIN DE POUVOIR LE

CONSULTER ULTERIEUREMENT.

AVERTISSEMENT

PRIMA DI USARE QUESTA MACCHINA, STUDIARE IL MANUALE PER PRENDERE ATTO

DEGLI AVVERTIMENTI E DELLE ISTRUZIONIPER LA SICUREZZA.

TENERE QUESTE ISTRUZIONI INSIEME ALLO STRUMENTO PER CONSULTAZIONI FUTURE.

ATTENZIONE

PARA EVITAR GRAVES DAÑOS PERSONALES O EN LA PROPIEDAD.

ANTES DE EMPLEAR LA HERRAMIENTA, LEER CON ATENCIÓN Y COMPRENDER LOS

SIGUIENTES INSTRUCCIONES DE SEGURIDAD.

ATENCIÓN

Page 2

2

DEFINITIONS OF SIGNAL WORDS

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

NOTE: Emphasizes essential information.

DEFINITIONEN DER HINWEISBEZEICHNUNGEN

ACHTUNG! Zeigt eine eventuell gefährliche Situation an, die den Tod oder schwere Verletzungen

zur Folge haben könnte, wenn sie nicht vermieden wird.

VORSICHT! Zeigt eine eventuell gefährliche Situation an, die leichte oder mittelschwere

Verletzungen zur Folge haben könnte, wenn sie nicht vermieden wird.

HINWEIS: Hebt wichtige Informationen hervor.

DÉFINITIONS DES DIFFÉRENTS DEGRÉS D’ AVERTISSEMENTS

AVERTISSEMENT Indique une situation éventuellement dangereuse qui, si elle n’est pas contournée,

pourrait provoquer la mort ou des blessure sérieuses.

ATTENTION Indique une situation éventuellement dangereuse qui, si elle n’est pas contournée,

pourrait provoquer des blessures légères à moyennement sérieuses.

REMARQUE Souligne des informations importantes.

DEFINIZIONE DELLE INDICAZIONI DI AVVERTIMENTO

ATTENZIONE: Indica l’eventualità che possa verificarsi una situazione pericolosa, la quale se non

viene evitata, può risultare letale o provocare gravi lesioni.

AVVERTENZA: Indica l’eventualità che possa verificarsi una situazione pericolosa, la quale se non

viene evitata, può provocare lesioni di lieve o media entità.

NOTA: Evidenzia informazioni importanti.

DEFINICIÓN DE LAS INDICACIONES DE ADVERTENCIA

¡

ATENCIÓN! Indica una situación potencialmente peligrosa que podría causar la muerte o graves

lesiones si no se evita.

¡

PRECAUCIÓN! Indica una situación potencialmente peligrosa que podría causar lesiones menos

graves o leves si no se evita.

NOTA: Resalta informaciones importantes.

ENGLISH Page 3 to 16 Page

DEUTSCH Page 17 to 30 Page

FRANÇAIS Page 31 to 44 Page

ITALIANO Page 45 to 58 Page

ESPAÑOL Page 59 to 72 Page

INDEX INHALTSVERZEICHNIS INDEX INDICE INDICE

Page 3

3

OPERATING and MAINTENANCE MANUAL

INDEX

1. SAFETY INSTRUCTIONS

…… …… …… …… …… …… …… …… …… …… …… …… …… …… …… ……

3

2. SPECIFICATIONS & TECHNICAL DATA

…… …… …… …… …… …… …… …… …… …… ……

7

3. AIR SUPPLY AND CONNECTIONS

…… …… …… …… …… …… …… …… …… …… …… …… ……

8

4. INSTRUCTIONS FOR OPERATION

…… …… …… …… …… …… …… …… …… …… …… …… ……

10

5. MAINTENANCE

…… …… …… …… ……………………………………………………………………………………

15

6. STORAGE

…… …… …… ……………………………………………………………………………………………………

15

7. TROUBLESHOOTING/REPAIRS

…… …… …… …… …… …… …… …… …… …… …… …… …… ……

15

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY

WARNING AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

WARNING

1. SAFETY INSTRUCTIONS

TO AVOID SEVERE PERSONAL INJURY OR

PROPERTY DAMAGE

BEFORE USING THE TOOL, READ

CAREFULLY AND UNDERSTAND THE

FOLLOWING “SAFETY INSTRUCTIONS”.

FAILURE TO FOLLOW WARNINGS COULD

RESULT IN DEATH OR SERIOUS INJURY.

WARNING

1. WEAR SAFETY GLASSES OR GOGGLES

Danger to the eyes always exists due to the

possibility of dust being blown up by the

exhausted air or of a fastener flying up due to

the improper handling of the tool. For these

reasons, safety glasses or goggles shall

always be worn when operating the tool.

The employer and/or user must ensure that

proper eye protection is worn. Eye protection

equipment must conform to the requirements

of Council Directive 89/686/EEC of 21 DEC.

1989 (the American National Standards

Institute, ANSI Z87.1) and provide both frontal

and side protection.

The employer is responsible to enforce the

use of eye protection equipment by the tool

operator and all other personnel in the work

area.

NOTE: Non-side shielded spectacles and

face shields alone do not provide adequate

protection.

ENGLISH

PRECAUTIONS ON USING THE TOOL

Page 4

ENGLISH

4

2. EAR PROTECTION MAY BE REQUIRED IN

SOME ENVIRONMENTS

As the working condition may include

exposure to high noise levels which can lead

to hearing damage, the employer and user

should ensure that any necessary hearing

protection is provided and used by the

operator and others in the work area.

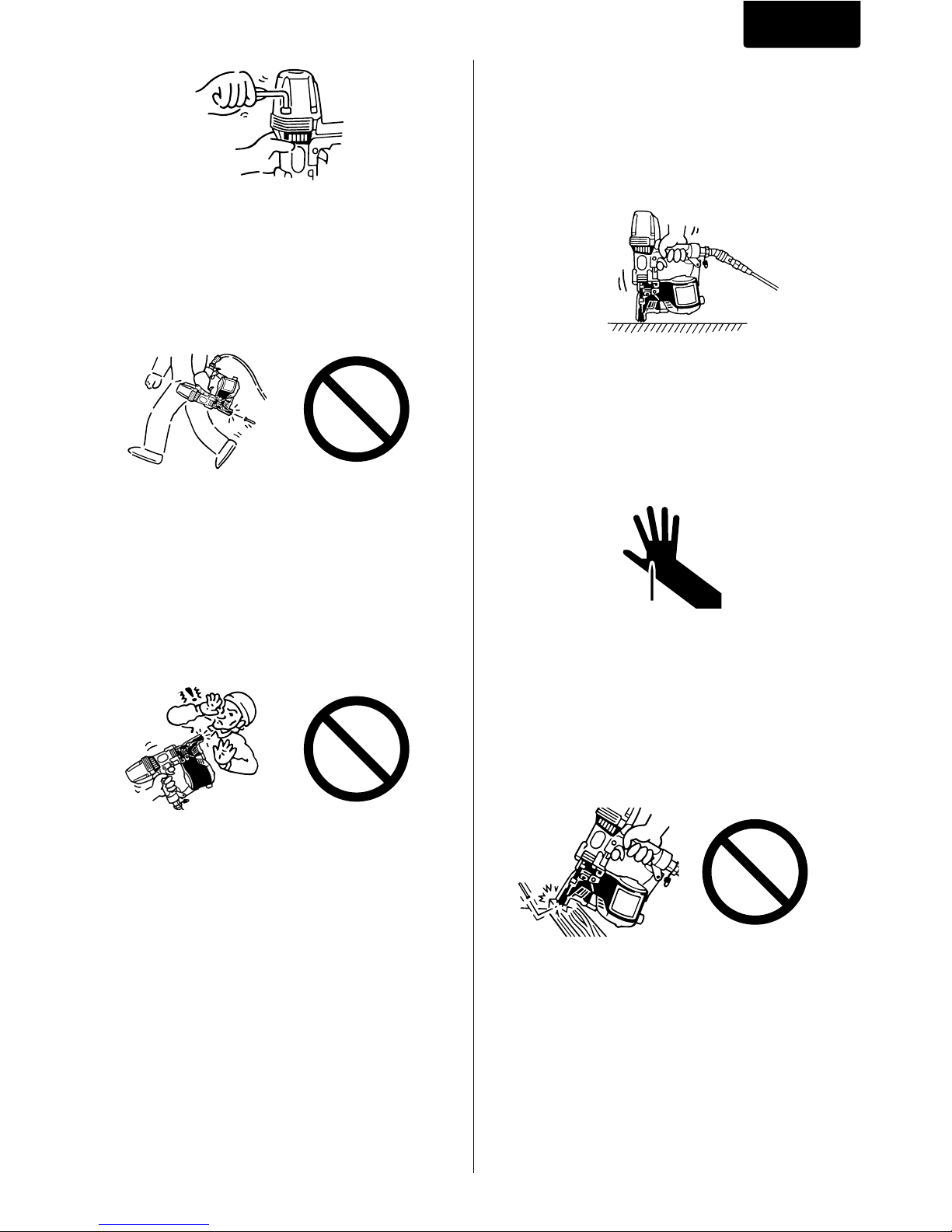

3. WHEN USING THE TOOL, BE SURE TO

USE A SPECIAL AIR COMPRESSOR AND

AIR HOSE

In order to improve its performance, it has set

its working pressure higher than the

conventional nailers. To use the tool, you

always need the special air compressor and

air hose. Use of combusible pressure gas (for

example, oxygen, acetylene, etc.) causes

abnormal combustion, possibly resulting in

explosion. Use only the special air

compressor and air hose.

4. OPERATE WITHIN THE PROPER AIR

PRESSURE RANGE

The tool is designed to operate within an air

pressure range of 10 to 23 bar (140 to 320

p.s.i.).

The pressure should be adjusted to the type

of the work being fastened. The tool shall

never be operated when the operating

pressure exceeds 23 bar (320 p.s.i.).

5. DO NOT OPERATE THE TOOL NEAR A

FLAMMABLE SUBSTANCE

Never operate the tool near a flammable

substance (e.g., thinner, gasoline, etc.).

Volatile fumes from these substances could

be drawn into the compressor and

compressed together with the air and this

could result in an explosion.

6. NEVER USE THE TOOL IN AN EXPLOSIVE

ATMOSPHERE

Sparks from the tool may ignite atmospheric

gases, dust or other combustible materials.

7. DO NOT USE A WRONG FITTINGS

The connector on the tool must not hold

pressure when air supply is disconnected. If a

wrong fitting is used, the tool can remain

charged with air after disconnecting and thus

will be able to drive a fastener even after the

air line is disconnected, possibly causing

injury.

8. DISCONNECT THE AIR SUPPLY AND

EMPTY THE MAGAZINE WHEN THE TOOL

IS NOT IN USE

Always disconnect the air supply from the tool

and empty the magazine when operation has

been completed or suspended, when

unattended, moving to a different work area,

adjusting, disassembling, or repairing the tool,

and when clearing a jammed fastener.

10bar

140psi

23bar

320psi

Thinner

Gasoline

Page 5

ENGLISH

5

12. USE SPECIFIED FASTENERS

(SEE PAGE 7)

The use of fasteners other than specified

fasteners will cause the tool malfunction. Be

sure to use only specified fasteners when

operating the tool.

13. PLACE THE DISCHARGE OUTLET ON THE

WORK SURFACE PROPERLY

Failure to place the discharge outlet of the

nose in a proper manner can result in a

fastener flying up and is extremely

dangerous.

14. KEEP HANDS AND BODY AWAY FROM

THE DISCHARGE OUTLET

When loading and using the tool, never place

a hand or any part of body in fastener

discharge area of the tool. It is very

dangerous to hit the hands or body by

mistake.

15. DO NOT DRIVE FASTENERS CLOSE TO

THE EDGE AND CORNER OF THE WORK

AND THIN MATERIAL

The workpiece is likely to split and the

fastener could fly free and hit someone.

9. INSPECT SCREW TIGHTNESS

Loose or improperly installed screws or bolts

cause accidents and tool damage when the

tool is put into operation. Inspect to confirm

that all screws and bolts are tight and

properly installed prior to operating the tool.

10. DO NOT TOUCH THE TRIGGER UNLESS

YOU INTEND TO DRIVE A FASTENER

Whenever the air supply is connected to the

tool, never touch the trigger unless you intend

to drive a fastener into the work. It is

dangerous to walk around carrying the tool

with the trigger pulled, and this and similar

actions should be avoided.

11. NEVER POINT THE DISCHARGE OUTLET

TOWARD YOURSELF AND OTHER

PERSONNEL

If the discharge outlet is pointed toward

people, serious accidents may be caused

when misfiring. Be sure the discharge outlet

is not pointed toward people when connecting

and disconnecting the hose, loading and

unloading the fasteners or similar operations.

Page 6

ENGLISH

6

20. NEVER USE THE TOOL IF ANY PORTION

OF THE TOOL CONTROLS (e.g., TRIGGER,

CONTACT ARM) IS INOPERABLE,

DISCONNECTED, ALTERED OR NOT

WOKING PROPERLY

21. NEVER ACTUATE THE TOOL INTO FREE

SPACE

This will avoid any hazard caused by free

flying fasteners and excessive strain of the

tool.

22. ALWAYS ASSUME THAT THE TOOL

CONTAINS FASTENERS

23. RESPECT THE TOOL AS A WORKING

IMPLEMENT

24. NO HORSEPLAY

25. NEVER LOAD THE TOOL WITH

FASTENERS WHEN ANY ONE OF THE

OPERATING CONTROLS (e.g., TRIGGER,

CONTACT ARM) IS ACTIVATED

26. WEAR THE GLOVES DEPENDING ON THE

WORKING CONDITION

27. WHEN DISPOSING THE MACHINE OR ITS

PARTS, FOLLOW THE RELEVANT

NATIONAL RULES

OBSERVE THE FOLLOWING GENERAL

CAUTION IN ADDITION TO THE OTHER

WARNINGS CONTAINED IN THIS

MANUAL

• Do not use the tool as a hammer.

• Always carry the tool by the grip, never

carry the tool by the air hose.

• The tool must be used only for the purpose

it was designed.

• Never remove, tamper with the operating

controls (e.g., TRIGGER, CONTACT ARM)

• Keep the tool in a dry place out of reach of

children when not in use.

• Do not use the tool without Safety Warning

label.

• Do not modify the tool from original design

or function without approval by MAX CO.,

LTD.

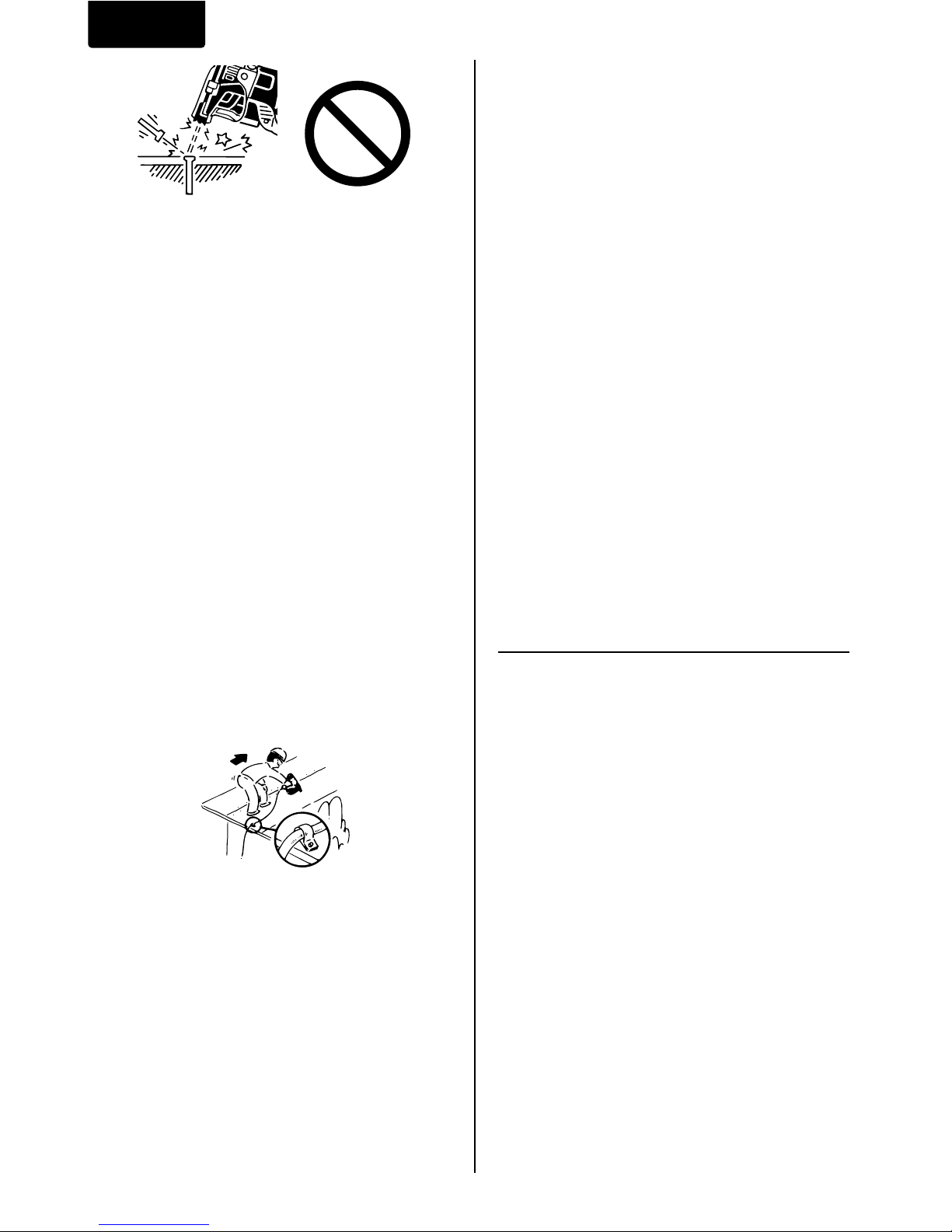

16. DO NOT DRIVE FASTENERS ON TOP OF

OTHER FASTENERS

Driving fasteners on the top of other fasteners

may cause deflection fasteners which could

cause injury.

17. REMOVING THE FASTENERS AFTER

COMPLETING OPERATION

If fasteners are left in the magazine after the

completion of operation, there is the danger

of a serious accident occurring prior to the

resumption of operation, should the tool be

handled carelessly, or when connecting the

air fitting. For this reason, always remove all

fasteners remaining in the magazine after

completion of the operation.

18. CHECK OPERATION OF THE CONTACT

TRIP MECHANISM FREQUENTLY IN CASE

OF USING A CONTACT TRIP TYPE TOOL

Do not use the tool if the trip is not working

correctly as accidental driving of a fastener

may result. Do not interfere with the proper

operation of the contact trip mechanism.

19. WHEN USING THE TOOL OUTSIDE OR

ELEVATED PLACE

When fastening roofs or similar slanted

surface, start fastening at the lower part and

gradually work your way up. Fastening

backward is dangerous as you may lose your

foot place.

Secure the hose at a point close to the area

you are going to drive fasteners. Accidents

may be caused due to the hose being pulled

inadvertently or getting caught.

Page 7

ENGLISH

7

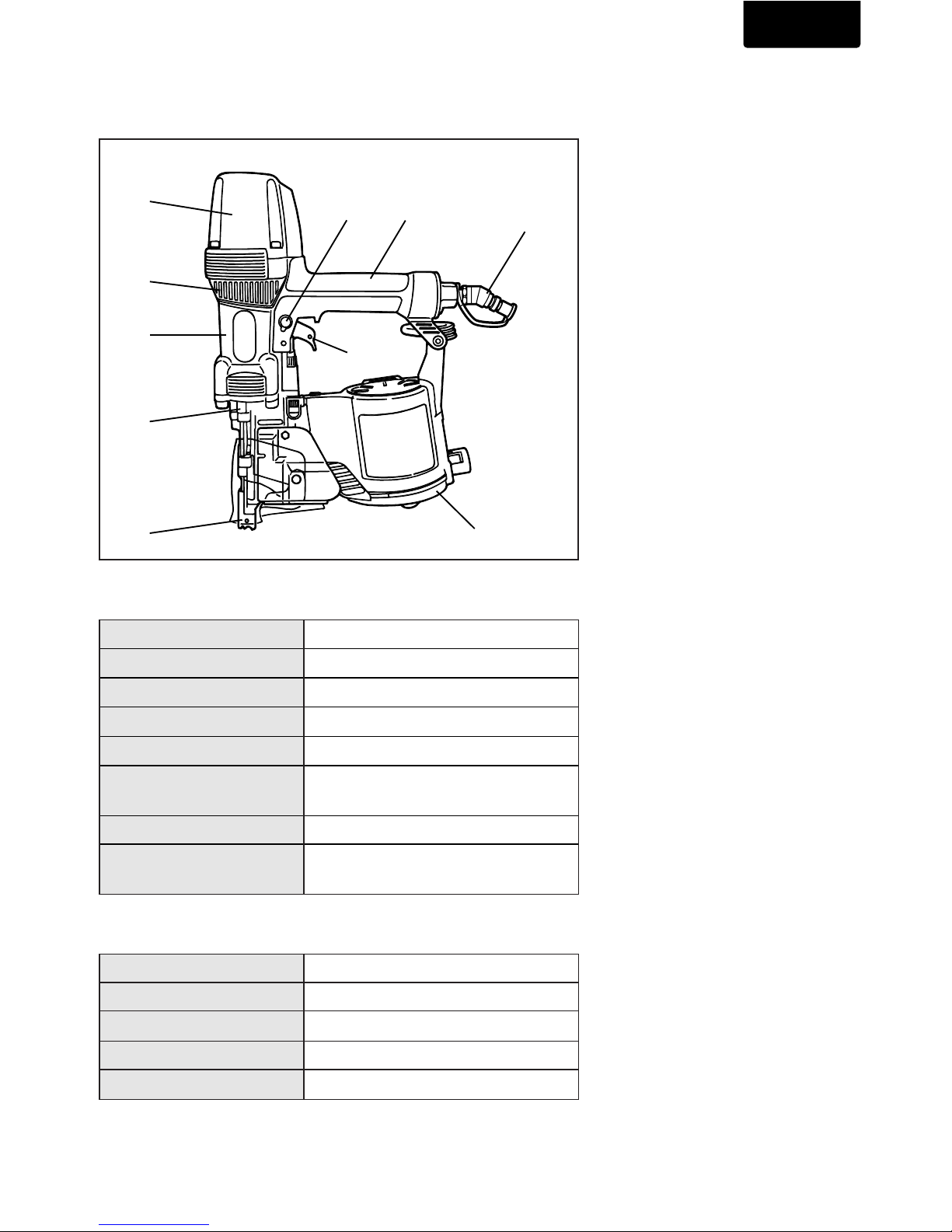

1. NAME OF PARTS

2. TOOL SPECIFICATIONS

3. FASTENER SPECIFICATIONS

i

uo

!0

w

q

r

e

t

y

q

Frame

w

Cylinder Cap

e

Contact Arm

r

Nose

t

Magazine

y

Trigger

u

Grip

i

Exhaust Cover

o

Trigger Lock Dial

!0

Plug

2. SPECIFICATIONS AND TECHNICAL DATA

PRODUCT NO. HN100

HEIGHT 378 mm (14.9”)

WIDTH 117 mm (4.6”)

LENGTH 317 mm (12.5”)

WEIGHT 2.9 kg (6.4 lbs.)

RECOMMENDED

10 to 23 bar (140 to 320 p.s.i.)

OPERATING PRESSURE

LOADING CAPACITY 50 Nails

AIR CONSUMPTION

3.6R at 18 bar (257 p.s.i.)

operating pressure

PRODUCT NO. HN100

NAIL LENGTH 65 to 100 mm (2-1/2” to 4”)

SHANK DIAMETER φ2.9 to φ4.1 mm (.113” to .162”)

SHANK TYPE Smooth, Ring, Screw

HEAD DIAMETER φ7.5 to φ8.4 mm (.295” to .330”)

Page 8

ENGLISH

8

RECOMMENDED OPERATING

PRESSURE:

10 to 23 bar (140 to 320 p.s.i.). Select the

operating air pressure within this range for best

fastener performance.

DO NOT EXCEED 23 bar (320 p.s.i.).

5. APPLICATIONS

*Framing

*Sheathing

*Decking

*Subflooring

*Hard wood

4. TECHNICAL DATA

q NOISE

A-weighted single-event sound power level

------ LWA, 1s, d 92.81 dB

A-weighted single-event emission sound

pressure level at work station

------- LpA, 1s, d 83.35 dB

These values are determined and documented

in accordance to EN12549 : 1999.

w VIBRATION

Vibration characteristic value = 6.6 m/s

2

These values are determined and documented

in accordance to ISO 8662-11.

This value is a tool-related characteristic value

and does not represent the influence to the

hand-arm-system when using the tool. An

influence to the hand-arm-system when using

the tool will, for example, depend on the

gripping force, the contact

pressure force, the working

direction, the adjustment of

mains supply, the workpiece,

the workpiece support.

3. AIR SUPPLY AND

CONNECTIONS

Read section titled “SAFETY

INSTRUCTIONS”.

DO NOT USE ANY POWER SOURCE EXCEPT

AN AIR COMPRESSOR

The tool is designed to operate on compressed

air. Do not operate the tool on any other

combustible gases (e.g., oxygen, acetylene, etc.)

since there is the danger of an explosion. For this

reason, absolutely do not use anything other than

an air compressor to operate the tool.

OPERATE WITHIN THE PROPER AIR

PRESSURE RANGE

The tool is designed to operate within an air

pressure range of 10 to 23 bar (140 to 320 p.s.i.).

The pressure should be adjusted to the type of

the work being fastened. The tool shall never be

operated when the operating pressure exceeds

23 bar (320 p.s.i.).

WARNING

10bar

140psi

23bar

320psi

Page 9

ENGLISH

9

DO NOT OPERATE THE TOOL NEAR A

FLAMMABLE SUBSTANCE

Never operate the tool near a flammable

substance (e.g., thinner, gasoline, etc.). Volatile

fumes from these substances could be drawn into

the compressor and compressed together with

the air and this could result in an explosion.

DO NOT USE A WRONG FITTINGS

The connector on the tool must not hold pressure

when air supply is disconnected. If a wrong fitting

is used, the tool can remain charged with air after

disconnecting and thus will be able to drive a

fastener even after the air line is disconnected,

possibly causing injury.

DISCONNECT THE AIR SUPPLY AND EMPTY

THE MAGAZINE WHEN THE TOOL IS NOT IN

USE

Always disconnect the air supply from the tool

and empty the magazine when operation has

been completed or suspended, when unattended,

moving to a different work area, adjusting,

disassembling, or repairing the tool, and when

clearing a jammed fastener.

WHEN USING THE TOOL, BE SURE TO USE A

SPECIAL AIR COMPRESSOR AND AIR HOSE.

In order to improve its performance, it has set its

working pressure higher than the conventional

nailers. To use the tool, you always need the

special air compressor and air hose (MAX

PowerLite Compressor and MAX PowerLite

Hose). Use of high-pressure gas (for example,

oxygen, acetylene, etc.) causes abnormal

combustion, possibly resulting in explosion. Use

only the special air compressor and air hose.

NOTE:

Frequent, but not excessive, lubrication is

required for the best performance. Oil added thru

the air line connection will lubricate the internal

parts.

Air compressor

[

AIR COMPRESSOR / AIR HOSE

]

Used at 10 to 23 bar (140 to 320 p.s.i.)

10bar

140psi

23bar

320psi

Air hose

Thinner

Gasoline

Page 10

ENGLISH

10

4. INSTRUCTIONS FOR

OPERATION

2. OPERATION

Wear safety glasses or goggles. Danger to the

eyes always exists due to the possibility of dust

being blown up by the exhausted air or of a

fastener flying up due to the improper handling of

the tool. For these reasons, safety glasses or

goggles shall always be worn when operating the

tool.

The employer and/or user must ensure that

proper eye protection is worn. Eye protection

equipment must conform to the requirements of

Council Directive 89/686/EEC of 21 DEC. 1989

(the American National Standards Institute, ANSI

Z87.1) and provide both frontal and side

protection.

The employer is responsible to enforce the use of

eye protection equipment by the tool operator and

all other personnel in the work area.

NOTE: Non-side shielded spectacles and face

shields alone do not provide adequate protection.

WARNING

WARNING

Keep hands and body away from the discharge

outlet when driving the fasteners because of

dangerous of hitting the hands or body by

mistake.

Door Latch

Nail

Feed Pawl

q

Open the Magazine:

Pull up Door Latch and swing Door open.

Swing Magazine Cover open.

NAIL LOADING

w

Nail loading:

Place a coil of nails over the Nail Post in the

Magazine. Uncoil enough nails to reach the

Feed Pawl, and place the second nail between

the teeth on the Feed Pawl. The nail heads fit

in slot on Nose.

Read section titled “SAFETY

INSTRUCTIONS”.

1. BEFORE OPERATION

Check the following prior operation.

q

Wear Safety Glasses or Goggles.

w

Do not connect the air supply.

e

Inspect screw tightness.

r

Check operation of the contact arm & trigger if

moving smoothly.

t

Connect the air supply.

y

Check the air-leakage. (The Tool must not

have the air-leakage.)

u

Hold the Tool with finger-off the trigger, then

push the contact arm against the work-piece.

(The tool must not operate.)

i

Hold the Tool with contact arm free from workpiece and pull the trigger. (The Tool must not

operate.)

o

Disconnect the air supply.

Page 11

ENGLISH

11

e

Swing Magazine Cover closed.

r

Close the Door.

Check that Door Latch engages. (If it does not

engage, check that the nail heads are in the

slot on the Nose).

TEST OPERATION

q

Adjust the air pressure at 10 bar (140 p.s.i.)

and connect the air supply.

w

Without touching the trigger, depress the

contact arm against the work-piece.

Pull the trigger. (The tool must fire the

fastener.)

e

With the tool off the work-piece, pull the

trigger.

Then depress the contact arm against the

work-piece. (The tool must fire the fastener.)

r

Adjust the air pressure as much as the lowest

possible according the length of fastener and

the hardness of work-piece.

MODEL IDENTIFICATION

CONTACT TRIP

The common operating procedure on “Contact

Trip” tools is for the operator to contact the work

to actuate the trip mechanism while keeping the

trigger pulled, thus driving a fastener each time

the work is contacted. This will allow rapid

fastener placement on many jobs, such as

sheathing, decking and pallet assembly.

All pneumatic tools are subject to recoil when

driving fasteners. The tool may bounce, releasing

the trip, and if unintentionally allowed to recontact

the work surface with the trigger still actuated

(finger still holding trigger pulled) an unwanted

second fastener will be driven.

SEQUENTIAL TRIP

The Sequential Trip requires the operator to hold

the tool against the work before pulling the trigger.

This makes accurate fastener placement easier,

for instance on framing, toe nailing and crating

applications. The Sequential Trip allows exact

fastener location without the possibility of driving

a second fastener on recoil, as described under

“Contact Trip”.

The Sequential Trip Tool has a positive safety

advantage because it will not accidentally drive a

fastener if the tool is contacted against the workor anything else-while the operator is holding the

trigger pulled.

SEQUENTIAL TRIP

Identified by ORANGE TRIGGER.

CONTACT TRIP WITH ANTI-DOUBLE FIRE

MECHANISM

(US patent 5597106, UK patent 2286790)

Identified by RED TRIGGER.

Page 12

ENGLISH

12

1

2

DRIVING FASTENERS

CONTACT FIRE OPERATION

(CONTACT TRIP)

For contact fire operation, hold the trigger and

depress the contact arm against the work surface.

PROCEDURE

q

Hold the trigger.

w

Depress the contact arm.

2

1

SINGLE FIRE OPERATION

(ANTI-DOUBLE FIRE MECHANISM AND

SEQUENTIAL TRIP)

For single fire operation, depress the contact arm

against the work surface and pull the trigger. Tool

can not fire a second fastener until the trigger is

released and tool can cycle.

PROCEDURE

q

Depress the contact arm.

w

Pull the trigger.

Adjustment Dial

Contact Arm

ALWAYS disconnect air supply before dial

adjustment.

q

With air pressure set, drive nails into a

representative material sample to determine if

adjustment is necessary.

w

If adjustment is required, disconnect air

supply.

e

Refer to the mark on the Adjust Spacer for

direction to turn the adjustment dial.

r

Reconnect air supply.

WARNING

Trigger lock dial

Trigger

(LOCK)

(UNLOCK)

The tool is equipped with a trigger lock

mechanism. Push and rotate the trigger LOCK to

the trigger UNLOCK position before driving nails.

Deeper Shallow

ADJUSTABLE DIAL DEPTH CONTROL

TRIGGER LOCK MECHANISM

Page 13

ENGLISH

13

Hammer

Contact Tip

Contact Arm

ALWAYS disconnect air supply before

attaching / detaching the contact tip.

Attach the Contact Tip on the tip of Contact Arm,

when driving nails to a soft material.

The Contact Tip can be kept on the Contact Tip

holder when not using.

WARNING

Contact Tip holder

As nails are driven the plastic sheet will feed out

of the tool. When sufficient strip has been fed out

it can be torn away by pulling against the rear

edge in the nose.

When removing jamming of nails, be sure to

lock the trigger prior to disconnecting the air

hose.

PROCEDURE

q

Lock the trigger and disconnect the air hose.

w

Remove the nails out of the magazine.

e

Open the door, put a punch through the

discharge outlet and hit it with a hammer.

WARNING

Punch

r

Remove the nails jamming inside the nose or

contact nose using the punch or a regular

screwdriver.

t

Set the nails properly onto the feed pawl again

and close the door.

Regular screwdriver

CONTACT TIP

HOW TO REMOVE PLASTIC SHEET

HOW TO REMOVE JAMMING OF NAILS

Page 14

ENGLISH

14

WHEN USING THE TOOL FOR STEEL PLATES

●

Carry out work based on the required Work

Standards.

●

If there is no specified work standard, refer

the following as a reference.

●

Never use the nails for the ceilings (ceiling

foundations included) or roofs (roof

foundations included).

●

Be sure to apply discharge outlet to an

object at a right angle.

●

Do not drive the nails into the steel plate

directly.

WARNING

This tool is exclusively designed for 2.3 mm

(.091”) to 3.2 mm (1/8”) thick light gage steel.

When using it, comply with the Work Standards,

considering the object condition and work site

environment.

q

Select appropriate nails according to the

object thickness, seeing the right table.

※ The nails may not be driven into the object

depending on its hardness or thickness.

※ If the object is thinner than an appropriate

range of thickness, the nails may not be driven

into it because of being bent.

Light gage steel:

2.3 mm (.091”) to

3.2 mm (1/8”) thick

Penetration amount

Object thickness

(Total) range

Wood

※

For the 3.2 mm (1/8”) thick light gage steel, use the

φ

2.9〜3.4 mm (.113”〜.134”) nails for steel plates.

w

If the thickness of the light gauge steel

foundations material used is 3.2 mm (1/8”),

use the φ2.9〜3.4 mm (.113”〜.134”) nails for

steel plate.

e

Never drive the nails directly into the light

gauge steel because they will fly off,

endangering you.

r

Be sure to apply the discharge outlet to the

object at a right angle. If applied obliquely, the

nails will fly off, endangering you.

t

Never use the nails for the roofs (roof

foundations included) or ceilings (ceiling

foundations included).

y

If the nails are driven into the steel plate too

deeply, their holding force will be extremely

reduced. When working with the tool, fully

check the driven conditions.

Page 15

ENGLISH

15

5. MAINTENANCE

w

DO NOT FIRE THE NAILER WHEN IT IS

EMPTY

e

USE RECOMMENDED OIL

The velocite or turbine oil should be used to

lubricate the tool. Upon completion of

operations, place 5 or 6 drops of oil into the air

plug inlet with the jet oiler. (Recommended Oil

: ISO VG32)

r

INSPECT AND MAINTAIN DAILY OR

BEFORE OPERATION

6. STORAGE

q

When not in use for an extended period, apply

a thin coat of the lubricant to the steel parts to

avoid rust.

w

Do not store the tool in a cold weather

environment. Keep the tool in a warm area.

e

When not in use, the tool should be stored in a

warm and dry place. Keep out of reach of

children.

r

All quality tools will eventually require servicing

or replacement of parts because of wear from

the normal use.

7. TROUBLE

SHOOTING/REPAIRS

The troubleshooting and/or repairs shall be

carried out only by the MAX CO., LTD. authorised

distributors or by other specialists.

WARNING

Disconnect air supply and empty the

magazine when inspecting or maintaining the

tool.

(1) Tighten all screws

(2) Keep contact arm moving smoothly

q

ABOUT PRODUCTION YEAR

This product bears production number at the

lower part of the grip of the main body. The

two digits of the number from left indicates the

production year.

(Example)

0 8 8 2 6 0 3 5 D

Year 2008

Page 16

ENGLISH

16

Supplement to the operating instruction

According to the European Norm EN 792-13 the

regulation is valid from 01.01.2001 that all

fastener driving tools with contact actuation must

be marked with the symbol “Do not use on

scaffoldings, ladders” and they shall not be used

for specific application for example:

*when changing one driving location to another

involves the use of scaffoldings, stairs, ladders

or ladder alike constructions e.g. roof laths,

*closing boxes or crates,

*fitting transportation safety systems e.g. on

vehicles and wagons.

Page 17

73

109

O-RING KIT

Parts marked

are included

in the O-ring kit

69

71

29

20

25

53

33

67

24

26

25

28

113

31

35

34

40

70

32

32

19

2

27

3

4

14

15

66

9

12

118

6

5

6

7

6

21

22

6

52

42

49

116

117

43

48

43

44

45

47

72

73

75

74

88

87

76

91

103

89

81

82

94

84

85

65

112

51

6

41

46

50

114

A

B

68

A

23

83

1

8

10

11

13

16

17

18

105

111

36

37

38

39

86

93

92

70

104

95

100

115

B

99

90

97

98

96

57

60

58

59

61

62

63

64

54

95

96

108

107

106

102

101

101

110

125

124

55

121

126

122

123

79

78

77

70

80

55

EXPLODED

VIEW AND SPARE

PARTS LIST

EINZELTEILDAR-

STELLUNG UND

ERSATZEILLISTE

SCHEMA ECLATE ET

LISTE DES PIECEC

DE RECHANGE

ESPLOSO DEI

COMPONENTI DE

ELENCO DELLE

PARTI DI RICAMBIO

DESPIECE DE LA

MAQUINA Y LISTA

DE RECAMBIOS

HN100

PNEUMATIC STAPLER

Page 18

74

HN100

ESPAÑOLITALIANOFRANÇAISENGLISHMATERIAL DEUTSCH

ITEM

NO.

PART

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

HN10067 Steel SCREW 6X35 SCHRAUBE 6X35 VIS 6X35 VITE 6x35 TORNILLO 6x35

HN10064 Magnesium CYLINDER CAP ZYLINDERDECKEL

COUVERCLE DE CYLINDRE

COPERCHIO CILINDRO CUBIERTA DE CILINDRO

HN10068 Magnesium INNER CAP INNEREKAPPE CAPOT INTÉRIEURE CAPPUCCIO INTERNA CAPERUZA INTERNO

KK23650 Stainless steel

COMPRESSION SPRING 3650

DRUCKFEDER 3650

RESSORT À PRESSION 3650

MOLLA DI COMPRESSIONE 3650 MUELLE DE COMPRESIÓN 3650

HN10072 Urethane PISTON STOP KOLBENANSCHLAG BUTÉE DE PISTON FERMO STANTUFFO TOPE ÉMBOLO

HH19127 Rubber O-RING 1A 1.5X6.6 O-RING 1A 1.5X6.6

JOINT TORIQUE 1A 1.5X6.6

O-RING 1A 1.5X6.6

ANILLO TÓRICO 1A 1.5X6.6

HN10069 Aluminum PIPE ROHR TUYAU TUBO TUBO

HH19216 Rubber O-RING 1B 2.6X37.7 O-RING 1B 2.6X37.7

JOINT TORIQUE 1B 2.6X37.7

O-RING 1B 2.6X37.7

ANILLO TÓPRICO 1B 2.6X37.7

HN10070 Polyacetal HEAD VALVE PISTON KOPFVENTILKOLBEN

PISTON DE CLAPET DE TÉTE

STANTUFFO VALVOLA DI MANDATA

EMBORO VÁLVULA DEL CABEZAL

HH11156 Rubber O-RING AS568-137 O-RING AS568-137

JOINT TORIQUE AS568-137

O-RING AS568-137

ANILLO TÓRICO AS568-137

HH11157 Rubber O-RING AS568-136 O-RING AS568-136

JOINT TORIQUE AS568-136

O-RING AS568-136

ANILLO TÉRICO AS568-136

HN10071 Aluminum HEAD VALVE GUIDE DRUCKVENTILFÜHRER

GUIDE DE CLAPET DE TÊTE

GUÍA DE LA VÁLVULA DEL CABEZAL

HH19138 Rubber O-RING 1A 1.8X58.5 O-RING 1A 1.8X58.5

JOINT TORIQUE 1A 1.8X58.5

O-RING 1A 1.8X58.5

ANILLO TÓRICO 1A 1.8X58.5

HN10076 Urethane CYLINDER SEAL ZYLINDERDICHTUNG JOINT DE CYLINDRE

GUARNIZIONE DEL CILINDRO

SELLO DEL CILINDRO

HN10077 Aluminum CYLINDER ZILINDER CYLINDRE CILINDRO CILINDRO

HH19178 Rubber O-RING 1A 3.1X47.4 O-RING 1A 3.1X47.4

JOINT TORIQUE 1A 3.1X47.4

O-RING 1A 3.1X47.4

ANILLO TÓRICO 1A 3.1X47.4

HH11146 Rubber O-RING AS568-128 O-RING AS568-128

JOINT TORIQUE AS568-128

O-RING AS568-128

ANILLO TÓRICO AS568-128

HH11806 Urethane O-RING P27 O-RING P27 JOINT TORIQUE P27 O-RING P27 ANILLO TÉRICO P27

HN10073 Magnesium, Steel MAIN PISTON UNIT ARBEITSKOLBEN KOMPL

PISTON DE TRAVAIL COMPLET

GRUPPO STANTUFFO OPERATORE

EMBORO DE TRAVAJO COMPL.

HN10106 Nylon, Rubber EXHAUST COVER UNIT ABSAUGHAUBEKOMPL

CAPOT D'ASPIRATION COMPLET

CAMPANA DE ASPIRACIÓN COMP.

HN10097 Polyacetal FILTER B FILTER B FILTRE B FILTRO B FILTRO B

HN10096 Stainless steel FILTER A FILTER A FILTRE A FILTRO A FILTRO A

HN81026 Magnesium FRAME ASSY GEHÄUSE KOMPL BOÎTIER COMPLET

GRUPPO ALLOGGIAMENTO

CARCASA COMP

CN34309

Polyethylene terephthalate

COUPLING CAUTION SEAL

KOPPELUNGSVORSICHTSSCHILD

HN11741

Polyethylene terephthalate

LOGO SEAL LOGOSIEGEL SCEAU LOGO SIGILLO LOGO SELLO LOGO

FF21201 Steel ROLL PIN 2.5X10 ROLLENBOLZEN 2.5X10

TOURILLON DE CYLINDRE 2.5X10

PERNO DI ROTOLAMENT 2.5X10

PERNO DE RODILLO 2.5X10

HN10327 Nylon TRIGGER LOCK DIAL

BETÄTIGUNGSSPERREKNOPF DISCO DI SICURA GRILLETTO

KK23507 Stainless steel

COMPRESSION SPRING 3507

DRUCKFEDER 3507

RESSORT À PRESSION 3507

MOLLA DI COMPRESSIONE 3507 MUELLE DE COMPRESIÓN 3507

FF21235 Steel ROLL PIN 3X30 ROLLENBOLZEN 3X30

TOURILLON DE CYLINDRE 3X30

PERNO DI ROTOLAMENT 3X30

PERNO DE RODILLO 3X30

CN34699 Nylon TRIGGER LOCK LEVER

BETÄTIGUNGSSPERREHEBEL LEVA DI SICURA GRILLETTO

HN10087 Rubber PROTECTOR A

SCHUTZVORRICHTUNG A

DISPOSITIF DE PROTECTION A

DISPOSITIVO DI PROTEZIONE A DISPOSITIVO DE PROTECCIÓN A

HN10050 Rubber GRIP COVER A GRIFFBELAG A

RÊVETEMENT DE POIGNÉE A

REVESTIMIENTO DE SUJECIÓN A

HN10051 Rubber GRIP COVER B GRIFFBELAG B

RÊVETEMENT DE POIGNÉE B

REVESTIMIENTO DE SUJECIÓN B

BB40437 Steel SCREW 5X30 SCHRAUBE 5X30 VIS 5X30 VITE 5X30 TORNILLO 5X30

HH12118 Rubber O-RING 1A G35 O-RING 1A G35 JOINT TORIQUE 1A G35 O-RING 1A G35 ANILLO TÓRICO 1A G35

HN10313 Magnesium END CAP ABSCHLUSSKAPPE

CAPOT DE RECOUVREMENT

CAPPUCCIO DI CHIUSURA

CAPERUZA DE CIERRE

HN10316 Vinyl acetate END PLUG CAP ENDENSTECKERKAPPE

CAPOT DE PRISE D'EXTRÉMITÉ

TT05425 Steel AIR PLUG H-FPM LUFTSTECKER H-FPM PRISE D'AIR H-FPM

PRESA DELL'ARIA H-FPM

ENCHUFE DEL AIRE H-FPM

HH12904 Rubber O-RING 1A 1X6.2 O-RING 1A 1X6.2 JOINT TORIQUE 1A 1X6.2 O-RING 1A 1X6.2

ANILLO TÓRICO 1A 1X6.2

HN10043 Steel PILOT CAP STEUERVENTILSKAPPE CAPOT VANNE-PILOTE

HN10018 Urethane PILOT SEAL

STEUERVENTILSDICHTUNG

JOINT VANNE-PILOTE

SELLO DE VALVULA DE CONTROL

HH12105 Rubber O-RING 1A 1.5X12.8 O-RING 1A 1.5X12.8

JOINT TORIQUE 1A 1.5X12.8

O-RING 1A 1.5X12.8

ANILLO TÓRICO 1A 1.5X12.8

HN10016 Polyacetal

TRIGGER VALVE HOUSING

BETÄTIGUNGSVENTILGEHÄUSE

HH11208 Rubber O-RING 1B P6 O-RING 1B P6 JOINT TORIQUE 1B P6 O-RING 1B P6 ANILLO TÓRICO 1B P6

HN80049 PILOT VALVE ASSY STEUERVENTIL KOMPL

VANNE-PILOTE COMPLET

VÀLVULA DE CONTROL COMP

HH11132 Rubber O-RING 1A P10A O-RING 1A P10A JOINT TORIQUE 1A P10A O-RING 1A P10A ANILLO TÓRICO 1A P10A

KK23619 Stainless steel

COMPRESSION SPRING 3619

DRUCKFEDER 3619

RESSORT À PRESSION 3619

MOLLA DI COMPRESSIONE 3619 MUELLE DE COMPRESIÓN 3619

HH19707 Rubber O-RING 1A 1.4X2.5 O-RING 1A 1.4X2.5

JOINT TORIQUE 1A 1.4X2.5

O-RING 1A 1.4X2.5

ANILLO TÓRICO 1A 1.4X2.5

HN80023 TRIGGER VALVE ASSY

BETÄTIGUNGSVENTILAUFBAU

HH19214 Rubber O-RING 1B 1.5X3 O-RING 1B 1.5X3

JOINT TORIQUE 1B 1.5X3

O-RING 1B 1.5X3

ANILLO TÓRICO 1B 1.5X3

HN10019 Steel TRIGGER VALVE CAP

BETÄTIGUNGSVENTILDECKEL

KK33237 Stainless steel TORSION SPRING 3237 TORSIONSFEDER 3237

RESSORT DE TORSION 3237

MOLLA DI TORSIONE 3237 MUELLE DE TORSIÓN 3237

HN10104 Steel CONTCT LEVER KONTAKTHEBEL LEVIER DE CONTACT LEVA DI CONTATTO PALANCA DE CONTACTO

FF22402 Stainless steel ROLL PIN 3X16 ROLLENBOLZEN 3X16

TOURILLON DE CYLINDRE 3X16

PERNO DI ROTOLAMENT 3X16

PERNO DE RODILLO 3X16

HN80037 TRIGGER ASSY

BETÄTIGUNGSHEBEL KOMPL.

LEVIER DE COMMANDE COMPLET

UNITÀ DEL GRILLETTO

CN34800 Nylon SWITCH LEVER FAHRSCHALTHEBEL

LEVIER D'INTERRUPTEUR

LEVA DELL'INTERRUTTORE PALANCA DEL INTERUPTOR

CN34500 Stainless steel SWITCH SPRING SCHALTERFEDER

RESSORT D'INTERRUPTEUR

MOLLA DELL'INTERRUTTORE

MUELLE DEL INTERRUPTOR

HN10022 Steel CONTACT ARM A KONTAKTARM A BARRE DE CONTACT A

BRACCIO DI CONTATTO A

BRAZO DE CONTACTO A

GUIDA DELLA VALVOLA A

BATTENTE

ÉTIQUETTE DE PRECAUTION

D'ACCOUPLEMENT

ETICHETTA DI PRECAUZIONE

DELL'ACCOPPIAMENTO

UNITÀ DEL COPERCHIO DELLO

SCARIO

ETIQUETA DE PRECAUCIÓN

DEL ACOPLADOR

DISQUE DE BLOCAGE

DE LA COMMANDE

DISCO, BLOQUE

DE ACCIONAMIENTO

LEVIER DE BLOCAGE

DE LA COMMANDE

PALANCA, BLOQUEO

DE ACCIONAMIENTO

RIVESTIMENTO DI

IMPUGNATURA A

RIVESTIMENTO DI

IMPUGNATURA B

CAPERUZA DEL ENCHUFE

DE EXTREMIDAD

CAPPUCCIO DI PRESA

D'ESTREMITA

CAPERUZA DE VALVULA DE

CONTROL

PROTEZIONE VALVOLA DI

COMANDO

GUARNIZIONE VALVOLA DI

COMANDO

CARTER DE SOUPAPE

DE DÉCLENCHEMENT

ALLOGGIO DELLA VALVOLA

DI INNESCO

UNITÀ DELLA VALVOLA DI

COMANDO

CUBIERTA DE VÁLVULA

DEL DISPARADOR

ENSEMBLE DE SOUPAPE

DE COMMANDE

CONJUNTO VÁLVULA

DE ACCIONAMIENTO

GRUPPO VALVOLA DI

AZIONAMENTO

CAPUCHON DE SOUPAPE

DE COMMANDE

COPERCHIO VALVOLA

DI AZIONAMENTO

CAPERUZA VÁLVULA

DE ACCIONAMIENTO

PALANCA DE ACCIONAMIENTO

COMP

Page 19

75

HN100

ESPAÑOLITALIANOFRANÇAISENGLISHMATERIAL DEUTSCH

ITEM

NO.

PART

NO.

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

ANILLO DE RETENCIÓN EN C 24

SUS

ANELLO DI RITEGNO E 3.2

(BASTONE)

ZUFUHRSPERRKLINKENABDECKUNG

HN10021 Steel ARM GUIDE ARMFÜHRER

GUIDE DE BRAS DE CONTACT

GUIDA DEL BRACCIO DI CONTATTO

GUÌA DEL BRAZO

KK23620 Stainless steel

COMPRESSION SPRING 3620

DRUCKFEDER 3620

RESSORT À PRESSION 3620

MOLLA DI COMPRESSIONE 3620 MUELLE DE COMPRESIÓN 3620

HN10041 Rubber CONTACT BUMPER

KONTAKTSTOSSDÄNPFER

AMORTISSEUR DE CONTACT

AMMORTIZZATORE DI CONTATTO

AMORTIGUADOR DE CONTACTO

HN10042 Steel CONTACT COLLAR KONTAKTSTELLRING COLLIER DE CONTACT COLLARE DI CONTATTO COLLAR DE CONTACTO

HN10026 Polyacetal ADJUST DIAL

EINSTELLVORWAHLKNOPF

CADRAN DE RÉGLAGE

MANOPOLA DI REGOLAZIONE

CUADRANTE DE AJUSTE

HN10082 Polyacetal ADJUST SPACER

EINSTELLDISTANZSCHEIBE

ENTRETOISE DE RÉGLAGE

DISTANZIATORE DI REGOLAZIONE

ESPACIADOR DE AJUSTE

HN10078 Rubber BUMPER STOSSDÄMPFER AMORTISSEUR AMMORTIZZATORE AMORTIGUADOR

HH19168 Rubber O-RING 1A 1.5X44 O-RING 1A 1.5X44

JOINT TORIQUE 1A 1.5X44

O-RING 1A 1.5X44

ANILLO TÓRICO 1A 1.5X44

HN10081 Steel NOZE NAGLERNASE NEZ DE CLOUEUR PUNTA SPARACHIODI NARIZ

BB40206 Steel SCREW 8x30 SCHRAUBE 8x30 VIS 8x30 VITE 8x30 TORNILLO 8x30

EE39602 Urethane RUBBER WASHER 7 GUMMISCHEIBE 7

DISQUE DE CAOUTCHOUC 7

RONDELLA IN GOMMA 7

ARANDELO DE CAUCHO 7

FF41599 Steel STEP PIN 1599 STUFENBOLZEN 1599

BOULON À GRADINS 1599

PERNO SCALARE 1599

PERNO ESCALONADO 1599

KK33261 Stainless steel TORSION SPRING 3261 TORSIONSFEDER 3261

RESSORT DE TORSION 3261

MOLLA DI TORSIONE 3261 MUELLE DE TORSIÓN 3261

CN33679 Steel DOOR LATCH TÜRVERSCHLUSS FERMETURE DE PORTE CHISURA SPORTELLO CIERRE PUERTA

HN10085 Steel DOOR TÜR PORTE SPORTELLO PUERTA

EE39609 Urethane

RUBBER WASHER 1.8X6X2

GUMMISCHEIBE 1.8X6X2

DISQUE DE CAOUTCHOUC 1.8X6X2

RONDELLA IN GOMMA 1.8X6X2 ARANDELO DE CAUCHO 1.8X6X2

FF31520 Steel PARALLEL PIN 1520 PARALLELBOLZEN 1520

GOUPILLE PARALLELE 1520

PERNO PARALLELO 1520

PERNO PARALELO 1520

HN10083 Steel FEED PAWL VORSCHUBKLINKE CLIQUET D'AVANCE

NOTTOLINO DI AVANZAMENTO

TRINQUETE DE AVANCE

FF41509 Steel STEP PIN 1509 STUFENBOLZEN 1509

BOULON À GRADINS 1509

PERNO SCALARE 1509

PERNO ESCALONADO 1509

KK23573 Stainless steel

COMPRESSION SPRING 3573

DRUCKFEDER 3573

RESSORT À PRESSION 3573

MOLLA DI COMPRESSIONE 3573 MUELLE DE COMPRESIÓN 3573

HH11113 Rubber O-RING 1A P9 O-RING 1A P9 JOINT TORIQUE 1A P9 O-RING 1A P9 ANILLO TÓRICO 1A P9

HN10084 Steel FEED PISTON VORSCHUBKOLBEN PISTON D'AVANCE

STANTUFFO DI AVANZAMENTO

EMBOLO DE AVANCE

HH11106 Rubber O-RING 1A P16 O-RING 1A P16 JOINT TORIQUE 1A P16 O-RING 1A P16 ANILLO TÓRICO 1A P16

KK23173 Stainless steel

COMPRESSION SPRING 3173

DRUCKFEDER 3173

RESSORT À PRESSION 3173

MOLLA DI COMPRESSIONE 3173 MUELLE DE COMPRESIÓN 3173

CN32093 Urethane FEED PISTON STOP

VORSCHUBKOLBENSCHLAG BUTÉE DE PISTON D'AVANCE

TOPE ÉMBOLO DE AVANCE

HN10388 Steel SPRING COLLAR FEDERSSTELLRING COLLIER DE RESSORT COLLARE DELLA MOLLA COLLAR DE MUELLE

JJ22408 Stainless steel

C-RETAINING RING 24 SUS

C-HALTERING 24 SUS

BAGUE DE RETENUE C 24 SUS ANELLO DI RITEGNO C 24 SUS

HN10027 Steel CONTACT BOLT

KONTAKTSCHRAUBBOLZEN

BOULON DE CONTACT BULLONE DI CONTATTO PERNO DE CONTACTO

JJ10404 Stainless steel

E-RETAINING RING 3.2 (STICK)

E-HALTERING 3.2 (STOCK)

BAGUE DE RETENUE E 3.2 (BÂTON)

HN10109 Steel CONTACT ARM B UNIT KONTACTARM B KOPML

BARRE DE CONTACT B COMPLET

GRUPPO BRACCIO DI CONTATTO B

BRAZO DE CONTACTO B COMPL

HN11602 Urethane CONTACT TIP KONTAKTKAPPE CAPUCHON DE CONTACT

COPERCHIO DI CONTATTO CAPERUZA DE CONTACTO

BB40428 Steel SCREW 6X25 SCHRAUBE 6X25 VIS 6X25 VITE 6X25 TORNILLO 6X25

HN10086 Nylon FEED PAWL COVER

CC49406 Steel, Nylon NUT 406 MUTTER 406 ECROU 406 DADO 406 TUERCA 406

KK23627 Stainless steel

COMPRESSION SPRING 3627

DRUCKFEDER 3627

RESSORT À PRESSION 3627

MOLLA DI COMPRESSIONE 3627 MUELLE DE COMPRESIÓN 3627

HN10089 Polycarbonate MAGAZINE CAP MAGAZINKAPPE CAPOT DE MAGASIN

CAPPUCCIO DEL CARICATORE

CAPERUZA DEL CARGADOR

HN11742

Polyethylene terephthalate

NAME SEAL NAMENSDICHTUNG SCEAU DU NOM SIGILLO DEL NOME SELLO DEL NOMBRE

DUM0000 Steel, Nylon NUT M5 MUTTER M5 ECROU M5 DADO M5 TUERCA M5

HN10003 Nylon HOOK HAKEN CROCHET GANCIO GANCHO

HN10088 Nylon MAGAZINE MAGAZIN MAGASIN CARICATORE CARGADOR

FF31254 Steel PARALLEL PIN 1254 PARALLELBOLZEN 1254

GOUPILLE PARALLELE 1254

PERNO PARALLELO 1254

PERNO PARALELO 1254

CN31083 Rubber DUST COVER FITTING

SCHUTZABDECKUNGSBEFESTIGUNG

HN10090 Polyvinyl chloride DUST COVER STAUBDECKEL

COUVERCLE ANTI-POUSSIERE

COPERCHIO PARAPOLVERE

TAPA GUARDAPOLVO

HH11903 Rubber O-RING 1A 1.2X4 O-RING 1A 1.2X4 JOINT TORIQUE 1A 1.2X4 O-RING 1A 1.2X4

ANILLO TÓRICO 1A 1.2X4

HN10102 Steel NEEDLE POINT GUIDE A NADELPUNKTFÜHRER A

GUIDE DE POINT D'AIGUILLE A

GUIDA DI PUNTO D'AGO A

GUÍA DE PUNTO DE AGUJA A

HN81185 MAGAZINE CAP ASSY MAGAZINKAPPE KOMPL

CAPOT DE MAGASIN COMPLET

HN11744 Steel FRAME HANGER GEHÄUSEAUFHÄNGER SUPPORT DE BOÎTIER

SUPPORTO DI ALLOGGIAMENTO

SUSPENSIÓN DE CARCASA

HS10704 Steel SCREW 6X38 SCHRAUBE 6X38 VIS 6X38 VITE 6X38 TORNILLO 6X38

HN81188 FRAME HANGER KIT

GEHÄUSEAUFHÄNGERSKIT

KIT DE SUPPORT DE BOÎTIER

KIT DE SUSPENSIÓN DE CARCASA

HN81187 O-RING KIT ASSY

O-RING-KIT-VERSAMMLUNG ENSEMBLE DE KIT DE BAGUE

INSIEME DI KIT D'ANELLO

CONJUNTO DE KIT DE ANILLO “O”

HN81186 DS KIT ASSY DS-INSTALLATIONSKIT ENSEMBLE DE KIT DS INSIEME DEL KIT DS

CONJUNTO DE EQUIPO DS

TA17024 Nylon END CAP FILTER KM-23

ABSCHLUSSKAPPEFILTER KM-23

HN81190 ARM GUIDE KIT ARMFÜHRERSKIT KIT DE GUIDE DE BRAS

KIT DELLA GUIDA BRACCIO KIT DE LA GUÍA DEL BRAZO

HN10757

Polyethylene terephthalate

TRIGGER LOCK SEAL

BETÄTIGUNGSSPERREDICHTUNG

HN81189 TRIGGER VALVE KIT BETÄTIGUNGSVENTILKIT

KIT DELLA VALVOLA DI INNESCO

HN70226 MAGAZINE MODULE MAGAZIN-MODUL MODULE DU MAGASIN

MODULO DEL MAGAZZINO

MÓDULO DEL CARGADOR

HN10017 Polyacetal PILOT VALVE STEUERVENTIL VANNE-PILOTE VALVOLA DI COMANDO VÁLVULA DE CONTROL

HN10057 Steel TRIGGER VALVE STEM

BETÄTIGUNGSVENTILSCHAFT

TIGE DE SOUPAPE DE COMMANDE STELO VALVOLA DI AZIONAMENTO

CN34494 Polyacetal TRIGGER BETÄTIGUNGSHEBEL LEVIER DE COMMANDE GRILLETTO

PALANCA DE ACCIONAMIENTO

FERMO STANTUFFO DI

AVANZAMENTO

ANILLO DE RETENCIÓN EN E 3.2

(PALILLO)

AJUSTAGE DE COUVERCLE

ANTI-POUSSIÉRE

MONTAGGIO DEL COPERCHIO

ANTIPOLVERE

GUARNICIÓN DE TAPA

GUARDAPOLVO

GRUPPO DI CAPPUCCIO DEL

CARICATORE

KIT DI SUPPORTO DI

ALLOGGIAMENTO

CAPERUZA DEL CARGADOR

COMPL

FILTRE KM-23 DE CAPOT DE

RECOUVREMENT

FILTRO DE CAPERUZA DE

CIERRE KM-23

FILTRO DEL CAPPUCCIO DI

CHIUSURA KM-23

JOINT DE BLOCAGE DE

DÉCLENCHEMENT

GUARNIZIONE DI BLOCCAGGIO

DI INNESCO

SELLO DE BLOQUEO DEL

DISPARADOR

KIT DE LA VÁLVULA DEL

DISPARADOR

KIT DE SOUPAPE DE

DÉCLENCHEMENT

VÁSTAGO VÁLVULADE

ACCIONAMIENTO

COUVERCLE DU CLIQUET

D’AVANCEMENT

COPERCHIO DEL DENTE

D'ARRESTO DI AVANZAMENTO

CUBIERTA DEL TRINQUETE

DE AVANCE

Page 20

76

HN100

ESPAÑOLITALIANOFRANÇAISENGLISHMATERIAL DEUTSCH

ITEM

NO.

PART

NO.

119

120

121

122

123

124

125

126

CN35260 Polyacetal TRIGGER BETÄTIGUNGSHEBEL LEVIER DE COMMANDE GRILLETTO

PALANCA DE ACCIONAMIENTO

HN10100 Steel CONTCT LEVER KONTAKTHEBEL LEVIER DE CONTACT LEVA DI CONTATTO PALANCA DE CONTACTO

HN10101 Steel CONTACT ARM A KONTAKTARM A BARRE DE CONTACT A

BRACCIO DI CONTATTO A

BRAZO DE CONTACTO A

HN10103 Steel CONTACT COLLAR KONTAKTSTELLRING COLLIER DE CONTACT COLLARE DI CONTATTO COLLAR DE CONTACTO

KK23902 Stainless steel

COMPRESSION SPRING 3902

DRUCKFEDER 3902

RESSORT À PRESSION 3902

MOLLA DI COMPRESSIONE 3902 MUELLE DE COMPRESIÓN 3902

KK33346 Stainless steel TORSION SPRING 3346 TORSIONSFEDER 3346

RESSORT DE TORSION 3346

MOLLA DI TORSIONE 3346 MUELLE DE TORSIÓN 3346

Page 21

Recycled paper is used for this manual and its recyclable.

www.max-ltd.co.jp/int/ (GLOBAL Site)

www.max-europe.com (EUROPE Site)

★

080313-00/01

OSTSTRASSE 22, 40211

DÜSSELDORF, GERMANY

TEL: +49-211-9365300

FAX: +49-211-93653017

Camerastraat 19

1322 BB Almere The Netherlands

Phone: +31-36-546-9699

FAX: +31-36-536-3985

PRINTED IN JAPAN GEDRUCKT IN JAPAN IMPRIMÉ AU JAPON STAMPATO IN GIAPPONE IMPRESO EN JAPÓN

• The content of this manual might be changed without notice for improvement.

• Änderungen der Betriebsanleitung zum Zwecke der Verbesserung ohne Ankündigung

vorbehalten.

• Le contenu de ce manuel est sujet à modification sans préavis à des fins

d’amélioration.

•I contenuti di questo manuale possono essere cambiati senza preavviso per motivi di

miglioramento del prodotto.

• El contenido de este manual puede ser cambiado sin noticia previa para mejoramiento.

•

The specifications and design of the products in this manual will be subject to change without

advance notice due to our continuous efforts to improve the quality of our products.

•

Änderungen bei technischen Daten und Design der Produkte in diesem Handbuch im Sinne der

Produktverbesserung bleiben vorbehalten.

•

Les caractéristiques et la conception des produits mentionnés dans ce manuel sont sujettes à

des modifications sans préavis en raison de nos efforts continus pour améliorer la qualité de nos

produits.

•

Le caratteristiche e la concezione dei prodotti menzionati in questo manuale sono soggette a

modifiche senza preavviso a causa dei nostri sforzi continui per migliorare la qualità dei nostri

prodotti.

•

Las características y la concepción de los productos mencionados en este manual están sujetas

a modificaciones sin preaviso debido a nuestros esfuerzos continuos para mejorar la calidad de

nuestros productos.

Loading...

Loading...