Max 1500 PRO, 2200 PRO, F18 PRO Installation Manual

Installation Guide for

MAX 1500 PRO/2200 PRO/f18 PRO

MATRIX III

CONFORMS TO UL STD 325

MAX 1500 PRO/2200 PRO UL CLASS - I, II, III, IV

MAX F18 PRO UL CLASS - III, IV ONLY

CERTIFIED TO CAN/CSA STD

C22.2 NO. 247

Slide Gate Operators

SAFETY SENSORS REQUIRED

Version 7a

Residential/Commercial

Brushless DC Slide Gate Operators

Made in USA

www.max.us.com

4009963

ul 325 compliant installation

requirements

a) Install the gate operator only when:

a) N’installez l’ouvre-barrière que si :

1) The operator is appropriate for the construction of the gate and the usage Class of the gate,

1) l’ouvre-barrière est approprié pour la structure et la classe d’utilisation de la barrière;

2) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 1.83 m (6 ft) above the ground

to prevent a 57.2 mm (2-1/4 inch) diameter sphere from passing through the openings anywhere in the gate, and in that portion of the

adjacent fence that the gate covers in the open position,

2) toutes les ouvertures de la barrière coulissante sont protégées ou grillagées du bas de la porte jusqu’à unminimum de 1,83 m (6 pi) du sol

si bien qu’une sphère de 57,2 mm (2 1/4 po) de diamètre ne peut passer par une ouverture au niveau de la barrière et de la portion de la

clôture adjacente que la barrière couvre en position ouverte;

3) All exposed pinch points are eliminated or guarded, and

3) tous les points de pincement sont éliminés ou protégés;

4) Guarding is supplied for exposed rollers.

4) des protections sont fournies pour les galets exposés.

b) The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access opening. The

pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that persons will not come in contact with the

vehicular gate during the entire path of travel of the vehicular gate.

b) L’ouvre-barrière est destiné à n’être installé que sur des barrières utilisées pour les véhicules. Il faut fournir une autre voie d’accès aux

piétons. La voie d’accès pour les piétons doit être conçue pour favoriser le passage des piétons. Placez la barrière de sorte que personne ne

puisse entrer en contact avec la barrière pour les véhicules sur l’ensemble de sa trajectoire.

c) The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when opening and

closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

c) Pour réduire les risques de coincement lors de l’ouverture et de la fermeture, la barrière doit être installée dans un endroit où la barrière et

les structures avoisinantes sont suffisamment éloignées l’une de l’autre. Les barriers battantes ne doivent pas ouvrir dans une zone d’accès

public.

d) The gate must be properly installed and work freely in both directions prior to the installation of the gate operator. Do not over-tighten the

operator clutch or pressure relief valve to compensate for a damaged gate.

d) La barrière doit être bien installée et fonctionner librement dans les deux directions avant d’entreprendre l’installation de l’ouvre-barrière.

Ne serrez pas trop l’embrayage ou la soupape de surpression de l’ouvre-barrière pour compenser une barrière endommagée.

e) For gate operators utilizing Type D protection:

e) Pour les ouvre-barrières qui utilisent des protections de type D :

1) The gate operator controls must be placed so that the user has full view of the gate area when the gate is moving,

1) les commandes de l’ouvre-barrière doivent être placées de sorte que l’utilisateur voit l’ensemble de la zone de la barrière lorsque cette

dernière est en mouvement;

2) The placard as required by 62.1.6 shall be placed adjacent to the controls,

2) l’étiquette requise selon la clause 62.1.6 doit être placée à côté des commandes;

3) An automatic closing device (such as a timer, loop sensor, or similar device) shall not be employed, and

3) un dispositif de fermeture automatique (comme une minuterie, une boucle de détection ou un dispositif similaire) ne doit pas être utilisé;

4) No other activation device shall be connected.

4) aucun autre appareil d’activation ne doit être connecté.

f) Controls intended for user activation must be located at least 1.83 m (6 ft) away from any moving part of the gate and where the user is

prevented from reaching over, under, around or through the gate to operate the controls.

f) Les commandes destinées à l’activation par l’utilisateur doivent être situées à au moins 1,83 m (6 pi) des pieces mobiles de la barrière et à

un endroit où l’utilisateur ne peut pas atteindre les commandes par le dessus, par le dessous, par les côtés et au travers de la barrière.

Exception: Emergency access controls only accessible by authorized personnel (e.g. fire, police, EMS) may be placed at any location in the

line-of-sight of the gate.

Exception : Les commandes d’accès d’urgence accessibles au personnel autorisé seulement (p. ex. pompier, policier, SMU) peuvent être

placées à tout endroit dans le champ de visibilité de la barrière.

UL 325 2018 Standard - MAX 1500 PRO/2200 PRO/F18 PRO Matrix III Instal

2

Safety - 1

l Version 7a

ul 325 compliant installation

requirements continued

g) The Stop and/or Reset button must be located in the lineof-sight of the gate. Activation of the reset control shall not cause the operator to

start.

g) Le bouton d’arrêt, le bouton de réenclenchement ou ces deux boutons doivent être situés dans le champ de visibilité de la barrière.

L’activation des commandes de réenclenchement ne doit pas mettre en marche l’ouvrebarrière.

h) A minimum of two (2) WARNING SIGNS shall be installed, in the area of the gate. Each placard is to be visible by persons located on the

side of the gate on which the placard is installed. Also see 62.1.1.

h) Au moins deux panneaux de mise en garde doivent être installés dans la zone de la barrière. Chaque étiquette doit être visible des

personnes situées de chaque côté de la barrière sur laquelle l’étiquette est installée. Voir aussi la clause 62.1.1.

i) For gate operators utilizing a non-contact sensor in accordance with 32.1.1:

i) Pour les ouvre-barrières qui fonctionnent avec des capteurs sans contact conformément à la clause 32.1.1 :

1) See instructions on the placement of non-contact sensors for each Type of application,

1) Voir les instructions sur le positionnement des capteurs sans contact pour chaque type d’utilisation.

2) Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor while the gate is still moving, and

2) Des précautions doivent être prises pour réduire les risques de déclenchement inutile, comme lorsqu’un véhicule déclenche le capteur alors

que la barrière est encore en mouvement.

3) One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the perimeter reachable by a

moving gate or barrier.

3) Un capteur sans contact ou plus doit être situé où il existe un risque de coincement ou d’obstruction, comme dans l’espace que peut

occuper la barrière lorsqu’elle est en mouvement.

j) For a gate operator utilizing a contact sensor in accordance with 32.1.1:

j) Pour les ouvre-barrières qui fonctionnent avec des capteurs de contact conformément à la clause 32.1.1 :

1) One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the leading edge, trailing edge,

and postmounted both inside and outside of a vehicular horizontal slide gate.

1) Au moins un capteur de contact doit être situé où il existe un risque de coincement ou d’obstruction, comme sur le bord d’ouverture, sur le

bord de fermeture et sur les poteaux montés sur l’intérieur ou l’extérieur d’une barrière coulissante pour véhicules.

2) One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

2) Au moins un capteur de contact doit être situé sur le bord inférieur d’une barrière levante pour véhicules.

3) One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

3) Au moins un capteur de contact doit être situé au point de pincement d’une barrière à pivot vertical pour véhicules.

4) A hardwired contact sensor shall be located and its wiring arranged so that the communication between the sensor and the gate operator is

not subjected to mechanical damage.

4) Un capteur de contact doit être installé et câblé de sorte à éviter que la communication entre le capteur et l’ouvrebarrière soit gênée par des

dommages mécaniques.

5) A wireless device such as one that transmits radio frequency (RF) signals to the gate operator for entrapment protection functions shall be

located where the transmission of the signals are not obstructed or impeded by building structures, natural landscaping or similar obstruction. A wireless device shall function under the intended end-use conditions.

5) Un dispositif sans fil, comme un appareil qui transmet des signaux de radiofréquence (RF) à l’ouvre-barrière pour prévenir le coincement,

doit être situé à un endroit où la transmission des signaux ne sera pas obstruée ou gênée par des structures, des arbres ou d’autres obstacles

similaires. Un dispositif sans fil doit fonctionner selon les conditions d’utilisation finale prévues.

6) One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally, if the bottom edge of a

swing gate is greater than 152 mm (6 inches) but less than 406 mm (16 inches) above the ground at any point in its arc of travel, one or more

contact sensors shall be located on the bottom edge.

6) Au moins un capteur de contact doit être situé sur les bords d’ouverture intérieur et extérieur d’une barrière battante. De plus, si le dessous

d’une barrière battante est situé à plus de 152 mm (6 po) mais à moins de 406 mm (16 po) du sol à l’un des points de sa trajectoire, au moins

un capteur de contact doit être situé sur le bord inférieur.

7) One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

7) Au moins un capteur de contact doit être situé sur le bord inférieur d’une barrière verticale (bras).

UL 325 2018 Standard - MAX 1500 PRO/2200 PRO/F18 PRO Matrix III Instal

3

Safety - 2

l Version 7a

important safety information

IMPORTANT SAFETY INSTRUCTIONS WARNING – To reduce the risk of injury or death:

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES AVERTISSEMENT – Pour réduire les risques de blessures et de mort :

1. READ AND FOLLOW ALL INSTRUCTIONS.

1. LISEZ ET SUIVEZ TOUTES LES INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control away from children.

2. Ne laissez jamais les enfants manoeuvrer les commandes de la barrière ou jouer avec celles-ci. Laissez la télécommande hors de la portée

des enfants.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE.

3. Tenez toujours à l’écart de la barrière toute personne ou tout objet avoisinant. IL NE FAUT JAMAIS PASSER DANS LA TRAJECTOIRE D’UNE

BARRIÈRE EN MOUVEMENT.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object activates the non-contact

sensors. After adjusting the force or the limit of travel, retest the gate operator. Failure to adjust and retest the gate operator properly can

increase the risk of injury or death.

4. Vérifiez le fonctionnement de l’ouvre-barrière une fois par mois. Le sens de la course DOIT s’inverser lorsque la barrière entre en contact

avec un objet dur ou la barrière DOIT s’arrêter lorsqu’un objet active les capteurs sans contact. Vérifiez à nouveau l’ouvre-barrière après tout

réglage de la force de déclenchement ou du seuil de fin de course. Un réglage incorrect de l’ouvre-barrière ou l’omission de vérifier à nouveau

le fonctionnement de l’ouvre-barrière peut causer des blessures, voire la mort.

5. Use the emergency release only when the gate is not moving.

5. Ne déclenchez le dispositif de désaccouplement d’urgence que lorsque la barrière ne bouge pas.

6. KEEP GATES PROPERLY MAINTAINED. Read the user’s manual. Have a qualified service person make repairs to gate hardware.

6. ASSUREZ-VOUS QUE LA BARRIÈRE EST CORRECTEMENT ENTRETENUE. Lisez le manuel de l’utilisateur. Confiez la réparation du matériel

de la barrière à un technicien qualifié.

7. The entrance is for vehicles only. Pedestrians must use separate entrance.

7. La voie d’accès est réservée aux véhicules seulement. Les piétons doivent utiliser une voie d’accès différente.

8. SAVE THESE INSTRUCTIONS.

8. CONSERVEZ CES INSTRUCTIONS.

4

Safety - 3

UL 325 2018 Standard - MAX 1500 PRO/2200 PRO/F18 PRO Matrix III Instal

l Version 7a

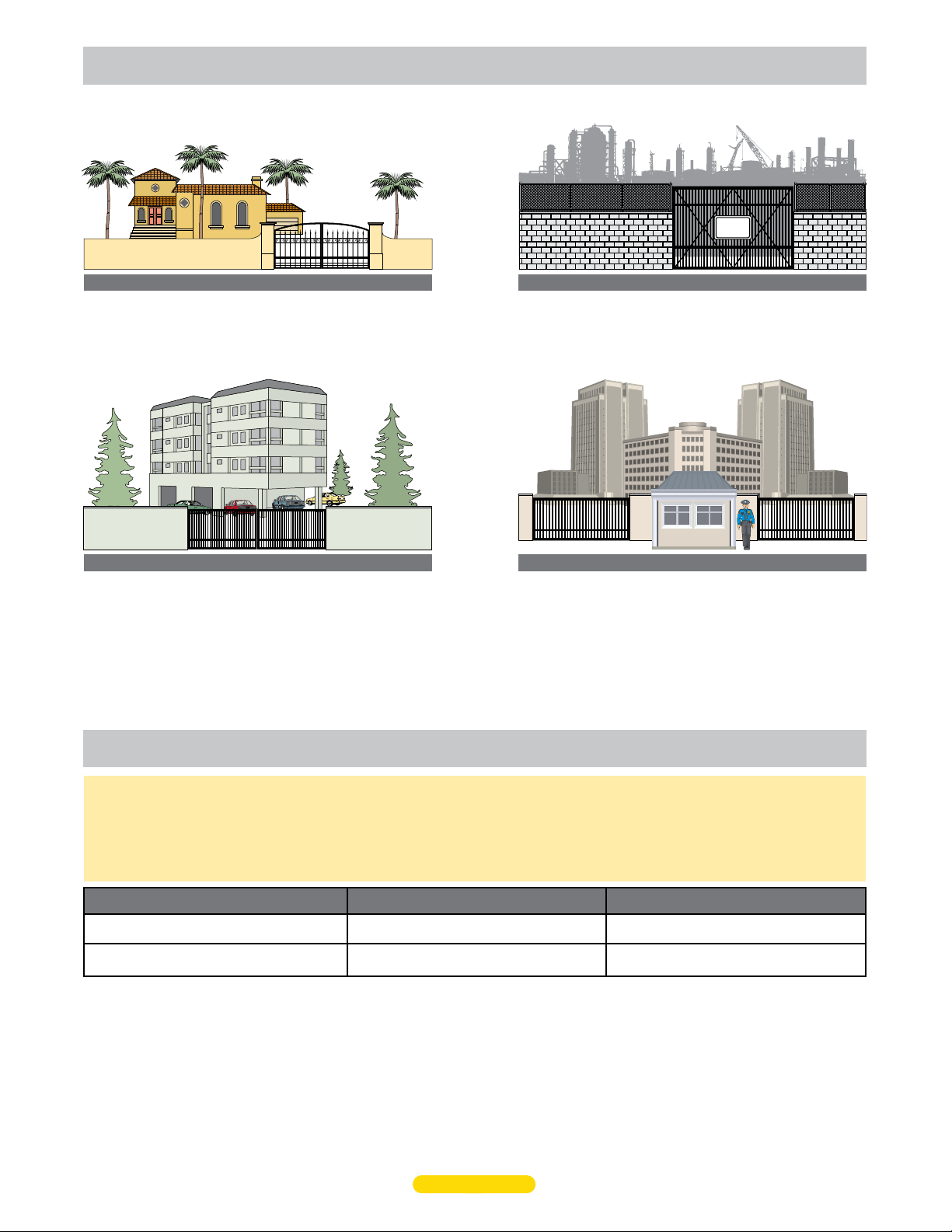

ul 325 model classifications

AUTHORIZED

PERSONNEL

ONLY

CLASS I

Residential Vehicular Gate Operator - A vehicular gate operator

(opener or system) intended for use in a home of one to four

single family dwellings, or a garage or parking area associated

therewith.

CLASS II

Commercial/General Access Vehicular Gate Operator - A

vehicular gate operator (opener or system) intended for use in

a commercial location or building such as a multi-family

housing unit (five or more single family units) hotel, garages,

retail store or other building servicing the general public.

CLASS III

Industrial/Limited Access Vehicular Gate Operator - A

vehicular gate operator (opener or system) intended for uses

in an industrial location, loading dock area or other location

not intended to service the general public.

SECURITY

CLASS IV

Restricted Access Vehicular Gate Operator - A vehicular gate

operator (opener or system) intended for use in a guarded

industrial location or buildings such as airport security area or

other restricted access locations not servicing the general

public, in which unauthorized access is prevented via

supervision by security personnel.

ul 325 required entrapment protection

This vehicular gate operator must be installed with at least two independent entrapment protection means as specified in the table and

definitions below.

The same type of device shall not be used for both entrapment protection means. Use of a single device to cover both the opening and

closing directions is in accordance with the requirement, however, a single device is not required to cover both directions. This operator

has been provided with type A entrapment protection. The installer is required to install additional entrapment protection devices in each

entrapment area.

Gate Type Class I & II

Swing Gate

Slide Gate

A - Inherent entrapment protection system.

B1 - Provision for connection of a non-contact sensor

(photoelectric sensor or the equivalent).

B2 - Provision for connection of a contact sensor

(edge device or the equivalent).

A, B1*, B2*, C, D

A, B1*, B2*, D

* B1 and B2 means of entrapment protection must be MONITORED.

5

Safety - 4

C - Inherent adjustable clutch or pressure relief device.

D - Provision for connection of an actuating device

requiring continuous pressure to maintain opening

or closing motion of the gate.

E - An audio alarm.

UL 325 2018 Standard - MAX 1500 PRO/2200 PRO/F18 PRO Matrix III Instal

Class III & IV

A, B1*, B2*, C, D, E

A, B1*, B2*, D, E

l Version 7a

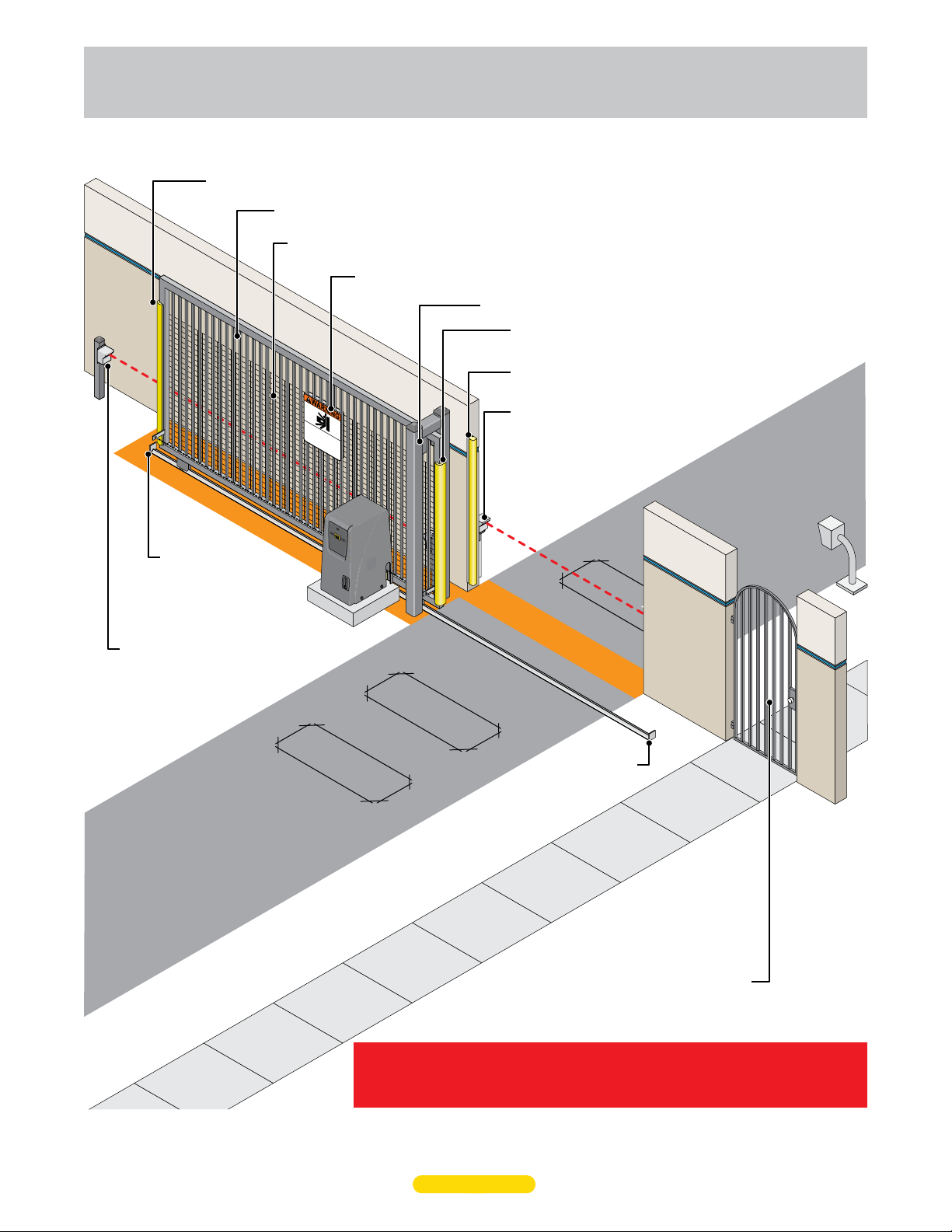

intended use of

slide gate operator

The operator is intended for use on a VEHICULAR slide gate ONLY. It is intended to be used WITH appropriate entrapment

protection safety devices and in-ground vehicle loop detection system. Pedestrians MUST use a separate entrance.

OPENING Direction Reverse Edge: Helps guard against the opening gate from entrapment.

Gate Pickets: The space between the gate pickets should be LESS than 2 1/4” or wire mesh should be installed.

Wire Mesh: 2” x 2” at least 6 ft high. Installed on gate when the space between the gate pickets is MORE than 2 1/4”.

Warning Signs: Should be installed on BOTH sides of gate area and easily visible.

Guide Rollers: Must be installed for safety.

CLOSING Direction Reverse Edge: Helps guard

against the closing gate from entrapment.

OPENING Direction Reverse Edge: Helps guard against the

opening gate from entrapment between wall and gate.

CLOSING Direction Photocell: Helps

guard against the closing gate from

entrapment.

Entrapment Area

Moving Gate Can

Serious Injury or Death

KEEP CLEAR! Gat

without

Do

prior

not let children operate the gat

in the gate area.

warning.

e may

This entrance is for veh

Pedestrians

must use separate entrance.

Cause

move at any time

e or

icles only.

play

Physical Stops:

Install on BOTH ends of

gate rail to limit the travel

of gate to the fully open

and fully closed positions.

OPENING Direction Photocell:

Helps guard against the opening

gate from entrapment between

wall and gate.

In-Ground Loops: Help

protect the gate operator

from accidentally opening

and/or closing on vehicles

in the gate’s path

Automatic Exit

Loop

Safety Loop

Entrapment Area

Safety Loop

Physical Stop

Pedestrians MUST use a separate entrance.

Gate operator IS NOT intended to be used on a PEDESTRIAN gate.

Entrapment sensors must be installed where entrapment or pinch point exist.

A minimum of TWO entrapment protection sensors MUST be installed, ONE in EACH

direction of gate travel or operator will NOT function.

UL 325 2018 Standard - MAX 1500 PRO/2200 PRO/F18 PRO Matrix III Instal

6

Safety - 5

l Version 7a

Table of Contents

Gate Safety

UL 325 Compliant Installation Requirements

UL 325 Model Classifications

Intended Use of Slide Gate Operator

Step-By-Step Installation

1A

Operator Placement (Standard)

1A

Connect Chain to Gate (Standard)

1B

Rear Mounting Position (Alternate)

1B

Connect Chain to Gate (Rear Pos)

2

AC Input Power

3

Ground Operator

4

Opening Direction/ID Plug/Operator

5

Entrapment Protection Wiring

6

Program Virtual Limit Sensors

7

Learn Gate Positions

8

Adjust ERD Reverse Sensor

9

Loops & Loop Detectors

10

Matrix III Settings

11

Wiring Opening Device Options

12

Learn Unlearned Sensor Inputs

Page

Safety-1-3

Safety-4

Safety-5

7-8

10

10

11

11

12

12

Additional Features

Programming

DIP-Switch Settings

Gate Shut-Off Switch

Electronic Gate OPEN / CLOSE

Gate Tamper Feature

Dropping the Chain - Gate Tamper is Armed (ON)

1

2

3

4

5

6

6

Dual Gate Operators Wiring

Gate Disable Feature

Troubleshooting

USB Black Box Port

Test Entrapment Sensors

Gate Cycling Troubleshooting

Matrix III LED Troubleshooting

Page

13

13

14

14

15

16

17

18

19

19

20

21-22

Commonly Used Safety Sensors

9

Omron E3K-R10K4

Omron IRB-RET

EMX IRB-MON Single Gate

EMX IRB-MON Dual Gates

Miller RBAND Monitored Wireless

Wiring Overview

Optional Magnet Limit Sensors

Optional Solar Power

23

23

24

25

26

27

28

29

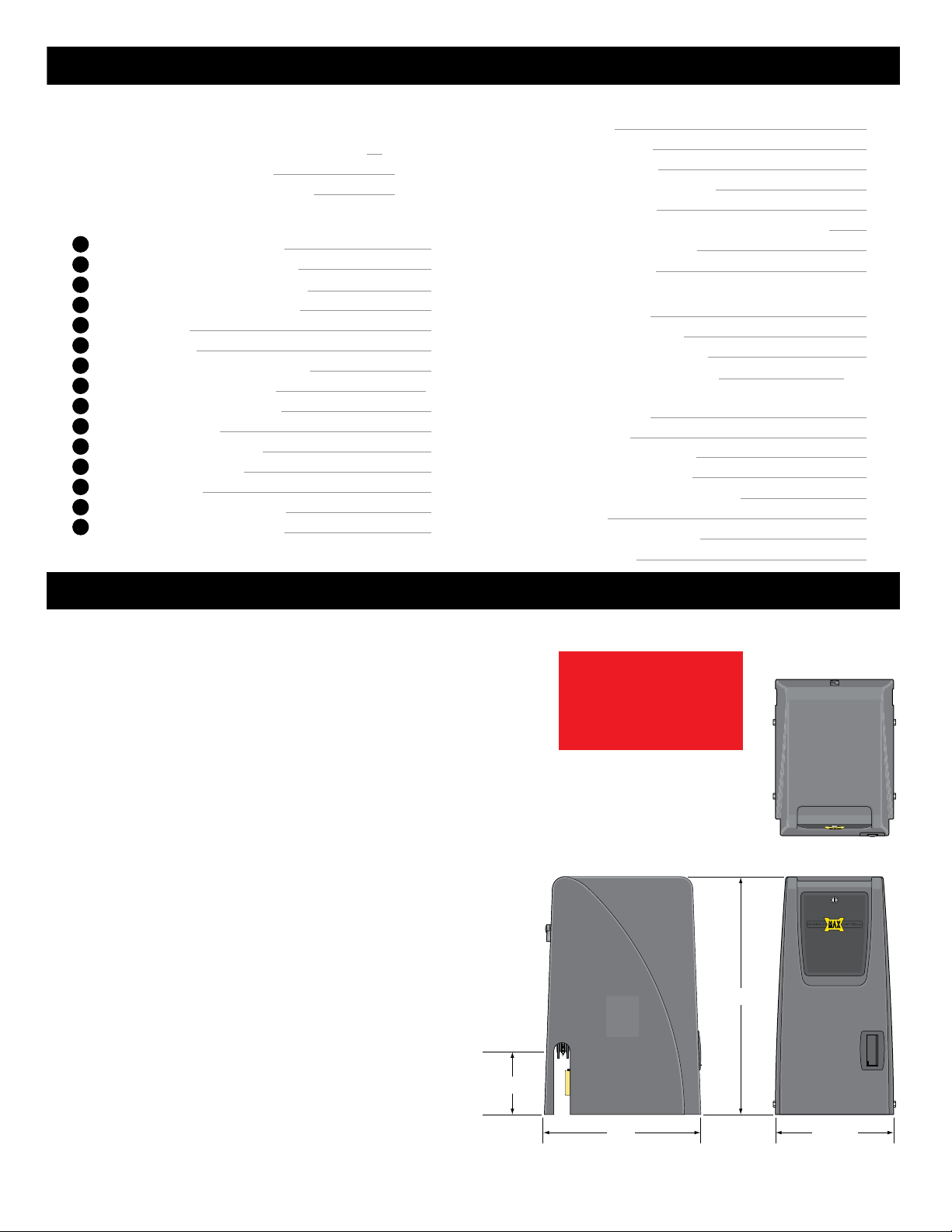

specifications

UL 325 Class of Operation - MAX 1500 PRO/2200 PRO - Class I, II, III, IV.

MAX F18 PRO - Class III, IV ONLY.

Gate Type - Vehicular Slide Gate

Max Gate Length - 50 ft

Max Gate Weight:

• MAX 1500 PRO - 1500 lbs Level Gate

• MAX 2200 PRO - 2200 lbs Level Gate

• MAX F18 PRO - 1600 lbs Level Gate

Opening Time - Selectable speed control: (MAX 1500 PRO/2200 PRO - Up to 12 inch/sec)

(MAX F18 PRO - Up to 18 inch/sec)

Cycles per Hour AC Power - Continuous

Battery Back-Up Cycles (2- 7 Amp/Hr Batteries fully charged):

• Approximately 100 cycles

NOTE: The number of gate cycles using ONLY battery back-up power will vary

depending on the weight of the gate, the gate length, the operating condition

of the gate, temperature and the amount of charge the batteries have at the

beginning of the battery power only operation.

Input AC Power/Amps - Switchable: 115VAC / 6 Amp, 1 phase

or 230VAC / 2 Amp, 1 phase

Motor:

• MAX 1500 PRO - 1/2 HP 24VDC Brushless (6 million cycles)

• MAX 2200 PRO/F18 PRO - 1 HP 24VDC Brushless (6 million cycles)

Chain Size - #40

Operating Temperature: -4°F to 158°F (-20°C to 70°C)

Entrapment Protection:

- UL 325 Type A Inherent (ERD sensor)

- Inputs for NORMALLY CLOSED (N.C.) and 10K Type

UL 325 Type B1 (photocell)

and Type B2 (sensing edge)

7 1/2”

UL 325 2018 Standard - MAX 1500 PRO/2200 PRO/F18 PRO Matrix III Instal

7

TWO Entrapment protection

sensors MUST be installed,

ONE in EACH direction of

gate travel or operator will

NOT function.

29”

14 1/2”19”

l Version 7a

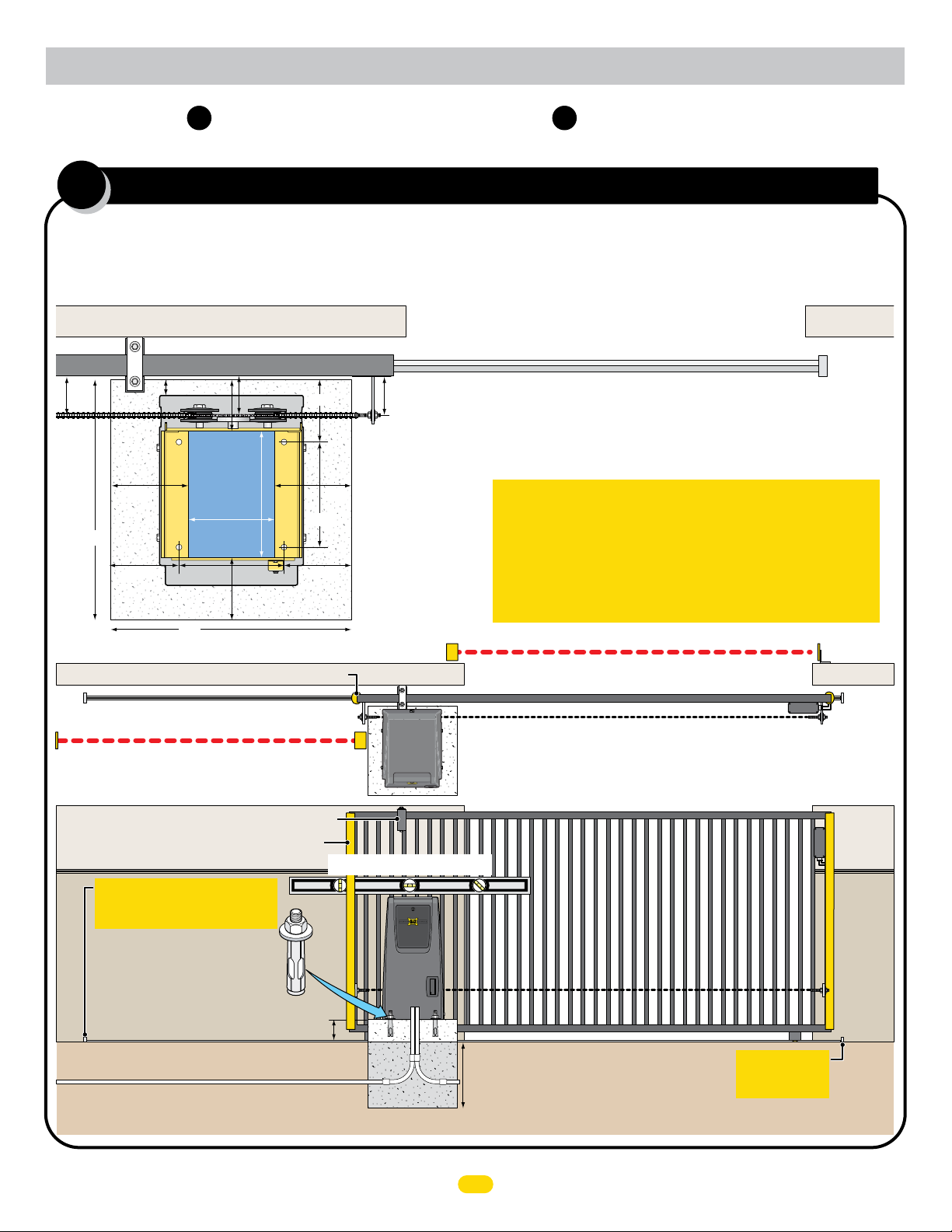

step-by-step installation

Choose either Front Mounting Position (Standard) or Rear Mounting Position (Alternate).

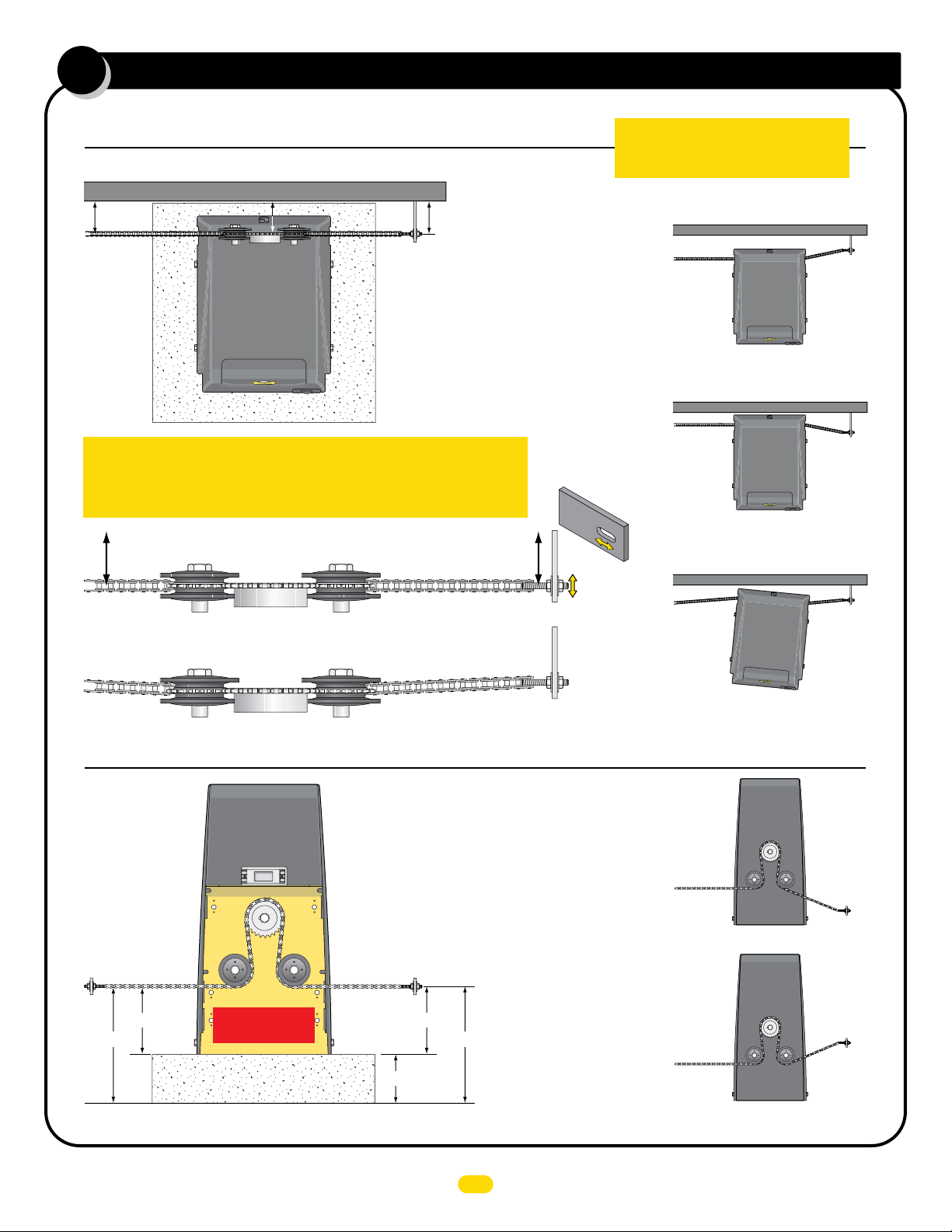

1A

Operator Placement (standard)

1A 1B

The gate must be properly installed and work freely in both directions prior to installation of the gate operator.

Operator in Front Position (Standard)

Guide Rollers

1.5”

4”5”

12.75”

Conduit

Area

24”

6.75”

Outside Property

OPENING Sensing Edge with Wireless Module

Inside Property

OPENING Photocell Beam

8.625”

10.5”

6.5”

24”

2” Gate Frame

Cover

Concrete Pad

6.2”

10.5”

6.75”

4”4”

7.5”7.5”

Operator

Position on

Concrete Pad

V-Rail

Conduit Guidelines and Suggestions

• REQUIRED - AC input power wire.

• REQUIRED - Entrapment protection OPENING and CLOSING photocell

and/or sensing edges.

• In-ground loop wires.

UL 325 2018 Standard

Safety sensors (Photocell or contact EDGE) must be

installed in BOTH opening and closing direction of gate

movement where entrapment or pinch point exist. TWO

safety sensor min. (N.C. or 10K type) MUST be installed or

operator will NOT function. All sensors must be UL325,

2018 compliant. See pages 7-8.

CLOSING Photocell Beam

Gate in Closed Position

See next page for chain information.

Operator in Front Position (Standard)

Wireless

Module

Physical Stop

Reflector

CLOSING

Sensing

Edge with

Wireless

Module

Guide rollers MUST be Installed to keep gate upright.

OPENING Sensing Edge with Wireless Module

Operator MUST be level.

IMPORTANT: Physical stops MUST

be installed on BOTH ends of rail to

keep gate from traveling off of rail.

Secure gate operator to

concrete pad with four

(4) 1/2” x 3” (min)

sleeve anchors.

6” above ground to avoid flooding.

Input Power

Concrete Depth Note: The heavier the gate, the deeper the concrete pad should be. At least two feet recommended for heavier gate.

1/2

Conduit Run

Concrete Pad

Check local building

codes in your area for

depth of concrete

before installation.

UL 325 2018 Standard - MAX 1500 PRO/2200 PRO/F18 PRO Matrix III Install Version 7a

1

MUST be installed

IMPORTANT:

Physical Stop

Module

Wireless

CLOSING

Sensing

Edge with

Wireless

Module

1A

YES

NO

YES

YES

NO

NO

NO

NO

NO

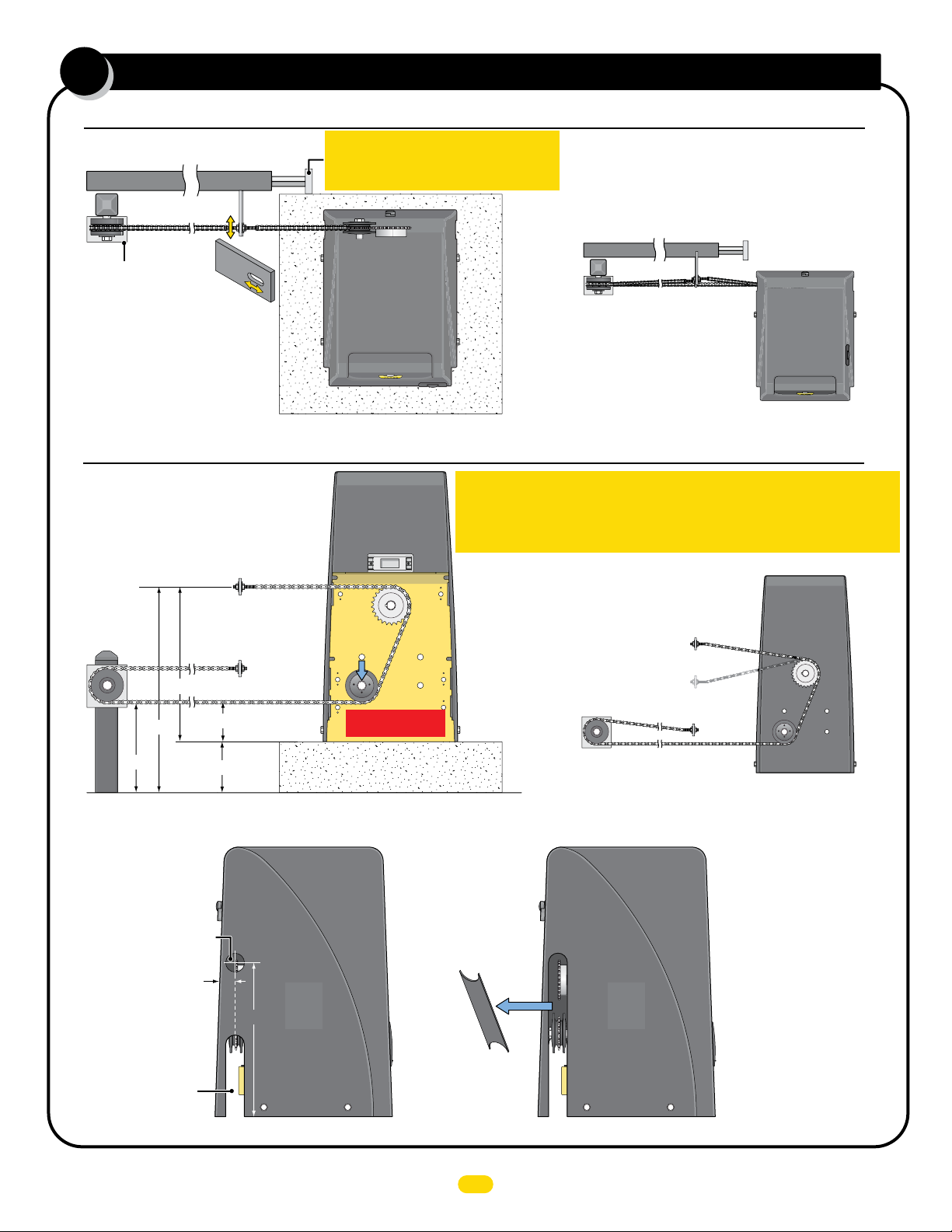

connect chain to gate (standard)

Top View of Operator

NOTE: 25 ft of #40 nickel plated chain included.

Minimum distance between the drive gear and gate is 4”.

4” Min4” Min

Drive

Gear

Chain

Bracket

YES

IMPORTANT: Operator and chain MUST be parallel to gate or the idler

wheels could fail. Use the “Fine Tune” adjustment on the gate bracket

connection bolt and make sure the chain runs through the idler wheels

without binding on the side chain guides.

YES

Side Chain Guide

Side Chain Guide

Idler Wheel

4” Min4” Min

NO

Gate Bracket

Fine Tune

Adjustment

IMPORTANT: Physical stops MUST be

installed on BOTH ends of gate rail to

keep gate from traveling off of rail.

NO

Operator is too far from gate.

Chain is NOT parallel to gate.

NO

Operator is too close to gate.

Chain is NOT parallel to gate.

NO

Operator is NOT parallel to gate.

Chain is NOT parallel to gate.

Back View of Operator

YES

Chain brackets MUST

remain same height as

idler wheels.

Chain

Bracket

Idler Wheels

Factory installed

position

Concrete Pad

Operator in Front Position (Standard)

Bracket

6”

Chain

7.5”7.5”

NOTE: The chain should

sag no more than one (1)

inch per 10 feet of travel.

Do not over tighten the

chain.

13.5”13.5”

2

NO

Chain

Bracket

DO NOT mount chain bracket too low on gate.

NO

Chain

Bracket

DO NOT mount chain

bracket too high on gate.

UL 325 2018 Standard - MAX 1500 PRO/2200 PRO/F18 PRO Matrix III Instal

l Version 7a

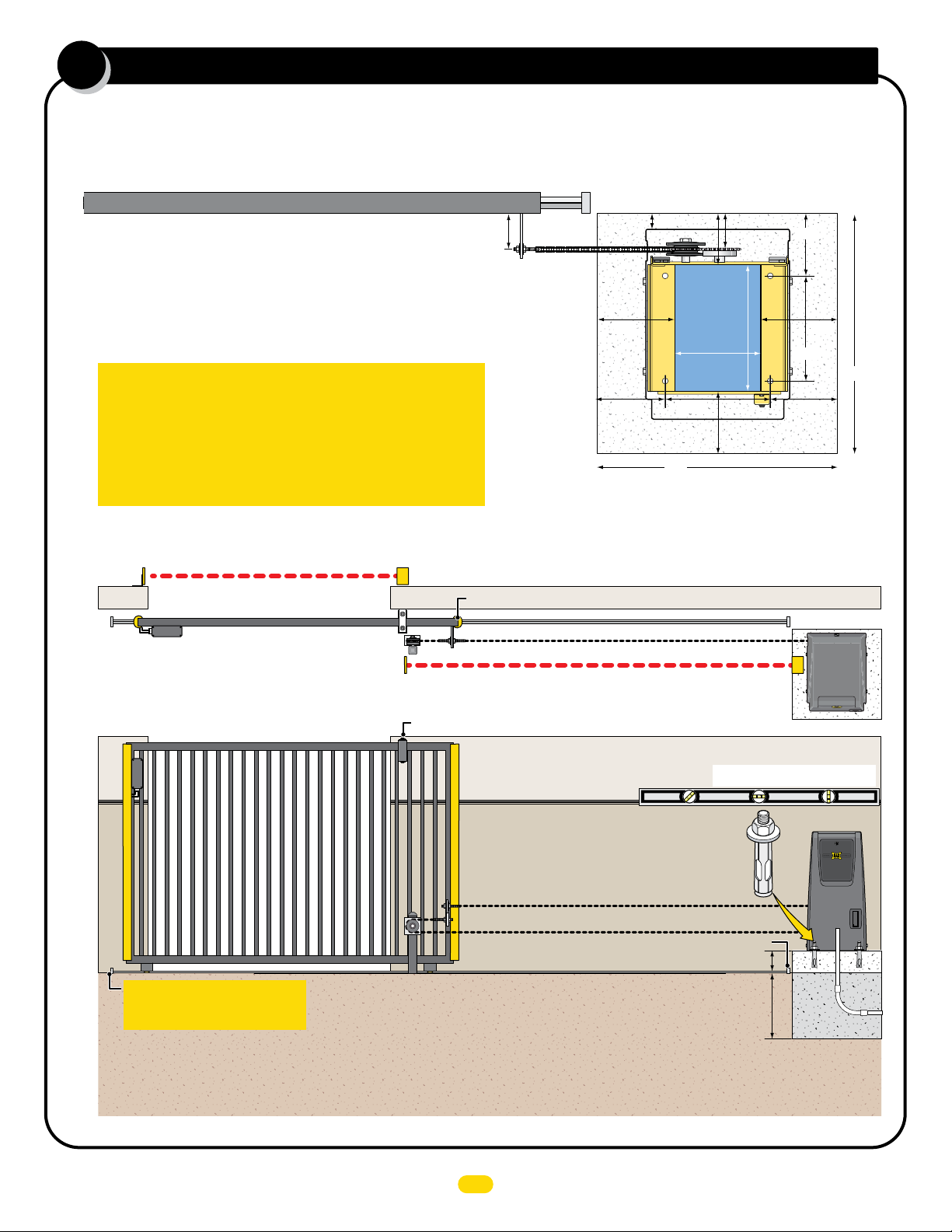

1B

rear mounting position (alternate)

The gate must be properly installed and work freely in both directions prior to the installation of the gate operator.

The chain is not visible when looking from outside of the property.

2” Gate Frame

Conduit Guidelines and Suggestions

• REQUIRED - AC input power wire.

• REQUIRED - Entrapment protection OPENING and CLOSING photocell and/or sensing edges.

• In-ground loop wires.

UL 325 2018 Standard

Safety sensors (Photocell or contact EDGE) must be

installed in BOTH opening and closing direction of gate

movement where entrapment or pinch point exist. TWO

safety sensor min. (N.C. or 10K type) MUST be installed or

operator will NOT function. All sensors must be UL325,

2018 compliant. See pages 7-8.

V-Rail

Physical Stop

4”

1.5”

4”5”

12.75”

6.2”

Conduit

7.5”7.5”

10.5”

24”

6.75”

Concrete Pad

6.75”

24”

8.625”

10.5”

Area

Cover

6.5”

Operator Position on Concrete Pad

Outside Property

CLOSING Sensing

Edge with Wireless

Module

Inside Property

CLOSING

Sensing

Edge with

Wireless

Module

CLOSING Photocell Beam

Wireless

Module

Gate in Closed Position

Wireless

Module

IMPORTANT: Physical stops MUST

be installed on BOTH ends of rail to

keep gate from traveling off of rail.

Operator in Rear Position

OPENING Sensing Edge with Wireless Module

OPENING Photocell Beam

Photcell to OPEN ONLY NC Input

Guide rollers MUST be Installed to keep gate upright.

OPENING Sensing Edge

with Wireless Module

Secure gate operator to

concrete pad with four

(4) 1/2” x 3” (min)

See next page for chain information.

6” above ground to avoid any flooding of the operator.

Illustrations not to scale

Operator MUST be level.

sleeve anchors.

Physical Stop

Check local building

codes in your area for

depth of concrete

before installation.

1/2

Conduit

Run

Input Power

Concrete Pad

Concrete Depth Note: The heavier the gate, the deeper the concrete

pad should be. At least two feet recommended for heavier gate.

UL 325 2018 Standard - MAX 1500 PRO/2200 PRO/F18 PRO Matrix III Instal

3

l Version 7a

1B

YES

YES

NO

NO

connect chain to gate (rear pos)

Top View of Operator

NOTE: 25 ft of #40 nickel plated chain included.

Gate

Gate Bracket

Pulley Wheel

Safety Cover

Fine Tune

Adjustment

Operator and chains

MUST remain

parallel to gate.

Upper and lower

chain MUST align

with each other.

Operator in Rear Position

Back View of Operator

NOTE: The chain should sag

no more than one (1) inch per

10 feet of travel. Do not over

tighten the chain.

Upper chain bracket

MUST remain same

height as drive gear.

IMPORTANT: Physical stops MUST be

installed on BOTH ends of gate rail to

keep gate from traveling off of rail.

Drive

Gear

YES

IMPORTANT: Operator and chain MUST be parallel to gate or the idler

wheels could fail. Use the “Fine Tune” adjustment on the gate bracket

YES

connection bolt and make sure the chain runs through the idler wheels

without binding on the side chain guides.

Gate

Lower chain does NOT

align with upper chain.

NO

Pulley Wheel

(not supplied)

Same height as

idler wheel.

10.5”

22.5”

Lower chain Bracket

MUST remain same

height as pulley wheel.

16.5”

4.5”

6”

Drive

Gear

Move operator wheel

to lower hole position.

Concrete Pad

Idler

Wheel

Modify Cover for Rear Mounting Position

Drill 2” dia. hole for

upper chain exit.

Approx.1.5”

16.5”

Existing chain

exit slot.

Remove

DO NOT mount

chain brackets

too high or too

low on gate.

Chain

Bracket

Chain

Bracket

NO

Cut out cover

between new hole

and existing chain

exit slot.

Make sure cuts are

plumb with existing

chain exit slot.

UL 325 2018 Standard - MAX 1500 PRO/2200 PRO/F18 PRO Matrix III Instal

4

l Version 7a

W

ARNING

HIGH

VOLT

AG

E

ATTENTION!

HI

GH

VOLT

AG

E

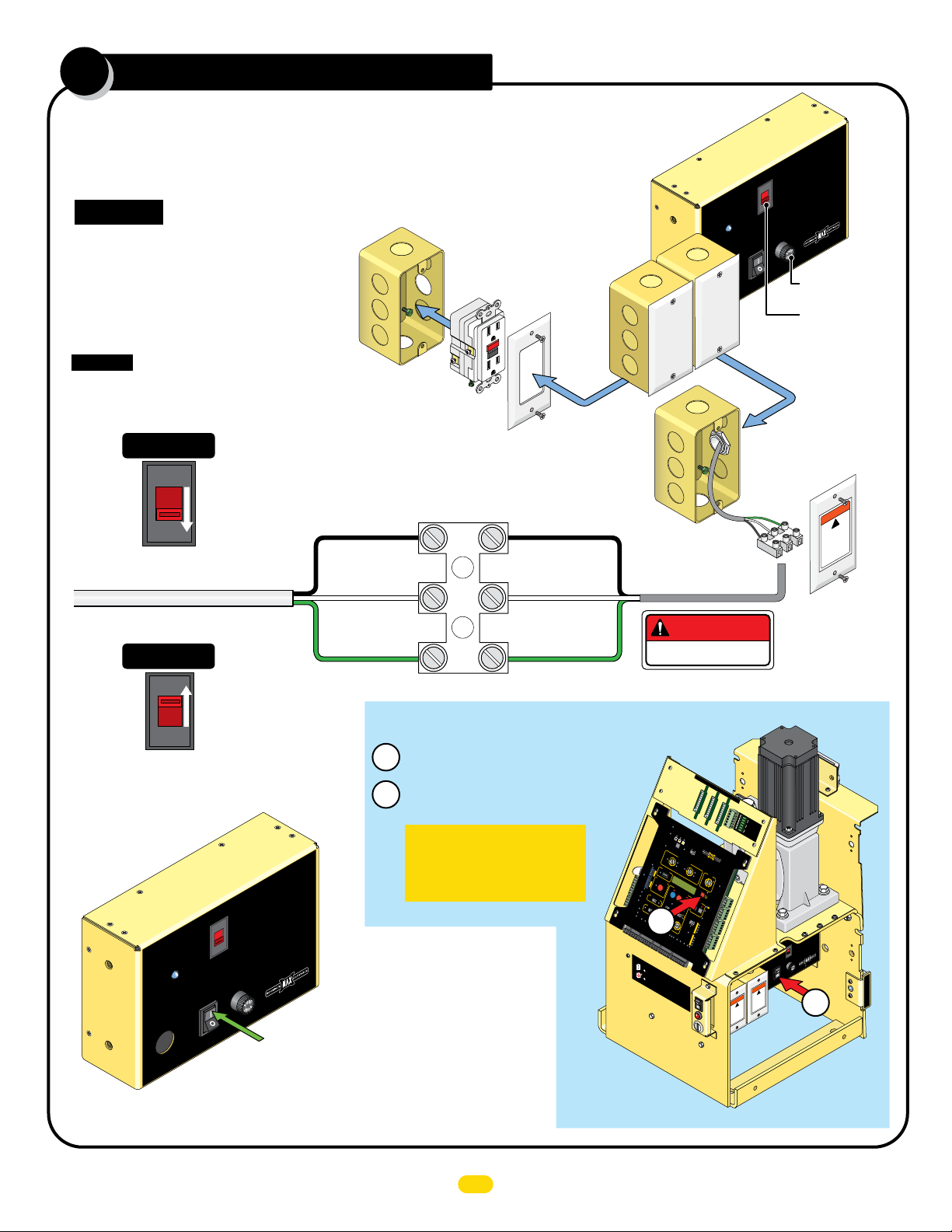

ac input power

WARNING

HIGH

VOLTAGE

2

Choose either 115V or 230V setting on input AC power selector switch.

Wire desired input AC power wire to power terminal. A additional single gang box is provided to

install power outlets if desired. GFCI outlet type is recommended.

CAUTION: Make sure circuit

breaker is OFF from incoming

AC input wire BEFORE wiring!

Additional single gang box

provided. Wire GFCI outlet

to the input AC wire

BEFORE connecting to

operator power terminal if

power outlets are desired.

Input AC Power Options

Additional

Power

Box

MAX

Toroid Box

AC

IN

On

Off

AC

Box

POWER

MAX Toroid 15 Amp

Select Input

Voltage

115V

115VAC or

230VAC

www.Max.US.com

FUSE

7 Amp

7 Amp Fuse

Input AC Power

Selector Switch

CAUTION: If input AC power selector

switch is set for 115V but input power

is actually 230 V, 7 Amp Fuse will blow.

Single Phase 115VAC Only

115VAC

Set to 115V

115 OR 230VAC

Power Wire

Single Phase 230VAC Only

115V

230VAC

Set to 230V

230V

Turn Power

ON

MAX

Toroid Box

AC

IN

LEDs should light up on operator.

Battery power automatically turns ON.

POWER

On

Off

Select Input

Voltage

115V

115VA C or

230VAC

FUSE

7 Amp

MAX Toroid 15 Amp

Turn Power ON

www.Max.US.com

Additional

Gang Box

GFCI Outlet

NOT provided

IMPORTANT: Make sure there are NO exposed bare

wires at the power terminal connection.

Line (Black)

Power Terminal

Neutral (White)

Chassis (Green)

Line (Black)

Neutral (White)

Chassis (Green)

Turn ALL Power OFF

Turn OFF AC POWER switch on MAX Toroid box.

1

Battery power will remain ON.

Press and HOLD Red ON/OFF BATTERY button

2

on the board until BEEP is heard, release button.

IMPORTANT: This procedure

must be followed whenever

ALL power must be turned

OFF on operator.

DO NOT

CYCLE

OPERATOR!

HIGH VOLTAGE!

BATT

E

RY

INP

UT

POW

ER /

SOL

AR IN

P

OWE

R

MOD

U

LE

P

ORT

MAX

MA

SENSE

NUAL

R

E

LEASE /

R

ES

E

T

O

1

A

FF

O

L

BD

AR

2

BLACK BOX

M

PORT

3

4

I

D

P

B

L

5

U

E

G

R

R

6

O

R

1

ID

2

PRO

PLU

3

G

G

4

R

AMMING

5

6

AMODE

7

8

DE

9

10

E

XIT P

MO

WR

O

FF

EXIT LOOP

GND

P

ROGR

AM

CENT

LOOP

ER

SOL

PWR

LOOP

A

SA

R MODE

FET

FA

Y

U

OFF

LTS

S

A

FET

Y

24VDC

ON

ON

OUTPU

GN

OPE

D

T

12VD

R

ATOR

C

OUTPU

PRIMARY

GN

D

T

SECONDARY

MI

NM

MA

XM

AL

N

IG

D

S

N

G

IO

D

IO

A

D

R

A

DEPT

EN

R

E

D

2

D

FIR

R

E

A

L

GN

I

NK

D

C

E

MAX OP

OK

/

EAS

IK

GN

D

P

A

D

REL

RIMARY/

STR

SE

L

GN

CO

EYP

D

NDARY

K

GN

LINK

D

MANUA

GN

D

+)

(

GN

-)

(

OPE

To

N

O

Turn OF

OFF

1

POWER

T

urn

B

OFF

atte

F

A

r

ALL PO

y

C

power w

P

OW

FF

O

N/

O

2

Pres

E

tery

t

Ba

R s

il

on t

l

r

wit

s and

em

ch

ain ON

he

HOLD

boar

d

R

un

ed

t

i

ON

l

BE

/

OFF BATTE

EP is heard

DANGER

EXIT CENTER SAFETY

B

A

TTERY

INPU

ERR

BATTE

T

OR

RY

E

VOL

B

A

TTERY

TAGE

1/2

IN U

S

E

F

BATT

BACKU

E

LE

BATTERY

RY

A

V

P M

OPE

E

TES

OD

N

R

EPLA

T

E

BATTE

C

OPE

E

R

1 TIME

N

Y

LEA

16

C

V

14

LO

E

MIN

S

ERD SENSITIVITY

E

12

D

1

3

ERD

9

MO

16

O

14

T

P

7

OVER

O

MIN

E

R

NING CLO

12

L

OAD

1

MAX

S

E

N

SE

3

ERD

9

MOTOR

7

OV

S

E

R

LOAD

ING

MAXIMUM CONTROLS

SWINGER / SLIDER

MI

NM

O

MOTION CONTROL

ON

/

OFF

OPEN

B

A

TTER

Y

J

S

OG

TO

QU

PCLOSE

I

CK

CLO

S

E

OFF

OP

E

N

LE

F

LE

T

FT

OPEN

G

GAT

A

RIGHT

E

R

I

GHT

G

ATE

MAGLOC

SP

EE

MAG

DEL

D

K

AY

LO

IN

CK

OF

C.

A

.

F

X

N

2.5 sec

OP

1.5 sec

R

E

N

ONLY

PHOTO C

NSO

CLO

E

SI

S

LS

N

OPEN

GOPENING

N

C

UL

/

C

LS N

UL

12VDC OUT

ENTRA

C

0K

P

1

R

GN

OPEN ONLY

O

D

C

ENS

LS

10

K

ONLY

LE

N

B

OP

10K

A

UL S

E

E

N

S

OP

/

S

I

C

T

O

LS

O

D

S

10K

L

N

12VDC

E

C

OM

T

ER

C

OUT

IN

P

GA

M

GN

PER

TA

OM

D

IGHT

M

C

FT

D

A

T

G R

GN

G LE

JO

O

D

J

GN

WE

on

R:

M

A

.

X

T

or

oi

d

box

.

R

,

Y

r

ele

button

a

s

e but

t

on.

MATRIX III

CLOSE

TIMER

FF

TE CLOS

N

C

AX

GATE O

C

OM

N

C

GN

N

O

P

E

N

C

OM

ED

D

MOTOR

INPUTS

MOTOR

POSITION

INPU

TS

SLIDE

R

LIMIT

SWIN

G

LIMIT

AC Power

Gang Box

EXIT

CENTER

SAFETY

TENTION!

AT

!

E

HIGH

TAG

L

ncher

VO

ra

nt

'b

a

e

ien

t

d

av

e

r

t

n

'e

l

Power

Terminal

AC

POWE

IN

On

Off

WARNING

!

HIGH

ect

e

nn

VOLTAGE

for

isco

it

d

ing un

power be

servic

WARNING

!

HIGH

ect

VOLTAGE

disconn

power before

servicing unit

Select Input

or

Voltage

AC

1

1

5V

m

115V

230VAC

www.Max.US.co

FUSE

R

mp

7 A

mp

A

Toroid 15

MAX

1

L

I

M

I

T

S

E

N

S

O

R

UL 325 2018 Standard - MAX 1500 PRO/2200 PRO/F18 PRO Matrix III Instal

l Version 7a

5

Loading...

Loading...