Page 1

CN445R2

PNEUMATIC ROOFING COIL NAILER

DISPOSITIVO NEUMÁTICO DE CLAVETEADO

DE BOBINA DE TEJADO

CLOUEUR A BOBINE DE TOITURE PNEUMATIQUE

OPERATING AND MAINTENANCE MANUAL

MANUEL D'UTILISATION ET D'ENTRETIEN

MANUAL DE OPERACIONES Y MANTENIMIENTO

WARNING

AVERTISSEMENT

ADVERTENCIA

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY WARNING AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

AVANT D’UTILISER CET OUTIL, LIRE CE MANUEL ET LES CONSIGNES DE SÉCURITÉ AFIN DE

GARANTIR UN FONCTIONNEMENT SÛR.

CONSERVER CE MANUEL EN LIEU SÛR AVEC L’OUTIL AFIN DE POUVOIR LE CONSULTER ULTÉRIEUREMENT.

ANTES DE UTILIZAR ESTA HERRAMIENTA, LEA DETENIDAMENTE ESTE MANUAL PARA FAMILIARIZARSE CON

LAS ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD.

CONSERVE ESTAS INSTRUCCIONES JUNTO CON LA HERRAMIENTA PARA FUTURAS CONSULTAS.

Page 2

INDEX INDEX ÍNDICE

ENGLISH Page 3 to 12

FRANÇAIS Page 13 to 22

ESPAÑOL Page 23 to 32

DEFINITIONS OF SIGNAL WORDS

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in mi-

NOTE: Emphasizes essential information.

DÉFINITIONS DES DIFFÉRENTS DEGRÉS D’ AVERTISSEMENTS

AVERTISSEMENT: Indique une situation éventuellement dangereuse qui, si elle n’est pas

ATTENTION:

REMARQUE: Souligne des informations importantes.

DEFINICIÓN DE LAS INDICACIONES DE ADVERTENCIA

ADVERTENCIA: Indica una situación potencialmente peligrosa que podría causar la muerte o

PRECAUCIÓN: Indica una situación potencialmente peligrosa que podría causar lesiones menos

NOTA: Resalta informaciones importantes.

death or serious injury.

nor or moderate injury.

contournée, pourrait provoquer la mort ou des blessure sérieuses.

Indique une situation éventuellement dangereuse qui, si elle n’est pas contournée,

pourrait provoquer des blessures légères à moyennement sérieuses.

graves lesiones si no se evita.

graves o leves si no se evita.

2

Page 3

ENGLISH

OPERATING AND MAINTENANCE MANUAL

INDEX

1. GENERAL SAFETY WARNINGS ........................................................3

2. SAFETY WARNING .............................................................................4

3. SPECIFICATIONS AND TECHNICAL DATA......................................7

4. AIR SUPPLY AND CONNECTIONS....................................................7

5. INSTRUCTIONS FOR OPERATION....................................................8

6. MAINTAIN FOR PERFORMANCE ....................................................12

7. STORING ...........................................................................................12

8. TROUBLE SHOOTING/REPAIRS .....................................................12

BEFORE USING THIS COMPRESSOR, STUDY THIS MANUAL TO ENSURE SAFETY WARNING

AND INSTRUCTIONS.

WARNING

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

1. GENERAL SAFETY WARNINGS

WARNING

READ ALL SAFETY WARNINGS AND ALL

INSTRUCTIONS.

Failure to follow the warnings and instructions

may result in death serious injury.

ings and instructions for future reference.

Save all warn-

1. WEAR SAFETY GLASSES OR GOGGLES

Danger to the eyes always exists due to the possibility of

dust being blown up by the exhausted air or of a fastener flying up due to the improper handling of the tool. For these

reasons, safety glasses or goggles shall always be worn

when operating the tool.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment must conform to

the requirements of the American National Standards Institute, ANSI Z87.1 (Council Directive 89/686/EEC of 21 DEC.

1989) and provide both frontal and side protection.

The employer is responsible to enforce the use of eye protection equipment by the tool operator and all other personnel in the work area.

NOTE: Non-side shielded spectacles and face shields

alone do not provide adequate protection.

2. EAR PROTECTION MAY BE REQUIRED IN SOME ENVIRONMENTS

As the working condition may include exposure to high noise

levels which can lead to hearing damage, the employer and

user should ensure that any necessary hearing protection is

provided and us ed by the operator and others in the work area.

3

Page 4

3. KEEP HANDS AND BODY AWAY FROM THE DISCHARGE OUTLET

When loading and using the tool, never place a hand or any

part of body in fastener discharge area of the tool. It is very

dangerous to hit the hands or body by mistake.

4. DO NOT USE ON SCAFFOLDINGS AND LADDERS

Do not use on scaffoldings and ladders with fastener driving

tools equipped with contact actuation or continuous contact

actuation.

2. SAFETY WARNING

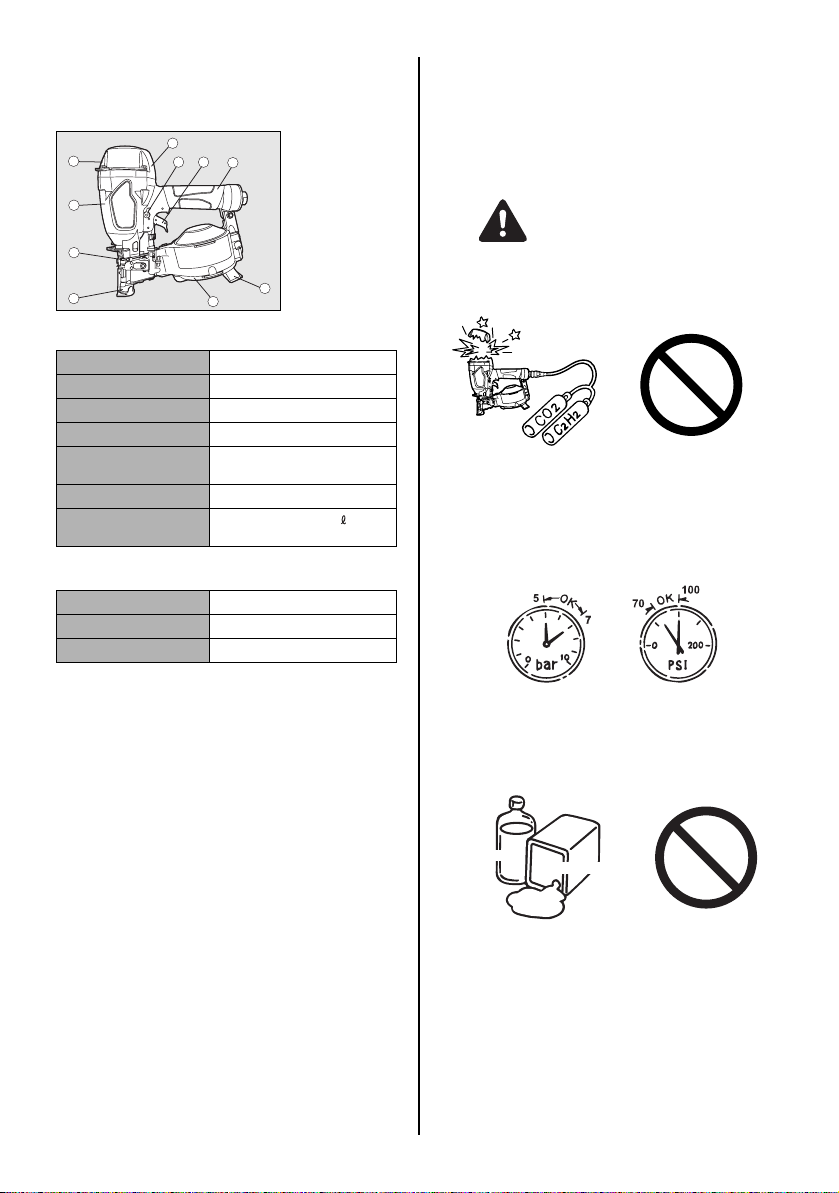

1. DO NOT USE ANY POWER SOURCE EXCEPT AN AIR COMPRESSOR

The tool is designed to operate on compressed air. Do not

operate the tool on any other highpressure gas, combustible gases (e.g., oxygen, acetylene, etc.) since there is the

danger of an explosion. For this reason, absolutely do not

use anything other than an air compressor to operate the

tool.

Thinner

3. DO NOT OPERATE THE TOOL NEAR A FLAMMABLE SUBSTANCE

Never operate the tool near a flammable substance (e.g.,

thinner, gasoline, etc.). Volatile fumes from these substances could be drawn into the compressor and compressed together with the air and this could result in an explosion.

4. NEVER USE THE TOOL IN AN EXPLOSIVE ATMOSPHERE

Sparks from the tool may ignite atmospheric gases, dust or

other combustible materials.

5. DO NOT USE A WRONG FITTINGS

The connector on the tool must not hold pressure when air

supply is disconnected. If a wrong fitting is used, the tool

can remain charged with air after disconnecting and thus

will be able to drive a fastener even after the air line is disconnected, possibly causing injury.

6. DISCONNECT THE AIR SUPPLY AND EMPTY THE MAGAZINE WHEN THE TOOL IS NOT IN USE

Always disconnect the air supply from the tool and empty

the magazine when operation has been completed or suspended, when unattended, moving to a different work area,

adjusting, disassembling, or repairing the tool, and when

clearing a jammed fastener.

Gasoline

2. OPERATE WITHIN THE PROPER AIR PRESSURE RANGE

The tool is designed to operate within an air pressure range

of 70 to 100 p.s.i. (5 to 7 bar).

The pressure should be adjusted to the type of the work being fastened. The tool shall never be operated when the operating pressure exceeds 120 p.s.i. (8.3 bar).

Never connect the tool to air pressure which potentially exceeds 200 p.s.i. (13.8 bar) as the tool can burst.

7. INSPECT SCREW TIGHTNESS

Loose or improperly installed screws or bolts cause accidents and tool damage when the tool is put into operation.

Inspect to confirm that all screws and bolts are tight and

properly installed prior to operating the tool.

4

Page 5

8. DO NOT TOUCH THE TRIGGER UNLESS YOU INTEND TO DRIVE A FASTENER

Whenever the air supply is connected to the tool, never

touch the trigger unless you intend to drive a fastener into

the work. It is dangerous to walk around carrying the tool

with the trigger pulled, and this and similar actions should

be avoided.

9. NEVER POINT THE DISCHARGE OUTLET TOWARD YOURSELF AND OTHER PERSONNEL

If the discharge outlet is pointed toward people, serious accidents may be caused when misfiring. Be sure the discharge outlet is not pointed toward people when connecting

and disconnecting the hose, loading and unloading the fasteners or similar operations.

10. USE SPECIFIED FASTENERS (SEE PAGE 7)

The use of fasteners other than specified fasteners will

cause the tool malfunction. Be sure to use only specified

fasteners when operating the tool.

13. DO NOT DRIVE FASTENERS ON TOP OF OTHER FASTENERS

Driving fasteners on the top of other fasteners may cause

deflection fasteners which could cause injury.

14. REMOVING THE FASTENERS AFTER COMPLETING OPERATION

If fasteners are left in the magazine after the completion of

operation, there is the danger of a serious accident occurring prior to the resumption of operation, should the tool be

handled carelessly, or when connecting the air fitting. For

this reason, always remove all fasteners remaining in the

magazine after completion of the operation.

15. CHECK OPERATION OF THE CONTACT TRIP MECHANISM FREQUENTLY INCASE OF USING A CONTACT

TRIP TYPETOOL

Do not use the tool if the trip is not working correctly as accidental driving of a fastener may result. Do not interfere

with the proper operation of the contact trip mechanism.

16. WHEN USING THE TOOL OUTSIDE OR ELEVATED PLACE

When fastening roofs or similar slanted surface, start fastening at the lower part and gradually work your way up.

Fastening backward is dangerous as you may lose your foot

place.

Secure the hose at a point close to the area you are going

to drive fasteners. Accidents may be caused due to the

hose being pulled inadvertently or getting caught.

11. PLACE THE DISCHARGE OUTLET ON THE WORK SURFACE PROPERLY

Failure to place the discharge outlet of the nose in a proper

manner can result in a fastener flying up and is extremely

dangerous.

12. DO NOT DRIVE FASTENERS CLOSE TO THE EDGE AND CORNER OF THE WORK AND THIN MATERIAL

The workpiece is likely to split and the fastener could fly free

and hit someone.

17. NEVER USE THE TOO L IF ANY PORTION OF THE TOOL

CONTROLS (e.g., TRIGGER, CONTACT ARM) IS INOPERABLE, DISCONNECTED, ALTERED OR NOT WOKING PROPERLY

18. NEVER ACTUATE THE TOOL INTO FREE SPACE

This will avoid any hazard caused by free flying fasteners

and excessive strain of the tool.

19. ALWAYS ASSUME THAT THE TOOL CONTAINS FASTENERS

20. RESPECT THE TOOL AS A WORKING IMPLEMENT

21. NO HORSEPLAY

22. NEVER LOAD THE TOOL WITH FASTENERS WHEN

ANY ONE OF THE OPERATING CONTROLS (e.g., TRIGGER, CONTACT ARM) IS ACTIVATED

5

Page 6

23. WHEN DISPOSING THE MACHINE OR ITS PARTS, FOLLOW THE RELEVANT NATIONAL RULES

OBSERVE THE FOLLOWING GENERAL CAUTION IN ADDITION TO THE OTHER WARNINGS

CONTAINED IN THIS MANUAL

• Do not use the tool as a hammer.

• Always carry the tool by the grip, never carry the

tool by the air hose.

• The tool must be used only for the purpose it was

designed.

• Never remove, tamper with the operating controls

(e.g., TRIGGER, CONTACT ARM)

• Keep the tool in a dry place out of reach of chil-

dren when not in use.

• Do not use the tool without Safety Warning label.

• Do not modify the tool from original design or

function without approval by MAX CO., LTD.

6

Page 7

3. SPECIFICATIONS AND TECHNI-

CAL DATA

1. NAME OF PARTS

8

1

4

3

2. TOOL SPECIFICATIONS

HEIGHT 10-5/8" (271 mm)

WIDTH 4-5/8" (116 mm)

LENGTH 12-3/8" (313 mm)

WEIGHT 5.2 lbs. (2.4 kg)

RECOMMENDED

OPERATING PRESSURE

LOADING CAPACITY 120 Nails

AIR CONSUMPTION 0.046 ft3 at 90 p.s.i. (1.3 at 6 bar)

3. FASTENER SPECIFICATIONS

NAIL LENGTH 3/4" to 1-3/4" (19 to 45 mm)

SHANK DIAMETER .120" (3.0 mm)

SHANK TYPE Smooth, Ring

2

9

6

5

7

operating pressure

1 Frame

2 Cylinder Cap

3 Contact Arm

4 Nose

5 Magazine

6 Trigger

7 Grip

8 Exhaust Port

9 Trigger Lock

Dial

0 Shingle gauge

10

70 to 100 p.s.i.

(5 to 7 bar)

5. APPLICATIONS

∗ Fastening asphalt and fiberglass shingles

∗ Siding installation

∗ Fastening lath wire on the plywood

∗ Wooden box assembly

4. AIR SUPPLY AND CONNECTIONS

WARNING

Read section titled "SAFETY INSTRUCTIONS"

DO NOT USE ANY POWER SOURCE EXCEPT AN AIR COMPRESSOR

The tool is designed to operate on compressed air. Do not operate the tool on any other highpressure gas, combustible gases

(e.g., oxygen, acetylene, etc.) since there is the danger of an explosion. For this reason, absolutely do not use anything other

than an air compressor to operate the tool.

TOOL AIR FITTINGS:

This tool uses a 1/4" N.P .T. male plug. The inside diameter should

be .28" (7 mm) or larger. The fitting must be capable of discharging

tool air pressure when disconnected from the air supply.

RECOMMENDED OPERATING PRESSURE:

70 to 100 p.s.i. (5 to 7 bar). Select the operating air pressure within this range for best fastener performance.

DO NOT EXCEED 120 p.s.i. (8 bar).

4. TECHNICAL DATA 1 NOISE

A-weighted single-event sound power level

A-weighted single-event emission sound pressure level at

work station

These values are determined and documented in accordance to EN12549 : 1999.

2 VIBRATION

Vibration characteristic value = 3.81 m/s2

These values are determined and documented in accordance to ISO 8662-11.

This value is a tool-related characteristic value and does not

represent the influence to the hand-arm-system when using

the tool. An influence to the hand-arm-system when using

the tool will for example depend on the gripping force, the

contact pressure force, the working direction, the adjustment of mains supply, the workpiece, the workpiece support.

------ LWA, 1s, d 100.7 dB

------ LpA, 1s, d 93.8 dB

OPERATE WITHIN THE PROPER AIR PRESSURE RANGE

The tool designed to operate within an air pressure range of 70

to 100 p.s.i.. (5 to 7 bar)

The pressure should be adjusted to the type of the work being

fastened. The tool shall never be operated when the operating

pressure exceeds 120 p.s.i.. (8 bar)

Thinner

DO NOT OPERATE THE TOOL NEAR A FLAMMABLE SUBSTANCE

Never operate the tool near a flammable substance (e.g., thinner,

gasoline, etc.). Volatile fumes from these substances could be

drawn into the compressor and compressed together with the air

and this could result in an explosion.

DO NOT USE A WRONG FITTINGS

The connector on the tool must not hold pressure when air supply

is disconnected. If a wrong fitting is used, the tool can remain

charged with air after disconnecting and thus will be able to drive

a fastener even after the air line is disconnected, possibly causing injury.

Gasoline

7

Page 8

DISCONNECT THE AIR SUPPLY AND EMPTY THE MAGAZINE WHEN THE TOOL IS NOT IN USE

Always disconnect the air supply from the tool and empty the

magazine when operation has been completed or suspended,

when unattended, moving to a different work area, adjusting, disassembling, or repairing the tool, and when clearing a jammed

fastener.

[AIR SUPPLY & CONNECTIONS]

Air compressor

Air hose

Air filter

Regulator

Oiler

5. INSTRUCTIONS FOR OPERATION

Read section titled "SAFETY INSTRUCTIONS".

1. BEFORE OPERATION

Check the following prior operation.

1 Wear Safety Glasses or Goggles. 2 Do not connect the air supply. 3 Inspect screw tightness. 4 Check operation of the contact arm & trigger if moving

smoothly.

5 Connect the air supply. 6 Check the air-leakage. (The Tool must not have the air-

leakage.)

7 Hold the Tool with finger-off the trigger, then push the con-

tact arm against the work-piece. (The tool must not operate.)

8 Hold the Tool with contact arm free from work-piece and pull

the trigger. (The Tool must not operate.)

9 Disconnect the air supply.

3-piece airset

Used at 70 to 100 p.s.i. (5 to 7 bar)

FITTINGS: Install a male plug on the tool which is free flowing

and which will release air pressure from the tool when disconnected from the supply source.

HOSES: Hose has a min. ID of 1/4" (6 mm) and max. length of

no more than 17" (5 meters).

The supply hose should contain a fitting that will provide "quick

disconnecting" from the male plug on the tool.

SUPPLY SOURCE: Use only clean regulated compressed air as

a power source for the tool.

3-PIECE AIRSET (Air filter, Regulator, Oiler):

Refer to TOOL SPECIFICATIONS for setting the correct operating pressure for the tool.

NOTE:

A filter will help to get the best performance and minimum wear

from the tool because dirt and water in the air supply are major

causes of wear in the tool.

Frequent, but not excessive, lubrication is required for the best

performance. Oil added thru the air line connection will lubricate

the internal parts.

WARNING

2. OPERATION

Wear safety glasses or goggles danger to the eyes always exists

due to the possibility of dust being blown up by the exhausted air

or of a fastener flying up due to the improper handling of the tool.

For these reasons, safety glasses or goggles shall always be

worn when operating the tool.

The employer and/or user must ensure that proper eye protection

is worn. Eye protection equipment must conform to the requirements of the American National Standards Institute, ANSI Z87.1

(Council Directive 89/686/EEC of 21 DEC. 1989) and provide

both frontal and side protection.

The employer is responsible to enforce the use of eye protection

equipment by the tool operator and all other personnel in the work

area.

NOTE: Non-side shielded spectacles and face shields alone do

not provide adequate protection.

WARNING

Keep hands and body away from the discharge outlet when driving the fasteners because of dangerous of hitting the hands or

body by mistake.

8

Page 9

NAIL LOADING

Door latch

Magazine cover

Door

1 Open the magazine:

Pull down door latch and swing door open. Swing magazine

cover open.

Nail support

Magazine

2 Check adjustment:

The nail support can be moved up and down to four settings. To change setting pull up on the post and twist to the

correct step. The nail support should be adjusted correctly

to the position as follows;

1-3/4" (45 mm) nails - use bottom step

1-1/4", 1-1/2" (32, 38 mm) nails - use middle step

3/4", 7/8", 1" (19, 22, 25 mm) nails - use top step

Nail

Feed pawl

3 Nail loading:

Place a coil of nails over the post in the Magazine. Uncoil

enough nails to reach the Feed Pawl, and place the second

nail between the teeth on the Feed Pawl. The nail heads fit

in slot on nose.

4 Swing Cover closed. 5 Close the Door.

Check that latch engages. (If it does not engage, check that

the nail heads are in the slot on the Nose).

TEST OPERATION

1 Adjust the air pressure at 70 p.s.i. (5 bar) and connect the

air supply.

2 Without touching the Trigger, depress the Contact Arm

against the work-piece.

Pull the Trigger. (The tool must fire the fastener.)

3 With the tool off the work-piece, pull the Trigger.

Then depress the Contact Arm against the work-piece.

(The tool must fire the fastener.)

4 Adjust the air pressure as much as the lowest possible ac-

cording to the diameters and length of fastener and the

hardness of work-piece.

DRIVING DEPTH ADJUSTMENT DIAL

Adjustment dial

WARNING

• ALWAYS disconnect air supply before Adjust-

ment dial.

1 With air pressure set, drive nails into a representative mate-

rial sample to determine if adjustment is necessary.

2 If adjustment is required, disconnect air supply.

9

Page 10

3 Refer to the mark on the Contact Arm cover for direction to

turn the Adjustment dial.

Deeper Shallower

4 Reconnect air supply.

Deeper Shallower

TRIGGER LOCK MECHANISM

Trigger lock dial

Trigger

SHINGLE GAUGE

Shingle exposure

WARNING

• ALWAYS disconnect the air supply before mak-

ing adjustment.

This gauge can be used to control shingle spacing. Loosen the

screw to adjust gauge to desired shingle exposure, as shown.

CLEANING THE ROOFING NAILER

The tool is equipped with a trigger lock mechanism. Push and rotate the Trigger Lock Dial to the trigger free position before driving

nails.

WARNING

• Do not use gasoline or similar highly flammable

liquids to clean the nailer.

Vapor could be ignited by a spark causing an explosion.

Tar and dirt may build up on the Nose and Contact Arm. This can

prevent correct operation. Remove any build-up with kerosene,

#2 fuel oil or diesel fuel. Do not dunk the nailer into these solvents

beyond the height of the nail heads, to avoid getting the solvent

into the drive cylinder.

Dry off the nailer before use. Any oil film left after cleanup will accelerate the tar buildup, and the nailer will require more frequent

re-cleaning.

NOTE:

Solvent s sprayed on Nos e to clean and free up the tri p may have

the opposite effect! The solvent may soften the tar on the shingles and cause tar build-up to be accelerated. Dry operation is

better, as noted above.

10

Page 11

MODEL IDENTIFICATION

CONTACT TRIP

The common operating procedure on "Contact Trip" tools is for

the operator to contact the work to actuate the trip mechanism

while keeping the trigger pulled, thus driving a fastener each time

the work is contacted. This will allow rapid fastener placement on

many jobs, such as sheathing, decking and pallet assembly.

All pneumatic tools are subject to recoil when driving fasteners.

The tool may bounce, releasing the trip, and if unintentionally allowed to recontact the work surface with the trigger still actuated

(finger still holding trigger pulled) an unwanted second fastener

will be driven.

CONTACT TRIP Identified by BLACK TRIGGER.

SEQUENTIAL TRIP (Optional kit)

The Sequential Trip requires the operator to hold the tool against

the work before pulling the Trigger. This makes accurate fastener

placement easier, for instance on framing, toe nailing and crating

applications. The Sequential Trip allows exact fastener location

without the possibility of driving a second fastener on recoil, as

described under "Contact Trip".

The Sequential Trip Tool has a positive safety advantage because it will not accidentally drive a fastener if the tool is contacted against the work-or anything else-while the operator is holding

the Trigger pulled.

SEQUENTIAL TRIP Identified by ORANGE TRIGGER.

CONTACT TRIP WITH ANTI-DOUBLE FIRE MECHANISM Identified by RED TRIGGER.

CONTACT FIRE OPERATION

For contact fire operation, hold the Trigger and depress the Contact Arm against the work surface.

SINGLE FIRE OPERATION (ANTI-DOUBLE FIRE MECHANISM)

For single fire operation, depress the Contact Arm against the

work surface and pull the Trigger.

Tool cannot fire a second nail until the Trigger is released and

tool can cycle.

DRIVING FASTENERS

CONTACT FIRE OPERATION (CONTACT TRIP)

For contact fire operation, hold the Trigger and depress the Contact Arm against the work surface.

1

2

CONTACT TRIP WITH ANTI-DOUBLE FIRE MECHANISM

(Optional kit)

(US patent 5597106, UK patent 2286790)

The common operating procedure on "Contact Trip" tools is for

the operator to contact the work to actuate the trip mechanism

while keeping the trigger pulled, thus driving a fastener each time

the work is contacted. This will allow rapid fastener placement on

many jobs, such as sheathing, decking and pallet assembly.All

pneumatic tools are subject to recoil when driving fasteners. The

tool may bounce, releasing the trip,and if unintentionally allowed

to recontact the work surface with the trigger still actuated (finger

still holding trigger pulled) an unwanted second fastener will be

driven.

PROCEDURE

1 Hold the Trigger. 2 Depress the Contact Arm.

11

Page 12

6. MAINTAIN FOR PERFORMANCE

1 DO NOT FIRE THE NAILER WHEN IT IS EMPTY 2 USE A 3-PIECE AIRSET

Failure to use a 3-piece airset allows the moisture and dirt inside

compressor to pass into the tool directly. This causes rust and

wear, and results in a poor operating performance. The hose

length between airset and tool should be no longer than 5 m since

a longer length results in a reduction in air pressure.

3 USE RECOMMENDED OIL

The velocite or turbine oil should be used to lubricate the tool.

Upon completion of operations, place 2 or 3 drops of oil into the

Air Plug inlet with the jet oiler. (Recommended Oil : ISO VG32)

4 INSPECT AND MAINTAIN DAILY OR BEFORE OPERA-

TION

WARNING

Disconnect air supply and empty the Magazine when inspecting or maintaining the tool.

(1) Drain air line filter and compressor

(2) Keep lubricator filled in air 3-pieces set

(3) Clean filter element of air 3-pieces set

(4) Tighten all screws

(5) Keep Contact Arm moving smoothly

7. STORING

1 When not in use for an extended period, apply a thin coat of

the lubricant to the steel parts to avoid rust.

2 Do not store the tool in a cold weather environment. Keep

the tool in a warm area.

3 When not in use, the tool should be stored in a warm and

dry place. Keep out of reach of children.

4 All quality tools will eventually require servicing or replace-

ment of parts because of wear from the normal use.

8. TROUBLE SHOOTING/REPAIRS

The troubleshooting and/or repairs shall be carried out only by

the MAX CO., LTD. authorised distributors or by other specialists.

Supplement to the operating instruction

According to the European Norm EN 792-13 the regulation is valid from 01.01.2001 that all fastener driving tools with contact actuation must be marked with the symbol "Do not use on

scaffoldings, ladders" and they shall not be used for specific application for example:

∗ when changing one driving location to another involves the

use of scaffoldings, stairs, ladders or ladder alike constructions e.g. roof laths,

∗ closing boxes or crates,

∗ fitting transportation safety systems e.g. on vehicles and wag-

ons.

12

Page 13

FRANÇAIS

MANUEL D’UTILISATION ET D’ENTRETIEN

INDEX

1. CONSIGNES DE SECURITE GENERALES......................................13

2. CONSIGNE DE SECURITE ...............................................................14

3. CARACTERISTIQUES TECHNIQUES ET ACCESSOIRES .............17

4. ALIMENTATION EN AIR COMPRIME ET CONNEXIONS ................17

5. INSTRUCTIONS D’EMPLOI ..............................................................18

6. ENTRETIEN POUR OBTENIR LES MEILLEURES PERFORMANCES.....22

7. EMMAGASINAGE..............................................................................22

8. REPARATION....................................................................................22

AVANT D’UTILISER CE COMPRESSEUR, LIRE CE MANUEL ET LES CONSIGNES DE SECURITE AFIN DE

GARANTIR UN FONCTIONNEMENT SUR.

AVERTISSEMENT

CONSERVER CE MANUEL EN LIEU SUR AVEC L’OUTIL AFIN DE POUVOIR LE CONSULTER ULTERIEUREMENT.

1. CONSIGNES DE SECURITE GENERALES

AVERTISSEMENT

LIRE TOUTES LES CONSIGNES DE

SECURITE ET TOUTES LES INSTRUCTIONS.

Un non-respect des consignes et des instructions

peut entraîner la mort ou des blessures graves.

Conserver toutes les consignes et

instructions pour une consultation ultérieure.

1. PORTEZ DES LUNETTES PROTECTRICES OU DE SÉCURITÉ

Un danger aux yeux est toujours présent provenant de la

poussière rejetée par l’air s’échappant ou de l’éjection de

clous à cause d’une manipulation incorrecte de l’outil. Dans

ce cas, il est nécessaire de porter toujours des lunettes

protectrices ou de sécurité quand l’outil est utilisé.

L’employeur et/ou l’usager doivent assurer une protection

appropriée des yeux des opérateurs de l’outil.

L’équipement de protection des yeux doit répondre aux

exigences du American National Standards Institute,

Norme ANSI Z87.1 (Directive du Conseil 89/686/CEE du 21

décembre 1989) et assurer une protection frontale et

latérale de la tête.

L’employeur est responsable pour imposer l’usage de

l’équipement de protection des yeux par l’opérateur de

l’outil et par tous les autres membres du personnel dans la

surface de travail.

REMARQUE : Les lunettes sans protection latérale et

frontale n’assurent pas une protection correcte.

2. DANS CERTAINS ENVIRONNEMENTS UNE PROTECTION AUDITIVE PEUT ETRE EXIGEE

Etant donné que les conditions de travail peuvent entraîner

une exposition à des niveaux de bruit élevés qui peuvent

provoquer des dommages d’audition, l’employeur et

l’utilisateur doivent s’assurer qu’un équipement de protection

auditive est mis à disposition et utilisé par l’opérateur et les

autres personnes se trouvant sur le lieu de travail.

13

Page 14

3. ELOIGNER VOTRE CORPS ET VOS MAINS DU NEZ DE L’APPAREIL

Lors du chargement et de l’utilisation de l’outil, ne jamais

placer votre main ou une partie de votre corps dans la zone

de décharge de l’élément de fixation de l’outil. It is very

dangerous to hit the hands or body by mistake.

Diluant

3. NE PAS UTILISER L’OUTIL PRES D’UNE SUBSTANCE INFLAMMABLE

Ne jamais utiliser l’outil près d’une substance inflammable

(ex. diluant, de l’essence, etc.). Les fumées volatiles de ces

substances peuvent être attirées dans le compresseur,

comprimées en même temps avec l’air, cela risquant de

produire une explosion.

4. N’UTILISEZ JAMAIS L’OUTIL DANS UNE AMBIANCE EXPLOSIVE

Les étincelles de l’outil peuvent mettre à feu les gaz

atmosphériques, la poussière ou d’autres matériaux

combustibles.

Essence

4. NE PAS UTILISER SUR DES ECHAFAUDAGES OU DES ECHELLES

Ne pas utiliser sur des échafaudages et des échelles avec

des machines à enfoncer les fixations équipées d'une

commande par contact ou par contact continu.

2. CONSIGNE DE SECURITE

1. NE PAS UTILISER D’AUTRE SOURCE D’ALIMENTATION QU’UN COMPRESSEUR D’AIR

L’outil est concu pour fonctionner avec de l’air comprimé.

Ne pas utiliser l’outil avec d’autres gaz sous haute pression,

des gaz combustibles (ex. l’oxygène, l’acétylène, etc.), car

il y a risque d’explosion. Par conséquent, ne rien utiliser

d’autre que le compresseur d’air pour faire fonctionner cet

outil.

2. RESPECTER LA PLAGE DE PRESSION D’AIR APPROPRIEE POUR L’UTILISATION

L’outil est concu pour fonctionner dans une plage de

pression de 70 to 100 p.s.i. (5 à 7 bar).

La pression doit être ajustée au type de pièce à clouer.

L’outil ne doit jamais être utilisé lorsque la pression de

fonctionnement dépasse 120 p.s.i. (8,3 bar).

Ne jamais brancher d’outil sur l’alimentation en air

comprimé dont la pression peut éventuellement dépasser

200 p.s.i. (13,8 bars), l’outil risquant d’exploser.

5. NE PAS UTILISER DES ELEMENTS DE FIXATION INADEQUATS

Le connecteur sur l’outil ne doit pas retenir la pression

lorsque l’admission d’air est débranchée. Si une fixation

non appropriée est utilisée, l’outil peut rester chargé d’air

après le débranchement et sera ainsi capable d’enfoncer

un élément de fixation même après le débranchement de

l’arrivée d’air, provoquant ainsi des dommages éventuels.

6. COUPER L’ALIMENTATION EN AIR COMPRIME ET VIDER LE MAGASIN LORSQUE L’OUTIL N’EST PAS UTILISE

Veillez à toujours débrancher l’arrivée d’air de l’outil et à

vider le magasin en fin de travail ou lorsque le travail est

suspendu, lorsque l’outil est laissé sans surveillance, est

déplacé vers un autre lieu de travail, réglé, démonté ou

réparé, ou encore lorsque vous dégagez un fermoir.

7. CONTROLER LE SERRAGE DES VIS

Des vis ou des boulons desserrés ou incorrectement

installés peuvent provoquer des accidents et endommager

l’outil lorsqu’il est mis en service. Contrôler et vérifier que

tous les vis et boulons sont bien serrés et correctement

installés avant d’utiliser l’outil.

14

Page 15

8. NE PAS TOUCHER LE DECLENCHEUR SAUF POUR ENFONCER UN ELEMENT DE FIXATION

Chaque fois que l’arrivée d’air est connectée à l’outil, ne jamais

toucher le déclencheur sauf si on a l’intention d’enfoncer des

éléments de fixation dans la pièce. ll est dangereux de porter

l’outil tout en mar chant avec le déclencheur enclenché. Ceci,

ainsi que des actions similaires doivent être évités.

9. NE JAMAIS DIRIGER L’ORIFICE DE REFOULEMENT VERS VOUS OU VERS UNE AUTRE PERSONNE

En cas de râté, les personnes qui se trouveraient dans la

trajectoire de l’orifice de refoulement risquent d’être

grièvement blessées. Lorsque vous branchez ou

débranchez le tuyau, montez ou démontez les fermoirs ou

effectuez une intervention quelconque, vérifiez toujours que

l’orifice de refoulement n’est orienté vers personne.

10. UTILISER LES ELEMENTS DE FIXATION APPROPRIÉS (SEE PAGE 17)

L’utili sation d’éléments de fixation autres que ceux spécifiés

provoque le mauvais fonctionnement de l’outil. Sassurer d’utiliser

uniquement les éléments de fixation appropriés avec l’outil.

11. PLACER CORRECTEMENT LA SORTIE DE DÉCHARGE SUR LA SURFACE DE TRAVAIL

Si l’on oublie de placer la sortie de décharge du nez de

façon appropriée, on risque d’avoir comme conséquence

un détachement violent de l’attache vers le haut et ceci est

extrêmement dangereux.

13. NE PAS ENFONCER DES POINTES OU AGRAFES SUR D’AUTRES ELEMENTS DE FIXATION

Le fait d’enfoncer des éléments de fixation par dessus

d’autres éléments de fixation risque de provoquer un

éclatement de ces élément qui pourrait provoquer des

blessures.

14. RETRAIT DES PROJECTILES APRES LA FIN DE L’OPERATION

Si les projectiles sont laissés dans le magasin après la fin

de l’opération, il y a danger d’accident grave qui risque de

se produire avant la reprise de l’opération, au cas où l’outil

est manipulé négligemment ou lors du branchement de la

fixation d’air. Par conséquent, toujours enlever tous les

projectiles restant dans le changeur après la fin de

l’opération.

15. VERIFIER FREQUEMMENT LE FONCTIONNEMENT DU MECANISME DE DECLENCHEMENT AU COUP A COUP EN CAS D’UTILISATION D’UN OUTIL DE TYPE A DECLENCHEMENT AU COUP A COUP

Ne pas utiliser l’outil si le déclencheur ne fonctionne pas

correctement, car un enfoncement accidentel d’un

projectile de fixation risque de se produire. Ne pas gêner le

fonctionnement correct du mécanisme de déclenchement

au coup à coup.

16. UTILISATION DE L’OUTIL A L’EXTERIEUR OU SUR UN ENDROIT SURELEVE

Pour fixer un toit, ou une surface similaire inclinée,

commencer la fixation sur la partie inférieure et exécuter le

travail en montant progressivement. ll est dangereux de

faire des fixations en reculant, car on risque de perdre pied

en glissant.

Fixer le tuyau à un point près de la zone où les éléments de

fixation doivent être enfoncés. Des accidents risquent de se

produire à cause d’un tuyau coincé ou tiré par inadvertance.

17. NE JAMAIS UTILISER L’OUTIL SI N’IMPORTE QUELLE PARTIE DES COMMANDES D’OUTIL (PAR EXEMPLE, DÉCLENCHEUR, BRAS DE CONTACT) EST INOPÉRABLE, DÉBRANCHÉE, CHANGÉE OU NE FONCTIONNANT PAS CORRECTEMENT

18. NE JAMAIS LANCER LES POINTES DANS UN ESPACE LIBRE

Les pointes voltigeant dans l’air présentent un certain

danger;

12. NE PAS APPLIQUER LES ELEMENTS DE FIXATION PRES DU BORD DE LA PIECE ET SUR UN MATERIAU MINCE

La pièce a tendance à éclater et l’élément de fixation risque de

sauter et de heurter quelqu’un. Faire attention lors de la fixation

d’un matériau mince ou près des bords et des coins de la pièce.

19. TOUJOURS PRÉSUMER QUE L’OUTIL EST MUNIS DE FERMOIRS

20. CONSIDEREZ L’OUTIL COMME UN INSTRUMENT DE TRAVAIL

15

Page 16

21. NE FAITES PAS DE GESTES BRUSQUES

22. NE JAMAIS MONTER LES FERMOIRS SUR L’OUTIL LORSQU’UNE COMMANDE (DÉTENTE OU BRAS DE CONTACT par exemple) EST ACTIVÉE

23. LORSQUE LA MACHINE OU SES PIECES SONT MISES AU REBUT, SUIVEZ LES REGLEMENTS NATIONAUX RELATIFS

RESPECTER LES PRECAUTIONS GENERALES

SUIVANTES EN PLUS DES AUTRES

AVERTISSEMENTS DECRITS DANS CE

MANUEL

• Ne pas utiliser l’outil comme un marteau.

• Saisissez toujours l’outil par la poignée, et ne le

transportez jamais en tenant les tuyaux d’air.

• L’outil doit être utilisé uniquement pour l’usage

préconisé.

• Ne jamais retirer ou altérer les commandes

(DÉTENTE OU BRAS DE CONTACT par exemple).

• Conserver l’outil dans un endroit sec, hors de

portée des enfants, lorsqu’il n’est pas utilisé.

• Ne pas utiliser l’outil sans l’étiquette de sécurité.

• Ne pas modifier la conception originale ou les

caractéristiques de l’outil sans le consentement

de MAX CO. LTD.

16

Page 17

3. CARACTERISTIQUES

TECHNIQUES ET ACCESSOIRES

1. NOM DES PIÈCES

8

1

4

3

2. SPÉCIFICATIONS DE L’OUTIL

Hauteur 10-5/8" (271 mm)

Largeur 4-5/8" (116 mm)

Longeur 12-3/8" (313 mm)

Poids 2,4 kg

Pression de service

recommandée

Capacite de charge 120 Pointes

Consommation en air

comprimé

3. SPÉCIFICATS DU MATÉRIEL DE FIXATION

Longueur de pointe 3/4" à 1-3/4" (19 à 45 mm)

Diamètre de tige .120" (3,0 mm)

Type de queue Droite, annulaire

2

9

6

5

pieds 3 à 90 p.s.i. (1,3 à 6 barres)

1 Boîtier

2 Couvercle de

7

Pression de fonctionnement 0,046

cylindre

3 Barre de contact

4 Nez

5 Magasin

6 Levier de

commande

7 Poignée

8 Orifice

d'échappement

10

9 Blocage de la

commande

0 Jauge de bardeau

70 à 100 p.s.i. (5 à 7 bar)

l’on utilise l’outil dépendra, par exemple, de la force de

saisie, la force de pression de contact, la direction de

fonctionnement, le réglage de l’air principal, la pièce de

travail, le support de pièce de travail.

5. APPLICATIONS

∗ Fixation de bardeaux en asphalte et fibre de verre

∗ Installation de parement

∗ Fixation de câble pour lattis sur le contreplaqué

∗ Assemblage de boîtes en bois

4. ALIMENTATION EN AIR COMPRIME ET CONNEXIONS

AVERTISSEMENT

Lire le paragraphe intitulé “CONSIGNES DE

SECURITE”

NE PAS UTILISER D’AUTRE SOURCE D’ALIMENTATION

QU’UN COMPRESSEUR D’AIR

L’outil est concu pour fonctionner avec de l’air comprimé. Ne pas

utiliser l’outil avec d’autres gaz sous haute pression, des gaz

combustibles (ex. l’oxygène, l’acétylène, etc.), car il y a risque

d’explosion. Par conséquent, ne rien utiliser d’autre que le

compresseur d’air pour faire fonctionner cet outil.

PIECES DE RACCORDEMENT D’AIR

COMPRIME :

Cet appareil est équipé d’une prise mâle avec filet extérieur de

1/4" min. Le diamètre intérieur devrait être de 0,28" (7 mm) au

moins. Le raccord doit permettre de décharger l’air comprimé de

l’appareil lorsque l’alimentation en air comprimé est interrompue.

PRESSION DE SERVICE RECOMMANDEE:

De 70 à 100 p.s.i. (5 à 7 bar) Régler l’air comprimé à l’intérieur de cette

plage pour garantir la meilleure performance possible de fixation.

LA PRESSION DE SERVICE NE DOIT PAS DEPASSER 8 BARS

(120 p.s.i.)

4. CARACTÉRISTIQUES TECHNIQUES 1 BRUIT

Niveau de puissance sonore puls ée par rapport à la courbe A

Niveau de pression acoustique pulsée par rapport à la courbe A

Ces valeurs out été calculées et documentées, en

conformité avec EN12549:1999.

2 VIBRATIONS

Valeur caractéristique de vibration = 3,81 m/s2

Ces valeurs sont déterminées et documentées

conformément à la norme ISO 8662-11.

Cette valeur représente une valeur caractéristique connexe

à l’outil et non l’influence au système main-bras lorsque l’on

utilise l’outil. Une influence au système main-bras lorsque

------ LWA, 1s, d 100,7 dB

------ LpA, 1s, d 93,8 dB

RESPECTER LA PLAGE DE PRESSION D’AIR APPROPRIEE

POUR L’UTILISATION

L'outil est conçu pour fonctionner dans une plage de pression de

70 à 100 p.s.i. (5 à 7 bar).

La pression doit être ajustée au type de pièce à clouer. L'outil ne

doit jamais être utilisé lorsque la pression de fonctionnement

dépasse 8 bar.

Diluant

NE PAS UTILISER L’OUTIL PRES D’UNE SUBSTANCE

INFLAMMABLE

Ne jamais utiliser l’outil près d’une substance inflammable (ex.

diluant, de l’essence, etc.). Les fumées volatiles de ces

substances peuvent être attirées dans le compresseur,

comprimées en même temps avec l’air, cela risquant de produire

une explosion.

Essence

17

Page 18

NE PAS UTILISER DES ELEMENTS DE FIXATION

INADEQUATS

Le connecteur sur l’outil ne doit pas retenir la pression lorsque

l’admission d’air est débranchée. Si une fixation non appropriée

est utilisée, l’outil peut rester chargé d’air après le

débranchement et sera ainsi capable d’enfoncer un élément de

fixation même après le débranchement de l’arrivée d’air,

provoquant ainsi des dommages éventuels.

COUPER L’ALIMENTATION EN AIR COMPRIME ET VIDER LE

MAGASIN LORSQUE L’OUTIL N’EST PAS UTILISE

Veillez à toujours débrancher l’arrivée d’air de l’outil et à vider le

magasin en fin de travail ou lorsque le travail est suspendu,

lorsque l’outil est laissé sans surveillance, est déplacé vers un

autre lieu de travail, réglé, démonté ou réparé, ou encore lorsque

vous dégagez un fermoir.

5. INSTRUCTIONS D’EMPLOI

Lire le paragraphe intitulé “CONSIGNES DE

SECURITE”.

1. AVANT DE TRAVAILLER:

Vérifiez les points suivants avant d’utiliser l’outil.

1 Mettre les lunettes de protection. 2 Ne pas encore brancher l’alimentation en air comprimé. 3 Vérifier la bonne assise des vis. 4 Vérifier le fonctionnement de la barre de contact et

s’assurer que le levier de commande se déplace librement.

5 Brancher l’alimentation en air comprimé. 6 Rechercher l’éventuelle présence d’une fuite d’air.

(L’appareil ne doit pas avoir de fuite d’air.)

7 Tenir l’outil (ne pas mettre de doigt sur le levier de

commande) et appuyer la barre de contact contre la pièce

à fixer. (L’outil ne doit pas fonctionner.)

8 Tenir l’outil en sorte que la barre de contact ne repose pas

sur la pièce à fixer et appuyer sur le levier de commande.

(L’outil ne doit pas fonctionner.)

9 COUPER L’ALIMENTATION EN AIR COMPRIME ET

VIDER LE MAGASIN LORSQUE L’OUTIL N’EST PAS

UTILISE.

[ARRIVEE D’AIR ET RACCORDEMENTS]

Regulateur

Tuyau

Pression 70 à 100 p.s.i. (5 à 7 bar)

FIXATIONS : Installer le raccord mâle sur l’outil, qui est à flux

libre et qui relâche la pression d’air de l’outil lorsqu’il est

débranché de la source d’alimentation.

TUYAUX : Le diamètre intérieur du tuyau doit être de 1/4" (6 mm)

min. et d’une longueur maximale de 17" (5 mètres).

Le tuyau d’alimentation doit avoir une fixation qui assure un

“débranchement rapide” de la fiche mâle sur l’outil.

SOURCE D'ALIMENTATION : Utiliser uniquement l’air

comprimé régulé comme source d’alimentation pour l’outil.

ENSEMBLE DE REGULATION (Filtre à air, mano-detendeur,

graisseur):

Se référer aux SPECIFICATIONS DE L’OUTIL pour le réglage de

la pression de fonctionnement appropriée pour l’outil.

REMARQUE:

Un filtre assure une meilleure performance et un minimum

d’usure de l’outil, parce que l’encrassement et l’eau dans l’arrivée

d’air sont les sources principales d’usure de l’outil.

Des graissages fréquents, mais non excéssifs sont nécessaires

pour conserver la meilleure performance. L’huile ajoutée à

travers le raccord de ligne d’air lubrifie les pièces internes.

Regulateur

Filtre

Ensemble de regulation

Graisseur

AVERTISSEMENT

2. TRAVAILLER

Un danger aux yeux est toujours présent provenant de la

poussière rejetée par l’air s’échappant ou de l’éjection de clous à

cause d’une manipulation incorrecte de l’outil. Dans ce cas, il est

nécessaire de porter toujours des lunettes protectrices ou de

sécurité quand l’outil est utilisé.

L’employeur et/ou l’usager doivent assurer une protection

appropriée des yeux des opérateurs de l’outil. L’équipement de

protection des yeux doit répondre aux exigences du American

National Standards Institute, Norme ANSI Z87.1 (Directive du

Conseil 89/686/CEE du 21 décembre 1989) et assurer une

protection frontale et latérale de la tête.

L’employeur est responsable pour imposer l’usage de

l’équipement de protection des yeux par l’opérateur de l’outil et

par tous les autres membres du personnel dans la surface de

travail.

REMARQUE : Les lunettes sans protection latérale et frontale

n’assurent pas une protection correcte.

AVERTISSEMENT

Veillez à tenir les mains et le reste du corps hors de portée de

l’ouverture de sortie pendant l’agrafage/le pointage pour éviter de

toucher accidentellement les mains ou le corps.

18

Page 19

CHARGEMENT DE CLOUS

Fermeture de porte

Capot de magasin

Porte

1 Ouvrir le magasin :

Tirer le dispositif de fermeture de porte et pivoter la porte

pour l'ouvrir. Pivoter le capot du magasin pour l'ouvrir.

Support de

pointes

Magasin

2 Vérifier le réglage :

Le support de pointes peut être déplacé vers le haut et le

bas sur quatre réglages. Pour modifier le réglage, tirer le

support vers le haut et le tourner jusqu'au cran souhaité. Le

support de pointes doit être réglé correctement comme

suit :

Clous de 1-3/4" (45 mm) - utiliser le cran inférieur

Clous de 1-1/4", 1-1/2" (32, 38 mm) - utiliser le cran du

milieu

Clous de 3/4", 7/8", 1" (19, 22, 25 mm) - utiliser le cran

supérieur

Clou

Cliquet d'avance

3 Chargement des clous :

Placer une bobine de clous sur le support du magasin.

Dérouler un nombre suffisant de clous pour atteindre le

cliquet d'avance, et placer le second clou entre les dents du

cliquet d'avance. Les têtes de clou s'adaptent dans la fente

du nez.

4 Capot pivotant fermé. 5 Fermer la porte.

Vérifier que le dispositif de fermeture s'engage. (S'il ne

s'engage pas, vérifier que les têtes de clou sont bien

installées dans la fente sur le nez).

TEST

1 Régler l’air comprimé sur 70 p.s.i. (5 bars) et brancher

l’alimentation en air comprimé.

2 Appuyer la barre de contact contre la pièce à fixer sans

cependant toucher au levier de commande.

Tirer le déclencheur. (L’outil doit tirer la pointe.)

3 Appuyer sur le levier de commande, l’outil ne devant pas

toucher la pièce à fixer.

Appuyer ensuite la barre de contact contre la pièce à fixer.

(L’outil doit tirer la pointe.)

4 Régler la pression atmosphérique à un niveau aussi bas

que possible, selon les diamètres, la longueur de l'attache

et la dureté de la pièce de travail.

DISQUE DE RÉGLAGE DE LA PROFONDEUR

D'ENTRAINEMENT

Disque de réglage

AVERTISSEMENT

• TOUJOURS débrancher l’alimentation d’air avant

de régler le cadran.

19

Page 20

1 Enfoncer, après avoir réglé l’air comprimé, quelques

pointes dans un échantillon du matériau à fixer pour voir s’il

est nécessaire de régler la profondeur des pointes.

2 Si oui, couper l’alimentation en air comprimé. 3 Se référer à la marque sur le capot de la barre de contact

pour la direction de rotation du cadran de réglage.

Plus profond Moins profond

4 Rebrancher l’alimentation en air comprimé.

Plus profond Moins profond

MODE D’EMPLOI DU MÉCANISME DE BLOCAGE DU

DÉCLENCHEUR

Blocage de la

commande

JAUGE DE BARDEAU

Exposition du bardeau

AVERTISSEMENT

• TOUJOURS débrancher l’alimentation d’air avant

tout réglage.

Cette jauge peut être utilisée pour contrôler l'espacement des

bardeaux. Desserrer la vis pour régler la jauge selon l'exposition

de bardeau souhaitée, comme illustré.

NETTOYAGE DU CLOUEUR DE TOITURE

Levier de

commande

Cet appareil est équipé d’un mécanisme de blocage du

déclencheur. Appuyer sur le mécanisme de blocage de la

commande et le tourner afin de le libérer avant d’utiliser

l’appareil.

AVERTISSEMENT

• Ne pas utiliser d'essence ou de liquides similaires

inflammables pour nettoyer le cloueur.

Une étincelle pourrait enflammer la vapeur et entraîner une

explosion.

Du goudron et de la saleté pourraient s'accumuler sur le nez et la

barre de contact. Ceci peut gêner le fonctionnement. Eliminer

toute accumulation à l'aide de kérosène, de fioul n° 2 ou de

carburant diesel. Ne pas tremper le cloueur dans ces solvants

au-delà de la hauteur des têtes de clous, afin d'éviter que du

solvant pénètre dans le cylindre d'entraînement.

Sécher le cloueur avant de l'utiliser. La présence d'une pellicule

d'huile a près le nettoyage a ccélère l'accumulation de goudron et

le cloueur requiert plus souvent un deuxième nettoyage.

20

Page 21

REMARQUE:

Les solvants pulvérisés sur le nez pour nettoyer et libérer le

déclencheur peuvent avoir l'effet contraire. Le solvant peut ramollir

le goudron sur les bardeaux et accél érer l'accumulation de goudron.

Un fonctionnement à sec est préférable, tel qu'indiqué ci-dessus.

IDENTIFICATION DES DIFFERENTES MODELES

DECLENCHEMENT AU COUP À COUP

La méthode de fonctionnement commune sur les outils à

“déclenchement par contact” permet à l’opérateur d’entrer en

contact avec la piè ce de travail pour actionner le déclenc heur tout en

le maintenant tiré, ceci permettant d’enfoncer un clou chaque fois

que la pièce de travail entre en contact. Ceci permettra une pose

rapide des clous sur beaucoup de pièces de travail, comme dans le

cas de mise en gaine, pose de plancher et assemblage de palettes.

Tous les outils pneumatiques sont sujets à un recul lorsque l’on

place des clous. L’outil risque de rebondir, en cas de

déclenchement, et d’entrer par mégarde en contact avec la surface

de la pièce de travail avec le déclencheur tou jours actionné (pendant

que le doigt de l’opéra teur tire toujours le déclencheur). Dans ce cas

un deuxième clou non prévu sera enfoncé.

DECLENCHEMENT AU COUP À COUP

Identifié par le DECLENCHEUR NOIR.

DECLENCHEMENT SEQUENTIEL (kit en option)

Avec le déclenche ment séquentiel, l’opérateur doit tenir l’outil contre

la pièce de travail avant de tirer le déclencheur. Ceci facilite une

pose précise des clous, par exemple dans le cas d’enca drement, de

clouage de plancher et d’assemblag e de caisses. Le déclenchement

séquentiel permet un positionnement exact des clous sans risque

d’enfoncer un deuxième clou en cas de recul, comme décrit dans le

paragraphe “Déclenchement par contact”.

L’outil de déclenchement séquentiel présente un avantage de

sécurité parce qu’il ne cause pas une pose accidentelle des clous

si l’outil entre en contact avec la pièce de travail ou toute autre

objet, pendant que l’opérateur maintient le déclencheur tiré.

DÉCLENCHEMENT SÉQUENTIEL

Identifié par le DECLENCHEUR ORANGE.

cas de mise en gaine, pose de plancher et assemblage de palettes.

Tous les outils pneumatiques sont sujets à un recul lorsque l’on

place des clous. L’outil risque de rebondir, en cas de

déclenchement, et d’entrer par mégarde en contact avec la surface

de la pièce de travail ave c le déclencheur toujours actionné (penda nt

que le doigt de l’opérateur tire toujours l e déclencheur) ; dans ce cas

un deuxième clou non prévu sera enfoncé.

MODÈLE DE DÉCLENCHEMENT PAR CONTACT AVEC

MÉCANISME DE DÉCLENCHEMENT ANTI-DOUBLE

Identifié par le DÉCLENCHEUR ROUGE.

OPÉRATION DE DÉCLENCHEMENT PAR CONTACT

Pour l’opération de déclenchement par contact, tenir le

déclencheur et enfoncer le bras de contact contre la surface de

la pièce de travail.

OPÉRATION DE DÉCLENCHEMENT SIMPLE (MÉCANISME

DE DÉCLENCHEMENT ANTIDOUBLE)

Pour l’opération de déclenchement simple, presser le bras de

contact contre la surface de la pièce de travail, puis tirer le

déclencheur.

L’outil ne peut pas déclencher un deuxième clou jusqu’à ce que

le déclencheur soit libéré et l’outil peut faire un cycle.

ATTACHE POUR ENFONCEMENT

OPÉRATION DE DÉCLENCHEMENT PAR CONTACT

(DÉCLENCHEMENT AU COUP À COUP)

Pour l’opération de déclenchement par contact, tenir le

déclencheur et enfoncer le bras de contact contre la surface de

la pièce de travail.

1

MODÈLE DE DÉCLENCHEMENT PAR CONTACT AVEC

MÉCANISME DE DÉCLENCHEMENT ANTI-DOUBLE

(kit en option)

(Brevet 5597106 USA, Brevet GB 2286790)

La méthode de fonctionnement commune sur les outils à

“déclenchement par contact” permet à l’opérateur d’entrer en

contact avec la piè ce de travail pour actionner le déclenc heur tout en

le maintenant tiré, ceci permettant d’enfoncer un clou chaque fois

que la pièce de travail entre en contact. Ceci permettra une pose

rapide des clous sur beaucoup de pièces de travail, comme dans le

2

MÉTHODE

1 Tenir le déclencheur. 2 Presser le bras de contact.

21

Page 22

6. ENTRETIEN POUR OBTENIR LES MEILLEURES PERFORMANCES

1 NE PAS DÉCLENCHER LE CLOUEUR QUAND IL EST

VIDE

2 UTILISER UN ENSEMBLE DE REGULATION Le fait de ne pas utiliser un ensemble de régulation, permet l’entrée de l’humidité et l’encrassement à l’intérieur du compresseur qui passe directement dans la cloueuse. Cela crée une formation de rouille et provoque l’usure conduisant à une mauvaise performance pendant l’utilisation. La longueur du tuyau entre le regulateur et la cloueuse ne doit pas dépasser 5 m, étant donné qu’une longueur supérieure réduit la pression d’air. 3 UTILISER UNE HUILE RECOMMANDEE L’huile de turbine fluide doit être utilisée pour lubrifier la cloueuse. Après la fin des opérations, placer 2 ou 3 gouttes d’huile dans l’entrée d’air de graisseur à jet. (Huile recommandée : ISO VG32) 4 VERIFIER ET ENTRETENIR L’OUTIL TOUS LES JOURS

OU AVANT CHAQUE UTILISATION.

AVERTISSEMENT

Couper l’alimentation en air comprimé et vider le magasin

avant toute vérification ou mesure d’entretien de l’outil.

(1) Vider le filtre de la conduite d’air et le compresseur.

(2) Veiller à ce que le graisseur soit toujours plein dans l’unité

d’air comprimé à trois éléments.

(3) Nettoyer l’élément filtrant de l’unité d’air comprimé à trois

éléments.

(4) Bien serrer toutes les vis.

(5) Faire en sorte que la barre de contact garde sa liberté de

mouvement.

8. REPARATION

Le dépistage de dérangements et/ou les réparations ne doivent

être réalisés que par des distributeurs autorisés de la société

MAX CO.,LTD. ou tout autre spécialiste qui respectera les

informations contenues ici.

Supplément au mode d’emploi

Selon Ia norme européenne EN 792-13 le réglement suivant est

valable du 1.1.2001, que toutes machines à enfoncer les

fixations équipées de commande par contact doivent être

marquées avec le symbole "Ne pas utiliser sur des échafaudages

ou e’chelles" et elles ne seront pas utilisées pour utilisations

spécifiques, par example:

∗ en cours de déplacement d’un lieu d’enfoncement à l’autre sur

des échafaudages, escaliers, échelles ou constructions de

même qu‘êchelles comme p.e. lattis du toit

∗ pour fermer des boîtes ou des caisses

∗ pour fixer des systèmes d’arrimages p.e. sur véhicules ou

wagons.

7. EMMAGASINAGE

1 Si l’outil doit rester inutilisé pendant un certain temps,

appliquer une mince couche de lubrifiant sur les pièces en

acier pour éviter l’apparition de rouille.

2 Ne pas entreposer l’outil dans un endroit exposé au froid.

Le conserver dans un endroit chaud.

3 Si l’outil reste inutilisé, il faut le conserver dans un endroit

chaud et sec. Le mettre hors de portée des enfants.

4 Même les outils de qualité peuvent éventuellement

nécessiter des mesures d’entretien ou le remplacement de

pièces en raison de l’usure normale.

22

Page 23

ESPAÑOL

MANUAL DE OPERACIONES Y MANTENIMIENTO

INDICE

1. ADVERTENCIAS GENERALES DE SEGURIDAD ...........................23

2. ADVERTENCIA DE SEGURIDAD .....................................................24

3. DATOS TECNICOS Y ACCESORIOS ...............................................27

4. EL SUMINISTRO DE AIRE Y CONEXIONES....................................27

5. INSTRUCCIONES PARA EL FUNCIONAMIENTO ...........................28

6. MANTENIMIENTO .............................................................................32

7. ALMACENAMIENTO .........................................................................32

8. SUBSANACION DE AVERIAS ..........................................................32

ANTES DE USAR EL COMPRESOR ESTUDIE ESTE MANUAL PARA CONOCER LAS ADVERTENCIAS E

INSTRUCCIONES DE SEGURIDAD.

ADVERTENCIA

CONSERVE ESTAS INSTRUCCIONES JUNTO CON LA HERRAMIENTA PARA FUTURAS CONSULTAS.

1. ADVERTENCIAS GENERALES

DE SEGURIDAD

ADVERTENCIA

LEA TODAS LAS INSTRUCCIONES Y

ADVERTENCIAS DE SEGURIDAD.

Si no respeta las siguientes advertencias e

instrucciones pueden producirse lesiones graves e

incluso la muerte.

e instrucciones para futuras consultas.

Conserve todas las advertencias

1. LLEVE GAFAS PROTECTORAS O DE SEGURIDAD

Un peligro a los ojos siempre está presente debido al polvo

rechazado por el aire o a la eyección de clavos por medio

de una manipulación incorrecta de la herramienta. En este

caso, es necesario utilizar siempre gafas protectoras o de

seguridad al operar la herramienta.

El patrono y/o el usuario deben asegurar una protección

apropiada de los ojos de los operadores de la herramienta.

El equipamiento de protección de los ojos debe responder

a las exigencias del American National Standards Institute,

Norma ANSI Z87.1 (Directiva del Consejo 89/686/CEE de

21 de diciembre de 1989) y asegurar una protección frontal

y lateral.

El patrono es responsable para imponer el uso del

equipamiento de protección de los ojos por el operador de

la herramienta y por todos los demás miembros del

personal en la superficie de trabajo.

NOTA: Las gafas sin protección lateral y frontal no

aseguran una protección correcta.

2. EN ALGUNOS CIRCUNSTANCIAS PUEDE SER NECESARIO LA PROTECCIÓN DE OÍDOS

El usuario puede ser expuesto a un nivel alto de ruido, lo cual

puede causar daños al oído. El usuario debería as egurarse de

que se emplea la p rotección necesaria, y de que sea empleado

por los demás trabajadores en la zona de trabajo.

23

Page 24

3. MANTENER LAS MANOS Y EL CUER PO ALEJADOS DE LA SALIDA DE DESCARGA

Al cargar y usar la herramienta no colocar ni la mano ni

ninguna parte del cuerpo sobre la salida de descarga, ya

que puede resultar muy peligroso. Es muy peligroso

golpear las manos o el cuerpo por error.

Aguarrás

3. NO MANEJAR LA HERRAMIENTA CERCA DE SUSTANCIAS INFLAMABLES

Nunca manejar la herramienta cerca de sustancias

inflamables (por ejemplo aguarrás, gasolina, etc.). Gases

volátiles de estas sustancias, pueden ser arrastradas

dentro del compresor y el aire comprimido puede provocar

una explosión.

4. NUNCA UTILIZAR LA HERRAMIENTA EN UN AMBIENTE EXPLOSIVO

Las chispas de la herramienta pueden poner a fuego los

gases atmosféricos, el polvo o otros materiales

combustibles.

Gasolina

4. NO UTILICE ANDAMIOS NI ESCALERAS DE MANO

No use andamios ni escaleras de mano cuando utilice

remachadoras de clavos equipadas con acción por

contacto o acción por contacto continuo.

2. ADVERTENCIA DE SEGURIDAD

1. NO UTILIZAR NINGUNA FUENTE DE ENERGÍA SALVO UN COMPRESOR DE AIRE

La herramienta esta designada para funcionar con aire

comprimido. No utilizar la herramienta con ningún otro gas

de alta presión, gases combustibles (por ejemplo, oxigeno,

acetileno, etc.) ya que existe el peligro de una explosión.

Por esta razón, es imprescindible que no se utilice otra cosa

que un compresor de aire para manejar la herramienta.

2. UTILIZAR DENTRO DEL LIMITE PRECISO DE PRESIÓN DE AIRE

La herramienta está designada para funcionar dentro de

limite de presión de aire de 70 a 100 p.s.i. (5 a 7 bar).

La presión debería ser adaptada a la clase de trabajo

indicado. La herramienta no debería ser manejada cuando

la presión sobrepasa 120 p.s.i. (8,3 bar).

No conecte la herramienta nunca a una alimentación de

aire comprimido cuya presión pueda superar posiblemente

los 200 p.s.i. (13,8 bar), ya que la herramienta podría

reventar.

5. NO UTILIZAR ACCESORIOS IMPROPIOS

El enchufe de la herramienta no debe contener presión,

cuando el suministro de aire este desconectado. Si se

utiliza un accesorio impropio, la herramienta puede

quedarse cargada con aire después de desconectar, de

este modo seguirá funcionando incluso después de haber

desconectado el suministro de aire, con la posibilidad de

causar daños.

6. MIENTRAS LA HERRAMIENTA NO ESTE EN USO, DESCONECTE LA ALIMENTACIÓN DE AIRE COMPRIMIDO Y VACÍE EL CARGADOR

Siempre desconecte el suministro de aire desde la

herramienta y vacíe el cartucho, cuando la operación ha

sido completada o está suspendida, cuando permanece sin

atender, cambiando a una área de trabajo diferente,

ajustando, desarmando o reparando la herramienta, y al

despejar un afianzador atascado.

7. COMPROBAR LA TENSIÓN DEL TORNILLO

Los tornillos flojos o mal instalados pueden causar

accidentes y daños a la herramienta, cuando se utiliza.

Compruebe que todos los tornillos estén apretados y bien

instalados antes de utilizar la herramienta.

24

Page 25

8. NO TOCAR EL DISPARADOR AL MENOS QUE TENGA INTENCIÓN DE REMACHAR UN CLAVO

Cuando el suministro de aire este conectado a la herramienta,

no tocar nunca el disparador a menos que tenga intención de

remachar un clavo. Es peligroso llevar la herramienta con

disparador apretado, y esto debe ser evitado.

9. NUNCA APUNTE LA SALIDA DE DESCARGA HACIA UD. MISMO Y OTRO PERSONAL

Si la salida de descarga es apuntada hacia personas,

pueden ocasionarse serios accidentes cuando se dispara

equivocadamente. Asegúrese de que la salida de descarga

no está apuntada hacia las personas cuando conecta y

desconecta la manguera, carga y descarga los

afianzadores u operaciones similares.

10. UTILIZAR GRAPAS ESPECIFICAS (VÉASE LA PÁGINA 27)

El uso de grapas que no sean las especificas pueden

causar la mala función de la herramienta. Asegurarse de

utilizar únicamente grapas especificas.

13. NO GRAPAR SOBRE OTRAS GRAPAS

Grapando encima de otras grapas puede causar desvío, lo

cual puede causar daños.

14. QUITAR LAS GRAPAS DESPUÉS DE COMPLETAR LA OPERACIÓN

Si se dejan las grapas puestas después de completar la

operación, existe el peligro de un accidente grave, si se

maneja la herramienta de forma descuidada, o en la hora

de conectar las instalaciones de aire. Por esta razón es

imprescindible quitar todas las grapas que sobran después

de completar la operación.

15. COMPRUEBE FRECUENTE MENTE EL FUNCIONAMIENTO DEL MECANISMO DE DISPARO POR CONTACTO EN EL CASO DE UTILIZAR UNA HERRAMIENTA DEL TIPO DE ACCIÓN POR CONTACTO.

No utilizar la herramienta si el disparador no funciona

correctamente, ya que puede grapar sin querer. No

interfiera el funcionamiento correcto del mecanismo de

disparo por contacto.

16. LA UTILIZACIÓN DE LA HERRAMIENTA AL AIRE LIBRE O EN SITIOS ELEVADOS

A la hora de grapar tejados o otras superficies inclinadas,

empezar en la parte baja y poco a poco subir. Grapar hacia

atrás es peligroso ya que se puede resbalar.

Asegurar la manguera cerca de la zona donde se va a

grapar. Accidentes pueden resultar debido a que la

manguera se enganche.

11. PONGA CORRECTAMENTE EL ENCHUFE DE DESCARGA EN LA SUPERFICIE DE TRABAJO

Si se olvida de poner el enchufe de descarga de la nariz de

manera apropiada, se puede causar una separación

violenta del sujetador para arriba y esto es

extremadamente peligroso.

12. NO GRAPAR JUNTO AL BORDE DE LAS SUPERFICIES O MATERIALES FINOS

Es probable que la superficie se divida y la grapa podría

saltar y dañar a alguien. Tener cuidado a la hora de grapar

materiales finos y los bordes y las esquinas de las

superficies.

17. NUNCA UTILICE LA HERRAMIENTA SI CUALQUIER PORCIÓN DE LOS CONTROLES DE L A HERRAMIENTA (POR EJEMPLO, DISPARADOR, BRAZO DE CONTACTO) ES INOPERABLE, DESCONECTADA, ALTERADA O NO OPERA CORRECTAMENTE

18. NO CLAVE NUNCA EN EL AIRE

De lo contrario, existe peligro por los clavos que salen

disparados, y la herramienta sufre un sobreesfuerzo

innecesario.

19. SUPONGA SIEMPRE QUE LA HERRAMIENTA CONTIENE LOS AFIANZADORES

20. RESPECTO A LAS HERRAMIENTAS COMO UN ELEMENTO DE TRABAJO

21. NO JUEGUE HACIENDO BROMAS

22. NUNCA CARGUE LA HERRAMIENTA CON LOS AFIANZADORES CUANDO CUALQUIERA DE LOS CONTROLES DE OPERACIÓN (ej.: DISPARADOR, BRAZO DE CONTACTO) SE ENCUENTRA ACTIVADO

25

Page 26

23. CUANDO LA MÁQUINA O SUS PIEZAS SE PONEN AL RECHAZO, POR FAVOR SIGUE LOS REGLAMENTOS NACIONALES RELATIVOS

OBSERVAR LAS SIGUIENTES PRECAUCIONES,

ASÍ COMO LAS OTRAS ADEVERTENCIAS QUE

SE RECOGEN EN ESTE MANUAL

• No utilizar la herramienta como martillo.

• Siempre tenga la herramienta por el puñado, y

nunca transporte teniendo la herramienta por los

tubos de aire.

• La herramienta debe ser utilizada únicamente

para el propósito a que fue designada.

• Nunca retire, fuerce los controles de operación

(ej.: DISPARADOR, BRAZO DE CONTACTO).

• Guardar la herramienta en sitios secos y

mantener fuera del alcance de niños.

• No utilizar la herramienta sin la etiqueta de

Advertencia de Seguridad.

• No modificar la herramienta del diseño original

función sin la aprobación de MAX CO., LTD.

26

Page 27

3. DATOS TECNICOS Y

ACCESORIOS

1. DENOMINACIÓN DE LAS PIEZAS

8

1

4

3

2. DATOS TÉCNICOS DE LA HERRAMIENTA

ALTO 10-5/8" (271 mm)

ANCHO 4-5/8" (116 mm)

LARGO 12-3/8" (313 mm)

PESO 5.2 lbs. (2,4 kg)

PRESIÓN DE SERVICIO

RECOMENDADA

CAPACIDAD DE CARGA 120 Clavos

CONSUMO DE AIRE

COMPRIMIDO

3. DATOS TÉCNICOS DE LOS CLAVOS

LONGITUD DE L OS CLAVOS

DIÁMETRO DEL VÁSTAGO

TIPO DE VÁSTAGO Suave, anillo

2

9

6

5

0,046 pies3 a 90 p.s.i. (1,3 con

una presión de servicio de 6 bar es)

1 Carcasa

2 Tapa del cilindro

7

3 Brazo de contacto

4 Pico del clavador

5 Cargador

6 Disparador

7 Asa o mango

8 Salida de humos

9 Seguro del

disparador

0 Calib rador de tejas

10

70 a 100 p.s.i. (5 a 7 bar)

3/4" a 1-3/4" (19 a 45 mm)

.120" (3,0 mm)

brazo al usar la herramienta. Una influencia al sistema manobrazo cuando se usa la herramienta, por ejemplo, dependerá

de la fuerza de agarre, la fuerza de presión de contacto, la

dirección de trabajo, el ajuste del suministro de aire principal,

el lugar de trabajo, el soporte de los objetos de trabajo.

5. CAMPOS DE APLICACIÓN

∗ Fijación de asfalto y tejas de fibra de vidrio

∗ Instalación de láminas protectoras

∗ Fijación de malla metálica en madera contrachapada

∗ Montaje de cajas de madera

4. EL SUMINISTRO DE AIRE Y CONEXIONES

ADVERTENCIA

Lea el apartado con el título “INSTRUCCIONES

PARA LA SEGURIDAD”

NO UTILIZAR NINGUNA FUENTE DE ENERGÍA SALVO UN

COMPRESOR DE AIRE

La herramienta esta designada para funcionar con aire

comprimido. No utilizar la herramienta con ningún otro gas de

alta presión, gases combustibles (por ejemplo, oxigeno,

acetileno, etc.) ya que existe el peligro de una explosión. Por esta

razón, es imprescindible que no se utilice otra cosa que un

compresor de aire para manejar la herramienta.

PIEZAS DE CONEXIÓN PARA EL AIRE

COMPRIMIDO:

Este aparato está equipado con una conexión macho con rosca

exterior de 1/4" N.P.T.. El diámetro interior debería ser de .28" (7

mm) como mínimo. La pieza de empalme debe permitir la

descarga de presión del aparato en caso de interrupción de la

alimentación de aire comprimido.

PRESION DE SERVICIO RECOMENDADA:

70 a 100 p.s.i. (5-7 bar) Para garantizar el rendimiento óptimo del

clavador, la presión del aire debe ser regulada dentro de este

campo.

LA PRESION DE SERVICIO NO DEBE SUPERAR LOS 8 BAR.

4. DATOS TÉCNICOS 1 NIVEL DE RUIDO

Nivel de potencia acústica por impulsos A

Nivel de intensidad acústica por impulsos A en el puesto de

trabajo.

La determinación y documentación de estos valores se

realiza según EN12549 : 1999

2 VIBRACIONES

Valor característico de vibración = 3,81 m/s2

Estos valores se determinan y se documentan de acuerdo

con la Norma ISO 8662-11.

Este valor es un valor característico relacionado a la

herramienta y no representa la influencia al sistema mano-

------ LWA, 1s, d 100,7 dB

------ LpA, 1s, d 93,8 dB

UTILIZAR DENTRO DEL LIMITE PRECISO DE PRESIÓN DE

AIRE

La herramienta está diseñada para trabajar en un intervalo de

presión de aire de 70 a 100 p.s.i. (5 a 7 bar).

La presión debería ser adaptada a la clase de trabajo indicado.

Nunca haga funcionar la herramienta a una presión de más de 120

p.s.i. (8 bar).

Aguarrás

NO MANEJAR LA HERRAMIENTA CERCA DE SUSTANCIAS

INFLAMABLES

Nunca manejar la herramienta cerca de sustancias inflamables

(por ejemplo aguarrás, gasolina, etc.). Gases volátiles de estas

sustancias, pueden ser arrastradas dentro del compresor y el

aire comprimido puede provocar una explosión.

Gasolina

27

Page 28

NO UTILIZAR ACCESORIOS IMPROPIOS

El enchufe de la herramienta no debe contener presión, cuando

el suministro de aire este desconectado. Si se utiliza un

accesorio impropio, la herramienta puede quedarse cargada con

aire después de desconectar, de este modo seguirá funcionando

incluso después de haber desconectado el suministro de aire,

con la posibilidad de causar daños.

MIENTRAS LA HERRAMIENTA NO ESTE EN USO,

DESCONECTE LA ALIMENTACIÓN DE AIRE COMPRIMIDO Y

VACÍE EL CARGADOR

Siempre desconecte el suministro de aire desde la herramienta

y vacíe el cartucho, cuando la operación ha sido completada o

está suspendida, cuando permanece sin atender, cambiando a

una área de trabajo diferente, ajustando, desarmando o

reparando la herramienta, y al despejar un afianzador atascado.

5. INSTRUCCIONES PARA EL FUNCIONAMIENTO

Lea el apartado con el título “INSTRUCCIONES

PARA LA SEGURIDAD”.

1. ANTES DE LA PUESTA EN MARCHA

Verifique los puntos siguientes antes de utilizar la herramienta.

1 Póngase gafas protectoras. 2 No conecte todavía el aire comprimido. 3 Compruebe los tornillos en cuanto a su firme asiento. 4 Compruebe el funcionamiento del brazo de contacto y la

marcha fácil del disparador.

5 Conecte el aire comprimido. 6 Compruebe la herramienta en cuanto a fugas de aire. (No

deben existir fugas de aire.)

7 Sujete la herramienta (sin colocar el dedo en el disparador)

y apriete el brazo de contacto contra la pieza. (La

herramienta no debe funcionar.)

8 Mantenga la herramienta de modo que el brazo de contacto

no esté aplicado contra la pieza, y accione el disparador.

(La herramienta no debe funcionar.)

9 Desconecte la alimentación de aire.

[EL SUMINISTRO DE AIRE Y CONEXIONES]

Compresor de

Mangueras de aire

Presión 70 a 100 p.s.i. (5 a 7 bar)

ACOPLAMIENTOS:

que no obstruya el caudal de aire y libere la presión de la

herramienta cuando se desconecta de la fuente de suministro.

MANGUERAS: La manguera tiene un diámetro interior mínimo

de 1/4" (6 mm) y una longitud máxima de 17" (5 metros).

La manguera debe estar provista de un acoplamiento que

permita la liberación rápida de la conexión macho.

FUENTE DE SUMINISTRO: Utilizar únicamente aire comprimido

regularizado limpio como fuente de energía para la herramienta.

CONJUNTO DE 3 PIEZAS (Filtro de Aire, Regulador, Deposito

de Aceite):

Ver especificaciones de la herramienta para ajustar la presión de

operación adecuada para la herramienta.

NOTA:

El uso de un filtro mejora el funcionamiento y reduce el desgaste de

la herramienta, ya que la suciedad y el agua en el suministro de aire

son las causas principales del desgaste de la herramienta.

Es necesario engrasar pero no excesivamente para obtener un

perfecto funcionamiento. El aceite que se añade a la conexión de

suministro de aire engrasa las partes internas.

Instale una conexión macho a la herramienta

Regulador

Filtro de Aire

Conjunto de 3 piezas

Deposito de Aceite

ADVERTENCIA

2. FUNCIONAMIENTO

Póngase gafas protectoras o de seguridad para reducir el riesgo

constante al que están expuestos los ojo; debido al polvo que

levanta el aire expulsado o a la proyección de clavos cuando la

herramienta se manipula indebidamente. Por estos motivos, es

necesario utilizar siempre gafas protectoras o de seguridad al

operar la herramienta.

El patrono y/o el usuario deben asegurar una protección

apropiada de los ojos de los operadores de la herramienta. El

equipamiento de protección de los ojos debe responder a las

exigencias del American National Standards Institute, Norma

ANSI Z87.1 (Directiva del Consejo 89/686/CEE de 21 de

diciembre de 1989) y asegurar una protección frontal y lateral.

El patrono es responsable para imponer el uso del equipamiento

de protección de los ojos por el operador de la herramienta y por

todos los demás miembros del personal en la superficie de

trabajo.

NOTA: Las gafas sin protección lateral y frontal no aseguran una

protección correcta.

ADVERTENCIA

Durante el proceso de grapar/clavar, las manos y el cuerpo

deben mantenerse alejados del orificio de salida ya que existe el

riesgo de que puedan ser heridos accidentalmente.

28

Page 29

CARGA DE CLAVOS

Pestillo de la puerta

Cubierta del

cargador

Puerta

1 Abra el cargador:

Tire hacia abajo del pestillo de la puerta y gírela hacia un

lado. Gire la cubierta del cargador hacia un lado.

Soporte del clavo

Cargador

2 Comprobación del ajuste:

El soporte del clavo puede moverse arriba y abajo para

cuatro configuraciones. Para cambiar la configuración tire

hacia arriba del mástil y gírelo hasta el paso indicado. El

soporte del clavo debe ajustarse correctamente en su

posición del siguiente modo;

Clavos de 1-3/4" (45 mm) - use el paso inferior

Clavos de 1-1/4", 1-1/2" (32 y 38 mm) - use el paso

intermedio

Clavos de 3/4", 7/8", 1" (19, 22 y 25 mm) - use el paso

superior

Clavo

Trinquete de alimentación

3 Carga de clavos: