Mauell ME 3011b Instruction Manual

Manual ME3011b_E_v0707_Pre.doc 1/50

ME 3011b

Instruction Manual

Alarm Systems

SERIAL PRODUCTS

Digital Alarm Annunciator

Manual ME3011b_E_v0707_Pre.doc 2/50

1 – Information and Technical Data

Introduction

4

Warranty

4

Installation

5

Operation Principles

6

Technical Data 7

Modularity and arrangements 9

Dimensions

10

Panel Mounting 11

Product Identification 12

Product Code 13

Front display engraving/printing 14

Signaling sequences 15

Special Options 16

2 – Product Description

CM-0x – Master CPU’s Module 17

CM-03 – Master CPU 2v x 4h 17

CM-04 – Master CPU 4x x 2h 18

SM-02 – Slave CPU Module 20

EM-0x - Expansion Modules 21

EM-02 – Expansion Module 2v x 4h 21

EM-03 – Expansion Module 4v x 2h 22

EM-04 – Expansion Module 2v x 2h 23

Functions 24

3 - Installation

Power Supply 26

Inputs 27

Alarm Inputs 27

Remote push-button 27

GPS Synchronization (Option) 28

Power consumption 32

Outputs 29

24Vdc field output 29

External Buzzer output 29

Programmable relay outputs 29

Repeater relay outputs (RRO) (Option)l 29

Repeat relays for power fault detection (Option) 30

Flashing synchronization (Option) 31

Recommendations 32

Connection diagram examples 33

Standard connections – 24 Vdc – without RRO or Special

33

Connections with Vdc Fault at Point 2 and Vac Fault at Point 4 35

Terminal identification 37

New arrangements 41

SM-02 module positions 42

SM-02 position on 4h enclosure 42

SM-02 position on 8h enclosure 43

SM-02 position on 12h enclosure 44

Manual ME3011b_E_v0707_Pre.doc 3/50

SM-02 position on 16h enclosure 45

Configuration modes 46

4 - e.Tool ME3011 config - Configuration via serial interface

5 - Configuration via keyboard

6 – Communication Protocol - Serial Modbus RTU

7- e.Tool ME2011 view

This manual is subject to changes without previous advice

Revision Control

Author Version/Rev Date

mbe 0 16/07/2007

Manual ME3011b_E_v0707_Pre.doc 4/50

Dear Customer,

Mauell thanks you for trusting us on choosing our products. It is a pleasure to provide you all

necessary information on the newest member of its Mauell annunciator family.

This manual presents all information needed to connect and power up the annunciator, as well as

instructions for configuring it.

Mauell hopes that this manual helps you explore totally the potential of the new ME 3011

annunciator.

Please contact us, if any doubt persists about the equipment operation, after reading it. Our technical

team is always available to clear any doubt you may deem necessary.

Contact the nearest Mauell unit (please refer to the appendix) or send an email to

mauell@mauell.com.br; visit the website www.mauell.com.br; send a fax to +55 11 2117 5354 or

call +55 11 2117 5353.

In order to help us on our support service have the series number and the firmware version with

you, as these data are essential for clearing the doubts and for technical assistance.

The equipment manufactured and supplied by Mauell is guaranteed against any project and

manufacturing defect, when stored and used according to its technical characteristics, for a 12

(twelve)-month period from its installation or 18 (eighteen) month-period from the ex works delivery

date (which is the earliest).

During this period, Mauell will replace or correct, without any charges to the client, all out of

technical specification equipment parts. In other words, our warranty covers materials and labor in

the correction of eventual defects eligible for being covered by our warranty.

These operations will be carried out in our nearest unit (as previously agreed upon) or at Helmut

Mauell do Brasil to where the equipment may be sent.

In case of doubt about the use of the equipment, due to the warranty and its effects, please contact

our commercial and technical departments.

INTRODUCTION

WARRANTY

Manual ME3011b_E_v0707_Pre.doc 5/50

All annunciators have an appropriate package for air or road transportation. When receiving the

equipment, the visual inspection may be carried out to check if there were damages during

transportation. If so, it is necessary to contact immediately the receiving sector of your company,

which may notify your insurance company and Mauell so the involved parts may adopt the necessary

measures to repair the damages and to initiate the reimbursement of eventual expenses.

The incorrect use and wrong handling of the equipment are not covered by Mauell general

guarantee. Therefore, it is essential that the installer takes some measures, before executing the

installation and powering of the equipment, as mentioned below:

Avoid mechanical impacts to the equipment or falls, which cause frame arching or back

terminal breaking.

Avoid that water or other liquid gets into the annunciator, as the liquid may cause short-

circuit to the internal circuits and, consequently, bad contacts in the future.

Avoid that exte rnal objects get into the annunciator through the vents, thus, whenever it is

necessary to carry out any work involving drilling or panel plate thinning, where the

annunciator is installed, the equipment may be protected with paper, plastic and other

material so the debris do not get into the annunciator, causing poor operation.

Check the voltage levels and the correct identification of the cables before executing the

equipment connection. A wrong connection can cause short-circuit and damage to the

equipment in an irreparable way.

The frontal modules may be removed with the aid of a blade, which may be inserted

between two modules, carefully, forcing the removal of the desired module. This operation

may be carried out carefully and patiently in order to prevent damages to the front part of

the modules or to the grid brackets of the module.

The access to the electronic circuits of the equipment is carried out from the front part,

removing the front modules, as described above, disconnecting the back pluggable

terminals, without disconnecting the wires, from which the electronic part of the equipment

may be removed. After the repair, the electronic part may be replaced and the terminals

plugged again. When reconnecting, note with the maximum care, the proper position of

each terminal.

The cleaning of the front part of the annunciator may be carried out with a soft cloth,

slightly wet, with neutral detergent. The equipment may not be submitted to the direct

spray of liquids and care must be taken so the liquids do not get into it.

INSTALLATION

Manual ME3011b_E_v0707_Pre.doc 6/50

Alarm annunciators have the main function of safely signaling critical statuses of installations, aiming

at their integrity.

They signal acoustically and optically equipment alarms in a standardized way, within the highest

ergonomic and cognitive possible standard.

It is recommended, in general, to carry out the direct connection of electric field alarm signals to the

annunciator, preventing loops through digital automation and control systems. Thus, the necessary

operating safety level is achieved.

The maximum alarm signal cable length is 600 m (unshielded) or 1000 m (shielded). These

maximum values may be strongly reduced in areas with very high electromagnetic fields, for example

in the case of open air cable trays within substations. It is, also, of paramount importance to place

the signal cables in trays carrying cables with homogeneous voltages. Placing high and low voltage

cables in conjunction within the same cable tray may cause serious annunciator malfunctions or even

hardware damages.

The ME 3011 annunciator, the new member of Mauell annunciator family, keeps one of the most

important characteristics of ME 3010 series, which is the modularity of the alarm windows. The

processing fundament of the alarm signs is now carried out through latest generation micro

controllers, with high performance RISC architecture.

So, ME 3011 annunciator incorporates all the advantages of a micro processed system, such as

configuration of the annunciators main functions through the front keyboard, or also via

configuration software, available at

www.mauell.com.br for download.

This way, the ME 3011 annunciator provides all conventional functions of alarm announcing together

with new and advanced communication function in local network and event recording, among

others.

These functions will be described in details throughout this manual.

OPERATION PRINCIPLES

Manual ME3011b_E_v0707_Pre.doc 7/50

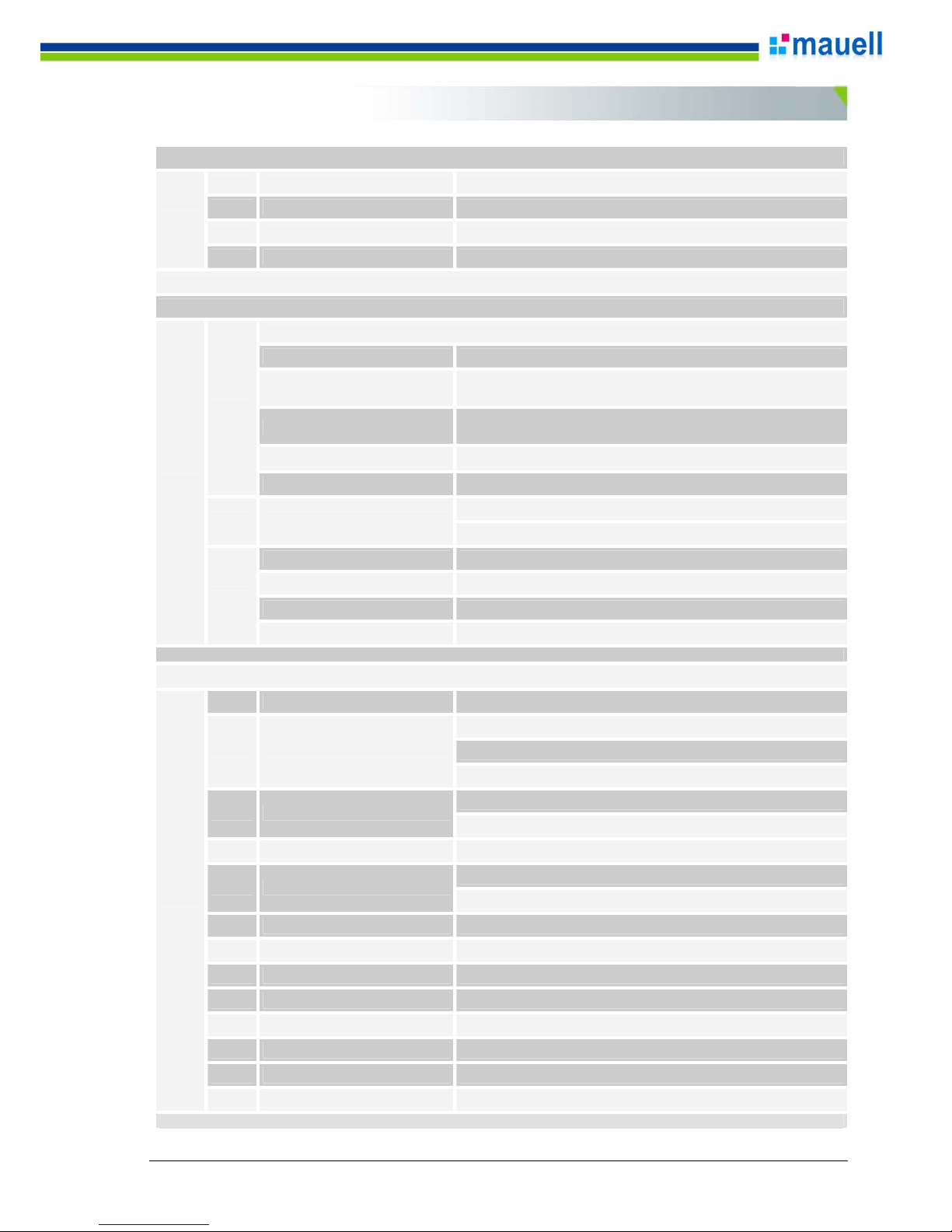

1 - Supply Voltage

1.1 PS-05 Power Supply

24 Vdc ± 20%

Input: 19 to 264 Vdc and / or 90 to 264 Vac

1.2 PS-06 Power Supply (Option)

Auxiliary field output: 24Vdc / 0,75A

1.3 Special Option PSFD Power Supply Fault Detector (PSFD) for Vdc and/or Vac

1.4 Note: All power supplies are integrated into the annunciator

2 - Inputs

Alarm Inputs 4 up to 252

Isolation Opto couplers

Input Voltages

24, 48 , 60, 110 / 125 Vdc ± 20%; 110 / 127, 220 Vac ± 20%

Input Current 3 mA (typical)

2.1

Input Filter lower value = 5 ms, programmable in steps of 2.5 ms

External Push-Button Station 24Vdc

Isolation Opto couplers

2.2

Functions

Sound Acknowledge (HA), Light Acknowledge (LA), Reset (RE),

Light Test / Function Test , Sleep Mode (SLM), Keyboard OFF

(K

BOFF

)

Synchronism with GPS and/or

Flashing

24Vdc

2.3

Isolation Opto couplers

3 - Outputs

3.1 Relays

3 contact free freely programmable relays for various functions,

e.g., external buzzer, voltage fault, alarm group, etc

3.2 Sound Indication 90 db / 10 cm, 4 kHz

3.3 Repeat relays (Option)

1 contact for each alarm point, as option

Note: Field Voltages over 125 Vdc or Vac do not support repeater

relays.

3.4

Repeat relays for Power Supply

Fault Detector (PSFD) (Option)

1 contact for each Power Supply Fault detector (PSFD)

Note:

Contact capacity for all relays is 5A / 24Vdc for resistive load.

Maximal switching voltage: 125Vdc/250 Vac

4 - Interfaces

RS232C bi-directional

Baud rate: 9600,n,8,1

4.2

Communication RS232C

(Option)

Protocol: Modbus RTU (Slave) or Modbus RTU (Slave)+TS

RS 485 Bi-directional serial communication (configurable)

Baud rate: 100 a 19200

Parity: even, odd or none

Stop bits: 1 or 2

4.3 Communication (Option)

Protocol: Modbus RTU (Slave)

TECHNICAL DATA

Manual ME3011b_E_v0707_Pre.doc 8/50

5 - Event Register (Option)

5.1 Events 1000, with Time Stamp

5.2 Resolution 1 ms, samples 2,5 ms

5.3 Interfaces RS232C or RS485

5.4 Protocols Modbus RTU (Slave)

6 - Visualization

Light Indication

Back light Available in red, yellow, green, white and blue colors

Ultra Bright Back light Available in red, yellow, green, white and blue colors

Back Light Socket (Option)

Available in red, yellow, green, white and blue colors, on sockets

to allow color change at the field.

Led 5 mm visible red, yellow, and green color leds

6.1

Special Option More than 1 color per annunciator

Fast: approx. 1.2 Hz

6.2 Flashing frequency

Slow: approx. 0.4 Hz

Windows

Dimension 24 x 48 mm

Back light White translucent modules

6.3

Led Gray RAL 7032 polycarbonate modules

7 – General

7.1 Alarm sequence ISA 1, 1A, 1B, 2A, 2C, 4A, 4AR; others on request

Operation temperature: 0 to 55°C

Storage temperature: -20 to 80°C

7.2 Environment

Relative Humidity: 0 to 95 %, without condensation

Front: IP41

7.3 Protection class

Enclosure: IP30

7.4 Isolation 3000 V

eff

: IEC 60950-1 FAZER com Lote Piloto !!!

Immunity: DIN EN 61000-6-2

7.5 EMC Compliance

Emission: DIN EN 61000-6-4

7.6

ESD DIN EN 61000-4-2

7.7 Electromagnetic Field Immunity DIN EN 61000-4-3

7.8 RF Frequency Immunity DIN EN 61000-4-6

7.9 Burst DIN EN 61000-4-4

7.10 Surge DIN EN 61000-4-5

7.11 Voltage Dips DIN EN 61000-4-11

7.12 Terminals Terminal connectors (removable) for cables up to 2.5 mm²

7.13 Tropicalization Special Option

TECHNICAL DATA

Manual ME3011b_E_v0707_Pre.doc 9/50

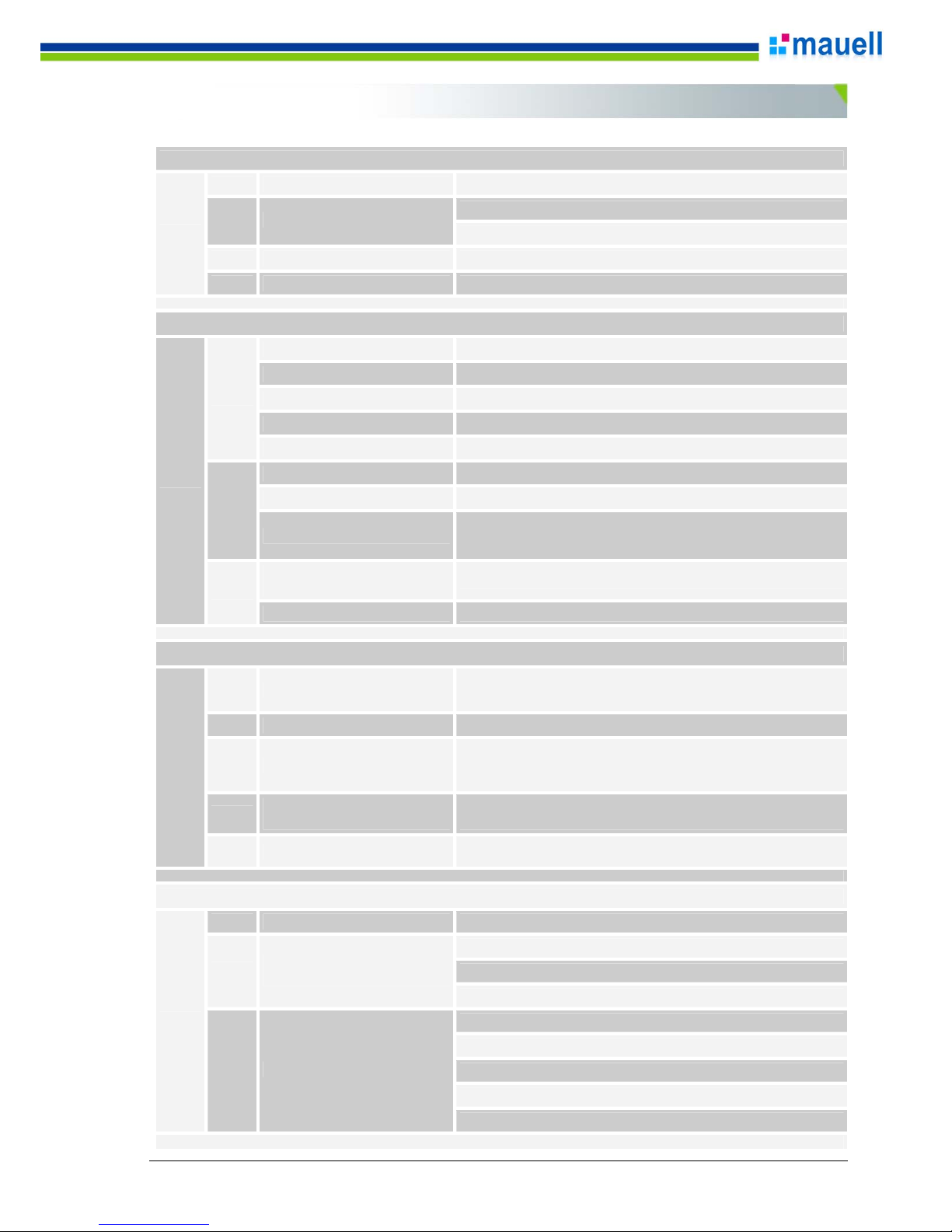

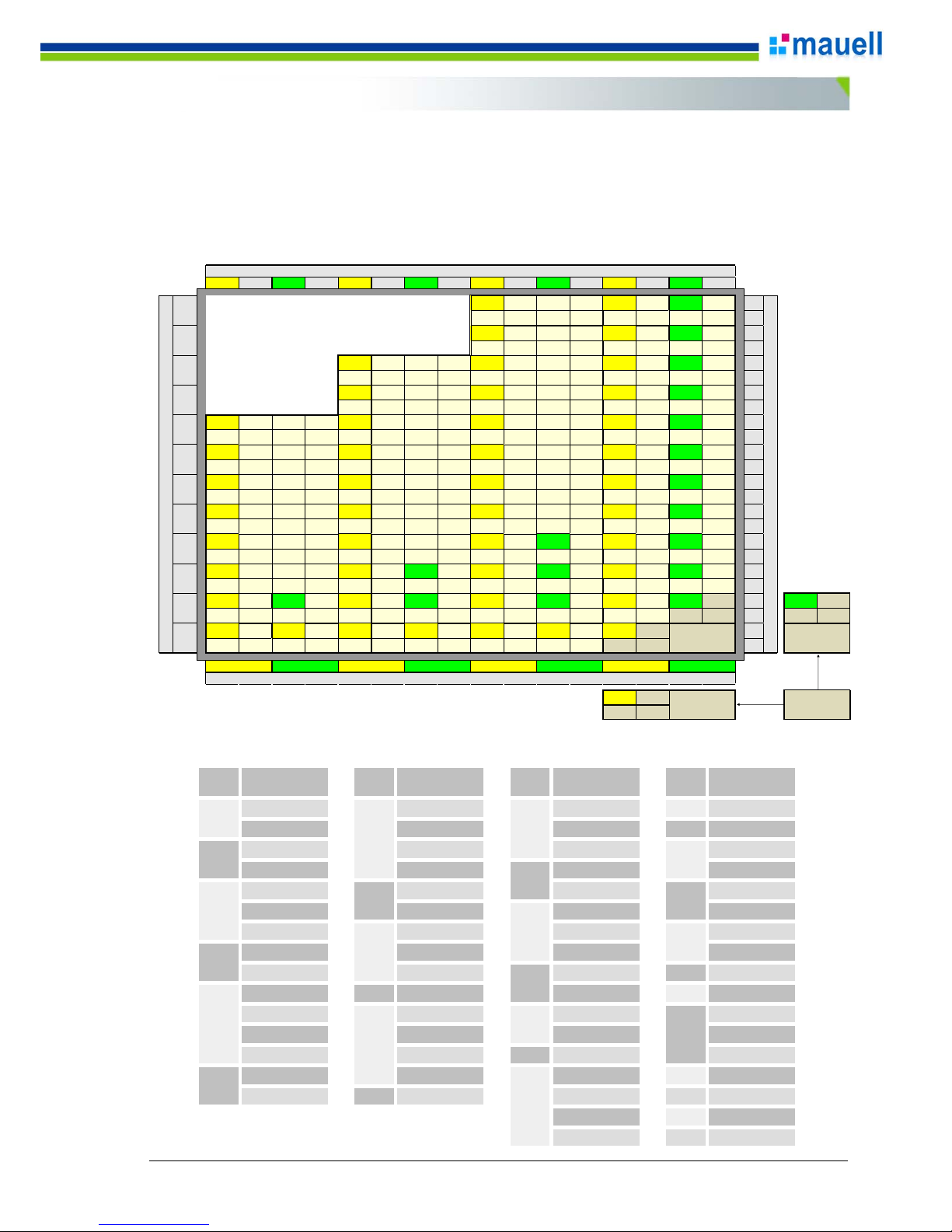

The minimum configuration possible for the annunciator is a central module with 4 alarm points, and dimension of 2V x

4H or 4V x 2H. (see shaded portion on lower right corner of diagram below)

Expansion modules can be added to this central unit, with 4 or 8 alarm points each, always in 2V x 2H or 2V x 4H

modularity basis. So the subsequent configurations are: 8, 12, 16, 20, 24, 28 points and so on, up to a maximum of

252 alarm points.

The module arrangement follows the diagram below.

Enclosure arrangement:

MODULARITY AND ARRANGEMENTS

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

24vx8h=

188P

24vx4h=

92P

24vx2h=

44

P

24

23

22vx8h=

172P

22vx4h=

84P

22vx2h=

40

P

22

21

20vx12h=

236P

20vx8h=

156P

20vx4h=

76P

20vx2h=

36

P

20

19

18vx12h=

212P

18vx8h=

140P

18vx4h=

68P

18vx2h=

32

P

18

17

16vx16h=

252P

16vx12h=

188P

16vx8h=

124P

16vx4h=

60P

16vx2h=

28

P

16

15

14vx16h=

220P

14vx12h=

164P

14vx8h=

108P

14vx4h=

52P

14vx2h=

24

P

14

13

12vx16h=

188P

12vx12h=

140P

12vx8h=

92P

12vx4h=

44P

12vx2h=

20

P

12

11

10vx16h=

156P

10vx12h=

116P

10vx8h=

76P

10vx4h=

36P

10vx2h=

16

P

10

9

8vx16h=

124P

8vx12h=

92P

8vx8h=

60P

8vx6h=

44

P

8vx4h=

28P

8vx2h=

12

P

8

7

6vx16h=

92P

6vx12h=

68P

6vx10h=

56

P

6vx8h=

44P

6vx6h=

32

P

6vx4h=

20P

6vx2h=

8

P

6

5

4vx16h=

60P

4vx14h=

52

P

4vx12h=

44P

4vx10h=

36

P

4vx8h=

28P

4vx6h=

20

P

4vx4h=

12P

4vx2h

=4

P

4

4vx2h

=4

P

4

3

2vx16h=

28P

2vx14h=

24P

2vx12h=

20P

2vx10h=

16P

2vx8h=

12P

2vx6h=

8P

2vx4h

=4P

2

1

4

3,5

3

2,5

2

1,5

1

0,5

2vx4h

=4P

43

CM-0x

Número de Módulos na Vertical

y = 12

y = 11

y = 10

y = 9

Number of horizontal points (h)

y = 8

y = 7

CM-03

CM-04

Min.

arrangements

Number of vertical poinsl (v)

Number of horizontal modules

y = 2

y = 1

y = 6

y = 5

y = 4

y = 3

Nr. of

Points

Nr. of

Points

Nr. of

Points

Nr. of

Points

4v x 2h 16v x 2h 28v x 2h

108

14 v x 8 h

2v x 4h 8v x 4h 14v x 4h

116

10 v x 12 h

2v x 6h 4v x 8h 4v x 14h 16v x 8h

6v x 2h 2v x 16h 10v x 6h 8v x 16h

8v x 2h 18v x 2h 6v x 10h 18v x 8h

4v x 4h 6v x 6h 16v x 4h 12v x 12h

2v x 8h 20v x 2h 8v x 8h 20v x 8h

10 v x 2 h 10 v x 4 h 4 v x 16 h 10 v x 16 h

2v x 10h 4v x 10h 18v x 4h

164

14 v x 12 h

12 v x 2 h

40

22v x 2h 6v x 12h

172

22 v x 8 h

6v x 4h 12v x 4h 20v x 4h 24v x 8h

4v x 6h 8v x 6h 10v x 8h 16v x 12h

2v x 12h 6v x 8h

84

22 v x 4 h 12 v x 16 h

14v x 2h 4v x 12h 24v x 4h

212

18 v x 12 h

2v x 14h

48

26 v x 2 h 12 v x 8 h

220

14 v x 16 h

8v x 12h

236

20 v x 12 h

6v x 16h

252

16 v x 16 h

188

24

92

16

68

20

44

76

140

60

36

156

Arrangement Arrangement

4

28

52

8 124

56

12

32

Arrangement Arrangement

Manual ME3011b_E_v0707_Pre.doc 10/50

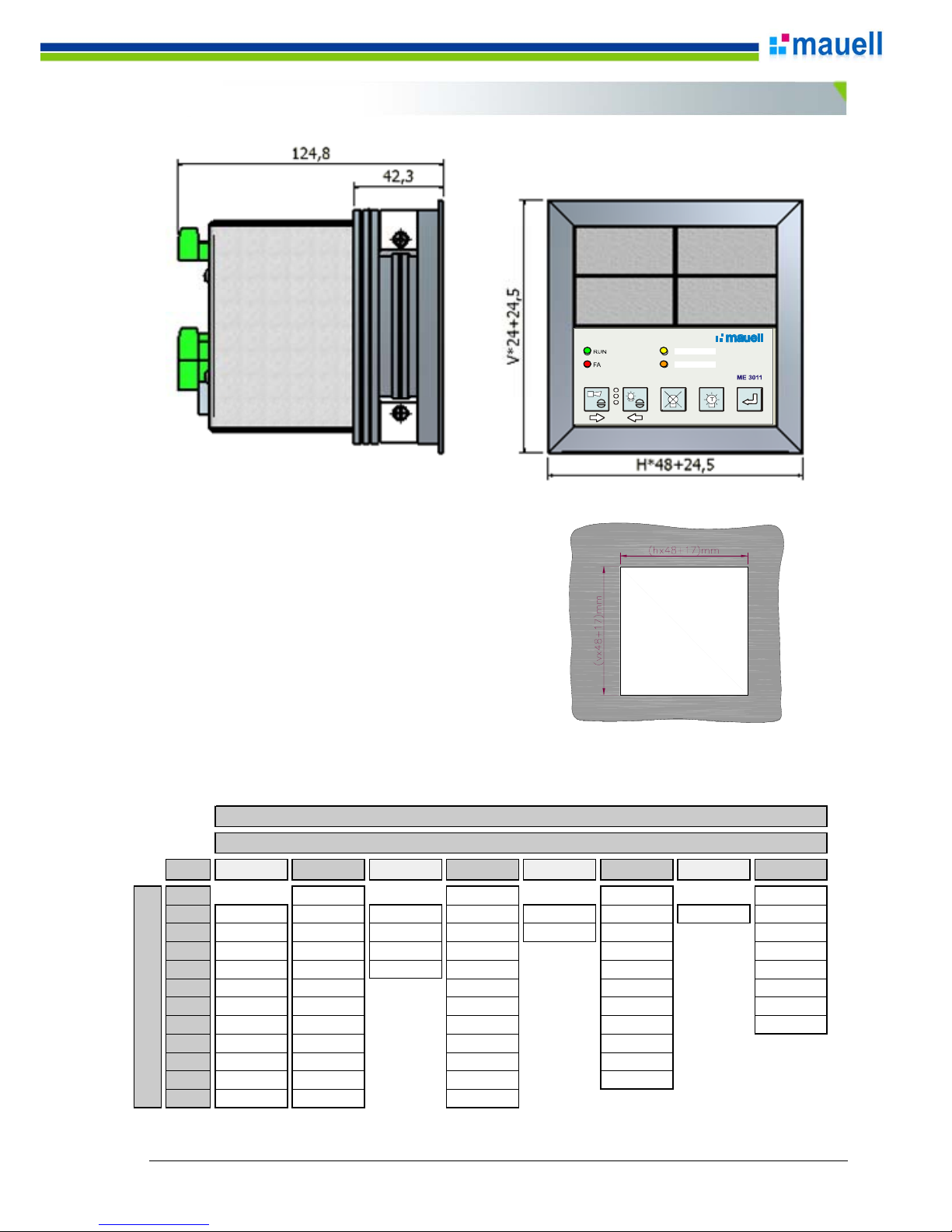

DIMENSIONS

Points

2

65 x 209 65 x 401 65 x 593 65 x 785

4

113 x 113 113 x 209 113 x 305 113 x 401 113 x 497 113 x 593 113 x 689 113 x 785

6

161 x 113 161 x 209 161 x 305 161 x 401 161 x 497 161 x 593 161 x 785

8

209 x 113 209 x 209 209 x 305 209 x 401 209 x 593 209 x 785

10

257 x 113 257 x 209 257 x 305 257 x 401 257 x 593 257 x 785

12

305 x 113 305 x 209 305 x 401 305 x 593 305 x 785

14

353 x 113 353 x 209 353 x 401 353 x 593 353 x 785

16

401 x 113 401 x 209 401 x 401 401 x 593 401 x 785

18

449 x 113 449 x 209 449 x 401 449 x 593

20

497 x 113 497 x 209 497 x 401 497 x 593

22

545 x 113 545 x 209 545 x 401 545 x 593

24

593 x 113 593 x 209 593 x 401

16

v

(y)

Cutout table [height (h) x widt h (v)] mm

h (x)

2468101214

Manual ME3011b_E_v0707_Pre.doc 11/50

Each ME 3011 is shipped with a certain amount of panel clamps according the annunciator’s size.

1 – Locate the panel clamps inside the packing box and prepare the mounting

2 – Insert the annunciator into the cutout

3 – Insert the panel clamps into the lateral orifice, selecting the sides that provides the best mounting

4 - Srew, pressing lightly onto panel front plate

PANEL MOUNTING

Panel clamp

Manual ME3011b_E_v0707_Pre.doc 12/50

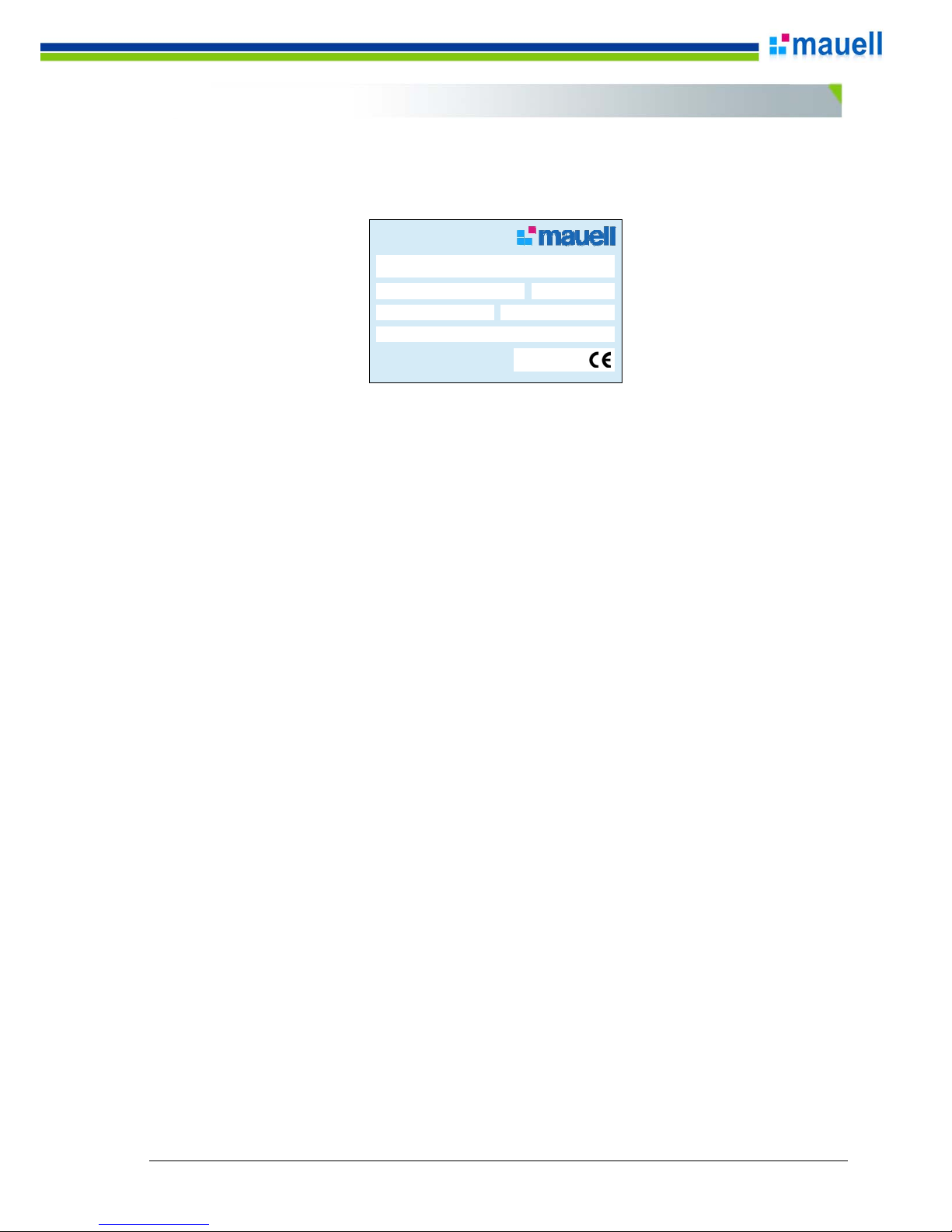

1 – Identification Label

1.1 Code

Product code with 15 digits

1.2 Serial#

Product serial number YY/9999, where YY is the year and 9999 is a sequential number

1.3 FW:

Identifies the firmware version from the annunciator

YYMMDD999 = year, month, day and firmware version

1.4 Power Supply:

Power supply voltages

Standard:

19-264Vdc/90-264Vac

With Power Supply Fault Detector (PSFD) are specified the requested voltages.

Example: Digit 7 = E, indicates this option and the voltages specified by the customer was 125Vdc and 220Vac:

125Vdc/220Vac

1.5 Field:

Indicates the field voltage of the annunciator

PRODUCT IDENTIFICATION

Indústria Brasileira / M ade in Brazil / Fabriqué au Brési l

www.mauell.com.br

Power Supply:

19-264 Vdc / 90-264 Vac

Helmut Mauell do Brasil

ME3011b

Alarm Annunciator

Field:

Serial #:

07/b1001

FW:

Code:

004424D11612000

70515300 24 Vdc

Manual ME3011b_E_v0707_Pre.doc 13/5

0

Go to the ME3011b Codification:

PRODUCT CODE

ME3011b - Code

012 28 FE 44 512 00 1

Code:

012 28 FE 44 51 2 00 1

Dígito >1234567891011121314

15

Enclosure

12

0

Power Supply

PSFD Vdc Vac

Light Indication

7

Y

2

G

1

B

1

W

1 TOT= 12

RS485 Protocol Engraving

Lines

Cable

PÇ P

Ç

Return to Manual

Set Quantity for each color!

11

Tropicalization

PC

R

B and W only for Back Light

Complementar Informations

ISA Sequence

2

ME3011b BL Alarm Annunciator - 12 Alarm Points - 2V x 8H:

Special Options

Only for more that one color

Interface

Set the PSFDs Voltages !!

ME3011b QTY =

Nr. of Points

1

Power Supply Fail Detector

SoftwaresQTY QTY

Power Supply 19-264 Vdc / 90-264 Vac - PSFD at Keyboard, BL 5 Colors, 110/125 Vdc Field Voltage with RRO,

RS232C (R) + RS485 + ER + GPS Sync, Modbus RTU (Slave) + ER, with Engraving and Special Options.

RRO (Repeater Relays)Field Voltage

w/ SO

= Nr. of Points

012

BL 5 Colors

19-264 Vdc / 90-264 Vac - PSFD at Keyb o ard

110/125 Vdc

110/125 Vdc

RS232C (R) + RS485 + ER + GPS Sync

Low reliefModbus RTU (Slave) + ER

w/ SO

no (Standard)

ISA 2C / (M) - Standard

012P - 2V x 8H

Cable CS-02 - RS232C - 5 m

e.Tool ME3011b -view

110 Vdc

220 Vac

Manual ME3011b_E_v0707_Pre.doc 14/50

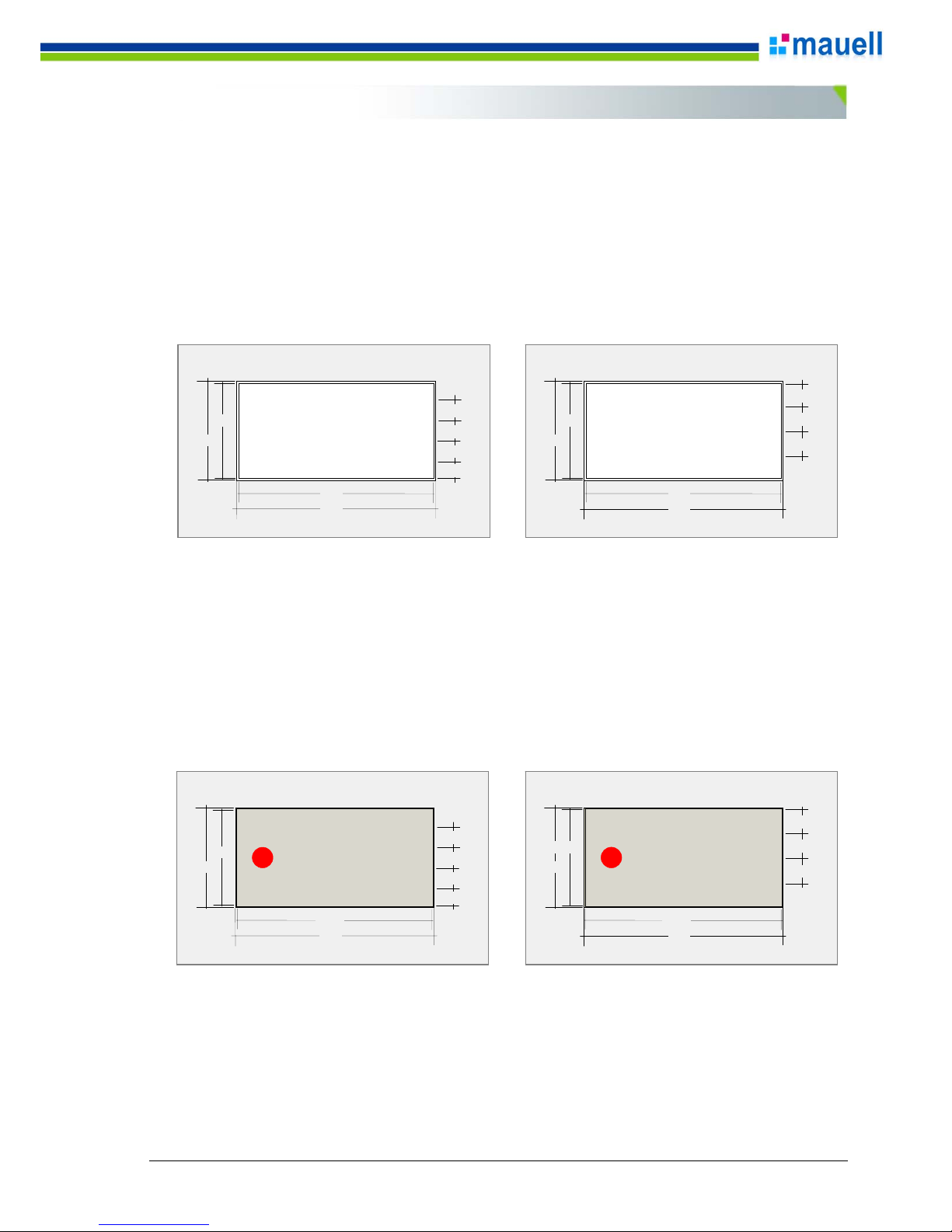

1 – Low Relief Engraving

1.1 – Back Light Display

LB 24 x 48 – White Translucent - Code: 83.53.002

Character height = 3 mm Maximum number of characters per line = 19 Maximum number of lines = 4

1.2 – LED Display

MK 24 x 48 - RAL 7032 color - Code: 83.52.003

Character height = 3 mm Maximum number of characters per line = 15 Maximum number of lines = 4

ABCDEFGHJKLMNOPRSTU

ABCDEFGHJKLM

ABCDEFGH

47

48

24

23

5,5

6

6

ABCDEFGHJKLMNOPRSTU

ABCDEFGHJKLM

ABCDEFGH

47

48

24

23

5

5

4

5

ABCDEFGHJKLMNOP

ABCDEFGH

ABCDEFGHJKLMNOP

47,5

48

24

23,5

6

6

6

ABCDEFGHJKLMNOP

ABCDEFGH

ABCDEFGHJKLMNOP

ABCDEFGH

47,5

48

24

5

5

4

5

23,5

FRONT DISPLAY INSCRIPTIONS

Manual ME3011b_E_v0707_Pre.doc 15/50

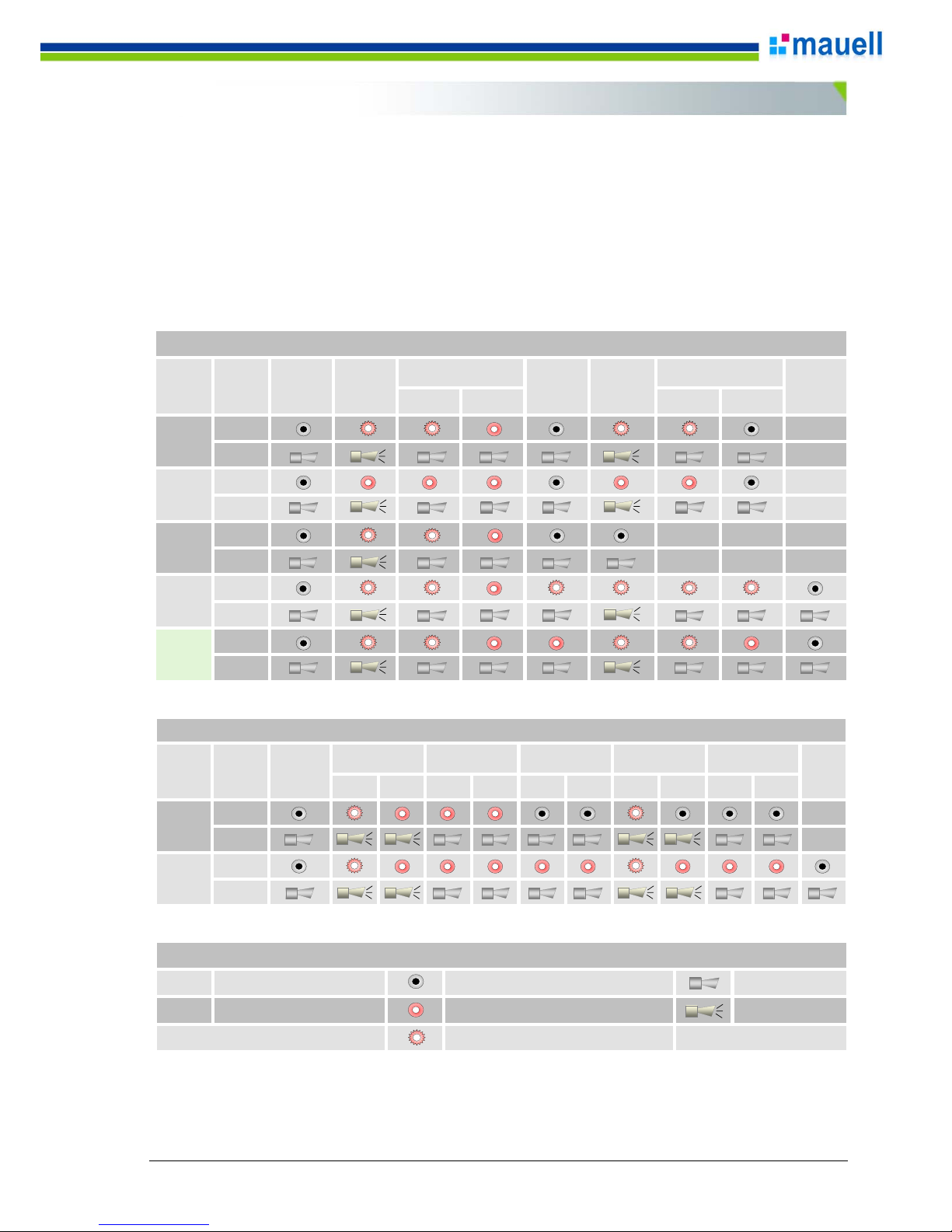

The ME 3011 can be configured in order to comply with 16 signaling sequence. Among them the most important are

the following:

ISA-RP 18.1/

(ISA-S18.1)

:

ISA1/

(A)

, ISA-1A/

(A-5)

, ISA-1B/

(A-4)

, ISA-2A/

(R-8)

, ISA-2C/

(M)

, ISA-4A/

(F1A)

, ISA-4AR/

(F1M)

etc.

Other sequences can be implemented on request.

SIGNALING SEQUENCES

F

S

Fast

Slow

Led off

Led on

Led intermittent

Buzzer off

Buzzer on

LEGEND

SOUND LIGHT SOUND LIGHT

Light

Sound

Light

Sound

Light

Sound

Light

F F S F F S

Sound

Light

Sound

ISA 2C

(M)

(default)

ALARM NORMAL

ISA 1

(A)

ISA 1A

(A-5)

ISA 1B

(A-4)

ISA 2A

(R-8)

REF ISA

ALARM SEQUENCE

ACKNOWLEDGE

RESETABNORMAL

ACKNOWLEDGE

BACK TO

NORMAL

BACK TO

NORMAL

BEFORE

ACKNOWL.

INITIAL SUBSEQ. INITIAL SUBSEQ. INITIAL SUBSEQ. INITIAL SUBSEQ. INITIAL SUBSEQ.

Light

Sound

Light

Sound

ISA 4R

(F1M)

REF ISA

ALARM NORMAL

ACKNOWLEDGE

RESET

PRIMARY ALARM SEQUENCE (1st. EVENT)

ISA 4A

(F1A)

ABNORMAL ACKNOWLEDGE BACK TO NORMAL

BACK TO NORMAL

BEFORE ACKNOWL.

Loading...

Loading...