Page 1

User’s Guide:

Fluidized Filling System

45490 Ruritan Circle

Sterling, Virginia 20164

703.964.0400

info@matsys.com

www.matsys.com

Page 2

Table of Contents

• Introduction 2

• Fluidized Fill Shoe 2

• Control Cabinet 3

• Fluidization Principle 4

• System Set-up and Installation 5

• Gas Supply 5

• Fluidizer Control 6

• Mounting the Shoe 7

• Connection to Control Cabinet 8

• Initial Set-up 8

• Check-out Procedure 9

• Operation 10

• Fluidizer Care 10

• Calibration Chart A 12

• Appendix A – Quick Reference 13

• Appendix B – Operation 14

• Electrical Wiring Diagram 16

1

Page 3

INTRODUCTION

The MATSYS Fluidized Fill Shoe System (FFS) is a powder delivery system

designed for consistent, fast and uniform filling of small die cavities. It can be used on a

wide variety of particulate materials. The FFS system includes a fluidized fill shoe and a

control cabinet. The fluidized fill shoe design incorporates two main components: a

transport tube and a delivery chute. Fluidization of the transport tube and delivery

chute is controlled separately using gas pressure control and individual adjustable flow

meters.

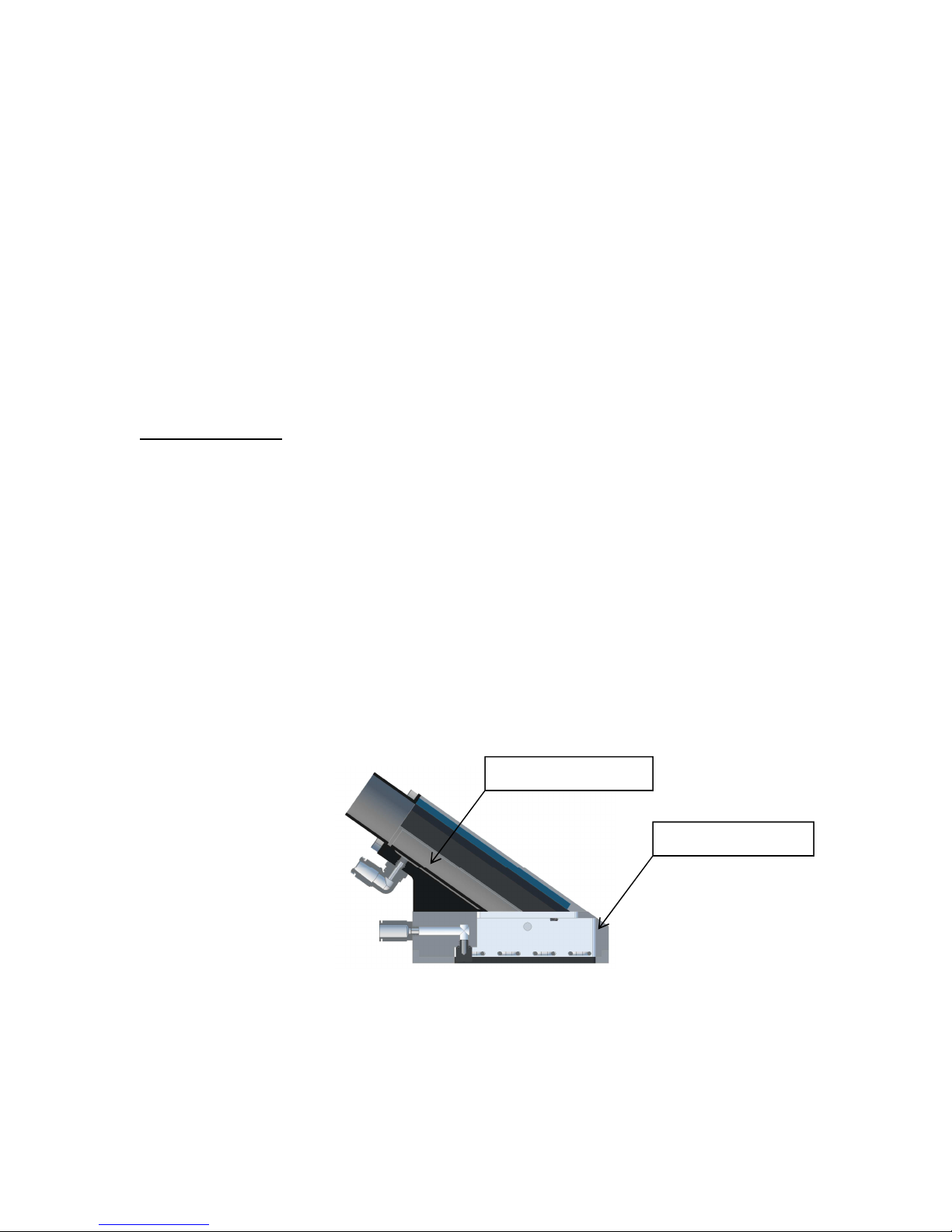

Fluidized Fill Shoe

The fluidized fill shoe design consists of two main components: a transport tube

and a delivery chute. These are independent gas chambers used to fluidize the

particulate material prior to delivery and fill of the die cavities. These chambers are

illustrated in Figure 1. Powder is supplied to the fluidized fill shoe by connecting a 2”

I.D. hose to the connection on the top of the fluidized fill shoe transport tube. The

fluidizing process begins in the transport tube and conveys the particulate material to

the delivery chute. When the particulate material reaches the delivery chute, two multi-

loop fluidizers, a top loop and a bottom loop, located inside the delivery chute keep the

particulate material in a fluidized or loose state until it reaches the die opening. These

two loop fluidizers inside the delivery chute are controlled independently.

Transport Tube

Delivery Chute

Figure 1. Illustration of the fluidized fill shoe components.

The following is a brief description of each of the fluidized fill shoe components:

2

Page 4

1. Transport tube. The transport tube provides the connection between the

particulate material supply hose and the delivery chute. It begins the process

of conditioning the particulate material to a fluidized or loose state and

conveys the particulate material to the delivery chute.

2. Delivery chute. The delivery chute functions as the powder discharge unit

directly above the die cavity. It has two multi-loop fluidizers, a top loop and

a bottom loop, to loosen and fluidize the particulate material before it

reaches the die opening.

Control Cabinet

The control cabinet houses the gas controls for the FFS system. These controls

regulate powder fluidization in relation to the movement of the fluidized fill shoe on the

press. An optional combination in-line moisture separator, filtration system and gas

dryer to remove moisture and solid contaminants from the gas supply. Three

independent pressure regulators (0-5 psi) and pneumatic solenoids are used to regulate

the flow of gas to each of the three FFS independent fluidizers, namely, the transport

and the two fluidizer loops inside the delivery chute. The solenoids are timed to control

fluidization of the powder when the fill shoe is over the die cavity. Three flow meters

(up to 30 SCFH) are used to independently monitor the gas flow to each of the three

fluidizers independently.

3

Page 5

FFS BASIC PRINCIPLE

Powder flows like a fluid when supported by a column of gas. The result is a

reduction in the effects of head pressure, clumping and surge, both of which are

common in gravity fed systems. The fluidized fill shoe creates a low pressure gas

bearing below the powder inside the shoe to reduce the friction along the powder path

to the fill point.

The FFS was developed to improve powder flow consistency, powder flow

uniformity, increase powder flow rates, and improve the speed of filling die cavities. By

flowing gas through a bed of solid particles from the bottom to the top, the bed is

loosened and fluidized, and particles are easier to move. The FFS uses a dry gas, such as

air, nitrogen, or argon to “coat” particles and separate them, thereby greatly reducing

inter-particle friction, improving powder flow consistency, and increasing powder flow

rates. The gas provides a transport mechanism reducing inter-particle friction and

thereby reducing the need for bulk lubricants in the powder blend.

4

Page 6

SYSTEM SETUP AND INSTALLATION

1. Gas Supply

The most optimal method of fluidizing is to use an inert gas such as Argon,

alternatively compressed air can be used when properly treated, dried and filtered.

When a compressed air source is used to supply air pressure to the fluidized fill shoe,

the gas control supply pressure should be between 30 and 60 psi. The FFS control

cabinet will provide instrument quality air to the fluidized fill shoe as long as care is

taken to maintain a quality air supply, i.e. air that is free of oil, dirt, and moisture. To

prevent moisture build up in the gas lines it is common practice to install an

appropriately sized after-cooler and moisture separator system on a shop air

compressor. As an extra precaution, it is recommended that a secondary liquid

separator and trap be installed ahead of the FFS control cabinet as shown in Figure 2.

During normal use, and especially during initial setup of a new system, the

quality of the air supply should be closely monitored for any oil, moisture, or solid

contamination.

For systems equipped with a desiccant dryer

The functionality of a desiccant gas dryer can be readily checked by observing

the dew-point indicator particles which are mixed into the desiccant located inside the

dryer:

♦ When the indicator particles color is blue, the dryer function is normal and it

is O.K. to operate the system.

♦ When the indicator particles color is pink, the outlet air is humid. It is time to

replace the desiccant before you operate the system.

For systems equipped with a membrane dryer (optional)

The desiccant dryer can be upgraded to a very low maintenance membrane

dryer. With a membrane dryer you can readily check outlet moisture condition by

observing the dew-point indicator which is located on the top of the membrane dryer:

♦ When the dew-point indicator is blue, the operation is normal.

♦ When the dew-point indicator is pink, the outlet air is humid.

Note: It takes approximately 1 hour to change the color of the dew-point

indicator from the start-up of supply air.

5

Page 7

Figure 2. It is recommended that the customer air supply line be plumbed as

shown with a vertical inlet pipe to separator, trap, and drain valve.

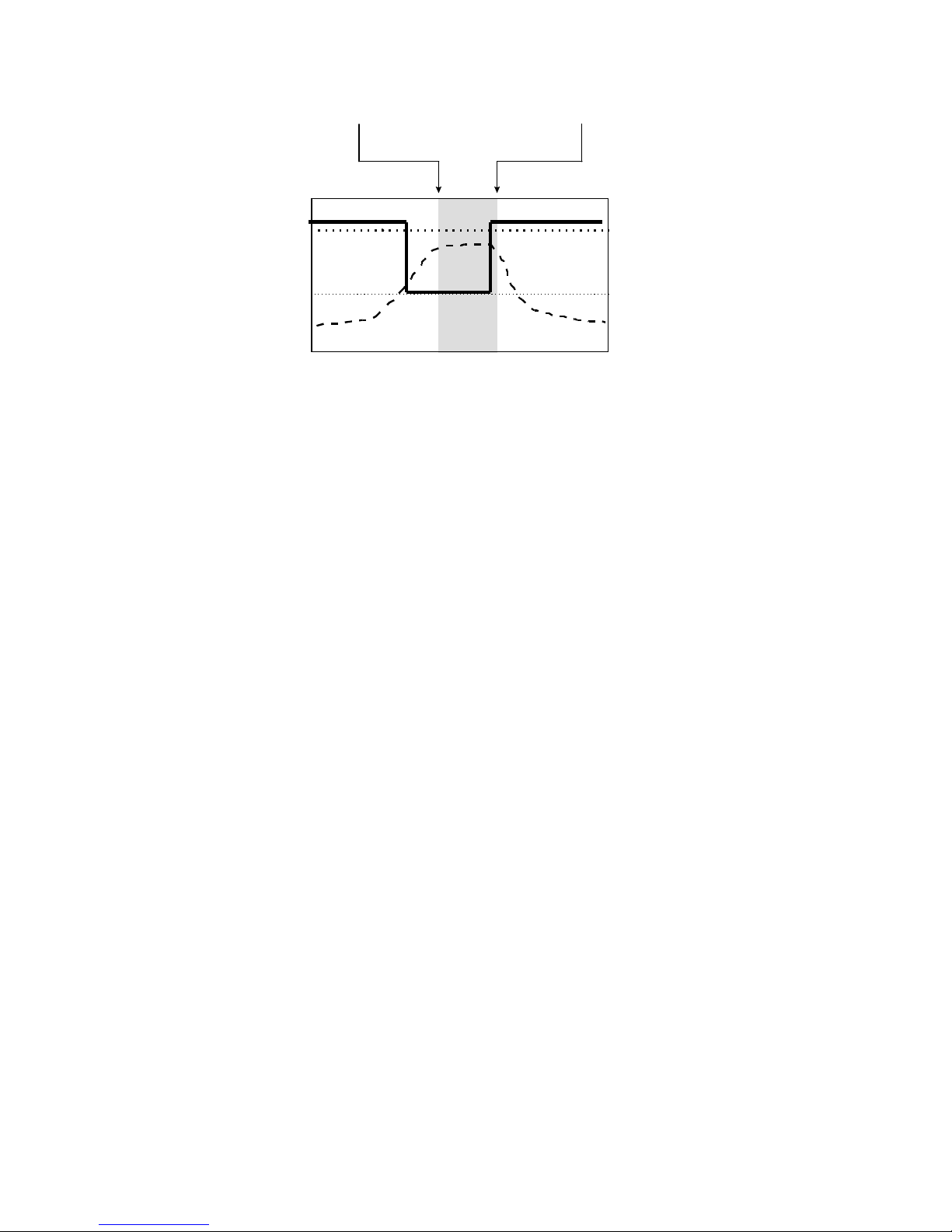

2. Fluidizer Control

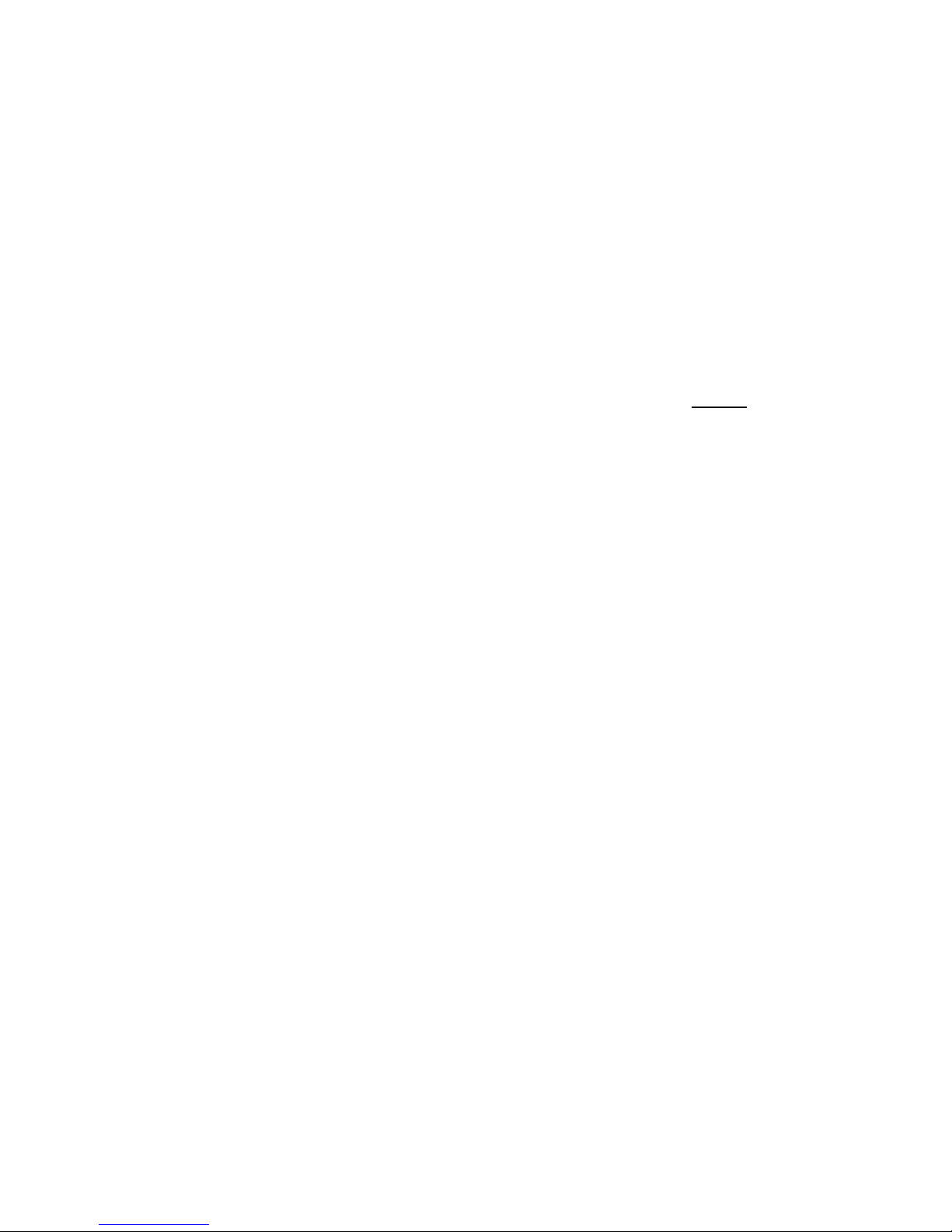

Fluidization ‘ON’ / ‘OFF’ control is used to optimize the filling process. To use

fluidization ‘ON’ / ‘OFF’ control you will need to connect a dry contact closure control

from your press to the remote control signal connection terminals fluidizer control box.

When the 24-volt DC control signal is present gas is supplied to the fluidizers. The

optimum timing used in most applications is called “continuous off.” This timing

configuration refers to the fluidization being off for the entire stroke except when the fill

shoe is extended toward the die cavity, as shown in Figure 3. In other words, the gas is

turned on just before the fill shoe is pushed forward and remains on during the dwell

time over the die cavity. The gas is then turned off just before the shoe is pulled back.

6

Page 8

fill shoe centered over die cavity

“dwell time”

OFF

ON

relative

degree

0

90

180

270

solenoid

fill shoe

movement rate

360

Figure 3. Typical fluidized fill shoe solenoid timing chart, “continuous off.”

3. Mounting the Shoe on the Press

Mounting the fluidized fill shoe on the press is a simple procedure. However, it

is important to strictly observe the following mounting requirements:

1. Center the delivery chute over the die cavity. Because the fluidized fill shoe

delivery chute is typically smaller than a conventional gravity fill shoe, the

accurate centering of the delivery chute over the die cavity is very important.

The alignment tolerance of side-to-side and front-to-back positioning of the

chute should be kept to within approximately +/- 1/16”. Alignment can be

performed by using a marking pen and square to draw the die centerline

crosshairs directly on the press table. These cross hairs can then be aligned

with scribe marks located on the front and sides of the delivery chute.

2. Check the action of the seal between the delivery chute and the die. Before

applying a hold down force to the fluidized fill shoe, check for clean wipe or

scrape of the powder during retraction.

3. Apply pressure to hold down the fluidized fill shoe. After centering the

delivery chute over the die cavity and inspecting the seal, apply down arm

pressure to the fluidized fill shoe. The down arm force should be minimized.

Use just enough downward force to maintain a good seal around the die

cavity during the dwell portion of the stroke. It is recommended at this time

to manually cycle the fill shoe in and out over the die cavity and observe the

action of the fill shoe. Note that hold down force is adjusted by rotating the

four ½” threaded spring plungers located on each corner of the filler.

While manually cycling the fill shoe watch for the following:

7

Page 9

The fluidized fill shoe should follow a reproducible path for

each stroke. This can be observed by sprinkling some excess

powder around the die opening and observing the powder

wipe trail during each stroke of the shoe. If there is excessive

lateral or axial play in the fluidized fill shoe retraction

mechanism, the shoe will wander as it moves in and out. This

will sometimes show up as a series of powder streaks left by

the seal on the delivery chute. The streaks typically show up

on each side of the delivery chute seal rather than a single

continuous line of excess powder. If there is too much play in

the fluidized fill shoe retraction mechanism use washers or

shims to remove this play before beginning a production run.

A loose fluidized fill shoe retraction mechanism can cause

large variations in part weight consistency.

4. Connecting the Fluidized Fill Shoe to the Control Panel

Two (or three, depending on the model) tubes are provided to connect the

fluidized fill shoe to the control cabinet. Each tube is 10 ft (3 m) long. The control

cabinet should be mounted vertically. The hoses connect to the fittings on the side of

the control cabinet to the fittings on the fluidized fill shoe.

5. Initial Setup

The following steps should be followed for initial setup of the FFS:

1. The control box must be mounted vertically so that the flow meters, gas

dryer and filter work properly.

2. Connect clean, DRY, oil free gas (30-60 psi) to the inlet on the box

3. Bolt or clamp the tubing strain relief connector block to a rigid point on the

press to avoid undue mechanical forces acting on the fluidized fill shoe from

the1/4” tubing during use. Connect the white or blue tubing to the delivery

chute and the green tubing to the transport tube.

8

Page 10

6. Checkout Procedure

If you are using the system for the first time you must complete the initial setup

outlined above before performing the following checkout procedure. You should also

perform this checkout procedure if the system has been out-of-service for an extended

period of time or if you suspect a performance problem.

This checkout procedure will verify proper operation of the gas control system as

well as the condition of the transport tube and delivery chute fluidizers.

1. With gas supply off, read pressure gauges and adjust reading to “0” as

necessary.

2. With gas supply on and no output tubing connected to the control box, set all

of the regulators to 1 psi and fully open all of the flow control valves.

3. Test correct operation of the solenoid valves by turning on the manual pilot

switch on the primary relay. This should turn on all of the solenoids and as a

result an increase in gas flow should be seen in the flowmeters. If included,

the lights in the solenoid electrical connectors as well as the blue indicator

light should also illuminate. With correct operation of the control box

confirmed, turn off the manual pilot switch on the primary relay.

4. Make sure that all tubing is connected properly (refer to Figure 2).

5. With no material in the fill shoe, adjust the gas pressure regulator to the

values shown in the “Fluidizer Gas Calibration Chart” supplied with your

system and read the gas flow values on each of the flow meters. Compare

readings with the values in the calibration chart.

6. Verify that you get approximately the same flow values as those printed in

the “Fluidizer Gas Calibration Chart”.

If you experience problems obtaining similar values to those given in the chart,

contact MATSYS before proceeding. Otherwise you are ready to operate the fluidized

fill shoe.

9

Page 11

7. Operation

For first time use you should adjust the gas pressure regulator and flow meters

as follows:

1. Connect powder hose from hopper to transport tube.

2. With particulate material in the fluidized fill shoe, set the gas pressure

regulator to a minimum of 0.25 psi.

3. Run press and check the fill quality.

4. Increase the gas pressure in 0.25 psi increments as needed to achieve the

flow rate you want. The lowest possible gas pressure which yield full fill is

normally the optimum operational set point.

5. Once you have set the pressure, no further adjustment is necessary. It is

recommended that you periodically perform the initial checkout to verify

that the system is functioning properly. Under continuous production

operation the initial checkout procedure should be performed on a weekly

basis.

Factors that can affect the flow set point are:

• Powder type – density, and general flow characteristics.

• Flow rate - production speed and fill volume.

• Punch, die geometry and number of die cavities.

8. Transport Tube and Delivery Chute Fluidizer Care

Care should be taken not to contaminate the fluidizer porous plates with foreign

matter that might cause flow restriction. Avoid contacting the porous plates with the

following material types: ultra fine particulate (particles smaller than the porous

fluidizer plate 0.5 micron rating), adhesives, gelatins, pastes or hardening resins, and

non-evaporative liquids.

If contamination of the fluidizer porous plates is suspected, you may be able to

clean the plate with isopropyl alcohol to revive it. To clean the porous plate, adjust the

gas pressure to approximately 3 psi with the flow meters fully open (counterclockwise).

This will allow the gas to flow through the porous plate while you swab the plate with an

alcohol soaked Q-tip.

10

Page 12

If cleaning the fluidizer porous plates in this manner does not remove the

contamination, the plate will need to be cleaned with an ultrasound cleaner. In this

case, you need to remove the fluidizer loop, and follow the basic process steps:

1. Presoak the fill shoe in 70 % isopropyl alcohol* for approximately 5 minutes.

2. With no gas flow, ultrasound for 5 minutes.

3. With 2-3 psi gas pressure, ultrasound for another 5 minutes.

4. (This step is required only when substituting # 222 cleaning solution or

similar for isopropyl alcohol, refer to note below). Post soak in 70 %

isopropyl alcohol* for approximately 5 minutes. This post soak should be at

room temperature for 2 minutes with no gas flow, and then with gas flow

pressure set at 2-3 psi.

5. Air dry at room temperature with 2-3 psi gas pressure for 1 hour.

6. Test the flow again referring to the flow calibration sheet and return the fill

shoe to service if flows are within 1 SCFH of the original values on the flow

calibration sheet.

* Important Note:

Isopropyl alcohol is considered a flammable liquid

To be safe avoid heat, sparks, and open flame. The typical rated

flashpoint for isopropyl alcohol is 72o F. Ultrasonic cleaners generate heat and

therefore must be appropriately cooled or purged when containing alcohol. A

recommended substitute for alcohol is L&R Manufacturing # 222 ultrasonic

cleaning solution. If # 222 or similar cleaner is used you must use Step

# 4

above after ultrasound to flush residual cleaner from the filler.

If cleaning the fluidizer porous plate in the described manner does not remove

the contamination, the plate may need to be repaired or replaced. In this case it is

recommended that the fill shoe be returned to MATSYS for service.

11

Page 13

Fluidizer Gas Calibration Chart A

Gas

Pressure

(psi)

Transport

Tube

(SCFH)

Delivery

Loop

(SCFH)

0.25

0.5

0.75

1.0

Gas Type: Air

Length of Tubing: 6 feet

Delivery Chute Type: PTFE Loop

Transport Rating: 5 micron

12

Page 14

APPENDIX A

QUICK REFERENCE

FOR

PROPER OPERATION OF THE FLUIDIZED FILL SHOE

Before connecting the hose from the hopper to the fill shoe (with no material in the

fill shoe)

1. Check desiccant:

• Desiccant dryer color should be blue. If color is pink replace desiccant.

2. Check tubing:

• White/Blue tubing is connected to the Delivery Chute.

• Green tubing is connected to the Transport Tube.

3. Check pressure gage:

• Gage should read “0” with supply air disconnected. If not “0” readjust prior to

connecting the air supply.

4. Check for leaks or clogs in Transport Tube and Delivery Chute:

• Set regulator to 1 psi and read flow rates.

• Flow rates should be within +/- 2 SCFH of those listed on the calibration chart.

Flow outside of the range of the flowmeter indicates a leak. Very low flow may

indicate a clog.

After connecting the hose from the hopper to the fill shoe (with material in the fill

shoe)

1. Set pressure:

• Set pressure to 1 psi (or known optimum pressure for the part and material).

2. Start press.

During Press Downtime, Maintenance, Service, Lunch Break, etc. (with material in the

Fill Shoe)

Always turn off the airflow supply to the Transport Tube and Delivery Chute.

13

Page 15

APPENDIX B

FFS OPERATION

Once the fluidized fill shoe is mounted on the press and proper operation is

verified, it is important to periodically check the fluidized fill shoe performance during

extended production runs. The following chart summarizes the fluidized fill shoe

operational readiness checks along with the recommended time periods between

checks.

CHECK

GAS SUPPLY

GAS SUPPLY

FLUIDIZER CONTROL

FLUIDIZER GAS

PRESSURE

DETAIL

MOISTURE - If a gas dryer is used,

inspect desiccant site gauge for

moisture contamination:

blue = GOOD

pink = REPLACE

CONTAMINATION - Sub-micron

porous plate should be monitored

for excess pressure drop.

TIMING - Check that the

“ON”/”OFF” timing of the fluidizer

solenoid valves is correctly set by

observing solenoid indicator lights

and gas flow meters in

relationship to the fill shoe

position over the die.

SET POINT – The fluidizer gas

pressure settings should be

checked to verify that they are at

the correct values (about 1.25 psi

average).

WHEN

Before / after each

run

Before / after each

run

Before each run

Before each run

14

Page 16

FLUIDIZER GAS FLOW

WEAR PLATE

SHOE ALIGNMENT

SHOE TRACKING

SET POINT – The fluidizer gas flow

settings should be checked to

verify that they are at the correct

values. See factory calibration

values below.

The wear plate around the chute

opening should lay flat along the

press table with no gaps.

Be sure that the chute opening is

centered over the die cavity at the

peak of the press fill stroke.

Scribe lines on the front and both

sides of the shoe can be used to

locate left to right center and

front to back center.

Be sure the shoe is tracking

perpendicular to the front edge of

the press table as it moves in and

out.

Before each run

Before each run

Before each run

Before each run

15

Page 17

16

Loading...

Loading...