Page 1

JET LOADER

JL4-V・VC-3~6 MODELS

(U version)

OPERATION MANUAL

Thank you for choosing our product.

Before operating this equipment, please read this manual thoroughly.

Keep this manual in a location near the equipment so that it may be readily

referred to whenever a question arises during equipment operation.

WARNING

Issued March 2005

Page 2

Introduction

Thank you for purchasing of our JL4 JET LOADER. Please read this manual carefully for proper and

safe operation. This instruction manual contains warranty information. Please carefully store this

manual after you have read it.

1. Warranty Period

If any defect is found in our equipment under normal operating conditions, and we determine it to be a

defective, we will repair it or replace the parts free of charge within the following period and terms:

1) This warranty shall remain valid for twelve (12) months fro m the date when the new product s you

purchased leave our fa cility.

2. Scope

This warranty shall be limited to repair of our equipment or replacement of its parts, and shall not

cover any products manufactured by means of our equipment or defects in manufacturing such

products.

3. Exceptions

This warranty shall not apply to the following defects:

1) Defects caused by modifications or repairs made by any party other than our company;

2) Defects resulting from natural disasters such as earthquakes, hurricanes, typhoons and floods,

accidents and fires;

3) Defects resulting from use exceeding limitations in the specifications set forth in the instruction

manuals or catalogs;

4) Defects resulting from non-performance of maintenance and inspection by not observing manual

instructions.

5) Defects in the equipment caused by outside factors such as peeling of coating caused by generated

gas and malfunction due to electrical noise;

6) Defects resulting from non use of genuine parts (oil, medium, filters, etc.)

7) Consumables (hoses, filters, gaskets, O-rings, etc.).

4. After the warranty period expires

We will make repairs for a charge, if the performance of our equipment can be maintained by such

repairs.

5. Period during which parts can be supplied

As an approximate standard, service parts for our equipment can be supplied for eight (8) years after

the equipment is discontinued. However, some parts may be supplied even after the period elapses. So,

please make an inquiry at our service department about the availability of service parts.

[WO-4841;JL4-V・VC-3~6]

Page 3

Contents

The following marked chapters are very

important. Please read them in advance and pay

attention to them.

Introduction

Contents ································································································································· I - II

Chapter 1 Configuration of Equipment

1. Product model ·················································································· 1

2.

Flow diagrams ·················································································· 2

3.

Packing list ······················································································· 4

Chapter 2 For Safe Operation

1. Label and meaning of each indication ············································· 7

2. Items to be observed for safety ······················································· 8

3. Labels ····························································································· 9

Chapter 3 Installation

1. Mounting the collection hopper························································· 10

2. Installation ························································································ 14

3. Connecting the power······································································· 17

Chapter 4 Preparations for Operation

1. Checking the status of each component··········································· 19

2. Control panel description ·································································· 21

Chapter 5

Operating Procedures

1. Starting procedure ··········································································· 22

2. Stopping procedure ·········································································· 23

3. Cleaning procedure ·········································································· 24

[WO-4841;JL4-V・VC-3~6-Ⅰ]

- Ⅰ -

Page 4

Chapter 6 Operational Descriptions and Timing Charts

1. Jet Clone types- limit or level switch control collection hopper ······· 25

2. Vacuum hopper types, E2K control collection hopper ····················· 27

3. Jet Clone types- cylinder control or suction hopper type ASD control

collection hopper ············································································· 29

Chapter 7 Respective Parameter Setup

1. Setting guide ··················································································· 31

2. Setting procedures ··········································································· 36

Chapter 8 Inspection and Maintenance

1. Daily inspection ················································································ 38

2. Monthly inspection············································································ 41

3. Component adjustment procedure ··················································· 44

Contents

4. Operation check procedure of 3-6 way selector valve ······················47

5. Operation check procedure of automatic slide gate ························ 48

Chapter 9 Troubleshooting ························································ 49

Chapter 10 List of Consumables······················································ 59

Chapter 11 Specifications········································································60

Chapter 12 Options ························································································ 61

[WO-4841;JL4-V・VC-3~6-Ⅱ]

- Ⅱ -

Page 5

Chapter 1 Configuration of Equipment

The following marked chapters are very

important. Please read them in advance and pay

attention to them.

1. Product model

1) Collection Hopper and Control Procedure

Collection Hopper Control Procedure

Jet Clone

Vacuum hopper

2) Loader Unit

3) Flow Diagrams

Limit control

Level switch control

Cylinder control

E2K control

ASD control

Model

JL4-4V-3~6

JL4-5V-3~6

JL4-6V-3~6

JL4-4VC-3~6

JL4-5VC-3~6

JL4-6VC-3~6

[WO-4841;JL4-V・VC-3~6-1]

Flow Diagrams No.

Flow diagram type1

Flow diagram type2

Flow diagram type3

Flow diagram type4

Flow diagram type5

Flow diagram type6

Flow diagram type7

Flow diagram type8

Flow diagram type9

Flow diagram type10

- 1 -

Page 6

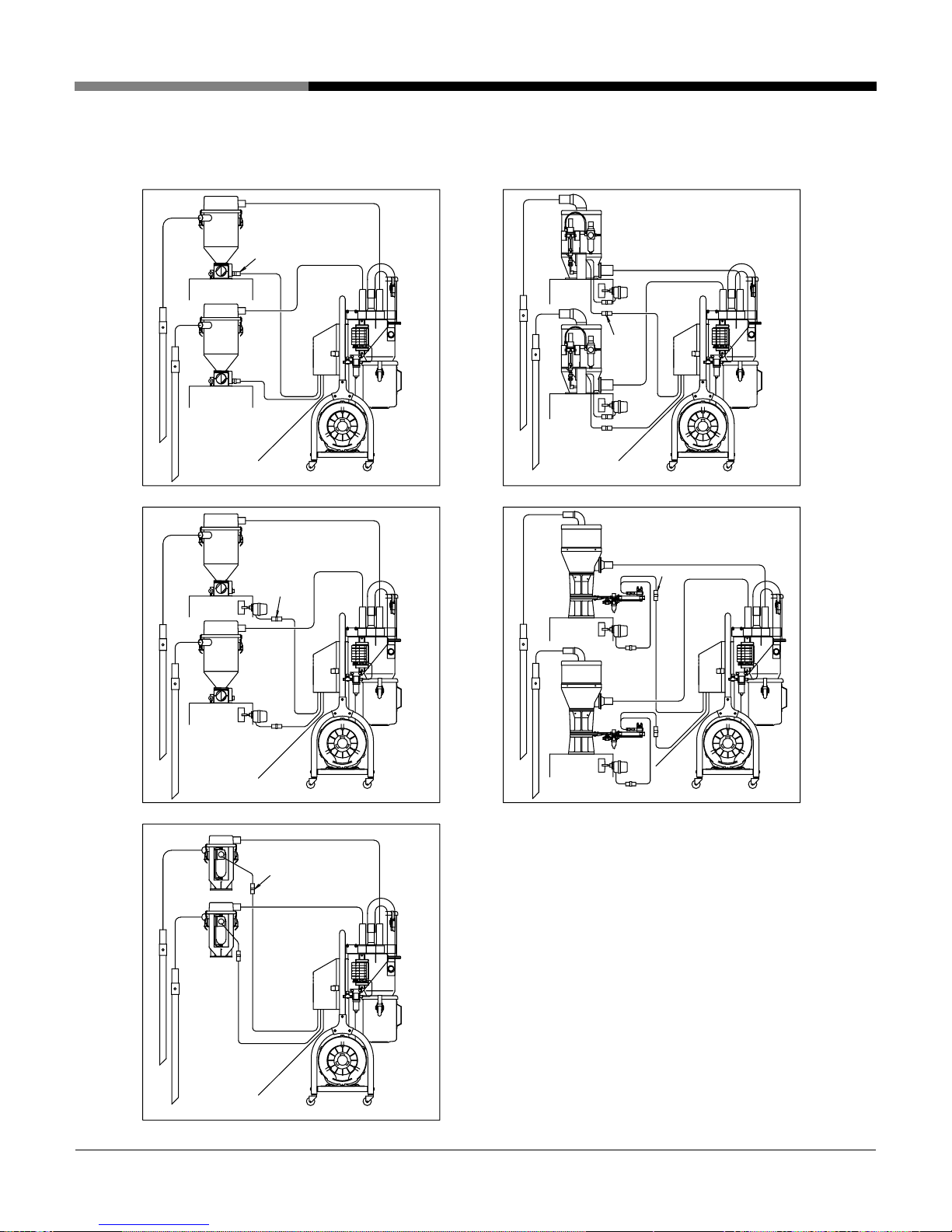

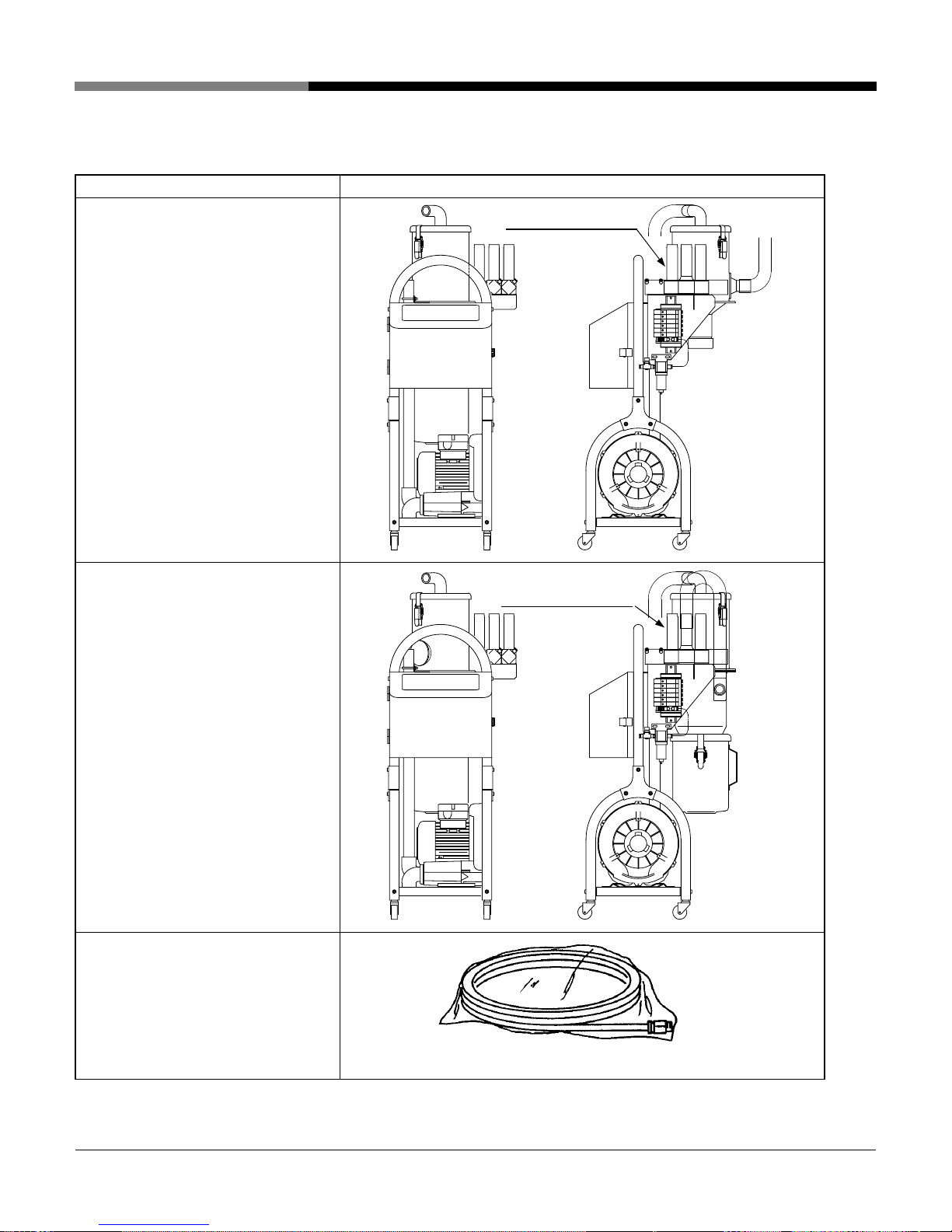

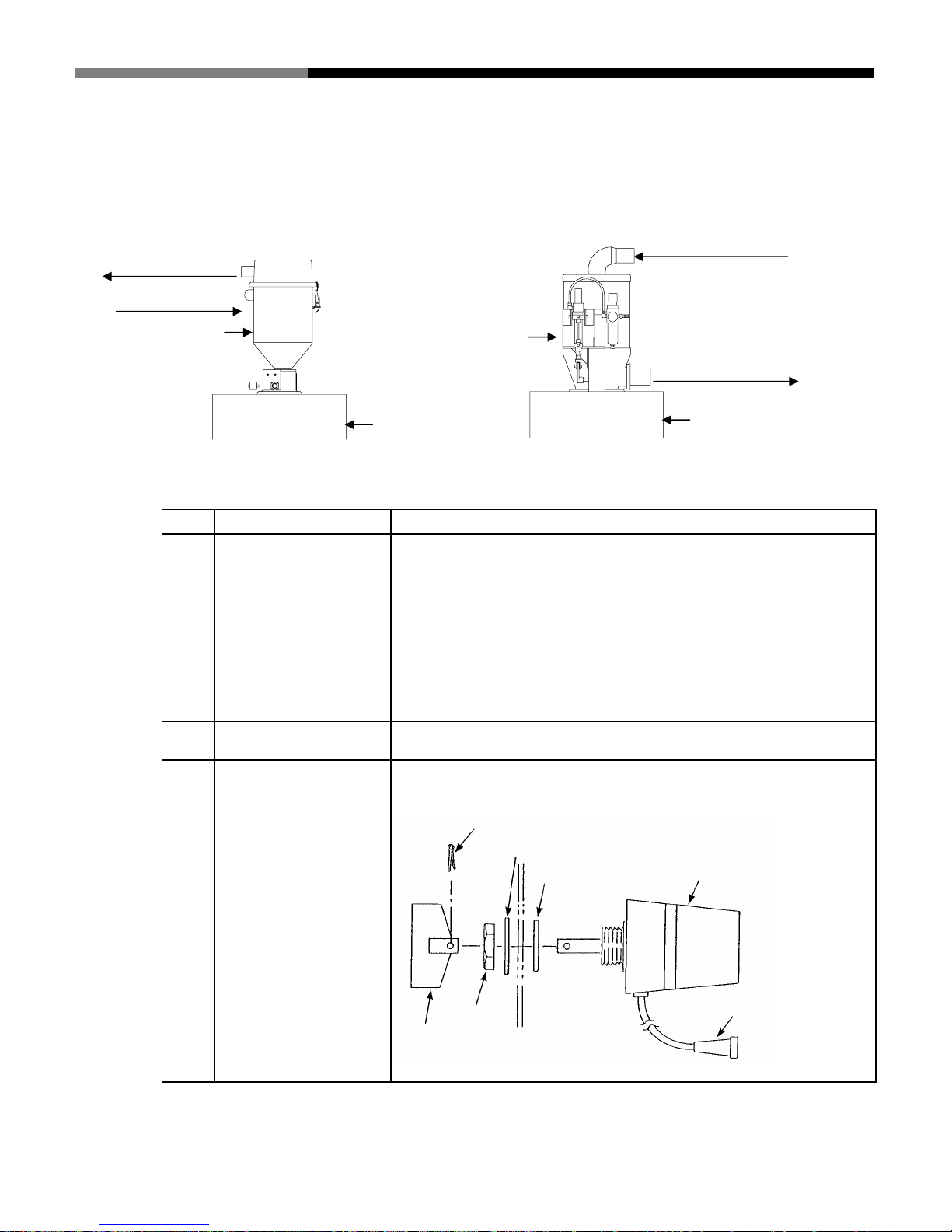

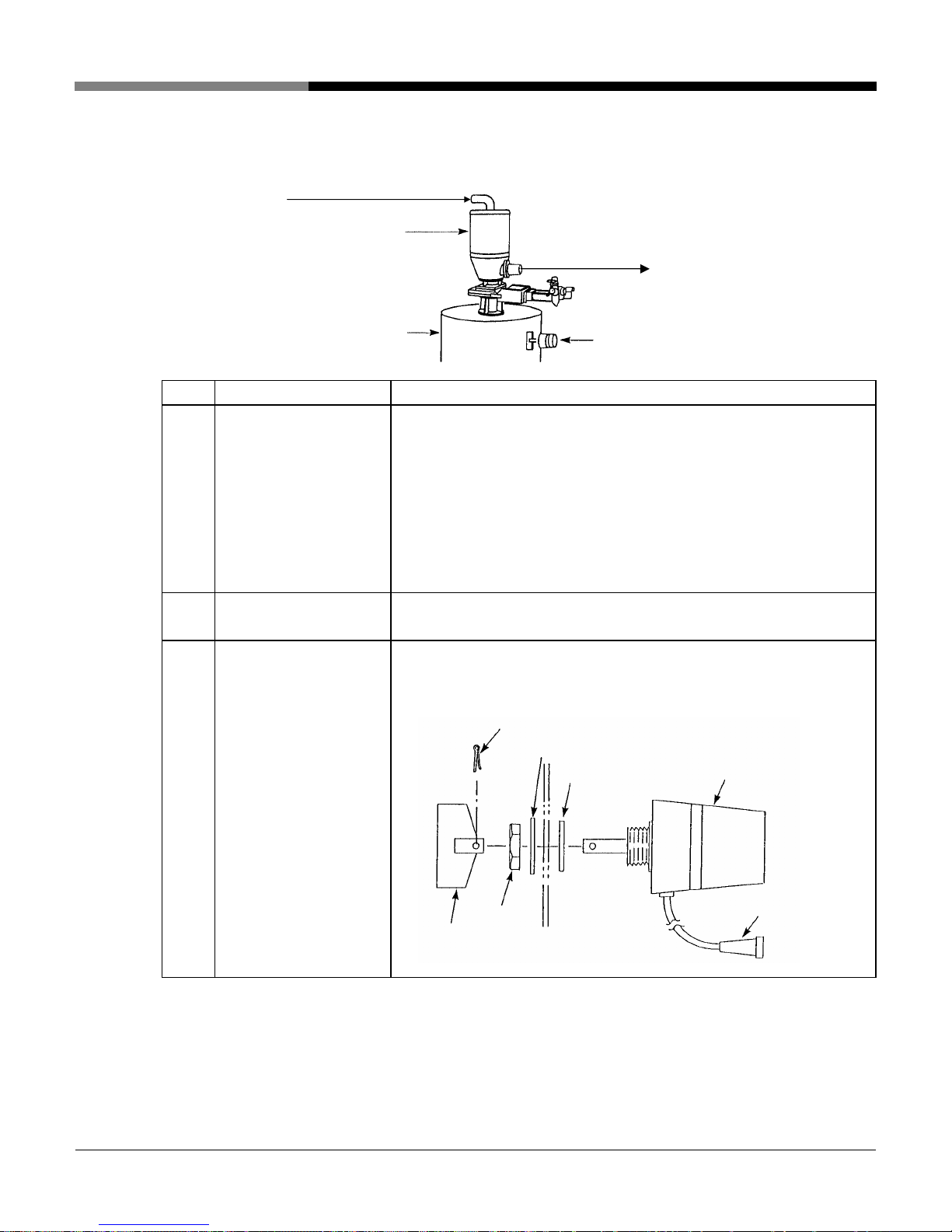

2. Flow diagrams (V type)

Flow diagram type 1

Suction hose

GL-1V Hose

Jet Clone type

limit control

Connector

PVC hose

Conveying hose

Signal cord

d

r

o

c

Suction nozzle

r

e

w

o

P

Suction unit

Flow diagram type 2

Jet Clone type

limit control

Chapter 1 Configuration of Equipment

2-way valves are shown in the following diagrams, however, in actuality,

3-6-directional valves can additionally be installed.

Flow diagram type 4

Jet Clone type

cylinder control

Connector

Suction unit

Flow diagram type 5

Suction hopper type

SD control

Connector

Suction unit

Flow diagram type 3

Suction hoppertype

E2K control

Connector

Connector

Suction unit

Suction unit

[WO-4841;JL4-V・VC-3~6-2]

- 2 -

Page 7

Flow diagrams (VC type)

Flow diagram type 6

GL-1V Hose

Jet Clone type

limit control

Connector

PVC hose

Conveying hose

Signal cord

d

Suction nozzle

Flow diagram type 7

r

o

c

r

e

w

o

P

Chapter 1 Configuration of Equipment

2-way valves are shown in the following diagrams, however, in actuality,

the valve is additionally installed in 3 to 6 directions, similarly.

Flow diagram type 9

Jet Clone type

cylinder control

Connector

Suction unit

Flow diagram type 10

Jet Clone type

limit control

Connector

Power cord

Flow diagram type 8

Suction unit

E2K control

Connector

Suction hopper type

SD control

Connector

Suction unit

Suction unit

[WO-4841;JL4-V・VC-3~6-3]

- 3 -

Page 8

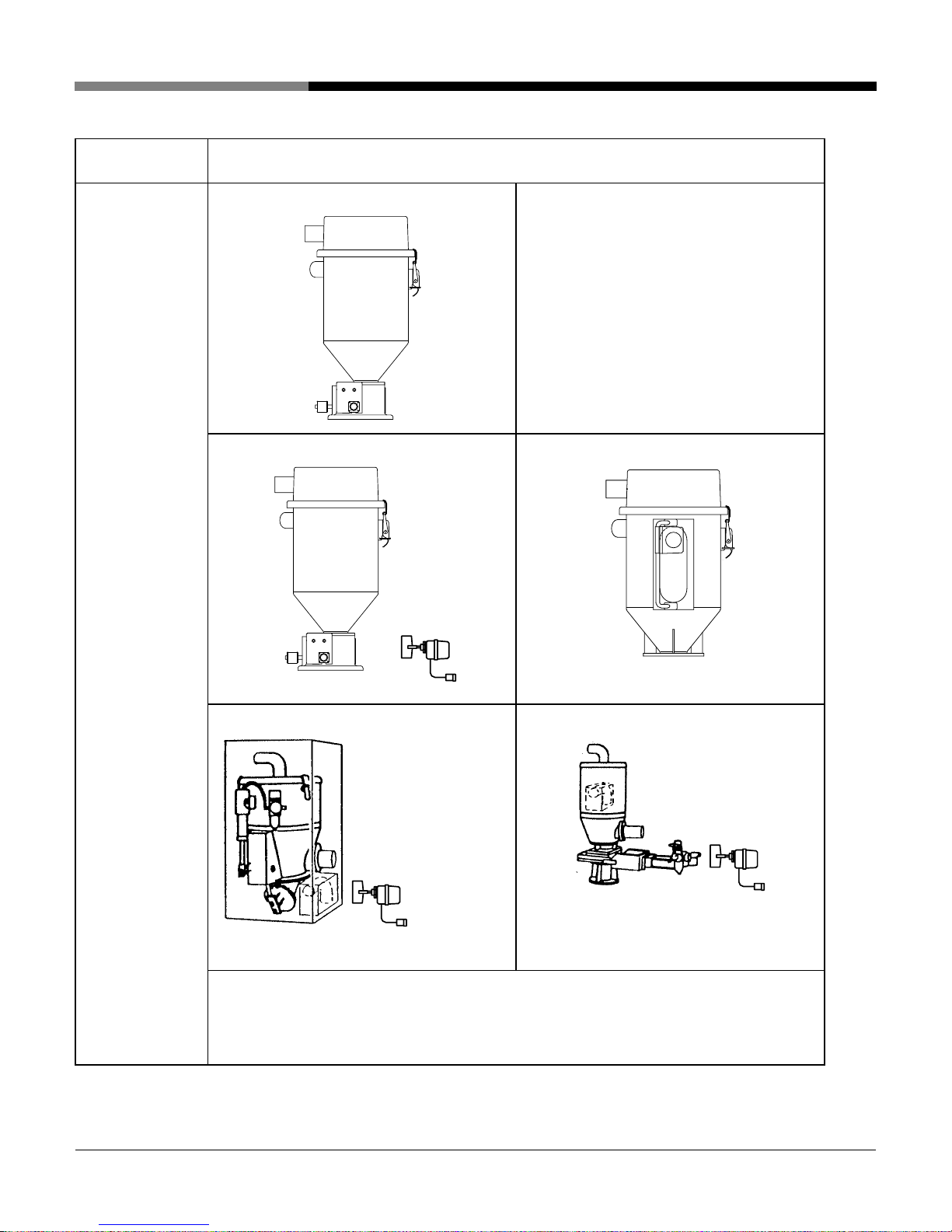

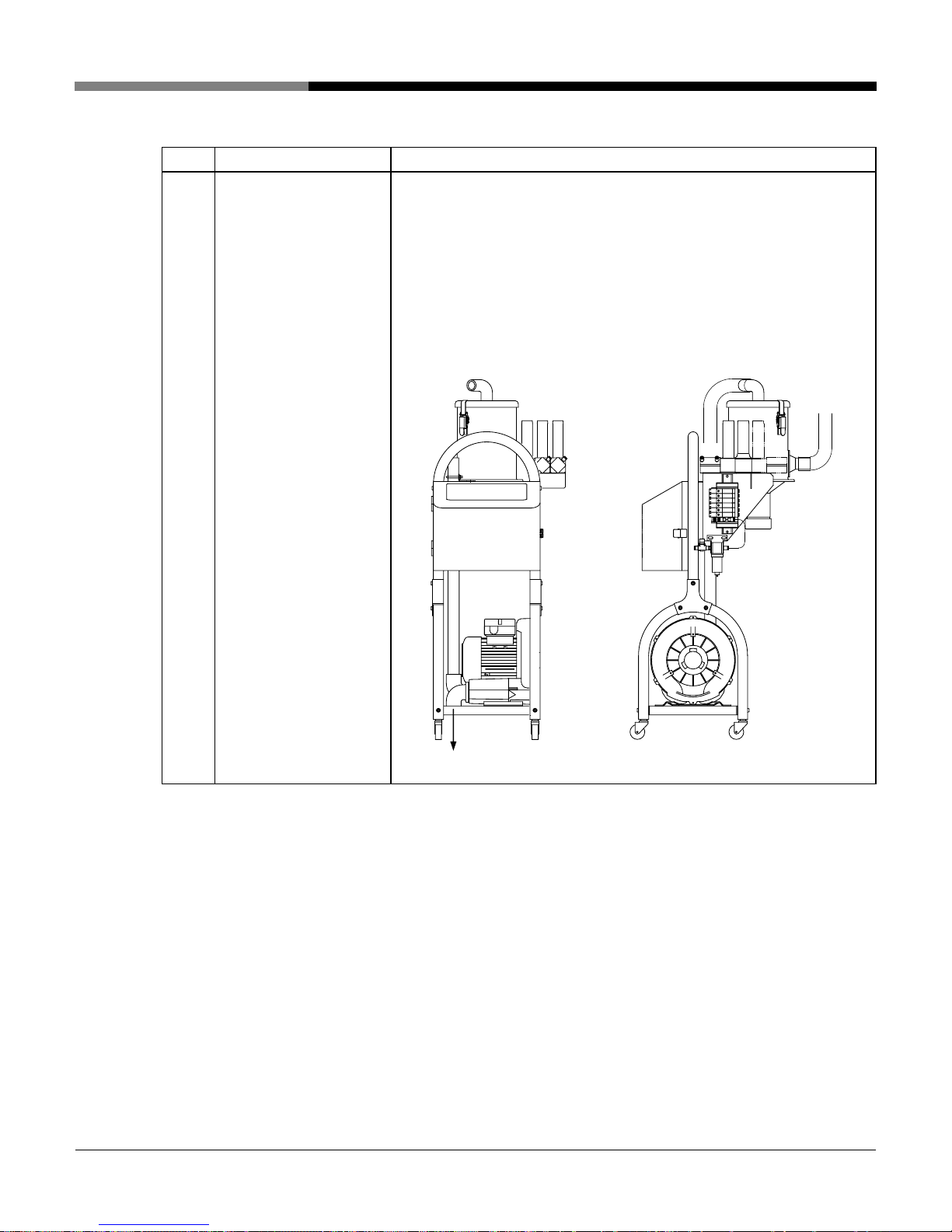

3. Packing list

Please confirm that all purchased devices are included.

Component Name Style of Packing

●Vacuum unit

JL4-(4,5,6)V-3~6 type

Chapter 1 Configuration of Equipment

3~6 way selector valve

●Vacuum unit

JL4-(4,5,6)VC-3~6 type

●Nylon hose

Aperture φ6, Length 5m

(Standard)

With one touch joint (1 pc.)

※1/4B equivalent product should be

used for coupler connection.

3~6 way selector valve

* The hose is contained in shrink wrap.

[WO-4841;JL4-V・VC-3~6-4]

- 4 -

Page 9

Component

Name

Collection hopper

● Jet Clone type limit control

● Jet Clone type level switch control

Style of Packing

●

Chapter 1 Configuration of Equipment

Suction hopper type E2K control

*

● Jet Clone type cylinder control

This unit is supplied with an injection

molding machine match base or chute.

● Suction hopper type ASD control

This unit is contained in a corrugated

*

cardboard case.

<NOTES> The elbow is contained for the Jet Clone type cylinder control and Vacuum

hopper type ASD control. The conditions are as follows.

1. For collection hoppers with an SUS lid, the elbow is attached to the lid.

2. For collection hoppers with an aluminum lid, the elbow is contained in

the corrugated cardboard case or the hopper in the collection hopper.

[WO-4841;JL4-V・VC-3~6-5]

- 5 -

Page 10

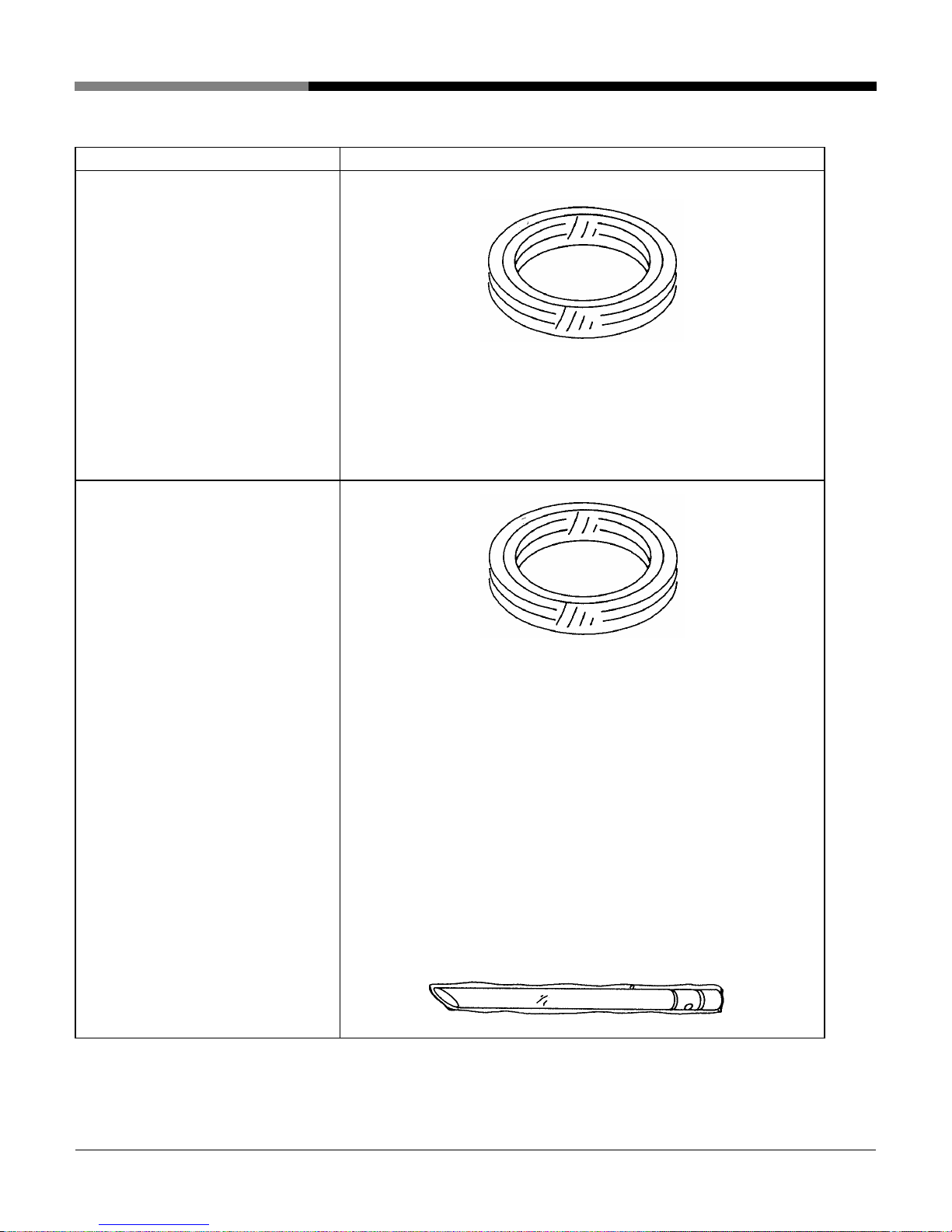

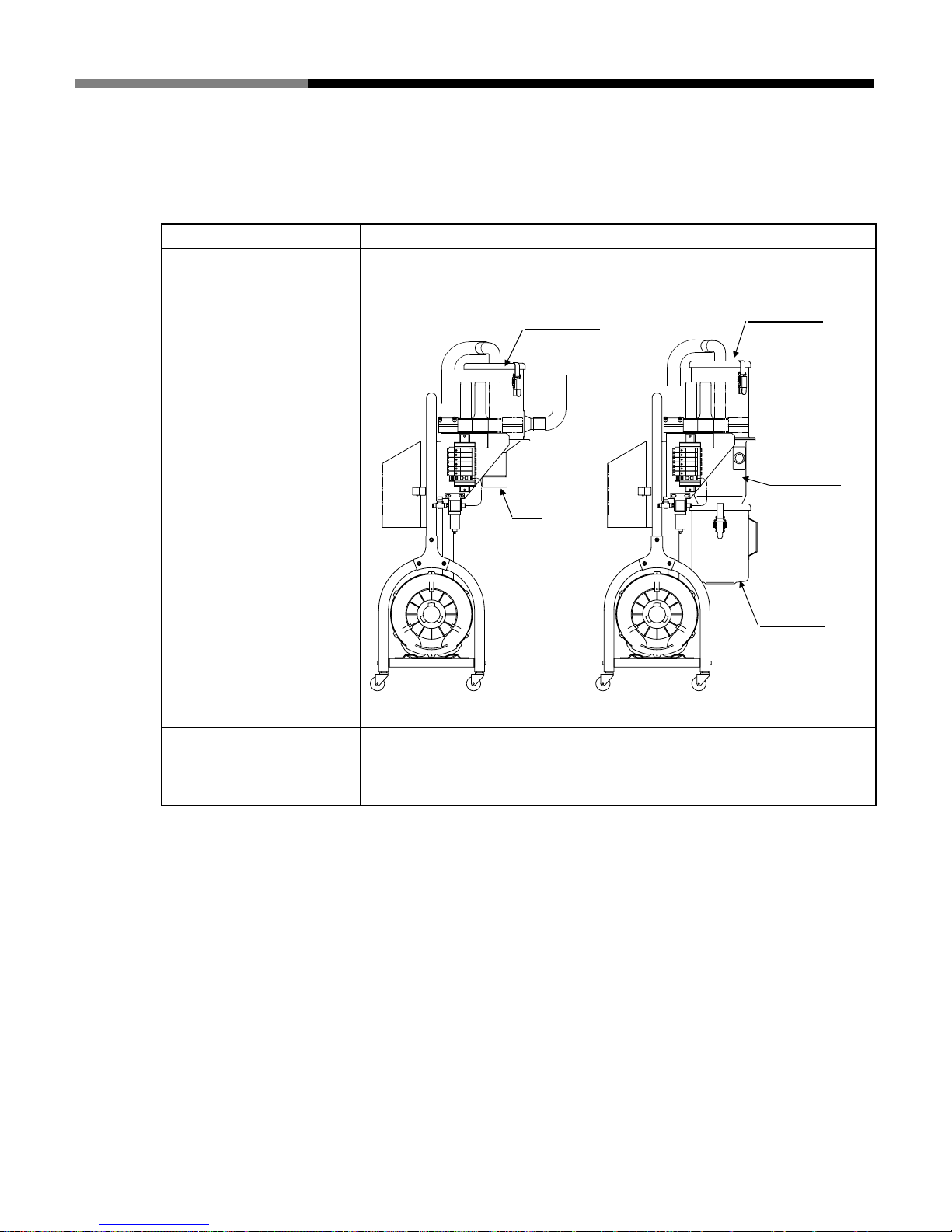

JL4-4V(VC)

JL4-5V(VC)

● Conveying hose (φ38 PVC hose)

JL4-4V(VC): Length 15 ft.

JL4-5V(VC): Length 15 ft.

● Vacuum hose (φ38 GTG hose)

Length 15 ft.

● Hose band (One set is 4 pcs.)

● Suction nozzle (φ38)

JL4-6V(VC)

Chapter 1 Configuration of Equipment

Style of Packing

Material & Vacuum hoses are wound with shrink wrap.

● Material hose (φ50 PVC hose)

Length 15 ft.

● Vacuum hose (φ65 GTG hose)

Length 15 ft.

(One set including 2 pcs.)

● Hose band (One set including 4

pcs.)

● Suction nozzle (φ50)

Material & Vacuum hoses are wound with shrink wrap.

*

The suction nozzle is wrapped in shrink wrap.

[WO-4841;JL4-V・VC-3~6-6]

- 6 -

Page 11

Chapter 2 For Safe Operation

This chapter contains instructions for operation, maintenance, and repair to operate

this equipment properly and safely. Also, this chapter explains the labels and

meaning of each indication on the product.

Indications for safety described in this manual should be observed when

operating or inspecting this product.

We shall not be responsible for any injury or accidents caused by failure to

observe these indications and we make no warranty against such injury or

accidents.

WARNING

1. Label and meaning of each indication

This instruction manual uses different indications depending on the extent of

danger as follows:

Label Meaning

WARNING

DANGER

This indication is used when failure to observe this may cause

user death. Instructions with this indication explain how to

prevent it.

This indication is used when failure to observe this may cause

users to be seriously injured. Instructions with this indication

explain how to prevent the injury.

CAUTION

NOTE

*

[WO-4841;JL4-V・VC-3~6-7]

This indication is used when failure to observe this may cause

users to be injured slightly or products to be damaged.

Instructions with this indication explain how to prevent them.

This indication is used when special care must be taken in

operation procedure or descriptions, and when the information

should be emphasized.

This mark is used when special care must be taken in handling.

This mark is used when exceptional conditions or cautions are

described in Tables and Figures.

- 7 -

Page 12

2. Items to be observed for safety

To operate this product safely, general instructions which should be

observed are described below.

Chapter 2 For Safe Operation

WARNING

1) Using environment

・ This equipment should be used indoors only.

・ This equipment should be used at ambient temperatures from 32°F / 0°C

to 104°F / 40°C and an ambient humidity of 25-85%.

2) Knowledge of electricity

Inspection or replacement by persons without sufficient knowledge of

electricity may cause defects or danger. Therefore, inspection and

replacement should be performed by a person at your company who has

sufficient knowledge about electricity.

3) Prohibition against operation in gases

Do not operate this equipment in flammable or explosive gases or vapors.

Operating this equipment in such an environment is very dangerous.

4) Prohibition against Modifications

This equipment must not be modified or altered by users without

obtaining our approval. We shall not be responsible for any accidents

caused by modifications or alterations.

5) Inspection

6) Maintenance

Before maintenance and inspection, be sure to stop operation and turn

“OFF” the power of the primary power supply of your equipment and

power switch of the control panel.

Also stop the compressed air fed to the air kit, press the drain valve of the

filter regulator to release residual pressure in air pipe.

Inspection and replacement of parts must be performed by persons who

have sufficient knowledge about this product. Inspection and replacement

by persons without sufficient knowledge about the product may cause

defects or danger.

When maintenance or repair advice is necessary, contact the Matsui

service department, or your local sales representative.

[WO-4841;JL4-V・VC-3~6-8]

- 8 -

Page 13

Chapter 2 For Safe Operation

1) Disposal of the product and parts

This product and parts are handled as industrial waste and are regulated

by the “Waste Disposal and Public Cleaning Law.” Request subcontractors

who have received an “industrial waste collecting and transporting

permit” or “industrial waste disposal permit” to dispose of products and

parts. For details, contact your local or state environmental development

office.

2) Power supply

This equipment should be operated with a line voltage and frequency

conforming to local or state specifications.

* Be sure to connect the ground wire (to earth).

3) Use of the equipment

This product is a conveying unit for resin pellets. This is not suitable for

other materials, and conveying materials other than resin pellets may

cause defects.

We make no warranty against any problems caused by using materials

other than resin pellets.

CAUTION

3. Labels

1) Handling of label

1) Wiping

Labels are pasted where special care must be taken to prevent danger.

Warnings or cautions must be thoroughly understood before starting an

operation.

● Keep the labels legible until scrapping the equipment.

● When a label becomes dirty, wipe it with a soft cloth soaked in warm

water and well wrung out.

NOTE

Do not wipe the equipment using petroleum solvents. Cleaning with

benzene, thinner, and polishing powder will scratch the surface.

When equipment is blemished badly, wipe it with a soft cloth soaked in

warm water.

[WO-4841;JL4-V・VC-3~6-9]

- 9 -

Page 14

Chapter 3 Installation

This Chapter describes installation work of the product for each piece of

equipment according to the procedure.

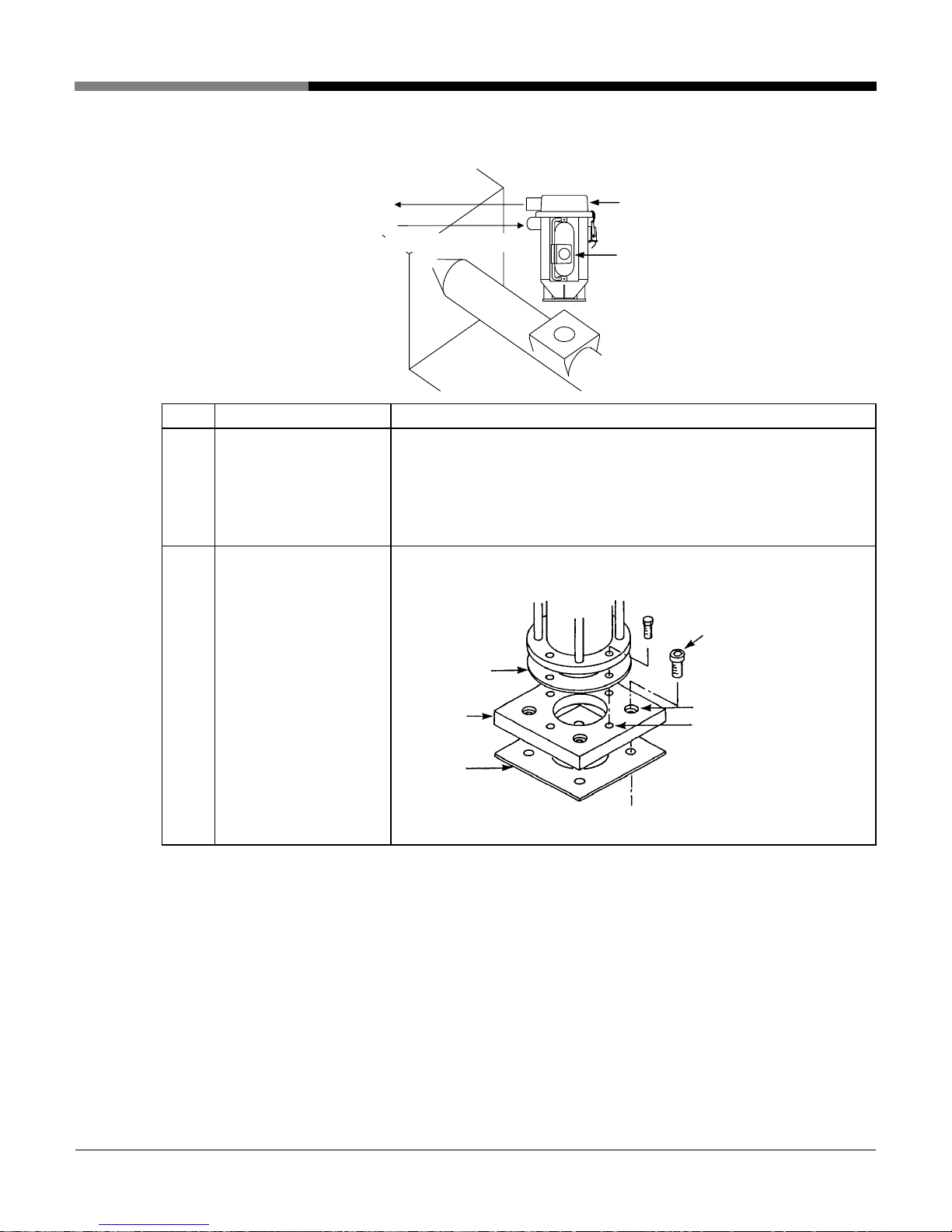

1. Mounting collection hopper

1) Jet Clone type limit, level, cylinder control

Material port hose

Vacuum port hose

Material port

hose

Jet Clone

Hopper

Jet Clone- limit switch control Jet Clone- pneumatic cylinder control (not common)

Jet Clone

Step Task Description

Drilling mounting holes Drill holes in the hopper to be mounted so that they match the

1

mounting holes in the Jet Clone.

* It is recommended to tap the hopper holes so that the collection

hopper can be secured with bolts alone. When the holes are not

tapped, the collection hopper should be secured with bolts and

nuts. In this case, an adequate measure should be taken to

prevent the bolts and nuts from falling into the hopper if they

loosen and fall off.

Mounting Jet Clone

2

Mounting level switch

3

* Only when the

collection hopper is

controlled by the

level switch

(not common)

Mount the Jet Clone on the hopper on which mounting holes are

drilled.

Drill holes at the specified positions in the hopper on which the

suction hopper is mounted, and install the level switch.

Pneumatic

Split pin

Flat washer

Packing

Vacuum port hose

Hopper

Level switch main body

[WO-4841;JL4-V・VC-3~6-10]

Nut

Connector

Blade

- 10 -

Page 15

The hopper on which the Jet Clone is mounted should be sized so that the damper of the Jet Clone

○

does not contact the inner wall of the hopper.

○ Install the Jet Clone horizontally. Otherwise, it may not accurately detect the hopper is full of

material.

○ The damper of the Jet Clone has been adjusted at the factory, therefore do not adjust, or knock it.

Otherwise, it may not accurately detect the hopper is full of material.

NOTE

Chapter 3 Installation

[WO-4841;JL4-V・VC-3~6-11]

- 11 -

Page 16

2) Vacuum hopper type- E2K control

Step Task Description

Mounting the base Attach the base to the molding machine.

1

2

Vacuum hopper

mounting

Chapter 3 Installation

Inlet Vac. hose

Material port hose

Molding

machine

Vacuum hopper

Proximity switch (E2K)

(Fix with hexagon socket head cap screws.)

* Be sure to install a gasket between the hopper base and the

molding machine mounting plate.

Mount the vacuum hopper flange (sight glass section) on the base.

Use hexagon socket head

socket screws.

Packing

Matching

base

Countersunk hole (for

molding machine

mounting)

Tap hole (for suction hopper

mounting)

Packing

[WO-4841;JL4-V・VC-3~6-12]

- 12 -

Page 17

3) Vacuum hopper type ASD control (not common)

Material port hose

Vacuum hopper

Step

Drilling the mounting

1

Task Description

holes

Mounting suction hopper Mount the suction hopper to the hopper on which the mounting holes

2

Hopper

Drill holes in the hopper to be mounted so that they match the

mounting holes in the Jet Clone.

* It is recommended to tap the hopper holes so that the collection

hopper can be secured with bolts alone. When the holes are not

tapped, the collection hopper should be secured with bolts and

nuts. In this case, an adequate measure should be taken to

prevent the bolts and nuts from falling into the hopper if they

loosen and fall off.

are drilled.

Vacuum port hose

Level switch

Chapter 3 Installation

3 Mounting level switch Drill holes at the specified positions in the hopper on which the

suction hopper is mounted, and install the level switch.

Split pin

Flat washer

Packing

Level switch (main body)

Blade

Nut

Connector

[WO-4841;JL4-V・VC-3~6-13]

- 13 -

Page 18

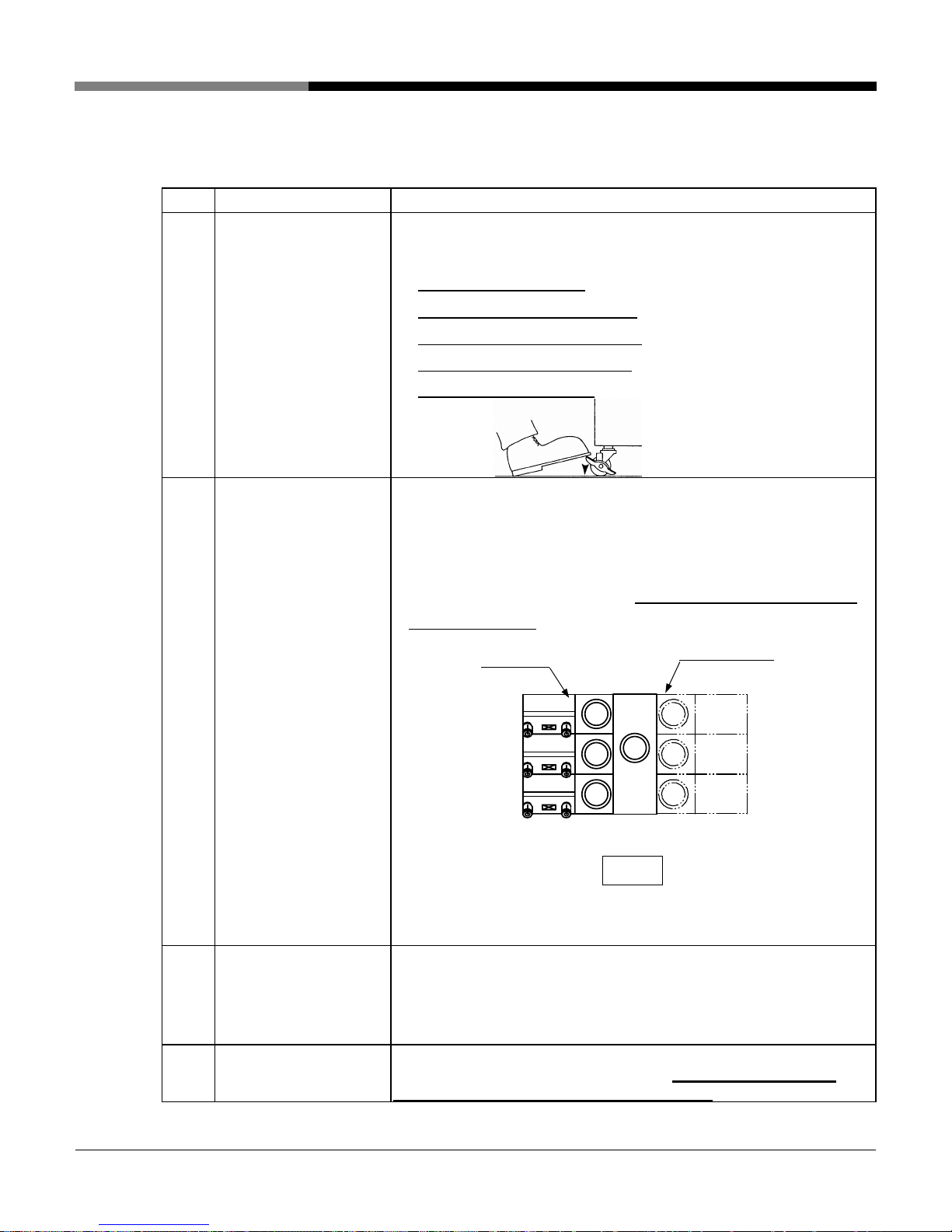

2. Installation

Install the equipment as shown in 2. Flow diagrams in Chapter 1.

Step Task Description

1

Installing the Loader Install the loader near each collection hopper (within the reach of the

2

Mounting the vacuum

hoses (Grey GTG Hose)

Chapter 3 Installation

5m-long air suction hose) in the vicinity of respective collectors.

* When the installing location is

determined, be sure to apply the caster

brakes (4 locations) to secure. As shown

in the diagram, the brake is applied by

stepping down on the ON side.

Connect the vacuum hoses to the suction ports of each collection

hopper and the 3 ~ 6 way selector valve of the loader.

* Be sure to secure with a hose clamp.

Connecting the material

3

hose (White PVC Hose)

Connecting the signal

4

cords

* A direction label (No1.~ No.6) is attached to respective hose

openings on the selector valves. Please make sure to connect to

each proper valve.

For 3 way

For 4 – 6 way

(3 ~ 6 way selector valve viewed from above)

NOTE

Securely tighten the hose clamps to avoid leaks at the intake ports of

the material & vacuum hoses.

Connect the material hose to the material port of each collection

hopper.

Install the suction nozzle to the end (conveying source side) of the

conveying hose.

* Firmly secure with a hose clamp.

Connect the signal cords (with connector) of the loader to the signal

cord, or socket, of the collection hopper. Make sure each cable

matches the corresponding hose direction!

[WO-4841;JL4-V・VC-3~6-14]

- 14 -

Page 19

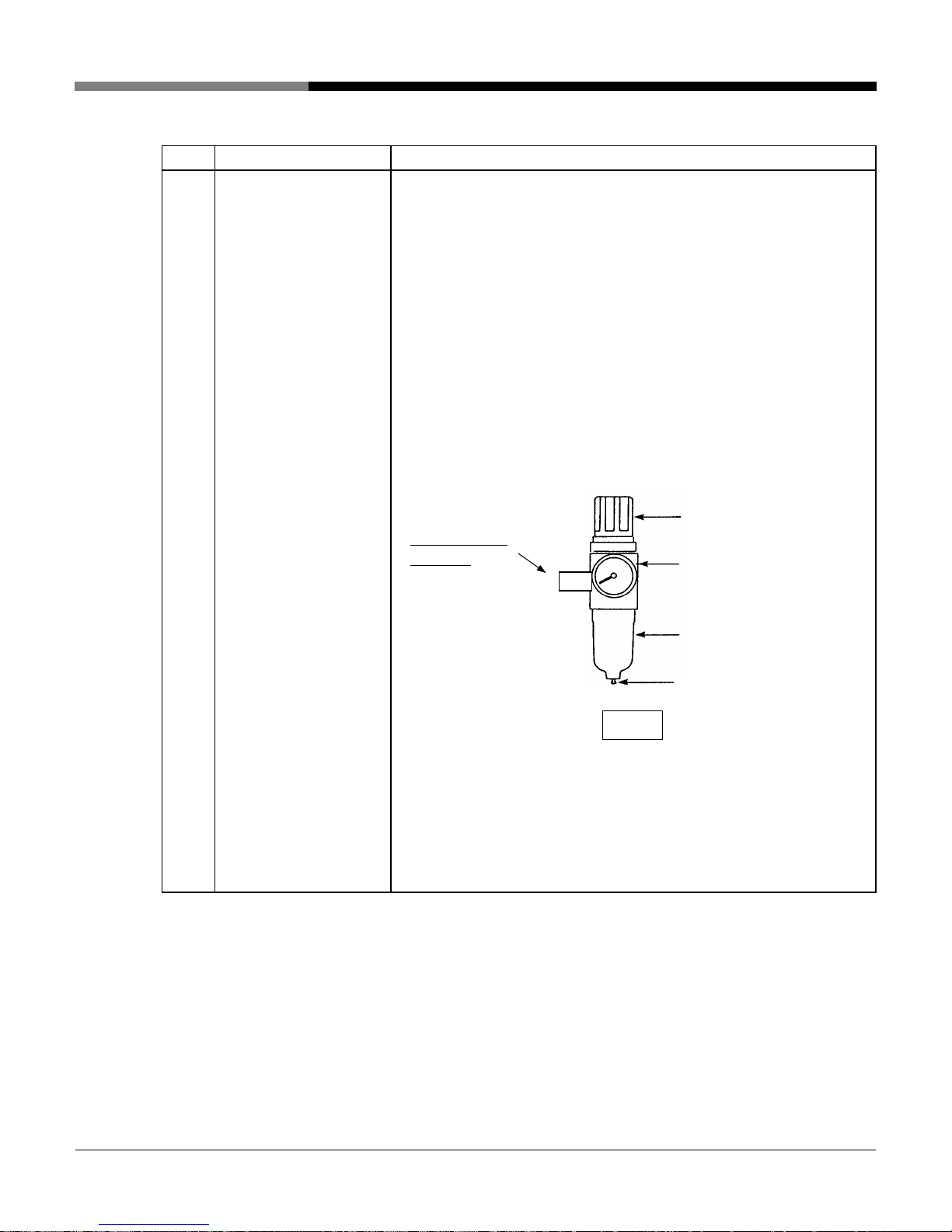

Step Task Description

5

Supplying compressed

air to the (3 ~ 6 way)

selector valve

Chapter 3 Installation

Connect an air hose of compressed air source from your facility

to the air supply valve (1/4”) of the 3~6 way valve.

Fully open the valve of the air kit to supply dry compressed air

of 0.5 MPa or higher from the compressed air source.

↓

Set the filter regulator outlet pressure of the air kit within a range of 0.4 to 0.5 MPa.

① Pull up the filter regulator adjustment knob to unlock it.

② Adjust the indication of the pressure gauge to 0.4 to 0.5

MPa by turning the adjustment knob clockwise or

counterclockwise. Turning the knob clockwise causes the

indicated value to rise, and vice versa.

③ After setting the pressure, push down the adjustment

knob to lock it.

Adjustment

knob

Supply valve

(1/4”)

(Your valve may

Pressure

gauge

differ).

Bowl

Drain valve

NOTE

○ Set the pressure to

0.5 MPa or higher for dry compressed air

from a compressed air source.

Use an air dryer or air filter to obtain clean, dry compressed

air. Periodically drain to prevent freezing of the drain water,

especially in cold climates.

[WO-4841;JL4-V・VC-3~6-15]

- 15 -

Page 20

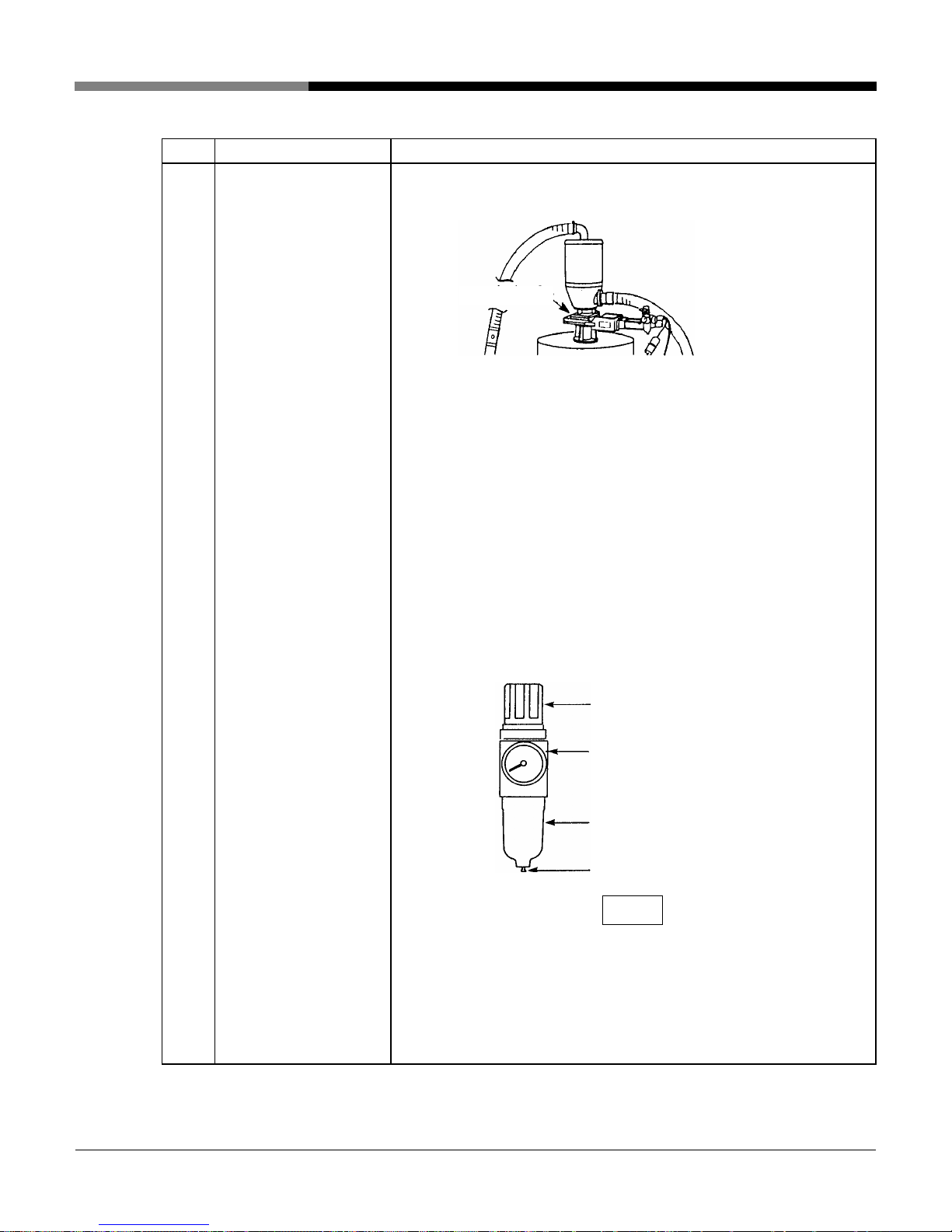

Step

Supplying compressed

6

Task

air to collection hopper

air kit

* Only when the

collection hopper is Jet

Clone pneumatic

cylinder control type or

suction hopper type has

ASD control.

(not common)

Chapter 3 Installation

Description

Connect an air hose for a compressed air source to the air supply

port valve of the automatic slide gate air kit from your existing source.

Fully open the valve of the air kit to supply dry compressed air of 0.5

MPa or higher from the compressed air source.

Set the filter regulator outlet pressure of the air kit within a range of

0.4 to 0.5 MPa.

AutoSlide gate

↓

↓

① Pull up the filter regulator adjustment knob to unlock it.

② Adjust the indication of the pressure gauge to 0.4 to 0.5 MPa

by turning the adjustment knob clockwise or counterclockwise.

Turning the knob clockwise causes the indicated value to rise,

and vice versa.

③ After setting the pressure, push down the adjustment knob to

lock it.

Adjustment knob

Pressure gauge

Bowl

Drain valve

NOTE

○ Secure pressure of 0.5 MPa or higher for dry compressed air from

the compressed air source.

Properly process with an air dryer or air filter to use clean dry

compressed air. Sufficiently drain to prevent freezing of drain

water especially in cold climates.

[WO-4841;JL4-V・VC-3~6-16]

- 16 -

Page 21

3. Power cord Information

WARNING! Only qualified personnel should attempt any electrical connections!

Step Task Description

1

Connecting / Checking

the power cord

2

Checking forward and

reverse phase

After checking that the power breaker in the control panel is OFF, check

the 15ft. long power cord to the primary power of your existing source.

R phase …Red

Power cord … S phase …White …For the primary

T phase …Black

E phase …Green …………For grounding

○ Before any power cord connection, be sure to set the power circuit

○ The power cord should be securely connected to the power source. A

○ Be sure to connect the ground.

Turn OFF the primary power of your existing source.

↓

CAUTION

breaker in the control panel to OFF.

loose power cord connection may cause abnormal equipment

operation, single-phase operation and heat generation, or danger.

Turn ON the primary power of your existing source.

↓

Turn on the power breaker in the control panel.

↓

Chapter 3 Installation

1

Press the operation panel No. 1 start/stop switch

blower for the suction unit starts after the predetermined time.

↓

Apply your hand to the blower exhaust port to check that air is

blowing out from the exhaust port. If so, the blower rotates in the

forward direction (forward phase). Connection of the power cord is

completed.

↓

Continued on the next page.

No.

and the

- 17 -

[WO-4841;JL4-V・VC-3~6-17]

Page 22

Step Task Description

3

Checking forward and

reverse phase

Chapter 3 Installation

↓

If no air is blowing out from the exhaust port, it means that the blower

rotates in the reverse direction (reverse phase). In this case, turn OFF

the primary power and reverse the R phase and T phase of the three

wires of the power cord.

↓

Again, turn ON the primary power and check that air is blowing out

from the exhaust port.

Exhaust port

[WO-4841;JL4-V・VC-3~6-18]

- 18 -

Page 23

Chapter 4 Preparations for Operation

This chapter describes checks before starting operation.

1. Check status of each component

Unit to be checked Check

Filter case for suction unit Check that the cartridge and cap are set to the filter case.

Filter case

Filter case

Separator

Dust box for suction unit

* Only for VC type

Cap

V type VC type

Check that the dust box is installed on the lower part of the separator.

(Refer to the above diagram.)

Dust box

[WO-4841;JL4-V・VC-3~6-19]

- 19 –

Page 24

A

p

Unit to be checked Check

Each collection hopper

Chapter 4 Preparations for Operation

Check that no foreign matter intrudes inside, and further check that the

packing and metal mesh filter are properly set.

fter checking, firmly fix the lid of the collection hopper with the catch clips

(3 pieces).

Lid

Packing

Filter

Catch cli

[WO-4841;JL4-V・VC-3~6-20]

- 20 –

Page 25

2. Control panel description

・Discharging display/Engineering setting mode display (green)

・Conveying display/User setting mode display (green)

・Digital displayer (red)

PV value/Function

・Digital displayer (green)

SV value/Parameter

Chapter 4 Preparations for Operation

・Reset switch

Jet Loader

PV SV

Conveyance

/User Setting

Discharge

/Engineering Setting

Feed to

Run

Stop

Setting

・SV switch

・Down switch

/Function /Parameter

21

No.No.

3456

No. No. No. No.

SV

Reset

・ Confirmation

switch

・Up switch

・No. 1 start/stop

Switch/display (green)

~

・No. 6 start/stop

Switch/display (green)

[WO-4841;JL4-V・VC-3~6-21]

- 21 –

Page 26

Chapter 5 Operating Procedures

This Chapter describes starting, stopping and cleaning procedures according

to the steps.

1. Starting procedure

Step Operation Description Display

Turning on power Turn ON the power breaker in the control panel.

1

2

Starting operation Press a desired switch from the No. 1 start/stop

1

switch

No.

The equipment starts conveyance in response to

a request signal.

However, when the collection hopper is full, the

equipment does not start conveyance.

* For details on operation, refer to Chapter 6.

Operational Descriptions and Timing Chart.

No.

to the No. 6 start/stop switch

6

on the operation panel.

↓

↓

The display

corresponding to

operation of

1

No.

through

No.

6

is turned on during

start.

Conveying set time

(green) and conveying

time (red) appear on the

digital displayer during

conveyance.

Discharge set time

(green) and discharge

time (red) appear on the

digital displayer during

discharge.

[Adjusting the amount of secondary air suctioned by

the suction nozzle]

Put the suction nozzle into the material and adjust the

secondary air regulator to achieve smooth material

conveyance.

Secondary air regulator

NOTE

Throttling secondary air flow excessively may cause the hose to be clogged with material.

[WO-4841;JL4-V・VC-3~6-22]

- 22 –

Page 27

2. Stopping procedure

Step Operation Description Display

Chapter 5 Operating Procedures

1

Operation is continued for operation performance during cycle stop.

Stopping

operation

Press a desired switch from the No. 1 start/stop

1

No.

switch

No.

6

on the operation panel.

The equipment stops operation.

If operation is stopped during conveyance

operation, the device is stopped after

conveyance operation. (Cycle stop)

to the No. 6 start/stop switches

↓

NOTE

The display

corresponding to

operation of

1

No.

through

No.

6

is turned on during

start.

[WO-4841;JL4-V・VC-3~6-23]

- 23 –

Page 28

3. Cleaning procedure

This section describes the procedure for cleaning the conveying hoses and

collection hoppers after stopping equipment operation.

Step Operation Description Display

1 Preparation work Remove the suction nozzle at the end of the

conveying hose from the material supply

section.

2 Starting operation Perform the operation to start conveyance to the

collection hopper. (Refer to the previous page.)

3

Cleaning inside

of conveying

hose

Play up the suction nozzle opening with your

hand at intervals of several seconds during

conveyance to completely feed the material

remaining in the conveying hose to the

collection hopper.

Chapter 5 Operating Procedures

(Refer to the previous

page.)

Stopping

4

operation

Cleaning inside

5

of collection

hopper

Perform the stopping operation to stop the

conveyance to the collection hopper. (Refer to

the previous page.)

Remove the lid of the collection hopper to clean

the inside.

(Refer to the previous

page.)

[WO-4841;JL4-V・VC-3~6-24]

- 24 –

Page 29

Chapter 6 Operational Descriptions and Timing Charts

r

This Chapter describes the operation for the collection hopper.

1. Jet Clone type limit or level switch control collection hopper

1) Description of operations

Set the control panel power circuit breaker to ON.

↓

When the equipment starts conveyance by the start of

operation, the blower starts rotating in response to the

request signal from the limit switch. At the same time, the

collection hopper gate closes.

↓

Material is conveyed to the collection hopper of the period

of time set by the conveyance timer.

↓

Gate operations

ダンパー動作説明図

(1) Normal condition

(1)自然状態

Limit switch

リミットスイッチ

Cam

カム ダンパー

Dampe

When the conveyance timer has run out, the blower stops.

As the suction pressure decreases the collection hopper

gate opens to discharge material into the lower receiver

hopper for the period of time set on the discharge timer.

↓

The above operations are repeated.

In a case where respective request signals from multiple

conveyance directions are simultaneously sent, the

material is conveyed in the order of No. 1 → No. 2 → No. n

→ No.2, alternatively.

When the receiver hopper has become full, the collection

hopper limit switch (in the case of limit control) or the

receiver hopper level switch (in the case of level switch

control) senses the condition to stop conveyance.

When a request signal is sensed again, conveyance is

started.

(2) Closed

(during conveyance)

(3) Full condition

condition

(2)閉(輸送中)状態

(Limit switch actuation

(3)材料満杯状態

Æ Material conveyance stop)

(リミットスイッチ作動

→輸送停止)

材料

Material

[WO-4841;JL4-V・VC-3~6-25]

- 25 -

Page 30

2) Timing chart

The following is the time chart for No.1 and No. 2 directions, however, operation for No. 3 direction or

more is similarly carried out.

Start/stop switch

1

No.

No.

2

Request

No. 1 Request signal

Request

No. 2 Request signal

No. 1 Discharge timer

ON

Chapter 6 Operational Descriptions and Time Charts

Full

Request

Full

Operating

UP

Operating

No. 1 Discharge timer

Ring blower

No. 1 collection hopper gate

No. 2 collection hopper gate

No. 1 Conveyance timer

No. 2 Conveyance timer

3~6 way selector valve

UP

Start

Stop

Stop

Start

Stop

Open

Close

Close

Open

Close

Close

Operating

UP

Operating

UP

No. 1direction

No. 2 direction

Close Close

Start

Open

Operating

No. 1direction

[WO-4841;JL4-V・VC-3~6-26]

- 26 -

Page 31

Chapter 6 Operational Descriptions and Time Charts

2. Suction hopper type E2K control collection hopper

1) Description of operations

Set the control panel power circuit breaker to ON.

↓

When the equipment starts conveyance by the start of operation, the blower starts rotating in response

to the request signal from the E2K.

↓

Material is conveyed to the collection hopper for the period of time set by the conveyance timer.

↓

When the conveyance timer has run out, the blower stops.

↓

The above operations are repeated.

In a case where respective request signals from multiple conveyance directions are simultaneously

sent, the material is conveyed in the order of No. 1 → No. 2 → No. n → No.2, alternatively.

When the collection hopper has become full, the E2K installed on the collection hopper senses the

conditions to stop conveyance.

When a request signal is sensed again, conveyance is started.

[WO-4841;JL4-V・VC-3~6-27]

- 27 -

Page 32

2) Timing chart

The following is the time chart for No.1 and No.2 directions, however, operation for No.3 direction or

more is similarly carried out.

Start/stop switch

1

No.

No.1 Request signal

No.2 Request signal

No.1 Discharge timer

No.2 Discharge timer

No.

2

ON

Request

Request

Chapter 6 Operational Descriptions and Time Charts

Full

Request

Full

Operating

UP

Operating

UP

Ring blower

No.1 Conveyance timer

No.2 Conveyance timer

3 - 6-way selector valve

Start

Stop

Operating

Stop

Start

Stop

Operating

UP

UP

No.1 direction

Close Close

No.2 direction

Start

Operating

No.1 direction

[WO-4841;JL4-V・VC-3~6-28]

- 28 -

Page 33

Chapter 6 Operational Descriptions and Timing Charts

3. Jet Clone cylinder control or suction hopper type SD control

collection hopper

1) Description of operation

Set the control panel power circuit breaker to ON.

↓

When the equipment starts conveyance by the start of operation, the discharge timer starts and after

the lapse of the preset time, the blower starts rotating in response to the request signal from the level

switch.

↓

Material is conveyed to the collection hopper for the period of time set by the conveyance timer.

↓

When the conveyance timer has run out, the blower stops. The collection hopper gate opens to

discharge material for the period of time set on the discharge timer.

↓

The above operations are repeated.

In a case where respective request signals from multiple conveyance directions are simultaneously

sent, the material is conveyed in the order of No. 1 → No. 2 → No. n → No. 2, alternatively.

When the receiver hopper has become full, the level switch installed on the receiver hopper senses the

conditions to stop conveyance.

When a request signal is sensed again, conveyance is started.

[WO-4841;JL4-V・VC-3~6-29]

- 29 -

Page 34

2) Timing chart

The following is the time chart for No.1 and No.2 directions, however, operation for No.3 direction or

more is similarly carried out.

Start/stop switch

1

No.

No.1 Request signal

No.2 Request signal

No.1 Discharge timer

No.

2

ON

Request

Request

Operating

UP

Chapter 6 Operational Descriptions and Timing Charts

Full

Request

Full

Operating

UP

No.2 Discharge timer

Ring blower

No. 1 collection hopper gate

No. 2 collection hopper gate

No.1 Conveyance timer

No.2 Conveyance timer

3~6-way selector valve

Operating

Start

Stop

Open

Close

Close

Close

Operating

Open

Close

Open

UP

No.1 direction

Close Close

UP

Start

Close

Operating

No.2 direction

Operating

UP

Start

Stop

Open

Close

Operating

UP

No.1 direction

[WO-4841;JL4-V・VC-3~6-30]

- 30 -

Page 35

Chapter 7 Respective Parameter Setup

This chapter describes respective parameter setup carried out on the operation

panel.

Respective parameter setup is classified into user setting mode and engineering

setting mode.

NOTE

The parameters of the engineering setting mode have been set according to the

specification at shipment or at installation. In general, there is no need to change

the setting. When changing the setting, sufficiently understand the functions.

When in doubt, contact our responsible personnel.

1. Setting guide

User setting mode

No. Code Setting item

1 Fd1 No. 1

Conveyance

timer

2 Fd2 No.2

Conveyance

timer

3 Fd3 No.3

Conveyance

timer

4 Fd4 No.4

Conveyance

timer

5 Fd5 No.5

Conveyance

timer

6 Fd6 No.6

Conveyance

timer

The timer should be set for No.1 conveyance

time.

The time for conveyance varies with the

conveying distance, the type of material, and

the type of collection hopper.

The conveyance timer should be set so that

conveyance ends before the collection hopper

becomes full of material.

The timer should be set for No.2 conveyance

time. Hereinafter, same as above.

The timer should be set for No.3 conveyance

time. Hereinafter, same as above.

The timer should be set for No.4 conveyance

time. Hereinafter, same as above.

The timer should be set for No.5 conveyance

time. Hereinafter, same as above.

The timer should be set for No.6 conveyance

time. Hereinafter, same as above.

Function

Setting

range

0 - 999 sec 5 sec

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

Initial

value

Same

as

above

Same

as

above

Same

as

above

Same

as

above

Same

as

above

[WO-4841;JL4-V・VC-3~6-31]

- 31 -

Page 36

No. Code Setting item

7 dC1

Conveyance

8 dC2

Conveyance

9 dC3

Conveyance

10 dC4

Conveyance

11 dC5

Conveyance

12 dC6

Conveyance

13 dUC Dust cleaning

14 dUP Dust cleaning

No. 1

timer

No.2

timer

No.3

timer

No.4

timer

No.5

timer

No.6

timer

counter

count

Chapter 7 Respective Parameter Setup

Function

The timer should be set for No.1 conveyance

time.

The time for conveyance varies with the

conveying distance, the type of material, and

the type of collection hopper.

The conveyance timer should be set so that

conveyance ends before the collection hopper

becomes full of material.

The timer should be set for No.2 conveyance

time.

The timer should be set for No.3 conveyance

time.

The timer should be set for No.4 conveyance

time.

The timer should be set for No.5 conveyance

time.

The timer should be set for No.6 conveyance

time.

The counter should be set for conveyance

times to inform filter cleaning interval.

If this counter is set to OFF, this does not

function. When the conveyance times reach

the set value, E15 appears on the digital

displayer on the operation panel, informing of

the cleaning interval.

The set times vary with properties of the

conveying material and operating status.

This displays the count number of the dust

cleaning counter.

When this is set to 0, the count number is

reset.

Setting

range

0 - 999 sec 20

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

oFF,

1 – 999

times

0 – 999

times

Initial

value

sec

Same

as

above

Same

as

above

Same

as

above

Same

as

above

Same

as

above

oFF

0

[WO-4841;JL4-V・VC-3~6-32]

- 32 -

Page 37

No. Code Setting item

1 L1d No. 1

Request signal

delay timer

2 L2d No.2 Request

signal delay

3 L3d No.3 Request

signal delay

4 L4d No.4 Request

signal delay

5 L5d No.5 Request

signal delay

6 L6d No.6 Request

signal delay

7 1Ed No. 1

Conveyance

error timer

8 2Ed No. 2

Conveyance

error timer

9 3Ed No. 3

Conveyance

error timer

10 4Ed No. 4

Conveyance

error timer

11 5Ed No. 5

Conveyance

error timer

12 6Ed No. 6

Conveyance

error timer

13 1rL No. 1

Request signal

input select

timer

timer

timer

timer

timer

Chapter 7 Respective Parameter Setup

Engineering setting mode

Function

The timer should be set for the time to judge

No.1 request signal.

The timer should be set so as to disregard a

false request signal in short time due to flowing

of material.

The timer should be set for the time to judge

No.2 request signal. Hereinafter same as

above.

The timer should be set for the time to judge

No.3 request signal. Hereinafter same as

above.

The timer should be set for the time to judge

No.4 request signal. Hereinafter same as

above.

The timer should be set for the time to judge

No.5 request signal. Hereinafter same as

above.

The timer should be set for the time to judge

No.6 request signal. Hereinafter same as

above.

The timer should be set for level switch

request status monitoring time during No. 1

conveying operation.

The timer should be set for level switch

request status monitoring time during No. 2

conveying operation.

The timer should be set for level switch

request status monitoring time during No. 3

conveying operation.

The timer should be set for level switch

request status monitoring time during No. 4

conveying operation.

The timer should be set for level switch

request status monitoring time during No. 5

conveying operation.

The timer should be set for level switch

request status monitoring time during No. 6

conveying operation.

This should be set for the type of No.1 request

signal.

no: State where input circuit is open should be

a request signal.

nC: State where input circuit is close should be

a request signal.

Setting

range

0 - 99 sec

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

oFF,

1 - 999 sec

oFF,

1 - 999 sec

oFF,

1 - 999 sec

oFF,

1 - 999 sec

oFF,

1 - 999 sec

oFF,

1~999

sec

nC/no

Initial

value

5 sec

Same

as

above

Same

as

above

Same

as

above

Same

as

above

Same

as

above

oFF

oFF

oFF

oFF

oFF

oFF

no

[WO-4841;JL4-V・VC-3~6-33]

- 33 -

Page 38

No. Code Setting item

14 2rL No. 2

Request signal

input select

15 3rL No.3 Request

signal input

16 4rL No.4 Request

signal input

17 5rL No.5 Request

signal input

18 6rL No.6 Request

signal input

19 bt1 No. 1

Batch gate timer

20 bt2 No.2 Batch gate

21 bt3 No.3 Batch gate

22 bt4 No.4 Batch gate

23 bt5 No.5 Batch gate

24 bt6 No.6 Batch gate

select

select

select

select

timer

timer

timer

timer

timer

Chapter 7 Respective Parameter Setup

Function

This should be set for the type of No. 2

request signal.

Hereinafter same as above.

This should be set for the type of No. 3

request signal.

Hereinafter same as above.

This should be set for the type of No. 4

request signal.

Hereinafter same as above.

This should be set for the type of No. 5

request signal.

Hereinafter same as above.

This should be set for the type of No. 6

request signal.

Hereinafter same as above.

No.1 Batch gate timer should be set for

opening time of automatic slide gate when the

batch conveyance option is performed.

This should be set so that any desired amount

is conveyed.

No.2 Batch gate timer should be set for

opening time of automatic slide gate when the

batch conveyance option is performed.

Hereinafter same as above.

No.3 Batch gate timer should be set for

opening time of automatic slide gate when the

batch conveyance option is performed.

Hereinafter same as above.

No.4 Batch gate timer should be set for

opening time of automatic slide gate when the

batch conveyance option is performed.

Hereinafter same as above.

No.5 Batch gate timer should be set for

opening time of automatic slide gate when the

batch conveyance option is performed.

Hereinafter same as above.

No.6 Batch gate timer should be set for

opening time of automatic slide gate when the

batch conveyance option is performed.

Hereinafter same as above.

Setting

range

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

0.0 - 99.9

sec

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

Initial

value

Same

as

above

Same

as

above

Same

as

above

Same

as

above

Same

as

above

1.0

Same

as

above

Same

as

above

Same

as

above

Same

as

above

Same

as

above

[WO-4841;JL4-V・VC-3~6-34]

- 34 -

Page 39

No. Code Setting item

25 bn_ Batch gate

interlocking

direction

26 bS_ Batch gate When batch conveyance option is performed,

27 Jd_

28 JAt

29 Jbt

30 JC_

31 Ab_

32 JS_

-

-

-

-

-

-

Chapter 7 Respective Parameter Setup

Function

This should be set for interlocking conveying

direction when the batch conveyance option is

performed.

oFF: No batch conveyance

1: Interlocking in No. 1 direction

2: Interlocking in No. 2 direction

3: Interlocking in No. 3 direction

4: Interlocking in No. 4 direction

5: Interlocking in No. 5 direction

6: Interlocking in No. 6 direction

ALL: Interlocking in all directions

this should be set to select the type.

0: Automatic slide gate

1-2: These cannot be set for standard

specifications and options This should be set

for special specification.

(Remark) 1: Idling valve

2: MSD

This should be set in case of special

specifications. Keep the initial value.

Same as above

Same as above

Same as above

Same as above

Same as above

Setting

range

oFF,

1,2,3,4,5,6

ALL

0 0

-

-

-

-

-

-

Initial

value

oFF

oFF

0

3

3

1

A

[WO-4841;JL4-V・VC-3~6-35]

- 35 -

Page 40

2. Setting procedure

The codes for each setting item are displayed on the left digital display (red).

The set values are displayed on the right digital display (green).

NOTE

Carry out the respective setting procedures after stopping operation. The setting mode cannot

be turned on during operation

Step

1

Press the SV switch

The User Setting Mode display flashes.

2

3

Codes for setting items and set values are displayed on the digital display.

With this state, respective setting items are sequentially displayed each time when the SV

switch

Display code for any desired setting item.

Press the ENTER switch with the code for any desired setting item displayed.

The set value can now be changed.

SV

.

SV

.

is depressed.

Chapter 7 Respective Parameter Setup

User setting mode

or DOWN switch .

is depressed. It is

SV

is depressed while the

4

Set the set value to any desired value with the UP switch

The set value is written when the ENTER switch

[Remark]

1 setting unit is added every time the UP switch is depressed. It is continuously

added when the switch is kept depressed.

1 setting unit is subtracted every time the UP switch

continuously subtracted when the switch is kept depressed.

The mode returns to the normal mode when the SV switch

last setting item (dUP) is displayed.

NOTE

is depressed.

Unless operation is performed for ten seconds or longer, the mode automatically exits the setting mode

and returns to the normal mode.

[WO-4841;JL4-V・VC-3~6-36]

- 36 -

Page 41

1

Keep pressing the SV switch

The Engineering Setting Mode display blinks.

2 Codes for setting items and set values are displayed on the digital display.

Operate in the same way as the User Setting Mode from now on.

After the setting procedure is completed, the mode returns to the normal mode when the SV

3

SV

switch

Unless operation is performed for ten seconds or longer, the mode automatically exits the setting mode

and returns to the normal mode.

Chapter 7 Respective Parameter Setup

Engineering setting mode

SV

for five seconds or longer.

is kept depressed for five seconds or longer.

NOTE

[WO-4841;JL4-V・VC-3~6-37]

- 37 -

Page 42

Chapter 8 Inspection and Maintenance

This chapter describes inspection and maintenance items and the procedures

in order of inspecting frequency in order to always keep the product in a

favorable state.

1. Daily inspection

Maintenance and

inspection item

Cartridge filter within filter

case of the suction unit

V type

Filter case

Cap

Filte

Descriptions

1. After removing a catch clip on the filter case, remove the filter

case lid.[①→②]

2. After removing a filter clip,take out the cartridge filter from the

filter case lid to clean.[③→④→⑤]

3. Remove the fine particles that adhere to the filter with a vacuum

cleaner.

4. Be sure to recover after cleaning.

Elbow pipe

②

Filter case lid

Filter hook

④④

①①

⑤

③

Cartridge filter

Filter clip

Catch clip

Filter case

Dust box

VC type

[WO-4841;JL4-V・VC-3~6-38]

1. Install the cartridge filter so that the opening having the packing is

directed toward the filter case lid.

2. If the equipment is used in a state where packing of the cartridge filter

does not closely contact the filter case lid, the fine particles will mix into

the blower and cause blower trouble.

3. Replace with a new cartridge filter, in the case where a damaged

cartridge filter, a cartridge filter that is severely deteriorated, deformed or

is adhered with deposits cannot be removed. Replace when the blower

has trouble and cannot carry out material conveyance, the filter mesh is

clogged, or fine particles result of a damaged part.

- 38 -

CAUTION

Page 43

Maintenance and

inspection item

Discharging dust in suction

unit

Air kit for 3-6 way selector

valve

Chapter 8 Inspection and Maintenance

Descriptions

V type

Remove the cap below the filter case and discharge the accumulated

dust. Be sure to recover after discharging.

VC type

Remove the catch clip on the upper part of the dust box and discharge

the accumulated dust. Be sure to recover after discharging.

* Replace with new packing if the U type packing for the dust box is

severely deteriorated, deformed, discolored or hardened.

Discharge drainage accumulated in the bowl of the air filter by pressing the

drain valve on the lower part of the bowl. Catch drainage with an empty

can.

Stop valve

Air supply port

Air filter

Drain valve

[WO-4841;JL4-V・VC-3~6-39]

- 39 -

Page 44

Maintenance and

inspection item

Air kit for slide gate of

collection hopper

* Only for a suction hopper

type SD control collection

hopper

Chapter 8 Inspection and Maintenance

Descriptions

Pull up the adjusting knob of the filter regulator to unlock, turn the adjusting

knob the to left, and check that the indicated pressure on the pressure

gauge has reached “0 (zero)” and then discharge the drainage

accumulated in the bowl. Drainage can be discharged by pushing the drain

valve of the bowl lower part.

Drainage should be received by an empty can.

Adjustment knob

Pressure gauge

Bowl

Drain valve

[WO-4841;JL4-V・VC-3~6-40]

- 40 -

Page 45

2. Monthly Inspection

Maintenance and

inspection item

Metal screen filter inside the

collection hopper

Open the lid of the collection hopper to take out the filter, and check that it

is not clogged.

If clogged, blow clean dry air to remove the deposits.

* If the deposits cannot be removed even by blowing dry air, use sharp

metal wire.

* Replace with new packing if the packing is severely deteriorated,

deformed, discolored or hardened.

Chapter 8 Inspection and Maintenance

Descriptions

Lid

Packing

Filter

Catch clip

Conveying hose (PVC hose)

Air hose (GL-IV hose)

CAUTION

Exercise sufficient care when handling the filter.

A deformed metal screen filter may cause air leakage, resulting in

conveyance failure.

If the filter is deformed, fix it by tapping it with a soft object such as a

wooden or rubber hammer. If the filter still cannot be fixed, replace it with a

new one.

Inspect each hose connection for suction leakage, and additionally tighten

the hose bands.

* Replace with a new hose if the hose is severely deteriorated, hardened

or damaged.

[WO-4841;JL4-V・VC-3~6-41]

- 41 -

Page 46

Chapter 8 Inspection and Maintenance

- 42 -

[WO-4841;JL4-V・VC-3~6-42]

Maintenance and

inspection item

Descriptions

Check each component of jet

clone

A: Please check that the stopper (M6) on the upper and lower two

points are not loosened, respectively.

※Please retighten the stopper according to the “Stopper adjusting

diagram” on the following page, if loosened.

B: Remove the cover and check that the hexagon socket head locking

screw of the removable cam is not loosened. Simultaneously, open

and close the damper to check that no abnormality for the limit

switch exists.

※Please retighten according to the “Stopper adjusting diagram” on

the following page, if loosened.

C: Please check that the hexagon socket head locking screw fixing

the balance weight is not loosened.

※Tighten the screw for fixing if loosened.

D: Please check that no abnormality for the spring, bolt, nut and

split pin exists.

※If any abnormality is found, please replace it with a new one.

C

D

B

A

A

Page 47

Chapter 8 Inspection and Maintenance

- 43 -

[WO-4841;JL4-V・VC-3~6-43]

Maintenance and

inspection item

Descriptions

Check each component of

jet clone

6mm

A

p

p

r

o

x

i

m

a

t

e

l

y

8

5゚

A

p

p

r

o

x

i

m

a

t

e

l

y

7

0

゚

Stopper adjustment diagram

Upper stopper adjustment

position

Lower stopper

adjustment position

(Clearance 6mm)

Limit switch ON

p

osition

Page 48

Chapter 8 Inspection and Maintenance

- 44 -

[WO-4841;JL4-V・VC-3~6-44]

3. Component adjustment procedure

This section describes the adjustment procedure of the full detecting

device attached to each collection hopper.

1) Jet Clone gate cam

Adjust the gate cam when full is not detected

regardless of whether the material is full.

Step Details of operation

1 Loosen the set-screw with a hexagon rod spanner (2.5mm).

2 Adjust the gate cam position so that the limit switch is ON with the gate

lowering from the horizon by 45-50°.

3 After adjusting the cam, secure it by tightening the set-screw.

2) Balance weight for Jet clone

In a case where material is attached to the damper

due to static electricity, the state shown on the right

is brought about in rare cases. In such a case, adjust

the damper by loosening two locking screws for

the balance weight rearward by 5mm, respectively,

so as to be horizontally positioned. Retighten screws

for fixing after adjustment.

Limit switch

Gate

Set-screw

Page 49

Chapter 8 Inspection and Maintenance

- 45 -

[WO-4841;JL4-V・VC-3~6-45]

3) Suction hopper level switch

If the level switch does not accurately detect the full level for the material used, make a

sensitivity adjustment of the level switch. Adjust the sensitivity according to the specific

gravity of the material.

Step Details of operation

1 Set the control panel power circuit breaker to ON.

2 Remove the lid of the level switch.

3 Change the spring hook position.

Moving the spring toward the HIGH

position causes the sensitivity to increase,

and vice versa.

[Confirmation method]

(1) The spring of the level switch is set up

in the strongest direction.

(2) The material is fed slowly until the blade

of the level switch is filled up with the material.

(3) The adjustment confirmation performs under this condition from the

HIGH to LOW direction step by step. Then, the adjustment is completed

in the position where the blade rotation stops securely.

Page 50

Chapter 8 Inspection and Maintenance

- 46 -

[WO-4841;JL4-V・VC-3~6-46]

4) Suction hopper proximity switch (E2K)

If the proximity switch does not detect the full level, make a sensitivity adjustment of the

proximity switch by the following steps.

Step Details of operation

1 Remove the materials in the collection hopper.

Turn ON the power circuit breaker on the control panel.

2 Confirm that there is no gap of 1mm or more between the end of the proximity

switch and the hopper sight glass.

If there is a gap between them, loosen the fastening screws (2 pieces) of the

proximity switch fitting bracket and adjust the distance between the end of

the proximity switch and the hopper sight glass to approximately 1mm, and

then fix them.

3 Remove the rubber cap at the back of the proximity switch.

4 Perform the following ①, ② and ③ operations while adjusting the

sensitivity adjustment screw with the attached screwdriver.

① Adjust the sensitivity to a point where the sensor switches from ON to OFF

without material (Detection indication lamp turns OFF).

② Adjust the sensitivity to a point where the sensor switches from OFF to ON

with material (Detection indication lamp turns ON).

③ Set the sensitivity adjustment screw at the middle point between the ON to

OFF point ① without material and the OFF to ON point ② with material.

NOTE:

Perform the sensitivity setting with the actually used material. And, when there are

various materials, the ①, ② and ③ operations should be performed with a light

material of appearance specific gravity.

5 Install the rubber cap removed in step 3.

Perform the material conveyance and confirm that the detection indicator

turns on.

Sensitivity

adjustment

Rubber cap

(-side) ←―――②―――――――③―――――――①――→ (+side)

With material Without material

ON (turns ON) ▲ OFF (turns OFF)

Setting point

Detection indication lamp

Page 51

Chapter 8 Inspection and Maintenance

4. Operation check procedure of 3 – 6 way selector valve

Manually operate the 3 – 6 way selector valve and describe the Operation check

the Operation check procedure according to the steps.

Step Details of operation

Turn OFF the power breaker on the rear face of the control panel.

1

2

Supply dry compressed air of –0.3 MPa - 0.9 MPa to the air kit of the 3-6 way selector

valve.

3

Press the manual button of the solenoid valve.

Manual button

When the manual button of the solenoid valve is pressed, the air cylinder operates.

[WO-4841;JL4-V・VC-3~6-47]

- 47 -

Page 52

Chapter 8 Inspection and Maintenance

5. Operation check procedure of automatic slide gate

In the case of the suction hopper type SD control collection hopper, manually operate the

automatic slide gate. The methods for checking the operation are described according to the

steps.

Step Details of operation

Turn “OFF” the control panel power circuit breaker.

1

Supply dry compressed air of 0.4 MPa to 0.5 MPa to the air kit of the automatic slide

2

gate.

3

Press the manual button on the solenoid valve. The air cylinder starts to operate.

Stop valve

ストップバルブ

Movable part

可動部

Filter regulator

フィルター

レギュレーター

Main body of automatic slide gate

自動スライドダンパー本体

Cylinder

シリンダー

Safety cover

安全カバー

CAUTION

注 意

WATCH YOUR FINGERS

指 づ め 注 意

1. 運転中は指や手を可動部に入

1.Do not place fingers or hands in movable

sections during operations.

れるな。

2.Take care to avoid lacerations to fingers or

2. 裂傷や骨折するおそれがあ

hands and danger of them being broken.

る。

3.When performing cleanup of or inspection

3. 清掃・点検作業は電源を OFF

turn power OFF and shut off air supply.

DO NOT SOIL OR PEEL THIS LABEL

このラベルをはがしたり、よごしたりしないこと。 6-21-1

にしてエアー供給源を遮断して

WARNING

Do not place fingers or hands into the movable parts (slide part) during operation.

○

Tears or bone fractures may result.

○ Never operate with the cover of the movable part removed.

○ Never operate with material caught in the slide damper. Failure may result.

[WO-4841;JL4-V・VC-3~6-48]

- 48 -

Page 53

Chapter 9 Troubleshooting

This chapter describes troubleshooting of the product. Check before requesting

repair.

Before inspection, be sure to stop the operation and set the control panel power

circuit breaker and the primary power supply to “OFF.”

Error by digital display on control panel

Code

“E 0”

Memory error

“E 3”

Conveying

blower overload

error

Location to be

checked

Check the control

board.

Check that

material is not

clogged in the

conveying hose.

Check that the

thermal relay in

the control panel

is set to the rated

value.

Action Precaution

・ Restart.

・ Turn “OFF” the power

circuit breaker once, and

turn it “ON” again.

・ Remove the material in the

conveying hose.

・ Adjust the secondary air

intake amount with the

secondary air adjustment

ring on the suction nozzle

at the end of the conveying

hose.

・ Set the thermal relay to the

rated value.

・ Press the reset button for

the thermal relay to reset

the alarm.

WARNING

・ Be sure to turn “OFF” the power

supply of your facility before

carrying out work.

・ If the “E0” is displayed even after

restarting, the control board has

failed.

・ Contact your local Matsui SDI

dealer.

・ When the suction part (metal

mesh) on the secondary air

adjustment ring is clogged, blow

clean dry air to remove the

deposits.

・ Be sure to turn “OFF” the power

supply of your facility, and then set

to the rated value of the thermal

relay and reset the alarm with the

reset button.

“E 14”

Control board

error

Check the control

board.

[WO-4841;JL4-V・VC-49]

・ Restart.

・ Turn “OFF” the power

circuit breaker once, and

turn it “ON” again.

- 49 -

・ Be sure to turn “OFF” the power

supply of your facility before

carrying out work.

・ If the “E14” is displayed even after

restarting, the control board has

failed.

・ Contact your local Matsui SDI

dealer.

Page 54

A

Code

“E 15”

larm for filter

cleaning

“E 21”

No. 1 Conveying

error

“E 22”

No. 2 Conveying

error

Location to be

checked

Clean the cartridge

filter and check

powder dust in the

dust box.

Check that material is

not clogged in the

conveying hose in the

No. 1 direction.

Check the limit switch

for the level switch in

the No. 1 direction (Jet

Clone type), E2K for

the suction hopper

type, and level switch

for level switch type.

Check that material is

not clogged in the

conveying hose in the

No. 2 direction.

Check the limit switch

for the level switch in

the No. 2 direction (Jet

Clone type), E2K for

the suction hopper

type, and level switch

for level switch type.

Action Precaution

・ Clean the filter, and

dispose powder dust

in the dust box. (see

Chapter 8 Inspection

and Maintenance).

・ Set the dust cleaning

count (dUP) to “0” to

reset.

・ Remove the material

in the conveying hose.

・ Adjust the secondary

air intake amount with

the secondary air

adjustment ring on the

suction nozzle at the

end of the conveying

hose.

・ See “Blower does not

rotate” in the next

item.

・ Remove the material

in the conveying hose.

・ Adjust the secondary

air intake amount with

the secondary air

adjustment ring on the

suction nozzle at the

end of the conveying

hose.

・ See “Blower does not

rotate” in the next

item.

Chapter 9 Troubleshooting

・ If the cartridge filter is damaged or

deposits cannot be removed,

replace the filter.

・ Contact your local Matsui SDI

dealer for a new filter.

・ When the suction part (metal

mesh) on the secondary air

adjustment ring is clogged, blow

clean dry air to remove the

deposits.

・ See “Blower does not rotate” in

the next item.

・ When the suction part (metal

mesh) on the secondary air

adjustment ring is clogged, blow

clean dry air to remove the

deposits.

・ See “Blower does not rotate” in

the next item.

[WO-4841;JL4-V・VC-50]

- 50 -

Page 55

Code

“E 23”

No. 3 Conveying

error

“E 24”

No. 4 Conveying

error

Location to be

checked

Check that material is

not clogged in the

conveying hose in the

No. 3 direction.

Check the limit switch

for the level switch in

the No. 3 direction (Jet

Clone type), E2K for

the suction hopper

type, and level switch

for level switch type.

Check that material is

not clogged in the

conveying hose in the

No. 4 direction.

Check the limit switch

for the level switch in

the No. 4 direction (Jet

Clone type), E2K for

the suction hopper

type, and level switch

for level switch type.

Action Precaution

・ Remove the material

in the conveying hose.

・ Adjust the secondary

air intake amount with

the secondary air

adjustment ring on the

suction nozzle at the

end of the conveying

hose.

・ See “Blower does not

rotate” in the next

item.

・ Remove the material

in the conveying hose.

・ Adjust the secondary

air intake amount with

the secondary air

adjustment ring on the

suction nozzle at the

end of the conveying

hose.

・ See “Blower does not

rotate” in the next

item.

Chapter 9 Troubleshooting

・ When the suction part (metal

mesh) on the secondary air

adjustment ring is clogged, blow

clean dry air to remove the

deposits.

・ See “Blower does not rotate” in

the next item.

・ When the suction part (metal

mesh) on the secondary air

adjustment ring is clogged, blow

clean dry air to remove the

deposits.

・ See “Blower does not rotate” in

the next item.

[WO-4841;JL4-V・VC-51]

- 51 -

Page 56

Code

“E 25”

No. 5 Conveying

error

“E 24”

No. 6 Conveying

error

Location to be

checked

Check that material is

not clogged in the

conveying hose in the

No. 5 direction.

Check the limit switch

for the level switch in

the No. 5 direction (Jet

Clone type), E2K for

the suction hopper

type, and level switch

for level switch type.

Check that material is

not clogged in the

conveying hose in the

No. 6 direction.

Check the limit switch

for the level switch in

the No. 6 direction (Jet

Clone type), E2K for

the suction hopper

type, and level switch

for level switch type.

Action Precaution

・ Remove the material

in the conveying hose.

・ Adjust the secondary

air intake amount with

the secondary air

adjustment ring on the

suction nozzle at the

end of the conveying

hose.

・ See “Blower does not

rotate” in the next

item.

・ Remove the material

in the conveying hose.

・ Adjust the secondary

air intake amount with

the secondary air

adjustment ring on the

suction nozzle at the

end of the conveying

hose.

・ See “Blower does not

rotate” in the next

item.

Chapter 9 Troubleshooting

・ When the suction part (metal

mesh) on the secondary air

adjustment ring is clogged, blow

clean dry air to remove the

deposits.

・ See “Blower does not rotate” in

the next item.

・ When the suction part (metal

mesh) on the secondary air

adjustment ring is clogged, blow

clean dry air to remove the

deposits.

・ See “Blower does not rotate” in

the next item.

[WO-4841;JL4-V・VC-52]

- 52 -

Page 57

Power circuit breaker trips.

Location to be checked Action Precaution

Check that foreign matter is not

caught in the blower fan.

Check that the magnetic switch

(MS-1) in the control panel

operates normally.

Check that the power circuit is

not short-circuited.

Remove the fan cover to

remove foreign matter.

Replace the magnetic switch

(MS-1).

Eliminate the short-circuit. Entrust Matsui SDI or your employee who

Turn “OFF” the primary power supply and

power circuit breaker before carrying out

work.

Tolerance: 1,000,000 times

Even if it is normal, replace by the time

the above times are reached or within 2

years after starting use.

Entrust Matsui SDI or your employee who

has sufficient working knowledge of

electricity to carry out inspection or

exchange, since the operation includes

the potential for failure or danger.