Matrixx MX-100, MX-150, MX-200 Maintenance Manual

Installation, Operation and

Maintenance Manual

US Water Matrixx Water

Softener

Hardness and Scale Prevention

System.

Matrixx MX-100

Matrixx MX-150

Matrixx MX-200

& HTO Systems

US Water Systems, Inc.

1209 Country Club Road

Indianapolis, IN 46234

1-800-608-8792

info@uswatersystems.com

www.uswatersystems.com

Installation, Operation and Maintenance Manual

Matrixx MX-100, MX-150, MX-200 System

Table of Contents

System Specifications ............................................................................. 3

How Your Water Conditioner Works ....................................................... 4

Main Valve Functions .............................................................................. 5

Tank Installation……………………………………………………………….7

General Installations ............................................................................... 8

Start-up Instructions………………………………………………………....10

Level 1 User Programming.....................................................................11

Level 2 User Programming………………………………………………….13

Level 2 Programming Flow Chart……………………………………….….14

Diagnostic Mode & Vacation Setting.......................................................15

Valve Cycle Settings...............................................................................16

Maintenance……………..…………………………………………………...18

Valve Drive Assembly Exploded View……………………………...……..20

Control Valve Assembly Exploded View………………………..…………21

Troubleshooting………………….…………………………………………..22

Warranty……………………….……………………………………………...23

HTO Installation & Quick Start Sheet……………………………………...24

2

Installation, Operation and Maintenance Manual

Matrixx MX-100, MX-150, MX-200 System

System Specifications

Figure 1. Specifications

US Water Systems classifies each softener according to the actual resin capacity. However, this is not the

regeneration capacity. The regeneration capacity will be lower than the actual resin capacity. This is due to

the resin ’ s regeneration salt curve. For example:

A 53,000 grain unit would require 30 lbs of salt during regeneration if the capacity was set to the actual resin

capacity ( 53,000 grains ) . If the unit is set at 37,000 grains it can be regenerated using only 10 lbs of salt.

The unit is much more efficient when it is set using the proper salt curve capacity and salt dosage levels. So

you can see that to get the final 16,000 grains from a 53,000 grain unit the salt usage will more than double.

Please use the chart below when setting you softener. This will ensure efficiency and longevity of your unit.

Maximum Water Temperature = 110°F (43°C)

Maximum Operating Pressure = 100

PSIG (689 kPa)

Voltage = 110 volts standard

Pipe Size = 3/4”

At the stated service flow rates, the pres-

sure drop through these devices will not

exceed 15 psig.

Changing salt settings from factory setting

may require changing injector sizes to

achieve stated capacities.

The manufacturer reserves the right to make

product improvements which may deviate from

the specifications and descriptions stated herein,

without obligation to change previously manufac-

Model # System Capacity Grains Flow Rate Regeneration Water Mineral

@ 10

lbs/cu ft

085-MX-100 25,000 20,000 13,000 10.0 2.0 38.0 48.0 9 X 48 1.00 15 X 15 X

085-MX-150 37,000 30,000 18,000 12.0 2.4 48.5 60.5 10 X 54 1.50 15 X 15 X

085-MX-200 50,000 40,000 25,000 15.0 3.5 80.5 95.5 12 X 52 2.00 20.3 X 37.4 385 158

@6 lbs/

cu ft

(Factory

Settings)

@ 3 lbs/

cu ft

Service

USGPM

Back-

wash

USGPM

Clean

Water

(Factory

Setting)

tured products or to note the change.

Problem

Water

Tank

Size

Resin

Cu. Ft.

Brine Tank/

Cabinet

Size Inches

34.7

34.7

Salt

Capacity

(Lbs)

230 122

230 155

Weight

For the HTO systems use the following chart.

Ship

(Lbs)

24,000

4.7

37,000 44,000

7.1 9.5

3

Installation, Operation and Maintenance Manual

Matrixx MX-100, MX-150, MX-200 System

How Your Water Conditioner Works

The principle behind water softening is simple chemistry. A water softener contains resin beads which hold electrically

charged ions. When hard water passes through the softener, calcium and magnesium ions are attracted to the charged resin

beads. It's the resulting removal of calcium and magnesium ions that produces soft water.

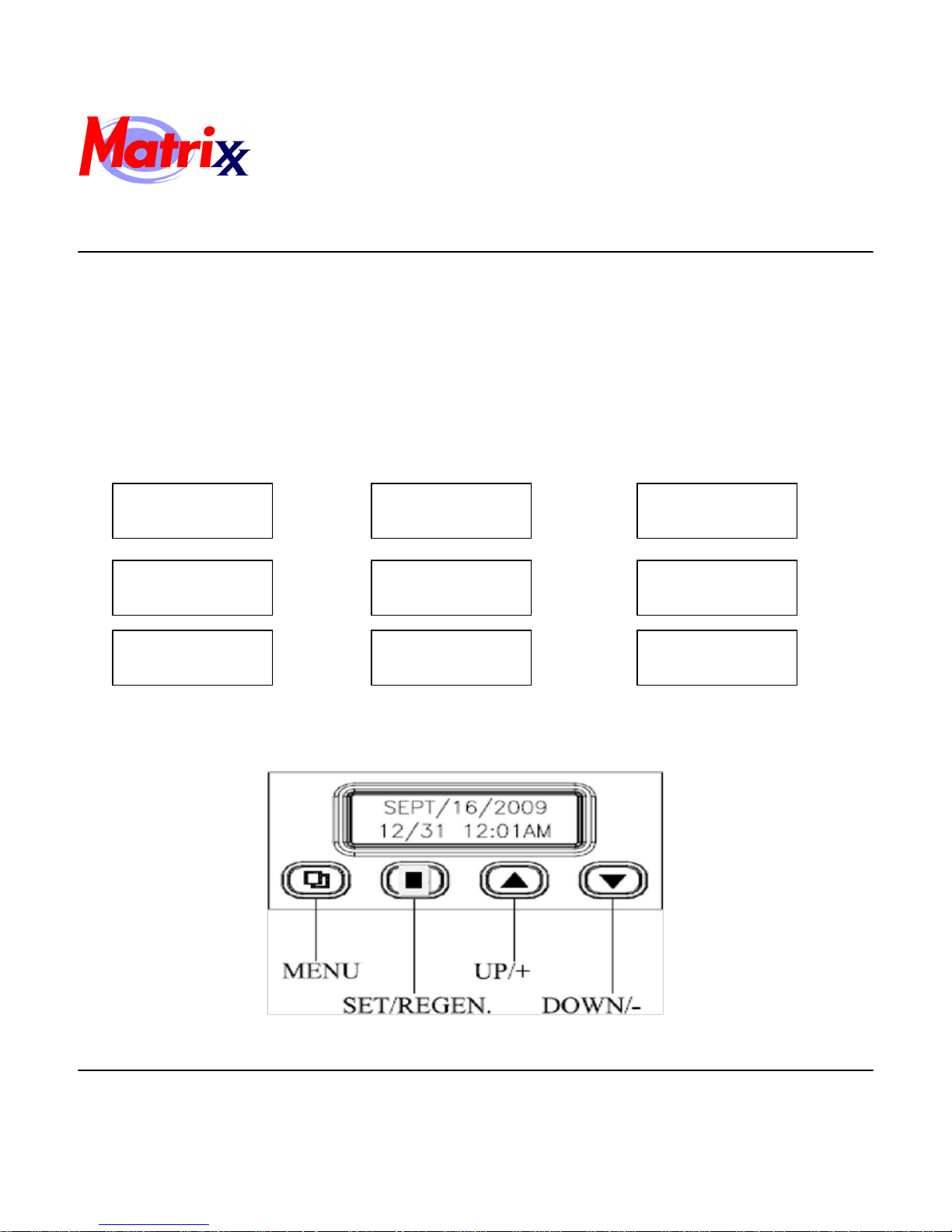

This valve is controlled with simple, user-friendly electronics displayed on a large LCD screen. The main page displays the

current date and time. In addition, the main page also shows key valve information and statistics including: current capacity

setting, volume remaining, date of last regeneration, current flow rate, and peak flow rate.

Figure 2. Main Page Displays

MAY 8, 2012

2:30 PM

REGEN DAYS

7 DAYS

LAST REGEN

MAY 2, 2012

CAPACITY

1,545 GAL

REMAINING DAYS

5 DAYS

CURRENT FLOW

15 GPM

VOLUME REMAING

1,295 GAL

REGENERATION

TIME 2:00 AM

PEAK FLOW

5.8 GPM

NOTE:REGEN DAYS and REMAINING DAYS are only shown in the CALENDAR CLOCK mode or METER OVERRIDE mode.

Figure 3. Key Pad Configuration

4

Installation, Operation and Maintenance Manual

Matrixx MX-100, MX-150, MX-200 System

MENU BUTTON The function of this key is to enter level one programming mode where the valve settings

can be adjusted.

SET / REGEN BUTTON This button has two functions. The first is to initiate a manual regeneration by holding the

button for 3 or more seconds. The second function is while in programming mode, pressing

this key allows the user to change the value of each setting.

UP / DOWN ARROWS These buttons are used to increase or decrease the value of the settings while in the

programming mode.

System Initialization

When power is first supplied, the valve may take up to two minutes to initialize the valve. During this time the valve will

show “INTIALIZING WAIT PLEASE”. Do not touch any buttons at this time. When the valve reaches the service position, it will display the current date and time.

Figure 4. System Initialization Display

Main Valve Functions

VALVE OPERATION MODE:

SOFTENER: Standard water softener operation.

FILTER: Automatic back washing filters such as Multi-Media Depth Filter or Carbon Filter.

IRON FILTER: This mode is typically used with Manganese Green Sand Filters.

RE G ENERATION M O D E: 1. METER DELAYED 2. METER I M MEDIATE 3. CALENDAR C LOCK

4. METER OVERRIDE

CAPACITY CALCULATION: 1. AUTOMATIC 2. MANUAL

ADJUSTABLE CYCLES: All of the valve cycles are fully adjustable.

1. BACKWASH 2. BRINE / RINSE

3.RINSE 4. REFILL

NOTE: Refer to Level II User Programming for description of each mode.

5

Installation, Operation and Maintenance Manual

Matrixx MX-100, MX-150, MX-200 System

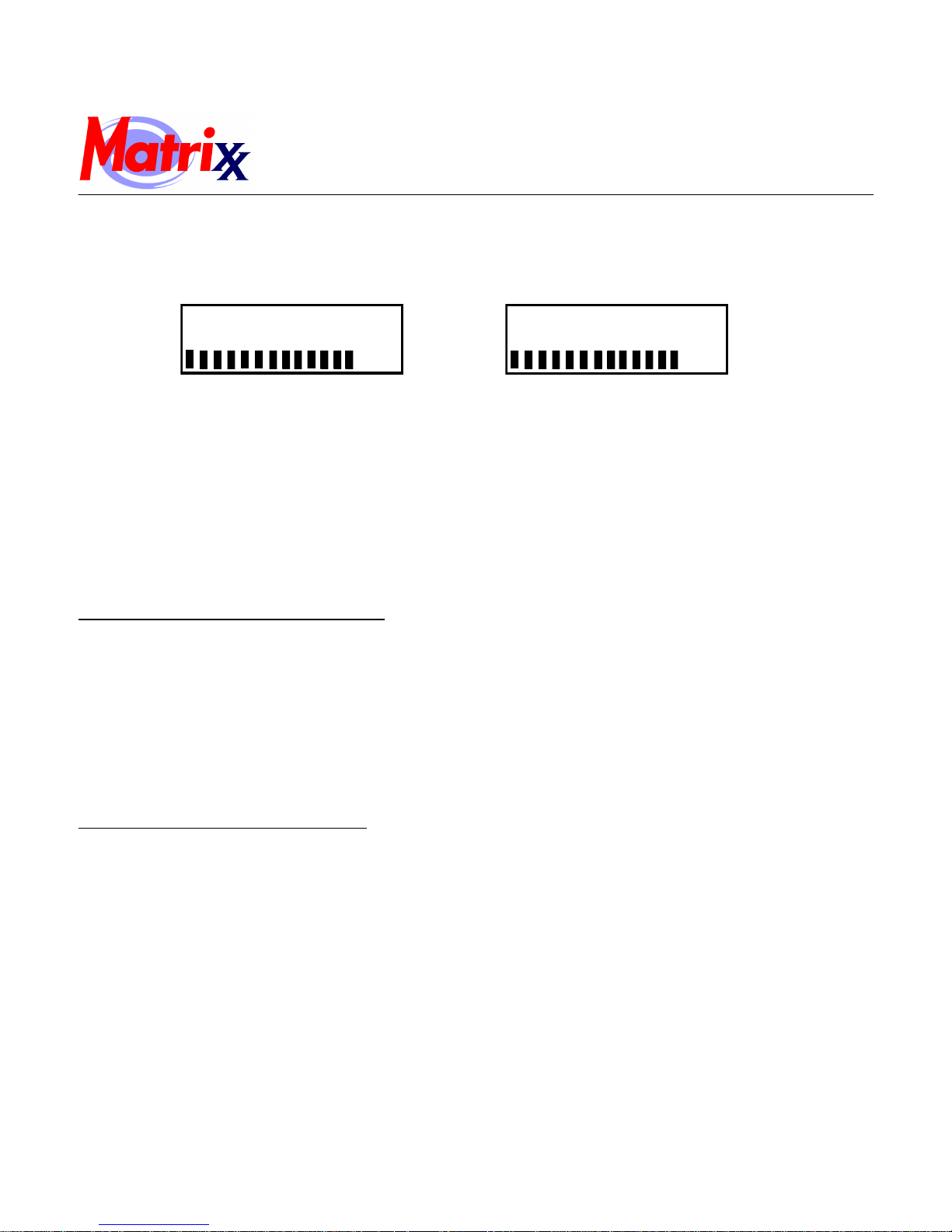

During a regeneration cycle, the valve will display what position it is advancing to. Once in the correct position, the valve

will display the current position along with the time remaining for that cycle. On the bottom row, the time remaining is also

graphically displayed.

BACKWASH

Figure 4. Regeneration Cycle Valve Display

“MENU BUTTON”: The funcon of this key is to enter the level one programming mode where the valve set

tings can be adjusted.

“SET / REGEN BUTTON”: This buon has two funcons. The rst is to initiate a manual regeneration by holding the

button for 3 or more seconds. The second function is while in programming mode,

pressing this key allows the user to change the value of each setting.

“UP / DOWN”: These buons are used to increase or decrease the value of the settings while in the

programming mode.

REMAINING 6 MIN

Manual Regeneration (Delayed or Immediate)

If screen is locked, press “MENU” for 3 seconds to unlock. To iniate an immediate regeneration, press the SET / REGEN

button for 3 seconds, an option for delayed or immediate regeneration will appear. Press the SET / REGEN button again and

delayed will begin flashing, press the down arrow button to have immediate flash, press the SET / REGEN button and then

press the menu button and the valve will immediately start into manual regeneration.

To initiate a delayed regeneration, press the SET / REGEN button for 3 seconds, then press the menu button and a regeneration

will be queued to the next pre-set regeneration time (2:00 a.m.).

Control Operation During A Power Failure

In the event of power failure, the valve will keep track of the time and day for 48 hours. The programmed settings are stored in

a non-volatile memory and will not be lost during a power failure.

If power fails while the unit is in regeneration, the valve will move to the service position from the point it is at once power is

restored. However, since the unit did not complete its regeneration, it will queue another regeneration at the next scheduled

regeneration time.

If the valve misses a scheduled regeneration due to a power failure, it will queue a regeneration at the next regeneration ti me

once power is restored.

6

Installation, Operation and Maintenance Manual

Matrixx MX-100, MX-150, MX-200 System

Matrixx Tank Installation Instructions

WATER PRESSURE: A minimum of 20 pounds of water pressure is required for regeneration valve to operate effectively.

ELECTRICAL FACILITIES: An uninterrupted alternating current (A/C) supply is required. Note: Other voltages are availa-

ble. Please make sure your voltage supply is compatible with your unit before installation.

EXISTING PLUMBING: Condition of existing plumbing should be free from lime and iron buildup. Piping that is built up heavily

with lime and/or iron should be replaced.

LOCATION OF MATRIXX TANK AND DRAIN: The Infusion tank should be located close to a drain to prevent air breaks and

back flow.

CAUTION: Water pressure is not to exceed 80 psi, water temperature is not to exceed 110°F (43°C), and the unit cannot be subjected to

freezing conditions.

Media Installation

Assembly Instructions

Media Installation (for HTO systems please refer to the Quick Start Guide)

1) Remove the tank from carton.

2) Verify the riser tube is centered in the bottom center of the tank. A flashlight may be necessary.

3) Place a piece of duct tape over the riser tube so no media enters the riser while filling.

4) Make sure the riser is centered to facilitate the valve installation after installation of the media.

5) Use the Blue Funnel provided, to pour the media into the

tank. Pour it evenly around the hole to ensure it is well distributed in the tank and pour slow enough, to keep from

plugging the hole.

6) When media is installed move tank side to side to settle the

media.

7

Installation, Operation and Maintenance Manual

Matrixx MX-100, MX-150, MX-200 System

Assembly Instructions

Valve Installation

1) Remove the tape from the riser and discard.

2) Lubricate the two o-rings with a light coat of Silicone.

3) Install the Upper Basket to the valve, twisting it to lock it in place (if not already installed).

4) Slip the Upper Basket over the Riser sliding it down into place and screw the valve on and tighten.

5) Follow the installation procedures in this manual and program accordingly.

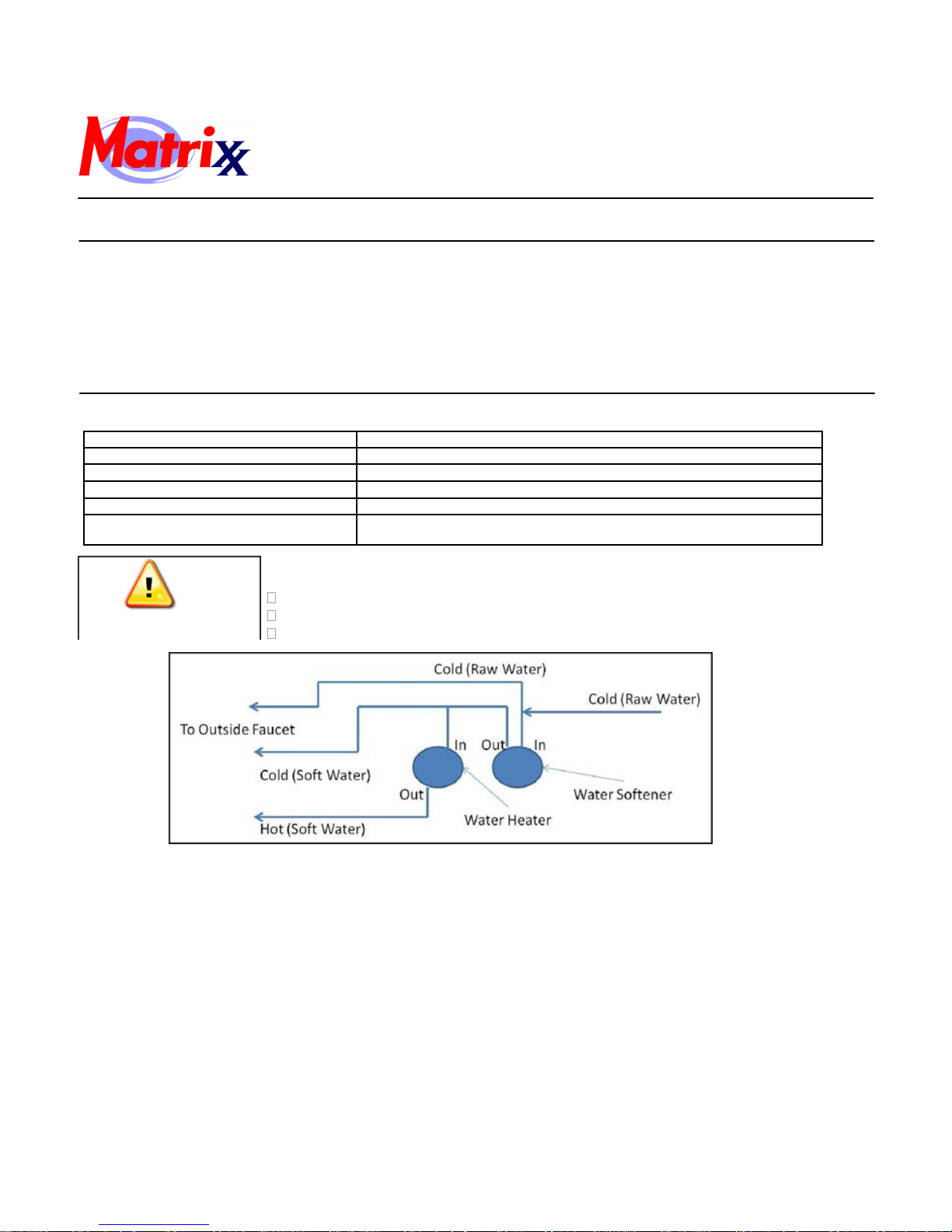

General Installation

Water Pressure Minimum 25 PSI

Electrical Supply Uninterrupted AC

Existing Plumbing Free of any deposits or build-ups inside pipes.

Unit Location

Bypass Valves Always provide for bypass valve if unit is not equipped with one.

Plumbing

Locate close to drain and connect according to plumbing codes

Softener and or other water treatment equipment should be installed to local plumbing codes

CAUTION

Do not exceed 120 psi water pressure.

Do not exceed 110°F water temperature.

Do not subject unit to freezing conditions.

Figure 5. Piping Diagram

1. Locate the softener tank and brine tank close to a drain where the system will be installed. The surface should be clean a nd

level.

8

Loading...

Loading...