Page 1

mvBlueFOX

Technical Manual

Page 2

CONTENTS i

Contents

1 About this manual 2

1.1 Composition of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 How to get started? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.2 Driver concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.3 Image acquisition concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.4 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Imprint 7

3 Revisions 8

4 Graphic Symbols 12

4.1 Notes, Warnings, Attentions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Webcasts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Important information 13

5.1 High-Speed USB design guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 European Union Declaration of Conformity statement . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Legal notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3.1 For customers in the U.S.A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3.2 For customers in Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3.3 Pour utilisateurs au Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 Introduction 19

6.1 Order code nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 mvBlueFOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 mvBlueFOX-M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.4 mvBlueFOX-IGC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.5 mvBlueFOX-MLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.6 What's inside and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

MATRIX VISION GmbH

Page 3

ii CONTENTS

7 Quickstart 24

7.1 Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1.1 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1.2 Installing the mvIMPACT Acquire driver . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.1.3 Installing the hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2 Linux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2.1 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2.2 Installing the mvIMPACT Acquire driver . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2.3 Installing the hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3 Relationship between driver, firmware and FPGA file . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3.1 FPGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.3.2 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

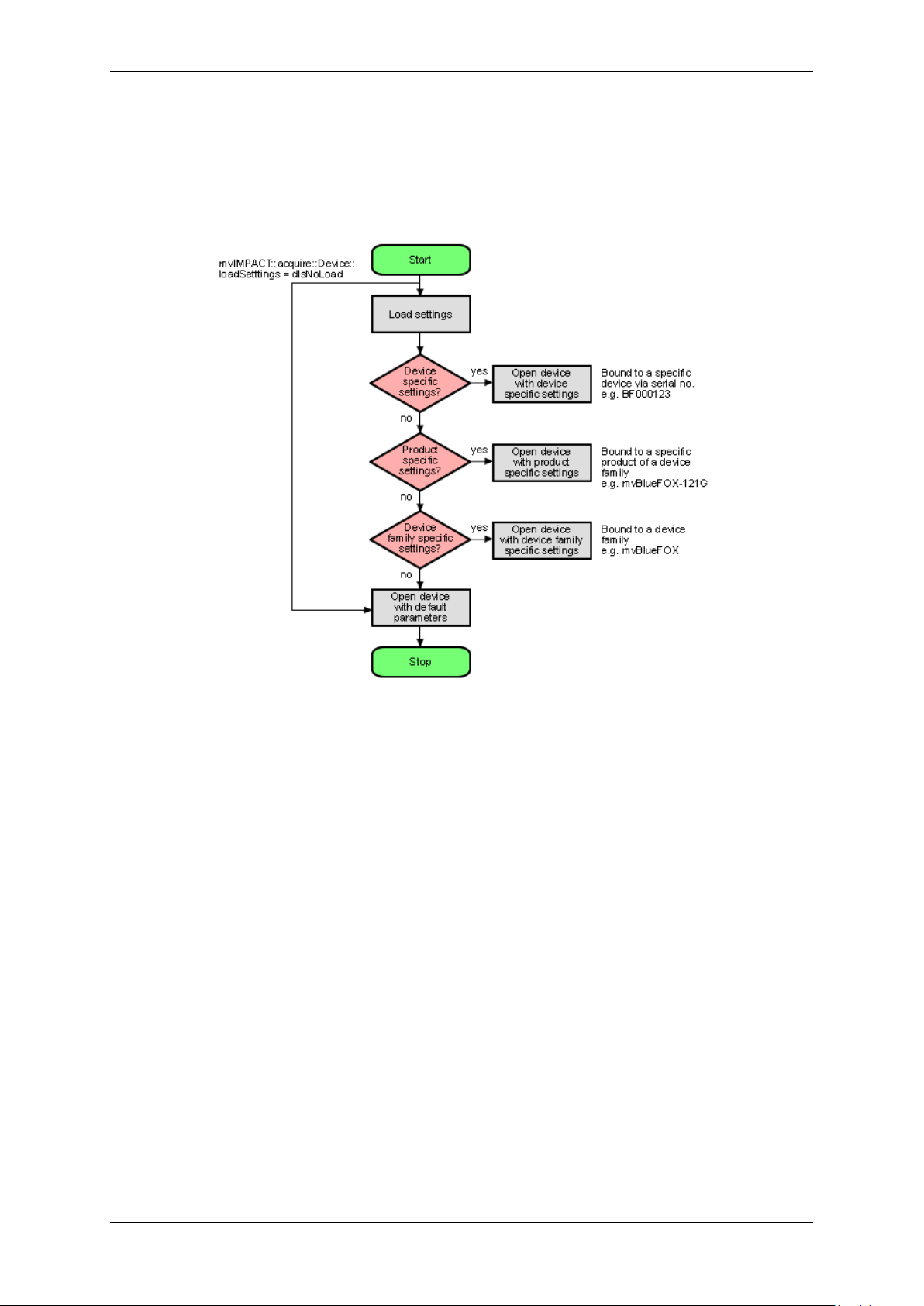

7.4 Settings behaviour during startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8 Technical data 45

8.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.2 Standard version (mvBlueFOX-xxx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

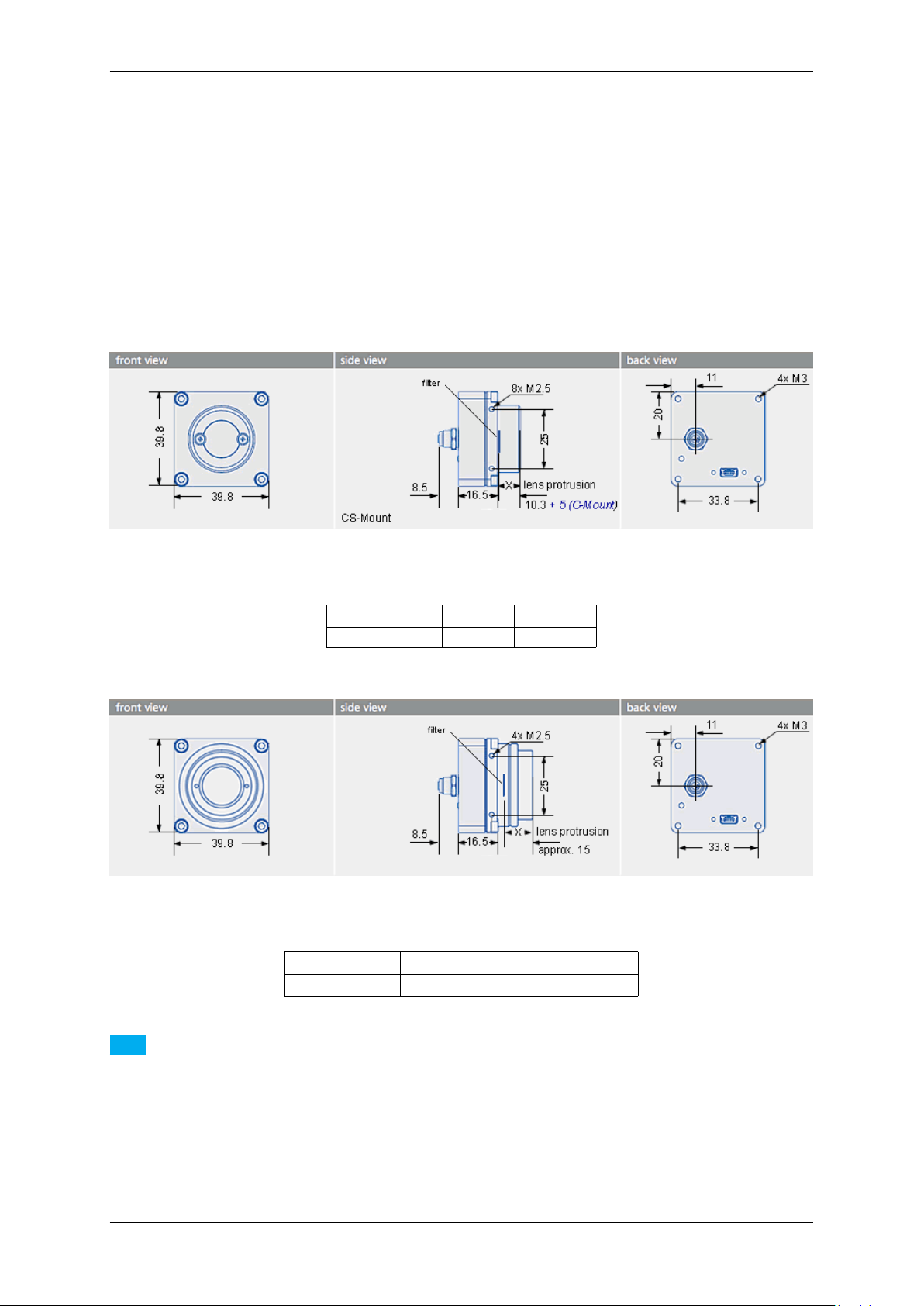

8.2.1 Dimensions and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.2.2 LED states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.2.3 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.3 Board-level version (mvBlueFOX-Mxxx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.3.1 Dimensions and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.3.2 LED states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.3.3 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.3.4 Accessories mvBlueFOX-Mxxx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.4 Single-board version (mvBlueFOX-MLC2xx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.4.1 Typical Power consumption @ 5V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.4.2 Dimensions and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.4.3 LED states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.4.4 Assembly variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.5 Single-board version with housing (mvBlueFOX-IGC2xx) . . . . . . . . . . . . . . . . . . . . . . 67

8.5.1 Dimensions and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.5.2 LED states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.5.3 Positioning tolerances of sensor chip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

MATRIX VISION GmbH

Page 4

CONTENTS iii

9 Sensor overview 70

9.1 CCD sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.2 CMOS sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.3 Output sequence of color sensors (RGB Bayer) . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.4 Bilinear interpolation of color sensors (RGB Bayer) . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10 Filters 75

10.1 Hot mirror filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.2 Cold mirror filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.3 Glass filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

11 Application Usage 77

11.1 wxPropView . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11.1.1 How to work with wxPropView . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11.1.2 How to configure a device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

11.1.3 Command-line options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.2 mvDeviceConfigure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

11.2.1 How to set the device ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

11.2.2 How to update the firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

11.2.3 How to disable CPU sleep states a.k.a. C states (< Windows 8) . . . . . . . . . . . . . . 120

11.2.4 Command-line options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

12 HRTC - Hardware Real-Time Controller 124

12.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

12.1.1 Operating codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

12.2 How to use the HRTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

13 C developers 126

14 C++ developers 127

15 .NET developers 128

MATRIX VISION GmbH

Page 5

iv CONTENTS

16 Python developers 129

16.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

16.2 Building . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

16.2.1 Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

16.2.2 Linux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

16.3 Using . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

17 DirectShow Interface 133

17.1 Supported Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

17.1.1 IAMCameraControl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

17.1.2 IAMDroppedFrames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

17.1.3 IAMStreamConfig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

17.1.4 IAMVideoProcAmp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

17.1.5 IKsPropertySet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

17.1.6 ISpecifyPropertyPages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

17.2 Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

17.3 Registering and renaming devices for DirectShow usage . . . . . . . . . . . . . . . . . . . . . . . 134

17.3.1 Registering devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

17.3.2 Renaming devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

17.3.3 Make silent registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

18 Troubleshooting 138

18.1 Accessing log files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

18.1.1 Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

18.1.2 Linux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

MATRIX VISION GmbH

Page 6

CONTENTS v

19 Use cases 139

19.1 Introducing acquisition / recording possibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

19.1.1 Generating very long exposure times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

19.1.2 Using VLC Media Player . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

19.2 Improving the acquisition / image quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

19.2.1 Correcting image errors of a sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

19.2.2 Optimizing the color fidelity of the camera . . . . . . . . . . . . . . . . . . . . . . . . . . 151

19.3 Working with triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

19.3.1 Using external trigger with CMOS sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 160

19.4 Working with HDR (High Dynamic Range Control) . . . . . . . . . . . . . . . . . . . . . . . . . . 161

19.4.1 Adjusting sensor -x00w . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

19.4.2 Adjusting sensor -x02d (-1012d) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

19.5 Working with LUTs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

19.5.1 Introducing LUTs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

19.6 Saving data on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

19.6.1 Creating user data entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

19.7 Working with device features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

19.8 Working with several cameras simultaneously . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

19.8.1 Using 2 mvBlueFOX-MLC cameras in Master-Slave mode . . . . . . . . . . . . . . . . . . 173

19.8.2 Synchronize the cameras to expose at the same time . . . . . . . . . . . . . . . . . . . . 178

19.9 Working with the Hardware Real-Time Controller (HRTC) . . . . . . . . . . . . . . . . . . . . . . 179

19.9.1 Single camera samples (HRTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

19.9.2 Multiple camera samples (HRTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

MATRIX VISION GmbH

Page 7

vi CONTENTS

20 Appendix A.1 CCD specific camera / sensor data 190

20.1 mvBlueFOX-[Model]220 (0.3 Mpix [640 x 480]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

20.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

20.1.2 Details of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

20.1.3 CCD Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

20.1.4 Reprogramming CCD Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

20.1.5 CCD Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

20.1.6 CCD Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

20.1.7 Device Feature And Property List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

20.2 mvBlueFOX-[Model]220a (0.3 Mpix [640 x 480]) . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

20.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

20.2.2 Details of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

20.2.3 CCD Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

20.2.4 Reprogramming CCD Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

20.2.5 CCD Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

20.2.6 Device Feature And Property List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

20.3 mvBlueFOX-[Model]221 (0.8 Mpix [1024 x 768]) . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

20.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

20.3.2 Details of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

20.3.3 CCD Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

20.3.4 Reprogramming CCD Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

20.3.5 CCD Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

20.3.6 CCD Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

20.3.7 Device Feature And Property List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

20.4 mvBlueFOX-[Model]223 (1.4 Mpix [1360 x 1024]) . . . . . . . . . . . . . . . . . . . . . . . . . . 214

20.4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

20.4.2 Details of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

20.4.3 CCD Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

20.4.4 Reprogramming CCD Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

20.4.5 CCD Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

20.4.6 CCD Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

20.4.7 Device Feature And Property List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

20.5 mvBlueFOX-[Model]224 (1.9 Mpix [1600 x 1200]) . . . . . . . . . . . . . . . . . . . . . . . . . . 222

20.5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

20.5.2 Details of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

20.5.3 CCD Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

20.5.4 Reprogramming CCD Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

20.5.5 CCD Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

20.5.6 CCD Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

20.5.7 Device Feature And Property List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

MATRIX VISION GmbH

Page 8

CONTENTS 1

21 Appendix A.3 CMOS specific camera / sensor data 231

21.1 mvBlueFOX-[Model]200w (0.4 Mpix [752 x 480]) . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

21.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

21.1.2 Details of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

21.1.3 Measured frame rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

21.1.4 Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

21.1.5 Device Feature And Property List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

21.2 mvBlueFOX-[Model]202a (1.3 Mpix [1280 x 1024]) . . . . . . . . . . . . . . . . . . . . . . . . . . 234

21.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

21.2.2 Details of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

21.2.3 Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

21.2.4 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

21.2.5 Device Feature And Property List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

21.3 mvBlueFOX-[Model]202b (1.2 Mpix [1280 x 960]) . . . . . . . . . . . . . . . . . . . . . . . . . . 237

21.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

21.3.2 Details of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

21.3.3 Measured frame rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

21.3.4 Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

21.3.5 Device Feature And Property List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

21.4 mvBlueFOX-[Model]202d (1.2 Mpix [1280 x 960]) . . . . . . . . . . . . . . . . . . . . . . . . . . 241

21.4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

21.4.2 Details of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

21.4.3 Measured frame rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

21.4.4 Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

21.4.5 Device Feature And Property List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

21.5 mvBlueFOX-[Model]205 (5.0 Mpix [2592 x 1944]) . . . . . . . . . . . . . . . . . . . . . . . . . . 244

21.5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

21.5.2 Details of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

21.5.3 Measured frame rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

21.5.4 Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

21.5.5 Device Feature And Property List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

MATRIX VISION GmbH

Page 9

2 CONTENTS

1 About this manual

1.1 Composition of the manual

This manual is based on a modular concept and contains several individual books. That means like in many objectoriented programming languages for each specific functionality you will have your own "class". Instead of classes,

you have books. For example, if you want to know anything about the GUI based applications, then you have to go

to the Application Usage (p. 77) book. If you want to know how images are acquired with your device, have a look

in the respective programming language chapter.

Here is a short summary about all books that form this manual:

• The manual starts with technical data about the device like sensors (for cameras) or electrical characteristics

as well as a quick start chapter.

Afterwards, you will find the different books:

• The installation package comes with a couple of tools offering a graphical user interface (GUI (p. 77)) to

control mvIMPACT Acquire compliant devices.

– wxPropView (p.77) can be used to capture image data and to change parameters like AOI or gain

– mvDeviceConfigure (p. 116) can be used to e.g. perform firmware updates, assign a unique ID to a

device that is stored in non-volatile memory or to configure to log-message output.

• HRTC - Hardware Real-Time Controller (p. 124)

– It is possible to define sequences of operating steps to control acquisition or time critical I/O. This FPGA

built-in functionality is called Hardware Real-Time Controller (short: HRTC).

• DirectShow developers (p. 133)

– This is the documentation of the MATRIX VISION DirectShow_acquire interface.

• Use cases (p. 139)

– This book offers solutions and explanations for standard use cases.

For C, C++, .NET developers, there are separate mvIMPACT Acquire manuals describing the API. Please refer to

the Programming (p.6) section

These documents can either be downloaded from http://www.matrix-vision.com or come as part of an

installation package. The manuals e.g. contain information about

• how to link and build applications using mvIMPACT Acquire

• how the log output for mvIMPACT Acquire devices is configured and how it works in general

• how to create custom client installers packages for Windows and Linux

• the API itself

1.2 How to get started?

This chapter gives you a short overview, how to get started with your device and where to find the necessary

information in the manual. It will also explain or link to the concepts behind the driver and the image acquisition.

Furthermore it explains how to get started programming own applications.

MATRIX VISION GmbH

Page 10

1.2 How to get started? 3

1.2.1 Installation

To install the mvBlueFOX properly you have to follow these steps:

(Please follow the links for detailed descriptions.)

• Windows:

– Check the system requirements (p.24).

– Install the software and driver (p. 25).

– Install the hardware (p.27).

– Configure the mvBlueFOX (p. 77)

e.g. make a white balance (p. 102) (color sensors).

*

• Linux:

– Check the system requirements (p.31).

– Install the software and driver (p. 33).

– Install the hardware (p.39).

– Configure the mvBlueFOX (p. 77)

e.g. make a white balance (p. 102) (color sensors).

*

1.2.2 Driver concept

The driver supplied with the MATRIX VISION product represents the port between the programmer and the

hardware. The driver concept of MATRIX VISION provides a standardized programming interface to all image

processing products (excluding mvBlueLYNX) made by MATRIX VISION GmbH.

The advantage of this concept for the programmer is that a developed application runs without the need for any

major modifications to the various image processing products made by MATRIX VISION GmbH. You can also

incorporate new driver versions, which are available for download free of charge on our website: http://www.←-

matrix-vision.com.

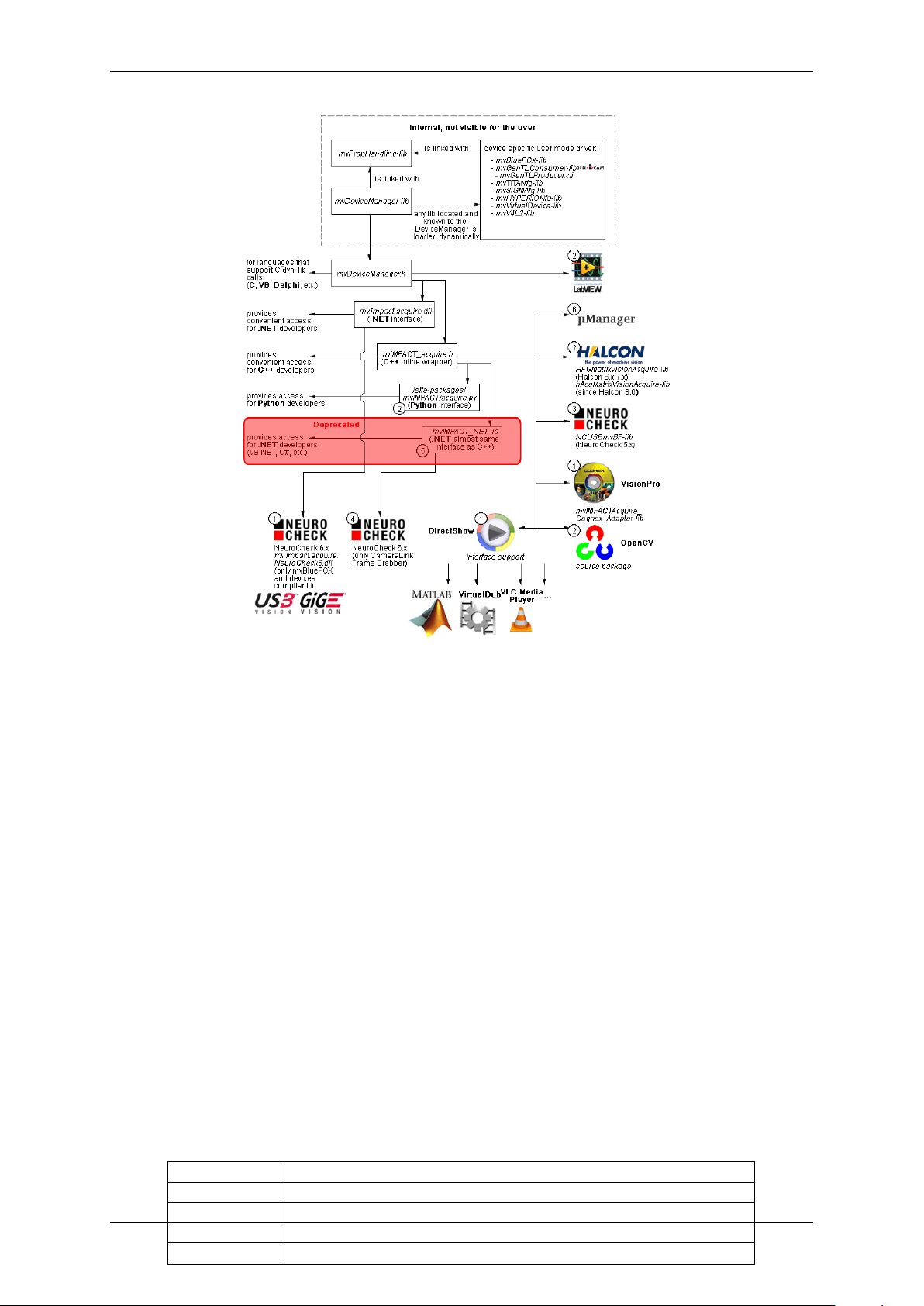

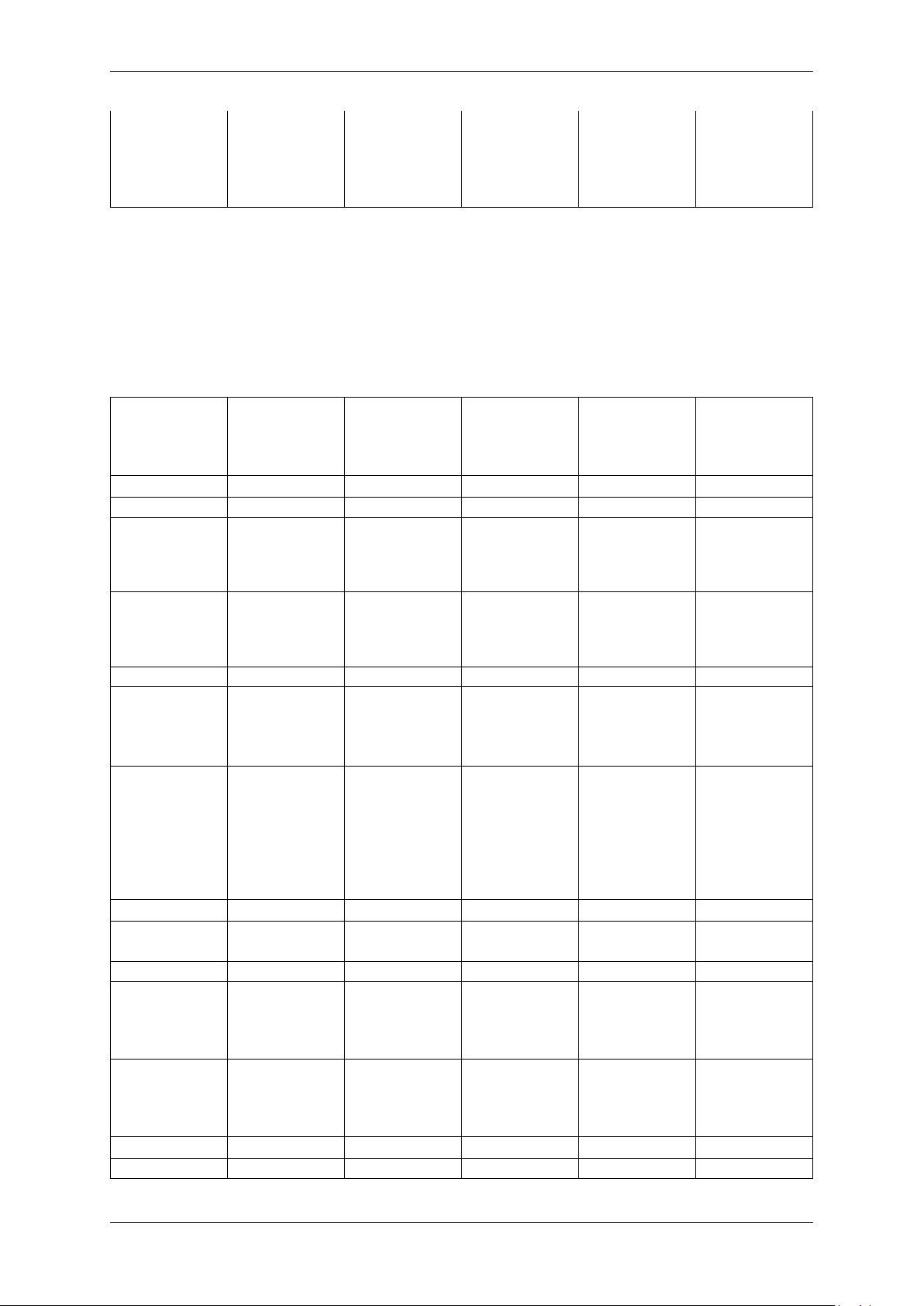

The following diagram shows a schematic structure of the driver concept:

MATRIX VISION GmbH

Page 11

4 CONTENTS

Figure 1: Driver concept

• 1 Part of any mvIMPACT Acquire driver installation package (Windows).

• 2 Separately available for 32 bit and 64 bit. Requires at least one installed driver package.

• 3 See 2, but requires an installed version of the mvBlueFOX driver.

• 4 Part of the NeuroCheck installer but requires at least one installed frame grabber driver.

• 5 Part of the mvIMPACT SDK installation. However, new designs should use the .NET libs that are now part

of mvIMPACT Acquire ("mv.impact.acquire.dll"). The namespace "mv.impact.acquire" of

"mv.impact.acquire.dll" provides a more natural and more efficient access to the same features

as contained in the namespace "mvIMPACT_NET.acquire" of "mvIMPACT_NET.dll", which is why

the latter one should only be used for backward compatibility but NOT when developing a new application.

• 6 Part of Micro-Manager.

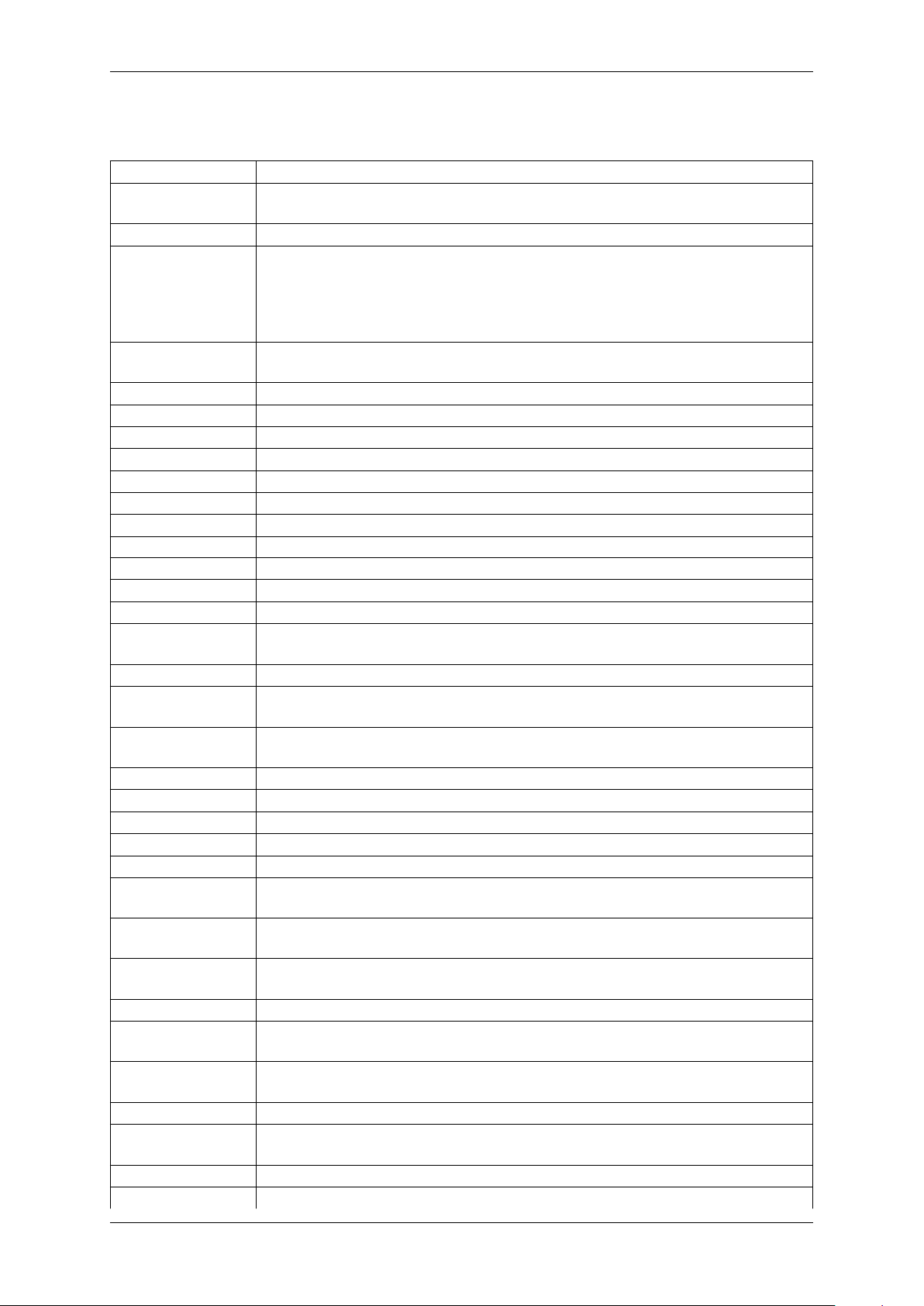

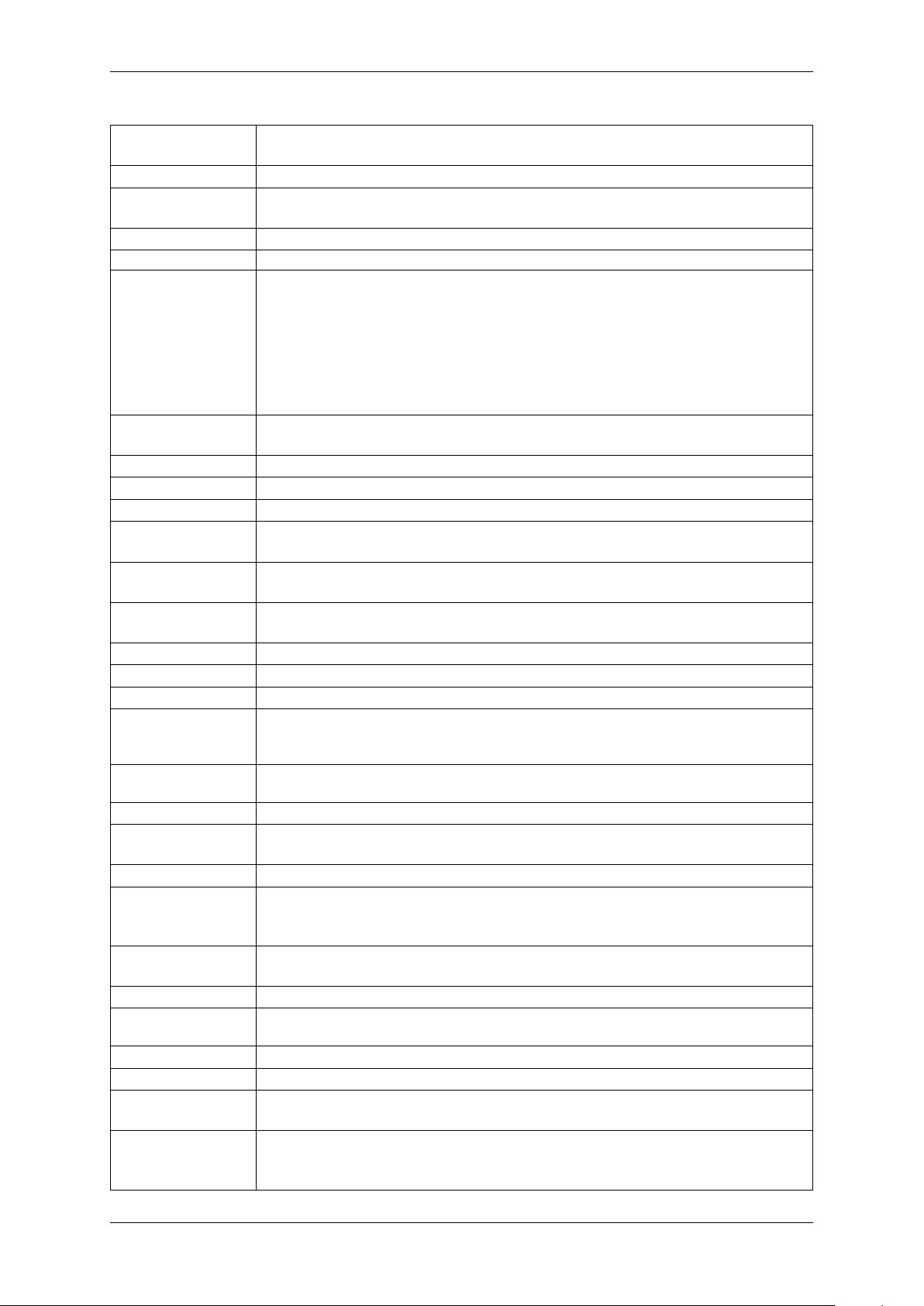

1.2.2.1 NeuroCheck support

A couple of devices are supported by NeuroCheck. However between NeuroCheck 5.x and NeuroCheck 6.x there

has been a breaking change in the internal interfaces. Therefore also the list of supported devices differs from one

version to another and some additional libraries might be required.

For NeuroCheck 5.x the following devices are supported:

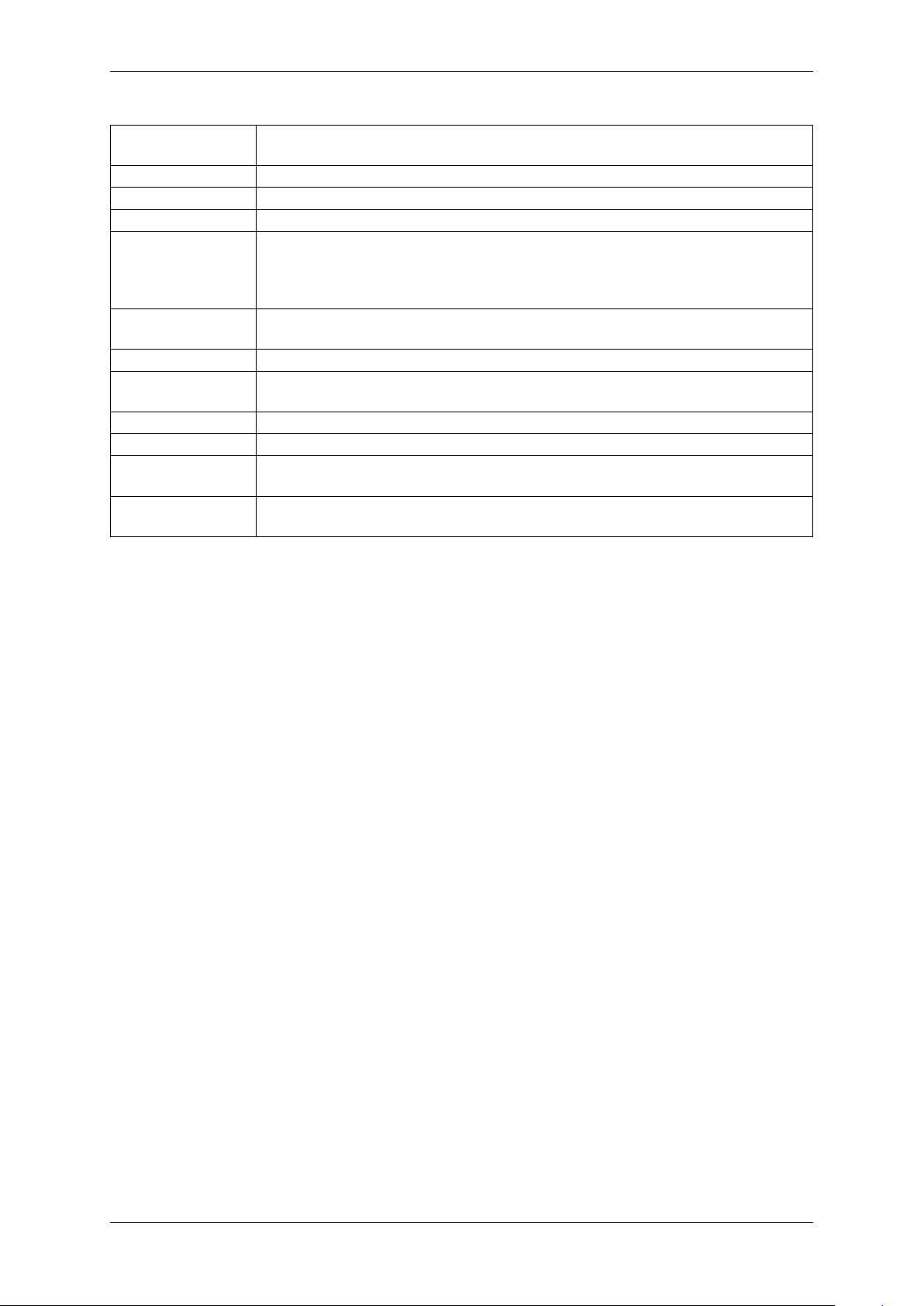

Device Additional software needed

mvTITAN-G1 mvSDK driver for mvTITAN/mvGAMMA devices

mvTITAN-CL mvSDK driver for mvTITAN/mvGAMMA devices

mvGAMMA-CL mvSDK driver for mvTITAN/mvGAMMA devices

mvBlueFOX mvIMPACT Acquire driver for mvBlueFOX devices, "NCUSBmvBF.dll"

MATRIX VISION GmbH

Page 12

1.2 How to get started? 5

For NeuroCheck 6.0 the following devices are supported:

Device Additional software needed

mvTITAN-G1 mvIMPACT Acquire driver for mvTITAN/mvGAMMA de-

vices

mvTITAN-CL mvIMPACT Acquire driver for mvTITAN/mvGAMMA de-

vices

mvGAMMA-CL mvIMPACT Acquire driver for mvTITAN/mvGAMMA de-

vices

mvHYPERION-CLb mvIMPACT Acquire driver for mvHYPERION devices

Every other mvIMPACT Acquire compliant device mvIMPACT Acquire driver for the corresponding device

family, "mv.impact.acquire.NeuroCheck6.←-

dll" (comes with the driver package, but the driver

package must be installed AFTER installing NeuroCheck 6

For NeuroCheck 6.1 the following devices are supported:

Device Additional software needed

mvTITAN-G1 mvIMPACT Acquire driver for mvTITAN/mvGAMMA de-

vices

mvTITAN-CL mvIMPACT Acquire driver for mvTITAN/mvGAMMA de-

vices

mvGAMMA-CL mvIMPACT Acquire driver for mvTITAN/mvGAMMA de-

vices

mvHYPERION-CLb mvIMPACT Acquire driver for mvHYPERION devices

Every other mvIMPACT Acquire compliant device mvIMPACT Acquire driver for the corresponding device

family, "mv.impact.acquire.NeuroCheck6_←-

1.dll" (comes with the driver package, but the driver

package must be installed AFTER installing NeuroCheck

6.1

1.2.2.2 VisionPro support

Every mvIMPACT Acquire driver package under Windows comes with an adapter to VisionPro from Cognex. The

installation order does not matter. After the driver package and VisionPro has been installed, the next time VisionPro

is started it will allow selecting the mvIMPACT Acquire device. No additional steps are needed.

MATRIX VISION devices that also comply with the GigE Vision or USB3 Vision standard don't need any software

at all, but can also use VisionPro's built-in GigE Vision or USB3 Vision support.

1.2.2.3 HALCON support

HALCON comes with built-in support for mvIMPACT Acquire compliant devices, so once a device driver has been

installed for the mvIMPACT Acquire device, it can also be operated from a HALCON environment using the corresponding acquisition interface. No additional steps are needed.

MATRIX VISION devices that also comply with the GigE Vision or USB3 Vision standard don't need any software

at all, but can also use HALCON's built-in GigE Vision or USB3 Vision support.

As some mvIMPACT Acquire device driver packages also come with a GenTL compliant interface, these can also

be operated through HALCON's built-in GenTL acquisition interface.

MATRIX VISION GmbH

Page 13

6 CONTENTS

1.2.2.4 LabVIEW support

Every mvIMPACT Acquire compliant device can be operated under LabVIEW through an additional set of VIs which

is shipped by MATRIX VISION as a separate installation ("mvLabVIEW Acquire").

MATRIX VISION devices that also comply with the GigE Vision or USB3 Vision standard don't need any additional

software at all, but can also be operated through LabVIEW's GigE Vision or USB3 Vision driver packages.

1.2.2.5 DirectShow support

Every mvIMPACT Acquire compliant device driver package comes with an interface to DirectShow. In order to be

usable from a DirectShow compliant application, devices must first be registered for DirectShow support. How to

this is explained here (p.134).

1.2.2.6 Micro-Manager support

Every mvIMPACT Acquire compliant device can be operated under https://micro-manager.org when

using mvIMPACT Acquire 2.18.0 or later and at least Micro-Manager 1.4.23 build AFTER 15.12.2016. The

adapter needed is part of the Micro-Manager release. Additional information can be found here: https←-

://micro-manager.org/wiki/MatrixVision.

1.2.2.6.1 code

• https://valelab4.ucsf.edu/svn/micromanager2/trunk/DeviceAdapters/Matrix←-

Vision/

• https://valelab4.ucsf.edu/trac/micromanager/browser/DeviceAdapters/←-

MatrixVision

1.2.3 Image acquisition concept

The image acquisition is based on queues to avoid the loss of single images. With this concept you can acquire images via single acquisition or triggered acquisition. For detailed description of the acquisition concept, please have

a look at "How the capture process works" in the mvIMPACT_Acquire_API manual matching the programming

language you are working with.

1.2.4 Programming

To understand how to control the device and handle image data you will have a good introduction by reading the

main pages of the corresponding mvIMPACT Acquire interface reference. Additionally, please have a look at the

example programs. Several basic examples are available. For details please refer to

• the C API (p. 126) section

• the C++ API (p. 127) section

• the .NET API (p. 128) section

• the Python API (p. 129) section

depending on the programming language you will use for your application.

MATRIX VISION GmbH

Page 14

2 Imprint 7

2 Imprint

MATRIX VISION GmbH

Talstrasse 16

DE - 71570 Oppenweiler

Telephone: +49-7191-9432-0

Fax: +49-7191-9432-288

Website: http://www.matrix-vision.de

E-Mail:

info@matrix-vision.de

support@matrix-vision.de

jobs@matrix-vision.de

Author

U. Lansche

Date

2016

This document assumes a general knowledge of PCs and programming.

Since the documentation is published electronically, an updated version may be available online. For this reason we

recommend checking for updates on the MATRIX VISION website.

MATRIX VISION cannot guarantee that the data is free of errors or is accurate and complete and, therefore, assumes no liability for loss or damage of any kind incurred directly or indirectly through the use of the information of

this document.

MATRIX VISION reserves the right to change technical data and design and specifications of the described products

at any time without notice.

Copyright

MATRIX VISION GmbH. All rights reserved. The text, images and graphical content are protected by copyright

and other laws which protect intellectual property. It is not permitted to copy or modify them for trade use or

transfer. They may not be used on websites.

• Windows® XP, Windows® Vista, Windows® 7 are trademarks of Microsoft, Corp.

• Linux® is a trademark of Linus Torvalds.

All other product and company names in this document may be the trademarks and tradenames of their

respective owners and are hereby acknowledged.

The manual has been generated with Doxygen (Website: http://www.doxygen.org).

Parts of the log file creation and the log file display make use of Sarissa (Website: http://dev.←-

abiss.gr/sarissa) which is distributed under the GNU GPL version 2 or higher, GNU LGPL version

2.1 or higher and Apache Software License 2.0 or higher. The Apache Software License 2.0 is part of this

driver package.

MATRIX VISION GmbH

Page 15

8 CONTENTS

3 Revisions

Date Description

21. December 2016 Updated Setting up multiple display support and/or work with several capture set-

tings in parallel (p. 91).

15. December 2016 Added Micro-Manger in Driver concept (p. 3).

23. August 2016 Added measured frame rates of sensors mvBlueFOX-[Model]200w (0.4 Mpix [752 x

480]) (p. 231)

mvBlueFOX-[Model]202b (1.2 Mpix [1280 x 960]) (p. 237)

mvBlueFOX-[Model]202d (1.2 Mpix [1280 x 960]) (p. 241)

mvBlueFOX-[Model]205 (5.0 Mpix [2592 x 1944]) (p. 244).

01. August 2016 Extended use case Take two images with different expose times after an external

trigger (HRTC) (p. 184).

11. May 2016 Added Quick Setup Wizard (p. 77).

02. December 2015 Updated CE declarations (p.14).

25. November 2015 Added Troubleshooting (p. 138).

27. October 2015 Added Command-line options (p. 115).

04. August 2015 Added Windows 10 support.

19. June 2015 Restructured chapter Use cases (p. 139).

23. April 2015 Added use case Edge controlled triggering (HRTC) (p. 186).

16. April 2015 Updated supported Windows versions.

15. April 2015 Added lens protrusion.

11. March 2015 Added chapter Accessing log files (p. 100).

26. February 2015 Moved Creating double acquisitions (HRTC) (p. 183) to HRTC Use Cases.

27. January 2015 Added use case Using VLC Media Player (p. 140). Renewed Order code nomencla-

ture (p. 19).

09. January 2015 Extended sample Using 2 mvBlueFOX-MLC cameras in Master-Slave mode (p. 173).

10. December 2014 Corrected Order code nomenclature (p. 19) : mvBlueFOX cameras without filter have

the order code 9 (excluding mvBlueFOX-MLC).

01. December 2014 Extended use case Using 2 mvBlueFOX-MLC cameras in Master-Slave mode

(p. 173).

25. November 2014 Corrected the possible HRTC - Hardware Real-Time Controller (p. 124) steps to 256.

21. October 2014 Added description about the record mode in How to see the first image (p.82).

17. July 2014 Added use case Introducing LUTs (p.168).

25. April 2014 Added description about Working with the hardware Look-Up-Table (LUT) (p.113).

25. March 2014 Added use case Correcting image errors of a sensor (p.143).

10. March 2014 mvDeviceConfigure (p.116) extended.

Added S-mount lensholder for mvBlueFOX-MLC in Order code nomenclature (p. 19).

18. February 2014 Updated Characteristics (p.243) of mvBlueFOX-[Model]202d (1.2 Mpix [1280 x 960])

(p. 241).

13. January 2014 Changed figure 3 in Using 2 mvBlueFOX-MLC cameras in Master-Slave mode

(p. 173).

12. December 2013 Changed figure in Using 2 mvBlueFOX-MLC cameras in Master-Slave mode (p. 173).

06. December 2013 Added information about Changing the view of the property grid to assist writing

code that shall locate driver features (p. 99).

22. November 2013 Extended information in Adjusting sensor -x00w (p. 161) and Adjusting sensor -x02d

(-1012d) (p. 165).

30. October 2013 Enhanced cable description in 12-pin Wire-to-Board header (USB 2.0 / Dig I/O) (p. 60).

15. October 2013 Added Webcasts (p. 12) links.

Added chapter Bit-shifting an image (p. 98).

09. October 2013 Added information about Positioning tolerances of sensor chip (p. 69).

02. September 2013 Updated Order code nomenclature (p. 19).

MATRIX VISION GmbH

Page 16

3 Revisions 9

22. April 2013 Added chapter Sensor's optical midpoint and orientation (p. 60) and corrected feature

table in CMOS sensors (p.72) (software trigger).

19. March 2013 Update Figure 4 in chapter Dimensions and connectors (p.45) and added Figure 5.

24. January 2013 Added information about image error counts and disabling CPU sleep states: How to

disable CPU sleep states a.k.a. C states (< Windows 8) (p. 120).

16. January 2013 Added status LED description of the mvBlueFOX-MLC (p. 66).

14. December 2012 New version of technical documentation.

07. December 2012 All parts of the manual to do with programming are available as a separate manual now:

• "mvIMPACT_Acquire_API_CPP_manual.chm",

• "mvIMPACT_Acquire_API_C_manual.chm", and

• "mvIMPACT_Acquire_API_NET_manual.chm". These manuals can be download from http://www.matrix-vision.com.

30. September 2012 Moved Working with the Hardware Real-Time Controller (HRTC) (p. 179) to Use

cases (p. 139).

20. September 2012 Added chapter "Porting existing code written with versions earlier then 3.0.0".

17. August 2012 Added use case Adjusting sensor -x02d (-1012d) (p. 165).

16. July 2012 Extended "Characteristics of the digital inputs" in D-Sub 9-pin (male) (p. 45).

21. June 2012 Added description, how to install the Linux driver using the installer script (Installing the

mvIMPACT Acquire driver (p. 33)).

21. June 2012 Added information (electrical characteristic, pinning (p. 59)) about LVTTL version

(mvBlueFOX-MLC2xxx-XLW).

02. April 2012 Enhanced chapter Output sequence of color sensors (RGB Bayer) (p. 73) and

added chapter Bilinear interpolation of color sensors (RGB Bayer) (p. 74).

17. February 2012 Renewed chapter wxPropView (p.77).

09. November 2011 Added Settings behaviour during startup (p. 42) in chapter Quickstart (p. 24).

21. September 2011 Added SXGA sensor (p. 241) -202d. Added mvBlueFOX-IGC (p. 67) information.

26. July 2011 Removed chapter

EventHandling. See "Porting existing code written with versions earlier then 2.←-

0.0".

11. July 2011 Added chapters

"Callback demo".

08. Juli 2011 Added chapter Using 2 mvBlueFOX-MLC cameras in Master-Slave mode (p.173).

06. June 2011 Added chapters

"Porting existing code written with versions earlier then 2.0.0".

31. May 2011 Added chapter Creating double acquisitions (HRTC) (p. 183).

26. April 2011 Added chapter Using external trigger with CMOS sensors (p.160).

Updated chapter Dimensions and connectors (p. 59) (digital inputs TTL, digital outputs

TTL) of mvBlueFOX-MLC version.

18. January 2011 Added chapter Setting up multiple display support and/or work with several capture

settings in parallel (p. 91).

29. Nov. 2010 Added ADC resolutions in Sensor overview (p. 70).

19. October 2010 Added chapters

"Chunk data format".

07. Oct. 2010 Added High-Speed USB design guidelines (p. 14).

22. Sep. 2010 Added suitable for mvBlueFOX-MLC What's inside and accessories (p. 22).

26. Aug. 2010 Added cable end color of board-to-wire cable in Dimensions and connectors (p. 59).

Added chapter about Creating user data entries (p. 171).

02. Aug. 2010 mvBlueFOX-200W and mvBlueFOX-MLC100W support flash control output: CMOS

sensors (p.72).

Added chapter Import and Export images (p. 90).

MATRIX VISION GmbH

Page 17

10 CONTENTS

21. Jun. 2010 Included exposure modes in the frame rate calculator of the Sensor overview (p. 70).

31. May 2010 Added chapter Single-board version (mvBlueFOX-MLC2xx) (p.59).

19. Apr. 2010 Added new example ContinuousCaptureDirectX.

01. Apr. 2010 Added Use cases (p. 139) about high dynamic range (p. 161) of sensor mvBlueFOX-

[Model]200w (0.4 Mpix [752 x 480]) (p. 231).

10. Feb. 2010 Added note about Windows XP Embedded in System Requirements (p.24).

28. Jan. 2010 Added chapter Copy grid data to the clipboard (p. 90).

13. Jan. 2010 Added chapters

"Porting existing code written with versions earlier then 1.12.0".

11. Jan. 2010 Due to a software update, documentation of CMOS sensor (-x00w) (p.231) updated.

10. Nov. 2009 Added Windows 7 as supported operating system.

22. Oct 2009 Updated sensor data (p. 70).

19. Oct 2009 Updated wxPropView (p. 77) description about handling settings.

22. Sep. 2009 Added Wide-VGA sensor (p. 231) and removed sensor -x02.

17. Sep. 2009 Updated frame rate calculator of CCD sensors (p.70).

05. May 2009 Added figures which shows "how to connect flash to digital output".

05. May 2009 Added book Use cases (p. 139), which offers solutions and explanations for standard

use cases.

22. Jan. 2009 Added information about how to test the gerenal trigger functionality of the camera Set-

ting up external trigger and flash control (p.105).

26. Nov. 2008 Added chapter Setting up external trigger and flash control (p.105).

28. Oct 2008 Added mvBlueFOX-M accessory Accessories mvBlueFOX-Mxxx (p.56).

21. Jul. 2008 Added power supply note in 4-pin circular plug-in connector with lock (USB 2.0)

(p. 45).

11. Jun. 2008 Added preliminary sensor data of -105 in Sensor overview (p. 70).

10. Jun. 2008 Updated sensor data of -121 in Sensor overview (p.70).

09. Apr. 2008 Corrected Figure 4: DIG OUT mvBlueFOX-1xx in Dimensions and connectors (p. 45).

25. Feb. 2008 Added note about EEPROM of mvBlueFOX-M in Dimensions and connectors (p.51).

19. Feb. 2008 Corrected sensor data in Sensor overview (p.70).

30. Jan. 2008 Added note about the obsolete differentiation between 'R' and 'U' version in chapter

Dimensions and connectors (p.45).

01. Oct 2007 Update sensor data in chapter Order code nomenclature (p. 19).

20. Aug. 2007 Added part number of JST connectors used on the mvBlueFOX-M (see: Dimensions

and connectors (p.51)).

31. Jul. 2007 Rewritten "How rto use this manual". This book now includes a getting started chapter

(see: Composition of the manual (p. 2)).

11. Jun. 2007 Updated images in digital I/O description of mvBlueFOX-M (see: Dimensions and con-

nectors (p.51)).

29. May 2007 Added an attention in chapter Quickstart (p. 24) section Installing the hardware (p. 27)

(Windows) and Installing the hardware (p. 39) (Linux).

23. May 2007 Added calculators to calculate the frame rate of the sensors (see specific sensor

documentation: Sensor overview (p. 70)).

23. Apr. 2007 Updated sensor description and added description of Micron's CMOS 1280x1024 (-

102a) (p. 234) sensor.

02. Apr. 2007 Updated description of mvBlueFOX-M1xx digital I/O in chapter Dimensions and con-

nectors (p.51).

29. Jan. 2007 Repainted DigI/O images (see: Dimensions and connectors (p. 45)).

24. Nov. 2006 Added attention to the DigI/O description of the mvBlueFOX-M (see: Dimensions and

connectors (p.51)).

14. Nov. 2006 Updated Linux installation documentation (see: Quickstart (p. 24)).

20. Oct 2006 Updated Linux installation documentation (see: Quickstart (p. 24)).

11. Sep. 2006 Devided the Quickstart chapter into Linux® and Windows® (see: Quickstart (p. 24)).

MATRIX VISION GmbH

Page 18

3 Revisions 11

8. Sep. 2006 Updated CCD timing in CCD 640 x 480 (1/3") documentation (see: mvBlueFOX[Model]220a (0.3 Mpix [640 x 480]) (p. 198)).

5. Sep. 2006 Updated the sensor data (see: Sensor overview (p. 70)).

23. Aug. 2006 Added general tolerance of the housing (see: Technical data (p.45)).

28. Jul. 2006 Removed some linking errors.

19. Jul. 2006 Added WEEE-Reg.-No. (see: European Union Declaration of Conformity statement

(p. 14)).

Added ambient temperature of the mvBlueFOX standard version (see: Components

(p. 50)).

17. Jun. 2006 New chapter "Configure the log output using mvDeviceConfigure" (see: "Configure the

log output using mvDeviceConfigure").

07. Jun. 2006 Extended the HRTC documentation (see: How to use the HRTC (p. 124)).

02. Jun. 2006 Fixed image errors in CCD 640 x 480 (1/3") documentation (see: mvBlueFOX-

[Model]220a (0.3 Mpix [640 x 480]) (p. 198)).

01. Jun. 2006 Updated the chm index.

18. May 2006 Sensor description: Changed black/white to gray scale (see: Sensor overview (p. 70)).

14. Feb. 2006 Added CCD 640 x 480 (1/3") (see: mvBlueFOX-[Model]220a (0.3 Mpix [640 x 480])

(p. 198)).

13. Feb. 2006 Corrected the image of the "4-pin circular plug-in connector" (see: Dimensions and

connectors (p.45)).

MATRIX VISION GmbH

Page 19

12 CONTENTS

4 Graphic Symbols

4.1 Notes, Warnings, Attentions

Note

A note indicates important information that helps you optimize usage of the products.

Warning

A warning indicates how to avoid either potential damage to hardware or loss of data.

Attention

An attention indicates a potential for property damage, personal injury, or death.

All due care and attention has been taken in preparing this manual. In view of our policy of continuous product

improvement, however, we can accept no liability for completeness and correctness of the information contained in

this manual. We make every effort to provide you with a flawless product.

In the context of the applicable statutory regulations, we shall accept no liability for direct damage, indirect damage

or third-party damage resulting from the acquisition or operation of a MATRIX VISION product. Our liability for intent

and gross negligence is unaffected. In any case, the extend of our liability shall be limited to the purchase price.

4.2 Webcasts

This icon indicates a webcast about an issue which is available on our website.

MATRIX VISION GmbH

Page 20

5 Important information 13

5 Important information

We cannot and do not take any responsibility for the damage caused to you or to any other equipment

connected to the mvBlueFOX. Similarly, warranty will be void, if a damage is caused by not following

the manual.

Handle the mvBlueFOX with care. Do not misuse the mvBlueFOX. Avoid shaking, striking, etc. The

mvBlueFOX could be damaged by faulty handling or shortage.

Use a soft cloth lightly moistened with a mild detergent solution when cleaning the camera.

Never face the camera towards the sun. Whether the camera is in use or not, never aim at the sun or

other extremely bright objects. Otherwise, blooming or smear may be caused.

Please keep the camera closed or mount a lens on it to avoid the CCD or the CMOS from getting

dusty.

Clean the CCD/CMOS faceplate with care. Do not clean the CCD or the CMOS with strong or abrasive

detergents. Use lens tissue or a cotton tipped applicator and ethanol.

Never connect two USB cables to the mvBlueFOX even if one is only connected to a PC.

The mvBlueFOX is bus powered < 2.5 W.

The mvBlueFOX meets IP40 standards.

Using the single-board or board-level versions:

MATRIX VISION GmbH

• Handle with care and avoid damage of electrical components by electrostatic discharge (ESD):

– Discharge body static (contact a grounded surface and maintain contact).

– Avoid all plastic, vinyl, and styrofoam (except antistatic versions) around printed circuit

boards.

– Do not touch components on the printed circuit board with your hands or with conductive

devices.

Page 21

14 CONTENTS

5.1 High-Speed USB design guidelines

If you want to make own High-Speed (HS) USB cables, please pay attention to following design guidelines:

• Route High-Speed (HS) USB signals with a minimum number of vias and sharp edges!

• Avoid stubs!

• Do not cut off power planes VCC or GND under the signal line.

• Do not route signals no closer than 20 ∗ h to the copper layer edge if possible (h means height over the

copper layer).

• Route signal lines with 90 Ohm +- 15% differential impedance.

– 7.5 mil printed circuit board track with 7.5 mil distance result in approx. 90 Ohm @ 110 um height over

GND plane.

– There are other rules when using double-ply printed circuit boards.

• Be sure that there is 20 mil minimum distance between High-Speed USB signal pair and other printed circuit

board tracks (optimal signal quality).

5.2 European Union Declaration of Conformity statement

The mvBlueFOX complies with the provision of the following European Directives:

• 2014/30/EU (EMC directive)

• 2014/35/EU (LVD - low voltage directive)

• For EN 61000-6-3:2007, mvBlueFOX-IGC with digital I/O needs the Steward snap-on ferrite

28A0350-0B2 on I/O cable.

• For EN 61000-6-3:2007, mvBlueFOX-MLC with digital I/O needs the Würth Elektronik snap-on

ferrite WE74271142 on I/O cable and copper foil on USB.

MATRIX VISION corresponds to the EU guideline WEEE 2002/96/EG on waste electrical and electronic equipment and is registered under WEEE-Reg.-No. DE 25244305.

MATRIX VISION GmbH

Page 22

5.2 European Union Declaration of Conformity statement 15

MATRIX VISION GmbH

Page 23

16 CONTENTS

MATRIX VISION GmbH

Page 24

5.3 Legal notice 17

5.3 Legal notice

5.3.1 For customers in the U.S.A.

MATRIX VISION GmbH

Page 25

18 CONTENTS

Class B

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a residential environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. However there is no guarantee that interferences will not occur in a particular

installation. If the equipment does cause harmful interference to radio or television reception, the user is encouraged

to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the distance between the equipment and the receiver.

• Use a different line outlet for the receiver.

• Consult a radio or TV technician for help.

You are cautioned that any changes or modifications not expressly approved in this manual could void your authority

to operate this equipment. The shielded interface cable recommended in this manual must be used with this

equipment in order to comply with the limits for a computing device pursuant to Subpart B of Part 15 of FCC Rules.

• To be compliant to FCC Class B, mvBlueFOX-IGC requires an I/O cable with an retrofittable ferrite to be used

such as

– Company: Steward Type: 28A0350-0B2

5.3.2 For customers in Canada

This apparatus complies with the Class B limits for radio noise emissions set out in the Radio Interference Regulations.

5.3.3 Pour utilisateurs au Canada

Cet appareil est conforme aux normes classe B pour bruits radioélectriques, spécifiées dans le Règlement sur le

brouillage radioélectrique.

MATRIX VISION GmbH

Page 26

6 Introduction 19

6 Introduction

The mvBlueFOX is a compact industrial CCD & CMOS camera solution for any PC with a Hi-Speed USB (USB

2.0) port. A superior image quality makes it suited for most applications. Integrated preprocessing like binning

reduces the PC load to a minimum. The standard Hi-Speed USB interface guarantees an easy integration without

any additional interface board. To make the cameras flexible to any industrial applications, the image processing

tools mvIMPACT as well as different example solutions are available

Figure 1: mvBlueFOX

The mvBlueFOX is suitable for following tasks:

• machine vision

• robotics

• surveillance

• microscopy

• medical imaging

With the name mvBlueFOX-M1xx, the industrial camera mvBlueFOX is also available as a single-board version.

6.1 Order code nomenclature

6.2 mvBlueFOX

The mvBlueFOX nomenclature scheme is as follows:

mvBlueFOX - A B - (1) (2) (3) (4)

- A: Sensor model

220: 0.3 Mpix, 640 x 480, 1/4", CCD

220a: 0.3 Mpix, 640 x 480, 1/3", CCD

200w: 0.4 Mpix, 752 x 480, 1/3", CMOS

221: 0.8 Mpix, 1024 x 768, 1/3", CCD

202a: 1.3 Mpix, 1280 x 1024, 1/2", CMOS

223: 1.4 Mpix, 1360 x 1024, 1/2", CCD

224: 1.9 Mpix, 1600 x 1200, 1/1.8", CCD

205: 5.0 Mpix, 2592 x 1944, 1/2.5", CMOS

- B: Sensor color

G: Gray scale version

C: Color version

- (1): Lensholder

1: C-mount with adjustable backfocus (standard)

MATRIX VISION GmbH

Page 27

20 CONTENTS

2: CS-mount with adjustable backfocus

3: S-mount

- (2): Filter

1: IR-CUT (standard)

2: Glass

3: Daylight cut

9: None

- (3): Case

1: Color blue (standard)

2: Color black, no logo, no label MATRIX VISION

3: Color blue, no logo, no label MATRIX VISION

9: None

- (4): Misc

1: None (standard)

6.3 mvBlueFOX-M

The mvBlueFOX-M nomenclature scheme is as follows:

mvBlueFOX-M A B - (1) (2) (3) (4)

- A: Sensor model

220: 0.3 Mpix, 640 x 480, 1/4", CCD

220a: 0.3 Mpix, 640 x 480, 1/3", CCD

200w: 0.4 Mpix, 752 x 480, 1/3", CMOS

221: 0.8 Mpix, 1024 x 768, 1/3", CCD

202a: 1.3 Mpix, 1280 x 1024, 1/2", CMOS

223: 1.4 Mpix, 1360 x 1024, 1/2", CCD

224: 1.9 Mpix, 1600 x 1200, 1/1.8", CCD

205: 5.0 Mpix, 2592 x 1944, 1/2.5", CMOS

- B: Sensor color

G: Gray scale version

C: Color version

- (1): Lensholder

1: No holder (standard)

2: C-mount with adjustable backfocus

3: CS-mount with adjustable backfocus

4: S-mount #9031

5: S-mount #9033

- (2): Filter

1: None (standard)

2: IR-CUT

3: Glass

4: Daylight cut

- (3): Misc

1: None (standard)

- (4): Misc

1: None (standard)

6.4 mvBlueFOX-IGC

The mvBlueFOX-IGC nomenclature scheme is as follows:

mvBlueFOX-IGC A B - (1) (2) (3) (4)

- A: Sensor model

200w: 0.4 Mpix, 752 x 480, 1/3", CMOS

202b: 1.2 Mpix, 1280 x 960, 1/3", CMOS

202d: 1.2 Mpix, 1280 x 960, 1/3", CMOS

202a: 1.3 Mpix, 1280 x 1024, 1/2", CMOS

205: 5.0 Mpix, 2592 x 1944, 1/2.5", CMOS

- B: Sensor color

G: Gray scale version

C: Color version

MATRIX VISION GmbH

Page 28

6.5 mvBlueFOX-MLC 21

- (1): Lensholder

1: CS-mount without adjustable backfocus (standard)

2: C-mount without adjustable backfocus (CS-mount with add. 5 mm extension ring)

3: C-mount with adjustable backfocus

- (2): Filter

1: IR-CUT (standard)

2: Glass

3: Daylight cut

4: none

- (3): Case

1: Color blue (standard)

2: Color black, no logo, no label MATRIX VISION

9: None

- (4): I/O

1: None (standard)

2: With I/O #08727

6.5 mvBlueFOX-MLC

The mvBlueFOX-MLC nomenclature scheme is as follows:

mvBlueFOX-MLC A B - C D E - (1) (2) (3) (4)

- A: Sensor model

200w: 0.4 Mpix, 752 x 480, 1/3", CMOS

202b: 1.2 Mpix, 1280 x 960, 1/3", CMOS

202d: 1.2 Mpix, 1280 x 960, 1/3", CMOS

202a: 1.3 Mpix, 1280 x 1024, 1/2", CMOS

205: 5.0 Mpix, 2592 x 1944, 1/2.5", CMOS

- B: Sensor color

G: Gray scale version

C: Color version

- C: Mini USB

U: with Mini USB (standard)

X: without Mini USB

- D: Digital I/Os

O: 1x IN + 1x OUT opto-isolated (standard)

T: 2x TTL IN + 2x TTL OUT

L: 3x LVTTL IN

- E: Connector

W: board-to-wire (standard)

B: board-to-board

- (1): Lensholder

1: No holder (standard)

2: C-mount with adjustable backfocus (CS-mount with add. 5 mm extension ring)

3: CS-mount with adjustable backfocus

4: C-mount without adjustable backfocus

5: CS-mount without adjustable backfocus

6: LENSHOLDER SH01F08V3 #09851

7: LENSHOLDER SH02M13V2 #09951

8: LENSHOLDER SH03H16V2 #09850

- (2): Filter

1: None (standard)

2: IR-CUT

3: Glass

4: Daylight cut

- (3): Misc

1: None (standard)

- (4): Misc

1: None (standard)

Examples:

MATRIX VISION GmbH

Page 29

22 CONTENTS

mvBlueFOX-120G

mvBlueFOX-102C

mvBlueFOX-M121C

1

1

1

640 x 480, CCD 1/4", gray

1280 x 1024, CMOS 1/2", color

1024 x 768, CCD 1/3", color, module

mvBlueFOX-MLC200wC-XOW-5111 752 x 480, CMOS 1/3", color, single-board, without Mini-USB, 1x IN +

1x OUT opto-isolated, board-to-wire, CS-mount (w/o backfocus adjustment)

1

: -1111 is the standard delivery variant and for this reason it is not mentioned.

6.6 What's inside and accessories

Due to the varying fields of application the mvBlueFOX is shipped without accessories. The package contents:

• mvBlueFOX

• mvIMPACT CD-ROM or DVD-ROM with example application and manual

• instruction leaflet

For the first use of the mvBlueFOX we recommend the following accessories to get the camera up and running:

• A USB 2.0 cable

Attention

According to the customer and if the mvBlueFOX-MLC is shipped without lensholder, the mvBlueFOX-MLC

will be shipped with a protective foil on the sensor. Before usage, please remove this foil!

Accessories for the mvBlueFOX:

Part code Description

ADAPTER CS-MOUNT Lens fixing for mvBlueFOX to match with CS-mount lenses

KS-USB2-AA-EXT 05.0 USB 2.0 extension, activeUSB2 A plug to USB2 A jack, length 5m

KS-USB2-AB 03.0 TR USB 2.0 cable A-B, transparent, Profi Line. Length 3m

KS-USB2-B4ST 02.0 USB 2.0 cable for mvBlueFOX, Binder 4pol to USB2-A. Length: 2m

KS-USB2-B4ST 03.0 USB 2.0 cable for mvBlueFOX, Binder 4pol to USB2-A. Length: 3m

KS-USB2-B4ST 05.0 USB 2.0 cable for mvBlueFOX, Binder 4pol to USB2-A. Length: 5m

KS-USB2-PHR4 01.5 USB connector cable for mvBlueFOX-M1xx. Length: 1.5m

KS-PHR12 500 Cable for mvBlueFOX-M1xx dig. I/O, 12-pin. Length: 500mm

1..4 brown

5..8 gray

9 red

10 black

11 yellow

12 black

KS-MLC-IO-TTL 00.5 mvBlueFOX-MLC board-to-board TTL IO cable for master-slave synchroniza-

tion (Molex plug to Molex plug), Length: 0.5m

MATRIX VISION GmbH

Page 30

6.6 What's inside and accessories 23

KS-MLC-IO-W mvBlueFOX-MLC board-to-wire I/O data cable, Molex 0510211200 with crimp

terminal 50058. Length: up to 1m

KS-MLC-USB2-IO-W mvBlueFOX-MLC board-to-wire I/O data and USB 2.0 cable, Molex

0510211200 with crimp terminal 50058 to USB2-A. Length: up to 1m

MV-Lensholder BFM-C C-mount lensholder for mvBlueFOX-M,incl. IR-Cut filter

MV-Lensholder BFM-S 9031 S-mount lensholder M12 x 0,5 type MS-9031 for mvBlueFOX-M102

MV-Lensholder BFM-S 9033 S-mount lensholder M12 x 0,5 type: MS-9033 for mvBlueFOX-M102

MV-LENSHOLDER SH02M13 S-mount lensholder M12 x 0.5, height 13mm for mvBlueFOX-MLC

MV-LENSHOLDER SH01F08 S-mount lensholder M12 x 0.5, height 8mm for mvBlueFOX-MLC

ADAPTER S-C AD01S Adapter for S-mount lens (M12x0,5) to C-mount, high penetration depth for

mvBlueFOX-IGC

ADAPTER S-C AD02F Adapter for S-mount lens (M12x0,5) to CS-mount, penetration depth: 5.5mm,

outside diameters: 31mm for mvBlueFOX-IGC

MV-Tripod Adapter BF Tripod adapter for mvBlueFOX

MATRIX VISION GmbH

Page 31

24 CONTENTS

7 Quickstart

7.1 Windows

7.1.1 System Requirements

Currently supported Windows versions are:

• Microsoft Windows 7 (32-bit, 64-bit)

• Microsoft Windows 8.1 (32-bit, 64-bit)

• Microsoft Windows 10 (32-bit, 64-bit)

Other Windows version can be used at the user's own risk.

Note

Since mvIMPACT Acquire version 2.8.0 it could be possible that you have to update your Windows installer at

least using Windows XP. The necessary packages are available from Microsoft's website: http://www.←-

microsoft.com/en-US/download/details.aspx?id=8483

All necessary drivers for Windows are contained in the standard mvIMPACT CD-ROM or DVD-ROM. For newer

driver versions we recommend to visit the MATRIX VISION website at www.matrix-vision.de, section "Products

-> Cameras -> your interface -> your product -> Downloads".

Note

For Windows XP Embedded

As mvBlueFOX cameras will register as an 'imaging device' in the systems device manager please make

sure that your Windows XP Embedded (XPe) distribution is shipped/build with support for the corresponding

device class ("Class GUID {6bdd1fc6-810f-11d0-bec7-08002be2092f}") before installing

the mvBlueFOX device driver. Otherwise, an installing of the driver when connecting a camera will fail with an

error message like "a required section in the INF file could not be found". The camera will not be accessible

then.

The mvBlueFOX is a USB 2.0 compliant camera device and needs therefore a functioning USB 2.0 port. If you are

not sure about this, please follow these steps:

1. Press "Start" and click on "Run"

2. Enter

msinfo32

3. Click on "Components" and look after "USB"

4. If there is a entry like "USB 2.0 Root Hub" or "ROOT_HUB20", your system has USB 2.0.

Please be sure that your system has at least one free USB port.

MATRIX VISION GmbH

Page 32

7.1 Windows 25

7.1.2 Installing the mvIMPACT Acquire driver

Warning

Before connecting the mvBlueFOX, please install the software and driver first!

To install the software and driver insert the mvIMPACT CD-ROM or DVD-ROM into your CD drive or download the

latest driver from our website: https://www.matrix-vision.com "Products -> Hardware ->

mvBlueFOX -> Downloads Tab".

By double clicking on "mvBlueFOX-x86-n.n.n.msi" (for 32-bit systems) or "mvBlueFOX-x86_64-n.n.n.msi" (for

64-bit systems), the mvBlueFOX installer will start automatically.

Figure 1: mvBlueFOX installer - Start window

Select the folder, where you want to install the software.

MATRIX VISION GmbH

Figure 2: mvBlueFOX installer - Select folder

Page 33

26 CONTENTS

Select the features you want to install. Following features exist:

• "Base Libraries"

This feature contains all necessary files for property handling and display. Therefore, it is not selectable.

• "mvBlueFOX driver"

This is also not selectable.

• "Tools"

This feature contains tools for the mvBlueFOX (e.g. to configure MATRIX VISION devices (mvDevice←-

Configure) or to acquire images (wxPropView)).

• "Developer API"

The Developer API" contains the header for own programming. Additionally you can choose the examples,

which installs the sources of wxPropView and three mini samples. The project files of the mini samples are

for Visual C++ 7, Visual C++ 6 and Borland C Builder 6. The wxPropView project exists only for Visual C++

7. - \b "Documentation"

This will install this mvBlueFOX manual a single HTML help file (.chm).

Figure 3: mvBlueFOX installer - Select features

Confirm the installation by clicking "Next".

MATRIX VISION GmbH

Page 34

7.1 Windows 27

Figure 4: mvBlueFOX installer - Confirm installation

The installation is finished now you can close the window.

Figure 5: mvBlueFOX installer - Finished installation

7.1.3 Installing the hardware

Warning

Before connecting the mvBlueFOX, please install the software and driver first!

It is not necessary to shutdown your system. On an USB port, it is possible to hot plug any USB device (hot plug

lets you plug in new devices and use them immediately).

MATRIX VISION GmbH

Page 35

28 CONTENTS

Warning

If using the Binder connector first connect the cable to the camera, then connect the camera to the PC.

Plug the mvBlueFOX to an USB 2.0 Port. After plugging the mvBlueFOX Windows® shows "Found New Hardware"

and starts the Windows Hardware Wizard.

Figure 6: Windows - Found new hardware

The Wizard asks you for the driver. The installation doesn't need any Windows® automatic at this step and it is

recommended to type the driver directory by hand. Choose "No, not this time" and press "Next".

Figure 7: Windows Hardware Wizard - Driver Installation

Choose "Install the software automatically" and press "Next".

MATRIX VISION GmbH

Page 36

7.1 Windows 29

Figure 8: Windows Hardware Wizard - Driver location

The Hardware Wizard installs the driver.

Figure 9: Windows Hardware Wizard - Driver location

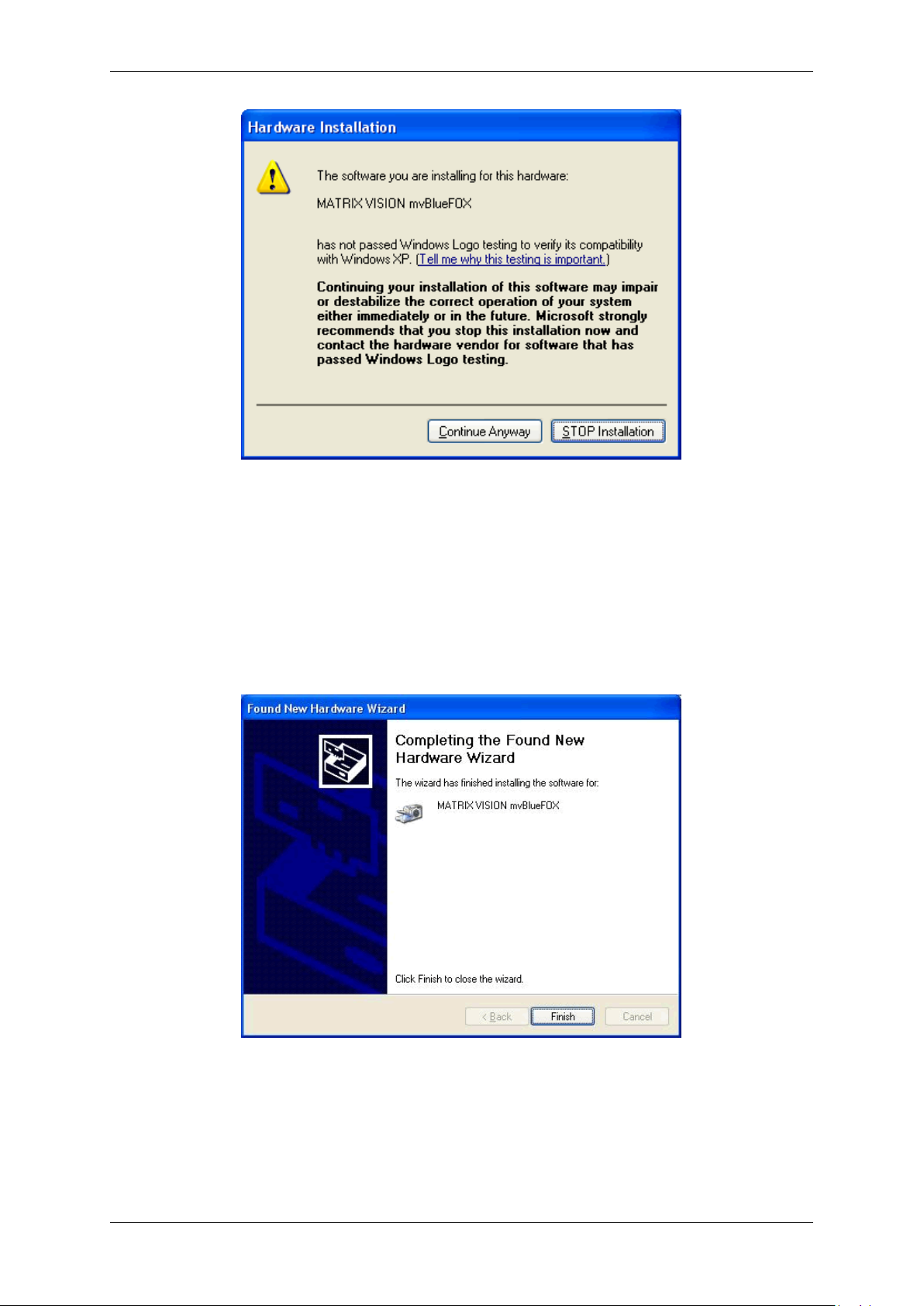

The Hardware Wizard will search the registry for the device identification and after a while the Wizard prompts you

to continue the installation or to abort it. Also Windows® will display the following message to inform the user that

this driver digitally signed by Microsoft. You have to select 'Continue anyway' otherwise, the driver can't be installed.

If you don't want to install a driver that is not signed you must stop the installation but can't work with the mvBlueFOX

camera then.

Press "Continue Anyway" and finish the driver installation.

MATRIX VISION GmbH

Page 37

30 CONTENTS

Figure 10: Windows Hardware Wizard - Windows logo testing

After the Windows® Logo testing, you have to click "Finish" to complete the installation.

Figure 11: Windows Hardware Wizard - Complete the installation

Now, you can find the installed mvBlueFOX in the Windows® "Device Manager" under image devices.

MATRIX VISION GmbH

Page 38

7.2 Linux 31

Figure 12: Windows Device Manager - Installed mvBlueFOX

After this installation, you can acquire images with the mvBlueFOX. Simply start the application wxPropView (p. 77)

(wxPropView.exe) from

mvBlueFOX/bin.

See also

wxPropView (p.77)

7.2 Linux

7.2.1 System Requirements

Kernel requirements

Kernel 2.6.x .. Kernel 3.x.x.

• usbfs support (CONFIG_USB_DEVICEFS)

Note

This is different from devfs! support. The USB device file system should, of course, be mounted at

/proc/bus/usb.

• SysV IPC support (CONFIG_SYSVIPC).

Note

Most distributions will have these kernel options turned on by default.

MATRIX VISION GmbH

Page 39

32 CONTENTS

7.2.1.1 Software requirements

• Linux x86 (32-bit)

– The 32 bit version will run on a 64-bit Linux system if the other library requirements are met with 32-bit

libraries. I.e. you cannot mix 64 and 32-bit libraries and applications.

– Versions for Linux on x86-64 (64-bit), PowerPC, ARM or MIPS may be possible on request.

• GNU compiler version GCC 3.2.x or greater and associated tool chain.

Note

Our own modified version of libusb has been statically linked to our library and is therefore included, so

libusb is not a requirement.

7.2.1.2 Other requirements

• libexpat (http://expat.sourceforge.net)

• Optional: wxWidgets 2.6.x (non Unicode) for the wxWidget test programs.

• Optional: udev or hotplug subsystem (see also 4. below).

As an example of which packets need to be installed, consider OpenSuSE 10.1:

• The compiler used is gcc 4.1.0 and may need to be installed. Use the "gcc" und "gcc-c++" RPMs. Other

RPMs may be installed automatically due to dependencies (e.g. make).

• libexpat will almost definitely be installed already in any software configuration. The RPM is called "expat".

• Install the wxWidgets "wxGTK" and "wxGTK-develop" RPMs. Others that will be automatically installed due

to dependencies include "wxGTK-compat" and "wxGTK-gl". Although the MATRIX VISION software does not

use the ODBC database API the SuSE version of wxWidgets has been compiled with ODBC support and the

RPM does not contain a dependency to automatically install ODBC. For this reason you must also install the

"unixODBC-devel" RPM.

• OpenSuSE 10.1 uses the udev system so a separate hotplug installation is not needed.

7.2.1.3 Hardware requirements

USB 2.0 Host controller (Hi-Speed) or USB 1.1 Host controller will also work (with a max. frame rate of 3 to 4 fps

at 640x480 only).

Note

We have noticed problems with some USB chip sets. At high data rates sometimes the image data appears

to be corrupted. If you experience this you could try one or more of the following things.

• a different PC.

• a plug-in PCI/USB-2.0 card without any cables between the card and the USB connector.

• turning off the image footer property - this will ignore data errors.

Note

The driver contains libraries for Linux x86 (32 bit) or Linux 64-bit (x86_64). There are separate package files

for systems with tool chains based on GNU gcc 3.2.x - 3.3.x and those based on GNU gcc >= 3.4.x. gcc 3.1.x

may work but, in general, the older your tool chain is, the lass likely it is that it will work. Tool chains based on

GNU gcc 2.x.x are not supported at all.

GCC 4.x (4.1.0) has been tested on OpenSuSE 10.1 and should work on other platforms.

This version (32-bit only) will also run in a VMware (http://www.vmware.com) virtual machine!

MATRIX VISION GmbH

Page 40

7.2 Linux 33

7.2.2 Installing the mvIMPACT Acquire driver

To use the mvBlueFOX camera within Linux (grab images from it and change its settings), a driver is needed,

consisting of several libraries and several configuration files. These files are required during run time.

To develop applications that can use the mvBlueFOX camera, a source tree is needed, containing header files,

makefiles, samples, and a few libraries. These files are required at compile time.

Both file collections are distributed in a single package:

mvBlueFOX-x86_ABI2-n.n.n.tgz

1. Please start a console and change into a directory e.g. /home/username/workspace

cd /home/username/workspace

2. Copy the install script (available as download from https://www.matrix-vision.com) and the

hardware driver to the workspace directory (e.g. from a driver CD or from the website):

~/workspace$ cp /media/cdrom/drv/Linux/install_mvBlueFOX.sh /

. && cp /media/cdrom/drv/Linux/mvBlueFOX-x86_ABI2-1.12.45.tgz -t ./

3. Run the install script:

~/workspace$ ./install_mvBlueFOX.sh

Note

The install script has to be executable. So please check the rights of the file.

During installation, the script will ask, if it should build all tools and samples.

You may need to enable the execute flag with

chmod a+x install_mvBlueFOX.sh.

The installation script checks the different packages and installs them with the respective standard packages manager (apt-get) if necessary.

Note

The installation script ("install_mvBlueFOX.sh") and the archive ("mvBlueFOX-x86_ABI2-n.←-

n.n.tgz") must reside in the same directory. Nothing is written to this directory during script execution, so

no write access to the directory is needed in order to execute the script.

You need Internet access in case one or more of the packages on which the GenICam™ libs depend are not yet

installed on your system. In this case, the script will install these packages, and for that, Internet access is required.

The script takes two arguments, both of which are optional:

1. target directory name

2. version

The target directory name specifies where to place the driver. If the directory does not yet exist, it will be created.

The path can be either absolute or relative; i.e. the name may but need not start with "/.".

MATRIX VISION GmbH

Page 41

34 CONTENTS

Note

This directory is only used for the files that are run time required.

The files required at compile time are always installed in "$HOME/mvimpact-acquire-n.n.n". The script

also creates a convenient softlink to this directory:

mvimpact-acquire -> mvIMPACT_acquire-1.12.45

If this argument is not specified, or is ".", the driver will be placed in the current working directory.

The version argument is entirely optional. If no version is specified, the most recent mvBlueFOX-x86_AB←-

I2-n.n.n.tgz found in the current directory will be installed.

You can now start wxPropView (p. 77), after installing the hardware (p. 39) like

wxPropView

because the installer script added the needed symbolic links.

Note

If you want to install the mvBlueFOX Linux driver without installer script manually, please have a look at the

following chapter:

7.2.2.1 Installing the mvIMPACT Acquire driver manually

Note

We recommend to use the installer script to install the mvBlueFOX driver (p. 33).

The mvBlueFOX is controlled by a number of user-space libraries. It is not necessary to compile kernel modules for

the mvBlueFOX.

1. Logon to the PC as the "root" user or start a super user session with "su". Start a console with "root"

privileges.

2. Determine which package you need by issuing the following command in a terminal window:

gcc -v

This will display a lot of information about the GNU gcc compiler being used on your system. In case of the

version number you have to do following:

Version Description

2.x.x (obsolete) You cannot use the mvBlueFOX on your computer. Upgrade to a newer distribution.

3.2.x or 3.3.x (obsolete) Use the C++ ABI 1. This package has ABI1 in its name.

3.4.x or 4.x.x Use the C++ ABI 2. This package has ABI2 in its name.

MATRIX VISION GmbH

Page 42

7.2 Linux 35

3. You can now install the mvBlueFOX libraries as follows:

• create a new directory somewhere on your system.

• copy the correct mvbluefox package file to this directory and change into this directory with "cd".

The mvBlueFOX libraries are supplied as a "tgz" archive with the extension ".tgz". The older

"autopackage" format is now deprecated since it cannot handle 64-bit libraries.

(a) Unpack the archive using "tar" e.g.:

tar xvzf mvBlueFOX-x86_ABI2-1.12.45.tgz

Note

Current versions of the ABI1 libraries were compiled using a SuSE 8.1 system for maximum compatibility with older Linux distributions. These libraries should work with all SuSE 8.x and SuSE

9.x versions as well as with Debian Sarge and older Red Hat / Fedora variants.

Current versions of the ABI2 libraries were compiled using a SuSE 10.1 system for maximum

compatibility with newer Linux distributions. These libraries should work with SuSE 10.x as well

as with Ubuntu 6.06 or newer, with up-to-date Gentoo or Fedora FC5.

(b) After installing the mvBlueFOX access libraries you will see something like the following directory struc-

ture in your directory (dates and file sizes will differ from the list below):

drwxr-xr-x 10 root root 4096 Jan 5 15:08 .

drwxr-xr-x 23 root root 4096 Jan 4 16:33 ..

drwxr-xr-x 3 root root 4096 Jan 5 15:08 DriverBase

-rw-r--r-- 1 root root 1079 Jan 5 15:08 Makefile

drwxr-xr-x 7 root root 4096 Jan 5 15:08 apps

drwxr-xr-x 4 root root 4096 Jan 5 15:08 common

drwxr-xr-x 3 root root 4096 Jan 5 15:08 lib

drwxr-xr-x 3 root root 4096 Jan 5 15:08 mvDeviceManager

drwxr-xr-x 2 root root 4096 Jan 5 15:08 mvIMPACT_CPP

drwxr-xr-x 3 root root 4096 Jan 5 15:08 mvPropHandling

drwxr-xr-x 1 root root 4096 Jan 5 15:08 scripts

The directory "lib/x86" contains the pre-compiled 32-bit libraries for accessing the mvBlueFOX.

If 64-bit libraries are supplied, they will be found in "lib/x86_64". The "apps" directory contains test

applications (source code). The other directories contain headers needed to write applications for the

mvBlueFOX.

Since the libraries are not installed to a directory known to the system i.e. not in the "ldconfig"

cache you will need to tell the system where to find them by...

• using the "LD_LIBRARY_PATH" environment variable,

• or copying the libraries by hand to a system directory like "/usr/lib" (or using some symbolic

links),

• or entering the directory in "/etc/ld.so.conf" and running "ldconfig".

e.g. to start the application called "LiveSnap":

Note