Engineering Safety • Advancing Automation

Matrix IntelliZone™

Proximity Detection System

Basic Information • 3rd Party

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

DO NOT DISTRIBUTE

Engineering Safety • Advancing Automation

IntelliZone™ System Index

Basic Information

System Warnings & Disclaimers (Page 3)

System Warnings & Disclaimers, System Warning Labels

System Introduction (Pages 4-6)

Objective, Overview, Expanding Zones, Directional Zones, Articulating Machi nery, “Green” Zone

System Components (Pages 7-10)

Overview, Driver, Locator, Controller, Software Key, Interconnect Board, XP Boxes, Antenna Mounts

Maintenance Guide

Driver (Page 12-14)

Overview, Splitter Layout, Driver Installation

Controller (Pages 15)

Overview, LED Statuses

System Information (Pages 16-18)

Available System Drawings, Fasteners, System Installation Guidelines

System Troubleshooting (Pages 19-22)

Driver LEDs, Locator LEDs, Audible Alarm, Locator OLED Screen, Troubleshooting Tips, System Diagnostic Codes

User Guide

Operating Guidelines (Page 24)

System Warnings, Precautions, System Overview

Driver and Locators (Page25-27)

Driver Overview, Locator Overview, LED Statuses

Emergency Stop Override (Pages 28-29)

DC, C2C, JNA

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

2

DO NOT DISTRIBUTE

System Warnings & Disclaimers

Engineering Safety • Advancing Automation

System Warnings & Disclaimers

It is important that all users / personnel that may come into contact with the IntelliZone™ Proximity Detection

System understand it’s purpose. It is NOT a safety system. It is a training aid developed to teach users safe

operating habits. User / Operator assumes full responsibility for control of the machine upon which the system

is installed. User / Operator assumes full liability for the maintenance and operation of the IntelliZone™

Proximity Detection System.

System Warning Label

The Matrix IntelliZone™ System includes several highly visible WARNING labels located on the front of the

machine-mounted Drivers, and the user-carried Locators. All users / personnel that may come into contact

with an IntelliZone™ Proximity Detection System equipped machine should familiarize themselves with all

WARNINGS associated with the system. Additional WARNING labels for the IntelliZone™ System are

available free-of-charge as requested.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

3

DO NOT DISTRIBUTE

IntelliZone™ System Introduction

Engineering Safety • Advancing Automation

Objective

The intent of IntelliZone™ Proximity Detection is to provide a practical, mine-duty system that will

automatically warn personnel when they are entering a potentially hazardous area around a machine. The

system must be able to disable some or all machine functions if a particular zone is breached.

System Overview

The Matrix IntelliZone™ Proximity Detection System assists with training personnel to stay clear of dangerous

zones present around potentially hazardous equipment. The System is designed for use on mobile equipment

such as continuous miners, mobile haulage, and other light and heavy vehicles. The System is typically

configured for two operational awareness zones: a “shutdown zone” (red) can be defined closest to the

equipment and a “warning zone” (yellow) can be defined to extend a moderate distance from the equipment.

When an IntelliZone™ Locator is detected within the red zone, the System will prompt the equipment to

immediately shutdown some or all of its functions. When an IntelliZone™ Locator is detected within the

yellow zone, the System will prompt the equipment to reduce its speed or influence other changes in

operation. If a Locator is detected within either zone, the System will initiate highly-visible flashing lights and

an audible alarm on the Locator and Drivers to warn personnel of potential hazards.

Additional IntelliZone™ awareness zones can be

configured as needed and are customizable to specific

equipment and applications.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

4

DO NOT DISTRIBUTE

Engineering Safety • Advancing Automation

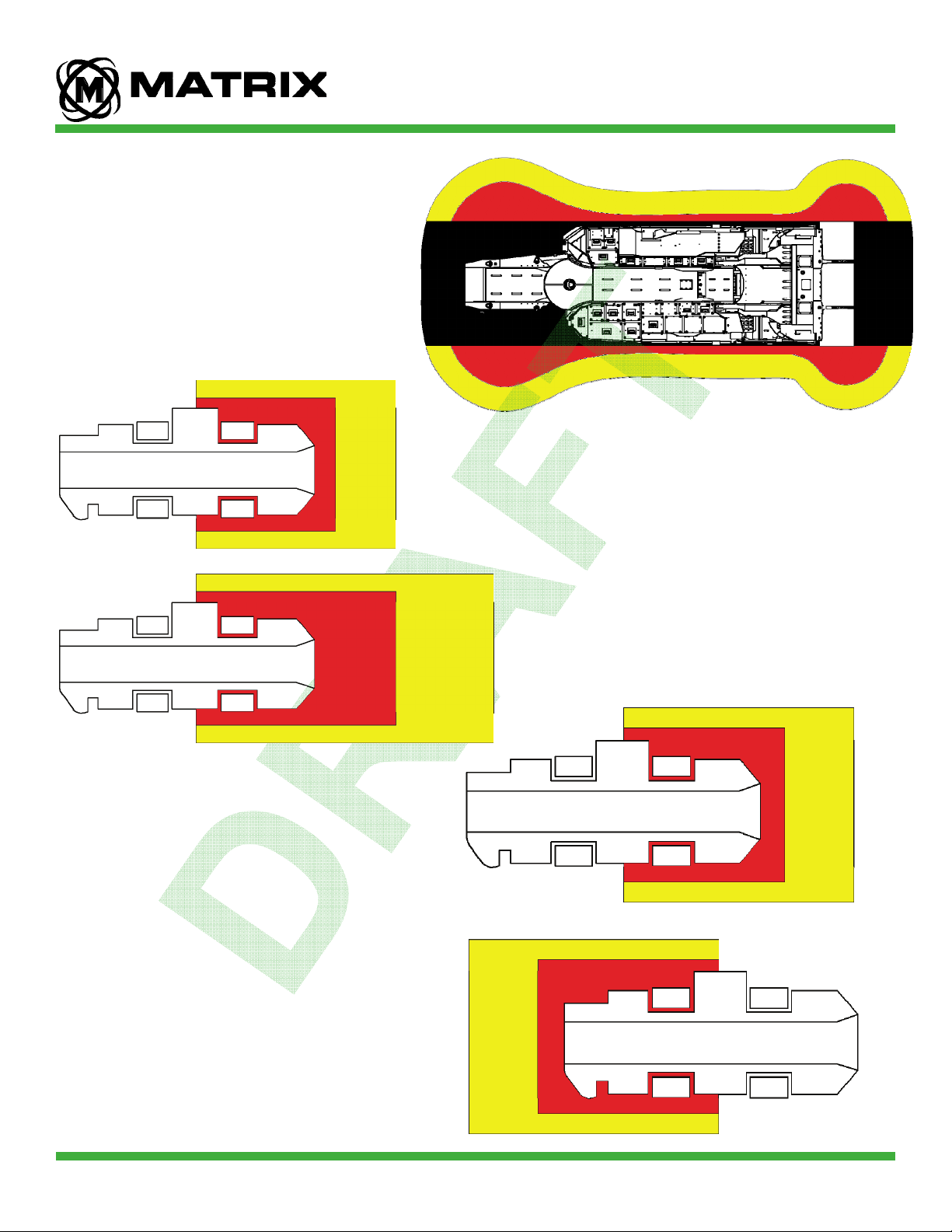

Standard Miner Configuration

Consists of a shutdown zone (red) and

warning zone (yellow), as well as operator

zone (green) while cutting. These zones are

configurable through software.

IntelliZone™ System Introduction

Expanding Mobile Equipment Zones

Directional Mobile Equipment Zones

On mobile equipment, zones can be

configured to react to the equipment’s

direction. This prevents the machine from

being shut down by personnel walking behind

it.

On mobile equipment, zones can be

configured to expand as the machine

accelerates. Oversized zones are no longer

required on faster moving equipment.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

5

Engineering Safety • Advancing Automation

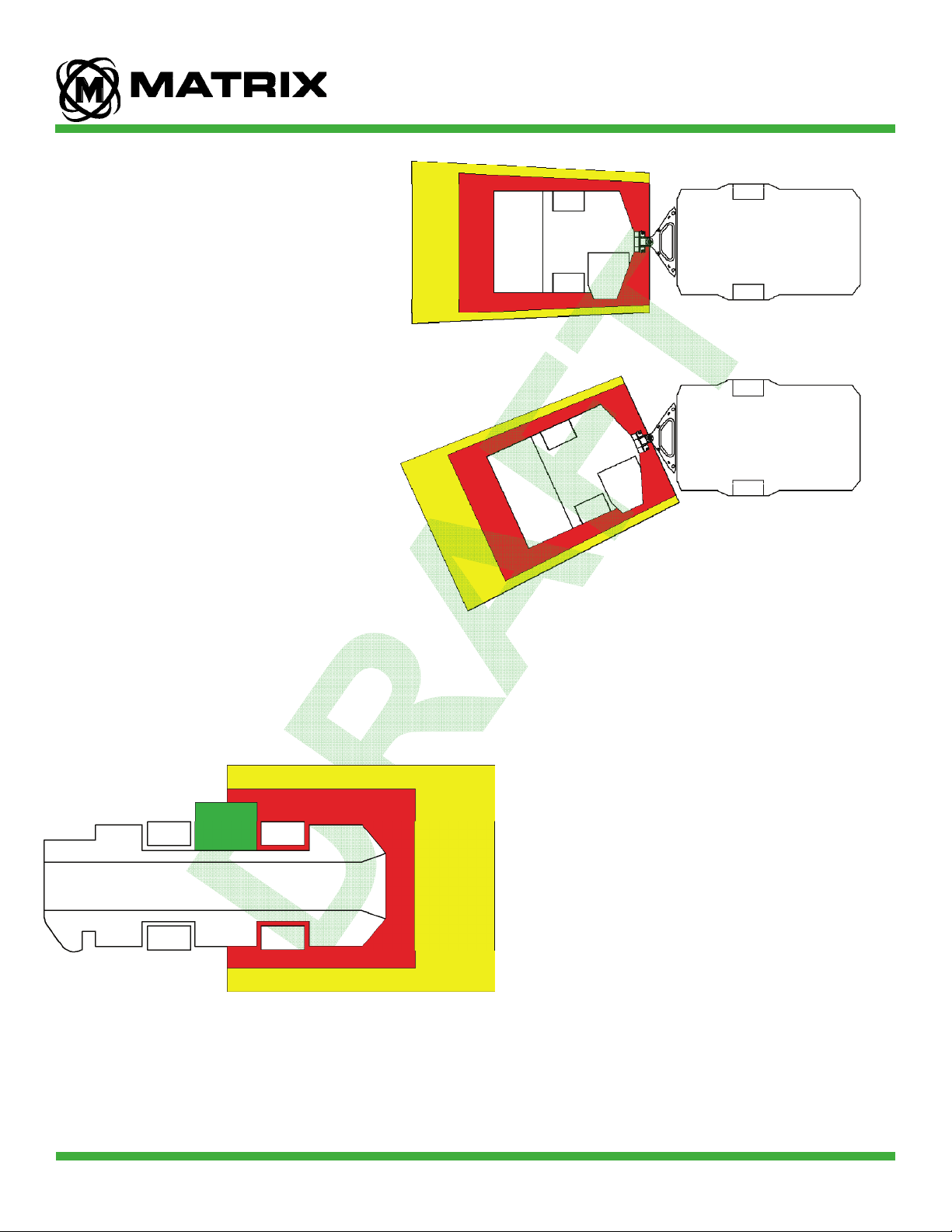

Articulating Machinery

On articulating machinery, the zones can

configured to react to the pivoting of the

machine. This enables the zones to remain

consistent even when the machine is

articulated.

DO NOT DISTRIBUTE

IntelliZone™ System Introduction

10002008 rev 0

Operator (Green) Zone

Operator zones can be configured using the

Intellizone GUI. These operator zones are

critical in that it allows the associated Locator

to be in the area without shutting down the

machinery.

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

6

DO NOT DISTRIBUTE

IntelliZone™ System Introduction

Engineering Safety • Advancing Automation

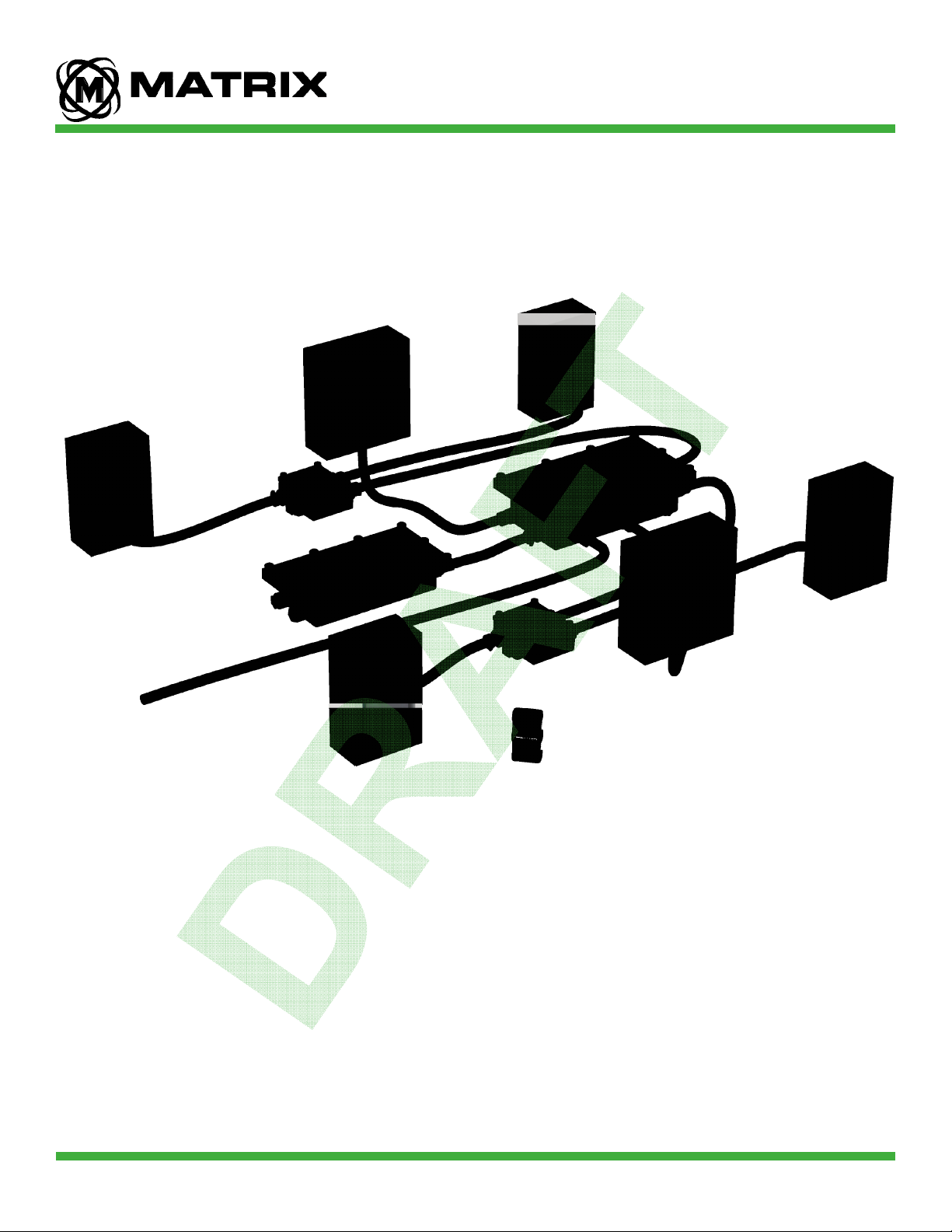

System Components

The IntelliZone™ System is approved for use in potentially hazardous MSHA-regulated environments. Below

is a typical layout for a system on a machine. System components may vary in quantity and location

depending on the machine upon which it is mounted.

❽

❼

❶

❶MX3-IZ Driver (4 shown)

❷ MX3-IZ Locator

❸ MX3-IZ Splitter Box (2 shown)

❹ M3-1000 Guarding (2 shown)

❺ MX3-IZ Antenna Mounting Kit, Retrofit (2 shown)

❷

❸

❻

❺

❹

❻ MX3-IZ Guarding (4 shown)

❼ MX3-IZ Power Supply Box

❽ MX3-IZ Proximity Controller Box

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive New-

burgh, IN 47630, USA | 812.490.1525 |

7

DO NOT DISTRIBUTE

Engineering Safety • Advancing Automation

MX3-IZ Driver

The MSHA-approved Driver allows for tracking of multiple

Locators. The Driver is machined from rugged polycarbonate and

incorporates multi-color LEDs used for diagnostics and zone

identifications.

MX3-IZ Locator

The MSHA-approved Locator is the device the operator wears

and that is tracked around the machine. The Locator also has a

built-in audible and visible warning. The operator uses this device

to associate/dissociate. It can be worn in a pouch or using a belt

clip.

IntelliZone™ System Introduction

MX3-IZ Controller

The Controller is the central processor for the IntelliZone™

System. It communicates to the mobile equipment and

Locators and provides power to 4 machine-mounted Drivers.

Personnel can connect to the Controller wirelessly (w/ adaptor)

or with an Ethernet cable to adjust settings and view system

diagnostics. This device IS NOT intrinsically safe and

MUST be inside an explosion-proof enclosure when used in

MSHA-regulated environments.

MX3-IZ Software Key

The Software Key must be installed on the Controller for the

system to function. It can be moved to a new Controller in

event of a failure. This stores the machine configuration and

provides an Industrial Ethernet connection. The Software

Key IS NOT intrinsically safe and MUST be inside an explosionproof enclosure when used in MSHA-regulated environments.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

8

DO NOT DISTRIBUTE

Engineering Safety • Advancing Automation

MX3-IZ Interconnect Board

The Interconnect Board is the hub for all relays, inputs,

outputs, power, etc. that interfaces to the Controller. This

board mounts below the Controller and is designed for easy

access to all wiring terminals. The Interconnect Board IS NOT

intrinsically safe and MUST be inside an explosion-proof

enclosure when used in MSHA-regulated environments.

Controller XP Box

This MSHA-approved enclosure houses the Controller,

Software Key, and Interconnect Board. It features 7 ports

that use 1.125-12 packing gland assemblies to ensure

the enclosure remains explosion proof.

IntelliZone™ System Introduction

Power Supply XP Box

This MSHA-approved enclosure houses the Intellizone

Power Supply. It features 4 ports that use 1.125-12

packing gland assemblies to ensure the enclosure

remains explosion proof.

Splitter XP Box

This MSHA-approved enclosure is used to minimize the number

of Controller XP Box ports needed. Typically 2 Splitter XP Boxes

are used per system; one being placed on each side of the

machinery. It features 4 ports that use 1.125-12 packing gland

assemblies to ensure the enclosure remains explosion proof.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

9

DO NOT DISTRIBUTE

Engineering Safety • Advancing Automation

Driver Guarding

The guarding around Driver is MSHA-approved and therefore

must be manufactured to specific dimensions. The outer guarding

must be at minimum 1/4” thick. The backing must be at minimum

5/8’” thick. The gap between the guarding and Driver can not

exceed 1/2”. For more information see drawing # 10000099.

IntelliZone™ System Introduction

Whip Antenna Kit

This kit includes a 2.45Ghz Whip antenna, mounting hardware,

polycarbonate cover, pipe nipple, and elbow for a large range of

custom mounting configurations. This antenna kit is a proven

design for haulage equipment such as shuttle cars and battery

haulers. It requires much less room than the retrofit Antenna Kit.

Retrofit Antenna Kit

This kit includes a 2.45Ghz Whip antenna, mounting hardware,

and a polycarbonate cover. It was designed to mount directly into

existing guarding on equipment fitted with previous generation

proximity detection systems.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

10

DO NOT DISTRIBUTE

Engineering Safety • Advancing Automation

MX3-IZ Driver Installation

Driver Cable

❸

❷

❹

❺

Maintenance Guide

10000050

❶

❶

❶ Shield

❷ White (Data +)

❸Green (Ground)

Red (+72VDC)

❹

❺ Black (Data -)

10002008 rev 0

Front Driver

Back Driver

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

Splitter Cable

12

DO NOT DISTRIBUTE

IntelliZone™ System Kits

Engineering Safety • Advancing Automation

MX3-IZ Driver Standard Installation

The MX3-IZ Guarding that protects the Drivers is specifically designed for the new smaller MX3-IZ Drivers

unlike previous Matrix Proximity Systems with larger guarding. The Driver cable must be inside conduit for its

entire run and must be connected to either a MX3-IZ Conduit Mounting Plate or a conduit mounting nipple that

is attached to the back or top of the guarding. The driver is mounted using M12 x 85mm Hex head bolts with

washers and lock washers.

❹

❸

❶

❷

❻

❺

❶ M12 Mounting Hardware

❷ MX3-IZ Driver

10002008 rev 0

❸ MX3-IZ Conduit Mounting Plate

❹ MX3-IZ Guard

❺ 3/4” I.D. Rubber Hose Conduit

❻ S.S. Worm Gear Hose Clamp

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

13

DO NOT DISTRIBUTE

IntelliZone™ System Kits

Engineering Safety • Advancing Automation

MX3-IZ Driver Retrofit Installation

The MX3-IZ Driver Adapter Kit is specifically designed for mounting the MX3-IZ Driver in the larger guarding

that is standard on the older M3K-1000 Matrix Proximity System. The Driver cable must be inside conduit for

its entire run and must be connected to either a MX3-IZ Conduit Mounting Plate or a conduit mounting nipple

that is attached to the back or top of the guarding. The driver is mounted using M12 x 90mm Hex head bolts

with lock washers.

❺

❹

❸

❶

❷

❼

❻

❶ M12 Mounting Hardware

❷ MX3-IZ Driver Adapter Kit

❸ MX3-IZ Driver

10002008 rev 0

❹ MX3-IZ Conduit Mounting Plate, Retrofit

❺ M3-1000 Guard

❻ 3/4” I.D. Rubber Hose Conduit

❼ S.S. Worm Gear Hose Clamp

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

14

DO NOT DISTRIBUTE

Engineering Safety • Advancing Automation

MX3-IZ Controller

Overview

The Controller is the central processor for the

IntelliZone™ System. It communicates to

the mobile equipment and Locators

and provides power to 4 machinemounted Drivers. Personnel can

connect to the Controller wirelessly (w/

adaptor) or with an Ethernet cable to

adjust settings and view system

diagnostics. This device IS NOT

intrinsically safe and MUST be

inside an explosion-proof enclosure

when used in MSHA-regulated

environments.

Maintenance Guide

10000050

LED States

The Controller features (9) LEDs that

can provide the operator with basic

system diagnostics information. The

LEDs are located on the top surface

of the Controller, and can be in either

a blinking or continuously lit (solid).

Blinking

Solid

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

FUNCTION LED RESPONSE

POWER

HEARTBEAT

I/O ACTIVITY

RF RF ACTIVITY

ETHERNET

DRIVER 0-3

CONTROLLER SOFTWARE IS ACTIVE

INTERFACE & PROXIMITY ARE ACTIVE

I/O ACTIVITY (SD CARD OR SENSORS)

CONTROLLER HAS POWER

WIRED NETWORK ACTIVITY

NORMAL OPERATION

DRIVER DISABLED

POWER FAILURE

15

DO NOT DISTRIBUTE

Maintenance Guide

Engineering Safety • Advancing Automation

Available System Drawings

Drawing Product Category Description

10000058 Driver Installation Detail Shows proper installation of Driver w/ and w/o adapter kit

10001901 Charger Product Overview Provides generic Locator Charger dimensions and specs

10001691 Charging Rack Product Overview Provides generic Locator Charging Rack dimensions and specs

10001659 Power Supply Box Schematic Wiring Schematic for system power supply box

10001978 Controller Box Schematic Wiring Schematic for system Controller box

10001638 Controller Box Product Overview Provides generic Controller XP Box dimensions and specs

10001685 Controller Box Installation Detail Shows proper installation of Controller XP Box w/ use of weld blocks

10001639 Power Supply Box Product Overview Provides generic Power Supply Box dimensions and specs

10001950 Antenna Kit Installation Detail Shows proper installation of the Whip Antenna Mounting Kit

10001950 Retrofit Antenna Kit Installation Detail Shows proper installation of the Retrofit Antenna Mounting Kit

10000152 Overall System Product Overview Provides a generic overview of the entire system

10001288 Overall System Schematic Provides a generic overall system wiring schematic

10001974 C2C System Schematic Provides an overall system wiring schematic for a JOY C2C machine

10001975 JNA System Schematic Provides an overall system wiring schematic for a JOY JNA machine

10001976 DC System Schematic Provides and overall system wirin g schematic for a JOY DC machine

10001977 BH-18 System Schematic Provides an overall system wiring schematic for a JOY BH-18 machine

10000112 Shuttle Car System Installation Detail Provides a generic system layout on a Standard Shuttle Car

10000127 Shuttle Car System Installation Detail Provides a generic layout of Driver Guarding on a Standard Shuttle Car

10000132 14CM15 R. System Installation Detail Provides a generic retrofit system layout on a JOY 14CM15 machi ne

10001603 14CM15 System Installation Detail Provides a generic s ystem layout on a JOY 1 4CM1 5 machine

††† Multiple Drawing Numbers are available for product under the listed cat egory. Please request drawings by “Product” column

name to receive a list of available drawings for the desired product.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

16

DO NOT DISTRIBUTE

Maintenance Guide

Engineering Safety • Advancing Automation

Fasteners

Fastener Quantity

MX3-IZ Driver

Hex Head M12-1.75x85 4

Washer M12 4

Washer Split Lock M12 4

MX3-IZ Driver Retrofit Kit

Hex Head M12-1.75x90 4

Washer Split Lock M12 4

MX3-IZ Controller XP Box

Hex Head 1/2-13x1.25 10

Washer Split 1/2 10

Nut Hex Jam 3/8-16 4

MX3-IZ Power Supply XP Box

Hex Head 1/2-13x1.25 10

Washer Split 1/2 10

Nut Hex 1/4-20 4

MX3-IZ Machine Mount Blocks

Hex Head 1/2-13x1.0 1

Washer Split 1/2 1

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

17

DO NOT DISTRIBUTE

Maintenance Guide

Engineering Safety • Advancing Automation

Installation Requirements

Drivers can be mounted upside down, but must be vertical

Controller and Power Supply XP Enclosures must pass 0.004 feeler gauge inspection

Splitter XP Enclosures must pass 0.002 feeler gauge inspection

XP Gland Gap (Between Gland Plug and XP Box Steel Port) must measure between 1/8” MIN, 1/4” MAX

Glands must be secured with a lead tie or set screw

Open gland ports must be sealed using Steel Plug, and plug must be spot welded in place

Components on a common frame must be solidly frame grounded

The Intrinsically safe portion of the RF Barrier must be kept isolated from the non-Intrinsically safe wiring

Ensure that RF antennas are isolated from machine ground

Driver cables and 8-pair Matrix Cable must be installed with protective conduit and clamps

Antenna cables (LMR195-fr) do not require conduit but are highly recommended for prote ction

Though not required, ferrules or tinning the end of all wires inside the Controller XP Box and Splitter XP Box is

recommended

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

18

DO NOT DISTRIBUTE

Maintenance Guide

Engineering Safety • Advancing Automation

MX3-IZ Driver LED States

The Driver features an array of (27) LEDs that can provide the operator with basic system diagnostic

information. The LEDs are visible from the front of the Driver, and assume either a blinking or solid state.

Knowledge of Driver LED codes can help isolate system errors, should a problem arise. The error codes are

communicated to personnel by means of LED color and duration.

DEFINITION TIME DURATION (SECONDS)

System operational; no Locator associated as operator 1.0 1.0 1.0

System operational; Locator associated as operator Continuous

Warning Zone Breach

Shutdown Zone Breach

Proximity Protection System is bypassed

System Error Continuous

MX3-IZ Locator Error Continuous

MX3-IZ Driver Error (Diagnostic Warning); single LED Continuous

MX3-IZ Driver Error (Diagnostic Error); single LED Continuous

½ ½ ½ ½ ½ ½

¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼

½ ½ ½ ½ ½ ½

MX3-IZ Locator LED States

The Locator features (3) LEDs that can provide the operator with basic system diagnostic information. The

LEDs are visible from the front of the Locator, and assume either a blinking or solid state. Knowledge of

Locator LED codes can help isolate system errors, should a problem arise. The error codes are

communicated to personnel by means of LED color and duration.

DEFINITION TIME DURATION (SECONDS)

System Operation Normal 1.0 1.0 1.0

Warning Zone Breach

Shutdown Zone Breach

System, Locator, or Driver Error Continuous

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

½ ½ ½ ½ ½ ½

¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼

19

DO NOT DISTRIBUTE

Maintenance Guide

Engineering Safety • Advancing Automation

MX3-IZ Audible Alarm

The Locator also features an audible alarm that can alert users and/or nearby personnel of a zone breach.

DEFINITION TIME DURATION (SECONDS)

Warning Zone Breach

Red Zone Breach

½ ½ ½ ½ ½ ½

¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼

OLED Screen

The user-interface screen on the front of the Locator provides personnel with important system diagnostics

information. It allows users to initiate key features of the IntelliZone™ System. It is important to understand

the information provided and how to properly interact with the Locator. User input is provided through the

push-button found atop the Locator and prompts on the OLED screen.

STATUS SCREEN (PRESS + HOLD)

❶Signal Strength and Battery Level

❷System Status and Locator Operating Voltage

❸When displayed, test using MX3-IZ Locator Tester

❹Locator Identification

❺Development Information

❻Development Information

ASSOCIATE / DISSOCIATE (DOUBLE CLICK)

If user requests association / dissociation but fails to confirm within

(10) seconds, the Locator will timeout and default to normal operation.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

This allows users to associate / dissociate themselves as an

operator of a particular piece of machinery. In order to do so,

there must first be an Initiation Zone configured using the

IntelliZone™ System GUI (Graphical User Interface). Standing

inside this zone, the user may associate or dissociate as operator

by double-clicking the Locator’s push-button. Double-click again

to confirm association / dissociation. There will be (2) quick

audible signals confirming that the process was successful.

20

DO NOT DISTRIBUTE

Maintenance Guide

Engineering Safety • Advancing Automation

Troubleshooting

These issues have been observed by Matrix Technicians.

Inspections

Locators should be inspected for physical damage before every shift. Locators should also be tested above ground

before every shift.

Drivers should be inspected for physical damage before every shift.

Operator Dissociating Issues

RF is CRITICAL to the operation of the system. If the zones are not consistent or the Locator is not tracking well

check RF cables and antenna.

If the operator moves too far from the machine, he will have to re-associate to use the piece of equipment. The opera-

tor will see the green LEDs flashing on the Drivers when he is NOT the operator.

If the operator is having to re-associate often, there is likely an issue with the RF antenna or cabling.

Power Supply

If the system is not powering up, check 72VDC and 24VDC power in the interface board.

If no voltage found on the interface board, check 3A glass fuses in the Power Supply XP box.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

21

DO NOT DISTRIBUTE

System Diagnostic Errors

Engineering Safety • Advancing Automation

System Diagnostic Codes

The IntelliZone™ Proximity Detection System features machine status codes to assist the user in determining

the source of an issue should one arise during operation. These codes result from diagnostic tests that are

continuously executed by the Controller, and can be viewed in the IntelliView Diagnostic Data Inspection

window or on an associated Locator’s OLED screen. Press and hold the Locator’s Push-button to display a 7digit machine status code.

PART ERROR CODE

Driver 3.02.0000, 4.02.0000

Driver 3.02.0001, 4.02.0001

Driver 3.02.0002, 4.02.0002 Check Driver power wires, Replace Driver

Driver 3.02.0003, 4.02.0003 Check Interface board, Replace Interfaceboard, Replace Driver

Driver 3.02.0004, 4.02.0004 Contact Matrix

Driver 3.02.0005, 4.02.0005 Check 72V power supply and fuses

Driver 3.02.0006, 4.02.0006 Reboot, Replace Driver

RF Module 3.03.0000, 4.03.0000 Replace Controller

RF Module 3.03.0002, 4.03.0002 Too many locators or controllers in area

RF Module 3.03.0003 Will display when Analog inputs are not in use

Prox Sensor 3.05.0000, 4.05.0000 Too many controllers in area

Controller 3.10.0000, 4.10.0000 Call Matrix

Reboot, Replace Driver

Check Driver data wires, Replace Driver

CORRECTIVE ACTION

Controller 3.10.0001, 4.10.0001 Call Martix, Replace controller

Controller 3.10.0002 Order new Software Key

Controller 4.10.0002 Replace Software Key

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

22

DO NOT DISTRIBUTE

User Guide

Engineering Safety • Advancing Automation

Operating Guidelines

System Warning

It is important that all users / personnel who may come into contact with the IntelliZone™ Proximity Detection

System understand it’s purpose. It is NOT a safety system. It is a training aid developed to teach users safe

operating habits. User / Operator assumes full responsibility for control of the machine upon which the system

is installed. User / Operator assumes full liability for the maintenance and operation of the IntelliZone™

Proximity Detection System. Based upon this understanding, the following precautions must be taken.

Precautions

Do not use the IntelliZone™ system without proper training and documentation

The Locator must be worn at all times

Position the Locator between shoulder and waist height on the front side of the body for proper operation

Do not position the Locator near metal tools, cap lamp battery, or other metal items while operating the system

When operating the machinery on a grade use extra caution as the machine may coast further than normal

System Overview

The Matrix IntelliZone™ Proximity Detection System assists with training personnel to stay clear of dangerous

zones present around potentially hazardous equipment. The System is designed for use on mobile equipment

such as continuous miners, mobile haulage, and other light and heavy vehicles. The System is typically

configured for two operational awareness zones: a “shutdown zone” (red) can be defined closest to the

equipment and a “warning zone” (yellow) can be defined to extend a moderate distance from the equipment.

When an IntelliZone™ Locator is detected within the red zone, the System will prompt the equipment to

immediately shutdown some or all of its functions. When an IntelliZone™ Locator is detected within the

yellow zone, the System will prompt the equipment to reduce its speed or influence other changes in

operation. If a Locator is detected within either zone, the System will initiate highly-visible flashing lights and

an audible alarm on the Locator and Drivers to warn personnel of potential hazards.

Additional IntelliZone™ awareness zones can be configured as needed and are customizable to specific

equipment and applications.

.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

24

DO NOT DISTRIBUTE

Engineering Safety • Advancing Automation

MX3-IZ Driver

Overview

The MSHA-approved Driver allows for tracking of multiple

Locators. The Driver is machined from rugged

polycarbonate and incorporates multi-color LEDs used for

diagnostics and zone identifications.

Operators Guide

10000050

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

25

DO NOT DISTRIBUTE

Engineering Safety • Advancing Automation

MX3-IZ Locator

Overview

The MX3-IZ Locator should be worn by the operator at all

times. The device has audible and visible alarms to alert the

operator of zone breaches. The device has LEDs the also

indicate zone breaches and errors on the system. An OLED

screen displays the Locator status and is used in conjunction

with the multifunction button to associate or dissociate with the

machine.

User Guide

OLED Screen

STATUS SCREEN (PRESS + HOLD)

ASSOCIATE / DISSOCIATE (DOUBLE CLICK)

❶Signal Strength and Battery Level

❷System Status and Locator Operating Voltage

❸When displayed, test using MX3-IZ Locator Tester

❹Locator Identification

❺Development Information

❻Development Information

This allows users to associate / dissociate themselves as an

operator of a particular piece of machinery. In order to do so,

there must first be an Initiation Zone configured using the

IntelliZone™ System GUI (Graphical User Interface). Standing

inside this zone, the user may associate or dissociate as operator

by double-clicking the Locator’s push-button. Double-click again

to confirm association / dissociation. There will be (2) quick

audible signals confirming that the process was successful.

10002008 rev 0

If user requests association / dissociation but fails to confirm within

(10) seconds, the Locator will timeout and default to normal operation.

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

26

DO NOT DISTRIBUTE

User Guide

Engineering Safety • Advancing Automation

MX3-IZ Driver LED States

Under normal operation the user should see these LEDs on the Drivers.

DEFINITION TIME DURATION (SECONDS)

System operational; no Locator associated as operator 1.0 1.0 1.0

System operational; Locator associated as operator Continuous

Warning Zone Breach

Shutdown Zone Breach

Proximity Protection System is bypassed

½ ½ ½ ½ ½ ½

¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼

½ ½ ½ ½ ½ ½

If there is an error on the system, the Drivers will display these LEDs.

DEFINITION TIME DURATION (SECONDS)

Proximity Protection System is bypassed

System Error Continuous

MX3-IZ Locator Error Continuous

MX3-IZ Driver Error (Diagnostic Warning); single LED Continuous

MX3-IZ Driver Error (Diagnostic Error); single LED Continuous

½ ½ ½ ½ ½ ½

MX3-IZ Locator LED States

Under normal operation the user should see these LEDs on the Locator.

DEFINITION TIME DURATION (SECONDS)

System Operation Normal 1.0 1.0 1.0

Warning Zone Breach

Shutdown Zone Breach

½ ½ ½ ½ ½ ½

¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼

If there is an error on the system, the Locator will display this LED.

DEFINITION TIME DURATION (SECONDS)

System, Locator, or Driver Error Continuous

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

27

DO NOT DISTRIBUTE

User Guide

Engineering Safety • Advancing Automation

Emergency Stop Override

The IntelliZone™ Proximity Detection System features an ESO (Emergency Stop Override). This function is

only to be used in Emergency situations where the Proximity System must be bypassed. For Continuous

Miners this feature is activated with the machine’s remote control. This mode has limited functionality in that it

will only allow low speed tram. It is important that all miner operators and/or other personnel that come into

contact with the system daily know how this process works in the event of an emergency.

JOY C2C & DC Continuous Miner

1. Toggle and hold the ESO/MMO switch ❷ in the ESO position.

2. Toggle and hold the Pump switch ❶.

3. Release the pump switch ❶, but continue to hold the ESO/MMO switch ❷ in the ESO position.

4. Activate the tram functions and move the machine to safe location.

5. Release the ESO switch to resume normal machine operation.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

28

DO NOT DISTRIBUTE

DO NOT DISTRIBUTE

User Guide

Engineering Safety • Advancing Automation

JOY JNA Continuous Miner

1. Toggle and hold the ESO/MMO switch ❷ in the position.

2. Toggle and hold the Pump switch ❶and2ND/3RDswitch❸intheUPposion.

3. Release the pump switch ❶and2NDswitch❸, but continue to hold the ESO/MMO switch ❷ in the ESO position.

4. Activate the tram functions and move the machine to safe location.

5. Release the ESO switch to resume normal machine operation.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

29

DO NOT DISTRIBUTE

Engineering Safety • Advancing Automation

FCC Compliance

US FCC Compliance Statements:

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received,

including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to

User Guide

operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmfu l int erference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

This portable transmitter with its antenna complies with FCC/IC RF

exposure limits for general population / uncontrolled exposure.

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

30

DO NOT DISTRIBUTE

User Guide

Engineering Safety • Advancing Automation

Canada IC Compliance / Canada États IC conformité

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of

a type and maximum (or lesser) gain approved for the transmitter by Industry Canada. To

reduce potential radio interference to other users, the antenna type and its gain should be so

chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary

for successful communication.

En vertu des règlements d'Industrie Canada, cet émetteur de radio ne peut fonctionner à l'aide d'une antenne d'un type

et le gain maximal (ou inférieur) approuvé pour l'émetteur par Industrie Canada. Pour réduire le risque d'interférence aux

autres utilisateurs, le type d'antenne et son gain doivent être choisis afin que la puissance isotrope équivalente (e.i.r.p)

rayonnée ne dépasse pas ce qui est nécessaire pour une communication réussie.

This Device complies with Industry Canada License-exempt RSS standard(s). Operation is

subject to the following two conditions: 1) this device may not cause interference, and 2) this

device must accept any interference, including interference that may cause undesired operation

of the device.

Cet appareil est conforme avec Industrie Canada RSS exemptes de licence standard (s). Son fonction nement est

soumis aux deux conditions suivantes:

1) ce dispositif ne doit pas causer d'interférences, et

2) ce dispositif doit accepter toute interférence, y compris celles pouvant causer un mauvais fonctionnement de

l'appareil.

MX3-IZ Locator IDs

FCC ID:USK-10000615

IC ID:11898A-1000615

10002008 rev 0

Matrix Design Group, LLC | 3299 Tower Drive Newburgh, IN 47630, USA | 812.490.1525 | www.matrixteam.com

Copyright © 2013 Matrix. All rights reserved. Do not distribute without prior consent.

31

Loading...

Loading...