Page 1

T7XE-04 TREADMILL

SERVICE MANUAL

Page 2

TABLE OF CONTENTS

CHAPTER 1: SERIAL NUMBER LOCATION ................................................................... 1

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

2.1 Before Getting Started .............................................................................................. 2

2.2 Read and Save These Instructions ........................................................................... 3

2.3 Electrical Requirements ............................................................................................ 4

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.1 Recommended Cleaning Tips ................................................................................... 5

3.2 Check for Damaged Parts ......................................................................................... 5

3.3 Care and Maintenance Instructions .......................................................................... 6

3.4 Touch Screen Care and Cleaning .............................................................................. 7

3.5 Auto Calibration Procedure ........................................................................................ 8

3.6 Adjusting the Running Belt ........................................................................................ 8

CHAPTER 4: USING THE CONSOLE AND PROGRAM DESCRIPTION

4.1 Console Description .................................................................................................. 9

4.2 Manual Workout Operation ........................................................................................ 10

4.3 Operating Level Based Programs ............................................................................. 10

4.4 Heart Rate Control Workout Operation ...................................................................... 11

4.5 Fitness Test Workout Operation ................................................................................. 11

CHAPTER 5: MANAGER MODE

5.1 Using Manager Mode ................................................................................................ 13

5.2 Manager Mode - About .............................................................................................. 14

5.3 Manager Mode - Time ................................................................................................ 15

5.4 Manager Mode - Speed ............................................................................................. 15

5.5 Manager Mode - Defaults .......................................................................................... 16

5.6 Manager Mode - TV ................................................................................................... 17

5.7 Manager Mode - Language ........................................................................................ 18

5.8 Manager Mode - Other ............................................................................................... 19

CHAPTER 6: ENGINEERING MODE

6.1 Using Engineering Mode ........................................................................................... 20

6.2 Engineering Mode - Calibration ................................................................................. 20

6.3 Engineering Mode - Statistics .................................................................................... 21

6.4 Engineering Mode - Errors ......................................................................................... 21

6.5 Engineering Mode - Clubs ......................................................................................... 22

6.6 Engineering Mode - Club ID....................................................................................... 22

6.7 Engineering Mode - Erp Time .................................................................................... 23

CHAPTER 7: SERVICE MODE:

7.1 Using Service Mode. .................................................................................................. 24

7.2 Service Mode - Set Up ............................................................................................... 24

7.3 Service Mode - Test.................................................................................................... 25

7.4 Service Mode - Log .................................................................................................... 26

7.5 Service Mode - Date & Time ...................................................................................... 26

CHAPTER 8: TROUBLESHOOTING

8.1 Electrical Diagrams .................................................................................................... 27

8.2 Motor Control Board (MCB) LED Instructions ........................................................... 30

8.3 MCB Wiring ................................................................................................................ 31

8.4 0140 / 01A0 01A2 Error Troubleshooting .................................................................. 33

8.5 01A3 Error Troubleshooting ....................................................................................... 33

8.6 01A8 / 02B6 / 02B7 / 02B8 Error Troubleshooting .................................................... 33

8.7 029F Error Troubleshooting ....................................................................................... 34

8.8 02AD Error Troubleshooting....................................................................................... 34

8.9 02B2 Error Troubleshooting ....................................................................................... 35

ii

Page 3

TABLE OF CONTENTS

8.10 02B9 / 02BA / 02BD Error Troubleshooting ............................................................... 35

8.11 04A0 Error Troubleshooting ....................................................................................... 36

8.12 Troubleshooting - No Power to the Console ............................................................. 37

8.13 Troubleshooting - Heart Rate Issues ......................................................................... 38

8.14 Troubleshooting - Display Color Issues ..................................................................... 39

8.15 Troubleshooting - Speed Shown is Higher than Belt Speed ..................................... 40

8.16 Entertainment Troubleshooting - Overview ................................................................ 41

8.17 Entertainment Troubleshooting - Picture Fuzzy or Unclear ....................................... 42

8.18 Entertainment Troubleshooting - TV Will Not Turn On .............................................. 43

8.19 Entertainment Troubleshooting - Entertainment Keypad Issues ................................ 44

CHAPTER 9: PART REPLACEMENT GUIDE

9.1 Motor Cover and Lower Shroud Removal ................................................................. 45

9.2 Rear Roller Removal ................................................................................................. 46

9.3 Deck Removal ........................................................................................................... 47

9.4 Deck Cushion Replacement....................................................................................... 48

9.5 Front Roller Removal ................................................................................................. 49

9.6 Running Belt Removal .............................................................................................. 50

9.7 Side Rail Removal...................................................................................................... 51

9.8 Motor Control Board (MCB) Removal ....................................................................... 52

9.9 Motor Removal ........................................................................................................... 53

9.10 Drive Belt Replacement ............................................................................................ 54

9.11 Incline Motor Replacement ........................................................................................ 55

9.12 Console Replacement ................................................................................................ 57

9.13 Console Mast Arm Replacement ................................................................................... 58

9.14 Console Cable Replacement .......................................................................................... 60

9.15 Handlebar Service ...................................................................................................... 62

9.16 Emergency Stop Switch Replacement ....................................................................... 63

9.17 Heart Rate Board Replacement ................................................................................ 64

9.18 Blower Motor Replacement ....................................................................................... 65

9.19 Overlay / Keypad Replacement ................................................................................. 66

CHAPTER 10: TREADMILL SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 Treadmill Specifications ............................................................................................. 68

10.2 Fasteners and Assembly Tools .................................................................................. 69

10.3 Assembly Instructions ............................................................................................... 70

10.4 Leveling the Unit ........................................................................................................ 74

10.5 Entering the Serial Number into the Console ............................................................ 75

10.6 TV Programming Instructions..................................................................................... 76

CHAPTER 11: SOFTWARE UPGRADE INSTRUCTIONS

11.1 Software Upgrade Instructions ................................................................................... 78

iii

Page 4

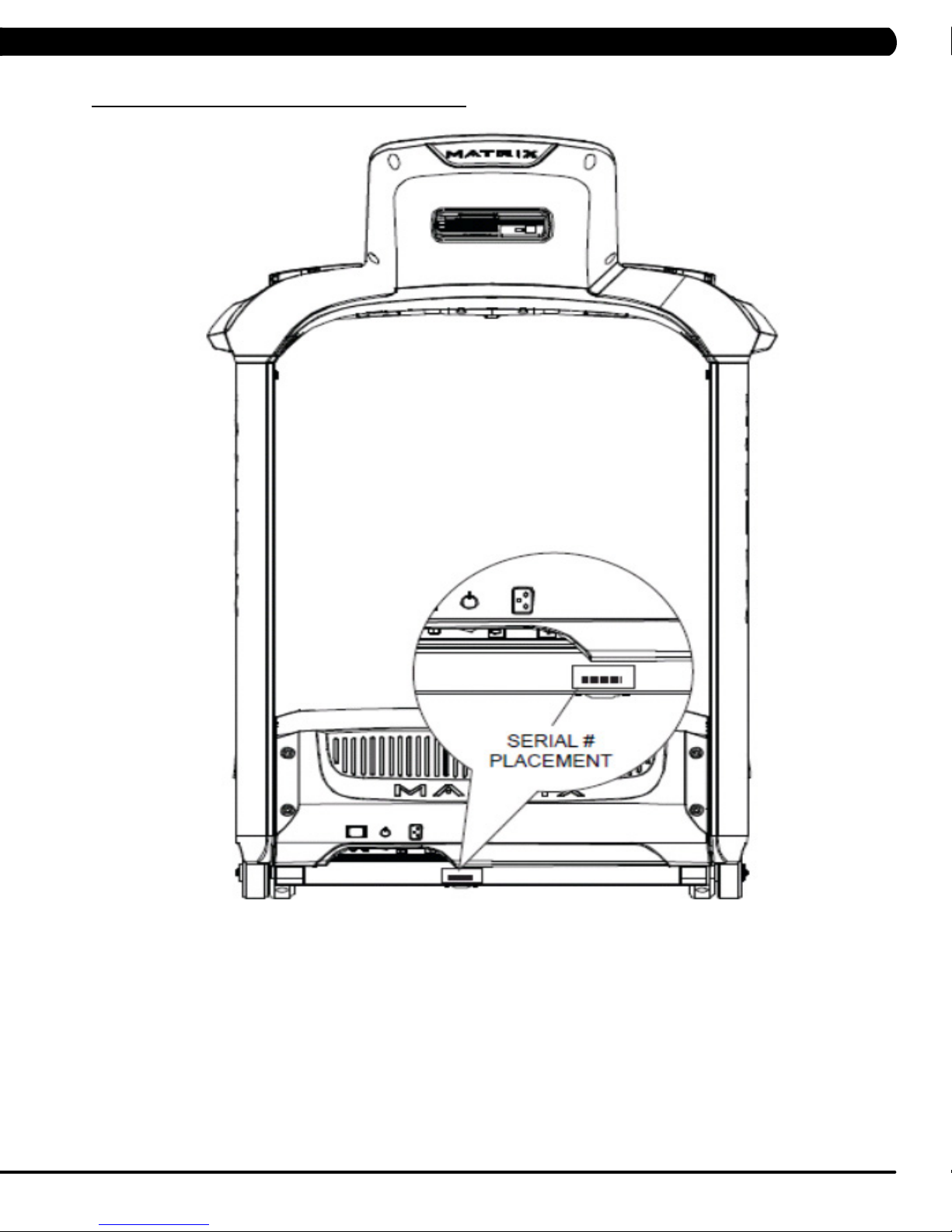

1.1 SERIAL NUMBER LOCATION

CHAPTER 1: SERIAL NUMBER LOCATION

1

Page 5

CHAPTER 2: IMPORTANT SAFETY INFORMATION

2.1 BEFORE GETTING STARTED

This treadmill is intended for commercial use. To ensure your safety and protect the equipment, read all instructions before operating the Matrix

Treadmill.

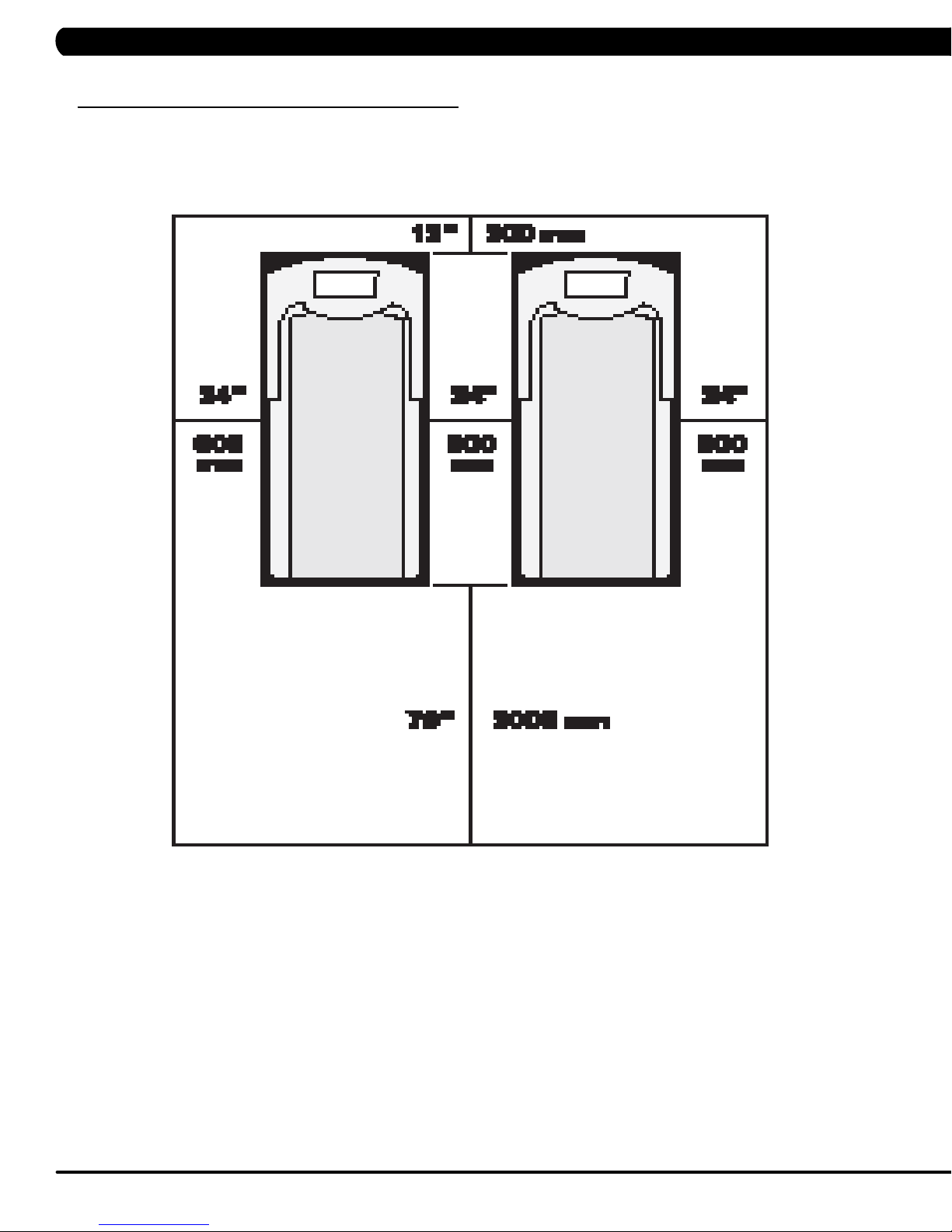

Place the treadmill on a level and stable surface away from direct sunlight. The intense UV light can cause discoloration on the plastics. Locate

your treadmill in an area with cool temperatures and low humidity. Please leave a clear zone behind the treadmill that is at least the width of the

treadmill and at least 79” (2000 mm) long. This zone must be clear of any obstruction and provide the user a clear exit path from the machine.

For ease of access, there should be an accessible space on both sides of the treadmill of at least 24” (600 mm) to allow a user access to the

treadmill from either side. Do not place the treadmill in any area that will block any vent or air openings. The treadmill should not be located in a

garage, covered patio, near water or outdoors.

2

Page 6

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

2.2 READ AND SAVE THESE INSTRUCTIONS

This treadmill is intended for commercial use. To ensure your safety and protect the equipment, read all instructions before operating the

MATRIX T7xe-04 treadmill.

When using an electrical product, basic precautions should always be followed including the following:

DANGER: To reduce the risk of electric shock: Always unplug this equipment from the electrical outlet immediately after using and before

cleaning.

WARNING: To reduce the risk of burns, fire, electrical shock or injury to persons that may be associated with using this product.

An appliance should never be left unattended when plugged in. Unplug from the outlet when not in use and before putting on or taking off parts.

This product must be used for its intended purpose described in this service manual. Do not use other attachments that are not recommended by

the manufacturer. Attachments may cause injury.

To prevent electrical shock, never drop or insert any object into any opening.

Do not remove the console covers. Service should only be done by an authorized service technician.

Never operate the treadmill with the air opening blocked. Keep the air opening clear, free of lint and hair.

Never operate product if it has a damaged cord or plug, if it is working improperly, if it has been damaged, or immersed in water.

Do not carry this unit by its supply cord or use the cord as a handle.

Keep any power cords away from heated surfaces.

Close supervision is necessary when the treadmill is used by or near children or disabled persons.

Do not use outdoors.

Do not operate where aerosol (spray) products are being used or when oxygen is being administered.

To disconnect, turn all controls to the off position, then remove the plug from the outlet.

Connect this treadmill to properly grounded outlets only.

CAUTION: If you experience chest pain, nausea, dizziness or shortness of breath, STOP exercising immediately and consult a physician

before continuing.

• Donotusetheequipmentinanywayotherthandesignedorintendedbythemanufacturer.ItisimperativethatallMatrixFitnessSystemsequip

ment is used properly to avoid injury.

• Keephandsandfeetclearofmovingpartsatalltimestoavoidinjury.

• Unsupervisedchildrenmustbekeptawayfromthisequipment.

• Donotwearlooseclothingwhileonequipment.

-

3

Page 7

CHAPTER 2: IMPORTANT SAFETY INFORMATION

2.3 ELECTRICAL REQUIREMENTS

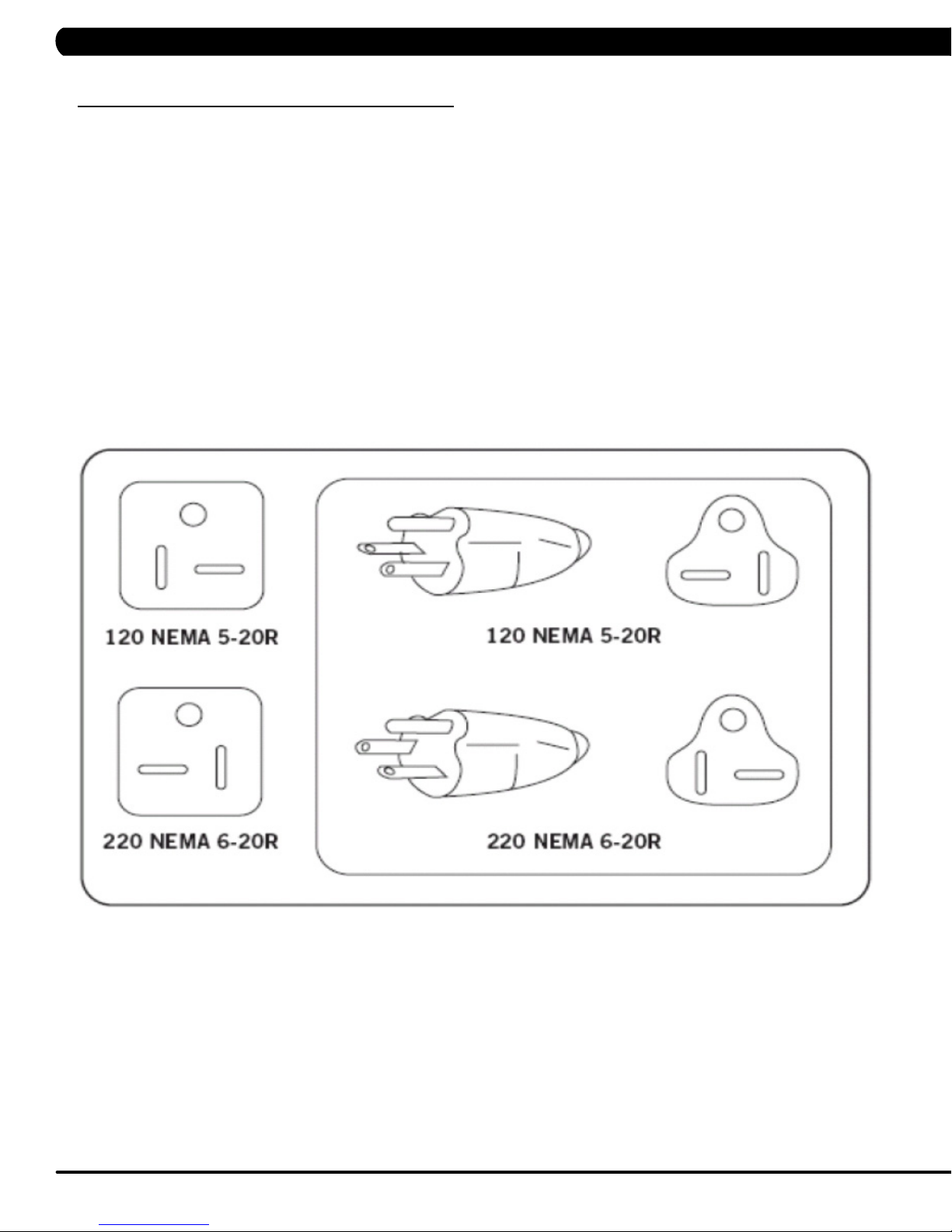

MATRIX DEDICATED CIRCUIT / ELECTRICAL REQUIREMENT INFO

All Matrix treadmills require the use of a 20 amp "dedicated circuit":, with a non-looped (isolated) neutral / ground, for the power requirement.

Quite simply this means that each outlet you plug your treadmill into should not have anything else running on that same circuit. The easiest

way to verify this is to locate the main circuit breaker box, and turn off the breaker(s) one at a time. Once a breaker has been turned off, the

only thing that should not have power to it is the treadmill. No lamps, vending machines, fans, sound systems, or any other item should lose

power when you perform this test.

Non-looped (isolated) neutral / grounding means that each circuit must have an individual neutral / ground connection coming from it, and

terminating at an approved earth ground. You cannot "jumper" a single neutral / ground from one circuit to the next.

In addition to the dedicated circuit requirement, the proper gauge wire must be used from the circuit breaker box, to each outlet that will have

the maximum number of units running off of it. If the distance from the circuit breaker box, to each outlet, is 100 feet or less, then 12 gauge wire

may be used. For any distance greater than 100 feet from the circuit breaker box to the outlet, 10 gauge wire must be used.

For your safety and to ensure good treadmill performance, the ground on this circuit must be non-looped. Please refer to NEC article 210-21 and

210-23. Your treadmill is provided with a power cord with a plug listed below and requires the listed outlet. Any alterations of this power cord could

void all warranties of this product..

4

Page 8

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.1 RECOMMENDED CLEANING TIPS

In order to maximize life span, and minimize down time, all Matrix Fitness Equipment requires regularly

scheduled cleaning.

YOU WILL NEED:

- Mild dish soap and water mixture in a spray bottle (10:1 water to soap ratio).

- Lint free 100% cotton cleaning cloths or Micro fiber cleaning cloths.

- Vacuum / Shop Vac with extendable hose and soft brush attachment.

- Corrosion Block (available from Matrix - part # ZMS4001374).

DAILY:

1. Wipe down the unit after each use with a mild dish soap and water mixture. NOTE: Spray the soap / water mixture onto the cloth.

NEVER spray directly onto the equipment. We recommend that you do NOT allow customers to use spray bottles to clean the equipment. If

the cleaner is sprayed directly on the equipment or over spray is present, it may cause your equipment to rust and / or cause damage to con

sole overlays.

WEEKLY:

-

1. With a clean dry 100% lint free cloth and water / soap mixture, wipe any dust and dirt from the sides of the running deck between the run

ning belt and side rails.

2. With a clean dry 100% lint free cloth and water / soap mixture, wipe the dust from the top of the motor cover.

3. With a clean dry 100% lint free cloth and water / soap mixture, wipe down the entire console area including the hand grips and hand rails.

4. Use a computer screen cleaner or LCD / LED screen cleaner on the touch screen portion of the console (see Section 3.4).

MONTHLY:

1. Vacuum under and around the Treadmill. If you need to move it, unplug the unit first.

2. Vacuum the air vent on the front of the unit.

3. Apply Corrosion Block to the metal part of the iPod cable.

QUARTERLY:

1. Unplug the unit. Remove the motor cover. Use a vacuum with a soft brush extension, vacuum the dust and dirt from the motor, MCB, fan,

and surrounding areas. Be careful not to hit any of the wire connections.

-

3.2 CHECK FOR DAMAGED PARTS

DO NOT use any equipment that is damaged or has worn or broken parts. Use only replacement parts supplied by Matrix Fitness Systems.

MAINTAIN LABELS AND NAMEPLATES. Do not remove labels for any reason. They contain important information. If unreadable or

missing, contact Matrix Fitness Systems for a replacement at 866-693-4863 or www.matrixfitness.com.

MAINTAIN ALL EQUIPMENT. Preventative maintenance is the key to smoothly operating equipment. Equipment needs to be inspected at

regular intervals. Defective components must be kept out of use until they are repaired. Ensure that any person(s) making adjustments or

performing maintenance or repair of any kind is qualified to do so. Matrix Fitness Systems will provide service and maintenance training at

our corporate facility upon request or in the field if proper arrangements are made.

5

Page 9

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.3 CARE AND MAINTENANCE INSTRUCTIONS

In order to maximize life span, and minimize down time, all Matrix Fitness System's equipment requires regular cleaning, and maintenance items

performed on a scheduled basis. This section contains detailed instructions on how to perform these items, the frequency of which they should

be done, and a check list to sign off on each time service is completed for a specific machine. Some basic tools and supplies will be necessary

to perform these tasks which include (but may not be limited to):

* Metric Allen wrenches

* #2 Phillips head screwdriver

* Adjustable wrench

* Lint free cleaning cloths

* Teflon based spray lubricant such as "Super Lube" or other Matrix approved products.

* Vacuum cleaner with an extendable hose and crevasse tool attachment.

You may periodically see addendums to this document, as the Matrix Technical Support Team identifies items that require specific attention, the

latest version will always be available on the Matrix web site at www.matrixfitness.com.

DAILY MAINTENANCE ITEMS

1) Clean the entire machine using water and mild detergent such as "Simple Green", or other Matrix approved solutions (cleaning agents MUST

be alcohol and ammonia free).

2) Check the emergency stop button and cord for proper operation.

3) Check the power cord for damage, and make sure that the power cord retainer is installed and securely fastened.

MONTHLY MAINTENANCE ITEMS

1) Check the alignment of the running belt (see Section 3.5).

2) Check the tension of the running belt (see Section 3.5).

NOTE: If there is any damage to the running belt or deck, replace with new. If you are replacing (or flipping) a deck, it should always be

accompanied by a new belt.

QUARTERLY MAINTENANCE ITEMS

1) Unplug the unit. Remove the motor cover and vacuum the entire inside area of the machine being careful not to bump any wires or

connections loose.

2) While the motor cover is off, inspect the drive belt for visible wear. Replace if any signs of damage.

3) While the motor cover is off, start the unit and raise incline settings to maximum height. Turn the power switch off at the front of the machine

to prevent it from lowering accidentally. Lubricate incline motor Acme screw (Matrix recommends Super Lube brand grease with PTFE additive).

BI-ANNUAL MAINTENANCE ITEMS

1) Remove wax build up from the front and rear rollers of the machine.

2) Inspect the underside of the running belt for damage, check for cracking or glazed surfaces.

3) During normal operating conditions, the running belt replacement and deck service should be done every 25,000 miles.

6

Page 10

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.4 TOUCH SCREEN CARE & CLEANING

TOUCH SCREEN CARE AND CLEANING

* The touch screen requires very little maintenance. We recommend that you periodically clean the touch screen surface with a clean dry 100%

lint free cloth and water / soap mixture or a computer or LCD / LED screen cleaner.

* It is very important to avoid using any other chemical on the touch screen.

* Always dampen the cloth and clean the screen. Do not spray the water / soap mixture on the screen itself, the drips can seep into the display

or stain the bezel.

* After cleaning, make sure the surface is dry. There should not be any left over solvent to seep into the display.

* It is very important to handle the touch screen with care. Do not use excessive force when cleaning.

* Do not use any sharp materials to clean the touch screen surfaces.

* Do not use high pressure air, water, or steam to clean the touch screen surface.

7

Page 11

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.5 AUTO CALIBRATION INSTRUCTIONS

Run Auto Calibration to calibrate incline after assembly and after

replacing any electronic component.

AUTO CALIBRATION PROCEDURE:

1) Press "ENTER, 2, 0, 0, 1, ENTER". Engineering Mode will

appear on the display.

2) CALIBRATION and AUTO CALIBRATION should be already high

lighted. You just need to press the START button (Figure A). You

SHOULD NOT be standing on the unit while it is calibrating.

3) After completion, the display will state either Complete or Auto

Calibration failed.

3.6 ADJUSTING THE RUNNING BELT

After placing the treadmill in the position it will be used, the belt

must be checked for proper tension and centering. The belt may

need to be adjusted after the first 2 hours of use. Temperature,

humidity, and use cause the belt to stretch at different rates. If

the belt starts to slip when a user is on it, be sure to follow the

directions below.

STEP 1: Locate the two hex head bolts on the rear of the treadmill.

The bolts are located at each end of the frame at the back of the

treadmill. These bolts adjust the rear roller. Do not adjust until the

treadmill is on. This will prevent over tightening of one side.

STEP 2: The belt should have equal distance on either side

between the frame. If the belt is touching one side, do not start

the treadmill. Turn the bolts counter clockwise approximately one

full turn on each side. Manually center the belt by pushing the belt

from side to side. Tighten the bolts the same amount as when the

user loosened them, approximately one full turn. Inspect the belt

for damage.

STEP 3: While the treadmill is running at 3 mph, observe the belt

position. If it is moving to the right, tighten the right bolt by turning

it clockwise 1/4 turn, and loosen the left bolt 1/4 turn. If it is moving

to the left, tighten the left bolt by turning it clockwise 1/4 turn and

loosen the right 1/4 turn. Repeat Step 3 until the belt remains

centered for several minutes.

STEP 4: Check the tension of the belt. The belt should be very

snug. When a person walks or runs on the belt, it should not

hesitate or slip. If this occurs, tighten the belt by turning both bolts

clockwise 1/4 turn. Repeat if necessary.

8

Page 12

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.1 T7XE-04 CONSOLE DESCRIPTION

The Matrix treadmill is inspected before it is packaged. It is shipped in four pieces: the base, the upright console supports, the handlebar, and

the console. Carefully unpack the unit and dispose of the box material.

The T7xe-04 has a fully integrated touch screen display. All information required for workouts is explained on screen. Exploration of the

interface is highly encouraged. The information explaining how to program for various workouts will give an explanation about the contents of

each screen on the T7xe-04.

QUICK START / GO: One touch Start and Quick Start.

STOP: Ends workout and shows workout summary data.

COOL DOWN: Puts treadmill into Cool Down mode. Cool Down time is dependent on the length of the workout. Workouts 19 minutes and

shorter will have a cool down length of 2 minutes. Workouts 20 minutes and longer will have a cool down length of 5 minutes.

EMERGENCY STOP / IMMOBILIZATION: To stop all functions and immobilize the unit. The emergency stop on this treadmill must be returned

to its original position in order to allow normal operation of the unit.

INCLINE TOGGLES: Adjust incline during workout.

SPEED TOGGLES: Adjust speed during workout.

T7XE ENTERTAINMENT ZONE

iPOD: Will take the user directly to the iPod screen to allow for iPod control and play list selection.

VOLUME UP / DOWN: Adjust the volume output through the headphone jack of either the integrated console TV or the iPod output.

NUMBER KEYPAD: Allows for easy TV channel selections. These buttons work for the integrated console TV.

CHANNEL UP / DOWN: Allows for channel selection on the integrated console TV.

DISPLAY MODE: Allows user to cycle through console display options, iPod, TV, or profile display.

LAST CHANNEL: Allows the user to cycle between the current channel and the previous channel they were viewing.

CC/MUTE:

Mutes sound and turns closed captioning on or off.

9

Page 13

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.2 MANUAL WORKOUT OPERATION

QUICK START OPERATION

Press the GO or QUICK START button(s) and the treadmill will

count down "3, 2, 1" and enter into a manual mode of operation.

All energy expenditure values will be calculated using the default

weight measurement.

MANUAL WORKOUT OPERATION

Manual is a workout that allows you to manually adjust the speed

and incline values at anytime. The manual workout also contains a

setup screen which allows you to input your weight to help calculate

a more accurate caloric burn rate.

To enter into the Manual Workout:

1) Choose MANUAL WORKOUT by selecting the manual workout

button.

2) Enter the desired workout time using the ARROW KEYS or the

SLIDER.

3) Enter the user's weight (the user's weight is used to calculate

the caloric expenditure value-providing an accurate weight helps to

ensure an accurate caloric expenditure rating for each user) using

the ARROW KEYS or the SLIDER.

4) Enter the desired start speed using the ARROW KEYS or the

SLIDER.

5) Press GO or QUICK START to begin the workout.

4.3 OPERATING LEVEL BASED PROGRAMS

Your Matrix treadmill offers a variety of level-based workouts to

challenge users of all fitness levels. The following information will

briefly explain the workout and how to program the treadmill for

each workout selection.

ROLLING HILLS WORKOUT OPERATION

Rolling Hills is a level based workout that automatically adjusts the

incline value to simulate walking or running up hills.

1) Choose ROLLING HILLS by selecting the rolling hills workout

button.

2) Enter the desired workout time using the ARROW KEYS or the

SLIDER.

3) Enter the desired workout level using the ARROW KEYS or the

SLIDER.

4) Enter the user's weight (the user's weight is used to calculate

the caloric expenditure value, providing an accurate weight helps to

ensure an accurate caloric expenditure rating for each user) using

the ARROW KEYS or the SLIDER.

5) Enter the desired start speed using the ARROW KEYS or the

SLIDER.

6) Press GO or QUICK START to begin the workout.

FAT BURN WORKOUT OPERATION

Fat Burn is a level-based workout that is designed to help users

burn fat through various incline changes.

1) Choose FAT BURN by selecting the fat burn workout button.

2) Enter the desired workout time using the ARROW KEYS or the

SLIDER.

3) Enter the desired workout level using the ARROW KEYS or the

SLIDER.

4) Enter the user's weight (the user's weight is used to calculate

the caloric expenditure value, providing an accurate weight helps to

ensure an accurate caloric expenditure rating for each user) using

the ARROW KEYS or the SLIDER.

5) Enter the desired start speed using the ARROW KEYS or the

SLIDER.

6) Press GO or QUICK START to begin the workout.

10

5K RUN WORKOUT OPERATION

5K Run is a workout with a fixed distance of 5 km. Incline is

adjusted automatically throughout the workout. You control the

speed.

1) Choose 5K RUN by selecting the 5k run workout button.

2) Enter the desired workout level using the ARROW KEYS or the

SLIDER.

3) Enter the user's weight (the user's weight is used to calculate

the caloric expenditure value, providing an accurate weight helps to

ensure an accurate caloric expenditure rating for each user) using

the ARROW KEYS or the SLIDER.

4) Enter the desired start speed using the ARROW KEYS or the

SLIDER.

5) Press GO or QUICK START to begin the workout.

Page 14

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.4 HEART RATE CONTROL WORKOUT OPERATION

Your Matrix treadmill offers a heart rate control workout mode. The

heart rate control workout mode allows the user to program their

desired heart rate zone and maximum allowable incline and the

treadmill will automatically adjust the incline based upon the user's

heart rate. The heart rate zone is calculated using the following

equation: (220-Age)*%=target heart rate zone. The user must wear

a telemetric heart rate monitor or continually hold onto the contact

heart rate grips for this workout.

1) Choose TARGET HEART RATE by selecting the target heart rate

workout button.

2) Enter the desired workout time using the ARROW KEYS or the

SLIDER.

3) Enter the user's age using the ARROW KEYS or the SLIDER.

4) Enter the desired percentage of maximum heart rate using the

ARROW KEYS or the SLIDER.

5) Enter the user's weight (the user's weight is used to calculate

the caloric expenditure value, providing an accurate weight helps to

ensure an accurate caloric expenditure rating for each user) using

the ARROW KEYS or the SLIDER.

6) Press GO or QUICK START to begin the workout.

4.5 FITNESS TEST WORKOUT OPERATION

Your Matrix treadmill offers a variety of fitness tests - the Gerkin Firefighter Protocol, the Army, Navy, USMC, and USAF as well as the Physical

Efficiency Battery (PEB).

The Gerkin Protocol was developed by Dr. Richard Gerkin of the Phoenix (Arizona) Fire Department. It is a sub-maximal graded treadmill

evaluation used by many Fire Departments across the United States to assess the physical condition of the firefighters. The test requires

constant monitoring of the user's heart rate so the use of a telemetric chest strap is highly encouraged. The workout operates as follows:

WARM UP: The warm up is 3 minutes long and runs at 3.0 mph (4.8 kph) and 0% incline.

STAGE 1: At the 3 minute mark, the treadmill will gradually increase speed to 4.5 mph (7.2 kph). The actual test begins at 4.5 mph (7.2 kph).

STAGE 2: After one minute, the treadmill incline will increase to 2%.

STAGE 3: After one minute, the treadmill speed increases to 5.0 mph (8.0 kph).

STAGES 4 THROUGH 11: After every odd minute the treadmill incline will increase by 2%. After every even minute the treadmill speed will

increase by 0.5 mph (0.8 kph). Once the user's heart rate exceeds the target heart rate (85% of maximum as determined by the equation

(220-Age)*%=target heart rate zone), the individual continues the evaluation for an additional 15 seconds. During the 15 second period, the

evaluation remains at the stage where the target heart rate is exceeded, without any change to speed or incline. If the heart rate does not return

to or below the target heart rate, the evaluation ends and the final evaluation stage is recorded. If the heart rate returns to or below the target

heart rate, the program continues at the point where it would have been had the program not stabilized for 15 seconds.

TEST COMPLETION: The test is completed when user's heart rate exceeds the target for more than 15 seconds or when the user completes

all 11 stages, whichever occurs first. The treadmill will enter a cool down cycle for 3 minutes at 3.0 mph (4.8 kph), 0% incline.

1) Choose the GERKIN TEST by pressing the fitness test workout button and then press the GERKIN button.

2) Enter the user's age using the ARROW KEYS or the SLIDER.

3) Enter the user's weight (the user's weight is used to calculate the caloric expenditure value, providing an accurate weight helps to ensure an

accurate caloric expenditure rating for each user) using the ARROW KEYS or the SLIDER.

4) Enter the user's gender by pressing the MALE or FEMALE button.

5) Press GO or QUICK START to begin the workout.

11

Page 15

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.5 FITNESS TEST WORKOUT OPERATION - CONTINUED

SUBMAXIMAL TREADMILL EVALUATION

CONVERSION TABLE

Stage Time Converted VO2max

1 1:00 31.15

2.1 1:15 32.55

2.2 1:30 33.6

2.3 1:45 34.65

2.4 2:00 35.35

3.1 2:15 37.45

3.2 2:30 39.55

3.3 2:45 41.3

3.4 3:00 43.4

4.1 3:15 44.1

4.2 3:30 45.15

4.3 3:45 46.2

4.4 4:00 47.5

5.1 4:15 48.6

5.2 4:30 50

5.3 4:45 51.4

5.4 5:00 52.8

6.1 5:15 53.9

6.2 5:30 54.9

6.3 5:45 56

6.4 6:00 57

7.1 6:15 57.7

7.2 6:30 58.8

7.3 6:45 60.2

7.4 7:00 61.2

8.1 7:15 62.3

8.2 7:30 63.3

8.3 7:45 64

8.4 8:00 65

9.1 8:15 66.5

9.2 8:30 68.2

9.3 8:45 69

9.4 9:00 70.7

10.1 9:15 72.1

10.2 9:30 73.1

10.3 9:45 73.8

10.4 10:00 74.9

11.1 10:15 76.3

11.2 10:30 77.7

11.3 10:45 79.1

11.4 11:00 80

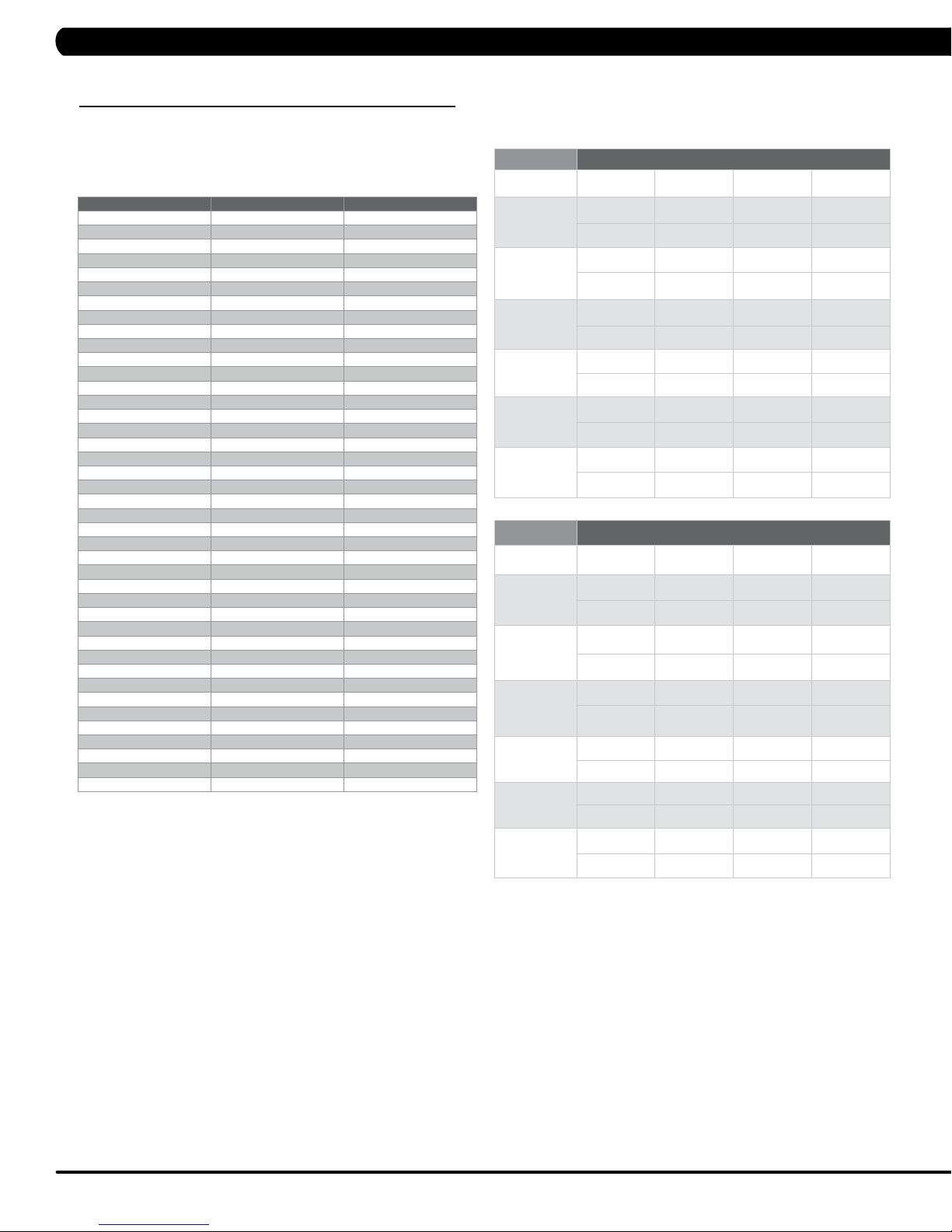

CARDIOVASCULAR FITNESS PERCENTILES

Males: VO2 max (ml/kg/min)

0-29 30-39 40-49 50-59

SUPERIOR

EXCEL-

LENT

GOOD

FAIR

POOR

VERY

POOR

Females: VO2 max (ml/kg/min)

SUPERIOR

EXCEL-

LENT

GOOD

FAIR

POOR

VERY

POOR

>58.8 >58.9 >55.4 >52.5

54.0 52.5 50.4 47.1

51.4 50.3 48.2 45.3

48.2 46.8 44.1 41.0

46.8 44.6 41.8 38.5

44.2 42.4 39.9 36.7

42.5 41.0 38.1 35.2

41.0 38.9 36.7 33.8

39.5 37.4 35.1 32.3

37.1 35.4 33.0 30.2

34.5 32.5 30.9 28.0

31.6 30.9 28.3 25.1

20-29 30-39 40-49 50-59

>53.0 >48.7 >46.8 >42.0

46.8 43.9 41.0 36.8

44.2 41.0 39.5 35.2

41.0 38.6 36.3 32.3

38.1 36.7 33.8 30.9

36.7 34.6 32.3 29.4

35.2 33.8 30.9 28.2

33.8 32.3 29.5 26.9

32.3 30.5 28.3 25.5

30.6 28.7 26.5 24.3

28.3 26.5 25.1 22.3

25.9 25.1 23.5 21.1

The Military Test programs and the Physical Efficiency Battery (PEB) provide workouts of a preset distance. These distances are established by

the various branches of the Military with the objective of each test to complete the distance as quickly as possible. At the completion of the test,

a time-based score as defined by the respective Military branch will be shown on the console.

1) Choose your desired Military Test by pressing the FITNESS TEST WORKOUT button, and then press the desired MILITARY TEST or PEB

button.

2) Enter the user's age using the ARROW KEYS or the SLIDER.

3) Enter the user's weight (the user's weight is used to calculate the caloric expenditure value, providing an accurate weight helps to ensure an

accurate caloric expenditure rating for each user) using the ARROW KEYS or the SLIDER.

4) Enter the user's gender using the MALE and FEMALE buttons.

5) Press GO or QUICK START to begin the workout.

12

Page 16

5.1 USING MANAGER MODE

CHAPTER 5: MANAGER MODE

1) To enter Manager Mode, press "ENTER, 1, 0, 0, 1, ENTER" on the number keypad and Manager Mode will appear on the display.

2) Manager Mode is divided into 7 tabs, located on the left side of the screen. They are About, Time, Speed, Defaults, TV, Language, and Other.

3) Choose a tab by touching the screen over the desired tab.

4) Each of the tabs have options that will appear once you have chosen that particular tab.

5) Press the "HOME" button or the EMERGENCY STOP to exit Manager Mode..

13

Page 17

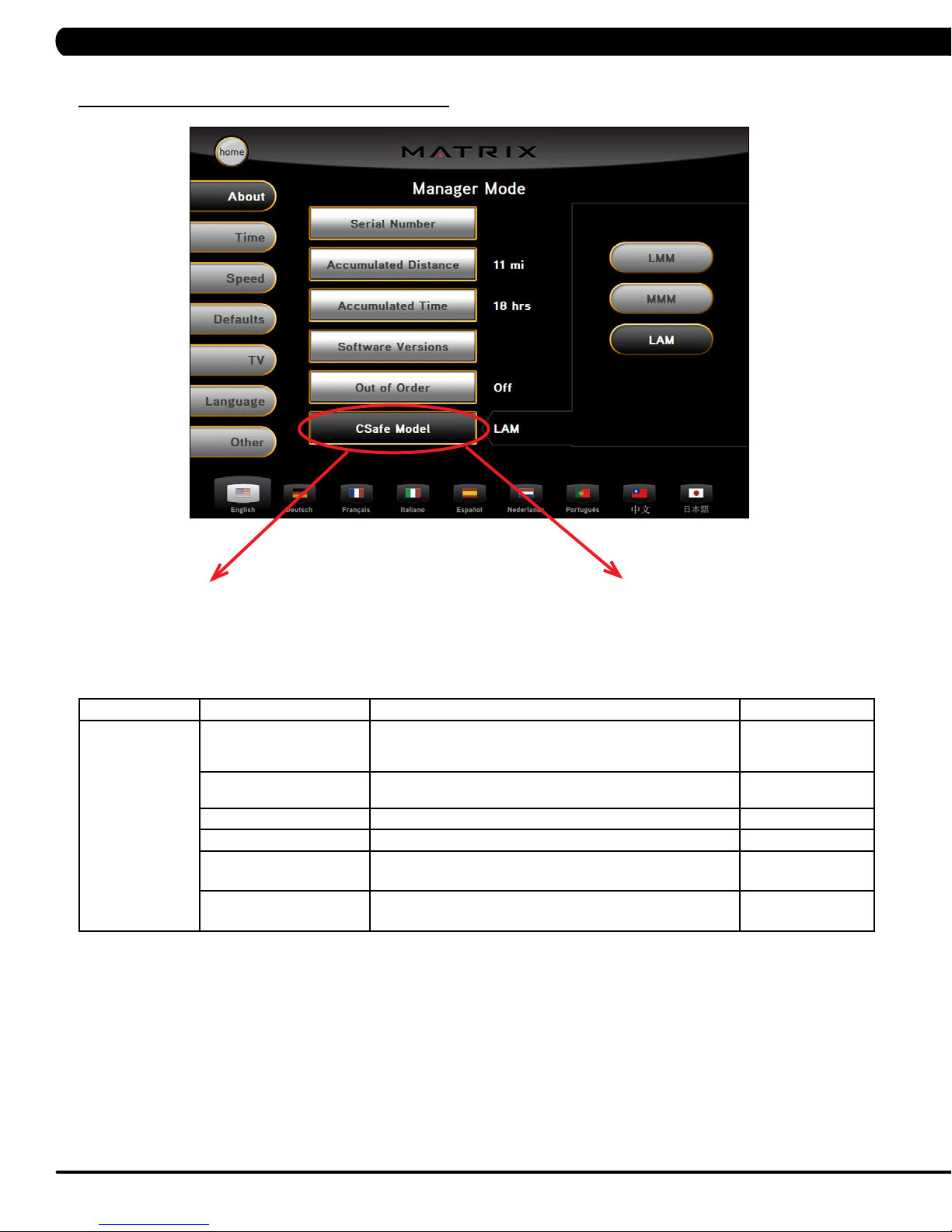

5.2 MANAGER MODE - TAB 1

CHAPTER 5: MANAGER MODE

T7xe-02-C - If the unit has the old MMM board, the

CSafe Model should be set for MMM.

MANAGER MODE

About

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Serial Number This option displays the serial number of the platform and

Accumulated Distance Total distance displayed in native units (miles or kilometers), not

Accumulated Time Total time, not editable. Cannot be modified.

Software Version Software version, not editable Cannot be modified

Out of Order

Default: Off

CSafe Model This option controls whether the console is Fitlinxx compatible. LMM / MMM / LAM

console, not editable (see Service Mode to change serial

numbers).

editable.

This option allows the club to show "out of order" on the console

before repair.

T7xe-03-C - If the unit has the LMM board, the CSafe

Model should be set for LMM.

T7xe-04-C - If the unit has the LAM console (the

console cover back will have holes for ventilation),, the

CSafe Model should be set for LAM.

Cannot be modified.

Cannot be modified

On / Off

14

Page 18

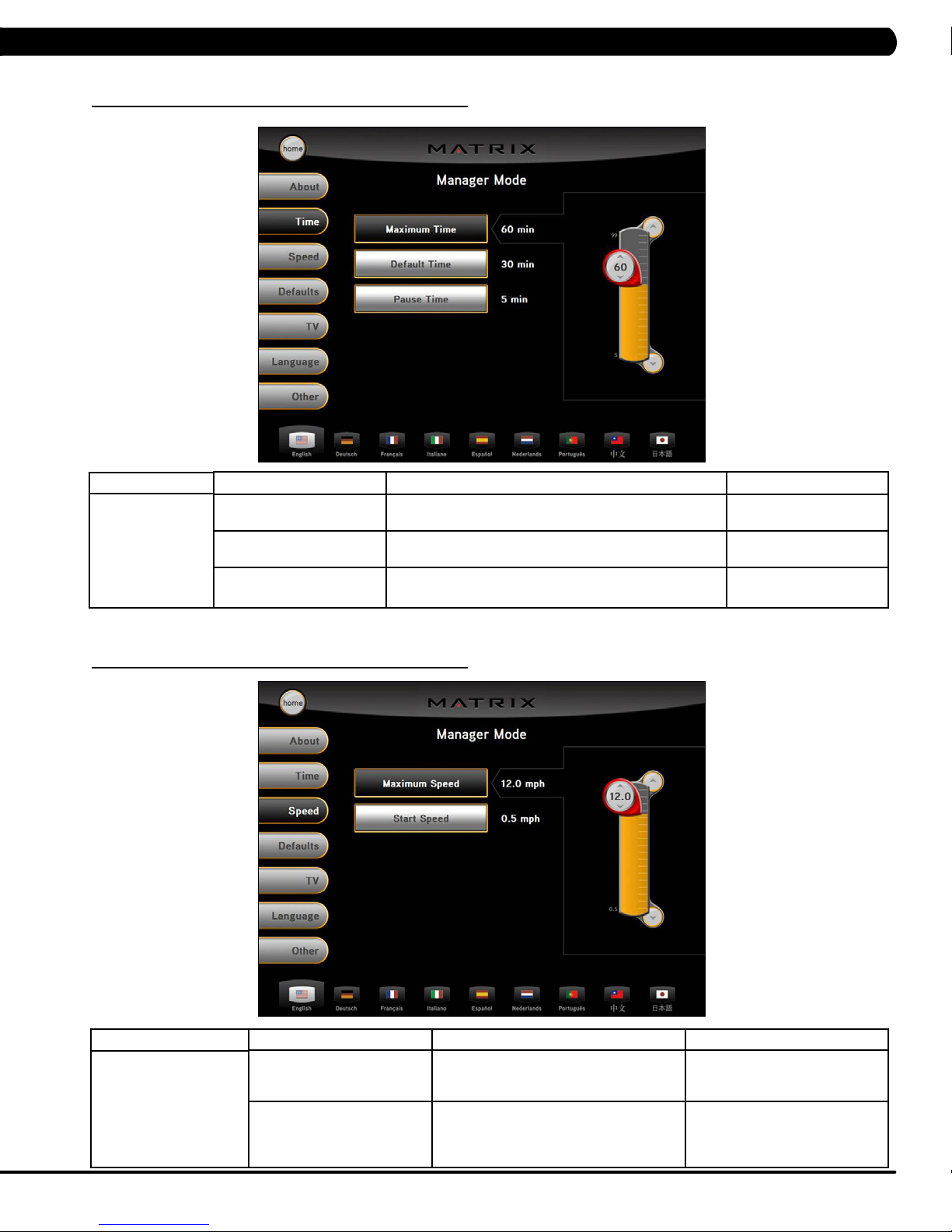

5.3 MANAGER MODE - TAB 2

CHAPTER 5: MANAGER MODE

MANAGER MODE

Time

5.4 MANAGER MODE - TAB 3

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Maximum Time

Default: 60 Minutes

Default Time

Default: 30 Minutes

Pause Time

Default: 5 Minutes

This option enables clubs to set the maximum workout

duration limits during peak and non peak hours of traffic.

This option controls the default program time. Maximum: Maximum Time

This option controls the default pause time. Maximum: 10 Minutes

Maximum: 99 Minutes

Minimum: 5 Minutes

Minimum: 5 Minutes

Minimum: 1 Minute

MANAGER MODE

Speed

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Maximum Speed

Default: 12 MPH / 19.3 KPH

Start Speed

Default: 0.5 MPH / 0.8 KPH

This option controls the maximum speed

for all programs. Displayed in native units

(miles or kilometers).

This option controls the starting speed

for all programs (minimum speed not

affected). Displayed in native units (miles

or kilometers).

Maximum: 15 MPH / 24.1 KPH

Minimum: 0.5 MPH / 0.8 KPH

Maximum: 1.4 MPH / 2.3 KPH

Minimum: 0.5 MPH / 0.8 KPH

15

Page 19

5.5 MANAGER MODE - TAB 4

CHAPTER 5: MANAGER MODE

MANAGER MODE

Defaults

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Default Level

Default: 1

Default Age

Default: 30

Default Weight

Default: 150 lb / 68 kg

Gender

Default: Male

Key Sound

Default: On

This option controls the default program

levels.

This option controls the default user's age

used in the target heart rate calculations.

This option controls the default weight

used in the calorie calculations. Displayed

in native units (pounds or kilograms).

This option sets the user's gender as

either male or female.

This option can set the keypad tone to

sound or not sound.

Maximum: 20

Minimum: 1

Maximum: 100

Minimum: 10

Maximum: 400 lb / 180 kg

Minimum: 50 lb / 22 kg

Male or Female

ON or OFF

16

Page 20

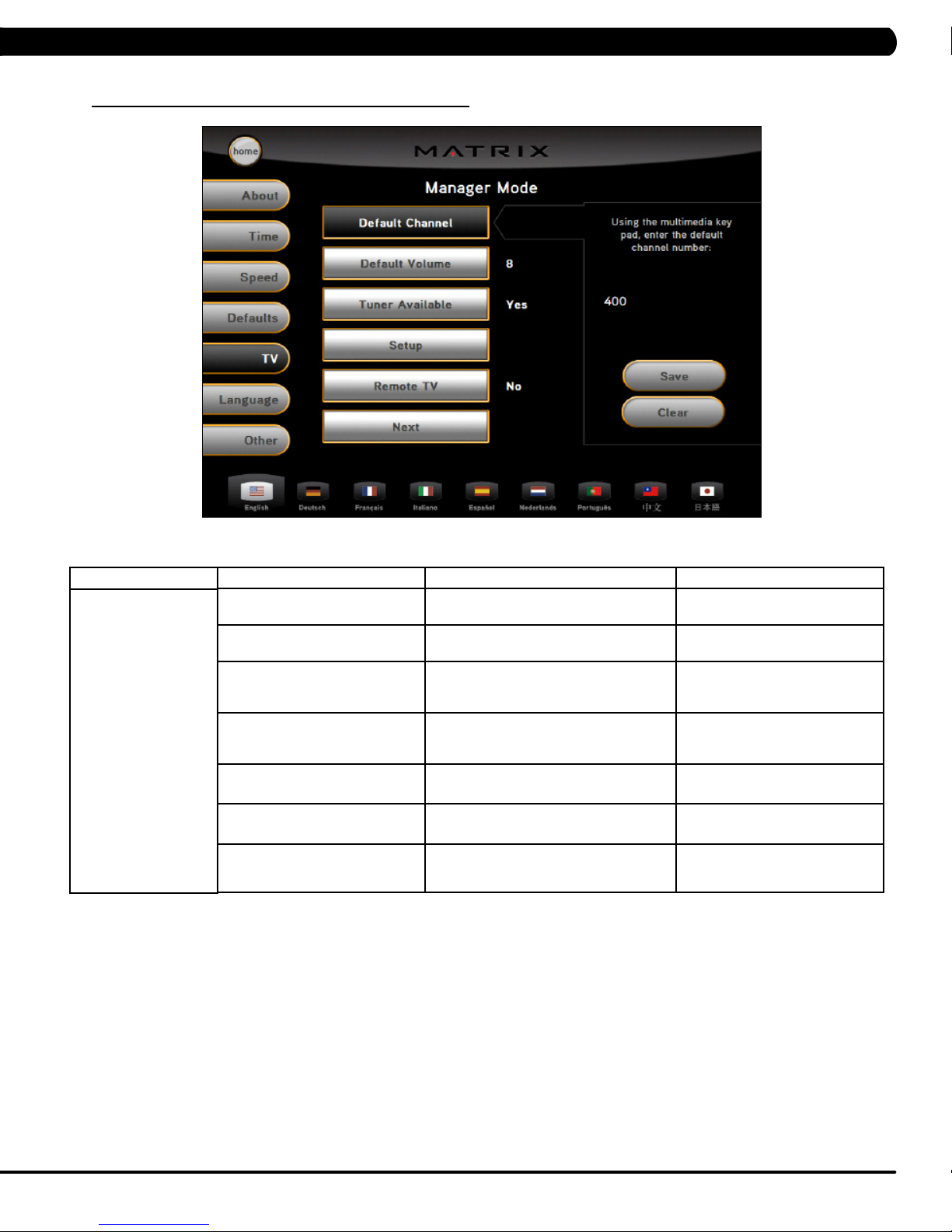

5.6 MANAGER MODE - TAB 5

CHAPTER 5: MANAGER MODE

MANAGER MODE

TV

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Default Channel

Default: 3

Default Volume

Default: 5

Tuner Available

Default: Yes

Setup This option is for setting the TV tuner

Remote TV

Default: No

Remote TV channel

Default: 1

Remote TV volume

Default: 15

This option controls the default TV channel

on start up.

This option controls the default TV volume

on start up.

This option controls the default TV

function. If NO is selected, the TV tab will

be removed from the normal function.

functions. Press the "-" key on the

NUMBER KEYPAD to enter this function.

This option controls the remote TV

function.

This option controls the default remote TV

channel on start up.

This option controls the default remote TV

volume on start up.

Maximum: 99

Minimum: 1

Maximum: 17

Minimum: 0

YES or NO

N/A

ON or YES

Maximum: 37

Minimum: 1

Maximum: 15

Minimum: 1

17

Page 21

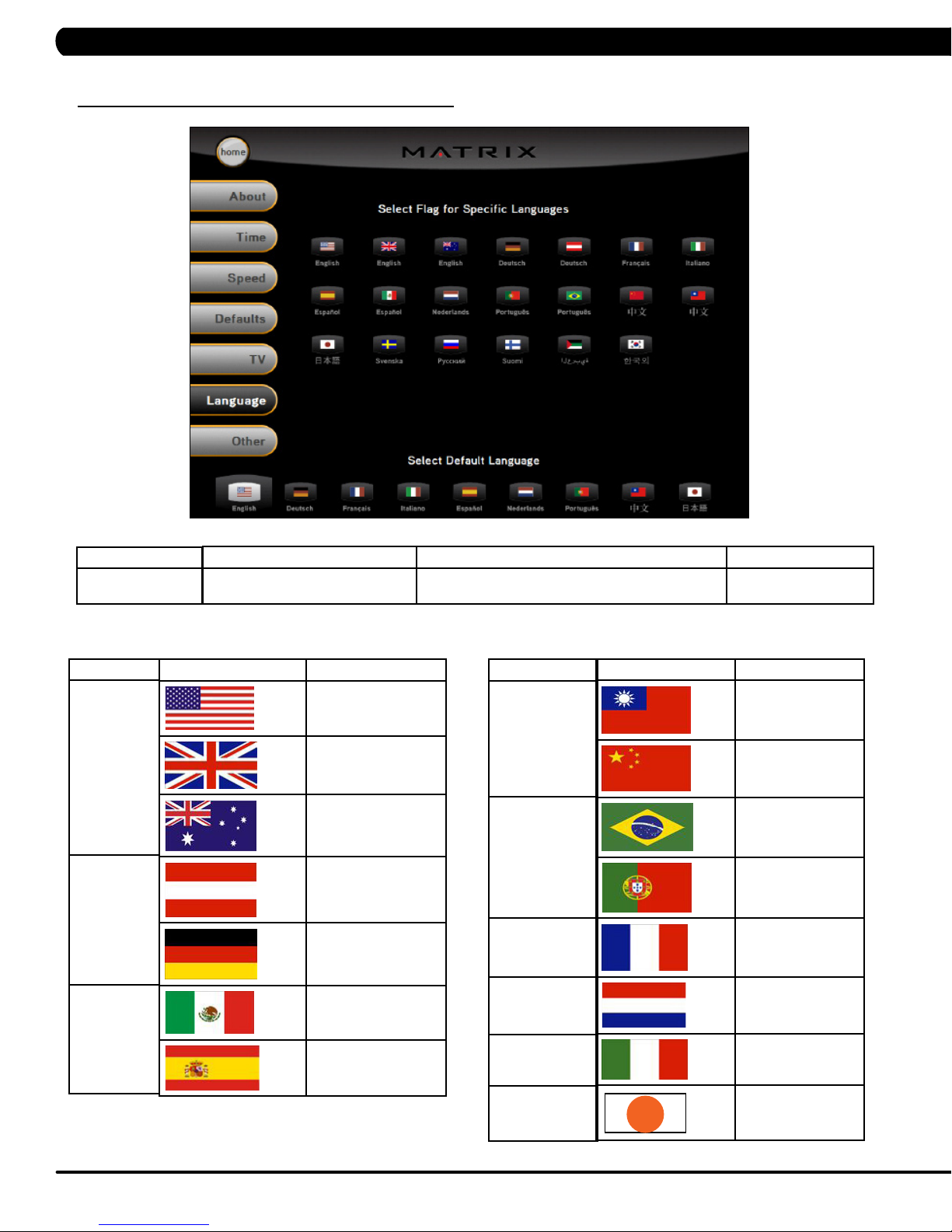

5.7 MANAGER MODE - TAB 6

CHAPTER 5: MANAGER MODE

MANAGER MODE

Language

LANGUAGE

ENGLISH

GERMAN

SPANISH

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Default Language This option allow the user to select the flag for the

FLAG UNIT

MILE

MILE

KM

KM

KM

KM

specific language shown on the display.

LANGUAGE

CHINESE

PORTUGUESE

FRENCH

DUTCH

FLAG UNIT

N/A

KM

KM

KM

KM

KM

KM

KM

18

ITALIAN

JAPANESE

KM

KM

Page 22

5.8 MANAGER MODE - TAB 7

CHAPTER 5: MANAGER MODE

MANAGER MODE

Other

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Altitude

Default: 5000 ft

Asset Management

Default: Off

Virtual Active

Default: ON

Belt Stop

Default: Off

This option controls the default altitude used in

the fitness test score calculations.

This option allows the fitness club to collect the

machine data to a PC server.

This option controls the Virtual Active function. ON

This option is to check the running belt to see

if a user is there. If there is no user, and the

status is over the default time, the machine will

enter into a pause mode for 5 minutes. If no

user is present within 5 minutes, the display will

return to the start up screen.

ON or OFF

OFF, 30, 60, or 90

19

Page 23

CHAPTER 6: ENGINEERING MODE

6.1 USING ENGINEERING MODE

1) To enter Engineering Mode, press "ENTER, 2, 0, 0, 1, ENTER" on the number keypad and Engineering Mode will appear on the display.

2) Engineering Mode is divided into 6 tabs, located on the left side of the screen. They are Calibration, Statistics, Errors, Clubs, Club ID, and

Other.

3) Choose a tab by touching the screen over the desired tab.

4) Each of the tabs have options that will appear once you have chosen that particular tab.

5) Press the "HOME" button or the EMERGENCY STOP to exit Engineering Mode..

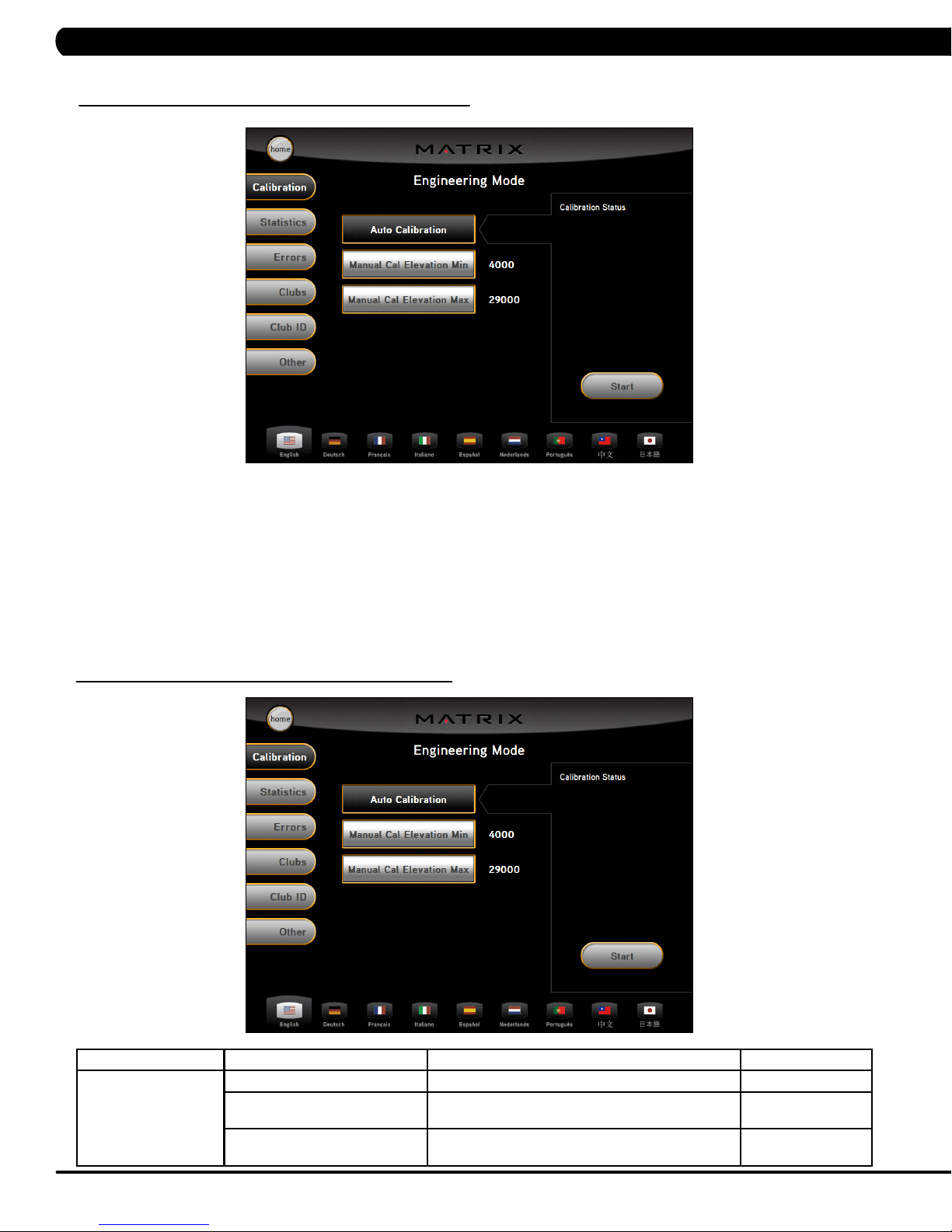

6.2 ENGINEERING MODE - TAB 1

ENGINEERING MODE

Calibration

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Auto Calibration This option is to calibrate the elevation parameters. N/A

Manual Cal Elevation Minimum

Default: 4000

Manual Cal Elevation Maximum

Default: 29000

20

This option controls the minimum elevation parameter. Range: 2500-12000

This option controls the maximum elevation

parameter.

Range: 25000-32700

Page 24

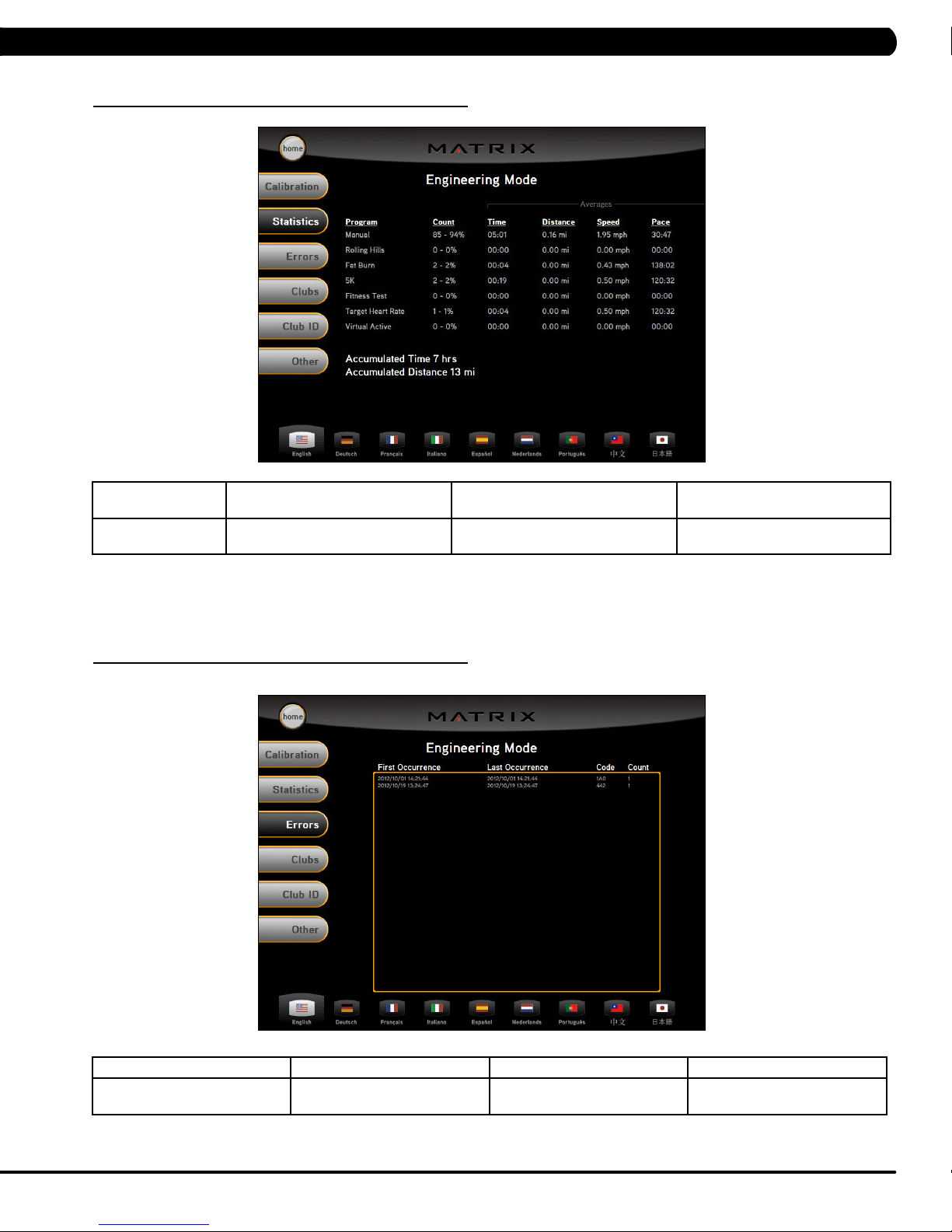

6.3 ENGINEERING MODE - TAB 2

CHAPTER 6: ENGINEERING MODE

ENGINEERING

MODE

6.4 ENGINEERING MODE - TAB 3

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Statistics This option displays workout

information for the various programs.

N/A

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Errors This option displays the error

code history on the treadmill.

N/A

21

Page 25

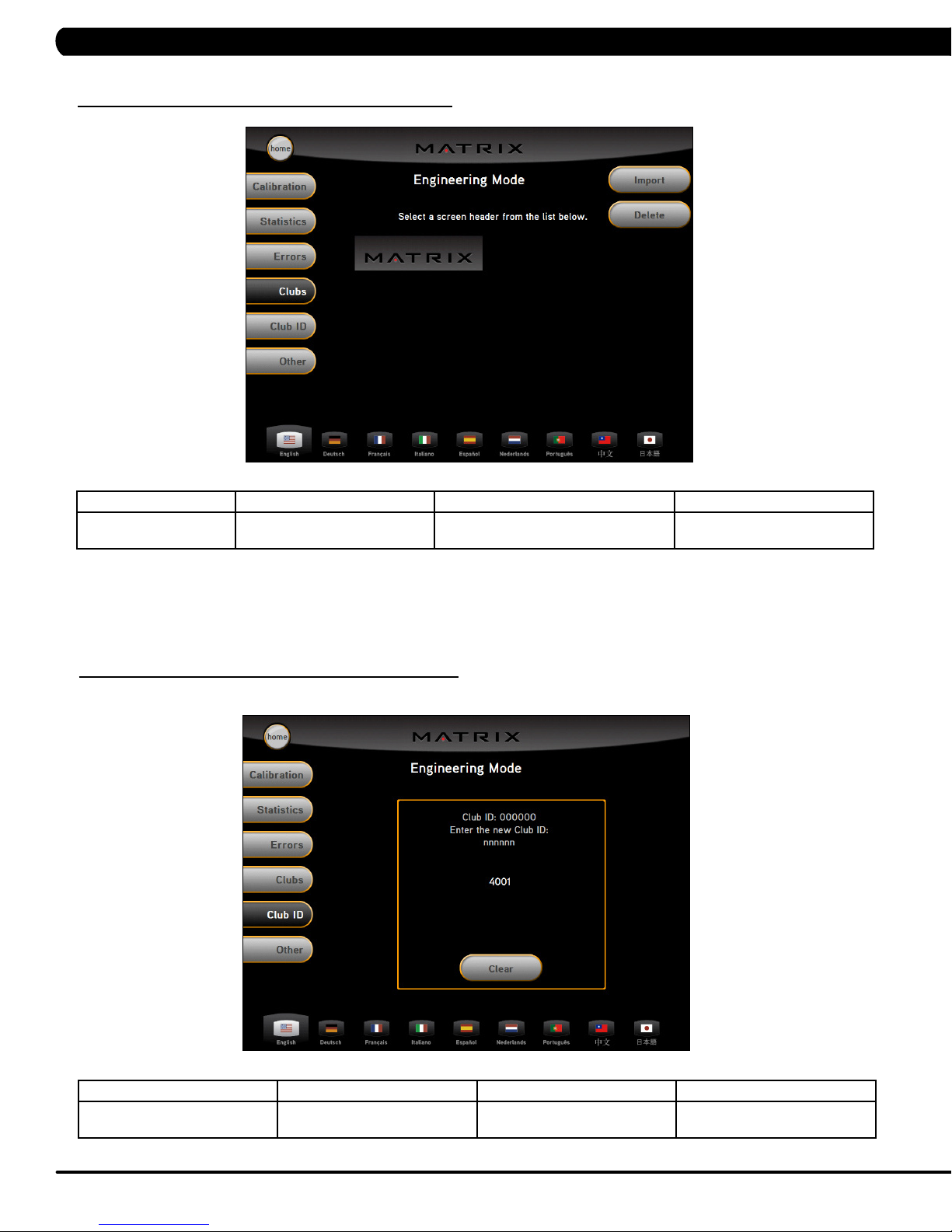

6.5 ENGINEERING MODE - TAB 4

CHAPTER 6: ENGINEERING MODE

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Clubs

Default: MATRIX

6.6 ENGINEERING MODE - TAB 5

This option allows the user to select the

screen header from a list.

N/A

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Club ID This option records the club ID of

22

the fitness facility.

N/A

Page 26

CHAPTER 6: ENGINEERING MODE

6.7 ENGINEERING MODE - TAB 6

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Other Erp Time

Default: 0 minute

If there is no use of the machine over a

period of time, the console LEDs will turn

off (go into ErP mode).

Maximum: 30 minute

Minimum: 0

CHAPTER 6:

CHAPTER 6:

CHAPTER 6:

CHAPTER 6:

CHAPTER 6:

ENGINEERING MODE

ENGINEERING MODE

ENGINEERING MODE

ENGINEERING MODE

ENGINEERING MODE

23

Page 27

CHAPTER 7: SERVICE MODE

7.1 USING SERVICE MODE

1) To enter Service Mode, press "ENTER 3, 0, 0, 1, ENTER" on the number keypad and Service Mode will appear on the display.

2) Service Mode is divided into 4 tabs, located on the left side of the screen. They are Setup, Test, Log, and Date & Time.

3) Choose a tab by touching the screen over the desired tab.

4) Each of the tabs have options that will appear once you have chosen that particular tab.

5) Press the "HOME" button or the EMERGENCY STOP to exit Service Mode..

7.2 SERVICE MODE - TAB 1

SERVICE MODE

Setup

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Machine Type

Default: Treadmill

Serial Number This option displays the serial number of the console and frame. N/A

Accumulated Distance Total distance displayed in native units (miles or kilometers), not editable. N/A

Accumulated Time Total time, not editable. N/A

Show Service on Boot Factory Setting Only N/A

24

This option is to select the current model. N/A

Page 28

7.3 SERVICE MODE - TAB 2

CHAPTER 7: SERVICE MODE

T7xe-02--C Keypad - Old keypad Includes Quick Start Key

T7xe-03--C Keypad - Old keypad - Does

NOT Includes Quick Start Key

SERVICE MODE

Test

T7xe-04-C Keypad - New keypad -

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Keypad This option is for a keypad test. N/A

Touch Calibration This option allows for a touch calibration of the

Keypad Type

Default: LAM

Radio Test This option will test the radio signal for function. N/A

console. Follow the cross mark and touch the

screen to catch. After 5 positions are tested, touch

the center of the screen to exit this test.

This option sets the type of keypad for the

treadmill. It should always be set for T7xe-04 for

this treadmill.

N/A

Quick Start or No Quick Start or

LAM

25

Page 29

7.4 SERVICE MODE - TAB 3

CHAPTER 7: SERVICE MODE

SERVICE MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Log This option allows the club to record key

components replacement history.

7.5 SERVICE MODE - TAB 4

N/A

SERVICE MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Date & Time This option allows the club to set the current date

26

and time.

N/A

Page 30

8.1 ELECTRICAL DIAGRAMS

CHAPTER 8: TROUBLESHOOTING

27

Page 31

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

Digital Communication Wire

Hand Pulse Sensor Wire

28

Page 32

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

UCB Little Board Wire

Hand Pulse Wire

29

Page 33

8.2 MCB LED INSTRUCTIONS

CHAPTER 8: TROUBLESHOOTING

LED REFERENCE DESIGNATOR DESCRIPTION

RS485 DSP2

MCU DSP1

DOWN DSP5

UP DSP6

+12V DSP4

30

Indicates if the digital communication is working normally between the console and the MCB.

Blinking = Normal.

Off = Fault

Indicates if the console is working normally.

Blinking - Normal.

Light = MCU Fault.

Off = MCU No Power.

Indicates if the console is commanding elevation down.

Light = Normal.

Off - No command from console received by the elevation motor.

Indicates if the console is commanding elevation up.

Light = Normal.

Off = No command from console received by the elevation motor.

Indicates if the console voltage supply is present.

Light = Normal.

Off - 12 Volts are not provided by the MCB.

Page 34

8.3 MCB WIRING

CHAPTER 8: TROUBLESHOOTING

TB1 - AC Motor Cable Socket

TB2 - Input Power Cable Socket

J9 - Inside Fan Cable Socket

J10 - Digital Communication Cable Socket

J12 - Elevation Motor Cable Socket

J16 - External Fan Cable Socket

31

Page 35

CHAPTER 8: TROUBLESHOOTING

8.4 0140 / 01A0 / 01A2 ERROR TROUBLESHOOTING

ERROR MESSAGES 0140 / 01A0 / 01A2

1) SYMPTOM:

a. 0140 - Incline motor operation failed.

b. 01A0 - Incline motor disconnected.

c. 01A2 - Incline motor is detected in the reverse of the position indicated by the potentiometer.

2) SOLUTION

a. Check the connection of the incline motor cable at the MCB.

b. Run auto calibration (See Section 3.5).

c. If auto calibration fails, re-enter Engineering Mode and again go to Calibration.

- Select Incline Minimum, and then Go To Value.

- Check the MCB LEDs. If LED DOWN (Figure A) has no light, check the console cable connections at the console and MCB.

Replace the console or cable as needed. If LED DOWN has a light, replace the incline motor.

d. If the incline motor does not resolve the issue, replace the MCB.

FIGURE A

32

Page 36

CHAPTER 8: TROUBLESHOOTING

8.5 01A3 ERROR TROUBLESHOOTING

ERROR MESSAGE 01A3

1) SYMPTOM:

a. Motor is disconnected.

2) SOLUTION:

a. Check the connection of the motor cable at the MCB (Figure A).

b. Check to see if the MCB LED DSP1 (MCU) is lit (Figure B).

c. If LED DSP1 is blinking, the motor should be replaced.

d. If LED DSP1 is a solid light, replace the motor.

e. If LED DSP1 is not lit, replace the MCB.

FIGURE A FIGURE B

8.6 01A8 / 02B6 / 02B7 / 02B8 ERROR TROUBLESHOOTING

ERROR MESSAGE 01A8 / 02B6 / 02B7 / 02B8

1) SYMPTOM:

a. 01AB - Motor over current.

b. 02B6 - Speed up is overcurrent.

c. 02B7 - Speed down is overcurrent.

d. 02B8 - Running status is overcurrent.

2) SOLUTION:

a. Check the condition of the running deck and belt. Replace the belt and flip or replace the running deck as needed.

b. Replace the MCB.

33

Page 37

CHAPTER 8: TROUBLESHOOTING

8.7 029F ERROR TROUBLESHOOTING

ERROR MESSAGE 029F

1) SYMPTOM:

a. Motor over temperature.

2) SOLUTION:

a. Check the connection of the motor cable at the MCB (Figure A).

b. Use a multi-meter to check the motor wire circuit. Set the multi-meter to Ohms and place both terminals on the blue wires of the

motor cable (Figure B). There should be an Ohm reading of 0. If there is an Ohm reading above 0, replace the motor. If the Ohm reading is 0,

replace the MCB.

FIGURE BFIGURE A

8.8 02AD ERROR TROUBLESHOOTING

ERROR MESSAGE 02AD

1) SYMPTOM:

a. MCB is over temperature.

2) SOLUTION:

a. Check to see that both fans are operating (there is a fan mounted to the MCB itself as well as an external fan). Also check the

connection of the fans at the MCB (Figure A).

b. If the fans are running correctly, replace the MCB.

34

FIGURE A

Page 38

CHAPTER 8: TROUBLESHOOTING

8.9 02B2 ERROR TROUBLESHOOTING

ERROR MESSAGE 02B2

1) SYMPTOM:

a. The emergency circuit on the interface board active.

2) SOLUTION:

a. Check the connection of the safety key (emergency stop) switch (Figure A). If the switch is always open or shorted out, replace the

switch.

b. If the emergency stop does not resolve the issue, replace the console.

FIGURE A

8.10 02B9 / 02BA / 02BD ERROR TROUBLESHOOTING

ERROR MESSAGE 02B9 / 02BA / 02BD

1) SYMPTOM:

a. 02B9 - The inner memory IC data write error.

b. 02BA - The inner memory IC data read error.

c. 02BD - Inverter hardware interrupt error.

2) SOLUTION:

a. Check LED DSP1 (MCU) on the MCB (Figure A).

b. If this LED is blinking, replace the console.

c. If this LED is a constant light, replace the MCB.

d. If this LED is not lit at all, check the power to the MCB.

FIGURE A

35

Page 39

CHAPTER 8: TROUBLESHOOTING

8.11 04A0 ERROR TROUBLESHOOTING

ERROR MESSAGE 04A0

1) SYMPTOM:

a. No communication received.

2) SOLUTION:

a. If the display is giving an 04A0 error, LED DSP2 (RS485) should be off (Figure A). If this light is not on and an 04A0 error is present,

replace the console.

b. Check the connection of the console communication cable at both the console and the MCB.

c. Replace the console communication cable.

d. Replace the MCB.

FIGURE A

36

Page 40

CHAPTER 8: TROUBLESHOOTING

8.12 TROUBLESHOOTING - NO POWER TO THE CONSOLE

POWER SWITCH IS ON, BUT THE CONSOLE HAS NO DISPLAY

1) SYMPTOM:

a. The unit is not getting power from the outlet.

b. The MCB is not getting power from the power receptacle.

c & d. The power switch and MCB LEDs are lit, but there is no power to the console.

2) SOLUTION:

a. Check to see if the power switch is lit. If it is not, plug the power cord into a known working outlet and re-test.

- If the power switch is still not lit, replace the power switch, receptacle, and / or the power cord.

b. Remove the motor cover and check to see if LED +12V (DSP4) is lit on the MCB (Figure A).

- If the LED +12V is not lit, check the incoming AC voltage to the MCB.

- Replace the MCB if all power components are OK, and there is AC volts to the MCB.

c. If LED +12V is lit, check the switch on the back of the LMM Board (Figure B).

- If the unit has a power board (Figure C), the switch should be towards the left.

- If the unit does not have a power board, the switch should be towards the right .

d. If LED +12V is lit, check the connection of the console communication cable.

- If the console communication cable is connected correctly, D18 on the console UCB should be lit.

- If D18 on the console UCB is not lit, replace the console communication cable.

- If D18 on the console UCB is lit, but there is still no power to the console, replace the console.

FIGURE BFIGURE A

FIGURE C

37

Page 41

CHAPTER 8: TROUBLESHOOTING

8.13 TROUBLESHOOTING - HEART RATE ISSUES

HEART RATE ISSUES

1) SYMPTOM:

a. No heart rate.

b. No or high heart rate.

2) SOLUTION:

a. With a multi meter set for DC Voltage, place one prong of the multi meter on each of the HR plates on the handlebar (Figure A). A

correctly connected HR grip will have a DC Voltage reading of between 0.5 and 2.0. If this reading is correct, skip to Step b.

- If the reading is not correct, remove the screws holding the 2 halves of the HR grip together and check the connection of the HR grip

wiring to the grips (Figure B). Replace the grips if any damage is seen to the plates.

- Remove the console to expose the HR board.

- Check the connection of the HR grip wiring to the 6 pin Y cable attached to one side of the HR board. Use a multi meter set for

ohms to verify the continuity of these wires. If the ohm reading is more than 1 (or not there at all), replace the HR grip wiring (this will require

replacing the HR handlebar). If the ohm reading is correct, your issue is not with the HR grip / HR wire portion of the HR system.

b. Perform a continuity test on the treadmill console (see Service Bulletin - Continuity Test on Matrix Treadmills).

- Verify the HR board ground wire. With a multi meter set for ohms, place one prong on the HR board ground wire, and the other on

the console ground screw. You should get a resistance reading of 1 or less. If you get a reading over 1 (or none at all), replace the HR board.

- Check the continuity of the wire that goes from the HR board to the Translator Board. With a multi meter set for ohms, place one

prong on the 3 pin wire connecting to the HR board (Figure C) and the other on where this wire connects to the Translator Board (Figure D). If

you get a reading of over 1 (or no reading at all), replace this wire.

- Check the connection of the wire that goes from the Translator Board to the UCB. Replace this wire if needed.

- If all wiring checks out good and the unit is still having HR issues, replace the HR board.

- If the HR board does not resolve the issue, replace the UCB.

FIGURE A FIGURE B

FIGURE C FIGURE D

38

Page 42

CHAPTER 8: TROUBLESHOOTING

8.14 TROUBLESHOOTING - DISPLAY COLOR ISSUES

CONSOLE DISPLAY COLOR ISSUES

1) SYMPTOM:

a. The display colors are off or there are a "rainbow" of colors on the display.

2) SOLUTION:

a. Check the console cable connections at the upper and lower control boards.

b. Check the LED display wire connection (Figure A).

- This wire connection should be taped in place, add tape if needed.

- This wire should be tie strapped to the frame (Figure B). Add a tie strap if needed.

FIGURE BFIGURE A

39

Page 43

CHAPTER 8: TROUBLESHOOTING

8.15 TROUBLESHOOTING - SPEED SHOWN IS HIGHER THAN BELT SPEED

SCREEN SHOWS A HIGH SPEED, BUT THE BELT MOVING SLOWER THAN SHOWN

1) SYMPTOM:

a. The unit speed does not match the console display.

2) SOLUTION:

a. Perform an amp draw on the incoming power (see Field Work Instruction - Running an Amp Draw on Matrix Treadmills).

b. If the amp draw is too high regardless if a user is present or not, the issue is likely with the drive system (drive belt or motor).

- Make sure that there is enough tension from the idler on the drive belt so that it is not slipping.

- Check the rotation of the motor to find any dead spots or a wobble in the motor axle.

- Check the condition of the drive belt. Look for any wear or tears. Replace as needed.

c. If the amp draw is too high with a user, the issue is likely with the deck / running belt.

- Inspect the running deck for sticky or worn spots. If any wear is seen, flip the deck (it is waxed on both sides). A new running belt

should be installed any time a running deck is flipped.

- Replace the running belt.

40

Page 44

CHAPTER 8: TROUBLESHOOTING

8.16 ENTERTAINMENT TROUBLESHOOTING - OVERVIEW

1. Sections 8.16 - 8.19 will help with diagnosing problems with TV and entertainment related equipment that is produced by Matrix Fitness.

2. The Matrix T7xe treadmill includes an integrated TV that shows in the large display window. The TV is capable of being shown as a 7" or 15"

screen (Figures A & B). Your treadmill should be equipped with an Entertainment keypad similar to Figure C.

FIGURE A FIGURE B

FIGURE C

41

Page 45

CHAPTER 8: TROUBLESHOOTING

8.17 ENTERTAINMENT TROUBLESHOOTING – PICTURE FUZZY OR UNCLEAR

1. Usingaveriedgoodpieceofcoaxcable(agoodcoaxcablewillhaveasignalstrengthof10hzorgreater),removetheconsolebackcover

(Figure A) and hook the coax directly to the TV jack on the tuner. This bypasses internal connections for your machine (Figure B).

2. Checkyourinternalcablesandttingsinsideyourmachineattheconsole(FigureB)andbelowthemotorcover(FigureC).Makesureyou

havenodamage(kinks,cutsetc)andnostraywiresorpoorttingsontheendsofthecables.FittingsshouldlooklikeFigureD,withaclean

ushconnectorandnostrayaluminumstrandstouchingthecenterconductor.Replaceorrepairanysuspectcables.

3. Ifnodamagecanbefoundoncables,ttings,orconnectorsbeginreplacingcablesandconnectorswithknowngoodpartsuntilthe

damaged part is found. It is also possible that the console tuner is damaged, replace as needed.

FIGURE A FIGURE B

FIGURE C FIGURE D

42

Page 46

CHAPTER 8: TROUBLESHOOTING

8.18 ENTERTAINMENT TROUBLESHOOTING -TV WILL NOT TURN ON

1. If you have no picture at all, check to see if you have any status lights on your Entertainment keypad (next to the power button). The status

light should be red when off or in standby mode, and green when the TV is powered on. If you have lights of any color skip to Section 8.19.

2. Remove the console back (Figure A) and check the electrical connections for the TV (Figures B & C).

3.Afteryouhaveveriedallconnectionsaresecureandproblemstillexistsverifypowerattheoutlet(FigureD).Iftheoutletisnotoutputting

120V,checkthetnessroompower.

4. If internal electrical connections are good,, and the outlet is outputting 120V, the issue is likely with the TV, contact Matrix Customer Technical

Support.

FIGURE A FIGURE B

FIGURE C FIGURE D

43

Page 47

CHAPTER 8: TROUBLESHOOTING

8.19 ENTERTAINMENT TROUBLESHOOTING - ENTERTAINMENT KEYPAD ISSUES

1. If you have a status light on the Entertainment keypad but the On / Off button gives no response, disconnect and then reconnect the power to

the treadmill from the wall. Attempt to turn on the TV again using the On / Off button.

2. If TV still does not power on, remove the console back (Figure A) and check the Entertainment keypad connections at the console (Figure B).

3. If the TV does not power on after the Entertainment keypad connection is reset, the issue it is likely with the TV itself, contact Matrix Customer

Technical Support.

FIGURE A

FIGURE B

44

Page 48

CHAPTER 9: PART REPLACEMENT GUIDE

9.1 MOTOR COVER AND LOWER SHROUD REMOVAL

1) The motor cover is split into two pieces (called the motor cover and lower shroud

2) Remove the 2 screws holding motor cover to the frame (Figure A ).

3) Pull up on the rear of the motor cover to release the Velcro, and remove the motor cover (Figure B).

FIGURE A FIGURE B

4) Remove the 4 screws holding the lower shroud to the frame (Figure C).

5) Figure D shows a unit with both the motor cover and lower shroud removed.

FIGURE C FIGURE D

45

Page 49

CHAPTER 9: PART REPLACEMENT GUIDE

9.2 REAR ROLLER REPLACEMENT

1) Turn off power to the unit and disconnect the cord from the machine.

2) Remove one of the end caps using a Phillips screwdriver (Figure A).

3) Remove both roller adjustment screws using an 8 mm Allen wrench (Figure B).

FIGURE A

4) Remove the roller from the running belt (Figures C & D).

FIGURE C

5) Reverse Steps 1-4 to install a new rear roller.

6) Tension the running belt as outlined in Section 3.6.

FIGURE B

FIGURE D

46

Page 50

CHAPTER 9: PART REPLACEMENT GUIDE

9.3 RUNNING DECK REPLACEMENT

1) Remove the motor cover as outlined in Section 9.1.

2) Remove the four running deck screws using a 5 mm Allen wrench (Figure A).

FIGURE A

3) Remove the running deck from the running belt (Figures B & C). NOTE: Be careful not to pinch fingers during removal / installation of the

running deck.

FIGURE B FIGURE C

4) Reverse Steps 1-3 to install a new running deck. NOTE: The running deck is waxed on both sides so the opposite side surface may be

usable. New running deck surfaces must ALWAYS be matched to a new running belt.

5) Tension the running belt as outlined in Section 3.6.

47

Page 51

CHAPTER 9: PART REPLACEMENT GUIDE

9.4 RUNNING DECK CUSHION REPLACEMENT

1) Remove the running deck as outlined in Section 9.3.

2) Hold the running deck cushion bolt with a 5 mm Allen wrench and loosen the nut with 13 mm socket (Figures A & B).

FIGURE A FIGURE B

3) Remove the rear cushion by holding the cushion while removing the 13 mm nut (Figure C).

FIGURE C

4) Reverse Steps 1-3 to install new running deck cushions.

5) Tension the running belt as outlined in Section 3.6.

48

Page 52

CHAPTER 9: PART REPLACEMENT GUIDE

9.5 FRONT ROLLER REPLACEMENT

1) Remove the motor cover as outlined in Section 9.1.

2) Using a hook or loop of wire, remove the spring from the drive belt tensioner. The tensioner should now pivot away from the drive belt

(Figures A & B).

FIGURE A FIGURE B

3) Remove the front roller mounting screws using an 8 mm Allen wrench (Figures C & D).

4) Remove the drive belt from the front roller and remove the roller from the running belt (Figure E).

FIGURE C FIGURE D

5) Reverse Steps 1-4 to install a new front roller.

6) Tension the running belt as outlined in Section 3.6.

FIGURE E

49

Page 53

CHAPTER 9: PART REPLACEMENT GUIDE

9.6 RUNNING BELT REPLACEMENT

1) Remove the motor cover as outlined in Section 9.1.

2) Remove the rear roller as outlined in Section 9.2.

3) Remove the running deck as outlined in Section 9.3.

4) Remove the front roller as outlined in Section 9.5.

5) Once the rollers and deck are removed, the running belt can be lifted up and off the unit (Figures A & B).

FIGURE A

6) Reverse Steps 1-5 to install a new running belt. NOTE: A new running belt should ALWAYS be installed on a new deck surface (deck

should either be flipped or replaced to gain a new surface).

7) Tension the running belt as outlined in Section 3.6.

FIGURE B

50

Page 54

CHAPTER 9: PART REPLACEMENT GUIDE

9.7 SIDE RAIL REPLACEMENT

1) Remove the 4 screws holding on the end cap on the same side as the broken side rail using a Phillips screwdriver and remove the end cap

(Figure A).

2) Loosen the four screws under the frame of the side rail using a 5 mm Allen wrench (Figure B).

FIGURE A FIGURE B

3) Slide the rail off the back of the treadmill (Figures C & D).

FIGURE C

4) Reverse Steps 1-3 to install a new side rail. NOTE: After reinstalling the side rail, make sure the end cap is on first before tightening the

screws for proper gap spacing. Also be careful not to over tighten the screws, or they will poke through the top of the side rail.

FIGURE D

51

Page 55

CHAPTER 9: PART REPLACEMENT GUIDE

9.8 MOTOR CONTROL BOARD (MCB) REPLACEMENT

1) Turn off power and disconnect the cord from the machine.

2) Remove the motor cover as outlined in Section 9.1.

3) Cut any wire ties that are secured to the MCB panel.

4) Disconnect wires from the MCB - five total connections.

5) Remove two MCB mounting screws using a Phillips head screwdriver (Figures A & B).

6) Reverse Steps 1-5 to install a new MCB. Be sure to re-connect the 5 wires removed from the old MCB in Step 4 (Figure C). NOTE: The

speed sensor wire from the motor is no longer used and can be tie strapped to a bracket.

7) Auto Calibration must ALWAYS be run after replacing the MCB (see Section 3.5).

J10 - 8 pin black connector

to the console.

J16 - 2 pin white

connector to the

external fan.

FIGURE A

FIGURE B

TB2 - 3 pin connector from

the choke (2 wires) and a

ground (1 wire).

TB1 - 5 pin connector from

the motor.

J12 - 6 pin white

connector to the

incline motor.

52

FIGURE C

Page 56

CHAPTER 9: PART REPLACEMENT GUIDE

9.9 MOTOR REPLACEMENT

1) Turn off the power and disconnect the cord from the machine.

2) Remove the motor cover as outlined in Section 9.1.

3) Release the drive belt tensioner as outlined in Section 9.5.

4) Disconnect the motor power cable from the MCB (Figure A).

5) Use an 8 mm Allen wrench to remove the four motor mounting screws (Figure B).

FIGURE A FIGURE B

6) Lift the motor away from the treadmill (Figure C).

7) Reverse Steps 1-6 to install a new motor. NOTE: When reinstalling the motor, make sure the red vibration pad is in place (Figure D).

FIGURE C FIGURE D

8) Auto Calibration must ALWAYS be run when installing a new motor. (see Section 3.5)

53

Page 57

CHAPTER 9: PART REPLACEMENT GUIDE

9.10 DRIVE BELT REPLACEMENT

1) Remove the motor cover as outlined in Section 9.1.

2) Release the drive belt tensioner from the drive belt as outlined in Section 9.5.

3) Remove the front roller screw on the drive belt side and loosen the screw on the opposite side (Figure A).

FIGURE A

4) Lift the roller and remove the old drive belt (Figure B).

FIGURE B

5) Reverse Steps 1-4 to install a new drive belt. NOTE: After installing a new belt, check it for correct alignment to the motor pulley before

setting the tensioner in place.

6) Tension the running belt as outlined in Section 3.6.

54

Page 58

CHAPTER 9: PART REPLACEMENT GUIDE

9.11 INCLINE MOTOR REPLACEMENT

1) Turn off the power and disconnect the cord from the machine.

2) Lift the treadmill and support it so that the front wheels are off the floor, or the unit may be tipped on its side (Figure A).

FIGURE A

3) Remove the clip from the pin attaching the bottom of the incline motor to the rack (Figure B).

4) Remove the pin attaching the bottom of the incline motor to the rack (Figure C).

FIGURE B FIGURE C

55

Page 59

CHAPTER 9: PART REPLACEMENT GUIDE

9.11 INCLINE MOTOR REPLACEMENT - CONTINUED

5) Disconnect the incline motor power cable from the MCB (Figure D).

6) Disconnect the pin from the top of the incline motor (Figure E).

FIGURE D FIGURE E

7) Lift the incline motor away from the treadmill (Figure F).

8) Reverse Steps 1-7 to install a new incline motor. When installing the new motor, the worm screw should be turned as short as possible, and

then rotated out 2 full turns prior to being re-attached to the rack. NOTE: When installing the new incline motor, make sure to replace the white

washers at the top and bottom connection points of the incline motor (Figure G).

FIGURE F FIGURE G

9) Auto Calibration must ALWAYS be run after replacing the incline motor (see Section 3.5).

56

Page 60

CHAPTER 9: PART REPLACEMENT GUIDE

9.12 CONSOLE REPLACEMENT

1) Turn off the power and disconnect the cord from the machine.

2) Remove the 4 screws holding the console back to the front (Figure A).

3) Lean the console back away from the console and disconnect the coax cable connection.

4) Remove the six 6 mm screws from underneath the console. There are arrows stamped in the plastic at the proper openings (Figure B).

FIGURE A FIGURE B

5) Disconnect the remaining connectors holding the console to the frame and remove the console.

6) Reverse Steps 1-5 to install a new console. NOTE: Be sure to re-connect any wire connections removed in Steps 3 and 5 (Figure C).

FIGURE C

7) Auto Calibration must ALWAYS be run after replacing the console (see Section 3.5).

57

Page 61

CHAPTER 9: PART REPLACEMENT GUIDE

9.13 CONSOLE MAST ARM REPLACEMENT

1) Turn off power and disconnect the cord from the machine.

2) Remove the console as outlined in Section 9.12.

3) Take off the cup holder from the right side of the treadmill (Figure A).

4) Use a 6 mm Allen wrench to remove one screw and take off the plastic hand rail (Figure B).

FIGURE A FIGURE B

5) Remove the 5 Phillips screws and remove the right side upper plastic cover (Figures C, D, & E).

FIGURE C FIGURE D FIGURE E

6) Cut the wire ties and begin to unthread the console cable (Figures F & G).

FIGURE F

58

FIGURE G

Page 62

CHAPTER 9: PART REPLACEMENT GUIDE

9.13 CONSOLE MAST ARM REPLACEMENT - CONTINUED

7) Remove the screws holding the console frame to the mast arms with a 6 mm Allen wrench in the openings with arrows (Figure H).

8) Lift the frame from the mast arms and set it aside (Figure I).

FIGURE H FIGURE I

9) Use a 6 mm Allen wrench to remove the lower mast arm mounting screws (Figure J).

10) Pull the mast arm from the side of the machine (Figure K).

FIGURE J

11) Reverse Steps 1-10 to install a new console mast. NOTE: If replacing the right side mast arm, the console cable must be threaded through

it prior to it being mounted to the frame.

FIGURE K

59

Page 63

CHAPTER 9: PART REPLACEMENT GUIDE

9.14 CONSOLE CABLE REPLACEMENT

1) Turn off power and disconnect the cord from the machine.

2) Remove the console as outlined in Section 9.12.

3) Take off the cup holder from the right side of the treadmill (Figure A).

4) Use a 6 mm Allen wrench to remove one screw and take off the plastic hand rail (Figure B).

FIGURE A FIGURE B

5) Remove the 5 Phillips screws and remove the right side upper plastic cover (Figures C, D, & E).

FIGURE C FIGURE D FIGURE E

6) Cut the wire ties and begin to unthread the wire harness (Figures F & G). .

FIGURE F FIGURE G

60

Page 64

CHAPTER 9: PART REPLACEMENT GUIDE

9.14 CONSOLE CABLE REPLACEMENT - CONTINUED

7) Remove the spiral protective wrap from the top and bottom portions of the wire harness (Figures H & I).

FIGURE H FIGURE I

8) Attach a pulling wire to the top of the defective console cable (Figure J).

9) Slowly remove the defective console cable starting at the bottom of the machine and pulling it down to the motor compartment (Figure K).

FIGURE J FIGURE K

10) Connect the new console cable at the motor tray - 4 connections total. Figures L & M show 2 of these connections, the 3rd is the coax

cable.

FIGURE L FIGURE M

11) Attach the new console cable to the pulling wire and gently pull the new cable up through the machine. NOTE: Once the wire is in place,

reinstall the spiral wrap and wire ties.

12) Reverse Steps 1-7 to finish installing a new console cable.

13) Auto Calibration must ALWAYS be run after the installation of a new console cable (see Section 3.5).

61

Page 65

CHAPTER 9: PART REPLACEMENT GUIDE

9.15 HANDLE BAR SERVICE

1) Turn off the power and disconnect the cord from the machine.

2) All items on the handle bar are removed using a Phillips screwdriver from the underside of the bar.

3) Once the screws are removed, lift the part carefully and disconnect any wire connections to fully remove the handle bar.

4) Replace the parts as needed on handle bar including the Quick Start Key, Resistance and Incline Toggles, and the Heart Rate Grip Plates

(Figures A-F).

FIGURE A FIGURE B

FIGURE C

FIGURE E FIGURE F

62

FIGURE D

Page 66

CHAPTER 9: PART REPLACEMENT GUIDE

9.16 EMERGENCY STOP SWITCH REPLACEMENT

1) Turn off power and disconnect the cord from the machine.

2) Remove the console as outlined in Section 9.12.

3) Use a Phillips screwdriver to remove two screws, one from each side of the red button (Figure A).

4) Lift the button from bracket by pulling one side out at a time (Figure B).

FIGURE A FIGURE B

5) Use a Phillips screwdriver to remove two screws, one from each side of the mounting bracket (Figure C).