Page 1

JOHNS

O

A

Kyl

J

o

N

Issu

eRevda

A

pproval

e Schweit

z

hns

o

date 20

1

ision

te

er

n In

d

TF3

6-09-27

ustri

e

0/TF

5

Ser

v

Editio

n

Edition ti

Revie

w

s (S

h

0/T5

0

ice

M

01

e01

ang

h

-02/T

7

anua

l

Doc N

o

Page

ai)

C

0-02

. SM-T

M

Editor

A

lex Tan

g

o., L

t

1

-AF-003

26

d

2017-08-08

Page 2

M

M

atrix

R

atrix

R

etail T

etail T

5

F30

0-02

Produ

ct Bro

Mat

r

Matri

x

wse

ix Ret

a

Retail

il TF50

T70-0

2

2

Page 3

3

Contents

CHAPTER 1: SERIAL NUMBER LOCATION ................................................................................................... 4

CHAPTER 2: TROUBLESHOTING

2.1 Electrical Diagram…………………………………………………………………………………………………5

2.2 MCB instructions……………………………………….……………………………….…………………….......8

2.3.1 Troubleshooting - No Function For Safety Key ................................................................................... 12

2.3.2 Troubleshooting - No Response For Machine When Pressing Start……………………………………..13

2.3.3 Troubleshooting - Incline Motor Issues ................................................................................................. 14

2.3.4 Troubleshooting - Noise Issues ............................................................................................................ 15

2.3.5 Troubleshooting - Heart Rate Function Issues ..................................................................................... 16

CHAPTER 3: PART REPLACEMENT GUIDE

3.1 Motor Replac

ement .................................................................................................................................. 17

3.2 Side Rail Replacement ............................................................................................................................ 19

3.3 Rear Roller Replacement ......................................................................................................................... 20

3.4 Running Deck Replacement .................................................................................................................... 21

3.5 Front Roller Replacement ........................................................................................................................ 22

3.6 Running Belt Replacement ...................................................................................................................... 23

3.7 Motor Control Board (MCB) Replacement ............................................................................................... 24

3.8 Incline Motor Replacement ...................................................................................................................... 25

3.9 Console Replacement

..............................................................................................................................26

Page 4

Serial N

u

mber Lo

c

C

H

ation

APTER 1 : Serial N

u

mber Location 4

Page 5

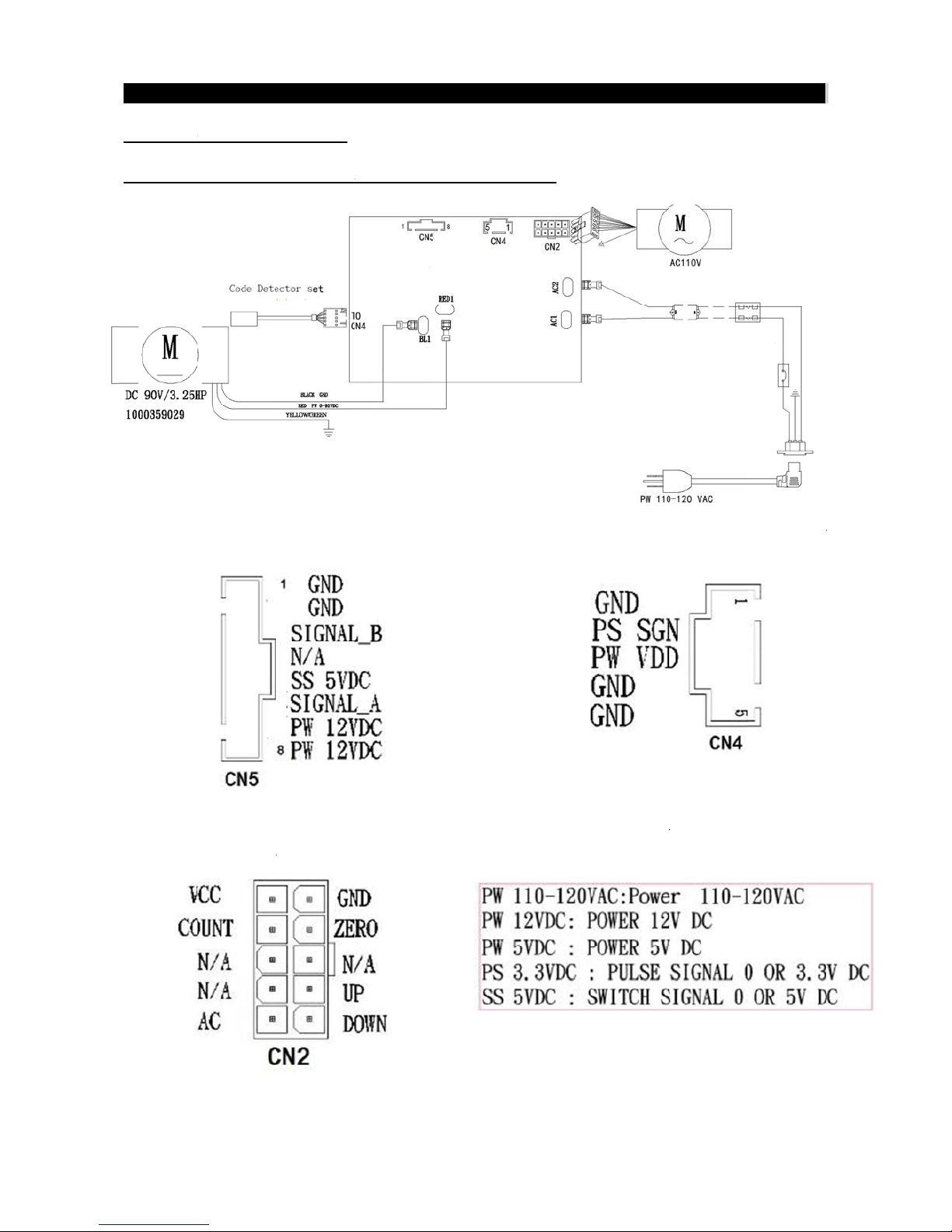

2.1 ELEC

1. MCB E

Fig-1 the

M

Fig-

3

TRICAL

D

LECTRIC

A

CB TO CO

The MCB

T

PIN

L

IAGRAM

L DIAGR

A

NSOLE PIN

O INCLINE

AYO U T

CHAPTE

R

M---TF3

0

LAYOUT

MOTOR

2: Trou

/

TF50/TF

Fig

-

bleshooti

n

50-02

2 the MC

B

TH

g

TO SPEE

D

E PIN VOLT

A

SENSOR

P

GE INFO

R

5

IN LAYOU

T

MATION

Page 6

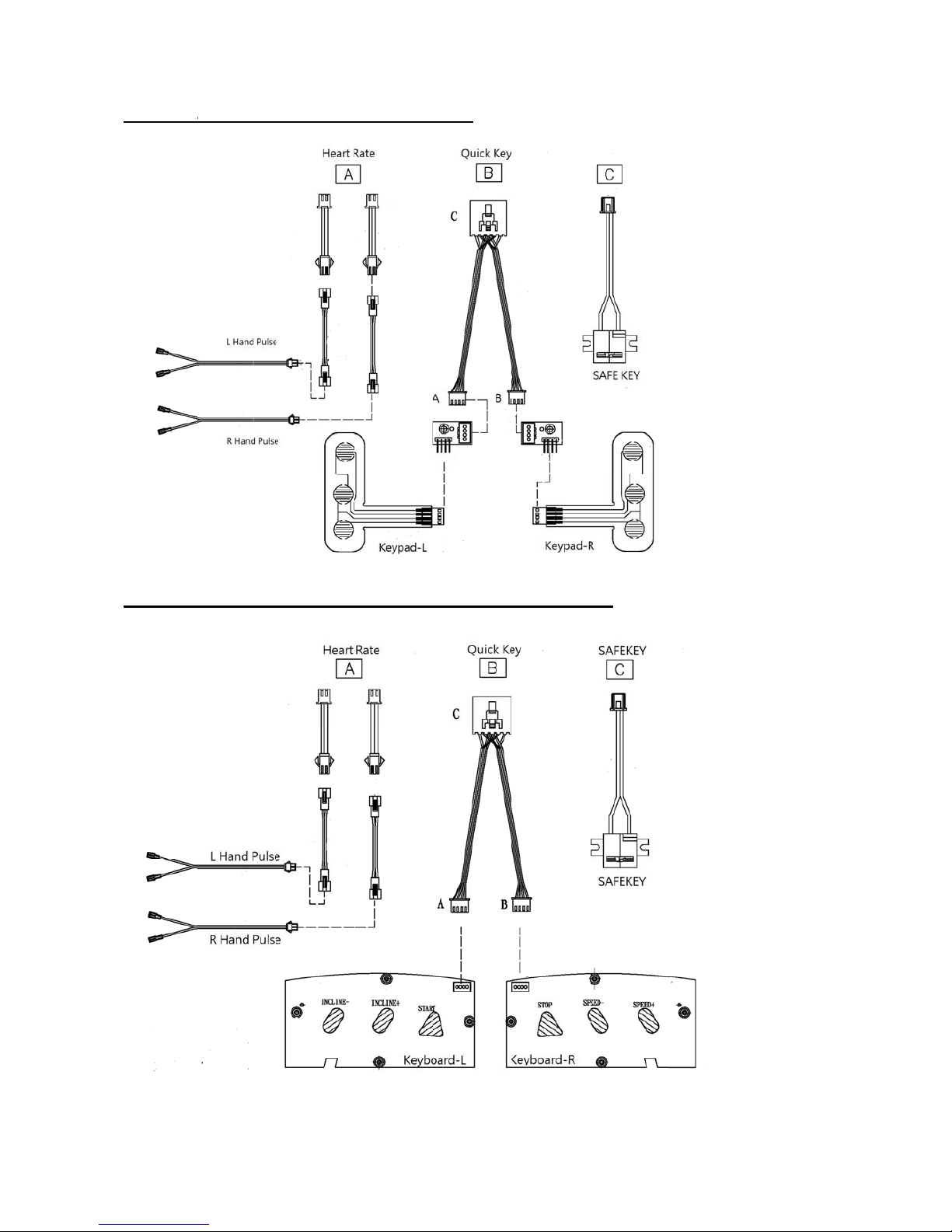

CONSO

L

2. CONS

O

E ELECT

R

LE ELE

C

ICAL DI

A

TRICAL

D

GRAM---

T

IAGRAM

F30

---TF50/T50-02/T70-02

6

Page 7

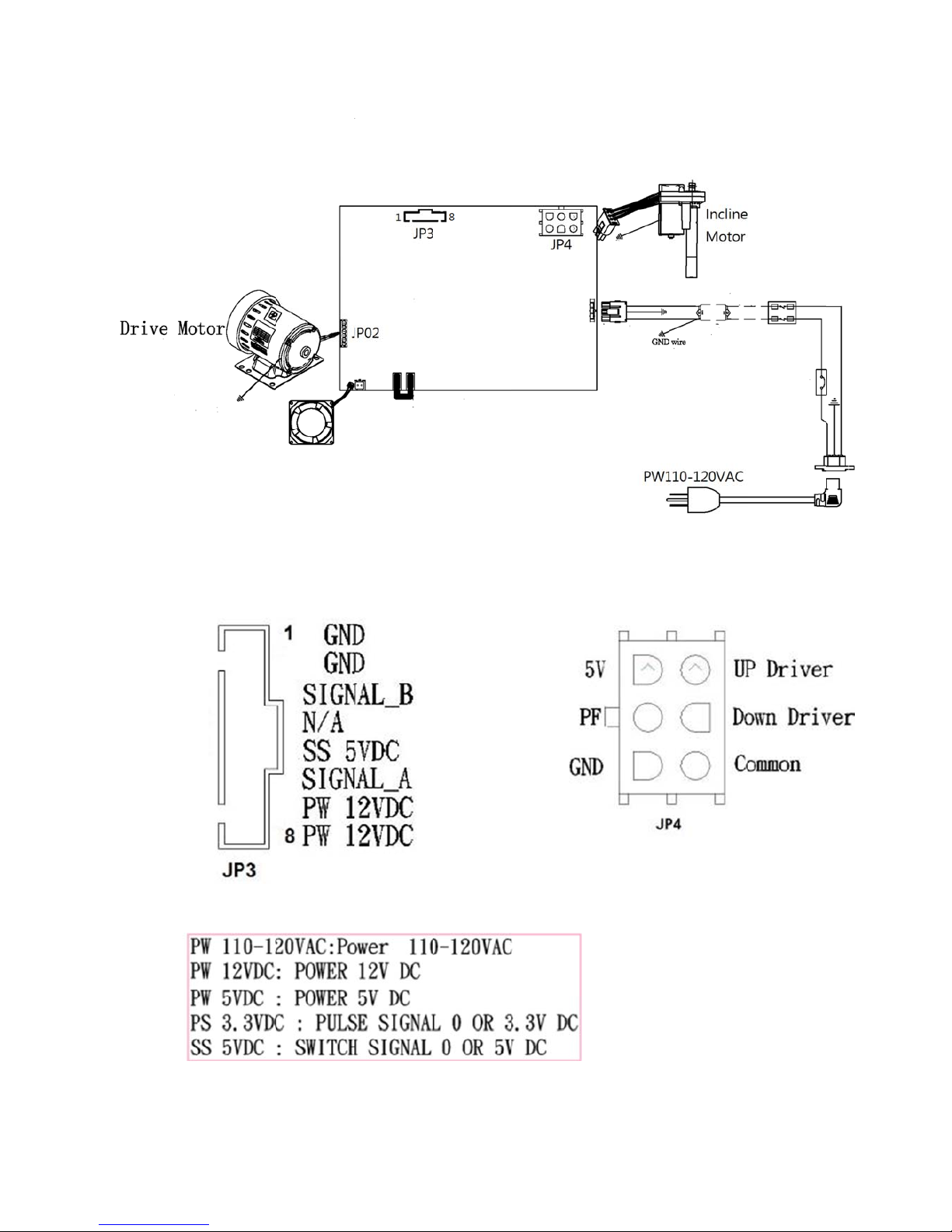

3. MCB E

Fig-1 t

h

LECTRIC

A

e MCB TO

C

Fig-3 Th

e

L DIAGR

A

ONSOLE

P

PIN VOLT

A

M---T70

-

IN LAYOU

T

GE INFOR

M

02

ATIO N

Fig-1 MCB TO INCLINE PI7N LAYOUT

Page 8

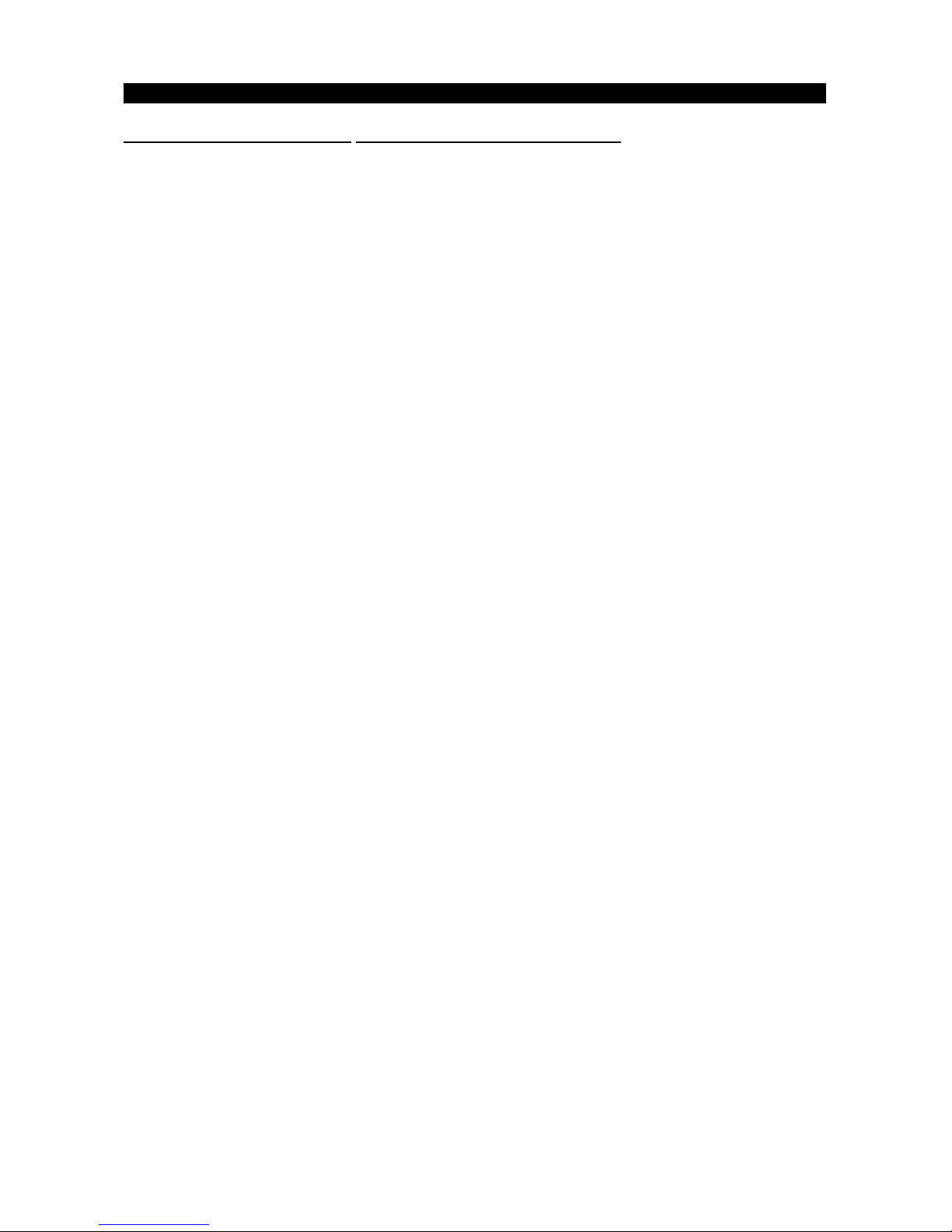

2.3. MCB

1. TF30/

T

CN1

CN2

CN3

CN4

CN5

CN6

instructio

n

F50/TF50

-

Power Line

Incline mot

o

Drive motor

Speed sens

Console ca

b

Software b

u

s

02

in terminals

r power cab

cable termi

n

or cable so

c

le socket

rning cable

s

le socket

als

ket

ocket

Fig -1

8

Page 9

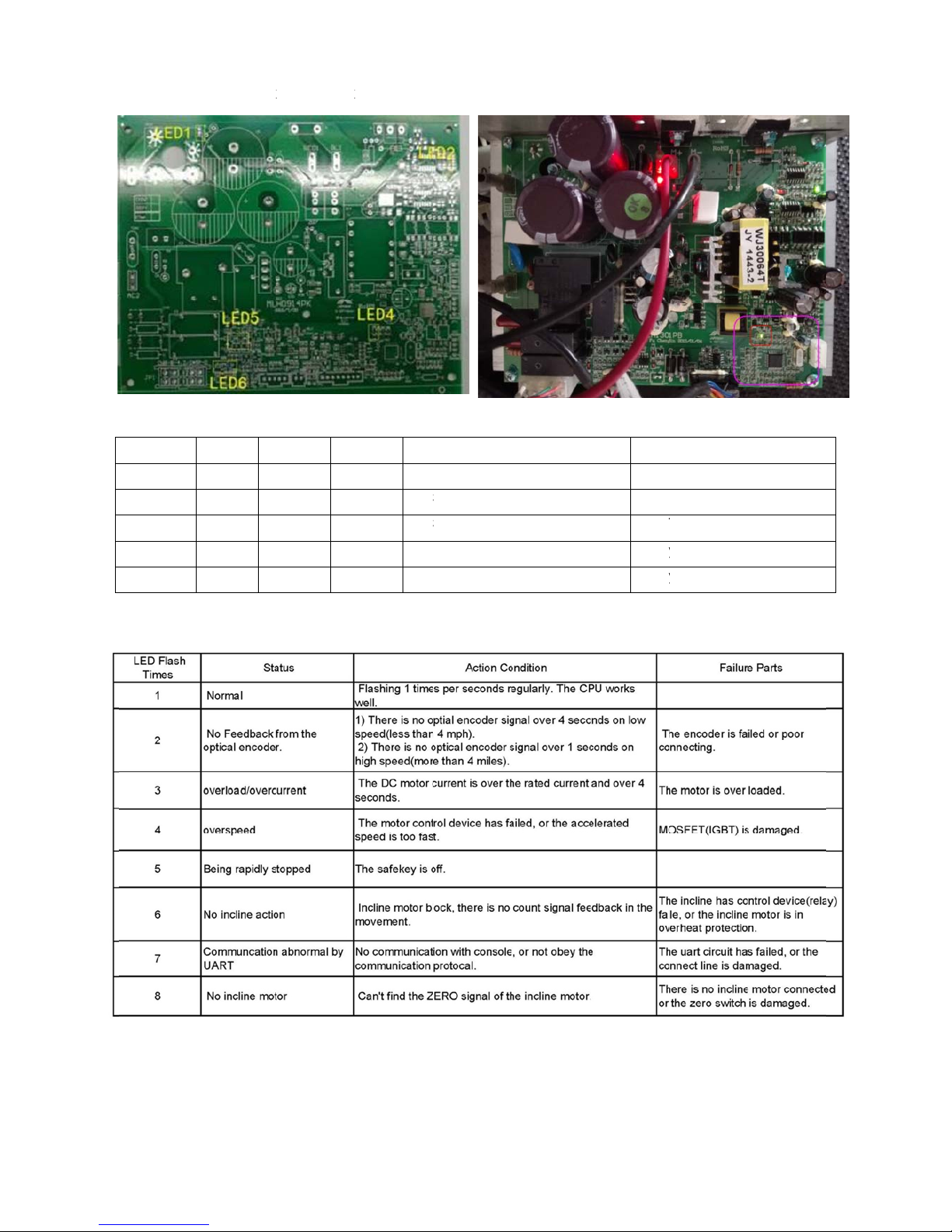

2. MCB L

Table1-M

C

LED No

LED1

LED2

LED4

LED5

LED6

Table2-M

C

ED’s func

t

B LED FU

Color A

Red li

g

Green li

g

Green fl

a

Green li

g

Green li

g

U STATU

S

ion indica

t

NCTION

ctive In

a

ht on lig

h

ht on lig

h

sh

-

ht on lig

h

ht on lig

h

(LED4)

or (TF30/

T

ctive Fu

n

t off Dri

v

t off MC

----- MC

t off Incl

t off Incl

F50/TF5

0

ction

er Motor ac

t

B Power ind

U status se

e

ine down in

d

ine up indic

a

-02)

ive

icator

Table2

icator

tor

Sym

p

Not

v

Not

v

See

T

Rela

y

Rela

y

ptom

oltage to dr

oltage outp

u

Table2

y not active

y not active

9

ve motor

t

MCB fail

MCB fail.

Page 10

3. MCB

C

JP01

JP02

JP3

JP4

JP05

IRCUIT B

O

Drive m

o

Power Li

Console

Incline

m

Fan cabl

e

FI

F

ARD IN

S

tor cable so

c

ne in socket

set cable so

otor cable s

o

socket

TRUCTI

O

Fig-1

ket

ket

cket

NS (T70-02)

1

0

Page 11

4. MCB L

Table1-MC

B

T

Table 2-

M

ED’s funct

LED FUN

C

CU STATU

ion indica

t

TION

S (LED6)

or -TF70-02 (Fig1&Fig2)

11

Page 12

12

CHAPTER 2: Troubleshooting

2.3.1. TROUBLESHOOTING – NO FUNCTION FOR SAFETY KEY

SOLUTION:

a.Check if the safety key is totally inserted into the console.

- If not, remove and insert again.

b.

Check if the s

afety key is oxidized or damaged.

- If yes, try cleaning it or replace it.

c. If the safety key is not damaged, check the alignment of the reed switch (safety key sensor)

and wire connection in the console.

Page 13

13

CHAPTER 2: Troubleshooting

2.3.2 TROUBLESHOOTING – NO RESPONSE FOR MACHINE When Pressing Start

SOLUTION:

a. Check if the console beeps when all keys are pressed. If no, replace the keypads

b. Enter Engineering Mode, and scroll to ENG 1 (Hardware Test). Press the “ENTER” key first and

then the key “START”.

- When press the key “SPEED + / -“, if the data on windows “TIME” & “DISTANCE” change, the

Console is ok. If not, replace the UCB.

c. Verify the motor or running belt spins freely - remove any obstructions from under the running belt

or motor compartment that may cause a block in movement.

d.

Check the console cable connection. Also, console cable continuity can be tested with Ohms

on each wire of the cable.

e. Test the drive motor.

1. 30/50 series short test - Disconnect power from the unit. Remove the motor cover. Remove

the red and black motor wires from the MCB. Using a jumper wire (or metal paper clip), make

the connection between the red and black leads of the motor. Without the jumper wire, the running

belt will move freely with little to no resistance. With the jumper wire in place there will be a great

amount of resistance when trying to push the running belt. If there is resistance, the motor is good.

30/50 series battery test - Disconnect power from the unit. Remove the motor cover. Remove the

red and black motor wires from the MCB. Using a DC battery from a cordless drill or other device,

touch the red on the positive lead of the battery and the black to the negative lead. If the motor

runs, the motor is good.

2. 70 series windings test - Disconnect power from the unit. Remove the motor cover. Remove the

motor connection from the MCB. With an Ohm meter test the resistance level between the

motors three phases; pin 1 and pin 2, pin 1 and pin 3, then pin 2 and pin 3. If all three resistance

levels are the same, the motor is good. If one or more are different, replace the motor.

f. If the drive motor is ok. Then,

- Check the connection of the speed sensor (encoder disk group) at the MCB.

- Remove the speed sensor from the motor and clean it, then re-test.

- If the speed sensor is clean and has a good connection but still will not operate, replace the speed

sensor.

- Replace the MCB as the last step if machine does still not run after to take above actions.

Page 14

14

CHAPTER 2: Troubleshooting

2.3.4 TROUBLESHOOTING - INCLINE MOTOR ISSUES

SOLUTIO

N:

a. While using the machine press the "INCLINE" keys, the console should beep and display incline

change, if no, replace the key pad

.

b. Enter Engineering Mode, and scroll to ENG 1 (Hardware Test). Press the “ENTER” key

first and then the “START

” key.

c.

Press the “INCLINE ▲/▼” key.

If can hear clicks from two relays and LED light (see table 2.2.2 and 2.2.4) at the MCB,

the MCB is

ok.

Then check the connection of the elevation motor at the MCB. Firs

t try to unplug and re-plug

connection . If this does not resolve the i

ssue, replace the elevation motor.

If there is no clicks from these two relays or LED light, MCB is defective and replace the MC

B.

Page 15

15

CHAPTER 2: Troubleshooting

2.3.4 TROUBLESHOOTING - NOISE ISSUES

SOLUTION:

a.Thumping noise twice per rotation on new machine

.

This noise is from the roller or running belt.

-If this is a new unit, some noise is normal as the running belt forms around the rollers.

-

Check that the belt is centered and tensioned co

rrectly.

-

Remove and clean the rollers if needed.

-

Replace the rollers or running belt as nee

ded.

b. High pitched “bell

-like” sound from under the motor cover.

This sound is likely a moving component.

-Remove the motor cover and check the drive belt for alignment and make sure it is not slipping or is

frayed / cut in any way.

Replace the driv

e belt if needed.

-

Make sure the optic disk on the motor is not rubbing the speed sensor

.

-

Turn the motor by hand to see if motor bearings are rubbing. Replace the motor if ne

eded.

-

Check the front and rear rollers, replace if need

ed.

c

. Rubbing / grinding noise.

This sound is likely caused by the optic disk.

-

Check that the optic disk is tight on the motor and not rubbing the speed se

nsor.

d. Banging or clunking sound/slapping / squeaking sound with each footstep.

T

he sound is likely due to the unit not being level.

-Check that all levelers are touching the ground.

-Move the treadmill to another flat surface.

-Thi

s sound is from the runni

ng deck / belt.

-Remove the side rails and tighten the deck bolts and elastomers.

-Check the deck shocks for disintegration or crumbling. Replace if needed.

e. Rubbing sound underneath the treadmill.

This sound is likely due to the air shock.

-Lubricate or repl

ace the air shock as needed

.

f. Squeaking / grinding noise when using elevation.

This sound is likely from the incline motor.

- Check that the incline motor and incline rack connection points to the main frame are tight.

Replace Teflon washers on the frame as needed.

-Lubricate the in

cline motor worm screw and connection points wi

th grease.

-

Replace the incline motor.

Page 16

16

CHAPTER 2: Troubleshooting

2.3.5 TROUBLESHOOTING- HEART RATE FUNCTION ISSUE

SOLUTION:

a.Telemetric heart rate:

1. Re-center

the chest strap below the user's pectoral muscle and check again.

2.Replace the battery in the chest strap

.

b.Heart rate gr

ip:

1.

W

et the use

r's hand, and then reestablish contact with the HR grip.

2.Replace new HR grip if console can display proper HR rate.

W

ith a multi-meter set for DC voltage, place one terminal on each of the HR grip plates. The HR

Grip should give a voltage reading of between 0.5 and 2.0VDC. If the voltage is not between 0.5

And 2.0VDC, remove the screws holding the HR grip together and check the connection of the

HR grip wiring.

3.Check a-d. If still cannot work, Suggest install new console.

Page 17

3.1 MOT

O

1.TF30/T

F

1) Discon

n

2) Remov

3) The co

v

4) Fig-3 &

F

5) Unplug t

h

6) Remove

outer ed

g

7) Remove

8) Rever

se

pulley. In

s

the drive

10) Test at

v

R REPL

A

50

ect power

c

e the 2 scre

w

er is secur

e

ig-4 shows

t

e motor co

n

the drive be

e of the tre

a

the four mo

t

steps to ins

t

tall belt on

d

belt, roll the

arious spe

e

C

H

CEMEN

T

ord.

s holding t

h

d to the fra

m

he motor M

C

nector from

lt by spinnin

g

dmill.

or bolts and

all motor.

W

rive motor

p

belt on. Co

n

ds.

APTER

3

e motor co

v

e with Velc

r

Fig-1

B area wit

h

Fig-3

LCB, speed

the flywhe

e

remove mo

t

hen installin

g

ulley. Then

tinue to wal

k

: Part R

e

er to the fra

m

o so you wil

the motor

c

sensor, cut

l (or runnin

g

or.

Flexonic d

by rotating

t

belt on unt

i

placeme

n

e (Fig-1)

l have to pul

over remov

e

any wire tie

s

belt) and

w

rive belt, sta

he front roll

e

l centered o

t Guide

l up with so

m

d. (Fig-3 &

F

as needed

.

alking the d

r

t with belt o

n

r pulley whil

both pulle

y

e force (Fi

g

ig-4)

.

ive belt off t

o

n inside of f

r

e applying

p

s.

1

7

-2)

Fig-2

Fig-4

ward the

ont roller

ressure on

Page 18

2.

MOTOR

1) Discon

n

2) Remov

e

3) Note.

T

3) Disconn

e

4) Remov

e

5) Remov

e

6) Revers

e

Note: wh

e

rol

7) Test at v

a

R

ect power

c

the 2 scre

w

he cover is

Fig

-

ct motor wi

r

Fig

-

spring fro

m

4 bolts se

c

steps to in

s

n installing

ler pulley.

rious spee

d

REPLACCEMENT (Cont'd)

ord.

s holding t

h

secured to

t

1

es and grou

3

the belt te

n

uring motor

tall motor.

R

the drive be

l

s.

T70-02 ONLY

e motor co

v

he frame wi

t

nds, cut any

sioner. R

e

and remove

eplace any

t, rotate by

h

er to the fra

m

h Velcro so

wire ties as

move drive

b

motor from

wire ties th

a

and severa

l

e (Fig-1).

you will hav

e

needed.

elt from m

o

drive comp

a

t were remo

rotations,

m

to pull up

w

tor pulley.

rtment.

ed.

ake sure it i

s

ith some fo

r

s aligned wi

t

1

8

ce (Fig-2)

Fig-2

Fig-4

h the front

Page 19

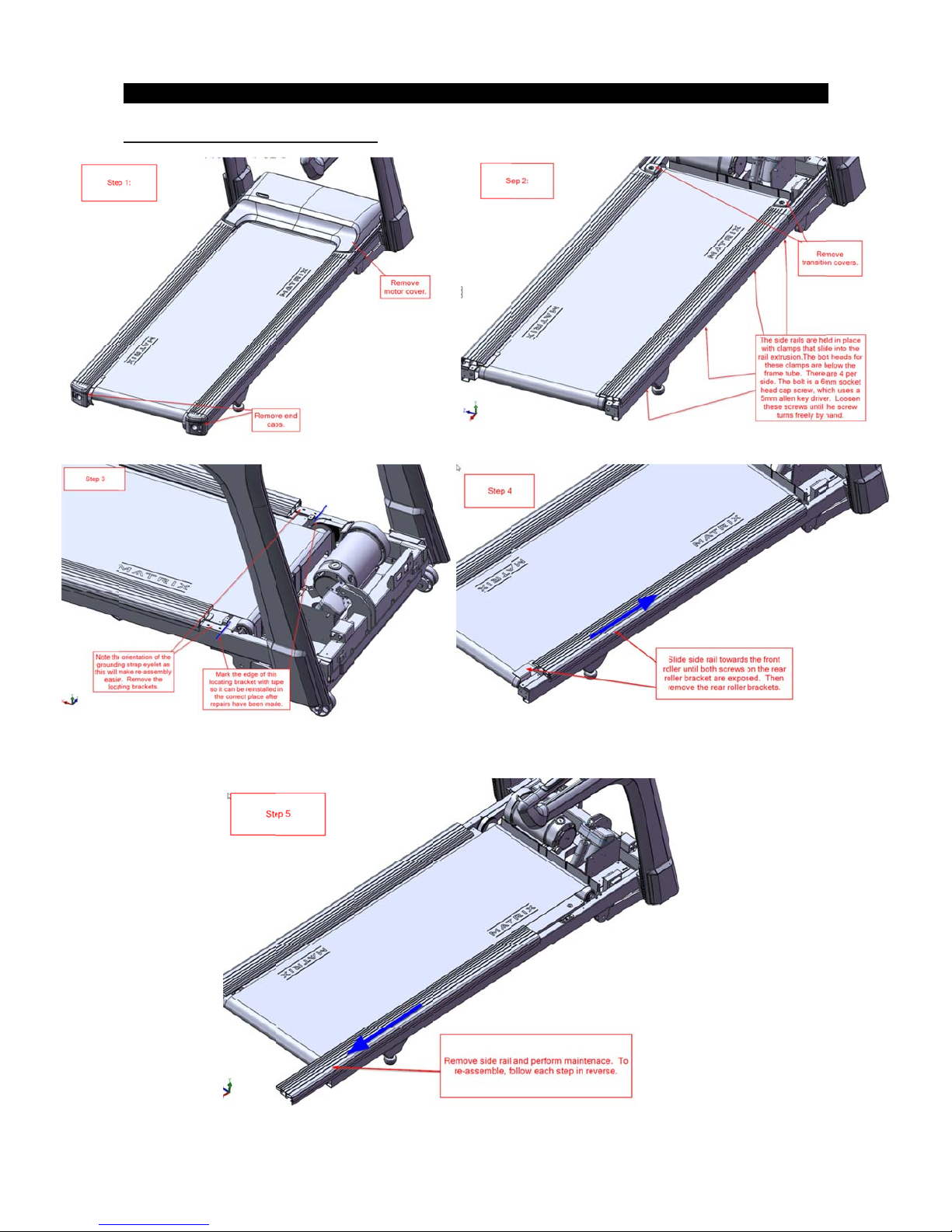

3.2 SIDE RAIL RE

P

C

H

LACEME

APTER

3

NT

: Part R

e

placeme

n

t Guide

1

9

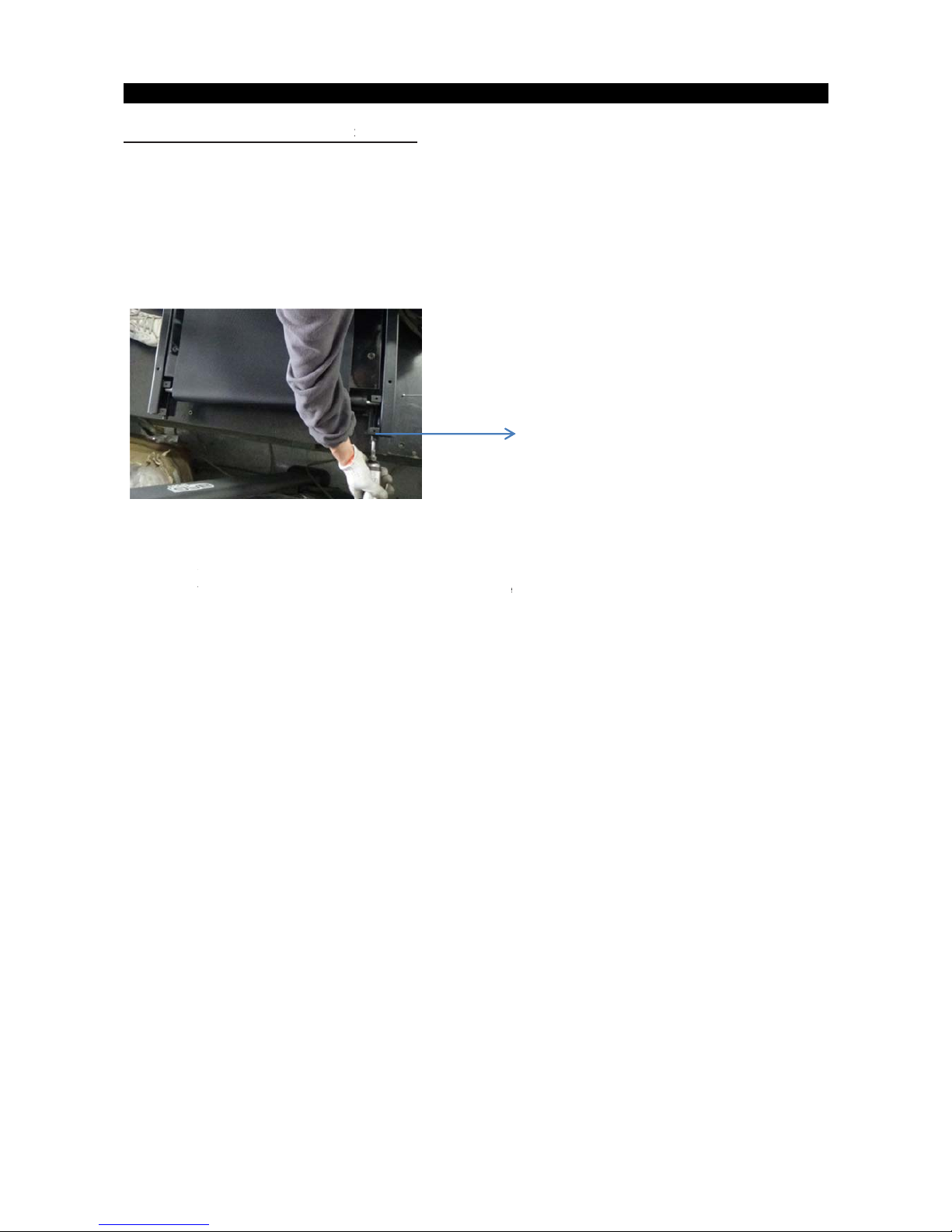

Page 20

3.3 REA

R

1) Remov

e

2) Remov

e

3) Replac

e

4) Revers

e

Not

e

1. be s

u

2. Over

3.

A

lwa

y

4. Final

to st

o

ROLLE

R

side rail in

rear roller

new rear r

o

step 2 to s

t

Fi

g-1

re to set th

e

or under te

n

ys bring ten

s

steps of ten

p the belt

w

5.

C

H

REPLA

C

section 3.2

ller and tig

h

ep 1

correct run

n

sion can re

s

ion up eve

n

sioning are

w

ith you r fee

t

APTER

3

EMENT

tness bolts

(

ing belt ten

s

ult in dama

g

ly from the l

e

hen the ru

n

using an a

b

: Part R

e

Fig-1)

ion after re

p

e or injury.

ft to right t

e

ning belt jus

rupt stop at

placeme

n

lacing the

b

nsioning bol

t stoops slip

p

a walking s

p

1 bolt

t Guide

elt.

s using sm

a

ing and slo

w

eed.

each side

ll adjustme

n

s the moto

r

2

0

ts.

when trying

Reference section 3.6 note 2 to adjust the running belt.

Page 21

3.4 RUN

N

1) Remov

e

2) Remov

e

3) Remov

4) Remov

5) Remov

6) Revers

Note:

1

. The run

new runnin

g

2. For the

ING DEC

the motor

c

rear roller

a

e the side r

a

e the runnin

g

e the runnin

g

e steps 1-5

t

ning deck

is

belt and o

n

A

DJUSTIN

G

C

K REPLA

C

over as out

l

s outlined i

n

il as outline

d

deck 8 bol

t

deck from

o install a n

e

silicon on o

n

ly T70-02

m

THE RUN

N

HAPTER

EMENT

ined in Sect

section 3.

2

in Section

3

s and grou

n

the frame.(

F

w running

d

Fig-1

e side onT

F

odels is par

a

ING BELT

3: Part

R

ion 3.1.

.3.

d strap.

ig-1)

eck.

30/TF50. N

e

ffin waxed

d

reference s

e

eplacem

e

w deck surf

a

eck only 1

s

ction 3.6 no

t

nt Guide

ces must A

ide.

e 2

LWAYS be

m

21

atched to a

Page 22

3.5 FRO

N

1) Remove

2)

3)

Fi

g

3) Remov

e

4) Remov

e

5) Revers

e

T ROLL

E

the motor c

o

T70-02 only:

-1

the drive b

front roller

steps to re

C

H

R REPLA

ver as outli

n

elt from the

m

bolts and re

APTER

3

EMENT

ed in Secti

o

otor pulley

move front r

o

: Part R

e

n 3.1.

.(Fig-1)

ller and dri

v

place front roller and drive belt.

placeme

n

Fig

-

e belt.

t Guide

2

2

2

Remove the spring from the drive belt tensioner (Fig-2). The tensioner should now pivot

away from the drive belt.

Loosen both of the rear roller bolts to remove tension from the running belt (Fig-1).

Page 23

3.6 RUN

N

1) Rem

ove

2) Remove

3) Remove

4) Remove

5) Re

move

5) R

evers

e

Note1:

1. A

d

j

2. Th

e

matche

:

Note:2

A

DJUSTIN

G

After pla

c

centering.

T

cause the

b

direction b

e

Step1: Loc

a

frame at th

e

Step2:

Th

the belt is t

o

Manually c

e

as they we

r

Step3: Whil

Right

bolt

b

y

left tighten

t

remains ce

n

Step4: Che

c

should not

h

necessary.

ING BEL

T

the motor c

o

the rear roll

e

the running

the front roll

the running

Steps 1-5

t

ust running

running de

c

d to a new r

u

THE RUN

ing the trea

d

he belt may

elt to stretc

h

low.

te the two h

back of tre

a

ere should

b

uching one

nter the bel

t

e loosened.

e the tread

m

turning it c

l

he left bolt

b

tered for s

e

k the tensi

o

esitate or s

l

C

H

REPLA

C

ver as outli

n

r as outline

d

deck as outl

er as outlin

e

belt

Fig-1

o install a r

u

belt tension

k is silicon

o

nning belt

a

NING BELT

mill in the p

need to be

a

at different

ex head bol

t

dmill. Thes

e

e an equal

a

side, turn th

e

by pushing

ill is runnin

g

ockwise 1/4

y turning it

c

veral minut

e

n of the belt

ip. If this oc

c

APTER

3

EMENT

ed in Secti

o

in Section

3

ined in Secti

d in Section

nning belt.

after replac

e

n one side

o

nd Only T7

0

osition it will

djusted aft

e

rates. If the

on the rear

bolts adju

s

mount of s

p

bolts coun

t

the belt tow

a

at 3 mph,

o

turns, and l

o

lockwise 1/4

s.

. The belt s

h

urs, tighten

: Part R

e

n 3.1.

3.2.

on 3.4.

3.5.( Fig-2)

ment (Note

2

nTF30/TF

5

-02 models

be used, th

e

r the first 2

h

belt starts t

o

of the tread

m

t the rear ro

l

ace on eith

e

ter clockwis

e

rd the cent

e

bserve the

b

osen the le

f

turn and lo

o

ould be ver

y

the belt by t

placeme

n

)

0/TF50-2. N

is waxed de

belt must

b

ours of use

slip when a

ill. The bol

t

ler.

r side of the

approxima

t

r. Tighten

elt position.

t bolt 1/4 tur

n

sen the righ

snug. Whe

n

urning both

b

t Guide

Fig-

2

ew deck sur

f

ck only 1 si

d

e checked f

o

Temperatu

r

user is on it

s are locate

d

running bel

t

ely one full

t

the bolts th

e

If it is movin

. If it is mov

1/4 turn. R

e

a person

w

olts clockwi

faces must

A

e

r proper te

n

re and humi

d

, be sure to

f

at each e

n

and the sid

urn on eac

h

same amo

u

g to the righ

ing to the le

f

peat step 3

alks or run

o

se 1/4 turn,

2

3

LWAYS be

sion and

ity, and us

e

ollow the

d of the

rails. If

side.

nt of turns

, tighten th

e

t, tighten th

e

until the bel

t

n the belt, i

t

Repeat if

Page 24

3.7 MOT

O

1) Turn off

p

2) Remove

3) Remove

4) Remove

5) Remove

6) Reverse

Note. Re

p

R CONT

R

ower and d

the motor c

o

the wire co

n

the 2 screw

s

Fig-1

the MCB.

Steps 1-5 t

o

lace any wi

r

C

H

OL BOA

R

isconnect th

e

ver as outli

n

nectors at t

h

holding ea

c

install a M

C

e ties remo

v

APTER

3

D (MCB

)

power cor

d

ed in Secti

o

e MCB. (Fi

g

h side of th

e

B. Make su

r

ed.

: Part R

e

REPLAC

from the m

n 3.1.

-1)

MCB to th

e

e that all wi

r

placeme

n

EMENT.

achine.

frame (Fig

-

es removed

t Guide

2).

Fi

g

during Step -2 3 are re-co

n

2

4

nected.

Page 25

3.8 INCLI

1) Turn of

f

2) Remov

e

3) Disco

n

n

4) Lift or ti

5) R

emov

e

6) Remove

5)

Disconn

e

6) Reverse

6) Test ful

NOTE:

When insta

l

conn

ection

NE MOT

O

power to th

the motor

c

ect incline

m

lt the tread

m

the bolt fr

o

the bolt fro

m

Fig-1

ct the inclin

e

Steps 1-5 t

o

Fig-2

l range of el

e

ling a new i

n

points of th

e

C

H

R REPL

A

e treadmill

a

over as out

l

otor wires

f

ill until ther

e

m the eleva

t

the elevati

o

motor fro

m

install a ne

w

vation.

cline motor

,

incline mot

o

APTER

3

CEMENT

nd disconn

e

ined in Sect

rom MCB a

n

is access t

o

ion rack.(Fi

g

n with sprin

g

the top mo

u

incline mo

t

make sure

t

r .Replace

a

: Part R

e

ct the powe

r

ion 3.1.

d ground.

C

lower conn

-2)

g.

nting brack

e

or.

Fig-3

to replace t

h

ny wire ties

placeme

n

cord.

ut any wire

t

ecting bolt.

(

t (Fig-3).

e black zinc

that were r

e

t Guide

ies as need

e

Fig-1)

washers at

t

moved.

d.

Fig

-

the top and

b

2

5

4

ottom

Page 26

3.9 CON

S

1) Turn of

f

2)

Remov

e

3)

Discon

n

4)

Install t

h

5)

Turn o

n

OLE RE

P

power to th

the 4 scre

w

ect all wire

s

e new con

s

the power

a

Fi

g

Fig-3

C

H

LACEME

e treadmill

a

s holding t

h

from conso

ole by rever

nd select c

o

-1

APTER

3

NT

nd disconn

e

e console fr

le.

ing steps 1

rrespondin

g

: Part R

e

ct the powe

r

om the con

s

- 3.

model (Re

f

placeme

n

cord.

ole mast (Fi

g

erence XR/

X

t Guide

-1and Fig-

2

ER/XIR co

n

Fig

Fi

g

).

sole servic

e

-2

g-4

2

6

manual)

Loading...

Loading...