Page 1

T 3 X - 0 3 T R E A D M I L L

S E R V I C E M A N U A L

Page 2

TABLE OF CONTENTS

CHAPTER 1: SERIAL NUMBER LOCATION ........................................................... 1

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

2.1 Before Getting Started ............................................................................................... 2

2.3 Read and Save These Instructions ............................................................................ 3

2.4 Electrical Requirements ............................................................................................. 4

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.1 Recommended Cleaning Tips .................................................................................... 5

3.2 Check for Damaged Parts ......................................................................................... 5

3.3 Care and Maintenance Instructions ........................................................................... 6

3.4 Auto Calibration Procedure ......................................................................................... 7

3.5 Adjusting the Running Belt ........................................................................................ 7

3.6 Knowing When to Replace the Running Belt and Deck ............................................. 8

CHAPTER 4: USING THE CONSOLE AND PROGRAM DESCRIPTION

4.1 Console Description ................................................................................................... 9

4.2 Manual Workout Operation ......................................................................................... 10

4.3 Operating Level Based Programs .............................................................................. 10

4.4 Heart Rate Control Workout Operation ....................................................................... 11

4.5 Fitness Test Workout Operation .................................................................................. 11

CHAPTER 5: MANAGER MODE

5.1 Using Manager Mode ................................................................................................. 13

5.2 Manager Mode Overview ............................................................................................ 13

CHAPTER 6: ENGINEERING MODE

6.1 Using Engineering Mode ............................................................................................ 14

6.2 Engineering Mode Overview ....................................................................................... 14

CHAPTER 7: SERVICE MODE:

7.1 Using Service Mode. .................................................................................................. 15

7.2 Service Mode Overview ............................................................................................. 15

CHAPTER 8: TROUBLESHOOTING

8.1 Electrical Diagrams .................................................................................................... 16

8.2 MCB Wiring ................................................................................................................. 19

8.3 MCB LED Placement and Definitions ......................................................................... 20

8.4 Error Messages on the Console ................................................................................. 21

8.5 0140 / 01A0 Error Troubleshooting ............................................................................. 22

8.6 01A4 / 01A5 / 01A6 Error Troubleshooting ................................................................. 23

8.7 01A8 / 01AD / 02B6 / 02B7 / 02B8 Error Troubleshooting ......................................... 23

8.8 01AB Error Troubleshooting ........................................................................................ 24

8.9 02A0 Error Troubleshooting ........................................................................................ 25

8.10 02A1 / 02A2 Error Troubleshooting ............................................................................ 26

8.11 02AD Error Troubleshooting ....................................................................................... 26

8.12 02B5 Error Troubleshooting ........................................................................................ 27

8.13 02B3 / 02BA / 02BC / 02BD Error Troubleshooting .................................................... 28

8.14 04A0 Error Troubleshooting ........................................................................................ 28

8.15 Troubleshooting Heart Rate Issues............................................................................. 29

8.16 Entertainment Troubleshooting - Overview ................................................................. 30

8.17 Entertainment Troubleshooting - Picture Fuzzy or Unclear ........................................ 31

8.18 Entertainment Troubleshooting - TV Will Not Turn On ............................................... 32

8.19 Entertainment Troubleshooting - Controller Issues ..................................................... 33

Page 3

TABLE OF CONTENTS

CHAPTER 9: PART REPLACEMENT GUIDE

9.1 Motor Cover Replacement .......................................................................................... 34

9.2 Rear Roller Replacement ............................................................................................ 35

9.3 Running Deck Removal .............................................................................................. 36

9.4 Deck Cushion Replacement ....................................................................................... 37

9.5 Front Roller Replacement ........................................................................................... 38

9.6 Running Belt Removal ............................................................................................... 39

9.7 Side Rail Replacement ............................................................................................... 40

9.8 Motor Control Board (MCB) Replacement ................................................................. 41

9.9 Motor Replacement ..................................................................................................... 42

9.10 Drive Belt Replacement ............................................................................................. 44

9.11 Incline / Elevation Motor Replacement ....................................................................... 46

9.12 Console Replacement ................................................................................................... 48

9.13 Emergency Stop Switch Replacement ........................................................................... 49

9.14 Console Frame Replacement ..................................................................................... 51

9.15 Heart Rate Board Replacement .................................................................................. 52

9.16 Speed and Incline Keypads Replacement ................................................................. 53

9.17 Handlebar Replacement ............................................................................................ 54

9.18 Heart Rate Handlebar Replacement ........................................................................... 55

9.19 Heart Grips Replacement ........................................................................................... 56

9.20 Console Mast Replacement ........................................................................................ 57

9.21 Testing the Treadmill ................................................................................................... 58

CHAPTER 10: TREADMILL SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 Treadmill Specifications .............................................................................................. 59

10.2 Fasteners and Assembly Tools ................................................................................... 60

10.3 Assembly Instructions ................................................................................................ 61

10.4 TV Bracket Installation Instructions ............................................................................. 65

CHAPTER 11: SOFTWARE UPGRADE INSTRUCTIONS

11.1 Software Upgrade Instructions .................................................................................... 68

III

Page 4

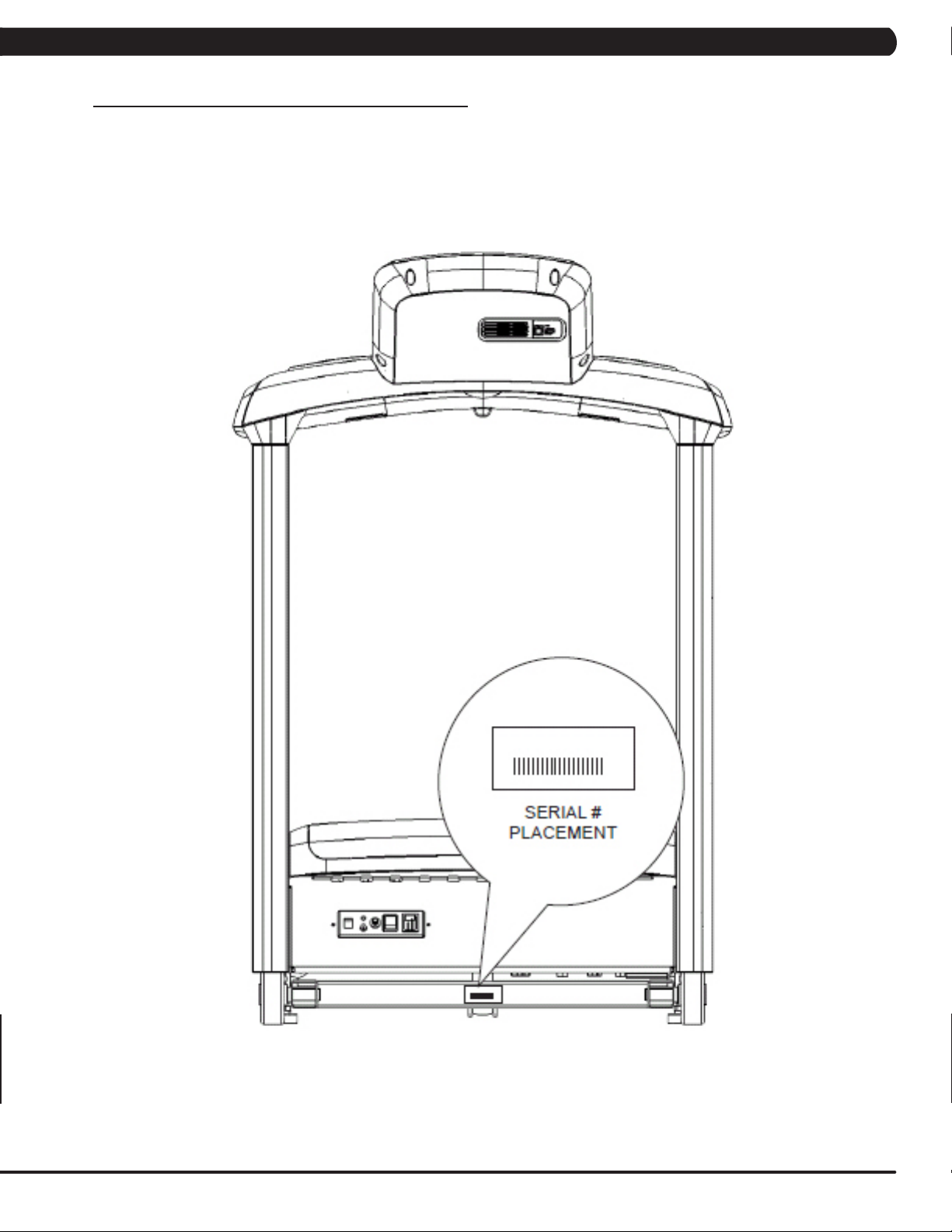

1.1 SERIAL NUMBER LOCATION

CHAPTER 1: SERIAL NUMBER LOCATION

1

Page 5

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

2.1 BEFORE GETTING STARTED

This treadmill is intended for commercial use. To ensure your safety and protect the equipment, read all instructions before operating the Matrix

Treadmill.

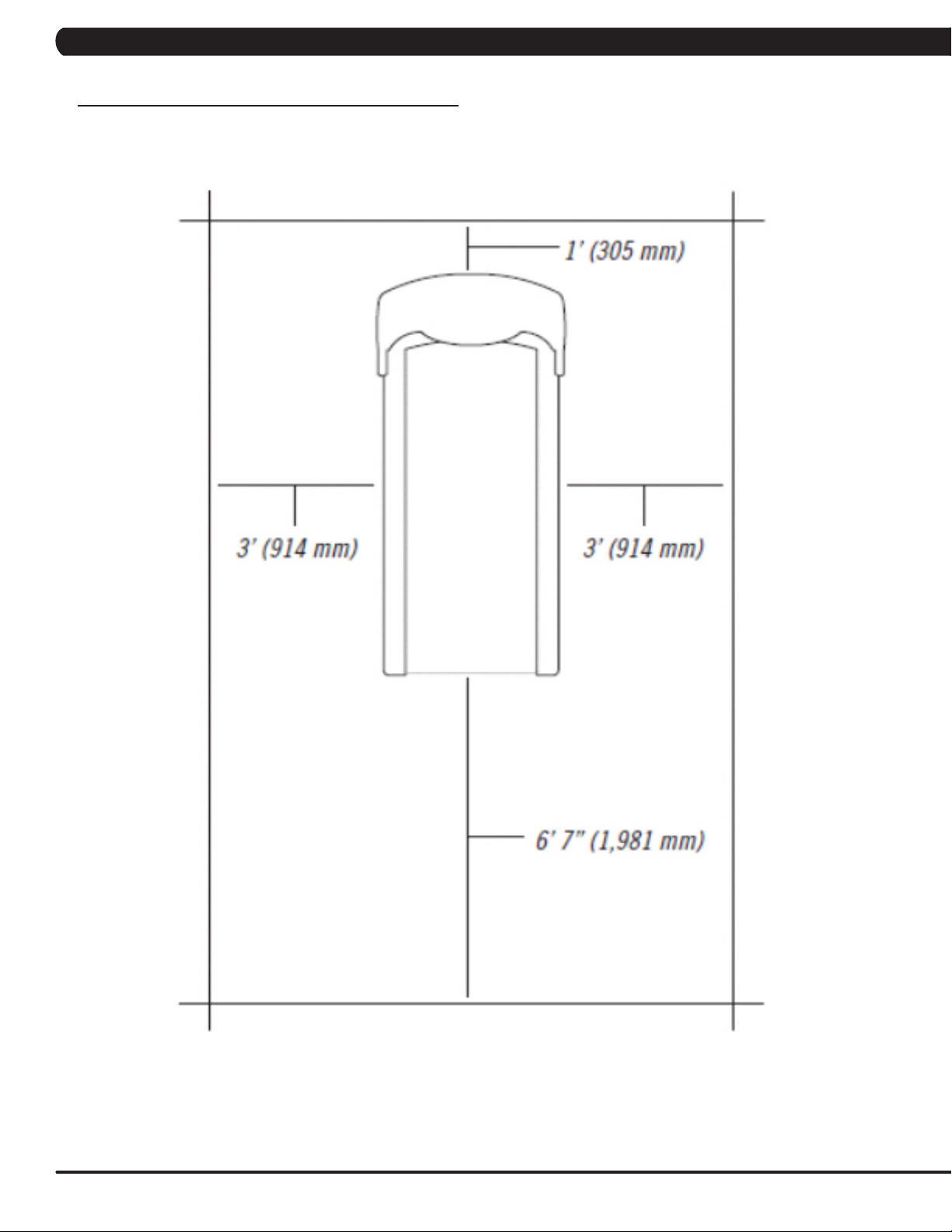

Please leave a 78.75" (2000 mm) x 39.50" (1000 mm) landing zone behind the treadmill. This zone is to allow easy access to the treadmill and

gives the user an easy exit path from the machine. In case of an emergency, place both hands on the side arm rests to hold yourself up and

place your feet onto the side rails.

2

Page 6

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

2.2 READ AND SAVE THESE INSTRUCTIONS

This treadmill is intended for commercial use. To ensure your

safety and protect the equipment, read all instructions before

operating the MATRIX T3x-03 treadmill.

When using an electrical product, basic precautions should always

be followed including the following:

DANGER: To reduce the risk of electric shock: Always unplug

this equipment from the electrical outlet immediately after

using and before cleaning.

WARNING: To reduce the risk of burns, fire, electrical shock

or injury to persons that may be associated with using this

product.

An appliance should never be left unattended when plugged in.

Unplug from the outlet when not in use and before putting on or taking off parts.

This product must be used for its intended purpose described in this

service manual. Do not use other attachments that are not recommended by the manufacturer. Attachments may cause injury.

To prevent electrical shock, never drop or insert any object into any

opening.

Do not remove the console covers. Service should only be done by

an authorized service technician.

Never operate the treadmill with the air opening blocked. Keep the

air opening clear, free of lint and hair.

Never operate product if it has a damaged cord or plug, if it is working improperly, if it has been damaged, or immersed in water.

CAUTION: If you experience chest pain, nausea, dizziness or

shortness of breath, STOP exercising immediately and consult a physician before continuing.

• Donotusetheequipmentinanywayotherthandesignedor

intended by the manufacturer. It is imperative that all Matrix

Fitness System's equipment is used properly to avoid injury.

• Keephandsandfeetclearofmovingpartsatalltimestoavoid

injury.

• Unsupervisedchildrenmustbekeptawayfromthisequipment.

• Donotwearlooseclothingwhileonequipment.

Do not carry this unit by its supply cord or use the cord as a handle.

Keep any power cord away from heated surfaces.

Close supervision is necessary when the treadmill is used by or near

children or disabled persons.

Do not use outdoors.

Do not operate where aerosol (spray) products are being used or

when oxygen is being administered.

To disconnect, turn all controls to the off position, then remove plug

from the outlet.

Connect this treadmill to properly grounded outlets only.

3

Page 7

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

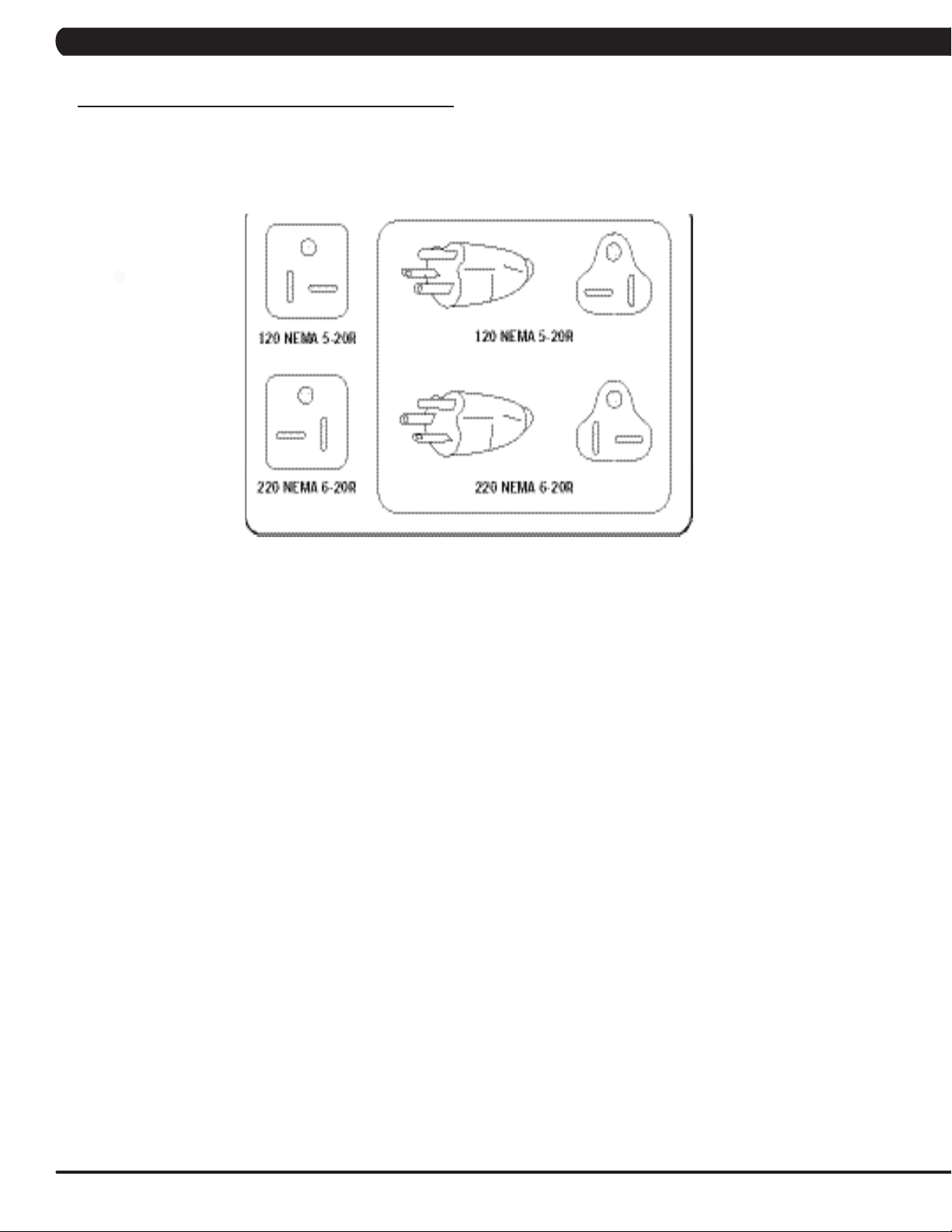

2.3 ELECTRICAL REQUIREMENTS

For your safety and to ensure good treadmill performance, the ground on this circuit must be non-looped. Please refer to NEC articles 210-21 and 210-23.

Your treadmill is provided with a power cord with a plug listed below and requires the listed outlet. Any alterations of this power cord could void all warranties

of this product..

MATRIX DEDICATED CIRCUIT / ELECTRICAL REQUIREMENT INFO

All Matrix treadmills require the use of a 20 amp "dedicated circuit" with a non-looped (isolated) neutral / ground for the power requirement.

Quite simply this means that each outlet you plug your treadmill into should not have anything else running on that same circuit. The easiest

way to verify this is to locate the main circuit breaker box, and turn off the breaker(s) one at a time. Once a breaker has been turned off, the

only thing that should not have power to it is the treadmill. No lamps, vending machines, fans, sound systems, or any other item should lose

power when you perform this test.

Non-looped (isolated) neutral / grounding means that each circuit must have an individual neutral / ground connection coming from it, and

terminating at an approved earth ground. You cannot "jumper" a single neutral / ground from one circuit to the next.

In addition to the dedicated circuit requirement, the proper gauge wire must be used from the circuit breaker box, to each outlet that will have

the maximum number of units running off of it. If the distance from the circuit breaker box, to each outlet, is 100 feet or less, then 12 gauge

wire may be used. For any distance greater than 100 feet from the circuit breaker box to the outlet, 10 gauge wire must be used.

TV POWER REQUIREMENTS

If a TV will be added to the treadmill via a bracket, separate power must be provided for the TV. Matrix MYE TVs require the use of a 15 amp

or 20 amp “dedicated circuit,” with a non-looped (isolated) neutral/ground, for the power requirement. Up to 3 TVs can be daisy chained per 15

amp circuit or 4 per 20 amp circuit via a Matrix provided daisy chain.

4

Page 8

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.1 RECOMMENDED CLEANING TIPS

Preventative maintenance and daily cleaning will prolong the life and

look of your MATRIX T3x-03 Treadmill.

Please read and follow these tips.

• Positiontheequipmentawayfromdirectsunlight.TheintenseUV

light can cause discoloration on plastics.

• Locateyourequipmentinanareawithcooltemperaturesand

low humidity.

• Cleanwithasoft100%cottoncloth.

• Cleanwithsoapandwaterorothernon-ammoniabasedallpur-

pose cleaners.

• Wipefootrails,console,heartrategrips,andhandlebarsclean

after each use.

• Donotpourliquidsdirectlyontoyourequipment.Thiscancause

damage to the equipment and in some cases electrocution.

• Checktherunningbeltforpropertensionandrouting.

• Adjustthelevelingfeetwhenequipmentwobblesorrocks.

• Maintainacleanareaaroundequipment,freefromdustanddirt.

3.2 CHECK FOR DAMAGED PARTS

DO NOT use any equipment that is damaged or has worn or

broken parts. Use only replacement parts supplied by Matrix

Fitness Systems.

MAINTAIN LABELS AND NAMEPLATES. Do not remove labels

for any reason. They contain important information. If unreadable

or missing, contact Matrix Fitness Systems for a replacement at

866-693-4863 or www.matrixfitness.com.

MAINTAIN ALL EQUIPMENT. Preventative maintenance is the

key to smoothly operating equipment. Equipment needs to be

inspected at regular intervals. Defective components must be

kept out of use until they are repaired. Ensure that any person(s)

making adjustments or performing maintenance or repair of any

kind is qualified to do so. Matrix Fitness Systems will provide

service and maintenance training at our corporate facility upon

request or in the field if proper arrangements are made.

5

Page 9

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.3 CARE AND MAINTENANCE INSTRUCTIONS

In order to maximize life span, and minimize down time, all Matrix Fitness System's equipment requires regular cleaning, and maintenance items

performed on a scheduled basis. This section contains detailed instructions on how to perform these items and the frequency of which they

should be done. Some basic tools and supplies will be necessary to perform these tasks which include (but may not be limited to):

* Metric Allen wrenches

* #2 Phillips head screwdriver

* Adjustable wrench

* Torque wrench (capability to read foot lbs and inch lbs)

* Lint free cleaning cloths

* Teflon based spray lubricant such as "Super Lube" or other Matrix approved products.

* Mild water soluble detergent such as "Simple Green" or other Matrix approved products

* Vacuum cleaner with an extendable hose and crevasse tool attachment.

You may periodically see addendums to this document, as the Matrix Technical Support Team identifies items that require specific attention, the

latest version will always be available on the Matrix web site at www.matrixfitness.com.

DAILY MAINTENANCE ITEMS

1) Clean the entire machine using water and mild detergent such as "Simple Green", or other Matrix approved solutions (cleaning agents MUST

be alcohol and ammonia free).

2) Check the emergency stop button and cord for proper operation.

MONTHLY MAINTENANCE ITEMS

1) Inspect the power cord for damage, inspect the hand grip areas, and inspect the emergency stop button and cord for proper operation.

2) Check the running belt for proper tension, adjust as needed.

QUARTERLY MAINTENANCE ITEMS

1) Remove the front plastic cover, and vacuum the entire inside area of machine. Be careful when working around the MCB not to bump any

wires or connections loose.

2) Check the drive belt for visible wear, ie, cracking, tears, etc. The belt should be replaced if there are any visible signs of damage. Proper

alignment of the pulley / tensioner should be verified at this time as well.

3) Remove the motor cover at the front of the machine. Start the unit and raise the incline settings to maximum height. Turn the power switch

off at the front of the machine to prevent it from lowering accidentally. Lubricate the incline motor Acme screw (Matrix recommends Super Lube

brand grease with PTFE additive).

BI-ANNUAL MAINTENANCE ITEMS

1) Remove any wax build up from the front and rear rollers of the machine.

2) Inspect the underside of the running belt for damage, check for cracking or glazed surfaces.

3) If the belt has damage or wear to it that warrants replacement, note that a new running belt should ALWAYS be installed on a new deck

surface (deck should either be flipped or replaced to gain a new surface).

4) During normal operating conditions, the running belt replacement and deck service should be done every 15,000 miles.

6

Page 10

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.4 AUTO CALIBRATION INSTRUCTIONS

Run Auto Calibration to calibrate incline after assembly and after

replacing any electronic component.

AUTO CALIBRATION PROCEDURE:

1) Press and hold the INCLINE DOWN and SPEED DOWN keys for

three seconds until Manager appears on the middle LED display.

2) Press the SPEED or INCLINE UP key until Engineering appears on

the display.

3) Press ENTER once Engineering is displayed.

4) Scroll between programs in the Engineering Mode using any UP or

DOWN key until Auto Calibration appears on the middle LED display.

5) Press ENTER once Auto Calibration is displayed., you should not

be standing on the running belt.

6) After completion, the display will either return to normal operation (if

the unit passed the Auto Calibration) or display that the Auto Calibration

failed.

3.5 ADJUSTING THE RUNNING BELT

After placing the treadmill in the position it will be used, the belt

must be checked for proper tension and centering. The belt may

need to be adjusted after the first 2 hours of use. Temperature,

humidity, and use cause the belt to stretch at different rates. If

the belt starts to slip when a user is on it, be sure to follow the

directions below.

STEP 1: Locate the two hex head bolts on the rear of the treadmill.

The bolts are located at each end of the frame at the back of the

treadmill. These bolts adjust the rear roller. Do not adjust until the

treadmill is on. This will prevent over tightening of one side.

STEP 2: The belt should have equal distance on either side

between the frame. If the belt is touching one side, do not start

the treadmill. Turn the bolts counter clockwise approximately one

full turn on each side. Manually center the belt by pushing the belt

from side to side. Tighten the bolts the same amount as when the

user loosened them, approximately one full turn. Inspect the belt

for damage.

STEP 3: While the treadmill is running at 3 mph, observe the belt

position. If it is moving to the right, tighten the right bolt by turning

it clockwise 1/4 turn, and loosen the left bolt 1/4 turn. If it is moving

to the left, tighten the left bolt by turning it clockwise 1/4 turn and

loosen the right 1/4 turn. Repeat Step 3 until the belt remains

centered for several minutes.

STEP 4: Check the tension of the belt. The belt should be very

snug. When a person walks or runs on the belt, it should not

hesitate or slip. If this occurs, tighten the belt by turning both bolts

clockwise 1/4 turn. Repeat if necessary.

7

Page 11

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.6 KNOWING WHEN TO REPLACE THE RUNNING BELT AND DECK

One of the most common wear and tear items on a treadmill is the deck and belt combination. If these two items are not properly maintained,

they can cause damage to other components. Always keep your deck and belt free of dirt and dust by wiping the edges of the belt and deck and

up to 2" under the belt with a clean dry cloth.

To tell if your deck and belt combination needs to be replaced:

1) Have someone between 150-200lbs run on the treadmill at about 3 MPH.

2) Use a multi - meter to measure the amp draw with the user running. During normal use, the amp draw should be close to 5 amps. If the amp

draw is significantly higher than 5 amps, replace the belt and / or flip / replace the running deck.

8

Page 12

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.1 T3X-03 CONSOLE DESCRIPTION

WORKOUT KEYS: Simple program view and selection buttons.

GO: One touch Start and Quick Start.

ENTER: To confirm each program setting.

UP / DOWN INCLINE: Easy information and incline selection.

UP / DOWN SPEED: Easy information and speed selection.

EMERGENCY STOP / IMMOBILIZATION: To stop all functions and immobilize the unit. The emergency stop on this treadmill must be returned

to its original position in order to allow normal operation of the unit.

STOP: Ends workout and shows workout summary data.

PAUSE: Pauses workout. Pause duration can be set in Manager Mode.

COOL DOWN: Puts treadmill into Cool Down mode. Cool Down time is dependent on the length of the workout. Workouts 19 minutes and

shorter will have a cool down length of 2 minutes. Workouts 20 minutes and longer will have a cool down length of 5 minutes.

9

Page 13

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.2 MANUAL WORKOUT OPERATION

QUICK START OPERATION

Press the GO button(s) and the treadmill will enter into a manual mode of operation. All energy expenditure values will be calculated using the

default weight measurement.

MANUAL WORKOUT OPERATION

Manual is a workout that allows you to manually adjust the speed and incline values at anytime. The manual workout also contains a setup

screen which allows you to input your weight to help calculate a more accurate caloric burn rate.

To enter into this Manual Workout:

1) Choose the Manual Workout by selecting the MANUAL WORKOUT button and press ENTER.

2) Enter the desired workout length using the INCLINE or SPEED KEYS and press ENTER.

3) Enter the user's weight (the user's weight is used to calculate the caloric expenditure value-providing an accurate weight helps to ensure an

accurate caloric expenditure rating for each user) using the INCLINE or SPEED KEYS and press ENTER.

4) Enter the desired initial incline value using the INCLINE or SPEED KEYS and press ENTER.

5) Enter the desired start speed using the INCLINE or SPEED KEYS and press ENTER.

6) Press GO to begin the workout. The display will read 3, 2, 1, and then the workout will begin.

4.3 LEVEL BASED WORKOUT OPERATION

Your Matrix T3x-03 Treadmill offers a variety of level-based workouts to challenge users of all fitness levels. The following information will briefly

explain the workouts and how to program the treadmill for each workout selection.

ROLLING HILLS WORKOUT OPERATION

Rolling Hills is a level based workout that automatically adjusts the incline value to simulate walking or running up hills.

1) Choose the Rolling Hills workout by selecting the ROLLING HILLS workout button and press ENTER.

2) Enter the desired intensity using the INCLINE or SPEED KEYS and press ENTER.

3) Enter the desired workout length using the INCLINE or SPEED KEYS and press ENTER.

4) Enter the user's weight (the user's weight is used to calculate the caloric expenditure value, providing an accurate weight helps to ensure an

accurate caloric expenditure rating for each user) using the INCLINE or SPEED KEYS and press ENTER.

5) Press GO to begin the workout. The display will read 3, 2, 1, and then the workout will begin.

FAT BURN WORKOUT OPERATION

Fat Burn is a level-based workout that is designed to help users burn fat through various incline changes.

1) Choose the Fat Burn workout by selecting the FAT BURN workout button and press ENTER.

2) Enter the desired intensity level using the INCLINE or SPEED KEYS and press ENTER.

3) Enter the desired workout length using the INCLINE or SPEED KEYS and press ENTER.

4) Enter the user's weight (the user's weight is used to calculate the caloric expenditure value, providing an accurate weight helps to ensure an

accurate caloric expenditure rating for each user) using the INCLINE or SPEED KEYS and press ENTER.

5) Press GO to begin the workout. The display will read 3, 2, 1, and then the workout will begin.

5K RUN WORKOUT OPERATION

10

5K Run is a level-based workout with a fixed distance of 5 kilometers. Incline is adjusted automatically throughout the workout. You control the

speed.

1) Choose the 5K Run workout by selecting the 5K RUN workout button and press ENTER.

2) Enter the desired intensity level using the INCLINE or SPEED KEYS and press ENTER.

3) Enter the user's weight (the user's weight is used to calculate the caloric expenditure value, providing an accurate weight helps to ensure an

accurate caloric expenditure rating for each user) using the INCLINE or SPEED KEYS and press ENTER.

4) Press GO to begin the workout. The display will read 3, 2, 1, and then the workout will begin.

Page 14

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

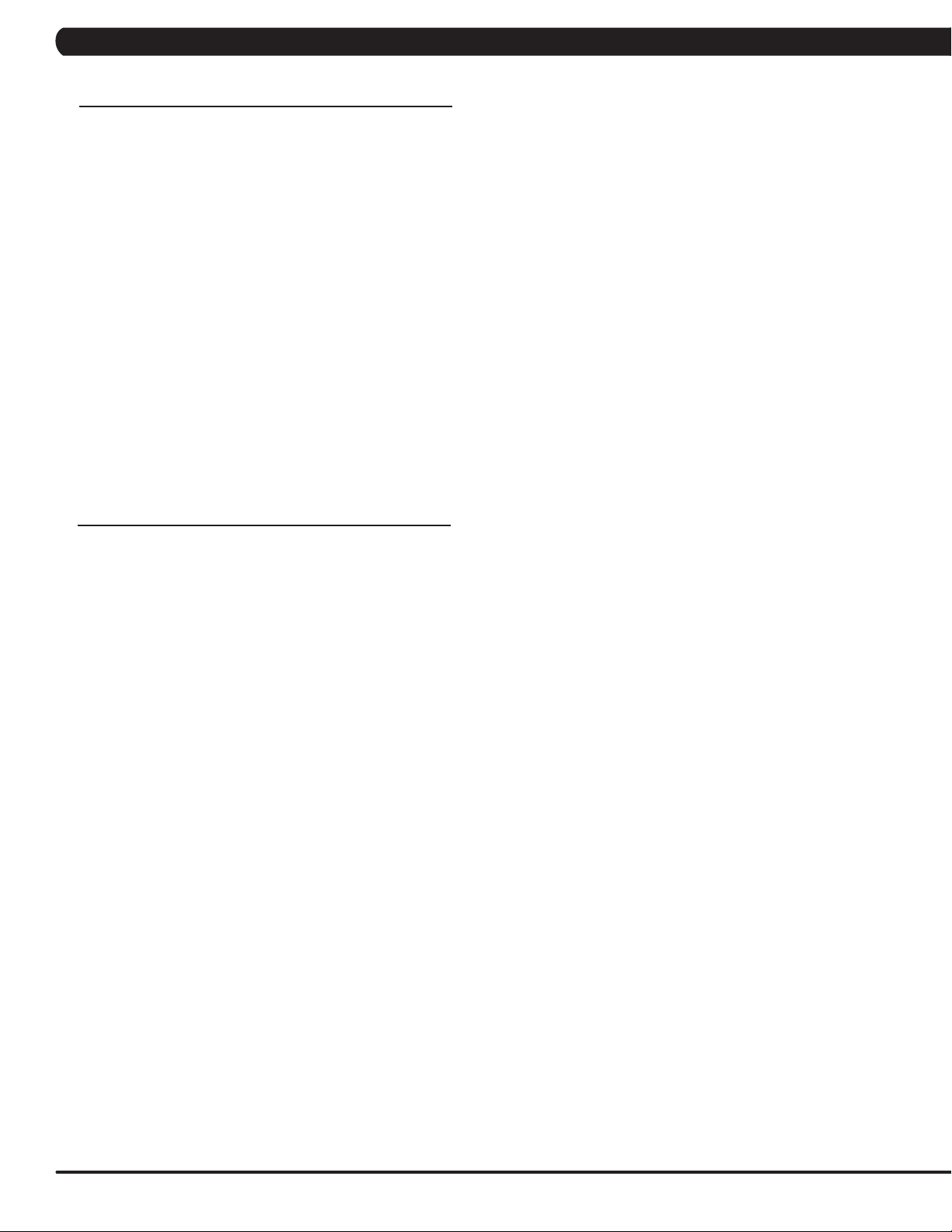

4.4 HEART RATE CONTROL WORKOUT OPERATION

Your Matrix T3x-03 Treadmill offers a heart rate control workout

mode. The heart rate control workout mode allows the user to

program their desired heart rate zone and maximum allowable

incline and the treadmill will automatically adjust the incline based

upon the user's heart rate. The heart rate zone is calculated using

thefollowingequation:(220-Age)*%=targetheartratezone.The

user must wear a telemetric heart rate monitor or continually hold

onto the contact heart rate grips for his workout.

1) Choose the Target Heart Rate workout by selecting the HEART

RATE workout button and press ENTER.

2) Enter the user's age using the INCLINE or SPEED KEYS and

press ENTER.

3) Enter the desired percent of maximum heart rate using the

INCLINE or SPEED KEYS and press ENTER.

4) Enter the user's weight (the user's weight is used to calculate

the caloric expenditure value, providing an accurate weight helps to

ensure an accurate caloric expenditure rating for each user) using

the INCLINE or SPEED KEYS and press ENTER.

5) Press GO to begin the workout. The display will read 3, 2, 1,

and then the workout will begin.

4.5 FITNESS TEST WORKOUT OPERATION

Your Matrix T3x-03 Treadmill offers a Gerkin Firefighter Protocol Fitness Test, The Gerkin Protocol was developed by Dr.. Richard Gerkin of the

Phoenix (Arizona) Fire Department. It is a sub-maximal graded treadmill evaluation used by many fire departments across the United States to

assess the physical condition of the firefighters. The test requires constant monitoring of the user's heart rate so the use of a telemetric chest

strap is highly encouraged. The workout operates as follows:

WARM UP:Thewarmupis3minuteslongandrunsat3.0mph(4.8kph)and0%incline.

STAGE 1: At the 3 minute mark, the treadmill will gradually increase speed to 4.5 mph (7.2 kph). The actual test begins at 4.5 mph (7.2 kph).

STAGE 2:Afteroneminute,thetreadmillinclinewillincreaseto2%.

STAGE 3: After one minute, the treadmill speed increases to 5.0 mph (8.0 kph).

STAGES 4 THROUGH 11:Aftereveryoddminutethetreadmillinclinewillincreaseby2%.Aftereveryevenminutethetreadmillspeedwill

increaseby0.5mph(0.8kph).Oncetheuser'sheartrateexceedsthetargetheartrate(85%ofmaximumasdeterminedbytheequation

(220-Age)*%=targetheartratezone),theindividualcontinuestheevaluationforanadditional15seconds.Duringthe15secondperiod,the

evaluation remains at the stage where the target heart rate is exceeded, without any change to speed or incline. If the heart rate does not

return to or below the target heart rate, the evaluation ends and the final evaluation stage is recorded. If the heart rate returns to or below the

target heart rate, the program continues at the point where it would have been had the program not stabilized for 15 seconds.

TEST COMPLETION: The test is completed when user's heart rate exceeds the target for more than 15 seconds or when the user completes

all11stages,whicheveroccursfirst.Thetreadmillwillenteracooldowncyclefor3minutesat3.0mph(4.8kph),0%incline.

1) Choose the Gerkin Test by pressing the FITNESS TEST workout button and press ENTER.

2) Enter the user's age using the INCLINE or SPEED KEYS and press ENTER.

3)Themessagewindowwilldisplayyourtargetheartratebaseduponyourageandthetargetheartratezoneof85%.

4) Select the user's gender using the INCLINE or SPEED KEYS and press ENTER.

5) Enter the user's weight (the user's weight is used to calculate the caloric expenditure value, providing an accurate weight helps to ensure an

accurate caloric expenditure rating for each user) using the INCLINE or SPEED KEYS and press ENTER.

6)Themessagewindowwillnotifytheuserthatthestartspeedis3.0mph(4.8kph)and0%inclineduringthewarm-up.

7) Press GO to begin the workout. The display will read 3, 2, 1, and the workout will begin.

11

Page 15

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.5 FITNESS TEST WORKOUT OPERATION - CONTINUED

SUB MAXIMAL TREADMILL EVALUATION

CONVERSION TABLE

Stage Time Converted VO2max

1 1:00 31.15

2.1 1:15 32.55

2.2 1:30 33.6

2.3 1:45 34.65

2.4 2:00 35.35

3.1 2:15 37.45

3.2 2:30 39.55

3.3 2:45 41.3

3.4 3:00 43.4

4.1 3:15 44.1

4.2 3:30 45.15

4.3 3:45 46.2

4.4 4:00 47.5

5.1 4:15 48.6

5.2 4:30 50

5.3 4:45 51.4

5.4 5:00 52.8

6.1 5:15 53.9

6.2 5:30 54.9

6.3 5:45 56

6.4 6:00 57

7.1 6:15 57.7

7.2 6:30 58.8

7.3 6:45 60.2

7.4 7:00 61.2

8.1 7:15 62.3

8.2 7:30 63.3

8.3 7:45 64

8.4 8:00 65

9.1 8:15 66.5

9.2 8:30 68.2

9.3 8:45 69

9.4 9:00 70.7

10.1 9:15 72.1

10.2 9:30 73.1

10.3 9:45 73.8

10.4 10:00 74.9

11.1 10:15 76.3

11.2 10:30 77.7

11.3 10:45 79.1

11.4 11:00 80

CARDIOVASCULAR FITNESS PERCENTILES

Males: VO2 max (ml/kg/min)

0-29 30-39 40-49 50-59

SUPERIOR

EXCEL-

LENT

GOOD

FAIR

POOR

VERY

POOR

Females: VO2 max (ml/kg/min)

SUPERIOR

EXCEL-

LENT

GOOD

FAIR

POOR

VERY

POOR

>58.8 >58.9 >55.4 >52.5

54.0 52.5 50.4 47.1

51.4 50.3 48.2 45.3

48.2 46.8 44.1 41.0

46.8 44.6 41.8 38.5

44.2 42.4 39.9 36.7

42.5 41.0 38.1 35.2

41.0 38.9 36.7 33.8

39.5 37.4 35.1 32.3

37.1 35.4 33.0 30.2

34.5 32.5 30.9 28.0

31.6 30.9 28.3 25.1

20-29 30-39 40-49 50-59

>53.0 >48.7 >46.8 >42.0

46.8 43.9 41.0 36.8

44.2 41.0 39.5 35.2

41.0 38.6 36.3 32.3

38.1 36.7 33.8 30.9

36.7 34.6 32.3 29.4

35.2 33.8 30.9 28.2

33.8 32.3 29.5 26.9

32.3 30.5 28.3 25.5

30.6 28.7 26.5 24.3

28.3 26.5 25.1 22.3

25.9 25.1 23.5 21.1

12

The Military Test programs and the Physical Efficiency Battery (PEB) provide workouts of a preset distance. These distances are established by

the various branches of the Military with the objective of each test to complete the distance as quickly as possible. At the completion of the test,

a time-based score as defined by the respective Military branch will be shown on the console.

1) Choose your Military Test by pressing the FITNESS TEST button until the desired test is shown on the screen.

2) Enter the user's age using the INCLINE or SPEED KEYS and press ENTER.

3) Select the user's gender using the INCLINE or SPEED KEYS and press ENTER.

4) Enter the user's weight (the user's weight is used to calculate the caloric expenditure value, providing an accurate weight helps to ensure an

accurate caloric expenditure rating for each user) using the INCLINE or SPEED KEYS and press ENTER.

5) Enter the desired intensity level using the INCLINE or SPEED KEYS and press ENTER.

6) Press GO to begin the workout. The display will read 3, 2, 1, and the workout will begin.

Page 16

CHAPTER 5: MANAGER MODE

5.1 USING MANAGER MODE

1) To enter Manager Mode, press & hold INCLINE DOWN and

SPEED DOWN keys at the same time for 3-5 seconds until Manager

appears on the display.

2) To enter the Manager Mode, press ENTER once Manager Mode

appears on the display (Figure A).

3) To scroll between settings in the Manager Mode, press the

INCLINE or SPEED keys.

4) Press ENTER to modify the settings once displayed.

5) Press any INCLINE or SPEED key to change the value of the setting.

6) Once the setting is correct, press ENTER to save.

7) Press the EMERGENCY STOP to exit Manager Mode..

FIGURE A

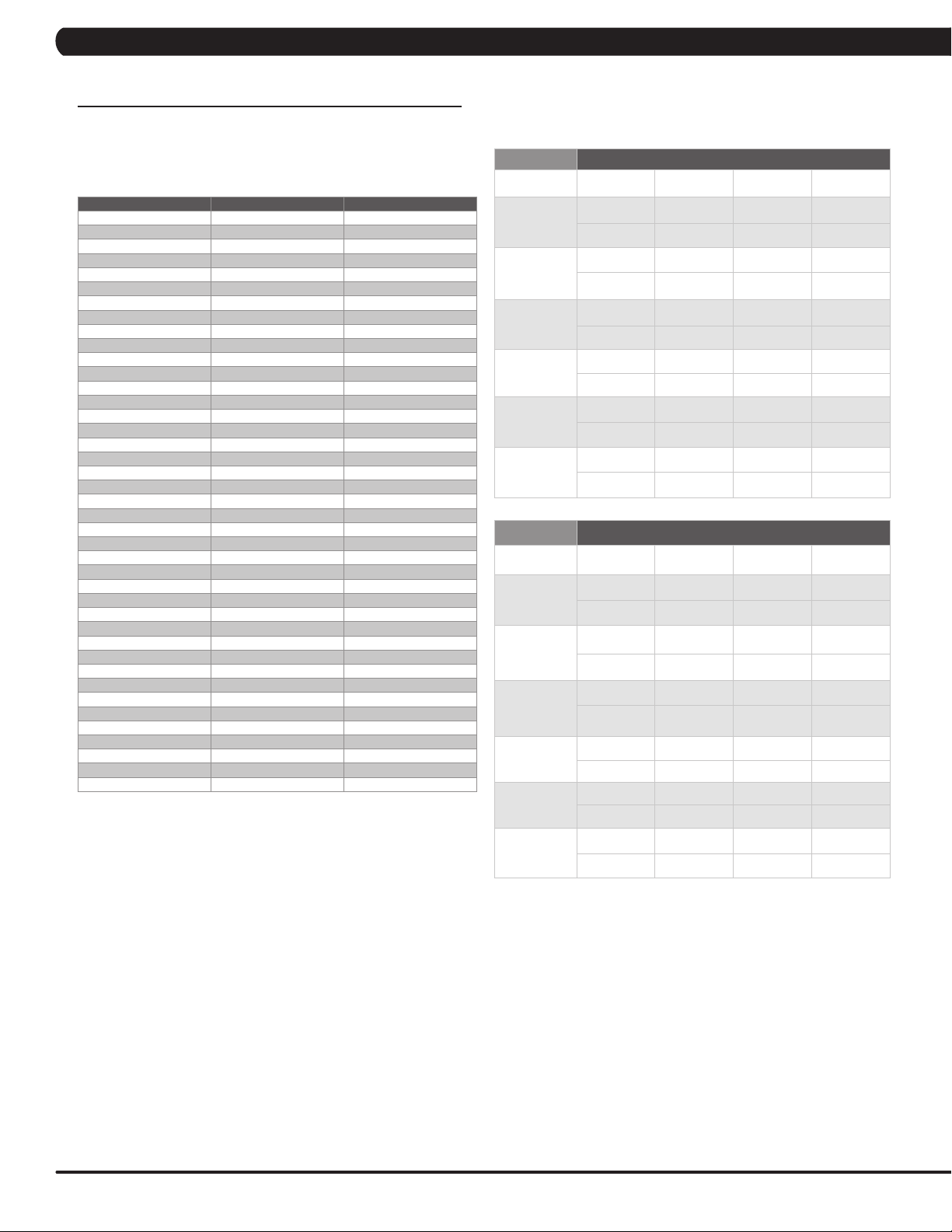

5.2 MANAGER MODE OVERVIEW

CUSTOM

DEFAULT MINIMUM MAXIMUM UNIT DESCRIPTION

SETTINGS

MAXIMUM TIME 60 5 99 MINUTE Maximum workout duration.

DEFAULT TIME 60 5 99 (limited to max

DEFAULT LEVEL 1 1 10 LEVEL Default start level in all programs.

DEFAULT AGE 30 15 100 AGE Default age used in HR programs.

DEFAULT

WEIGHT

ACCUMULATED

DISTANCE

ACCUMULATED

TIME

SOFTWARE N/A N/A N/A N/A Software Version, not editable.

START SPEED 0.5 MPH /

MAXIMUM

SPEED

TIMER MODE DOWN DOWN UP N/A Controls whether the user time counts up or

SPEED MODE MILE MILE KILOMETER N/A Measurement unit used for calorie

OUT OF ORDER OFF OFF ON OFF OR ON Locks the machine.

GENDER MALE MALE FEMALE N/A Sets the user's gender.

LANGUAGE ENGLISH N/A N/A N/A Sets the language shown on the console.

SOUND MODE ON ON OFF N/A Controls whether the display broadcasts

BELT STOP OFF OFF 30, 60, OR 90

150 LB / 68 KG50 LB / 23 KG 400 LB / 182 KG POUND /

N/A N/A 65,000 MILES /

N/A N/A 65,000 HOURS HOUR Total time on treadmill, not editable. TO

0.8 KPH

12 MPH / 20

KPH

0.5 MPH / 0.8

KPH

2.0 MPH / 3.2

KPH

time setting)

104,000 KM

2.0 MPH / 3.2 KPH MPH / KPH Controls the starting speed for all programs

12 MPH / 20 KPH MPH / KPH Controls the maximum speed for all

SECONDS

MINUTE Default start time in all programs.

KILOGRAM

MILE / KILOMETER Total distance on treadmill, not editable. TO

SECONDS This option checks for a user on the running

Default weight used in calorie calculations

and HR programs.

RESET: Press and hold INCLINE DOWN and

SPEED DOWN for 3-5 seconds.

RESET: Press and hold INCLINE DOWN and

SPEED DOWN for 3-5 seconds.

(does not affect minimum speeds).

programs.

down.

calculations, distance, and speed.

chime when buttons are pressed.

belt. If there is no user detected, the unit will

go into pause mode, and reset if no user for

5 minutes.

13

Page 17

CHAPTER 6: ENGINEERING MODE

6.1 USING ENGINEERING MODE

1) To enter Engineering Mode, press & hold the INCLINE DOWN

and SPEED DOWN keys at the same time for 3-5 seconds until

Manager Mode appears on the display.

2) Press the INCLINE or SPEED keys until Engineering Mode

appears on the display (Figure A) and press ENTER.

3) To scroll between settings in the Engineering Mode, press the

INCLINE or SPEED keys.

4) Press ENTER to modify the settings once displayed.

5) Press any INCLINE or SPEED key to change the value of the

setting.

6) Once the setting is correct, press ENTER to save.

7) Press the EMERGENCY STOP to exit Engineering Mode..

FIGURE A

6.2 ENGINEERING MODE OVERVIEW

CUSTOM SETTING DEFAULT MINIMUM MAXIMUM UNIT DESCRIPTION

Disable Errors OFF OFF ON N/A Off - Shows Class A-C errors. On - Shows Class C errors

Elevation Minimum 28 20 239 N/A Controls the low incline parameter.

Elevation Maximum 230 20 239 N/A Controls the high incline parameter.

Auto Calibration N/A N/A N/A N/A This function is to calibrate the treadmill incline.

Speed Units MILE MILE KILOMETER DISTANCE Measurement unit used for calorie calculations, distance,

Pause Time 5 MINUTES 5 SECONDS 10 MINUTES SECOND /

Serial Number Serial Number input is available for both the Console and

Reset Defaults N/A N/A N/A N/A Reset the default values to factory settings.

Club ID N/A N/A N/A N/A This sets the club ID for clubs using Asset Management.

Audio Source OFF OFF TV / PCTV /

REMOTE TV

MINUTE

N/A Sets which outside TV will have audio through the console

only.

and speed.

Controls the maximum time the treadmill can be paused

during a workout.

Frame. Due to the limited LED characters, 2 layers are

used to enter the serial number. First Layer:

- PPPPP V

- PPPPP is the product name

- V is the version. If the version is A, just leave this blank.

Second Layer

- YY MM nnnnn.

- YY is the year (11, 12).

- MM is the month (e.g. 08, 09, 10).

- nnnnn is the actual serial number.

Use the UP / DOWN LEVEL keys to navigate the layers

and the number keys to input the serial number. The

product name is dependent on the Machine Type setting.

For example, the console is TM509 with ver. C and the

manufactured date is 2011.08 with 98765. The frame is

TM509 with ver. D and the manufactured date is 2011.06

with 12345. Their serial numbers are:

Console SN: TM509C 1rst layer, 110898765 2nd layer.

Frame SN: TM509D 1rst layer, 110612345 2nd layer.

audio ports.

14

Page 18

CHAPTER 7: SERVICE MODE

7.1 USING SERVICE MODE

1) To enter Service Mode, press & hold the INCLINE DOWN and

SPEED DOWN keys at the same time for 3-5 seconds until Manager

Mode appears on the display.

2) Press the INCLINE or SPEED keys until Service Mode appears on

the display (Figure A) and press ENTER.

3) To scroll between settings in the Service Mode, press the INCLINE

or SPEED keys.

4) Press ENTER to modify the settings once displayed.

5) Press any INCLINE or SPEED key to change the value of the setting.

6) Once the setting is correct, press ENTER to save.

7) Press the EMERGENCY STOP to exit Service Mode..

FIGURE A

7.2 SERVICE MODE OVERVIEW

CODE DEFAULT OPTIONS DESCRIPTION

Service 1 Display Test Press the ENTER key repeatedly

Service 2 Keypad Test Press any key and the display

Service 3 Distance / Time Distance:

Mile 0 - 99999

Kilometer 0 - 160898

Time:

0 - 999999

Service 4 CSafe / RF Test Press the ENTER key to test CSafe.

Service 5 Error Log Shows the last 10 errors. Press

Service 6 Set Date / Time Press the LEVEL keys to move

to check each set of LEDs on the

display sequentially.

should show the corresponding

message.

Manually sets the Accumulated

Distance and Time.

Press the ENTER key again to test

the RF module.

and LEVEL UP and DOWN for 3

seconds to clear the errors.

cursor, the number keys to set date

/ time, and the ENTER key to save.

15

Page 19

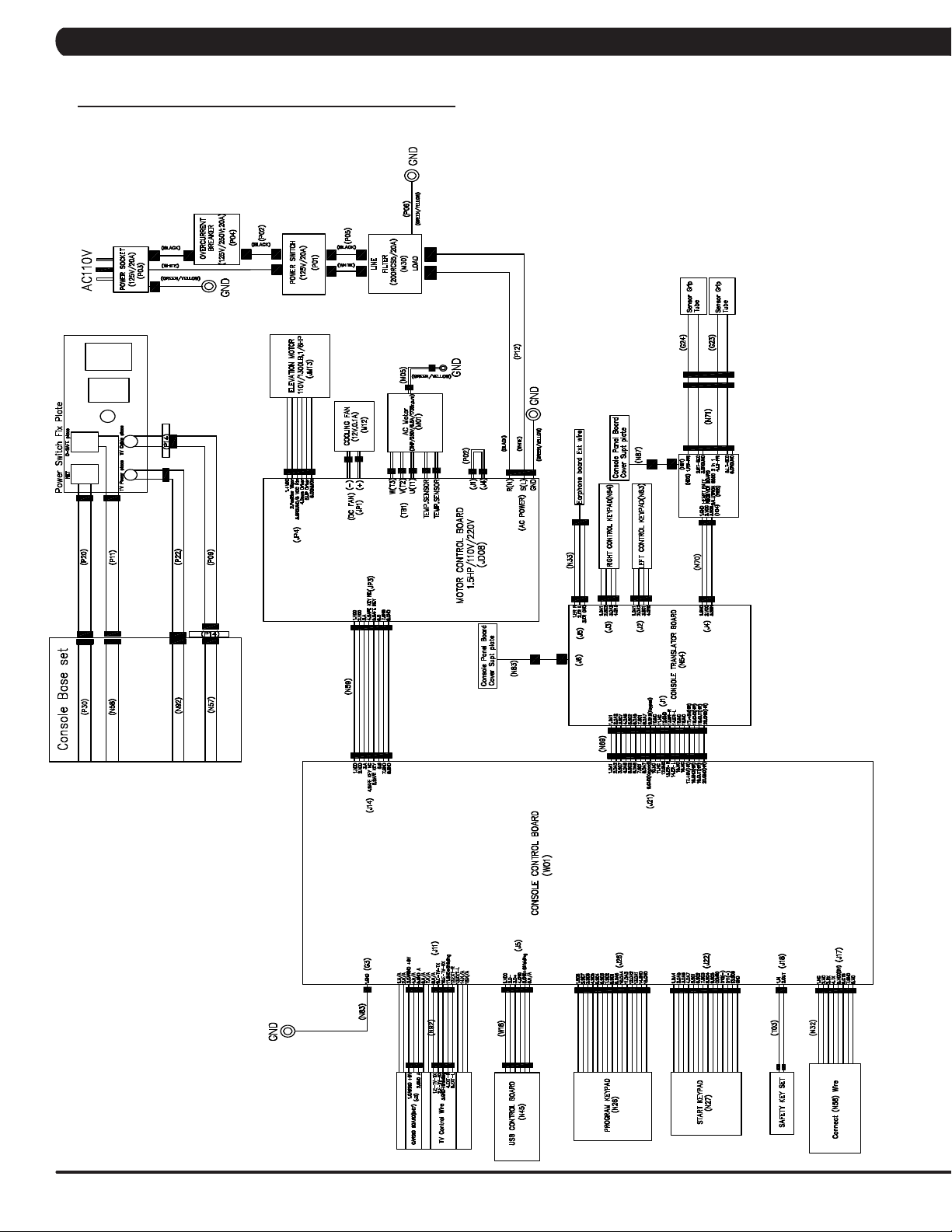

8.1 ELECTRICAL DIAGRAMS

CHAPTER 8: TROUBLESHOOTING

16

Page 20

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

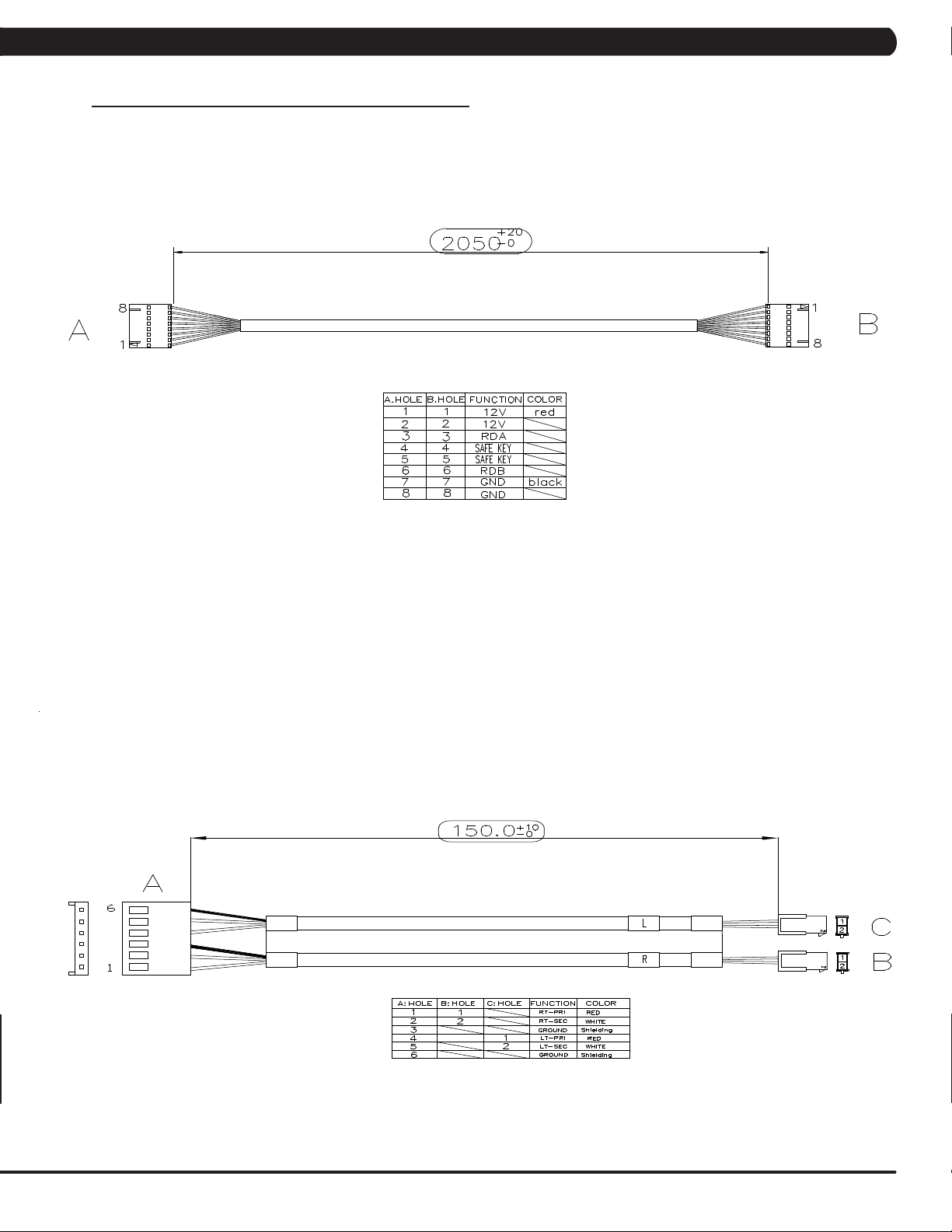

DIGITAL COMMUNICATION WIRE - N59

PULSE GRIP WIRE - N71

17

Page 21

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

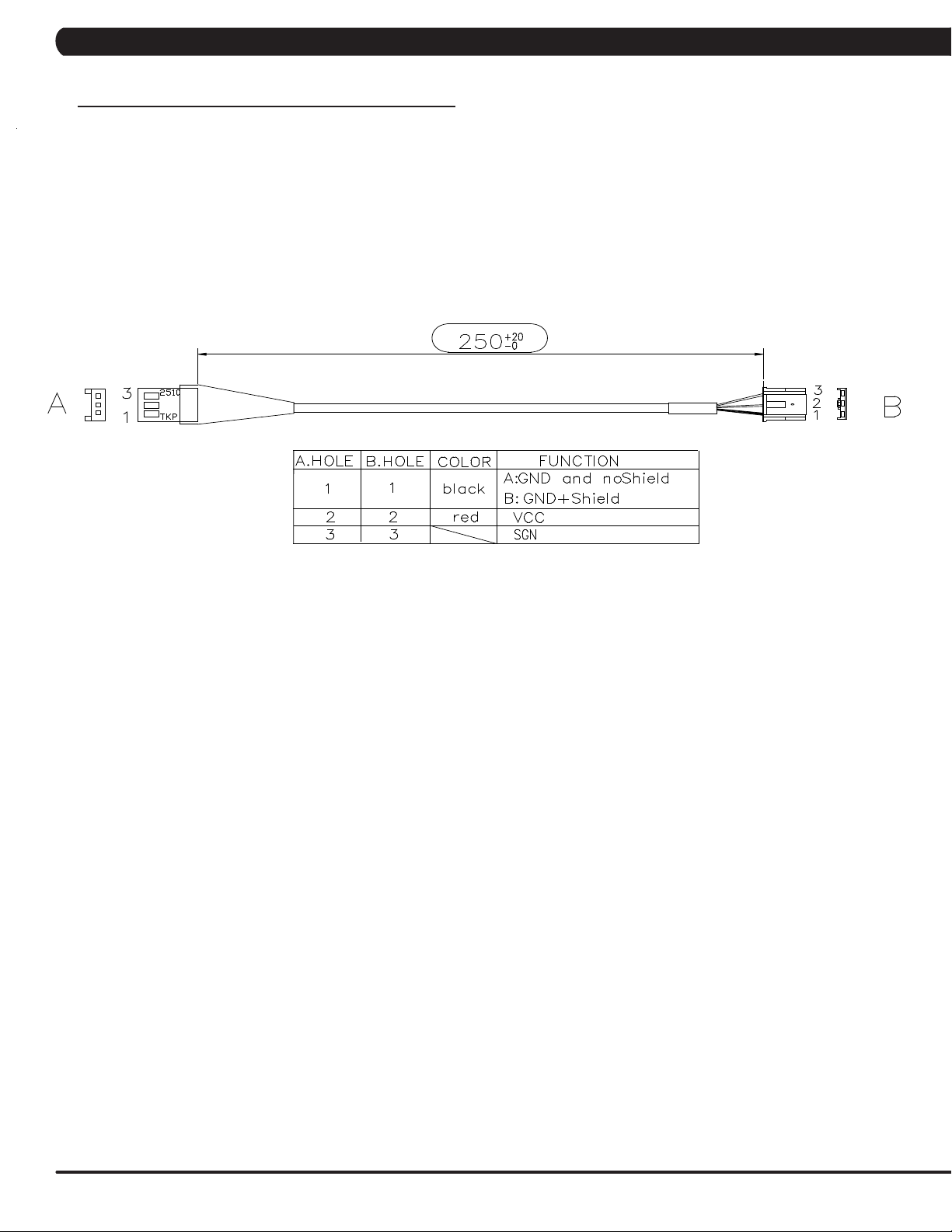

PULSE GRIP CONNECTING WIRE - N70

18

Page 22

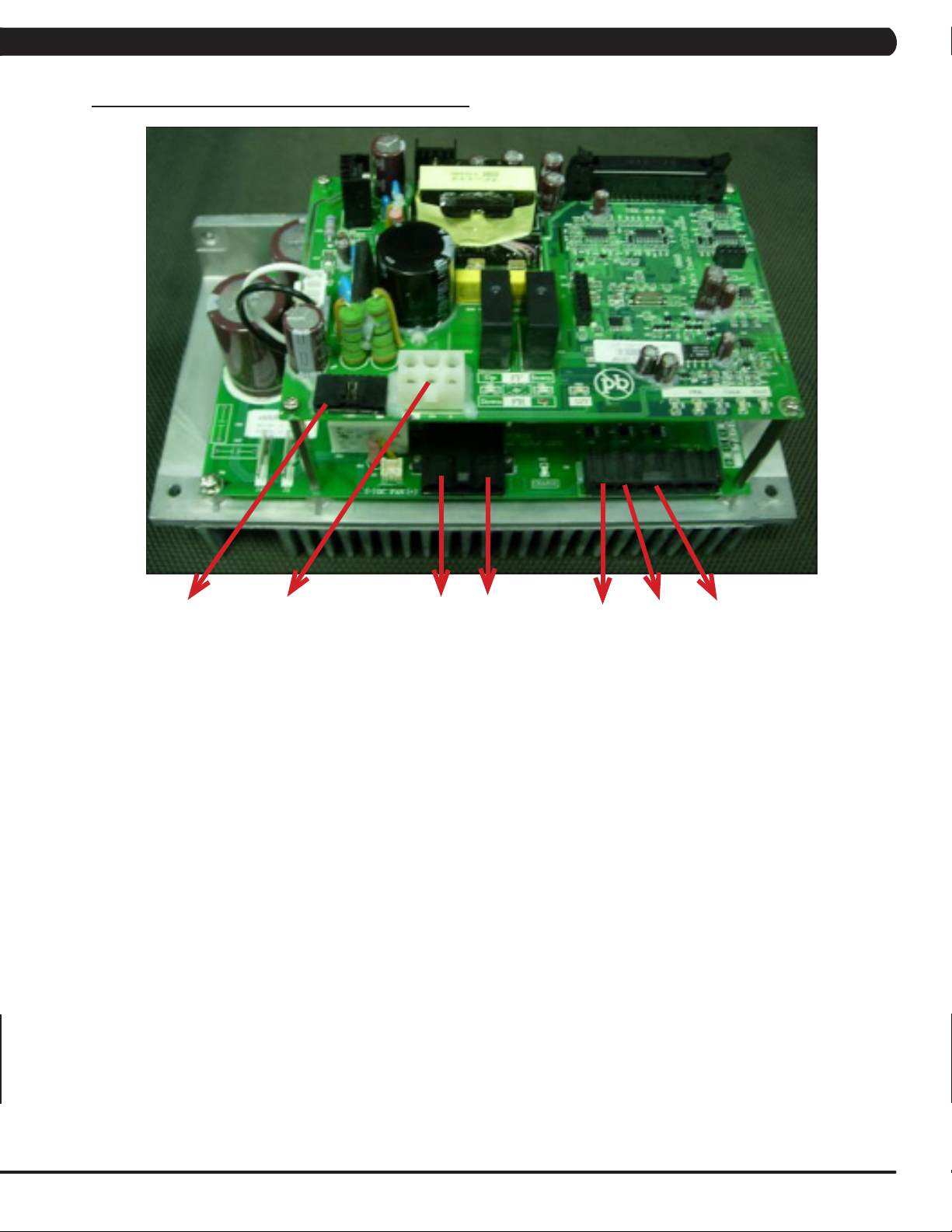

8.2 MCB WIRING

CHAPTER 8: TROUBLESHOOTING

JP3 JP4

JP3 - Console Cable

JP4 - Incline Motor Cable

N - Power Input (white)

L - Power Input (Black)

U - Motor Wire (red)

V - Motor Wire (White)

W - Motor Wire (Black)

N L

U

V

W

19

Page 23

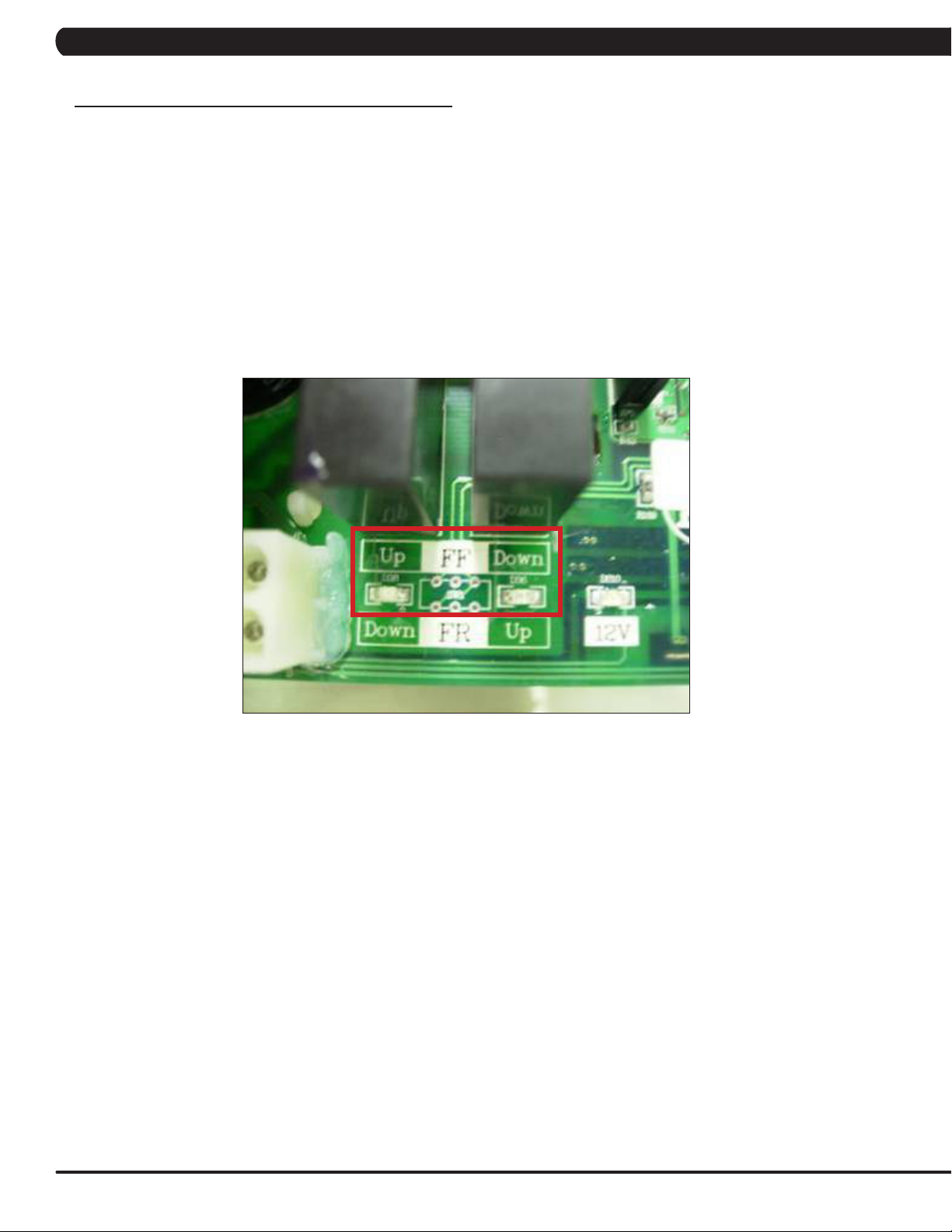

CHAPTER 8: TROUBLESHOOTING

8.3 MCB LED PLACEMENT AND DEFINITIONS

PWM - Console PWM signal light (when

the motor is running, the light should

flash).

COM - Digital communication light.

FAULT - The machine has stopped due

to any C class error.

UP / DOWN (FF) - Incline motor status

light.

20

Page 24

CHAPTER 8: TROUBLESHOOTING

8.4 ERROR MESSAGES ON THE CONSOLE

CLASS

ERROR CODE DESCRIPTION CONDITION

LEVEL

B 0140 Incline motor fail. When the incline motor is supposed to move, it does not move.

C 01A0 Incline motor disconnection. When the incline position cable is not connected.

C 01A4 Main motor U phase

disconnection.

C 01A5 Main motor V phase

disconnection.

C 01A6 Main motor W phase

disconnection.

C 01A8 Main motor over current. Main motor over current of 7 amps.

C 01AB Inverter Error. Internal error of the inverter.

C 01AD Motor over temperature. When a heavy user makes the motor over load over go over

C 02A0 Main motor failed. The belt does not move when commanded.

C 02A1 Over AC power input voltage. Power input voltage over range.

C 02A2 Over / low DC bus voltage. Power input voltage over range.

C 02A8 Inverter circuit of motor drive

failed.

C 02AD LCB over temperature. LCB over temperature.

C 02B5 Inverter senses that the normal

ratedcurrentisover150%for

over 60 seconds.

C 02B6 Speed up has over current. Software issue.

C 02B7 Speed down has over current. Software Issue.

C 02B8 Running status over current. Software Issue.

C 02B9 The inner memory IC data write

error.

C 02BA The inner memory IC data read

error.

C 02BC Ground connection or fuse error. MCB failure.

C 02BD Inverter hardware interrupt error. MCB failure.

C 04A0 Digital communication failure.

LCB has no return message from

the UCB within 3 seconds.

C 04B0 UCB no response. Check the console cable connection at the UCB and LCB.

When the error happens the incline motor will be locked. The

command "initialize" is needed to unlock the incline.

Main motor U phase disconnection.

Main motor V phase disconnection.

Main motor W phase disconnection.

current.

Motor resistance closed.

Inverter sensor is reading the normal rated current is over 10.5

amps for 60 seconds.

MCB failure.

MCB failure.

Check the console cable connection at the UCB and LCB.

Replace the console cable, UCB, or LCB as needed.

Replace the console cable, UCB, or LCB as needed.

CLASS LEVEL

Class B - Will make a record in the error log. The machine will keep working.

Class C - The machine will stop and not work.

21

Page 25

CHAPTER 8: TROUBLESHOOTING

8.5 0140 / 01A0 ERROR TROUBLESHOOTING

ERROR MESSAGE 0140 / 01A0

1) CAUSE:

a. Incline motor operation failed.

2) SOLUTION:

a. Check the connection of the incline motor cable at the MCB.

b. Run auto calibration (See Section 3.5).

c. If auto calibration fails, press GO and attempt to incline the treadmill.

- Check the MCB UP and DOWN (FF) LEDs (Figure A). If the LEDs do not light up when incline is commanded, replace the console

cable or console. If the LEDs do light up, replace the incline motor.

d. If replacing the console, console cable, and incline motor do not resolve the issue, replace the MCB.

FIGURE A

22

Page 26

CHAPTER 8: TROUBLESHOOTING

8.6 01A4 / 01A5 / 01A6 ERROR TROUBLESHOOTING

ERROR MESSAGE 01A4 / 01A5 / 01A6

1) CAUSE:

a. 01A4 - Main motor U phase disconnection.

b. 01A5 - Main motor V phase disconnection.

c. 01A6 - Main motor W phase disconnection.

2) SOLUTION:

a. Check the connection of the motor cable at the MCB (Figure A).

b. Replace the motor.

c. Replace the MCB.

FIGURE A

U V

8.7 01A8 / 01AD / 02B6 / 02B7 / 02B8 ERROR TROUBLESHOOTING

ERROR MESSAGE 01A8 / 01AD / 02B6 / 02B7 / 02B8

1) CAUSE:

a. 01A8 - Main motor over current of 7 Amps.

b. 01AD - Motor over temperature.

c. 02B6 - Speed up is over current.

d. 02B7 - Speed down is over current.

e. 02B8 - Running status over current.

2) SOLUTION:

a. See Section 3.6 for checking the status of the running deck and belt. Replace as needed.

b. Replace the MCB.

W

23

Page 27

CHAPTER 8: TROUBLESHOOTING

8.8 01AB ERROR TROUBLESHOOTING

ERROR MESSAGE 01AB

1) CAUSE:

a. Inverter error.

2) SOLUTION:

a. When the display is showing an 01AB error, the MCB Fault LED should be lit (Figure A).

b. If the MCB Fault LED is not lit, replace the console.

c. If the MCB Fault LED is lit, replace the MCB.

FIGURE A

24

Page 28

CHAPTER 8: TROUBLESHOOTING

8.9 02A0 / 02A8 ERROR TROUBLESHOOTING

ERROR MESSAGE 02A0 / 02A8

1) CAUSE:

a. 02A0 - Main motor failure. The belt does not move when it is supposed to move.

b. 02A8 - Inverter circuit of the motor failed. Motor resistance is closed.

2) SOLUTION:

a. Check the connection of the motor cable at the MCB (Figure A).

b. Use a multi - meter to check the motor cable for resistance at 3 points (Figures B, C, & D).

c. If the motor cable displays an ohm value, replace the MCB.

d. If the motor cable does not display an ohm value, replace the motor.

FIGURE A

FIGURE C

FIGURE B

FIGURE D

25

Page 29

CHAPTER 8: TROUBLESHOOTING

8.10 02A1 / 02A2 ERROR TROUBLESHOOTING

ERROR MESSAGE 02A1 / 02A2

1) CAUSE:

a. 02A1 - Over AC power input voltage.

b. 02A2 - Over / low DC bus voltage.

2) SOLUTION:

a. Use a multi - meter to check if the input power is over 260V.

b. If the power outlet is ok, replace the MCB.

8.11 02AD ERROR TROUBLESHOOTING

ERROR MESSAGE 02AD

1) CAUSE:

a. MCB over temperature.

2) SOLUTION:

a. Check the condition and connection of the motor cable at the MCB (Figure A).

b. Use a multi - meter to check the motor cable for resistance at the 2 blue wires in the cable (Figure B).

c. If the blue wires of the motor cable display an ohm value, replace the motor.

d. If the blue wires of the motor cable do not display an ohm value, replace the MCB.

26

FIGURE A

FIGURE B

Page 30

CHAPTER 8: TROUBLESHOOTING

8.12 02B5 ERROR TROUBLESHOOTING

ERROR MESSAGE 02B5

1) CAUSE:

a. The inverter sensor is reading the normal rated current is over 10.5 amps for 60 seconds.

2) SOLUTION:

a. Use a multi - meter to check the motor cable for resistance at 3 points (Figures A, B, & C).

b. If the motor cable displays an ohm value over 4, replace the motor.

c. If the motor cable displays an ohm value under 4, replace the MCB.

FIGURE A

FIGURE B FIGURE C

27

Page 31

CHAPTER 8: TROUBLESHOOTING

8.13 02B9 / 02BA / 02BC / 02BD ERROR TROUBLESHOOTING

ERROR MESSAGE 02B9 / 02BA / 02BC / 02BD

1) CAUSE:

a. 02B9 - The inner memory IC data write error.

b. 02BA - The inner memory IC data read error.

c. 02BC - Ground connection or fuse error.

d. 02BD - Inverter hardware interrupt error.

2) SOLUTION:

a. Replace the MCB.

8.14 04A0 ERROR TROUBLESHOOTING

ERROR MESSAGE 04A0

1) CAUSE:

a. No communication response.

2) SOLUTION:

a. If an 04A0 error is displayed, MCB Com LED should not be lit (Figure A).

b. Check the connection of the digital communication wire at the MCB (Figure B).

c. Replace the digital communication wire.

d. Replace the console.

e. Replace the MCB.

28

FIGURE A FIGURE B

Page 32

CHAPTER 8: TROUBLESHOOTING

8.15 TROUBLESHOOTING - HEART RATE ISSUES

HEART RATE ISSUES

1) SYMPTOM:

a. No heart rate.

b. No or high heart rate.

2) SOLUTION:

a. With a multi meter set for DC Voltage, place one prong of the multi meter on each of the HR plates on the handlebar (Figure A). A

correctly connected HR grip will have a DC Voltage reading of between 0.5 and 2.0. If this reading is correct, skip to Step b.

- If the reading is not correct, remove the screws holding the 2 halves of the HR grip together and check the connection of the HR grip

wiring to the grips (Figure B). Replace the grips if any damage is seen to the plates.

- Remove the console and split the plastic and metal portions of the console frame to expose the HR board (Figure C).

- Check the connection of the HR grip wiring to the 6 pin Y cable attached to one side of the HR board. Use a multi meter set for

ohms to verify the continuity of these wires. If the ohm reading is more than 1 (or not there at all), replace the HR grip wiring (this will require

replacing the HR handlebar). If the ohm reading is correct, your issue is not with the HR grip / HR wire portion of the HR system.

b. Perform a continuity test on the treadmill console (see Service Bulletin - Continuity Test on Matrix Treadmills).

- Verify the HR board ground wire. With a multi meter set for ohms, place one prong on the HR board ground wire, and the other on

the console ground screw. You should get a resistance reading of 1 or less. If you get a reading over 1 (or none at all), replace the HR board.

- Check the continuity of the wire that goes from the HR board to the Translator Board. With a multi meter set for ohms, place one

prong on the 3 pin wire connecting to the HR board and the other on where this wire connects to the Translator Board (Figure D). If you get a

reading of over 1 (or no reading at all), replace this wire.

- Check the connection of the wire that goes from the Translator Board to the UCB. Replace this wire if needed.

- If all wiring checks out good and the unit is still having HR issues, replace the HR board.

- If the HR board does not resolve the issue, replace the UCB.

FIGURE A FIGURE B

FIGURE C FIGURE D

29

Page 33

CHAPTER 8: TROUBLESHOOTING

8.16 ENTERTAINMENT TROUBLESHOOTING - OVERVIEW

1. Sections 8.16 - 8.19 will help with diagnosing problems with TV and entertainment related equipment that is produced by Matrix Fitness Systems.

2. The T3x-03 treadmill has the capability of adding an external 15" TV with a bracket. A Matrix brand external TV will look similar to the TV in

Figure A. Your control keypad should look similar to Figure B. If your equipment looks different contact Matrix or the manufacturer of your TV

equipment if known.

FIGURE A FIGURE B

3. Verify how your TV is mounted, compare your machine to Figure C which shows an external 15" TV directly mounted to a T3x Treadmill.

FIGURE C

4. For Matrix produced and mounted equipment you can use the information outlined in this section to help with any connection and power

issuesyoumayhave.IfyouhavequestionsthatarespecictotheTValone(settings,programming,menuoptions,etc)pleaseseethe

entertainment owner’s manual.

30

Page 34

CHAPTER 8: TROUBLESHOOTING

8.17 ENTERTAINMENT TROUBLESHOOTING – PICTURE FUZZY OR UNCLEAR

1.RemovetheTVandconsolebackcovers(FigureA)Usingaveriedgoodpieceofcoaxcable,hookthecoaxdirectlytotheTVjack.This

bypasses internal connections for your machine or TV stand (Figure B).

FIGURE A FIGURE B

2. If this does not clear your picture the issue is with the club's signal. Make sure that the coax has a signal strength of at least 10db.

3.IfStep1doesclearyourpicture,checktheinternalcablesandttingsinsideyourmachine.Makesureyouhavenodamage(kinks,cutsetc)

andnostraywiresorpoorttingsontheendsofthecablesanywherethatthecoaxcableisconnected(FiguresC&D).Fittingsshouldhavea

cleanushconnectorandnostrayaluminumstrandstouchingthecenterconductor.Replaceorrepairanysuspectcables.

FIGURE C FIGURE D

4.Ifnothingisvisiblywrongwithanyofthecables,ttings,orconnectorsreplacetheinternalcoaxcablesandconnectorswithknowngood

parts.

31

Page 35

CHAPTER 8: TROUBLESHOOTING

8.18 ENTERTAINMENT TROUBLESHOOTING -TV WILL NOT TURN ON

1. If you have no picture at all check to see if you have any status lights on your controller or TV. Status lights should be red when off or in

standby mode, and green when the TV is powered on. If you have lights of any color skip to Section 8.19.

2. Remove the TV back cover (Figure A) and check the connection of the TV power wire at the TV (Figure B). Also check the TV power wire

connection at the bracket (Figure C) and at the base of the treadmill (Figure D).

FIGURE A

FIGURE B

FIGURE C FIGURE D

3.Afteryouhaveveriedallconnectionsaresecureandaproblemstillexistsverifypowerattheoutlet(FigureD).Iftheoutletisnotoutputting

120Volts,checktnessroompower.

4. If internal TV power wire connections are good, verify 12 Volts power at the TV power wire where it plugs into the TV (wire in Figure B, shown

with multi - meter in Figure E). If 12 Volts are present, the issue is likely with the TV itself, contact Matrix Customer Service.

32

FIGURE E

FIGURE F

Page 36

CHAPTER 8: TROUBLESHOOTING

8.19 ENTERTAINMENT TROUBLESHOOTING - CONTROLLER ISSUES

1. If you have status lights on the TV, but the On / Off button gives no response, disconnect and then re-connect the power to the treadmill from

the wall. Attempt to turn on the TV again using the On / Off button.

2. If the TV does not power on check the TV keypad connection at the console (Figure A).

3. Also check the connection of the TV controller wire at the TV (Figure B) and the console (Figure C).

4. If the TV does not power on with the TV keypad, attempt to power on the TV using the small handheld remote that came with the TV (Figure D)

(Used for changing menu and other settings). If the TV will function with the handheld remote, replace the TV keypad. If the TV will not function

with handheld remote it is likely an issue with the TV itself, contact Matrix Customer Technical Support.

FIGURE A FIGURE B

FIGURE DFIGURE C

33

Page 37

CHAPTER 9: PART REPLACEMENT GUIDE

9.1 MOTOR COVER REPLACEMENT

1) Remove the 2 screws holding the motor cover to the frame using a 6 mm Allen wrench (Figures A).

2) The motor cover is velcroed to the frame, so you will have to pull up with some force (Figure B).

FIGURE A

3) Figure C shows the motor area with the cover removed.

4) Reverse Steps 1-2 to install a new motor cover. NOTE: When reinstalling the motor cover, be sure to tuck the sides in so they do not bow

outward (Figure D).

FIGURE C

FIGURE B

FIGURE D

34

Page 38

CHAPTER 9: PART REPLACEMENT GUIDE

9.2 REAR ROLLER REPLACEMENT

1) Remove one of the rear end caps using a Phillips screwdriver (Figure A).

2) Remove both rear roller adjustment screws using an 8 mm Allen wrench (Figure B).

FIGURE A FIGURE B

3) Remove the rear roller from the running belt (Figures C & D).

FIGURE C FIGURE D

4) Reverse Steps 1-3 to install a new roller. NOTE: Be sure to follow the instructions in Section 3.5 to re-tension the running belt.

5) Test the treadmill for function as outlined in Section 9.21.

35

Page 39

CHAPTER 9: PART REPLACEMENT GUIDE

9.3 DECK REMOVAL

1) Remove the motor cover as outlined in Section 9.1.

2) Remove the four deck screws using a 5 mm Allen wrench (Figure A).

FIGURE A

3) Remove the deck from the running belt (Figures B & C).

FIGURE B

4) Be careful not to pinch fingers during removal / installation of deck board.

5) Deck is waxed on both sides so the opposite side surface may be usable.

6) New deck surfaces must ALWAYS be matched to a new running belt.

7) Test the treadmill for function as outlined in Section 9.21.

FIGURE C

36

Page 40

CHAPTER 9: PART REPLACEMENT GUIDE

9.4 DECK CUSHION REPLACEMENT

1) Remove the deck as outlined in Section 9.3.

2) Holding the bolt with a 5 mm Allen wrench, loosen the nut with a 13 mm socket (Figure A & B).

FIGURE A FIGURE B

3) For the rear cushion, hold the cushion and remove the 13 mm nut (Figure C).

FIGURE C

4) Reverse Steps 1-3 to install new deck cushions.

5) Test the treadmill for function as outlined in Section 9.21.

37

Page 41

CHAPTER 9: PART REPLACEMENT GUIDE

9.5 FRONT ROLLER REPLACEMENT

1) Remove the motor cover as outlined in Section 9.1.

2) Using a hook or loop of wire, remove the spring from the drive belt tensioner. The tensioner should now pivot away from the drive belt

(Figure A).

3) Loosen the rear roller screws to remove tension from the running belt.

4) Remove the front roller mounting screws using an 8 mm Allen wrench (Figures B & C).

5) Remove the drive belt from the front roller and remove the roller from the running belt (Figure D).

FIGURE A

FIGURE C

6) Reverse Steps 1-4 to install a new roller.

7) Test the treadmill for function as outlined in Section 9.21.

FIGURE B

FIGURE D

38

Page 42

CHAPTER 9: PART REPLACEMENT GUIDE

9.6 RUNNING BELT REPLACEMENT

1) Remove the motor cover as outlined in Section 9.1.

2) Remove the rear roller as outlined in Section 9.2.

3) Remove the deck as outlined in Section 9.3.

4) Remove the front roller as outlined in Section 9.5.

5) Remove the running belt and replace it with a new belt (Figures A & B). NOTE: New running belts should ALWAYS be installed on a new

deck surface (deck should either be flipped or replaced to gain a new surface).

FIGURE A FIGURE B

6) Reverse Steps 1-5 to install a new running belt.

7) Test the treadmill for function as outlined in Section 9.21.

39

Page 43

CHAPTER 9: PART REPLACEMENT GUIDE

9.7 SIDE RAIL REPLACEMENT

1) Remove the rear end cap using a Phillips screwdriver (Figure A).

2) Loosen the four screws under the frame using a 5 mm Allen wrench (Figure B).

FIGURE A FIGURE B

3) Slide the rail off the back of the treadmill (Figures C & D).

FIGURE C

4) Reverse Steps 1-3 to install a new side rail.

5) After reinstalling the side rail, make sure the rear end cap is on first before tightening the screws for proper gap spacing.

6) Be careful not to over tighten the screws, or they will poke through the top of the side rail.

FIGURE D

40

Page 44

CHAPTER 9: PART REPLACEMENT GUIDE

9.8 MOTOR CONTROL BOARD (MCB) REPLACEMENT

1) Turn off power and disconnect the cord from the machine.

2) Remove the motor cover as outlined in Section 9.1.

3) Remove the wire connections to the MCB.

4) Remove the 2 screws holding the MCB to the base frame (Figures A & B).

FIGURE A

5) Remove the MCB.

6) Reverse Steps 1-5 to install a new MCB. NOTE: Be sure to plug in all wire connections removed in Step 3 (Figure C). The wire coming

from the speed sensor on the motor is not used on this model and should not be plugged in.

7) Test the treadmill for function as outlined in Section 9.21.

6 pin connector from

the incline motor.

8 pin connector from

the console cable.

3 pin connector from

the choke (Inductance).

FIGURE C

FIGURE B

5 pin connector from

the motor.

41

Page 45

CHAPTER 9: PART REPLACEMENT GUIDE

9.9 MOTOR REPLACEMENT

1) Turn off power to the treadmill and disconnect the power cord.

2) Remove the motor cover as outlined in Section 9.1.

3) Release the drive belt tensioner spring (Figure A).

4) With the spring released, rotate the tensioner to relieve tension on the drive belt (Figure B).

FIGURE A

5) The drive belt can now be walked off of the motor pulley (Figure C).

6) Disconnect the motor cables from the MCB and cut any tie straps holding them in place (Figure D).

FIGURE C FIGURE D

FIGURE B

42

Page 46

CHAPTER 9: PART REPLACEMENT GUIDE

9.9 MOTOR REPLACEMENT - CONTINUED

7) Disconnect the motor ground wire from the motor and cut any tie straps holding the ground wire in place (Figure E).

FIGURE E

8) Using an 8 mm Allen wrench, remove the four motor mounting screws (Figure F).

9) Lift the motor away from the treadmill (Figure G).

FIGURE F FIGURE G

10) Reverse Steps 1-9 to install a new motor. NOTE: The speed sensor on the motor is not used on this model and should not be plugged into

the MCB.

11) Test the treadmill for function as outlined in Section 9.21.

43

Page 47

CHAPTER 9: PART REPLACEMENT GUIDE

9.10 DRIVE BELT REPLACEMENT

1) Turn off power to the treadmill and disconnect the power cord.

2) Remove the motor cover as outlined in Section 9.1.

3) Release the drive belt tensioner spring (Figure A).

FIGURE A

4) With the spring released, rotate the tensioner to relieve tension on the drive belt and walk the drive belt off of the motor pulley (Figures B & C).

FIGURE B FIGURE C

44

Page 48

CHAPTER 9: PART REPLACEMENT GUIDE

9.10 DRIVE BELT REPLACEMENT - CONTINUED

5) Loosen the rear roller screws to relieve tension on the running belt (Figure D).

6) Remove the two 8 mm front roller screws (Figures E & F).

7) Lift the roller and remove the old drive belt (Figure G).

FIGURE D FIGURE E

8) Reverse Steps 1-7 to install a new drive belt. NOTE: After installing a new belt, check it for correct alignment to the motor pulley before

setting the tensioner in place.

9) Test the treadmill for function as outlined in Section 9.21.

FIGURE F FIGURE G

45

Page 49

CHAPTER 9: PART REPLACEMENT GUIDE

9.11 INCLINE MOTOR REPLACEMENT

1) Turn off power to the treadmill and disconnect the power cord.

2) Lift the treadmill and support it so that the front wheels are off the floor, or the unit may be tipped on its side (Figure A).

FIGURE A

3) Remove the clip from the pin and remove the pin attaching the incline motor to the rack (Figure B & C).

FIGURE B FIGURE C

46

Page 50

CHAPTER 9: PART REPLACEMENT GUIDE

9.11 INCLINE MOTOR REPLACEMENT - CONTINUED

4) Disconnect the incline motor power cable from the MCB (Figure D).

5) Disconnect the incline motor from the top mounting bracket (Figure E).

FIGURE D FIGURE E

6) Lift the incline motor away from the treadmill (Figure F).

7) Reverse Steps 1-6 to install a new incline motor. NOTE: When installing the new incline motor, make sure to replace the white washers at

the top and bottom (Figure G).

FIGURE F FIGURE G

8) Test the treadmill for function as outlined in Section 9.21.

47

Page 51

CHAPTER 9: PART REPLACEMENT GUIDE

9.12 CONSOLE REPLACEMENT

1) Turn off power to the treadmill and disconnect the power cord.

2) Remove the 4 screws holding the back cover onto the console (Figure A).

3) Remove the four 6 mm screws from underneath the console (Figure B).

FIGURE A FIGURE B

4) Disconnect the 4 wire connections from the console (Figure C).

5) Remove the console (Figure D).

FIGURE C FIGURE D

6) Reverse Steps 1-5 to install a new console.

7) Test the treadmill for function as outlined in Section 9.21.

48

Page 52

CHAPTER 9: PART REPLACEMENT GUIDE

9.13 EMERGENCY STOP SWITCH REPLACEMENT

1) Turn off power to the treadmill and remove the power cord.

2) Remove the console as outlined in Section 9.12.

3) Remove the 2 screws holding the red emergency stop key to the emergency stop frame (Figure A).

4) Remove the 2 screws holding the emergency stop frame to the console frame (Figure B).

FIGURE A FIGURE B

5) Using a flat screwdriver, flex the red emergency stop key to remove it from the emergency stop frame (Figures C & D).

FIGURE C FIGURE D

49

Page 53

CHAPTER 9: PART REPLACEMENT GUIDE

9.13 EMERGENCY STOP SWITCH REPLACEMENT - CONTINUED

6) Disconnect the 2 wires plugged into the back of the emergency stop switch (Figure E).

7) Depress the tabs on the top and the bottom of the emergency stop switch (Figure F).

FIGURE E FIGURE F

8) This will allow the emergency stop to be removed from the emergency stop frame (Figure G).

9) Reverse Steps 1-8 to install a new emergency stop switch. NOTE: If replacing the red emergency stop key, be sure to attach the safety clip

string to the red emergency stop key before re-installing it (Figure H).

FIGURE G FIGURE H

10) Test the treadmill for function as outlined in Section 9.21.

50

Page 54

CHAPTER 9: PART REPLACEMENT GUIDE

9.14 CONSOLE FRAME REPLACEMENT

1) Turn off power to the treadmill and disconnect the power cord.

2) Remove the console as outlined in Section 9.12.

3) Remove the 2 screws on each side holding the console frame to the handlebar frame (Figure A).

FIGURE A

4) Remove the console frame from the handlebar frame. NOTE: The console cable wiring will need to be removed from the console frame as

it is removed (Figure B).

FIGURE B

5) Reverse Steps 1-4 to install a new console frame.

6) Test the treadmill for function as outlined in Section 9.21.

51

Page 55

CHAPTER 9: PART REPLACEMENT GUIDE

9.15 HEART RATE BOARD REPLACEMENT

1) Turn off power to the treadmill and remove the power cord.

2) Remove the console as outlined in Section 9.12.

3) Remove the console frame as outlined in Section 9.14.

4) Remove the 2 screws holding the emergency stop frame to the console frame (Figure A).

5) Lay the console frame on its face and remove the 7 screws holding the back panel to the console frame and lean the console back out of

the way (Figure B).

FIGURE A FIGURE B

6) Disconnect the wire connections that go to the heart rate board (Figure C).

7) Remove the 2 screws holding the heart rate board to the console frame and remove it (Figure D).

FIGURE C FIGURE D

8) Reverse Steps 1-7 to install a new heart rate board.

9) Test the treadmill for function as outlined in Section 9.21.

52

Page 56

CHAPTER 9: PART REPLACEMENT GUIDE

9.16 SPEED OR INCLINE KEYPAD REPLACEMENT

1) Turn off power to the treadmill and remove the power cord.

2) Remove the console as outlined in Section 9.12.

3) Remove the console frame as outlined in Section 9.14.

4) Remove the 2 screws holding the emergency stop frame to the console frame (Figure A).

5) Lay the console frame on its face and remove the 7 screws holding the back panel to the console frame and lean the console back out of the

way (Figure B).

FIGURE A FIGURE B

6) Disconnect the ribbon cable of the affected keypad (Figures C & D).

FIGURE C

7) Peel the keypad up from the front side of the console and remove it.

8) Reverse Steps 1-7 to install a new keypad.

9) Test the treadmill for function as outlined in Section 9.21.

FIGURE D

53

Page 57

CHAPTER 9: PART REPLACEMENT GUIDE

9.17 HANDLEBAR FRAME REPLACEMENT

1) Turn off power to the treadmill and remove the power cord.

2) Remove the console as outlined in Section 9.12.

3) Remove the console frame as outlined in Section 9.14.

4) Remove the 3 screws on each side holding the handlebar frame to the console mast (Figure A).

FIGURE A

5) Lift the handlebar frame up and away from the console mast (Figure B). NOTE: The console cable wiring will need to be removed from the

handlebar frame on the user's right side as it is removed.

FIGURE B

6) Reverse Steps 1-5 to install a new handlebar frame.

7) Test the treadmill for function as outlined in Section 9.21.

54

Page 58

CHAPTER 9: PART REPLACEMENT GUIDE

9.18 HEART RATE HANDLEBAR REPLACEMENT

1) Turn off power to the treadmill and remove the power cord.

2) Remove the console as outlined in Section 9.12.

3) Remove the console frame as outlined in Section 9.14.

4) Remove the 3 screws on each side holding the handlebar frame to the console mast (Figure A).

5) Lift the handlebar frame up and away from the console mast (Figure B). NOTE: The console cable wiring will need to be removed from the

handlebar frame on the user's right side as it is removed.

FIGURE A FIGURE B

6) Remove the screw on each side holding the heart rate handlebar to the handlebar frame (Figure C).

FIGURE C

7) Pull the two sides of the handlebar frame away from each other and remove the heart rate handlebar from the handlebar frame.

8) Reverse Steps 1-7 to install a new heart rate handlebar.

9) Test the treadmill for function as outlined in Section 9.21.

55

Page 59

CHAPTER 9: PART REPLACEMENT GUIDE

9.19 HEART RATE GRIPS REPLACEMENT

1) Turn off power to the treadmill and remove the power cord.

2) Remove the 2 Phillips screws holding the 2 halves of the HR grip together (Figure A).

3) Disconnect the white wire from the bottom HR terminal and remove it (Figure B).

FIGURE A

4) Disconnect the red wire from the top HR terminal and remove it (Figure C).

FIGURE C

5) Reverse Steps 1-4 to install new HR grips.

6) Test the treadmill for function as outlined in Section 9.21.

FIGURE B

56

Page 60

CHAPTER 9: PART REPLACEMENT GUIDE

9.20 CONSOLE MAST REPLACEMENT

1) Turn off power to the treadmill and remove the power cord.

2) Remove the console as outlined in Section 9.12.

3) Remove the console frame as outlined in Section 9.14.

4) Remove the handlebar frame as outlined in Section 9.17.

5) Remove the motor cover as outlined in Section 9.1.

6) Remove the 4 screws holding the console mast to the base frame (Figure A).

7) Remove the console mast. NOTE: You will need to pull the console cable wiring through the hole in the bottom of the right side console

mast (Figure B).

FIGURE A FIGURE B

8) Reverse Steps 1-7 to install a new console mast. NOTE: Be sure to run the console cable wiring through the right side console mast prior

to mounting it to the base frame.

9) Test the treadmill for function as outlined in Section 9.21.

57

Page 61

CHAPTER 9: PART REPLACEMENT GUIDE

9.21 TESTING THE TREADMILL

ONCE THE TREADMILL OR REPLACEMENT PART IS FULLY INSTALLED AND

ASSEMBLED AND PROPERLY PLACED ON THE FLOOR, USE THE FOLLOWING

INSTRUCTIONS TO SETUP AND TEST THE MACHINE:

1) If the treadmill was just assembled or if any electronic component has been replaced (including if the console cable is unplugged for any

reason), the treadmill MUST be auto calibrated. Refer to the procedure in Section 3.4.

2) If the treadmill was just assembled or if the running belt, deck, or rollers are replaced, center and tension the running belt. Refer to the

procedure in Section 3.5.

3) Once Auto Calibration has been run and the running belt is centered, press GO on the display. Listen for any odd noises or squeaks.

4) Press the INCLINE UP key until the treadmill is raised to the maximum incline, then lower back down to the minimum incline. Listen for any

odd noises or squeaks during this procedure.

5) Press the SPEED UP key until the treadmill is raised to the maximum speed, then lower back down to the minimum speed. Listen for any

odd noises or squeaks during this procedure.

6) Grasp the heart rate grips to check for proper heart rate response.

7) Press and release the Emergency Stop to return to normal operation.

58

Page 62

CHAPTER 10: TREADMILL SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 TREADMILL SPECIFICATIONS

FEATURES

Deck Type Ultimate Hard-Wax reversible 1" deck

Belt Type Habisat - 2 ply commercial grade

Running Area 60" x 20"

Deck Step Height 7.5"

Cushion System Ultimate Deck Cushioning System

Incline Range 0-15%(1300lb.thrustinclinemotor)

Speed Range 0.5 - 12 mph / 0.8 - 20 km/h

Contact HR Sensors Yes

Telemetric HR Receiver Yes

Transport Wheels Yes

DRIVE SYSTEM

Motor Matrix 4.2 hp AC Dynamic Response Drive System™

Motor Controller Commercial Treadmill AC Drive

CONSOLE

Display Type Dot-Matrix LED

Display Feedback Time, Distance, Calories, Speed, Incline, Pace, Heart Rate,

Workouts Manual, Rolling Hills, Fat Burn, 5K, Target HR, Gerkin Protocol,

One-Button Quick Start Yes

CSAFE, FitLinxx Ready Yes

Pause Function Yes

On-the-fly Program Change Yes

Integrated Vista Clear Digital Ready TV No

Manager Mode Re-settable defaults with accumulated time and distance.

TECH SPECS

Overall Dimensions 84"L x 33.25"W x 52"H

Maximum User Weight 400 lbs / 181.4 kg

Weight 345 lbs / 156 kg

Shipping Weight 350 lbs / 159 kg

Electrical Requirements 120 Volt 20 Amp Dedicated Circuit required with a non-looped

METs, Watts, and Profile.

Army PFT, Navy PRT, Marine PFT, and Air Force PRT

ground.

59

Page 63

CHAPTER 10: TREADMILL SPECIFICATIONS AND ASSEMBLY GUIDE

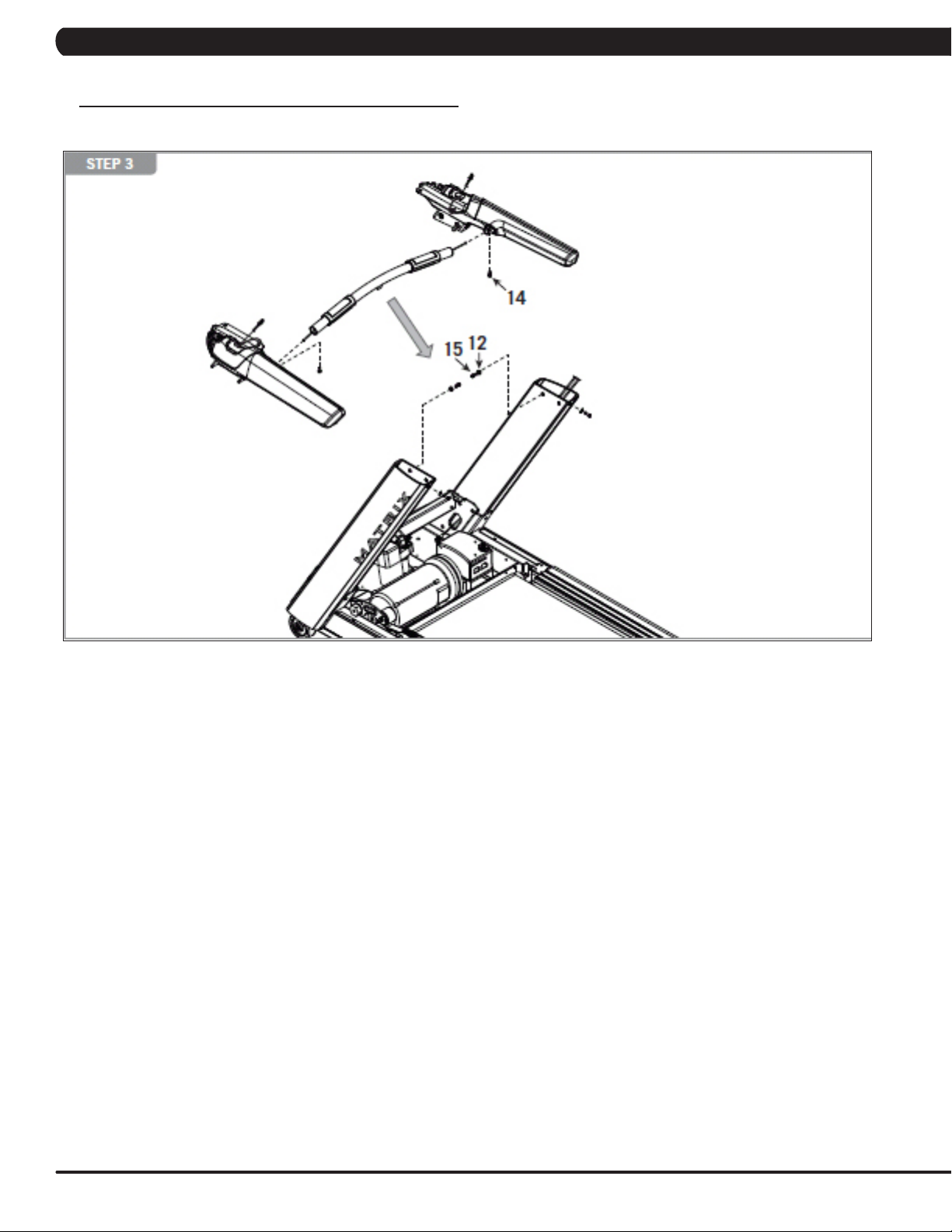

10.2 FASTENERS AND ASSEMBLY TOOLS

FRAME SET

PART # PART NAME DIAGRAM SPECIFICATION QUANTITY COLOR

11 Hex Head Cap Screw M8 x 1.25P x 25L 8 Blue

12 Flat Washer 8.2 x 19 2.0t 8 Blue

13 Hex Head Cap Screw M8 x 1.25P x 15L 6 Black

14 Button Head Screw M8 x 1.25P x 25L 6 White

15 Flat Washer 8.2 x 19 x 2.0t 6 White

CONSOLE SET

PART # PART NAME DIAGRAM SPECIFICATION QUANTITY COLOR

41 Hex Head Cap Screw M8 x 1.25P x 40L 4 Yellow

60

Page 64

CHAPTER 10: TREADMILL SPECIFICATIONS AND ASSEMBLY GUIDE

10.3 ASSEMBLY INSTRUCTIONS

ATTENTION

After assembly and installation is complete, the treadmill will need to be calibrated using the auto-calibration procedure outlined in Section 3.4.

DO NOT stand on the belt while the auto-calibration sequence is in progress.

Prior to assembling the treadmill, unpack all of the contents of the box and make sure that all necessary components are present. Review the

contents of the hardware package for completeness. Contact Matrix customer service at 866.693.4863 to report any missing items.

ASSEMBLY INSTRUCTIONS

Please make sure that the power cord is not plugged into the wall outlet while completing the following procedure.

To ensure correct assembly of the treadmill, carefully read and follow these steps:

Remove the motor cover(s) and set aside. The motor cover(s) need

to be removed to gain access to the motor compartment so that wire

harness connections can occur.

Open Blue Assembly Bag. Assemble both the left and right console

masts to the treadmill base using item 11 hex head cap screw and

item12atwasher.Threadtheconsolecablethroughtheright