Page 1

OPERATION & INSTALLATION MANUAL

MATRIX S3600 SILVER SERIES

REVERSE OSMOSIS

SYSTEM

Page 2

2

TABLE OF CONTENTS

PREFACE ....................................................................................................................... 5

A DISCUSSION OF REVERSE OSMOSIS ..................................................................... 6

THE MAIN COMPONENTS OF A WATERMAKER ........................................................ 8

THE SUBCOMPONENTS AND ACCESSORIES ......................................................... 10

DESIGN CONSIDERATIONS ....................................................................................... 13

TEMPERATURE CORRECTION TABLE ............................................................................................................ 15

OPERATING INSTRUMENTS ............................................................................................................................... 16

OPERATING INSTRUMENTS ............................................................................................................................... 17

PRODUCT WATER CONDUCTIVITY MEASUREMENT ................................................................................ 17

PRODUCT AND CONCENTRATE FLOW MEASUREMENT .......................................................................... 17

OPERATING PRESSURE MEASUREMENT ....................................................................................................... 17

FEED PRESSURE MEASUREMENTS .................................................................................................................. 17

MATRIX WATERMAKER LOG SHEET ............................................................................................................. 19

INSTALLATION INSTRUCTIONS ................................................................................ 20

PIPING MATERIAL ................................................................................................................................................ 20

FEED PIPING ................................ ................................................................ ............................................................ 20

CONCENTRATE PIPE ............................................................................................................................................ 20

OPERATING INSTRUCTIONS ..................................................................................... 26

MANUAL UNIT INITIAL START UP PROCEDURES ....................................................................................... 26

MANUAL UNIT NORMAL OPERATION ............................................................................................................ 28

AUTOMATIC UNIT INITIAL START UP PROCEDURES ................................................................ ................ 29

AUTOMATIC UNIT NORMAL OPERATION ..................................................................................................... 31

AUTOMATIC UNIT MANUAL START UP AND SHUT DOWN PROCEDURES .......................................... 32

Page 3

3

ROUTINE MAINTENANCE ........................................................................................... 33

SILVER SERIES MAINTENANCE SCHEDULE ................................................................................................. 33

MAINTENANCE OF PRE-FILTRATION COMPONENTS ............................................................................... 34

TO CHANGE THE BAG .......................................................................................................................................... 36

THE WATERMAKER .................................................................................................... 38

MEMBRANE STERILIZATION AND CLEANING PROCEDURES ............................... 39

TROUBLESHOOTING .................................................................................................. 44

ENGINEERING DATA .................................................................................................. 47

COMPONENT ILLUSTRATIONS ................................................................................. 48

Page 4

Page 5

5

PREFACE

This material is restricted and is for use only by the personnel who

need this information. It shall not be reproduced in any manner or

distributed for any purpose, whatsoever, except by written permission

of MATRIX Desalination, Inc.

The illustrations and instructions in this manual are based on

information available at the time of issue. We reserve the right to make

subsequent changes, or revise pages or sections, and to replace

existing copies without penalty.

INTRODUCTION

This manual is intended to aid you in understanding the principles of

Reverse Osmosis, and instruct you on how to properly operate the

MATRIX watermaker system.

Before you operate your new MATRIX watermaker it is recommended

that you READ THIS MANUAL FIRST!

Familiarize yourself with this manual now so that in the event of

complications, you can competently evaluate and correct the situation.

Page 6

6

SEAWATER DESALINATION:

A Discussion of Reverse Osmosis

Seawater contains many kinds of solids dissolved in solution. The most prevalent is

common table salt (Sodium Chloride). Present as well are other minerals, including

Calcium, Magnesium, Sulfate, Bicarbonate Alkalinity, Silica, and others. The sum of these

dissolved solids is referred to as the Total Dissolved Solids or T.D.S.

When sodium chloride (NaCl) is dissolved in water, the sodium (Na+) and the chloride (Cl-)

actually separate. When this occurs, each is called an ion and each has an electrical

charge. Sodium has a positive charge and is referred to as a cation (Na+). Chloride has a

negative charge and is referred to as an anion (Cl-). As the number of these cations and

anions increases, the ability of the water to conduct an electrical current increases, thus

one can measure the T.D.S. of the water by its ability to conduct current.

Most seawater averages between 35,000 and 38,000 PPM T.D.S., although variations of

up to 7,000 ppm are common in Middle East waters.

Required of any desalination process is the reduction of dissolved solids in water.

Thermal, membrane, or ion exchange processes are the most common methods of

desalination.

Reverse Osmosis (RO) is essentially a process for reducing dissolved solids in water.

This is accomplished by passing pressurized water over a semi-permeable membrane.

The membrane can be visualized as containing numerous tiny holes that allow the water

molecules to pass through. However, the holes are so small that they do not allow most

of the dissolved solids to pass through the membrane. These solids and the remaining

water (called the concentrate or brine) flow past the membrane surface and are piped to

drain. The water which goes through the membrane is called the permeate, or product

water.

The equipment used to desalinate water is referred to as a Reverse Osmosis system. It

must be remembered that the system cannot remove (“reject”) all the dissolved solids

from seawater. It is actually designed to reject approximately 99% of the T.D.S. or, in

other words, to allow 1% of the 38,000 PPM T.D.S. of the seawater to pass into the fresh

water. This yields water of less than 500 PPM of T.D.S (380 PPM). In this case, one

would refer to the system as having a T.D.S. passage, or salt passage, of 1%. However,

if the T.D.S. of the feed increases, there will be a corresponding increase in the level of

dissolved solids in the product water.

The fraction of the feedwater entering the system that then passes through the membrane

as product water is called the “recovery” (also called the conversion), and is usually stated

as a percentage, i.e., 25% recovery. Obviously, 100% of the feedwater cannot go through

Page 7

7

the membranes because there would be no water left to flush away the solids, which do

not pass through the membranes.

Normal recoveries for small seawater conversion units are in the range of 15-30%. At

20% recovery, for every 100 gallons of raw water fed to the RO system, 20 gallons are

recovered as purified water and 80 gallons are routed to waste as concentrated rejected

salts (brine). The same concept holds true for numbers expressed as gallons per minute,

cubic meters per hour, etc.

The rate at which water flows through the membrane is directly proportional to the driving

force available. The driving force is basically the difference between the pressure on the

feedwater (system pressure) and product water sides of the membrane and the difference

in osmotic pressure of the solutions on opposite sides of the membrane. The greater the

feed pressure the greater the driving force and product flow rate will be. Increasing the

pressure on the product side of the membrane decreases the driving force and therefore

lowers the product flow. The difference in salt concentration between the feedwater and

product water also reduces the driving force due to the difference in osmotic pressure,

which must be overcome.

It follows that if the pressure is raised and the concentrate flow rate consequently

decreases, the recovery increases. On the other hand, if the system pressure is held

fixed and the concentrate flow rate is made to decrease, the recovery also goes up. If, at

constant pressure, the concentrate flow is stopped altogether, the recovery is 100%. This

condition cannot last long. Most of the solid materials in the feedwater will adhere to the

membrane if not flushed from the membrane surface and vessel. Eventually, these

materials will so heavily coat the membrane that all flow will cease. This will result in the

rapid deterioration of the membrane. There must always be sufficient concentrate flow

to carry away the rejected dissolved solids and prevent concentrations that would

allow precipitation and resulting scaling of the membranes.

Pressure is not the only factor, which affects the product flow rate of the RO system.

Temperature of the feedwater can change the output by as much as 50% in the range

from nearly freezing to 95 degrees F (35 degrees C). As a general rule of thumb, product

flow from thin film composite RO systems will decrease by approximately 1.5% per 1

degree C decrease in feedwater temperature unless pressure corrections are made. The

capacity of the system therefore may vary seasonally with temperature.

The physical or chemical nature of many natural waters and industrial process waters is

such that it is not suitable to pump some waters directly into a Reverse Osmosis system.

Among the characteristics of water that may necessitate pre-treatment are suspended

solids (turbidity), the limited solubility of some salts, and strong chemicals such as acid or

chlorine, which chemically attack the membrane. Suspended solids (not to be confused

with dissolved solids) within the spiral wound element may gradually clog the flow path.

Some salts will crystallize from solution when concentrated, and may also clog the flow

paths.

Page 8

8

A common method of pretreatment is pre-filtration, which removes most of the suspended

matter from the feedwater. Although the RO system incorporates a pre-filter, some very

small particles pass through and have a tendency to collect on the membranes. In time ranging from months to years, depending on what is in the water - enough particles collect

inside the membrane housing that the membranes require cleaning. This is usually done

with detergents or other chemicals, as described in this manual.

Oxidizing chemicals, such as chlorine or bromine, dissolved oxygen, petroleum, solvents,

or halogens will degrade the salt rejection capability of the membranes. Adequate

pretreatment measures or operating procedures must ensure against their introduction

into the membrane systems.

Chemical post-treatment of RO water is often advisable. This is desirable to protect the

product water from re-contamination by harmful organisms such as bacteria while storing

the potable water. While the Reverse Osmosis process effectively removes bacteria from

seawater, the product water should be sterilized by chlorinating to guard against

contamination of the water after leaving the RO system's storage tanks.

Due to the very pure nature of RO product water, additional chemicals may be required to

protect against corrosion and add certain ions to the water for stability and/or taste.

THE MAIN COMPONENTS OF A WATERMAKER

The main components of any water maker, in order, are:

The supply pump, which supplies the feed water necessary for the high-

pressure pump to operate. The supply pump must have sufficient capacity

and good suction head properties to prevent cavitation. Dissolved gasses in

the feed water cause cavitation. As the feed water passes into the eye of the

impeller it is exposed to a low pressure. If the pressure is low enough for the

gasses to come out of solution it will make a crackling noise as the gasses

expand then collapse. Repeated or constant cavitation can be detrimental to

the pump impeller and casing. The noise level from cavitation will usually

increase and decrease with flow rate.

Another cause of noise in the supply pump is from air leaks in the suction

piping. This noise is usually constant. Air in the feed water will cause damage

to the ceramic plungers in the high-pressure pump as well as possible

damage to the membranes.

Filtration is the next and the most important part of any water-making unit.

This is done in various ways and usually in stages.

Cartridge filters are found on nearly all reverse osmosis systems. The

cartridge filter elements can be composed of different materials such as

paper, or polypropylene. They can be in a pleated, spun, melt-blown, or

Page 9

9

wound design. They are designed to be changed after they have become

fouled or clogged. Every water maker must have a final filter no larger than

five microns to help prevent fouling of the membranes. A 2-stage cartridge

filtration system incorporating a 30-micron filter followed by a 5-micron filter is

often used. This 2-stage configuration reduces the frequency at which the

filter elements become clogged.

Bag filters are another method of pre-filtering the water prior to the final

cartridge filter. These filters have a bag or sock inside, which are available in

different levels of micron filtration. These filters can be removed and cleaned

for reuse. The bag filter element can be cleaned several times before it needs

to be replaced.

A less common prefiltration type is the use of a multimedia tank, which will

have several different types of media (gravel, garnet, sand, etc.) loaded

inside, that will filter out the larger particles (25 microns) found in water. In

comparison, the diameter of a cross section of a human hair is 84 microns.

The advantage of using a media tank is in operating cost savings, as there

are no consumables required. To clean the filter, the flow of water is reversed,

and the particles that have been trapped by the filter, are then flushed out,

and dumped to waste.

Another type of filter, is an activated carbon filter. These filters can be

provided in configurations similar to the cartridge filter, or the media filter. The

activated carbon will absorb chlorine and organics in the water. Carbon filter

elements must be changed out periodically to remain effective.

High-pressure pumps or booster pumps vary in design, usually depending

on a specific application. Matrix uses only positive-displacement, plunger type

high-pressure pumps.

Pressure vessels house the membranes for a water maker. They are

manufactured from aluminum, stainless steel, or fiberglass. Generally

fiberglass pressure vessels are the most widely used because of their

resistance to corrosion, and lower cost. Pressure vessels can be produced in

assorted lengths, the shortest being for a single element (membrane).

Membranes consist of a semi-permeable thin-film composite layer

sandwiched between a permeate channel spacer and a feed channel spacer.

These layers are then spirally wound over a perforated plastic tube (product

tube). The layers are then covered with a shell of fiberglass. The actual

membrane is a thin porous film between two mesh like layers that serve as

spacers for the water to flow over. There are different types of membranes for

different purposes. The three basic types are freshwater, brackish, and

seawater. Their names refer to the type of feed water that will be applied.

Each membrane is designed for a specific rate of salt rejection, meaning that

Page 10

10

the membrane will only allow a certain amount of salts to pass through. When

two or more membranes are used in a pressure vessel, the product tubes are

connected by interconnects. These interconnects allow the product water to

flow continuously from one product tube of a membrane to another, without

being contaminated with the salt water feed flowing over them. The product

water then flows out the product tube and into the permeate port of the end

plug. The product water is then collected from each permeate port into a

manifold where there are sensors to detect the flow rate of water and the

quality of water.

The regulating valve is the primary means of controlling the operating

pressure of the system by restricting the concentrate flow rate.

THE SUBCOMPONENTS AND ACCESSORIES

Freshwater Flush Assembly

In order to extend the life of the membranes, MATRIX offers 4 fresh water flush options,

Manual, Solenoid Operated, Automatic, and Automatic with a flush tank. The first three

options use ship’s fresh water to flush the unit, and include a carbon filter to remove any

residual chlorine from the ship’s fresh water supply.

Manual System: This option incorporates a manual ball valve to isolate the feed

(seawater) and allow ship’s fresh water to the watermaker inlet. Ship’s pressure will flush

fresh water through the unit.

Solenoid Operated System: This option incorporates a solenoid-operated valve in place of

the manual ball valve, with a pushbutton on the RO unit control panel. Pressing the fresh

flush pushbutton starts the flush sequence. The solenoid valve will open allowing ship’s

water to flush the unit. After a pre-set time period, the solenoid valve will close.

Automatic System: This option is similar to the solenoid-operated system, except that the

flush sequence runs automatically whenever the unit shuts down, without operator

intervention.

Because the ship’s water may contain chlorine, the flush water is routed through a carbon

filter prior to the unit. The carbon filter will neutralize any residual chlorine in order to

protect the membranes from oxidation.

CAUTION: The carbon filter should be changed frequently to prevent damage to the

membranes by oxidation.

Automatic System with Flush Tank: This option includes a tank to store RO product water

to be used for flushing, and a flush pump to force the flush water through the unit. In this

configuration, the flush tank can also be used for chemical cleaning of the unit.

Page 11

11

Chemical Valve Assembly (Optional)

There are two (2) three way chemical valves that are available as an option that can be

plumbed to the suction port of the feed pump and the concentrate discharge on the unit.

Quick release fittings on one side of the valves enable chemical hoses to be stored when

the watermaker is in normal operation. In applications requiring a remote-mounted

supply pump, a separate cleaning system with pump can be provided for convenience.

Pressure gauges are used to indicate the pressure of the water at different

points in the system.

Flow meters show the flow of the concentrate (concentrated salt water that is

going to waste), and the product water. They are invaluable as they indicate

the recovery rate along with the production of the water maker. Again there

are different types such as the flow through indicators, and the digital or dial

type, which have small paddle wheels that spin as the water flows pass them.

The digital or dial type needs to be calibrated on a regular basis to insure their

accuracy.

Pressure switches are provided for safety, and for pump and membrane

protection. There are low pressure and high-pressure switches, each having a

certain function. The low-pressure switch is installed to shut down the water

maker in the event that the supply of water has been diminished for one

reason or another. This action protects the high-pressure pump. The high-

pressure switch is in place to shut down the water maker in the event that

the pressure after the high-pressure pump becomes too high. This action

prevents possible damage to the membranes, or other high-pressure

components.

Pressure relief valves are installed to prevent the build up of excessive

pressure in pipes and components. High-pressure relief valves are for safety

and to provide back up for the high-pressure switch, in case of failure. Lowpressure relief valves are used primarily for the accidental build up of

pressure in the PVC piping.

Conductivity Meters are included to monitor the quality of the water being

produced, and ensure that if the product quality does not meet specifications,

the water is diverted to waste. These monitors need to be calibrated on a

regular basis to ensure their accuracy.

ORP meters (optional) are used to monitor the incoming feed water to insure

that the oxidant level is low enough not to harm the membranes. They are

generally used to serve as a precautionary device. They measure the millivolt

level of the water, and they can be set up to shutdown the water maker in the

Page 12

12

event that an oxidant is found in the water. This action prevents membrane

damage.

Chemical injection systems (optional) are used to feed chemical solutions

to the feed and/or product water. Different chemicals can be applied to the

feed water depending on the need. The chemical tanks may have mixers if

the chemical is a powder and needs to stay mixed, to stay soluble. Since the

water that is produced is soft, from the lack of minerals and has no alkalinity,

chemicals may be added to raise the pH level and add minerals to reduce the

corrosivity and improve taste.

Accumulators (optional, depending on model) are containers, which have a

bladder inside that can dampen the pulsations that are produced from a

positive displacement pump. Pulsation dampener is another name for the

same component. Low-pressure accumulators use air to fill the bladder, high

pressure accumulators use nitrogen as it is inert and is not a flammable gas.

The pressures used, are generally 50 to 75% of the operating pressure that

the accumulator is in contact with.

Electrical control panels are used to provide the sequencing needed to

have a sequenced startup, and shut down of a reverse osmosis unit. They

also house the electrical controls and instruments. Matrix uses electric control

panels that are constructed to the NEMA 4X standard. The 4X rating ensures

that the electrical components will be protected from water, even if the water

is sprayed on the panel under pressure.

Remineralizers (optional) are vessels that contain a mixture of calcite and

corosex to add alkalinity and raise the pH of the product water in order to

reduce corrosivity and improve taste. The remineralizer incorporates a glove

valve to regulate the amount of minerals being added to the product water.

The remineralizer also includes a bypass valve to bypass the remineralizer

when it is out of service. The remineralizert should be located between the

product outlet on the RO unit and the inlet to the water storage tank.

The remineralizer load (calcite and corosex) will slowly lose it’s effectiveness

over time. The load should be replaced when the pH of the water leaving the

remineralizer is not higher than the pH of the water entering the remineralizer.

Ultraviolet Sterilizers (optional) are components that will destroy any

biological organisms in the water. Although the reverse osmosis system will

effectively remove all microorganisms, a UV sterilizer is recommended at the

outlet of the product water storage tank to ensure that any recontamination

that occurs in the tank (such as from contaminated shore water added to the

tank) is not passed to the point of use.

Page 13

13

DESIGN CONSIDERATIONS

WATER TEMPERATURE EFFECT

The water temperature significantly affects the product water flow rate through

the membrane. At any given pressure this flow increases with increasing

feedwater temperatures and decreases at lower feedwater temperatures. The

system design is based on expected product water output at 77°F. The water

temperature conversion chart illustrates the percent variance observed in

product water flow at temperatures other than the design basis (77°F). This data

set assumes that the operating pressure remains constant.

The graph of Production Capacity vs. Temperature demonstrates the capacity of

the watermaker versus temperature, when operating pressure adjustment is

taken into consideration. Starting at the right side of the graph, the watermaker

can be operated at constant production capacity as feedwater temperature

decreases, as long as the operating pressure is increased by closing the

concentrate control valve. At some minimum feedwater temperature, the

maximum operating pressure is reached, and no more adjustment can be made.

As the feedwater temperature continues to decline, the unit’s production capacity

will decline, since the operating pressure can no longer be increased to

compensate. The temperature at which the inflection point occurs varies with

watermaker model, feedwater salinity, membrane age, and a number of other

variables.

It is important that the maximum product flowrate, maximum operating pressure,

and maximum recovery rate of the watermaker are not exceeded.

It is recommended that the system not be operated at maximum pressures if

temperatures are significantly higher than 85°F for any length of time.

PRESSURE

The operating pressure has a direct effect on product water quality and quantity.

Both factors will increase as the system pressure increases (within design limits).

The system must be operated at the LOWEST pressure required to achieve the

designed product water flow rate. Always adjust the system pressure to the

specified PRODUCT flow, but do not exceed the specified recovery rate or

maximum operating pressure limit (950 psi).

BRINE VELOCITY

The brine flow over the membrane is very important to both product water quality

and quantity. The brine flow through an element should be maintained as given

Page 14

14

in the Design Data Sheet. At lower brine flows, concentration of sparingly

soluble salts will foul the membrane surface.

High brine velocities can also be a source of difficulty. At excessive flows the

elements are subjected to severe stress and physical damage such as

telescoping, glue-line fracture, etc. Irreparable membrane damage will result.

The total system has been designed with these factors in mind, and should be

controlled as specified in the operating procedures.

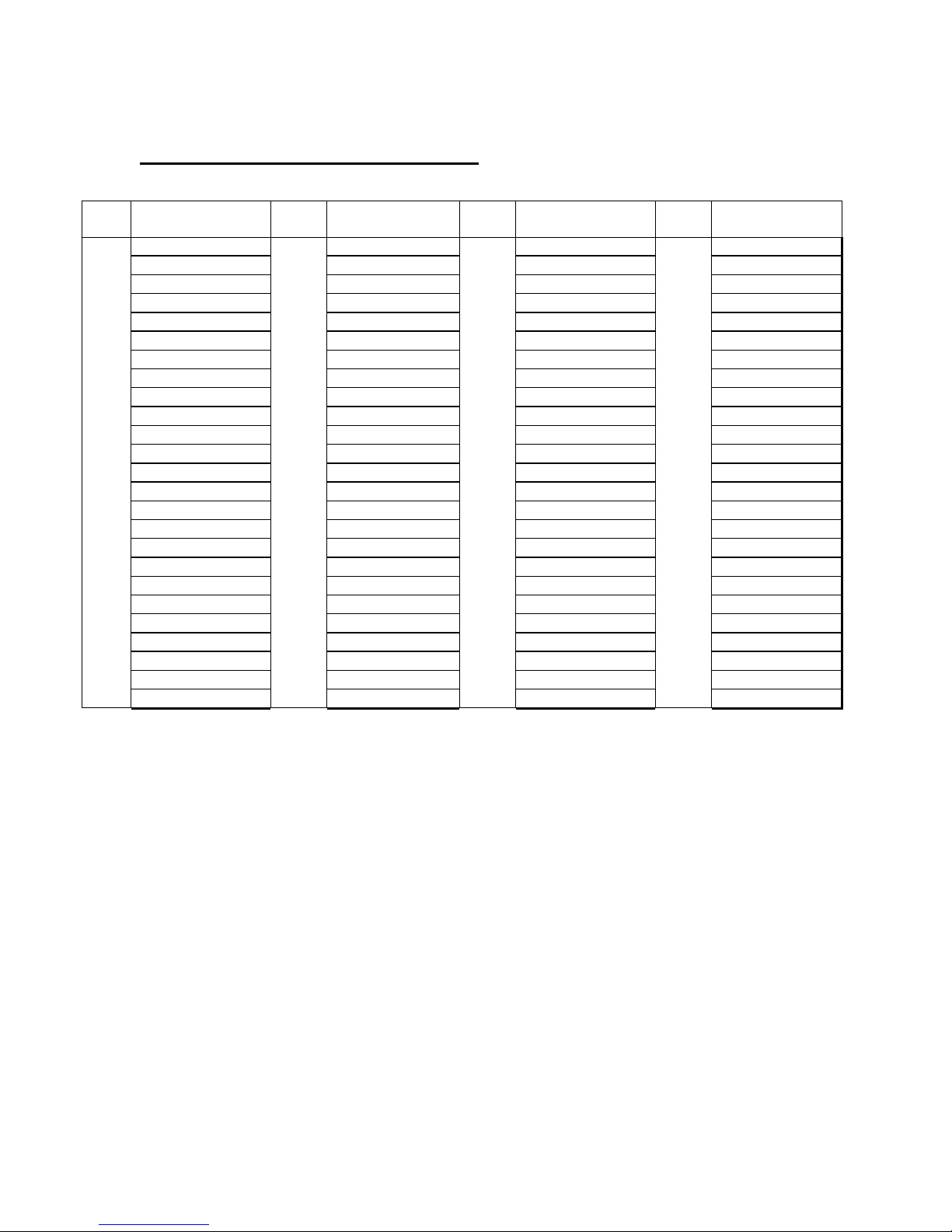

TEMPERATURE CORRECTION PROCEDURES

Procedure for correcting reverse osmosis system flow rate to compensate for

feed water temperature.

1. Refer to Section I of this manual for the Engineering Data on your unit.

2. Note the designed product flow at 77º Fahrenheit (25º C).

3. Note the temperature of the water presently being fed to the membranes.

4. From the “TEMPERATURE CORRECTION TABLE” find the correction factor

for the feed water temperature.

5. Divide the design product flow rate by the correction factor to get the product

flow rate for the feed temperature.

6. This quotient is the desired flow rate at the present temperature.

7. It may be possible to increase the product flow rate at lower temperatures by

increasing the operating pressure (by closing the concentrate control valve).

Caution should be exercised not to exceed the maximum product flowrate,

maximum operating pressure, or the maximum recovery rate of the

watermaker.

Note: In cold water expect to have less product flow from your watermaker. In

warm water your unit will produce more but you will extend the life of the

membranes by not exceeding the design flow rate. See the Temperature

Correction Chart for additional information on flow rates.

Page 15

15

°C

CORRECTION

°C

CORRECTION

°F

CORRECTION

°F

CORRECTION

FACTOR

FACTOR

FACTOR

FACTOR

1

3.64

26

0.97

34

3.47

82

0.90

2

3.23

27

0.94

36

3.18

84

0.88

3

3.03

38

0.91

38

2.93

86

0.82

4

2.78

29

0.88

40

2.68

88

0.79

5

2.58

30

0.85

42

2.47

90

0.79

6

2.38

31

0.83

44

2.29

92

0.77

7

2.22

32

0.80

46

2.14

94

0.75

8

2.11

33

0.77

48

2.01

96

0.73

9

2.00

34

0.75

50

1.88

98

0.70

10

1.89

35

0.73

52

1.77

100

0.68

11

1.78

36

0.71

54

1.68

102

0.65

12

1.68

37

0.69

56

1.59

104

0.63

13

1.61

38

0.67

58

1.51

106

0.61

14

1.54

39

0.65

60

1.44

108

0.59

15

1.47

40

0.63

62

1.36

110

0.57

16

1.39

41

0.61

64

1.30

112

0.55

17

1.34

42

0.60

66

1.24

114

0.53

18

1.29

43

0.58

68

1.17

116

0.51

19

1.24

44

0.56

70

1.12

118

0.49

20

1.19

45

0.54

72

1.08

120

0.47

21

1.15

46

0.53

74

1.05

122

0.45

22

1.11

47

0.51

76

1.02

23

1.08

48

0.49

77

1.00

24

1.04

49

0.47

78

0.97

25

1.00

50

0.46

80

0.93

TEMPERATURE CORRECTION TABLE

Page 16

16

Production Capacity vs. Temperature

Temperature (Deg F)

Product Capacity (GPD)

Operating Pressure vs. Temperature

Temperature (Deg F)

Operating Pressure (psi)

Page 17

17

OPERATING INSTRUMENTS

PRODUCT WATER CONDUCTIVITY MEASUREMENT

The conductivity meter that is located at the front of the electrical panel

measures the electrical conductivity of the product water. The meter is equipped

with an adjustable high point setting that allows the poor quality water to be

dumped to waste. This meter displays the salinity of the water in micromho’s or

microsiemens.

PRODUCT AND CONCENTRATE FLOW MEASUREMENT

The flow meters, located on the hydraulic control panel, monitor the flow rate of

the product and concentrate streams.

Reduced feedwater temperature, membrane fouling, etc., will cause a decrease

in product flow. An adjustment of the pressure control valve towards the closed

position will result in higher operating pressure; and increase the product flow.

OPERATING PRESSURE MEASUREMENT

The water pressure to which the membrane elements within the pressure

vessels are exposed is normally described as the R/O operating pressure.

Pressure gauges are mounted on the hydraulic panel for precise measurement

of the operating conditions.

Frequent reading and recording of each of these measurements is HIGHLY

important for evaluating system performance and in determining corrective

measures that may be required.

FEED PRESSURE MEASUREMENTS

Pressure gauges are provided at selected points in the feed system to monitor

the condition of the pretreatment components. The final feed pressure at the

high-pressure pump suction should never fall below 20 psi.

Page 18

Page 19

19

MATRIX WATERMAKER LOG SHEET

Date

System

Hours

Media/ Bag

Filter

Inlet

PSI

Media/

Bag

Filter

Outlet

PSI

Fine

Filter

Inlet

PSI

Fine Filter

Outlet

PSI

Mem. Feed

Press.

PSI

Product

Flow

GPM

Conc.

Flow

GPM

Product

Quality

Panel

(mmho)

Product

Quality

Hand

Meter

(mmho)

Initial

Date

Maintenance / Comments

Page 20

20

INSTALLATION INSTRUCTIONS

PIPING MATERIAL

In marine installations, when possible, the through-hull fitting, seacock, and feed piping

should be of non-corrosive materials such as fiberglass or thermo-plastics. However, in

cases where classification societies or insurance companies require metal through-hull

fittings and seacocks, the first choice of materials is 70/30 cupro-nickel. In cases where

other materials must be used, such as stainless steel or copper based alloys, it is

recommended to consult with MATRIX prior to installation.

In land-based applications, the recommended piping material is PVC Schedule 80.

PVC piping should be protected from direct sunlight, as UV light will cause the PVC

material to degrade over time.

NOTE: Iron, steel, copper, galvanized, or aluminum materials should never be used.

FEED PIPING

MATRIX recommends to increase the feedwater piping above the inlet size for the

system by one pipe diameter (except for stainless steel) whenever possible. Also

increasing the through-hull and seacock in marine applications, by one pipe size, is

normally a good practice.

Never reduce piping or valving diameters under the minimum specified size for your

particular watermaker.

CONCENTRATE PIPE

In normal conditions the concentrate overboard piping can remain the same size as

recommended in the watermaker specification sheet. Backpressure should be kept as

low as possible. Normal backpressure should be less than 25 psi.

PRODUCT WATER PIPING

No increase in product water piping, above the specified dimension, is normally

required.

It is very important to keep the pressure (membrane backpressure) of the product water

to a minimum. The membrane backpressure is ideally kept under 10 psi and in no case

should ever exceed 30 psi. It is strongly recommended that the product water piping be

configured such that there is an air gap where the product piping enters the product

Page 21

21

holding tank. The air gap will ensure that no stored water (which may contain chlorine)

can be drawn back into the watermaker when the watermaker is not in operation.

CAUTION: Rupture of the membrane envelope may occur if the product

backpressure is exceeded.

GENERAL INTAKE LOCATION

The intake (feedwater) location and associated plumbing is an aspect to be carefully

considered. Any restrictions in the feedwater plumbing could degrade the performance

of the watermaker as well as compromise the life of the system.

In marine installations, the through-hull fitting should be located as far below the water

line and normally as far forward as possible. Consideration of hull design should be

taken into account.

If the intake is to be incorporated into a sea chest, then locate this as low as practical

on the chest. Never take suction from the top of the sea chest, as air introduction may

occur.

If the ship has a sewage treatment system, the RO feed should be located as far away

as possible from the sewage plant discharge (preferably on the opposite side of the

hull). The treated sewage effluent usually contains high levels of chlorine, and if

ingested by the watermaker, will destroy the membranes.

CAUTION: Never place zinc anodes within 6 feet of the watermaker intake.

For land-based installations where a well or direct seawater intake is to be used, the

user must ensure that the feedwater is clean, and does not contain silt, suspended

solids, oils, or oxidizing agents.

FEED (SUPPLY) PUMP

The feed pump must have a flooded suction, as the pump is not self-priming. If the

pump is mounted above the vessel waterline, a suitable foot/check valve must be

installed and the pump primed prior to start up. The pump should be located as close

to the feed water supply as possible, with short and direct plumbing. Avoid high points,

which form air pockets.

If the feed pump is remote mounted (such as in a land-based application), ensure that it

is properly secured to a firm base. It will be necessary to run power wiring from the RO

cabinet to the remote mounted feed/supply pump. A suitable electrical disconnect

should be installed at the remote pump location in order to ensure personnel safety and

meet electrical code requirements.

Page 22

22

If you desire to provide your own supply pump, contact Matrix so that we can ensure

that the pressure and flow of the pump are sufficient, and that the control of the pump

can be properly integrated into the watermaker control system.

BAG FILTER (Optional)

This filter should be mounted vertically. It should be firmly secured at the base. In

marine installations, the filter should also be secured higher up on the chamber.

Allowance should be made to be able to unfasten the lug bolts securing the top plate of

the filter. Adequate clearance should be given at the top of the filter to enable bag

change when necessary.

Isolation valves can be installed on the suction and discharge lines to the housings to

reduce spillage when changing bags. These can be supplied as an option by request

MEDIA FILTER (Optional)

The media tank should be mounted vertically and, in marine installations, located with

consideration to unit weight and vessel displacement.

The filter should be mounted firmly at the base and, in marine applications also higher

up on the tank. Ensure that direction of flow through the tank is consistent with that

indicated on the tank hub. Gauges are supplied on the inlet and outlet to this filter for

monitoring of the differential pressure across it.

MEDIA TANK LOADING INSTRUCTIONS

After locating the MATRIX media filter to its permanent location the media tank will

have to be loaded. The media load will consist of bags and or boxes of pre-measured

ingredients, i.e. gravel, sand, garnet, carbon or anthracite. The media will have to be

loaded into the tank in the correct sequence and to the proper levels. The first media to

be loaded is the gravel. Before loading, some disassembly of the tank head and

plumbing is required.

The media tank assembly consists of a tank with a threaded head (cap) on top. This

head has two (2) ports on each side, which are plumbed to two (2) 3-way valves. There

is a small engraved “I” and “O” above the ports on the top of the head. To remove the

head from the tank, the two valves nuts must be unscrewed at the valves. The head

may now be unscrewed from the tank. Upon removal of the head, a PVC tube will be

found inserted into the center hole. This tube will have to be pulled out of the head, and

capped off with tape to prevent any media to fall inside and plugging the distributor on

the bottom of the tube. This PVC tube should be placed into the tank during the loading

of the media and held into position, so that the top end is flush with the top of the tank

and that it is in the center of the opening. After the media has been loaded, the tape

should be removed from the PVC tube. This procedure will enable the replacement of

the head to the tank.

Page 23

23

Once the head has been removed, mask off the tank internal threads with tape to

protect the threads during media loading. Locate the first load associated with that

particular tank. After the proper media is set aside for the tank, loading may begin.

First scoop or pour the gravel into the opening on top of the tank where the head was.

This first layer should cover the top of the distributor. Remember to hold the PVC tube

during this procedure. After all of the gravel has been loaded for that tank, use a pole or

piece of PVC pipe to level out the first layer. This should be done after each different

media is loaded. After the gravel is loaded, the pipe should stay in place, and will not

have to be held any longer.

The second media to load is the garnet #12; this is slightly coarser and larger in size

than the garnet #50. Again when a particular media is finished loading, level that layer.

The third media to be loaded is the garnet #50.

The next (fourth) media to be loaded is the sand.

The fifth and final load is the anthracite.

After the tank has been loaded, the top of the media should fill the tank two thirds (2/3)

to three-fourths (3/4) full. Remove the tape protecting the tank internal threads. Place a

hose in the tank to slowly fill the tank with water, without disturbing the media. During

this time the threads on top of the tank should be washed thoroughly to aid the

replacement of the head.

The head contains two (2) o-rings, which should be lubricated with a silicone-based

lubricant. Check that they are installed, and that they are in correct position. Remember

to remove the tape from the PVC pipe and slowly turn the head to install the head into

the tank. After this check the alignment of the piping and turn the tank if needed to

ensure proper alignment.

It is very important that the inlet (I) and outlet (O) are in the correct position after all the

plumbing has been reconnected. In the Service mode, the water will exit the supply

pump and enter the media tank through the inlet port. The water will then exit the outlet

port of the media tank and flow to the inlet of the cartridge filter(s).

In the Back flush mode the three way valves on either side of the head will be turned

180 degrees. This will reverse the flow of water so that it will enter the outlet of the tank

and exit the inlet side and be discharged to waste. It will be necessary to install a waste

discharge hose from the media filter backwash discharge fitting, and route the effluent

overboard. The backwash process removes any small debris or material that have

accumulated in the media filter. This process can take as little as fifteen (15) minutes or

as much as four hours depending on what has been accumulated during Service.

Page 24

24

After the tank is loaded, and the plumbing has been replaced the tank can now be

backflushed. The initial backwash will sometimes take two to four hours to discharge all

of the loose material in the media. During this time, loosen the vent plugs located on the

tank heads. This will expel the air in the system.

After the initial backwash is completed, and all air has been purged from the tank, the

media filter can be placed into service.

THE WATERMAKER CABINET

The cabinet requires a solid base. The cabinet should not be mounted above any

electrical apparatus. Allowances, with regard to access, should be made for ease of

maintenance. Ideally, there should be 48” of clearance on either side of the cabinet and

36” above the cabinet for easy maintenance.

Holes should be drilled in the base on which the watermaker is to be mounted that line

up with the vibration mounts for the watermaker. Once in place, the watermaker should

be secured to the base using stainless steel bolts, nuts, and lockwashers.

COMPONENT MODELS

Mount the individual components (hydropanel, supply pump, high-pressure pump

assembly, pressure vessel rack, and prefilters) in such a way to allow easy access for

maintenance, and to minimize piping lengths between components.

Make piping connections between each of the individual components using the piping

and hoses provided in the installation kit. Each individual IN/OUT connection is

lableled. Simply connect piping between matching letters (“A” to “A”, “B” to “B”, etc.).

See connection table at the end of this manual.

FRESHWATER FLUSH (Optional)

If the unit is using ship’s water (or house water) for flushing, plumb a hose from the

pressurized fresh water supply to the flush inlet on the watermaker. If the unit

incorporates a flush tank, ensure that the tank is securely mounted and plumb a hose

from the flush pump discharge to the flush inlet on the watermaker.

AUTOMATIC START/STOP

If your watermaker is configured to accept external inputs to start and stop the unit,

note the following information. Typically, 2 float switches are installed in the product

water storage tank. When the level in the storage tank becomes low, the LOW level

float switch is activated, closing a contact in the control circuit causing the unit to start.

When the product tank is full, the HIGH level float switch is activated, opening a second

Page 25

25

contact in the control circuit causing the unit to shut down. The unit will automatically

fresh flush after shutdown. No operator intervention is required when the unit is in

automatic operating mode.

Refer to the electrical schematic at the end of this manual for float switch wiring

instructions.

REMINERALIZER (Optional)

The remineralizer tank should be mounted vertically and, in marine installations, located

with consideration to unit weight and vessel displacement. The flow through a

remineralizer is reverse that of normal media filtration as the purpose is to chemically

modify the water and any filtration would be redundant. Connect the product outlet on

the RO watermaker to the fast&tite fitting inlet on the remineralizer tank assembly.

Connect the outlet to the product storage tank.

The filter should be mounted.

Page 26

26

OPERATING INSTRUCTIONS

MANUAL UNIT INITIAL START UP PROCEDURES

Normally after installation of the R/O either a MATRIX technician or authorized

representative should be present on initial system start up.

In all cases, if working with electricity, a qualified electrician should be present.

1. Ensure that all switches on the RO control panel are in the OFF position.

2. Turn the main breaker on.

3. Ensure that both the line voltage and frequency are correct for the unit.

4. Ensure all suction and discharge valves are in the correct position. Ensure that

chemical clean suction and discharge valves are in the correct position. Disconnect

the product water line to the storage tanks and direct to waste. This is to ensure that

all chemicals are adequately flushed out that were placed into the system at the

factory.

5. Ensure the high pressure-regulating valve is fully opened (counter-clockwise).

This valve is often in a closed position for membrane sterilization.

6. Ensure that the oil level of the high-pressure pump is half way up on the pump sight

glass.

7. Check rotation of the pumps. Open the electrical panel on the watermaker and

locate the contactor for the high-pressure pump, it should be labeled M1 and be

located at the bottom right of the panel. Turn the Off/Run/Start switch to the Run

position and then momentarily press the manual button on the contactor to supply

voltage to the high-pressure pump. The pump will momentarily start up. With the aid

of a second person check the rotation of the pump. Ensure the rotation complies

with the arrow found on top face the pump. If rotation is opposite to the direction of

the arrow and the unit is three-phase, turn off the control power and the main

breaker then switch two of the three wires supplying the main power to the electrical

panel. If the unit is single phase then the wiring will have to be corrected at each

motor. Repeat the process for the supply pump using the contactor labeled M2.

8. If the unit is equipped with a media filter, place the media filter valves in backwash

mode, restart the supply pump, and perform a thorough backwash of the media

filter.

Page 27

27

9. Once correct rotation has been verified, restart the supply pump by turning the

Off/Run/Start switch to Start and while the supply pump is running, check for leaks.

If leaks are observed turn off the control power and make necessary repairs.

10. With the supply pump running, purge air from the cartridge filter(s) by pressing the

small red button on the top of the cartridge filter housing. Hold the button in until no

more air escapes. If a media or bag filter is installed, purge air from the tank or filter

housing by opening the vent valve on the top of the tank or housing and allow all air

to escape.

11. When no large air bubbles are visible in the water flow in the concentrate flowmeter,

the high-pressure pump can be started up by turning the Off/Run/Start switch to the

Run position.

12. With both pumps running, check for leaks. If leaks are observed, turn off the control

power, and make necessary repairs.

13. With both pumps running, the high-pressure regulating valve should be adjusted to

achieve the desired flow rate of product water. The regulating pressure valve should

be slowly turned in the clockwise direction when bringing the system up to pressure.

If any leaks are observed, the pressure should be backed off slowly by turning the

regulating pressure valve counter clockwise.

14. After a period of one hour, the product water line can be reconnected to the storage

tanks.

15. With the unit operating at the correct product flow rate, record initial system readings

on the logsheet found in this manual.

YOU MUST ALWAYS USE EXTEME CAUTION WHEN ENTERING THE

ELECTRICAL CONTROL PANEL, OR WORKING ON ANY PART OF THE

ELECTRICAL SYSTEM OF THIS UNIT.

FAILURE TO DO SO CAN RESULT IN DEADLY SHOCK.

FAILURE TO COMPLY WITH ANY INSTRUCTIONS ABOVE, WILL, IN MOST

CASES, RESULT IN EQUIPMENT DAMAGE, AND POSSIBLY VOID THE

WARRANTY.

Page 28

28

MANUAL UNIT NORMAL OPERATION

1. Turn the main breaker on.

2. Ensure all suction and discharge valves are in the correct position.

3. Ensure the high pressure-regulating valve is fully opened (counter-clockwise).

4. Turn the Off/Run/Start switch to the Start position. The Feed Pump running light will

illuminate.

5. When there is water flowing in the Concentrate Flowmeter and the red Low

Pressure light has shut off, the high-pressure pump can be started.

6. Turn the Off/Run/Start switch to the Run position. The High-Pressure Pump running

light will illuminate.

7. With both pumps running, the high-pressure regulating valve can now be slowly

increased to achieve the desired flow rate for the product water.

8. With the unit operating at the correct pressures and flow rates, record system

readings on the logsheet. This will aid in diagnosing any problems that may occur in

the future.

9. When ready to shut down the unit, the regulating valve should be fully opened to

reduce the pressure.

10. After the pressure is reduced, turn the Off/Run/Start switch to the Off position.

11. The unit is now ready to be flushed.

a. If the unit has the “Automatic Solenoid Flush on Shutdown” option, flushing is

initiated by turning the Off/Run/Start to the “Off” position. If there is need to stop

the flush simply turn off the panel disconnect. Daily flushing can be

accomplished by momentarily placing the Off/Run/Start switch to “Run” and

returning to “Off”. The solenoid will automatically close after a preset time limit

(4-7 minutes).

b. If the unit has an automatic flush the switch should be returned to the run

position and the fresh water flush button depressed. It will automatically time

itself and shut off. The solenoid will automatically close after a preset time limit

(2-7 minutes).

c. If the unit has a manual fresh flush, open the flush valve, and allow fresh water

to flush the unit for 5 minutes.

Page 29

29

AUTOMATIC UNIT INITIAL START UP PROCEDURES

Normally after installation of the R/O either a MATRIX technician or authorized

representative should be present on initial system start up.

In all cases, if working with electricity, a qualified electrician should be present.

Turn the OFF/RUN/START switch to OFF. Turn the MANUAL/AUTO switch to

MANUAL. Turn the RUN/OFF/FLUSH switch to OFF.

Turn on the main breaker supplying power to the unit.

Ensure line voltage and frequency is correct for the unit.

Ensure all suction and discharge valves are in the correct position. Ensure that

chemical clean suction and discharge valves are in the correct position. Disconnect the

product water line to the storage tanks and direct to waste. This is to ensure that all

chemicals are adequately flushed out that were placed into the system at the factory.

Ensure the high pressure-regulating valve is fully opened (counter-clockwise).

Ensure that the oil level of the high-pressure pump is half way up on the pump sight

glass.

Check rotation of the pumps as follows:

Turn the OFF/RUN/START switch to the RUN position and then back off. The supply

pump will briefly operate. Ensure that the rotation is correct. Restart the supply pump by

turning the OFF/RUN/START switch to RUN. While the supply pump is running, check

for leaks. If leaks are observed turn off the control power and make necessary repairs.

Allow the supply pump to run to fully flush the feed piping. If a media filter is installed,

perform a backwash of the media filter.

Open the electrical panel on the watermaker and locate the contactor for the highpressure pump, it should be labeled M1 and be located at the bottom right of the panel.

Turn the OFF/RUN/START switch to the RUN position and then momentarily press the

manual button on the contactor to supply voltage to the high-pressure pump. The pump

will momentarily start up. With the aid of a second person check the rotation of the

pump. Ensure the rotation complies with the arrow found on top face the pump. If

rotation is opposite to the direction of the arrow and the unit is three phase, turn off the

control power and the main breaker then switch two of the three wires supplying the

main power to the electrical panel. If the unit is single phase then the wiring will have to

be corrected at each motor.

Page 30

30

When no large air bubbles are visible in the water flow in the concentrate flowmeter, the

unit can be started (see Startup and Shutdown Procedures)

With the unit running, check for leaks. If leaks are observed, turn off the unit, and make

necessary repairs.

With the unit running, the high-pressure regulating valve should be adjusted to achieve

the desired flow rate of product water. The pressure-regulating valve should be slowly

turned in the clockwise direction when bringing the system up to pressure. If any leaks

are observed, the pressure should be backed off slowly by turning the regulating

pressure valve counter clockwise.

After a period of one hour, the product water line can be reconnected to the storage

tanks.

With the unit operating at the correct product flow rate, record initial system readings on

the logsheet found in this manual.

YOU MUST ALWAYS USE EXTEME CAUTION WHEN ENTERING THE

ELECTRICAL CONTROL PANEL, OR WORKING ON ANY PART OF THE

ELECTRICAL SYSTEM OF THIS UNIT.

FAILURE TO DO SO CAN RESULT IN DEADLY SHOCK.

FAILURE TO COMPLY WITH ANY INSTRUCTIONS ABOVE, WILL, IN MOST

CASES, RESULT IN EQUIPMENT DAMAGE, AND POSSIBLY VOID THE

WARRANTY.

Page 31

31

AUTOMATIC UNIT NORMAL OPERATION

Prior to setting the unit to AUTO for the first time, run the unit in MANUAL to ensure that

the high-pressure regulating valve is set to the correct position. Once this has been

accomplished, shut the unit down.

Place the MANUAL/AUTO switch in AUTO

Turn the OFF/RUN/START switch to the RUN position.

Turn the FLUSH switch to RUN. This will arm the flush system to start automatically

after the unit shuts down.

When the product storage tank level is low, the tank level switch will close a contact,

commanding the unit to start automatically. The supply pump will start first, followed by

the high-pressure pump after a time delay.

With the unit operating at the correct pressures and flow rates, record system readings

on the logsheet. This will aid in diagnosing any problems that may occur in the future.

When the product storage tank is full, the level switch contact will open, and the unit will

automatically shut down. Once the unit has shut down, the fresh flush sequence will

automatically run.

After the fresh flush sequence is complete, the unit is in standby mode, and will restart

when the product storage tank level switch indicates a low condition.

It is recommended that the unit be tested in automatic mode by manually activivating

the float switches (bench test) prior to allowing the unit to operate unattended.

Page 32

32

AUTOMATIC UNIT MANUAL START UP AND SHUT DOWN PROCEDURES

If external float switches are not installed, it will be necessary to install a jumper wire on

terminals 3 and 4 in the control panel to simulate a normally closed contact from the

product storage tank level switch.

Ensure all suction and discharge valves are in the correct position.

Ensure the high pressure-regulating valve is fully opened (counter-clockwise).

Verify that the OFF/RUN/START switch is in the OFF position.

Place the MANUAL/AUTO switch in AUTO.

Place the RUN/OFF/FLUSH switch to RUN.

Turn the OFF/RUN/START switch to the START position and release. The switch is

spring loaded to return to the RUN position. The supply pump will start. After a time

delay, the high-pressure pump will start.

With both pumps running, the high-pressure regulating valve can now be slowly

adjusted to achieve the desired flow rate of product water.

To shut down the unit, turn the RUN/OFF/FLUSH switch to OFF. The unit will shut

down, and the fresh flush sequence will run automatically. At the end of the flush

sequence, turn the RUN/OFF/FLUSH switch to RUN.

The unit is now in standby mode. To restart the unit, turn the OFF/RUN/START switch

to START and release.

Page 33

33

ROUTINE MAINTENANCE

SILVER SERIES MAINTENANCE SCHEDULE

Seacock – Open and close each month to ease operation

Sea Strainer - Check every two weeks or when it is suspected that it needs cleaning.

Supply Pump – Replace mechanical seal when leakage occurs. Check impeller for

debris when rebuilding pump and when loss of flow occurs.

Supply Pump Motor – Grease motor bearings once every three months with MATRIX

SRI No. 2 Grease.

Media Filter – Backflush when there is a 15 psi or more differential between the inlet

and outlet of the filter. Sterilize filter with D-20 if the unit is not going to be used for two

weeks or more. Back flush filter for 30 minutes when returning to service.

Bag Filter – Change bag when there is a 15 psi or more differential between the inlet

and outlet of the filter. Ensure that the filter housing is clean of debris when replacing

bag by rinsing the housing and allowing to drain.

Cartridge Filter – Change filter(s) when the pump suction/fine filter outlet pressure is

between 15 and 20 psi. Ensure housing is free of debris and clean and rinse as is

necessary. Flush filters with fresh water before changing, this will prevent salt water

from spilling on other components.

CAUTION: Failure to completely clean all dirt and debris from the filter housing

will allow debris to enter the membranes. The will foul the membranes, and will

void the warranty.

Carbon Filter – Change filter(s) every three months.

CAUTION: Failure to change the carbon filter regularly may allow chlorine

contamination of the membranes. The will destroy the membranes, and will void

the warranty.

High Pressure Pump – Replace seals and valves when there is leakage or when there

is a loss of flow. Flush pump after each use with fresh water. Change pump oil first 50

hours and after every 500 hours with MATRIX Pump Oil.

High Pressure Pump Motor – Grease motor every three months with MATRIX SRI No. 2

grease.

Page 34

34

Membranes – Clean membranes every six months with general cleaning chemicals or

as needed. If there is suspected fouling then clean the membranes with the chemical

that is best prescribed. Always sterilize the membranes when they will not be used for

one week or more to prevent bacteria from growing. Flush the membranes with fresh

water after each use.

Gauges – Replace gauges when necessary. Clean glass and base when needed.

Flow Meters – Clean with mild detergent when necessary. Do not expose the flow

meters to Zylene or similar solvents and thinners. Flush flow meters after cleaning with

fresh water.

PVC Fittings – Threaded fittings should be removed and new Teflon tape applied when

leaks occur. The fitting should be replaced if necessary. Fittings should be cleaned on

the exterior when necessary.

Stainless Steel Fittings – The fittings should be cleaned and polished when necessary.

Leaks should be attended to immediately to prevent corrosion damage. Threaded

fittings should be removed and new Teflon tape applied when leaks occur. The fitting

and ferrules should be replaced if necessary.

High Pressure Switch – Should be adjusted as necessary to ensure the correct setting

of 950 psi. Switch should be replaced immediately if malfunctioning.

Low Pressure Switch – Should be adjusted as necessary to ensure the correct setting

of 15 psi. Switch should be replaced immediately if malfunctioning.

Electrical Components – Replace as is necessary.

Fuses - Replace as is necessary.

Frame, Supports and Brackets – Clean and polish when necessary. Touch-up any

marred or chipped paint to prevent corrosion.

MAINTENANCE OF PRE-FILTRATION COMPONENTS

The pretreatment of the feedwater is one of the most critical aspects of reliable, long-

term performance of the R/O elements.

Turbidity and suspended particles must be removed from the feedwater prior to the R/O

portion of the system, otherwise damage will occur to the sensitive instruments, highpressure pump, and specifically the membrane elements.

Mechanical plugging of the elements by particles is one of the most difficult forms of

fouling to correct. In some cases, mechanical fouling can be irreversible, resulting in

costly element replacement.

Page 35

35

Although this system utilizes the finest prefiltration available, improper service can still

result in this problem. By changing filters and not flushing out the chamber, or re-using

old cartridges; a "sludge" of particle contaminated water will flow to the elements and

some particles will become lodged within the brine spacer, or if large enough, plug the

feedwater end of the element. Repeated occurrences will obviously increase this fouling

problem.

Also, using other than specified types and qualities of prefilter replacements can

increase the potential of mechanical fouling.

MEDIA TANK FILTRATION

The media is designed to catch particles of 25 micron or greater. When the pressure

drop across the media filter exceeds 15 psi, it is necessary to backflush the system.

Only the supply pump is used to clean the media tank, pushing seawater through the

media, but in the opposite direction of normal flow.

BACKFLUSH PROCEDURE

1. Place the two three way valves in the backflush mode. This requires turning the

valve handles 180 degrees from the normal operating position.

2. Turn the Off/Run/Start switch to the Start position. The supply pump will then start

up and provide water to the media filter.

3. The duration of the time of the backflush depends on how badly the media tank is

clogged. With the watermaker in continuous duty it is recommended that the

operator perform this operation at least once a week.

4. Generally one hour is sufficient to adequately backflush the filter. Once this is done,

turn the Off/Run/Start switch to the Off position.

5. Place the valves in the normal service operating position.

6. The system is now ready for return to service. Note all pressure and flow rates on

system when restarted.

The high-pressure pump does not run in the media tank backflush mode.

BAG FILTER

The bag filter assembly is provided with a polypropylene large capacity bag filter. These

bags provide a large holding capacity and good particle retention while being

substantially lighter than media filters. Approximate wet weight of each of the filters is

250 pounds compared with a properly sized media filter, which would weigh between

Page 36

36

1000-2000 pounds. The bag filters are non-corrosive and are rated up to 150 psi.

operating pressure.

There is no backflushing procedure for this type of filter. When the pressure gauge

shows a pressure drop of 15 psi., simply remove the bag, and clean with fresh,

dechlorinated water. The bag can be cleaned several times before replacement. After

cleaning, carefully inspect the bag for holes or signs of wear. Replace the bag if any

defects are noted.

TO CHANGE THE BAG

1. Shut down the system.

2. Isolate the filter by closing valving on the intake and discharge (if installed ) of the

unit.

3. Remove the line that is attached to the top of the filter, if necessary. If hard piped,

there should be a union for easy removal. If connected by hose there should be

adequate hose to remove the cover with out disconnecting the hose.

4. Loosen the wing nuts found on top of the chamber which secure the cover plate.

The bolts should swing down to the sides.

5. Apply steady pressure and evenly lift up the cover plate.

6. Loosen the collar on top of the cover by holding the disk that is inside the bag, while

unscrewing the collar. Be careful not to fully unscrew the disk, only loosen enough

for bag removal.

7. If particles are noticed in the remaining water left in the chamber, flush out well with

dechlorinated fresh or salt water until cleared.

8. Carefully place a new bag in the chamber and place so that there are no folds or

pleats in the bag.

9. Replace cover and lugs. Do not overtighten these lugs. Hand tightening is adequate.

10. Return all valves to normal service positions.

11. Start the supply pump and purge air from the chamber with the air bleed fitting (if

installed) on the top of the cover plate.

12. Return system to normal operation. Note all pressure and flow rates.

Page 37

37

CARTRIDGE FILTRATION

Cartridge filter assemblies are provided for removal of suspended solids of 5 micron, or

greater, that could damage the high-pressure pump and/or foul the membranes.

A pressure gauge is provided to facilitate the monitoring of the feedwater supply

pressure to the H.P. pump.

The cartridge elements should normally be changed before the pressure to the high-

pressure pump suction falls below 15 psi. Each filter chamber requires one cartridge

element rated at five (5) microns.

NOTE: DO NOT OPERATE THE SYSTEM WITHOUT FILTER CARTRIDGE

ELEMENTS INSTALLED!

TO CHANGE THE FILTER CARTRIDGES

1. Shut down system.

2. Flush system with fresh water.

3. Press the small red button on top of the filter housing to release any pressure.

4. Unscrew the blue lower half of the prefilter housing.

5. Remove the old cartridge and discard.

6. Rinse or wash out the chamber with dechlorinated water being careful to remove all

accumulated dirt.

CAUTION: Failure to completely clean all dirt and debris from the filter

housing will allow debris to enter the membranes. This may foul the

membranes, and will void the warranty.

7. Place the new filter cartridge in the housing. An o-ring on top of the housing makes

the watertight seal. Inspect the o-ring for nicks or cuts and replace if necessary.

Lubricate the o-ring with silicone grease before reinstallation of the cartridge filter

housing.

8. Reinstall the lower half of the prefilter by screwing it into the head. Tighten to handtight plus ¼ turn using the wrench provided.

9. The prefilter is now ready to be put back into service.

10. Once the supply pump is running, press the small vent button to expel any air.

Page 38

38

THE WATERMAKER

GENERAL

Wash and rinse down equipment routinely. Touch up marred or chipped painted

surfaces, and spray equipment (except electrical parts) with a corrosion inhibitor such

as T-9 spray.

HIGH PRESSURE PUMP

Maintain the oil level in the crank end of the pump to one half the sight glass level. The

oil must be changed after the first fifty-(50) hours of running. Always use MATRIX Pump

Oil to maintain the warranty. Subsequent oil changes are at 500 hours or every three

months.

Lubricate the High Pressure Pump Motor every three-(3) months with MATRIX SRI #2

grease. Tighten drive belts (if supplied) when the deflection exceeds .5" or if a reduced

flow is observed when the high-pressure pump is running. Tighten belts with the control

power off.

REMINERALIZER

The remineralizer bed (corosex and calcite) should be replaced when there is a

noticeable drop in water pH at the remineralizer discharge. In general, the bed will

require replacement every 1-2 years, depending on usage.

CALIBRATION PROCEDURES

Calibration of electronic flowmeters can be accomplished by operating the unit, and

collecting the flow (either product or concentrate) in a measured container for a fixed

period of time to determine the actual flow rate. The meter is then adjusted to match

the measured flow rate.

Mechanical flowmeters do not require periodic recalibration.

Conductivity meter calibration is accomplished by measuring the conductivity of the

product water using a hand-held meter, and adjusting the unit’s meter to match the

hand-held reading. The hand-held meter should be calibrated periodically by using

standard calibration solutions available from Matrix.

Perform additional maintenance as specified in the individual components O&M

Manuals

Page 39

39

CHEMICAL

USE

QUANTITY

A-10

ALKALINE CLEANER

FOR ORGANICS

REMOVAL

4 OUNCES

A-11

ELEVATING THE pH

WHEN USING A-10 AND

A-20

AS NEEDED TO RAISE

pH TO 10-12

A-20

ALKALINE CLEANER

FOR ORGANICS

REMOVAL

1 PINT

B-10

ACID CLEANER FOR

REMOVAL OF METAL

OXIDES

1 PINT

C-15

ACID CLEANER FOR

REMOVAL OF METAL

OXIDES

1 PINT

D-20

SHORT TERM

STERILIZER FOR LESS

THAN 30 DAYS

4 OUNCES

E-25

LONG TERM

STERILIZER FOR

MORE THAN 30 DAYS

1 GALLON

M5-SW

ENZYME CLEANER

FOR OVERALL

CLEANING

4 OUNCES

MEMBRANE STERILIZATION AND CLEANING PROCEDURES

The following chemical cleaning procedures are intended to be applied through the use

of a standard Matrix cleaning system. Cleaning should be performed only by qualified

personnel. Contact Matrix for assistance if required.

The quantity of mixed cleaning solution required is as follows:

Silver A Series (600-1500 GPD) 5 Gallons

Silver B Series (2600-4400 GPD) 10 gallons

Silver C Series (6800-12000 GPD) 15 Gallons

MIXING INSTRUCTIONS (PER FIVE GALLON SOLUTION)

Page 40

40

MEMBRANE STERILIZATION PROCEDURES

SOLUTION D-20 - FOR SHORT-TERM SHUTDOWN - (FOUR WEEKS OR LESS)

AND

SOLUTION E-25 - FOR LONG-TERM SHUTDOWN (FOUR WEEKS TO SIX MONTHS)

STEP 1: Prepare Watermaker

1. Flush system with copious amounts of fresh, dechlorinated water. This step is to

remove all saline water and chemicals from the system and membrane elements.

2. The watermaker and any additional (optional) prefiltration equipment (i.e., media

filter, bag filter, etc.), should be flushed and sterilized prior to shutdown.

3. Install the chemical cleaning hoses to the cleaning connection fittings on the unit,

and the cleaning tank. Turn the chemical cleaning valves so the supply pump feed

is isolated and Concentrate water returns to the tank. This will allow recirculation of

the chemical solution through the watermaker.

4. If the supply pump is being used to recirculate the chemicals, the cleaning container

must be placed above the level of the pump since the pump is not self-priming.

5. Disconnect the product water supply tube from the storage tank. This will prevent

chemicals from entering the fresh water system.

STEP 2: Prepare Chemical Solution

READ CHEMICAL MSDS SHEET (PROVIDED WITH CHEMICAL) BEFORE

PROCEEDING

WHEN HANDLING CHEMICALS ALWAYS USE APPROPRIATE SAFETY

EQUIPMENT

1. Mix solution according to the mixing instructions described previously

STEP 3: Sterilizing Procedure

1. Start the cleaning/recirculation Pump ensuring that the regulating valve is fully

open, and re-circulate for forty-five (45) minutes. REMEMBER! ALL CHEMICALS

Page 41

41

ARE RE-CIRCULATED UNDER "MINIMUM PRESSURE"! CHEMICAL

SOLUTION TEMPERATURE MUST NEVER EXCEED 35°C (110°F).

2. During recirculation, the temperature of the cleaning solution will rise. Do not

allow the temperature to exceed 110 degF

3. After re-circulation, close all inlet and discharge valves to isolate the watermaker

and prevent the solution from draining out of the watermaker.

4. Disconnect the electrical power source (breaker) to the system.

MEMBRANE STERILIZATION IS NOW COMPLETED

STEP 4: Return Watermaker to Service

1. Set all valves to service positions.

2. Disconnect the product water line and allow it to dump to waste.

3. Fully open the concentrate control (pressure regulating valve) by turning

counterclockwise.

4. Start the system, and allow it to operate at low pressure for at least 30 minutes.

This should flush the majority of the preservation solution from the system.

5. Slowly increase pressure control valve to normal operating pressure.

6. After producing potable water for sixty (60) minutes, reconnect the product water

line so the product water may now go to the fresh water tank.

Page 42

42

CHEMICAL CLEANING INSTRUCTIONS