Page 1

PETROL 4-IN-1 GARDEN

MULTI-TOOL SET

PGT 4 in 1-S

Read these operating

instructions carefully before

use.

Matrix GmbH

Postauer Str. 26

D-84109 Wörth/Isar

Germany

Fax: +49 (0) 8702/45338 98

E-Mail: info@matrix-direct.net

Original Operating Instructions

EN

PETROL 4-IN-1 GARDEN MULTI-TOOL SET

Art.-No.: 310.550.630

PLU: 3.338

Page 2

17

1

16

3

19

5

2

18

4

20

6

2

Page 3

Table of Contents

1. Device 4

2. Safety Instructions 7

3. Technical data 14

4. Installation and commissioning 16

5. Operation 26

6. Working with petrol brush cutter/trimmer 27

7. Working with petrol pole-mounted powered

pruner 29

8. Cleaning, maintenance and storage 31

9. List of recommended cutting tools and

guards 37

10. Working with petrol hedge trimmer 37

11. Fault and rectication 48

12. Environmental protection 49

EN

3

Page 4

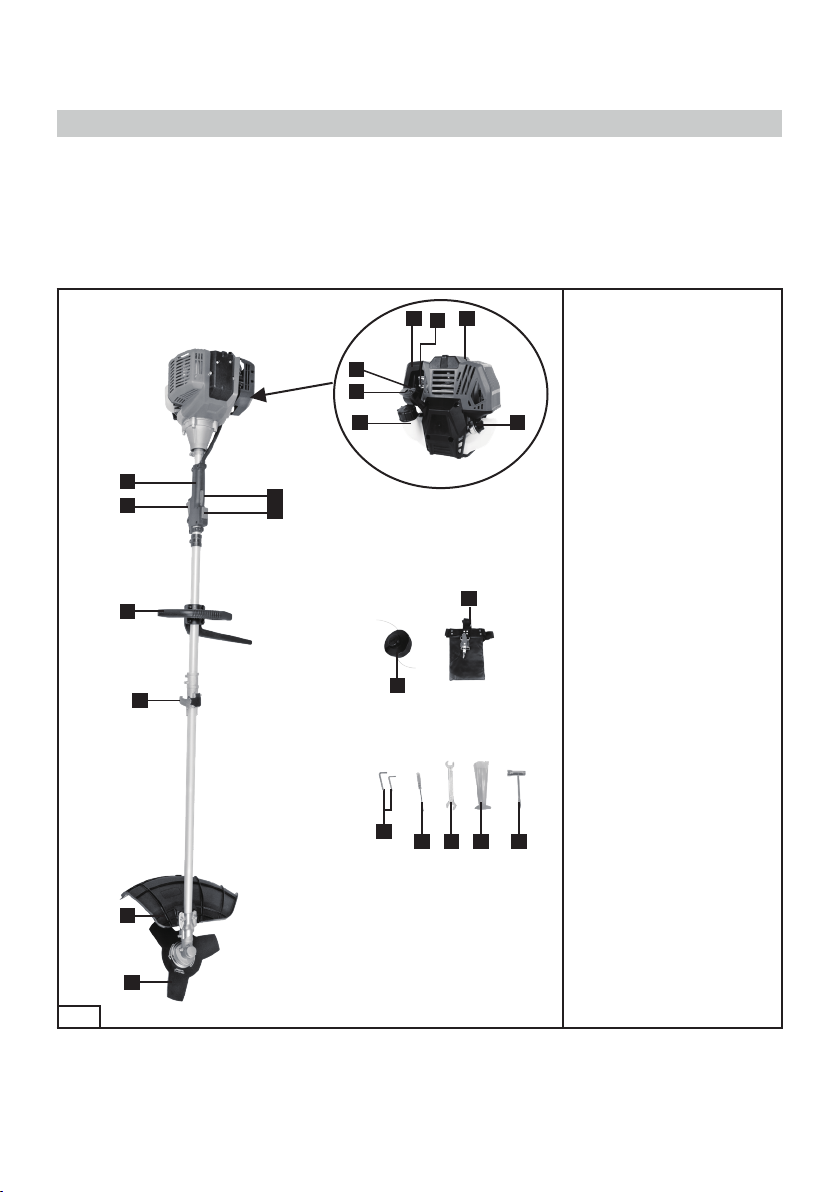

1. Device

Universally applicable brush cutter- grass trimmer-pole-mounted powered pruner-combination tool

for a perfect maintenance of garden and green areas. With just one device, you can do lawn care, tree

care and gardening.

1.1 Scope of delivery

1.1.1 Power unit and accessories

5 9

11

10

6

7 8

1b

2

1a

12

4

3

13

14

1a. Front handle

1b. Rear handle

2. Throttle lever

3. Operating switch

4. Unlocking

5. Air lter

6. Cable pull

7. Petrol tank

8. Oil ller pipe (dipstick)

9. Spark plug assembly

10. Choke lever

11. Primer

12. Locking screw

13. Shoulder strap

14. Spools of thread

15. Cutting protection

16. Knife

17. Support ange

18. Clamping ange

19. Retaining plate

20. Locking nut for the knife

Accessories:

21. Allen key

22. Spark plug wrench

21

24 25 2223

23. Screwdriver

24. Wrench

25. Measurement cup:

15

12

16

A1

4

Page 5

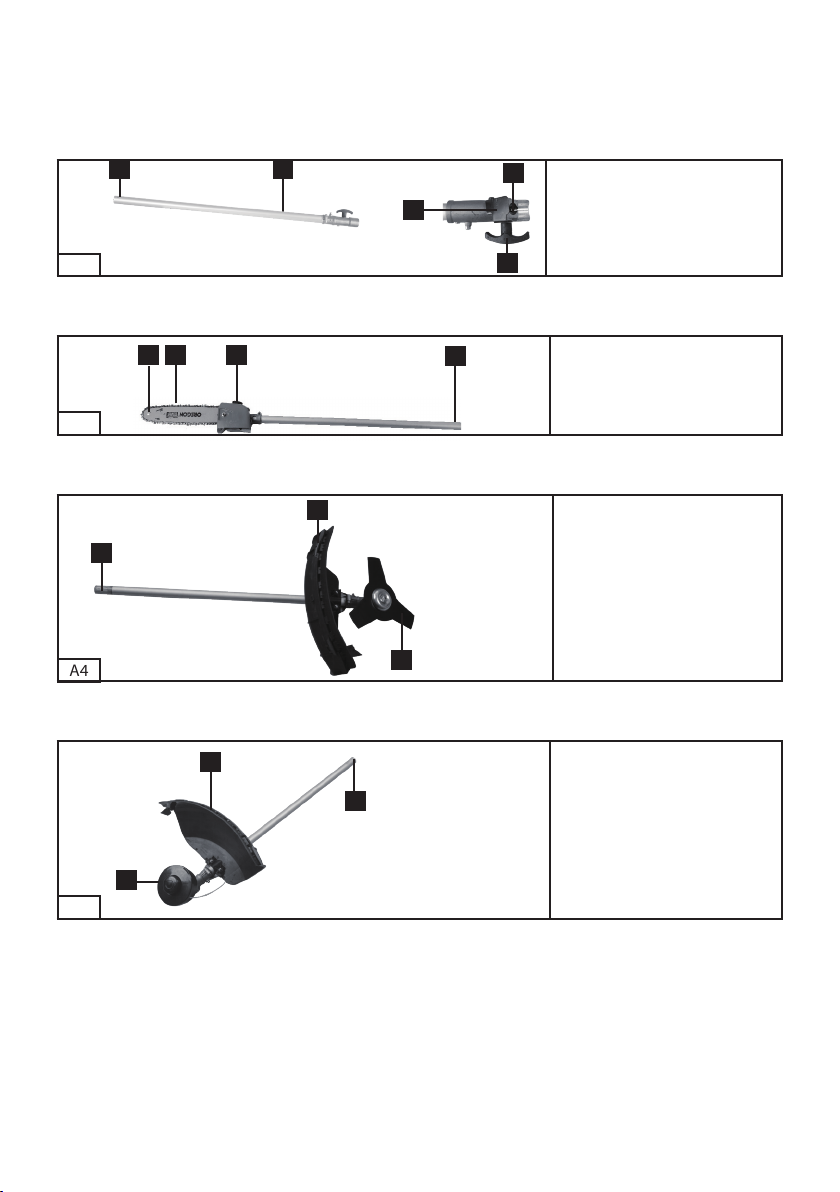

1.1.2 Extension

a

27

A2

1.1.3 Pole-mounted powered pruner

30

29

28

A3

1.1.4 Brush cutter

15.

a

A4

1.1.5 Grass trimmer

16

26a

12. Locking screw

26

26. Locking pin

26a. Cover

27. Extension

a. Lock-holes

12

a

a. Lock-holes

28. Oil tank

29. Chain

30. Blade

a. Lock-holes

15. Cutting protection

16. Knife

A5

14

15

a. Lock-holes

14. Spools of thread

a

15. Cutting protection

5

Page 6

1.1.6 Hedge trimmer

31

33

32

a. Lock-holes

31. Knife

32. Handle

33. Unlocking

34. Locking device

a

A6

34

6

Page 7

2. Safety instructions and warnings

Wear suitable tight, tight-tting work clothing.

This device complies with the mandatory safety

regulations for internal combustion engines.

Read the instructions carefully before operating

the machine.

An improper use can lead to damage to persons

and property.

Persons who are not familiar with the

instructions, may not operate the device.

Keep the safety instructions in a safe place.

Children and adolescents under 16 are not

allowed to use the device. Adolescents over the

age of 16 who work under the guidance of a

trained person are allowed to use it.

Make sure that there are no persons or animals in

the vicinity of the work area (minimum distance

of 15 m). Foreign matter such as stones may be

present in the cut and whirled-up grass. You are

responsible for the safety of your work area and

are liable for damage to persons or property.

Petrol brush cutters should not be started or used

near persons or animals.

Do not use the device if you are tired, ill, or

unfocused, under the inuence of alcohol or

drugs. Inattentiveness can lead to serious injury.

Wear personal protective equipment to protect

yourself from hazards to your safety and health.

This includes, inter alia, wearing approved

goggles, ear protection, protective gloves, nonslip foot protection and protective clothing.

Never work with the device with sandals or even

barefoot.

When carrying out forestry work, always wear an

approved safety helmet.

Do not wear loose clothing or jewellery.

Wear long pants to protect your legs.

For long hair use a headgear. Loose clothing,

jewellery, or long hair could get caught by the

moving parts.

Keep body parts and clothing away from the

cutting tool when starting or operating the

engine.

Make sure that you have a rm and secure

footing when working. Avoid going backwards

with the unit because of the risk of stumbling.

Avoid abnormal body posture.

Prolonged use of petrol brush cutters can lead to

a vibration-induced circulatory disorder (whitenger disease). White-nger syndrome is a

vascular disease in which the small blood vessels

in the ngers and toes cramp up, similar to

seizures. The aected areas are not supplied with

sucient blood any more and appear extremely

pale. Information on the duration of the use

cannot be given in this case, since this may vary

from person to person. The following factors can

inuence this phenomenon:

Circulatory disorders of the hands of the operator,

low external temperatures, long hours of use.

Therefore, it is recommended to wear warm work

gloves and to take regular breaks.

Dispose of the device, accessories and packaging

as well as the oil and petrol used in the locations

intended for them and so this will provide you

with an environmentally friendly recycling.

This little eort benets our environment.

The exhaust gases of internal combustion

engines are poisonous and can lead to

suocation, among other things.

The device may be used only outdoors.

Fill the fuel tank only outdoors or in suciently

ventilated areas.

Petrol and petrol fumes are highly ammable.

Keep the device away from ammable materials

and sources of ignition, such as ovens or stoves.

The resulting exhaust gases are poisonous and

stiing!

7

Page 8

CAUTION Fire hazard!

Petrol and petrol fumes are highly ammable!

The waste oil must be disposed of in accordance

with the applicable regulations.

Do not smoke while you refuel or

operate the device.

Dry up any spilled petrol immediately.

Start the device only at a location away from the

refuelling point.

Make sure that the lid of the tank is always tightly

closed. Pay attention to possible leaks.

While the engine is running or when the engine

is hot, do not open the fuel cap or rell fuel.

Always stand below the cutting tool when

cutting on the slope.

Always make sure that there are no objects or

similar things accumulate in the cord head in the

protective hood or in. the engine.

Do not use wire or the like in the thread spool.

Work only in daylight or under good articial

lighting.

Before each use, check the device and its

components and protective devices for damage

or wear and, if necessary, carry out the necessary

repairs. Never put devices of protection and

safety out of operation. Do not use the device , if

damage or signs of wear and tear have become

apparent.

Open the tank cap slowly, so that petrol fumes

can escape.

Make sure the handles are dry, clean, and free of

petrol mixture.

Do not use the device without exhaust and

properly installed exhaust protection.

Do not touch the exhaust. Danger of burns.

Use only the fuel recommended in the manual.

Store petrol only in designated containers in a

safe place.

Caution! Petrol and oil may leak if used

incorrectly, stored improperly or if there

is a damage. Take precautions to prevent

environmental damage in such a case. For

example, oil and petrol can be absorbed with

special binders.

In case of re, use CO2 extinguishers to smother

the re. Foam, powder or sand are also suitable

for extinguishing small res. Never extinguish

petrol and oil res with water. Risk of explosion!

In case of emergency, contact your re

department!

Keep the tools clean and functional, in order to

be able to work better and safer..

Always keep the device away from the body

when working.

Always switch o the device during breaks from

work and relocations, wait for the cutting tool to

stop and switch o the engine.

Never leave the device unattended at the

workplace. Store the device in a safe place during

work interruptions.

Do not be distracted while working with this

device. Through that, you could lose control of

the tool.

Never use the device in rainy, humid or wet

conditions and do not store it outdoors.

If the device gets wet, wait for it to dry

completely before using it again.

Locate and remove foreign objects from the

workspace before working with this equipment. If

you still encounter a foreign object while cutting,

turn o the device nd remove it.

8

Page 9

In the event of a blockage due to foreign material

(stone, grass collection), turn o the device and

remove it with a blunt object. Never remove

blocking foreign bodies with your ngers, as this

may result in serious injury.

Always keep the running device away from the

body.

Operate the device only with protection guard.

Always switch o the appliance from before you

turn it o.

Pay attention to the risk of injury in the area of

the cutting device, which serves to cut o the

thread.

Do not overload the machine or perform any

work for which it is not intended.

Make sure that the ventilation openings are

always free of dirt.

Keep the device out of the reach of children.

Store the device in a safe and dry place.

After impact or other damage, check the machine

for damage.

Especially when trimming lawn edges, gravel

borders and the like, please note particularly that

stones and soil can be ejected from the cutting

threads.

Never cross roads or paths when the device is

switched on.

Never cut hard objects such as stones, etc. to

prevent personal injury or damage to the device.

Never use the device without a protection guard.

Never stop the cutter with your hands. Always

wait until it stops by itself.

Guide the thread head as close to the ground as

possible.

Cut only grass that grows on the ground.

Grass in cracks or on stones may not be cut.

Always make sure that there are no objects or

similar things accumulate in the cord head in the

protective hood or in the engine.

Risk of blowback! There is always a risk of

blowback if the cutting blade touches branches

or other objects. The brush cutters will be

uncontrollable and can be pushed with great

force in the direction of the operator.

Do not use the device without exhaust and

properly installed exhaust protection.

Do not touch the exhaust. Danger of burns.

Do not use wire or the like in the spools of thread.

Never cut hard objects such as stones, etc. to

prevent personal injury or damage to the device.

Never use the device without a protection guard.

Always use only the original thread.

Never use a metal wire instead of the nylon

thread.

The petrol brush cutter is intended for trimming

grass or grass, for cutting scrub, shrubs, bushes

and young trees in the private sector, dependent

on the mounted cutting tool.

The device may not be used for other purposes.

The manufacturer does not assume any liability

in case of Improper use as well as changes to the

machine.

Please also pay attention to the safety

instructions, the instructions for installation and

operation, as well as the operating instructions

and the other generally applicable accident

prevention regulations.

9

Page 10

The appliance and cutting tools must be regularly

and properly inspected and maintained. Damage

must be repaired by a specialist workshop.

Use only accessories recommended by the

manufacturer.

Let your device repaired only by qualied

personnel and only with original spare parts.

This will ensure that the safety of the device is

maintained.

Make sure that the cutting tool is stationary,

when the engine is at idle mode.

Kickback – blowback

When working with metal cutting knives, it may

lead to a blowback of the whole device or to a

sudden forward movement, if solid objects (trees,

twigs, stones, or the like) are touched.

This blowback occurs without warning and

can lead to loss of control over the device and

endanger the user and bystanders. There is

special hazard looming in areas where visual

inspection is dicult and there is dense

vegetation.

Check this regularly and do not use the machine,

if you see a movement in idle mode. Take the

machine to a specialist workshop for checking

and repairing. The adjustment of the idle speed

should also be done only in a specialist workshop.

CAUTION: The cutting tool rotates for a few

seconds after switching o the machine.

Lay down the appliance only after the cutting

tool has come to a standstill and the engine has

been switched o.

Replace a damaged cutting tool with a new one

immediately.

Always use only the original thread.

Never use a metal wire instead of the nylon

thread.

The appliance and cutting tools must be regularly

and properly inspected and maintained. Damage

must be repaired by a specialist workshop.

Use only accessories recommended by the

manufacturer. The use of accessories, especially

cutting accessories and protective devices, which

are not recommended by the manufacturer, can

lead to serious injuries and property damage.

Let your device to be repaired only by qualied

personnel and only with original spare parts.

This will ensure that the safety of the device is

maintained.

So please maintain control in the event of a

blowback

• Always hold the device rmly with both hands

while working.

• Make sure that you are standing securely. Keep

your feet comfortably spread and always count

on a possible blowback.

• Do not overestimate yourself and maintain

balance at all times while working.

• Before you begin to cut, the cutting blade

should have reached full working speed.

Stones and rubble could be thrown up while

clearing vegetation and cause severe injuries.

Make sure that the protective hood is securely

mounted.

If rotating parts (cutting knives) are improperly

fastened, this can lead to serious accidents.

Before starting work, check the cutting blade for

tightness.

Other risks

Even if you operate this device properly, there

will still be other risks. The following risks may

occur in connection with the style and design

of this power tool:

1. Health risks, which resulted due to hand-arm

10

Page 11

vibrations, if the device is used for a longer period

or if it is not properly handled or maintained.

2. Injuries and property damage caused by

spinning tool attachments that are unexpectedly

thrown out of the machine due to sudden

damage, wear, or improper attachment.

3. For an adequate protective equipment during

the use, care must be taken in accordance with

the operating instructions. All other usages are

ruled out. Any damage or injury resulting from

misuse is the responsibility of the user / operator

and not the manufacturer. Use only 3-teeth

blades suitable for the machine as mentioned in

the operating instructions.

While the engine is running or if the engine is

hot, do not open the fuel cap and do not rell

fuel.

Do not touch the exhaust. Danger of burns.

Use only the fuel recommended in the manual.

Store petrol only in designated containers in a

safe place.

Always switch o the device before putting it

away.

Work only in daylight or under good articial

lighting.

Frequent use of vibrating devices may cause

nerve damage to persons whose blood

circulation is compromised (e.g., smokers,

persons with diabetics).

If you notice any unusual disturbances, stop

working immediately and consult a doctor.

Observe the following instructions to reduce the

risks:

1. Keep your body, especially your hands, warm

in cool weather.

2. Take regular breaks, moving your hands to

increase blood ow.

3. Keep changing work positions egularly to

avoid a one-sided load on the body and to

prevent health damage.

Make sure that the device vibrates as little as

possible by ensuring regular maintenance and by

xed parts on the device.

Do not smoke while you refuel or operate the

device.

Wipe up any spilled fuel immediately.

Examine the device for any leaks.

Do not use the device if you nd any leaks.

Carry out a visual inspection of the device before

each use.

Check if all screws and connecting parts are tight.

Always hold the device rmly with both hands.

Before each use, check the device and its

components and protective devices for damage

or wear and, if necessary, carry out the necessary

repairs. Never put protection and safety devices

out of operation. Do not use the device if damage

or signs of wear and tear have become apparent.

Keep the tools clean and functional, in order to

be able to work better and safer.

Always keep the device away from the body

when working.

Always switch o the device completely during

work interruptions and relocation, wait for the

chain saw to stop and put on the chain guard.

Never leave the device unattended at the

workplace. Store the device in a safe place during

work interruptions.

Do not be distracted while operating the device.

If you are distracted you could lose control of the

device.

Never use the device in rainy, humid or wet

11

Page 12

conditions and do not store it outdoors.

Do not use the chainsaw in the vicinity of

ammable liquids or gases and in wet or humid

environments. Failure to do so may cause re or

explosion.

Work only in suitable light conditions.

You are responsible for the safety of your work

area.

Never position the tip of the rail for cutting and

never saw with the rail's tip - risk of blowback!

- There is always danger of blowback, when the

tip of the rail touches wood or other objects.

The chain saw will become uncontrollable and

can be pushed with great force in the direction of

the operator.

Always saw through only one branch at a time.

When cutting to length, pay attention to adjacent

trunks.

Caution! Some tools / cutting tools have sharp

edges and tips. Be especially careful when

handling them and wear protective gloves to

protect yourself from injury!

Ensure a secure footing and wear non-slip, highheeled closed shoes.

Protect the device from rain and moisture.

When the engine is running, always hold the saw

rmly with both hands.

Use the claw as a starting point for each cut,

always start cutting with the saw chain running.

Make the cut so that the saw does not get stuck

in the wood.

Pay special attention to branches under tension.

Pull the device out of the wood only with a

running saw chain.

Never work above the shoulder level or with the

device with one hand.

Always stand outside the direction of fall.

Stay on slopes above the tree to be felled. Do

sawing work on a tree that stands on a slope,

always on the side, never from above or below.

Always pay attention to the fall direction of the

parts to be separated.

Do not use the appliance as a lever to move

objects.

Always use the chain guard during transport and

storage.

Secure the device during transport to avoid fuel

loss, damage or injury.

Warning!

Keep passers-by away from the running device,

but never work alone.

Stay within earshot of others if you need help.

Stop the engine immediately when someone

approaches you.

Make sure that the saw chain does not come

into contact with foreign objects such as stones,

fences, nails or similar objects. These objects

could be ung out, injuring the user or the

person passing by or damage the saw chain.

National regulations may restrict the use of the

device.

Do not use the machine in any position from

which it may come within the radius of 10 m of

high-voltage power lines.

For an adequate protective equipment during

the use, care must be taken in accordance with

the operating instructions. All other usages are

ruled out. Any damage or injury resulting from

misuse is the responsibility of the user / operator

and not the manufacturer. Use only 3-teeth

blades suitable for the machine as mentioned in

the operating instructions.

12

Page 13

Disconnect the spark plug before carrying out

any work on the device itself (e.g., transport,

installation, conversion, cleaning and

maintenance)!

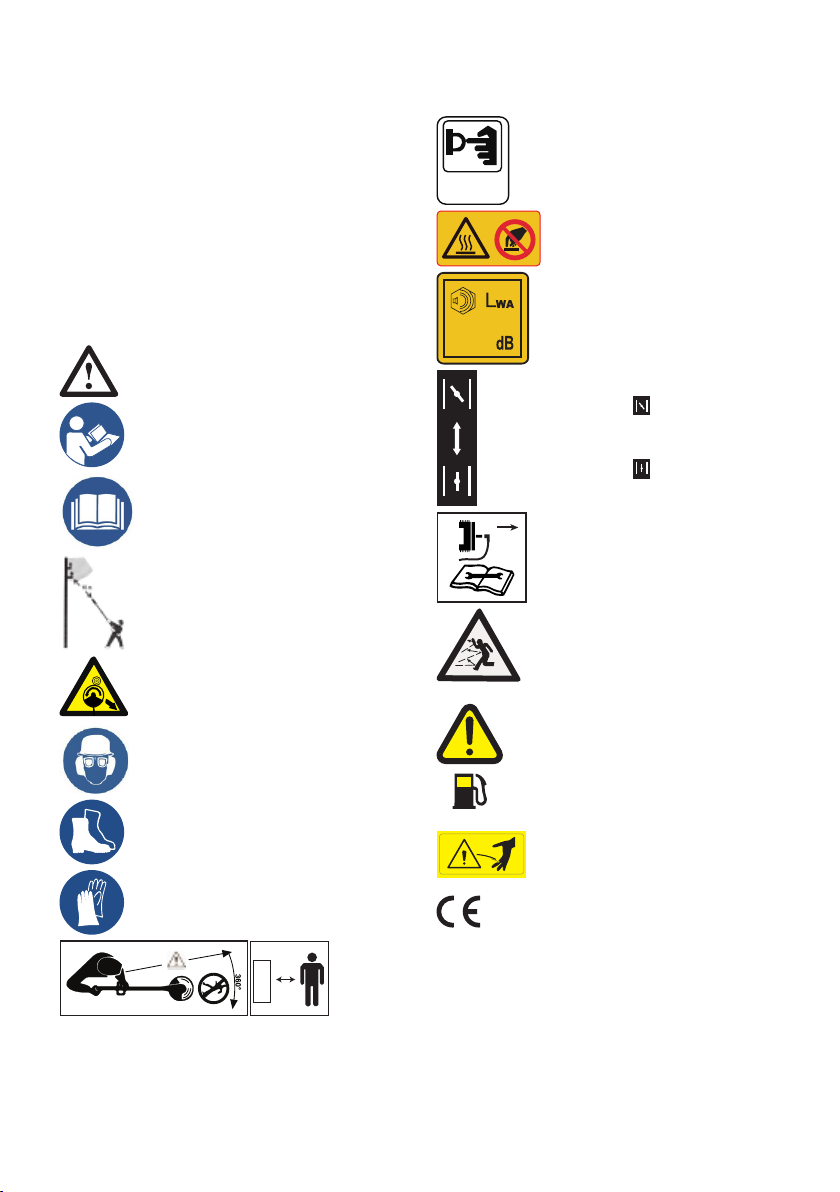

2.1 Markings on the device

Explanation of the symbols

The following symbols are used in this manual

and / or on the device:

Warning / Caution

Read the operating instructions

before use

Caution with regard to electric

cables.

Keep at least 10 m distance

5-6 X

114

Primer

Beware of hot surfaces

Guaranteed sound power level

During cold start, position the

choke lever

choke.

For a warm start, position the

choke lever

choke..

In case of repairs, remove spark

plug connector

Beware of parts thrown away

, to close the

, to open the

Beware of recoil

Use safety glasses, protective

helmet and ear protection

Wear safety shoes

Wear safety gloves

The distance between the machine and third

parties must be at least 15 m.

WARNING!

- Use petrol of 93 octane or

higher, with special 4-stroke

engine oil.

- Use pure petrol.

- Check the oil level before

starting.

Attention! Risk of injury!

Device manufactured in

accordance with European

directives.

13

Page 14

2.2 Intended use

3. Technical data

Brush cutter, grass trimmer

The petrol brush cutter is intended to trim lawns

or grass, to cut scrub, shrubs, bushes and young

trees in the private area, depending on the

mounted cutting tool.

The device may not be used for other purposes.

The manufacturer does not assume any liability

in case of Improper use as well as changes to the

machine.

-Please also note the safety instructions, the

instructions for installation and operation, as

well as the other generally applicable accident

prevention regulations.

Pole-mounted powered pruner

The petrol pole-mounted powered pruner is

in accordance with the latest technology and

the recognized technical safety rules. However,

improper or incorrect use may present a hazard

to life and limb of the user or a third party or a

damage to the device itself and/or other property

assets.

The petrol pole-mounted powered pruner is

a portable, hand-held device equipped with

a cutting set attached to a shaft. This pruner

is designed exclusively for pruning trees and /

or other wood from the ground. The inserted

cutting set is a saw chain with guide rail.

This device is designed for private or home

use only and may not be used in a continuous

operation for commercial purposes. Any other

us or use going beyond this is considered as

improper use. The risk is borne by the user.

Intended use also includes observing the

operating and installation instructions as well as

observing the maintenance conditions.

Engine:

Engine Type: 4-stroke engine; air cooled

Engine power (max.): 0.7 kW

Displacement: 31 cm

Max. engine speed: 10500 min

Volume (fuel tank): 650 cm3 (0.65 l)

Normal or premium petrol

Start System: Rewind starter

Speed range at idle mode: 2700-3400 min

Speed at engagement: 4700 min

Spark plug: TORCH, A5RTC/A7RTC

Oil specication: 4-stroke engine oil 15W40

Pole-mounted powered pruner

Weight with chainsaw and empty tank: 7.3 kg

Cutting length: 10"

Chain Clearance: 3/8"

Chain thickness: 0.050"

Chain type: 91P040X/OREGON

Guide rail type: 100SDEA318/OREGON

Max. engine speed with chain saw 10500 min

Noise level according to EN ISO 22868 and

ISO 3744

Sound pressure level L

Sound power level

: 90.28 dB(A)

pA

: 105.27 dB (A)

WA

Uncertainty K: 2.5 dB (A)

Guaranteed sound power level

: 114 dB (A)

WA

Vibration level according to EN ISO 22867

Front handle: 3.527 m/s

Rear handle: 6.874 m/s

Uncertainty K: 1.5 m/s

Brush cutter and grass trimmer

Weight without cutting accessories with empty

tank: 7.3 kg

Cutting diameter: 255 mm (brush cutter)

430 mm (grass trimmer)

Thicket knife: ø255 x ø25.4 x 1.4 mm,

3 teeth, max. 10000 min

Cutting thread / spools of thread:

ø2.4 mm, max. 10000 min

3

-1

-1

-1

-1

2

2

2

-1

-1

14

Page 15

Rotational speed of the cutting accessory at max.

engine speed:

7850 min

6750 min

-1

(brush cutter)

-1

(Grass trimmer)

Note: The specied vibration value has been

determined according to a standardized test

procedure and can be used to compare dierent

devices with one another.

Noise level according to EN ISO 22868 and

ISO 3744

Sound pressure level (cutter) L

: 91.61dB(A)

pA,av

Sound pressure level

(grass trimmer) L

: 92.63dB(A)

pA,av

Uncertainty K: 2.5dB(A)

Sound pressure level

(brush cutter) L

: 103.62 dB (A)

pA,av

Sound pressure level

(grass trimmer) L

: 105.06 dB (A)

pA,av

Uncertainty K: 2.5 dB (A)

Vibration level according to EN ISO 22867

Vibration levels (brush cutter) a

hv,eq:

Front handle: 5.587 m/s

Rear handle: 6.890 m/s

Vibration levels (grass trimmer) a

hv,eq

:

Front handle: 5.277 m/s

Rear handle: 7.665 m/s

Uncertainty K: 1.5 m/s

Hedge shears

Blades for hedge shears:

Knife spacing: 20 mm,

Max. cutting length 365 mm.

Noise level according to EN ISO 22868 and ISO

3744

Sound pressure level L

Sound power level

: 88.76 dB (A)

pA

: 103.50 dB (A)

WA

Uncertainty K: 2.5 dB (A)

Wear ear protection to prevent hearing damage.

In addition, this value is suitable in order to be

able to estimate loads for the user caused by

vibrations in advance.

Warning! Depending on how you use the device,

the actual vibration values may dier from those

specied.

Take measures to protect against vibration.

Take into account the entire workow, including

times when the tool operates without load or is

switched o.

2

Suitable measures include regular maintenance

2

and care of the device and the insertion tools,

keeping hands warm, regular breaks and good

2

planning of work processes.

2

2

Vibration level according to EN ISO 22867

Front handle: 5.065 m/s

Rear handle: 3.516 m/s

Uncertainty K: 1.5 m/s

Guaranteed sound power levelWA: 114 dB (A)

Angle range

The angle of the hedge trimmer can be adjusted

from 80 ° to -90 ° with respect to the shaft tube.

2

2

2

15

Page 16

4. Installation and commissioning

Note:

Before attaching cutting accessories, first remove the transport protection.

When replacing the spools of thread or knife, do not remove the cutting guard (15).

To avoid the risk of unintentional starting, pull out the spark plug connector.

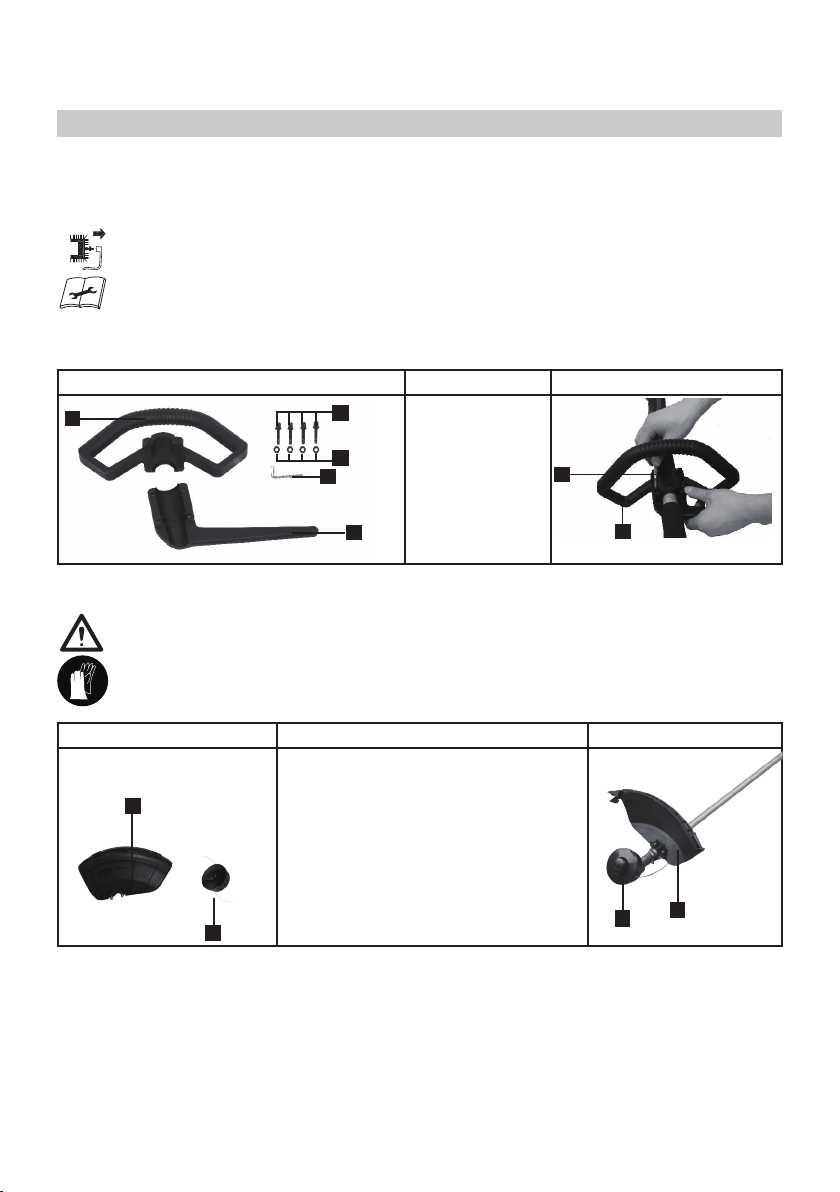

4.1 Brush cutter-Grass trimmer-Pruner-Hedge trimmer-Combination Device: Handle

Assembly 1 Assembly

1a

a

b

21

c

4.2 Brush cutter-Grass trimmer-Pruner-Hedge trimmer-Combination Device: Grass trimmer

RISK OF INJURY

CAUTION: Always wear protective gloves when working on and around cutting tools.

Secure the handle

(1a) to the drive

unit with the 4

xing screws (a)

and the nuts (b) of

the drive-unit (c)

21

1a

Assembly 2 Assembly

To use the device as a grass trimmer, the

cutting guard (15) and spools of thread (14)

15

14

must be mounted.

16

15

14

Page 17

- Fix the cutting guard (15) with the screws

to the holder on the shaft (if not already

mounted). In addition, the protective

cover with knife must be attached to the

protective cover for the cutting edges.

- Lock the shaft of the brush cutter at the

16

intended place with a screwdriver or with

the provided Allen key (21).

- Using the spark plug wrench (22), loosen

the locking nut for the blade (16) by

turning it clockwise (if already mounted).

- Remove the locking nut (20), the

clamping ange (18) and the holding plate

(19) for the thicket knife. Keep these parts

safe.

- Leave the support ange (17) on the

shaft.

- Lock the shaft of the brush cutter at the

intended place with a screwdriver or with

the provided Allen key (21).

- Turn the thread spool (14) counterclockwise onto the shaft.

CAUTION: Left-hand thread

Connecting the drive unit and assembly:

Insert the ends of the assemblies to be

connected. Make sure that the locking

pin (26) locks in place. Check pulling apart

on a trial and error basis. Fold down the

cover (26a) and secure the assemblies by

tightening the locking screw (12).

A7

Release of drive unit and assembly:

Loosen the locking screw (12). The cover

(26a) jumps back. Hold the locking pin (26)

pressed underneath the cover and loosen

the modules by carefully pulling them

apart simultaneously.

26a

26

12

17

Page 18

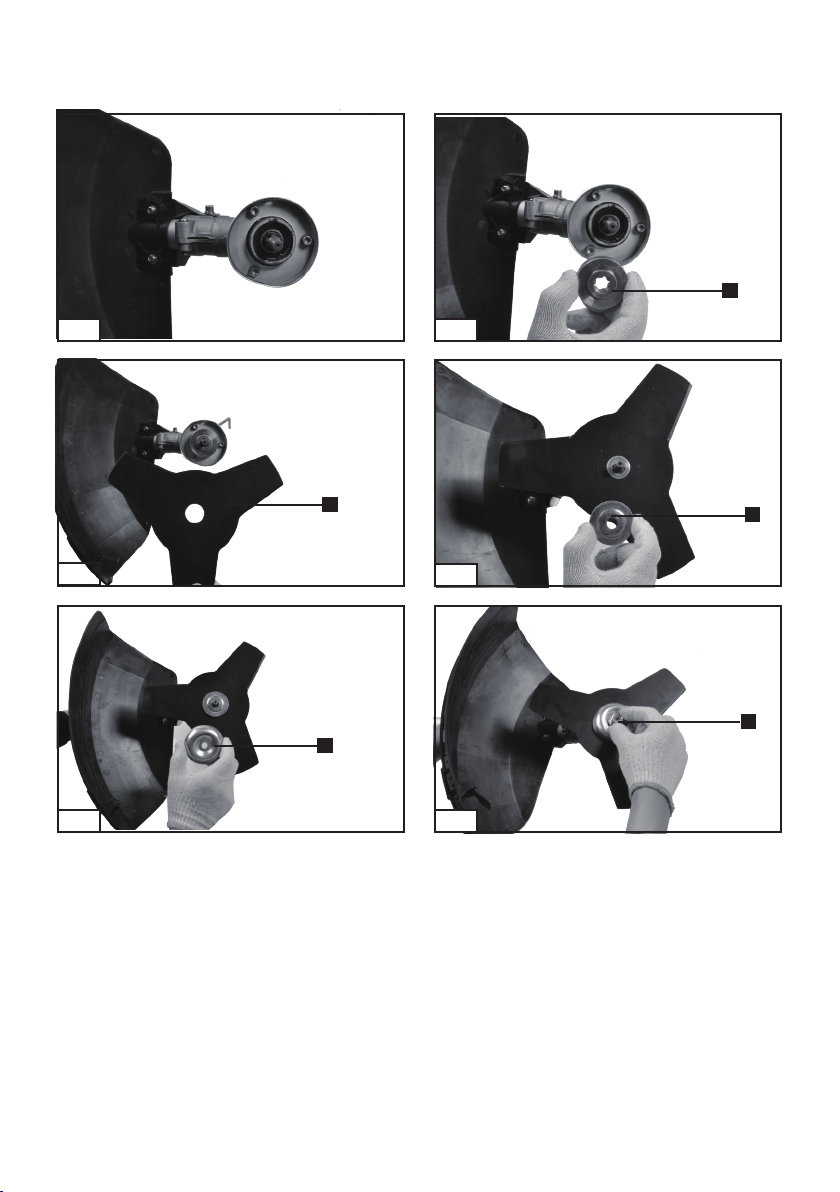

4.3 Brush cutter-Grass trimmer-Pruner-Hedge trimmer-Combination Device: Brush cutter

RISK OF INJURY

CAUTION: Always wear protective gloves when working on and around cutting tools.

– Risk of blowback! There is always a risk of blowback, if the blade tip touches branches

or other objects. The brush cutters will be uncontrollable and can be pushed with

great force in the direction of the operator.

Assembly 3 Assembly

26a

To use the device as a brush cutter,

the protective cover for the cutting

edges and the thicket knife must

26

be mounted.

Do not remove the protective cover

for the cutting edges (15) when

you replace the thread spool (14) or

12

blade (16).

- Fix the protective cover for the

cutting edges (15) with the 4 screws

on the holding device on the shaft

(if not already mounted). - Mount

knife (16) as shown in gures 1-6.

15

16

- Lock the shaft of the brush cutter

at the intended place with a

screwdriver or with the provided

Allen key (21).

- Turn the spools of thread (14)

clockwise o the shaft (if already

22

mounted).

- Leave the support ange (17) on

161

the shaft.

21

- Place the thicket knife (16) on

the supporting ange (inscription

facing the user).

15

15

- Place the clamping ange (18) and

the retaining plate (19) (observe

alignment) on the thicket blade

(16).

15

18

A8

Page 19

- Lock the shaft of the brush cutter

26a

at the intended place with a

screwdriver or with the provided

Allen key (21).

26

- Turn the hexagon nut anticlockwise onto the shaft and

tighten with the spark plug wrench

(22).

CAUTION: Left-hand thread

12

Connecting the drive unit and

assembly:

Teil C

Teil B

12

a

Insert the ends of the assemblies

26a

to be connected. Make sure that

the locking pin (26) locks in place.

Check pulling apart on a trial and

26

error basis. Fold down the cover

(26a) and secure the assemblies by

tightening the locking screw (12).

Release of drive unit and

assembly:

Loosen the locking screw (12).

The cover (26a) jumps back.

Hold the locking pin (26) pressed

underneath the cover and loosen

the modules by carefully pulling

them apart simultaneously.

Caution! The knife may only

be ground by a qualied and

experienced specialist.

Incorrectly ground blades increase

the risk of breakage and cracking.

19

Page 20

4.4 Brush cutter-Grass trimmer-Pruner-Hedge trimmer-Combination Device: Pole-mounted

powered pruner

RISK OF INJURY

CAUTION: Always wear protective gloves when working on and around cutting tools.

Assembly 4 Assembly

Before you can start with the tree care, it is necessary to mount

24

the saw chain and the blade to the device. The chain (29) is very

sharp-edged. Be sure to wear safety gloves when mounting the

chain (29).

1. First, remove the chain guard from the blade unit.

2. Then turn the locking screw on the cutting head (d)

counterclockwise with the wrench (24) and remove the upper

housing cover.

d

3. Insert the saw chain into the groove guide of the blade unit

(30). Start at the top of the blade if possible.

Be sure to pay attention to the correct cutting direction. There

are direction arrows, which must coincide with the running

direction on the blade on the blade unit and in the inner housing

30

30 29

29

g

f

e

f e

below the sprocket.

Now place the saw chain around the sprocket (e) and place the

blade unit on the pin of the cocking slide (f). Make sure that the

bolt engages in the corresponding opening on the blade.

If necessary, turn the tensioner screw (g).

To ensure the even wear of the chain blade, the chain blade (30)

should be turned after 8 - 10 working hours.

Always pay attention to the correct chain tension and check it

before every use of the device.

A loose chain could come o the groove guide of the blade

unit and cause serious injury. Furthermore, a loose chain also

increases the risk of blowback.

In addition, blade, chain and sprocket wear out faster.

28

20

A9

Page 21

Adjustment of the chain tension:

1. First, slightly tighten the locking screw on the sprocket cover.

2. The screw of the clamping device (g) is located below the chain link on the

front of the device head. Use the supplied spark plug wrench (22) to turn it in

the appropriate direction to increase or decrease the tension on the chain.

Turning clockwise: Tension of the chain is increased.

Turning counterclockwise: Tension of the chain is relaxed.

AA correct chain tension can be detected by the fact that the saw chain rests

evenly at each point of the blade unit and does not sag or overstress.

3. If the chain tension is correct, retighten the sprocket cover lock knob. New

chains expand. Check the new chain after a few minutes of operation. Let the

chain cool down and then adjust the chain tension again if necessary.

Fill in oil:

The prerequisite for perfect function and long product life is regular

lubrication. Therefore check the oil tank every time before using this device

and rell with oil if necessary. Proceed as follows:

1. Open the cap of the oil tank (28). Remove oil residue and other contaminants

by rubbing the ller cap and oil ller neck with a cloth.

2. Fill environmentally friendly and biodegradable chain lubricating oil into the

oil tank (28) and then close it again. To minimize the risk of re, make sure that

there are no oil residues outside the container when lling. Always use a funnel

to ll.

28

g

22

Never use waste oil for chain lubrication.

Used oil does not have the necessary lubricating properties, is harmful to

the environment and causes skin cancer after prolonged and repeated skin

contact. Use only lubricating oil, which has sucient resistance to aging so

that it does not become resinous and form solid deposits that could damage

the device.

Always adhere to the specied oil intervals. This device must be re -supplied

with oil after a working time of max. 15 minutes.

Adjustment of flow of the oil

Caution:

An increase in oil throughput speeds up oil consumption, leading to more

frequent checks / rells.

To ensure adequate lubrication, it may be necessary to check the oil level more

frequently than when relling the fuel tank.

The guide rail and the chain are automatically lubricated by a pump that works

when the chain turns.

The pump is factory set to provide a medium ow rate. However, it can be

set in the eld. Temporary increase in oil ow is often desirable when cutting

hardwood and resinous wood.

Set the pump as described below:

1. Stop the engine and make sure the stop switch is in the "STOP" position.

2. Place the device on the side with the oil tank on top. See the image A10.

3. Using a screwdriver, turn the adjusting screw of the oil-throughput in the

desired direction

.

In the clockwise direction : Reduce lubrication

.

Counter-clockwise: Increase lubrication

Caution:

The adjusting screw of the oil ow must be pressed slightly while turning,

otherwise the pump and screw will be damaged.

A10

21

Page 22

4.5 Brush cutter-Grass trimmer-Pruner-Hedge trimmer-Combination Device: Pole-mounted

powered pruner

RISK OF INJURY

CAUTION: Always wear protective gloves when working on and around cutting tools.

Assembly 5 Assembly

30

28

29

a

Remove transport cover.

Connecting the drive unit

and assembly:

A11

26a

assemblies to be connected.

Make sure that the locking

Insert the ends of the

26

pin (26) locks in place. Check

pulling apart on a trial and

error basis. Fold down the

cover (26a) and secure the

assemblies by tightening

12

Teil C

Teil B

12

a

the locking screw (12).

Release of drive unit and

assembly:

26a

Loosen the locking screw

26

(12). The cover (26a) jumps

back. Hold the locking pin

(26) pressed underneath

the cover and loosen the

modules by carefully pulling

them apart simultaneously.

22

Page 23

4.6 Brush cutter-Grass trimmer-Pruner-Hedge trimmer-Combination Device: Extension (only

pole-mounted powered pruners)

Assembly 6 Assembly

Remove transport cover.

a

27

12

Connecting the drive

unit, extension and

assembly:

Insert the ends of

the assemblies to be

connected. Make sure that

26a

the locking pin (26) locks in

place. Check pulling apart

on a trial and error basis.

26

Fold down the cover (26a)

and secure the assemblies

by tightening the locking

screw (12). Carry out

12

procedure separately for

drive unit and extension.

Release of drive unit,

Teil C

Teil B

12

a

extension and assembly:

26a

Loosen the locking screw

(12). The cover (26a) jumps

back. Hold the locking pin

26

(26) pressed underneath

the cover and loosen

the modules by carefully

pulling them apart

simultaneously. Carry out

procedure separately for

drive unit and extension.

A12

23

Page 24

4.7 Mounting the carrying belt system

Assembly 7 Assembly

Checks before use:

Distance from the shoulder strap suspension

to the cutting tool min. 750mm Distance

of the cutting tool from the ground when

using as trimmer 0-300mm and when using

with thicket knife 100-300mm. The fuel tank

should be lled up to half with normal or

premium petrol with 93 octane or higher.

Always keep a safe distance between yourself

and the cutting tool while working.

The petrol brush cutter / trimmer / polemounted powered pruner unit must be

used with the carrying strap (13). First of all,

balance the machine when it is switched o.

- Put on the carrying strap (13).

- Adjust the strap length in such a way that

the snap hook (b) is about a hand's breadth

below the right hip.

- Hang the petrol brush cutters on the snap

hook (karabiner).

- Let the machine sway.

The cutting tool may just touch the ground

c

during normal working posture.

With the engine running, attach the device to

the snap hook (b) of the harness.

24

Safety flap on the shoulder strap

CAUTION! In an emergency, the safety ap

(c) can be pulled on the carrying strap (13).

The machine is then released immediately

from the shoulder strap (13) and falls to the

ground.

A13

Page 25

4.8 Fuel and engine oil

CAUTION! Turn off the device, allow

it to cool and unplug the spark

plug before refuelling with fuel and

engine oil.

The machine is equipped with a 4-stroke engine.

Use only regular or premium grade petrol with 93

octane or higher.

Before starting the scythe, ll the engine with

4-stroke engine oil 15W40.

Caution: Do not use fuel that is older than 2-3

months.

In case of longer breaks from work, empty the

tank and rell before starting work.

Fill in petrol

- Wipe o any spilled oil and close the oil tank

cap again.

- Slowly unscrew the lid of the tank (7) so that

pressure and petrol vapours can escape safely.

- It is best to ll the fuel with a funnel and tighten

the lid again.

Fill in engine oil and check oil level

- Place the appliance on a level ground.

- Turn o the oil tank cap with dipstick (8) and

add oil to the tank.

- To check the oil level, wipe the dipstick with a

clean cloth and put it back into the tank as far as

it will go.

- After pulling out, read o the oil level on the

dipstick. The oil level must be in the marked eld

between the minimum and maximum marks.

25

Page 26

5. Operation

5.1 Starting the Brush cutter-Grass trimmer-Pruner-Hedge trimmer-Combination Device

Start the petrol multi-tool set for garden only when an attachment is connected!

Remove the appropriate transport protection and inspect the device for good operating

condition. Never use a damaged, poorly adjusted or badly maintained or incompletely

and safely mounted device.

3

Set the operating switch (3) to On-position "I".

A14

A15

A16

A17

F10OF

11

Place the choke lever (10) at "OFF" position.

Press primer (11) 5 to 6 times.

• Start the machine by controlled

pulling at the cable control (6).

• Press the device with the second hand

on the ground.

6

CAUTION: Never put your foot on the shaft or

kneel on it.

26

Page 27

Once the device is running, the choke lever (10)

can be returned to the "ON" position.

ON

10

A18

4

A19

2

Start with warm engine

- Corresponds to the procedure as for the cold

engine. The choke lever always stays in the "ON"

position.

5.2 Stop and switch off

Release the throttle (2).

- Allow the engine to return to idle mode without

gas and let the devoice to run for 10 to 15

seconds.

- Set the operating switch (3) on the operating

handle to "O".

6. Working with the brush cutter /

grass trimmer

- Familiarize yourself with the operation and

control when the appliance is switched o the

rst time you work with a petrol brush cutter.

- The petrol brush cutter is designed in such a

way that it is controlled by the operator only on

the right side of the body.

CAUTION. The cutting device continues to still

rotate for a few seconds

after stopping the engine. Hold both

handles firmly up to the complete standstill

of the cutting device.

Now press the release button (4) and then the

throttle lever (2) until the device runs smoothly

and has reached full speed.

- Always hold the petrol brush cutters by the

handles with both hands rmly.

- Hold the control handle with your right hand

and the handle of the handrail with your left

hand.

- Always make sure that the cutting tool

continues to rotate for a short time after the

throttle has been released.

- Always ensure proper engine idling so that the

cutting tool does not turn when the throttle is

depressed.

- Always work at high speed, through which you

will have the best cutting result.

- Control the device from left to right and back

with an evenly curved movement.

Then cut the next track.

Caution: Always return the device to its original

position before cutting the next length.

- If you hit against a stone or tree while working,

turn o the engine and disconnect the spark plug

27

Page 28

connector, then inspect the petrol brush cutters

for damage.

Caution: Always be extra cautious when working

in dicult terrain and on slopes.

When the grass is tall, cut in stages so as not to

overload the device. First cut the tips, then work

in stages.

For an adequate protective equipment during

the use, care must be taken in accordance with

the operating instructions. All other usages are

ruled out. Any damage or injury resulting from

misuse is the responsibility of the user / operator

and not the manufacturer. Only use 3-teeth

blades suitable for the machine as mentioned in

the operating instructions.

Always wear protective goggles and ear

protection and wear a protective helmet during

forestry work.

6.1 Mowing with a string trimmer head

- Use the thread cassette for obtain a clean cut

even on uneven surfaces, at fence posts and near

trees.

-- Carefully lead the trimming thread to an

obstacle and cut with the thread tip around the

obstacle. When the trimming string comes into

contact with stones, trees and walls, the thread

frays prematurely or breaks.

- Never replace the plastic thread with a metal

wire - risk of injury!

6.2 Mowing with thicket knife

- Use the thicket knife to comb through thickets,

wild growth, young trees (maximum 2 cm trunk

diameter) and tall grass.

- When using metal cutting tools there is always

a risk of blowback if the tool hits a solid obstacle

(stones, trees, branches, etc.).

The device is thrown back against the direction

of rotation.

- In the case of wild growth and scrub, "dip" the

thicket knife from above. As a result, the material

to be cut is chopped.

- To sift through young stocks of trees and for

cutting grass, run the device such as a brush

cutter close to the ground.

CAUTION: Misuse and abuse can damage the

thicket knife and cause serious injury from parts

slung away.

- In order to reduce the risk of accidents caused

by thickets, observe the following points:

- Never cut shrubs or wood larger than 2 cm in

diameter.

- Avoid contact with metal bodies, stones, etc.

- Check the thicket knife regularly for damage.

Never use a damaged thicket knife once again.

-- If there is noticeable dulling of the thicket knife,

it must be sharpened in accordance with the

instructions by a qualied specialist.

If noticeable imbalance, the thicket knife must be

replaced.

6.3 Trim lines in automatic mode

The petrol brush cutter comes with a lled thread

cassette.

The thread wears o during work.

To feed new thread, press the trigger on the

thread cassette rmly on the ground with the

motor running.

CAUTION: Take extra care with this technique,

because the greater the distance of the cutting

tool to the ground, the greater the risk that

cutting material and foreign objects are thrown

sideways.

28

The thread is automatically released by the

centrifugal force. The blade on the cutting guard

trims the trimming thread to the correct length.

Page 29

7. Working with the pole-mounted

powered pruner unit

A20

- Never stand directly under the branch you

want to saw o. The danger of the branch

unexpectedly falling on you is very great. In

general, it is recommended to set the branch saw

at an angle of 60 ° to the branch.

- Hold the appliance rmly with both hands

during the cutting process and always ensure

that the machine is in an equilibrium position

and that it is strong.

- Never try to operate your tool with one hand.

Losing control of your tool can result in serious

injury or death. Never work on a ladder, a tree

branch or other from an unsafe ground.

A21

A22

7.1 Precautions during the sawing procedure

In order to reduce the risk of injury and

accident as much as possible, it is important

to be suciently informed about the sawing

procedures and precautionary measures

for accident prevention. Therefore, read the

following instructions carefully and observe the

safety instructions in chapter 2 during your entire

work process:

o

max 60

A23

- Do not saw strong branches in one cut, but

always in several steps.

- Place the saw chain on the branch for cutting.

- Apply light pressure to guide the unit, but do

not overload the engine.

- Adhere to the cutting technique given

in chapter 7.2 to avoid injuries and to not

sustainably damage your trees.

Clear the work area before cutting o disturbing

branches and undergrowth. Then create a retreat

area, away from the place where cut branches

can fall, and remove all obstacles there. Keep

the work area clear, remove the cut branches

immediately. Pay attention to your position, the

wind direction and the possible fall direction of

the branches. Be prepared for fallen branches to

strike back. Place all other tools and equipment

at a safe distance from the branches to be cut,

but not in the blowback area.

Always observe the condition of the tree.

Look for decay and putrefaction in the roots

and branches. If these are rotten inside, they

can unexpectedly break away and fall o while

cutting. Also look for broken and dead branches

that could be released by the shock and fall on

you. For very thick or heavy branches, make

29

Page 30

a small incision below the branch rst, before

working from top to bottom, to prevent it from

breaking o.

7.2 Basic cutting technique

The most common eects are:

• Blowback,

• Recoil,

• Retraction.

Heavy branches break o easily while sawing

and tear away long strips of bark from the trunk,

which permanently damages the tree.

The following cutting technique can signicantly

reduce this risk:

1. Saw about 10 cm of the branch from the trunk,

at the bottom of the branch (see Fig. A20).

2. Make another cut of about 15 cm from the top

of the trunk.

Saw until the branch breaks o. The risk of a

damage to the bark at the trunk does not exist

anymore (see Fig. A21).

3. Finally, remove the remaining branch stump

(see Fig. A22), with a clean cut from above along

the trunk.

In order to minimize the damage to the tree, we

also recommend sealing the area of the cut with

tree wax.

7.3 Dangers due to reactive forces

Reactive forces occur while operating the saw

chain. The forces applied to the wood act against

the operator. They occur when the running chain

comes in contact with a solid object such as a

branch or is trapped. These forces can lead to

loss of control and injuries. Understanding the

formation of these forces can help you to avoid

the moment of shock and loss of control.

This saw is designed in such a way that the

blowback eects are not as noticeable as with

conventional chainsaws.

Nevertheless, always keep a rm grip and a good

footing to keep control of the tool in case of

doubt.

Blowback

The blowback can occur when the running saw

chain at the upper quarter of the guide rail hits

on a solid object or is jammed.

A23

The cutting force of the chain exerts a rotational

force on the saw in the opposite direction to

the chain’s movement. This leads to an upward

movement of the guide rail.

Avoid blowback

The best protection is to avoid situations that

lead to blowbacks.

1. Always keep an eye on the position of the

upper guide rail.

2. Never let this place come in contact with an

object. Do not cut anything with it. Be particularly

careful near wire fences and while cutting small,

hard branches, into which the chain can easily

jam.

3. Cut only one branch at a time.

30

Page 31

A = Retraction

uncontrollable and can be pushed with great

force in the direction of the operator.

1. Be aware of the forces and situations that can

cause the chain to jam to the top of the rail.

2. Do not cut more than one branch at a time.

A24

The retraction occurs when the chain suddenly

gets stuck on the underside of the rail, because

it gets jammed or hits a foreign object in the

wood. The chain then pulls the saw forward. The

retraction often happens when the chain does

not run at full speed when in contact with the

wood.

Avoid retraction

1. Be aware of the forces and situations that can

cause the chain to stick to the underside of the

rail.

2. Always start cutting with the chain running at

full speed.

B = Recoil

A25

The recoil occurs when the chain suddenly gets

stuck on the top of the rail because it gets caught

or hits a foreign object in the wood. The chain

could then press the saw against the operator

with a jerk. Recoiling often happen when the top

of the rail is used for cutting.

Avoid recoil

- Risk of blowback! There is always a risk of

blowback, if the blade tip touches branches

or other objects. The brush cutters will be

3. Do not tilt the rail aside when pulling it out of

a cutting gap, otherwise the chain could become

trapped.

8. Cleaning, maintenance, transport

and storage

RISK OF INJURY

CAUTION: Always wear protective

gloves when working on and around

cutting tools.

To avoid the risk of unintentional

starting, pull out the spark plug

connector.

8.1 Cleaning

Use a damp cloth to clean the plastic parts. Do

not use detergents, solvents or sharp objects.

Due to technical reasons, wet grass and weeds

wrap around the drive axle under the cutting

protection.

Remove them, otherwise the engine will overheat

due to excessive friction.

8.2 Maintenance

8.2.1 Regular checks

Please note that the following information refers

to normal use. Under certain circumstances

(longer daily work, heavy dust load, etc.), the

specied intervals shorten accordingly.

Before starting work and after each tank lling:

31

Page 32

Check for loose attachments, especially on the

cutting set and shoulder strap, fuel leaks and

damaged parts, such as for example cracks in

cutting unit (visual inspection).

Also, visually inspect each time the device is

dropped and after any other impact to identify

signicant defects.

Weekly examination: Gear lubrication (also as

required).

If necessary: Tighten accessible fastening screws

and nuts.

You will avoid excessive wear and damage to

the device if you follow the instructions in this

manual.

The user is responsible for all damage caused by

non-observance of the instructions given in this

manual.

This also applies to unauthorized modications

to the device, use of unauthorized spare parts,

add-on parts, work tools, non-conforming and

improper use, consequential damage through

the use of defective components.

Always keep the device and all cutting

equipment and protective equipment in good

working condition.

32

Page 33

8.2.2 Change of spark plug

i

h

A26

8.2.3 Wearing parts

Check the electrode gap of the spark plug (h) at least once

a year or if starting is dicult on a regular basis. The correct

distance between the starting ag and the ignition contact is

0.6-0.7 mm.

- Wait till the engine has cooled completely.

- Remove the 2 locking screws on the housing with the

screwdriver (23) and open the housing of the spark plug

0.6-0.7 mm

assembly.

- Remove the spark plug cap (i) from the spark plug (h) and

unscrew the spark plug with the spark plug wrench (22)

supplied.

- In case of excessive wear of the electrode or in case of very

h

strong encrustation, the spark plug must be replaced with

one of the same type. Strong encrustation on the spark plug

may be due to: Too much oil in the

petrol mixture, bad oil quality, overaged

petrol blend or clogged air lter.

- Turn the spark plug (h) completely into the winding

manually. Avoid tilting the spark plug.

- Tighten the spark plug (h) with the spark plug wrench (29)

supplied.

- When using a torque wrench, the tightening torque is 12-15

Nm.

- Insert the spark plug connector (i) correctly on the ignition

plug.

- Attach the spark plug assembly housing to the device with

2 locking screws.

Even when used as intended, some components

are subject to normal wear and tear.

These components must be replaced regularly

depending on the type and duration of use.

These parts include the cutting tool and the

retaining plate.

33

Page 34

8.2.4 Changing spools of thread

14

ON

A27

8.2.5 Air filter cleaning

OFF

To avoid the risk of unintentional starting, pull out

the spark plug connector.

- Pull o the cover for the spools of thread by

pressing the retaining tabs o the spools of thread

(14)

- Move the cover for the spools of thread to the

"o" position. Remove the spools of thread with

the thread residue and the compression spring.

- Remove the used winding (bobbin).

- Take the new thread spools and pull out 10 cm of

both threads.

- Now place the thread spools of thread (14) on the

tapered spring and guide both threads through

the eyes on the spools of thread case.

- Now place the thread spool cover on the new

15

spools of thread. Turn them so that the notches on

the thread spool cover align with the eyelets in the

spools of thread case.

- Now push the thread spool cover together with

the thread spools until it snaps into the thread

housing. Then put the thread spool cover in the

"On" position.

14

Because of the blade in the cutting guard (15), the

trimming thread is shortened to the correct length

when the machine starts up again.

After prolonged work, you should clean the air

lter (5). Dust and pollen clog the pores of the

foam lter.

- Remove the cover (j) and wash the lter (k) in

j

slightly soapy water. Caution: Do not use petrol or

solvents.

- Dry the lter before reinserting it.

To avoid shortening the life of the engine, a

damaged air lter must be replaced immediately.

34

k

A28

Page 35

8.2.6 Care of the guide rail

A29

• Turn over the rail each time you sharpen or

replace the chain. This will avoid one-sided wear

of the rail, especially at the top and bottom.

Clean the following regularly:

1 = the opening for the oil supply

2 = the oil channel

3 = the running groove of the rail

Pay attention to the angles and dimensions given

below. If the saw chain is not properly sharpened

or the depth gauge is too small, there is a higher

risk of blowback eects and resulting injuries!

The saw chain cannot be xed on the guide rail. It

is therefore best to take the chain o the rail and

then sharpen it.

• Select a sharpening tool suitable for the chain

pitch. See "Technical data" for the approved chain

pitches.

A30

The chain pitch (e.g., 3/8 ") is marked in the depth

gauge of each blade.

8.2.7 Maintenance and sharpening of the saw

chain

The properly sharpened chain

A properly sharpened chain goes eortlessly

through the wood and requires very little

pressure. Do not work with a dull or damaged saw

chain. It increases the physical eort, increases

the vibrations and leads to unsatisfactory results

and higher wear.

• Clean the chain.

• Check for breaks in the links and damaged

rivets.

• Replace damaged and worn chain parts with

matching spare parts, which you can trim to the

shape and size of the original parts if necessary.

• Sharpening a chain should only be done by

experienced users!

Use only special les for saw chains!

Other les have the wrong shape and the wrong

cut.

Select the diameter of the le according to your

chain pitch. Be sure to observe the following

angles when sharpening the chain’s blades.

A31

A = ling angle

B = angle of the side plate

The angle must also be maintained for all knives.

In case of uneven angles, the chain will

run irregularly, wear out quickly and break

prematurely.

35

Page 36

A32

Since these requirements can only be met with

sucient and regular practice:

• Use a le holder

A le holder must be used by hand to sharpen

the saw chain manually. The correct ling angles

are marked on it.

A33

A34

chain runs irregularly and it increases the risk of

breaking.

8.2.8 Gear lubrication

A35

Check the grease lling approx. every 25

operating hours.

- Unscrew the screw plug with a suitable cross-

headed screwdriver.

- If no further grease can be seen on the screw, ll

approx. 5 g of universal grease (DIY store) into the

gear housing and close the lling hole again.

• Hold the le horizontally (at the correct angle

to the guide rail) and le according to the angle

mark on the le holder. Support the le holder on

the top plate and the depth gauge.

• Always le the knife from the inside out.

• The le sharpens only in the forward movement.

Lift it o when moving backwards.

•• Do not touch the straps and dynamic parts

with the le.

• Continue to rotate the le regularly to avoid

one-sided wear.

• Take a piece of hard wood to remove the ridges

from cut edges.

All blades must be of the same length, otherwise

they are of dierent heights. As a result, the

36

Make sure that the gearbox housing is never

completely lled with grease.

8.2.9 Carburetor adjustment

The factory setting for the carburetor is for

optimum performance. Should an improved

setting be necessary, please contact a specialist

workshop.

8.2.10 Trimming knife with string

A36

Page 37

- If the trimming string is no longer cut cleanly

when lengthening, hone down the cutting

edge with a le. File in one direction and at the

specied angle.

and screw it into the opening.

2. Pull the cable quickly several times to clean the

engine compartment of oil and debris.

8.3 Transport

Disconnect the spark plug connector before

transport and empty the oil tank and fuel tank to

prevent leakage.

In order to prevent damage and / or injury,

remove the last cutting set installed before each

transport and store it in a designated transport

protection.

Clean and maintain the device before transport

(see above) and secure it from slipping.

For a longer transport, it is recommended to

remove the extension (27) from the drive unit.

8.4 Storage / Winter storage

Clean and service the device before storage.

To ensure that the Brush cutter-Grass trimmerPruner-Hedge trimmer-Combination device

works without any problem again after a long

period of storage, you should note the following:

- Empty the fuel tank (7) before storage.

- Start the engine and let it run up to a standstill.

- When the engine has cooled, remove the spark

plug.

- Fill a small spoonful of 4-stroke engine oil into

the spark plug opening and pull the cable slowly

several times.

As a result, soot deposits are blown out and the

piston and cylinder are lubricated.

- Store the Brush cutter-Grass trimmer-PrunerHedge trimmer-Combination device

in a dry place, out of the reach of children and

without risk of re.

8.4.1. Restart after longer work breaks

1. Check the spark plug, replace it if necessary

3. Fill normal or premium petrol with 93 octane

or higher in the gas tank.

9. List of recommended cutting tools

and guards

1. Cutting protection (Fig.A1-15)

(For installation see Fig.7)

2. Thread spools (Fig.A1-19

(For installation, see Fig.7)

3. Thicket blade (Fig.A1-11

(For assembly see Fig.8)

4. Oregon chain (Fig.A3-22)

5. Oregon blade (Fig.A3-23)

Genuine accessories and spare parts can be

obtained from your Matrix service centre.

10. Working with petrol hedge trimmer

The hedge-trimmer with articulated arm is

designed for high performance and reliability,

without compromising on quantity, ease of use,

safety or durability.

Safety Instructions

Danger!

The hedge trimmer with articulated arm is not

insulated against electric shock!

Approaching or making contact with power

cables with the hedge trimmer may result in

death or serious injury. Keep the hedge trimmer

at least 10 meters away from power cords or

branches that touch power cables.

An articulated hedge trimmer may cause serious

injury if wrongly used, inserted or handled. In

37

Page 38

order to minimize the risk of personal injury, you

must have the device under control at all times

and observe all safety instructions during use. Do

not allow a person who has not been trained or

given instructions, to work with the device.

Notes on use

Read the operating instructions

carefully before switching on the

device.

Incorrect use may result in personal injury

or property damage. Persons who have not

familiarized themselves with the operating

instructions must not use the device. Keep the

manual in a safe place.

Children and adolescents may not use the device.

Always wear a helmet to avoid head

injuries while using the device.

Also wear protective goggles and

ear protection. We also recommend

wearing a face shield as additional protection for

face and eyes.

Wear non-slip work gloves for holding

the hedge trimmer better. Wear sturdy

shoes with anti-slip sole for a secure

footing.

Safety shoes with steel caps are

recommended. Wear tight-tting

clothing that still allows you freedom of

movement.

Do not use this device or other

powered devices if you are tired,

sick, or under the inuence of

alcohol, medication, or other

substances that may aect your

ability or judgement.

A distance of at least 10 meters to the hedge

trimmer must be maintained to bystanders, so

that they are not hit by falling objects or ying

small parts.

Never cut branches over your head.

The severed branches could hit you

and cause serious injury.

Warning!

Do not allow a person who has not been trained

or given instructions, to work with the device.

Before use, make sure that the cutting

attachment is properly installed and secured.

Do not use a hedge trimmer or cutting

attachment if they are damaged or warped.

Replace or repair the components before use.

Make sure that there are no objects near the

hedge trimmer before starting the engine.

Turn o the engine immediately and inspect the

device for damage if it hits a hard object or the

device gets caught. Do not use the device if it is

broken or damaged.

Pay attention to the springback when cutting o

a branch under tension, so that you will not be

injured when the branch springs back.

Turn o the device immediately if it begins to

vibrate or shake suddenly. Check the device

for broken, missing or incorrectly mounted

components or attachments.

Do not smoke near the hedge trimmer and do

not light a re. Keep the hedge trimmer away

from excessive heat. The engine fuel is highly

ammable and a re can cause serious personal

injury and damage to property.

Never use the hedge trimmer with articulated

arm without silencer.

Ensure adequate ventilation when using the

hedge trimmer with articulated arm. The exhaust

fumes can cause serious injury or death. Never

start the engine indoors.

Make sure that there are no missing or loose

locks and that the stop switch and throttle levers

are working properly.

If the hedge trimmer gets locked, switch o the

engine immediately. Push the branch or bough

aside and free the hedge trimmer.

Before using the hedge trimmer with articulated

arm, make sure that the blades are properly

aligned. Never align the blades with the engine

running.

Make sure that no fuel leaks from the tank, from

the lid, from the fuel line and the carburetor or

from other parts that could leak fuel. Repair the

device when fuel leaks and make sure there is no

leak.

38

Page 39

Safety instructions for blowback and

jamming

Warning!

Through blowbacks or jamming, you could

lose control over the hedge trimmer and injure

yourself seriously. Do not rely solely on the

integrated safety device of the hedge trimmer.

You must take various measures to prevent

accidents or injuries.

1. Be prepared for blowbacks or jamming. Avoid

or eliminate the element of surprise. Surprise

moments contribute to accidents.

2. Hold the hedge trimmer rmly with both

hands when the engine is running. A good grip

reduces the eects of blowbacks or jamming and

keeps control of the device.

3. Make sure that the area where you work is free

of obstacles.

4. Cut at a high speed.

5. Use only the replacement blade or equivalent

one provided by the manufacturer.

Warning!

The hedge trimmer with articulated arm must

not be transported or put down with the engine

running. The running engine could accidentally

accelerate and thus cause the blade to vibrate.

If the hedge trimmer is to be carried with an

articulated arm, the cutting attachment must be

in the transport position. See A 37.

not be manipulated or deactivated.

Use only original parts and accessories for repair

and maintenance of this equipment.

Do not make any unauthorized changes to the

hedge trimmer with articulated arm.

When transporting in a vehicle, the hedge

trimmer must be secured in such a way that

fuel does not escape or the device cannot be

damaged.

Remove garbage and small parts from your work

area to ensure a secure footing.

Keep the blades sharp and properly aligned.

Keep the hedge trimmer with articulated arm as

clean as possible. Remove loose twigs, mud, dirt,

etc.

A37

Caution!

The safety devices of the hedge trimmer should

39

Page 40

Product description of the cutting attachment for hedge trimmer

31

38

A38

Before the assembly

Use Figure 3 as a reference and familiarize

yourself with the hedge trimmer and its various

components. Understanding the device ensures

excellent performance, longer life and safe use.

Check the completeness of all components of the

device before mounting the unit.

• Cutting attachment

• blade cover

• Operation manual

• Tool set for routine maintenance

Check all components and make sure that no

components are damaged.

32

33

34

31.Messer

32. Handle

33. Unlocking

34. Locking device

38. • Blade cover

Warning!

Do not make any unauthorized alterations

or modications to your hedge trimmer with

articulated arm or its components.

40

Page 41

Assembly of the pipes

1. Place the tube with the drive head (lower pipe)

and the upper pipe on a clean, even surface, so

that both ends can be inserted into each other.

The tube with the drive head (lower pipe) and

the bolt guard of the upper pipe must point

upwards.

Caution! The open ends of the tubes must be

clean and free of dirt!

2. Loosen the screw of the connector.

3. Press the latch down and push the tube with

the drive head (lower tube) into the connector

as far as it will go. Release the latch. Slide the

top tube back and forth until it snaps into the

connector. See A 39.

5

2

7

A40

Disassembly of the tubes

1. Place the hedge trimmer on a clean, even

surface and loosen the screw of the connecting

piece. Pull the latch protection out of the notch.

2. Press the latch down. This triggers the locking

of the connector. See A41.

5

6

3

4

1

2

A39

1). Latch

2). Latch protection

3). Indent