Page 1

Product instruction manual

Matrix Single Side Laminators

The Matrix has been designed to be user friendly,

however we strongly recommend you take a few minutes

to read through this manual to ensure correct operation.

Keep this manual safe for future reference.

Page 2

2 3

Page 3 - Introduction

Page 4 - Safety Instructions and environmental requirements

Page 5 - Control panel and display screen

Pages 6 & 7 - Operation & installation of laminating lms

Page 8 - Warranty and incorrect use

Thank you for purchasing the Matrix single sided laminator.

Matrix is a high performance single sided laminating system with a solid construction

built to last.

Please read these instructions carefully before starting to use the system to ensure you

get the best results and are competent at operation.

Should you experience any problems please contact us and we will be happy to help.

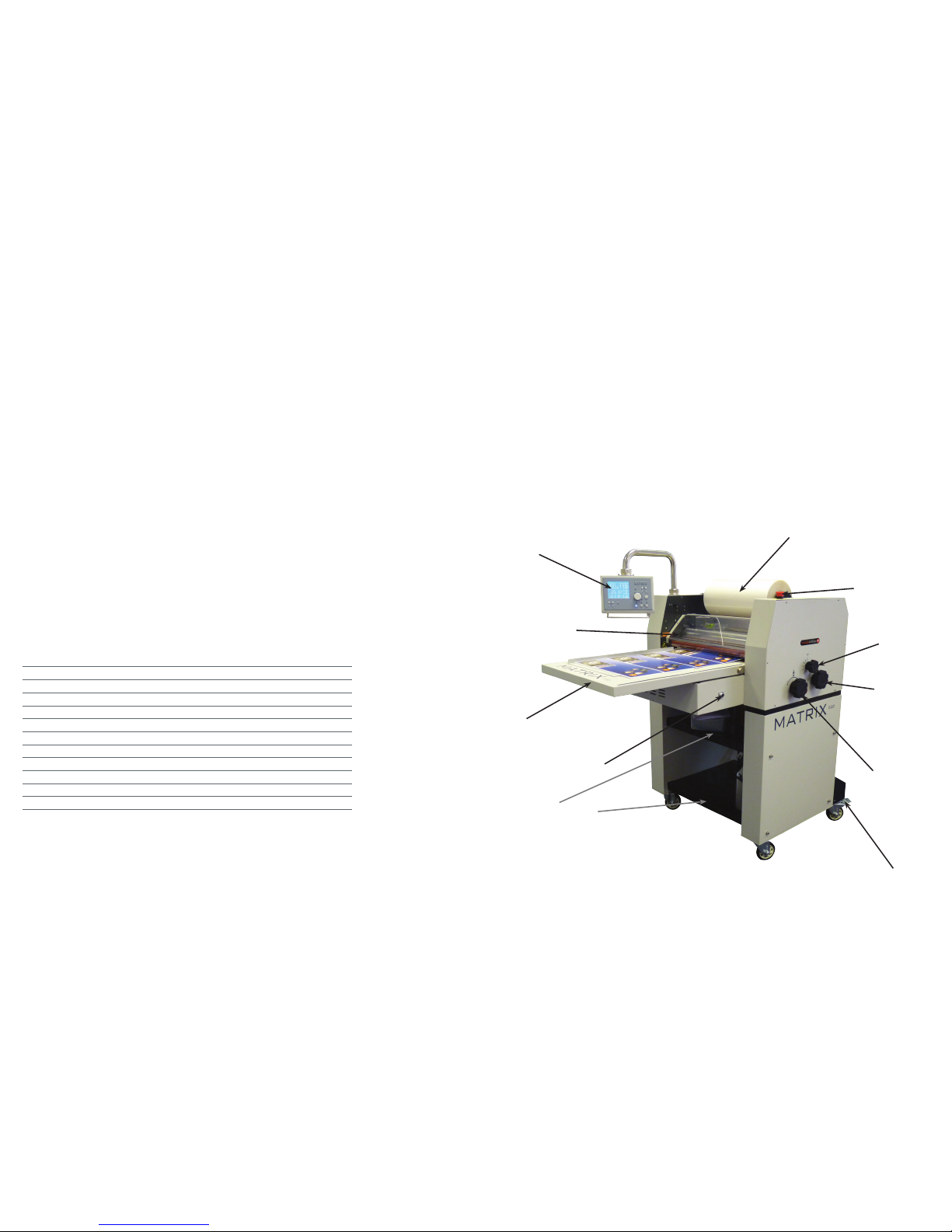

Matrix 370

Matrix 530

Contents Introduction

DIGITAL DISPLAY

SAFETY GUARD

FEED TRAY

FOOT SWITCH PLUG-IN

FILM STORAGE TRAYS

BRAKE LOCK

LAMINATING

ROLLER LIFT

REAR PULL

ROLLER LIFT

ANTI-CURL

SETTING

EMERGENCY STOP

FILM MANDREL

MX-370 MX-530

Max Laminating Width 340mm 500mm

Max Laminating Thickness 135gsm

Temperature Range 0-140°C

Approx. Highest Line Speed 10m/min

Maximum Sheet Width 420 550

Warm up Time 10 mins

Power consumption 2200 2400

Power Supply Required 13 Amps

Power Supply 220/240 V

Rate Input Power 900W 1000W

Dimensions 800 x 1800 x 1400mm 900 x 2050 x 1400mm

Gross Weight 190kg 220kg

Specications

Page 3

4 5

• Ambient temperature 10°C - 60°C, humidity 30% - 80%, Ideal humidity 55%

• Dust - Due to the static adherence of the lm, you should keep the environment clean, a

dust cover is provided with the machine

• Please do not keep the machines in direct sunlight

• Please do not keep the machine in or around dusty areas

• Enough space should be kept around the machine to ensure the secure and eective ap-

plication. The minimum holding areas are 2.5m x 3m

Environmental Requirements

Safety Instructions

The Control Panel

• Please ensure that the voltages of power supply you are using match with rated working

voltages before operating the machine

• The power supply should be close to the machine for convenient use

• The power supply should provide reliable protective earthing connection

• This machine must be earthed reliably so as to ensure the safety of the machine during

operation

• Only the operators of this machine should operate the electric or motion components/

controls

• Please don’t use damaged wires or sockets

• Please keep children away from touching and operating this machine

• Please do not spray water or other liquid on the machine otherwise electric shock or

machine faults could occur

• Please do not replace power cord or plugs yourself, do not put heavy objects on the

power lines as this may cause electric shocks

• During use please take care that no clothes, neckties, hair, necklaces etc are near the

machine otherwise injuries could occur

• Please don’t put burrs, sharp blades or over thick rigid materials into the two rubber cov-

ered rollers (for example, tools, rulers and knives etc.)

• Don’t cut adhesive lms directly on the surfaces of the rubber covered rollers to avoid

damage

• Please shut down this machine after laminating to avoid misuse of the machine

• At the end of the working day always gape the rollers to ensure no at spots or distor-

tions occur

• When you need to move this machine, please shut down the power switch and pull out

the plugs

• Please be aware of the location of the wheels during moving or operating this machine

to avoid foot injuries

• Always ensure the machine is positioned on a at and level oor

• Please shut o the power supply (pull out the power plug) when the machine isn’t going

to be used for long periods of time.

Display screen Function key Memory keys

Temperature

Setting

Screen

brightness

adjustment

Speed

setting

dial

Stop key

Reverse

rotation key

Crawl Key*Forward driveAnti-curl settingFine tune key for

cutting position

Paper

length

setting

*Functions with foot pedal only

Running

speed

The Display Screen

Sheet

length

Sheet

splitting

adjustment

Anti-curl setting (0-6) Actual temperature Screen brightness

Memory Set temperature

Sheet counter

Page 4

6 7

4. Set temperature, sheet length

and anti-curl setting.

5. Remove lm mandrel. 6. Using the allen key provided, loosen

screws on the core adaptor.

Set the required temperature using the

+ - temperature buttons

MATRIX set-up & Installation of Laminating Films

7. Remove one core adaptor. 8. Slide lm onto the mandrel and

centralize, replace core adaptor.

9. Place lm and mandrel back onto the

machine.

10. Ensure lm feeds from the bottom of

the roll.

11. Set the anti-curl device to the zero

position and ensure both laminating and

pull rollers are in the raised position.

12. Press rubber roller to drop gate and

slide in plain print, ensure it goes through

anti-curl device and into pull rollers.

1. Position the machine near a suitable 13

amp socket and plug into the mains.

2. Turn the power on. 3. Screen displayed, see large screen

diagram for functions on page 5.

13. Slide the second blank print around

the steel laminating roller, through the

anti-curl device and into the pull rollers.

14. Run the lm under the idler bar and

drape over the steel laminating roller.

15. Press second set-up print onto the

lm.

16. Replace the guard. 17. Ensure the micro switch is located,

otherwise the machine will not run.

18. Lower the laminating and pull rollers

and set the anti-curl to the desired

setting.

19. Set the perforation wheel, lock in

place on the edge of the lm which

should be in the paper margin (and not

on the print).

20. Turn the screw as the paper is feeding

until the perforation wheel starts to turn,

then lock into position.

21. Set the guide wheel to the opposite

side of the sheet from the perforation

wheel.

22. Finally, set the incline wheel on the

edge of the print on the same side as

the perforation wheel. Only a very small

angle is required.

1. Top paper feed roller. 2. Guide paper (end).

3. Front guard. 4. Steel laminating roller.

5. Idler bar. 6. Lamination roller lm. 7. Top pull roller.

8. Perforation wheel. 9. Top splitting roller.

10. Guide wheel. 11. Bottom roller for guide wheel.

12. Bottom splitting roller.

13. Perforation wheel support roller.

14. Bottom pull roller. 15. Anti-curl device.

16. Front bottom rubber laminating roller.

17. Paper stop. 18. Bottom paper feed roller.

19. Front operating panel. 20. Paper backing plate.

Place where the

paper core is stuck

to the lm

1st paper core

2nd paper core

Guide paper core (front end)

Page 5

Warranty & Incorrect Use

IMPORTANT INFORMATION

Your laminator should reach you in perfect condition, however please retain all original packaging once you have unpacked

your laminator in case you need to return it to us. If your laminator arrives damaged or faulty in anyway, this must be reported

to your supplier immediately. If you send your laminator back for repair under warranty at any time, then the warranty may be

void if the laminator is not packaged correctly and as a result is damaged in transit. The laminator you have purchased comes

with a 1 year warranty on defective parts. THIS DOES NOT COVER any jams, misfeeds or wrap arounds caused by operator error

and you will be liable for the repair costs (including delivery charges) if the damage is caused by operator error.

E&O.E

Loading...

Loading...