Page 1

MR311 Range Cooker

Manual for Installation, Use and Maintenance

GB, IE

Page 2

2

Important

This appliance must only be used for the purpose for which it is intended, i.e. domestic cooking. Any other use could be

dangerous and may lead to premature failure of the appliance.

The CDA Group Ltd cannot be held responsible for injuries or losses caused by incorrect use or installation of this

product. Please note that CDA reserve the right to invalidate the guarantee supplied with this product following incorrect

installation or misuse of the appliance.

This appliance is not designed to be used by people (including children) with reduced physical, sensorial or mental

capacity, or who lack experience or knowledge about it, unless they have had supervision or instructions on how to use

the appliance by someone who is responsible for their safety.

Under no circumstances should any external covers be removed for servicing or maintenance except by suitably qualified

personnel.

Appliance information:

Please enter the details on the appliance rating plate below for reference, to assist CDA Customer Care in the event of a

fault with your appliance and to register your appliance for guarantee purposes.

Appliance Model

Serial Number

CE Declarations of Conformity:

This oven has been designed, constructed and marketed in compliance with safety requirements of EEC Directive 2006/95/

EEC (Low voltage) and requirements of EMC Directive 2004/108/EEC.

This appliance has been manufactured to the strictest standards and complies with all applicable legislation, including

Electrical safety (LVD) and Electromagnetic interference compatibility (EMC). Parts intended to come into contact with food

conform to EEC/89/109.4

IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE PRODUCT IN ACCORDANCE WITH EC

DIRECTIVE 2002/96/EC.

At the end of its working life, the product must not be disposed of as urban waste. It must be taken to a special local

authority differentiated waste collection centre or to a dealer providing this service.

Disposing of a household appliance separately avoids possible negative consequences for the environment and health

deriving from inappropriate disposal and enables the constituent materials to be recovered to obtain significant savings

in energy and resources. As a reminder of the need to dispose of household appliances separately, the product is marked

with a crossed-out wheeled dustbin.

Page 3

3

User information:

Read the instructions carefully before using the cooker.

Keep the instructions in a safe place for future reference.

Follow the instructions for first use (page 4).

Always use oven gloves when removing shelves and trays from the cooker.

Always grill with the door closed.

Do not grill food containing fat without using the grill pan grid.

Do not use the grill pan for roasting.

Do not place cooking utensils or plates directly on the oven base.

Do not cover the grill pan grid or the oven walls with aluminium foil.

Do not attempt to repair the internal workings of your oven.

Cookers become hot during and immediately after use. Do not touch the pan stands, burners, hob spill tray or oven

internal parts until the appliance has been allowed to cool.

After use, ensure that all the control knobs are switched off.

Keep children away from the cooker when in use and immediately after use.

Ensure that the appliance is correctly adjusted for the type of gas available before installation.

The use of a gas appliance produces heat and humidity in the room in which it is installed. Ensure that the room is well

ventilated, either by the use of natural ventilation outlets (e.g. windows) or a ducted extractor.

This cooker has been designed for use only as a cooking appliance. Any other use (e.g. heating rooms) should be

considered incorrect and therefore dangerous.

This cooker must not be installed in a bed-sit room of less than 20m³.

These instructions are valid only for the intended countries of destination, the symbols of which appear on the cover,

the packaging and on the appliance. Use outside of these countries may or may not be possible. You should consult the

manufacturer for appropriate advice.

Do not spray aerosols in the vicinity of this appliance when in use.

Do not store or use flammable substances in the vicinity of this appliance when in use.

When correctly installed, your product meets all safety requirements laid down for this type of product.

However, special care should be taken around the rear or the underneath of the appliance as these areas

are not designed or intended to be touched and may contain sharp or rough edges that could cause injury

Page 4

4

Before first use

• Before using the oven for the first time we recommend that you

clean the oven with soapy water, rinse carefully , dry thoroughly

and then heat on the oven function at maximum temperature for

one hour. A slightly unpleasant smell may be produced, caused

by grease remaining on the oven elements from the

production process.

Please note:

• This oven has been fitted with a cooling fan to achieve maximum

efficiency and to maintain low surface temperatures. The cooling

fan will switch on automatically when the oven reaches a preset

temperature and switch off automatically when the oven has cooled

sufficiently, even after the oven is switched off.

• The oven is equipped with a safety thermostat which will switch

off the oven to prevent overheating. Overheating can be caused

by incorrect use of the oven or defective components. If the

oven switches off due to overheating, wait for the oven to cool

down before using it again. If the error continues, contact CDA

Customer Care.

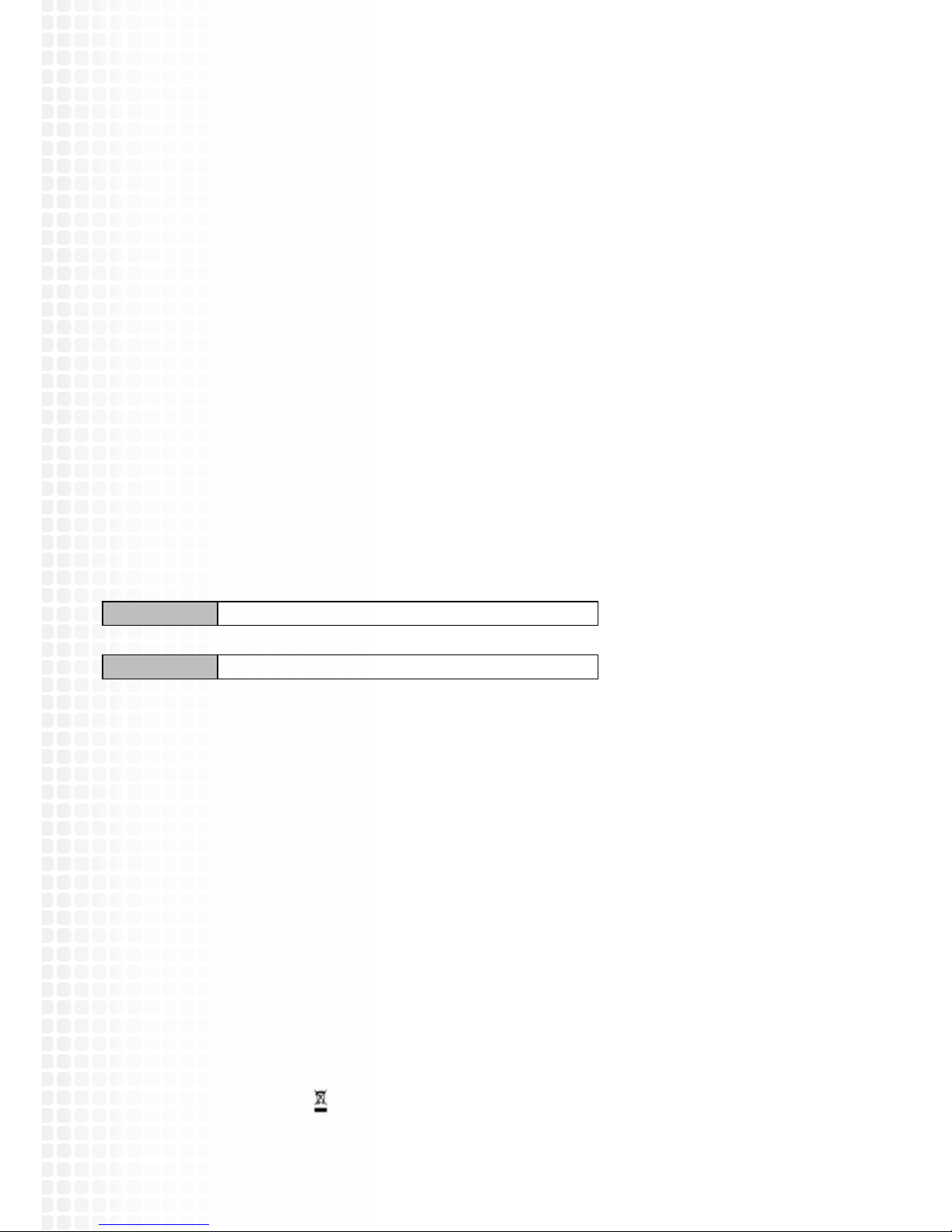

Before using the hob

• Before lighting the hob burners, check that the flame-spreaders (F)

are in position with their respective burner caps (C), ensuring

that the holes in the flame-spreaders are aligned with the ignition

electrodes (S) and thermocouples (T) as shown in fig. 1. 200

• Once the contents come to the boil, turn down the flame far

enough to prevent the liquid from boiling over. To prevent burns or

damage to the hob during cooking, all pans or griddle plates must

be placed inside the perimeter of the hob.

• Place the pan on the pan supports with the handles facing away

from the edge of the work top. This will reduce the risk of the pan

being knocked or pulled over.

Deep Fat Frying

• Only fill the pan one third full of oil.

• Do not put a lid on the pan and never leave the pan unattended.

• In the event of a fire, do not move the pan and turn off all

control knobs.

• Then put a damp cloth over the pan, or a correctly fitting lid to

smother the flames.

• Do not put water on the fire.

• Leave the pan to cool for at least 30 minutes before attempting to

move it.

fig. 1

C

F

S

T

Page 5

5

Using your hob

Gas burners:

Gas flow to the burners is controlled by the control knobs (7 - 11 on the diagram above). There are 3 positions shown on the

control panel. Turning the control knob to the positions shown below achieves the following:

Closed (OFF position)

Maximum position: Provides fast boiling function

Minimum position: Provides simmer function

The hob can be set to the desired position by turning the control knob through the adjustment range in an

anti-clockwise direction..

fig. 2

Gas burners:

1. Left Rapid 3.0kW

2. Left Semi-rapid 1.75kW

3. Triple-ring/Wok 3.7kW

4. Right Semi-rapid 1.75kW

5. Right Rapid 3.0kW

Control panel:

6. Timer control

7. Front left rapid burner control

8. Rear left semi-rapid burner control

9. Centre Triple ring/Wok burner control

10. Rear right semi-rapid burner control

11. Front right rapid burner control

12. Oven/Grill control

13. Light control

This appliance is class 2/1

1

432

5

6 7 8 9 10 11 12 13

200

Page 6

6

Igniting the Burners

The hob is fitted with a flame failure device. Flame failure devices

operate by shutting off the supply of gas to the burner in the event that

the flame is extinguished accidentally.

To ignite the burners, follow these instructions:

1. Lightly press the control knob down and turn the knob

anticlockwise to the maximum position. Firmly press and hold

down the control knob to begin the ignition process (a clicking

sound will be heard). Hold down the control knob for a few

seconds after ignition to allow the safety device to detect that the

burner is lit.

2. Once the burner is lit, adjust the burner power to the

required position.

Please note:

• The ignition device should not be operated for more than

15 seconds.

• If a burner does not ignite, or turns off accidentally, turn the

control knob to the ‘off’ position, and wait for one minute before

attempting to reignite the burner.

• If the burner does not ignite, repeat the ignition process with the

burner at the minimum position.

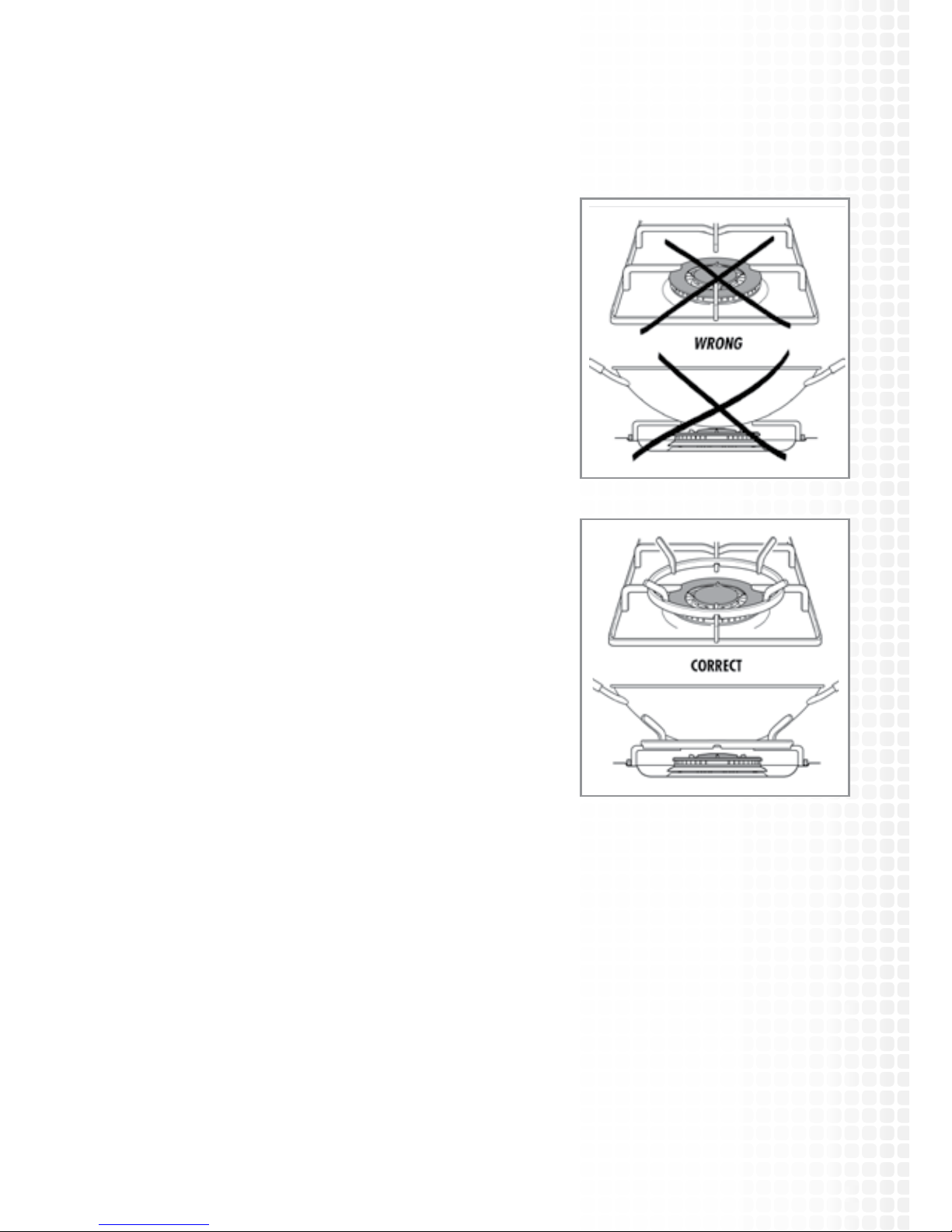

Efficient use of your Hob

The hob is equipped with burners of different sizes, designed to

accommodate most shapes and sizes of pan. For best results, only use

pans with flat bottoms and choose an appropriate burner depending on

the size of the pan. The most efficient use of the hob is shown below,

where the pan and burner are correctly chosen.

Ensure that the pans do not overlap the edge of the pan stand, or cover

the control panel. Position the pan centrally above the burner.

The table below shows the sizes of pan that should be used with

each burner:

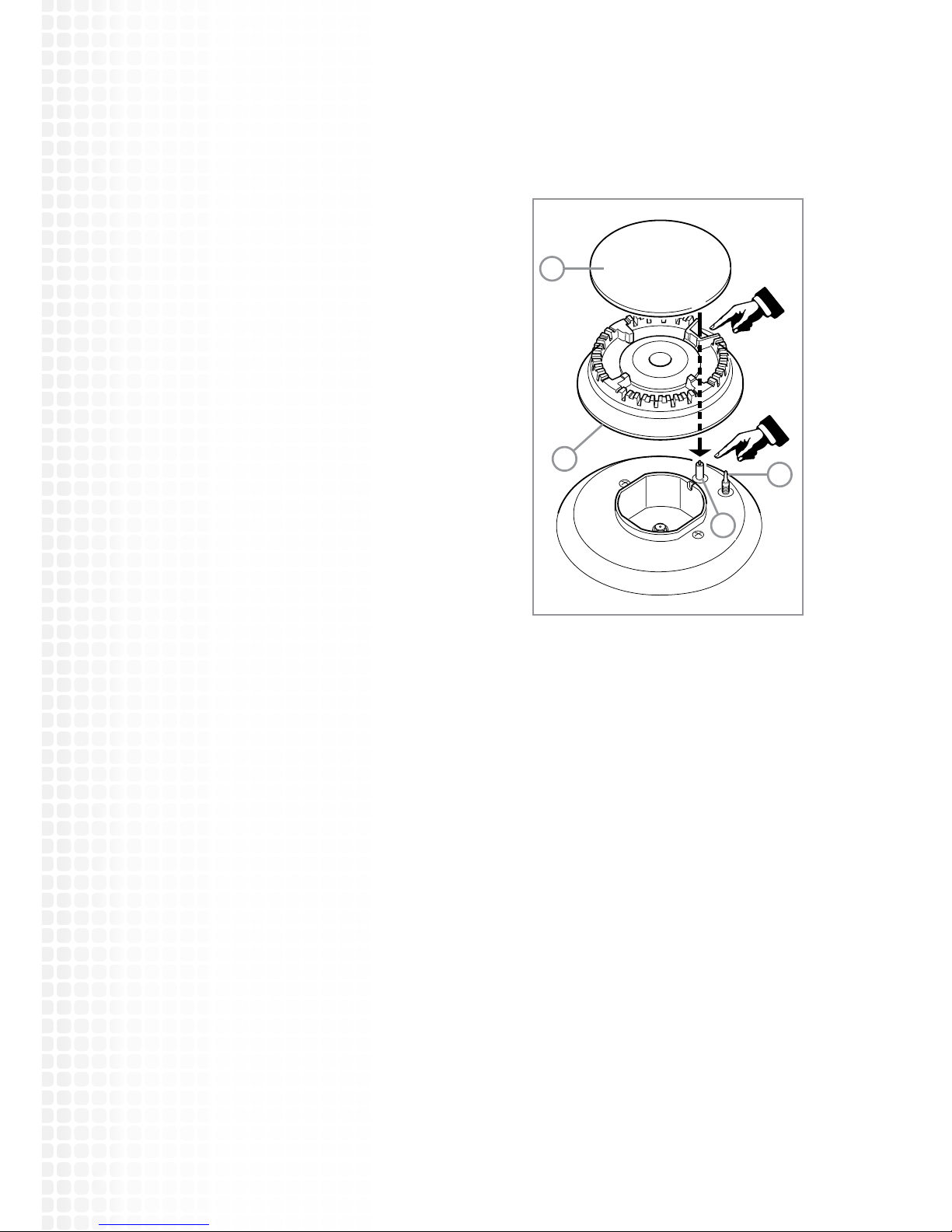

Fig.3

Fig.4

Burner Size Minimum Pan Diameter (cm) Maximum Pan Diameter (cm)

Semi-Rapid 12 20

Rapid 20 26

Triple ring 24 28

Wok - 36

Page 7

7

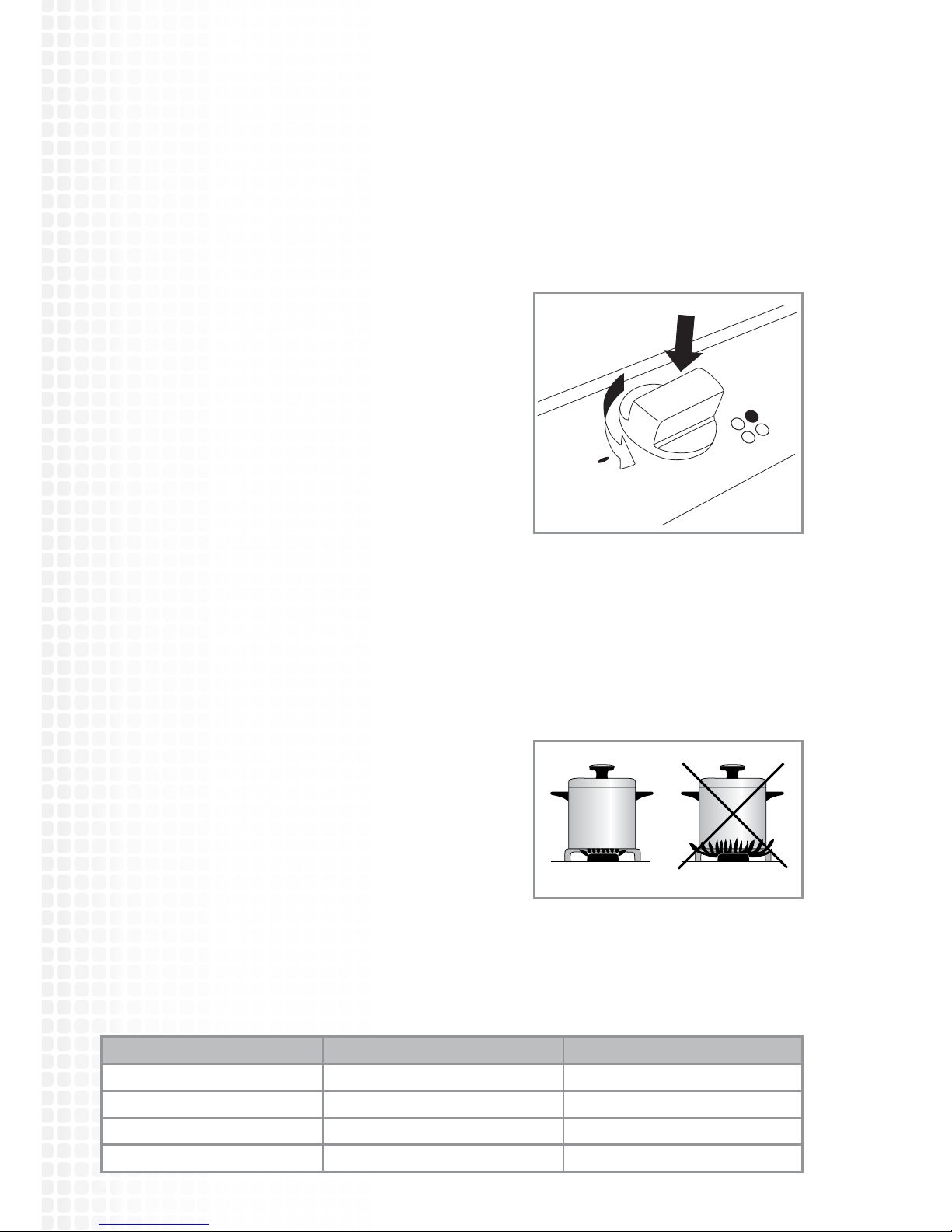

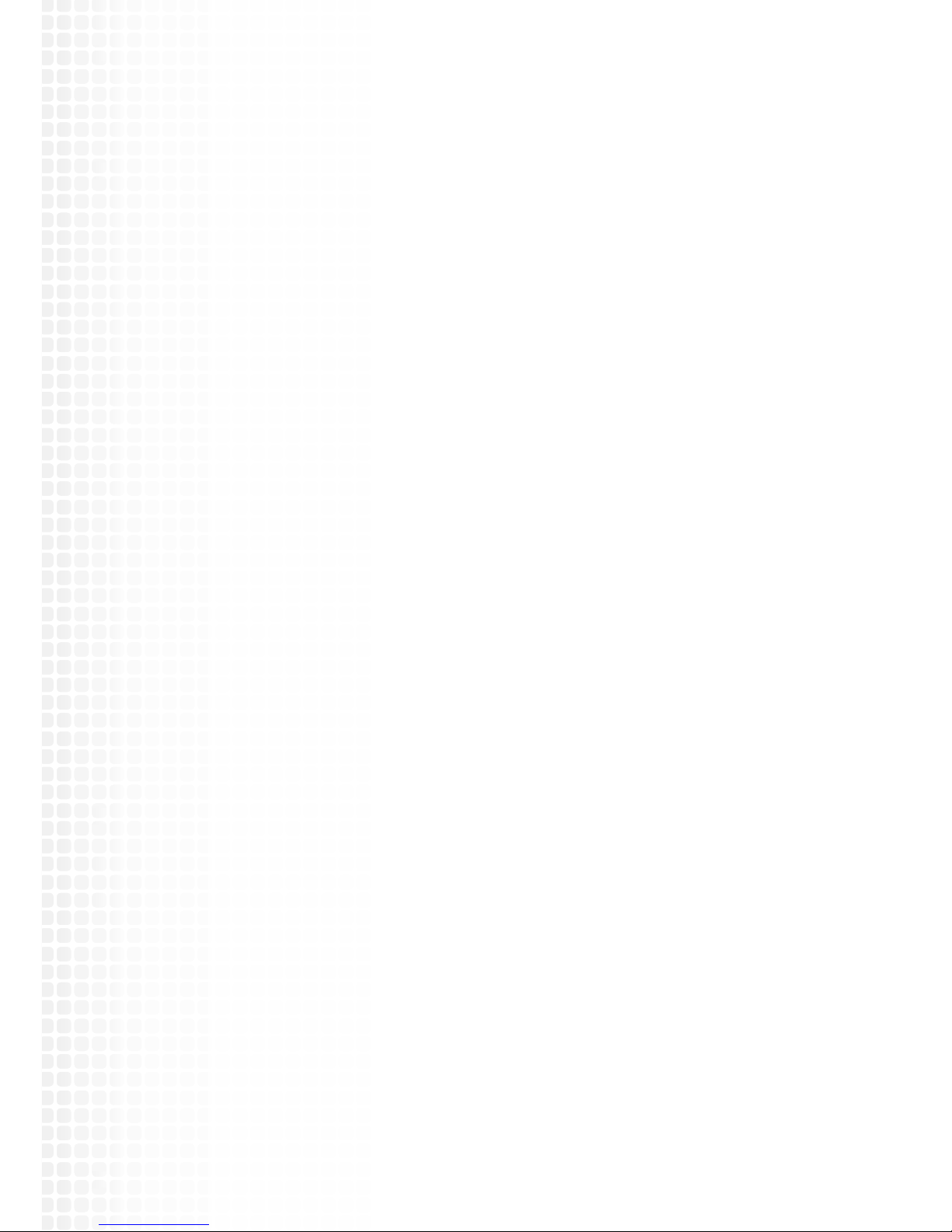

Correct use of the Wok Pan Adaptor

The wok pan adaptor is a special stand that is designed to be fitted over

the triple ring burner to give support to round bottomed woks.

When using a wok, always place the wok pan adaptor in position over

the pan support on the triple ring burner as shown in Fig.5.

IMPORTANT:

• The wok pan adaptor (Fig.5) must be placed over the pan support

on the triple ring burner.

• Do not use the wok pan adaptor for standard flat bottomed pans.

Fig.5

Fig.6

Page 8

8

The Oven and Grill

Using the light

The cooker is equipped with a light to illuminate the oven cavity allowing easy viewing of the food as it cooks.

To switch the oven light on, turn the oven light control knob to the light position.

To switch the oven light off, turn the oven light control knob to the off position.

Using the minute minder

The cooker is equipped with a minute minder, to count down the time to a maximum of 60 minutes.

To set the minute minder, turn the minute minder control knob fully clockwise to the maximum, and then anticlockwise

until the control knob indicates the required time.

At the end of the preset time, a buzzer will sound.

Please note: the minute minder will not switch off the oven, grill or burners at the end of the preset time.

Using the oven

The oven/grill control knob allows the oven temperature to be set as required.

The oven burner is fitted with a flame failure device. This will shut off the supply of gas to the burner in the event that

the flame is extinguished accidentally.

To light the oven burner, follow the instructions below:

1. Open the oven door fully. The oven door must be open during the ignition process – the oven is equipped

with a safety system which will prevent the oven lighting if the door is closed.

2. Push in and turn the oven control knob anticlockwise until the indicator points to the oven 240 * position.

3. Press the knob fully in to activate the ignition. Keep the control knob pushed fully in for a maximum of 15 seconds to

allow the safety device to detect that the burner is lit.

4. Close the oven door slowly.

5. Adjust the oven control knob to the required temperature position.

Please note:

If the burner does not ignite after 15 seconds, turn the oven control knob back to the off position, leave the

oven door ajar and wait for at least one minute before repeating the process above.

If the burner is extinguished accidentally, turn off the control knob and wait approximately one minute before attempting

to relight the burner.

You should allow the oven to preheat for 10 to 15 minutes prior to starting cooking.

Page 9

9

Using the grill

The grill burner is fitted with a flame failure device. This will shut off the supply of gas to the burner in the event that the

flame is extinguished accidentally.

To light the grill burner, follow the instructions below:

1. Open the oven door fully. The oven door must be open during the ignition process – the grill is equipped

with a safety system which will prevent the grill lighting if the door is closed.

2. Push in and turn the oven control knob clockwise until the indicator points to the Grill * position.

3. Press the knob fully in to activate the ignition. Keep the control knob pushed fully in for a maximum of 15 seconds to

allow the safety device to detect that the burner is lit.

4. Close the oven door slowly.

Please note:

If the burner does not ignite after 15 seconds, turn the control knob back to the off position, leave the oven

door ajar and wait for at least one minute before repeating the process above.

If the burner is extinguished accidentally, turn off the control knob and wait approximately one minute before attempting

to relight the burner.

You should allow the grill to preheat for 5 minutes prior to starting cooking

Do not grill for more than 30 minutes.

Page 10

10

Care and Maintenance

Cleaning the Cooker

IMPORTANT:

Always disconnect the appliance from the power supply before undertaking any cleaning or maintenance.

You should always allow the cooker to cool fully after use before undertaking any cleaning or maintenance.

• Steam cleaners must not be used when cleaning this appliance

• Clean the cooker regularly and remove spills as soon as they occur.

• Do not allow fat or oils to build up on the hob or in the oven.

• Do not place hot enamel parts (e.g. burner caps, grill pan) in water. Leave them to cool first.

• Do not allow vinegar, coffee, milk, saltwater, lemon or tomato juice to remain in contact with enamel parts

• Do not use abrasive or corrosive cleaners (including scouring pads or Cif) as these could scratch the appliance, remove

control panel markings or damage the cooker.

• Do not clean the removable parts of the cooker in a dishwasher, these must be washed by hand.

As the hob has a stainless steel surface, you should use a nonabrasive cleaner. Any abrasive cleaner (including Cif) will

scratch the surface and could erase the control panel markings. Stainless steel can be effectively cleaned by simply using a

dilute solution of water and mild detergent and drying to a shine with a clean cloth.

Over time with use, the stainless steel surface may discolour; this is normal and does not constitute a fault with this

appliance. Proprietary stainless steel cleaners are available.

Page 11

11

fig. 7

Cleaning the Oven Interior

To clean the oven interior, suitable proprietary chemical cleaners may be

used after first consulting with the manufacturer’s recommendations

and testing a small sample on the oven cavity.

If necessary, the oven floor can be removed for cleaning.

Do not use metal scrapers or harsh cleaners on the oven door glass.

These could cause scratches, which may result in the glass shattering.

To remove the side racks, press down on the top bar of the side rack to

free the rack from the top securing pin, then remove the side rack by

lowering it out so that the hooks on the lower edge are freed from the

oven cavity (as shown in fig. 7) .

To replace the side racks, locate the lower hooks in the oven cavity, then

pivot the side rack back into position, pressing the top bar down to

relocate it against the securing pin.

Ensure that all parts are correctly replaced after cleaning before

attempting to use the cooker, and that the rubber pads are in place on

the base of the pan stands before repositioning the pan stands on the

hob top. To replace the hob burner parts correctly, refer to fig. 6 on

page 7.

fig. 8

fig. 9

Page 12

12

Removing the Oven Door

The oven door can easily be removed as follows:

• Open the door to the full extent (fig. 10)

• Open the lever A completely on the left and right hinge

see (fig. 11)

• Hold the door as shown in Fig. 14

• Gently close the door (fig. 13) until left and right hinge

levers A are hooked to part B of the door (fig. 12)

• Withdraw the hinge hooks from their location following

arrow C (fig. 13)

• Rest the door on a surface.

To replace the door, repeat the above steps in reverse order.

Fig.10

Fig.11

Fig.14

Fig.13

Fig.12

Page 13

13

Care and Maintenance

Flexible gas pipe

Check the flexible gas pipe connecting the gas supply to the cooker regularly.

It must be always in perfect condition; in case of damage contact Customer Care for advice.

Control knobs

Should any of the control knobs become stiff, do not use force. Contact Customer Care for advice.

Changing the oven light

1. Disconnect the electrical power supply (for example, by switching off the main isolator switch).

2. Unscrew the light cover.

3. Fit a new bulb.

4. Refit the cover.

Note:

Use only bulbs designed to resist up to 300°C with the following characteristics: 230 V, type E14 and same power of the

replaced bulb (check watt power as stamped on the bulb itself).

What to do if you smell gas:

1. Open doors and windows

2. Turn the gas supply off

3. Call TRANSCO on 0800 111 999

Total rated gas input: 17.7 kW

Mains electrical voltage: 230-240Vac, 50Hz

Total rated electrical consumption: <1W

If your cooker is not working

1. Check that the mains supply has not been switched off.

2. Check that the fuse in the spur has not blown.

3. Ensure that the burner components are not excessively soiled as this can lead to ignition problems.

Burner size Nominal Rating

(kW)

Simmer Rating

(kW)

LPG flow rates (l/h)

G30 (Butane) G31 (Propane)

Semi-Rapid 1.75 0.6 127 12 5

Rapid 3.0 1.0 218 214

Triple ring / Wok 3.7 1.25 269 264

Page 14

14

Installation section

The manufacturer will not be held responsible for

any damage to property or injury to persons/animals

resulting from incorrect installation of this appliance

We recommend you seek the help of another individual

when installing this appliance to prevent damage or

injury.

Installation requirements

This range cooker is designed to be installed flush with

adjacent worktops however in situations where the hob top

will be lower than the worktop then a distance of 200mm

should be observed.

A distance of 500mm between the range cooker and any

adjacent combustible materials (e.g. curtains) should be

observed.

A distance of 200mm between the range cooker and adjacent

vertical surfaces should be observed.

This appliance is class 2/1 and is suitable for installation

adjacent to furniture cabinets.

If fitting a cooker hood above the

range cooker:

If a cooker hood is to be installed above the range cooker, the

height of the hood above the burners must be at least 700mm

(750mm is recommended). If the instructions supplied

with the hood dictate that the hood must be installed at a

height greater than 700mm, then that height is the minimum

required.

Wall furniture requirements:

The minimum height of any cabinet immediately above

the hob is 900mm. The minimum height of any adjacent

units (including light pelmets) is 450mm, unless they are

manufactured from a material resistant to fire (steel, for

example)

fig. 15

fig. 16

650 mm

500 mm

200 mm

450 mm

air ven t

700-900mm

200

900

Page 15

15

Notes:

• Do not position this appliance adjacent to a refrigeration

unit. The heat generated may cause the refrigeration unit

to fail.

• This appliance is designed to be installed adjacent to

cabinet units capable of withstanding temperatures of 65°C

or greater above ambient temperature.

Gas connection

This appliance is supplied with ½” BSP tapered male elbow

connection (fig 17)

Anti-tilt bracket/chain

This appliance is supplied fitted with safety chains and wall

mounted brackets to prevent it tilting forwards. These should

be fitted as part of the installation.

You must ensure that the fixings are suitable for the wall type.

Those included may not be suitable in all situations.

Height adjustable feet

The adjustable feet must be fitted to the base of the range

cooker before use.

Rest the rear of the appliance on the packaging exposing the

base to fit the feet.

Fit the four legs by screwing them hand tight into the support

base. To prevent damage, lift the range cooker into position.

Do not push it across the floor unnecessarily.

fig. 17

Page 16

16

DOUBLE POLE SWITCHED

FUSE SPUR OUTLET

USE A 3 AMP FUSE

Installation section

THIS APPLIANCE MUST BE CONNECTED TO THE MAINS

SUPPLY BY A COMPETENT PERSON, USING FIXED

WIRING VIA A DOUBLE POLE SWITCHED FUSE SPUR

OUTLET AND PROTECTED BY A 3A FUSE.

We recommend that the appliance is connected by a qualified

electrician, who is a member of the N.I.C.E.I.C. and who will

comply with the I.E.E. and local regulations.

The wires in the mains lead of this appliance are coloured in

accordance with the following code:

Green & Yellow = Earth, Blue + Neutral, Brown = Live.

As the colour of the wires in the mains feed for the appliance

may not correspond with the coloured markings identifying

the terminals connecting to the fuse spur, proceed as follows:

1. The wire which is coloured green and yellow must be

connected to the terminal marked E (Earth) or

coloured Green.

2. The wire which is coloured blue must be connected to the

terminal marked N (Neutral), or coloured Black.

3. The wire which is coloured brown must be connected to

the terminal marked L (Live), or coloured Red.

Note: Use a 3 AMP Fuse

Assembly and electrical connection should be carried out

by specialised personnel. When installing this product we

recommend you seek the help of another individual.

Page 17

17

Gas Supply Requirements

IMPORTANT: THIS APPLIANCE SHOULD BE FITTED BY A GAS SAFE REGISTERED FITTER OR OTHER SUITABLY

QUALIFIED PERSON.

• This installation must comply with the Gas Safety (installation and use) Regulations 1984.

• This appliance is category II2H3+ and is designed for use in the UK and Ireland. The installation must comply with the

Gas Safety (installation and use) Regulations 1984.

• The CDA Group Ltd is not legally able to provide any assistance in the installation of gas appliances except to

Gas Safe registered installers. Any Gas Safe registered fitter requiring help must provide their name, address and

registration number. Information supplied will be validated before help is provided.

• This appliance is suitable for conversion to Liquid Petroleum Gas (G30 Butane at a pressure of 28-30mbar or G31

Propane at a pressure of 37mbar). A kit is provided. Do not attempt to fit the conversion kit yourself.

• This appliance is adjusted for natural gas (G20) at 20mbar only.

• In the event that this appliance is not installed in accordance with the above requirements, the appliance may be

disconnected from the mains gas supply until any faults are rectified; this is a legal requirement.

• This appliance must not be connected to a combustion gas recovery scavenging system

• The connection to the gas supply must comply with all current regulations in force.

• We are not legally able to offer advice on the installation of gas appliances to non Gas Safe registered personnel.

• An isolation tap should be provided which must be accessible after installation.

Ventilation

All rooms require a window or equivalent (e.g. a door) which can be opened. Some rooms require a permanent vent in

addition to a window (see below).

This unit must not be used in a room which is less than 5m3. The following table details the requirements based on the

kitchen volume (L x W x H) in m3.

The above requirements also allow use of a gas oven and grill but if there are any other fuel burning appliances in the

same room, consult the relevant British Standard (BS5440-2:2000) or appropriate Gas Safe document.

Flexible gas hoses complying with BS669-1 may be used in situations where the ambient temperature of the hose will not

exceed 70C.

Please note that gas hoses designed for natural gas use only must not be used for supplying LPG.

LPG hoses can be identified by either a red band or stripe on

the outer coating of the hose. The hose should be positioned

in accordance with current gas regulations.

Room Volume (m³) Air Vent Req

5 100

6 to 10 50

6 to 11 No permanent vent if a

door opens to the outside

11 or more None required

Page 18

18

Natural Gas to LPG conversion

This appliance can be converted from natural gas to propane

operation at a nominal inlet pressure of 37mbar, or butane

operation at a nominal inlet pressure of 28/30mbar. This

conversion must only be carried out by a competent person

(i.e. a Gas Safe registered fitter)

Instructions to fit replacement hob injectors:

1. Disconnect the appliance from the gas and

electrical supplies.

2. Remove burner components and pan supports.

3. Remove the injectors with a 7mm socket spanner and

replace with the corresponding injectors as shown in the

table below.

4. Refit the burner components and pan supports.

5. Regulate the burner minimum flow rates (see page 20).

Instructions to fit replacement oven injectors:

1. Disconnect the appliance from the gas and

electrical supplies.

2. Remove the accessories and the oven floor from the oven.

3. Remove two securing screws at the left hand side of the

burner, marked A (as shown in fig. 20) and move the

burner to the right to allow access to the injector.

4. Remove the injector using a 7mm socket spanner and

replace with the corresponding injector as shown in the

table below.

5. Move the burner back into position and refit the securing

screws A.

6. Set the burner primary air rates (see page 20).

7. Refit the oven floor and accessories.

8. Regulate the oven burner reduced flow rate (see page 20).

fig. 19

fig. 18

Page 19

19

Instructions to fit replacement grill injectors:

1. Disconnect the appliance from the gas and

electrical supplies.

2. Remove the accessories from the oven.

3. Remove two securing screws at the left hand side of the

burner, marked A and move the burner to the right to allow

access to the injector.

4. Remove the injector using a 7mm socket spanner and

replace with the corresponding injector as shown in the

table below.

5. Move the burner back into position and refit the securing

screws A.

6. Set the burner primary air rates (see page 20).

7. Refit the accessories.

When converting from Natural Gas to LPG, it is important that

the LPG identity sticker is placed on or adjacent to the rating

plate on the appliance.

Burner LPG Injector Natural Gas Injector

Semi-Rapid 65 97

Rapid 85 118

Wok 95 14 0

Grill 82 122

Oven 105 140

Page 20

20

Setting up the Range Cooker for

Use

Primary air adjustment for the oven and grill burners

Loosen the adjustment screw A of the air regulation sleeve.

Turn the adjustment sleeve to the position that corresponds to

the type of gas to be used according to the table below.

Tighten the adjustment screw.

When the operation is completed, reassemble the burner and

check the burner is functioning correctly.

Regulation of the hob burner minimum flow rates

1. Natural gas

Light the burner and turn it to the minimum position.

Remove the gas control knob and turn the adjustment

screw at the side of the valve shaft until the required

minimum flame is achieved.

2. LPG

Remove the gas control knob and turn the adjustment

screw at the side of the valve shaft fully clockwise.

Once the above is complete, refit the knob and verify that the

burner flame is stable (the flame must not extinguish when

turning the control knob rapidly between maximum and

minimum position). Leave the control knob at the minimum

position for one minute to check the flame failure device

function. The flame should not extinguish. Repeat this process

for all hob burner controls.

Regulation of the oven burner reduced flow rate

Light the burner and allow the oven to heat up to maximum

temperature. Remove the oven burner control knob and turn

the adjustment screw until the required minimum flame is

achieved, normally 3-4mm flame height. Refit the knob and

verify that the burner flame is stable (the flame must not

extinguish when turning the control knob rapidly between

maximum and minimum position).

fig. 20

fig. 21

fig. 22

Correct flame

Flame faulty in

primary air

Flame with excess

primary air

Page 21

21

IMPORTANT

Failure to set the reduced rate of the oven burner correctly may

result in performance problems and prevent the oven from

functioning at low temperatures.

Final installation checks

1. Check that all connections are gas tight using appropriate

methods and that the flexible gas hose is positioned

correctly, hanging freely, is not kinked or trapped and is not

in contact with any sharp edges including unfinished

cabinet materials.

2. Check that the supply pressure is correct for the type of gas

being used (Natural Gas 20mbar, Butane 28-30mbar,

Propane 37mbar).

3. Check the correct functioning of all burners at nominal and

reduced rates.

fig. 23

Page 22

22

Page 23

23

Page 24

Customer Care Department • The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : service@cda.eu W : www.cda.eu

To contact our Customer Care Department, or for Service,

please contact us on the details below.

Serviced by

Loading...

Loading...