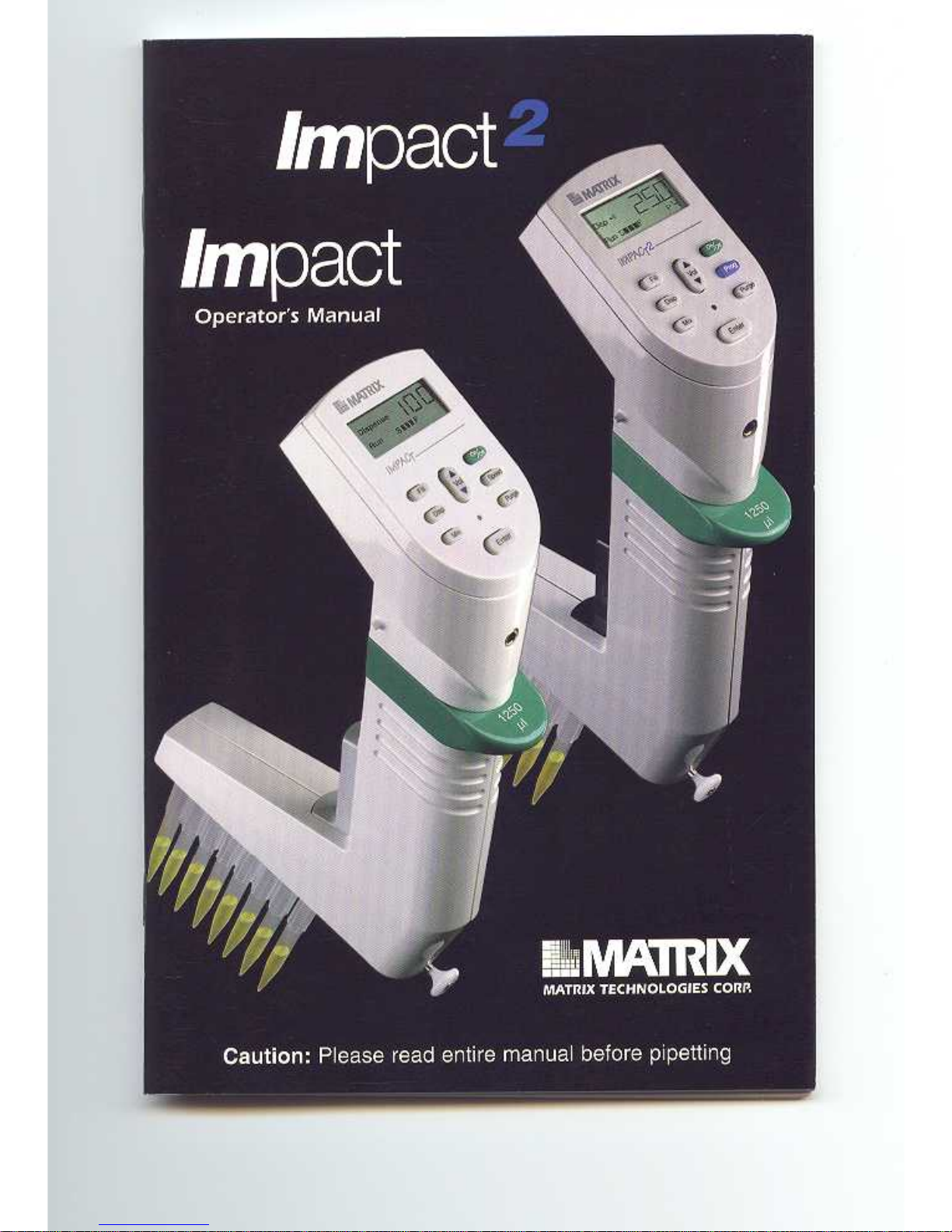

Page 1

Page 2

CONTENTS

Congratulations! .......................................................... 1

A. INTRODUCTION ..........................................................2

B. PIPETTOR OVERVIEW................................................4

B.1 General Description..............................................4

B.2 Keypad................................................................ 6

B.3 Display..............................................................12

B.4 Specifications ....................................................13

B.5 Hazards and Precautions ....................................14

C. PROGRAMMING AND OPERATION ........................... 15

C.1 Programming the IMPACT................................... 15

C.2 Programming the IMPACT2.................................19

C.2.1 Program Selection....................................19

C.2.2 Program Recall........................................19

C.2.3 Scratch Pad Mode (Program 0) .................20

C.2.4 Pipetting Speed Adjustment ......................20

C.3 Reviewing the Program........................................21

C.4 Programming Examples......................................22

C.4.1 Sample Transfers .....................................22

C.4.2 Incremental Pipetting ................................22

C.4.3 Serial Dilutions .........................................23

C.4.4 Simple Dilutions.......................................23

C.5 Operating Procedures .........................................24

D. CALIBRATION ..........................................................26

D.1 Calibrating the IMPACT....................................... 27

D.1.1 Volume Measurement ...............................27

D.1.2 Pipettor Calibration ...................................28

D.2 Calibrating the IMPACT2.....................................30

D.2.1 “EASY” CAL Mode...................................30

D.2.2 “CALC” Mode ...........................................31

D.3 CALVIEW ..........................................................31

D.4 CALRESET........................................................31

D.5 Recommendations for Accurate Pipetting .............32

iii

Page 3

CONTENTS (cont’d)

E. TROUBLESHOOTING AND MAINTENANCE................ 33

E.1 Troubleshooting ..................................................33

E.2 Maintenance ......................................................35

E.2.1 Pipettor Disassembly ...............................36

E.2.2 Pipettor Cleaning and Autoclaving ..............39

E.2.3 Pipettor Reassembly................................40

E.3 Recharging Batteries ..........................................42

E.4 Replacing Batteries ............................................44

F. APPENDICES............................................................48

F.1 Additional Pipetting Examples .............................48

F.1.1 Sample Transfers .....................................48

F.1.2 Incremental Pipetting................................49

F.1.3 Serial Dilutions.........................................49

F.1.4 Simple Dilutions .......................................50

F.2 Chemical Compatibility........................................50

F.3 Customer Service...............................................51

F.3.1 Warranty .................................................51

F.3.2 Customer Service .....................................51

G. IMPACT

2

STORED PR OGRAMS WORKSHEET ................53

iv

Page 4

Congratulations!

You have purchased the state-of-the-art in precision pipetting. The

IMPACT

®

is the first cordless electronic pipettor that "understands"

the myriad of liquid handling protocols typically performed in

today's laboratory.

Ergonomically designed and balanced to reduce fatigue, the

IMPACT functions so intuitively, that you may need no more than a

quick survey of this manual to use it.

The IMPACT allows you to accomplish your liquid pipetting tasks

quickly, accurately, and with less risk of developing repetitive

motion related injuries that are typical with manual pipettor use.

Laboratory results will become more standardized, while less time

is expended on tedious bench procedures.

Delivering power, precision, and performance.

is the latest word in liquid handling technology.

Before You Begin

Before using the IMPACT or IMPACT2, verify the contents of your

package. The package should contain the following items:

1 IMPACT or IMPACT2 Pipettor

1 Operator's Manual

2 Rechargeable Batteries

1 AC Power Transformer

1 Warranty Card

1 Accuracy/Precision Data Sheet

1 Coupon for Free Calibration Service

If you are missing any items, contact your Matrix Technologies

representative.

Note: Batteries must be installed and recharged before using the

IMPACT. Refer to the following sections in this manual:

n Section E.3, Installing/Replacing Batteries

n Section E.4, Recharging Batteries

1

Page 5

A. INTRODUCTION

The IMPACT is lightweight and cordless. It provides the

convenience of a manual pipettor, with the programming

capabilities of an electronic pipettor. It runs on rechargeable

batteries and can be used while recharging. The pipettor also has

an automatic shutoff feature to extend battery life.

The IMPACT uses a "paced dispense" feature that performs repeat

pipetting steps while the trigger is depressed.

The IMPACT uses integrated circuit technology to store its

programming information. It will hold up to 40 steps in a program.

The program information is retained in memory, even if the

batteries are fully discharged or removed.

The IMPACT2 is the second generation of the IMPACT pipettor

family. It is capable of performing all of the same pipetting

protocols available with the IMPACT, plus a few NEW features. The

expanded capabilities include:

§ Expanded memory for storing up to five pipetting programs.

Each program can hold a maximum of 40 steps.

§ “Scratch Pad” programming mode which allows for fast and

simple program changes that are not stored into memory.

§ Enhanced speed control which offers slower aspirating and

dispensing of viscous liquids. Excellent for Gel loading!

§ “EASY” CAL which simplifies in-lab calibration verification by

using distilled water.

2

Page 6

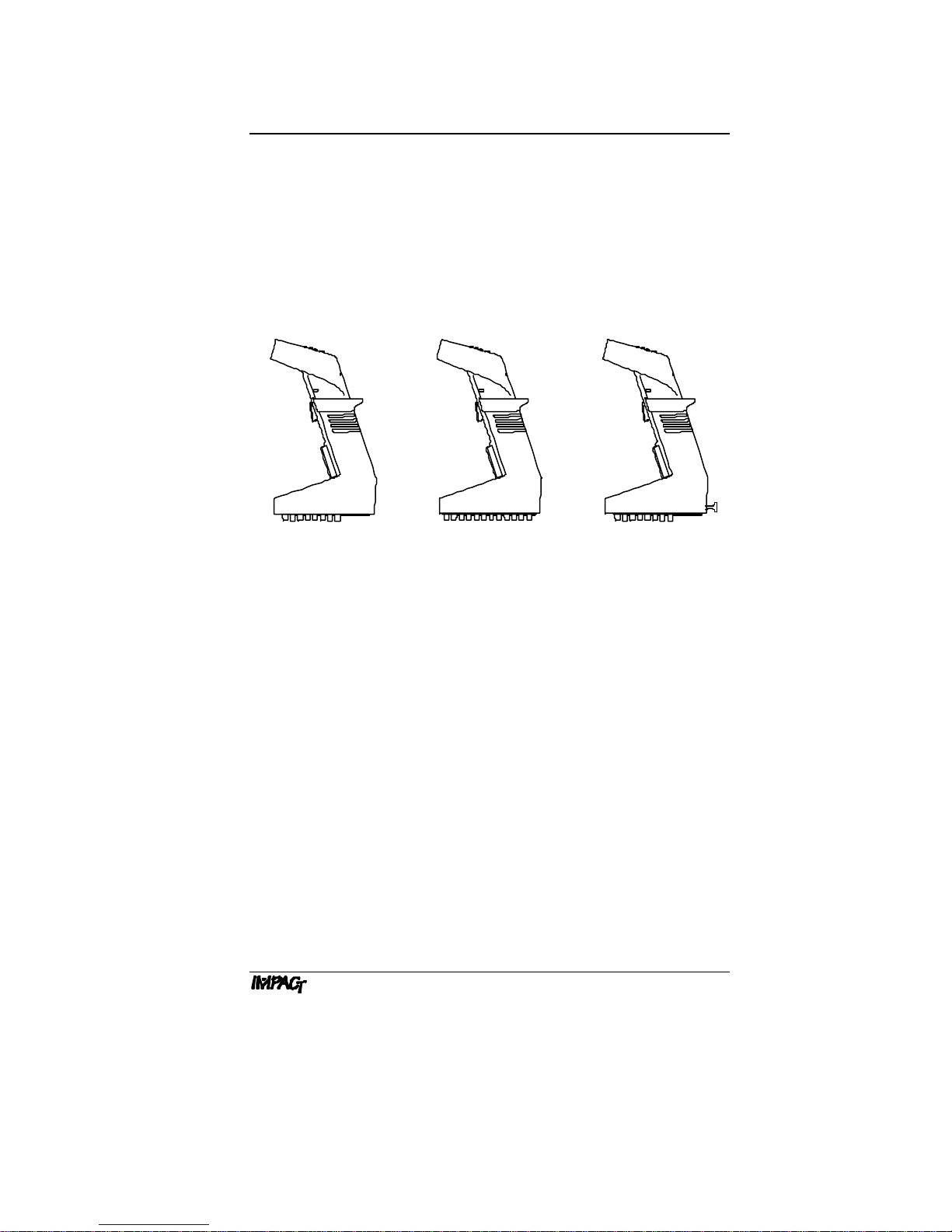

INTRODUCTION

The IMPACT and IMPACT2 are available in 8-channel and

12-channel formats (see Figure A). An expandable version of the

8-channel format is also available for pipetting samples from test

tubes in a rack. It comes in several models to handle fluid volumes

from 0.5 µl to 1250 µl. The handles are color-coded for easy

identification of different model types (IMPACT vs. IMPACT2) and

different volume ranges. See Section B.4, Specifications.

8-Channel 12-Channel 8-Channel

Expandable

Figure A: IMPACT Configurations

3

Page 7

B. PIPETTOR OVERVIEW

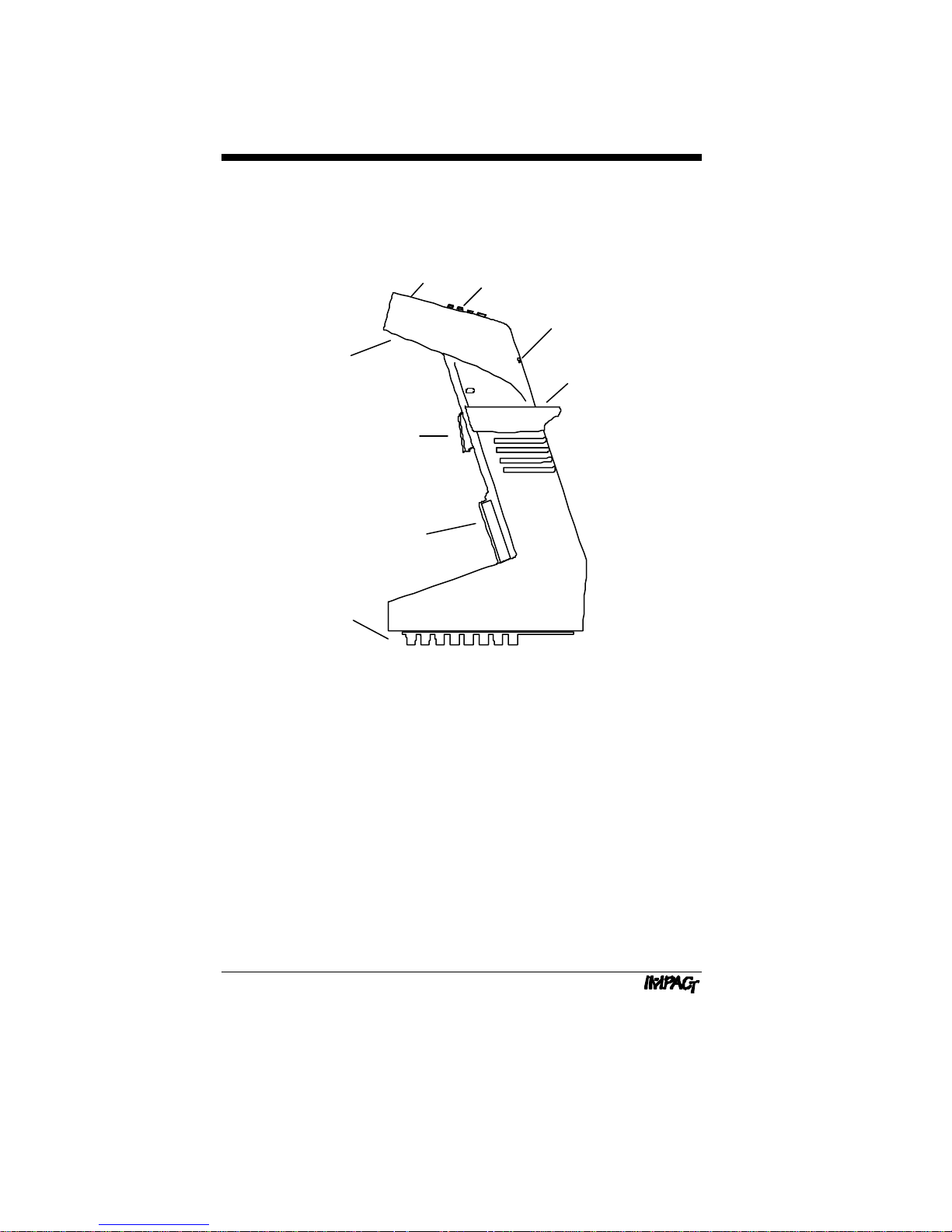

B.1 General Description

Battery

Case

Pipetting Trigger

Ejector Trigger

Tip Fittings

Figure B.1: Description of Components

Display

Keypad

Transformer

Connector

Color-coded

Ring

Keypad. The keypad contains the operation keys that are used

in programming the pipetting sequence and volumes. See Section

B.2, Keypad.

Display. The display is an LCD screen that shows the pipetting

operation (fill, dispense, mix, or purge) and fluid volume for each

step in the pipetting program. See Section B.3, Display.

4

Page 8

PIPETTOR OVERVIEW

Battery Case. The battery case contains two rechargeable nickel

cadmium batteries. Batteries are charged for 12– 14 hours. When

fully charged, the pipettor can perform up to 1200 cycles at full

stroke. Battery life is extended with automatic shutoff after 10

minutes of inactivity. See Section E.3, Installing/

Replacing Batteries.

Pipetting Trigger. The pipetting trigger initiates the pipetting

program. It is pressed when the "Run" or "Purge" command

appears in the display. A single pipetting step is performed by a

quick press and release of the trigger. Repeat pipetting (paced

dispense) is performed by pressing and holding the trigger.

Note: At the end of a paced dispense, the pipet tips should be

removed from the fluid before releasing the trigger, to prevent

aspiration of fluid.

Ejector Trigger. The ejector trigger is pressed to eject the pipet

tips from the pipettor.

Tip Fittings. The tip fittings form an airtight seal with the pipet

tips to ensure accuracy while pipetting.

Note: To extend instrument life, Matrix Technologies has

equipped all IMPACT and IMPACT2 pipettors with chemicallyresistant (PEEK) tip fittings. This material allows for pipetting of

acidic solutions without damage to the tip fittings.

Color-coded Ring. The flanged ring around the pipettor handle is

color-coded to identify the pipetting volume of the handle. See

Section B.4, Specifications.

Transformer Connector. The transformer connector receives the

plug from the power transformer for recharging the batteries. The

pipettor can be used while it is recharging.

5

Page 9

PIPETTOR OVERVIEW

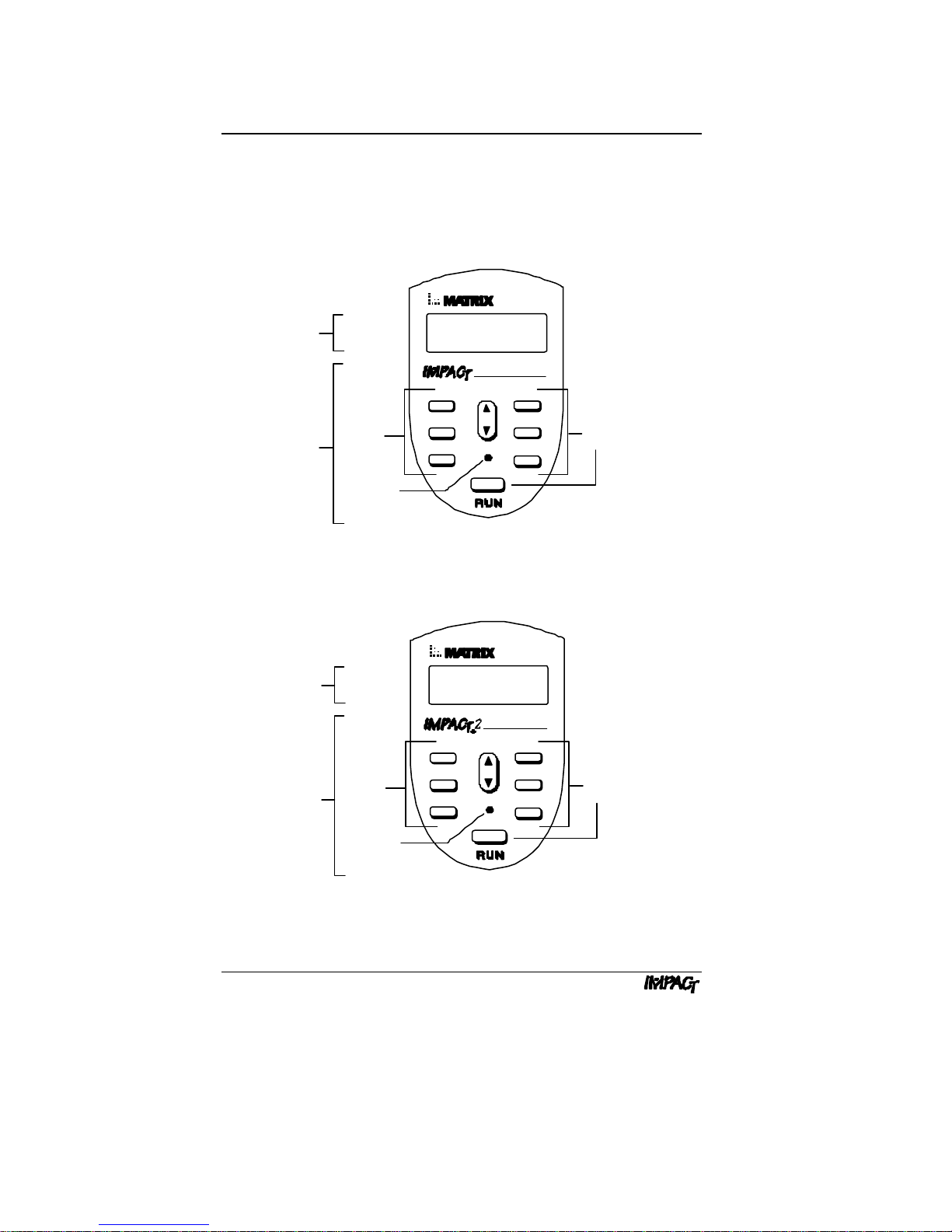

B.2 Keypad

The keypad contains the operation keys, program keys, and the

special function key.

Display

Keypad

Display

Keypad

Program

Keys

Special

Function

Fill On

Vol

Disp

Mix

Enter

Off/

Prog

Purge

Key

Figure B.2a: IMPACT Keypad

Program

Keys

Special

Function

Key

Fill On

Vol

Disp

Mix

Enter

Off/

Prog

Purge

Operation

Keys

Operation

Keys

6

Figure B.2b: IMPACT2 Keypad

Page 10

Operation Keys:

PIPETTOR OVERVIEW

[On/Off]

[Speed]

The On/Off key turns the pipettor on or off. When the

pipettor is turned on, it emits a beep tone, flashes

"ZERO" on the display, then automatically resets the

pistons to zero position. After zeroing, the display

shows the first step of the program in the RUN mode.

Note: If the pipettor is being programmed for the first

time, the first step will be the fill operation, with the

default fill volume. See Section C.1, Program-ming

the IMPACT, for the default settings.

The Speed key controls the rate at which the liquid is

aspirated or dispensed. The speed setting can be

changed by repeatedly pressing the Speed key.*

For the IMPACT, three speed settings are available:

Speed Setting Display

SLOW S F

MEDIUM S F

FAST S F

For the IMPACT2, five speed settings are available:

Speed Set ting Display

SLOW S

MEDIUM SLOW S

MEDIUM S

MEDIUM FAST S

FAST S F

The IMPACT2 also features independent speed

adjustment. Speed settings can be changed within a

stored program or during the execution of a program

(see Section C.2.4, Pipetting Speed Adjustment).

*NOTE: IMPACT2 speed settings are changed

through the Special Function key (see Special

Function key section on page 11) or by using the

volume key (see Section C.2.4, Pipetting Speed

Adjustment).

7

Page 11

PIPETTOR OVERV IEW

[Prog]

IMPACT

only

[Purge]

The current speed setting is always shown at the

bottom of the display. These settings can be selected

and changed at any time before a program step is

performed.

The Program key on the IMPACT2 enables you to

store up to five separate programs in memory for

2

future recall. Each program can hold up to 40 steps.

Programs are stored in reserved program location

numbers 1 – 5. Program “0” is used as a “scratch

pad” where temporary programs can be written, run,

and overwritten easily. Program “0” is considered to

be an “open” program (see Section C.2, Programming the IMPACT2).

The Purge key enters a purge prompt anytime during

a pipetting operation to abort the program. By

pressing the Purge key, then pressing the trigger,

you can dispense any remaining liquid from the pipet

tips and return to the beginning of the program.

The Purge key is also used to enter the purge step

into a program.

Note: If there is insufficient liquid for a final dispense

step, the pipettor emits a beep tone and automatically displays the purge prompt.

RUN The RUN mode performs the operation that is

displayed, such as fill, dispense, mix, or purge.

When "Run" appears in the display, you can activate

the RUN mode by pressing the trigger. At the end of a

pipetting sequence, the pipettor emits a triple beep

tone and returns to the beginning of the program. The

pipettor remains in RUN mode until you program a

new pipetting sequence.

8

Page 12

Program Keys:

PIPETTOR OVERVIEW

[Fill]

[Disp]

[Mix]

s

Vol

t

The Fill, Dispense, and Mix keys program the

pipetting operations. By pressing one of these keys,

you can enter the programming mode of the IMPACT.

The "Run" prompt disappears from the display and

the appropriate operation appears with a flashing

"Vol" prompt. Fill, dispense, or mix volumes can be

programmed by pressing the Volume key. Also, the

number of mix cycles can be programmed by

pressing the Mix key twice.

Automatic blowout. At the end of a final dispense

step, the pipettor automatically expels any remaining

liquid from the pipet tips with a short burst of air

(blowout). The pistons then reverse direction and

return to zero position.

Note: If you press and hold in the trigger during the

final dispense step, the pipettor performs the

automatic blowout and holds its position until you

release the trigger. This delay allows you sufficient

time to remove the tips from the liquid to prevent

aspiration of liquid, as the pistons return to zero

position.

The Volume key controls the quantity of liquid to be

aspirated or dispensed. The volume can be entered

when the "Vol" prompt appears.

IMPACT

only

Pipetting volume can be incremented quickly by

continuously depressing the Volume key. Short,

quick, depressions of the Volume key will increase or

decrease the volume by its smallest increment.

Longer depressions of the Volume key will increase

or decrease the volume in larger increments. Three

levels of volume increments are available to achieve

the desired volume (see Table C.1, Default Programming Volumes).

The Volume key can also be used to change

2

pipetting speeds within a stored program or during

the execution of a program (see Section C.2.4,

Pipetting Speed Adjustment).

9

Page 13

PIPETTOR OVERVIEW

[Enter]

The Enter key stores the program in memory. After

each step is programmed, the Enter key is pressed

once to accept the step. After the final step is

programmed, the Enter key is pressed twice to

denote the end of the program. The pipettor verifies

the end of the program with a triple beep tone.

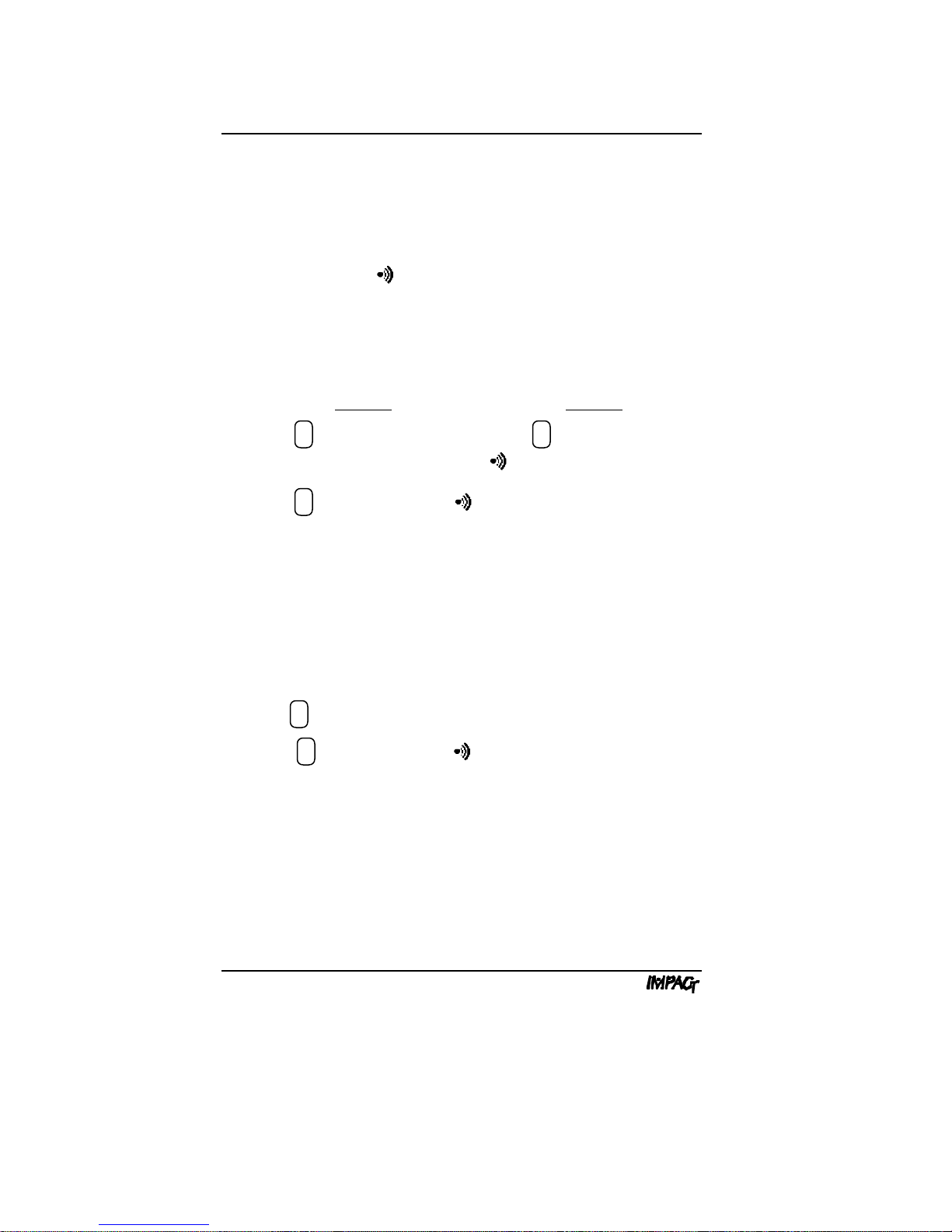

Special Function Key:

The Special Function key is the small hole below the Volume key.

It can be activated with a pipet tip. By repeatedly pressing the

Special Function key, you can display four functions: Beep Tone

(TONE), Paced Dispense Speed (PACE), Calibration (CAL), and

Pipetting Speed—IMPACT2 only (SPd). To exit the Special

Function key at any time, press the Enter key.

TONE The beep tone signals the completion of one or more

steps, or signals a warning:

n Single beep tone: end of pipetting step; insufficient

dispense volume, purge required.

n Double beep tone: operation or program key is not

active in current mode; illegal programming step

attempted. See Section E.1, Troubleshooting.

n Triple beep tone: end of pipetting sequence;

end of programming sequence.

The single beep tone, signaling the end of a pipetting

step, can be turned ON or OFF. All other beep tones

cannot be turned off. Press the Special Function key

once to display "TONE" and its current setting. To

change the setting, press the Volume key. If the beep

tone is turned ON, the beep tone symbol " " appears

at the bottom of the display.

Note: For paced dispensing, the beep tone should

be turned on, to prepare you for each dispense step.

PACE The pace controls the speed of repeat pipetting

(paced dispensing), FAST or SLOW. Press the

Special Function key twice to display "PACE" and its

current setting. To change the setting, press the

Volume key.

10

Page 14

PIPETTOR OVERVIEW

Paced Dispense. When you use the paced

dispense feature, the pipettor dispenses the

programmed volume at the specified pace (fast or

slow). Immediately after each dispense step, the

pipettor emits a single beep tone (if beep tone is on)

to prepare you for the next dispense step. See

Section C.5, Operating Procedures.

CAL The calibration of the pipettor is factory set for

distilled water at room temperature. If you are

pipetting fluids with significantly different specific

gravities or temperatures, use this setting to

recalibrate the pipettor. See Section D, Calibration.

SPd

IMPACT

only

Once in the special function mode, adjust the

pipetting speed by pressing the Volume key. Five

2

speed settings are available:

Speed Setting Display

SLOW S

MEDIUM SLOW S

MEDIUM S

MEDIUM FAST S

FAST S F

The current speed setting is always shown at the

bottom of the display. These settings can be selected

and changed at any time before a program step is

performed.

11

Page 15

PIPETTOR OVERVIEW

Low Battery Indicator

Program No.

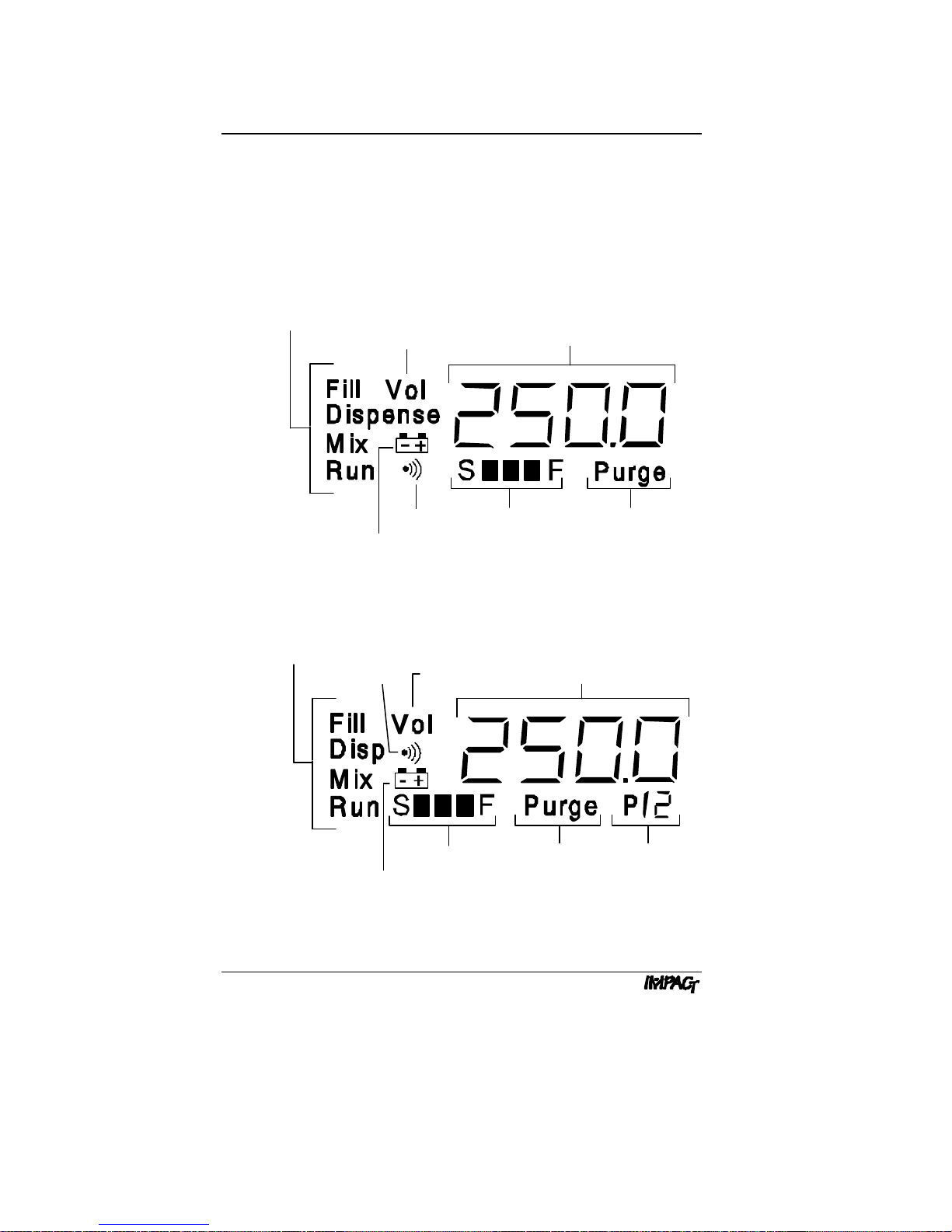

B.3 Display

The pipettor display is a dynamic LCD screen. It displays the

current operation, volume prompt (if you are entering a program),

pipetting volume, low battery indicator (appears if battery charge is

low), beep tone symbol (if the beep tone is on), pipetting speed,

and program number (IMPACT2 only).

Pipetting Operations

Volume Prompt Pipetting Volume

Beep Tone Speed Setting Purge Prompt

Low Battery Indicator

Figure B.3a: IMPACT Display

Pipetting Operations

Beep Tone

Volume Prompt

Speed Setting Purge Prompt

Pipetting Volume

Figure B.3b: IMPACT2 Display

12

Page 16

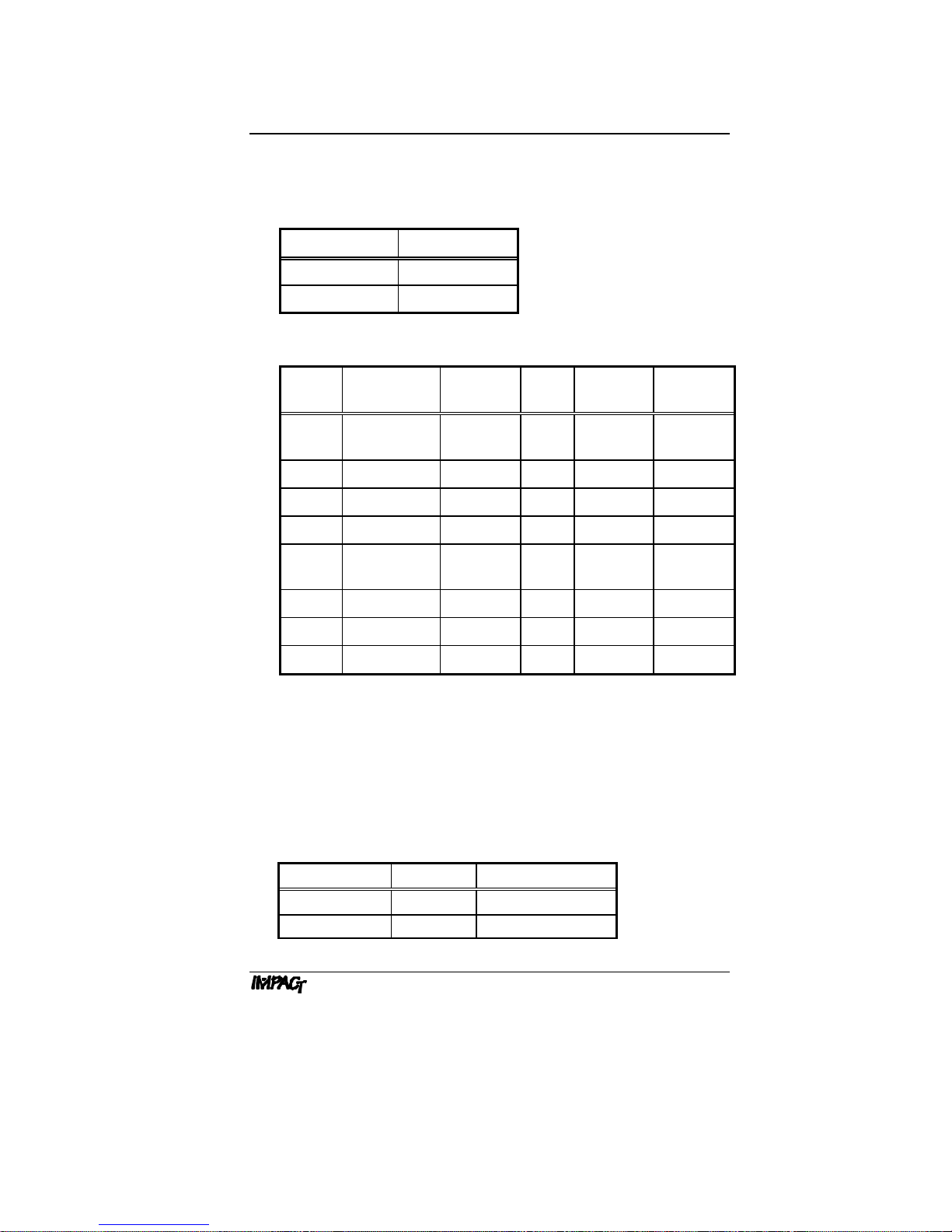

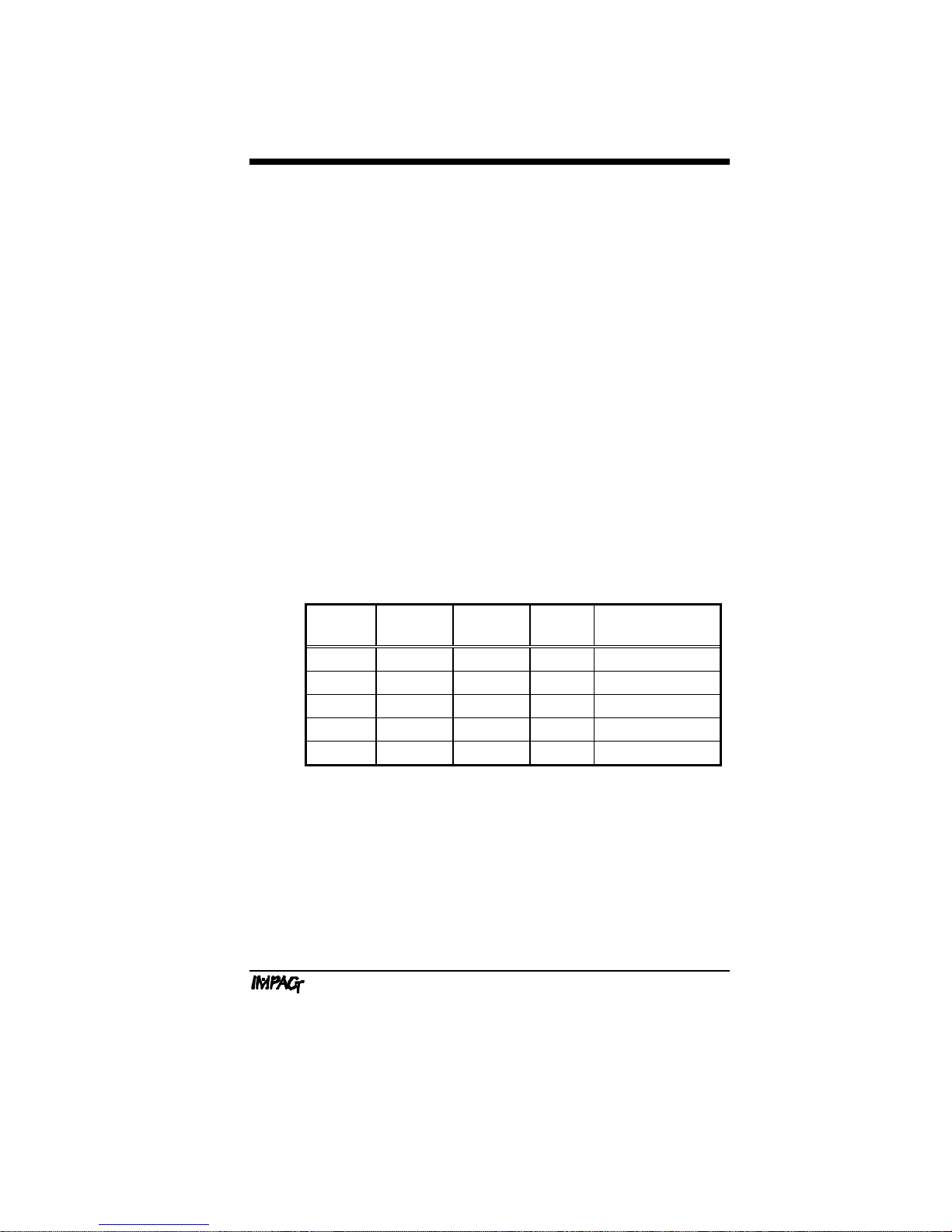

B.4 Specifications

2.5%/0.15 µl

2.5%/0.15 µl

Pipettor Type

Model Handle Color

IMPACT White

IMPACT2

Handle Specifications

PIPETTOR OVERVIEW

Gray

Handle

Size

12.50 µl 12-channel 0.50-12.50

125.0 µl 12-channel 2.0-125.0 µl Yellow 2.0%/1.0 µl 1.2%/0.8 µl

250.0 µl 12-channel 5.0-250.0 µl Blue 2.0%/1.5 µl 0.8%/1.2 µl

850 µl 12-channel 15-850 µl Orange 1.5%/4.0 µl 0.6%/2.5 µl

12.50 µl 8-channel 0.50-12.50

125.0 µl 8-channel 2.0-125.0 µl Yellow 2.0%/1.0 µl 1.0%/0.6 µl

250.0 µl 8-channel 5.0-250.0 µl Blue 2.0%/1.5 µl 0.7%/1.0 µl

1250 µl 8-channel 15-1250 µl Green 1.5%/6.0 µl 0.6%/3.0 µl

Handle Type Volume

Range

µl

µl

Color

Ring

Red

Red

Accuracy*

(±)

Precision**

(±)

2.0%/0.15

µl

2.0%/0.15

µl

Note: For Accuracy and Precision, values shown are expressed

as a percent (%) deviation or microliter (µl) value. When applied to

desired volume, the greater of the two values will always apply.

*Both values represent the deviation from the mean.

**Percentage values are expressed as the coefficient of variation.

Microliter values are expressed as the standard deviation.

Available Power Sources

Catalog No. Country Power Source

6096 England 240 V, 50 Hz

6097 Japan 100 V, 50 Hz

13

Page 17

PIPETTOR OVERVIEW

6098 USA 120 V, 60 Hz

6099 Europe 230 V, 50 Hz

14

Page 18

PIPETTOR OVERVIEW

B.5 Hazards and Precautions

There are no known hazards associated with the IMPACT when it

is operated in accordance with the instructions in this manual.

However, you should be aware of situations that can result in

serious injury.

Note: Do not perform troubleshooting procedures on the internal

components unless instructed by Matrix Technologies service

personnel.

WARNING! Ensure that the power transformer is connected to a

power receptacle that provides voltage and current specified by

Matrix Technologies. Use of an incompatible power receptacle can

cause shock and fire hazard.

CAUTION! Use only the power transformer supplied by Matrix

Technologies. Use of an incompatible power transformer can

damage the pipettor.

CAUTION! Always turn off the power and unplug the power

transformer before cleaning the exterior. Fluid seepage can

damage internal components.

CAUTION! Do not immerse the unit in liquid. Fluid seepage can

damage internal components.

CAUTION! Do not autoclave the entire unit. Extreme heat can

damage the display and other electronic components.

Note: For autoclaving specific portions of the pipettor, refer to the

Autoclaving Procedures, or call Matrix Technologies, Technical

Service Department, for instructions.

CAUTION! Do not clean the keypad with bleach solution or other

solvents. Caustic cleaning solutions can damage the keypad.

CAUTION! Avoid excessive charging of the batteries when the

pipettor is not in use. Excessive charge to the batteries will

shorten the battery life and may damage the batteries.

15

Page 19

C. PROGRAMMING AND OPERATION

Programming the IMPACT and IMPACT2 is fast and easy. Pipetting

steps and volume are entered in the sequence that they will be

performed, then the program is saved to memory. This program

will stay in memory (even if the pipettor is turned off, or the battery

runs low) until you change it. Up to 40 programming steps can be

entered and stored in the IMPACT pipettor. Five programs, each

capable of holding 40 steps, can be entered and stored in the

IMPACT

C.1 Programming the IMPACT

To enter a pipetting program:

1. Turn on pipettor. Press the green [On/Off] key to turn on

2

.

the pipettor. The pipettor will beep once and flash "ZERO" on

the display while resetting the pistons to zero position. The

first step of the current program is displayed.

Note: If the pipettor is being programmed for the first time,

the first step will be the fill operation, with the default fill

volume displayed (see the following table).

Handle

Volume

12.50 10.00 10.00 5.00 0.05 0.10 0.50

125.0 100.0 100.0 50.0 0.1 0.5 5.0

250.0 250.0 50.0 50.0 0.5 5.0 25.0

850 850 100 100 1 5 50

1250 1250 100 100 1 5 50

Fill

Volume

Dispense

Volume

Mix

Volume

Volume Increment

(slow –> fast)

Table C.1: Default Programming Volumes*

*All volumes shown are in microliters (µl).

15

Page 20

PROGRAMMING AND OPERATION

2. Select pipetting operation. Enter the programming mode

by pressing the [Fill] or [Mix] key.

For example, to begin programming with a filling operation,

press the [Fill] key. The display shows "Fill" with a flashing

"Vol" prompt:

Flashing Display

Note: The displayed volume defaults to the last volume

programmed for the selected operation, or to the default

volume for the pipettor, if it is being programmed for the first

time.

Fill. The [Fill] key programs the pipettor to aspirate a volume

of liquid. A single fill step can be programmed for fluid

transfers, or a combination of fill steps can be programmed for

dilutions or supernatant collection.

Dispense. The [Disp] key programs the pipettor to dispense

a volume of liquid. The dispense volume can be the entire fill

volume, or a smaller increment for repeat pipetting. You only

have to program the dispense volume once for repeat

pipetting. The pipettor will dispense the volume each time the

trigger is pressed (or repeatedly during a paced dispense) until

the fill volume is reached, or until insufficient volume remains.

Mix. The [Mix] key programs the pipettor to perform a

combination of fills and dispenses. You can program a mix

volume or mix cycle (single fill and dispense). You can press

[Mix] once to program a mix volume, or twice to program a

mix cycle. Mix cycles from 1 to 9 are available on the

IMPACT; mix cycles from 2 to 9 are available on the IMPACT

The default setting is three mix cycles.

16

2.

Page 21

PROGRAMMING AND OPERATION

Listed below are some programming considerations for the

mix operation:

n If the program begins a mix cycle from zero position, it will

complete the cycle with an automatic blowout, then

display "ZERO." Press the trigger to return the pistons to

zero position.

n If the program begins a mix cycle above zero position

(volume is greater than zero), the fluid is dispensed, and

the mix cycle begins. The mix cycle will end at the same

volume it started with. Also, the mix operation will remain

in the display so it can be repeated (useful for serial

dilutions). To end the mix operation, press the [Purge]

key, then press the trigger.

Purge. The [Purge] key programs the pipettor to purge the

fluid. This step can be entered as a program step, or it can be

pressed anytime while pipetting to terminate the program and

dispense the remaining liquid.

Note: If the program ends at a volume greater than zero, and

the last step is not a mix cycle, the "Purge" prompt

automatically appears. Also, the pipettor emits a beep tone to

warn you that some fluid remains. Press the trigger to

dispense the remaining fluid and return to the beginning of the

program.

Examples of pipetting programs with different mix steps are

shown in Section C.4, Programming Examples.

3. Enter volume. Enter the desired volume for [Fill], [Disp], or

[Mix] by pressing the up s or down t side of the [Vol] key. If

the [Vol] key is pressed and released quickly, the volume

changes by its smallest increment of measure (for example,

0.5 µl for the 250 µl pipettor); if the [Vol] key is pressed and

held, then the volume change occurs with larger increments

(see Table C.1, Default Programming Volumes, for volume

increment).

Note: The [Purge] key does not use a volume; therefore, if

you have entered a purge step, continue to the next step.

17

Page 22

PROGRAMMING AND OPERATION

Flashing

Display

4. Confirm programming step. Press [Enter] to confirm the

programming step. The display flashes all of the operation

keys to prompt you for the next programming step:

{

5. Select next pipetting operation. Repeat steps 2 to 4 until

all programming steps have been entered.

6. Save program and exit. When the display flashes all

operation keys, press [Enter] to save the program and exit

the programming mode. The pipettor emits a triple beep tone

to signal the end of the programming sequence. The first step

in the program is displayed. "Run" is displayed in the lower

left corner to indicate that the new program is ready to be run.

Go to Section C.3 for Reviewing the Program, or Sec tion C.5

for Operating Procedures.

18

Page 23

PROGRAMMING AND OPERATION

C.2 Programming the IMPACT2

C.2.1 Program Selection

To create and store programs in the IMPACT2:

1. Select the program number by pressing the [Prog] key,

then press the [Vol] key until the desired program number

is displayed.

2. Press and hold the [Prog] key, while simultaneously

pressing the Special Function key to enter the programming mode. The prompt “Prog” will appear on the display.

3. Begin entering your new program (see Section C.1,

Programming the IMPACT, for programming instructions).

NOTE: When programming mode is active, the Speed

setting and Beep Tone symbols will blink.

After you have pressed the [Enter] key to save and exit the

program, your new program will be stored under the

selected program number. The program number will be

displayed for two seconds. (The first step of the newly

written program is displayed).

This program is ready to be run.

C.2.2 Program Recall

To recall a stored program:

1. Press the [Prog] key, then the [Vol] key to select the

desired program number.

2. Press the [Enter] key to activate the displayed program.

19

Page 24

PROGRAMMING AND OPERATION

C.2.3 Scratch Pad Mode (Program 0)

While providing ample program storage, the IMPACT2 also

offers a “scratch pad” or open programming mode. This mode

is identified by “P/0,” which appears in the program section of

the display (refer to the IMPACT2 display on page 12). This

feature enables you to quickly change pipetting protocols

without affecting previously stored programs.

To use the “scratch pad” mode: From the start of any

program, simply begin entering a new protocol (selecting a

pipetting operation as described on page 16). This new

protocol can now be used, and will remain active until a stored

program is retrieved. “P/0” appears in the program ID section

of the display to indicate that the (O)pen programming mode,

or “scratch pad” mode, is active.

C.2.4 Pipetting Speed Adjustment

The IMPACT2 offers unique speed control that is function

based, enabling speeds for Fill, Dispense, Mix or Purge to be

independently programmed. Also, speeds within any of the five

stored programs can be independently set and stored as an

integral part of the pipetting protocol. Pipetting speed is easily

changed at the start of each pipetting function.

20

To change pipetting speed during the execution of a program:

Press the [Vol] key to select the speed for each pipetting

function (Fill, Dispense, Mix, or Purge).

This newly set speed will remain active with each function

even if the pipettor is turned off. Speed settings within any of

the five stored programs will also remain in memory with the

program functions until changed by the operator.

Page 25

C.3 Reviewing the Program

After you have programmed your pipettor, you may want to review

the programming steps:

1. Set pipettor for RUN mode. Ensure that the pipettor is in

the RUN mode ("Run" appears in the lower left corner of the

display). If the display is flashing all pipetting operations, you

are still in the programming mode; press [Enter] to save the

program and exit.

2. Begin program. Run the program without using pipet tips or

aspirating fluid. Press the trigger for each step in the program.

3. Observe display. At each step of the program, observe the

display. If necessary, re-enter the programming sequence.

Listed below are a few helpful hints for reviewing your program:

n If your program is complex and contains several steps,

you may want to write the steps on paper before entering

the program steps (or use a copy of the programming

worksheet at the end of this manual). Check off each step

as you review the program.

n If your program is intended for paced dispensing, review

the program again, with the trigger depressed until the last

step. Check the dispense pace to ensure that you can

keep up with the dispense steps.

PROGRAMMING AND OPERATION

21

Page 26

PROGRAMMING AND OPERATION

OR

[Enter] [Enter]

C.4 Programming Examples

Examples of different pipetting sequences are described below.

These examples are ideal for use as training exercises. Press the

keys shown in keycaps [ ], then press the [Vol] key until the

volume in parent heses ( ) is displayed. At the end of the program,

a triple beep tone is sounded. See Section F, Appendices, for

additional pipetting examples.

C.4.1 Sample Transfers

Example: Fill and dispense 100 µl.

Option 1 Option 2

[Fill]

s

Vol

(100) [Enter]

t

[Fill]

Vol

s

t

(100)

[Disp]

s

Vol

(100) [Enter] [Enter]

t

The second option is a one-step program. Because the program

ends at a volume greater than zero, and the last step is not a mix,

a "Purge" prompt automatically appears at the end of the fill to

dispense the liquid and return to the beginning of the program.

C.4.2 Incremental Pipetting

Example: Fill 250 µl and dispense 45 µl in 5 increments.

s

Vol

[Fill]

[Disp]

In this program, only one dispense step needs to be programmed.

If any program ends in a dispense step, the pipettor repeats the

dispense step until the volume is zero, or is less than the

programmed dispense volume. If the remaining volume is less than

the programmed dispense volume, the pipettor displays a "Purge"

prompt to discard the remainder.

22

(250) [Enter]

t

s

Vol

(45) [Enter] [Enter]

t

Page 27

PROGRAMMING AND OPERATION

C.4.3 Serial Dilutions

Example: Transfer 100 µl to the first column of a plate previously

filled with reagent. Mix 200 µl for 2 cycles. Transfer 100 µl to the

second column and repeat the mix step. Follow this procedure for

the rest of the plate.

s

Vol

[Fill]

[Mix]

(100) [Enter]

t

s

Vol

(200) [Mix]

t

s

Vol

(2) [Enter] [Enter]

t

That's the entire program! The mix step always returns to the

volume at which it started (100 µl); therefore, the pipettor

continues the mix step indefinitely, until you press the [Purge]

key to end the program. In this example, the mix cycle is

programmed for 2 cycles (default is 3 cycles).

C.4.4 Simple Dilutions

Example: Prepare 1:10 dilution with a 10 µl sample volume.

s

Vol

[Fill]

[Fill]

[Fill]

(90) [Enter]

t

s

Vol

(20) [Enter]

t

s

Vol

(10) [Enter]

t

[Purge] [Enter] [Enter]

The first fill volume is for the diluent (90 µl), followed by an air-gap

(20 µl), and finally by the sample volume (10 µl). The purge step

will dispense the total volume.

23

Page 28

PROGRAMMING AND OPERATION

C.4.5 Supernatant Collection

Example: Aspirate 100 µl from 8 rows of a microtiter plate and

discard the total volume.

s

Vol

[Fill]

[Fill] [Enter]

[Fill] [Enter]

[Fill] [Enter]

[Fill] [Enter]

[Fill] [Enter]

[Fill] [Enter]

[Fill] [Enter]

[Purge] [Enter] [Enter]

This program is performed with the 850 µl handle. All 100 µl fill

volumes are collected in the same tips. When completed, the total

volume is discarded with the purge step.

(100) [Enter]

t

24

Page 29

PROGRAMMING AND OPERATION

C.5 Operating Procedures

After you have programmed your pipettor, you are ready to begin

pipetting. The display should show the first program step, with the

"Run" prompt showing in the lower left corner:

The following steps describe a basic program for pipetting reagent

into a microtiter plate. The pipettor is programmed as follows:

[Fill]

[Disp]

s

Vol

(250) [Enter]

t

s

Vol

(30) [Enter] [Enter]

t

1. Attach pipet tips. When you are ready to begin pipetting,

attach the pipet tips to the pipettor.

2. Aspirate liquid. Immerse the pipet tips into the liquid to be

aspirated, then press the trigger to aspirate 250 µl.

3. Dispense liquid. Position the pipet tips over the first column

of wells in the microtiter plate, and press the trigger to

dispense 30 µl. At the completion of the dispense step, the

pipettor emits a single beep tone (if the beep tone is on).

4. Repeat dispense step. Repeat the previous step for the rest

of the columns in the microtiter plate. At the completion of the

eighth dispense, the pipettor emits a double beep tone (if the

beep tone is on, otherwise it emits a single beep tone) and

displays the "Purge" prompt. There is insufficient volume for

another 30 µl dispense, and the pipettor signals for a purge

step.

5. Discard remaining liquid. Position the pipet tips over a

waste container and press the trigger to purge the remaining

liquid. The pipettor emits a triple beep tone to signal the end of

the program, then returns to the first step of the program.

6. Eject tips. Press the ejector trigger to eject the used pipet

tips.

25

Page 30

PROGRAMMING AND OPERATION

Paced Dispense. Step 4 can also be performed as a paced

dispense. Instead of pressing the trigger for each dispense step,

press and hold the trigger to automatically dispense each volume.

Immediately after each dispense step, the pipettor emits a single

beep tone (if the beep tone is on), prompting you to prepare for the

next dispense step. To stop a paced dispense, release the trigger

before the end of the last dispense step.

Note: For paced dispensing of small volumes, set the pace to

SLOW. Ensure that you have fully released the trigger before the

end of the last dispense step to prevent an additional, unwanted

dispense step.

26

Page 31

D. CALIBRATION

The IMPACT and IMPACT2 are factory -calibrated for distilled water

at 20°C. For easy calibration, using distilled water, the IMPACT

2

pipettor features an “EASY ” CAL mode (see Section D.2,

Calibrating the IMPACT2 ). When pipetting liquids of significantly

different specific gravities or temperatures, however, the Calibration

(CALC) feature may be used for both the IMPACT and IMPACT

2

pipettors to achieve greater accuracy (see Section D.1, Calibrating

the IMPACT).

To prepare for calibration, ensure that the pipettor and tips are at

room temperature. When calibrating the pipettor, select only one

channel to pipet with. Using an analytical balance, first obtain the

actual value of the programmed volume at factory calibration. The

programmed volume (Vp) used is typically the full volume of the

pipettor (for example, 250 µl for the 250 µl 8-channel pipettor), but

is not limited to this volume.

27

Page 32

CALIBRATION

D.1 Calibrating the IMPACT

D.1.1 Volume Measurement

To measure the actual value of the programmed volume:

1. Fill the programmed volume (Vp), then dispense the entire

volume into a container on the analytical balance.

2. Read the weight on the analytical balance. Repeat this

procedure ten times.

Note: Use a clean and dry pipet tip with each pipetting cycle.

When filling the liquid, immerse the pipet tip approximately

¼ inch (approx. 0.6 cm) below the liquid surface. When

dispensing the liquid, touch the side of the container to ensure

a complete dispense.

3. Determine the average weight of the programmed volume and

convert it to volume. To convert to volume, correct the weight

for specific gravity and temperature.

If you are weighing water, use one of the correction factors

below:

Temperature Correction Factor

20°C - 22.5°C 1.003

23°C - 25°C 1.004

The resulting volume is the corrected actual volume. If the

pipettor is correctly calibrated, the programmed volume should

equal the actual volume (within the specifications of the

pipettor).

28

Page 33

D.1.2 Pipettor Calibration

To calibrate the pipettor:

CALIBRATION

1. Calculate display volume of the pipettor: Dv =

V

p x C

p

V

a

Vp = Programmed Volume

Va = Corrected Actual Volume (corrected for temperature)

Cp = Calibration Point (each pipettor handle has its own

calibration point, see the table below)

Dv = Display Volume

Handle

Size

12.50 µl 10.00 268

125.0 µl 100.0 483

250.0 µl 200.0 375

850 µl 700 882

1250 µl

Calibration

Point (µl)

1000 845

Calibration

Factory

Steps

Table D.1.2: Calibration Specifications

2. Enter the CALC mode on the pipettor by pressing the Special

Function key (use a pipet tip to press the key) until the

“CALC” function flashes on the display, followed by the

calibration point.

3. Press the [Vol] key to enter the Display Volume (Dv)

calculated above .

4. Press the [Enter] key to set the calibration point . The display

shows “CAL” then “SET” to confirm the new calibration point,

and returns to the current pipetting program.

29

Page 34

CALIBRATION

Example: Calibrate a 1250 µl 8-channel pipettor.

Water temperature = 24°C

Programmed Volume (Vp) = 1000 µl

Average of Actual Volume = 990 µl

Corrected Actual Volume (Va) = 990 x 1.004 = 994 µl

Calibration Point (Cp) = 1000

Vp

Dv =

Dv =

x C

V

a

1000 µl

994 µl

p

x 1000

Dv = 1006

30

Page 35

D.2 Calibrating the IMPACT2

CALIBRATION

IMPACT

using the “EASY ” CAL mode or with other liquids using the original

“CAL” mode (displayed as “CALC” on the IMPACT2).

2

users can calibrate their pipettors with distilled water

D.2.1 “EASY” CAL Mode

IMPACT

unique “EASY ” CAL feature. “EASY” CAL has been developed for

fast, easy, in-lab verification and/or calibration using distilled wat er

at room temperature (20-22.5°C).

1. Weigh out ten aliquots of distilled water on an analytical

Note: Ensure that the distilled water used is at room

2. Calculate an average for the ten readings of distilled water

2

users can quickly calibrate their pipettor by using the

balance, using one pipetting channel. The programmed

dispense volume must correspond to the calibration point for

that pipettor (for example, 200 µl for a 250 µl pipettor). Refer to

Table D.1.2, Calibration Specifications, for proper calibration

points.

temperature (20-22.5 °C). An internal correction factor of

1.003 is used by the pipettor to convert weight (gm) to volume

(µl).

obtained from the balance. If the resulting average weight is

within your accuracy specifications, no further calibration is

required. If the average weight does not meet expected

performance, enter the “EASY ” CAL mode to quickly re-

calibrate the IMPACT2.

3. Enter the “EASY” CAL mode by pressing the Special Function

key (using a pipet tip) until “EASY ” flashes, then press the

[Enter] key to display the calibration point.

4. Use the [Vol] key to adjust the displayed calibration point

until it matches the average weight obtained in step 2. Store

this number by pressing the [Enter] key . The new calibration

setting is confirmed by the “CAL” and “SET” messages on the

display.

31

Page 36

CALIBRATION

5. Verify this new calibration setting by repeating Steps 1 and 2.

D.2.2 “CALC” Mode

To calibrate the IMPACT2 pipettor for liquids other than water, use

the original CAL mode (displayed as “CALC” on the IMPACT2):

1. Measure the programmed volume (see Section D.1.1, Volume

Measurement).

2. Calculate the display volume of the pipettor (see step 1 in

Section D.1.2., Pipettor Calibration).

3. Enter the CAL mode on the pipettor by pressing the Special

Function key (using a pipet tip) until “EASY” appears on the

display.

4. Press the [Vol] key to display “CALC” (pressing the [Vol]

key again will return you to the “EASY ” mode).

5. Press the [Enter] key to display the calibration point.

6. Press the [Vol] key to enter the Display Volume (Dv)

calculated in Section D.1.2., Pipettor Calibration.

7. Press the [Enter] key to set the calibration point . The display

shows “CAL” then “SET” to confirm the new calibration point,

and returns to the current pipetting program.

D.3 CALVIEW

CALVIEW displays the pipetting stroke (number of steps) used to

reach the calibration point. This value allows you to confirm the

calibration during pipetting. To activate CALVIEW, enter the CAL

mode using the Special Function key . When the calibration point

is displayed, press the [Fill] key. The number of steps is

displayed. Press any key to exit CALVIEW.

D.4 CALRESET

CALRESET allows you to return to the factory calibration. To reset

the calibration, enter the CAL mode using the Special Function

key. When the calibration point is displayed, press the [Purge]

key. The display flashes “FACT,” “CAL,” then “SET” and the pipettor

32

Page 37

CALIBRATION

resets to factory setting (see Table D.1.2, Calibration

Specifications, for the factory calibration steps).

D.5 Recommendations for Accurate Pipetting

IMPACT and IMPACT

2

pipettors are factory calibrated to deliver

accurate volumes with distilled water at 20°C. By using the

calibration procedures described in Sections D.1, Calibrating the

IMPACT, and D.2, Calibrating the IMPACT

2

, you can pipet liquids

of different specific gravity with a high degree of accuracy and

reproducibility. For optimal pipetting results, refer to the following

recommendations:

n When using factory calibration, the liquid to be pipetted should

not contain specific gravity and vapor pressure that is

significantly different from distilled water.

n When pipetting liquids with low vapor pressure and/or high

surface tension, pre-wet the pipet tips with the liquid to reduce

possible loss of accuracy.

n Before aspirating any liquid, fully immerse pipet tips into the

liquid to prevent aspiration of air. Tips should be immersed

approximately ¼ inch (approx. 0.6 cm) below the liquid.

n When accurate dispensing of several increments of liquid are

needed, discard the last increment. The cumulative percentage of error from previous increments exists on the last

volume.

n Pipet viscous liquids at the slowest speed to ensure accurate

pipetting.

n During the dispensing of a liquid, touch the tip against the side

of the receiving container to prevent any liquid from remaining

on the tip.

n If you cannot touch the tip against the receiving container,

dispense the liquid at the fastest speed for crisp liquid

delivery.

33

Page 38

E. TROUBLESHOOTING AND MAINTENANCE

E.1 Troubleshooting

Listed below are possible procedural and system problems, as

well as recommended solutions. If you cannot resolve the problem,

call Matrix Technologies, Technical Service Depart -ment.

No power to the pipettor. Batteries are incorrectly installed.

n Recheck the orientation of the batteries, they should match

the diagram in the battery case.

Double beep tone occurs. An illegal programming step is

being entered, such as programming two fills that exceed the

maximum fill volume.

n Recheck your programming sequence. Ensure that you are

not attempting to fill above the maximum fill volume of the

pipettor, or attempting to dispense more than the total fill

volume.

“ERR_1” is displayed. This error message signifies one of the

following conditions:

n The pipettor cannot complete an automatic blowout. The

batteries are significantly drained of power, causing the motor

to stall.

Recharge the batteries immediately.

n The motor is defective or the flex circuit assembly is

damaged.

Contact Matrix Technologies, Technical Service Department.

The motor sounds rough and aspiration is very slow.

n The IMPACT

Verify the speed setting, the slowest speed setting normally

2

has been set to the slowest speed.

causes the motor to run very slowly and louder than usual.

34

Page 39

TROUBLESHOOTING AND MAINTENANCE

E.2 Cleaning

The IMPACT requires very little maintenance. The exterior of the

pipettor can be cleaned periodically with a soft cloth moistened

with methyl alcohol.

CAUTION! DO NOT AUTOCLAVE entire unit or clean the keypad

with bleach solution or other solvents. Extreme heat can damage

the display and other electronic components. Caustic cleaning

solutions can damage the keypad.

Note: For autoclaving specific portions of the pipettor refer to the

Autoclaving Procedures, or call Matrix Technologies, Technical

Service Department, for instructions.

Note: Avoid prolonged exposure to ultraviolet light. The handle

housing may become discolored or damaged.

35

Page 40

TROUBLESHOOTING AND MAINTENANCE

E.3 Installing/Replacing Batteries

Your IMPACT pipettor is shipped with batteries packaged

separately. Before using the pipettor, install the batteries and

recharge them for 12 – 14 hours. Use the following procedure to

install the batteries, then continue to Section E.4, Recharging

Batteries.

Under normal use, the batteries can be recharged approximately

400 times. When they can no longer hold their charge, the

batteries must be replaced. Replacement batteries can be

purchased through Matrix Technologies .

The following procedure describes installation, or replacement, of

the batteries:

Note: If you are replacing batteries, ensure that the pipettor is

turned off before removing the battery case.

1. Remove battery case. Position your thumb over the thumb

grips (see Figure E.3a) and brace your fingers against the front

of the keypad. Apply firm pressure to the panel with the thumb

grips to release the latch. Carefully slide the battery case out of

the pipettor, allowing sufficient slack for the attached wires.

Thumb Grips

Bottom of Keypad

Figure E.3a: Removing Battery Case

36

Page 41

TROUBLESHOOTING AND MAINTENANCE

Battery Case

(bottom)

Pipet Tip

Batteries (behind slot)

Battery Case

(top)

Nickel Cadmium Batteries

2. Remove batteries. Press a pipet tip against either battery

through the slot in the bottom of the battery case to remove the

batteries.

Figure E.3b: Removing Batteries

3. Install new batteries. Insert new batteries by placing the

positive end into the battery case first, then the negative end.

Ensure that the batteries are in the correct orientation (see

Figure E.3c, or diagram in the battery case).

+

+

Figure E.3c: Installing Batteries

4. Return battery case to pipettor. Carefully insert the battery

case into the pipettor. The case will click when the latch is

securely attached to the handle.

Note: If the case does not close easily, ensure that the wires

are not obstructing the opening.

5. Recharge batteries. Recharge the new batteries before using

the pipettor (see Section E.4, Recharging Batteries).

37

Page 42

TROUBLESHOOTING AND MAINTENANCE

E.4 Recharging Batteries

The IMPACT and IMPACT2 use two nickel cadmium rechargeable

batteries, located in a battery case under the keypad. The

batteries are charged while they are in the pipettor by using the

power transformer included in the package. You can operate the

pipettor while it is recharging; or you can operate it solely with the

power transformer (without batteries). When fully charged, the

pipettor will perform over 1200 cycles at full stroke. The batteries

can be recharged approximately 400 times. To extend battery life,

the pipettor will turn off automatically if it is not used within ten

minutes.

Note: Spare batteries and external battery chargers can be

ordered through Matrix Technologies.

Battery charge is low when the battery symbol

– +

Use the following steps to recharge the batteries:

1. Attach transformer. Attach the cable end of the transformer

into the pipettor. The plug receptacle is above the color ring.

Plug the transformer into the electrical outlet.

appears on the display . The pipettor will continue to

function, but should be recharged at the earliest

convenient time.

2. Recharge batteries. Recharge the batteries for 12-14 hours

to ensure a full charge. After the batteries have been recharged,

unplug the pipettor from the transformer. The pipettor is now

ready for use.

Note: Batteries hold their maximum charge if they are fully

discharged before recharging again. However, overnight

recharging is acceptable if the pipettor is in normal use during

the day.

CAUTION! Avoid excessive charging of the batteries when the

pipettor is not in use. Excessive charge to the batteries will

shorten the battery life and may damage the batteries.

38

Page 43

F. APPENDICES

F.1 Additional Pipetting Examples

F.1.1 Sample Transfers

Example #1: Transfer 100 µl and mix 200 µl for 2 cycles

immediately after transfer.

s

Vol

[Fill]

[Purge] [Enter]

[Mix]

When a purge is programmed before a mix cycle, the pipet tips

are emptied and mixing occurs automatically without pressing the

trigger. At the end of the mix, "ZERO" flashes in the display.

Remove the pipet tips from the liquid and press the trigger to

return the pistons to zero position.

Example #2: Mix 250 µl for 3 cycles, then transfer 150 µl.

[Mix]

[Fill]

[Disp]

(100) [Enter]

t

s

Vol

(200) [Mix]

t

s

Vol

(2) [Enter] [Enter] [Enter]

t

Option 1 Option 2

s

Vol

(250) [Enter] [Fill]

t

s

Vol

(150) [Enter] OR [Mix]

t

s

Vol

(150) [Enter] [Enter]

t

[Purge] [Enter] [Enter]

s

Vol

(150) [Enter]

t

s

Vol

(250) [Enter]

t

Option 1 requires an additional trigger press at the end of the mix

to zero the pistons (remove tips from liquid before zeroing).

Note: The mix cycle default is 3 cycles and does not need to be

programmed — unless it was changed in a previous program.

Option 2 minimizes the number of trigger presses and executes a

dispense by using the [Purge] key. First, fill the assigned volume

of liquid, then leave the tips in the liquid and execute the mix step.

Finally, transfer 150 µl by using the purge step.

Note: The mix step always returns to its starting volume;

therefore, the volume will be 150 µl at the end of the mix step.

39

Page 44

APPENDICES

F.1.2 Incremental Pipetting

Example: Fill 250 µl and dispense 45 µl in the first column of the

microtiter plate. Reduce each subsequent column by 5 µl for a

total of 8 columns. Discard the remainder.

[Fill]

[Disp]

[Disp]

[Disp]

[Disp]

s

Vol

(250) [Enter]

t

s

Vol

(45) [Enter]

t

s

Vol

(40) [Enter]

t

s

Vol

(35) [Enter]

t

s

Vol

(30) [Enter]

t

[Disp]

[Disp]

[Disp]

[Disp]

[Purge] [Enter] [Enter]

s

Vol

(25) [Enter]

t

s

Vol

(20) [Enter]

t

s

Vol

(15) [Enter]

t

s

Vol

(10) [Enter]

t

A purge step is entered as the last step in the program to limit the

dispense step to eight columns; otherwise, the pipettor would

dispense 10 µl until it was empty.

F.1.3 Serial Dilutions

Example: Transfer 50 µl to the first column of a plate, mix 100 µl.

Follow this procedure for exactly 4 columns.

s

Vol

[Fill]

[Mix]

(50) [Enter]

t

s

Vol

(100) [Enter]

t

[Mix] [Enter]

[Mix] [Enter]

[Mix] [Enter]

[Purge] [Enter] [Enter]

This program requires a specified number of steps; therefore, each

mix step is entered, and the program is ended with a purge step.

Since the subsequent mix steps use the same volume, the volume

does not need to be entered each time.

40

Page 45

APPENDICES

F.1.4 Simple Dilutions

Example: Prepare a 1:21 dilution with a 10 µl sample volume.

Dispense the total volume into a column and mix immediately.

s

Vol

[Fill]

[Fill]

[Fill]

[Purge] [Enter]

[Mix]

This program contains an air-gap (20 ul) and mix step at the end.

The mix step begins immediately after the purge, without pressing

the trigger. Then the pipettor empties the pipet tips and displays

"ZERO." Remove the tip from the liquid, and press the trigger to

return the pistons to zero position.

Note: Whenever a purge step is immediately followed by a mix

step, mixing will occur automatically, without pressing the trigger.

(200) [Enter]

t

s

Vol

(20) [Enter]

t

s

Vol

(10) [Enter]

t

s

Vol

(150) [Enter] [Enter ]

t

F.2 Chemical Compatibility

With the IMPACT family of pipettors, operators can confidently

pipet acidic solutions or stopping agents without damaging the

pipet tip fittings. All pipettors are equipped with chemicallyresistant tip fittings which can withstand the corroding effects of

any acidic solution. Also, the IMPACT tip fittings can be wiped with

a bleach solution (5% sodium hypochlorite) for decontamination.

41

Page 46

APPENDICES

F.3 Customer Service

F.3.1 Warranty

The IMPACT and IMPACT2 are warranted to the original purchaser

by Matrix Technologies Corp. to be free of defects in materials and

workmanship for a period of twelve (12) months from the date of

purchase, providing that it has been operated according to the

instructions, not abused or misused, that the serial number has not

been removed, and that the instrument has not been disassembled

(except for autoclaving). No other warranty is expressed or implied.

Upon receipt of your pipettor, please complete and return the

warranty card.

No IMPACT or IMPACT2 shall be returned without a prior Return

Goods Authorization from Matrix Te chnologies Corp. Should a unit

need to be returned, insurance and shipping charges must be paid

by the purchaser. Both the IMPACT and IMPACT2 with packaging

have been determined capable of withstanding normal shipping

hazards. If an instrument needs to be repaired, please return it to

Matrix Technologies Corp. in its original shipping carton.

F.3.2 Customer Service

To obtain repairs or replacements within the terms of the warranty,

contact Matrix Technologies Corp., Customer Service Department:

Matrix Technologies Corp.

44 Stedman Street

Lowell, Massachusetts 01851

800-345-0206

(508) 454-5690

Fax (508) 458-9174

March 1996

42

Page 47

MATRIX

AUTOCLAVING PROCEDURES

for IMPACT Pipettors

TECHNOLOGIES

CORPORATION

Page 48

INTRODUCTION

The IMPACT family of pipettors have been specifically designed for

serviceability. This design concept enables the user to service

instruments with relative ease. Under certain circumstances where

on-site service is not feasible, the instrument may need to be

returned to Matrix Technologies for repair.

In cases where pipettors have been exposed to biohazardous

materials, autoclaving internal components may be required.

Matrix Technologies provides the following Autoclave Kit:

Autoclave Kit (Part No. 9997)

12 replacement cross tubes

1 wooden applicator

O-ring lubricant

12 o-rings

Perform the following procedures for proper autoclaving of IMPACT

components.

2 /

Autoclaving

Page 49

PIPETTOR DISASSEMBLY

NOTE: Follow standard laboratory practices for using or servicing

equipment that is exposed to biohazardous material.

1. Remove the color ring by gently prying loose one of the edges

near the handle trigger.

2. Use a Phillips screwdriver to remove all three housing screws.

3. Carefully remove the plastic cover housing and observe the

layout of the internal parts.

Cover Housing

/

Figure 1: Removing Cover Housing

Autoclaving

3

Page 50

PIPETTOR DISASSEMBLY

Item Description Item Description

1. keypad 15. tip fitting

2. main board 16. console cover

3. flex circuit 17. console display

4. battery box 18. batteries

5. driver board 19. main housing

6. motor 20. trigger hinge pin

7. color ring 21. handle trigger

8. motor coupling 22. handle trigger spring

4 /

Autoclaving

Page 51

PIPETTOR DISASSEMBLY

Assembly

4. Remove the plastic ejector trigger with spring and slide the

aluminum ejector comb off of the tip fittings (see Figure 3).

Ejector Trigger

Ejector Comb

Figure 3: Removing Ejector Trigger and Ejector Comb

5. Remove the piston/cylinder assembly by pulling the motor

screw down from the motor shaft coupling and out of the main

housing. Also, remove the manifold assembly by firmly lifting it

out of the main housing support ribs (see Figure 4).

Motor Shaft

Coupling

Motor Screw

Main Housing

Support Ribs

Lot #

Pistons

Piston/Cylinder

Assembly

Cross Tubes

Manifold

Figure 4: Removing Piston/Cylinder and Manifold Assemblies

/

Autoclaving

5

Page 52

AUTOCLAVING

1. Remove the piston assembly from the cylinder.

2. Remove and discard the cross tubes into a biohazardous

container.

3. Remove the o-rings (only if necessary, see section “Replacing

O-rings”) and discard them into a biohazardous container.

4. Place all components (see Figure 5) into the autoclave and

autoclave at 121 °C for 20 minutes.

Figure 5: Components to be Autoclaved

5. After autoclaving, place all parts on a paper towel. The cylinder

should be inverted to allow for run-off of excess water. Allow

the parts to dry for approximately one hour.

6 /

Autoclaving

Page 53

PIPETTOR REASSEMBLY

8

After autoclaving, and once all of the components have

completely dried, the unit is ready for relubrication and

reassembly.

Cross Tube Replacement

Refer to the following table for proper connection of cross tubes

from the tip fittings to the cylinder positions.

Tip Fittings

Manifold Assembly

850, 250, 125, and 12.5 ul Cylinder 1250 ul Cylinder

850 ul

Cylinder

Type

1250 ul

Cylinder

Type

Number of

Pipetting

Channels

12

6

5

8

6

5

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

1 3 4 6 7 9 10 12 – – – –

1 2 3 10 11 12 – – – – – –

1 2 3 10 11 – – – – – – –

1 2 3 4 5 6 7 8 – – – –

1 3 4 6 7 8 – – – – – –

1 3 4 5 7 – – – – – – –

Tip Fitting Positions

Cylinder Positions

NOTE: IF THE CROSS TUBE ORIENTATION BETWEEN

THE CYLINDER AND TIP FITTINGS IS NOT CORRECT,

REASSEMBLY OF THE PIPETTOR WILL BE IMPAIRED.

/

Autoclaving

7

Page 54

PIPETTOR REASSEMBLY

O-ring Replacement

O-rings do not require replacement after autoclaving; however, the

o-rings may require replacement if liquids have been overfilled into

the cylinder of the pipettor. In this case, the o-rings should be

removed prior to autoclaving. Spare o-ring packs are available

through Matrix Technologies for all pipettor volumes.

1. Remove old o-rings

• 1250 ul, 850 ul, 250 ul Pipettors: O-rings can be removed

from the pistons by squeezing one side of the o-ring and

lifting it out of the o-ring groove on the piston. Once

removed, the o-rings should be discarded as biohazardous

waste.

• 125 ul, 12.5 ul Pipettors: O-rings from these pipettors are

located in the cylinder. To remove the o-rings, unscrew the

four screws that hold the cylinder cap to the cylinder (see

Figure 6). Once removed, the o-rings should be discarded

as biohazardous waste.

Cylinder Cap

O-rings

Figure 6: Removing O-rings

2. Install new o-rings

After the old o-rings have been removed and all components

have been autoclaved, the new o-rings may be installed.

Before installing the o-rings, apply a thin coat of lubricant to

each o-ring, using the o-ring lubricant supplied in the Autoclave

Kit.

8 /

Cylinder

Autoclaving

Page 55

PIPETTOR REASSEMBLY

Relubrication

• 1250 ul, 850 ul, 250 ul Pipettors: Use the wooden applicator

and O-ring lubricant supplied in the Autoclave Kit to apply a

thin layer of lubrication approximately 0.5 inches (approx.

1.3 cm) down into each piston hole that requires it. Spread the

lubricant evenly along the inner wall of each piston by using a

circular motion with the wooden applicator (see Figure 7).

Figure 7: Relubricating 1250 - 250 uL Pipettors

• 125 ul, 12.5 ul Pipettors: Spread the lubricant directly onto

the pistons, approximately 0.5 inches (approx. 1.3 cm) from

the bottom of each piston (see Figure 8)

/

Figure 8: Relubricating 125 - 12.5 uL Pipettors

Autoclaving

9

Page 56

PIPETTOR REASSEMBLY

Reassembly

1. Reinsert the piston assembly into the lubricated cylinder.

Ensure that the motor screw engages into the hole in the

center of the cylinder (see Figure 9).

NOTE: To correctly orient the piston and cylinder assembly,

ensure that the lot number of the cylinder is facing up and the

painted section of the piston backplate is facing down. Also,

care should be taken to keep the o-rings from being pinched

when inserting the pistons into the cylinder.

Piston Backplate

(painted section)

Motor Screw

Cylinder

Piston Assembly

Motor Screw Hole

Figure 9: Assembling Piston and Cylinder

2. Carefully insert the flat end of the motor screw into the hole of

the motor coupling. This can be accomplished by holding the

piston/cylinder assembly at a slight angle while inserting the

motor screw into the hole of the motor coupling (see Figure 10).

10 /

Autoclaving

Page 57

PIPETTOR REASSEMBLY

Slowly spin the motor screw until the flat end of the motor

screw is fully engaged into the motor coupling hole (see Figure

10). The cylinder can now be seated between the plastic ribs

in the main housing.

Motor Coupling

Motor Screw

Piston Backplate

(painted section

facing photosensor)

Photosensor

Lot #

Figure 10: Installing Piston/Cylinder Assembly

NOTE: The lot number on the face of the cylinder should

be facing toward you and the painted section of the piston

backplate should be facing the photosensor. The painted

section is used by the photosensor to track the location of

the pistons.

3. After installing the piston/cylinder assembly, install the

manifold assembly into the main housing.

/

Autoclaving

11

Page 58

PIPETTOR REASSEMBLY

To keep the tubing free from ejector contact, rotate the

manifold plate and tubing one complete turn

counterclockwise (see Figure 11). Insert the manifold

assembly into the main housing support ribs.

Figure 11: Rotating Manifold Assembly

4. Slide the ejector comb over the tip fittings with the slots on

the back of the comb exposed (see Figure 12).

Figure 12: Attaching Ejector Comb

12 /

Autoclaving

Page 59

PIPETTOR REASSEMBLY

5. Hold the ejector comb in place while inserting the ejector

trigger (see Figure 13). Place the end of the ejector spring

against the plastic stop and compress the spring while

positioning the ejector trigger over the aluminum ejector

comb (the ribs on the ejector trigger should mate with the

slots on the aluminum ejector comb).

Ejector Spring

Plastic Stop

Ejector Trigger

Figure 13: Inserting Ejector Trigger

NOTE: Be careful not to pinch the crosstubes when

inserting the ejector trigger.

Test the ejector trigger to ensure that the ejector comb

moves down when the trigger is pressed (hold the ejector

comb firmly in place while testing the trigger).

6. Place the cover housing onto the main housing and fasten

the three screws.

7. Re-attach the color ring.

The pipettor is now ready for use.

/

Autoclaving

13

Page 60

Page 61

STORED PROGRAMS

Use the following worksheet to determine the pipetting steps for each

program number, then keep it handy as a reference. The page is

perforated so that it can be removed and easily viewed while pipetting.

Date Program

No.

1

2

3

4

Program Description

ç Tear at the perforation to remove this page.

5

Page 62

Set Button

(Equalizer 384 only)

Indicator

Set Button

Control Rod

Figure A Figure B Figure C

The Matrix Impact and Impact2 Equalizer allows the Tip to Tip spacing of the pipettor to change. This allows pipeting into

or between vessels of varying center to center configurations. The set button(s), indicator and control rod all work together

to change the distance between the tips (see figure A).

To attach tips, the control rod should be in position such that the indicator is set at 9 mm (figure B). In the case of the

Equalizer384 (the Equalizer with two set buttons), tips arranged in racks of 384 can be attached when the indicator is set at

the 4.5 mm mark. Once tips are attached, follow the steps below to change the pipettor to a new tip spacing.

Matrix Equalizer:

1. Depress the set button using your thumb or finger.

2. While depressing, slide the set button to the desired tip-to-tip spacing marker on the window. Release the set button to

lock the spacing.

3. Using the control rod, slide the tips into the desired position. The indicator in the window will also move and will nest

into the set button when the desired position is achieved.

Matrix Equalizer384:

1. To set the tip spacing for the vessel with the widest spacing, depress the outer set button (the button closes t to the

control rod) using your finger or thumb.

2. While depressing, slide the set button to the desired tip-to-tip spacing marker on the window. Release the set button to

lock the spacing.

3. Check the spacing by using the control rod to slide the tips into position. The indicator in the window will also move

and will nest into the set button when the desired position is achieved.

4. For the vessel with the tightest spacing (from 4.5mm - the spacing for 384 well plates), depress the other set button

using your thumb or finger and repeat steps 2 and 3.

5. In the case of 8 channel Equalizer384 pipettors, when pushing or pulling the control rod past the 9 mm position, if

pressure is applied to the back side of the control rod (see figure B), a detent will be noticeable. This will indicate the

96 well or tip mounting position. Conversely, by applying pressure to the front side of the control rod (see figure C),

the detent can be by-passed for smoother slide operation.

Note: For maximum accuracy when adjusting the spacing of the tips from a compressed position to an expanded position it

is recommended that the control rod be actuated beyond the desired spacing and then compressed to the desired dimension.

This will maximize the spatial accuracy between the individual tips.

Important: Do not attempt to slide the set button(s) without depressing. Moving the set button(s) without first disengaging

will cause premature wear on the mechanism.

Important: Do not attempt to disassemble the unit. Please contact our Technical Services Department at 800-345-0206 for

all service related issues.

Man19755 Rev. B

Loading...

Loading...