Page 1

H7XE-05 BIKE

SERVICE MANUAL

Page 2

TABLE OF CONTENTS

CHAPTER 1: SERIAL NUMBER LOCATION ........................................................... 1

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

2.1 Read and Save These Instructions ............................................................................ 3

2.2 Electrical Requirements ............................................................................................. 4

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.1 Recommended Cleaning Tips .................................................................................... 5

3.2 Check for Damaged Parts ......................................................................................... 5

3.3 Care and Maintenance Instructions ........................................................................... 6

3.4 Touch Screen Care & Cleaning .................................................................................. 7

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.1 Console Description ................................................................................................... 8

4.2 Workout Setup Steps .................................................................................................. 9

CHAPTER 5: MANAGER MODE

5.1 Manager Mode Overview ........................................................................................... 10

5.2 Manager Mode - About Tab......................................................................................... 11

5.3 Manager Mode - Time Tab .......................................................................................... 12

5.4 Manager Mode - Default Tab ...................................................................................... 12

5.5 Manager Mode - TV Tab ............................................................................................. 13

5.6 Manager Mode - Language Tab .................................................................................. 14

5.7 Manager Mode - Other Tab ......................................................................................... 15

CHAPTER 6: ENGINEERING MODE

6.1 Engineering Mode Overview ....................................................................................... 16

6.2 Engineering Mode - Calibration ................................................................................. 16

6.3 Engineering Mode - Statistics ..................................................................................... 17

6.4 Engineering Mode - Errors .......................................................................................... 17

6.5 Engineering Mode - Clubs .......................................................................................... 18

6.6 Engineering Mode - Club ID ....................................................................................... 18

6.7 Engineering Mode - Other ........................................................................................... 19

CHAPTER 7: SERVICE MODE

7.1 Service Mode Overview .............................................................................................. 20

7.2 Service Mode - Setup Tab........................................................................................... 20

7.3 Service Mode - Test Tab ............................................................................................. 21

7.4 Service Mode - Log Tab .............................................................................................. 22

7.5 Service Mode - Date & Time Tab ................................................................................ 22

CHAPTER 8: TROUBLESHOOTING

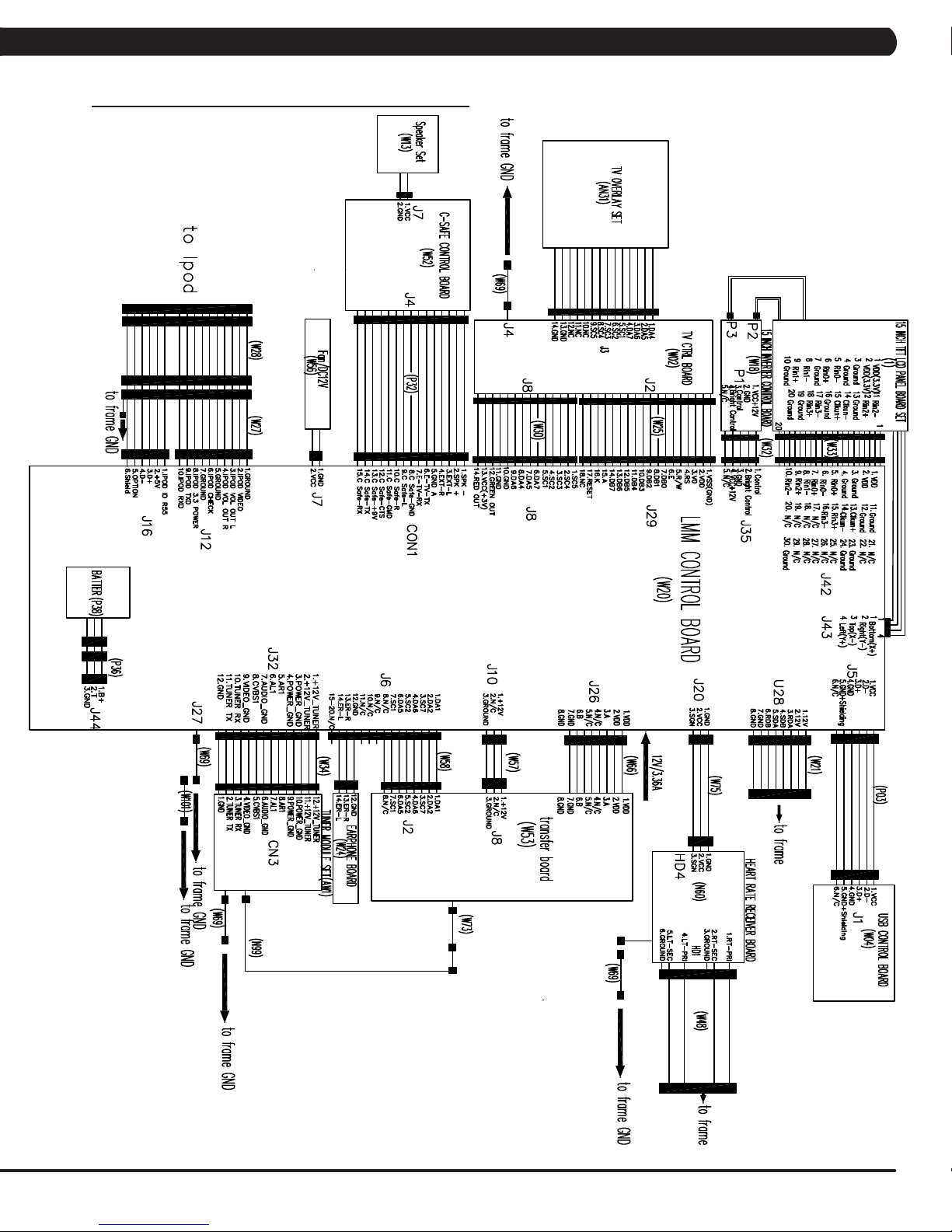

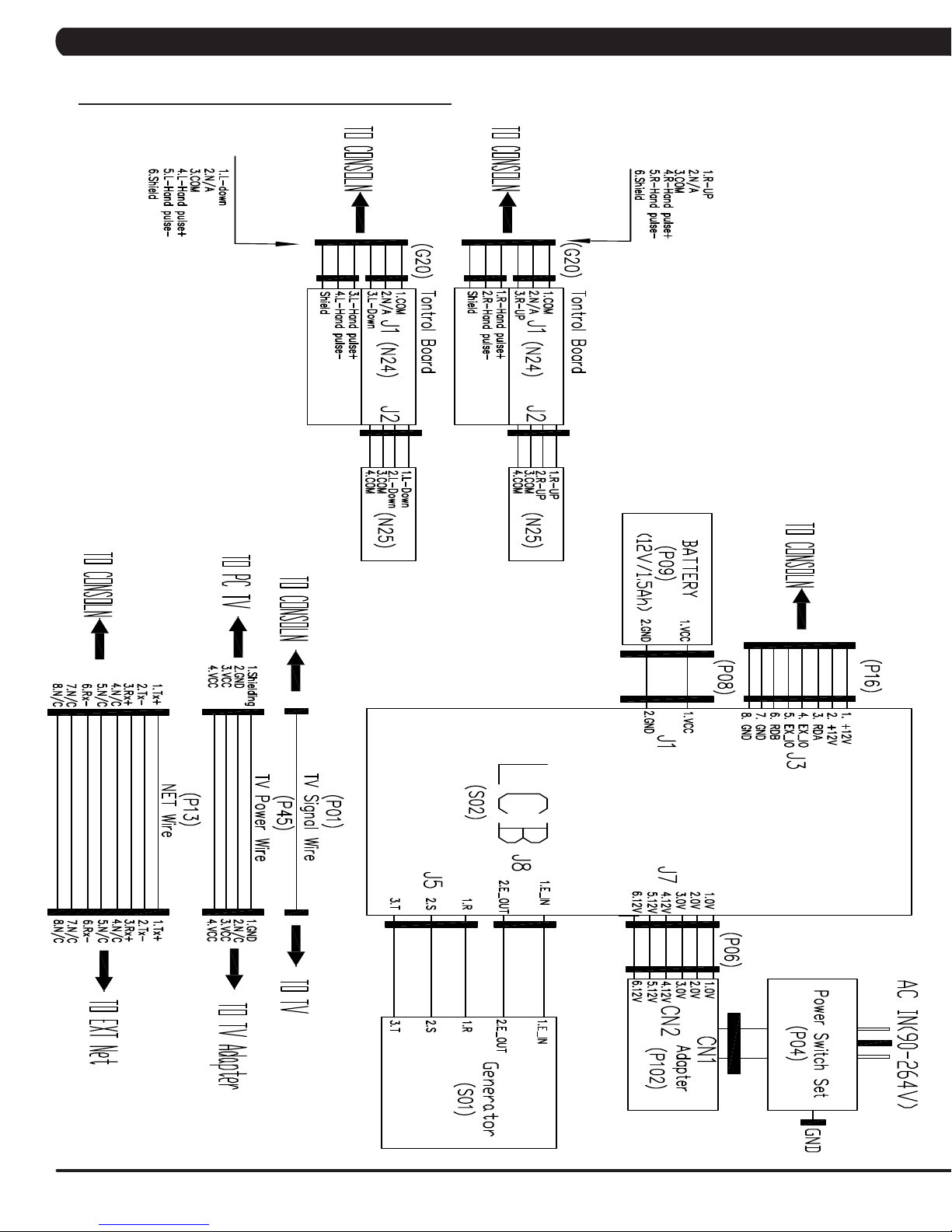

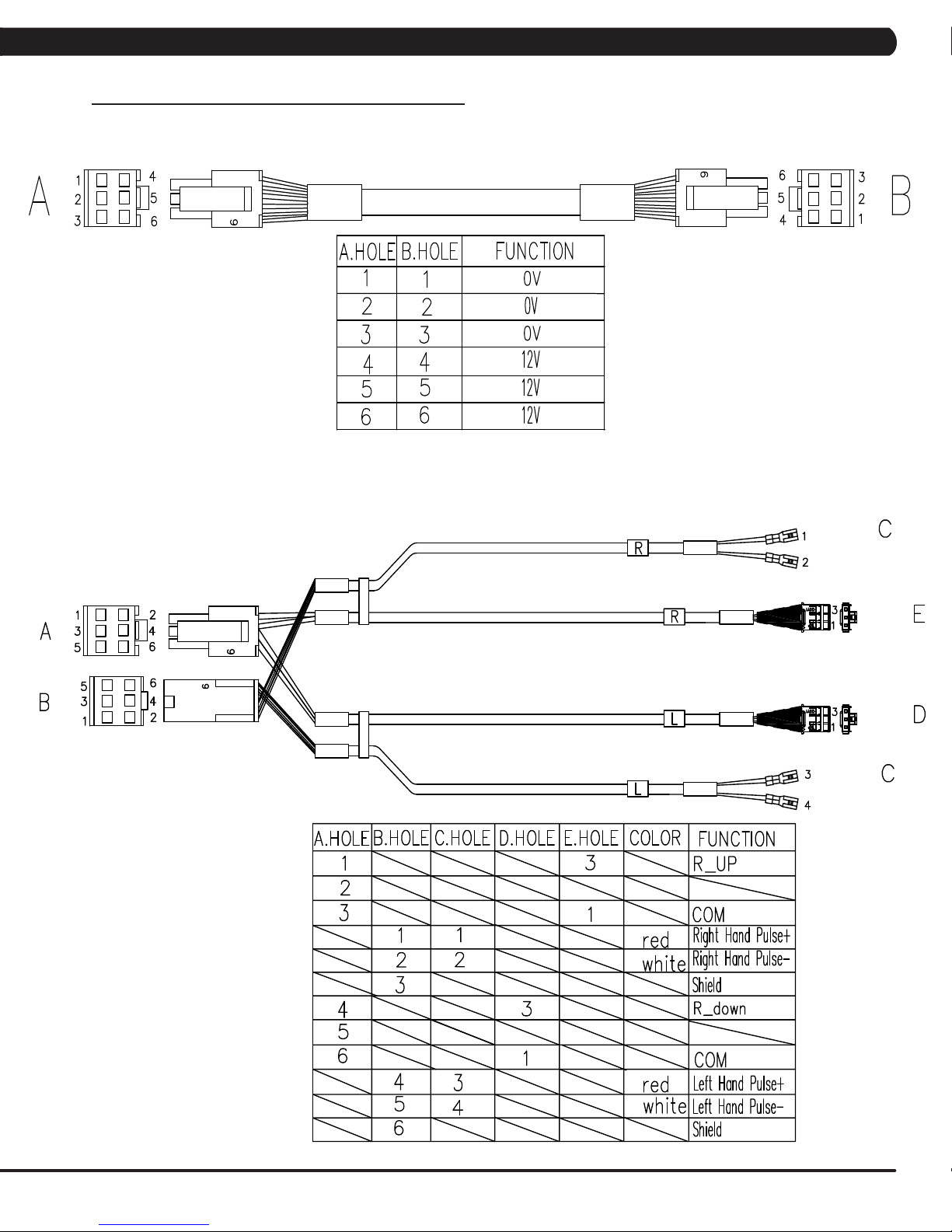

8.1 Electrical Diagram ...................................................................................................... 23

8.2 LCB LED Indicators .................................................................................................... 27

8.3 Troubleshooting - Error 04A0 / 0440 .......................................................................... 28

8.4 Troubleshooting - Error 04B0 ...................................................................................... 29

8.5 Troubleshooting - Error 0347 ...................................................................................... 30

8.6 Troubleshooting - Error 03A5 / 03A6 .......................................................................... 30

8.7 Troubleshooting - Error 0248 ...................................................................................... 31

8.8 Troubleshooting - Error 0247 ...................................................................................... 32

8.9 Troubleshooting - Error 02B4 / 03A8 / 02AB / 0441 ................................................... 32

8.10 Troubleshooting - Error 0149 / 01AF .......................................................................... 33

8.11 Troubleshooting - Error 01B4 ...................................................................................... 34

8.12 Troubleshooting - No Resistance Issues .................................................................... 35

8.13 Troubleshooting - Touch Pad Issues ........................................................................... 36

Page 3

TABLE OF CONTENTS

8.14 Troubleshooting - Heart Rate Issues .......................................................................... 37

8.15 TV Troubleshooting - Overview ................................................................................... 38

8.16 TV Troubleshooting - Picture Fuzzy or Unclear .......................................................... 39

8.17 TV Troubleshooting - TV Will Not Turn On ................................................................. 40

8.18 TV Troubleshooting - Entertainment Keypad Issues .................................................. 41

CHAPTER 9: PART REPLACEMENT GUIDE

9.1 Console Replacement ..................................................................................................... 42

9.2 Handlebar Replacement ................................................................................................ 43

9.3 Heart Rate Grips Replacement ..................................................................................... 44

9.4 Cup Holder Replacement ............................................................................................... 45

9.5 Console Keypad / Overlay Replacement ....................................................................... 46

9.6 Pedal Replacement ........................................................................................................ 48

9.7 Crank Axle Set Replacement .......................................................................................... 49

9.8 Front Shrouds Replacement ........................................................................................... 50

9.9 Front Covers Replacement ............................................................................................. 51

9.10 Rear Covers Replacement ............................................................................................. 52

9.11 Console Mast Removal ................................................................................................... 53

9.12 Seat Pad Replacement ................................................................................................... 54

9.13 Back Pad Replacement .................................................................................................. 55

9.14 Stationary Handlebar Replacement ................................................................................ 56

9.15 Lower Control Board Replacement ............................................................................... 57

9.16 Battery Replacement ...................................................................................................... 58

9.17 Drive Belt Replacement ................................................................................................. 59

9.18 Generator Replacement.................................................................................................. 60

9.19 Rear Stabilizer Replacement .......................................................................................... 61

9.20 Front Stabilizer Replacement ......................................................................................... 62

9.21 Slide Frame Replacement .............................................................................................. 63

9.22 Guide Rail Set Replacement .......................................................................................... 66

9.23 Drive Axle Set Replacement ........................................................................................... 67

9.24 Testing the Bike ............................................................................................................... 71

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 H7xe-04 Bike Specifications ....................................................................................... 72

10.2 Assembly Instructions ................................................................................................ 73

10.3 Adjusting the Pedal Straps and Seat .......................................................................... 79

10.4 Leveling the Bike ......................................................................................................... 80

10.5 TV Programming Instructions ..................................................................................... 81

CHAPTER 11: SOFTWARE UPGRADE GUIDE

11.1 Software Upgrade Instructions .................................................................................... 86

III

Page 4

1.1 SERIAL NUMBER LOCATION

CHAPTER 1: SERIAL NUMBER LOCATION

FRAME SERIAL NUMBER LOCATION

1

Page 5

CHAPTER 1: SERIAL NUMBER LOCATION

1.1 SERIAL NUMBER LOCATION - CONTINUED

CONSOLE SERIAL NUMBER LOCATION

2

SN # PLACEMENT

Page 6

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

2.1 READ AND SAVE THESE INSTRUCTIONS

To ensure your safety and protect the equipment, read all instructions

before operating the MATRIX H7xe-05 Bike.

To ensure proper use of the Matrix H7xe-05 Bike, make sure that all

users read this manual. Remind the users that before undertaking

any fitness program, they should obtain complete physical

examinations from their physicians. If, at any time while exercising,

the user experiences dizziness, pain, or shortness of breath, nausea

or feels faint, he or she must stop immediately.

* This bike is only to be used for its intended purpose described in this

manual. Do not use attachments that have not been recommended

by Matrix.

* Never drop or insert objects into any opening. Keep hands away

from moving parts. If the item cannot be reached, contact a Matrix

authorized dealer for assistance.

* Never operate the unit if it is damaged, not working properly, when

it has been dropped, or has been in water.

* Keep hands and feet clear at all times from moving parts to avoid

injury.

* Do not use this product outdoors, near swimming pools or in areas

of high humidity.

* Do not operate where aerosol (spray) products are being used or

when oxygen is being administered.

* Do not use this product in bare feet. Do not wear shoes with heels,

leather soles, cleats, or spikes while exercising.

CAUTION! If you experience chest pains, nausea, dizziness,

or shortness of breath, stop exercising immediately and consult your physician before continuing.

CAUTION! Any changes or modifications to this equipment

could void the product warranty.

* Do not remove the side covers. Service should only be done by an

authorized service technician.

* Close supervision is necessary when used near children, invalids,

or disabled people.

* When the bike is in use, young children and pets should be kept at

least 3 meters / 10 feet away.

* Assemble and operate the bike on a solid, level surface.

* Never face backward while using the Matrix H7xe-05 Bike.

* Use the stationary handlebars when mounting or dismounting the

bike.

* Do not wear clothing that might catch on any moving parts of this

bike.

3

Page 7

CHAPTER 2: IMPORTANT SAFETY INFORMATION

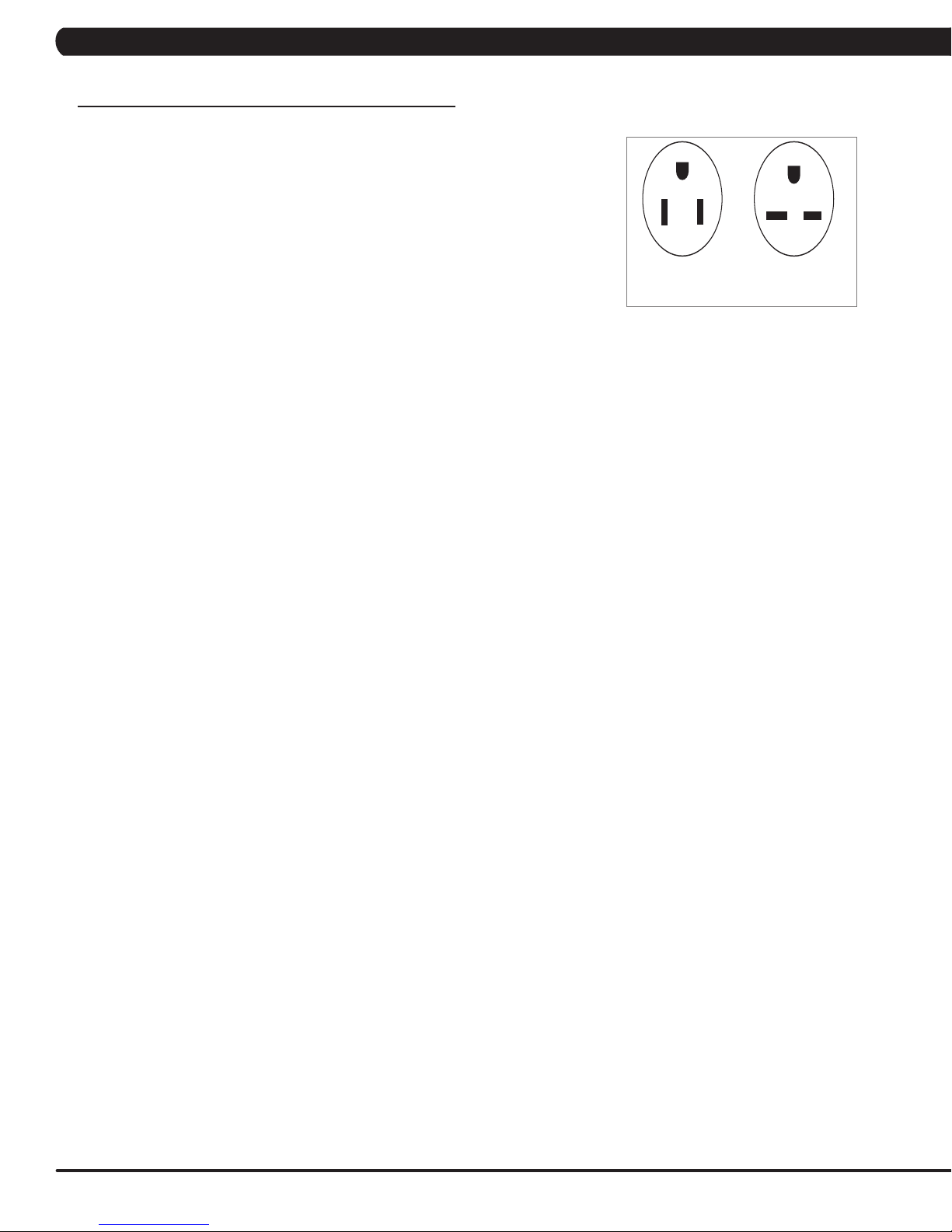

220 NEMA 6-15P

PLUG

110 NEMA 5-15P

PLUG

2.2 ELECTRICAL REQUIREMENTS

110 V UNITS

All Matrix 3x, 5x, 7xe and 7xi 110 V bikes require the use of a 100-125 V, 60 Hz and a 15 A

“Dedicated Circuit”, with a non-looped (isolated) neutral/ground for power. This outlet should be a

NEMA 5-15R and have the same configuration as the plug. No adapter should be used with this

product. These bikes can be daisy-chained together with up to 4 units per 15 A dedicated circuit.

Matrix daisy-chain cord adapters are sold separately.

220 V UNITS

All Matrix 3x, 5x, 7xe and 7xi 220 V bikes require the use of a 216-250 V, 50 Hz and a 15 A

“Dedicated Circuit”, with a non-looped (isolated) neutral/ground for power. This outlet should be a

NEMA 6-15R and have the same configuration as the plug. No adapter should be used with this

product. These bikes can be daisy-chained together with up to 4 units per 15 A dedicated circuit.

Matrix daisy-chain cord adapters are sold separately.

North American power cord plugs shown.

Depending on your country, the plug type may vary.

DEDICATED CIRCUIT AND ELECTRICAL INFO

A “Dedicated Circuit” means that each outlet you plug into should not have anything else running on that same circuit. The easiest way to verify

this is to locate the main circuit breaker box, and turn off the breaker(s) one at a time. Once a breaker has been turned off, the only thing that

should not have power to it are the units in question. No lamps, vending machines, fans, sound systems, or any other item should lose power

when you perform this test. Non-looped (isolated) neutral/grounding means that each circuit must have an individual neutral/ground connection

coming from it, and terminating at an approved earth ground. You cannot “jumper” a single neutral/ground from one circuit to the next.

ELECTRICAL REQUIREMENTS

For your safety and to ensure good unit performance, the ground on this circuit must be non-looped (isolated). Please refer to NEC article 210-21

and 210-23. Any alterations to the standard power cord provided could void all warranties of this product.

The 3x, 5x and 7xe bikes are designed to be self-powered and do not require an external power supply source to operate. Without an external

power supply, the console’s start-up time may be delayed. Add-on TV’s and other console accessories will increase the time needed for start-up.

An external power supply will ensure power is provided to the console at all times and is recommended when add-on accessories are used.

For units with an integrated TV (like the 7xe and 7xi), the TV power requirements are included in the unit. An RG6 coaxial cable with ‘F Type’

compression fittings on each end will need to be connected to the cardio unit and the video source. Additional power requirements are not

needed for the add-on digital TV (3x and 5x). For units with an add-on PCTV (3x and 5x), the TV power requirements are separate.

GROUNDING INSTRUCTIONS

The unit must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. The unit is equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances. If the user does

not follow these grounding instructions, the user could void the Matrix limited warranty.

ADDITIONAL ELECTRICAL INFO

In addition to the dedicated circuit requirement, the proper gauge wire must be used from the circuit breaker box, to each outlet that will have

the maximum number of units running off of it. If the distance from the circuit breaker box to each outlet, is 100 ft (30.5 m) or less, then 12

gauge wire should be used. For distances greater than 100 ft (30.5 m) from the circuit breaker box to the outlet, a 10 gauge wire should be

used.

ENERGY SAVING / LOW-POWER MODE

All units are configured with the ability to enter into an energy saving / low-power mode when the unit has not been in use for a specified period

of time. Additional time may be required to fully reactivate this unit once it has entered the low-power mode. This energy saving feature may be

enabled or disabled from within the ‘Manager Mode’ or ‘Engineering Mode.

4

Page 8

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.1 RECOMMENDED CLEANING TIPS

In order to maximize life span, and minimize down time, all Matrix Fitness Equipment requires regularly

scheduled cleaning.

YOU WILL NEED:

- Mild dish soap and water mixture in a spray bottle (10:1 water to soap ratio).

- Lint free 100% cotton cleaning cloths or Microfiber cleaning cloths.

- Vacuum / Shop Vac with extendable hose and soft brush attachment.

- Super Lube Multi Purpose Synthetic Lubricant with Syncolon® (PTFE) Aerosol - www.super-lube.com/sythetic-aerosol-spray-ezp-46.html.

- Computer or LCD / LED screen cleaner

- Corrosion Block (available from Matrix - part # ZMS4001374).

DAILY:

1. Wipe down the unit after each use with a mild dish soap and water mixture. NOTE: Spray the soap / water mixture onto the cloth.

NEVER spray directly onto the equipment. We recommend that you do NOT allow customers to use spray bottles to clean the equipment. If

the cleaner is sprayed directly on the equipment or over spray is present, it may cause your equipment to rust and / or cause damage to console overlays.

2. With a clean dry 100% lint free cloth and water / soap mixture, wipe any dust or dirt from the out of the seat wheel track (Figure A).

WEEKLY:

1. With a clean dry 100% lint free cloth and water / soap mixture, wipe down the entire frame so it is free of dust, dirt, and sweat.

2. With a clean dry 100% lint free cloth and water / soap mixture, wipe down the entire console area including the hand grips and hand rails.

3. Use a computer screen cleaner or LCD / LED screen cleaner on the touch portion of the console (see Section 3.4).

MONTHLY:

1. Vacuum under and around the Bike. If you need to move it, unplug the unit first.

2. Apply Corrosion Block to the metal part of the iPod cable.

FIGURE A

3.2 CHECK FOR DAMAGED PARTS

DO NOT use any equipment that is damaged or has worn or broken parts. Use only replacement parts supplied by Matrix Fitness Systems.

MAINTAIN LABELS AND NAMEPLATES. Do not remove labels for any reason. They contain important information. If unreadable or missing,

contact Matrix Fitness Systems for a replacement. 1-866-693-4863, www.matrixfitness.com

MAINTAIN ALL EQUIPMENT Preventative maintenance is the key to smooth operating equipment. Equipment needs to be inspected at regular

intervals. Defective components must be replaced immediately. Improperly working equipment must be kept out of use until it is repaired.

Ensure that any person(s) making adjustments or performing maintenance or repair of any kind is qualified to do so. Matrix Fitness Systems will

provide service and maintenance training at our corporate facility upon request or in the field if proper arrangements are made.

5

Page 9

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.3 CARE AND MAINTENANCE INSTRUCTIONS

In order to maximize life span, and minimize down time, all MATRIX equipment requires regular maintenance items performed on a scheduled

basis. This section contains detailed instructions on how to perform these items and the frequency of which they should be done. Some basic

tools and supplies will be necessary to perform these tasks which include (but may not be limited to):

* Metric Allen wrenches

* #2 Phillips head screwdriver

* Adjustable wrench

* Commercial Pedal wrench (available from Matrix - part # ZMS4001254)

* Teflon based spray lubricant such as “Super Lube”, or other Matrix approved product

* Computer or LCD / LED screen cleaner

You may periodically see an addendum to this document, as the Matrix Technical Support Team identifies items that require specific attention, the

latest version will always be available on the Matrix website, www.matrixfitness.com

DAILY MAINTENANCE ITEMS

1. Attempt to wobble the unit back and forth, level if needed (see Section 10.4).

MONTHLY MAINTENANCE ITEMS

1. Check the pedal straps for damage.

2. Clean the grooves on the foot pedals.

QUARTERLY MAINTENANCE ITEMS

1. Frequently vacuum the floor beneath the unit to prevent the accumulation of dust and dirt which can affect the smooth operation of the unit.

2. Check that the pedal and crank assembly are tight with no free play or wobble in them. Make sure to use a commercial grade pedal wrench

to get the pedals as tight as possible.

3. Check the condition of the seat upholstery. Make sure that the seat adjustment mechanism is operating correctly.

4. Clean and lubricate the seat guide rods with Super Lube.

YEARLY MAINTENANCE ITEMS

1. Remove the front shrouds and check the belts for damage, alignment, and proper tension.

6

Page 10

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.4 TOUCH SCREEN CARE & CLEANING

TOUCH SCREEN CARE AND CLEANING

* The touch screen requires very little maintenance. We recommend that you periodically clean the touch screen surface with a clean dry 100%

lint free cloth and water / soap mixture or a computer or LCD / LED screen cleaner.

* It is very important to avoid using any other chemical on the touch screen.

* Always dampen the cloth and clean the screen. Do not spray the water / soap mixture on the screen itself, the drips can seep into the display

or stain the bezel.

* After cleaning, make sure the surface is dry. There should not be any left over solvent to seep into the display.

* It is very important to handle the touch screen with care. Do not use excessive force when cleaning.

* Do not use any sharp materials to clean the touch screen surfaces.

* Do not use high pressure air, water, or steam to clean the touch screen surface.

7

Page 11

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.1 CONSOLE DESCRIPTION

The H7xe-05 has a fully integrated touch screen display. All information required for workouts is explained on screen. Exploration of the interface

is highly encouraged. The information explaining how to program for various workouts will give an explanation about the contents of each screen.

GO: One touch Start.

STOP: Ends workout and shows workout summary data.

COOL DOWN (displayed on-screen during workout): Puts unit into Cool Down mode. Cool Down time is dependent on the length of the workout.

Workouts 19 minutes and shorter will have a cool down length of 2 minutes. Workouts 20 minutes and longer will have a cool down length of 5

minutes.

H7XE-05 ENTERTAINMENT ZONE

iPOD®: Will take the user directly to the iPod screen to allow for iPod control and playlist selection.

VOLUME UP / DOWN: Adjusts the volume output through the headphone jack of the integrated console TV or iPod output.

NUMBER KEYPAD: Allows for easy TV channel selections.

CHANNEL UP / DOWN: Allows for channel selection.

DISPLAY MODE: Allows user to cycle through console display options, iPod, TV, or profile display.

LAST CHANNEL: Allows the user to cycle between the current channel and the previous channel viewed.

CC/MUTE: Mutes sound and turns closed captioning on or off.

8

Page 12

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.2 WORKOUT SETUP STEPS

To set up a workout, press the touch screen over the program you would like to use and then follow the prompts to begin your workout.

GO - Press to immediately begin a workout. Workout, resistance level, and time will automatically go to default settings. Pressing GO will not

prompt user for age, weight, or level settings.

MANUAL - Manual allows the user to input more information while defining their own workout. Calorie expenditure will be more accurate when

inputting information in Manual than by pressing GO.

FAT BURN - Fat burn is a level based program that is designed to help users burn fat through various resistance level changes.

ROLLING HILLS - The Rolling Hills program is a level based program that automatically adjusts the resistance level to simulate real terrain.

INTERVALS - The Intervals program is a level based program that automatically adjusts the resistance of the machine from low to high

intensity settings at regular intervals.

RANDOM - Random is a level based workout that randomly adjusts the resistance of the machine.

TARGET HEART RATE - The Matrix H7xe-05 bike comes with standard digital contact heart rate sensors and are POLAR telemetry

compatible. The heart rate control workout mode allows the user to program their desired heart rate zone, and the bike will automatically adjust

the level based upon the user's heart rate. The heart rate zone is calculated using the following equation: (220-Age)8%=target heart rate zone.

The user must wear a POLAR telemetric strap or continually hold onto the contact heart rate grips for this workout.

Locate the metal sensors on the handlebars of the bike. Notice that there are two separate pieces of metal on each grip. You must be making

contact with both pieces of each grip to get an accurate heart rate reading. You can grab these sensors in any program to view your current heart

rate.

FITNESS TEST -The Cooper Fitness Test measures cardiovascular fitness and proves an estimated sub-maximal VO2 result. It is based on

power output according to ACSM standards and was developed by the Cooper Institute© (www.cooperinstitute.org). User RPMs must remain

between 60-80 RPM during the test. The test will end when the user can no longer maintain this speed. Use of a heart rate strap is optional but

provides more data.

The test starts at a low intensity level and gradually increases in intensity (difficulty) every 2 minutes. As it increases, the user must maintain

60-80 RPM to advance to the next level. The test could take upwards of 30+ minutes for very fit individuals. Once the test ends a recovery period

(cool down) will begin and the user's results are calculated and displayed. Results are based on the number of stages completed. Incline will not

be adjustable during the test.

STAGE COMPLETE:

1 Well Below Average

2 Well Below Average

3 Below Average

4 Below Average

5 Average

6 Average

7 Above Average

8 Above Average

9+ Well Above Average

CONSTANT WATTS - Constant Watts is a unique program that allows you to vary your cadence or RPM and the bike's resistance level will

adjust accordingly to your selected goal. The quicker you pedal, the less resistance for the goal selected.

9

Page 13

CHAPTER 5: MANAGER MODE

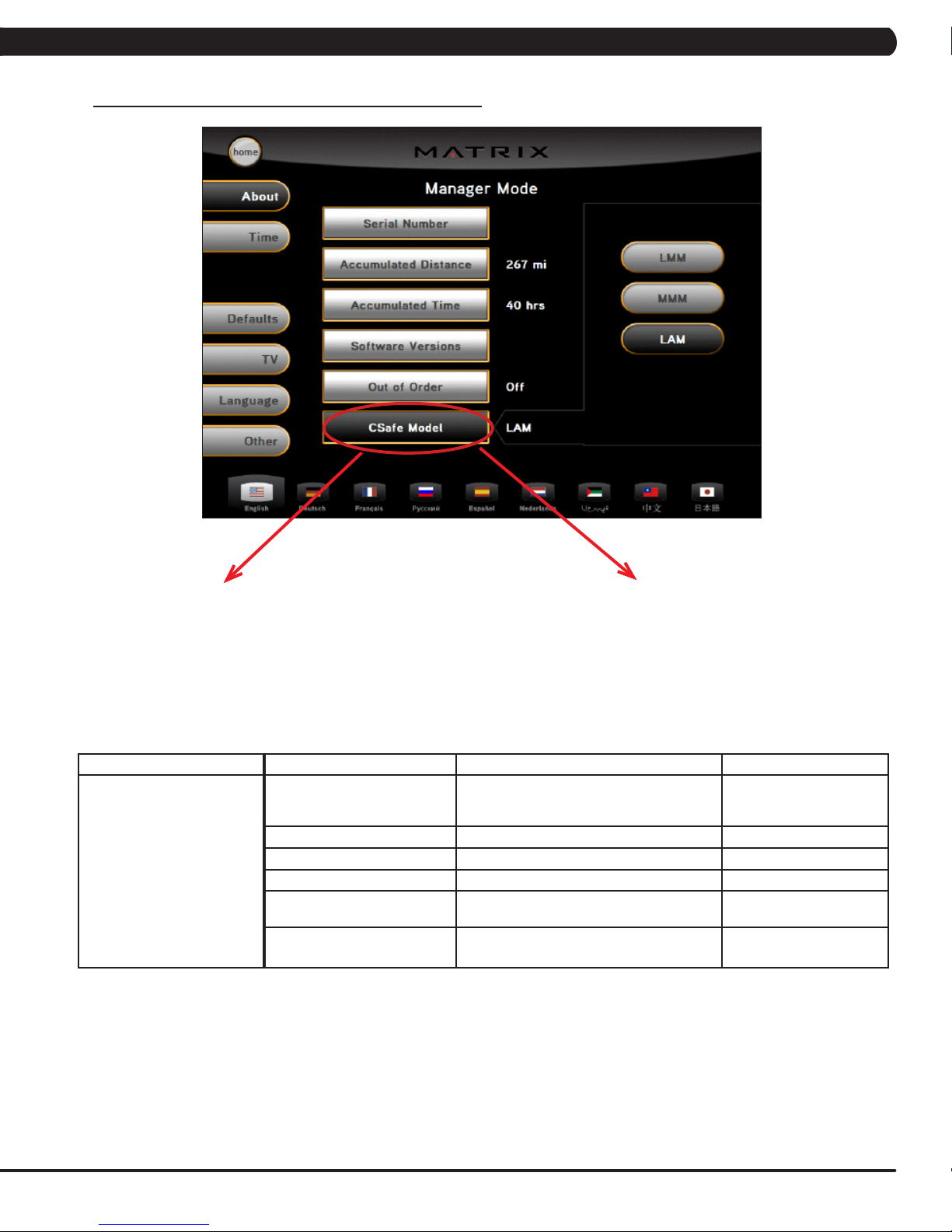

5.1 MANAGER MODE OVERVIEW

The Manager's Custom Mode allows the club owner to customize the bike for the club.

1) To enter Manager Mode, press ENTER, 1, 0, 0, 1, ENTER on the lower display. Manager Mode will appear on the display (Figure A).

2) Follow the prompts to change the desired setting.

3) Press the ENTER key once the desired setting is correct to save.

4) Press HOME to return to normal operation. NOTE: If a setting has been changed, the unit and console power should be reset. Cycle the

power switch, and press and hold the CHANNEL UP and CHANNEL DOWN keys for 3-5 seconds to reset the console power.

FIGURE A

10

Page 14

5.2 MANAGER MODE - ABOUT TAB

CHAPTER 5: MANAGER MODE

H7xe-02-C or H7xe-01-C - If the unit has the old MMM

board, the CSafe Model should be set for MMM (even

if the MMM console is replaced).

MANAGER MODE

About

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Serial Number This option displays the serial number of the

Accumulated Distance Total distance on the unit since production. Cannot be modified.

Accumulated Time Total time on the unit since production. Cannot be modified.

Software Versions Software version. Cannot be modified.

Out of Order

Default: Off

CSafe Model This option controls whether the console is

H7xe-03-C - If the unit has the LMM board, the CSafe

Model should be set for LMM. If the unit has an LMM

board, there will usually be a USB port on the front of

the console.

H7xe-04-C - If the unit has the LMM board and the

keypad type belong to LAM as outlined and the setup

in Section 7.3 (Service mode->Test->Keypad->LAM).

platform and console. See Service Mode to

edit the serial numbers.

This option allows the club to show the unit

"out of order" if an error is present.

Fitlinxx compatible.

Cannot be modified.

On / Off

LMM / MMM / LAM

11

Page 15

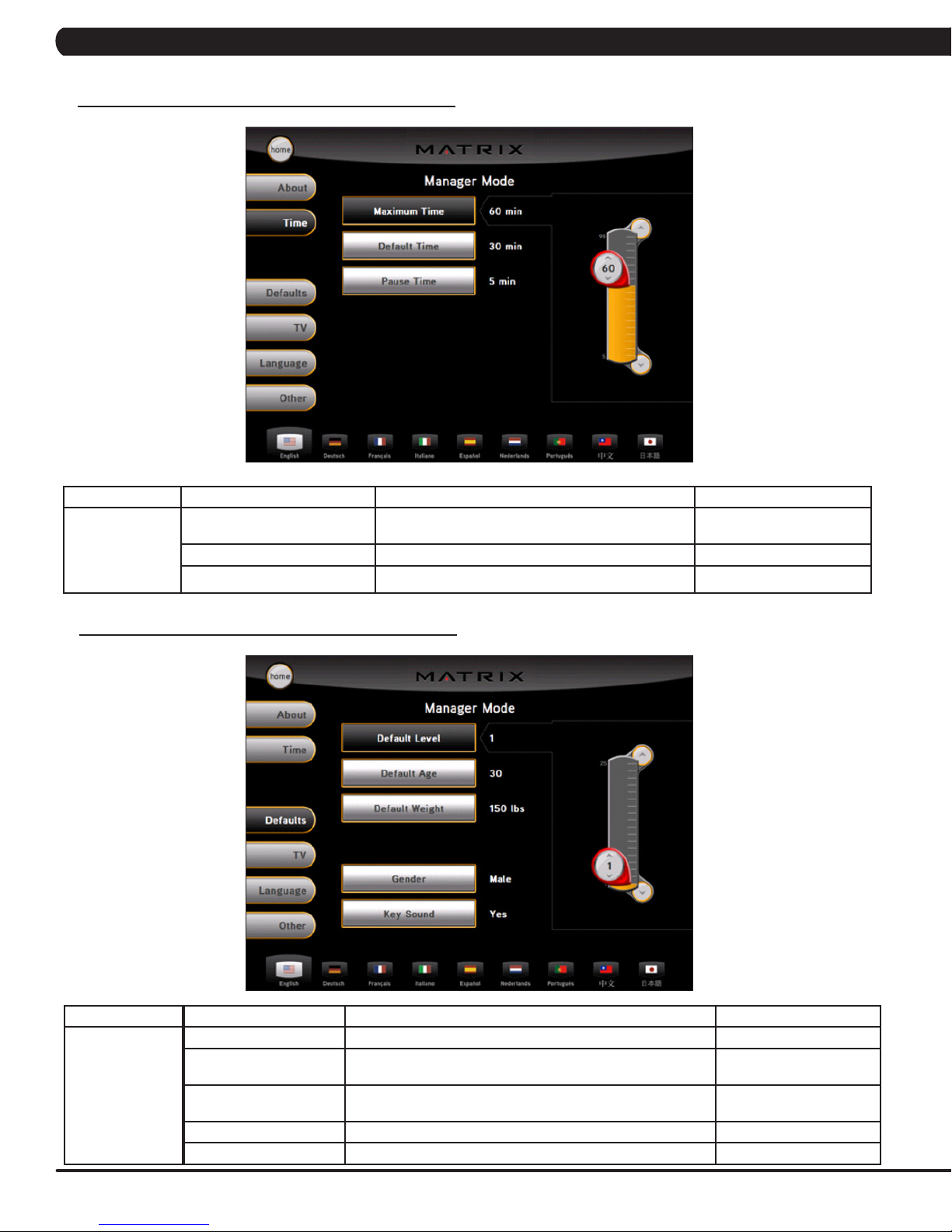

5.3 MANAGER MODE - TIME TAB

CHAPTER 5: MANAGER MODE

MANAGER MODE

Time

5.4 MANAGER MODE - DEFAULTS TAB

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Max Time Default: 60 Minutes This option allows the club to set the maximum workout

Default Time Default: 30 Minutes This option controls the default program time. Max: Max Time Min: 5 Min

Pause Time Default: 5 Minutes This option controls the default pause time. Max: 10 Min Min: 1 Min

duration limits during peak and non peak hours.

Maximum: 99 Minutes

Minimum: 5 Minutes

MANAGER MODE

Defaults

FUNCTION & DEFAULTS DESCRIPTION MODIFIED

Level Default: 1 This option controls the default program level. Max: 1 Min: 20

Age Default: 30 This option controls the default user's age used in the target HR

Weight Default: 150 lbs

/ 68 kg

Gender Default: Male Setting the user as Male or Female. Male or Female

Key Sound Default: Yes This option allows different sounds to be chosen for the keypad. Yes or No

12

calculations.

This option controls the default weight used in the calorie

calculations. Displayed in pounds or kilograms.

Maximum: 100

Minimum: 10

Maximum: 400 lbs / 182 kg

Minimum: 50 lbs / 22 kg

Page 16

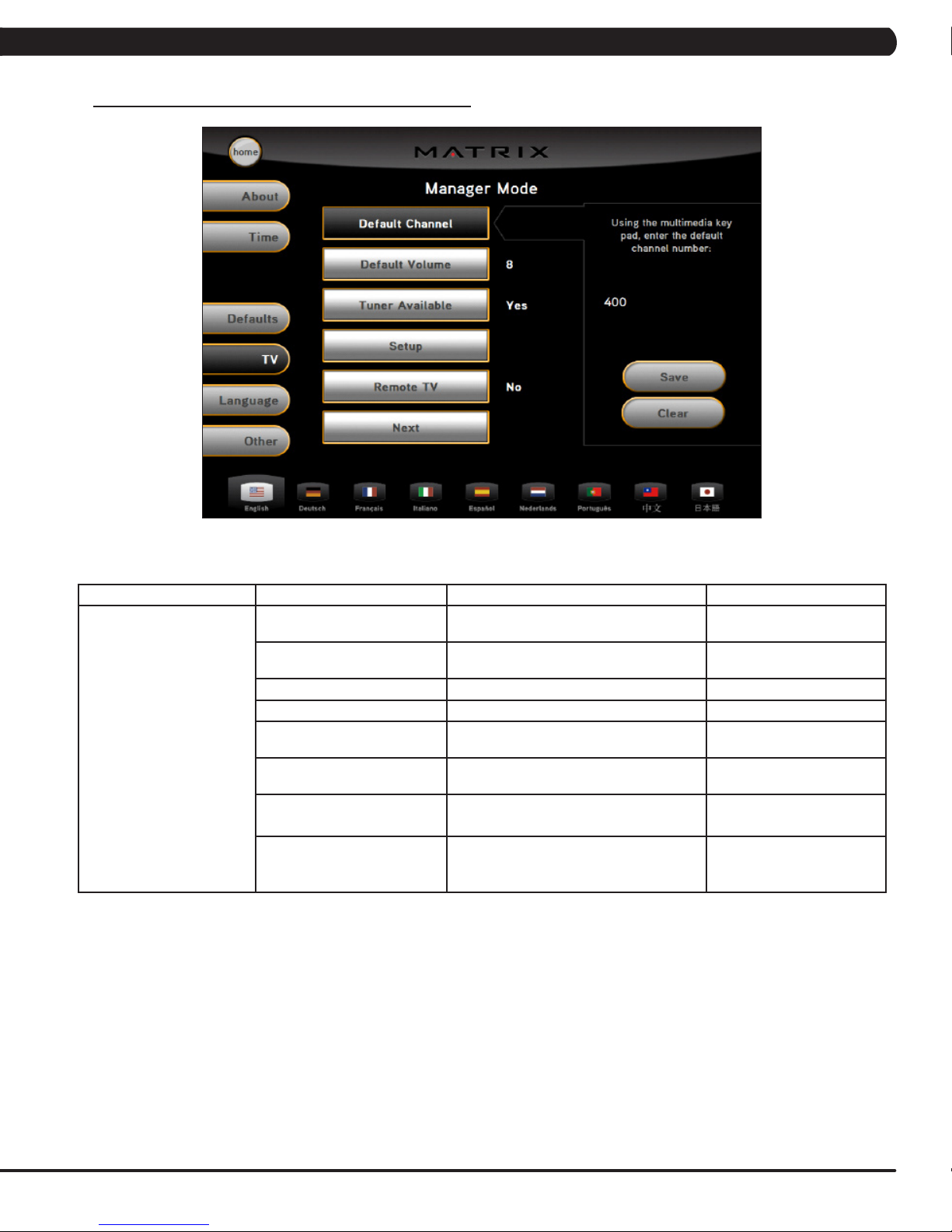

5.5 MANAGER MODE - TV TAB

CHAPTER 5: MANAGER MODE

MANAGER MODE

TV

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Default Channel

Default: 3

Default Volume

Default: 5

Tuner Available Default: Yes This option controls the default TV function. Yes or No

Setup This option sets the TV tuner function. On / Off

Remove TV

Default: No

Remove TV channel

Default: 1

Remove TV volume

Default: 15

CC / Mute

Default: Yes

This option controls the default TV channel

on start up.

This option controls the default TV volume

on start up.

This option controls the remote TV function. NO or YES

This option controls the default remove TV

channel on start up.

This option controls the default remove TV

volume on start up.

This option allows the Mutes sound and

turns closed captioning on or off to be

chosen from touch screen.

Channels 1-999

Maximum: 17

Minimum: 1

Maximum: 37

Minimum: 1

Maximum: 15

Minimum: 1

NO or YES

13

Page 17

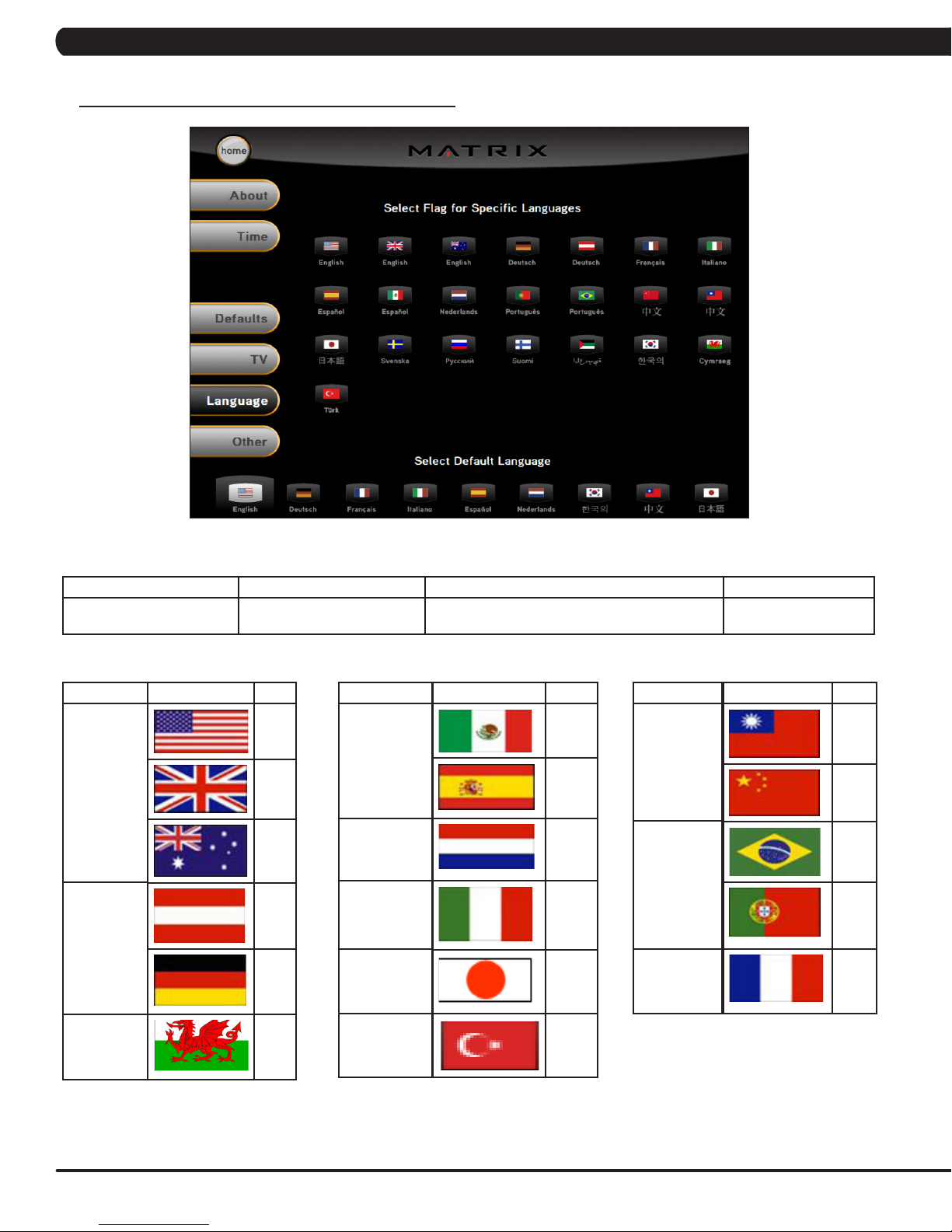

5.6 MANAGER MODE - LANGUAGE TAB

CHAPTER 5: MANAGER MODE

MANAGER MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Language Select default language. This option allows the user to select a flag for a

LANGUAGE

English

German

Welsh

FLAG UNIT

Mile

Mile

KM

KM

KM

KM

LANGUAGE

Spanish

Dutch

Italian

Japanese

Turkish

specific language.

FLAG UNIT

KM

KM

KM

KM

KM

KM

LANGUAGE

Chinese

Portuguese

French

N/A

FLAG UNIT

KM

KM

KM

KM

KM

14

Page 18

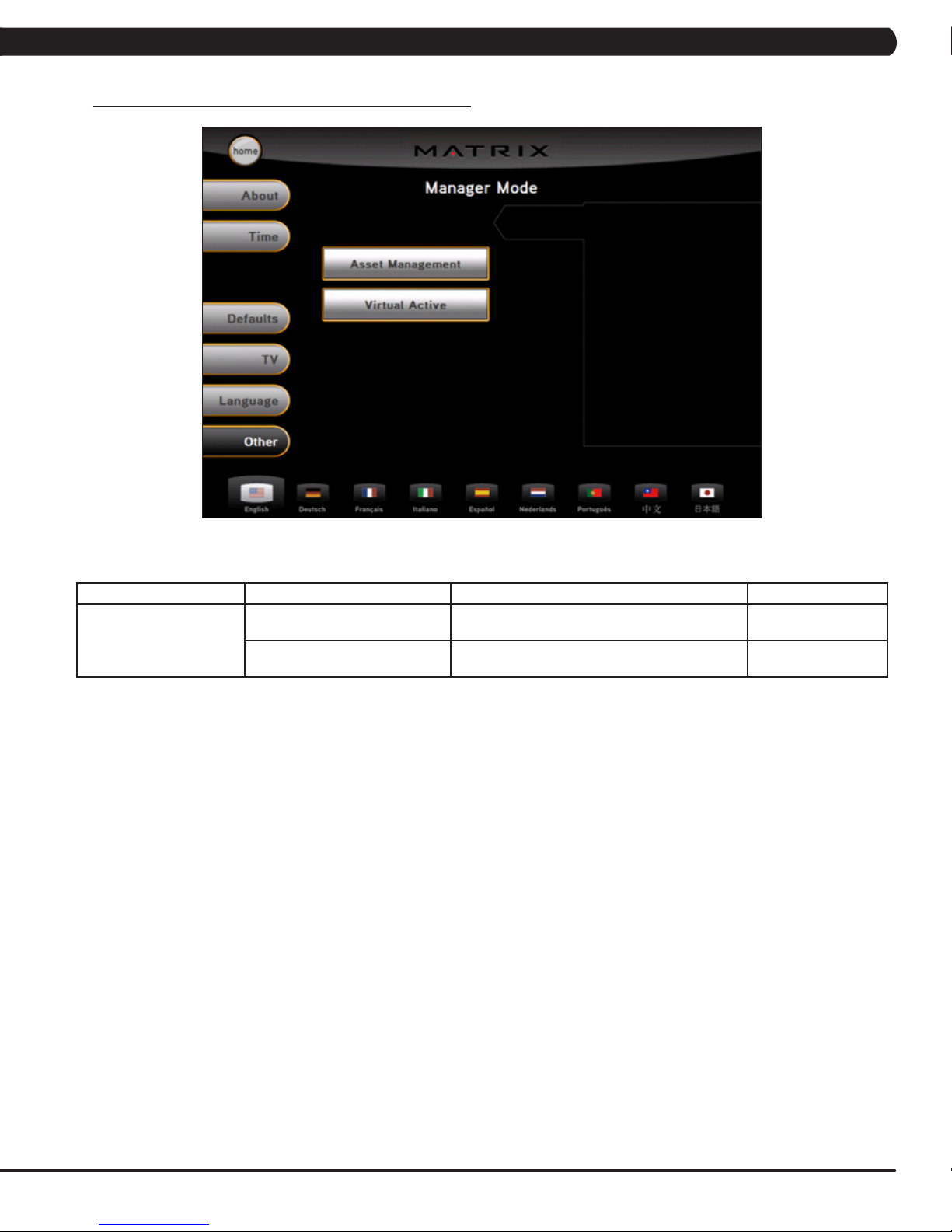

5.7 MANAGER MODE - OTHER TAB

CHAPTER 5: MANAGER MODE

ENGINEERING MODE

Other

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Asset Management

Default: Off

Virtual Active

Default: Off

This option allows fitness clubs to collect workout

data to a PC.

This option controls the Virtual Active function. On or Off

On or Off

15

Page 19

CHAPTER 6: ENGINEERING MODE

6.1 ENGINEERING MODE OVERVIEW

The Engineering Mode allows the club owner to keep track of the technical settings and error history for the bike.

1) To enter Engineering Mode, press ENTER, 2, 0, 0, 1, ENTER on the lower display. Engineering Mode will appear on the display (Figure A).

2) Follow the prompts to change the desired setting.

3) Press the ENTER key once the desired setting is correct to save.

4) Press HOME to return to normal operation. NOTE: If a setting has been changed, the unit and console power should be reset. Cycle the

power switch, and press and hold the CHANNEL UP and CHANNEL DOWN keys for 3-5 seconds to reset the console power.

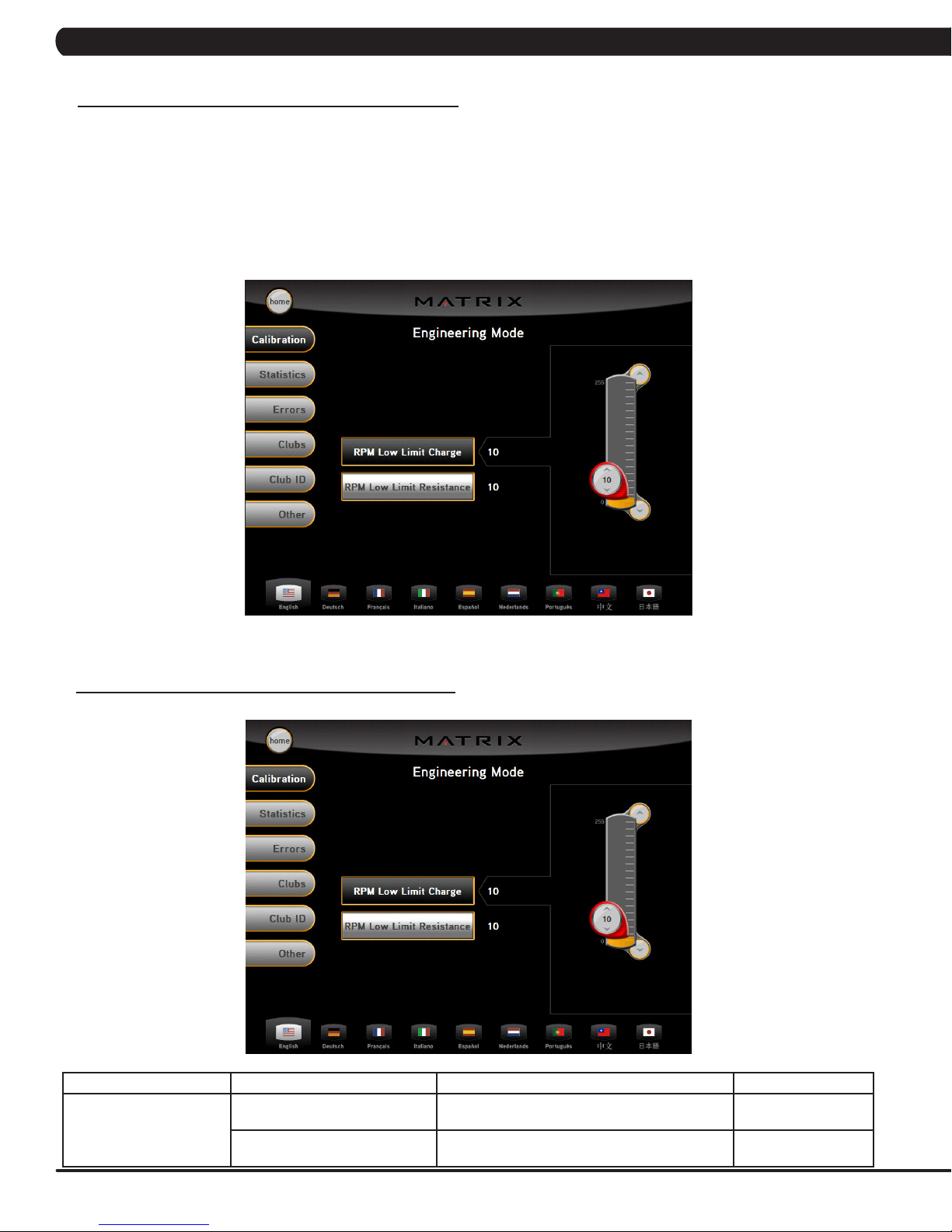

6.2 ENGINEERING MODE - CALIBRATION TAB

FIGURE A

ENGINEERING MODE

Calibration

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

RPM Low Limit Charge:

Default: 10

RPM Low Limit Resistance

Default: 10

16

This option controls the RPM low limit to iPod

charge.

This option controls the RPM low limit to show

resistance.

Range: 0 - 255

Range: 0 - 255

Page 20

CHAPTER 6: ENGINEERING MODE

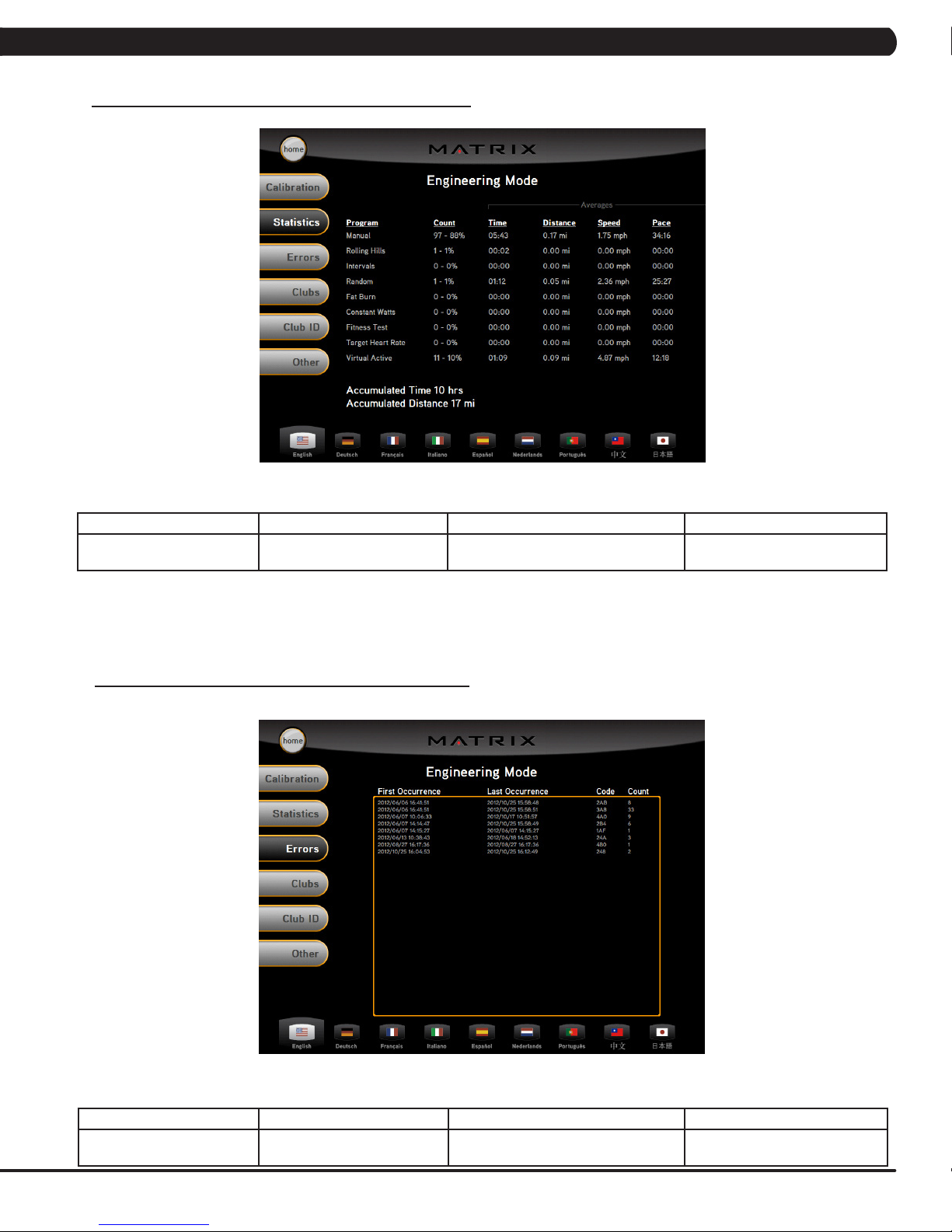

6.3 ENGINEERING MODE - STATISTICS TAB

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Statistics This option displays the workout

information for the unit.

6.4 ENGINEERING MODE - ERRORS TAB

N/A

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Errors This option displays the error code

history for the unit.

N/A

17

Page 21

6.5 ENGINEERING MODE - CLUBS TAB

CHAPTER 6: ENGINEERING MODE

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Clubs Clubs

Default: MATRIX

6.6 ENGINEERING MODE - CLUB ID TAB

This option allows the club to select a screen

header from a list.

N/A

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Club ID Club ID This option records the Club ID of

18

the fitness facility.

N/A

Page 22

6.7 ENGINEERING MODE - OTHER TAB

CHAPTER 6: ENGINEERING MODE

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Other Erp Time

Default: 0 minutes

If there is no use of the machine over a

period of time, the console LEDs will turn

off (go into ErP mode).

Maximum: 30 minutes

Minimum: 0

19

Page 23

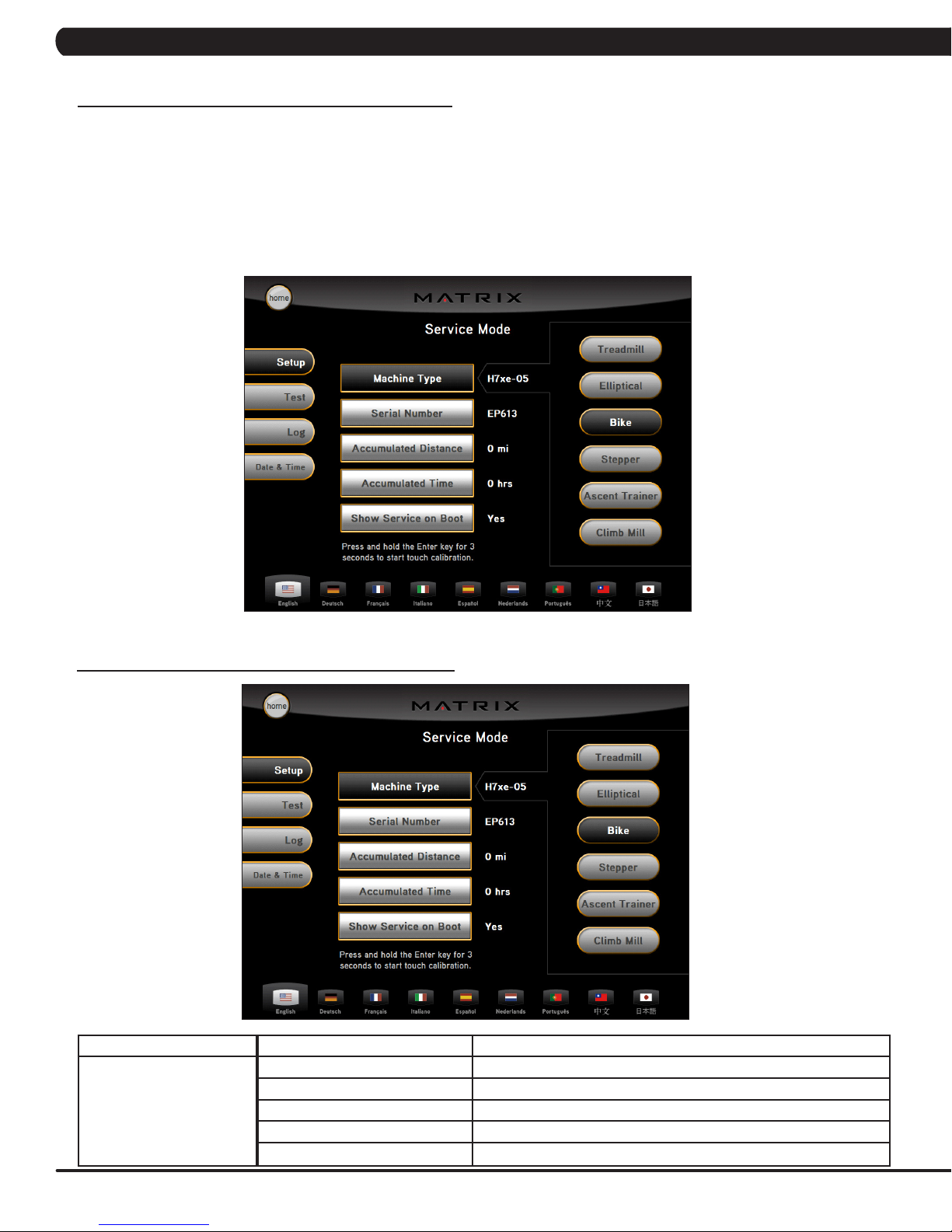

CHAPTER 7: SERVICE MODE

7.1 SERVICE MODE OVERVIEW

The Service Mode allows an authorized service provider to test and store information on the bike.

1) To enter Service Mode, press ENTER, 3, 0, 0, 1, ENTER on the lower display. Service Mode will appear on the display (Figure A).

2) Follow the prompts to change the desired setting.

3) Press the ENTER key once the desired setting is correct to save.

4) Press HOME to return to normal operation. NOTE: If a setting has been changed, the unit and console power should be reset. Cycle the

power switch, and press and hold the CHANNEL UP and CHANNEL DOWN keys for 3-5 seconds to reset the console power.

7.2 SERVICE MODE - SETUP TAB

SERVICE MODE

Setup

Machine Type Default: Hybrid Bike This option selects the current model.

Serial Number This option sets the serial number of the console and frame.

Accumulated Distance This option sets the accumulated workout distance since production.

Accumulated Time This option sets the accumulated workout time since production.

Show Service on Boot Factory Setting Only.

FIGURE A

FUNCTION & DEFAULTS DESCRIPTIONS

20

Page 24

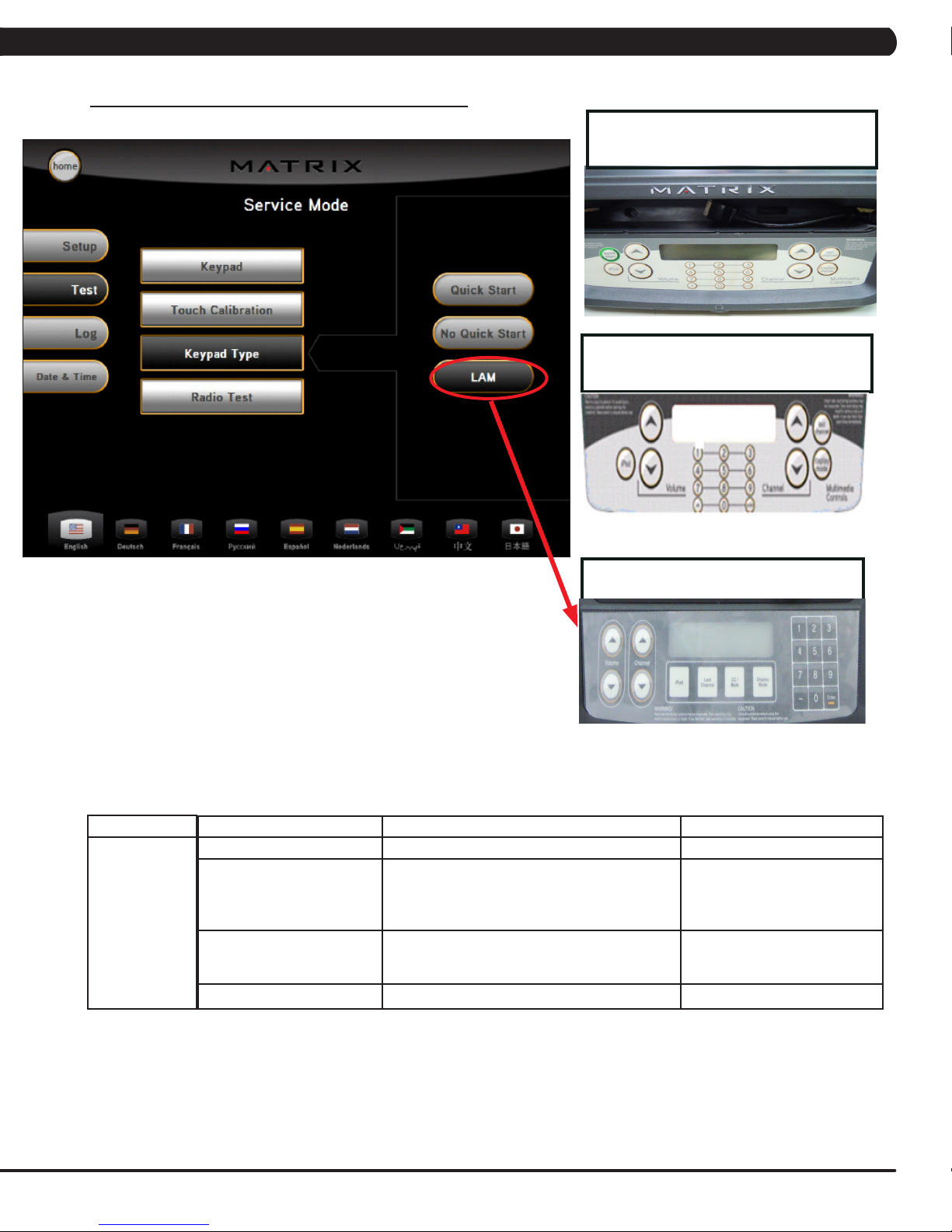

7.3 SERVICE MODE - TEST TAB

CHAPTER 7: SERVICE MODE

H7xe-02--C Keypad - Old keypad Includes Quick Start Key

H7xe-03--C Keypad - Old keypad - Does

NOT Includes Quick Start Key

SERVICE MODE

Test

H7xe-04-C Keypad - New keypad -

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Keypad This option is for a keypad test. N/A

Touch Calibration This option allows for a touch calibration of the

console. Follow the cross mark and touch the

screen to catch. After 5 positions are tested, touch

the center of the screen to exit this test.

Keypad Type This option sets the keypad type for the console. Quick Start or No Quick Start or

Radio Test This option will test the radio signal for function. N/A

N/A

LAM

21

Page 25

7.4 SERVICE MODE - LOG TAB

CHAPTER 7: SERVICE MODE

SERVICE MODE FUNCTION & DEFAULTS DESCRIPTIONS

7.5 SERVICE MODE - DATE & TIME TAB

Log This option records key component

replacement history.

SERVICE MODE

Date & Time This option sets the current date and time on the

22

FUNCTION & DEFAULTS DESCRIPTIONS

machine.

Page 26

8.1 ELECTRICAL DIAGRAMS

CHAPTER 8: TROUBLESHOOTING

23

Page 27

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

24

Page 28

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

MCB POWER WIRE

PULSE SENSOR WIRE

25

Page 29

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

DIGITAL COMMUNICATION WIRE

26

Page 30

8.2 LCB LED INDICATORS

CHAPTER 8: TROUBLESHOOTING

27

Page 31

CHAPTER 8: TROUBLESHOOTING

8.3 TROUBLESHOOTING - ERROR 04A0 / 0440

ERROR CODE 04A0 / 0440

1) SYMPTOM:

04A0 – UCB communication disconnected.

0440 – Timeout receive packet (LCB can not receive any data for 50 seconds).

2) SOLUTION:

If the display is giving a 04A0 error, check the LCB LED10 status.

- LED10 blinking: Turn off power and after 3 seconds, turn on power again. If console also show the 04A0, re-install UCB software again. If

this does not resolve the issue, replace the UCB.

- LED10 off: Check the connection of the digital communication wire at the UCB and LCB (Figures A & B). If the connection is good,

replace the digital communication wire.

- If replacing the UCB and digital communication wire does not work, replace the LCB.

FIGURE A FIGURE B

28

Page 32

CHAPTER 8: TROUBLESHOOTING

8.4 TROUBLESHOOTING - ERROR 04B0

ERROR CODE 04B0

1) SYMPTOM:

04B0 – LCB communication disconnected.

2) SOLUTION:

1) If the display is giving a 04B0 error, check the LCB LED10 status.

- LED10 blinking: Turn off power and after 3 seconds, turn on power again. If the console shows the 04A0 error, skip to Step 2.

- LED10 off: Check the connection of the digital communication wire at the UCB and LCB (Figure A & B). If the connection is good, replace

the digital communication wire.

2) If LEDs 7 / 8 / 9 / 10 blinking together, this should be LCB software problem. Re-install LCB software. If this does not resolve the issue,

replace the LCB.

FIGURE A FIGURE B

29

Page 33

CHAPTER 8: TROUBLESHOOTING

8.5 TROUBLESHOOTING - ERROR 0347

ERROR CODE 0347

1) SYMPTOM:

0347 - Can not load video in Virtual Active program.

2) SOLUTION:

1) Please remove the VA board SD card and plug in again.

2) If the error still happens, check the SD card for data.

- If yes, replace the VA board.

- If no, replace the SD card.

FIGURE A

8.6 TROUBLESHOOTING - ERROR 03A5 / 03A6

ERROR CODE 03A5 / 03A6

1) SYMPTOM:

03A5 - After program start, GUI can't load program.

03A6 - After GUI load program, the program can't be started.

2) SOLUTION:

1) Use a USB Flash disk to update to the latest GUI.

2) If the error is still happening after update, replace the LMM board.

30

Page 34

CHAPTER 8: TROUBLESHOOTING

8.7 TROUBLESHOOTING - ERROR 0248

ERROR CODE 0248

1) SYMPTOM:

0248 - Battery disconnection or fail. (When power is on, LCB battery voltage is less than 6 VAC).

2) SOLUTION:

1) Check the battery wire connection between the battery and LCB (Figure A).

2) Check the battery voltage (Figure B), if it is less than 6V, please plug in the power cord to charge battery for 1 hour. Replace the battery if it

will not hold a charge.

3) If the battery voltage is more than 6V, replace the LCB.

FIGURE A FIGURE B

31

Page 35

CHAPTER 8: TROUBLESHOOTING

8.8 TROUBLESHOOTING - ERROR 0247

ERROR CODE 0247

1) SYMPTOM:

0247 - MCU fail.

2) SOLUTION:

1) Replace LCB.

8.9 TROUBLESHOOTING - ERROR 02B4 / 03A8 / 02AB / 0441

ERROR CODE 02B4 / 03A8 / 02AB / 0441

1) SYMPTOM:

02B4 – Resistance type error.

03A8 – Control settings on the machine does not match the shape and setup of the controller keypad.

02AB – Machine Type Error.

0441 – Correct packet but LCB without the function (LCB does not support this command).

2) SOLUTION:

1) Check the machine type is matched with frame in Service Mode (Figure A).

2) Check if the console is matched with the correct frame.

3) Replace the LCB.

4) Replace the UCB.

32

FIGURE A

Page 36

CHAPTER 8: TROUBLESHOOTING

8.10 TROUBLESHOOTING - ERROR 0149 / 01AF

ERROR CODE 0149 / 01AF

1) SYMPTOM:

0149 – Electro-magnet over current.

01AF – Electro-magnet disconnected.

2) SOLUTION:

1) Check if the Electro-magnet is short circuited or open (Figure A).

- If the resistance data shows a short / open ohms or is outside the range of 12.8 ~14.2 ohms, replace the Electro-magnet.

- If the resistance data is in the range between 12.8 ~14.2 ohms, replace the LCB.

FIGURE A

33

Page 37

CHAPTER 8: TROUBLESHOOTING

8.11 TROUBLESHOOTING - ERROR 01B4

ERROR CODE 01B4

1) SYMPTOM:

01B4 – Battery connection reverse protection.

2) SOLUTION:

1) Check the battery wire connection between the battery and LCB (Figure A).

2) Check the battery voltage (Figure B).

- If there is no data on voltage, replace the battery

- If there is data on voltage, replace the LCB

FIGURE A

FIGURE B

34

Page 38

CHAPTER 8: TROUBLESHOOTING

8.12 TROUBLESHOOTING - NO RESISTANCE ISSUES

NO RESISTANCE ISSUES

1) SYMPTOM:

No resistance.

2) SOLUTION:

1) Check the resistance wire connection between the ECB and LCB (Figure A).

2) Check if the resistance is open (Figure B).

- If there is no data on resistance, replace the ECB.

- If there is data on resistance, replace the LCB.

FIGURE A FIGURE BFIGURE A FIGURE B

35

Page 39

CHAPTER 8: TROUBLESHOOTING

8.13 TROUBLESHOOTING - TOUCH PAD ISSUES

ALL OR SOME OF THE FUNCTION KEYS DO NOT RESPOND

POSSIBLE CAUSES:

1) The touch pad is not calibrated properly.

2) The UCB is damaged.

SOLUTION:

1) Perform a touch pad calibration in Service Mode:

a. Press ENTER, 3, 0, 0, 1, ENTER on the lower number keypad.

b. Press TEST on the display.

c. Press TOUCH CALIBRATION on the display.

d. Follow the cross mark moving across the screen and touch. After testing 5 positions, touch the center to exit the test (Figure A).

2) If the Touch Calibration does not work, replace the console.

36

FIGURE A

Page 40

CHAPTER 8: TROUBLESHOOTING

8.14 TROUBLESHOOTING - HEART RATE ISSUES

HEART RATE FUNCTION DOES NOT WORK OR IS READING INCORRECTLY

POSSIBLE CAUSES:

1) The HR grips are not hooked up correctly.

2) The HR grip wiring is damaged.

3) The console or HR board is not properly grounded.

4) The console, HR board, or wiring between are bad.

SOLUTION:

1) Perform a DC Voltage test on the HR grips.

a. With one prong of a multi meter on each of the plates on one side of the HR grip set (Figure A), a voltage reading of between .5 and 2.0

should be seen. If the reading is correct, the issue is not with the HR grips or grip wiring.

b. If the reading is not correct, remove the screws holding the halves of the HR grip together and check the connection of the wiring to the

grips (Figure B).

2) Remove the console from the unit and verify continuity of the HR grip wiring. With a multi meter set for ohms, place one prong on the HR grip

wiring coming up the console mast (Figure C), and the other on the appropriate plate (match red with red and white with white).

a. An ohm reading of less than 1 should be received. If it is higher, replace the HR grip wiring.

3) Perform a continuity check on the console (See Service Bulletin - Continuity Test on Matrix Bikes).

a. Once the console continuity is confirmed, perform a continuity check on the HR board ground wire. With a multi meter set for ohms, place

one prong on the HR board ground wire (Figure D), and the other on the console ground wire. An ohm reading of less than 1 should be received.

If it is higher, replace the HR board.

4) If all the troubleshooting listed above has been performed, and the unit still has HR issues, replace the HR board.

a. If the HR board does not resolve the issue, replace the console.

FIGURE A

FIGURE B

FIGURE C

FIGURE D

37

Page 41

CHAPTER 8: TROUBLESHOOTING

8.15 TV TROUBLESHOOTING - OVERVIEW

Sections 8.15 - 8.18 will assist with diagnosing problems with TV and entertainment related equipment sold

by Matrix FItness Equipment.

The Matrix Bike includes an integrated TV that shows in the large display window. The TV is capable of being shown as a 7" or 15" screen

(Figures A & B). The console should be equipped with an entertainment keypad similar to Figure C.

FIGURE A

FIGURE B

FIGURE C

38

Page 42

CHAPTER 8: TROUBLESHOOTING

8.16 TV TROUBLESHOOTING - PICTURE FUZZY OR UNCLEAR

1) For a fuzzy or unclear picture, see the TV programming instructions in Section 10. If the TV is still fuzzy or unclear after programming:

a) Check the coax connection at the entertainment port (Figure A).

b) Remove the 5 screws holding the console to the console mast and check the coax connection at the console (Figure B).

FIGURE A

c) Use a verified good piece of coax cable (a good coax cable will have a signal strength of 10db or greater) to plug directly into the back

of the console bypassing the entertainment port. If this resolves the issue, replace the internal coax cable.

d) If plugging the coax cable into the back of the console does not resolve the issue, remove the console back and check the console

cable connection at the tuner (Figure C).

e) Check the internal cables and fitting inside your machine at the console and below the front shroud (Figure D). Make sure you have

no kinks, cuts, or poor connectors at the end of the cable. Fittings should have a clean flush connector with no stray aluminum strands touching

the center conductor. Replace any suspect cables.

FIGURE B

FIGURE C FIGURE D

f) If no damage can be found on the cables, fittings, or connectors, and hooking the coax directly to the back of the console does not

resolve the issue, replace the TV tuner.

39

Page 43

CHAPTER 8: TROUBLESHOOTING

8.17 TV TROUBLESHOOTING - TV WILL NOT TURN ON

1) Remove the console back and check the electrical connections for the TV (Figures A & B).

FIGURE BFIGURE A

2) If internal electrical connections are good (the console turns on), and the outlet is outputting 120V, the issue is likely with the integrated TV.

Replace the console.

40

FIGURE C

Page 44

CHAPTER 8: TROUBLESHOOTING

8.18 TV TROUBLESHOOTING - ENTERTAINMENT KEYPAD ISSUES

ENTERTAINMENT KEYPAD IS NOT WORKING

1) SYMPTOM:

a. The entertainment keypad (Figure A) is not responding.

2) SOLUTION:

a. Remove the console and check the connection of the entertainment keypad (Figure B).

b. If the entertainment keypad cable is pinched, kinked, or cut replace the keypad.

c. If replacing the keypad does not resolve the issue, replace the console.

FIGURE A

FIGURE B

41

Page 45

CHAPTER 9: PART REPLACEMENT GUIDE

9.1 CONSOLE REPLACEMENT

1) Remove the 5 screws holding the console to the frame (Figure A).

FIGURE A

2) Disconnect the console cable and HR connections from the defective console and remove the console (Figure B).

FIGURE B

3) Reinstall the wire connections to the new console.

4) Carefully push the wires into the console and mast until they are clear of the console / mast connection and attach the console to the mast

using the 5 screws.

5) Test the bike for function as outlined in Section 9.24.

42

Page 46

CHAPTER 9: PART REPLACEMENT GUIDE

9.2 HANDLEBAR REPLACEMENT

1) Remove the 4 screws holding the heart rate handlebar to the console mast being careful to support the handlebar (Figure A).

2) Carefully pull the wires from the console mast until the connectors are showing, and then disconnect the 2 wires from the handlebar and

remove the defective handlebar (Figure B).

FIGURE A

3) Reverse Steps 1-2 to install a new handlebar.

4) Test the bike for function as outlined in Section 9.24.

FIGURE B

43

Page 47

CHAPTER 9: PART REPLACEMENT GUIDE

9.3 HEART RATE GRIPS REPLACEMENT

1) Remove the 3 screws holding the 2 halves of the HR grip together (Figure A).

2) Split the HR grip in half (Figure B).

FIGURE A FIGURE B

3) Disconnect the level key and HR plate wiring (Figure C) and remove the HR grip.

4) Reverse Steps 1-3 to install a new HR grip. NOTE: When plugging in the HR plate wiring, the red wire should go to the top plate, the white

wire to the bottom HR plate (Figure D).

FIGURE C

5) Test the Bike for function as outlined in Section 9.24.

FIGURE D

44

Page 48

CHAPTER 9: PART REPLACEMENT GUIDE

9.4 CUP HOLDER REPLACEMENT

1) Remove the 2 screws holding the cup holder to the console mast (Figure A).

FIGURE A

2) Remove the cup holder (Figure B).

3) Reverse Steps 1-2 to install a new cup holder.

FIGURE B

45

Page 49

CHAPTER 9: PART REPLACEMENT GUIDE

9.5 CONSOLE KEYPAD / OVERLAY REPLACEMENT

NOTE: The instructions below are for console overlays / keypads replacement, but the procedure is the same regardless of where the overlay /

keypad is.

1) Remove the console as outlined in Section 9.1.

2) Remove the back cover of the console (Figure A).

3) Unplug and remove the faulty overlay (Figure B).

FIGURE A

4) Clean the console area with alcohol to remove any left over adhesive (Figure C).

5) Peel part of the protective film from the back of the overlay / keypad (Figure D).

FIGURE C FIGURE D

FIGURE B

46

Page 50

CHAPTER 9: PART REPLACEMENT GUIDE

9.5 CONSOLE KEYPAD / OVERLAY REPLACEMENT - CONTINUED

6) Push the overlay / keypad ribbon cable through the hole in the console and plug it in (Figure E).

7) Match the overlay / keypad to the cutout in the console (Figure F).

FIGURE E FIGURE F

8) Press down on the corners of the overlay / keypad to keep it in place. Then remove the protective film (Figure G).

9) Once the overlay / keypad is in the correct position, press down on it to adhere it in positions (Figure H).

FIGURE G FIGURE H

10) Use the same procedure to replace any additional faulty overlays / keypads. NOTE: Overlays / keypads cannot be re-used.

11) Test the bike for function as outlined in Section 9.24.

47

Page 51

CHAPTER 9: PART REPLACEMENT GUIDE

9.6 PEDAL REPLACEMENT

1) Use a 15 mm pedal wrench to remove the pedal from the crank (Figure A). NOTE: For the right side pedal, the threads are normal. For the

left side pedal, the threads are reversed (the pedal turns off counterclockwise).

FIGURE A

2) Remove the pedal (Figure B).

3) Reverse Steps 1-2 to install a new pedal.

FIGURE B

48

Page 52

CHAPTER 9: PART REPLACEMENT GUIDE

9.7 CRANK AXLE SET REPLACEMENT

1) Remove the bolt that holds the crank to the drive axle set (Figures A & B).

FIGURE A FIGURE B

2) The crank can be removed (Figure C).

FIGURE C

3) Reverse Steps 1-2 to install a new crank axle set. NOTE: Torque the bolt removed in Step 1 to 80 N-m / 800 kgf-cm.

4) Test the bike as outlined in Section 9.24.

49

Page 53

CHAPTER 9: PART REPLACEMENT GUIDE

9.8 FRONT SHROUDS REPLACEMENT

1) Remove the 4 screws that hold the silver cover to the frame (Figure A).

2) Remove the silver cover (Figure B).

FIGURE A FIGURE B

3) Remove the 2 screws that hold the grey cover to the frame (Figure C).

4) Remove the grey cover (Figure D).

FIGURE C FIGURE D

5) Reverse Steps 1-4 to install new shrouds.

6) Test the bike for function as outlined in Section 9.24.

50

Page 54

CHAPTER 9: PART REPLACEMENT GUIDE

9.9 FRONT COVERS REPLACEMENT

1) Remove the pedals as outlined in Section 9.6.

2) Remove the crank as outlined in Section 9.7.

3) Remove the front shrouds as outlined in Section 9.8.

4) Remove the 6 screws to detach the front covers from the frame (Figure A & B).

FIGURE A FIGURE B

5) Figure C shows both the front covers removed.

6) Reverse Steps 1-4 to install new front covers.

FIGURE C

51

Page 55

CHAPTER 9: PART REPLACEMENT GUIDE

9.10 REAR COVERS REPLACEMENT

1) Remove the 4 screws holding the left side rear cover to the frame and remove it (Figure A).

2) Remove the 4 screws holding the right side rear cover to the frame and remove it (Figure B).

FIGURE A FIGURE B

3) Figure C shows both the rear covers removed.

4) Reverse Steps 1-2 to install new rear covers.

FIGURE C

52

Page 56

CHAPTER 9: PART REPLACEMENT GUIDE

9.11 CONSOLE MAST REMOVAL

1) Remove the console as outlined in Section 9.1.

2) Remove the handlebars as outlined in Section 9.2.

3) Remove the front shrouds as outlined in Section 9.8.

4) Remove the 4 screws holding the console mast to the frame (Figure A)

FIGURE A

5) Pull the wires out the bottom of the console mast and remove the mast (Figure B).

FIGURE B

6) Reverse Steps 1-5 to install a new console mast. NOTE: When installing a new console mast, be sure to pull the console wires up through

the new mast prior to installing the 4 screws into the frame.

7) Test the bike for function as outlined in Section 9.24.

53

Page 57

CHAPTER 9: PART REPLACEMENT GUIDE

9.12 SEAT PAD REPLACEMENT

1) Remove the 4 screws holding the seat pad to the seat post (Figure A).

FIGURE A

2) Lift the seat pad away from the seat post (Figure B).

3) Reverse Steps 1-2 to install a new seat pad.

FIGURE B

54

Page 58

CHAPTER 9: PART REPLACEMENT GUIDE

9.13 BACK PAD REPLACEMENT

1) Remove the 2 bolts holding the back pad to the seat frame (Figure A).

FIGURE A

2) Remove the back pad (Figure B).

3) Reverse Steps 1-2 to install a new back pad.

FIGURE B

55

Page 59

CHAPTER 9: PART REPLACEMENT GUIDE

9.14 STATIONARY HANDLEBAR REPLACEMENT

1) Remove the 2 bolts holding the stationary handlebar assembly to the seat frame (Figures A & B).

FIGURE A

2) Remove the stationary handlebar (Figure C).

3) Reverse Steps 1-3 to install a new stationary handlebar.

FIGURE B

FIGURE C

56

Page 60

CHAPTER 9: PART REPLACEMENT GUIDE

9.15 LOWER CONTROL BOARD REPLACEMENT

1) Remove the left side front cover as outlined in Section 9.9.

2) Disconnect the 5 wire connections to the lower board (Figure A).

3) Remove the 2 screws holding the lower control board to the frame (Figure B), and remove the lower control board.

FIGURE A

4) Reverse Steps 1-3 to install a new lower control board. Figure C shows the electrical connections to the lower control board.

2 Pin Connector

from the Battery

6 Pin Connector from

the DC power source

FIGURE B

8 Pin Connector

from the Console

2 Pin Connector

from the ECB

3 Pin Connector from

the Generator

FIGURE C

5) Test the bike for function as outlined in Section 9.24.

57

Page 61

CHAPTER 9: PART REPLACEMENT GUIDE

9.16 BATTERY REPLACEMENT

1) Remove the right side pedal as outlined in Section 9.6.

2) Remove the right side crank as outlined in Section 9.7.

3) Remove the right side front cover as outlined in Section 9.11 to expose the battery (Figure A).

4) Disconnect the 2 wires from the battery (Figure B).

FIGURE A FIGURE B

3) Disconnect the 2 cable ties from the battery bracket (Figure C).

4) Remove the battery (Figure D).

FIGURE C FIGURE D

5) Reverse Steps 1-4 to install a new battery.

58

Page 62

CHAPTER 9: PART REPLACEMENT GUIDE

9.17 DRIVE BELT REPLACEMENT

1) Remove the right side pedal as outlined in Section 9.6.

2) Remove the right side crank as outlined in Section 9.7.

3) Remove the right side front cover as outlined in Section 9.9 (Figure A).

4) Using a hook or loop of wire, remove the spring from the frame (Figure B). The tensioner should now pivot away from the drive belt.

FIGURE A FIGURE B

5) Remove the drive belt (Figure C).

6) Use a straight edge to make sure that the pulley and generator pulley are in a straight line (Figure D). If the belt is not on line, try to adjust

the generator location.

FIGURE C FIGURE D

7) Reverse Steps 1-6 to install a new drive belt. NOTE: Be sure to reattach the tension spring. Rotate the pulley to make sure that the motion

is smooth and that there is no wobbling to one side.

59

Page 63

CHAPTER 9: PART REPLACEMENT GUIDE

9.18 GENERATOR REPLACEMENT

1) Remove the pedals as outlined in Section 9.6.

2) Remove the cranks as outlined in Section 9.7.

3) Remove the front covers as outlined in Section 9.9.

4) Remove the drive belt as outlined in Section 9.17.

5) Cut the cable tie and disconnect the generator with ECB wire from the LCB (Figures A & B).

FIGURE A FIGURE B

6) Remove the 4 screws holding the generator to the frame (Figures C & D), and remove the generator.

FIGURE C FIGURE D

7) Reverse Steps 1-6 to install a new generator.

8) Test the bike for function as outlined in Section 9.24.

60

Page 64

CHAPTER 9: PART REPLACEMENT GUIDE

9.19 REAR STABILIZER REPLACEMENT

1) Remove the 2 screws holding the black cover to the rear stabilizer (Figure A).

2) Remove the black cover (Figure B).

FIGURE A FIGURE B

3) Remove the 6 screws holding the rear stabilizer to the frame (Figure C).

4) Remove the rear stabilizer (Figure D).

FIGURE C FIGURE D

5) Reverse Steps 1-4 to install a new rear stabilizer. NOTE: When installing a new rear stabilizer, be sure to make sure that the leveling is

stable as outlined in Section 10.4.

61

Page 65

CHAPTER 9: PART REPLACEMENT GUIDE

9.20 FRONT STABILIZER REPLACEMENT

1) Remove the 4 screws holding the rear stabilizer to the frame (Figures A & B).

FIGURE A FIGURE B

2) Remove the front stabilizer (Figure B).

3) Reverse Steps 1-2 to install new front side covers.

FIGURE C

62

Page 66

CHAPTER 9: PART REPLACEMENT GUIDE

9.21 SLIDE FRAME REPLACEMENT

1) Remove the right side rear cover as outlined in Section 9.10.

2) Remove the 2 screws holding the indicate cap to the seat slide set (Figure A) and remove the indicate cap (Figure B).

FIGURE A FIGURE B

3) Remove the 2 screws holding the end cap over to the guide rail set (Figure C)

4) Remove the end cap cover (Figure D)..

FIGURE C FIGURE D

5) Remove the 2 screws holding the stopper plate to the seat base (Figure E).

6) Remove the seat base (Figure F).

FIGURE E FIGURE F

63

Page 67

CHAPTER 9: PART REPLACEMENT GUIDE

9.21 SLIDE FRAME REPLACEMENT - CONTINUED

7) Pull out the slide frame set from guide rail set. Unfasten the nylon cord from the slide frame set (Figure G). Remove the slide frame set with

relative parts (Figure H).

8) Remove the relative parts from slide frame set as outlined in Section 9.12 ~ 9.14.

FIGURE G FIGURE H

9) Fasten the nylon cord into a new slide frame (Figures I & J).

FIGURE I FIGURE J

10) Insert a new slide frame set into guide rail set. Lock the slide frame set on the first slot of guide rail set (Figures K & L).

FIGURE K FIGURE L

64

Page 68

CHAPTER 9: PART REPLACEMENT GUIDE

9.21 SLIDE FRAME REPLACEMENT - CONTINUED

11) Pull the nylon cord to rotate the pulley set 2 circles by counter-clockwise (Figure M).

12) To continue use one hand to fix the pulley set, then rotate the nylon cord 2 rotations counter-clockwise around into the pulley set (Figure N).

FIGURE M

13) Put the nylon cord upon the small pulley (Figure O).

14) Reverse Steps 1-6 to recover the final assembly.

15) Test the bike for function as outlined in Section 9.24.

FIGURE N

FIGURE O

65

Page 69

CHAPTER 9: PART REPLACEMENT GUIDE

9.22 GUIDE RAIL SET REPLACEMENT

1) Remove the slide frame set as outlined in Section 9.21.

2) Use a 13mm wrench to remove the 6 screws holding the guide rail set to the frame (Figure A).

3) Remove the guide rail set (Figure B).

FIGURE A FIGURE B

4) Reverse Steps 1-3 to install a new guide rail set.

5) Test the bike for function as outlined in Section 9.24.

66

Page 70

CHAPTER 9: PART REPLACEMENT GUIDE

9.23 DRIVE AXLE SET REPLACEMENT

NOTE: A Matrix special tool is needed to correctly replace a drive axle. Order part # 1000323981 from Matrix CTS at 866-693-4863 ext 3.

1) Turn off the power and disconnect the cord from the machine.

2) Remove the front covers from the machine as outlined in Section 9.9.

3) Remove drive belt as outlined in Sections 9.17.

4) On the left side of the frame, remove the retainer clip that holds the drive axle bearings in the frame (Figure A).

5) Use a hammer to hit the screw until the drive axle assembly is loose in the frame, and remove it (Figure B).

FIGURE A FIGURE B

6) Install the tool into the hole in the frame and use a rubber mallet to hit the end of the tool until the bearing can be removed from the frame

(Figures C & D).

FIGURE C FIGURE D

7) The drive axle should have come with an iron plate installed (Figure E).

8) Assemble the Matrix tool as shown in Figure F.

FIGURE E FIGURE F

67

Page 71

CHAPTER 9: PART REPLACEMENT GUIDE

9.23 DRIVE AXLE SET REPLACEMENT - CONTINUED

9) Slide the drive axle assembly into the frame from the right side. Install the bearing cap portion of the tool into the left side of the frame (Figure

G).

10) Mount the other tool from Figure F behind the bearing cap portion of the tool. Use the M10 x 100L x 1.25P screw with a nut to attach the tool

to the drive axle (Figure H).

FIGURE HFIGURE G

11) Turn the screw until it is close into the drive axle (Figure I).

12) Then turn the nut until it is close to the cup portion of the tool (Figure J).

FIGURE I FIGURE J

13) Use a wrench to hold the screw, then turn the nut to pull the drive axle into the frame (Figure K).

14) Turn the nut until the iron plate is close to the frame on the right side (Figure L).

68

FIGURE LFIGURE K

Page 72

CHAPTER 9: PART REPLACEMENT GUIDE

9.23 DRIVE AXLE SET REPLACEMENT - CONTINUED

15) Remove the tools, then insert the bearing into the hole in the frame on the left side (Figure M).

16) Again use the M10 x 100L x 1.25P screw with a nut to attach the tool to the drive axle (Figure N).

FIGURE M FIGURE N

17) Turn the screw until it is close into the drive axle (Figure O).

18) Then turn the nut until it is close to the cup portion of the tool (Figure P).

19) Use a wrench to hold the screw, then turn the nut to push the bearing into the hole in the frame (Figure Q).

20) Insert the retainer clip to hold the bearing in the frame (Figure R).

FIGURE PFIGURE O

FIGURE RFIGURE Q

69

Page 73

CHAPTER 9: PART REPLACEMENT GUIDE

9.23 DRIVE AXLE SET REPLACEMENT - CONTINUED

21) Use a screwdriver to remove the iron plate from the drive axle (Figures S & T).

FIGURE TFIGURE S

22) Rotate the drive axle to make sure that the motion is smooth and that there is no wobbling to one side (Figures U).

23) Re-install the belts as outlined in Section 9.17.

24) Reverse Steps 1-2 to re-assemble the unit.

25) Test the Bike as outlined in Section 9.24.

70

FIGURE U

Page 74

CHAPTER 9: PART REPLACEMENT GUIDE

9.24 TESTING THE BIKE

ONCE THE UNIT OR REPLACEMENT PART IS FULLY INSTALLED AND ASSEMBLED AND

PROPERLY PLACED ON THE FLOOR, USE THE FOLLOWING INSTRUCTIONS TO SETUP

AND TEST THE MACHINE:

1) Enter Service Mode (ENTER, 3, 0, 0, 1, ENTER) and input the serial number of the console. Also set the Machine Type (See Section 7.2)

and Keypad (See Section 7.3) and verify that the Date and Time are correct (See Section 7.5). NOTE: If a setting has been changed, the

unit and console power should be reset. Cycle the power switch, and press and hold the CHANNEL UP and CHANNEL DOWN keys for 3-5

seconds to reset the console power.

2) Enter Manager Mode (ENTER, 1, 0, 0, 1, ENTER) and turn on or off Asset Management or Virtual Active depending on whether the club has

these functions. NOTE: If a setting has been changed, the unit and console power should be reset. Cycle the power switch, and press and

hold the CHANNEL UP and CHANNEL DOWN keys for 3-5 seconds to reset the console power. Enter into Virtual Active and test.

3) Program the TV channels as outlined in Section 10.5.

4) Without hitting start or entering any program modes, sit on the bike and hold the handlebars while pedaling to simulate exercising. While

moving, listen for any odd noises or squeaks.

5) After stopping movement, press the green GO key and begin pedaling.

6) Grasp the hand grips to check for proper heart rate response.

7) Press the level up and down buttons on the console and hand grips to make sure resistance is fully functional.

8) If everything functions properly, stop pedaling and the unit will reset to normal operation within 30 seconds.

71

Page 75

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 H7xe-05 BIKE SPECIFICATIONS

FEATURES

CONTACT & TELEMETRIC HR SENSORS YES

HANDLEBAR DESIGN SEAT SIDE AND FRONT VERTICAL ERGO BEND

INTEGRATED ARM RESTS YES

THUMB SWITCH CONTROLS YES

RESISTANCE SYSTEM

TECHNOLOGY JID BRUSHLESS GENERATOR

POWER REQUIREMENTS

MI NIMUM WATTS 44 SELF POWERED

MINIMUM RPM 10 POWERED / 25 SELF-POWERED

CONSOLE

DISPLAY TYPE 15” / 38.1 CM TOUCH SCREEN LCD

DISPLAY FEEDBACK

USER DEFINED MULTI-LANGUAGE

DISPLAY

RESISTANCE LEVELS 30

WORKOUTS

CSAFE READY - FITLINXX™ CERTIFIED NO

NETPULSE COMPATIBLE NO

ON-THE-FLY PROGRAM CHANGE YES

FIT TOUCH TECHNOLOGY™ YES

INTEGRATED VISTA CLEAR™ DIGITAL

READY TELEVISION

VIRTUAL ACTIVE™ COMPATIBLE YES

FITCONNEXION™ READY NO

WIFI YES

ETHERNET PORT YES

WEB CONNECTIVITY NO

FACILITY COMMUNICATOR PORTAL/

CALENDAR

ASSET MANAGEMENT COMPATIBLE YES

IPOD® COMPATIBLE YES

IPHONE® COMPATIBLE YES - CHARGING ONLY

USB PORT YES

MULTIMEDIA PLAYBACK NO

NIKE + IPOD® COMPATIBLE YES

PERSONAL FAN YES

TECH SPECS

OVERALL DIMENSIONS

L X W X H

CRANK DESIGN SINGLE PIECE

MAXIMUM USER WEIGHT 400 LBS/182 KG

WEIGHT 184 LBS/83.7 KG

SHIPPING WEIGHT 216 LBS/98.5 KG

H7xe HYBRID CYCLE™

SELF POWERED - POWERED 100-125 V, 60 HZ OR

216-250 V, 50 HZ

TIME ELAPSED, TIME REMAINING, TOTAL

PROGRAM TIME, CLOCK, DISTANCE

(KILOMETERS OR MILES), CALORIES, CALORIES

PER HOUR, SPEED, LEVEL, RPM, HEART RATE,

METS, WATTS, STATIC PROFILE DISPLAY,

DYNAMIC PROFILE DISPLAY

YES - ENGLISH, GERMAN, FRENCH, ITALIAN,

SPANISH, DUTCH, PORTUGUESE, CHINESE,

JAPANESE, KOREAN, SWEDISH, FINNISH,

RUSSIAN, ARABIC

MANUAL, ROLLING HILLS, INTERVAL TRAINING,

RANDOM, FAT BURN, FITNESS TEST, HEART

RATE, CON STA NT WAT TS

YES - 15” / 38.1 CM TOUCH SCREEN LCD

NO

57.4" X 28.8" X 58.6"

145.7CM X 73.2CM X 148.9CM

72

Page 76

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.2 ASSEMBLY INSTRUCTIONS

AFTER THESE ASSEMBLY STEPS ARE COMPLETE, BE SURE TO SETUP AND TEST THE UNIT AS OUTLINED

IN SECTION 9.24.

STEP 1

YELLOW HARDWARE BAGS

PART TYPE DESCRIPTION QTY

A SOCKET H EAD BOLT M8X25L 8

B F LAT WASHER Φ8.2XΦ16.0X2.0T 8

A Open YELLOW HARDWARE BAGS.

B Attach the FRONT STABILIZER TUBE

(1) to the MAIN FRAME (2) using 4

BOLTS (A) and 2 FLAT WASHERS (B).

C Attach the REAR STABILIZER TUBE (3)

to the MAIN FRAME (2) using 4 BOLTS

(A) and 2 FLAT WASHERS (B).

73

Page 77

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.2 ASSEMBLY INSTRUCTIONS - CONTINUED

STEP 2

BLACK HARDWARE BAG

PART TYPE DESCRIPTION QTY

C SOCKET HE AD BOLT M8X20L 2

D PHILLIP HEAD BOLT M5 X12L 2

A Open BLACK HARDWARE BAG.

B Attach the REAR FRAME HANDLE (3) to

the MAIN FRAME (2) using 2 BOLTS (C).

C Attach the REAR FRAME COVER (4) to

the MAIN FRAME (2) using 2 BOLTS (D).

RED HARDWARE BAGS

PART TYPE DESCRIPTION QTY

C SOCKET HE AD BOLT M8X20L 4

E TOOTH WASHER Φ8.5XΦ18.0X2.0T 4

A Carefully pull the CONSOLE CABLES (5)

through the CONSOLE MAST (6) using

the twist tie located inside the CONSOLE

MAST (6).

B Attach CONSOLE MAST (6) to MAIN

FRAME (2) using 4 BOLTS (C) and 4

TOOTH WASHERS (E).

74

Page 78

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.2 ASSEMBLY INSTRUCTIONS - CONTINUED

STEP 3

GREEN HARDWARE BAG

PART TYPE DESCRIPTION QTY

F PHILLIP HEAD BOLT M 5X12L 4

A Open GREEN HARDWARE BAG.

B Attach the FRONT SHROUD COVER (7) to

the MAIN FRAME (2) using 4 BOLTS (F).

BLUE HARDWARE BAG

PART TYPE DESCRIPTION QTY

G SOCKET HEAD BOLT M10X25L 2

H HEAVY WASHER Φ10.0XΦ28.0X5.0T 2

A Open BLUE HARDWARE BAG.

B Attach the ARM REST HANDLEBARS (8)

to the SEAT FRAME (9) using 2 BOLTS (G)

and 2 HEAVY WASHERS (H).

75

Page 79

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.2 ASSEMBLY INSTRUCTIONS - CONTINUED

STEP 4

PURPLE HARDWARE BAG

PART TYPE DESCRIPTION QTY

I SOCKET HEAD BOLT M 8X50L 4

J SPRING WASHER Φ8.2XΦ13.5.0X2.0T 4

K WAVE WASHER Φ8.2XΦ18.0X1.5T 4

A Open PURPLE HARDWARE BAG.

B Attach the SEAT BASE (10) to the SEAT

FRAME (9) using 4 BOLTS (I), 4 SPRING

WASHERS (J) and 4 WAVE WASHERS (K).

ORANGE HARDWARE BAG

PART TYPE DESCRIPTION QTY

L SOCKET HEAD BOLT M8X60 L 2

A Open ORANGE HARDWARE BAG.

B Attach the SEAT BACK (11) to the SEAT

FRAME (9) using 2 BOLTS (L).

76

Page 80

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.2 ASSEMBLY INSTRUCTIONS - CONTINUED

STEP 5

WHITE HARDWARE BAG

PART TYPE DESCRIPTION QTY

M SOCKET HEAD BOLT M8X 20L 4

A Open GREEN HARDWARE BAG.

B Attach the PULSE GRIP HANDLEBARS

(12) to the CONSOLE MAST (6) using 4

BOLTS (M).

C Attach the CONSOLE CABLES (5) to the

CONSOLE (13).

D Attach the CONSOLE (13) to the

CONSOLE MAST (6) using 4 PREINSTALLED BOLTS (14).

E Attach PEDALS (15) to the CRANK (16)

with the provided 15mm/17mm flat wrench.

77

Page 81

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.2 ASSEMBLY INSTRUCTIONS - CONTINUED

FINAL ASSEMBLY

78

Page 82

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.3 ADJUSTING THE PEDAL STRAPS AND SEAT

ADJUSTING THE PEDAL STRAPS

The straps are designed to fit your individual foot size and should be adjusted tight enough to keep your foot from slipping. The pedals include

spring loaded clips for easy adjustment. To tighten the strap, pull down the open end of the strap. To loosen the strap, push down on the top of

the clip and pull the strap up. Release the clip to lock the strap in place.

79

Page 83

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.4 LEVELING THE BIKE

STABILIZING THE MATRIX H7XE-05 BIKE

After positioning the bike in its intended location, check its stability by attempting to shake it side to side. Shaking or wobbling indicates that

your bike needs to be leveled. Determine which leveler is not resting completely on the floor. Rotate the left or right foot pad, and repeat the

adjustment as necessary until the bike is stable.

80

Page 84

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.5 TV PROGRAMMING INSTRUCTIONS (US)

Once the cardio equipment has been installed, and proper power and cable wiring is provided, The Television must be programmed to the club's

channels and settings.

Auto Scan - An auto scan will search for channel signals from the coax cable. It will tune in all channels that provide a signal.

1. Press ENTER, 1, 0, 0, 1, ENTER on the number keypad to enter Manager Mode.

2. Press TV on the display (Figure A).

3. Press SETUP on the display (Figure B). A TV will appear.

FIGURE BFIGURE A

4. Press the - key on the number keypad and a Menu will appear on the TV (Figure C). NOTE: Once the Menu is present on the screen, the

following buttons must be pressed quickly, or the Menu will minimize after 5 seconds of no key strokes.

5. Use the CHANNEL UP and DOWN keys to move, ENTER key to enter this action in the Menu. Use the VOLUME UP and DOWN keys to

select item and ENTER key to start / change / save this setting item in the sub-menu.

6. Use the CHANNEL UP and DOWN keys to scroll the cursor to Installation of the Menu, then press the ENTER key to enter the Installation

sub-menu(Figure D).

FIGURE C

7. Use the CHANNEL UP or DOWN keys to scroll down to Auto Scan (Figure E), then press the ENTER key to start the channel scan (Figure

F).

FIGURE D

FIGURE FFIGURE E

81

Page 85

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

10.5 TV PROGRAMMING INSTRUCTIONS (US) - CONTINUED

Auto Scan (continued):

8. If the channels are not coming in clearly after a channel scan (or if only some channels come in), follow Steps 4-7 to enter the Installation .

Use the CHANNEL UP or DOWN keys to change the TV System to match the club's incoming frequency (Figure G), then re-run Auto Scan.

10. If the channels are coming in clearly, press the HOME key to return to normal function (Figure H). If some channels are still not coming

in, are blurry, or are not scanning, follow the procedure below for adding / deleting a single channel. If no channels are coming in, see the

troubleshooting in Chapter 8.

FIGURE HFIGURE G

Adding or Deleting a Single Channel - At times the Channel Scan can pick up channels that do not have a strong enough signal to

come in clearly or will fail to pick up channels that do come in clearly. Use the following procedure to manually add or delete a channel.

1. Follow Steps 1-4 in the Auto Scan instructions to access the TV Menu.