Page 1

C7XI-03 CLIMB MILL

SERVICE MANUAL

Page 2

III

CHAPTER 1: SERIAL NUMBER LOCATION ........................................................... 1

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

2.1 Read and Save These Instructions ............................................................................. 3

2.2 Electrical Requirements ............................................................................................. 4

2.3 Locating the Unit ......................................................................................................... 5

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.1 Recommended Cleaning Tips .................................................................................... 6

3.2 Care and Maintenance Instructions ........................................................................... 7

3.3 Touchscreen Care & Cleaning .................................................................................... 8

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.1 Console Description ................................................................................................... 9

4.2 Workout Setup Steps ................................................................................................. 10

CHAPTER 5: MANAGER MODE

5.1 Using Manager Mode ................................................................................................ 11

5.2 Manager Mode - General ........................................................................................... 12

5.3 Manager Mode - Workout .......................................................................................... 16

5.4 Manager Mode - Setup Defaults ................................................................................ 18

5.5 Manager Mode - Network .......................................................................................... 19

5.6 Manager Mode - Asset Management ......................................................................... 20

5.7 Manager Mode - Weather .......................................................................................... 20

5.8 Manager Mode - TV ................................................................................................... 21

5.9 Manager Mode - Applications .................................................................................... 22

5.10 Manager Mode - Hardware ........................................................................................ 23

5.11 Manager Mode - Service ............................................................................................ 24

CHAPTER 6: ENGINEERING MODE

6.1 Using Engineering Mode ........................................................................................... 25

6.2 Engineering Mode - General ...................................................................................... 26

6.3 Engineering Mode - Workout ..................................................................................... 30

6.4 Engineering Mode - Setup Defaults ........................................................................... 32

6.5 Engineering Mode - Network ..................................................................................... 33

6.6 Engineering Mode - Asset Management .................................................................... 35

6.7 Engineering Mode - Weather ..................................................................................... 36

6.8 Engineering Mode - TV .............................................................................................. 36

6.9 Engineering Mode - Applications ................................................................................ 38

6.10 Engineering Mode - Hardware ................................................................................... 39

6.11 Engineering Mode - Service ....................................................................................... 40

6.12 Engineering Mode - Errors ......................................................................................... 41

CHAPTER 7: SERVICE MODE

7.1 Using Service Mode. .................................................................................................. 42

7.2 Service Mode - General ............................................................................................. 43

7.3 Service Mode - Workout ............................................................................................. 47

7.4 Service Mode - Setup Defaults .................................................................................. 49

7.5 Service Mode - Update .............................................................................................. 50

7.6 Service Mode - Network ............................................................................................. 51

7.7 Service Mode - Asset Management ........................................................................... 53

7.8 Service Mode - Weather ............................................................................................ 53

7.9 Service Mode - TV...................................................................................................... 54

7.10 Service Mode - Applications ....................................................................................... 55

7.11 Service Mode - Hardware ........................................................................................... 56

7.12 Service Mode - Virtual Active ..................................................................................... 59

7.13 Service Mode - Management ..................................................................................... 59

7.14 Service Mode - Service .............................................................................................. 60

7.15 Service Mode - Errors ................................................................................................ 60

7.16 Service Mode - Netpulse ............................................................................................ 61

7.17 Matrix fitness 7xi series feature access codes ........................................................... 62

CHAPTER 8: TROUBLESHOOTING

8.1 Electrical Diagram ...................................................................................................... 63

8.2 LCB Error Indicators .................................................................................................. 70

8.3 UCB Wiring Connections ............................................................................................ 72

8.4 Error Code Troubleshooting - 01AC ........................................................................... 73

8.5 Error Code Troubleshooting - 01AF ............................................................................ 74

8.6 Error Code Troubleshooting - 02A0 ........................................................................... 75

8.7 Error Code Troubleshooting - 02BE / 02BF ................................................................ 76

8.8 Error Code Troubleshooting - 02C0 ............................................................................ 77

8.9 Error Code Troubleshooting - 02C1 ............................................................................ 78

8.10 Error Code Troubleshooting - 02C2 ............................................................................ 79

8.11 Error Code Troubleshooting - 02C3 ............................................................................ 80

8.12 Error Code Troubleshooting - 04A0 ............................................................................ 81

8.13 Error Code Troubleshooting - 04B0 ............................................................................ 82

8.14 Troubleshooting - Heart Rate Issues .......................................................................... 83

8.15 Troubleshooting - Toggle Issues ................................................................................. 86

8.16 TV Troubleshooting - Overview ................................................................................... 89

8.17 TV Troubleshooting - Picture Fuzzy or Unclear .......................................................... 90

8.18 TV Troubleshooting - TV Will Not Turn On ................................................................ 91

8.19 TV Troubleshooting - Entertainment Keypad Issues .................................................. 92

8.20 Troubleshooting - No Netpulse Network Connectivity ............................................... 93

8.21 Troubleshooting - Unable to Access the Internet ....................................................... 95

8.22 Troubleshooting - Black Screen or Initializing TV in the TV APP .............................. 97

8.23 Troubleshooting - Virtual Active Content not Found ................................................. 98

8.24 Troubleshooting - Touch Screen User and Register Buttons Unresponsive.............. 99

8.25 Troubleshooting - BOOTMGR Error ........................................................................... 100

8.26 Troubleshooting - Weather Map Won't Load ............................................................. 101

8.27 Troubleshooting - The Time is Incorrect .................................................................... 102

8.28 Troubleshooting - Unable to Boot into Matrix Home Screen . ................................... 102

CHAPTER 9: PART REPLACEMENT GUIDE

9.1 Side Cover Replacement ........................................................................................... 103

9.2 Console Replacement ................................................................................................. 105

9.3 Console Overlay / Keypad Replacement .................................................................... 106

9.4 Front Shroud Replacement ......................................................................................... 108

9.5 Lower Control Board (LCB) Replacement .................................................................. 110

9.6 Upper Handlebar Replacement .................................................................................. 111

9.7 Lower Handlebar Replacement .................................................................................. 113

9.8 Handlebar Service ....................................................................................................... 114

9.9 Stair Replacement ....................................................................................................... 115

9.10 Drive Set Replacement ............................................................................................... 117

9.11 Chain Replacement ..................................................................................................... 119

9.12 Brake Replacement ..................................................................................................... 121

9.13 Fan Replacement ........................................................................................................ 122

9.14 ECB Belt Replacement ............................................................................................... 123

9.15 Drive Belt Replacement .............................................................................................. 124

9.16 ECB Replacement ....................................................................................................... 125

9.17 Speed Sensor Replacement ....................................................................................... 127

9.18 Control Zone Replacement ......................................................................................... 128

9.19 Proximity Sensor Replacement ................................................................................... 129

9.20 IR Sensor Replacement .............................................................................................. 130

9.21 CF Card Replacement .............................................................................................. 132

9.22 Console Parts Replacement ..................................................................................... 133

9.23 Testing the Climb Mill .................................................................................................. 135

CHAPTER 10: CLIMB MILL SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 Climb Mill Specifications ............................................................................................ 136

10.2 Assembly Hardware .................................................................................................... 137

10.3 Climb Mill Assembly Steps ......................................................................................... 138

10.4 Stabilizing the Climb Mill ............................................................................................. 142

10.5 TV Programming Instructions ..................................................................................... 143

10.6 Using Update Manager .............................................................................................. 153

10.7 Netpulse & AM Setting SOP ...................................................................................... 157

CHAPTER 11: SOFTWARE UPGRADE PROCEDURE

11.1

Software Upgrade Procedure from Website ............................................................... 176

11.2 Software Upgrade Procedure from USB .................................................................... 178

11.3 Software Upgrade Procedure for LCB ........................................................................ 181

TABLE OF CONTENTS TABLE OF CONTENTS

Page 3

1.1 SERIAL NUMBER LOCATION

CHAPTER 1: SERIAL NUMBER LOCATION

SERIAL NUMBER LOCATION

1

Page 4

3

2

1.1 SERIAL NUMBER LOCATION - CONTINUED

CHAPTER 1: SERIAL NUMBER LOCATION

2.1 READ AND SAVE THESE INSTRUCTIONS

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

console serial number location

CONSOLE SERIAL NUMBER LOCATION

This Climb Mill is intended for commercial use. To ensure your safety

and protect the equipment, read all instructions before operating the

MATRIX Climb Mill.

When using an electrical product, basic precautions should always be

followed including the following:

• Anapplianceshouldneverbeleftunattendedwhenplugged

in. Unplugtheunitfromtheoutlet whennotinuseandbefore

puttingonortakingoffanyparts.

• Thisproductmustbeusedforitsintendedpurpose

describedinthisservicemanual. Donot useother

attachmentsthatarenotrecommendbythe manufacturer.

Attachmentsmaycauseinjury.

• Topreventelectricalshock,neverdroporinsertanyobject

intoanyopening.

• Donotremovethesidecovers.Serviceshouldonlybedone

byanauthorizedservicetechnician.

• Neveroperatetheunitwiththeairopeningblocked.Keep

theairopeningclean,freeoflint andhair.

• Neveroperatetheunitifithas adamagedcordorplug,if it

isnotworkingproperly,if ithasbeendamaged,orimmersed

inwater.

• Closesupervisionisnecessary whentheunitisused byor

nearchildrenordisablepersons.

• Donotuseoutdoors.

• Donotoperatewhere aerosol(spray)productsarebeing

usedorwhenoxygenisbeingadministered.

• Donotusetheequipmentin anywayotherthandesignedor

intendedbythemanufacturer.Itisimperativethatall Matrix

FitnessSystemsequipmentisusedproperlyto avoidinjury.

• Keephandsandfeetclearofmoving partsatalltimesto

avoidinjury.

• Unsupervisedchildrenmustbekeptawayfrom thisequip

ment.

• Donotwearlooseclothingwhileon theequipment.

*AtNOtimeshouldpets orchildrenundertheageof 14be

closertotheunitthan10feet.

* AtNOtimeshouldchildrenunderthe ageof14usetheunit.

* Childrenovertheageof14or disabledpersonsshouldnot

usetheunit withoutadultsupervision.

* Neveroperatetheunitifithas adamagedcordorplug,if it

isnotworking properly,ifithasbeendroppedor damaged,or

immersedinwater.Returnthe unittoaservicecenterfor

examinationandrepair.

* Todisconnect,turnallcontrolstotheoffposition, then

removeplugfrom outlet.

* Donotremovetheconsolecoversunless instructedby

CustomerTechSupport.Service shouldonlybedonebyan

authorizedservicetechnician.

* Thisunitisnotequippedwitha freewheel.Stepspeed

shouldbe reducedinacontrolledmanner.

* Heartratemonitoringsystemsmaybeinaccurate.

* Overexercisingmayresultinseriousinjury ordeath.

* Ifyoufeelfaint,stopexercisingimmediately.

CAUTION! Ifyouexperiencechestpains, nausea,dizziness,or

shortnessofbreath,stopexercisingimmediatelyand consult

yourphysicianbeforecontinuing.

CAUTION! Anychangesormodificationstothis equipment

couldvoidtheproductwarranty.

Page 5

5

4

2.2 ELECTRICAL REQUIREMENTS

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

2.3 LOCATING THE UNIT

CHAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

DEDICATED CIRCUIT AND ELECTRICAL INFO

A “Dedicated Circuit” means that each outlet you plug into should not have anything else running on that same circuit. The easiest way to verify

this is to locate the main circuit breaker box, and turn off the breaker(s) one at a time. Once a breaker has been turned off, the only thing that

should not have power to it are the units in question. No lamps, vending machines, fans, sound systems, or any other item should lose power

when you perform this test.

Non-looped (isolated) neutral/grounding means that each circuit must have an individual neutral/ground connection coming from it, and

terminating at an approved earth ground. You cannot “jumper” a single neutral/ground from one circuit to the next.

ELECTRICAL REQUIREMENTS

For your safety and to ensure good unit performance, the ground on this circuit must be non-looped (isolated). Please refer to NEC article 21021 and 210-23. Any alterations to the standard power cord provided could void all warranties of this product.

The 3x, 5x and 7xe

Climbmills are designed to be self-powered and do not require an external power supply source to operate. Without an

external power supply, the console’s start-up time may be delayed. Add-on TV’s and other console accessories will increase the time needed

for start-up. An external power supply will ensure power is provided to the console at all times and is recommended when add-on accessories

are used.

For units with an integrated TV (like the 7xe and 7xi), the TV power requirements are included in the unit. An RG6 coaxial cable with ‘F Type’

compression fittings on each end will need to be connected to the cardio unit and the video source. Additional power requirements are not

needed for the add-on digital TV (3x and 5x). For units with an add-on PCTV (3x and 5x), the TV power requirements are separate.

NOTE: ALL UNITS WITH VIRTUAL ACTIVE™ MUST BE POWERED!

110 V UNITS

All Matrix 3x, 5x, 7xe and 7xi 110 V Climbmills require the use of a 100-125 V, 60 Hz and a 15 A

“Dedicated Circuit”, with a non-looped (isolated) neutral/ground for power. This outlet should be a

NEMA 5-15R and have the same configuration as the plug. No adapter should be used with this

product. These bikes can be daisy-chained together with up to 4 units per 15 A dedicated circuit.

Matrix daisy-chain cord adapters are sold separately.

220 V UNITS

All Matrix 3x, 5x, 7xe and 7xi 220 V Climbmills require the use of a 216-250 V, 50 Hz and a 15 A

“Dedicated Circuit”, with a non-looped (isolated) neutral/ground for power. This outlet should be a

NEMA 6-15R and have the same configuration as the plug. No adapter should be used with this

product. These bikes can be daisy-chained together with up to 4 units per 15 A dedicated circuit.

Matrix daisy-chain cord adapters are sold separately.

North American power cord plugs shown.

Depending on your country, the plug type may vary.

GROUNDING INSTRUCTIONS

The unit must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. The unit is equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances. If the user does

not follow these grounding instructions, the user could void the Matrix limited warranty.

ADDITIONAL ELECTRICAL INFO

In addition to the dedicated circuit requirement, the proper gauge wire must be used from the circuit breaker box, to each outlet that will have

the maximum number of units running off of it. If the distance from the circuit breaker box to each outlet, is 100 ft (30.5 m) or less, then 12

gauge wire should be used. For distances greater than 100 ft (30.5 m) from the circuit breaker box to the outlet, a 10 gauge wire should be

used.

ENERGY SAVING / LOW-POW ER MODE

All units are configured with the ability to enter into an energy saving / low-power mode when the unit has not been in use for a specified period

of time. Additional time may be required to fully reactivate this unit once it has entered the low-power mode. This energy saving feature may be

enabled or disabled from within the ‘Manager Mode’ or ‘Engineering Mode.

LOCATION OF THE UNIT

Place the unit on a level surface and away from direct sun light. The intense UV light can cause discoloration of plastics. Locate in an area

with cool temperatures and low humidity. Leave a clear zone behind the unit of at least 24". This zone must be clear of any obstruction and

allow the user a clear exit path from the unit. Do not place the unit in any area that will block the openings or vents. The unit should not be

used in a garage or covered patio.

LEVELING THE UNIT

Locate a level, stable surface to position the equipment. The equipment has levelers located below the bottom step. To access the levelers,

remove the end caps (C3X) or CONTROL ZONE (C5X, C7XE and C7XI). CAUTION: There is an electrical plug located under the CONTROL

ZONE and will need to be unplugged before the cover can be completely removed. Use an allen wrench to level the unit. Once stable, replace

parts as they were removed.

HEIGHT REQUIREMENTS

The Climb Mill adds 30" - 38" (76 - 96cm) to a user's height. For example, a 6' (183cm) tall user will be 7'8" (234.4cm - 254.4cm) off the floor.

Total height of the user on the Climb Mill should not exceed 9'10" (300 cm), which means that users taller than 6'8" (204cm) should not use this

equipment.

AUTO STOP

SENSOR

CONTROL ZONE

(C5X, C7XE, C7XI)

Page 6

7

6

3.1 RECOMMENDED CLEANING TIPS

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.2 CARE AND MAINTENANCE INSTRUCTION

CHAPTER 3: PREVENTATIVE MAINTENANCE

FIGURE A FIGURE B

In order to maximize life span, and minimize down time, all Matrix Fitness Equipment requires regularly

scheduled cleaning.

YOU WILL NEED:

- Mild dish soap and water mixture in a spray bottle (10:1 water to soap ratio).

- Lint free 100% cotton cleaning cloths or Micro fiber cleaning cloths.

- Vacuum / Shop Vac with extendable hose and soft brush attachment.

- iPod corrosion blocker - Available from Matrix (part # ZMS4001374).

- Super Lube Multi Purpose Synthetic Lubricant with Syncolon® (PTFE) Aerosol - www.super-lube.com/sythetic-aerosol-spray-ezp-46.html.

- Corrosion Block (available from Matrix - part # ZMS4001374).

- LCD / LED or computer screen cleaner.

DAILY or as needed:

1. Empty the dust tray under the stairs and under the unit (Figure A). If you need to move the unit, unplug it first.

WEEKLY:

1. With a clean dry 100% lint free cloth and water / soap mixture, wipe down the entire frame including the stairs so it is free of dust, dirt, and

sweat.

2. With a clean dry 100% lint free cloth and water / soap mixture, wipe down the entire console area including the hand grips and hand rails.

MONTHLY:

1. Vacuum under and around the Climb Mill If you need to move the unit, unplug it first. Make sure to reset the casters after moving the unit

back into position to stabilize the unit.

2. Apply corrosion block to the metal part of the iPod cable.

3. Use a computer screen cleaner or LCD / LED screen cleaner on the touch screen portion of the console (see Section 3.3).

QUARTERLY:

1. Remove the side access panels and vacuum out the inside of the unit (Figure B).

2. Unplug the Climbmill and clean the AUTO STOP SENSORS (located under the bottom step) / Control Zone sensor with a cotton swab

and rubbing alcohol.

In order to maximize life span, and minimize down time, all MATRIX equipment requires regular cleaning, and maintenance items performed on

a scheduled basis. This section contains detailed instructions on how to perform these items, the frequency of which they should be done, and a

check list to sign off each time service is completed for a specific machine. Some basic tools and supplies will be necessary to perform these tasks

which include (but may not be limited to):

* Metric Allen wrenches

* #2 Phillips head screwdriver

* Adjustable wrench

* Teflon based spray lubricant such as “Super Lube”, or other Matrix approved product

You may periodically see addendums to this document, as the Matrix Technical Support Team identifies items that require specific attention, the

latest version will always be available on the Matrix website, www.matrixfitness.com

DAILY MAINTENANCE ITEMS

1. Attempt to wobble the unit from side to side and front to back. Level the unit if needed (See Section 10.4).

QUARTERLY MAINTENANCE ITEMS

1. Check all connecting joint areas for tightness of fastened assemblies.

2. Remove the maintenance cover and check the fans for function. Also clean and remove any debris from the digital speed sensor.

3. Remove the maintenance cover and check the chains for damage, alignment and proper tension.

4. On units with a Control Zone, check to ensure the CZ is working properly by walking on the unit, then stepping on the CZ. The unit should stop

similar to an emergency stop on a treadmill.

5. Unplug the Climbmill and clean the AUTO STOP SENSORS (located under the bottom step) / Control Zone sensor with a cotton swab and

rubbing alcohol.

AUTO STOP

SENSORS

Page 7

9

8

3.3 TOUCH SCREEN CARE & CLEANING

CHAPTER 3: PREVENTATIVE MAINTENANCE

4.1 CONSOLE DESCRIPTION

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

The C7xi has a fully integrated touch screen display. All information required for workouts is explained on screen. Exploration of the interface is

highly encouraged. The information explaining how to program for various workouts will give an explanation about the contents of each screen.

Go: One touch Start.

stoP: Ends workout and shows workout summary data.

cool DoWn

(displayed on-screen during workout): Puts unit into Cool Down mode. Cool Down time is dependent on the length of the workout.

Workouts 19 minutes and shorter will have a cool down length of 2 minutes. Workouts 20 minutes and longer will have a cool down length of 5

minutes.

C7Xi ENTERTAINMENT ZONE

iPOD®: Will take the user directly to the iPod screen to allow for iPod control and play list selection.

Volume uP / DoWn: Adjusts the volume output through the headphone jack of the integrated console TV or iPod output.

NUMBERKEYPAD: Allows for easy TV channel selections.

cHannel uP / DoWn: Allows for channel selection.

DISPLAYMODE: Allows user to cycle through console display options, iPod, TV, or profile display.

last cHannel: Allows the user to cycle between the current channel and the previous channel viewed.

cc/mute:

Mutes sound and turns closed captioning on or off.

TOUCH SCREEN CARE AND CLEANING

* The touch screen requires very little maintenance. We recommend that you periodically clean the touch screen surface with a clean dry 100%

lint free cloth and water / soap mixture or a computer or LCD / LED screen cleaner.

* It is very important to avoid using any other chemical on the touch screen.

* Always dampen the cloth and clean the screen. Do not spray the water / soap mixture on the screen itself, the drips can seep into the display

or stain the bezel.

* After cleaning, make sure the surface is dry. There should not be any left over solvent to seep into the display.

* It is very important to handle the touch screen with care. Do not use excessive force when cleaning.

* Do not use any sharp materials to clean the touch screen surfaces.

* Do not use high pressure air, water, or steam to clean the touch screen surface.

Page 8

11

10

To set up a workout, press the touch screen over the program you would

like to use and then follow the prompts to begin your workout.

Go - Press to immediately begin a workout. Workout, resistance level,

and time will automatically go to default settings. All energy expenditure

values will be calculated using the default weight measurement.

manual - Manual allows the user to input more information while

defining their own workout. Calorie expenditure will be more accurate

when inputting information in Manual than by pressing GO.

rollinG Hills - The Rolling Hills program is a level based

program that automatically adjusts the resistance level to simulate real

terrain.

interVals - The Intervals program is a level based program that

automatically adjusts the resistance of the machine from low to high

intensity settings at regular intervals to burn calories.

Goal traininG - The Goal Training program is designed to help

users burn a target number of calories.

calorie traininG - The Calorie Training program is designed

to help users burn a target number of calories.

constant Watts - The Constant Watts program allows

you to vary your cadence or SPM and the machine's resistance will

adjust according to your selected goal. The quicker you step, the less

resistance for the goal selected.

Fat burn - The Fat Burn program is a level based workout that is

designed to help users burn fat through various resistance changes.

tarGet Heart rate - The Matrix Climb Mill comes with

standard digital contact heart rate sensors and are POLAR telemetry

compatible. The heart rate control workout mode allows the user

to program their desired heart rate zone, and the Climb Mill will

automatically adjust the level based upon the user's heart rate. The

heart rate zone is calculated using the following equation: (220-Age)*% =

target heart rate zone. The user must wear a POLAR telemetric strap or

continually hold onto the contact heart rate grips for this workout.

Locate the metal sensors on the handlebars of the Climb Mill. Notice

that there are two separate pieces of metal on each grip. You must be

making contact with both pieces of each grip to get an accurate heart

rate reading. You can grab these sensors in any program to view your

current heart rate.

FITNESSTEST(WFI) - The WFI (Wellness Fitness Initiative)

protocol is a test used by firefighters in a series of intervals lasting a

maximum of 16 minutes, where the speed is increased every minute

until the Target Heart Rate is exceeded for 15 seconds. When the

test is complete, the display provides a summary of V)2max, Highest

SPM, Elapsed Time, and Target Heart Rate. The test requires constant

monitoring of the user's heart rate, so the use of a telemetric heart rate

strap is highly recommended.

FITNESSTEST(SUBMAXIMAL)- The Submaximal test

measures cardiovascular fitness and provides an estimated Sub-maximal

VO2 max result. This assessment is a 4 stage test lasting 3-5 minutes

where the speed is increased until your Heart Rate is between 115 - 150

bpm for 2 of the stages. When the test is complete, a Fitness Rating is

displayed as High, Good, Average, Fair, or Low along with your age and

VO2 max. The test requires constant monitoring of the user's heart rate,

so the use of a telemetric heart rate strap is highly recommended.

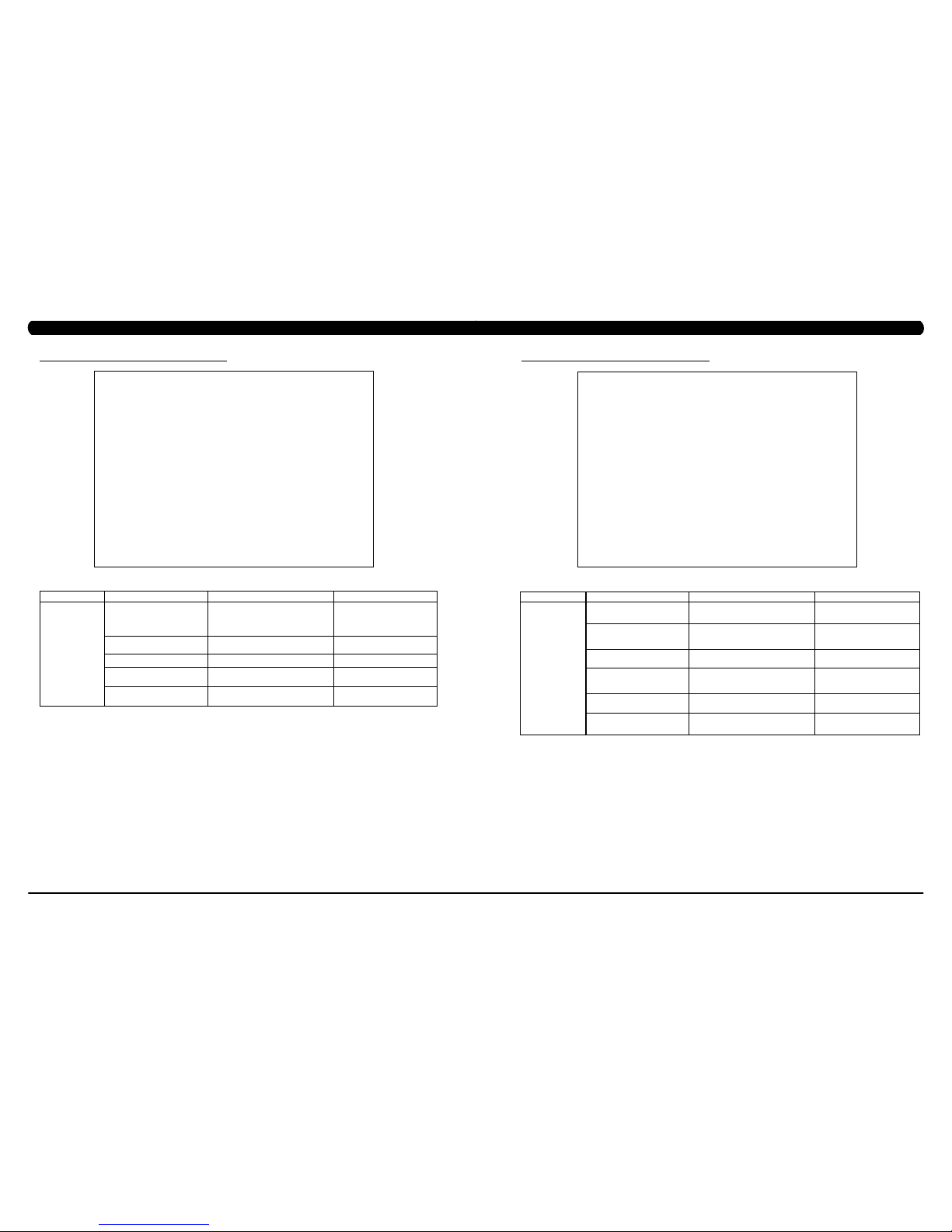

FITNESS RATING NORMS (V02 MAX)

AGE 20-29 30-39 40-49 50-59 60+

MEN

HIGH 51.4+ 50.4+ 48.2+ 45.3 42.5+

GOOD 51.3-46.8 50.3-44.6 48.1-41.8 45.2-38.5 42.4-35.3

AVERAGE 46.7-42.5 44.5-41.0 41.7-38.1 38.4-35.2 35.2-31.8

FAIR 42.4-39.5 40.9-37.4 38.0-35.1 35.1-32.3 31.7-28.7

LOW 39.4 OR

LESS

37.3 OR

LESS

35.0 OR

LESS

32.2 OR

LESS

28.6 OR

LESS

WOMEN

HIGH 44.2+ 41.0+ 39.5+ 35.2+ 35.2

GOOD 44.1-38.1 40.9-36.7 39.4-33.8 35.1-30.9 35.1-29.4

AVERAGE 38.0-35.2 36.6-33.8 33.7-30.9 30.8-28.2 29.3-25.8

FAIR 35.1-32.3 33.7-30.5 30.8-28.3 28.1-25.5 25.7-23.8

LOW 32.2 OR

LESS

30.4 OR

LESS

28.2 OR

LESS

25.4 OR

LESS

23.7 OR

LESS

4.2 WORKOUT SETUP STEPS

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

1) To enter Manager Mode, press "ENTER, 1, 0, 0, 1, ENTER" on the number keypad and Manager Mode will appear on the display.

2) Manager Mode is divided into 9 tabs, located on the left side of the screen. They are General, Workout, Setup Defaults, Asset Management,

Weather, TV, Applications, Hardware and Service.

3) Choose a tab by touching the screen over the desired tab.

4) Each of the tabs has options that will appear once you have chosen that particular tab.

5) Press the "HOME" button or the EMERGENCY STOP to exit Manager Mode.

5.1 USING MANAGER MODE

CHAPTER 5: MANAGER MODE

Page 9

13

12

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Accumulated Time Total time on the unit since production. Cannot be modified.

Accumulated Distance Total distance on the unit since production. Cannot be modified.

Serial Number - Console This option displays the serial number of the console, not

editable (see Service Mode to change serial numbers).

Cannot be modified.

Serial Number - Frame This option displays the serial number of the platform, not

editable (see Service Mode to change serial numbers).

Cannot be modified.

MANAGER MODE

General

5.2 MANAGER MODE – GENERAL – TAB 1

CHAPTER 5: MANAGER MODE

CHAPTER 6: MANAGER MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Date & Time This option sets the current date and time of the machine. N/A

MANAGER MODE

General

5.2 MANAGER MODE - GENERAL – TAB 2

5.2 MANAGER MODE - GENERAL – TAB 3

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Time zone This option sets the time zone.

Daylight Saving Time This option sets the daylight time. True or False

Auto Sync Date and Time This option is to set the date and time synchronized with

Microsoft server by internet.

True or False

Screen Timeout This option sets the machine show the

workout time of the machine.

Maximum: 120 sec

Minimum: 15 sec

MANAGER MODE

General

Page 10

15

14

5.2 MANAGER MODE – GENERAL – TAB 4

CHAPTER 5: MANAGER MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Language Setup Set the language used on the console. English (US), English (UK), English

(Australia), German, French, Italian,

Spanish, Dutch, Portuguese, Korean,

Israeli, Swiss, Russian, Finnish,

Taiwanese, Chinese, Japanese, Turkish

or Polish.

MANAGER MODE

General

5.2 MANAGER MODE – GENERAL – TAB 5

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Software Versions Software versions. Cannot be modified.

MANAGER MODE

General

CHAPTER 6: MANAGER MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Social Network Post This option allows the exercise time and

distance is post to social network.

N/A

MANAGER MODE

General

5.2 MANAGER MODE - GENERAL – TAB 6

Page 11

17

16

5.3 MANAGER MODE - WORKOUT – TAB 1

CHAPTER 5: MANAGER MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Maximum Workout Time This option allows the club to set the

maximum workout duration limits during

peak and non peak hours.

Maximum: 120 Minutes

Minimum: 10 Minutes

Maximum Workout Calories This option allows the club to set the

maximum workout duration limits during

peak and non peak hours.

Maximum: 10000

Minimum: 50

Maximum Workout Floors This option allows the club to set the

maximum workout duration limits during

peak and non peak hours.

Maximum: 10000

Minimum: 10

Pause Time This option controls the default pause time. Maximum: 10 Minutes

Minimum: 1 Minutes

Min Cooldown Time This option allows the club to set the

minimum cool down duration limits during

peak and non peak hours.

Maximum: 5 Minutes

Minimum: 1 Minutes

Max Cooldown Time This option allows the club to set the

minimum cool down duration limits during

peak and non peak hours.

Maximum: 10 Minutes

Minimum: 5 Minutes

MANAGER MODE

Workout

5.3 MANAGER MODE - WORKOUT – TAB 2

CHAPTER 5: MANAGER MODE

MANAGER MODE

Workout

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Max Cooldown Adjustment Time This option allows the club to set the

maximum cool down duration limits during

peak and non peak hours.

Maximum: 20 Minutes

Minimum: 5 Minutes

Max Level This option controls the default program

level.

Maximum: 20

Minimum: 1

E-Stop Enable This option controls the E-Stop function True / False

E-Stop Sensitivity This option controls the safety threshold

for the E-Stop function.

Maximum: 500

Minimum: 4

Hide Featured Content at Start of

Workout

This option sets whether

hide

the

Featured

Content at start of workout

.

True or False

Page 12

19

18

5.4 MANAGER MODE - SETUP DEFAULTS – TAB 1

CHAPTER 5: MANAGER MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Age This option controls the default user's age

used in the target heart rate calculations.

Maximum: 99

Minimum: 10

Weight This option controls the default weight

used in the calorie calculations. Displayed

in native units (pounds or kilograms).

79~401 lbs

Gender This option sets the user's gender as

either male or female.

Male or Female

Default Height This option controls the default height used

in the calorie calculations. Displayed in

native units (inch or cm).

40~90 inch

Default Workout Time This option controls the default program

time.

Maximum: 60

Minimum: 5

Default Workout Calories This option controls the default program

calories.

Maximum: 5000

Minimum: 50

MANAGER MODE

Setup Defaults

5.4 MANAGER MODE - SETUP DEFAULTS – TAB 2

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Default Workout Floors This option controls the default program

Distance.

Maximum: 10000

Minimum: 10

Default Web Brower Page This option controls the default machine Web

Brower Page.

N/A

Show Sliders In Workout This option controls the default Sliders bar of

True or False.

True or False

MANAGER MODE

Setup Defaults

CHAPTER 5: MANAGER MODE

5.5 MANAGER MODE - NETWORK

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Interface metric This option is to set the network routing data. N/A

MANAGER MODE

Network

Page 13

21

20

5.6 MANAGER MODE - ASSET MANAGEMENT

CHAPTER 5: MANAGER MODE

CHAPTER 5: MANAGER MODE

5.8 MANAGER MODE - TV – TAB 1

5.7 MANAGER MODE - WEATHER

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Default City This option controls the default City Weather. N/A

Enable Alerts This option controls the City Weather function True or False. True or False

Weather Temperature Unit This option controls how temperature is displayed. Fahrenheit or Celsius

MANAGER MODE

Weather

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Club ID This option records the club ID of the

fitness facility.

N/A

Show Custom Logo This option allows the user to change the

club logo.

True or False

Show Custom Background This option allows the user to change the

background piture.

True or False

MANAGER MODE

Asset Management

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

TV Channel Setup This option is for setting the TV tuner functions.

Press the "Start Scan" to search the TV Channel.

N/A

MANAGER MODE

TV

5.8 MANAGER MODE - TV – TAB 2

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Default TV Channel This option controls the default TV channel on start up. Maximum: 1000

Minimum: 2

Show Channel list This option allows the user to choose the TV channel

list on the TV screen.

True or False

Aspect Ratio Mode This option is to controls the TV screen ratio is

adjusted by automatically or filled to full.

Auto or Fill

MANAGER MODE

TV

Page 14

23

22

CHAPTER 5: MANAGER MODE

5.8 MANAGER MODE - TV – TAB 3

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Channel Button Setup This option is for setting the TV channel

button. Press the "Add" to edit the channel

icon, channel name and channel.

N/A

MANAGER MODE

TV

5.9 MANAGER MODE - APPLICATIONS

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Application Setup This option is for setting the screen table

functions.

N/A

MANAGER MODE

Applications

5.10 MANAGER MODE - HARDWARE – TAB 1

CHAPTER 5: MANAGER MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

ErP This option controls the ErP function is

Disabled or Enabled.

Disabled or Enabled

ErP Timeout Console will enter ErP mode if user does

not touch the screen or press any key pad

for couple minutes.

Maximum: 60

Minimum: 1

Backlight Brightness This option controls the screen backlight

Brightness.

Low / Medium / High

LCM Test Write test pattern.

N/A

Play Key Sound This option can set the keypad tone sound

on or off.

True or False

Play Workout Countdown Sound This option can set the play workout

countdown sound on or off.

True or False

MANAGER MODE

Hardware

Page 15

25

24

5.10 MANAGER MODE - HARDWARE – TAB 2

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Volume Basic This option controls the default volume on start

up.

Maximum: 30

Minimum: 0

MANAGER MODE

Hardware

CHAPTER 5: MANAGER MODE

5.11 MANAGER MODE - SERVICE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Service History This option allows the club to record key

components replacement history.

N/A

MANAGER MODE

Service

1) To enter Engineering Mode, press "ENTER, 2, 0, 0, 1, ENTER" on the number keypad and Engineering Mode will appear on the display.

2) Engineer ing Mode is divided into 12 tabs, located on the left side of the screen. They are General, Workout, Setup Defaults, Network, Asset

Management, Weather, TV, Applications, Calibration, Hardware, Service, Errors.

3) Choose a tab by touching the screen over the desired tab.

4) Each of the tabs has options that will appear once you have chosen that particular tab.

5) Press the "HOME" button or the EMERGENCY STOP to exit Engineering Mode..

6.1 USING ENGINEERING MODE

CHAPTER 6: ENGINEERING MODE

Page 16

27

26

6.2 ENGINEERING MODE - GENERAL – TAB 1

CHAPTER 6: ENGINEERING MODE

MANAGER MODE

General

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Accumulated Time Total time on the unit since production. Cannot be modified.

Accumulated Distance Total distance on the unit since production. Cannot be modified.

Serial Number - Console This option displays the serial number of

the console. See Service Mode to edit the

serial numbers.

Cannot be modified.

Serial Number - Frame This option displays the serial number of

the Frame. See Service Mode to edit the

serial numbers.

Cannot be modified.

Out of Order This option allows the club to show the unit

"out of order" if an error is present.

True / False

CHAPTER 6: ENGINEERING MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Date & Time This option sets the current date and time of the machine. N/A

ENGINEERING MODE

General

6.2 ENGINEERING MODE - GENERAL – TAB 2

6.2 ENGINEERING MODE - GENERAL – TAB 3

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Time zone This option sets the time zone.

Daylight Saving Time This option sets the daylight time. True or False

Auto Sync Date and Time This option is to set the date and time synchronized with

Microsoft server by internet.

True or False

Screen Timeout This option sets the machine show the

workout time of the machine.

Maximum: 120 sec

Minimum: 15 sec

ENGINEERING MODE

General

Page 17

29

28

6.2 ENGINEERING MODE - GENERAL – TAB 4

CHAPTER 6: ENGINEERING MODE

6.2 ENGINEERING MODE - GENERAL – TAB 5

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

General Software Versions Software versions. Cannot be modified.

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

General Language Setup Set the language used on the console. English (US), English (UK), English

(Australia), German, French, Italian,

Spanish, Dutch, Portuguese, Korean,

Israeli, Swiss, Russian, Finnish,

Taiwanese, Chinese, Japanese, Turkish

or Polish.

CHAPTER 6: ENGINEERING MODE

6.2 ENGINEERING MODE- GENERAL – TAB 6

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

General Social Network Post This option allows the exercise time and

distance is post to social network.

N/A

Page 18

31

30

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Maximum Workout Time This option allows the club to set the

maximum workout duration limits during

peak and non peak hours.

Maximum: 120 Minutes

Minimum: 10 Minutes

Maximum Workout Calories This option allows the club to set the

maximum workout duration limits during

peak and non peak hours.

Maximum: 10000

Minimum: 50

Maximum Workout Floors This option allows the club to set the

maximum workout duration limits during

peak and non peak hours.

Maximum: 10000

Minimum: 10

Pause Time This option controls the default pause time. Maximum: 10 Minutes

Minimum: 1 Minutes

Min Cooldown Time This option allows the club to set the

minimum cool down duration limits during

peak and non peak hours.

Maximum: 5 Minutes

Minimum: 1 Minutes

Max Cooldown Time This option allows the club to set the

maximum cool down duration limits during

peak and non peak hours.

Maximum: 10 Minutes

Minimum: 5 Minutes

MANAGER MODE

Workout

6.3 ENGINEERING MODE - WORKOUT – TAB 1

CHAPTER 6: ENGINEERING MODE

6.3 ENGINEERING MODE - WORKOUT – TAB 2

CHAPTER 6: ENGINEERING MODE

ENGINEERING MODE

Workout

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Max Cooldown Adjustment Time This option allows the club to set the

maximum cool down adjustment time

duration limits during peak and non peak

hours.

Maximum: 20 Minutes

Minimum: 5 Minutes

Max Level This option controls the default program

level.

Maximum: 20 Minutes

Minimum: 1 Minutes

E-Stop Enable This option controls the E-Stop function True or False

E-Stop Sensitivity This option controls the safety threshold

for the E-Stop function.

Maximum: 500

Minimum: 4

Hide Featured Content at Start of

Workout

This option sets whether

hide

the

Featured

Content at start of workout

.

True or False

Page 19

33

32

6.4 ENGINEERING MODE - SETUP DEFAULTS – TAB 1

CHAPTER 6: ENGINEERING MODE

6.4 ENGINEERING MODE - SETUP DEFAULTS – TAB 2

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Default Workout Floors This option controls the default program Floors Maximum: 10000

Minimum: 10

Default Web Brower Page This option controls the default machine Web

Brower Page.

N/A

Show Sliders In Workout This option controls the default Sliders bar of

True or False.

True or False

MANAGER MODE

Setup Defaults

CHAPTER 6: ENGINEERING MODE

6.5 ENGINEERING MODE - NETWORK – TAB 1

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Wireless Network Setup Wireless network setting N/A

ENGINEERING MODE

Network

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Age This option controls the default user's age

used in the target heart rate calculations.

Maximum: 99

Minimum: 10

Weight This option controls the default weight

used in the calorie calculations. Displayed

in native units (pounds or kilograms).

79~401 lbs

Gender This option sets the user's gender as

either male or female.

Male or Female

Default Height This option controls the default height used

in the calorie calculations. Displayed in

native units (inch or cm).

40~90 inch

Default Workout Time This option controls the default program

time.

Maximum: 60

Minimum: 5

Default Workout Calories This option controls the default program

calories.

Maximum: 5000

Minimum: 50

MANAGER MODE

Setup Defaults

Page 20

35

34

6.5 ENGINEERING MODE - NETWORK – TAB 2

CHAPTER 6: ENGINEERING MODE

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Network Wired Network Setup Wired Network Setup N/A

Interface metric This option is to set the network routing data. N/A

6.6 ENGINEERING MODE - ASSET MANAGEMENT

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Club ID This option records the club ID of the

fitness facility.

N/A

Show Custom Logo This option allows the user to change the

club logo.

True or False

Show Custom Background This option allows the user to change the

background picture.

True or False

ENGINEERING MODE

Asset Management

CHAPTER 6: ENGINEERING MODE

6.5 ENGINEERING MODE - NETWORK – TAB 3

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Network Proxy Setup This option is for the club to set the proxy server. Enable or Disable

Page 21

37

36

CHAPTER 6: ENGINEERING MODE

6.7 ENGINEERING MODE - WEATHER

6.8 ENGINEERING MODE - TV – TAB 1

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Default City This option controls the default City Weather . N/A

Enable Alerts This option controls the City Weather function True or False. True or False

Weather Temperature Unit This option controls how temperature is displayed. Fahrenheit or Celsius

ENGINEERING MODE

Weather

ENGINEERING

MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

TV

TV Channel Setup This option is for setting the TV tuner functions. Press the

"Start Scan" to search the TV Channel.

N/A

6.8 ENGINEERING MODE - TV – TAB 2

CHAPTER 5: ENGINEERING MODE

6.8 ENGINEERING MODE - TV – TAB 3

ENGINEERING

MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

TV

Default TV Channel This option controls the default TV channel on start up. Maximum: 1000, Minimum: 2

Show TV channel list This option allows the user to choose the TV channel

list on the TV screen.

True or False

Aspect Ratio mode This option is to control if the TV screen ratio is

adjusted by automatically or filled to full.

Auto or Fill

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Channel Button Setup This option is for setting the TV channel button. Press

the "Add" to edit the channel icon, channel name and

channel.

N/A

ENGINEERING MODE

TV

Page 22

39

38

CHAPTER 6: ENGINEERING MODE

6.9 ENGINEERING MODE - APPLICATIONS

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Application Setup This option is for setting the screen table

functions.

N/A

ENGINEERING MODE

Applications

6.10 ENGINEERING MODE - HARDWARE – TAB 1

CHAPTER 6: ENGINEERING MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

ErP This option controls the ErP function is Disabled

or Enabled.

Disabled or Enabled

ErP Timeout This option controls the console will enter ErP

mode if user does not touch the screen or press

any key pad for couple minutes.

Maximum: 60

Minimum: 1

Backlight Brightness This option controls the screen backlight

Brightness.

Low / Medium / High

LCM test Write test pattern N/A

Play Key Sound This option can set the play workout countdown

to sound or not sound.

True or False

Play Workout Countdown Sound This option can set the play workout countdown

to sound or not sound.

True or False

ENGINEERING MODE

Hardware

Page 23

41

40

6.10 ENGINEERING MODE - HARDWARE – TAB 2

CHAPTER 6: ENGINEERING MODE

6.11 ENGINEERING MODE - SERVICE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Service History This option allows the club to record key

components replacement history.

N/A

ENGINEERING MODE

Service

ENGINEERING MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Hardware Volume Basic This option controls the default volume on start up. Maximum: 30

Minimum: 0

Remove TV This option controls the remove TV function is disabled or

enabled.

Disabled or Enabled

CHAPTER 6: ENGINEERING MODE

6.12 ENGINEERING MODE - ERRORS

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Error Code History This option displays the error code history on

the treadmill.

N/A

ENGINEERING MODE

Errors

Page 24

43

42

1) To enter Service Mode, press "ENTER 3, 0, 0, 1, ENTER" on the number keypad and Service Mode will appear on the display.

2) Service Mode is divided into 15 tabs, located on the left side of the screen. They are General, Workout, Setup Defaults, Update, Network,

Asset Management, Weather, TV, Applications, Calibration, Hardware, Virtual Active, Management, Service, Errors.

3) Choose a tab by touching the screen over the desired tab.

4) Each of the tabs has options that will appear once you have chosen that particular tab.

5) Press the "HOME" button or the EMERGENCY STOP to exit Service Mode..

7.1 USING SERVICE MODE

CHAPTER 7: SERVICE MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Accumulated Time Total time on the unit since production. Cannot be modified.

Accumulated Distance Total distance on the unit since production. Cannot be modified.

Serial Number - Console This option displays the serial number of

the console. See Service Mode to edit the

serial numbers.

Cannot be modified.

Serial Number - Frame This option displays the serial number of

the Frame. See Service Mode to edit the

serial numbers.

Cannot be modified.

Demo Mode This option allows the engineer to try and

errors for console

True / False

Out of Order This option allows the club to show the unit

"out of order" if an error is present.

True / False

SERVICE MODE

General

CHAPTER 7: SERVICE MODE

7.2 SERVICE MODE - GENERAL - TAB 1

Page 25

45

44

CHAPTER 7: SERVICE MODE

7.2 SERVICE MODE - GENERAL – TAB 2

7.2 SERVICE MODE - GENERAL – TAB 3

SERVICE MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

General Date & Time This option sets the current date and time of the machine. N/A

CHAPTER 7: SERVICE MODE

7.2 SERVICE MODE - GENERAL - TAB 4

7.2 SERVICE MODE - GENERAL – TAB 5

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Software Versions Software versions. Cannot be modified.

Software Setup Wizard This option is to have the machine show the setup wizard on

the first setup screen.

True be False.

SERVICE MODE

General

SERVICE MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

General Language Setup Set the language used on the console. English (US), English (UK), English

(Australia), German, French, Italian,

Spanish, Dutch, Portuguese, Korean,

Israeli, Swiss, Russian, Finnish, Taiwanese,

Chinese, Japanese, Turkish or Polish.

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Time zone This option sets the time zone.

Daylight Saving Time This option sets the daylight time. True or False

Auto Sync Date and Time This option is to set the date and time

synchronized with Microsoft server by internet.

True or False

Screen Timeout This option sets the machine show the

workout time of the machine.

Maximum: 120 sec

Minimum: 15 sec

SERVICE MODE

General

Page 26

47

46

CHAPTER 6: SERVICE MODE

7.2 SERVICE MODE- GENERAL – TAB 6

SERVICE MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

General Social Network Post This option allows the exercise time and

distance is post to social network.

N/A

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Maximum Workout Time This option allows the club to set the

maximum workout duration limits during

peak and non peak hours.

Maximum: 120 Minutes

Minimum: 10 Minutes

Maximum Workout Calories This option allows the club to set the

maximum workout duration limits during

peak and non peak hours.

Maximum: 10000

Minimum: 50

Maximum Workout Floors This option allows the club to set the

maximum workout duration limits during

peak and non peak hours.

Maximum: 10000

Minimum: 10

Pause Time This option controls the default pause time. Max: 10 Minutes

Minimum: 1 Minutes

Min Cooldown Time This option allows the club to set the

minimum cool down duration limits during

peak and non peak hours.

Maximum: 5 Minutes

Minimum: 1 Minutes

Max Cooldown Time This option allows the club to set the

maximum cool down duration limits during

peak and non peak hours.

Maximum: 10 Minutes

Minimum: 5 Minutes

SERVICE

MODE

Workout

7.3 SERVICE MODE - WORKOUT – TAB 1

CHAPTER 7: SERVICE MODE

Page 27

49

48

CHAPTER 7: SERVICE MODE

7.3 SERVICE MODE - WORKOUT – TAB 2

SERVICE MODE

Workout

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Max Cooldown Adjustment Time This option allows the club to set the

maximum cool down adjustment time

duration limits during peak and non peak

hours.

Maximum: 20 Minutes

Minimum: 5 Minutes

Max Level This option controls the default program

level.

Maximum: 20 Minutes

Minimum: 1 Minutes

E-Stop Enable This option controls the E-Stop function TRUE / FALSE

E-Stop Sensitivity

This option controls the safety threshold

for the E-Stop function.

Maximum: 500

Minimum: 4

Hide Featured Content at Start of

Workout

This option sets whether

hide

the

Featured

Content at start of workout

.

True or False

7.4 SERVICE MODE - SETUP DEFAULTS – TAB 1

CHAPTER 7: SERVICE MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Age This option controls the default user's age

used in the target heart rate calculations.

Maximum: 99

Minimum: 10

Weight This option controls the default weight

used in the calorie calculations. Displayed

in native units (pounds or kilograms).

79~401 lbs

Gender This option sets the user's gender as

either male or female.

Male or Female

Default Height This option controls the default height used

in the calorie calculations. Displayed in

native units (inch or cm).

40~90 lbs

Default Workout Time This option controls the default program

time.

Maximum: 60

Minimum: 5

Default Workout Calories This option controls the default program

calories.

Maximum: 5000

Minimum: 50

SERVICE MODE

Setup Defaults

Page 28

51

50

7.4 SERVICE MODE - SETUP DEFAULTS – TAB 2

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Default Workout Floors This option controls the default program

Distance

Maximum: 10000

Minimum: 10

Default Web Brower Page This option controls the default machine Web

Brower Page

N/A

Show Sliders In Workout This option controls the default Sliders bar of

True or False

True or False

SERVICE MODE

Setup Defaults

CHAPTER 7: SERVICE MODE

7.5 SERVICE MODE - UPDATE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Check For Updates At boot This option will check software version for update

at boot form the machine.

True or False

Automatic Update Software update automatic

N/A

SERVICE

MODE

Update

7.6 SERVICE MODE - NETWORK – TAB 1

CHAPTER 7: SERVICE MODE

7.6 SERVICE MODE - NETWORK – TAB 2

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Wireless Network Setup Wireless Network Setup N/A

SERVICE MODE

Network

SERVICE MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Network Wired Network Setup Wired Network Setup N/A

Interface metric This option is to set the network routing

data.

N/A

Page 29

53

52

CHAPTER 7: SERVICE MODE

7.7 SERVICE MODE - ASSET MANAGEMENT

7.8 SERVICE MODE - WEATHER

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Club ID This option records the club ID of the fitness facility. N/A

Show Custom Logo This option allows the user to change the club logo. True or False

Show Custom Background This option allows the user to change the

background picture.

True or False

SERVICE MODE

Asset Management

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Default City This option controls the default City Weather . N/A

Enable Alerts This option controls the City Weather function True or False. True or False

Weather Temperature Unit This option controls how temperature is displayed. Fahrenheit or Celsius

SERVICE MODE

Weather

CHAPTER 6: SERVICE MODE

7.6 SERVICE MODE - NETWORK – TAB 3

SERVICE MODE FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Network Proxy Setup This option is for the club to set the proxy server. Enable or Disable

Page 30

55

54

CHAPTER 7: SERVICE MODE

7.9 SERVICE MODE - TV – TAB 1

7.9 SERVICE MODE - TV – TAB 2

SERVICE MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

TV

TV Channel Setup This option is for setting the TV tuner functions. Press the

"Start Scan" to search the TV Channel.

N/A

CHAPTER 7: SERVICE MODE

7.9 SERVICE MODE - TV – TAB 3

7.10 SERVICE MODE - APPLICATIONS

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Channel Button Setup This option is for setting the TV channel button.

Press the "Add" to edit the channel icon,

channel name and channel.

N/A

SERVICE MODE

TV

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Application Setup This option is for setting the screen table

functions.

N/A

SERVICE MODE

Applications

SERVICE

MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

TV

Default TV Channel This option controls the default TV channel on start up. Maximum: 1000, Minimum: 2

Show TV channel list This option allows the user to choose the TV channel

list on the TV screen.

True or False

Aspect Ratio mode This option is to control if the TV screen ratio is

adjusted automatically or filled to full.

Auto or Fill

Page 31

57

56

7.11 SERVICE MODE - HARDWARE – TAB 1

CHAPTER 7: SERVICE MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

ErP This option controls the ErP function is

Disabled or Enabled.

Disabled or Enabled

ErP Timeout Console will enter ErP mode if user does

not touch the screen or press any key pad

for couple minutes.

Maximum: 60

Minimum: 1

Backlight Brightness This option controls the screen backlight. Low / Medium / High

LCM test Write test pattern. N/A

LCM Version Show the LCM software version N/A

LCM Update If new firmware version is higher than the

current one, the "Update" button will show

up and user can hit it to start the process.

N/A

SERVICE MODE

Hardware

7.11

SERVICE MODE - HARDWARE – TAB 2

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Small LCD Reversed This option controls the ErP function is

Disabled or Enabled.

Disabled or Enabled

Play Key Sound Console will enter ErP mode if user does

not touch the screen or press any key pad

for couple minutes.

Maximum: 60

Minimum: 1

Play Workout Countdown Sound This option can set the play workout

countdown to sound on or off.

True or False

Volume Basic This option controls the default volume on

start up.

Maximum: 30

Minimum: 0

SERVICE MODE

Hardware

CHAPTER 7: SERVICE MODE

Page 32

59

58

7.11 SERVICE MODE - HARDWARE – TAB 3

CHAPTER 7: SERVICE MODE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Volume Advanced This option controls the default volume on

start up for Master, iPod, Virtual Active,

CSAFE, TV, Media Player

N/A

Remove TV This option controls the remove TV

function is disabled or enabled.

Disabled or Enabled

Default command expired seconds This option is to set the LCB default

command expired time.

Maximum: 15, Minimum: 3

SERVICE MODE

Hardware

CHAPTER 7: SERVICE MODE

7.12 SERVICE MODE - VIRTUAL ACTIVE

7.13 SERVICE MODE - MANAGEMENT

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Root Path This option can set the Virtual Active root path. D:

Auto Find This option can set to auto find the Virtual

Active.

True or False

SERVICE MODE

Virtual Active

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Setting Manager Setting Manager date N/A

SERVICE MODE

Management

Page 33

61

60

CHAPTER 7: SERVICE MODE

7.14 SERVICE MODE - SERVICE

7.15 SERVICE MODE - ERRORS

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Error Code History This option displays the error code history on

the treadmill.

N/A

SERVICE MODE

Errors

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Service History This option allows the club to record key

components replacement history.

N/A

SERVICE MODE

Service

CHAPTER 7: SERVICE MODE

7.16 SERVICE MODE - NETPULSE

FUNCTION & DEFAULTS DESCRIPTIONS MODIFIED

Test network and netpulse install. N/A

SERVICE MODE

Netpulse

Page 34

63

62

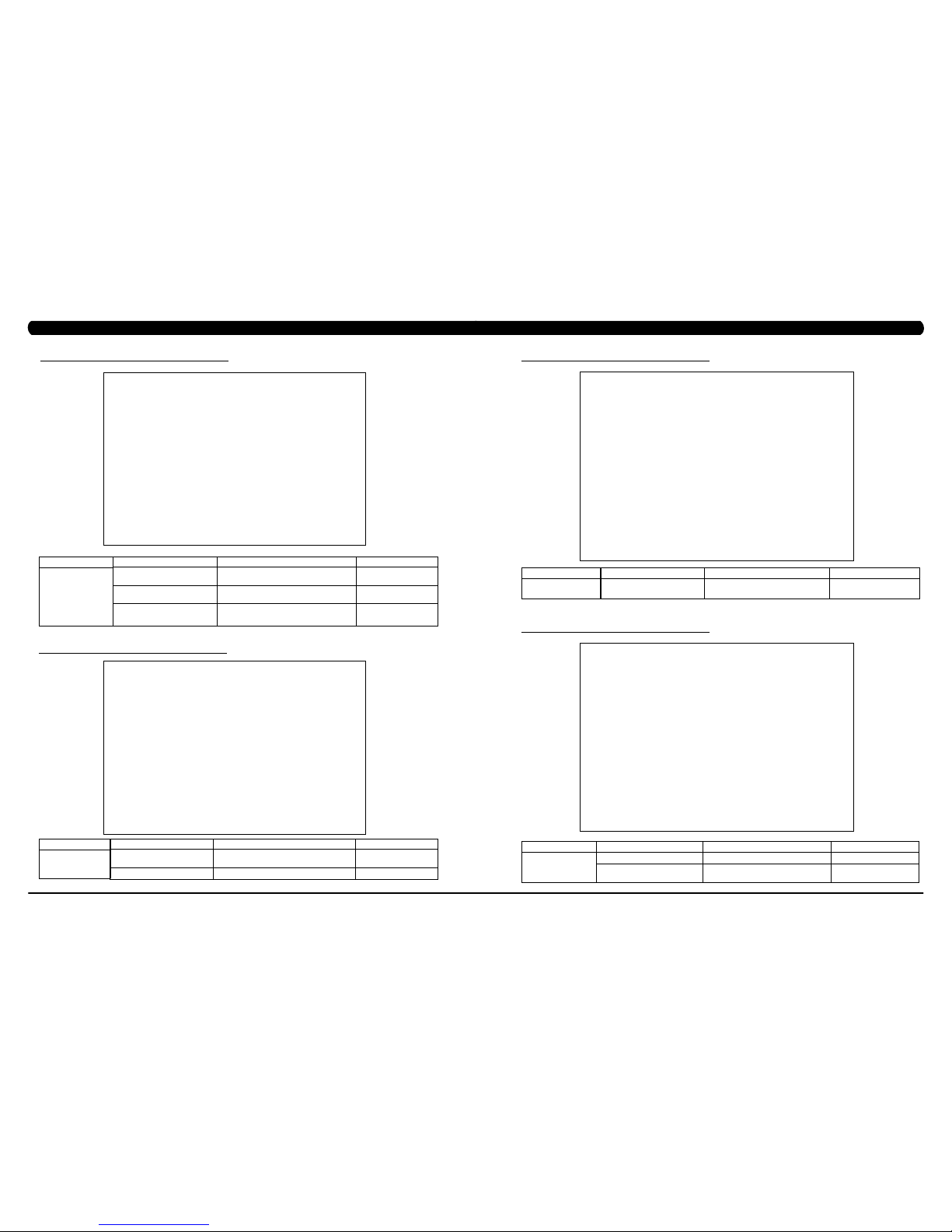

7.17 MATRIX FITNESS 7XI SERIES FEATURE ACCESS CODES

CHAPTER 7: SERVICE MODE

This document defines the supported feature access codes for the Matrix Fitness 7xi series fitness equipment.

Instruction

All codes are entered in by:

1. Press the “Enter” key.

2. Press the series of numbers in the code.

3. Press the “Enter” key.

CODE DESCRIPTION

1001

Enter manager screen.

2001

Enter engineering screen.

3001

Enter service screen

3002

Model selection

3004

Update manager

3008

Enable/disable all errors

4001

Take a screen shot of the current screen

4002

Show/hide the system resources window

4004

Show/hide CSAFE log window

4005

Set factory defaults

4006

Export the error logs to an external USB drive

732668

Reboot

7944357

Show help window

62728466

Marathon mode

287767

Show/hide cursor

999

Record workout data to USB drive at summary screen (INTERNAL USE ONLY)

8.1 ELECTRICAL DIAGRAMS

CHAPTER 8: TROUBLESHOOTING

Page 35

65

64

8.1 ELECTRICAL DIAGRAMS - CONTINUED

CHAPTER 8: TROUBLESHOOTING

P01 - DIGITAL COMMUNICATION WIRE

P13- SPEED SENSOR EXTENSION WIRE

8.1 ELECTRICAL DIAGRAMS - CONTINUED

CHAPTER 8: TROUBLESHOOTING

Page 36

67

66

8.1 ELECTRICAL DIAGRAMS - CONTINUED

CHAPTER 8: TROUBLESHOOTING

P27 - HAND PULSE WIRES P31 - PROXIMITY SENSOR WIRE

8.1 ELECTRICAL DIAGRAMS - CONTINUED

CHAPTER 8: TROUBLESHOOTING

P04 - ECB LOAD WIRE

Page 37

69

68

8.1 ELECTRICAL DIAGRAMS - CONTINUED

CHAPTER 8: TROUBLESHOOTING

P19 - POWER SENSOR WIRE

P18 - CONTROL ZONE SENSOR WIRE

8.1 ELECTRICAL DIAGRAMS - CONTINUED

CHAPTER 8: TROUBLESHOOTING

G18 - H/P CONNECT WIRE

P51 - IR SENSOR WIRE

Page 38

71

70

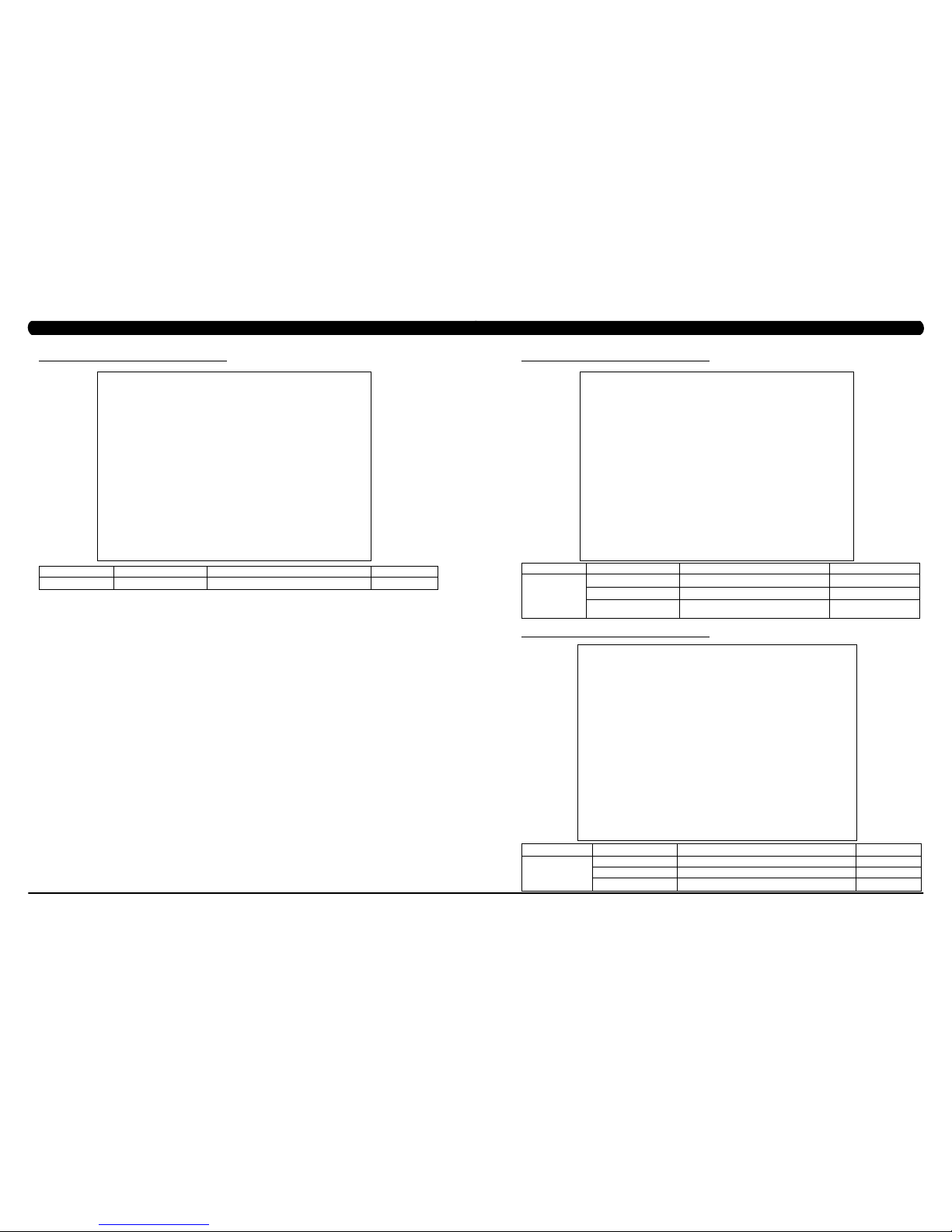

8.2 LCB ERROR INDICATORS

CHAPTER 8: TROUBLESHOOTING

8.2 LCB ERROR INDICATORS - CONTINUED

CHAPTER 8: TROUBLESHOOTING

LED STATUS DESCRIPTION

LED1 LCB status (blinking: OK).

LED2 Start or Stop( bright: start )

LED3 Safety stop ( bright: action )

LED4 Safety Key action status ( bright: trigger )

LED5 LCB Error status

LED6 UCB and LCB connection status (blinking: OK)

Status LED

---------------------------------------------------------------------------------Firmware definition-----------------------------------------------------------------------------------

--------------------------------------------------------------------------------

Hardware definition-----------------------------------------------------------------------------------

LED STATUS DESCRIPTION

LED7 MCU power lamp

LED8 Electro-magnet device 2 PWM lamp

LED9 Electro-magnet device 2 fan lamp

LED10 Electro-magnet device 1 PWM lamp

LED11 Electro-magnet device 1 fan lamp

LED12 DC brake release lamp

LED13 DC 26V lamp

D12 Safety switch power lamp

D35 RPM lamp

D8 Positioning sensor lamp

D15 DC 12V lamp

Page 39

73

72

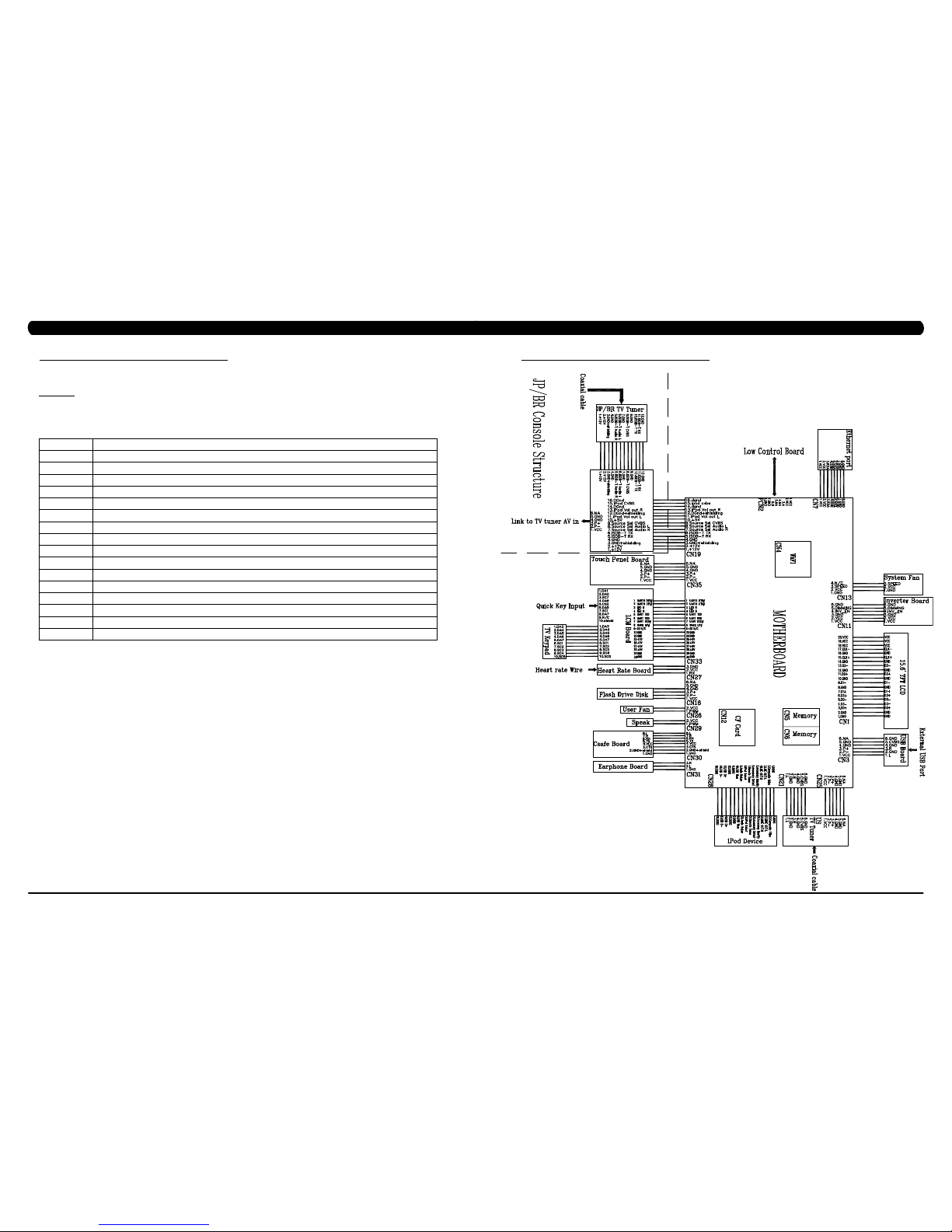

8.3 UCB WIRING

CONNECTIONS

CHAPTER 8: TROUBLESHOOTING

8.4 ERROR CODE TROUBLESHOOTING - 01AC

CHAPTER 8: TROUBLESHOOTING

ERROR CODE 01AC

1) SYMPTOM:

a. 01AC - Electro magnet (ECB) over current.

2) SOLUTION:

a. On standby mode, measure the resistance on ECB1 and ECB2. Please check the ECB extension cable connection at the LCB (pins 1 &

3 for ECB1, pins 2 & 4 for ECB2), there should be between 12.8 ~ 14.2 ohms. (Figure A)

- If the ECB resistance is out of the range, replace the ECB.

- If the ECB resistance is within the range, replace the LCB.

b. Check the gap of ECB1 and ECB2. There should be a gap of .5mm between the ECB and the flywheel.

- Adjust the gap as shown in Section 9.16.

FIGURE A

Page 40

75

74

8.5 ERROR CODE TROUBLESHOOTING - 01AF

CHAPTER 8: TROUBLESHOOTING

FIGURE A

ERROR CODE 01AF

1) SYMPTOM:

a. 01AF - Electro magnet (ECB) disconnected.

2) SOLUTION:

a. Check the connection of the ECB extension cable from the LCB to the ECB (Figure A).

b. Check to see if LED8 and LED10 on the LCB have a brief light for 3 second when you power on machine.

- If LED8 and LED10 do not have a brief light, replace the LCB.

- If LED8 and LED10 do have a brief light, check the ECB extension cable connection at the LCB (pins 1 & 3 for ECB1, pins 2 & 4 for

ECB2), there should be between 12.8 ~ 14.2 ohms. (Figure B)

- If the ECB resistance is out of the range, replace the ECB.

- If the ECB resistance is within the range, replace the LCB.

b. Check the gap of ECB1 and ECB2 (Figure B). There should be a gap of .5mm between the ECB and the flywheel.

- Adjust the gap as shown in Section 9.16.

FIGURE B

CHAPTER 8: TROUBLESHOOTING

8.6 ERROR CODE TROUBLESHOOTING - 02A0

ERROR CODE 02A0

1) SYMPTOM:

a. 02A0 - Encoder error.

b. The unit is in PAUSE Mode at all times.

2) SOLUTION:

a. Check the connection of the speed sensor cable from the LCB to the speed sensor.

b. Check to see if LED D35 on the LCB is on when the brake is turned to the left release position (Figure A).

If LED D35 is off, move the stairs about 3 stairs and check to see if LED D35 is flashing.

- If not, replace the speed sensor.

- If yes, adjust the speed sensor position and clean the speed sensor of any debris (Figures B), then re-test.

FIGURE BFIGURE A

Page 41

77

76

8.7 ERROR CODE TROUBLESHOOTING - 02BE / 02BF

ERROR CODE 02BE / 02BF

1) SYMPTOM:

a. 02BE - DC brake error (If movement is detected when the brake is in stop mode).

b. 02BF - DC brake error (The brakes current is over 1A for a continuous 3 sec.).

2) SOLUTION:

a. Check the power extend wire connection between the brake and LCB for any damage (Figures A & B).

b. Check to see if the stairs will move when you are in the stop position. If yes, replace the brake.

CHAPTER 8: TROUBLESHOOTING

FIGURE BFIGURE A

8.8 ERROR CODE TROUBLESHOOTING - 02CO

CHAPTER 8: TROUBLESHOOTING

ERROR CODE 02C0

1) SYMPTOM:

a. 02C0 - DC brake in manual mode.

2) SOLUTION:

a. Check if the DC brake is in the “ Right “ lock position (Figure A). Release the brake (move to the left) if in lock position.

b. Replace the brake.

FIGURE A

Page 42

79

78

8.9 ERROR CODE TROUBLESHOOTING - 02C1

CHAPTER 8: TROUBLESHOOTING

ERROR CODE 02C1

1) SYMPTOM:

a. 02C1 -Speed tracking error (the speed tracking is off by at least 10 rpms for a continuous 20 sec).

2) SOLUTION:

a. Adjust the speed sensor position and clean the speed sensor of any debris (Figure A).

b. Check the ECB extension cable connection at the LCB (pins 1 & 3 for ECB1, pins 2 & 4 for ECB2), there should be between 12.8 ~ 14.2

ohms, check which ECB is outside the range and replace it (Figure B).

FIGURE A FIGURE B

8.10 ERROR CODE TROUBLESHOOTING - 02C2

CHAPTER 8: TROUBLESHOOTING

ERROR CODE 02C2 (Control Zone 3 IR sensors error)

1) SYMPTOM:

a. The control zone 3 IR sensors are no communication or disconnected over 3 seconds.

b. Once power on, the control zone 3 IR sensors are no power or hidden over 3 seconds.

c. After power on, the control zone 3 IR sensors are no power or hidden over 4 hours.

2) SOLUTION:

a. Check if there's something in the control zone 3 IR sensors.

b. Check the connection of the control zone extension cable from the LCB to the control zone 3 IR sensors (Figure A & B).

c. Check if LED1 on the receiver board is flashing (Figure C).

- If yes, measure if the control zone extension cable (white wire- pin2) from the LCB to receiver board of control zone is good (Figure A

& B). Replace it if the cable is defective.

- If not, go to next step to verify.

d. Check if D12 on the LCB is light (Figure D).

- If not, replace the LCB.

- If yes, go to next step to verify.

e. Check LED1 status on the receiver board (control zone).

- If LED1 is light, replace the transmission board.

- If LED1 is off, replace the receiver board.

FIGURE A FIGURE B

FIGURE C FIGURE D

Page 43

81

80

8.11 ERROR CODE TROUBLESHOOTING - 02C3

CHAPTER 8: TROUBLESHOOTING

ERROR CODE 02C3 (Frame IR sensors error)

1) SYMPTOM:

a. The frame IR sensors are no communication or disconnected over 3 seconds.