Page 1

2016 5X CONSOLE

SERVICE MANUAL

Page 2

TABLE OF CONTENTS

CHAPTER 1: SERIAL NUMBER LOCATION ........................................................... 1

C

HAPTER 2: IMPORTANT SAFETY INSTRUCTIONS

2.1

3.1

3.2

4.1 Console Description .................................................................................................. 4

4.2 Workout Setup Steps - Manual .................................................................................. 6

4.3 Workout Setup Steps - Training Workouts ................................................................. 5

4.4 Workout Setup Steps - Fitness Test ........................................................................... 7

4.5 Workout Setup Steps - Target Heart Rate ................................................................. 8

4.6 Workout Setup Steps - Constant Watts ..................................................................... 8

4.7 Workout Setup Steps - Sprint 8 ................................................................................. 8

4.8 Workout Setup Steps - Goal Training ........................................................................ 8

4.9 Workout Setup Steps - Landmarks ............................................................................ 8

4.10 Workout Setup Steps - 5k Run .................................................................................. 9

4.11 Workout Setup Steps - Auto Calibration .................................................................... 9

5.1 Manager Mode Overview ........................................................................................... 10

6.1 Engineering Mode Overview ...................................................................................... 14

CHAPTER 7: SERVICE MODE/TEST MODE

Electrical Requirements

C

HAPTER 3: PREVENTATIVE MAINTENANCE

Recommended

Check for Damaged Parts

C

HAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

CHAPTER 5: MANAGER MODE

CHAPTER 6: ENGINEERING MODE

Cleaning Tips .................................................................................... 3

............................................................................................. 2

......................................................................................... 3

7.1 Service Mode Overview ............................................................................................. 15

7.2 Test Mode Overview................................................................................................... 16

CHAPTER 8: TROUBLESHOOTING

8.1

8.2

9.1

9.2

9.3

10.1

10.2

10.3 HURESA5X MYE TV/PCTV Bracket Installation .......................................................... 53

10.4

10.5

10.6

10.7

1.1

1

1.2

1

Electrical Diagram ...................................................................................................... 17

Error Codes List

CHAPTER 9: PARTS REPLACEMENT GUIDE

Console Replacement ..................................................................................................... 35

Console Keypad/Overlay Replacement

esting the Unit ............................................................................................................... 38

T

C

HAPTER 10: TREADMILL SPECIFICATIONS AND ASSEMBLY GUIDE

WiFi installation .............................................................................................................. 39

RFID installation

C5X MYE

C5X PCTV Bracket Installation ...................................................................................... 64

T5X MYE

T5X PCTV Bracket Installation ...................................................................................... 73

C

HAPTER 11: SOFTWARE UPGRADE GUIDE

Software Upgrade Instructions for UCB ...................................................................... 77

Software Upgrade Instructions for LCB ...................................................................... 78

.......................................................................................................... 30

........................................................................ 36

............................................................................................................. 45

TV Bracket Installation .................................................................................. 58

TV Bracket Installation .................................................................................. 69

Page 3

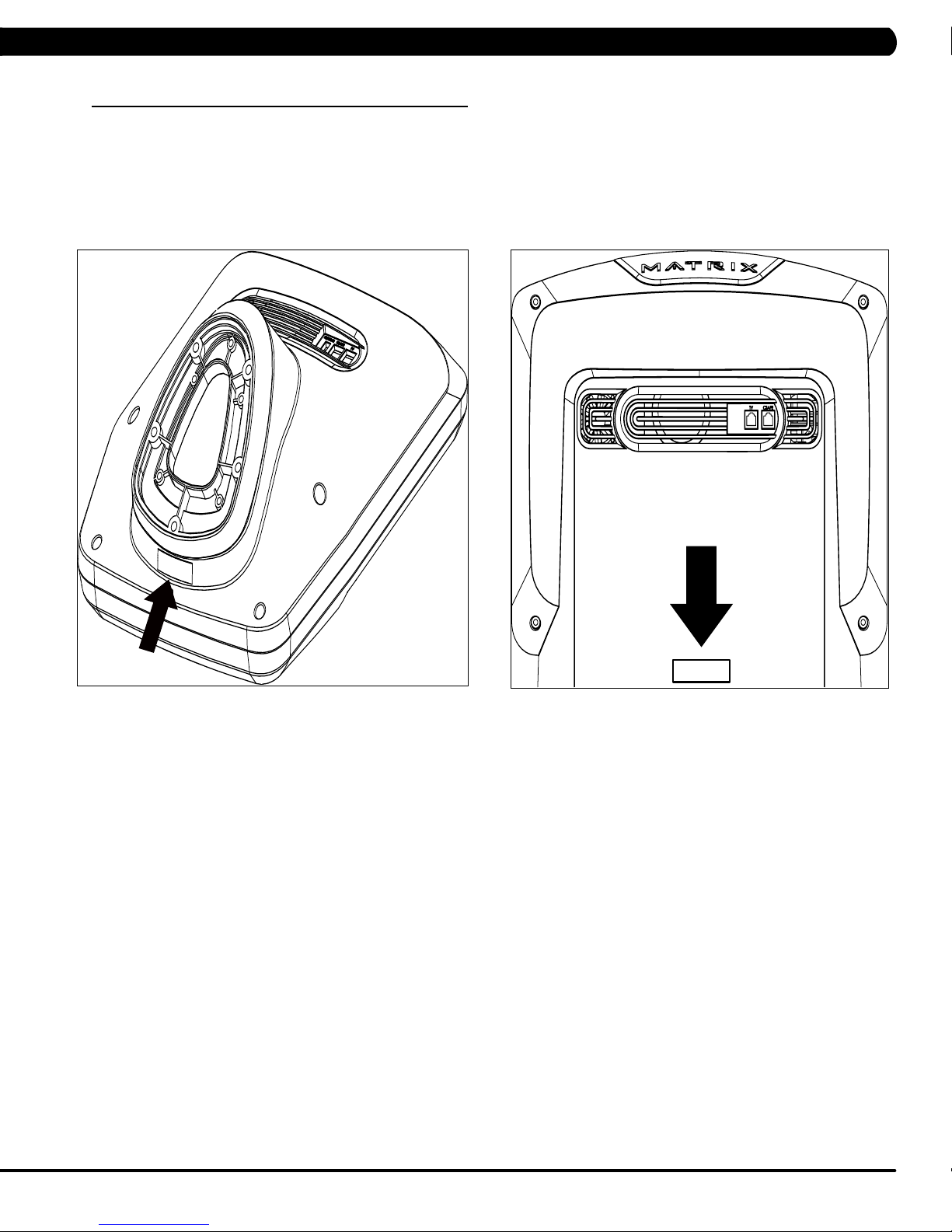

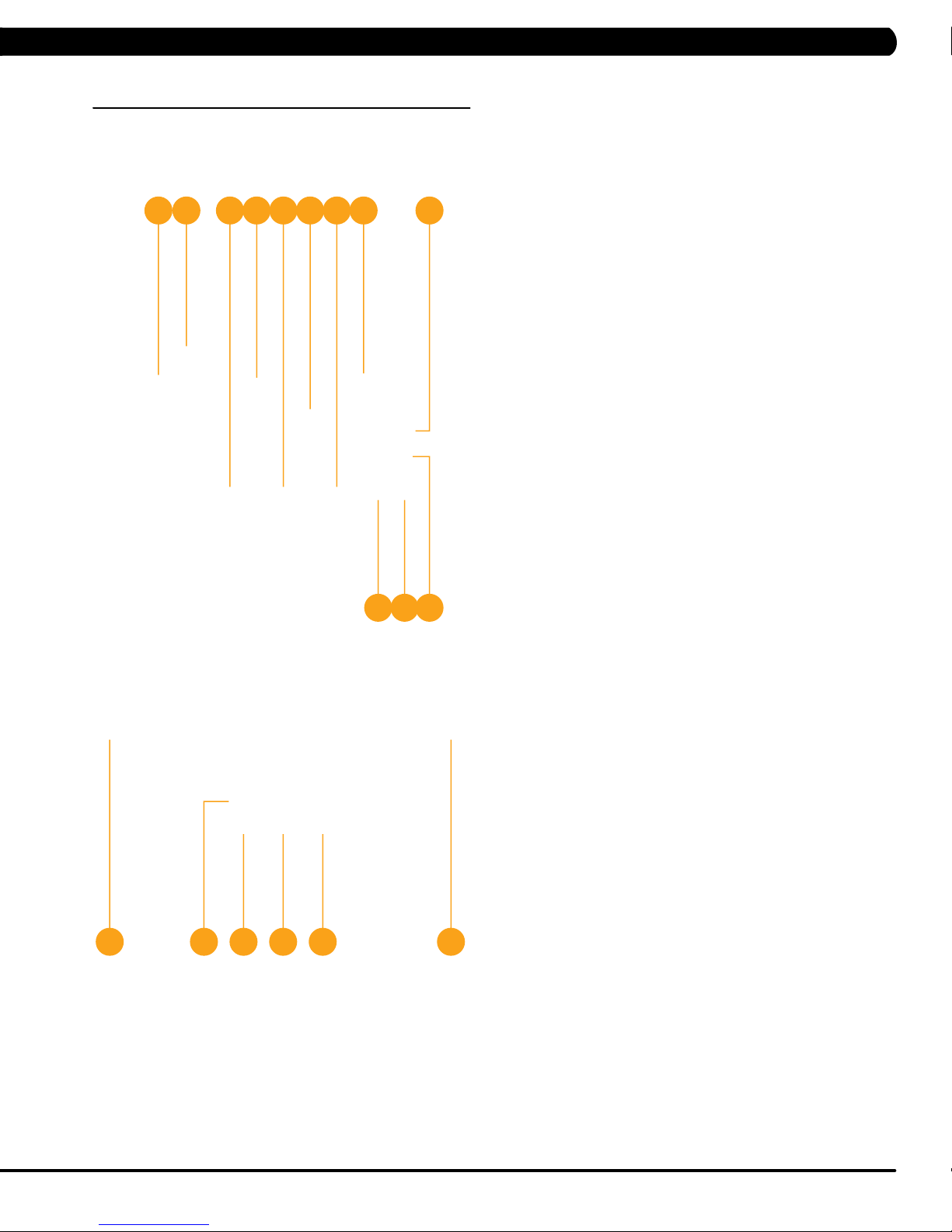

1.1 SERIAL NUMBER LOCATION

CHAPTER 1: SERIAL NUMBER LOCATION

CONSOLE SERIAL NUMBER LOCATION

5X

T5X

1

Page 4

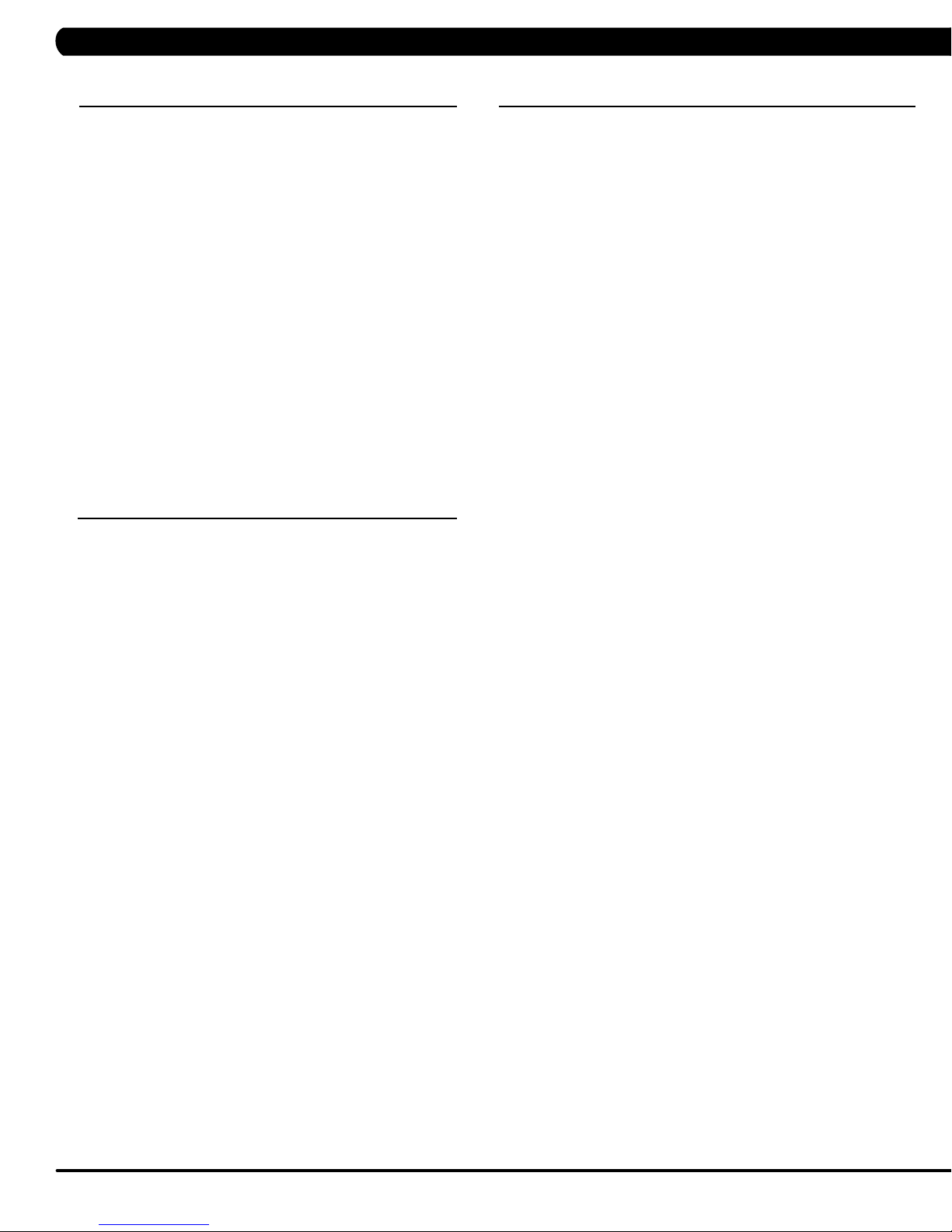

CHAPTER 2: IMPORTANT SAFETY INFORMATION

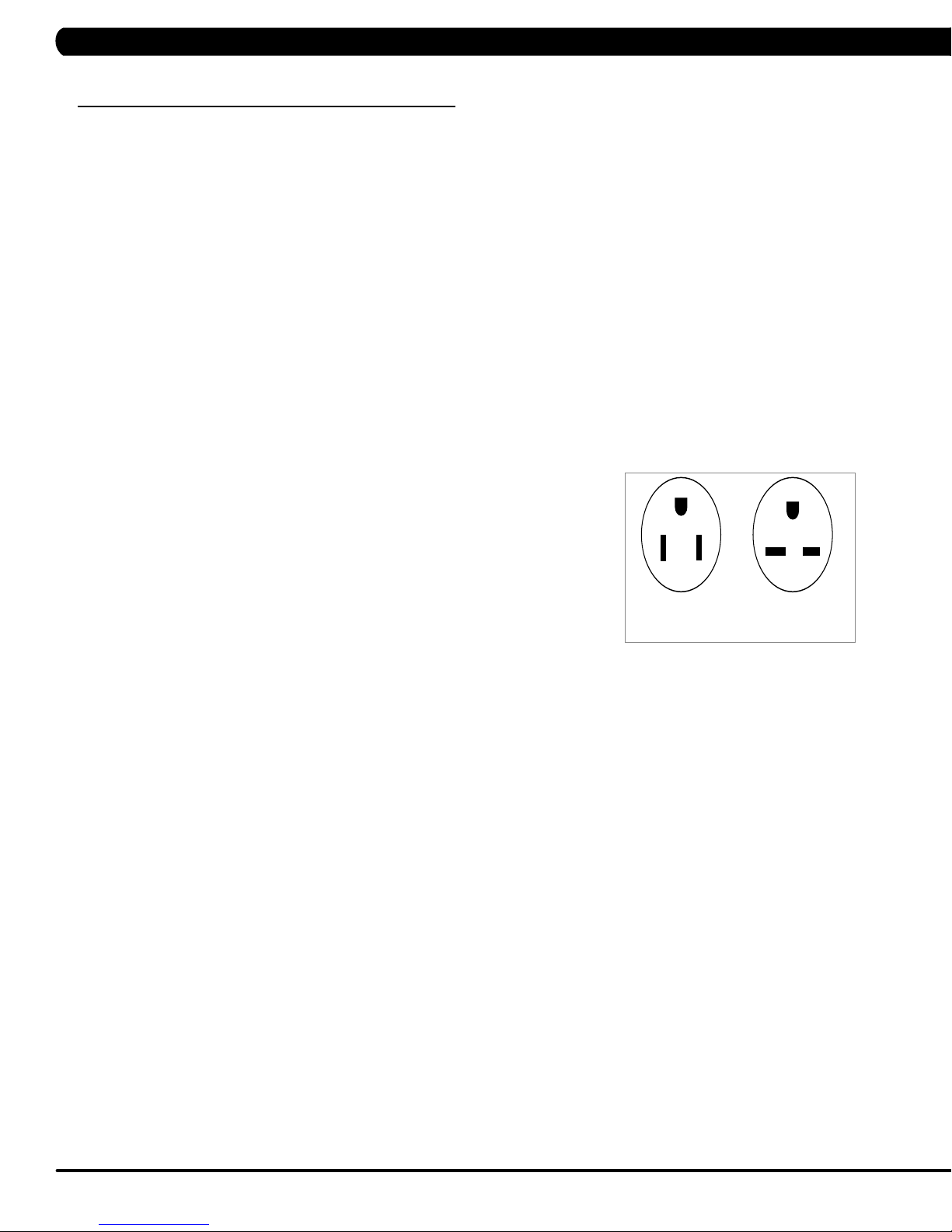

220 NEMA 6-15P

PLUG

110 NEMA 5-15P

PLUG

2.1 ELECTRICAL REQUIREMENTS

DEDICATED CIRCUIT AND ELECTRICAL INFO

A “Dedicated Circuit” means that each outlet you plug into should not have anything else running on that same circuit. The easiest way to verify

this is to locate the main circuit breaker box, and turn off the breaker(s) one at a time. Once a breaker has been turned off, the only thing that

should not have power to it are the units in question. No lamps, vending machines, fans, sound systems, or any other item should lose power

when you perform this test. Non-looped (isolated) neutral/grounding means that each circuit must have an individual neutral/ground connection

coming from it, and terminating at an approved earth ground. You cannot “jumper” a single neutral/ground from one circuit to the next.

ELECTRICAL REQUIREMENTS

For your safety and to ensure good unit performance, the ground on this circuit must be non-looped (isolated). Please refer to NEC article 210-21

and 210-23. Any alterations to the standard power cord provided could void all warranties of this product.

The 3x, 5x and 7xe bikes are designed to be self-powered and do not require an external power supply source to operate. Without an external

power supply, the console’s start-up time may be delayed. Add-on TV’s and other console accessories will increase the time needed for start-up.

An external power supply will ensure power is provided to the console at all times and is recommended when add-on accessories are used.

For units with an integrated TV (like the 7xe and 7xi), the TV power requirements are included in the unit. An RG6 coaxial cable with ‘F Type’

compression fittings on each end will need to be connected to the cardio unit and the video source. Additional power requirements are not needed

for the add-on digital TV (3x and 5x). For units with an add-on PCTV (3x and 5x), the TV power requirements are separate.

NOTE: ALL UNITS WITH VIRTUAL ACTIVE™ MUST BE POWERED!

110 V UNITS

All Matrix 3x, 5x, 7xe and 7xi 110 V bikes require the use of a 100-125 V, 60 Hz and a 15 A

“Dedicated Circuit”, with a non-looped (isolated) neutral/ground for power. This outlet should be a

NEMA 5-15R and have the same configuration as the plug. No adapter should be used with this

product. These bikes can be daisy-chained together with up to 4 units per 15 A dedicated circuit.

Matrix daisy-chain cord adapters are sold separately.

220 V UNITS

All Matrix 3x, 5x, 7xe and 7xi 220 V bikes require the use of a 216-250 V, 50 Hz and a 15 A

“Dedicated Circuit”, with a non-looped (isolated) neutral/ground for power. This outlet should be a

NEMA 6-15R and have the same configuration as the plug. No adapter should be used with this

product. These bikes can be daisy-chained together with up to 4 units per 15 A dedicated circuit.

Matrix daisy-chain cord adapters are sold separately.

GROUNDING INSTRUCTIONS

The unit must be grounded. If it should malfunction or breakdown, grounding provides a path of

least resistance for electric current to reduce the risk of electric shock. The unit is equipped with a cord having an equipment-grounding conduc

tor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local

codes and ordinances. If the user does not follow these grounding instructions, the user could void the Matrix limited warranty.

ADDITIONAL ELECTRICAL INFO

In addition to the dedicated circuit requirement, the proper gauge wire must be used from the circuit breaker box, to each outlet that will have the

maximum number of units running off of it. If the distance from the circuit breaker box to each outlet, is 100 ft (30.5 m) or less, then 12 gauge wire

should be used. For distances greater than 100 ft (30.5 m) from the circuit breaker box to the outlet, a 10 gauge wire should be used.

ENERGY SAVING / LOW- POWER MODE

All units are configured with the ability to enter into an energy saving / low-power mode when the unit has not been in use for a specified period

of time. Additional time may be required to fully reactivate this unit once it has entered the low-power mode. This energy saving feature may be

enabled or disabled from within the ‘Manager Mode’ or ‘Engineering Mode.

North American power cord plugs shown.

Depending on your country, the plug type may vary.

-

ADD-ON PCTV (3X AND 5X)

A 15 A or 20 A “Dedicated Circuit” with a non-looped (isolated) neutral/ground is required. Each PCTV requires at least 1.2 A of current. No more

than 12 PCTVs should be used for each 15 A circuit and no more than 16 PCTVs should be used for each 20 A circuit. The power outlet should

have the same configuration as the plug. No adapter should be used with this product. An RG6 coaxial cable with ‘F Type’ compression fittings

will need to be connected between the video source and each add-on PCTV unit. See the PCTV Manual for web connection requirements.

ADD-ON DIGITAL TV (3X AND 5X)

Additional power requirements are not needed for the add-on digital TV. An RG6 coaxial cable with ‘F Type’ compression fittings will need to be

connected between the video source and each add-on digital TV unit.

BATTERY CHARGING (3X AND 5X)

The bike saves its batter charge by moving into a shutdown mode whenever PEDAL FASTER appears on the display. If the user does not

maintain a pedal rate of 40 RPM or higher, a 30 second shutdown process begins. When the battery voltage is low, LOW BATTERY appears

on the display. This means it is time to recharge the battery. If the battery must be charged, use the optional power adapter charging unit. The

charger should be connected to the bike for a minimum of eight hours to ensure a thorough charge.

2

Page 5

CHAPTER 3: PREVENTATIVE MAINTENANCE

3.1 RECOMMENDED CLEANING TIPS

In order to maximize life span, and minimize down time, all Matrix Fitness Equipment requires regularly

scheduled cleaning.

YOU WILL NEED:

- Mild dish soap and water mixture in a spray bottle.

- Lint-free, 100% cotton cleaning cloths or Microfiber cleaning cloths.

DAILY:

1. Wipe down the unit after each use with a mild dish soap and water mixture. NOTE: Spray the soap/water mixture onto the cloth. NEVER

spray directly onto the equipment. We recommend that you do NOT allow customers to use spray bottles to clean the equipment. If the

cleaner is sprayed directly on the equipment or overspray is present, it may cause your equipment to rust and/or cause damage to console

overlays.

WEEKLY:

1. With a clean, dry, 100% lint-free cloth and water/soap mixture, wipe down the entire console area including the hand grips and hand

rails.

3.2 C

HECK FOR DAMAGED PARTS

DO NOT use any equipment that is damaged or has worn or broken parts. Use only replacement parts supplied by Matrix Fitness Systems.

MAINTAIN LABELS AND NAMEPLATES. Do not remove labels for any reason. They

contact Matrix Fitness Systems for a replacement. 1-866-693-4863, www.matrixfitness.com

MAINTAIN ALL EQUIPMENT Preventative maintenance is the key to smooth operating equipment. Equipment needs to be inspected at

regular intervals. Defective components must be replaced immediately. Improperly working equipment must be kept out of use until it is

repaired. Ensure that any person(s) making adjustments or performing maintenance or repair of any kind is qualified to do so. Matrix Fitness

Systems will provide service and maintenance training at our corporate facility upon request or in the field if proper arrangements are made.

contain important information. If unreadable or missing,

3

Page 6

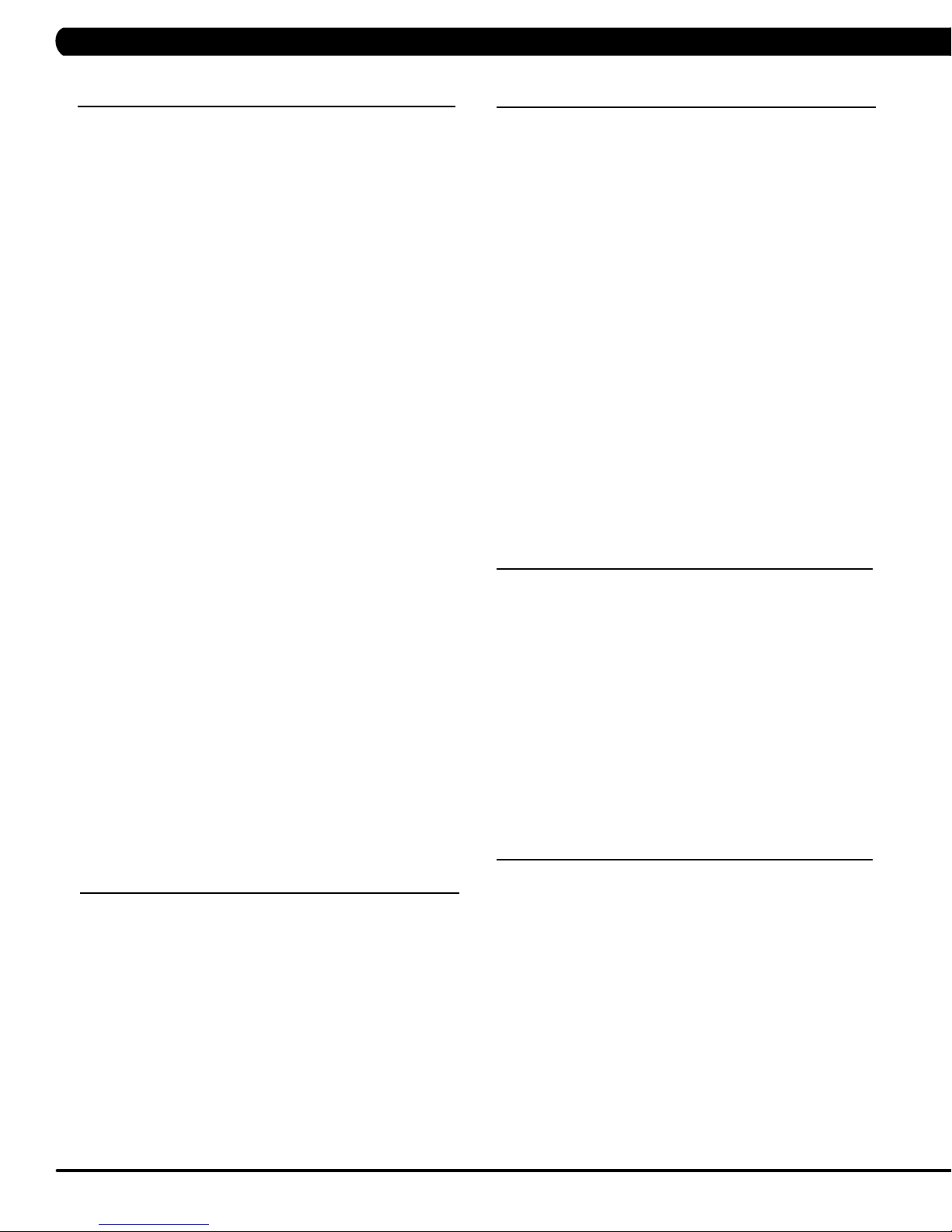

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.1 CONSOLE DESCRIPTION

e.g. A5X CONSOLE SHOWN

H

A B G

5X CONSOLE DESCRIPTION

ED F

I

A) WORKOUT KEYS: Simple program view and selection buttons.

B)GO

C)EN

D)UP/DOWN INCLINE (A5X ONLY):

E)U

F)U

G) STOP: Ends workout and shows workout summary data.

H)TOGGLE DISPLAY:

I)

J)

K)

L)F

M)

: One Touch Start.

TER: To confirm each program setting.

Easy information and incline

selection.

P/DOWN LEVEL: Easy information and level selection.

P/DOWN TIME: Easy information and time adjustment.

Cycles between 2 or 4 rows of workout

information displayed in LED window. The console will

automatically cycle between the workout information if the Toggle

Display button is pushed and held down for 3 seconds.

N

UMBER KEYPAD: W

adjustment during workout.

COOL D

LA

speeds).

R

feature).

OWN: Puts the Ascent into Cool Down mode.

NGUAGE: Select Language.

AN:

Allows for fan speed selection (fan has three operating

FID SENSOR:

orkout data input for workout setup. Level

Wireless login access location (optional add-on

5X ENTERTAINMENT ZONE

N) HOME: No function on this model.

O)LA

ST CHANNEL:

channel and the previous channel they were viewing.

P) CC

: Turns closed captioning on or off.

UTE: Mutes sound.

Q)M

VOL

J

N

P

Q

O

R

S

U

T

K

L

M

R)

C

S) NUMBER KEYPAD: Allows for easy number inputs.

T)

U)

UME UP/DOWN:

headphones.

CHA

NNEL UP/DOWN:

integrated

TV PO

WER: Turns external TV on or off.

Allows the user to cycle between the current

Adjusts the volume output through

Allows for channel selection on the

console TV.

4

Page 7

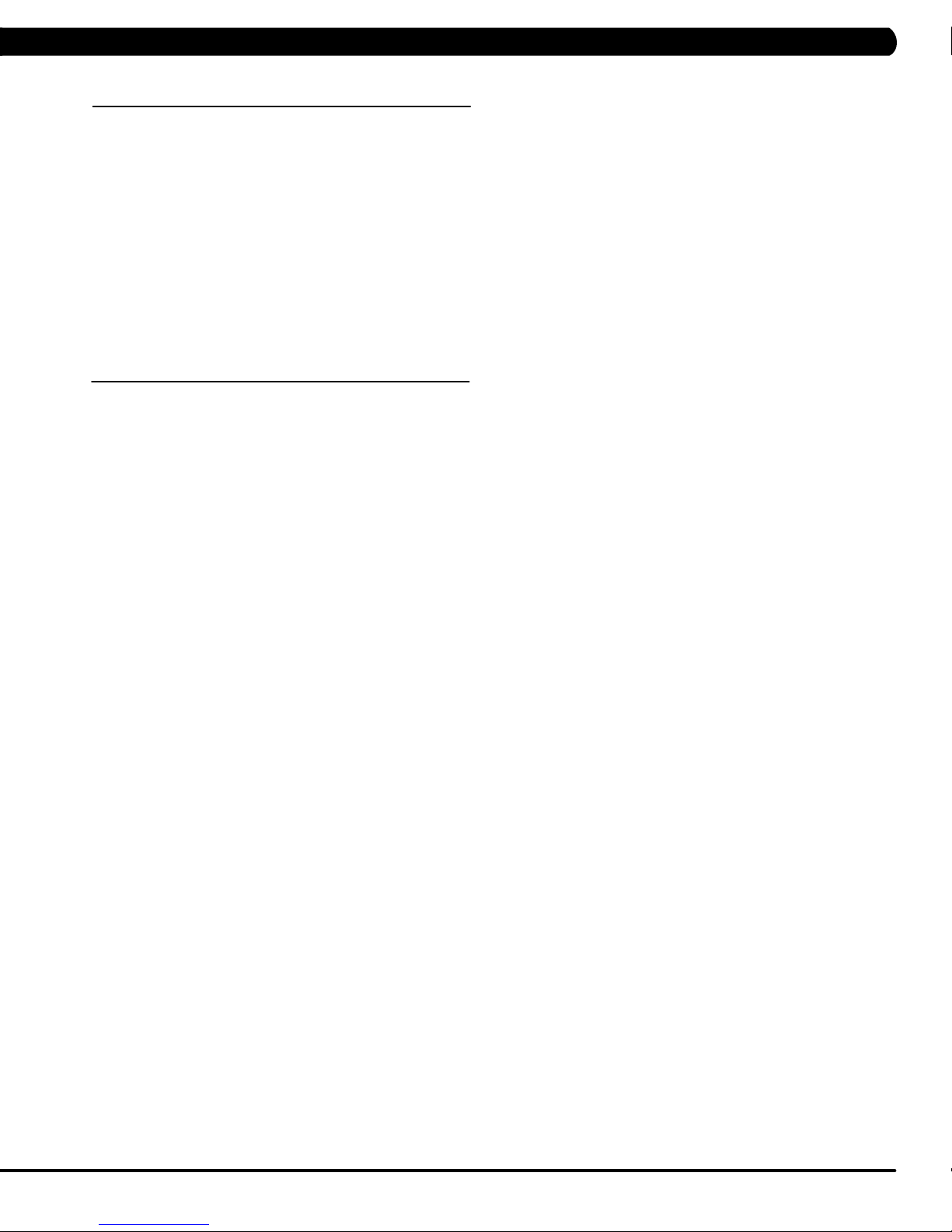

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.1 CONSOLE DESCRIPTION - CONTINUED

D M I F A H

B E

T5X CONSOLE DESCRIPTION

The Matrix machine is inspected before it is packaged. It is shipped

J

in two pieces: the base and the console. Carefully unpack the unit

and dispose of the box material. Note: There is a thin protective

sheet of clear plastic on the overlay of the console that should be

removed before use.

A)WORKOUT KEYS:

buttons. Press Fitness Test button to cycle through available

tests.

B)GO

C)EN

D)UP/DOWN INCLINE:

E)U

F)U

G)EM

N

L C

H)

I)PAUSE:

J)

: One Touch Start.

TER: To confirm each program setting.

selections.

P/DOWN SPEED:

selections.

P/DOWN TIME: Adjust time and make program selections.

ERGENCY STOP

functions and immobilize the unit. The emergency stop on

this treadmill must be returned to its original position in order

to allow normal operation of the unit.

P: Ends workout and shows workout summary data.

STO

Pauses workout. Pause duration can be set in

manager or engineering mode.

UMBER KEYPAD: W

N

Speed adjustment during workout.

Simple program view and selection

Adjust incline and make program

Adjust speed and make program

MMOBILIZATION: T

/ I

orkout data input for workout setup.

o stop all

K)

COOL D

Down time is dependent on the length of the workout.

Workouts 19 minutes and shorter will have a cool down

length of 2 minutes. Workouts 20 minutes and longer will

have a cool down length of 5 minutes.

L)F

speeds.)

T

M)

information displayed in LED window. The console will

BKD E

G

H

automatically cycle between the workout information if

the Toggle Display button is pushed and held down for 3

seconds.

N)LA

OWN:

Puts treadmill into Cool Down mode. Cool

Allows for fan speed selection (fan has three operating

AN:

OGGLE DISPLAY:

NGUAGE: Select Language.

Cycles between 4 rows of workout

5

Page 8

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.2 WORKOUT SETUP STEPS - MANUAL

GO - Press to immediately begin a workout. Workout, resistance

level, and time will automatically go to default settings. Pressing

GO will not prompt user for age, weight, or level settings.

1) Start pedaling and press the GO key to begin your workout. 2)

The display will read 3, 2, 1, Begin and then the program will start.

MANUAL - Manual allows the user to input more information

while defining their own workout. Calorie expenditure will be more

accurate when inputting information in Manual than by pressing GO.

1) Start pedaling, press the MANUAL

2) Select Level by using the UP

ENTER.

3) Select Time by using the UP or DOWN LEVEL

ENTER.

4) Select W

ENTER.

5) Press GO, and then the display will read 3, 2, 1, Begin and then

the program will start.

4.3

eight by using the UP or DOWN LEVEL

WORKOUT SETUP STEPS - TRAINING WORKOUTS

key.

or DOWN LEVEL keys and press

Then press ENTER.

keys and press

keys and press

FAT BURN - Fat burn is a level based program that is designed

to help users burn fat through various resistance level changes.

1) Start pedaling and press the

ENTER.

2) Select F

press ENTER.

3) Select Level by using the UP or DOWN LEVEL

ENTER.

4) Select

ENTER.

5) Select W

ENTER.

6) Press GO, then the display will read 3, 2, 1, Begin and then the

program will start.

AT BURN by using the UP or DOWN LEVEL keys and

Time by using the UP or DOWN LEVEL

eight by using the UP or DOWN LEVEL

Training Workouts.

Then press

keys and press

keys and press

keys and press

4.3 WORKOUT SETUP STEPS - TRAINING WORKOUTS

ROLLING HILLS - The Rolling Hills program is a level based

program that automatically adjusts the resistance level to simulate

real terrain.

1) Start pedaling and press the

ENTER.

2) Select Rolling Hills by using the UP

press ENTER.

3) Select Level by using the UP

ENTER.

3) Select

ENTER.

4) Select W

ENTER.

5) Press Go, then the display will read 3, 2, 1, Begin and then the

program will start.

Time by using the UP or DOWN LEVEL keys and press

eight by using the UP or DOWN LEVEL

Training Workouts.

or DOWN LEVEL

or DOWN LEVEL

keys and press

INTERVAL TRAINING - The Interval Training program is a

level based program that automatically adjusts the resistance of the

machine from low to high intensity settings at regular intervals.

1) Start pedaling and press the

ENTER.

2) Select Intervals by using the UP

press ENTER.

3) Select Level by using the UP

ENTER.

4) Select Time by using the UP or DOWN LEVEL keys and press

ENTER.

5) Select W

ENTER.

6) Press GO then the display will read 3, 2, 1, Begin and then the

program will start.

eight by using the UP or DOWN LEVEL

Training Workouts.

or DOWN LEVEL

or DOWN LEVEL

keys and press

- CONTINUED

Then press

keys and

keys and press

Then press

keys and

keys and press

6

Page 9

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.4 WORKOUT SETUP STEPS - FITNESS TEST

FITNESS TEST -The Cooper Fitness Test measures cardiovascular fitness and proves an estimated sub-maximal VO2 result. It is based

on power output according to

remain between 60-80 RPM during the test. The test will end when the user can no longer maintain this speed. Use of a heart rate strap is

optional but provides more data.

ACSM standards and was developed by the Cooper Institute© (www.cooperinstitute.org). User RPMs must

The test starts at a low intensity level and gradually increases in intensity (difficulty) every 2 minutes. As it increases, the user must maintain

60-80 RPM to advance to the next level.

period (cool down) will begin and the user's results are calculated and displayed. Results are based on the number of stages completed.

Incline will not be adjustable during the test.

1) Start pedaling and press the FITNESS

2) Select Age by using the UP or DOWN LEVEL

3) Select Gender by using the UP

4) Select W

5) Press GO, then the display will read 3, 2, 1, Begin and then the program will start.

6) Once the workout is complete, the display will read the results of the Fitness

eight by using the UP or DOWN LEVEL

The test could take upwards of 30+ minutes for very fit individuals. Once the test ends a recovery

TEST key. Then press ENTER.

keys and press ENTER.

or DOWN LEVEL keys and press ENTER.

keys and press ENTER.

Test.

STAGES COMPLETED:

1 Well Below Average

2 Well Below Average

3 Below Average

4 Below Average

5 Average

6 Average

7 Above Average

8 Above Average

9+ Well Above Average

7

Page 10

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.5 WORKOUT SETUP STEPS - TARGET HEART RATE

TARGET HEART RATE - The Matrix heart rate comes with

standard digital contact heart rate sensors and are POLAR telemetry

compatible.

program their desired heart rate zone, and the bike will automatically

adjust the level based upon the user's heart rate. The heart rate

zone is calculated using the following equation: (220-Age)8%=target

heart rate zone. The user must wear a POLAR telemetric strap or

continually hold onto the contact heart rate grips for this workout.

Locate the metal sensors on the handlebars of the bike. Notice

that there are two separate pieces of metal on each grip. You must

be making contact with both pieces of each grip to get an accurate

heart rate reading. You can grab these sensors in any program to

view your current heart rate.

1) Start pedaling and press the HEART RATE key. Then press

ENTER.

2) Select

SELECT.

3) Select

keys and press SELECT.

4) Select Time by using the UP or DOWN LEVEL

SELECT

5) Select W

SELECT.

6) Press GO, then the display will read 3, 2, 1, Begin and the

program will start.

The heart rate control workout mode allows the user to

Age by using the UP or DOWN LEVEL

Target HR Percentage by using the UP or DOWN LEVEL

.

eight by using the UP or DOWN LEVEL

keys and press

keys and press

keys and press

WORKOUT SETUP STEPS - SPRINT 8

4.7

-- Below for HUREAT5x only

S

PRINT 8

sciencebased sprint cardio training plan that stimulates the natural

release of human growth hormone, which burns fat and builds lean

muscle in just 20 minutes, 3 times a week. In two hospital-based

studies, participants who performed the Sprint 8 workout for 8

weeks lost, on average, 27% of their body fat.

T

o keep users on track, the Sprint 8 workout program

provides a Sweat Score after every sprint. The Sweat Score

is a measure of effort, and users should aim to match or

exceed their previous Sweat Score with each subsequent

sprint.

1) Start pedaling and press the SPRINT

ENTER.

2) Select one custom (Beginner/Intermediate/Advanced/Elite) by

using the UP

3) Select Level by using the UP

ENTER.

4) Select W

ENTER.

5) Press GO, then the display will read 3, 2, 1, Begin and the

program will start.

- The 20-minute Sprint 8 workout program is a

8 key.

Then press

or DOWN LEVEL keys and press SELECT

or DOWN LEVEL

eight by using the UP or DOWN LEVEL

.

keys and press

keys and press

4.6 WORKOUT SETUP STEPS - CONSTANT WATTS

CONSTANT WATTS - Constant Watts is a unique program

that allows you to vary your cadence or RPM and the bike's

resistance level will adjust accordingly to your selected goal.

quicker you pedal, the less resistance for the goal selected.

1) Start pedaling and press the CONSTANT WATTS key. Then

press ENTER.

2) Select W

SELECT.

3) Select

SELECT.

4) Select W

press SELECT.

5) Press GO, then the display will read 3, 2, 1, Begin and the

program will start.

atts by using the UP or DOWN LEVEL

Time by using the UP or DOWN LEVEL

eight by using the UP or DOWN LEVEL

keys and press

keys and press

keys and

The

WORKOUT SETUP STEPS - GOAL

4.8

TRAI

NING

-- Below for S/C5x only

GOAL TRAINING

is designed to help users burn a target number of calories.

1) Start stepping and press the GOAL

2) Select

LEVEL keys and press ENTER.

3) Select level by using the UP or DOWN LEVEL

ENTER.

4) Select weight by using the UP

ENTER.

5) Press GO then the display will read 3, 2, 1, Begin and then the

program will start.

4.9

Time or Floors or Calories by using the UP

WORKOUT SETUP STEPS - LANDMARKS

- Goal Training is a goal-based workout that

TRAINING key

or DOWN LEVEL

.

or DOWN

keys and press

keys and press

-- Below for SC5x only

LAN

DMARKS

designed to help users burn a target number of calories.

1) Start stepping and press the Landmark key.

2) Select one custom (Eif

Redeemer Statue, Empire State Building, One World Trade Center,

Tower of Pisa, Great Pyramid of Giza, St. Basil’s Cathedral,

Burj Khalifa, Taj Mahal and Taipei 101) by using the UP

LEVEL keys and press ENTER.

3) Select level by using the UP

ENTER.

4) Select weight by using the UP

ENTER.

5) Press GO then the display will read 3, 2, 1, Begin and then the

program will start.

- Goal Training is a goal-based workout that is

fel Tower, Statue of Liberty

or DOWN LEVEL

or DOWN LEVEL

, Christ the

or DOWN

keys and press

keys and press

8

Page 11

CHAPTER 4: CONSOLE OVERLAY AND WORKOUT DESCRIPTION

4.10 5K RUN WORKOUT OPERATION

-- Below for T5x only

5K RUN WORKOUT OPERATION

5K Run is a workout with a fixed distance of 5 km. Incline is adjusted automatically throughout the workout. You control the speed.

1) Choose 5K RUN by selecting the 5k run workout button.

2) Select the desired workout level by using the UP or DOWN SPEED keys and press ENTER.

3) Select the user's weight (the user's weight is used to calculate the caloric expenditure value, providing an accurate weight helps to ensure an

accurate caloric expenditure rating for each user) by using the UP or DOWN SPEED keys and press ENTER.

4) Enter the desired start speed uby using the UP

5) Press GO or QUICK ST

4.11 AUTO CALIBRATION INSTRUCTIONS

ART to begin the workout.

-- Below for A/T5x only

AUTO CALIBRATION PROCEDURE

After initial installation or replacement of the incline motor, auto calibration should be run.

or DOWN SPEED keys and press ENTER.

1) Press number key "ENTER, 2, 0, 0, 1, ENTER" on the number keypad. Engineer Mode will appear on the display

2) Press the LEVEL

3) Press ENTER to enter Auto Calibration. Press ENTER.

This will run the Auto Calibration. If the calibration passes, it will say calibration OK and automatically cycle to the Auto Calibration screen.

4)

Press and hold the STOP key to return to the normal start screen.

5) If the calibration does not pass, contact Matrix Customer

UP

or DOWN key until the display reads Calibration.

echnical Support at 866-693-4863 ext 3.

T

.

9

Page 12

CHAPTER 5: MANAGER MODE

5.1 MANAGER MODE OVERVIEW

1) To enter Manager Mode, press number key "ENTER, 1, 0, 0, 1, ENTER" on the number keypad. Manager Mode will appear on the display.

2) To scroll through the list of options in Manager Mode, use the UP and DOWN LEVEL keys. Each of the custom settings will show on the display.

3) To select a custom setting, press the ENTER key when the desired setting is shown.

4) To change the value of the setting, use the UP and DOWN LEVEL keys.

5) To confirm and save the value of the setting, press the ENTER key.

6) To exit the setting without saving, press the BACK key.

7) Press and hold the STOP key for 3-5 seconds to return to normal operation.

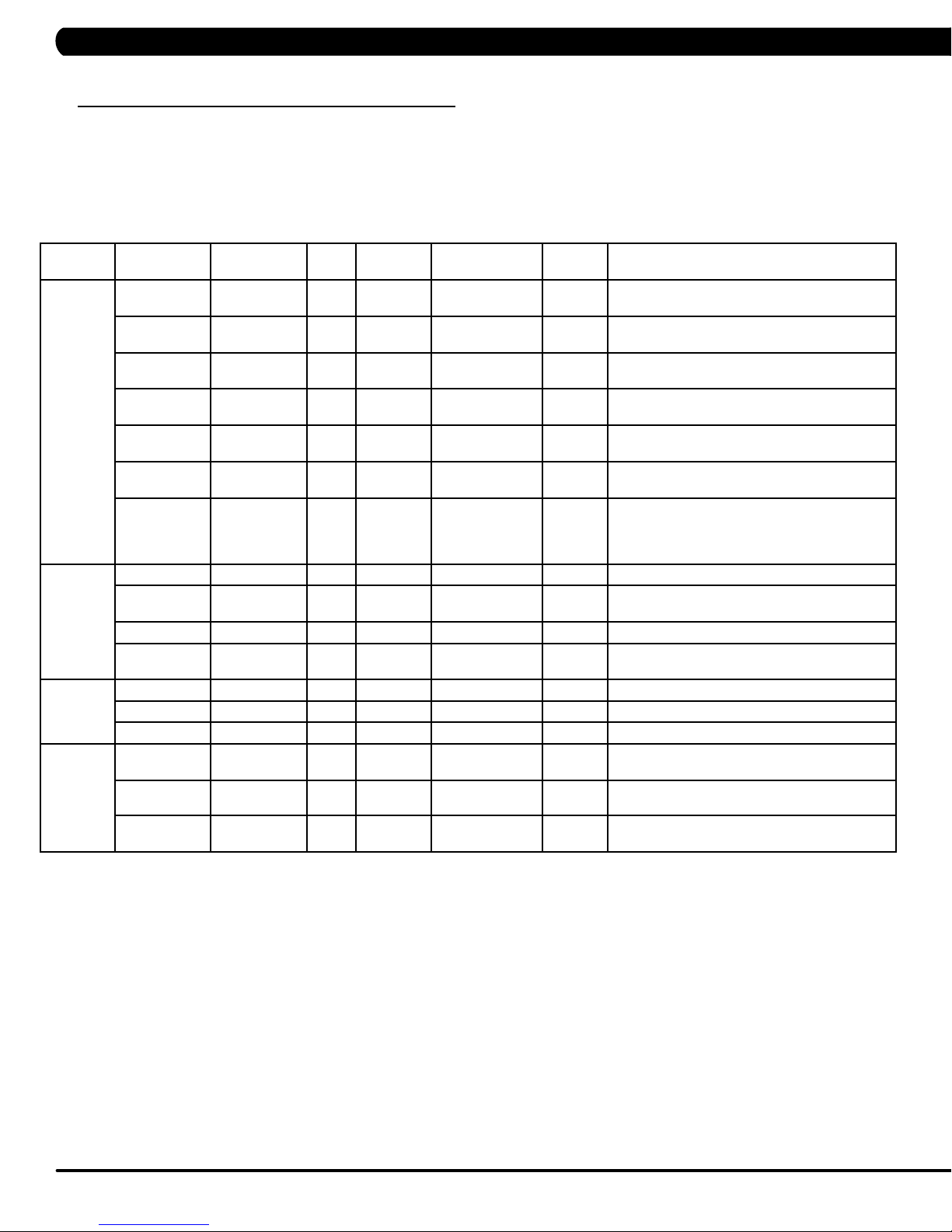

Group Model Item1 Item2 Default

Workouts THURESAC

THURESAC

THURESAC Default Level 1 1~10 Starting resistance when GO is pressed or when

THURESAC

C Maximum

T

T

User THURESAC

HURESAC

T

THURESAC

THURESAC

Data &

T

ime

Speed THURESAC Unit Standard Standard/Metric This option sets speed unit is standard (Mile) or

THURESAC

HURESAC

T

THURESAC Time Zone 21 1~78 This option sets the time zone (See Table 1).

T

Maximum

T

ime

Default T

Pause T

Level

HRT Speed

Based

NAVY Test Site 0 0/1 0: Test site elevation less than 5000 ft above

Age 30 10-100 This option controls the default user's age.

W

Default Height 72/ 83 36/91~96/244 Default height of user

Gender Male Male/Femal Determines the gender of the user when not

Data 2015/01/01 This option sets the current date of the machine.

T

Max. 12.0/20.0 2.0/3.2~15.0/24.1 mph/kph Controls the maximum speed for all programs.

ime 20 4~MAX Minutes Workout time when GO is pressed or when no

ime 5:00 0:30/1:00/2:00/

eight 150lb/

ime RTC time This option sets the current time of the machine.

Value

60 4~99 Minutes Sets the total run time of any program.

20 10~25 Set the level which is the max usable speed.

OFF ON/OFF This option allows the user to choose speed

68kg

Values/Range Unit Notes

time is selected during program set up.

no resistance is selected during program set up.

3:00/4:00/5:00

50lb/23kg ~

400lb/182kg

Minutes :

Second

This option controls the default pause time.

based target heart rate programs.

sea level.

1: Test site elevation greater than 5000 ft

above sea level.

This option controls the default weight.

selected during program set up.

Metric.

.

T

Start 0.5/0.8 0.5/0.8~1.4/2.3 mph/kph Controls the starting speed for all programs

10

(does not affect minimum speeds).

Page 13

CHAPTER 5: MANAGER MODE

5.1 MANAGER MODE OVERVIEW

1) To enter Manager Mode, press number key "ENTER, 1, 0, 0, 1, ENTER" on the number keypad. Manager Mode will appear on the display.

2) To scroll through the list of options in Manager Mode, use the UP and DOWN LEVEL keys. Each of the custom settings will show on the display.

3) To select a custom setting, press the ENTER key when the desired setting is shown.

4) To change the value of the setting, use the UP and DOWN LEVEL keys.

5) To confirm and save the value of the setting, press the ENTER key.

6) To exit the setting without saving, press the BACK key.

7) Press and hold the STOP key for 3-5 seconds to return to normal operation.

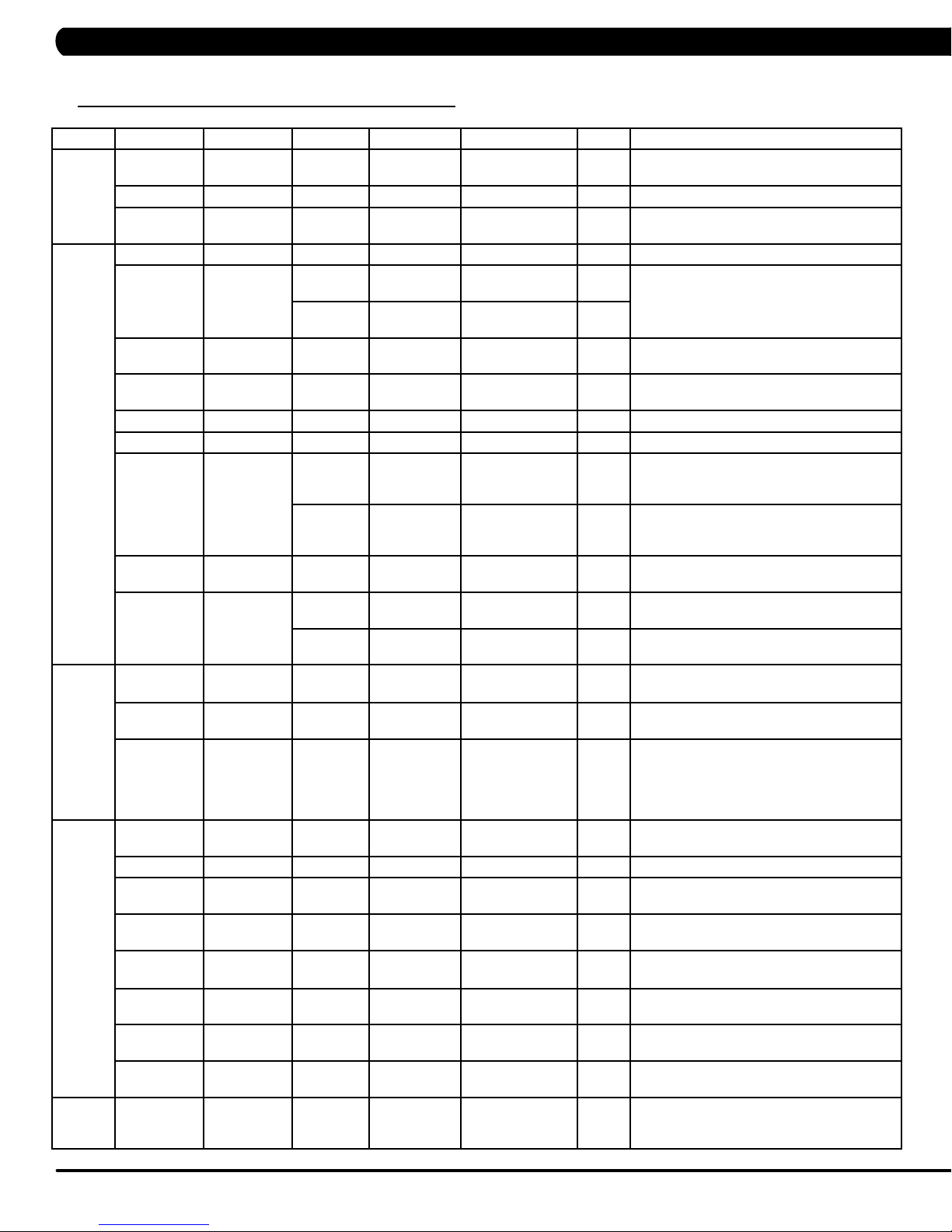

Group Model Item1 Item2 Default

Elevation TA Max 15% 0.0% ~ 15% Controls the high incline parameter.

A Default 0%

A Reset This is a software feature that resets machine

Software THURESAC Version UCB Current software version of UCB.

LCB-MCUB Current software version of LCB-MCUB.

LCB-MCUA

(option)

Language Sets the language for the console.

WiFi Current software version of WiFi.

Bootloader Current software version of bootloader.

THURESAC Update UCB UCB software update.

LCB-MCUB LCB-MCUB software update.

LCB-MCUA

(option)

Language Language software update.

General

Language

THURESAC Auto Update Disable/

THUREA Accumulate

HURESAC Accumulate

SC Accumulate

THURESAC Default

THURESAC Erase

Distance

T

ime

Floors

Language

EEPROM

Enable

Time 1:00 AM HH:MM Set time that software automatically updates.

Check

Update

Value

Enable

0 0~999999 Mile/KmT

0 0~999999

0 0~999999 F

English Sets the language for the console. Select between

Values/Range Unit Notes

0%~Max

H

loors Total floors for all programs. Hold UP and DOWN

Starting incline level at each program start.

elevation to 0 degrees

after 30 seconds of user inactivity. During incline

reset, movement

can be stopped by pressing any console key. The

display will scroll

"HOLD SELECT TO RESUME." To resume reset

to 0 degrees, hold

the SELECT key for 3 seconds.

Current software version of LCB-MCUA.

LCB-MCUA software update.

This

update function is Disabled or Enabled.

Manually check remote update. Auto updating

console software from DAPI if it has the latest

version.

otal distance for all programs. Hold UP and

DOWN LEVEL keys for 3 seconds to clear record.

ours Total time for all programs displayed in hours.Hold

UP and DOWN LEVEL keys for 3 seconds to clear

record.

LEVEL keys for 3 seconds to clear record.

English, Spanish, German, Italian,

French, Dutch, Portuguese Swedish, Finnish,

urkish and Polish.

T

Erase language data in EEPROM.

option controls whether the auto software

11

Page 14

CHAPTER 5: MANAGER MODE

5.1 MANAGER MODE OVERVIEW - CONTINUED

Group Model Item1 Item2 Default Value Values/Range Unit Notes

Logo THURESAC

T

HURESAC

T

HURESAC

Machine T

TV T

Internet THURESAC Enable/

ErP Thuresac Erp T

HURESAC Type This option selects the current model.

THURESAC Serial

THURESAC

T T

THURESAC

THURESAC

THURESAC

HURESAC

T

THURESAC Keypad Stuck

HURESAC

THURESAC

THURESAC

T

HURESAC

T

HURESAC

THURESAC

T

HURESAC

T

HURESAC

THURESAC

T

HURESAC

Default Logo M

Import Logo Import logo from USB to console.

Erase

EEPROM

Number

Out of Order OFF ON/OFF This option allows the club to show the unit

read Sensor 30 30/60/90/OFF Tread Sensor function for user’s existence

Speaker OFF ON/OFF Sets console speaker sound on / of

Beeper ON ON/OFF Sets console beeper sound on / of

Headphone

Jack

USB Port Protection Enable Enable/Disable

Power OFF ON/OFF OFF:

Input Source OFF OFF/TV/PCTV/

Default

Volume

Disable

MAC ID MAC ID data.

IP Automatically detects the available IP

MODE

AP

Signal

Strength

Export

setting

to USB

Import setting

from USB

Reset Reset internet connected data. SSID/

ime OFF OFF~ 30

Console Prefix+(Type)

Frame Prefix+(Type)

Notification Enable Enable/Disable

Times to

waring

Check

Notification Enable Enable/Disable

OFF ON/OFF Sets whether console wireless module is

ATRIX

+YYMM00000

+YYMM00000

30000 1000~1000000

Enable Enable/Disable

(Current

Status)

YY-MM-xxxxx Serial Number input is available for both the

YY-MM-xxxxx

TV/CAB

Remote

Disconnected/25%

/50%/75%/100%

(Minutes)

This

screen header from a list.

Erase all logo data in EEPROM

Console and Frame.

Type: B~Z (A not display).

"out of order" if an error is present.

detect.

This

Jack insertion times warning function is

disabled or enabled.

This

headphone Jack insertion times before

warning function displays.

This

protection is disabled or enabled.

This

check is disabled or enabled.

This

overlay error notification is disabled or enabled.

ON: Don't turn off TV power after reset

Sets the audio of the console to the type of TV

attached.

a. Input default (DF: 15/Range1~15)

b. Max (DF: 32/ Range: 1~32)

c. Output Default (DF: 13/Range:1~Max)

Remote TV support a/b/c item, others only

support c.

Sets whether the internet function (WiFi) is

disabled or enabled.

and displays it.

an access point (AP) or not.

This option shows the current WiFi signal

strength.

Export internet setting (WiFi) to USB.

Import internet (WiFi) setting from USB.

password Factory Default Restore.

Minute Console will enter ErP mode if user does not

touch the screen or press any key pad for

couple minutes.

option allows the user to select the

f.

f.

option controls whether the headphone

option controls the number of

option controls whether the USB port

option controls whether the keypad stuck

option controls whether the Keypad/

Turn off TV power after reset

address

12

Page 15

CHAPTER 5: MANAGER MODE

5.1 MANAGER MODE OVERVIEW - CONTINUED

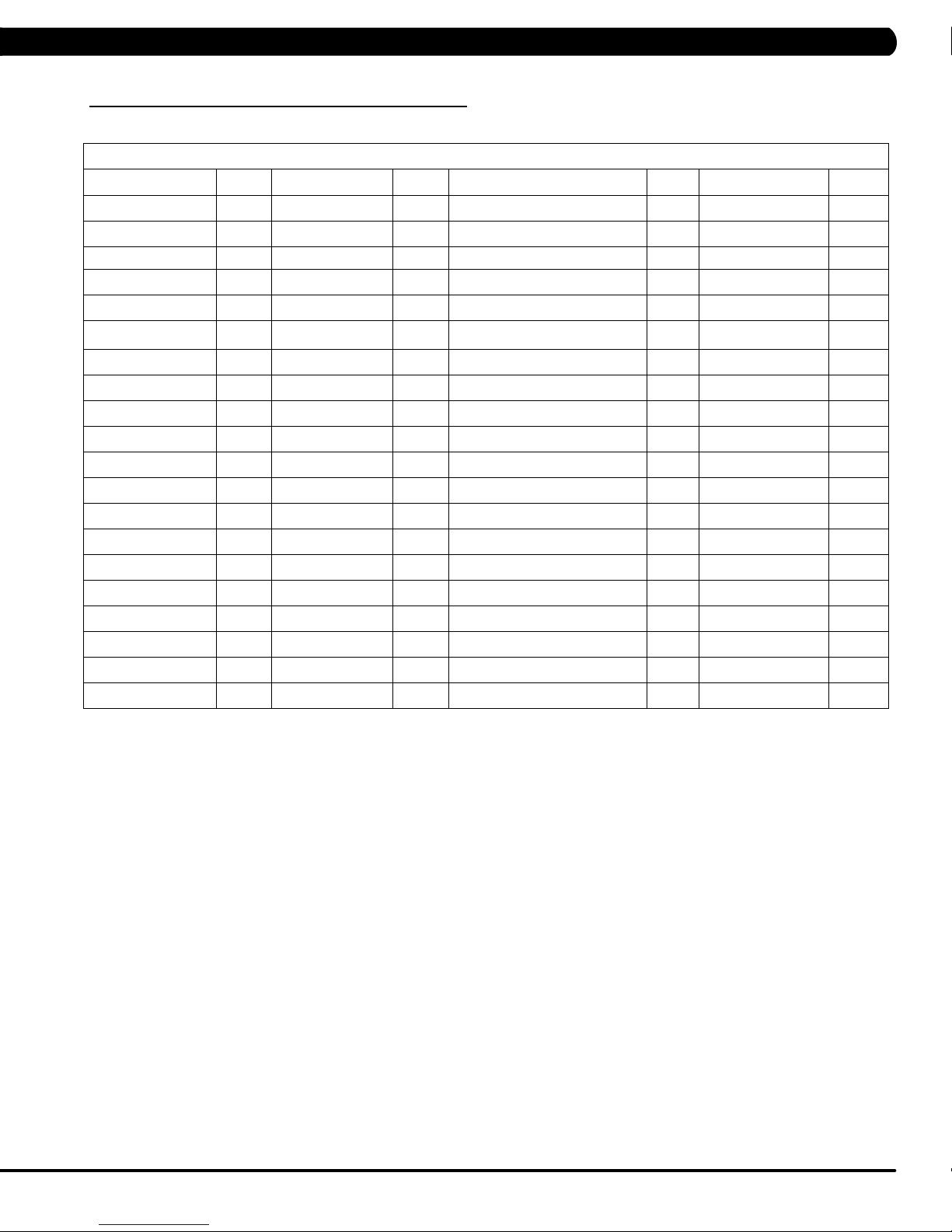

Table 1 - Time Zone list

Time Zone

Country Code Country Code Country Code Country Code

Asia/Kabul 1 America/Chicago 21 Asia/Jerusalem 41 Pacific/Apia 61

America/Anchorage 2 America/Monterrey 22 Asia/Seoul 42 Asia/Bangkok 62

Asia/Kuwait 3 Asia/Shanghai 23 Atlantic/South Georgia 43 Asia/Singapore 63

Asia/Muscat 4 Africa/Nairobi 24 America/Denver 44 Africa/Harare 64

Asia/Baghdad 5 Australia/Brisbane 25 America/Chihuahua 45 Asia/Colombo 65

America/Halifax 6 Europe/Minsk 26 Asia/Rangoon 46 Asia/Taipei 66

Australia/Darwin 7 America/Sao Paulo 27 Asia/Novosibirsk 47 Australia/Hobart 67

Australia/Sydney 8 America/New York 28 Africa/Windhoek 48 Asia/Tokyo 68

Asia/Baku 9 Africa/Cairo 29 Asia/Kathmandu 49 Pacific/Tongatapu 69

Atlantic/Azores 10 Asia/Yekaterinburg 30 Pacific/Auckland 50 America/Indianapolis 70

America/Edmonton 11 Pacific/Fiji 31 America/St Johns 51 America/Phoenix 71

Atlantic/Cape Verde 12 Europe/Riga 32 Asia/Irkutsk 52 Asia/Vladivostok 72

Asia/Yerevan 13 Asia/Tbilisi 33 Asia/Krasnoyarsk 53 Australia/Perth 73

Australia/Adelaide 14 Europe/London 34 America/Santiago 54 Africa/Lagos 74

America/Costa Rica 15 America/Godthab 35 America/Tijuana 55 Europe/Berlin 75

Asia/Almaty 16 Africa/Monrovia 36 Europe/Paris 56 Asia/Tashkent 76

America/Cuiaba 17 Europe/Istanbul 37 Europe/Moscow 57 Pacific/Guam 77

Europe/Belgrade 18 Pacific/Honolulu 38 America/Argentina/Buenos Aires 58 Asia/Yakutsk 78

Europe/Belgrade 19 Asia/Calcutta 39 America/Bogota 59

Pacific/Guadalcanal 20 Asia/Tehran 40 America/La Paz 60

13

Page 16

CHAPTER 6: ENGINEERING MODE

6.1 ENGINEERING MODE OVERVIEW

1) To enter Engineering Mode, press number key "ENTER, 2, 0, 0, 1, ENTER" on the number keypad. Engineer Mode will appear on the

display

.

2)

To scroll through the list of options in Engineering Mode, use the UP and DOWN LEVEL

display.

T

o select a custom setting, press the ENTER key when the desired setting is shown.

3)

To change the value of the setting, use the UP and DOWN LEVEL keys.

4)

5) To confirm and save the value of the setting, press the ENTER key

6)

To exit the setting without saving, press the BACK key

7) Press and hold the ST

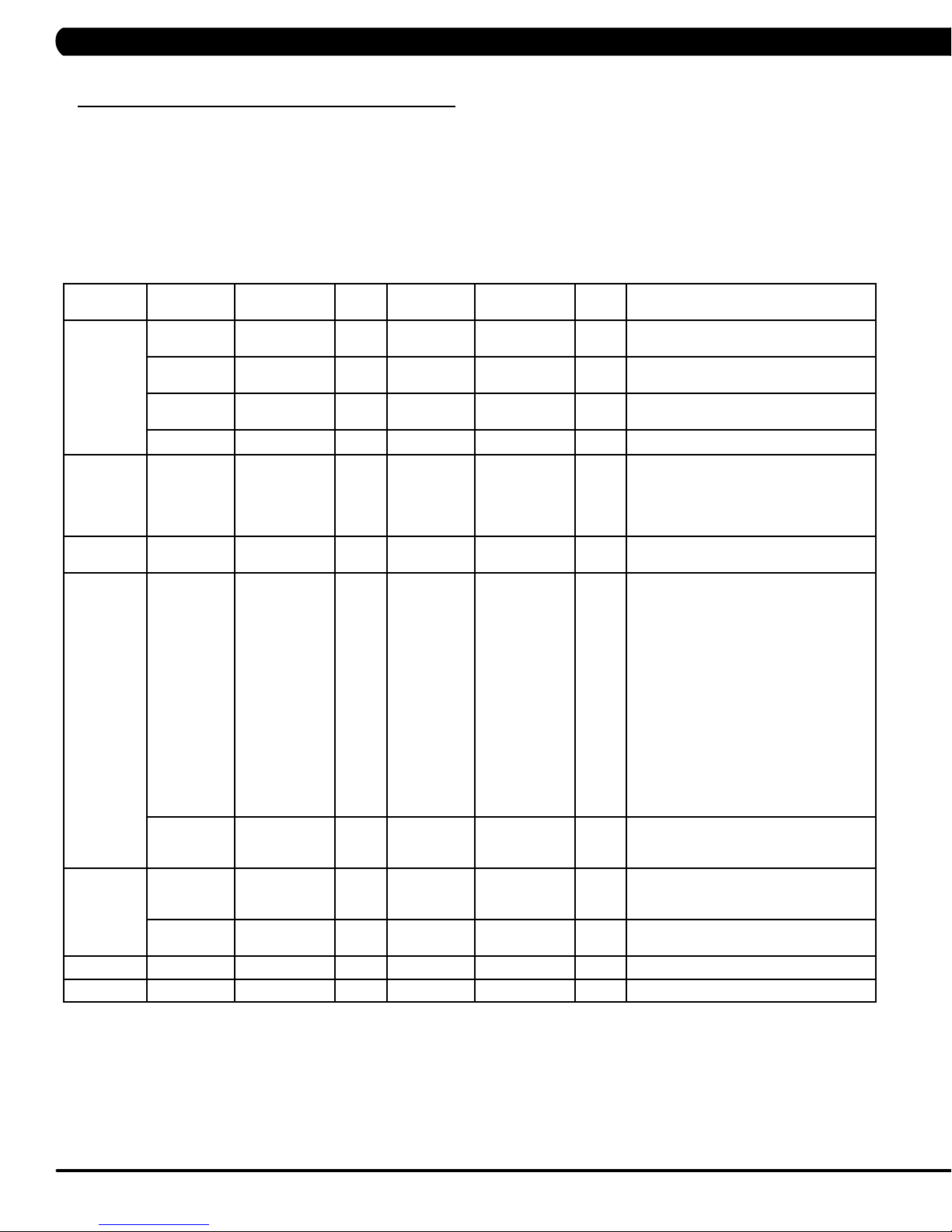

Group Model Item1 Item2 Default Value Values/Range Unit Notes

OP key for 3-5 seconds to return to normal operation.

.

.

keys. Each of the custom settings will show on the

Calibration

Running

Test

Error Codes THURESAC Disable/Enable Enable Disable/Enable This option displays the error code history

DAPI

Safety C Setting 100 4~500 This option controls the safety threshold

Back Up

Motor T Type 0~2 This option selects the frame motor type

TA Auto

T Elevation Min This option controls the minimum elevation

T Elevation Max This option controls the maximum

A Elevation Tuner Original Incline Tuner of A5x

T This option allows installers to do the belt

THURESAC Server Production Dev/

THURESAC SSL ON ON/OFF This option controls the internet

C Switch ON->5

THURESAC To backup current software into EEPROM.

Calibration

X,

OFF->3X

QA/

Staging/

Production

ON/OFF The function of control zone is enabled or

This option is to calibrate the elevation

parameters.

parameter

elevation parameter

adjustment and test. Also this function will

not stop until press Stop or

exit the mode, it will provide customer for

demonstration and other functions.

on the unit.

Dev

unsecure domain: dev

SSL domain: dev-dls.jfit.co port: 443

QA

unsecure domain: qa.dls.jfit.co port: 80

SSL domain: qa-dls.jfit.co port 443

Staging

unsecure domain: staging.dls.jfit.co port:

80

SSL domain: staging-dls.jfit.co port 443

Production

unsecure domain: dapi-ls.jfit.co port: 80

SSL domain: dapi-ls.jfit.co port: 443

transmission with SSL

Layer) or not.

for the E-Stop function. of old control zone

(capacitance sensor).

disabled.

.

.

.dls.jfit.co port: 80

(Secure Sockets

14

Page 17

CHAPTER 7: SERVICE MODE/TEST MODE

7.1 SERVICE MODE OVERVIEW

1) To enter Service Mode, press number key "ENTER, 3, 0, 0, 1, ENTER" on the number keypad. Engineer Mode will appear on the display.

2) To scroll through the list of options in Service Mode, use the UP and DOWN LEVEL keys. Each of the custom settings will show on the

display.

3) To select a custom setting, press the ENTER key when the desired setting is shown.

4) To change the value of the setting, use the UP and DOWN LEVEL keys.

5) To confirm and save the value of the setting, press the ENTER key.

6) To exit the setting without saving, press the BACK key.

Press and hold the STOP

7)

Group Model Item1 Item2 Default Value Values/Range Unit Notes

Accumulate

Log

Configuration

Factory Default

Asset

management

xID Login

THURESAC Distance Current value 0~999999 Mile/KmManually sets the Accumulated

THURESAC Time Current value 0~999999

SC Floors Current value 0~999999 Manually sets the Accumulated

THURESAC Error Display Error1~Error10

THURESAC Export to USB Export engineer parameters to

THURESAC Reset NO NO-YES Reset engineering default

THURESAC Disable/Enable Disable Disable/Enable

THURESAC Enable/Disable Disable Disable/Enable

key for 3-5 seconds to return to normal operation.

Distance.

Hour Manually sets the Accumulated

Time.

Floors.

/ None

Reset

Headphone Jack

Sensor

Import from USB Import engineer parameters

Club ID This option records the club ID

RFID link RFID card links with xID login

Insert Counts Current Value 0~999999

Reset NO NO-YES Reset headphone insert

NO NO-YES

Shows the last 10 errors.

Reset error log.

Insert headphone jack counts.

counts.

a USB device.

from a USB device.

to factory value.

This option controls

whether the AM function

is Disabled or Enabled.

of the fitness facility.

This option controls whether

the xID login function is

Disabled or Enabled.

data.

15

Page 18

CHAPTER 7: SERVICE MODE/TEST MODE

7.2 TEST MODE OVERVIEW

1) To enter Test Mode, press number key "ENTER, 5, 0, 0, 1, ENTER" on the number keypad. Engineer Mode will appear on the display.

2)

To scroll through the list of options in Test Mode, use the UP and DOWN LEVEL keys. Each of the custom settings will show on the display

o select a custom setting, press the ENTER key when the desired setting is shown.

3)

T

4)

To change the value of the setting, use the UP and DOWN LEVEL

To confirm and save the value of the setting, press the ENTER key

5)

To exit the setting without saving, press the BACK key.

6)

7) Press and hold the STOP key for 3-5 seconds to return to normal operation.

keys.

.

.

Group Model Item1 Item2 Default

Display

Keypad

C-SAFE

Headphone Jack

RFID Test

rP THURESAC

E

IR Frequency

CZ

THURESAC P

THURESAC Press any key and the display should

THURESAC P

THURESAC P

THURESAC Press the ENTER key to test RFID

Auto/5/10/30/60 Second Press the ENTER key and choice ErP

C Press the ENTER key to test IR sensor

Value

Values/

Range

Unit Notes

ress the ENTER key repeatedly to

check each set of LEDs on the display

sequentially.

show the corresponding message.

ress the ENTER key to test CSAFE.

ress the ENTER key to test the insert

headphone jack counts.

hardware and RFID card scan.

time to test ErP function.

frequency of control zone.

16

Page 19

CHAPTER 8: TROUBLESHOOTING

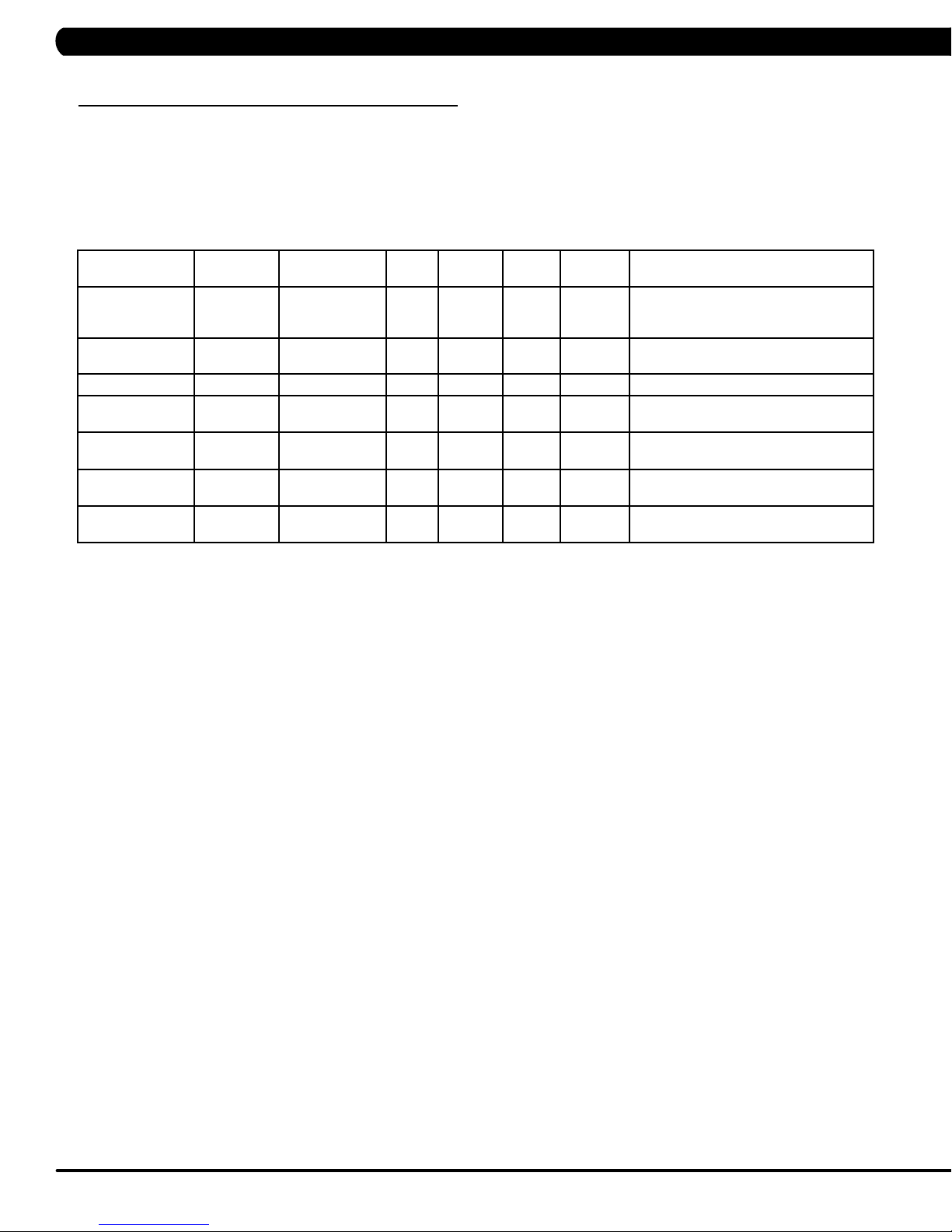

8.1 ELECTRICAL DIAGRAMS

HURES5X-05/A5X-06-C ELECTRICAL BLOCK DIAGRAM

17

Page 20

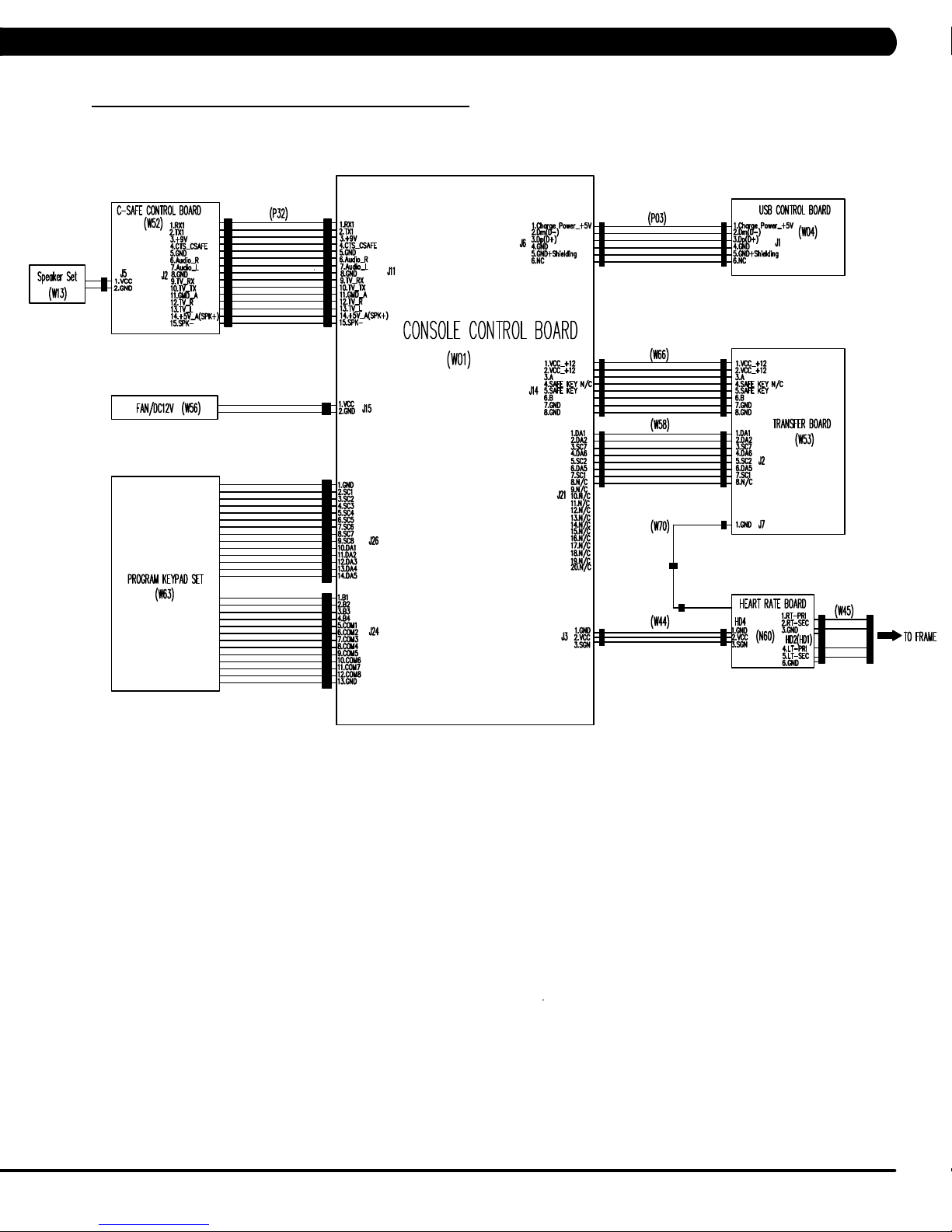

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

C5X-03-C ELECTRICAL BLOCK DIAGRAM

18

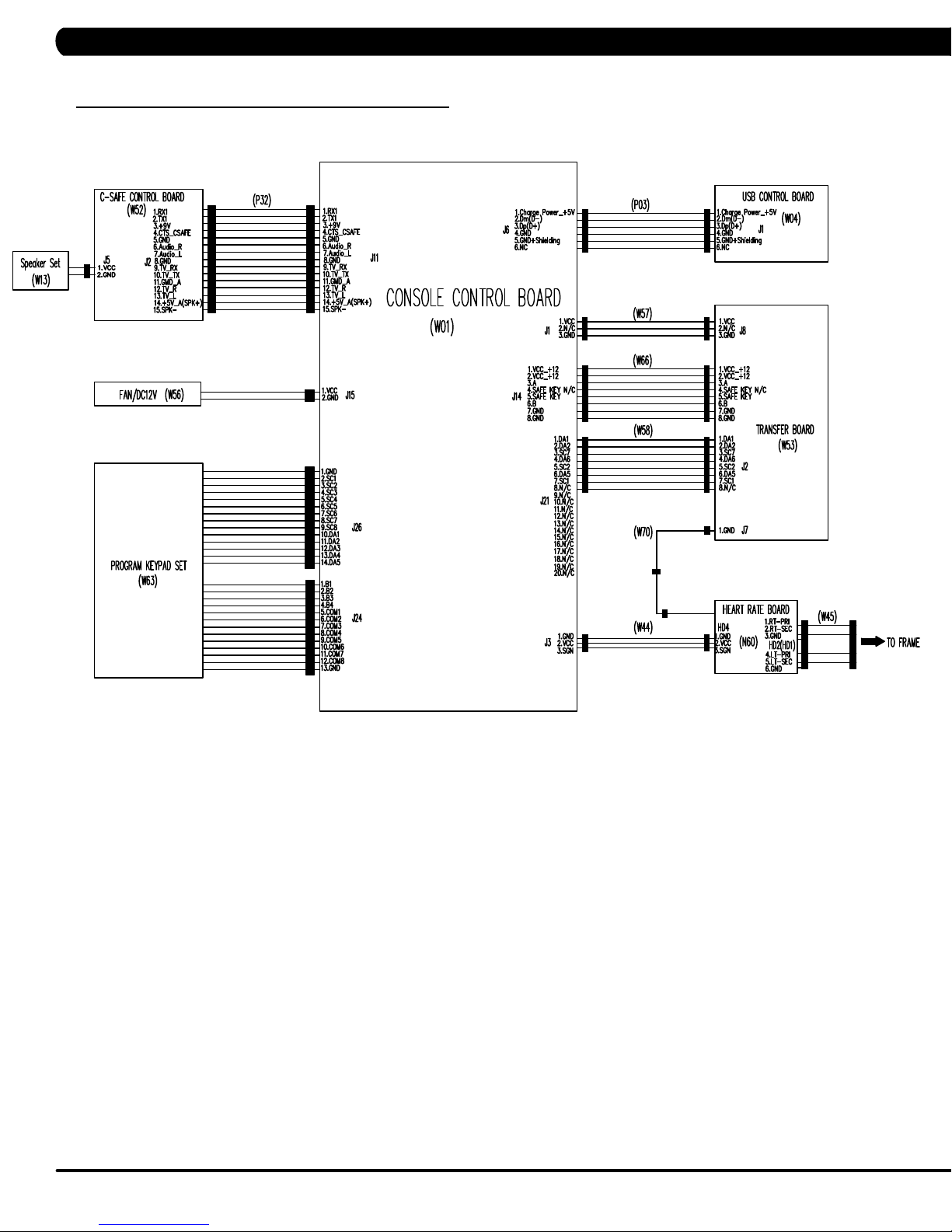

Page 21

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS

T5X-08-C ELECTRICAL BLOCK DIAGRAM

19

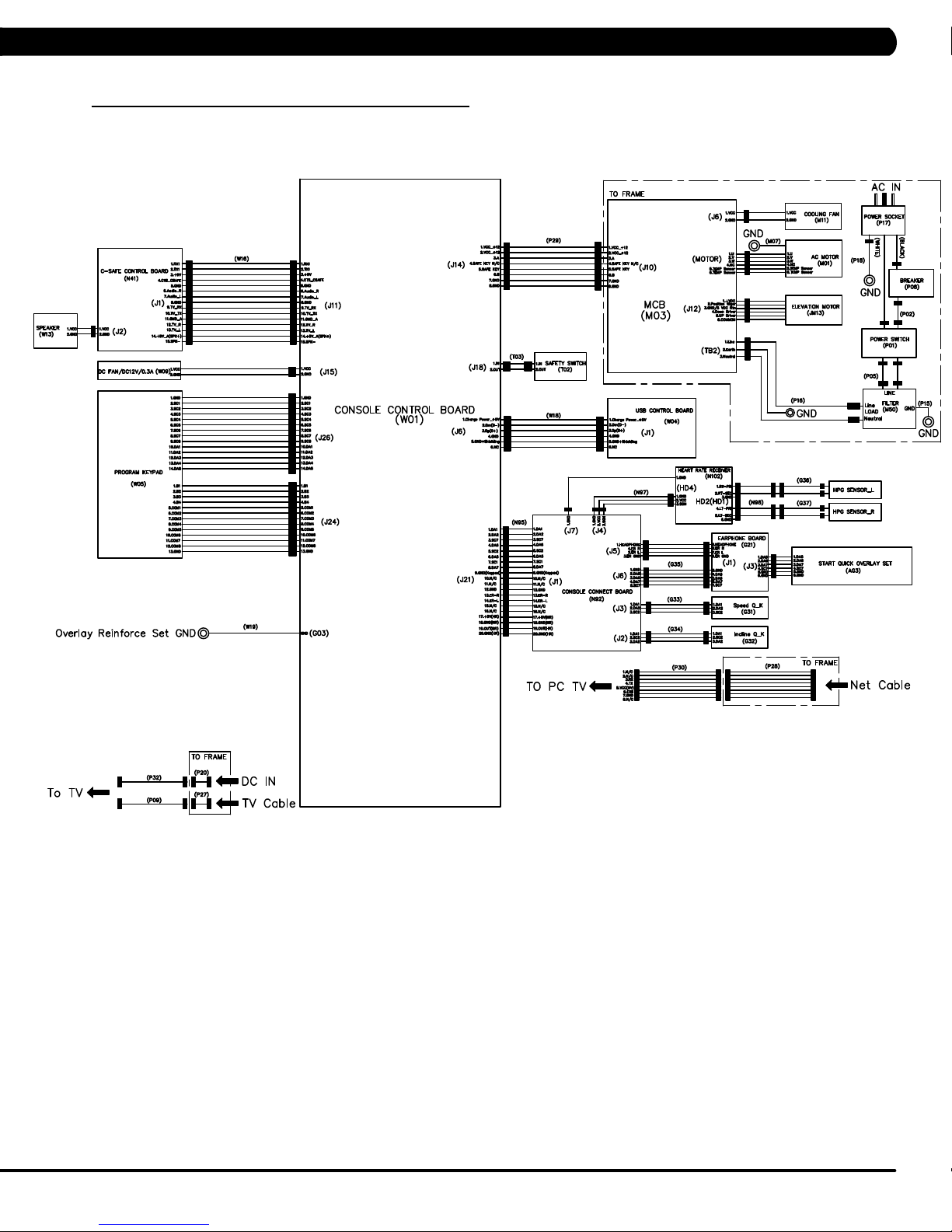

Page 22

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

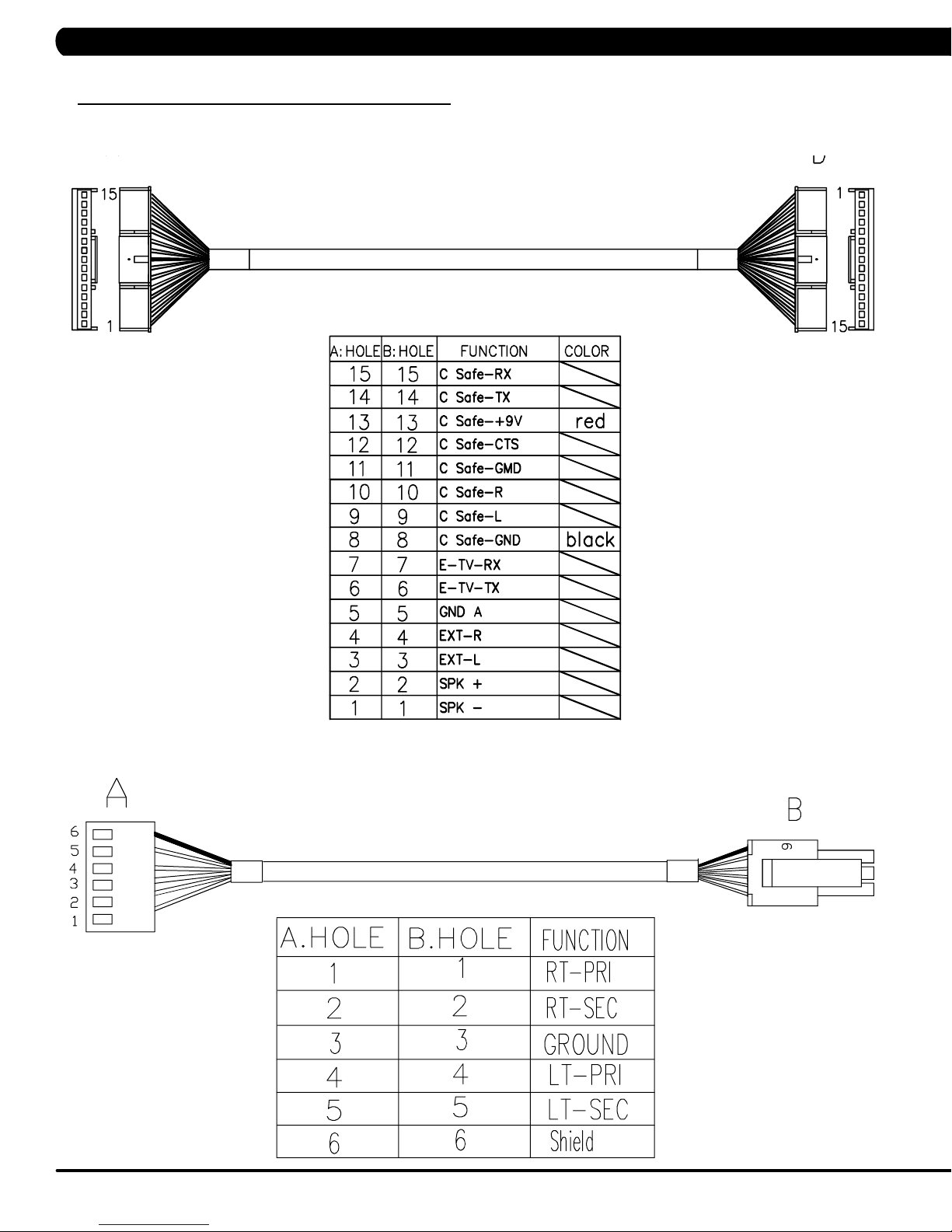

C-SAFE+TV CONNECT WIRE (HURESAC5X-C)

HAND PULSE WIRE (HURESAC5X-C)

20

Page 23

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

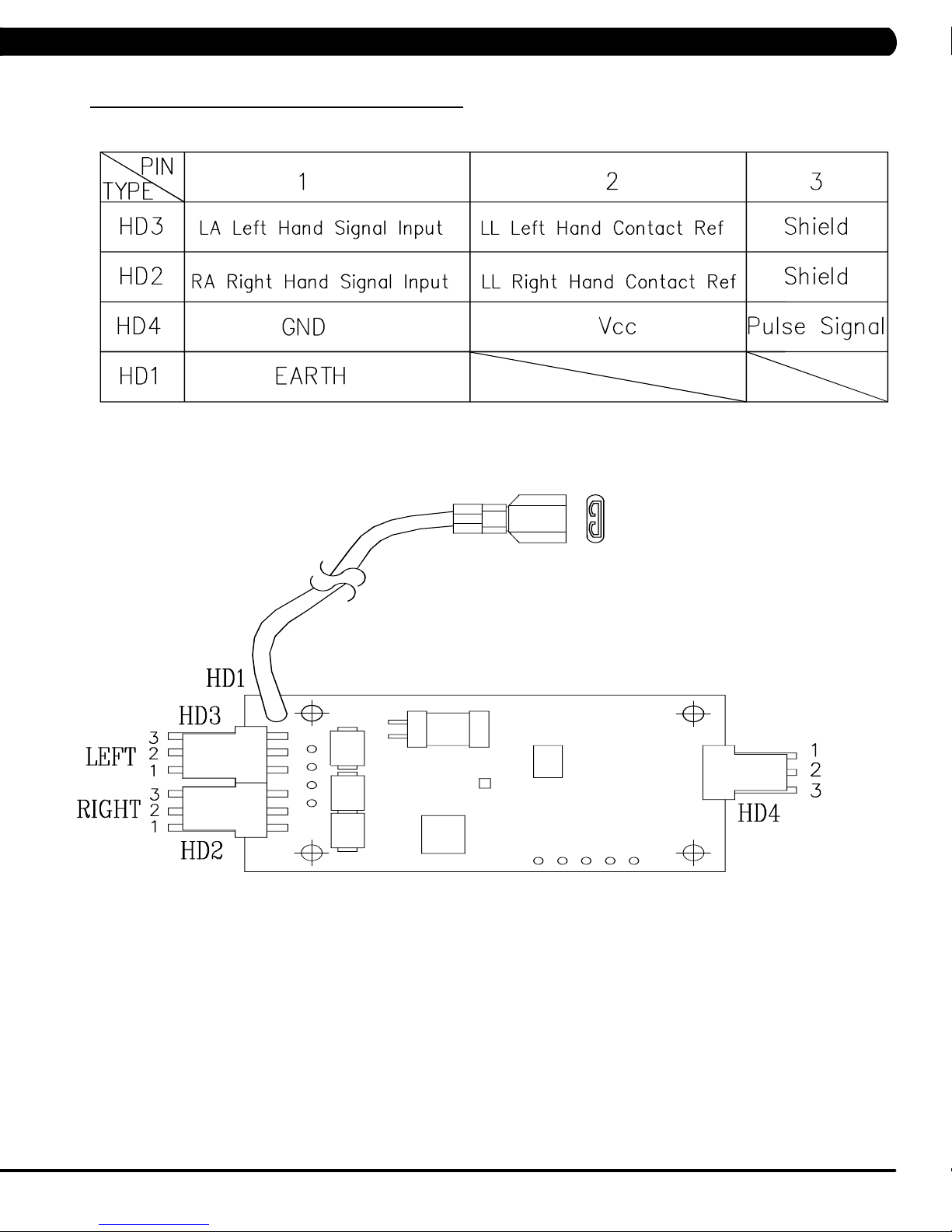

PULSE BOARD SET (HURESAC5TX-C)

21

Page 24

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

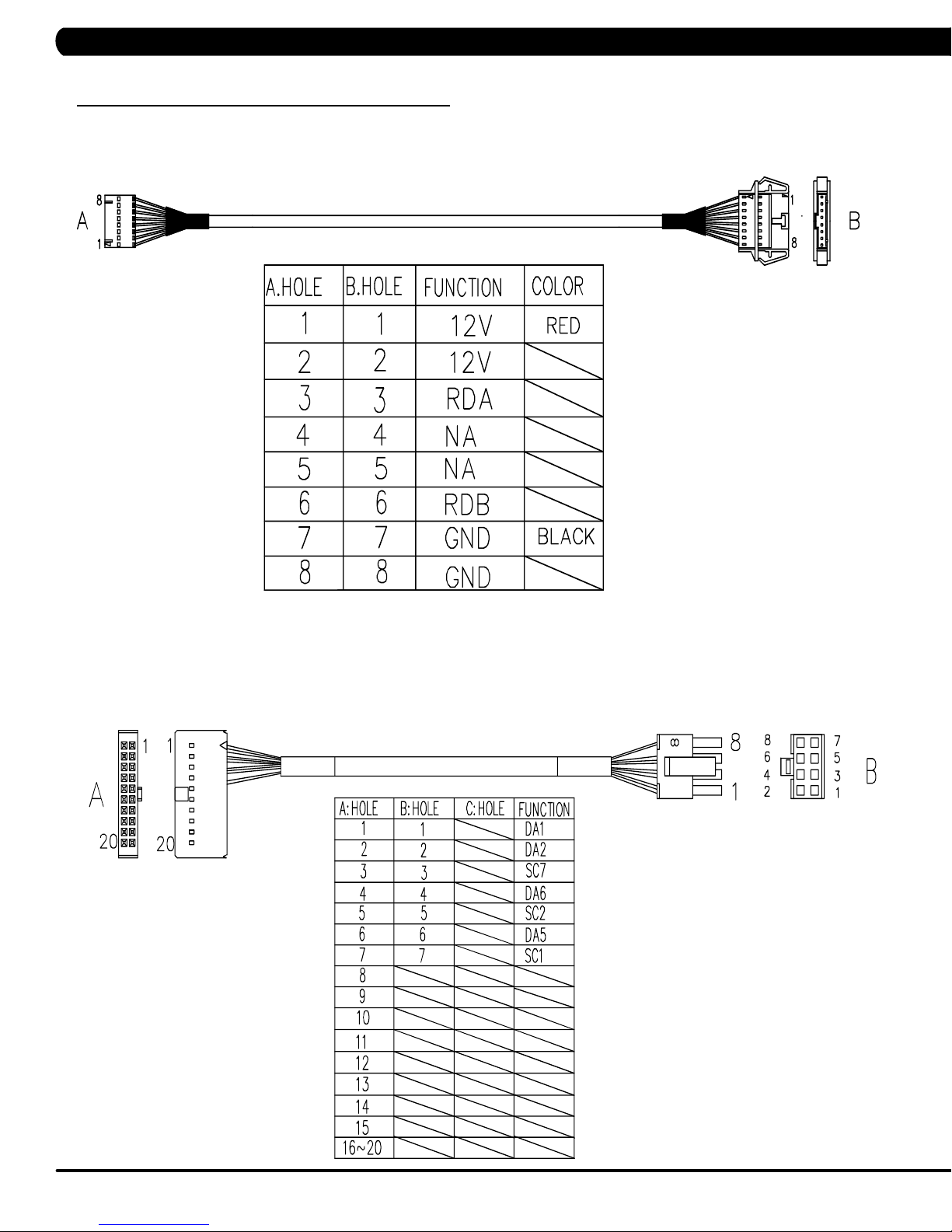

DIGITAL COMM WIRE (HURESAC5X-C)

QUICKLY KEY SET (HURESAC3X-C)

22

Page 25

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

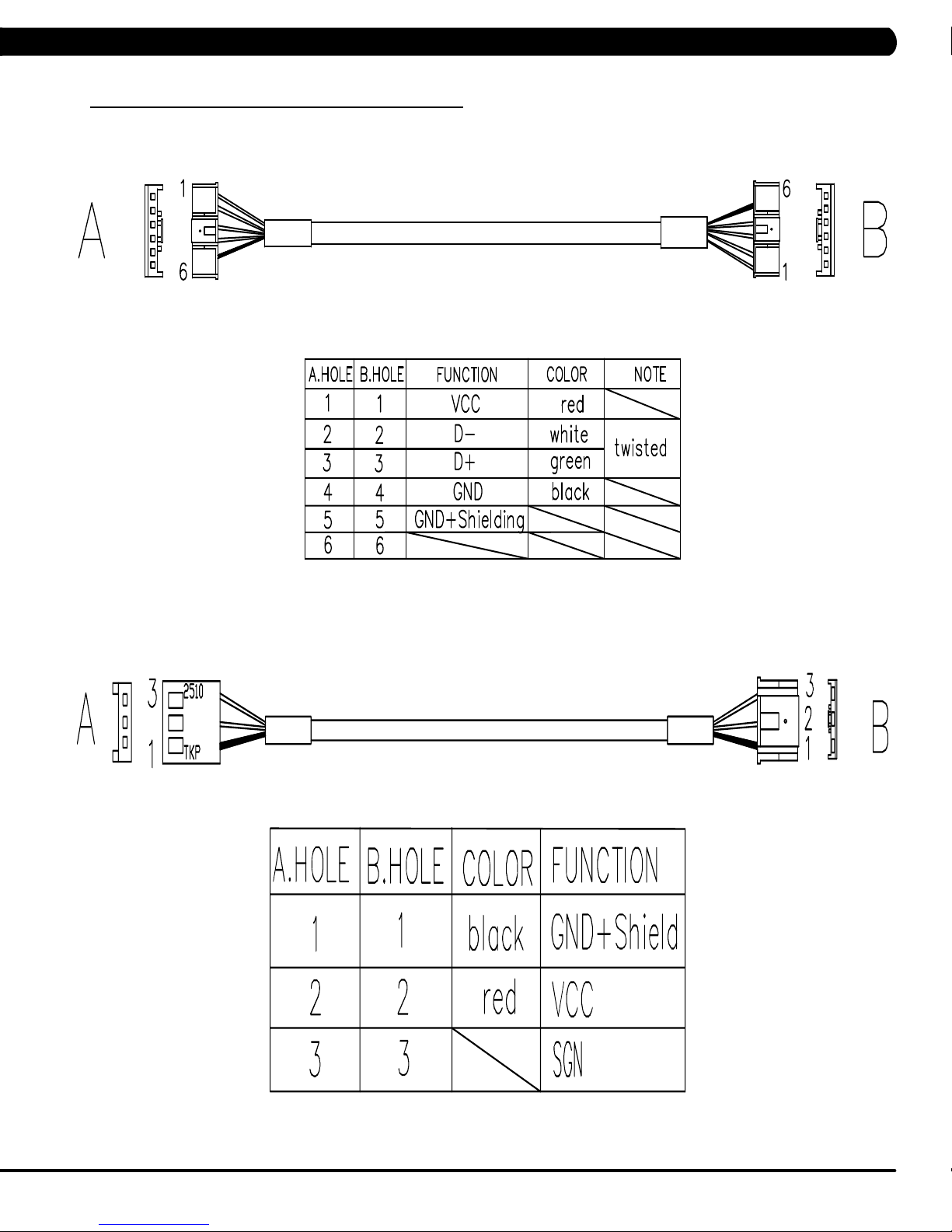

USB WIRE (HURESAC5X-C)

HEART RATE POWER WIRE (HURESAC5X-C)

23

Page 26

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

PROGRAM KEYPAD (HURESA5X-C)

24

Page 27

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

PROGRAM KEYPAD (C5X-C)

25

Page 28

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

POWER WIRE (C5X-C)

UCB LITTLE BOARD WIRE (T5X-C)

26

Page 29

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

PROGRAM KEYPAD- T5X

27

Page 30

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

HAND PULSE SENSOR WIRE- T5X

SAFETY SWITCH WIRE- T5X

28

Page 31

CHAPTER 8: TROUBLESHOOTING

8.1 ELECTRICAL DIAGRAMS - CONTINUED

USB WIRE- T5X

29

Page 32

CHAPTER 8: TROUBLESHOOTING

8.2 ERROR CODES LIST

CODE CLASS DESCRIPTION MACHINE SOLUTION

It occurs when the calibration time is too long or the calibration distance is too

a.

short.

01A1 C Incline calibration error A

01A3 C Motor is disconnected T

01A8 C Main motor over current T

01AC C

01AF C

01B4 C

014A

(01AE)

0140 B Incline motor operation fail A

0141 B Motor over temperature T

0144 B Motor over current T

Electro magnet (ECB) over

current.

Electro magnet (ECB) dis

connected.

Resistance disconnect A

Electro magnet (ECB) disconnected.

Battery connection reverse

protection.

LCB charge current is

B

abnormal

-

HUR

C

HUR

C

AHUR

AHUR

b. Don’t fix the incline motor tube then turn on the power.

- If the console still shows 01A1, please replace incline motor.

- If auto calibration is finished, please follow the incline motor installation

SOP

c. Replace LCB.

a. Check the connection of the motor cable at the MCB.

b. Check the MCB LED DSP1 (MCU):

a.

Check the condition of the running deck and belt. Replace the belt and flip or

replace the running deck as needed.

Replace the MCB.

b.

a.

Check if the Electro-magnet is short circuited or open.

b. If the resistance data shows a short/open ohms or is outside the range of 12.8

~14.2 ohms, replace the Electro-magnet.

If the resistance data is in the range between 12.8 ~14.2 ohms, replace the LCB.

c.

On standby mode, measure the resistance on ECB1 and ECB2. Please check the

a.

ECB extension cable connection at the LCB (pins 1 & 3 for ECB1, pins 2 & 4 for

ECB2), there should be between 12.8 ~ 14.2 ohms.

-

-

Check the gap of ECB1 and ECB2. There should be a gap of .5mm between the

b.

ECB and the flywheel.

a.

Check if the Electro-magnet is short circuited or open.

b. If the resistance data shows a short/open ohms or is outside the range of 12.8

~14.2 ohms, replace the Electro-magnet.

If the resistance data is in the range between 12.8 ~14.2 ohms, replace the LCB.

c.

a.

Check if the resistance is short circuit.

- If resistance data is under 10 ohms, please replace power resistance.

- If resistance data is over 10 ohms, please replace LCB.

a.

Check the connection of the ECB extension cable from the LCB to the ECB.

Check to see if LED8 and LED10 on the LCB have a brief light for 3 second when

b.

you power on machine.

If the ECB resistance is within the range, replace the LCB.

c.

Check the battery wire connection between the battery and LCB.

a.

b. Check the battery voltage.

- If there is no data on voltage, replace the battery.

- If there is data on voltage, replace the LCB.

a. Replace LCB.

a. Please run A

b. If the error code happens in Auto Calibration, the machine still can work, no need

to do anything.

c. If the error code happens in workout, please replace the incline motor.

a.

Check the connection of the motor cable at the MCB.

b. Use a multi-meter to check the motor wire circuit. Set the multi-meter to Ohms

and place both terminals on the blue wires of the motor cable.

-

-

a.

Check the condition of the running deck and belt. Replace the belt and flip or

replace the running deck as needed.

b. Replace the MCB.

to fix incline motor

- If LED DSP1 is blinking or

- If LED DSP1 is not lit, replace the MCB.

If the ECB resistance is out of the range, replace the ECB.

If the ECB resistance is within the range, replace the LCB.

If LED8 and LED10 do not have a brief light, replace the LCB.

If LED8 and LED10 do have a brief light, check the ECB extension cable

connection at the LCB (pins 1 & 3 for ECB1, pins 2 & 4 for ECB2), there

should be between 12.8 ~ 14.2 ohms.

If the ECB resistance is out of the range, replace the ECB.

-

uto Calibration.

If there is an Ohm reading above 0, replace the motor

If the Ohm reading is 0, replace the MCB.

.

solid light, replace the motor

.

30

Page 33

CHAPTER 8: TROUBLESHOOTING

8.2 ERROR CODES LIST

CODE CLASS DESCRIPTION MACHINE SOLUTION

a. Please check the incline motor wire connection between the incline

and LCB.

A

0147 B Incline motor disconnection

T

0148

(01A7)

0149 B

02AB C Machine type error. ESHURA

02AD C MCB is over temperature T

02A0 C Encoder error C

02A2 C Over DC bus voltage T

02A3 C

02A7 C

02BA C

02BB C

02BC C

02BD C

02BE C DC brake error. C

02BF C DC brake Over Current C

B Incline motor over current. A

The resistance current is

over

Low AC power input voltage

when motor running

over I rms of phase current

of motor

The inner memory IC data

read error.

Inverter hardware interrupts

error.

Ground connection or fuse

error

Drive hardware interrupt

error.

A

T

T

T

T

T

T

b. Please check the incline motor VR if there’s data.

- If there’s no data, replace the incline.

- If there’s data, replace the LCB.

a. Please check the incline motor wire connection between the incline

and MCB.

b. Run auto calibration.

c. If the issue is not solved by replacing the incline motor.

a. Don’t fix the incline motor tube then turn on the power.

- If the console still shows error, please replace incline motor.

- If the console does not show error, please follow the incline

motor installation SOP to fix incline motor.

b. Replace LCB.

a. Please check if the resistance is short circuit.

- If resistance data is under 10 ohms, please replace power

resistance.

- If resistance data is over 10 ohms, please replace LCB.

a. Change the machine type on the console to match the correct

frame

a. Check if that both fans are operating (there is a fan mounted to the

MCB itself as well as an external fan). Also check the connection

of the fans at the MCB.

b. If the fans are running correctly, replace the MCB.

a. Check the connection of the speed sensor cable from the LCB to

the speed sensor.

b. Check to see if LED D35 on the LCB is on when the brake is

turned to the left release position.

c. If LED D35 is off, move the stairs about 3 stairs and check to see

if LED D35 is flashing.

- If not, replace the speed sensor.

- If yes, adjust the speed sensor position and clean the speed

sensor of any debris then re-test.

a. Please check if the input power is normal(110V : over 140V/ 220V:

over 280V)

b. Replace the MCB.

a. Please check if the input power is normal(110V : low 76V/ 220V:

low 186V)

b. Replace the MCB.

a. Please check the Motor wire connection between the Motor and

MCB.

b. Please use the electric meter to check the 3 points (U/V/W) and

see if there’s data of inside impedance.

- If yes, replace MCB.

- If no, replace Motor set.

a. Reboot power, if error shows again, replace the MCB.

b. Reboot power, if error shows again, replace the MCB.

a. Check the Motor wire (3 points U/V/W) and ground wire whether

short

b. Replace the MCB.

a. Replace MCB.

a. Check the power extend wire connection between the brake and

LCB for any damage.

b. Check to see if the stairs will move when you are in the stop posi-

tion. If yes, replace the brake.

a. Check the power extend wire connection between the brake and

LCB for any damage.

b. Check to see if the stairs will move when you are in the stop posi-

tion. If yes, replace the brake.

31

Page 34

CHAPTER 8: TROUBLESHOOTING

8.2 ERROR CODES LIST - CONTINUED

CODE CLASS DESCRIPTION MACHINE SOLUTION

a. Check the connection of the safety key (emergency stop) switch. If the

02B2 C Safe key action response T

02B4 C Resistance Type Error. ESHURA

02B5 C

02B6 C Speed up have over current. T

02B7 C Speed down is overcurrent. T

02B8 C Running status is overcurrent T

02B9 C

02C0 C DC brake in manual mode. C

02C1 C Speed tracking error C

02C2 C

02C3 C Frame IR sensor error C

02C4 C

02C5 C

02C6 C

02C7 C

0201 A LCB battery low voltage. ESA a. Plug in the machine to charge battery for 24 hours.

0247 B LCB fail ESHURA a. Replace LCB.

0248 B

Inverter sensor the normal

rated current over 150% ,

can hold 60 sec.

The inner memory IC data

write error.

CZ 3IR sensors have no

communication or disconnected over 3 seconds.

The frequency error form

control zone.

The frequency error for frame

IR sensor.

The receiver disconnection

for control zone.

The receiver disconnection

for frame IR sensor

Battery disconnection or

fail ( LCB battery voltage is

less than 6 volts ).

T

T

C

C

C

C

C

ESHURA

switch is always open or shorted out, replace the switch.

b. If the emergency stop does not resolve the issue, replace the

a. Make sure machine type is set for the correct frame in console.

- If yes, replace LCB.

- If no, change to correct type and reboot the power.

a. Replace MCB.

a. Check the condition of the running deck and belt. Replace the belt and

flip or replace the running deck as needed.

b. Replace the MCB.

a. Check the condition of the running deck and belt. Replace the belt and

flip or replace the running deck as needed.

b. Replace the MCB.

a. Check the condition of the running deck and belt. Replace the belt and

flip or replace the running deck as needed.

b. Replace the MCB.

a. Reboot power, if error shows again, replace the MCB.

a. Check if the DC brake is in the Right “lock" position. Release the brake

(move to the left) if in lock position.

b. Replace the brake.

a. Adjust the speed sensor position and clean the speed sensor of any

debris.

b. Check the ECB extension cable connection at the LCB (pins 1 & 3

for ECB1, pins 2 & 4 for ECB2), there should be between 12.8 ~ 14.2

ohms, check which ECB is outside the range and replace it.

a. Check if there’s something blocking the control zone 3 IR sensors.

b. Check if the control zone 3IR sensors (transmitter and receiver) are

aligned.

c. Check the connection of the control zone extension cable from the

transmission board to the receiver board.

d. Replace the transmission board or control zone extension cable as

needed.

a. Check if there’s something blocking the frame IR sensors.

b. Check if the frame IR sensors (transmitter and receiver) are aligned.

c. Check the connection of the frame IR transmitter cable from the LCB

to the frame IR transmitter sensors.

d. Replace the frame IR transmitter cable if the cable is defective.

a. Replace the control zone transmission board or receiver board.

a. Replace LCB

a. Check the connection of the control zone extension cable from the

LCB to the control zone.

b. Replace the receiver board.

a. Check the connection of the frame IR receiver cable from the LCB to

the frame IR receiver sensor.

b. Replace the frame IR receiver cable.

a. Check battery wire connection to LCB.

b. Check to see if the battery voltage is less than 6 volt.

- If less than 6 volt, replace battery.

- If not, replace LCB.

UCB.

32

Page 35

CHAPTER 8: TROUBLESHOOTING

8.2 ERROR CODES LIST - CONTINUED

CODE CLASS DESCRIPTION MACHINE SOLUTION

03A5 C Failed to load program Console a. Replace

03A6 C Failed to run program Console a. Replace UCB

03A8 C Machine type error ESHURACT

0301 A Memory block damage Console a. Enter the Engineer mode disable B Level Error, by pass

0302 A UCB low battery voltage Console a. Enter the Engineer mode disable B Level Error, by pass

0303 A UCB low supply voltage Console a. Enter the Engineer mode disable B Level Error, by pass

0304 A Earphone Board Need

0305 A USB Hardware OT or OC Console a. Enter the Engineer mode disable B Level Error, by pass

0306 A Keypad press keep 60 sec-

0340 B Key pad in extraordinary

0341 B Fan over current Console a. Enter the Engineer mode disable B Level Error, by pass

0343 B UCB Over supply voltage Console a. Enter the Engineer mode disable B Level Error, by pass

0345 B Correct packet but LCB with-

0346 B UCB detect the error of LCB

0347 B VA Load program fail. Console a. Enter the Engineer mode disable B Level Error, by pass

0348 B Motor not to run. Console a. Enter the Engineer mode disable B Level Error, by pass

04A0 C

04B0 C

04B1 C

Replace

onds

operation

out the function

incline position error

If LCB have no message to

return UCB over 3 seconds

UCB not have communication response

IO board not have communication response.

Console a. Enter the Engineer mode disable B Level Error, by pass

Console a. Enter the Engineer mode disable B Level Error, by pass

Console a. Enter the Engineer mode disable B Level Error, by pass

Console a. Enter the Engineer mode disable B Level Error, by pass

Console a. Enter the Engineer mode disable B Level Error, by pass

Communication

Errors

Communication

Errors

Communication

Errors

a. Change the correct machine type in the console and reboot

power again.

CLASS A and B error code.

b. Replace

CLASS A and B error code.

b. Replace battery

CLASS A and B error code.

b. Make sure the RPM over 35, when the machine of self-power

mode

CLASS A and B error code.

b. Replace Earphone Board

CLASS A and B error code.

b. Replace

CLASS A and B error code.

b. Replace Keypad

CLASS A and B error code.

b. Replace Keypad

CLASS A and B error code.

b. Replace Fan

CLASS A and B error code.

b. Check the LCB provide power whether over 13 voltage

If yes, replace LCB

If not, replace

CLASS A and B error code.

b. Replace

CLASS A and B error code.

b. Running the incline motor calibration again

CLASS A and B error code.

b. Replace VA Micro SD card

CLASS A and B error code.

b. Replace

a. Check the connection of the console cable at both ends and

perform continuity test.

b. Replace LCB

a. Check the connection of the console cable at both ends and

perform continuity test.

b. Replace

a. Replace UCB

UCB

UCB

UCB

UCB

UCB

UCB

UCB

33

Page 36

CHAPTER 8: TROUBLESHOOTING

8.2 ERROR CODE LIST - CONTINUED

CODE CLASS DESCRIPTION MACHINE SOLUTION

Enter the Engineer mode disable B Level Error, by pass CLASS

a.

A

0440 B Timeout receive packet

0441 B

0442 B

When UCB implements a

command, LCB has no this

command.

the received command code

from the console is correct

and is supported, but it has

less or more data arguments

Communication

Errors

Communication

Errors

Communication

Errors

and B error code

b.

Check the connection of the console cable at both ends and perform continuity test.

Replace LCB

c.

a. Enter the Engineer mode disable B Level Error

a.

a. Enter the Engineer mode disable B Level Error, by pass CLASS

A and B error code

CLASS

A

and B error code.

, by pass

34

Page 37

CHAPTER 9: PARTS REPLACEMENT GUIDE

9.1 CONSOLE REPLACEMENT

1) Remove the 5 screws holding the console to the frame (Figure A).

2) Disconnect the console cable, ground cable and HR connections from the defective console and remove the console (Figure B).

e.g. HUR5X console

FIGURE A FIGURE B

--For A/E 5x console only

2.1) Remove the 5 screws that hold the mounting plate to the console (Figure C).

2.2) Attach the mounting plate to the new console.

FIGURE C

3) Reinstall the wire connections to the new console.

4) Carefully push the wires into the console and mast until they are clear of the console / mast connection and attach the console to the mast

using the 5 screws.

5) T

est the unit for function as outlined in Section 9.3.

35

Page 38

CHAPTER 9: PARTS REPLACEMENT GUIDE

9.2 CONSOLE KEYPAD/OVERLAY REPLACEMENT

1) Remove the console as outlined in Section 9.1.

2) Remove the 6 screws holding on the back cover of the console and remove it (Figure A).

3) Unplug the faulty keypad from the UCB - 2 ribbon cables for program (Figure B).

FIGURE A

FI

GURE B

4) Use a

5) Clean the console area with alcohol to remove any leftover adhesive (Figure D).

razor to remove the faulty keypad / overlay from the console faceplate (Figure C).

FIGURE C

6) Peel the backing off of the new keypad (Figure E).

7) Slide the ribbon cables through the slots in the console faceplate (Figure F).

FIGURE D

36

FIGURE FFIGURE E

Page 39

CHAPTER 9: PARTS REPLACEMENT GUIDE

9.2 CONSOLE KEYPAD/OVERLAY REPLACEMENT - CONTINUED

8) Plug the ribbon cables into the UCB (Figures G).

9) Carefully line up the new keypad to the outline in the console faceplate (Figure H).

FIGURE G

10) Peel the backing off of the new overlay (Figure I).

11) Carefully line up the new overlay to the outline in the console faceplate. Once it is in place, press down on the overlay so that the adhesive

on the overlay bonds to the keypad (Figure J).

FIGURE H

FIGURE JFIGURE I

12) Reverse Steps 1-2 to re-assemble the console.

13)

T

est the unit for function as outlined in Section 9.3.

37

Page 40

CHAPTER 9: PARTS REPLACEMENT GUIDE

9.3 TESTING THE UNIT

ONCE THE UNIT OR REPLACEMENT PART IS FULLY INSTALLED AND ASSEMBLED AND

PR

OPERLY PLACED ON THE FLOOR, USE THE FOLLOWING INSTRUCTIONS T

ND TEST THE MACHINE:

A

O SE

TUP

--For H/U/R/E/S/A5X-C

1) Enter Manager Mode and input the serial number of the console and frame. Also set the Machine Type and verify

are correct.

2) If the unit has an add-on TV, program the channels (see Entertainment Owner's Manual).

3) Without hitting start or entering any program modes, step on the pedals and hold the handlebars while initiating movement to simulate

exercising. While moving, listen for any odd noises or squeaks.

4) After stopping movement, press the green GO key and begin pedaling.

5) Grasp the hand grips to check for proper heart rate response.

6) Press the level up and down buttons on the console and hand grips to make sure resistance is fully functional.

7) If everything functions properly, stop pedaling and the unit will reset to normal operation within 30 seconds.

For C5X-C

--

1) To enter Manager Mode, press number key "ENTER, 1, 0, 0, 1, ENTER" on the number keypad. Input the serial number of the console. Also

set the Machine Type and verify that the Date and Time are correct.

2) Press the green GO key and begin using the machine. Stand on the machine and hold the handlebars while initiating movement to simulate

exercising. While moving, listen for any odd noises or squeaks.

3) Grasp the hand grips to check for proper heart rate response.

4) Press the level up and down buttons on the console to make sure resistance is fully functional.

5) Try stepping off the unit to make sure the proximity sensor is fully functional. Also test the STOP key on the grips, IR sensor for function.

that the Date and Time

38

Page 41

CHAPTER 10: SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 WIFI INSTALLATION

HURESACT5X WIFI Installation

MAIN COMPONENT LIST OF WIFI SET (PART NUMBER #1000366472)

Item Parts number Description Q’ty

1 1000385415 Control Board;;;HF-A11-0;V2.049;;; 1

1.1 1000385417 Control Board;;;V5.0;V2.049;;HF-A11-0; 1

1.2 1000385418

1.3 1000385725 Foam Tap;;;41x11;;3M 4945; 1

2 0000086721 SCREW;RND;M2X0.5PX6L;;PH;;BZN;; 2

3 1000309516 Tape;;;40x10x0.2;;EP614 1

WIFI Aerial;;;;;NB098-2400300PEX;;HF-A1

1

39

Page 42

CHAPTER 10: SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 WIFI INSTALLATION - CONTINUED

10.1.1 HURESAC5X WIFI Installation

1) Plug in the WiFi board (item #1.1 in the table) to the UCB and use the 2 screws (item #2 in the table) to fix it (Figure A).

2) Stick the foam tape (item #1.3 in the table) on the front cover (Figure B).

FI

FIGURE A

GURE B

3) Stick the WiFi aerial board (item #1.2 in the table) to foam tape and connect the signal wire to WiFi board (Figure C).

4) Use tape (item #3 in the table) to fix the signal connecting wire to the front cover of the console (Figure D).

FIGURE C

FIGURE D

40

Page 43

CHAPTER 10: SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 WIFI INSTALLATION - CONTINUED

10.1.2 T5X WIFI Installation

1) Plug in the WiFi board (item #1.1 in the table) to the UCB and use the 2 screws (item #2 in the table) to fix it (Figure A).

2)

Stick the foam tape (item #1.3 in the table) on the front cover (Figure B).

FIGURE A FIGURE B

3) Stick the WiFi

4) Use tape (item #3 in the table) to fix the signal connecting wire to the front cover of the console (Figure D).

aerial board (item #1.2 in the table) to foam tape and connect the signal wire to WiFi board (Figure C).

FIGURE C

FIGURE D

41

Page 44

CHAPTER 10: SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 WIFI INSTALLATION - CONTINUED

10.1.3 How to set up the “WIFI” function

1. Create a WiFi config file

Step 1: Use your computer and use "note" function to create a wifi config file ( the name is called 'wifi_set.cfg’ - Figure A).

Step 2: Check your

completed, put the 'wifi_set.cfg' file to USB flash drive (the access should read \MA

AP data and modifying SSID & Key (password) required by facility

Access Point (AP) to 'wifi_set.cfg' files. Once this is

TRIX\FW\ - Figure B).

FIGURE BFIGURE A

2. Install WiFi config software for WiFi connection.

Step 1: Insert USB driver with ‘wifi_set.cfg’

Step 2: Enter Manager Mode by pressing ‘enter

Step 3: Press the Level UP

Step 4: Pres Enter key to enter Enable/Disable setup (Figure E).

Step 5: Use the Level UP

and DOWN keys to select “Internet” and press Enter Key to enter

and DOWN keys to select "Enable" (Figure F).

file to console (Figure C).

, 1, 0, 0, 1, enter’.

(Figure D).

FIGURE DFIGURE C

42

FIGURE FFIGURE E

Page 45

CHAPTER 10: SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 WIFI INSTALLATION - CONTINUED

10.1.3 How to set up the “WIFI” function - continued

3. Install WiFi config software for WiFi connection - continued

Step 6: Press the <- key on the number keypad to back. Use the Level UP and DOWN keys to select "Import Setting" (Figure G).

Step 7: Press enter key to start wifi installation process (Figure H).

FIGURE HFIGURE G

Step 8: When the message shows “Success !!" in a short time, it means the update is completed (Figure I).

FIGURE I

4. Console WiFi function test

Step 1: Enter Manager mode-> Internet -> MAC ID (Figure A).

Step 2: If WiFi Module was installed correctly, the screen will show the MAC ID data (Figure B).

FIGURE BFIGURE A

43

Page 46

CHAPTER 10: SPECIFICATIONS AND ASSEMBLY GUIDE

10.1 WIFI INSTALLATION - CONTINUED

10.1.3 How to set up the “WIFI” function - continued

4. Console WiFi function test - continued

Step 3: Enter Manager mode-> Internet -> Signal Strength (Figure C). See if the wireless signal strength is OK (Figure D).

Note: For wireless connection quality

, the stable signal strength of wireless is necessary.

FIGURE DFIGURE C

Step 4: Enter Manager mode-> Internet -> IP (Figure E).

Step 5: If WiFi module was connected with AP, the screen will show the IP address (Figure F).

FIGURE FFIGURE E

44

Page 47

CHAPTER 10: SPECIFICATIONS AND ASSEMBLY GUIDE

10.2 RFID INSTALLATION

10.2.1 HURESAC5X RFID Installation

Note: For the HURESAC5x RFID installation first time, you must order and install WiFi set (part number

#1000366472) and RFID set (part number #1000364289) at the same time. The SAP # for the WIFI + RFID kit

is 1000390566.

WIFI + RFID kit SAP no.

Including kit

Item Parts number Description

1 1000366472

WiFi set

1000390566.

2 1000364289 RFID set

MAIN COMPONENT LIST OF RFID SET (PART NUMBER #1000364289)

Item Parts number Description Q’ ty

1 1000355790 Reader;;;GAT-RM310 3.0;V3.1.1.0/V1.2;;EP 1

2 004350-AB SCREW;BH;M3X0.5PX6L;;PH;;;;BP 2

3 1000355791 Antenna board;;;GAT-MAXI LA 3.0;;;EP614C; 1

4 1000364547 Ferrite Plate Absorber;;K5B,FT 10x1.0x10 1

5 1000204284 TAPE;FOAM;SINGLESIDE;15x30x4T; 2

6 1000364292 Signal CONN;;;;;;;500(IPEX,MHF37+JST,ZHR 1

7 1000309516 Tape;;;40x10x0.2;;EP614 4

8 1000363661 Fixing Bracket;;;ABS PA746;BL/Black C;;; 1

9 008864-A Screw; Round Head;Φ2.9x1.06Px7L;Hi/Lo Thr 2

45

Page 48

CHAPTER 10: SPECIFICATIONS AND ASSEMBLY GUIDE

10.2 RFID INSTALLATION - CONTINUED

10.2.1 HURESAC5x RFID Installation (continued)

1. Stick the foam tape (item #5 in the table) on the UCB as marked in yellow (Figure A).

FIGURE A

2. Stick the absorber (item #4 in the table ) on the reader board as marked in yellow (Figure B).

3. Plug in the Reader board to the UCB and use the 2 screws (item

#2 in the table) to fix it (Figure C).

FIGURE CFIGURE B

4. Put the antenna board on the front cover of the console. Connect the signal connecting wire (item #3/6 in the table) to antenna board (Figure

D).

5. Put the fixing bracket (item #8 in the table) on the antenna board. Use the two screws to fix it. (Figure E).

FIGURE D

46

FIGURE E

Page 49

CHAPTER 10: SPECIFICATIONS AND ASSEMBLY GUIDE

10.2 RFID INSTALLATION - CONTINUED

10.2.1 HURESAC5x RFID Installation (continued)

6. Connect the Signal connected wire to J8 of UCB (Figure F).

7. Use tape (item #7 in the table) to fix the signal connecting wire to the front cover of the console (Figure G).

FIGURE GFIGURE F

47

Page 50

CHAPTER 10: SPECIFICATIONS AND ASSEMBLY GUIDE

10.2 RFID INSTALLATION - CONTINUED

10.2.2 T5X RFID Installation

NOTE: For the T5x RFID function used, you must order and install WiFi set (part number #1000366472) and

RFID set (part number #1000364291) at the same time. The SAP # for the WIFI + RFID kit is 1000390648.

WIFI + RFID kit SAP no.

Including kit

Item Parts number Description

1 1000366472

WiFi set

1000390648

2 1000364291 RFID set

MAIN COMPONENT LIST OF RFID SET (PART NUMBER #1000364291)

Item Parts number Description Q’ ty

1 1000355790 Reader;;;GAT-RM310 3.0;V3.1.1.0/V1.2;;EP 1

2 004350-AB SCREW;BH;M3X0.5PX6L;;PH;;;;BP 2

3 1000355791 Antenna board;;;GAT-MAXI LA 3.0;;;EP614C; 1

4 1000364547 Ferrite Plate Absorber;;K5B,FT 10x1.0x10 1

5 1000204284 TAPE;FOAM;SINGLESIDE;15x30x4T; 2

6 1000364292 Signal CONN;;;;;;;500(IPEX,MHF37+JST,ZHR 1

7 1000309516 Tape;;;40x10x0.2;;EP614

8 1000356734 Fixing Bracket;;;PA746;BL/Black C;;TM521

9 008864-A Screw;Round Head;Φ2.9x1.06Px7L;Hi/Lo Thr 3

48

4

1

Page 51

CHAPTER 10: SPECIFICATIONS AND ASSEMBLY GUIDE

10.2 RFID INSTALLATION - CONTINUED

10.2.2 T5x RFID Installation (continued)

1. Stick the foam tape (item #5 in the table) on the UCB as marked in yellow (Figure A).

FIGURE A