Page 1

Target Support Pac

kage™ 4

User’s Guide

For Use with Texas Instruments C2000™

Page 2

How to Contact The MathWorks

www.mathworks.

comp.soft-sys.matlab Newsgroup

www.mathworks.com/contact_TS.html Technical Support

suggest@mathworks.com Product enhancement suggestions

bugs@mathwo

doc@mathworks.com Documentation error reports

service@mathworks.com Order status, license renewals, passcodes

info@mathwo

com

rks.com

rks.com

Web

Bug reports

Sales, prici

ng, and general information

508-647-7000 (Phone)

508-647-7001 (Fax)

The MathWorks, Inc.

3 Apple Hill Drive

Natick, MA 01760-2098

For contact information about worldwide offices, see the MathWorks Web site.

Target Support Package™ User’s Guide

© COPYRIGHT 2003–2010 by The MathWorks, Inc.

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from The MathW orks, Inc.

FEDERAL ACQUISITION: This provision applies to all acquisitions of the Program and Documentation

by, for, or through the federal government of the United States. By accepting delivery of the Program

or Documentation, the government hereby agrees that this software or documentation qualifies as

commercial computer software or commercial computer software documentation as such terms are used

or defined in FAR 12.212, DFARS Part 227.72, and DFARS 252.227-7014. Accordingly, the term s and

conditions of this Agreement and only those rights specified in this Agreement, shall pertain to and govern

theuse,modification,reproduction,release,performance,display,anddisclosureoftheProgramand

Documentation by the federal government (or other enti ty acquiring for or through the federal government)

and shall supersede any conflicting contractual terms or conditions. If this License fails to meet the

government’s needs o r is inconsistent in any respect with federal procurement law, the government agrees

to return the Program and Docu mentation, unused, to The MathWorks, Inc.

Trademarks

MATLAB and Simulink are registered trademarks of The MathWorks, Inc. See

www.mathworks.com/trademarks for a list of additional trademarks. Other product or brand

names may be trademarks or registered trademarks of their respective holders.

Patents

The MathWorks products are protected by one or more U.S. patents. Please see

www.mathworks.com/patents for more information.

Page 3

Revision History

November 2003 Online only New for Version 1.0 (Release 13SP1+)

June 2003 Online only New for V ersion 1.1 (Release 14)

October 2004 Online only Revised for Version 1.1.1 (Release 14SP1)

December 2004 Online only Revised for Version 1.2 (Release 14SP1+)

March 2005 Online only Revised for Version 1.2.1 (Release 14SP2)

September 2005 Online only Revised for Version 1.3 (Release 14SP3)

March 2006 Online only Revised for Version 2.0 (Release 2006a)

September 2006 Online only Revised for Version 2.1 (Release 2006b)

March 2007 Online only Revised for Version 2.2 (Release 2007a)

September 2007 Online only Revised for Version 2.3 (Release 2007b)

March 2008 Online only Revised for Version 3.0 (Release 2008a)

October 2008 Online only Revised for Version 3.1 (Release 2008b)

March 2009 Online only Revised for Version 3.2 (Release 2009a)

September 2009 Online only Revised for Version 4.0 (Release 2009b)

March 2010 Online only Revised for Version 4.1 (Release 2010a)

Page 4

Page 5

Getting Started

1

Product Overview ................................. 1-2

Introduction

Product Description

...................................... 1-2

............................... 1-2

Contents

Setting Up and Configuring

System Require ments

Supported Hardware

Installing and Configuring Software

Verifying the Configuration

Code Com poser Studio

Using Code Composer Studio with Target Support Package

Software

Default Project Configuration

Data Type Support

Scheduling and Timing

Overview

Timer-Based Interrupt Processing

Asynchronous Interrupt Processing

Sharing General Purpose Timers between C281x

Peripherals

Example 1

Example 2

....................................... 1-7

........................................ 1-10

..................................... 1-16

....................................... 1-17

....................................... 1-21

.............................. 1-3

............................... 1-3

................................. 1-9

........................ 1-3

.................. 1-3

......................... 1-4

............................. 1-7

....................... 1-7

............................ 1-10

.................... 1-10

................... 1-11

Overview of Creating Models for Targeting

Accessing the Target Support Package Block Library

Online Help

Blocks with Restrictions

Setting Simulation Configuration Parameters

Building Your Model

...................................... 1-26

............................ 1-26

............................... 1-29

.......... 1-25

.... 1-25

.......... 1-28

v

Page 6

Using the c2000lib Blockset ......................... 1-30

Introduction

Hardware Setup

Starting the c2000lib Library

Setting Up the Model

Adding Blocks to the Model

Generating Code from the Model

...................................... 1-30

.................................. 1-30

........................ 1-31

.............................. 1-33

......................... 1-35

..................... 1-38

Configuring Timing Parameters for CAN Blocks

2

The CAN Blocks ................................... 2-2

Setting Timing Parameters

Accessing the Timing Parameters

Determining Timing Parameter Values

CAN Bit Timing Example

Parameter Tuning and Signal Logging

Overview

Using External Mode

Using a Third Party Calibration Tool

........................................ 2-9

......................... 2-3

.................... 2-3

............... 2-6

........................... 2-7

.............. 2-9

.............................. 2-9

................. 2-18

Configuring Acquisition Window Width for ADC

3

What Is an Acquisition Window? .................... 3-2

Configuring ADC Parameters for Acquisition Window

Width

Accessing the ADC Parameters

Examples

.......................................... 3-5

...................... 3-5

........................................ 3-7

Blocks

vi Contents

Page 7

Using the IQmath Library

4

About the IQmath Library .......................... 4-2

Introduction

Common Characteristics

References

...................................... 4-2

............................ 4-3

....................................... 4-3

Fixed-Point Numbers

Notation

Signed Fixed-Point Numbers

Q Format Notation

Building Models

Overview

Converting Data Types

Using Sources and Sinks

Choosing Blo cks to Optimize Code

Double and Single-Precision Param eter Values

......................................... 4-4

........................................ 4-10

.............................. 4-4

........................ 4-5

................................ 4-5

................................... 4-10

............................. 4-10

........................... 4-11

.................... 4-11

......... 4-11

Programming Flash Memory

5

Introduction ...................................... 5-2

Installing TI Flash APIs

............................ 5-3

Configuring the DSP Board Bootloader

Configuring the Software for Automatic Flash

Programming

Selectively Erase, Program, or Verify Specific Flash

Sectors

......................................... 5-7

................................... 5-5

.............. 5-4

vii

Page 8

Placing Additional Code or Data on Unused Flash

Sectors

......................................... 5-8

Block Reference

6

C280x (c280xlib) ................................... 6-2

C2802x (c2802xlib)

C2803x (c2803xlib)

C281x (c281xlib)

C28x3x (c2833xlib)

C28x DMC (c28xdmclib)

C28x IQmath (tiiqmathlib)

Host SCI Blocks (c2000scilib)

RTDX Instrumentation (rtdxBlocks)

Target Preferences (c2000tgtpreflib)

................................. 6-4

................................. 6-6

................................... 6-8

................................. 6-10

............................ 6-12

.......................... 6-13

....................... 6-14

................. 6-15

................ 6-16

viii Contents

Page 9

7

Blocks — Alphabetical List

Index

ix

Page 10

x Contents

Page 11

Getting Started

• “Product Overview” on page 1-2

• “Setting Up and Configuring” on page 1-3

• “Code Composer Studio” on page 1-7

• “Data Type Support” o n page 1-9

• “Scheduling and Timing” on page 1-10

• “Sharing General Purpose Timers between C281x Peripherals” on page 1-16

• “Overview of Creating Models for Targeting ” on page 1-25

1

• “Using the c2000lib Blockset” on page 1-30

Page 12

1 Getting Started

Product Overview

Introduction

This chapter describes how to use Target Support Package™ software

to create and execute applications on Texas Instruments™ C2000™

microcontrollers. To use the targeting software, become familiar with creating

Simulink

for automatic code generation. For more information about these concepts,

refer to the “Real-Time Workshop” documentation.

Product Description

Use Targe t Support Package to deploy generated code for real-time execution

on embedded microprocessors, microcontrollers, and DSPs. Using Target

Support Package, you can integrate peripheral devices and real-time

operating systems with the algorithms created using Embedded MATLAB™,

Simulink®, and Stateflow®. You can deploy the resulting executable onto

embedded hardware for on-target rapid prototyping, real-time performance

analysis, and field production.

In this section...

“Introduction” on page 1-2

“Product Description” on page 1-2

®

models and with the basic concepts of using Real-Time Workshop

®

1-2

Page 13

Setting Up and Configuring

In this section...

“System Requirements” on page 1-3

“Supported Hardware” on page 1-3

“Installing and Configuring Software” on page 1-3

“Verifying the Configuration” on page 1-4

System Requirements

For detailed information about the software and hardware required to use

Target Support Package software, refer to the Target Support Package system

requirements areas on the MathWorks Web site:

• Requirements for Target Support Package:

www.mathworks.com/products/target-package/requirements.html

Setting Up and Configuring

• Requirements for use with TI’s C2000:

www.mathworks.com/products/target-package/ti-adaptor/

Supported Hardware

For a list of supported hardware, visit

http://www.mathworks.com/products/target-package/supportedio.html.

Installing and Configuring Software

Consult the System Requirements for Target Support Package on the

MathWorks website. Only use supported versions of the software listed under

“Third-Party Target Support Package Requirements”. Uninstall unsupported

versions before installing supported versions. Doing so prevents errors that

occur when the Windows Environment Variables points to the unsupported

versions.

The System Requirements Web page describes where you can obtain the

additional third-party software, and when available, provides links for

downloading that software.

1-3

Page 14

1 Getting Started

Requirements for Target Support Package:

www.mathworks.com/products/target-package/requirements.html

Install the software listed in the following order:

1 Install the required and optional MathWorks software. (The software

license y ou purchase determines which products are available.)

2 Install TI Code Composer Studio™ (CCS).

3 Install TI Service Release for CCS.

4 Install the TI Code Generation Tools for Windows.

5 If you are using a Spectrum Digital board, download and install the

matching Spectrum Digital Driver.

6 If you are using RTDX for C28x host/target communications, download

and install TI DSP/BIOS.

1-4

7 If you are going to program flash memory with stand-alone code, download

the TI Flash API for your target processor.

Configure CCS as follows:

1 In CCS, open Help > About > Component manager > Build tools >

TMS320C28XX and select (check) C2000 Code Generation Tools.

2 With the Component manager o pen, open Target Content(DSP/BIOS) >

TMS320C28XX and select Texas Instruments DSP/BIOS.

3 Save, exit, and restart CCS.

Verifying the Configuration

To determine whether Target Support Package software is present on your

system, enter this command at the MATLAB

c2000lib

MATLAB displays the C2000 block libraries, as shown here:

®

prompt:

Page 15

Setting Up and Configuring

If you do not see the listed libraries, or MATLAB does not recogniz e the

command, install the Target Support Package software. Without the software,

you cannot use Simulink and Real-Time Workshop software to develop

applications targeted to the TI boards.

To verify that Code Composer Studio (CCS) is present on your machine, enter

this command at the MATLAB prompt:

ccsboardinfo

With CCS installed and configured, MATLAB returns a list of the boards that

CCS recognizes on your machine like the following example:

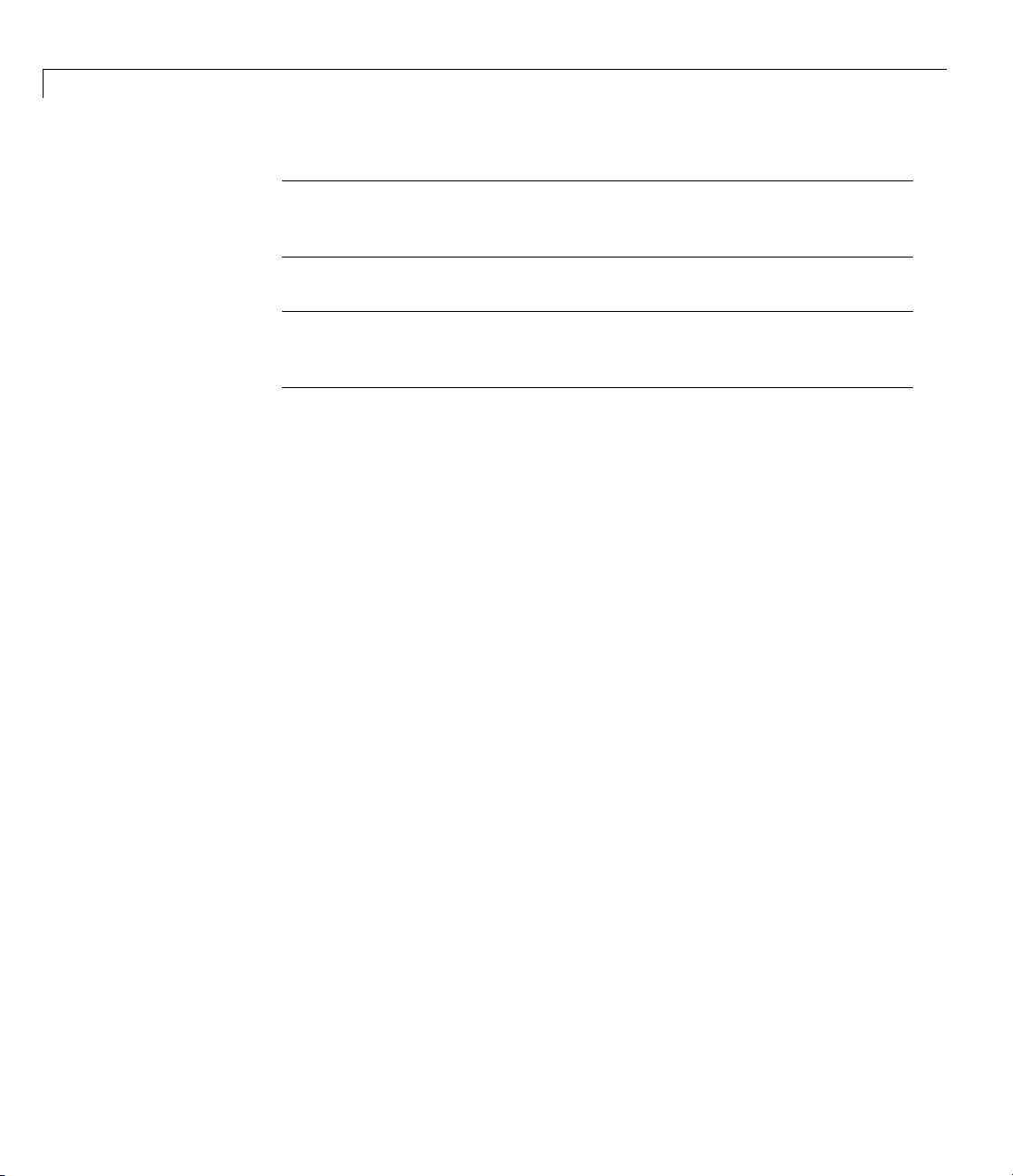

Board Board Proc Processor Processor

Num Name Num Name Type

--- ---------------------------------- --1 F2812 Simulator 0 CPU TMS320C28xx

0 F2812 PP Emulator 0 CPU_1 TMS320C28xx

1-5

Page 16

1 Getting Started

If M ATLAB does not return information about any boards, revisit your CCS

installation and setup in your CCS documentation.

As a final test, launch CCS to e n sure that it starts up successfully. For Target

SupportPackagesoftwaretooperatewithCCS,theCCSIDEmustbeableto

runonitsown.

Note For any model to work in the targeting environment, select the

discrete-time solver in the Solver pane of the Simulink Configuration

Parameters dialog box. Targeting does not work with continuous-time solvers.

To select the discrete-time solver, from the main menu in your model window,

select Simulation > Configuration Parameters.ThenintheSolver pane,

set the Solver option to

Discrete (no continuous states).

1-6

Page 17

Code Composer Studio

In this section...

“Using C ode Composer Studio with Target Support Package Software” on

page 1-7

“Default Project Configuration” on page 1-7

Using Code Composer Studio with Target Support Package Software

Texas Instruments (TI) facilitates development of software for TI DSPs by

offering Code Composer Studio (CCS) Integrated Development Environment

(IDE). Used in combination with Target Support Package software a nd

Real-Time Workshop software, CCS provides an integrated environment that,

once installed, requires no coding.

Executing code generated from Real-Time Workshop software on a particular

target requires that you tailor the code to the specific hardware target.

Target-specific code includes I/O device drivers and interrupt service routines

(ISRs). The software must use CCS to compile and link the generated source

code in order to load and execute on a TI DSP. To help you to build an

executable, Target Support Package software uses Embedded IDE Link™

software to start the code building process within CCS. After you download

your executable to your target and run it, the code runs wholly on the target.

You can access the running process only from the CCS debugging tools or

acrossalinkusingEmbeddedIDELinksoftware.

Code Composer Studio™

Default Project Configuration

CCS offers two standard project configurations, Re leas e and Debug. Project

configurations define sets of project build options. When you specify the build

options at the project level, the options apply to all files in your project. For

more information about the build options, refer to your TI documentation.

The models you build with Target Support Package software use a custom

configuration that provides a third combination of build and optimization

settings —

CustomMW.

1-7

Page 18

1 Getting Started

Default Build Options in the CustomMW Configuration

The default settings for CustomMW are the same as the Release project

configuration in CCS, except f or the compiler options.

Your CCS documentation provides complete details on the compiler build

options. You can change the individual settings or the build configuration

within CCS.

1-8

Page 19

Data Type Support

TI C2000 DSPs support 16 and 32–bit data types, but does not have native

8-bit data types. Simulink models and Target Support Package software

support many data types, including 8-bit data types.

Data Type Support

If you select

data, but in the generated code, that data will be represented as 16-bit. This

may cause instances where data overflow and wraparound occurs in the

simulation, but not in the generated code.

For ex ample, to make the ov erflo w behavior of the simulation and generated

code match for a Simulink Add block in your model, select Saturate on

integer overflow in that block.

int8 or uint8 in your model, your simulation runs with 8-bit

1-9

Page 20

1 Getting Started

Scheduling and Timing

In this section...

“Overview” on page 1-10

“Timer-Based Interrupt Processing” on page 1-10

“Asynchronous Interrupt Processing” on page 1-11

Overview

Normally the code generated by Target Support Package software runs in

the context of a timer interrupt. Model blocksruninaperiodicalfashion

clocked by the periodical interrupt whose period is tied to the base sample

time of the model.

This execution scheduling model, however, is not flexible enough for many

systems, especially control and communication systems, which must respond

to external events in real time. Such systems require the ability to handle

various hardware interrupts in an asynchronous fashion.

1-10

Target Support Package software lets you model and generate code for such

systems by creating tasks driven by Hardware Interrupt blocks in addition to

thetasksthatarelefttobehandledinthecontextofthetimerinterrupt.

Timer-Based Interrupt Processing

For code that runs in the context of the timer interrupt, each iteration of

the model solver is run after an interrupt has been posted and serviced by

an interrupt service routine (ISR). The code generated for the C280x, C281x,

and C28x3x uses

The t im er is configured so that the model’s base rate sample time corresponds

to the interrupt rate. The timer period and prescaler are calculated and set

up to ensure the desired rate as follows:

BaseRateSampleTime

CPU_timer0.

=

TimerClockSpeed

TimerPeriod

Page 21

Scheduling and Timing

The minimum achievable base rate sample time depends on the model

complexity. The maximum value depends on the maximum timer period value

32

(2

-1 for the F2812, F2808, and F28x35) and the CPU clock speed. The CPU

clock speed is 100 MHz for the F2808, and 150 MHz for the F2812 and F28335.

If all the blocks in the model inherit their sample time value, and no sample

time is explicitly defined, the default value is 0.2 s.

High-Speed Peripheral Clock

The Event Managers and their general-purpose timers, which drive PW M

waveform generation use the high-speed peripheral clock (HISCLK). By

default, this clock is always selected in Target Support Package software.

This clock is derived from the system clock (SYSCLKOUT):

HISCLK = [SYSCLKOUT / (high-speed peripheral prescaler)]

The high-speed peripheral prescaler is determined by the HSPCLK bits

set in SysCtrl. The default value of HSPCLK is 1, which corresponds to a

high-speed peripheral prescaler value of 2.

For e xample, on the F2812, the HISCLK rate becomes

HISCLK = 150 MHz / 2 = 75 MHz

Asynchronous Interrupt Processing

Simulink and Real-Time Workshop software facilitate the modeling and

generation of code for asynchronous event handling, including servicing of

hardware-generated interrupts, by using the following special blocks:

• Hardware Interrupt block

This block enables selected hardware interrupts, generates the

corresponding interrupt service routines (ISRs), and connects them to the

corresponding interrupt service vector table entries. When you connect

the output of the Hardware Interrupt block to the control input of a

triggered subsystem (for example, a function-call subsystem), the generated

subsystem code is called from the ISRs.

Target Support Package software provides a Hardware Interrupt block for

each of the supported processor families.

1-11

Page 22

1 Getting Started

• Rate Transition blocks

These blocks support data transfers between blocks running with different

sample rates. The built-in Simulink Rate Transition blocks can be used

for this purpose.

The following diagram illustrates a use case where a Hardware Interrupt

block triggers two tasks, connected to other blocks that run periodically in the

context of the synchronous scheduler.

1-12

In the p

interr

and the

Hardw

subsy

execu

The f

eCAN

1 Place the eCAN Receive block in a function-call subsystem, as shown in

receding figure, the Hardware Interrupt block is set to react on two

upts. Since only one Hardware Interrupt block is allowed in a model

output of this block is a vector of length two, you must connect the

are Interrupt block to a Demux block to trigger the two function-call

stems. The function-call subsystems contain the blocks that are

ted asynchronously in the context of the hardware interrupt.

ollowing example shows how to build and configure a model to react on an

message using a hardware interrupt and an asynchronous scheduler:

the following figure.

Page 23

Scheduling and Timing

2 On the eCAN Receive block dialog, check the box labeled Post interrupt

when message is received, as shown in the following figure.

3 Set the Sample Time of the eCAN Receive block to -1 s ince the block will

be triggered by the ISR, as shown in the preceding figure.

1-13

Page 24

1 Getting Started

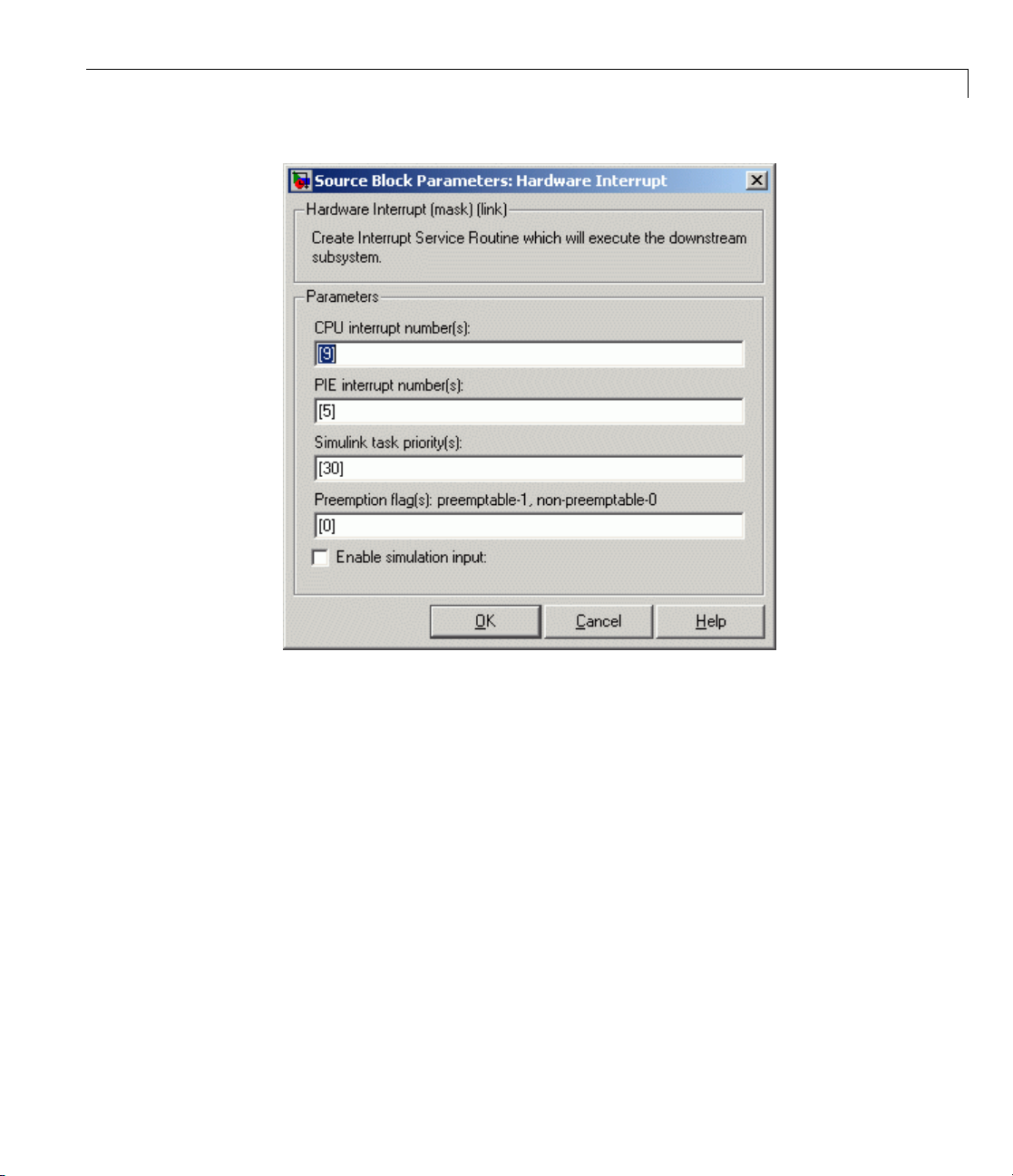

4 Add the C281x Hardware Interrupt block to your model, as shown in the

following figure.

5 The eCAN interrupt on C281x chips is on CPU line 9 and PIE line 5

for module 0 . These parameters canbefoundintheC281xHardware

Interrupt block, C281x P eripheral Interrupt Vector Values figure. Set the

hardware interrupt param eters CPU interrupt number(s): to

interrupt number(s): to

5 as shown in the following figure.

9,andPIE

1-14

Page 25

Scheduling and Timing

6 Connec

subsys

At exec

inter

is exe

funct

to the

For m

Real

t the output of the Hardware Interrupt block to the function-call

tem containing the eCAN block.

ution time, when a new eCAN message is received, the eCAN

rupt is triggered, and the code you placed in the function-call subsystem

cuted. In this example, the eCAN Receive block is placed in the

ion-call subsystem, which means that the message is read and is passed

rest of the code.

ore information, see the section on Asynchronous Support in the

-Time Workshop documentation.

1-15

Page 26

1 Getting Started

Sharing General Purpose Timers b etween C281x Peripherals

TMS320x281x DS

Event Manager (

• EVA includes G

• EVB includes G

You can use th

with the EV M

The followi

block libra

GP Timer Us

PWM1-PWM

PWM7-PWM12

QEP1-QEP2

QEP3-QEP4

CAP1-CAP3

CAP4-CAP6

e GP Timers independently or to operate peripherals associated

anager, such as PWM, QEP, and CAP.

ng table describes the timer-peripheral mapping of the c281xlib

ry.

e for C281x Peripheral Blocks

GP Timer 1 GP Timer 2 GP Timer 3 GP Timer 4

6

P devices have four General Purpose (GP) timers. Each

EV) module includes two GP timers:

PTimer1andGPTimer2.

PTimer3andGPTimer4.

1-16

PWM and QEP peripheral has access to only one timer, while each CAP

Each

pheral has access to two timers. In the PWM and QEP blocks, you ca n

peri

the Module option to

set

bination the block configures. By comparison, in the CAP block, you can

com

the Time base option to select one of two timers for each CAP peripheral.

use

ch GP timer is available to multiple peripherals. For example:

Ea

M1-PWM6andCAP1-CAP3shareGPTimer1

• PW

WM7-PWM12 and CAP4-CAP6 share GP Timer 3

• P

A or B to determine which unique timer-peripheral

Page 27

Sharing General Purpose Timers between C281x Peripherals

• QEP1-QEP2 and CAP1-CAP3 share GP Timer 2

• QEP3-QEP4 and CAP4-CAP6 share GP Timer 4

ThePWM,QEP,CAP,andTimerblockseach provide independent access to

key timer registers. If the blocks in your model share a specific GP timer,

ensure that all the timer-related settings are compatible. If the peripheral

settings for a shared timer are not compatible, the software generates an

error when you update the model or ge nerate code.

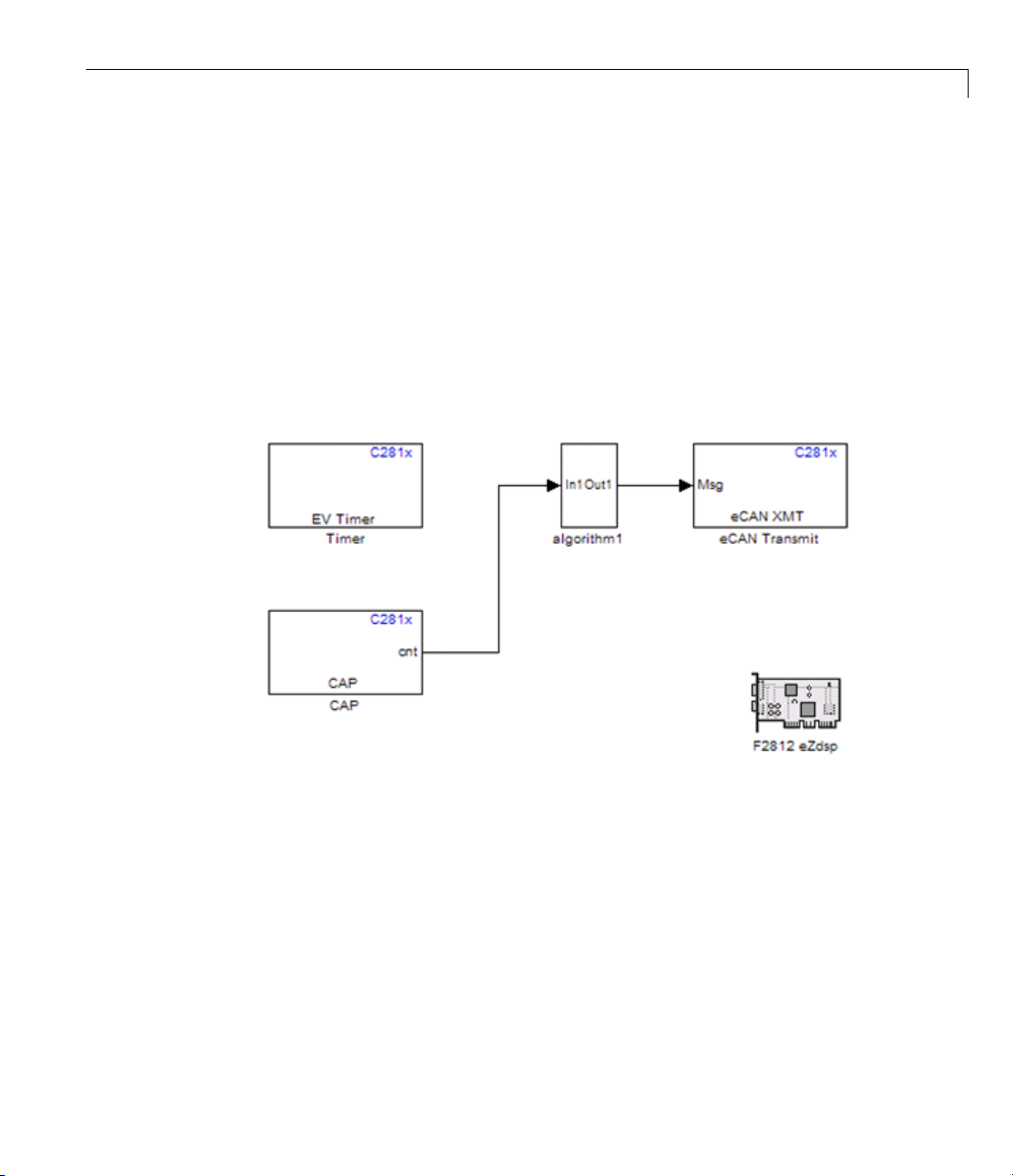

Example 1

The model contains Timer and CAP blocksthatbothuseTimer1(GPTimer1).

1-17

Page 28

1 Getting Started

1-18

Page 29

Sharing General Purpose Timers between C281x Peripherals

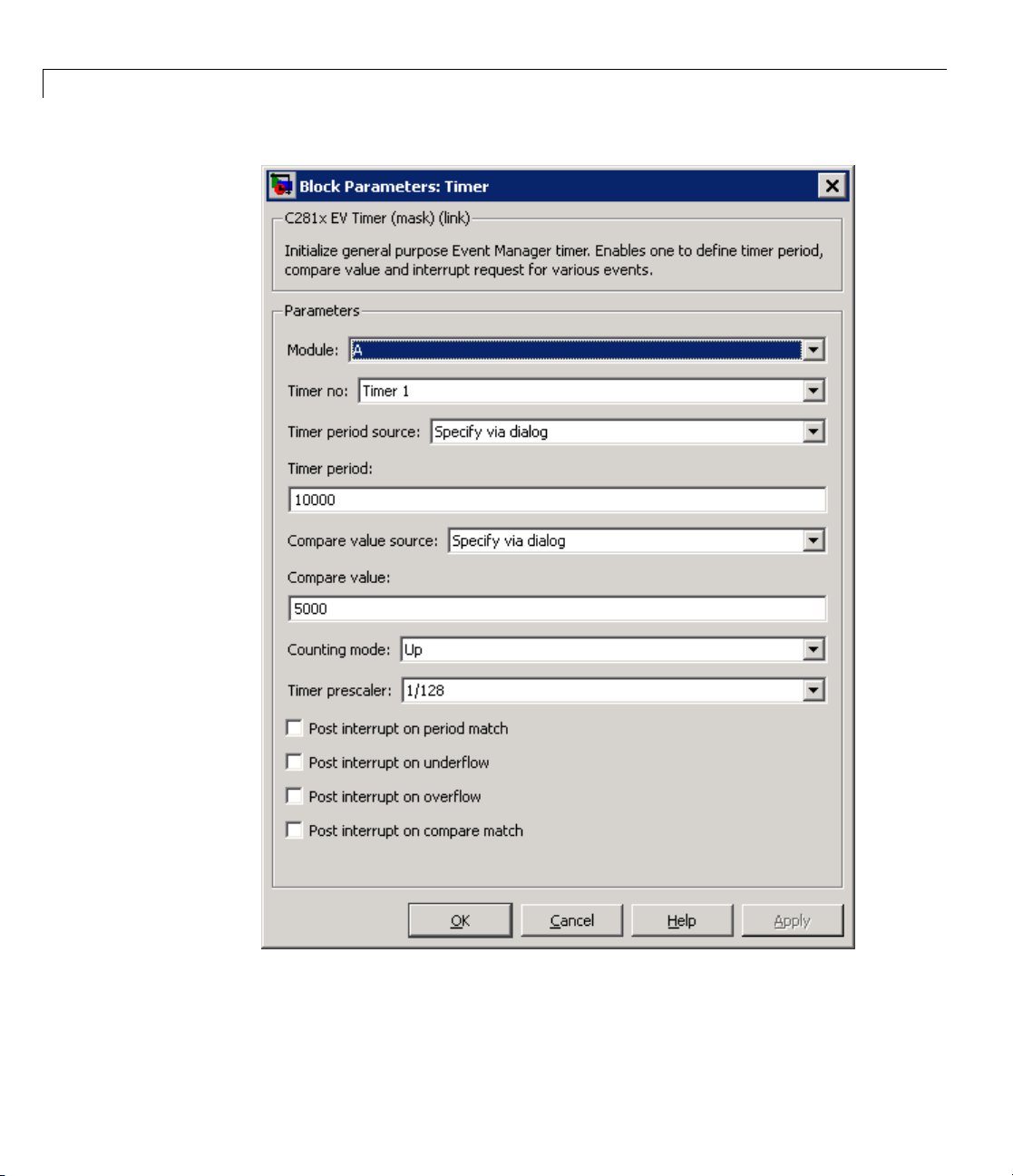

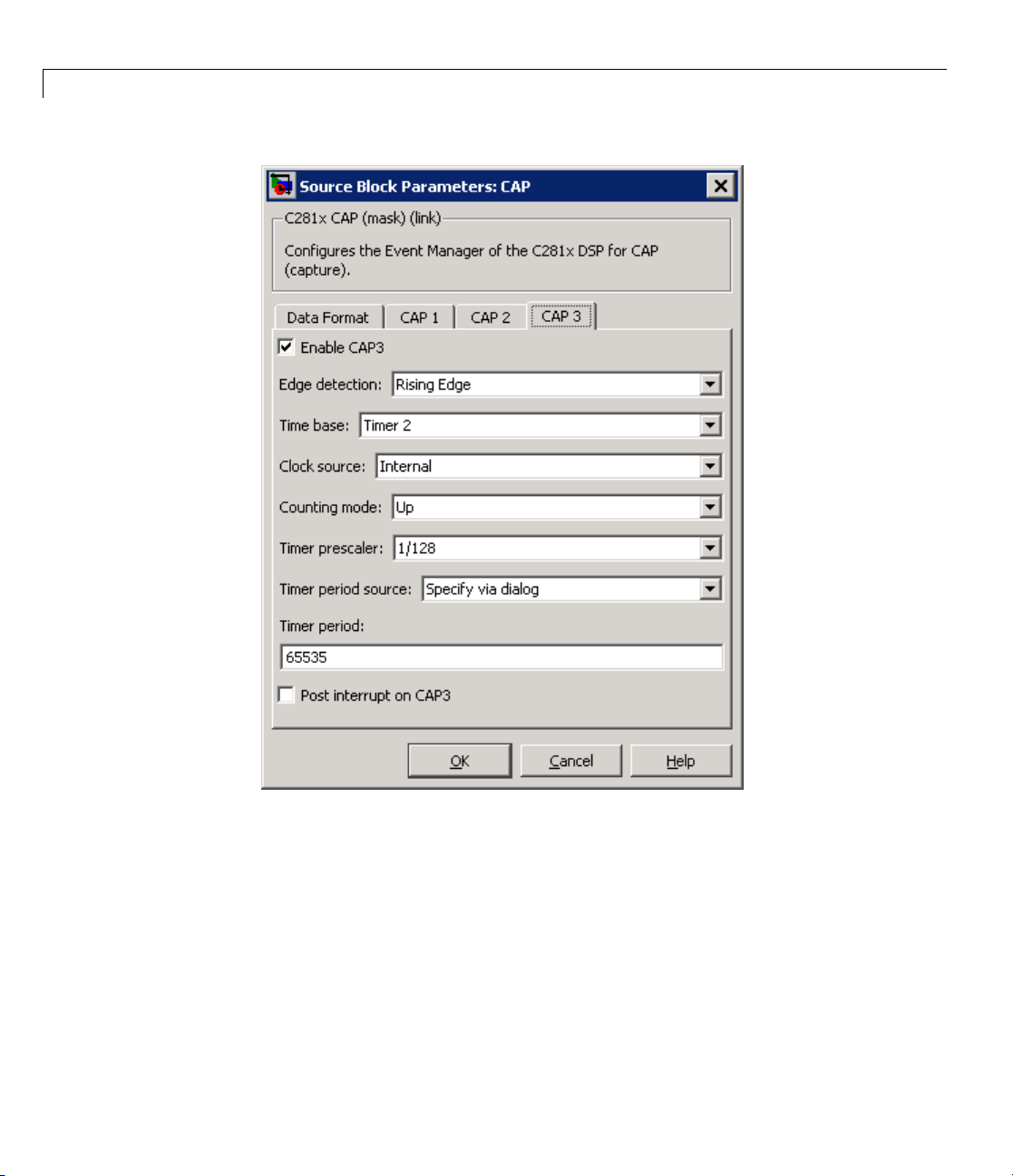

Both blocks have the same values for Timer prescaler and Counting

mode. However, each block has different values for Timer period.The

value of Timer period for Timer 1 is

65535 in the CAP block and 10000 in

the Timer block.

1-19

Page 30

1 Getting Started

1-20

Since both blocks configure the same timer, and settings conflict, the software

generates an error when you update the model.

Page 31

Example 2

Sharing General Purpose Timers between C281x Peripherals

The model

block, th

block, s

Timer Us

use Time

e Time base option shows which timer the block uses. In the QEP

etting Module to

contains QEP and CAP blocks that both use Timer 2. In the CAP

A configures the block to use QEP1–QEP2. GP

e for C281x Peripheral Blocks on page 1-16 shows that QEP1–QEP2

r2.

1-21

Page 32

1 Getting Started

1-22

Page 33

Sharing General Purpose Timers between C281x Peripherals

Currently, both blocks define different clock sources f or Timer 2. The CAP

block uses

Internal as a Clock source. The QEP block, which does not have

aconfigurableClock source setting, uses the QEP circuit as a clock source.

If you build the model, the software generates the following error message.

1-23

Page 34

1 Getting Started

1-24

To avoid generating errors when you build the model, change Clock source

in the CAP block to

QEP device.

Page 35

Overview of Creating Models for Targeting

Overview of Creating Models for Targeting

In this section...

“Accessing the Target Support Package Block Library” on page 1-25

“Online Help” on page 1-26

“Blocks with Re s triction s” on page 1-26

“Setting Simulation Configuration Parameters” on page 1-28

“Building Your Model” on page 1-29

Accessing the Target Support Package Block Library

After you have installed the supported developm ent board, start MATLAB. At

the MATLAB command prompt, type

c2000lib

This opens the c2000lib Simulink blockset that includes li braries containing

blocks predefined for C2000 input and output devices. As needed, add the

blocks to your model. See “Using the c2000lib Blockset” on page 1-30 for an

example of how to use this library.

Create your real-time model for your application the s ame way you create any

other Simulink model. Select blocks to build your model from the following

sources or products:

• The appropriate Target Preferences library block (for setting target and

application preferences)

• The appropriate libraries in the

and output functions for on your target hardware)

• Real-Time Workshop software

• Discrete time blocks from Simulink

• Any other blockset that meets your needs and operates in the discrete

time domain

c2000lib block library (for handling input

1-25

Page 36

1 Getting Started

Online Help

To get general he

in MATLAB. At the

help tic2000

lp for Target Support Package software, use the help feature

command prompt, type

to list the fun

software. Or s

in the MATLAB

Support Pack

Blocks with

Some blocks

for that re

have restr

communica

listed in

ctions and block libraries included in Target Support Package

elect Help > Full Product Family Help from the menu bar

desktop. When you see the C ontents in Help, select Target

age.

Restrictions

may not work on the target as they do on your desktop, and

ason, you should avoid them altogether. Other blocks may

ictions in their settings, which, when followed, ensure smooth

tions. All the blocks that require this special consideration are

the following sections.

Blocks to Avoid Using in Your Models

The bloc

the targ

process

The Mat

the Sco

you use

Library Category Block Name

Simulink

ks listed in the table below generate code, but they do not work on

et as they do on your desktop—in general, they slow your signal

ing application without adding instrumentation value. For this reason,

hWorks recommends that you avoid using certain blocks, such as

pe block and some source and sink blocks, in Simulink models that

for TI C2000 DSP targets.

Sinks

Scope

1-26

Sources

le

To Fi

To Workspace

From File

From Workspace

Page 37

Overview of Creating Models for Targeting

Library Category Block Name

Signal Processing

Blockset™

Signal Operations Triggered Signal From

Workspace

Signal Processing Sinks

Signal To Workspace

Spectrum Scope

Triggered to Workspace

To Wave Device

Signal Processing

Sources

Signal From Workspace

From Wave Device

Blocks That Require Specific Settings

Any block listed in the following table can be used with all your models.

However, such a block requires specific settings, as indicated under

“Restriction.”

Library

Signal

Processing

Blockset

Category

Signal

Processing

Sources

Block

Name

Random

Source

Block

Restriction

For this block, the only Outpu t data

type supported by the TI C2000 is

Single.Besuretosetthisparameter

correctly in the Block Parameters

dialog box. See the following figure.

1-27

Page 38

1 Getting Started

Setting Simulation Configuration Parameters

When you drag a Target Preferences block into your model, you are given the

option to set basic simulation parameters automatically.

To re fin e the automatic settings, or set the simulation parameters manually,

open your model and select Simulation > Configuration Parameters.

If you are setting your simulation parameters manually, you must make

at least the following two settings:

• You must specify discrete time by selecting

continuous states)

dialog box.

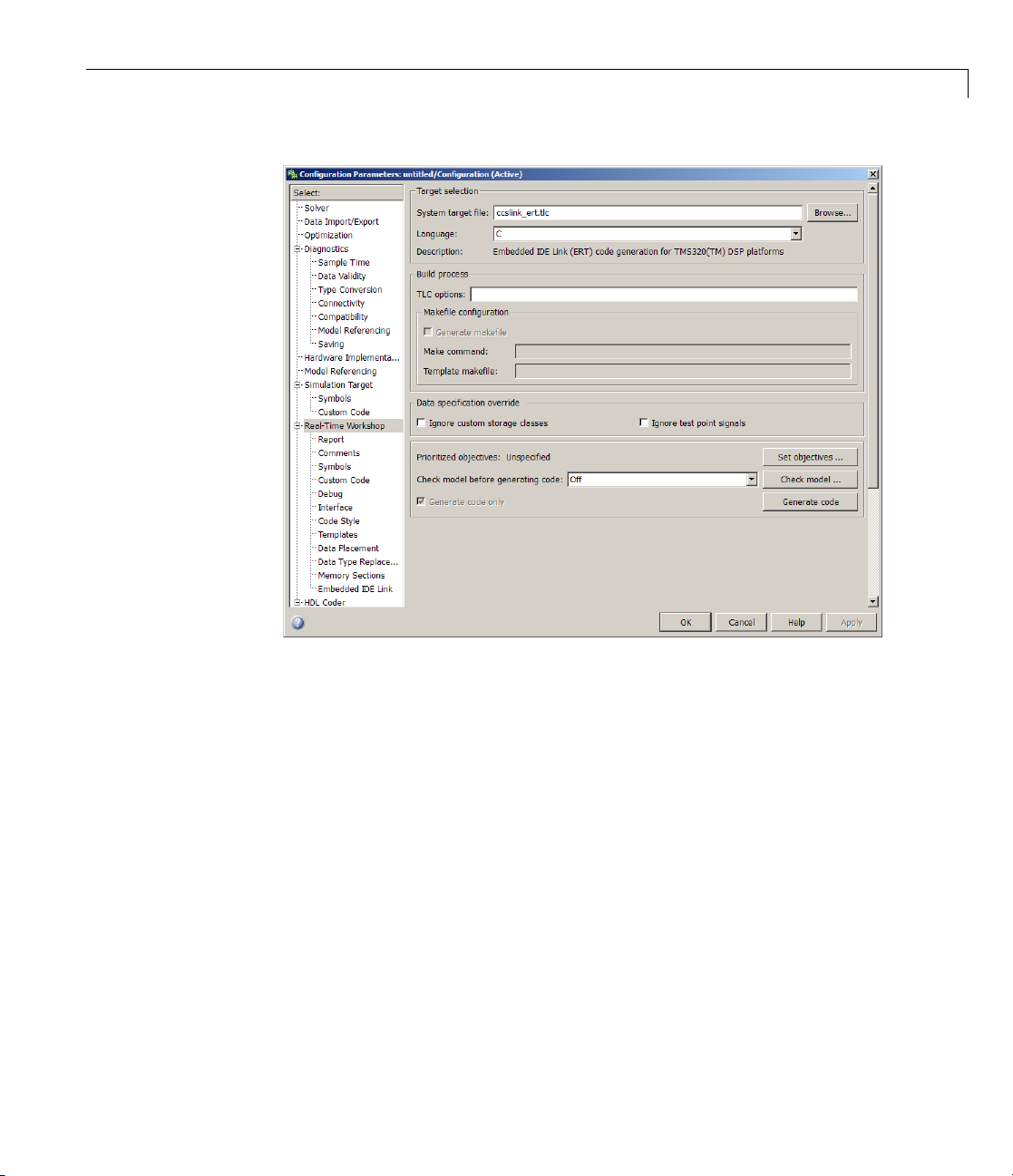

• You must also specify the appropriate version of the system targ et file in

the Real-Time Workshop pane. For Target Support Package softw a re,

specify one of the following system target files, or click Browse and select

from the list of targets.

ccslink_grt.tlc

ccslink_ert.tlc

The associated template filename is automatically filled in.

in the Solver pane of the Configuration Parameters

Fixed-step and Discrete (no

System Target Types and Memor y Management

There are two system target types that apply to Target Support Package

software. These correspond to the two system target files mentioned above.

A Generic Real-Time (GRT) target (such as

configuration that generates model code for a re al-time system as if the

resulting code was going to be executed on your workstation.

An Embedded Real-Time (ERT) target (such as

the target configuration that generates model code for execution on an

independent embedded real-time system. This option requires Real-Time

Workshop Embedded Coder.

ccslink_grt.tlc)isthetarget

ccslink_ert.tlc)is

1-28

The ERT target for Target Support Package software offers memory

management features that give you a way manage the performance o f your

code while working with limited memory resources. For more information

Page 39

Overview of Creating Models for Targeting

on this, see the chapter on Memory Sections in the Real-Time Workshop

Embedded Coder User’s Guide.

Building Your Model

With this configuration, you can generate a real-time executable and

download it to your TI development board by clicking Generate Code on the

Real-Time Workshop pane. Real-Time Workshop software automatically

generates C code and inserts the I/O device drivers as specified by the

hardware blocks in your block diagram, if any. These device drivers are

inserted in the generated C code.

During the same build operation, block parameter dialog box entries are

combined into a project file for CCS for your TI C2000 board. If you selected

the

Build and execute build action in the configuration settings, the TI

cross-compiler builds an executable file. After automatically dow n loading the

executable file to the target, the build process runs the file on the board’s DSP.

Note After using the run-time Build option to generate and build code for

your application, you must perform the following reset sequence before you

can run that code on your board. If you w an t to rerun your application

manually once it has been generated, you must also use this procedure.

F2812, F2808, and F28335 eZdsp Reset Sequence

1 Reset the board CPU.

2 Load your code onto the target.

3 Run your code on the target.

1-29

Page 40

1 Getting Started

Using the c2000lib Blockset

In this section...

“Introduction” on page 1-30

“Hardware Setup” on page 1-30

“Starting the c2000lib Library” on page 1-31

“Setting Up the Model” on page 1-33

“Adding Blocks to the Model” on page 1-35

“Generating Code from the Model” on page 1-38

Introduction

This section uses an example to demonstrate how to create a Simulink model

that uses Target Support Package blocks to target your board. The example

creates a model that performs PWM duty cycle control via pulse width change.

It uses the C2812 ADC block to sample an analog voltage and the C2812

PWM block to generate a pulse waveform. The analog voltage controls the

duty cycle of the PWM and you can observe the duty cycle change on the

oscilloscope. This model is also provided in the Demos library. The model in

the Demos library also includes a model simulation.

1-30

Hardware Setup

The following hardware is needed for this example:

• Spectrum Digital eZdsp F2812

• Function generator

• Oscilloscope and probes

To connect the hardware:

1 Connect the function generator output to the ADC input ADCINA0 on

the eZdsp F2812.

2 Connect the output of PWM1 on the eZdsp F2812 to the analog input of

the oscilloscope.

Page 41

Using the c2000lib Blockset

3 Connect VREFLO to AGND on the eZdsp F2812. See the section

on the Analog Interface in Chapter 2 of the eZdsp™ F2812

Technical Reference, available from the Spectrum Digital website at

http://c2000.spectrumdigital.com/ezf2812/

Starting the c2000lib Library

At the MA TLAB prompt, type

c2000lib

to open the c2000lib library blockset, which contains libraries of blocks

designed for targeting your board.

The libraries are in three groups, plus Info and Demos blocks.

General

• C2000 RTDX Instrumentation (rtdxBlocks)—BlocksforaddingRTDX

communications channels to Simulink m odels. See the tutorial in

Embedded IDE Link documentation for an example of using these blocks.

1-31

Page 42

1 Getting Started

• C2000 Target Preferences (c2000tgtpreflib)—BlockstospecifyTarget

Preferences and options. You do not connect this block to any other block in

your model.

• Host-side CAN Blocks (

canmsglib) — Blocks to configure CAN message

blocks.

• Host SCI Blocks (

c2000scilib) — Blocks to configure host-side serial

communications interface to send and receive data from serial port

Chip Support

• C280x (c280xlib) — Blocks to configure the F2808 eZdsp DSK or on

C280x-based custom boards

• C281x (

C281x-based custom boards

• C28x3x (

C28x3x-based custom boards

• C2802x (

C2802x-based custom boards

• C2803x (

C2803x-based custom boards

• Custom C2000 (

boards

c281xlib) — Blocks to configure the F2812 eZdsp DSK or on

c2833xlib) — Blocks to configure the F2833 eZdsp DSK or on

c2802xlib) — Blocks to configure t he C2802x eZdsp DSK or on

c2803xlib) — Blocks to configure t he C2803x eZdsp DSK or on

c2000xlib) — Blocks to configure C2000-based custom

1-32

Optimized Libraries

The Optimization library, c2000optimized blks,contains:

• C28x IQmath Library (

with C28x targets

• C28x DMC Library (

motor control with C28x DSPs

tiiqmathlib)—Fixed-pointmathblocksforuse

c28xdmclib) — Fixed-point math blocks for digital

Page 43

Using the c2000lib Blockset

Setting Up the Mo

Preliminary tas

Preferences blo

simulation par

1 In the Library

new Simulink m

2 In the Library: c2000lib window, double-click the C2000 Target Preferences

ks for setting up a new model include adding a Target

ck, setting or verifying Target Preferences, and setting the

ameters.

: c2000lib window, select File>New>Modelto create a

odel.

del

library block.

3 From the Target Preferences Library window, drag the F2812 eZdsp block

into your new model.

4 Click Yes to allow automatic setup. The following settings are

made, re ferenced in the table below by their locations in the

Simulation > Configuration Parameters dialog box:

Pane Field Setting

Solver Stop ti

Solve

Data

r

Type

Save t

me

o workspace - Time

10

Fixed

tout

-step

Import/Export

Data

Import/Export

dware

Har

plementation

Im

Real-Time

Workshop

Save to workspace Output

Device type

rget selection - System

Ta

rget file

ta

yout

C2000

slink_grt.tlc

cc

r

o

cslink_ert.tlc

c

1-33

Page 44

1 Getting Started

Note Generated code does not honor Simulink stop time from the

simulation. Stop time is interpreted as

generated code, you must put a Stop Simulation block in your model.

Note One Target Preferences block must be in each target model at the top

level. It does not connect to any other blocks, but stands alone to set the

Target Preferences for the model.

5 From your model’s main menu, select Simulation > Configuration

Parameters to verify and set the simulation p arameters for this model.

Parameters you set in this dialog box belong to the model you are building.

They are saved with the model and stored in the model file. R efer to your

Simulink documentation for information on the Configuration Parameters

dialog box.

6 Use the Real-Time Workshop pane to set options for the real-time

model. Refer to your “Real-Time Workshop” documentation for detailed

information on the Real-Time Workshop pane options.

inf. To implement a stop in

1-34

Page 45

Using the c2000lib Blockset

7 Use the Browse button to locate and select a target configuration file,

ccslink_grt.tlc or ccslink_ert.tlc. When you do this, Real-Time

Workshop software chooses the appropriate system target file, and

make

command.

8 Set the configuration parameters by typing Ctrl-E and adjust

these parameters. For descriptions of these fields, see the Target

Preferences/Custom Board reference page and “Setting Simulation

Configuration Parameters” on page 1-28 in the section titled “Overview of

Creating Models for Targeting” on page 1-25.

Adding Blocks to the Model

1 Open or double-click the C281x library, c281xlib.

1-35

Page 46

1 Getting Started

1-36

2 Drag th e C281x ADC block into your model. Double-click the ADC block

in the model and set Sample time to

for all other fields. Refer to the C281x ADC reference page for information

on these fields.

64/80000.Usethedefaultvalues

Page 47

Using the c2000lib Blockset

3 Drag the C281x PWM block into your model. Double-click the PWM block

in the model and set the follow ing parameters. Refer to the C281x PWM

reference page for informationonthesefields.

Pane Field Parameter

Timer

Module

Waveform

A

Specify via dialog

period source

Waveform

Clock cycles

period units

Waveform

64000

period

Waveform type

Asymmetric

Outputs

Enable

Selected

PWM1/PWM2

Duty cycle

Input port

source

Logic

PWM1 control

Active high

logic

PWM2 control

Active low

logic

Deadband

Use

Selected

deadband for

PWM1/PWM2

Deadband

16

prescaler

Deadband

12

period

ADC Control ADC start event

4 Enter Simulink at the MATLAB command line to open the Simulink

Period interrupt

Library browser. Drag a Gain block from the Math Operations library into

your model. Double-click the Gain block in the model and set the following

parameters in the Function Block Parameters dialog box. Click OK.

1-37

Page 48

1 Getting Started

Pane Field Parameter

Main

Signal Attributes

Parameter

Attributes

5 ConnecttheADCblocktotheGainblockandtheGainblocktothePWM

block as shown:

Gain

Multiplication

Sample time

Output data type

mode

Integer rounding

mode

Parameter data type

mode

30

Element-wise(K.*u)

-1

uint(16)

Floor

Inherit from input

1-38

Generating Code from the Model

This section summarizes how to generate code from your real-time model. For

details about generating code from models in Real-Time Workshop software,

refer to the “Real-Time Workshop” documentation.

You start the automatic code generation process from the Simulink model

window by clicking Generate code in the Real-Time Workshop pane of the

Configuration Parameters dialog. Other ways of starting the code generation

process are by clicking the Incremental Build buttononthetoolbarof

your model, or by pressing the keyboard shortcut, Ctrl+B, while your model

is open and in focus.

Note InCCS,youseeyourprojectwiththefilesinplaceinthefolder

structure.

Page 49

2

Configuring Timing Parameters for CAN Blocks

• “The CAN Blocks” on page 2-2

• “Setting Timing Parameters” on page 2-3

• “Parameter Tuning and Signal Logging” on page 2-9

Page 50

2 Config uring Timing Parameters for CAN Blocks

The CAN Blocks

The bit rate of these four CAN blocks cannot be set directly:

C281x eCAN Rece

C281x eCAN Transmit

C280x/C28x3x eCAN Receive

C280x/C28x3x

ive

eCAN Transmit

2-2

Page 51

Setting Timing Parameters

In this section...

“Accessing the Timing Parameters” on page 2-3

“Determining Timing Parameter Values” on page 2-6

“CAN Bit Timing Example” on page 2-7

Accessing the Timing Parameters

Tosetthebitratefor“TheCANBlocks”:

1 Confirm that your model includes the appropriate Target Preferences block

from the C2000 Target Preferences Library.

2 Double click the Target Preferences block in your model. This opens the

Target Preferences dialog box.

Setting Timing Parameters

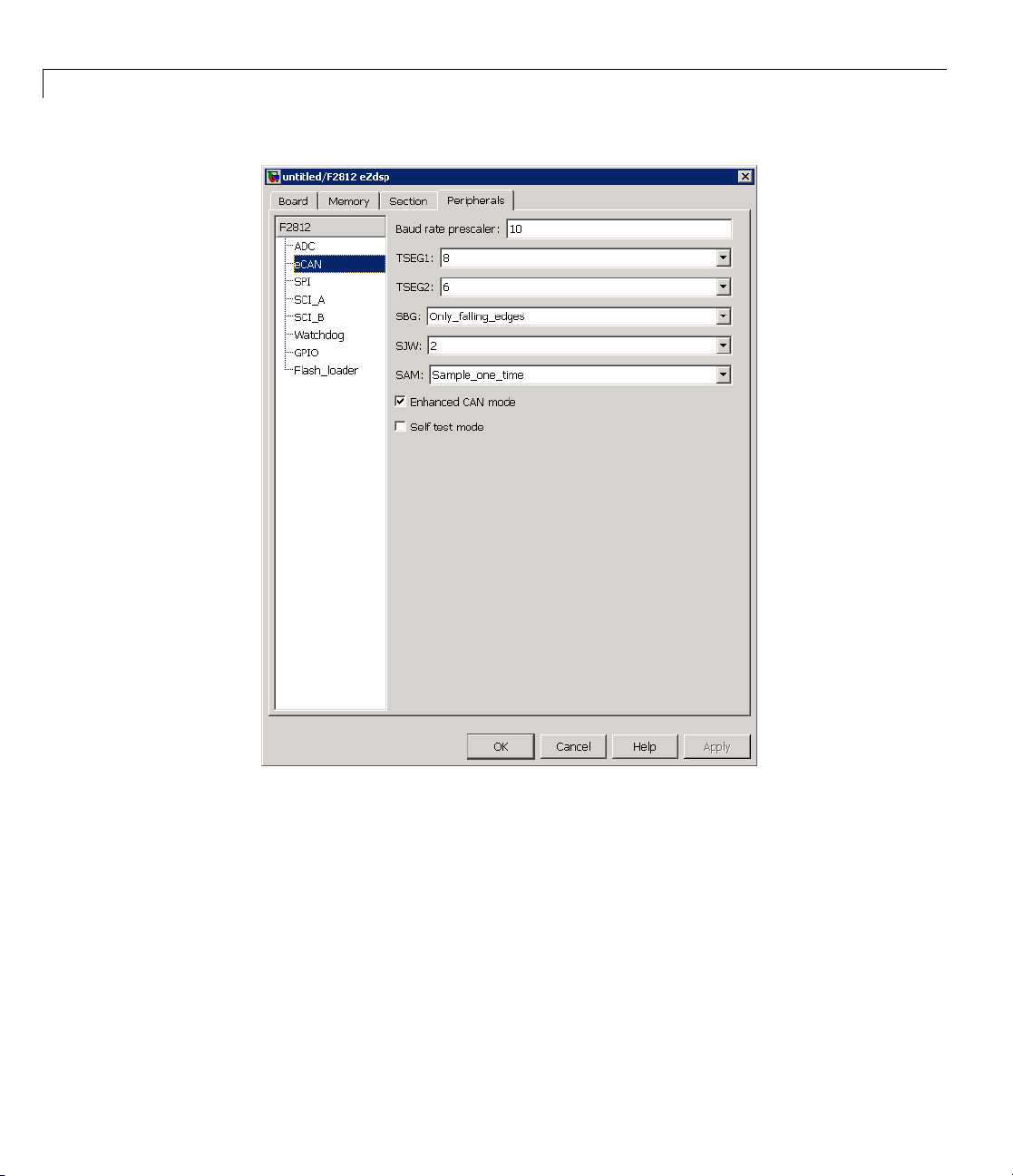

3 Under th

BaudRat

For exa

box is s

mple, the Target Preferences block for the F2812 eZdsp, this dialog

hown in the following figure.

e Peripherals tab, use the TSEG1, TSEG2,and

ePrescaler (BRP) parameters to set the bit rate.

2-3

Page 52

2 Config uring Timing Parameters for CAN Blocks

2-4

The C280x/C28x3x blocks have two independent eCAN modules, as shown by

the Target Preferences Setup dialog box.

Page 53

Setting Timing Parameters

The following sections describe the series of steps and rules that govern the

process of setting these timing parameters.

2-5

Page 54

2 Config uring Timing Parameters for CAN Blocks

Determining Tim

To determine the

following steps

1 Determine the C

2 Determine the frequency of the CAN module clock. For example:

:

ing Parameter Values

appropriate values for the timing para meters, comple te the

AN Bitrate specification based on your application.

• 100 MHz for the F2808 (Same as SYSCLKOUT)

• 150 MHz for the F2812 (Same as SYSCLKOUT)

• 75 MHz for the F28x3x (150 MHz SYSCLKOUT/2)

3 Estimate th

4 Solve this equation for BitTime:

evalueoftheBaudRatePrescaler (BRP).

BitTime = CAN module clock frequency/(BRP * Bitrate)

5 Solve thi

s equation for Bitrate:

Bitrate=CANmoduleclockfrequency/(BRP*BitTime)

6 Estimate values of TSEG1 and TSEG2 that satisfy the following equation:

BitTime TSEG TSEG=++121

2-6

7 Use the following rules to determine the values of TSEG1and TSEG2:

TSEG1 >= TSEG 2

IPT (Information Processing Time) = 3/BRP

IPT <=

TSEG1 <= 16 TQ

IPT <= TSEG2 <= 8 TQ

1TQ<=SJW <= min (4 TQ, TSEG2)

where IPT is Information Processing Time, TQ is Time Quanta, and SJW

is Synchronization Jump Width, also set in the Target Preferences

dialog box. .

rate steps 4 through 7 until the values selected for TSEG1, TSEG2, and

8 Ite

P meet all of the criteria.

BR

Page 55

Setting Timing Parameters

The following illustration shows the relationship between the eCAN bit

timing parameters.

CAN Bit Timing Example

Assume that SYSCLKOUT = 150 MHz, and a bit rate of 1 Mbits/s is required.

1 Set the BRP to 10. Then substitute the values of bit rate, BRP, and

SYSCLKOUT into the following equation, solving for BitTime:

BitTime SYSCLKOUT BRP Bitrate

BitTime TQ

2 Set the values of TSEG1 and TSEG2 to 8TQ and 6TQ respectively.

Substitute the values of BitTime from the previous equation, and the

chosen values for TSEG1 and TSEG2 into the following equation:

BitTime TSEG TSEG

TQ TQ TQ

15 8 6 1

3 Finally, check the selected values against the rules:

IPT = 3/BRP = 3/10 = .3

=

==

/( * )150 10 1 15

=++

121

/( * )

=++

2-7

Page 56

2 Config uring Timing Parameters for CAN Blocks

IPT <= TSEG1 <= 16 TQ True! .3<=8TQ<=16TQ

IPT <= TSEG2 <= 8TQ True! .3 <= 6TQ <= 8TQ

1TQ <= SJW <= min(4TQ, TSEG2)whichmeansthatSJW can be set to

either 2, 3, or 4

4 All chosen values satisfy the criteria, so no further iteration is necessary.

The following table provides common timing parameter settings for typical

values of Bit Rate and SYSCLKOUT = 150MHz. This clock frequency is the

maximum for the C281x blocks.

Bit Rate

.5 Mbit/s

1Mbit/s

2Mbit/s

The following table provides common timing parameter settings for typical

values of Bit Rate and SYSCLKOUT = 100MHz. This clock frequency is the

maximum for the C280x/C28x3x blocks.

Bit Rate

.5 6 3 10202

1

2631052

TSEG1 TSEG2

8 6 15202

8 6 15102

861552

TSEG1 TSEG2

5

4

Bit Time

Bit Time

10 10 2

BRP

BRP

SJW

SJW

2-8

Page 57

Parameter Tuning and Signal Logging

In this section...

“Overview” on page 2-9

“Using External Mode” on page 2-9

“Using a Third Party Calibration Tool” on page 2-18

Overview

Target Support Package software supports parameter tuning and signal

logging either using Simulink external mode or with a third party calibration

tool. In both cases the model must include a CAN Calibration Protocol block.

Using External Mode

The Simulink external mode feature enables you to log signals and tune

parameters without requiring a calibration tool. This section describes the

steps for converting a model to use external mode.

Parameter Tuning and Signal Logging

External mode is supported using the CAN Calibration Protocol block and

ASAP2 interface. The CAN Calibration Protocol block is used to communicate

with the target, download parameter updates, and upload signal informa t ion.

The ASAP2 interface is used to get information about where in the target

memory a parame ter or signal lives.

Note You must configure the host-side CAN application channel. See

“Configuring the Host Vector CAN Application Channel” on page 2-11.

To prepare your model for external m ode, follow these steps:

1 Add a CCP driver block.

2 Add a Switch External Mode Configuration Block (for ease of use; you can

also make changes manually).

2-9

Page 58

2 Config uring Timing Parameters for CAN Blocks

3 Identify signals you want to tune, and associate them with

Simulink.Parameter objects with ExportedGlobal storage class. It is

importanttosetthedatatypeandvalueofthe

See “Using Supported O bjects and Data Types” on page 2-11.

4 Identify signals you want to log, and associate them with canlib.Signal

objects. Itisimportanttosetthedatatypeofthecanlib.Signal.See

“Using Supported Objects and Data Types” on page 2-11.

For information about visualizing logged signal data, see “Viewing and

Storing Signal Data” on page 2-13.

5 Load the Simulink.Parameter and canlib.Signal data objects into the

base workspace.

6 Configure the model for building by double-clicking the Switch E xtern a l

Mode Configuration blo ck. In the dialog box, select Building an

executable,andclickOK.

7 Build the model, and download the executable to the target

Simulink.Parameter object.

2-10

8 Afterdownloadingtheexecutabletothe target, you can switch the model to

external mode by double-clicking the Switch External Mode Configuration

Block. In the dialog box that appears, select External Mode,andclickOK.

9 You can now connect to the target using external mode by clicking the

Connect button.

10 If you have set up tunable parameters, you can now tune them. See

“Tuning Parameters” on page 2-12.

If you do not want to use the Switch External Mode Configuration block, you

can configure for building and then external mode manually. For instructions,

see “Manual Configuration For External Mode” on page 2-16.

See the following topics for more information:

• “Configuring the Host Vector CAN Application Channel” on page 2-11

• “Using Supported O bjects and D ata Types” on page 2-11

• “Tuning Parameters” on page 2-12

Page 59

Parameter Tuning and Signal Logging

• “Viewing and Storing Signal Data” on page 2-13

• “Manual Configuration For External Mode” on page 2-16

• “Limitations” on page 2-17

Configuring the Host Vector CAN Application Channel

External mode expects that the host-side CAN connection is using the

'MATLAB 1' application channel. To configure the application channel used

by the Vector CAN drivers, enter the following at the MATLAB command line:

TargetsComms_VectorApplicationChannel.configureApplicationChannels

The Vector CAN Configuration tool appears. Use this tool to configure your

host-side CAN channel settings.

If you try to connect using an application channel other than

then you see the following warning in the command window:

Warning:

It was not possible to co nnec t to the target using CCP.

An error occurred when issuing the CONNECT command.

Using Supported Objects and Data Types

Supported objects:

•

Simulink.Parameter for parameter tuning

canlib.Signal for signal logging

•

Supported data types:

• uint8, int8

• uint16, int16

• uint32, int32

• single

'MATLAB 1',

2-11

Page 60

2 Config uring Timing Parameters for CAN Blocks

You need to define data objects for the signals and parameters of interest for

ASAP2filegeneration. Foreaseofuse,createaMATLABfiletodefinethe

dataobjects,sothatyouonlyhavetosetuptheobjectsonce.

To set up tunable parameters and signal logging:

1 Associate the parameters to be tuned with Simulink.Parameter objects

with ExportedGlobal storage class. It is important to set the data type

and value of the Simulink.Parameter object. See the following code for an

example of how to create such a Simulink.Parameter object for tuning:

stepSize = Simulink.Parameter;

stepSize.DataType = 'uint8';

stepSize.RTWInfo.StorageClass = 'ExportedGlobal';

stepSize.Value = 1;

2 Associate the signals to be logged with canlib.Signal objects. It is important

to set the data type of the canlib.Signal. The following code example shows

how to declare such a canlib.Signal object for logging:

2-12

counter = canlib.Signal;

counter.DataType = 'uint8';

3 Associate the data objects you defined in the MATLAB file with parameters

or signals in the model. For the previous code examples, you could set the

Constant value in a Source block to

to

counter in the Signal Properties dialog box. Remember that stepSize

stepSize,andsetaSignal name

and counter are data objects defined in the code.

Tuning Parameters

To tune a parameter, follow these steps:

1 Set dataobject.value in the workspace while the model is running in

external mode. For example, to tune the parameter

change its value) from 1 to 2, enter the following at the command line:

stepSize.value = 2

stepSize (that is, to

Page 61

Parameter Tuning and Signal Logging

You see output similar to the following:

stepSize =

Simulink.Parameter (handle)

RTWInfo: [1x1 Simulink.ParamRTWInfo]

Description: ''

DataType: 'uint8'

Min: -Inf

Max: Inf

DocUnits: ''

Value: 2

Complexity: 'real'

Dimensions: [1 1]

2 Return to your model, and update the model (press Ctrl+D) to apply the

changed parameter.

ViewingandStoringSignalData

To view the logged signals attach a supported scope type to the signal (see

“Limitations” on page 2-17 for supported scope types).

Select which signals you want to log by us ing the External Signal &

Triggering dialog box. Access the External Mode Control Panel from the Tools

menu, and click the Signal & Triggering button. By default, all displays

appear as s ele cted to be logged, as shown in the following example. Edit

these settings if you do not want to log all displays. Individual displays can

be selected manually.

2-13

Page 62

2 Config uring Timing Parameters for CAN Blocks

2-14

Storingsignaldataforfurtheranalysis. Itispossibletostorethelogged

data for further analysis in MATLAB.

1 To use the Data Archiving feature of external mode, click Data Archiving

in the External Mode Control Panel. The External D ata Archiving dialog

box appears.

Page 63

Parameter Tuning and Signal Logging

a Select the check box Enable archiving

b Edit the Folder and Filename and any other desired settings.

c Close the dialog box.

2 Open the Scope parameters, and select the check box Save data to

workspace.

2-15

Page 64

2 Config uring Timing Parameters for CAN Blocks

3 You may want to edit the Variable name in the edit box. The data that is

displayed on the scope at the end of the external mode session is available

in the workspace with this variable name.

The data that was previously disp layed in the scope is stored in

.mat files

as previously setup using Data Archiving.

For example, at the end of an external mode session, the following variable

and files could be available in the workspace and current folder:

• Avariable

ScopeData5

ScopeData5 =

ScopeData5 with the data currently displayed on the scope:

time: [56x1 double]

signals: [1x1 struct]

blockName: 'mpc555rt_ccp/Scope1'

• In the current folder, .mat files for the three previous Durations of

scope data:

ExternalMode_0.mat

ExternalMode_2.mat

ExternalMode_1.mat

Manual Configuration For External Mode

As an alternative to using the Switch External Mode Configuration block, you

can configure models manually for build and execution with external mode.

2-16

To configure a model to be built for external mode:

1 Select Inline parameters (under Optimization in the Configuration

Parameters dialog box). The Inline parameters option is required for

ASAP2 generation.

2 Select Normal simulation mode (in either the Simulation menu, or the

drop-down list i n the toolbar).

Page 65

Parameter Tuning and Signal Logging

3 Select ASAP2 as the Interface (under Real-Time Workshop, Interface,

in the Data Exchange pane, in the Configuration Parameters dialog box).

After you build the model, you can configure it for external mode execution:

1 Make sure Inline parameters are selected (under Optimization in the

Configuration Parameters dialog box). The Inline parameters option is

required for external mode.

2 Select External simulation mode (in either the Simulation menu, or

the drop-down list in the toolbar).

3 Select External mode as the Interface (under Real-Time Workshop,

Interface,intheData Exchange pane, in the Configuration Parameters

dialog box).

Limitations

Multiple signal sinks (e.g. scopes) are not supported.

Only the following kinds of scopes are supported with External Mode Logging:

• Simulink Scope block

• Simulink Display block

• Viewer type: scope — To use this option, right-click a signal in the model,

and select Create & Connect Viewer > Simulink > Scope. The other

scope t ypes listed there are not supported (e.g., floating scope).

Before connecting to external mode, you also need to right-click the signal,

and select Signal Properties.Inthedialogbox,selecttheTest point

check box, and click OK.

GRT is supported but only for parameter tuning.

Itisnotpossibletologsignalswithsampleratesinexcessof10kHz.

Subsystem builds are not supported for external mode, only top-level builds

are supported.

2-17

Page 66

2 Config uring Timing Parameters for CAN Blocks

Logging and tuning of nonscalars is not supported. It is possible to log

nonscalar signals by breaking the signal down into its scalar components. For

an example of how to do this signal deconstruction, see the CCP demo models,

which use a Demux and Signal Conversion block with contiguous copy.

Logging and tuning of complex numbers is not supported. It is possible to

work with complex numbers by breaking the complex number down into its

real and imaginary components. This breakdown can be performed using

the following b lock s in the Simulink Math Operations library: Complex to

Real-Imag, Real-Imag to Complex, Magnitude-Angle to Complex, Complex

to Magnitude-Angle.

Using a Third Party Calibration Tool

Target Support Package allows an ASAP2 data definition file to be generated

during the code generation process. This file can be used by a third party tool

to access data from the real-time application while it is executing.

ASAP2 is a data definition standard by the Association for Standardization

of Automation and Measuring Systems (ASAM). ASAP2 is a standard

description for data measurement, calibration, and diagn ostic systems.

Target Support Package software lets you export an ASAP2 file containing

information about your model during the code generation process.

2-18

Before you begin generating ASAP2 files with Target Support Package

software, you should read the “Generating an ASAP2 File” section of the

Real-Time Workshop documentation. That section describes how to define

the signal and parameter information required by the ASAP2 file generation

process.

Select the ASAP2 option before the build process as follows:

1 Select Simulation > Configuration Parameters.

The Configuration Parameters dialog box appears.

2 Select Interface (under Real-Time Workshop) in the tree.

3 Select the ASAP2 option from the Interface drop-down menu, in the Data

exchange frame.

Page 67

Parameter Tuning and Signal Logging

4 Click Apply .

The build process creates an ASAM-compliant ASAP2 data definition file for

the generated C code.

• The s tandard Real-Tim e Workshop ASAP2 file generation does not

include the memory address attributes in the generated file. Instead,

it leaves a placeholder that must be replaced with the actual address by

postprocessing the generated file.

• The map file options in the template project need to be set up a certain way

for this procedure to work. If you have created your own template projects,

and you do not have the correct settings, you see the following instructions:

Warning: It was not possible to do ASAP2 processing on your

.map file.This is because your IDE project template is n ot

configured to generate a .map file in the correct format.

To generate a .map file i n the correct format you need to

setup the following options in your IDE project template:

Generate section map should be checked on

Generate register map should be checked off

Generate symbol table should be checked on

Format list file into pages should be checked off

Generate summary should be checked off

Page width should be equal to 132 characters

Symbol colums should be 1

You can change these options via Project -> Project Options

-> Linker/Locator -> Map File -> Map File Format.

Target Support Package software performs this postprocessing for you. To

do this, it first extracts the memory address information from the map file

generated during the link process. Secondly, it replaces the placeholders in

the ASAP2 file with the actual memory addresses. This postprocessing is

performed automatically and requires no additional input from you.

2-19

Page 68

2 Config uring Timing Parameters for CAN Blocks

2-20

Page 69

Configuring Acquisition Window Width for ADC Blocks

• “What Is an Acquisition Window?” on page 3-2

• “Configuring ADC Parameters for A c quisition Wind o w Width” on page 3-5

3

Page 70

3 Confi g uring Acquisition Window Width for ADC Blocks

What Is an Acquisition Window?

ADC blocks take a signal from an analog source and measure it with a digital

device. The digital device does not measure in a continuous process, but in a

series of discrete measurements, close enough together to approximate the

source signal with the required accuracy, as shown in the following figure.

3-2

Analog Signal

The digi

measure

below.

Ideally, as soon as the measurement window is opened, the actual signal

coming in would be measured perfectly. In reality the signal does not reach

its full magnitude immediately. The measurement process can be modeled by

tal measurement itself is not an instantaneous process, but is a

ment window, where the signal is acquired and measured, as shown

Source

Signal

Measurement

Digital Measurement

Measurement

Acquisition

Window

Page 71

What Is an Acquisition Window?

a circuit similar to the one shown in the following figure for the ADC found on

the F2812 eZdsp

where the measurement circuit is characterized by a certain capacitance. In

the preceding figure, when the switch is closed, the measurement begins. In

this circuit, which is characterized by its capacitance, the signal received

is not in a form of a step function as shown by the ideal measurement, but

a ramp up to the true signal magnitude. The following figure shows what

happens to the signal when the sampler switch is closed and the signal is

received to be measured.

Actual Signal

Window

Width

Because the sig nal acqu isition is not instantaneous, it is very important to

set a wide enough acquisition window toallowthesignaltorampuptofull

strength before the measurement is taken. If the window is too narrow,

the measurement is taken before the signal has reached its full magnitude,

resulting in erroneous data. If the window is too wide, the source signal

itself may change, and the sampling may be too infrequent to reflect the

actual value, also resulting in erroneous data. You must calculate the

Acquisition

3-3

Page 72

3 Confi g uring Acquisition Window Width for ADC Blocks

necessary width of the acquisition window based on the circuit characteristics

of resistance and capacitance of your specific circuit. Then, using the ADC

parameters described in the following section, you can configure the necessary

acquisition window width.

3-4

Page 73

Configuring ADC Parameters for Acquisition Window Width

Configuring ADC Parameters for Acquisition Window

Width

In this section...

“Accessing the ADC Parameters” on page 3-5

“Examples” on page 3-7

Accessing the ADC Parameters

The ADC parameters can be set from the Peripherals tab of the Target

Preferences block.

• You can set ACQ_PS — Acquisition Prescaler — to a value from 0 to 15.

To obtain the actual value, increment the setting by 1. This produces an

actual range from 1 to 16.

• You can set ADCLKPS — AD Clock Prescaler — to a value from 0 to 15.

To obtain the actual value, increment the setting by 1. This produces an

actual range from 1 to 16.

• You can set CPS — Clock Prescaler — to a value from 0 to 1 . To obtain the

actual value, increment the setting by 1. This produces an actual range

from 1 to 2.

3-5

Page 74

3 Confi g uring Acquisition Window Width for ADC Blocks

3-6

These three prescalers serve to reduce the speed of the clock and to set the

acquisition window width. The following diagram shows how these prescalers

are used.

Page 75

Configuring ADC Parameters for Acquisition Window Width

ADCLKPS

1 - 16

(4 bit clock

divider)

HISPCLK

(high speed

peripheral

clock)

In the preceding diagram, the high speed peripheral clock frequency is

received and then divided by the ADCLKPS. The reduced clock frequency

is then further divided by CPS. The resulting frequency is the ADCCLK

signal. The value of ACQ_PS then determines how many ADCCLK ticks

comprise one S/H (sample and hold) period, or in other words, the length of

the acquisition window.

ADCLKPS reduces the

incoming clock

frequency by a

factor of 1 to 16

CPS

CPS

CPS further reduces

the clock

frequency by a

factor of 1 or 2

ACQ_PS

ADCCLK this is the

ADC clock

signal

ACQ_PS Acquisition

Prescaler indicates

how many

ADCCLK

ticks will

comprise

the window

Sample

Hold

clock

pulse

Examples

The following examples show how you can use ADC parameters to configure

the acquisition window width:

Example 1:

If the HISPCLK = 30 MHz, and ADCLKPS=1 (which is a value of 2), the

result is 15MHz.

If CPS= 1 (which is a value of 2), then ADCCLK = 7.5MHz.

If ACQ_PS = 0 (which is a value of 1), then the sample/hold period is 1

ADCCLK tick, or .1333 microseconds.

3-7

Page 76

3 Confi g uring Acquisition Window Width for ADC Blocks

Example 2:

If the HISPCLK = 30 MHz, and ADCLKPS=1 (which is a value of 2), the

result is 15MHz.

If CPS= 1 (which is a value of 2), then ADCCLK = 7.5MHz.

If ACQ_PS = 15 (which is a valu e of 16), then the sample/hold period is 16

ADCCLK ticks, or 2.1333 microseconds.

Note HISPCLK is set automatically for the user, and it is not possible to

change the rate. For more information, see “High-Speed Peripheral Clock”

on page 1-11

3-8

Page 77

Using the IQmath Library

• “About the IQmath Library” on page 4-2

• “Fixed-Point Numbers” on page 4-4

• “Building Models” on page 4-10

4

Page 78

4 Using the IQmath Library

About the IQmath Library

In this section...

“Introduction” on page 4-2

“Common Characteristics” o n page 4-3

“References” on page 4-3

Introduction

The C28x IQmath Library blocks perform processor-optimized fixed-point

mathematical operations. These blocks correspond to functions in the Texas

Instruments C28x IQmath Library, an assembly-code library for the TI C28x

family of digital signal processors.

Note The implementation of this library for the TI C28x processor produces

the same simulation and code-generation output as the TI version of this

library, but it does not use a global Q value, as does the TI version. The Q

format is dynamically adjusted based on the Q format of the input data.

4-2

The IQmath Library blocks generally input and output fixed-point data types

and use numbers in Q format. The C28x IQmath Library block reference

pages discuss the data types accepted and produced by each block in the

library. For more information, consult the “Fixed-Point Num bers” on page

4-4 and “Q Format Notation” on page 4-5topics,aswellastheSimulink

Fixed P oint™ product documentation, which includes more information on

fixed-point data types, scaling, and precision issues.

You can use IQmath Library blocks with some core Simulink blocks and

Simulink Fixed Point blocks to run simulations in Simulink models before

generating code. Once you develop your m odel, you can invoke Real-Time

Workshop software to generate equivalent code that is optimized to run on a

TI C28x DSP. During code generation, a call is made to the IQmath Library

for each IQmath Library block in your model to create target-optimized code.

To le arn more about creating models that include IQmath Library blocks and

blocks from other blocksets, consult “Building Models” on page 4-10.

®

Page 79

About the IQmath Library

Common Characte

The following ch

• Sample times ar

• Blocks are sin

• Parameters ar

• All blocks sup

To learn more

see “C28x IQ

reference p

Reference

For detail

C28x IQmat

SPRC087,

is includ

(registr

ed information on the IQmath library, see the user’s guide for the

ed in the zip file d ow n loa d that also contains the IQmath library

ation required).

aracteristics are common to all IQmath Library blocks:

e inherited from driving blocks.

gle rate.

e not tunable.

port discrete sample times.

about characteristics particular to each block in the library,

math (tiiqmathlib)” on page 6-13 for lin ks to the individual block

ages.

s

h Library - A Virtual Floating Point Engine,LiteratureNumber

available at the Texas Instruments website. The user’s guide

ristics

4-3

Page 80

4 Using the IQmath Library

Fixed-Point Numbers

In this section...

“Notation” on page 4-4

“Signed Fixed-Point Numbers” on page 4-5

“Q Format Notation” on page 4-5

Notation

In digital hardware, numbers are stored in binary words. A binary word is a

fixed-length sequence of binary digits (1s and 0s). How hardware components

or software functions interpret this sequence of 1s and 0s is defined by the

data type.

Binary numbers are used to represent either fixed-point or floating-point data

types. A fixed-point data type is characterized by the word size in bits, the

binary point, and whether it is signed or unsigned. The position of the binary

point is the means by which fixed-point values are scaled and interpreted.

4-4

For example, a binary representation of a fractional fixed-point number

(either signed or unsigned) is shown below:

where

• b

is the i th binary digit.

i

• ws is the word size in bits.

• b

• b

• The binary point is sh own four places to the left of the LSB . In this

is th e location of the most si gn i fi cant (highest) bit (MSB).

ws–1

is the location of the least significant ( low est) bit (LSB).

0

example, therefore, the number is said to have four fractional bits, o r a

fraction length of 4.

Page 81

Fixed-Point Numbers

Note For Target Support Package, the results of fixed-point and integer

operations in MATLAB/Simulink match the results on the hardware target

down to the least significant bit (bit-trueness). The results of floating-point

operations in MATLAB/Simulink do not match those on the hardware

target, because the libraries used by the third-party compiler may be

different from those used by MATLAB/Simulink.

Signed Fixed-Point Numbers

Signed binary fixed-point numbers are typically represented in one of three

ways:

• Sign/magnitude

• One’s comple ment

• Two’s complement